Antifouling paint, antifouling coating and preparation method thereof

An anti-fouling coating and raw material technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of environmentally harmful fluorides, complex preparation methods, restricted applications, etc., and achieves low cost, simple preparation method, The effect of good self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

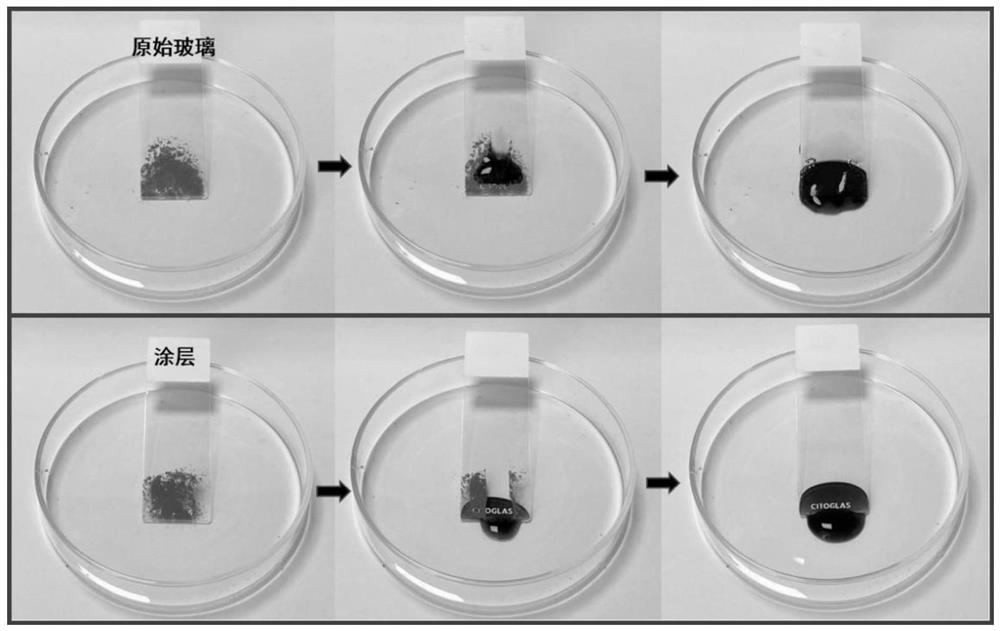

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of antifouling paint, and the steps are as follows:

[0032] (1) Dissolve 50 g of hexamethylene diisocyanate trimer and 10.5 g of amodimethicone in 190 g of N,N-dimethylformamide, stir for 3 hours, and react;

[0033] (2) Add 100 g of methyl etherified melamine formaldehyde resin to the reaction solution obtained in step (1), and then add 0.5 g of p-toluenesulfonic acid aqueous solution (pH value is 2), and stir to obtain an antifouling coating.

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of antifouling paint, and the steps are as follows:

[0036] (1) Dissolve 30 g of hexamethylene diisocyanate trimer and 1.5 g of amodimethicone in 207 g of N,N-dimethylformamide, stir for 3 hours, and react;

[0037] (2) Add 60g of methyl etherified melamine formaldehyde resin to the reaction solution obtained in step (1), then add 1.5g of p-toluenesulfonic acid aqueous solution (pH value is 3), stir to obtain antifouling coating.

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of antifouling paint, and the steps are as follows:

[0040] (1) Dissolve 45g of hexamethylene diisocyanate trimer and 4g of amodimethicone in 45g of N,N-dimethylformamide, stir for 3h, and react;

[0041] (2) Add 54.5g of methyl etherified melamine formaldehyde resin to the reaction solution obtained in step (1), then add 1.5g of an aqueous solution of p-toluenesulfonic acid (pH value is 2), and stir to obtain an antifouling coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com