Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Enhanced cycle life performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

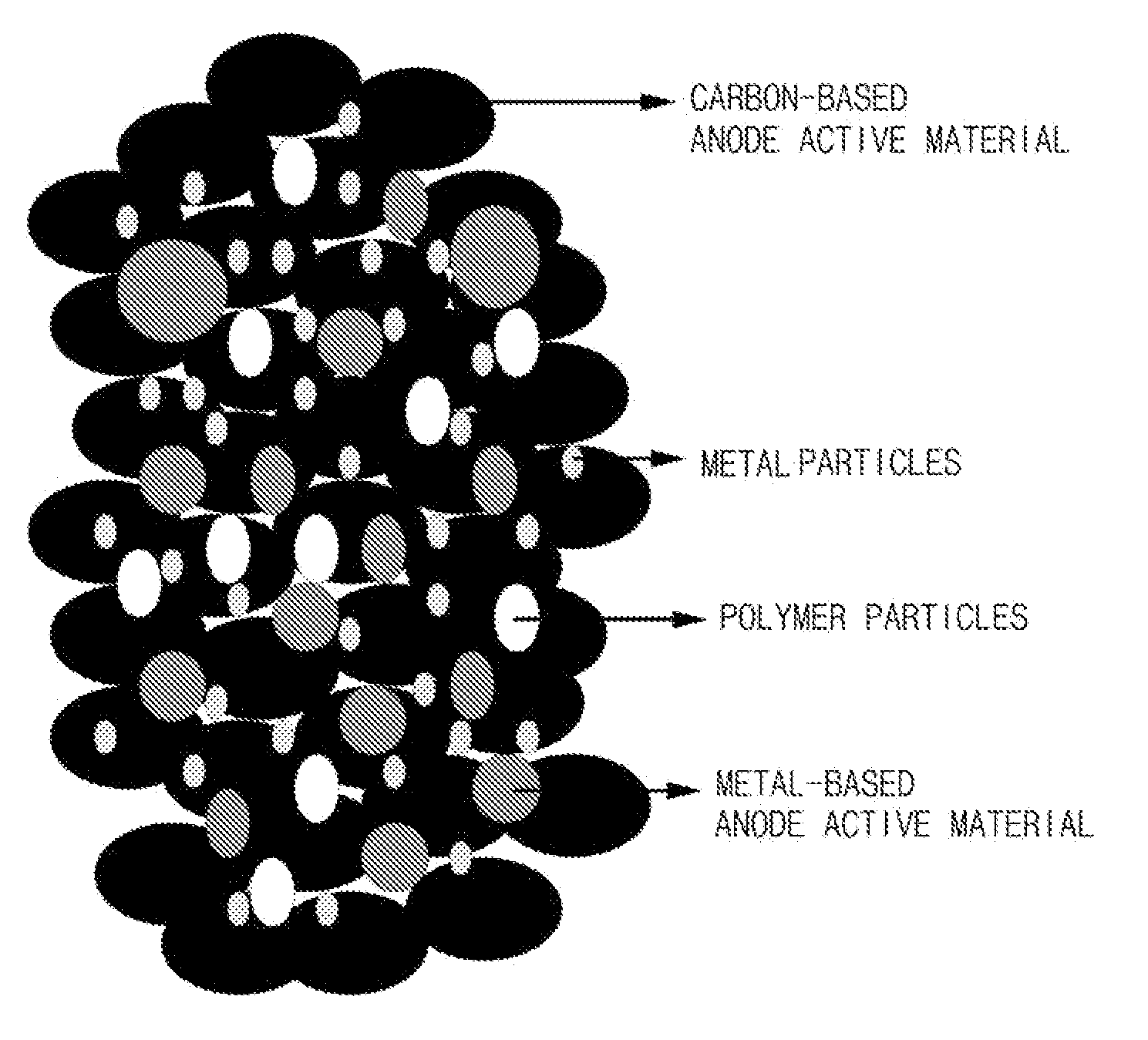

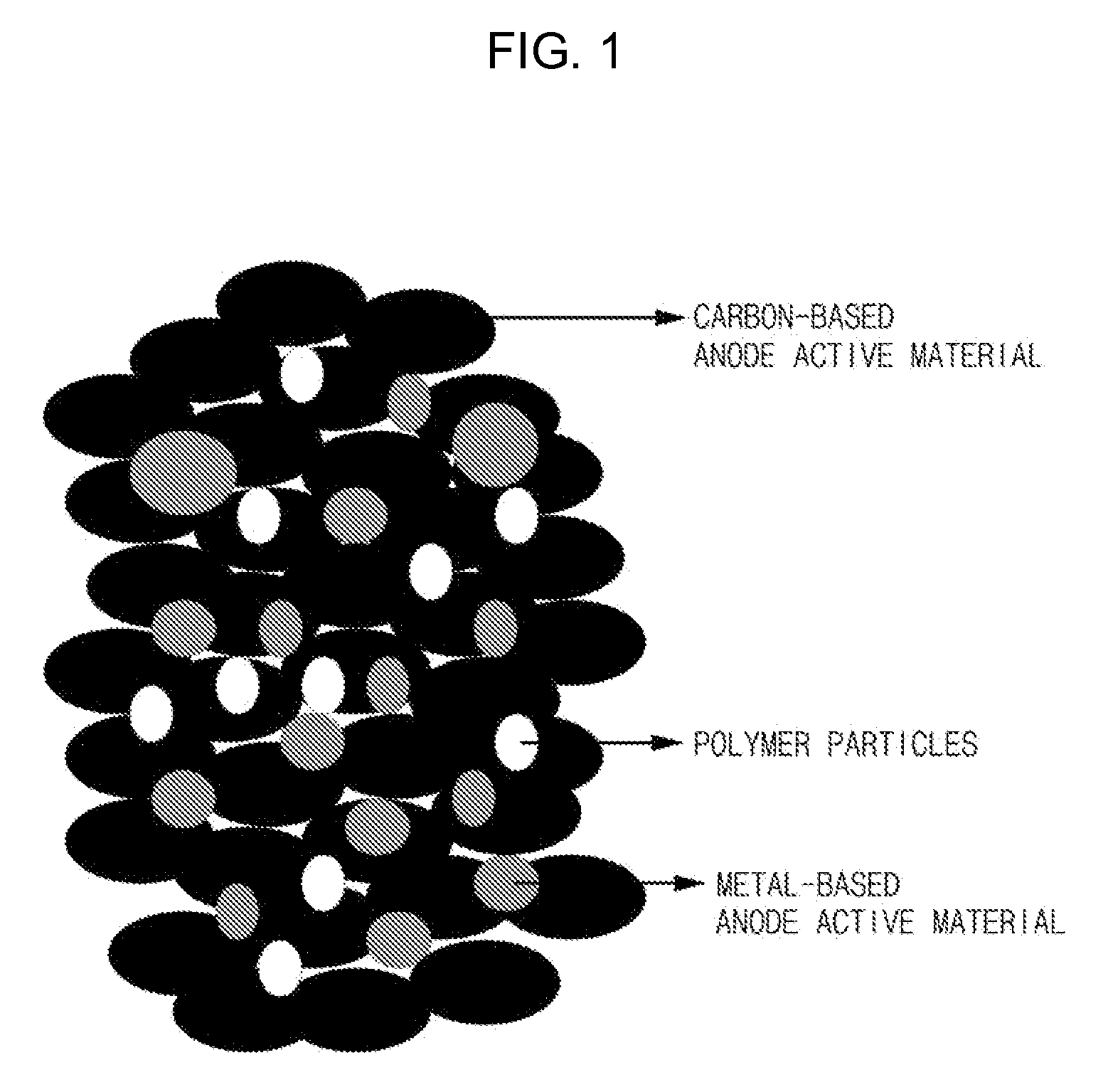

Composite anode active material, anode including the same and lithium battery using the anode

ActiveUS20090023065A1Large capacityEnhanced cycle life performanceFinal product manufactureLi-accumulatorsHigh ratePolymer

A composite anode active material includes a composite of a carbon-based anode active material, a metal-based anode active material and polymer particles. By increasing the conductivity of the composite anode active material, a lithium battery having a large capacity, high initial efficiency, high rate capability and improved cycle life performance can be obtained. An anode includes the composite anode active material and a lithium battery includes the anode.

Owner:SAMSUNG SDI CO LTD

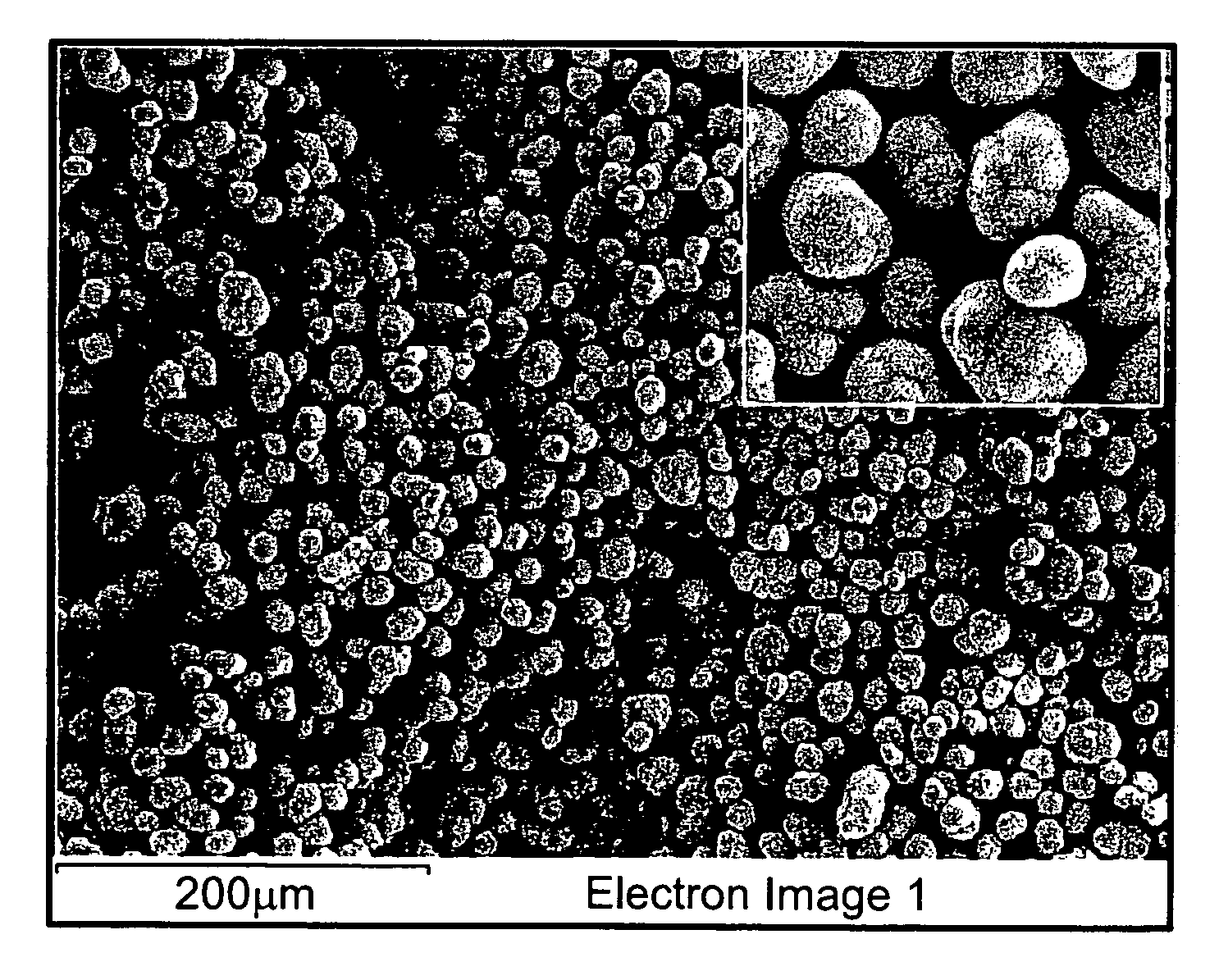

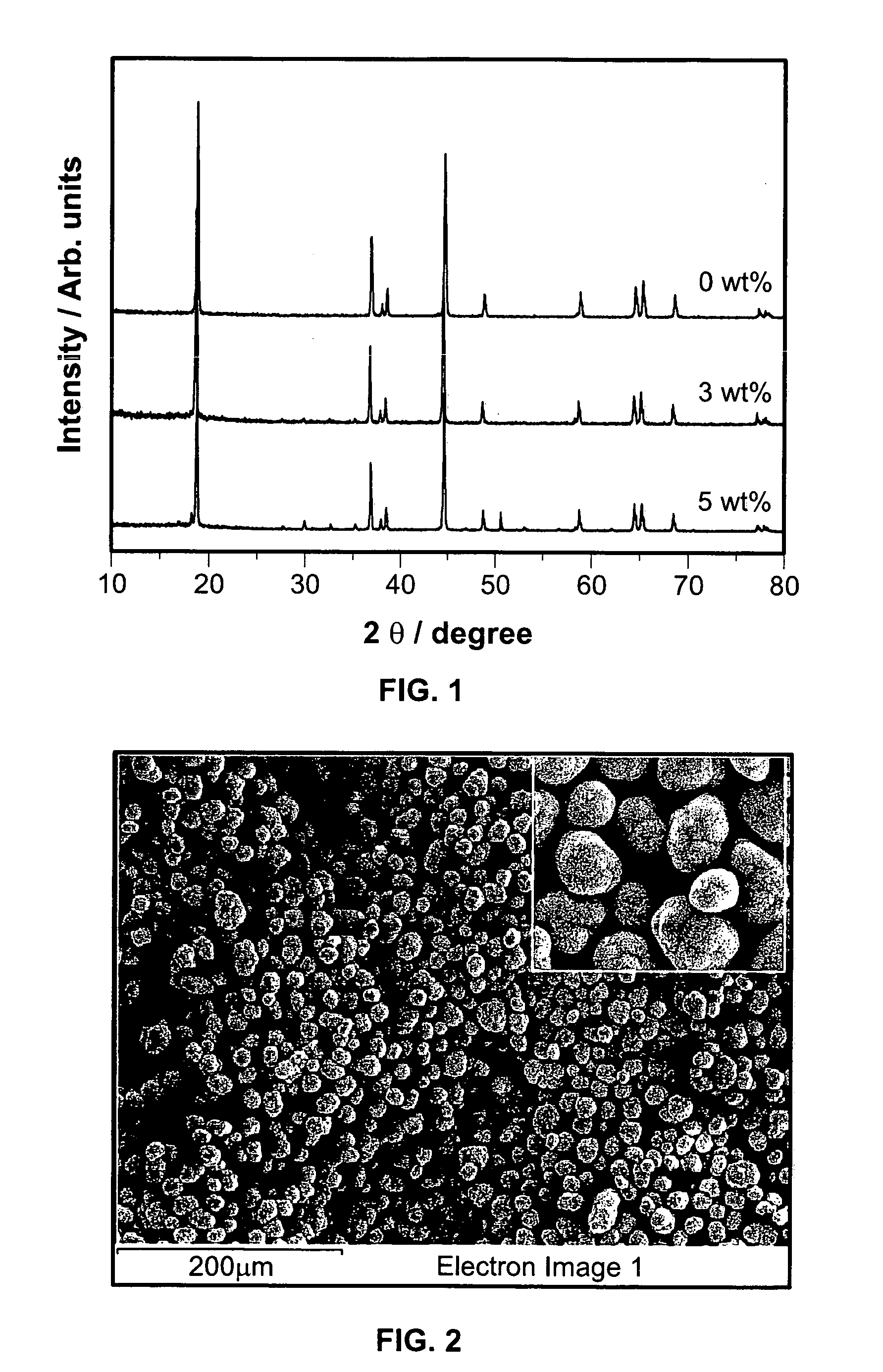

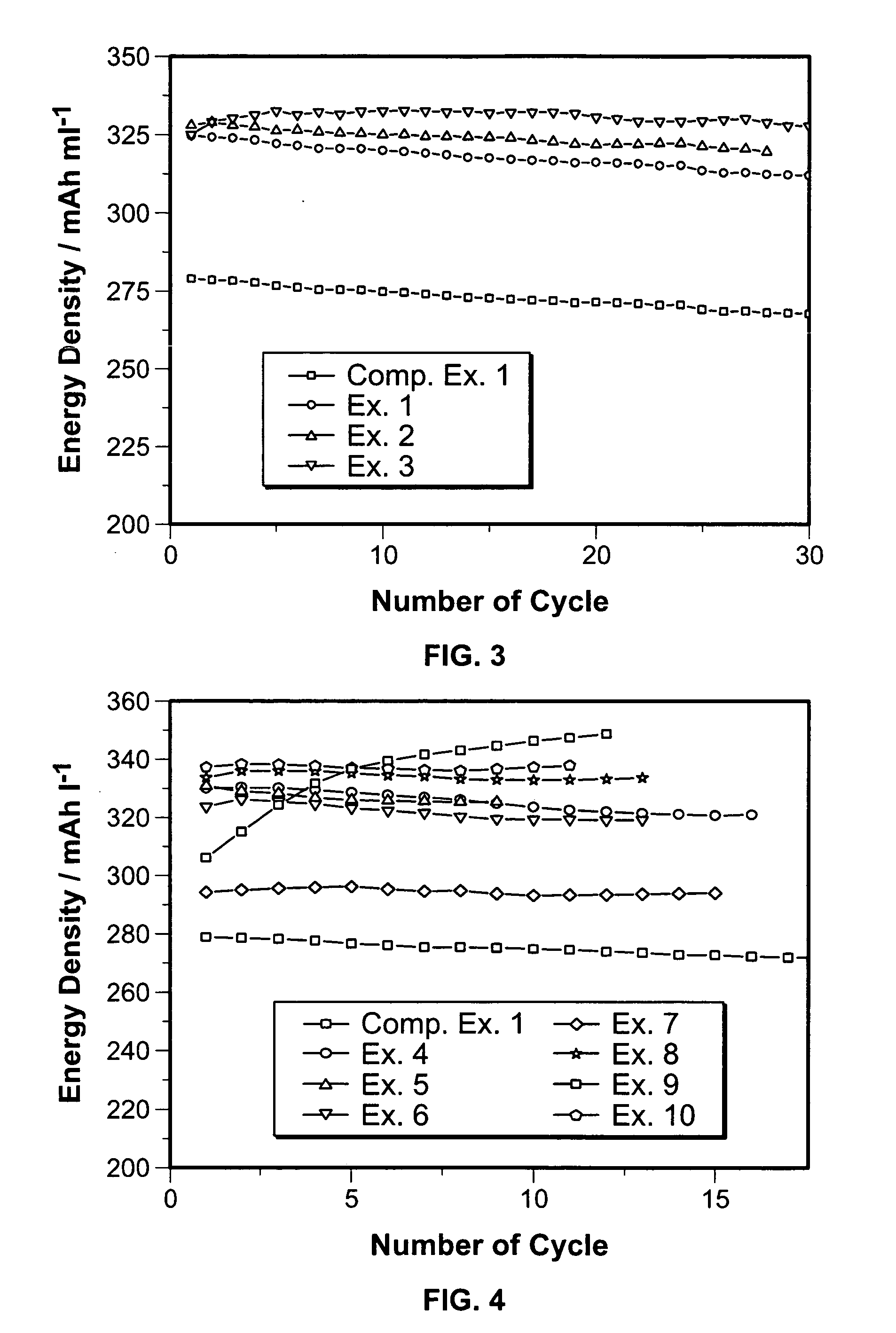

Cathode material for lithium batteries

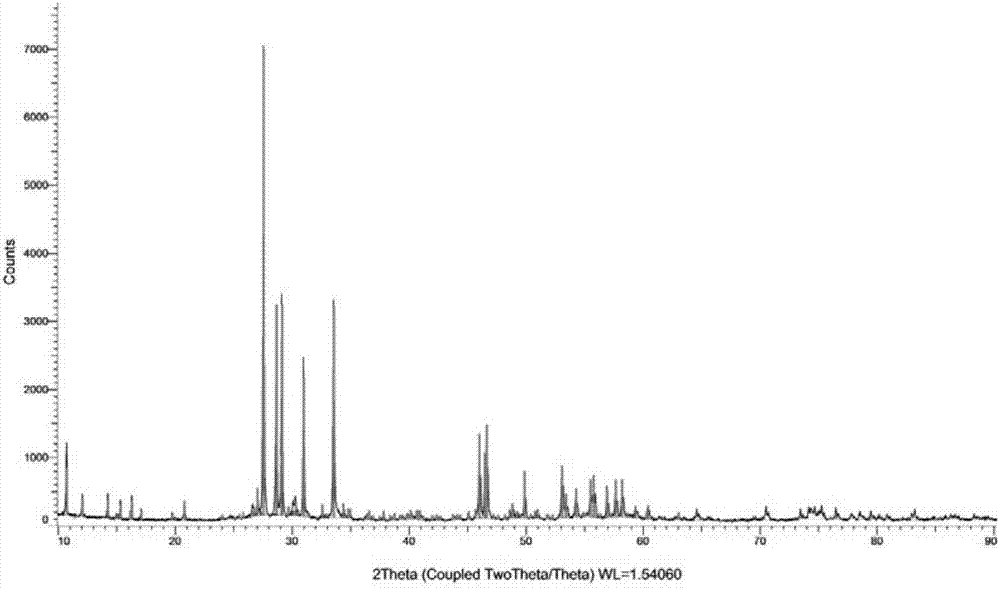

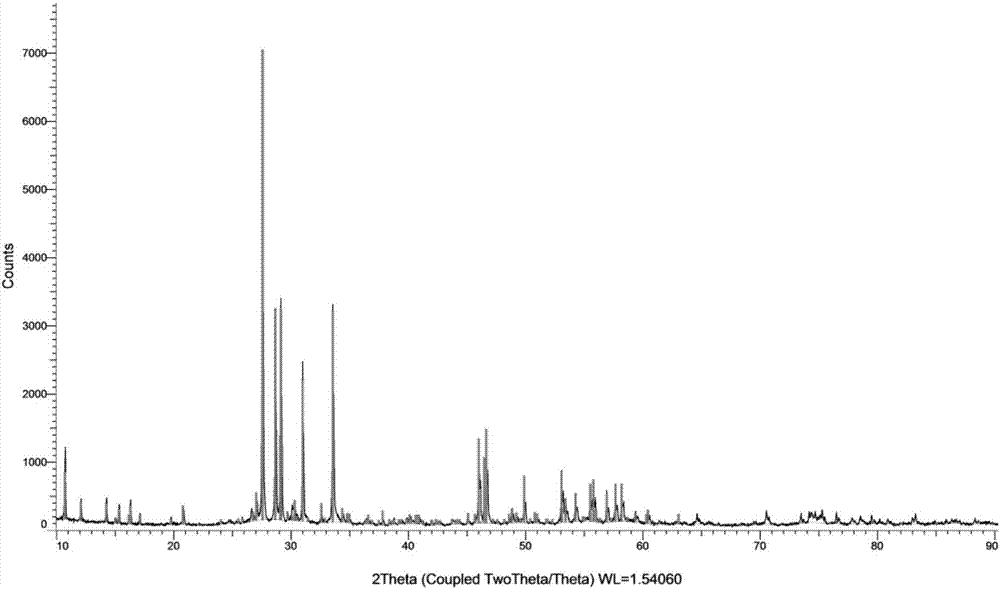

ActiveUS20070292763A1High tap densityIncrease energy densityAlkali metal oxidesCobalt compoundsOxide cathodeMaterials science

A method of manufacture an article of a cathode (positive electrode) material for lithium batteries. The cathode material is a lithium molybdenum composite transition metal oxide material and is prepared by mixing in a solid state an intermediate molybdenum composite transition metal oxide and a lithium source. The mixture is thermally treated to obtain the lithium molybdenum composite transition metal oxide cathode material.

Owner:UCHICAGO ARGONNE LLC

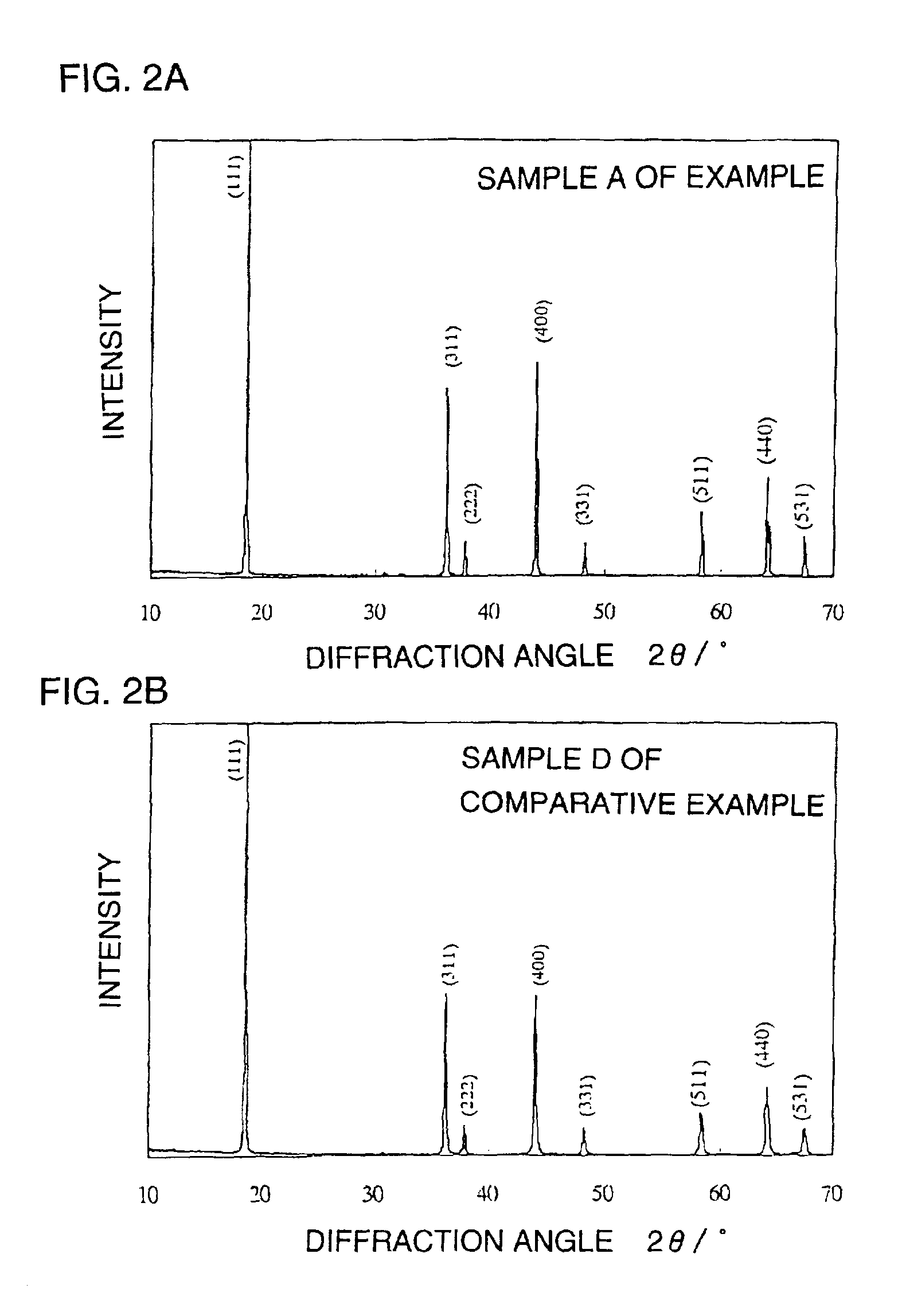

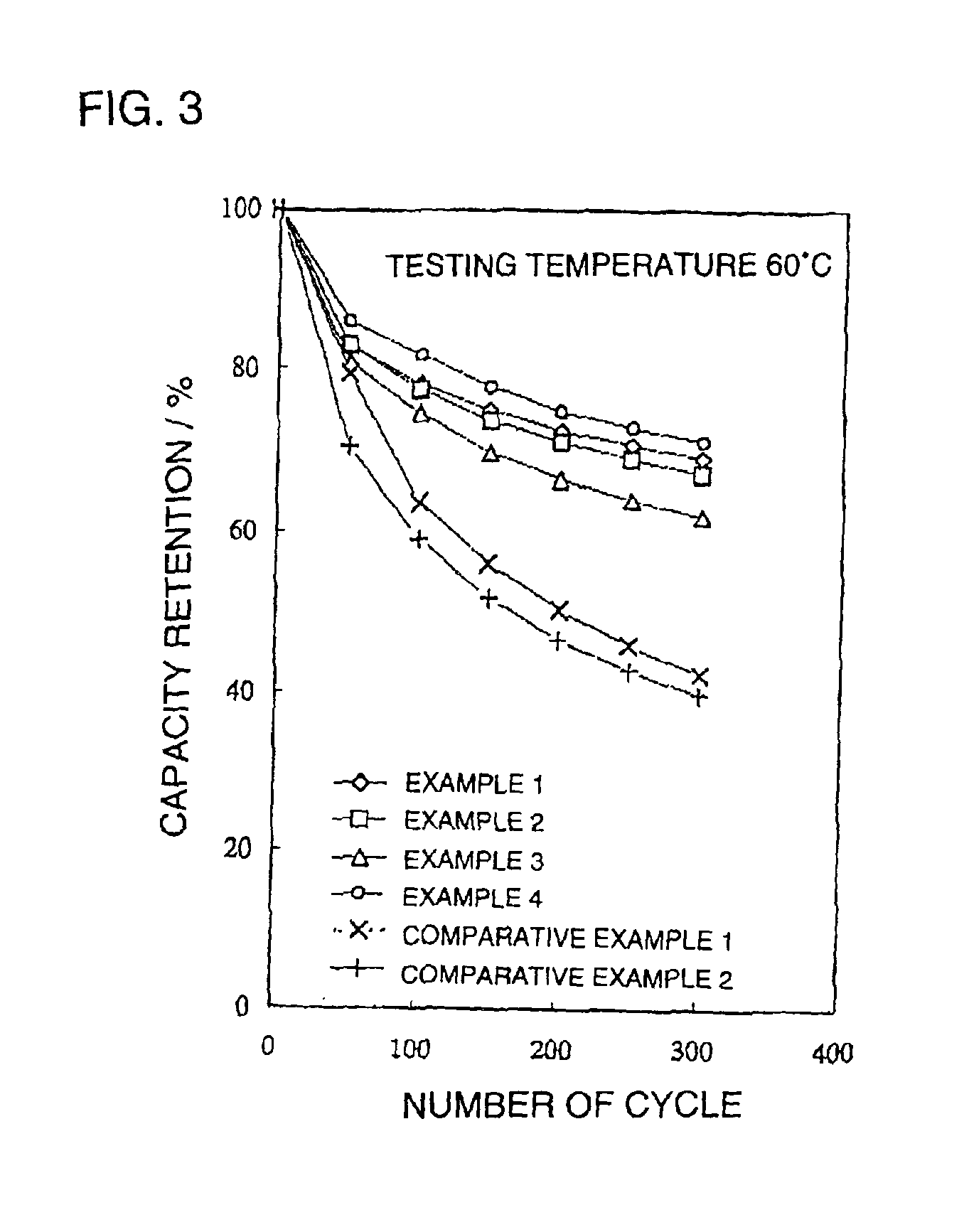

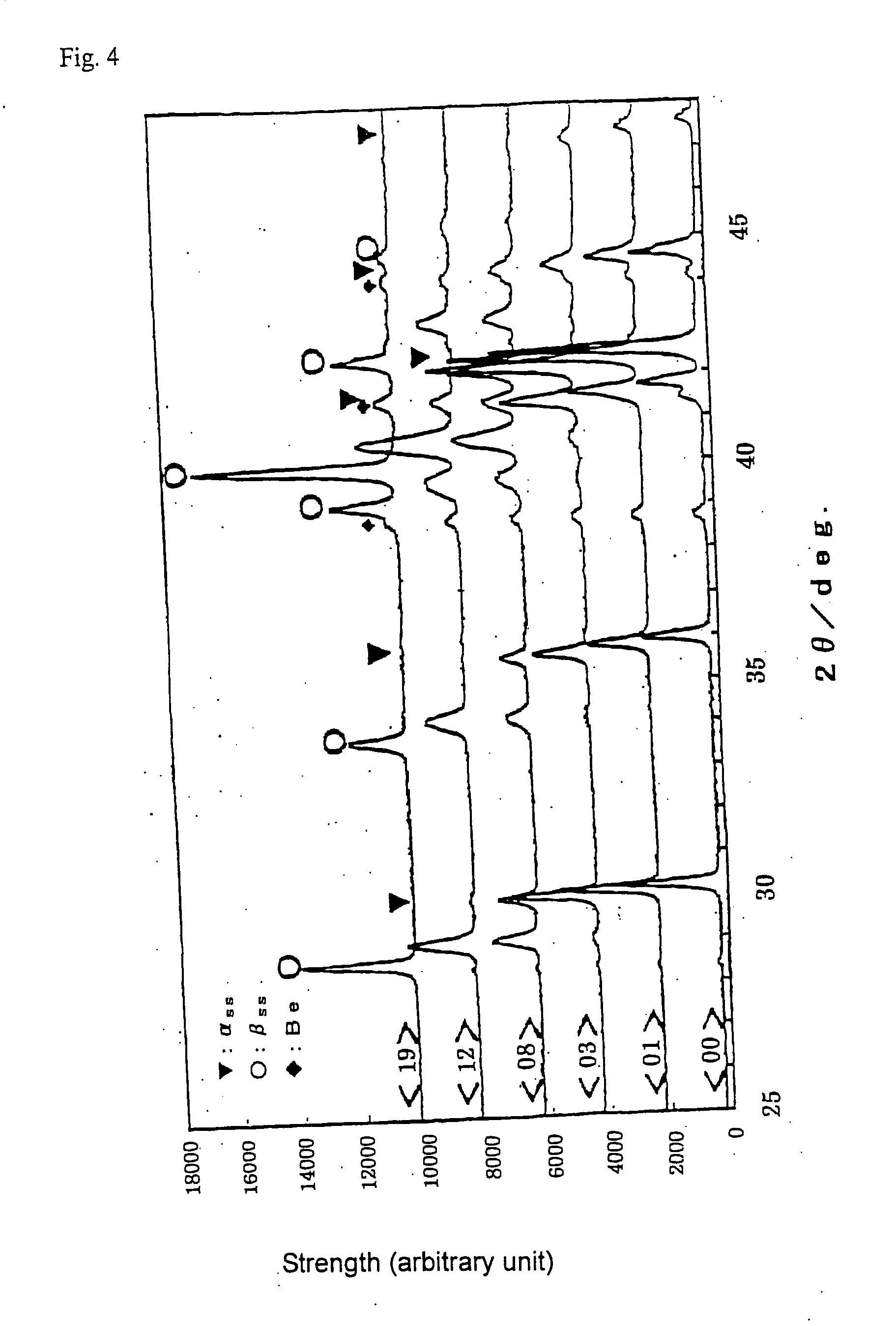

Positive active material for non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery comprising same

ActiveUS6924064B2Improve cycle performanceImprove charge and discharge performanceOxygen/ozone/oxide/hydroxideNon-aqueous electrolyte accumulatorsElectrical batteryRoom temperature

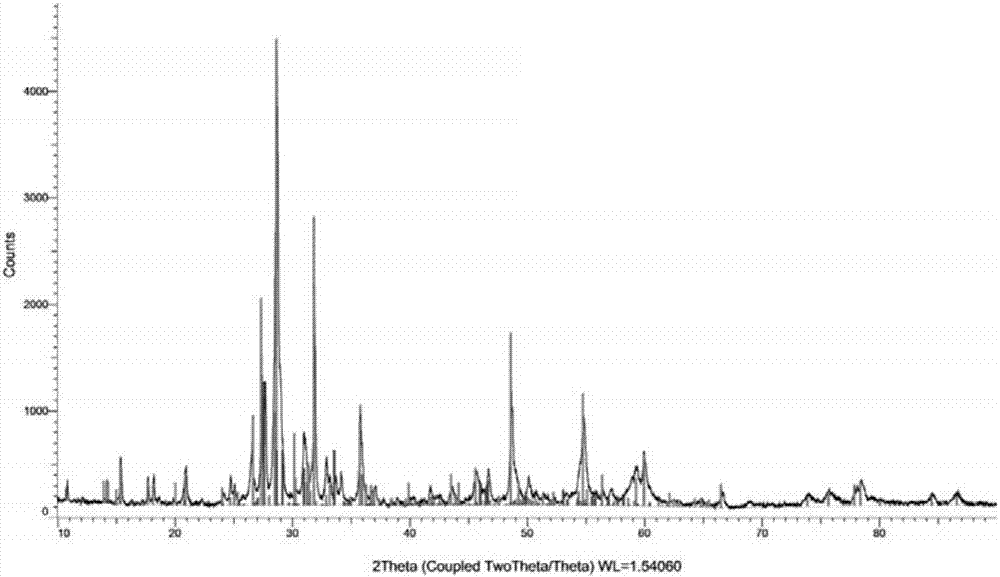

A positive active material for non-aqueous electrolyte secondary battery is provided comprising lithium manganese oxide having such a spinel structure that the half-width (2θ) of the reflection peak corresponding to 440 plane as determined by X-ray diffractometry using CuKα ray is not greater than 0.145°. The use of this positive active material makes it possible to obtain a secondary battery which exhibits a good cycle life performance at room temperature and high temperatures and a reduced capacity drop when stored at high temperatures.

Owner:GS YUASA INT LTD

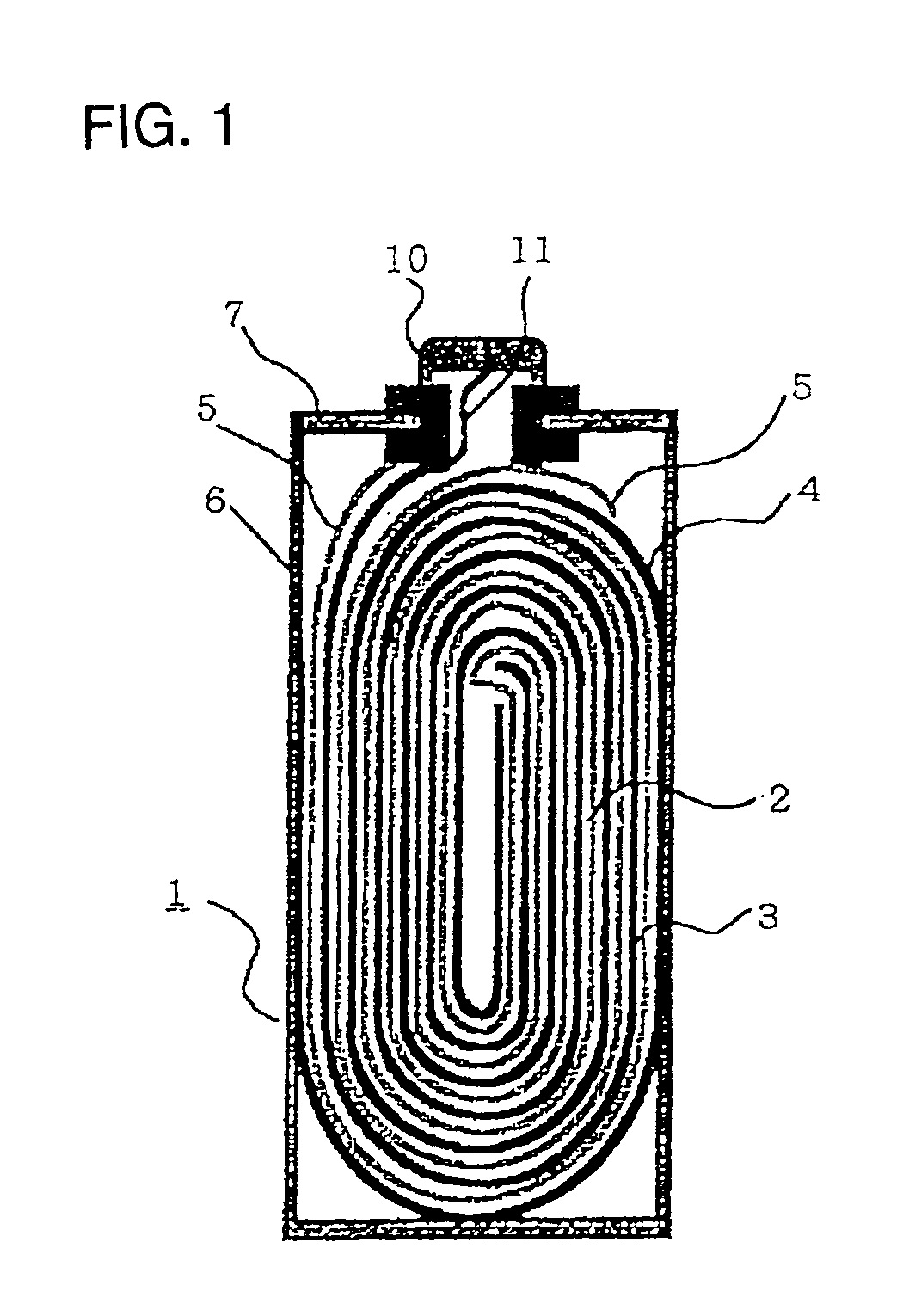

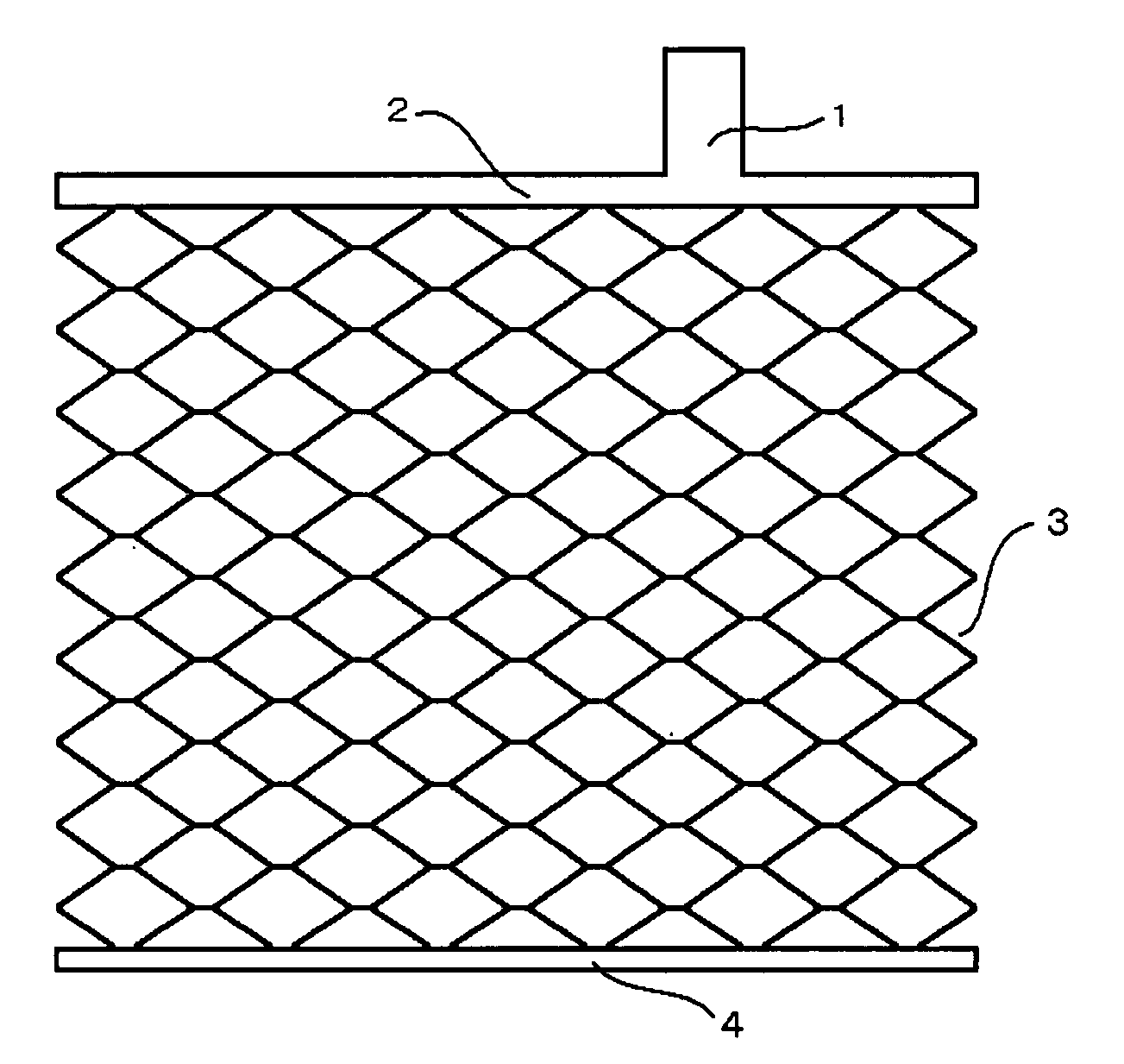

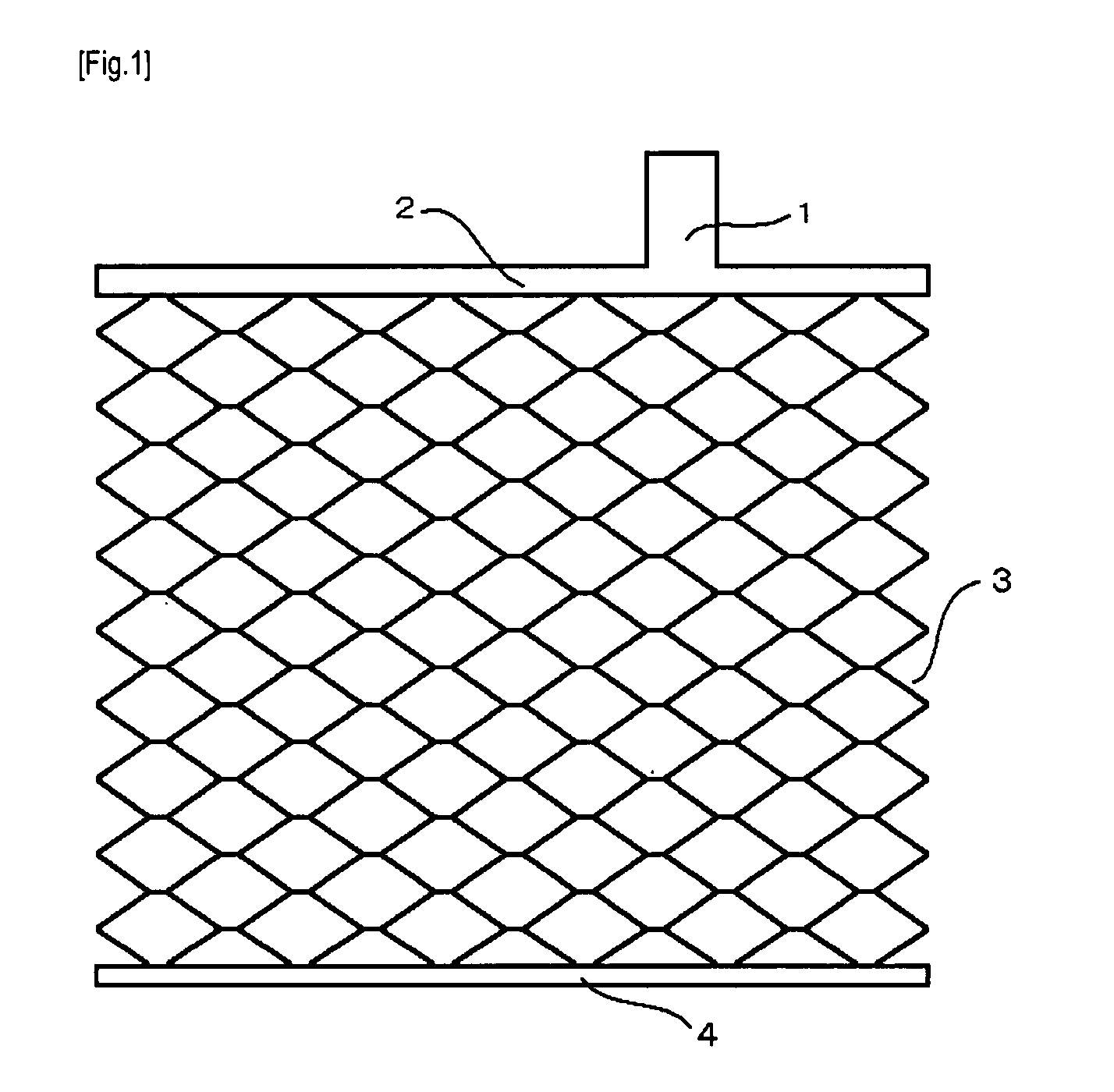

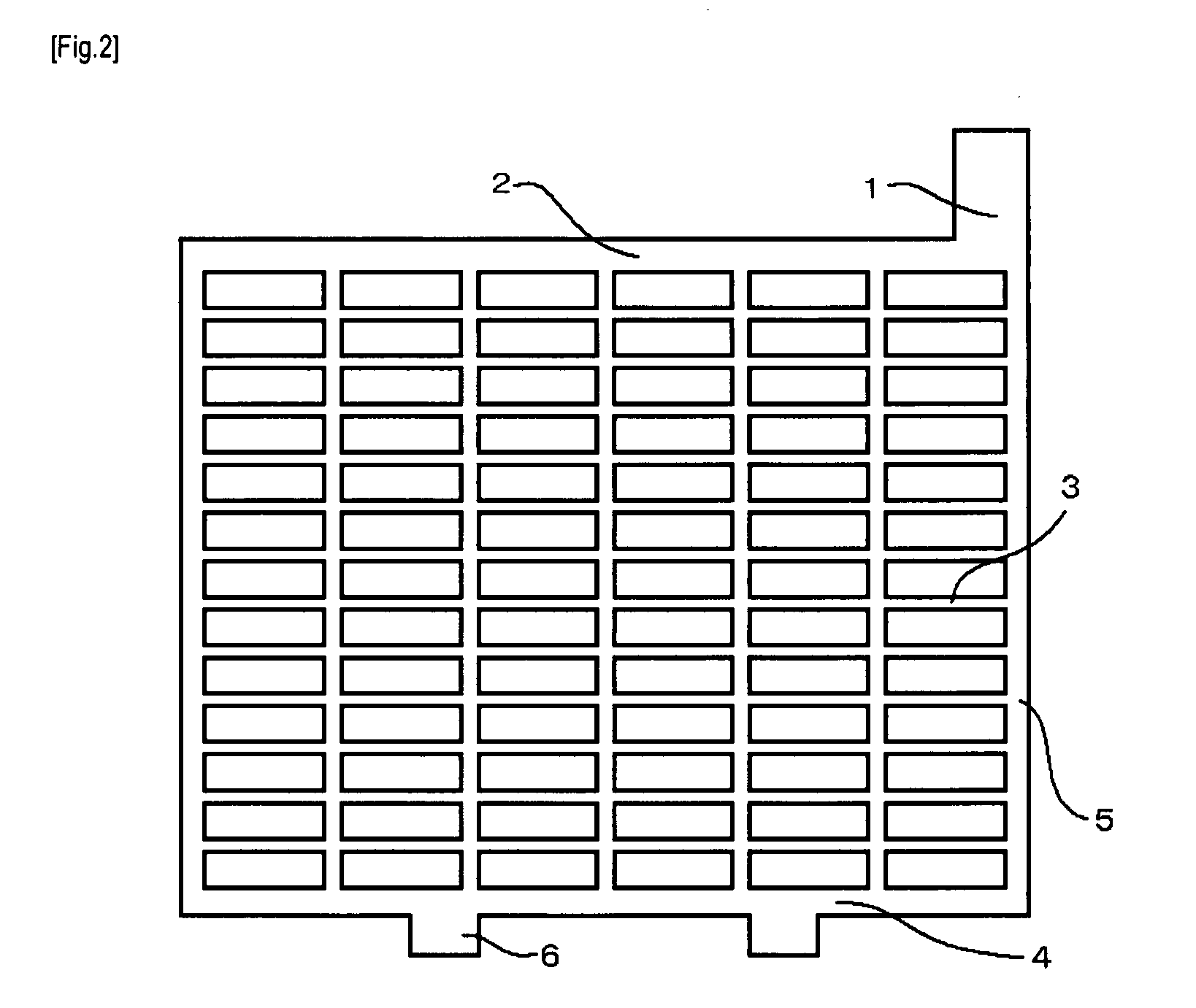

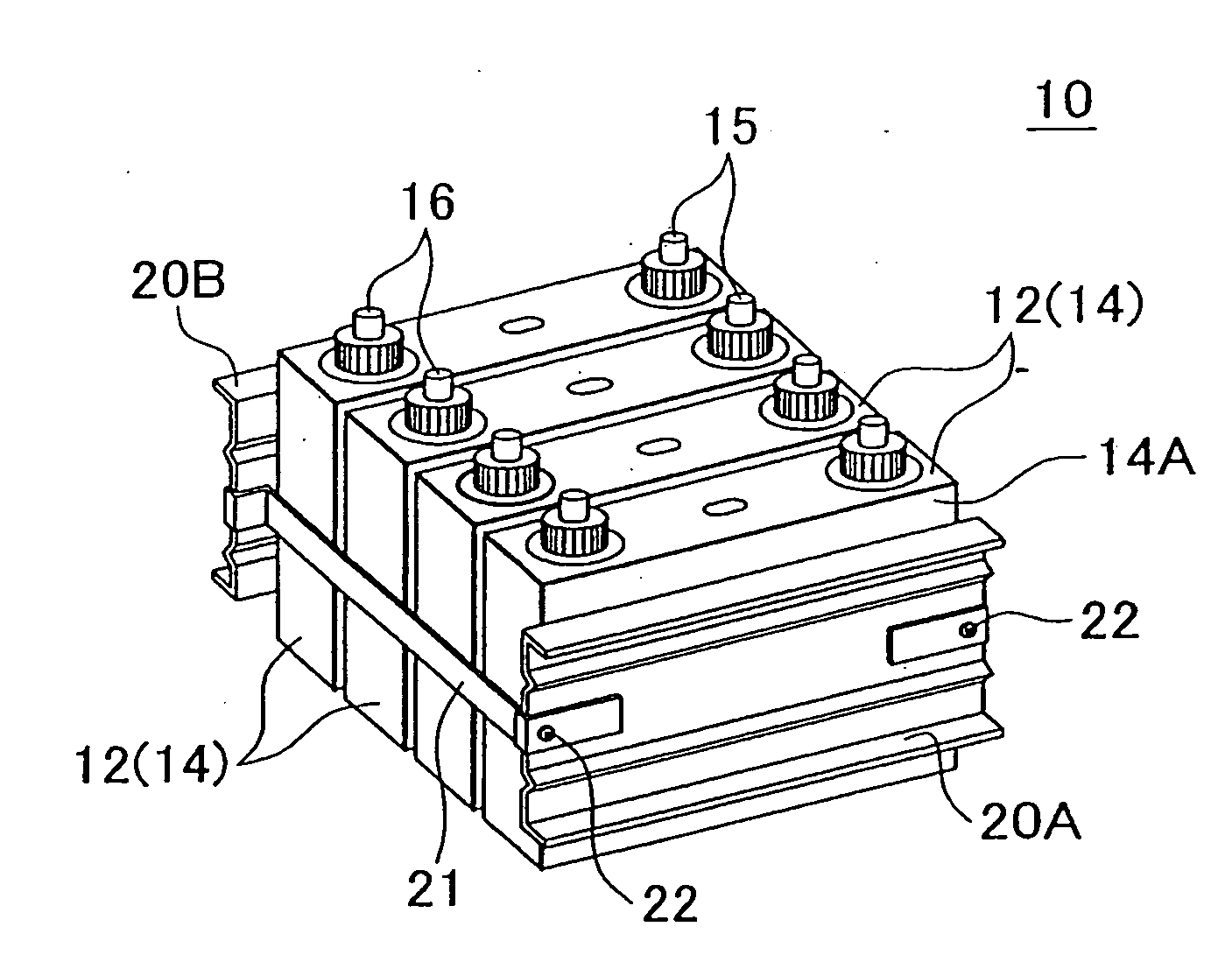

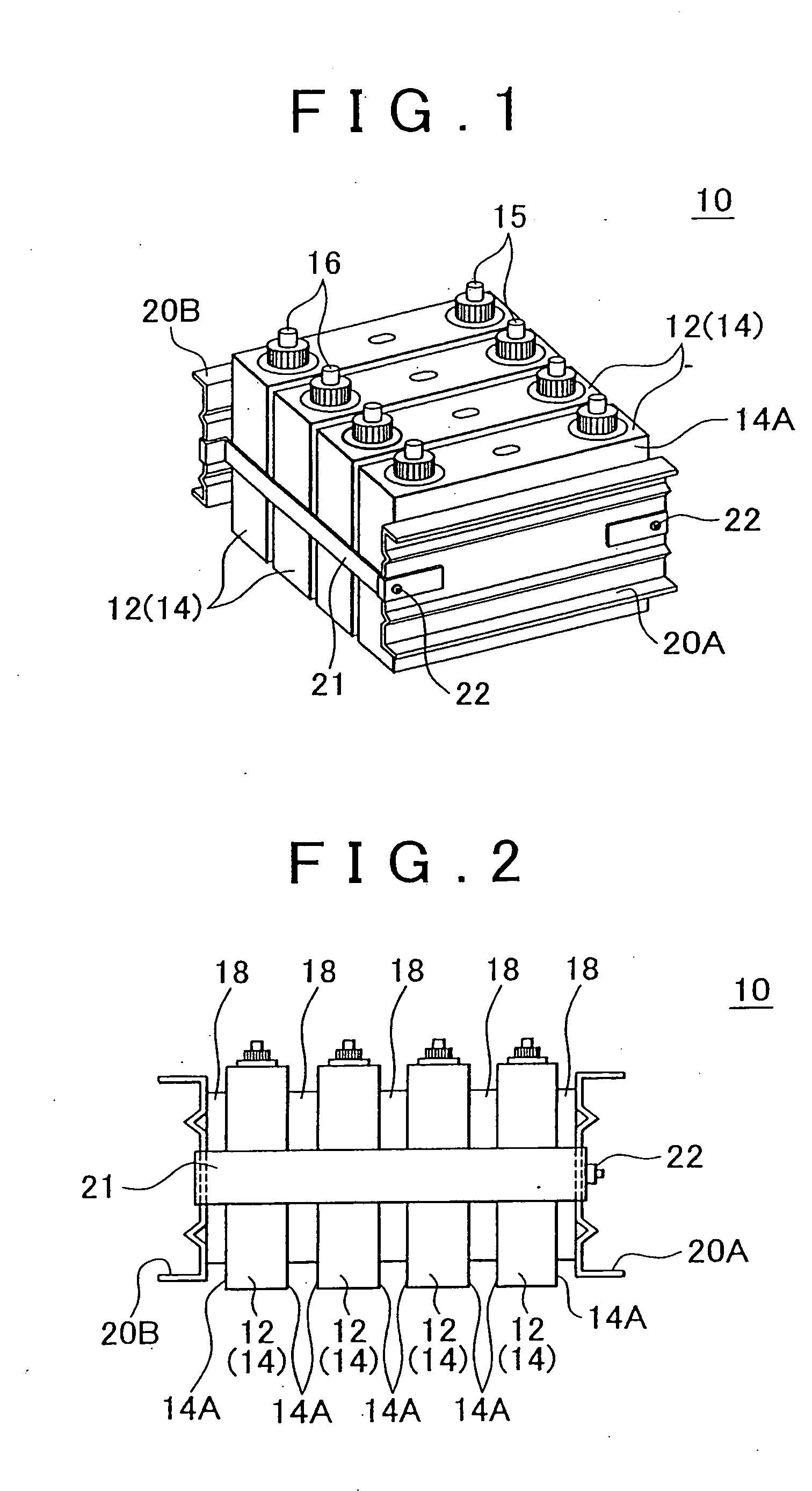

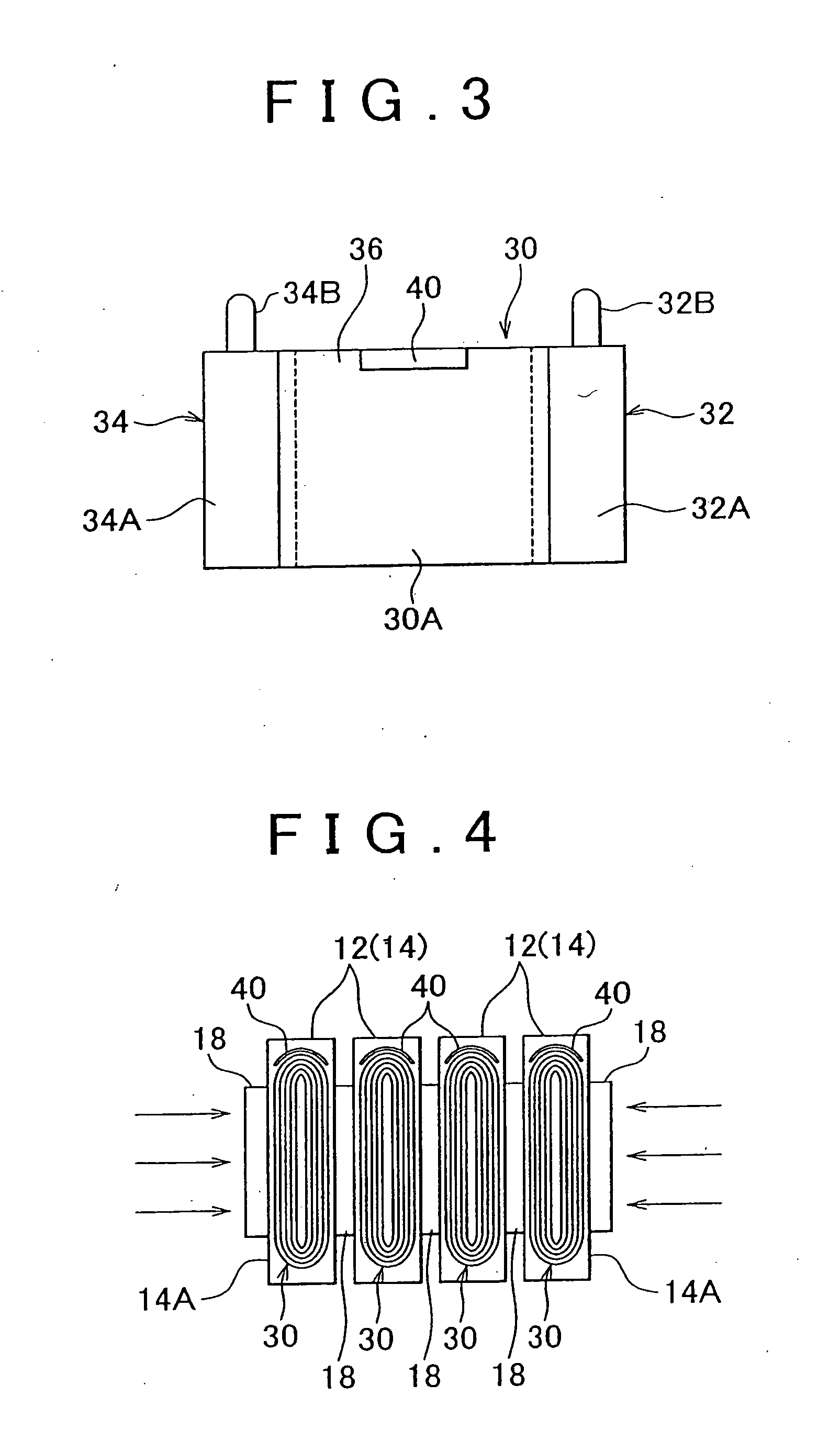

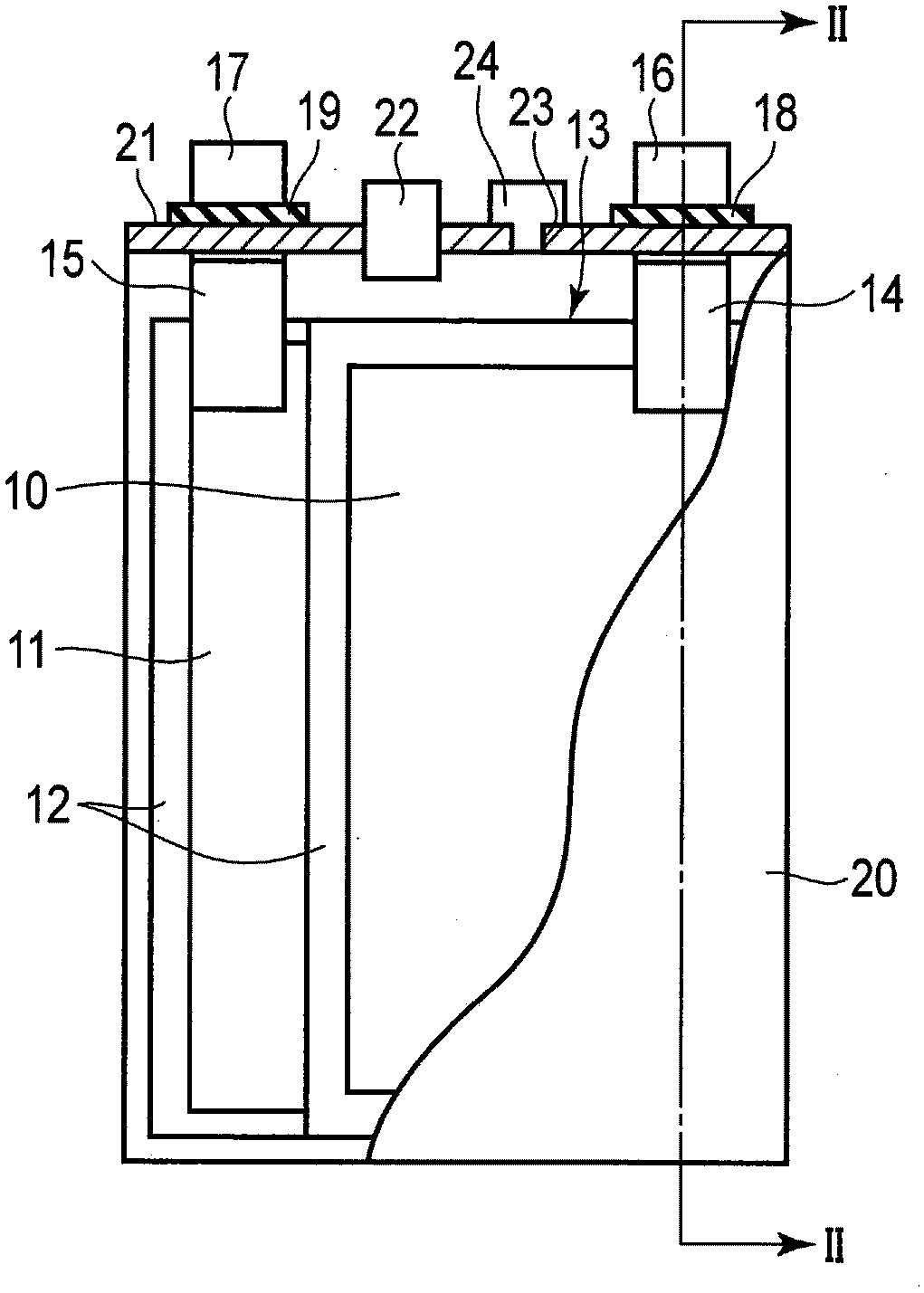

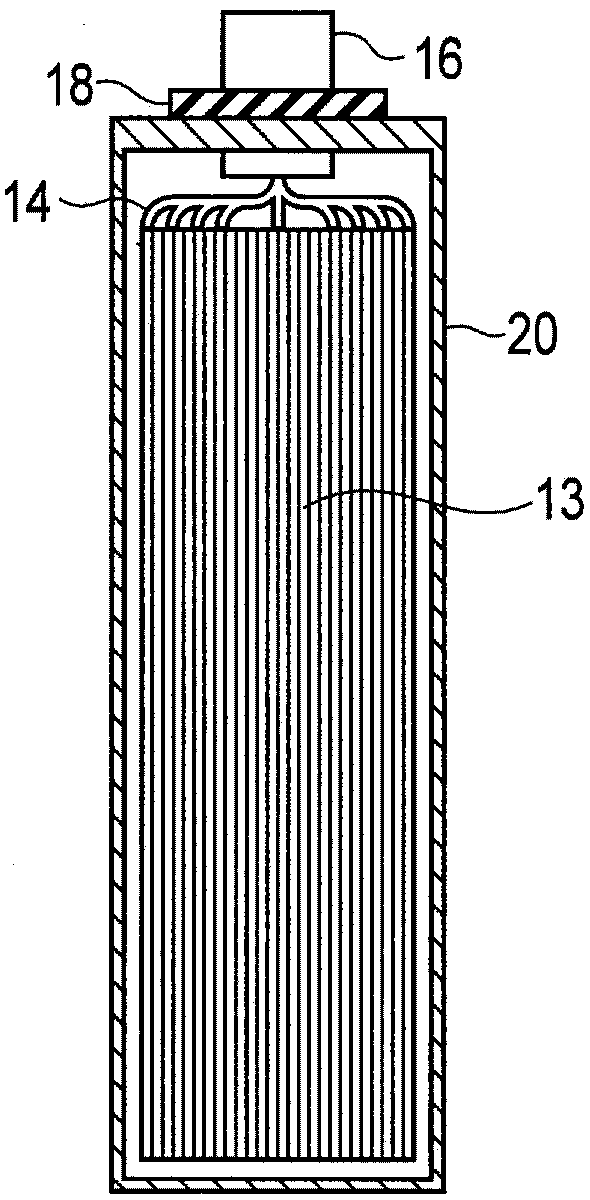

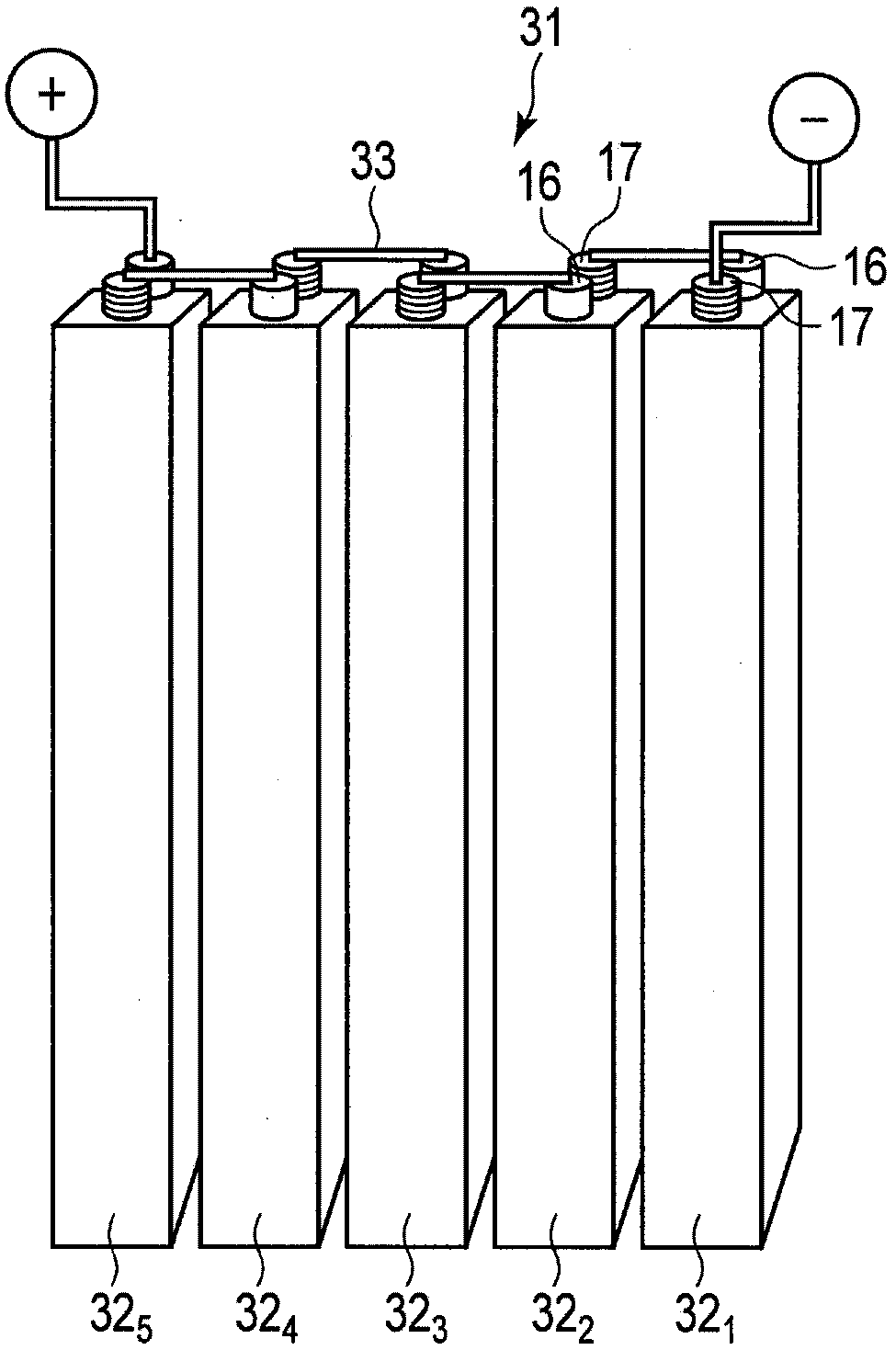

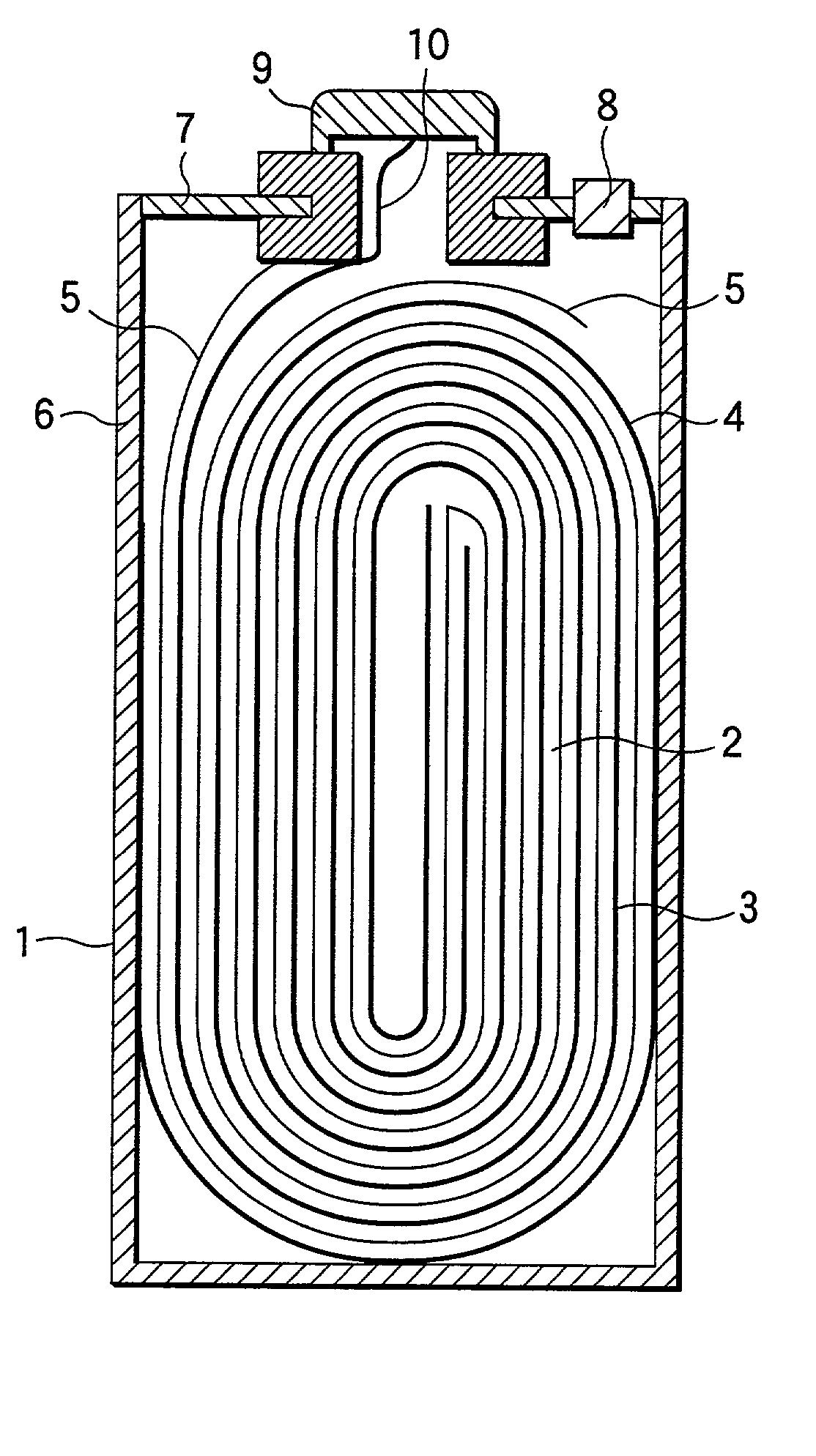

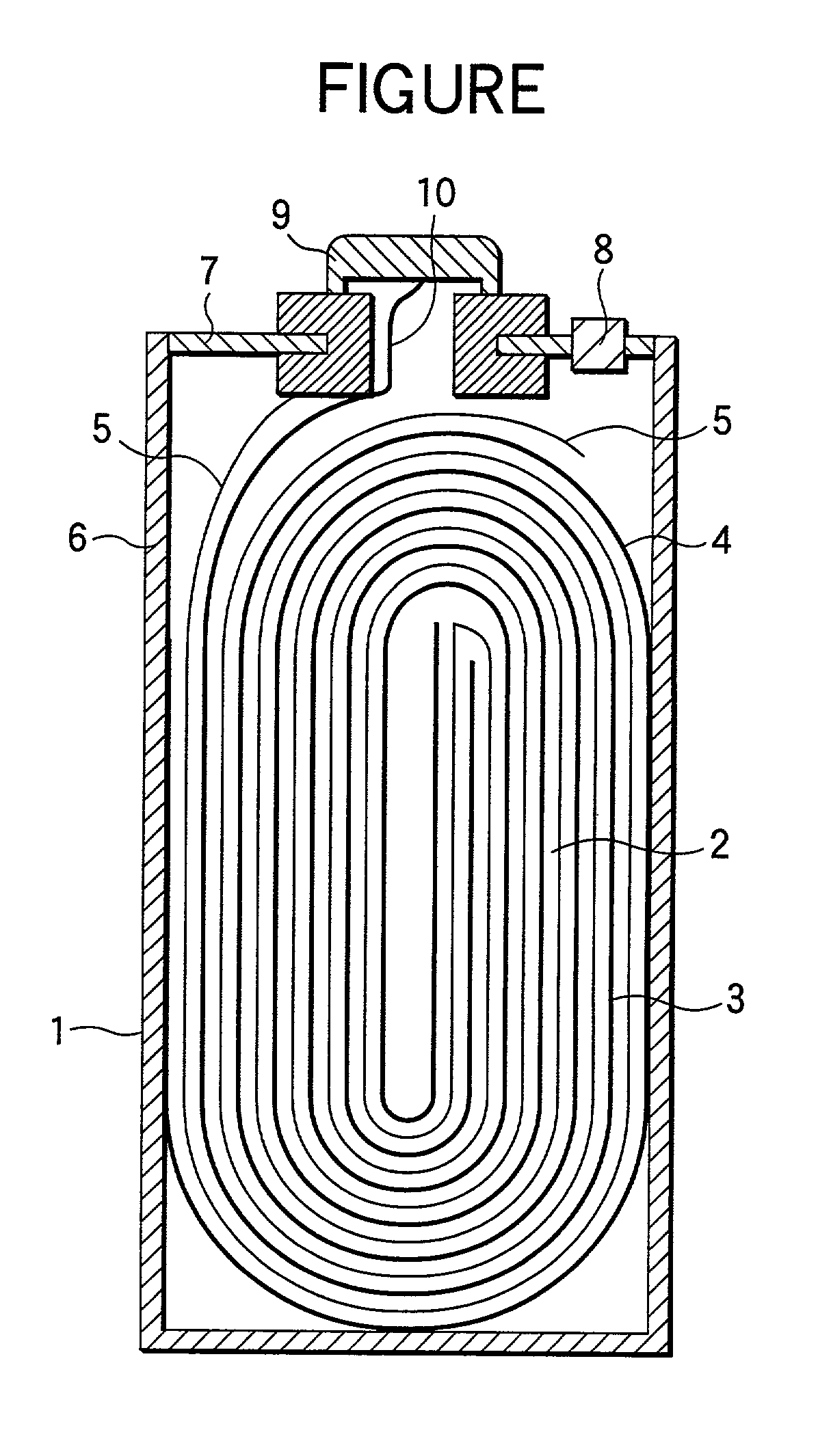

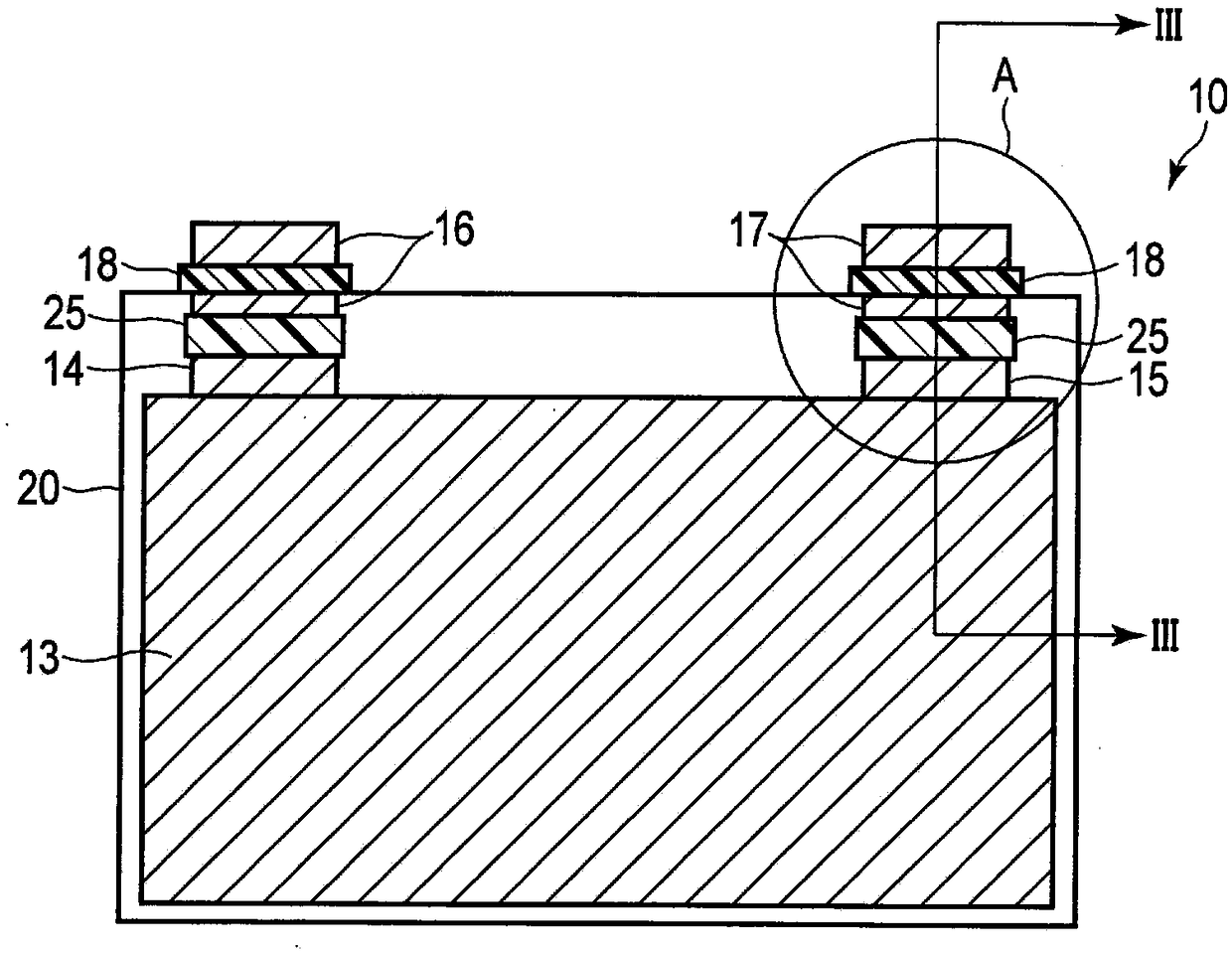

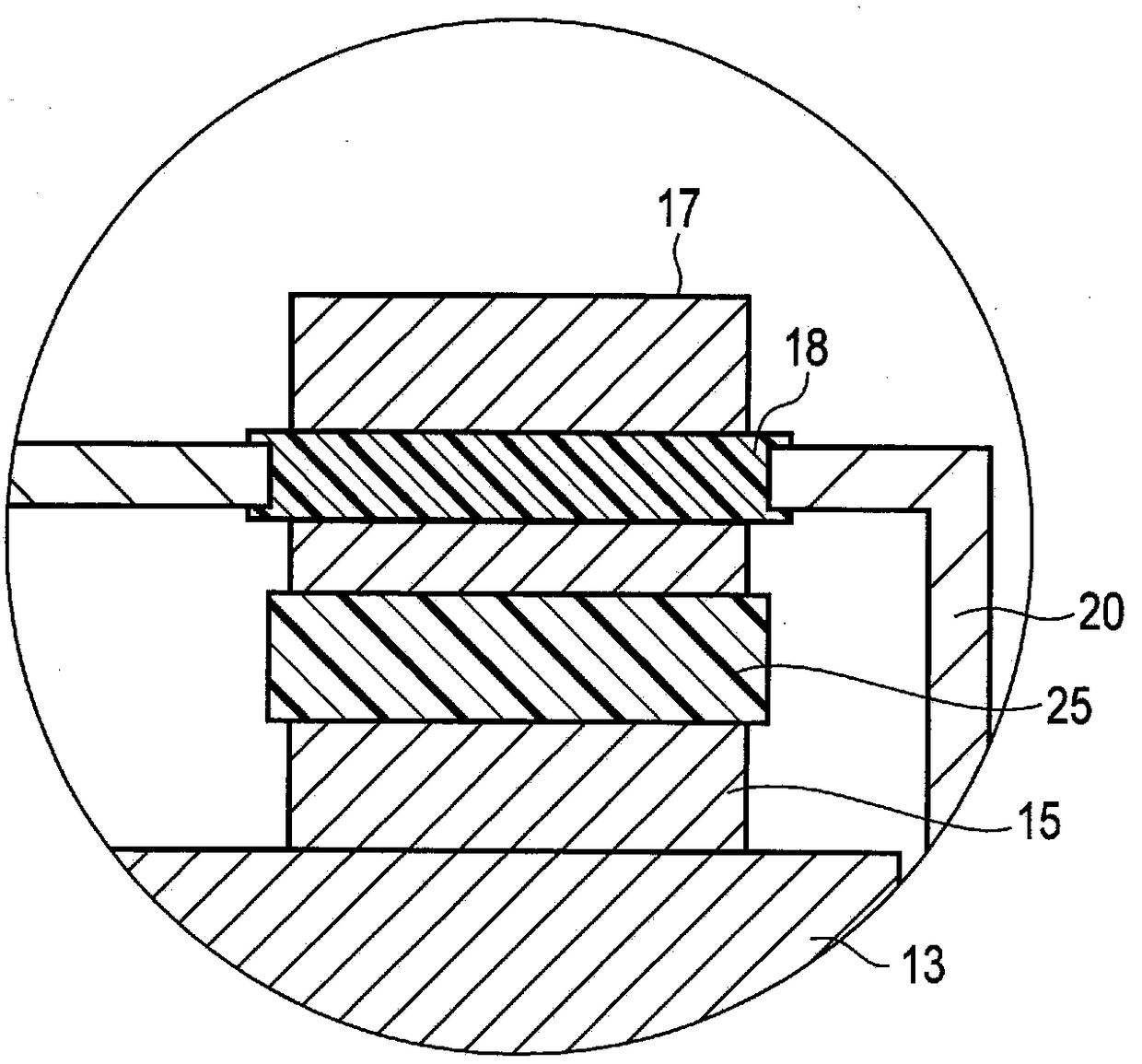

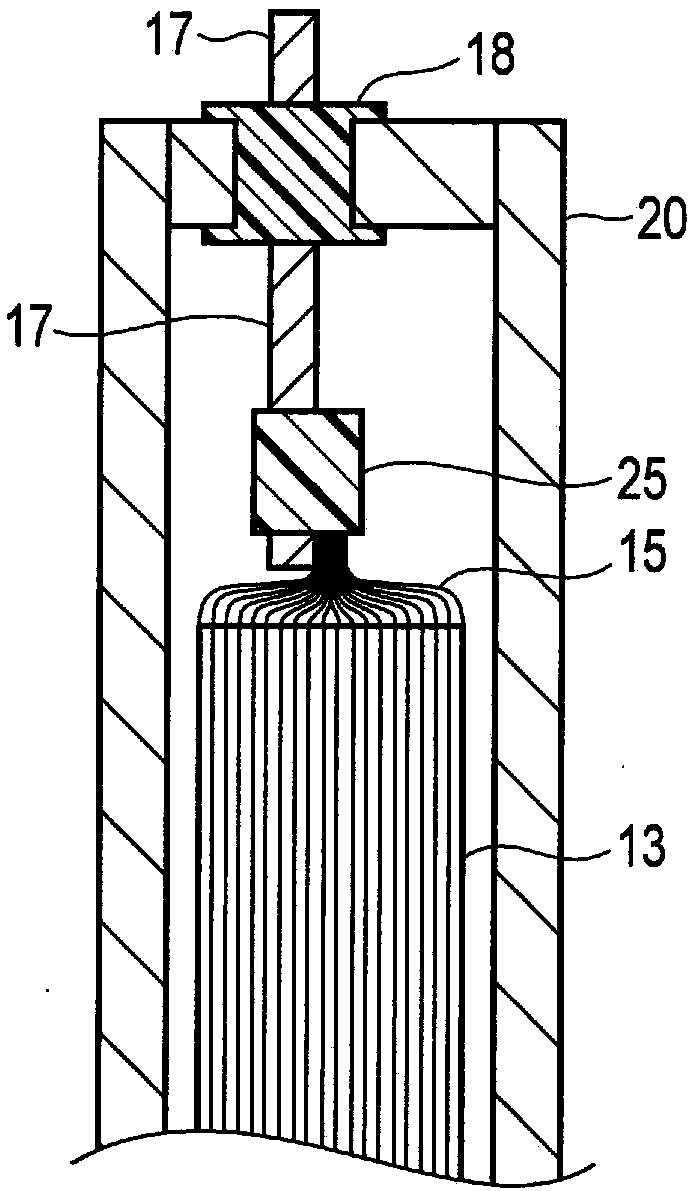

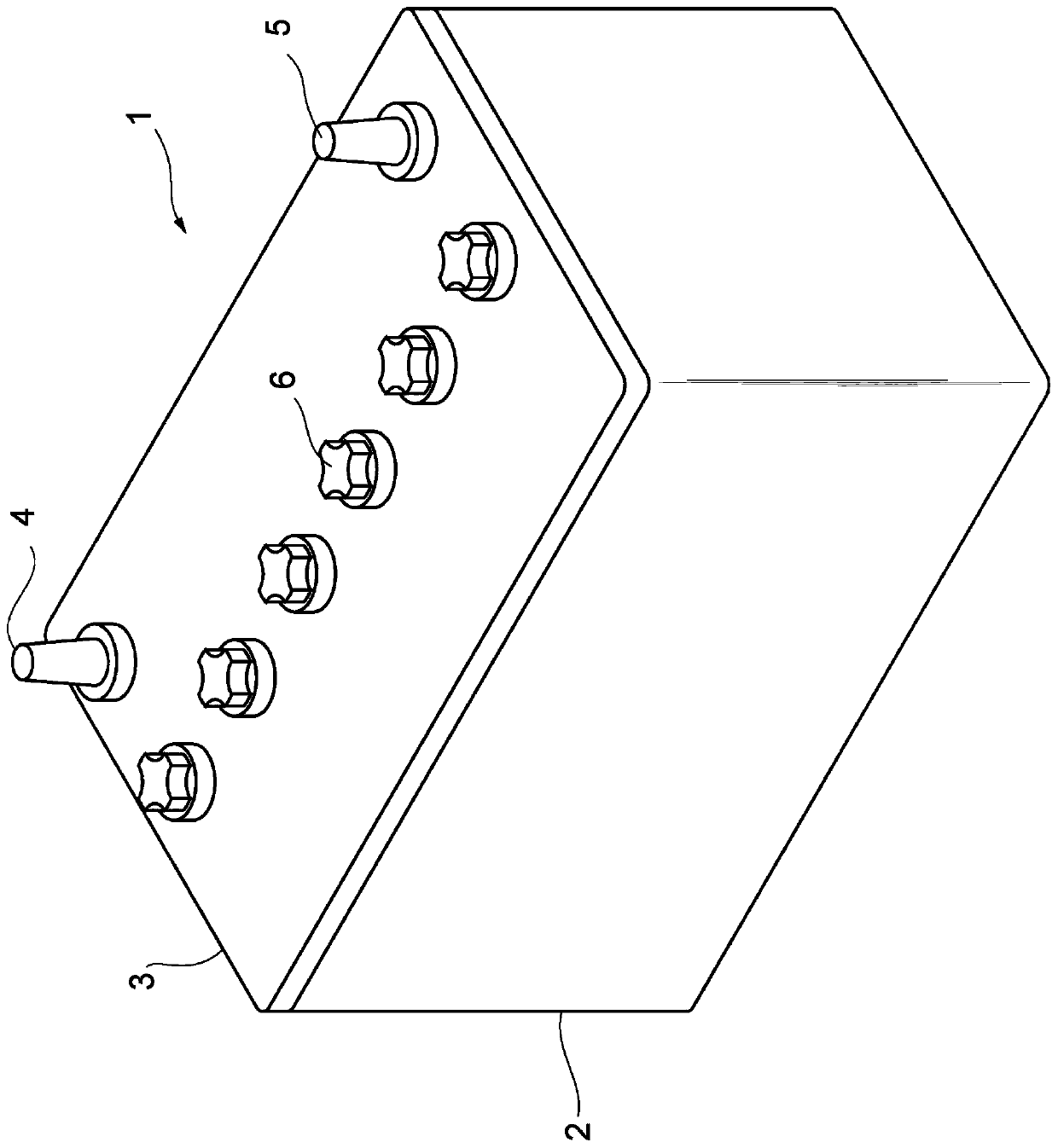

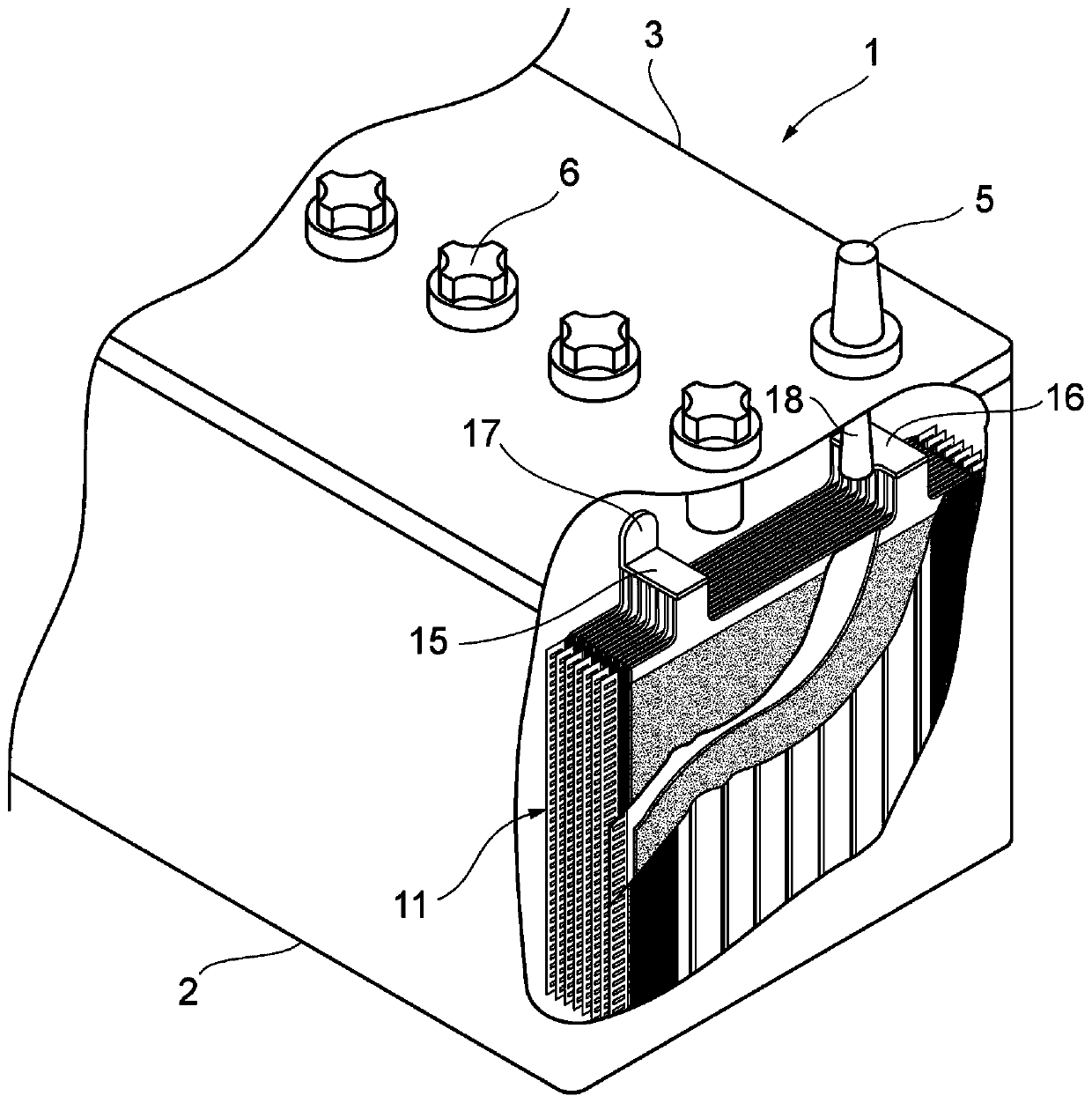

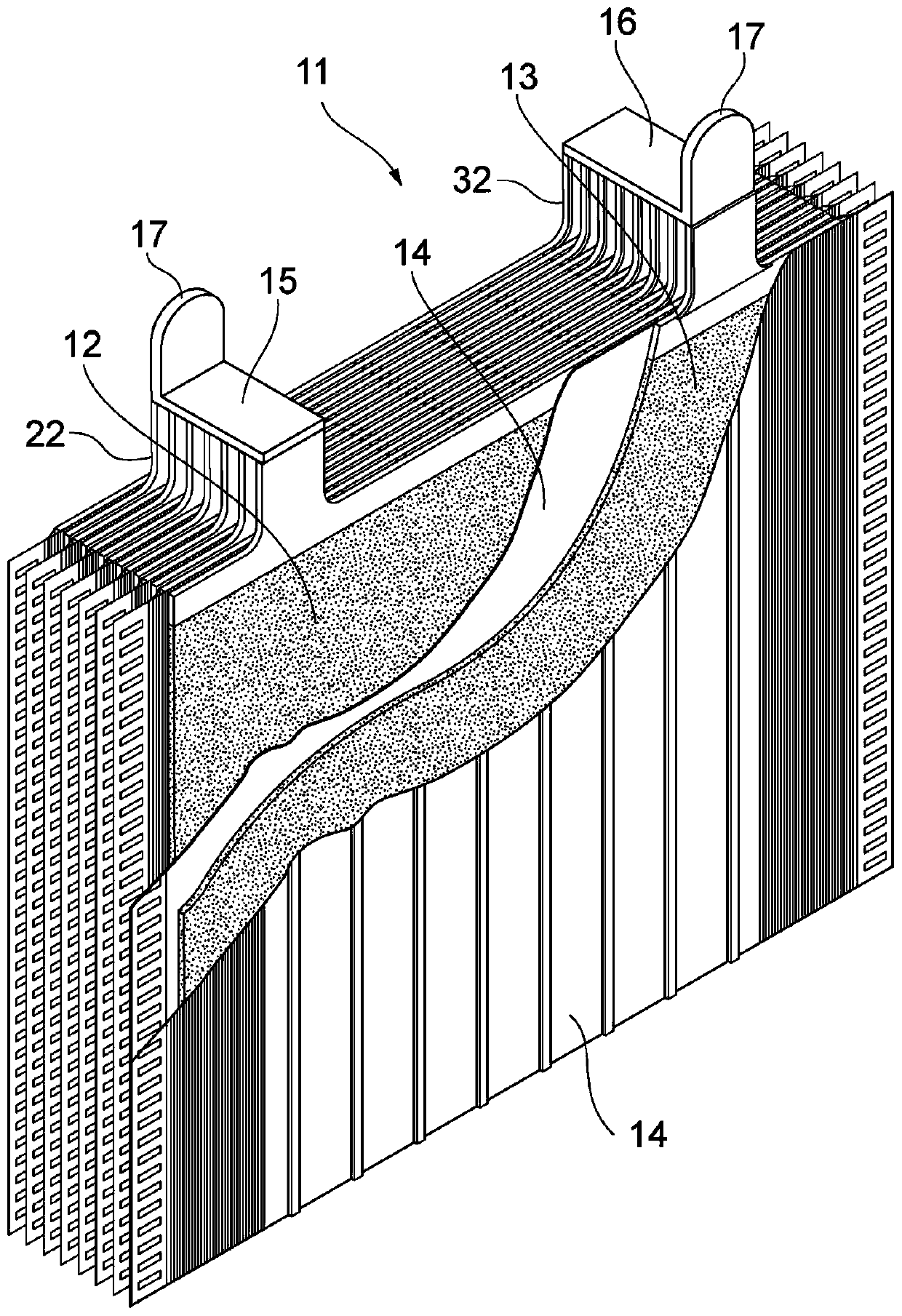

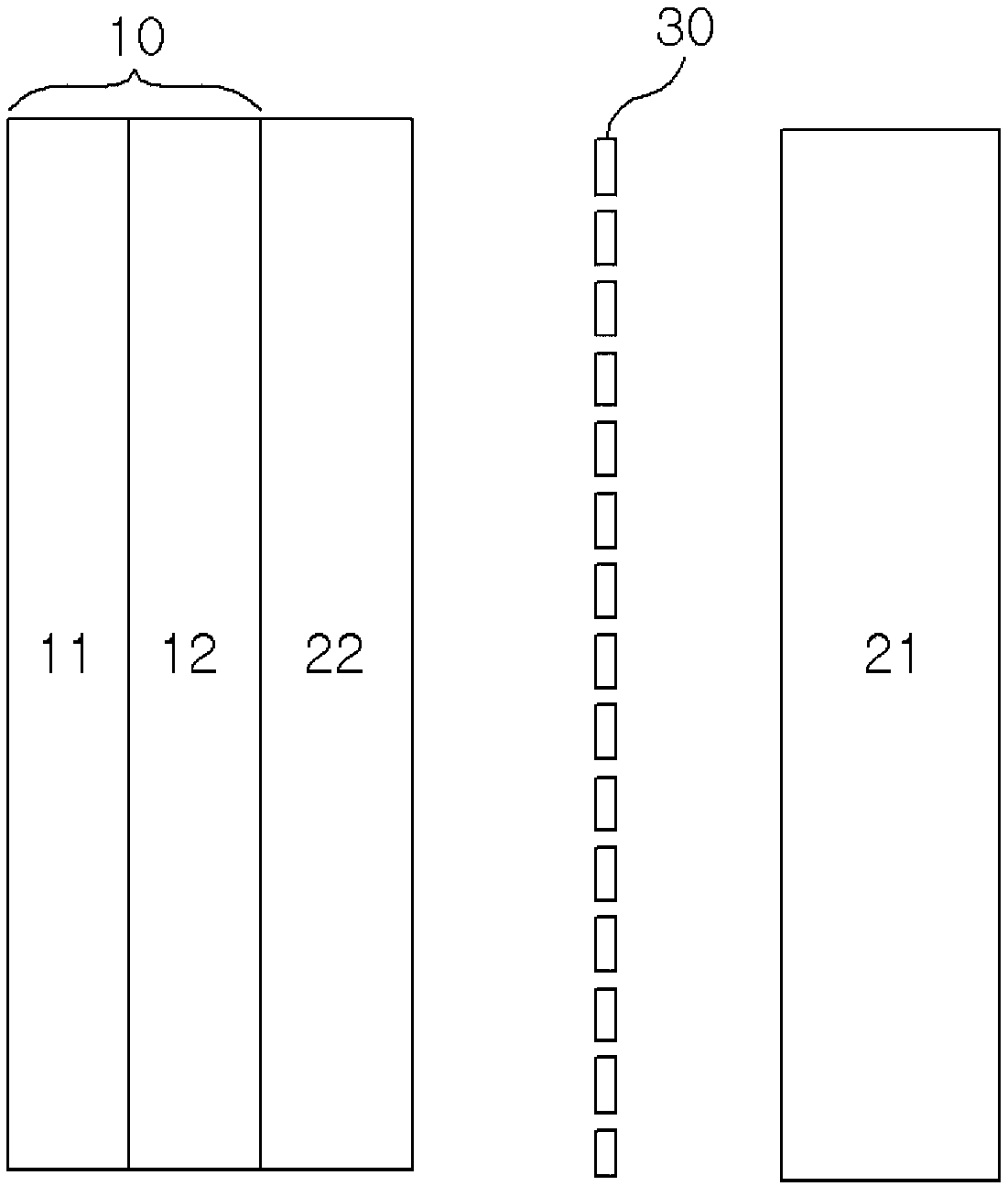

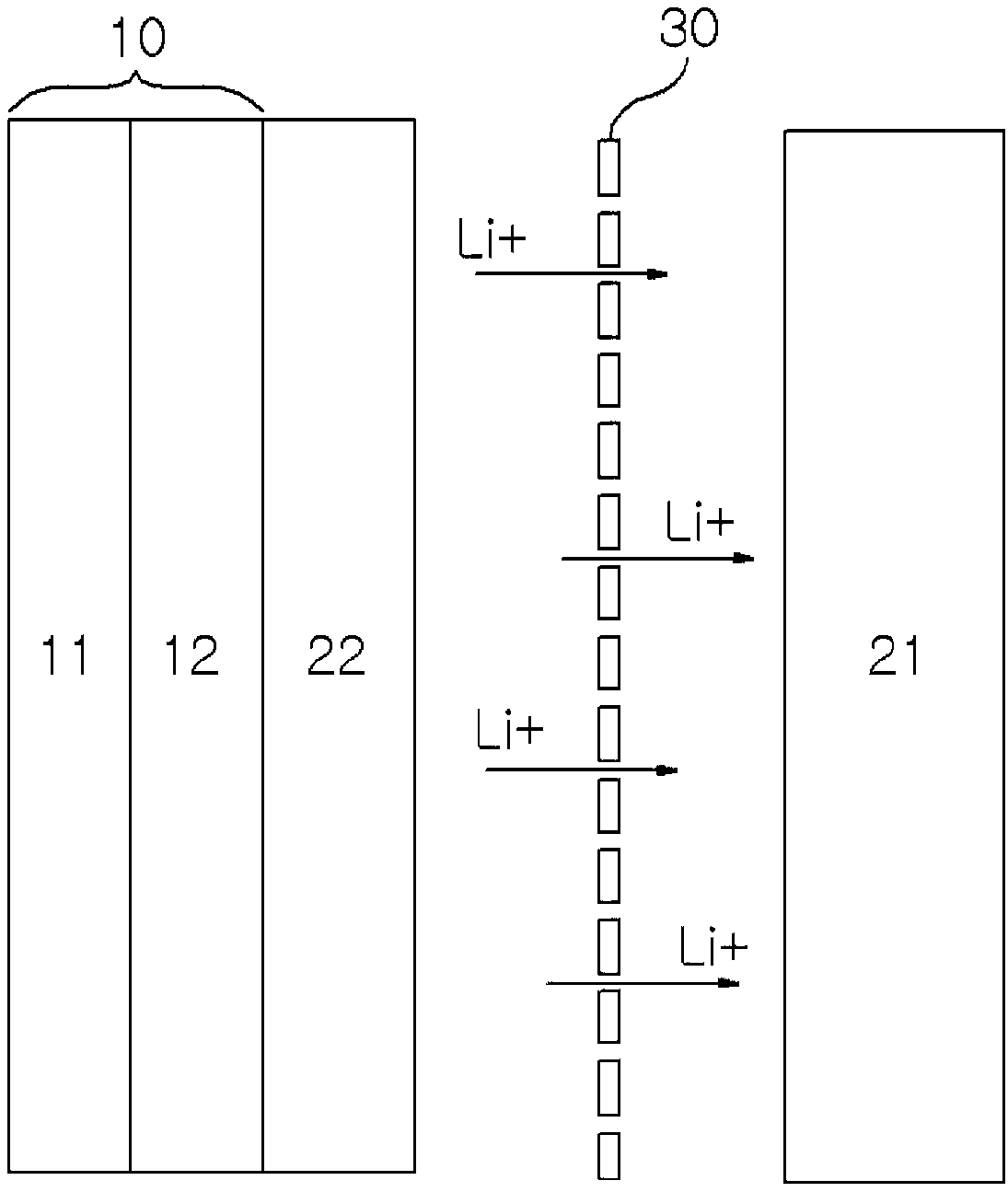

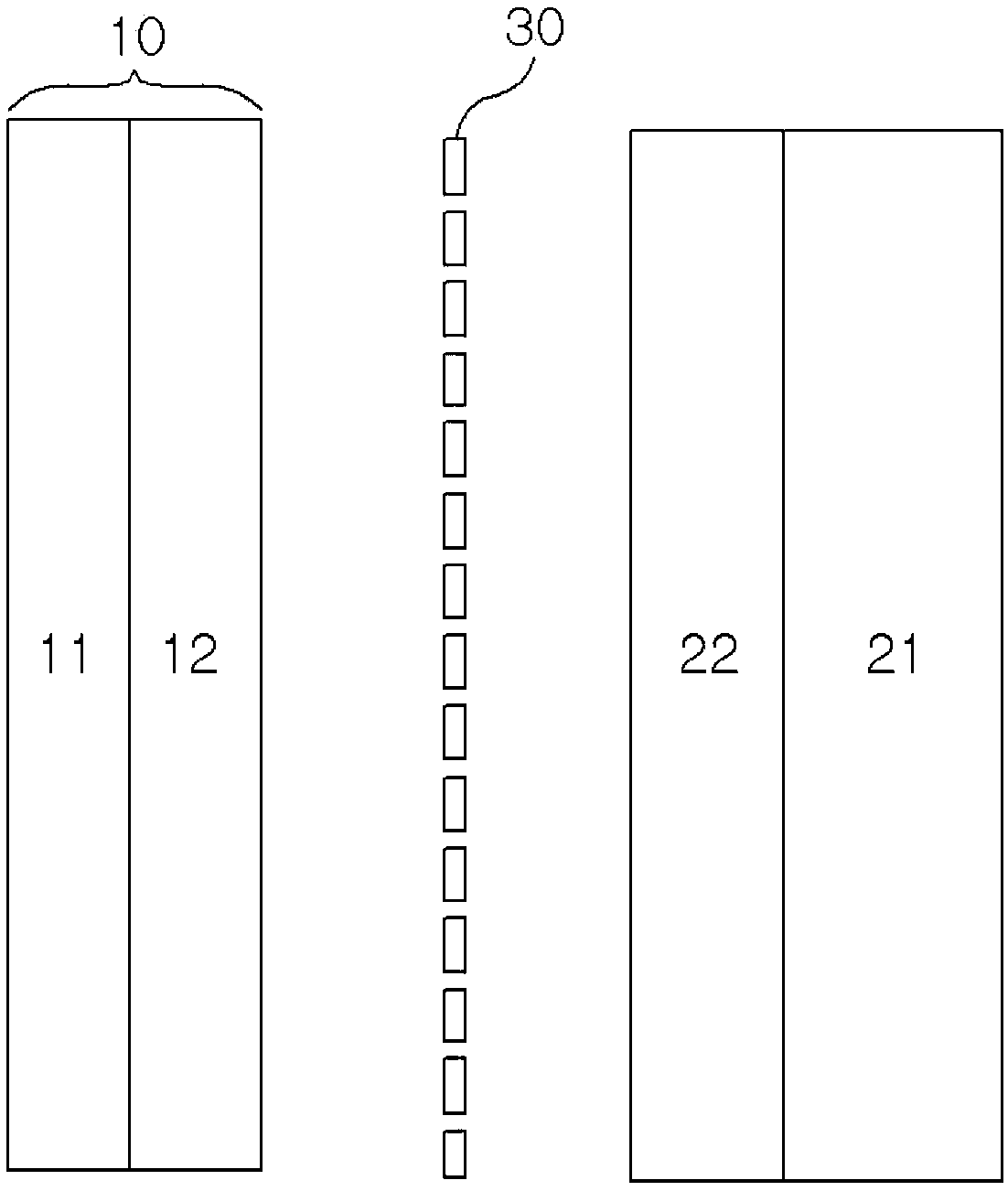

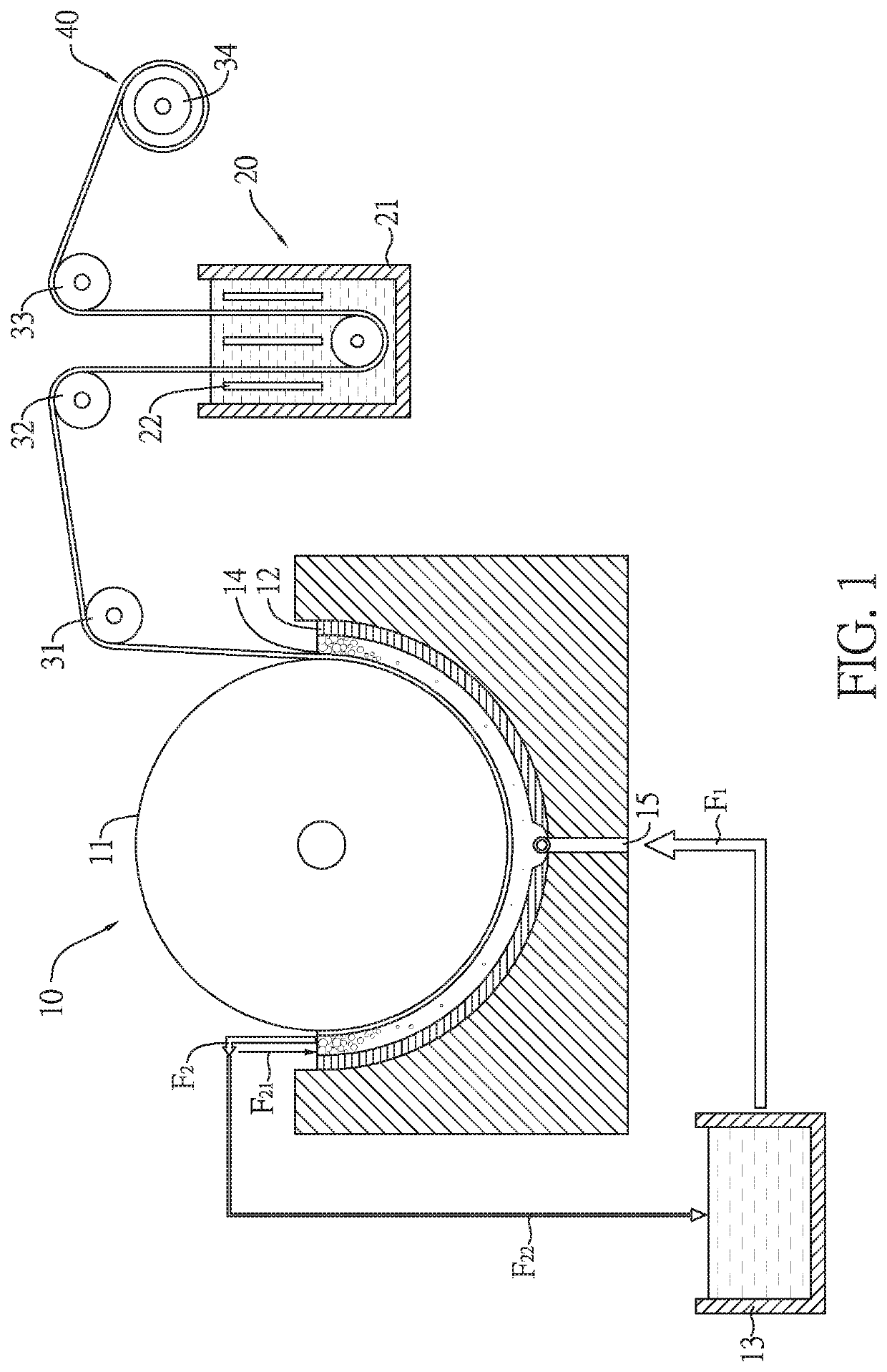

Battery module, method of fabricating the same, and vehicle having battery module

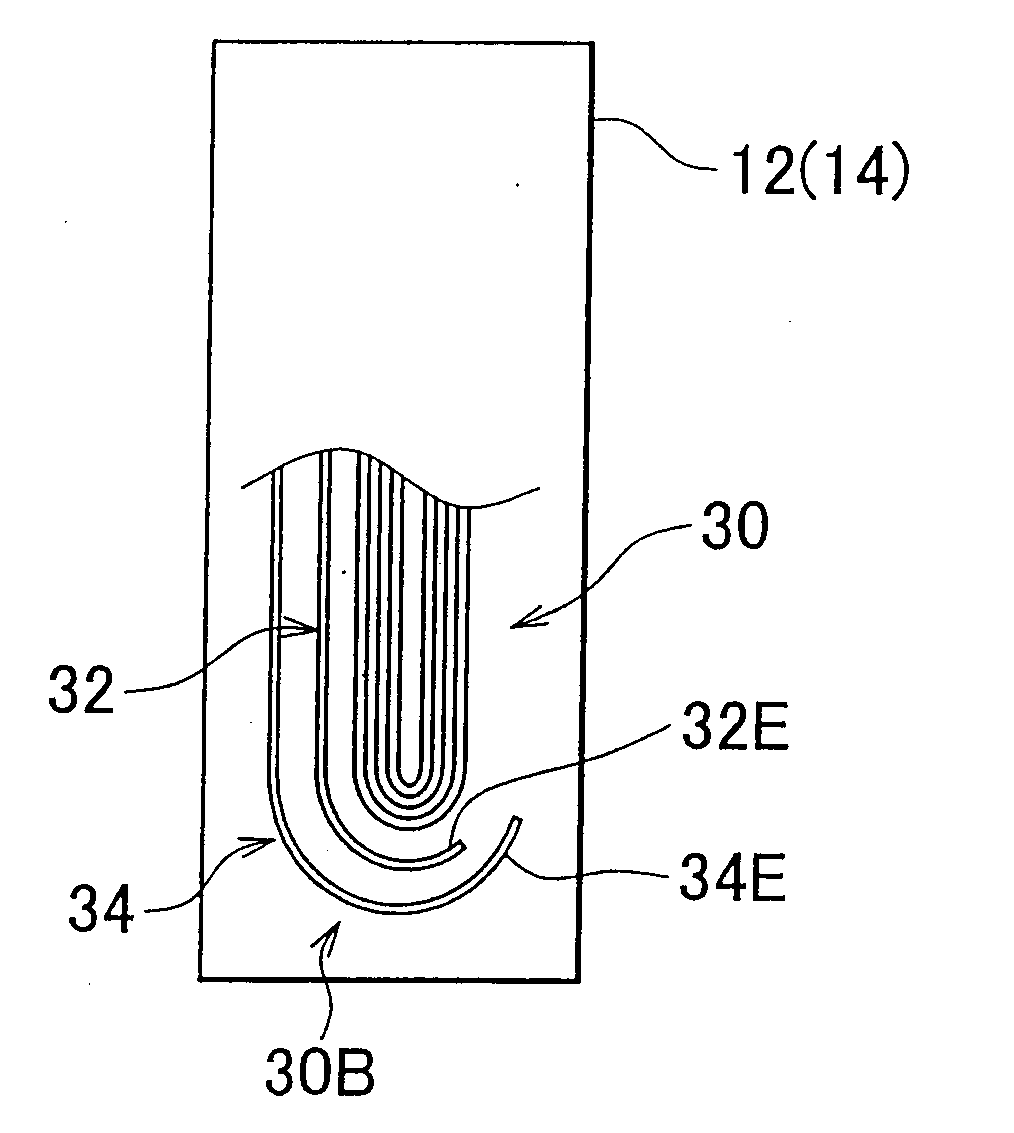

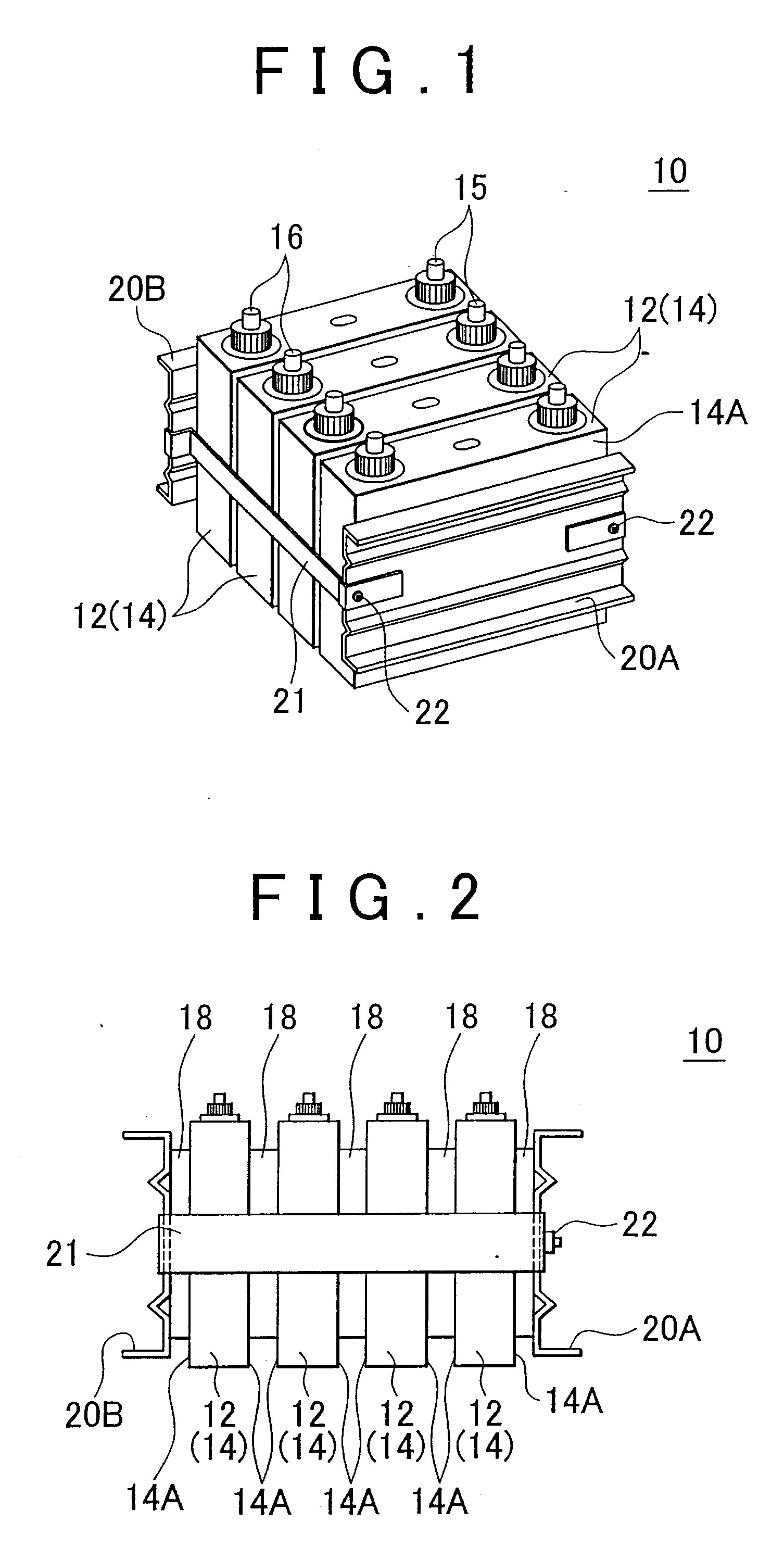

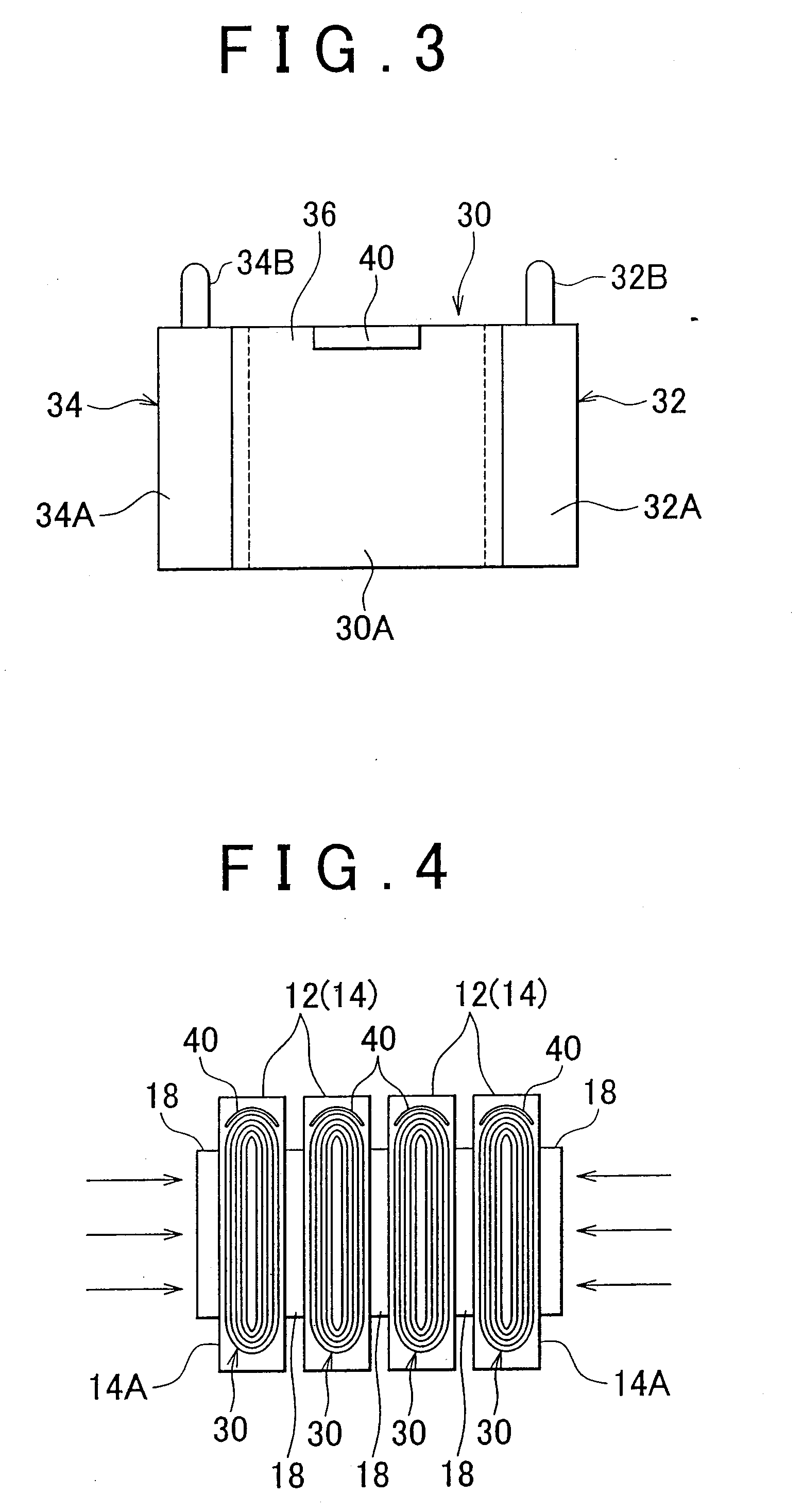

ActiveUS20090202900A1Easy to useEnhanced cycle life performancePrimary cell to battery groupingHybrid capacitor electrodesEngineeringTrailing edge

Each of battery cells (12) that constitute a battery module includes a flat-shaped rolled electrode body (30) formed by rolling a sheet-like anode collector (32) and a sheet-like cathode collector (34) along with a sheet-like separator, and a trailing edge (32E) of the sheet-like anode collector (32) and a trailing edge (34E) of the sheet-like cathode collector (34) are located at a position (30B) outside a portion of the rolled electrode body (30) which substantially receives a restraining load. The battery module, in which the restraining load is applied to the cells, achieves long service life while maintaining good output characteristics.

Owner:TOYOTA JIDOSHA KK

Cathode material for lithium batteries

ActiveUS8492030B2High tap densityIncrease energy densityAlkali metal oxidesCobalt compoundsNickel–lithium batteryOxide cathode

A method of manufacture an article of a cathode (positive electrode) material for lithium batteries. The cathode material is a lithium molybdenum composite transition metal oxide material and is prepared by mixing in a solid state an intermediate molybdenum composite transition metal oxide and a lithium source. The mixture is thermally treated to obtain the lithium molybdenum composite transition metal oxide cathode material.

Owner:UCHICAGO ARGONNE LLC

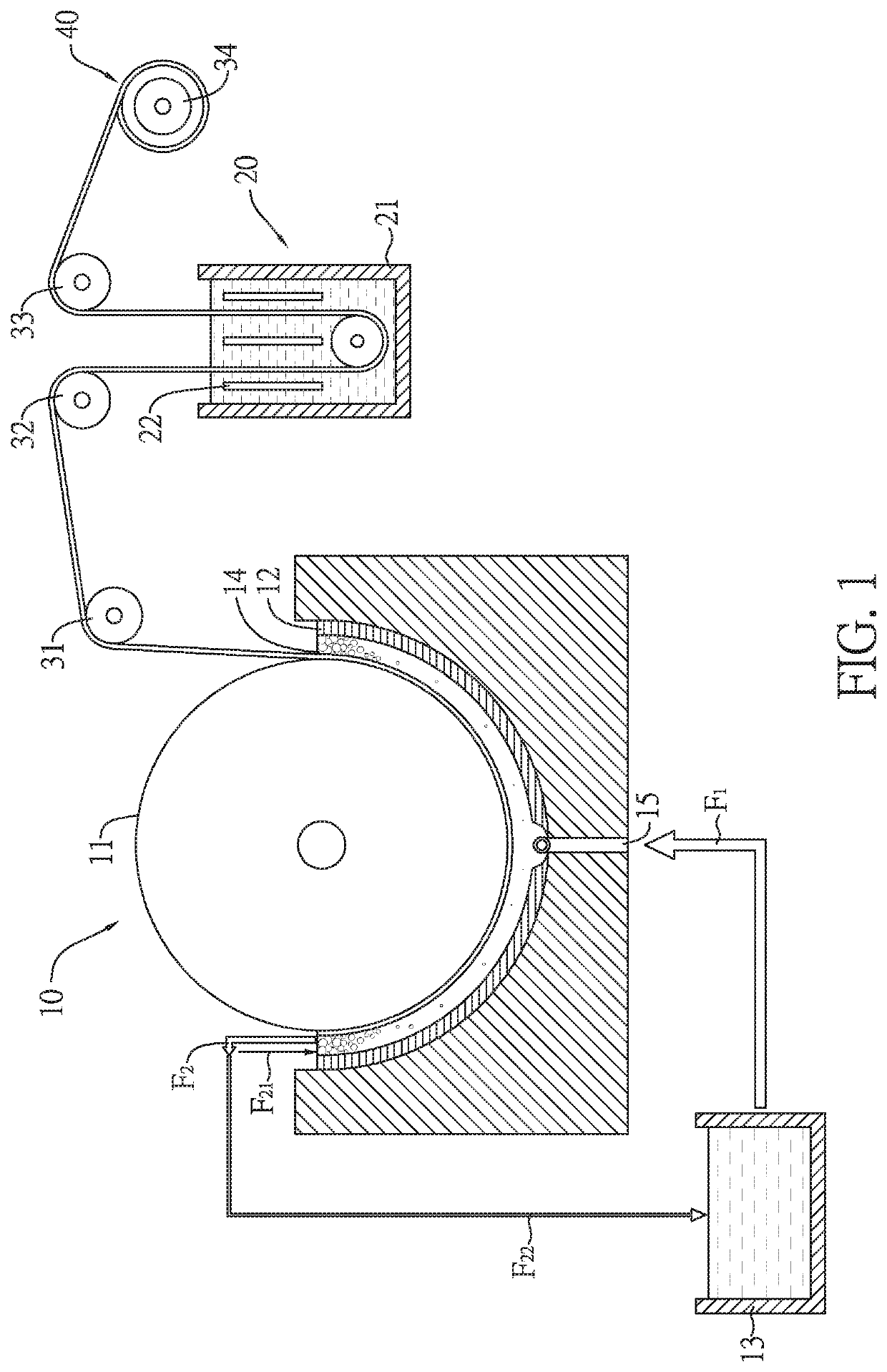

Processing technology of lead crystal battery positive pole plate and lead crystal battery

ActiveCN107221651AImprove Capacitive PerformanceEnhanced cycle life performanceFinal product manufactureLead-acid accumulator electrodesMicrometerEngineering

The invention discloses a processing technology of a lead crystal battery positive pole plate. The processing technology comprises the following steps of adding 4BS seed crystal in an amount of 1-2wt% of positive lead paste formula during preparation of positive lead paste; coating the lead paste on a surface of a grid to generate a green plate, and employing the following curing and drying process that 1) humidity is 99-100%, a temperature is 65-75 DEG C, an air speed is 25-35%, and time is 4-8 hours; 2) the humidity is 90-98%, the temperature is 65-75 DEG C, the air speed is 35-55%, and time is 12-24 hours; 3) the temperature is 65-75 DEG C, the humidity is 30-50%, the air speed is 35-55%, and time is 12-24 hours; and 4) the temperature is 65-75 DEG C, humidification is stopped, the air speed is 70-100%, and the time is 12-24 hours. The content of the 4BS crystal of the positive pole plate prepared by the technology accounts for 40-60%, and the length of the 4BS crystal is 10-20 micrometers; and when the 4BS crystal is prepared to form the lead crystal battery, the capacity of the battery can be effectively improved, and the cycle lifetime of the battery can be effectively prolonged.

Owner:SHENZHEN CENT POWER TECH

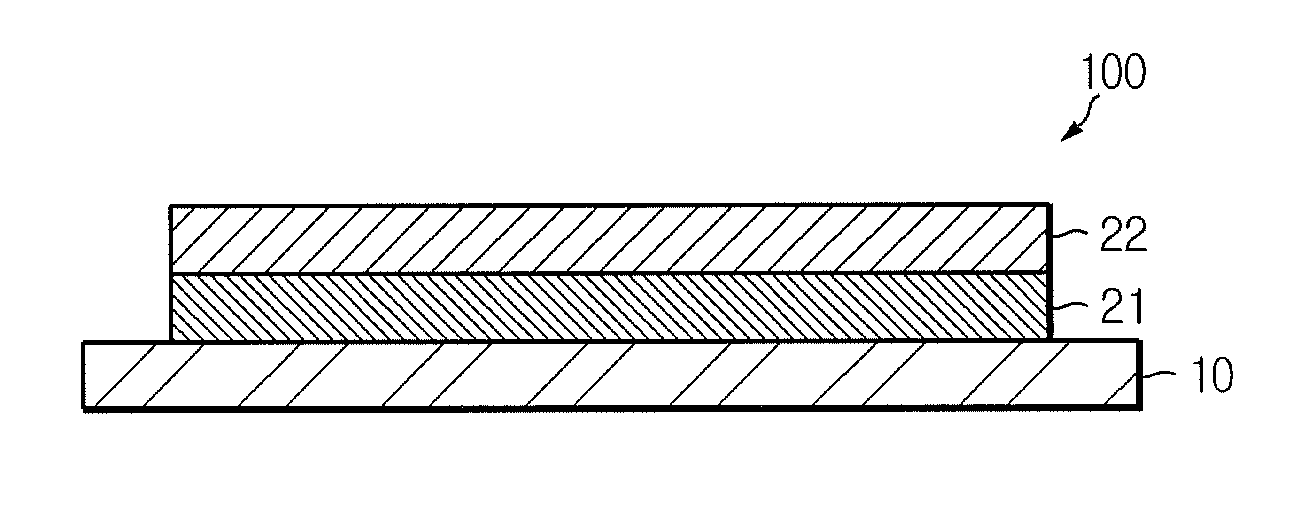

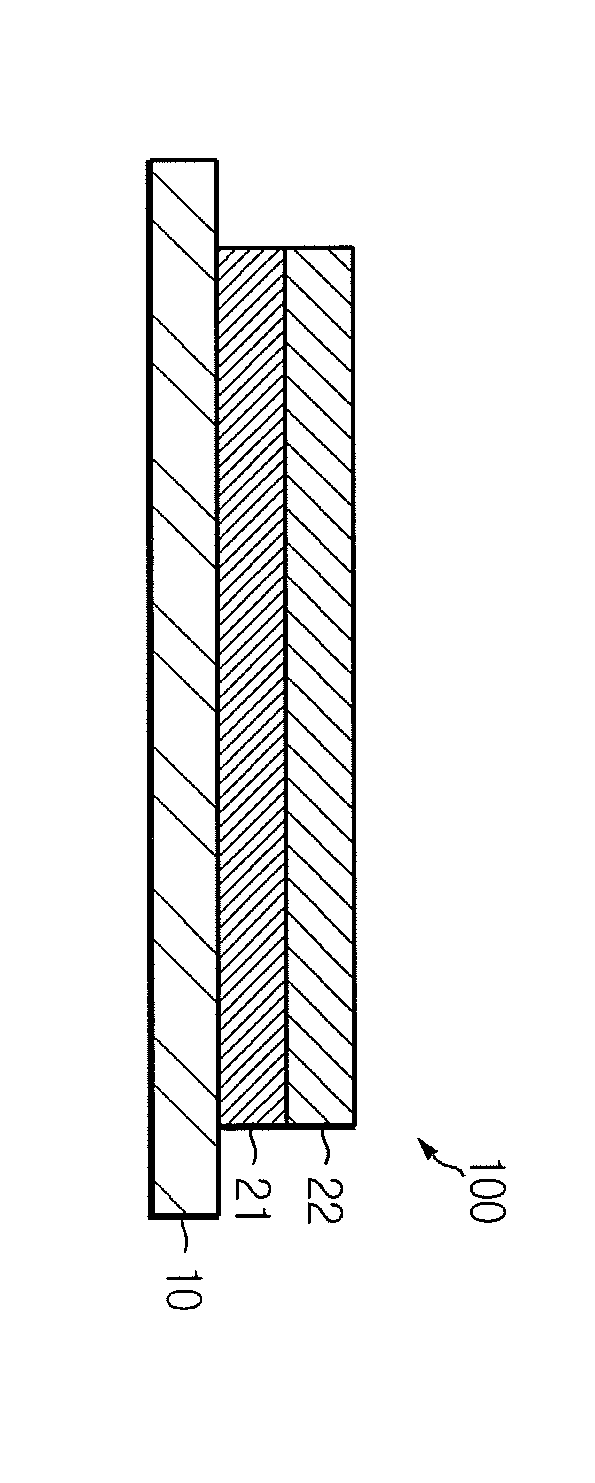

Cathode for lithium secondary battery and lithium secondary battery comprising the same

ActiveUS20130216897A1Improve stabilityIncrease energy densityElectrode carriers/collectorsPositive electrodesLithium iron phosphateHigh energy

Disclosed is a cathode for a lithium secondary battery and a lithium secondary battery comprising the same. The cathode for a lithium secondary battery may include a current collector, a first composite layer formed from a mixture of olivine-type lithium iron phosphate cathode active material powder and a binder on the current collector, and a second composite layer formed from a mixture of olivine-type lithium iron phosphate cathode active material powder and a binder on the first composite layer. A specific surface area of the olivine-type lithium iron phosphate cathode active material powder in the second composite layer may be 0.8 times or less that of the olivine-type lithium iron phosphate cathode active material powder in the first composite layer. The cathode for a lithium secondary battery has excellent stability, high energy density, and improved cycle life characteristics.

Owner:LG ENERGY SOLUTION LTD

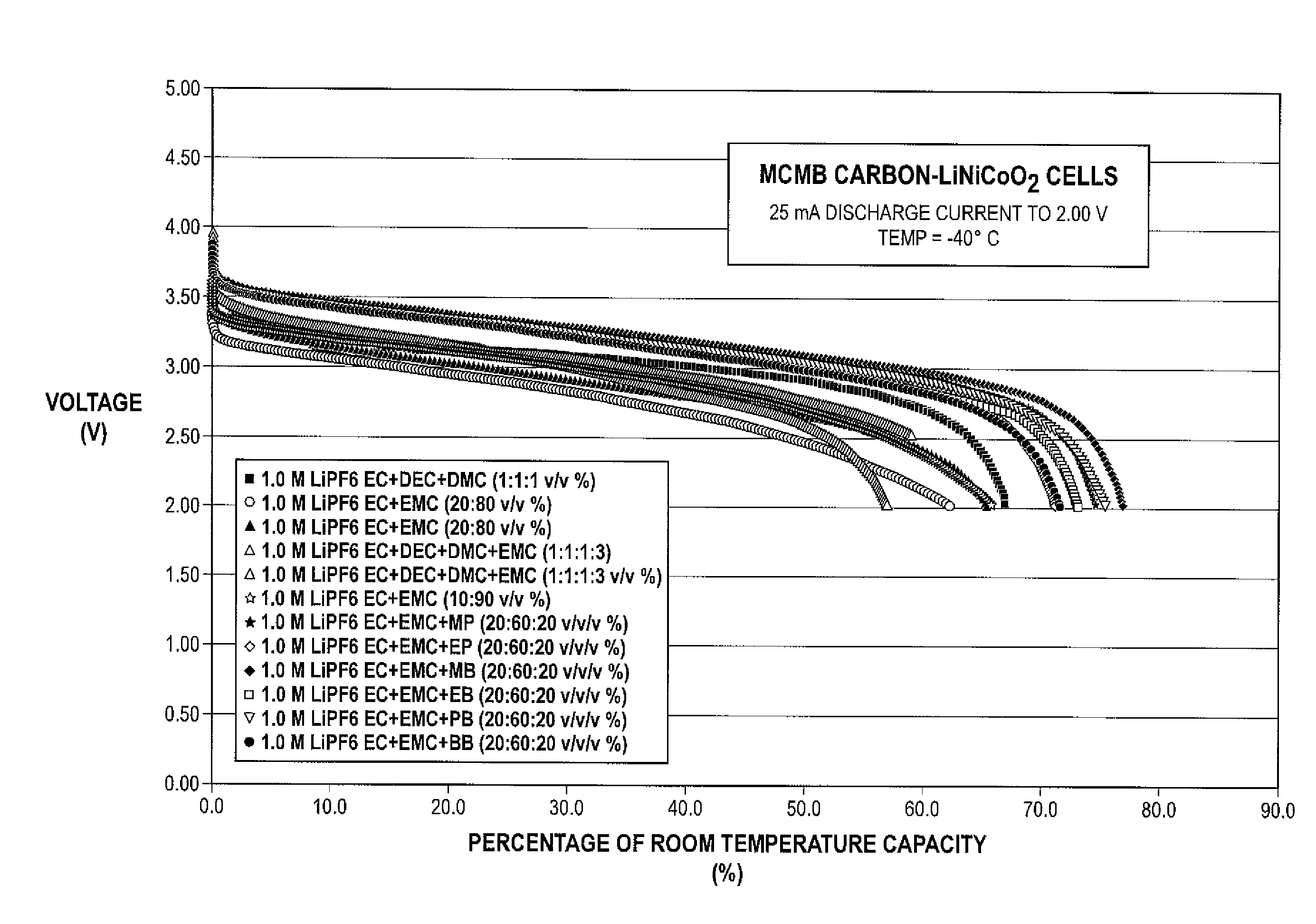

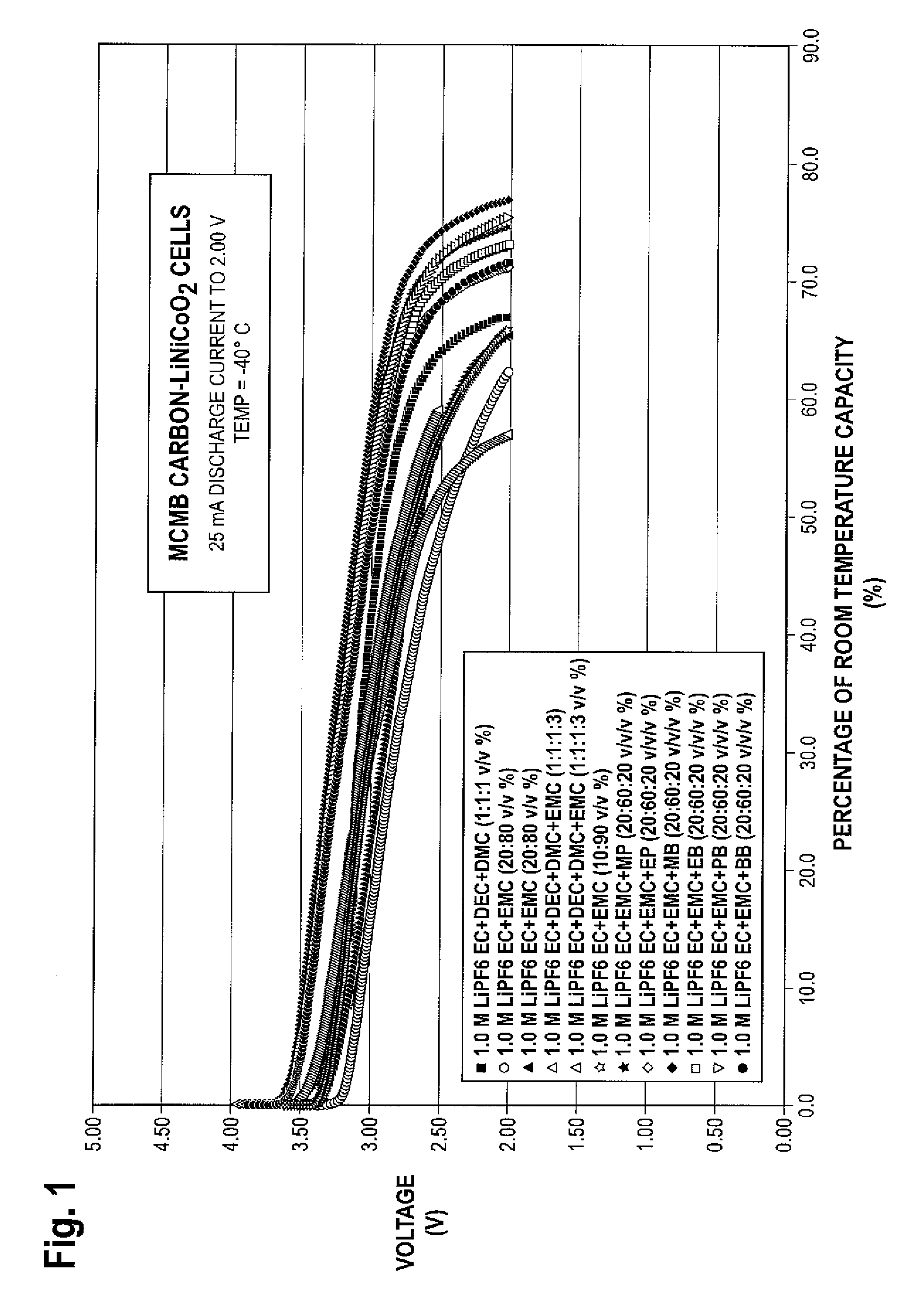

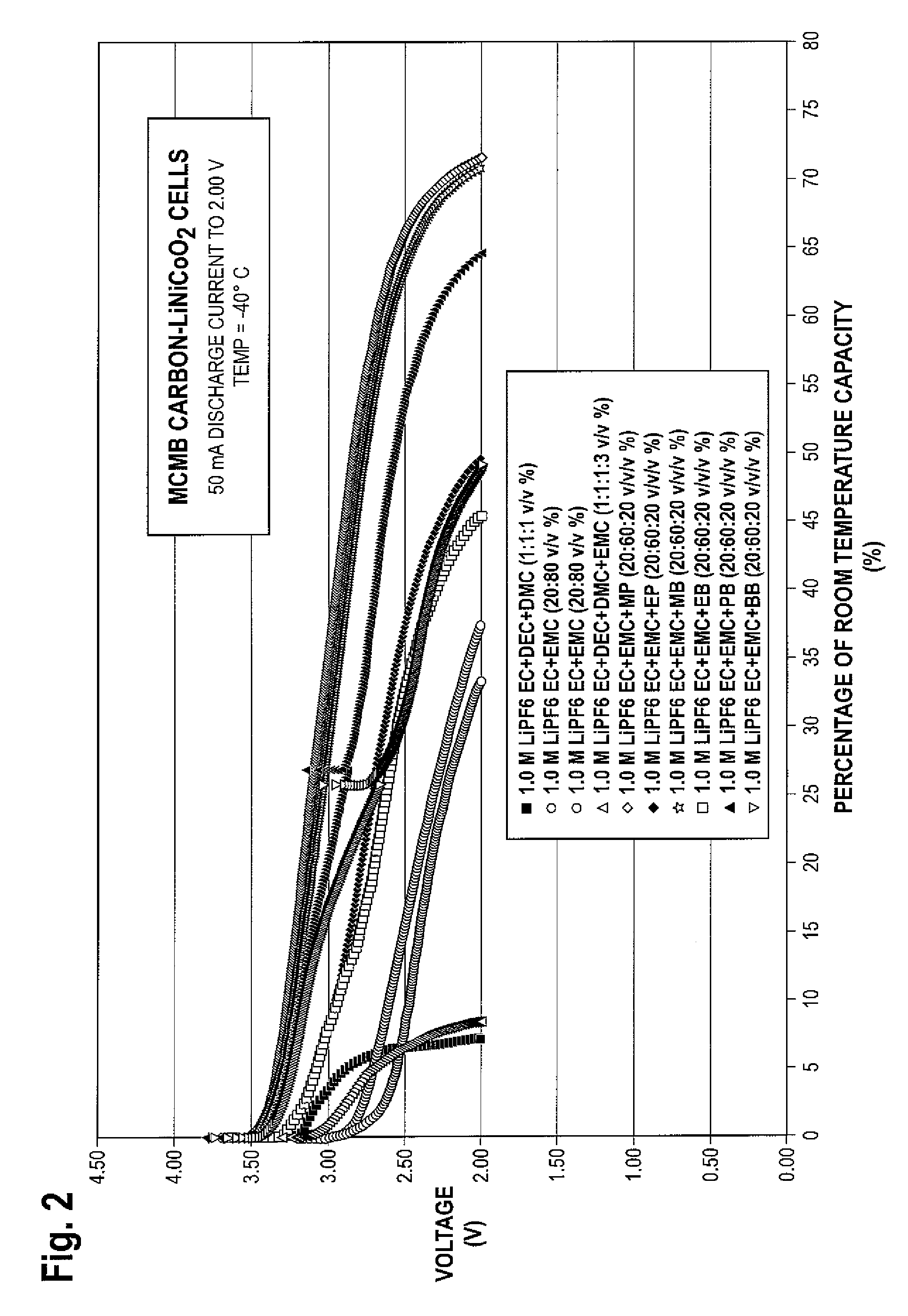

Lithium ion electrolytes and lithium ion cells with good low temperature performance

ActiveUS8920981B2Enhanced cycle life performanceIncrease elasticityElectrolytic capacitorsOrganic electrolyte cellsCelsius DegreeButyrate

Owner:CALIFORNIA INST OF TECH

Negative-pole active material for lead battery, negative pole and lead battery making method

InactiveCN1677721AEnhanced cycle life performanceElectrode manufacturing processesFinal product manufactureMetallurgyCharge and discharge

In method for preparing active material of cathode in use for lead accumulator, 0.5 - 1.5%Wt lignin and 0.5 - 5.0%Wt carbon related to lead powder are added to lead powder. In method for preparing cathode in use for lead accumulator through coating lead powder on basal body, 0.5 - 1.5%Wt lignin and 0.5 - 5.0%Wt carbon related to lead powder are added to lead powder. The lead accumulator prepared according to the disclosed method possesses good performance of charging and discharging cycle lifetime in high temperature.

Owner:GS YUASA CORP

Lithium battery electrolyte

InactiveCN108258316AInhibit swellingEnhanced cycle life performanceSecondary cellsOrganic solventPhysical chemistry

The invention provides a lithium battery electrolyte. The lithium battery electrolyte comprises lithium salt, a carbonate organic solvent, a carboxylate organic solvent, a silicon-carbon-type functional additive and other film-forming additive, wherein the molar concentration of the lithium salt component in the lithium battery electrolyte ranges from 0.1-2mol / L; the molar concentration of the other film-forming additive component in the lithium battery electrolyte ranges from 0-0.5mol / L; the mass percentage of the silicon-carbon-type functional additive component in the lithium battery electrolyte ranges from 1-10%. According to the technical scheme adopted by the invention, the stability of the electrolyte in a silicon-carbon-type lithium battery is improved, expansion of the lithium battery is suppressed, and thus the cycle life of the lithium battery is prolonged.

Owner:SHANDONG HIRONG POWER SUPPLY MATERIAL

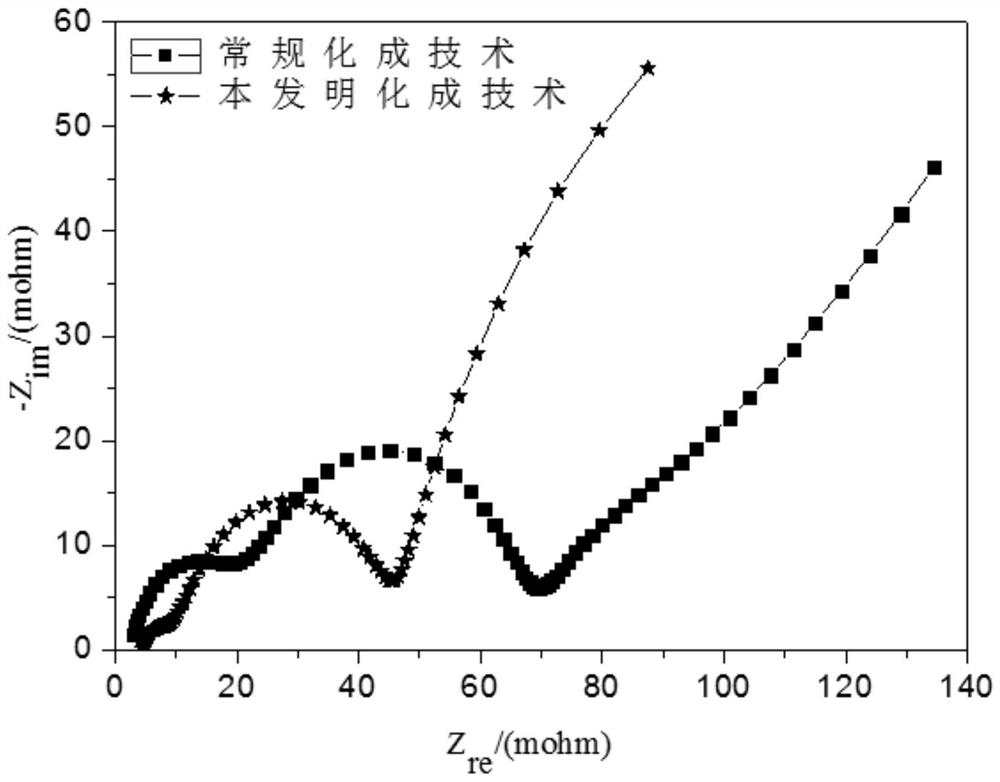

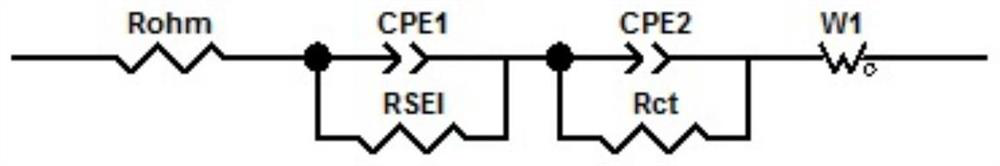

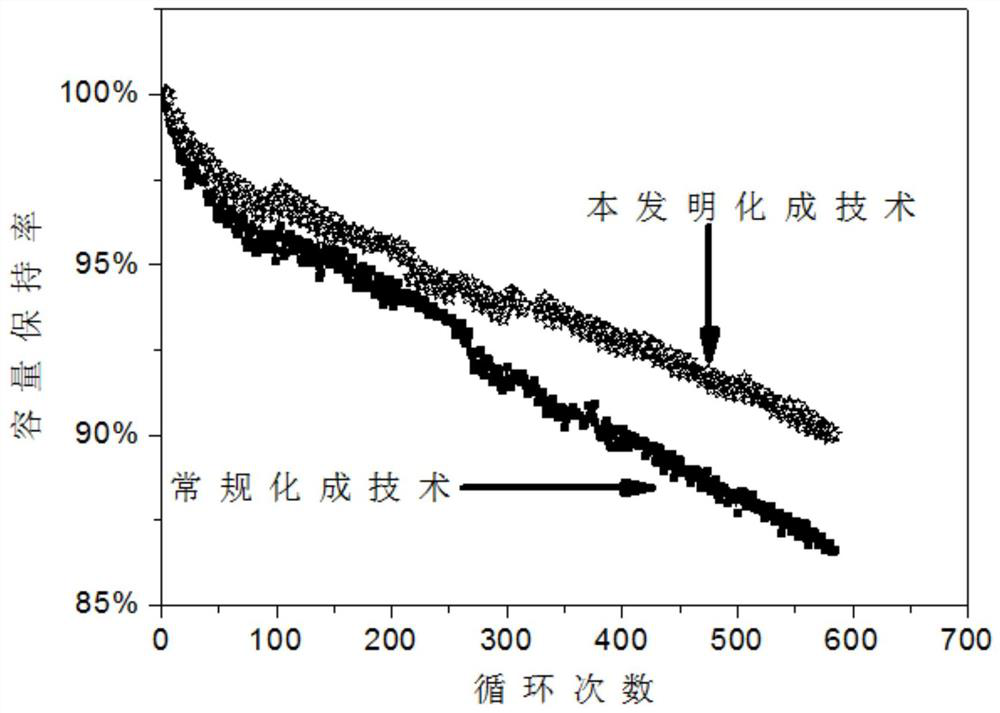

Method for prolonging cycle life of lithium ion battery

PendingCN113078363AImprove cycle lifeModerate thicknessFinal product manufactureElectrolyte accumulators manufactureCharge currentEngineering

The invention relates to a method for prolonging the cycle life of a lithium ion battery, and a formation method mainly comprises two steps: 1, after liquid injection of the lithium battery is completed, standing is performed, then pressure is applied to the lithium battery, stepped charging is performed under the conditions of different formation temperatures and formation charging currents, and after charging is completed, exhausting, vacuumizing and sealing are performed; 2, pressure is applied to the lithium battery, and then charging and discharging are performed for 1-3 cycles under the conditions of certain formation temperature, formation charging and discharging current and formation voltage range; and the low-impedance SEI film is prepared by regulating and controlling the growth mode of the SEI film, so that the formation method for prolonging the cycle life of the aluminum-plastic shell soft package lithium ion battery is realized. The method has the beneficial effects that the method is applied to MCM and NCA soft package battery systems; and by regulating and controlling the growth of the SEI film in the formation process, the SEI film which is moderate in thickness, uniform, compact and low in impedance is obtained, and the cycle life of the battery is remarkably prolonged.

Owner:TIANJIN LISHEN BATTERY

Negative Electrode Current Collector for Lead Storage Battery and Lead Storage Battery Including the Same

InactiveUS20080131774A1Enhanced cycle life performanceShortened battery lifeLead-acid accumulatorsElectrode carriers/collectorsSurface layerMass ratio

A negative electrode current collector for a lead-acid battery having a grid part, upper frame part, and lug part according to the present invention, where the upper frame part and lug part have a surface layer, a surface layer is an alloy of Pb and Sn and the mass ratio of Sn accounts for 10% or more in the whole alloy, an alloy of Pb and Sb and the mass ratio of Sb accounts for 10% or more in the whole alloy, an alloy of Pb, Sn and Sb and the total mass ratio of Sn and Sb accounts for 10% or more in the whole alloy, Sn, or Sb.Further, a negative electrode current collector for a lead-acid battery having a grid part, upper frame part, and lug part according to the present invention, only upper frame part and lug part have a surface layer.

Owner:GS YUASA INT LTD

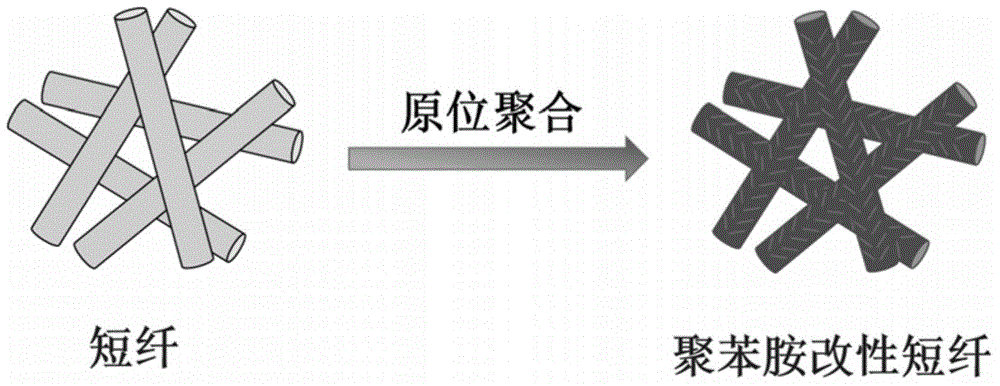

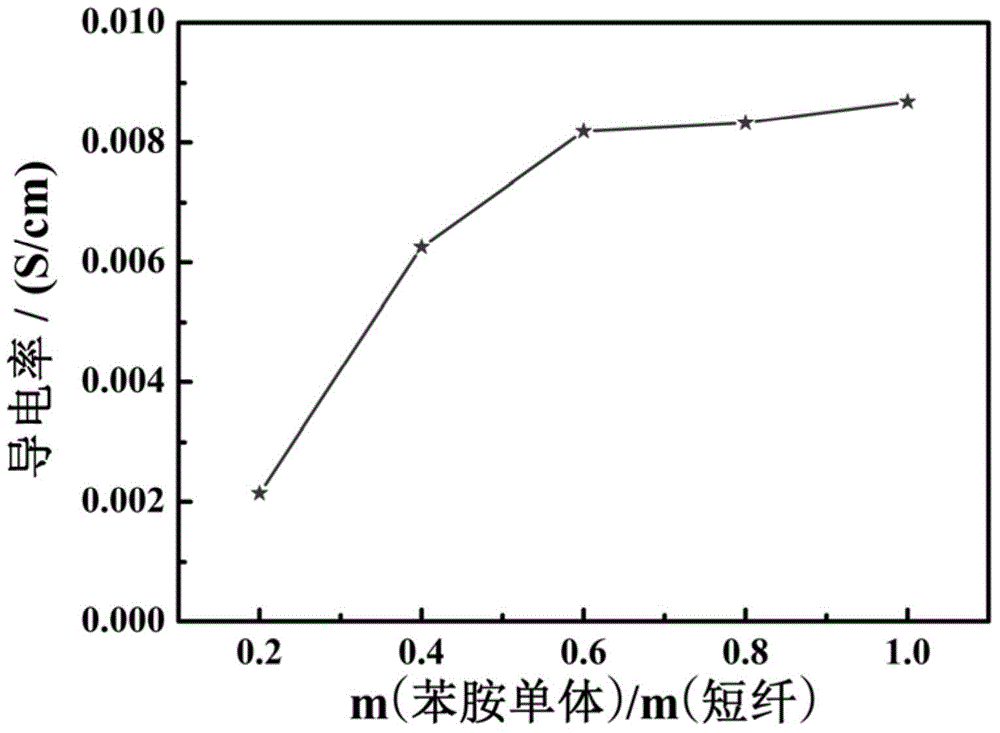

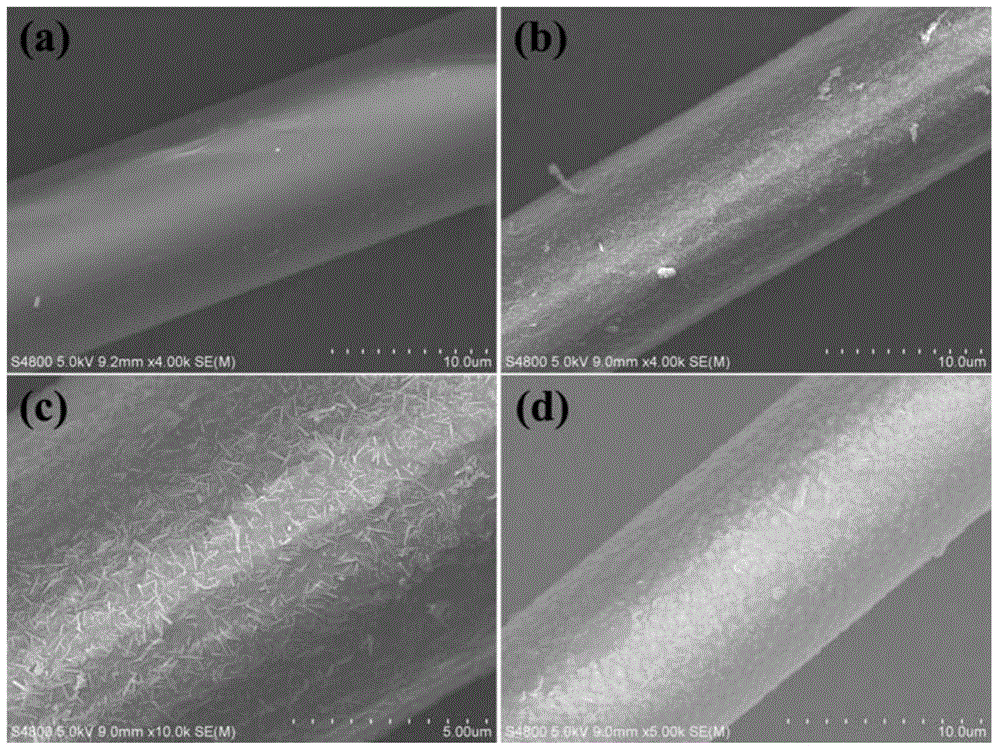

Preparation method of modified short fiber for lead-acid battery and negative plate containing modified short fiber

InactiveCN105047939ASimple preparation processShorten the production cycleElectrode carriers/collectorsFiberHigh rate

The invention provides a preparation method of a modified short fiber for a lead-acid battery and a negative plate containing the modified short fiber. A conductive polymer coats the surface of the short fiber so as to improve the conductivity of the short fiber. By the modified short fiber, the problems of low utilization rate of an active substance of the lead-acid battery and short cycle life in a high-rate partial state of charge are hopefully solved, and meanwhile, the addition proportion of the short fiber in lead paste is increased so as to further enhance the cyclic performance of the lead-acid battery. The short fiber is an important additive in industrial production of the lead-acid battery, and a few additive amount of the short fiber is required in the lead paste due to non-conductivity of the short fiber. An in situ polymerization method is used for coating the surface of the short fiber with the conductive polymer, so that the conductivity of the short fiber is substantially improved. When the modified short fiber is added into the negative electrode lead paste of the lead-acid battery, the capacity of a battery plate and the utilization rate of the active substance can be improved, and moreover, the cyclic service life of the battery in the high-rate partial state of charge (HRPSoC) can be substantially prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Battery module, method of fabricating the same, and vehicle having battery module

InactiveUS20110091755A1Deterioration in cycle life performanceEnhanced cycle life performancePrimary cell to battery groupingHybrid capacitor electrodesTrailing edgeBattery cell

Each of battery cells (12) that constitute a battery module includes a flat-shaped rolled electrode body (30) formed by rolling a sheet-like anode collector (32) and a sheet-like cathode collector (34) along with a sheet-like separator, and a trailing edge (32E) of the sheet-like anode collector (32) and a trailing edge (34E) of the sheet-like cathode collector (34) are located at a position (30B) outside a portion of the rolled electrode body (30) which substantially receives a restraining load. The battery module, in which the restraining load is applied to the cells, achieves long service life while maintaining good output characteristics.

Owner:TOYOTA JIDOSHA KK

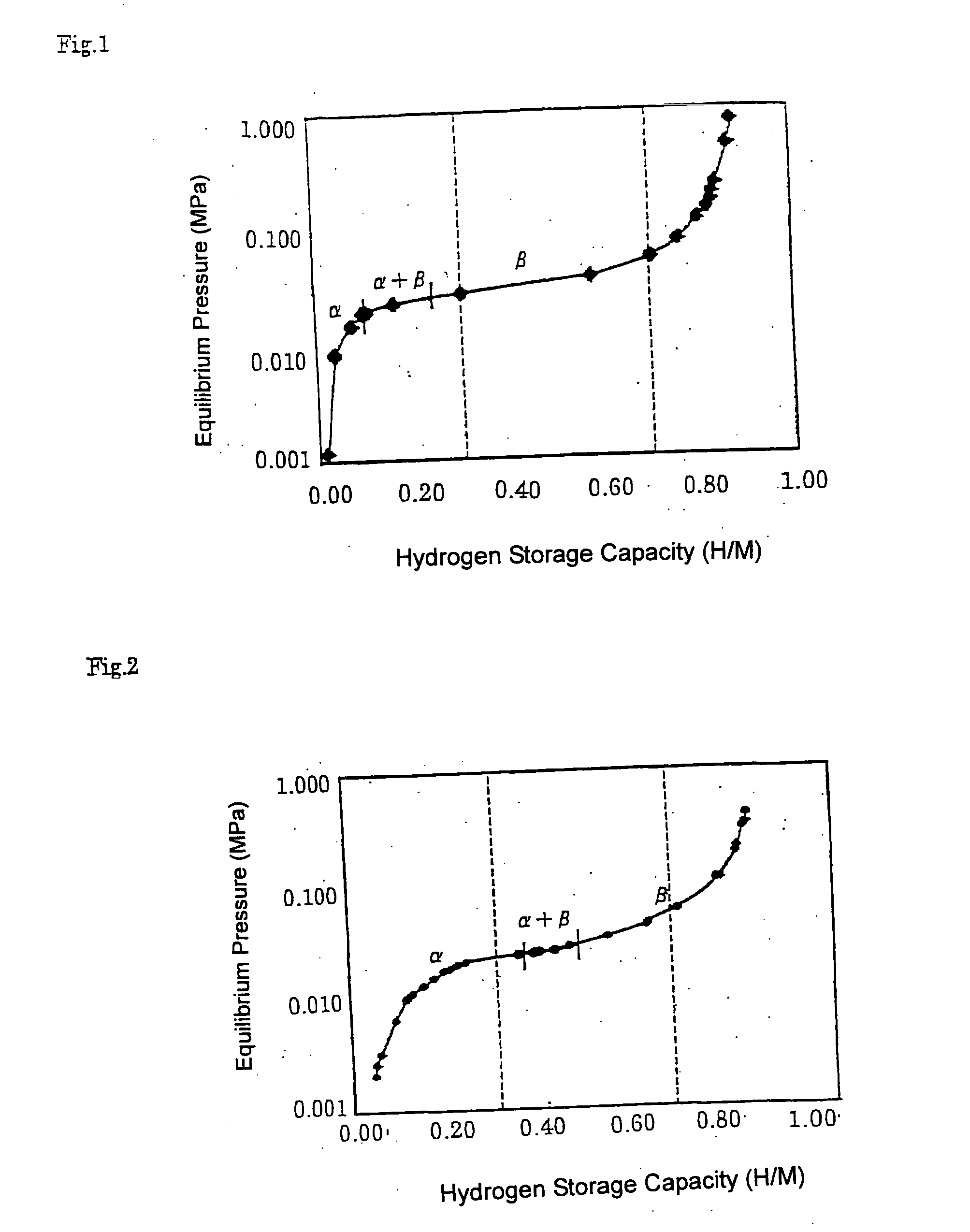

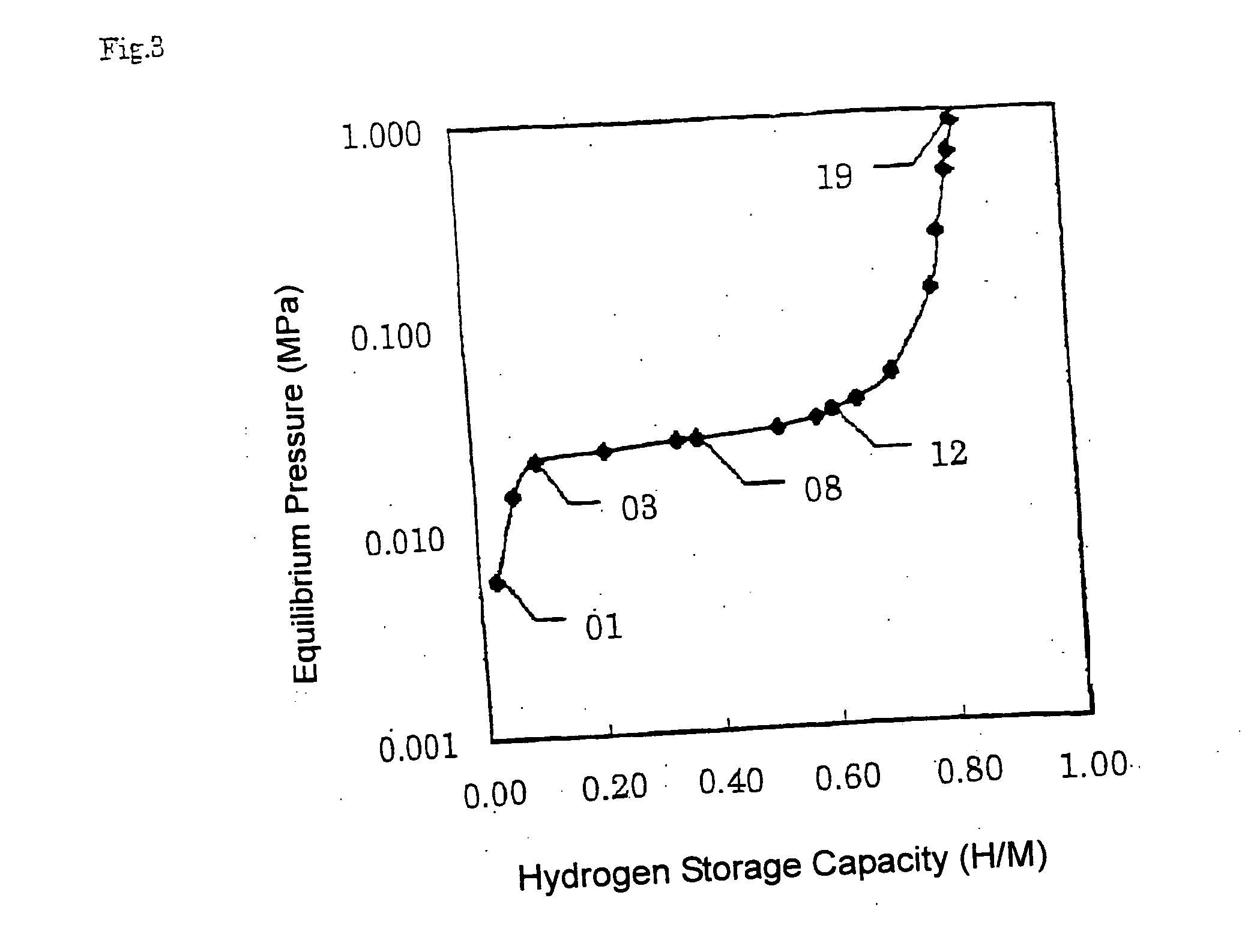

Hydrogen-occluding alloy

ActiveUS20060068286A1Improve charge acceptanceHigh drain (power) performance and charge acceptanceAlkaline accumulator electrodesNon-aqueous electrolyte accumulator electrodesPhase conversionMetallurgy

A hydrogen storage alloy is provided which, when used in a battery, has high drain (power) performance and charge acceptance that are excellent, and in addition, cracks are few, and cycle life performance are excellent, to be used in large batteries, in particular for electric vehicles, hybrid electric vehicles, high-power use, and the like. The hydrogen storage alloy is a hydrogen storage alloy having phase conversion accompanying the variation of hydrogen storage capacity (H / M) and is in a single phase or in a state close to a single phase when the above-mentioned hydrogen storage capacity (H / M) is in a range of 0.3 to 0.7 or 0.4 to 0.6.

Owner:MITSUI MINING & SMELTING CO LTD

Secondary battery, battery pack, and vehicle

ActiveCN107834075AEnhanced cycle life performanceBatteries circuit arrangementsFinal product manufactureLithiumBattery pack

The embodiments of the present invention relate to a secondary battery, a battery pack, and a vehicle. The present invention provides a secondary battery capable of achieving excellent cycle life performance, a battery pack including the secondary battery, and a vehicle including the battery pack. According to one embodiment, a secondary battery is provided. The secondary battery includes a positive electrode, a negative electrode, and an electrolyte including a water-containing solvent and a lithium ion. The negative electrode includes an aluminum-containing negative electrode current collector and a boehmite-containing cover layer, and the boehmite-containing cover layer is provided on at least a part of a surface of the negative electrode current collector, and has a thickness of 10 nmto 1000 nm.

Owner:KK TOSHIBA

Non-aqueous electrolyte secondary battery

InactiveUS20020127476A1Avoid decompositionImprove discharge performanceElectrolytic capacitorsOrganic electrolyte cellsPropylene carbonateSolvent

The present invention provides a non-aqueous electrolyte secondary battery comprising a positive electrode, a negative electrode comprising a carbonaceous material, an organic electrolyte comprising a lithium salt and a solvent, and a separator. The solvent comprises ethylene carbonate (EC), propylene carbonate (PC), a chain carbonate and phenylethylene carbonate, the content of the chain carbonate, ethylene carbonate (EC) and the propylene carbonate (PC) are from 50 to 90 vol %, from 5 to 45 vol % and from 5 to 45 vol %, respectively, based on the total volume of the ethylene carbonate (EC), the propylene carbonate and the chain carbonate, and the content of the phenylethylene carbonate is from 0.1 to 5.0 wt % based on the total weight of the electrolyte. The non-aqueous electrolyte secondary battery according to the invention exhibits a great discharge capacity, an excellent cycle life performance and an excellent low-temperature discharge performance.

Owner:JAPAN STORAGE BATTERY CO LTD

Secondary battery, battery pack, and vehicle

InactiveCN108631008AEnhanced cycle life performanceSynthetic resin layered productsBattery isolationAlloyZinc

The embodiment of the present invention relates to a secondary battery, a battery pack and a vehicle. The secondary battery, the battery packwith the secondary battery, and the vehicle with the battery pack, which are provided by the invention, are excellent incycle life performance. According to one approach, a secondary battery is provided. The secondary batteryincludes a negative electrode including a negative electrode current collector, a negative electrode terminal electrically connected to the negative electrode current collector, a joint electrically connecting the negative electrode terminal and the negative electrode current collector (3a), and a water repellent layer covering the joint. The joint is covered with the inner surface of the water repellent layer. A contact angle theta with respect to water on an outer surface of the water repellent layer satisfies theta <= 80 degrees.

Owner:KK TOSHIBA

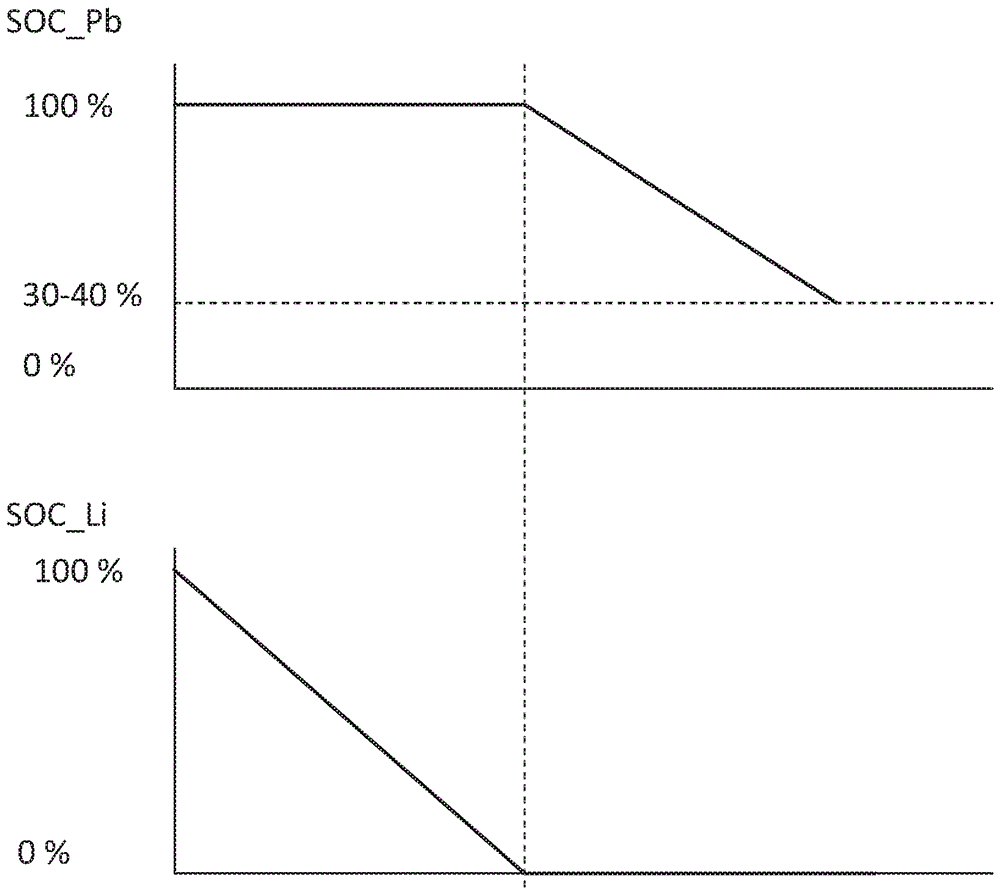

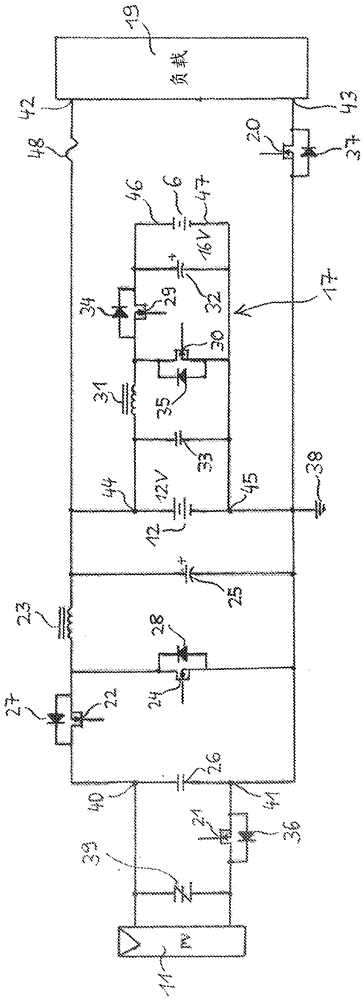

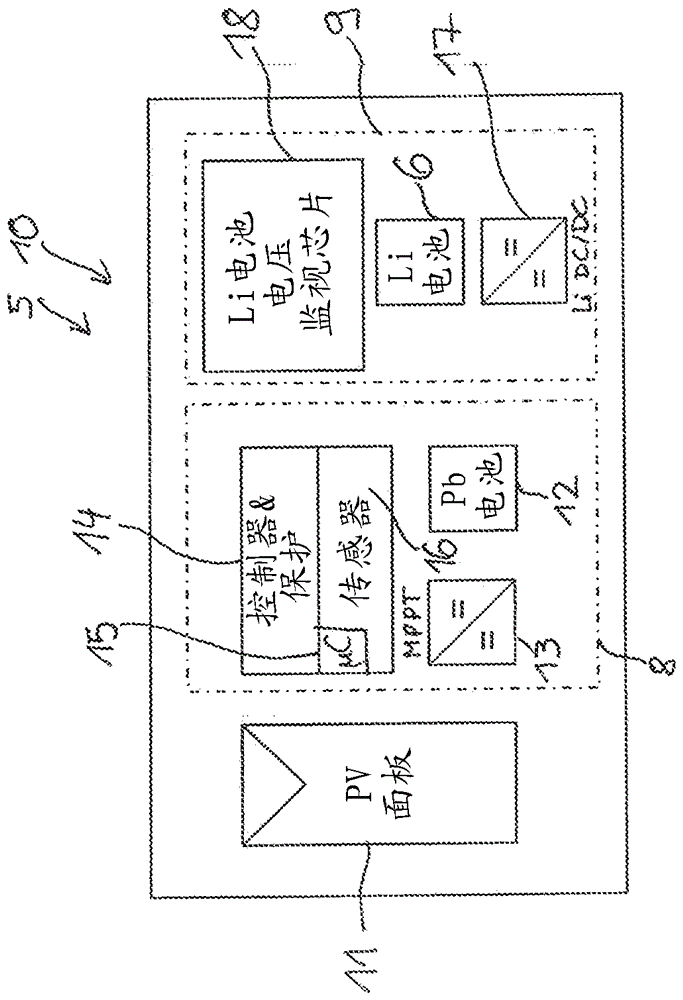

Topology and control strategy for hybrid storage systems

InactiveCN106165240AReduce chargeReduce discharge currentPhotovoltaicsEnergy storageInternal resistanceEngineering

The application discloses a hybrid battery-charging device with input terminals for connecting a current source, first battery connections for connecting a lead-acid battery and second battery connections for connecting a high-cycle chemi- cal battery. A two-way DC / DC converter with first and second sets of terminals is connected with the second battery con- nections, and with the first battery connections. A charge and discharge control system of the charging device comprises a controller unit, a control output for controlling the two- way DC / DC converter, and sensing inputs for sensing a state of charge, an internal resistance of the lead-acid-battery and a state of charge of the high-cycle chemical battery. The charge and discharge control system is operative to control the two-way DC / DC converter such that the charging of the lead-acid battery is provided if its state of charge is below a pre-determined threshold and that the charging of high- cycle chemical battery is provided if its state of charge is below a pre-determined threshold and if the state of charge of the lead-acid battery is above a pre-determined threshold.

Owner:ROBERT BOSCH GMBH

Lead acid storage battery

InactiveCN110036526AEnhanced cycle life performanceExcellent liquid reducing performanceFinal product manufactureElectrode carriers/collectorsElectrolytic agentEngineering

A lead acid storage battery according to the present disclosure is provided with: a positive electrode plate that comprises a positive electrode collector and a positive electrode material filled intothe positive electrode collector; a negative electrode plate that comprises a negative electrode collector and a negative electrode material filled into the negative electrode collector; and an electrolyte solution that contains sulfuric acid. This lead acid storage battery is configured such that: the negative electrode collector has a negative electrode lug part that is provided on the upper peripheral part of the negative electrode collector; the negative electrode lug part has a surface layer that contains Sn; and the ratio of the mass M2 of the electrolyte solution to the total M1 of themass of the positive electrode material and the mass of the negative electrode material (M2 / M1) is 0.7 or more.

Owner:HITACHI CHEM CO LTD

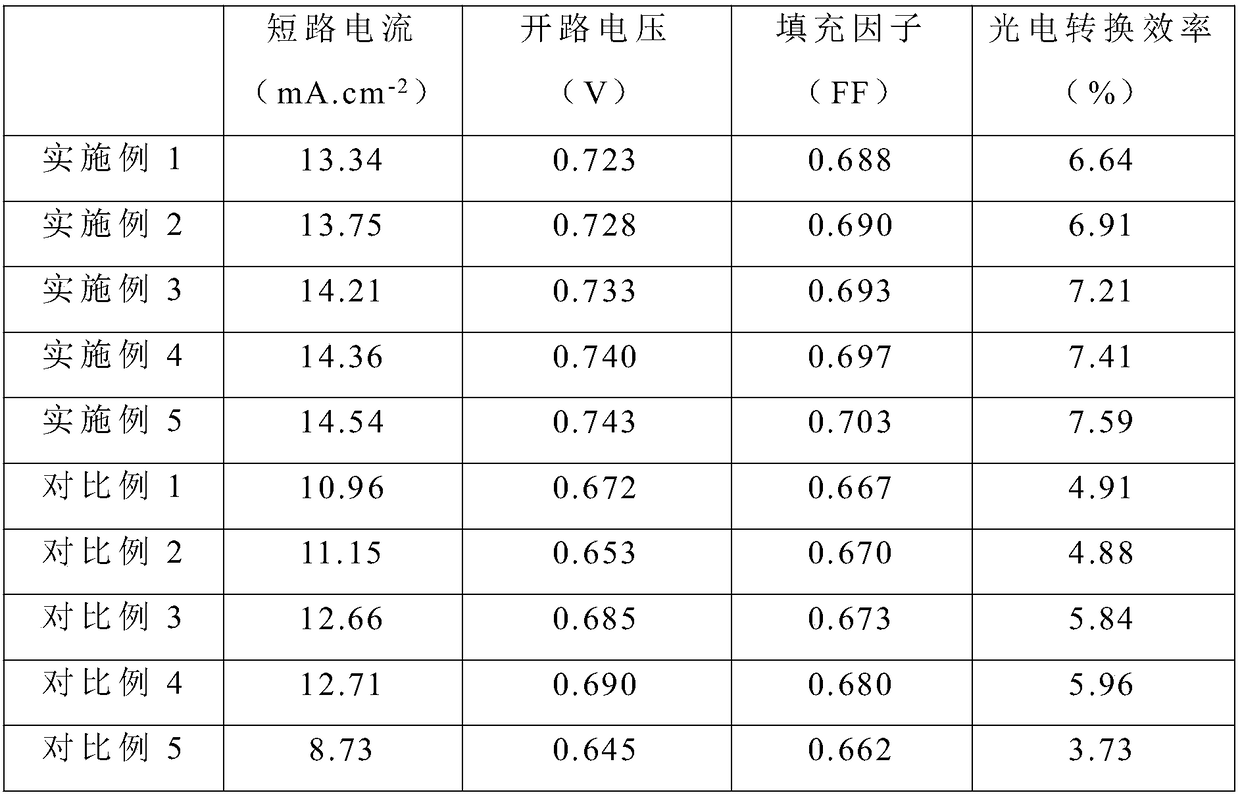

Solid electrolyte for dye-sensitized solar cell and preparation method thereof

ActiveCN108538606ASimple processRaw materials are easy to getLight-sensitive devicesCapacitor electrolytes/absorbentsSolid state electrolyteCyanoacetylene

The invention discloses solid electrolyte for a dye-sensitized solar cell. The solid electrolyte comprises the following components in parts by weight: 30-40 parts of benzonitrile type alkynyl quaternary ammonium salt ionic crystal, 20-30 parts of 3-cyanobenzyl tripropargyl quaternary ammonium salt organic ion, 2-5 parts of ferrocenyl-acetenyl, 1-3 parts of cyanoacetylene, 4-8 parts of elemental iodine, 4-8 parts of iodate and 5-10 parts of additives. The preparation method of the solid electrolyte for the dye-sensitized solar cell comprises the following steps: heating, melting, uniformly stirring to form a mixture, adding the elemental iodine and additives, heating, melting and uniformly stirring, cooling and curing. According to the solid electrolyte for the dye-sensitized solar cell disclosed by the invention, leakage and volatilization problems can be effectively solved, and the electrolyte is high in electrical conductivity and has obvious effects in improving the stability and photovoltaic conversion efficiency of the dye-sensitized solar cell and prolonging the service life cycle.

Owner:西安丝路知星科技服务有限公司

Lithium secondary battery having lithium metal formed on anode and manufacturing method therefor

ActiveCN108780915AInhibition formationEnhanced cycle life performanceFinal product manufactureElectrolyte/reactants regenerationElectrical batteryLithium metal

The invention relates to a lithium secondary battery and, more particularly, to a lithium secondary battery having lithium, serving as a cathode active material, formed on an anode side thereof and amanufacturing method therefor. In the lithium secondary battery according to the invention, a lithium thin film is coated under an air tight condition during a process of forming the lithium thin filmon a cathode current collector, which can restrain the formation of a native oxide layer, attributed to oxygen and moisture in air, on the lithium thin film, with the consequent improvement of cyclelife characteristics therein.

Owner:LG ENERGY SOLUTION LTD

Electrolytic copper foil and electrode and lithium-ion cell comprising the same

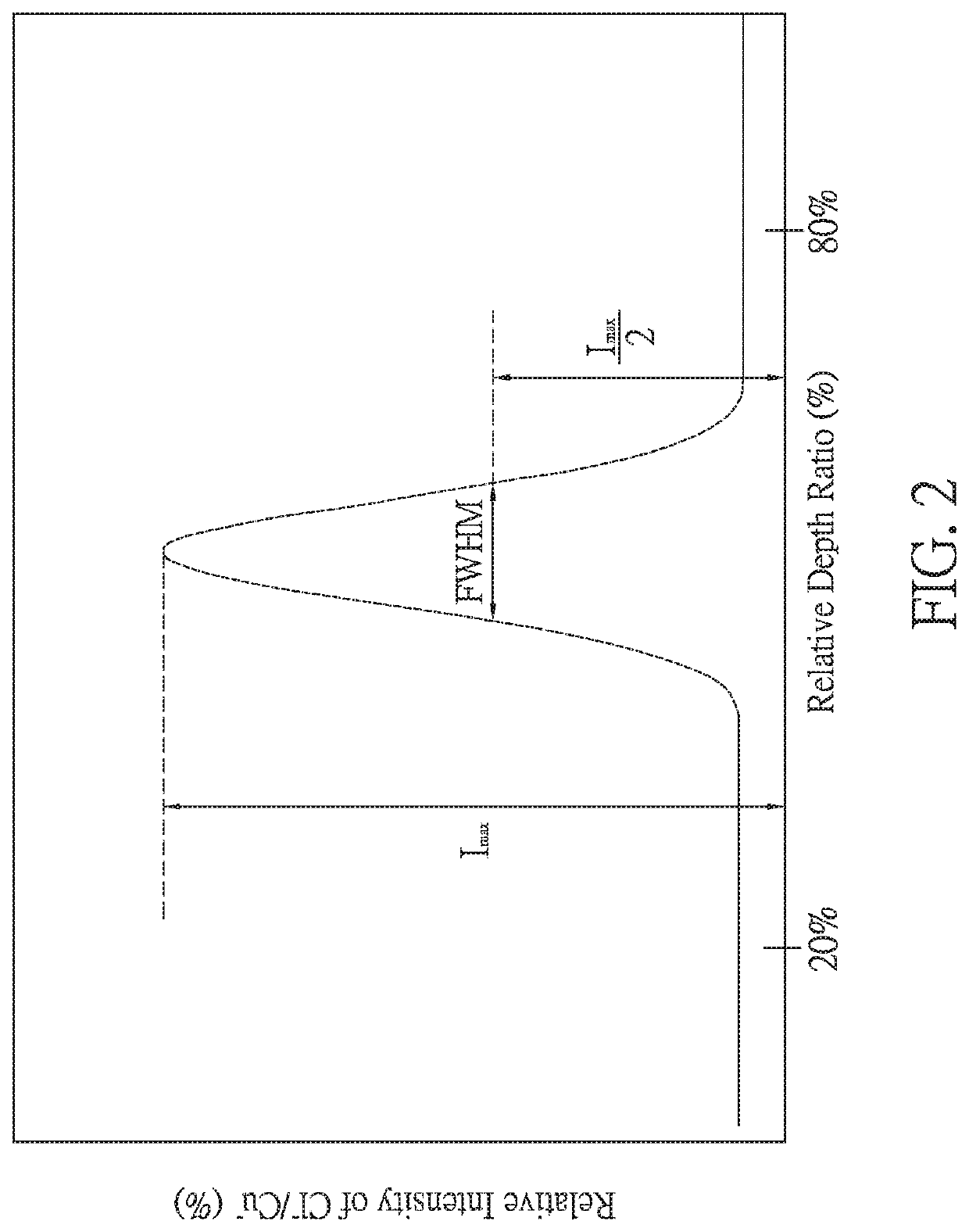

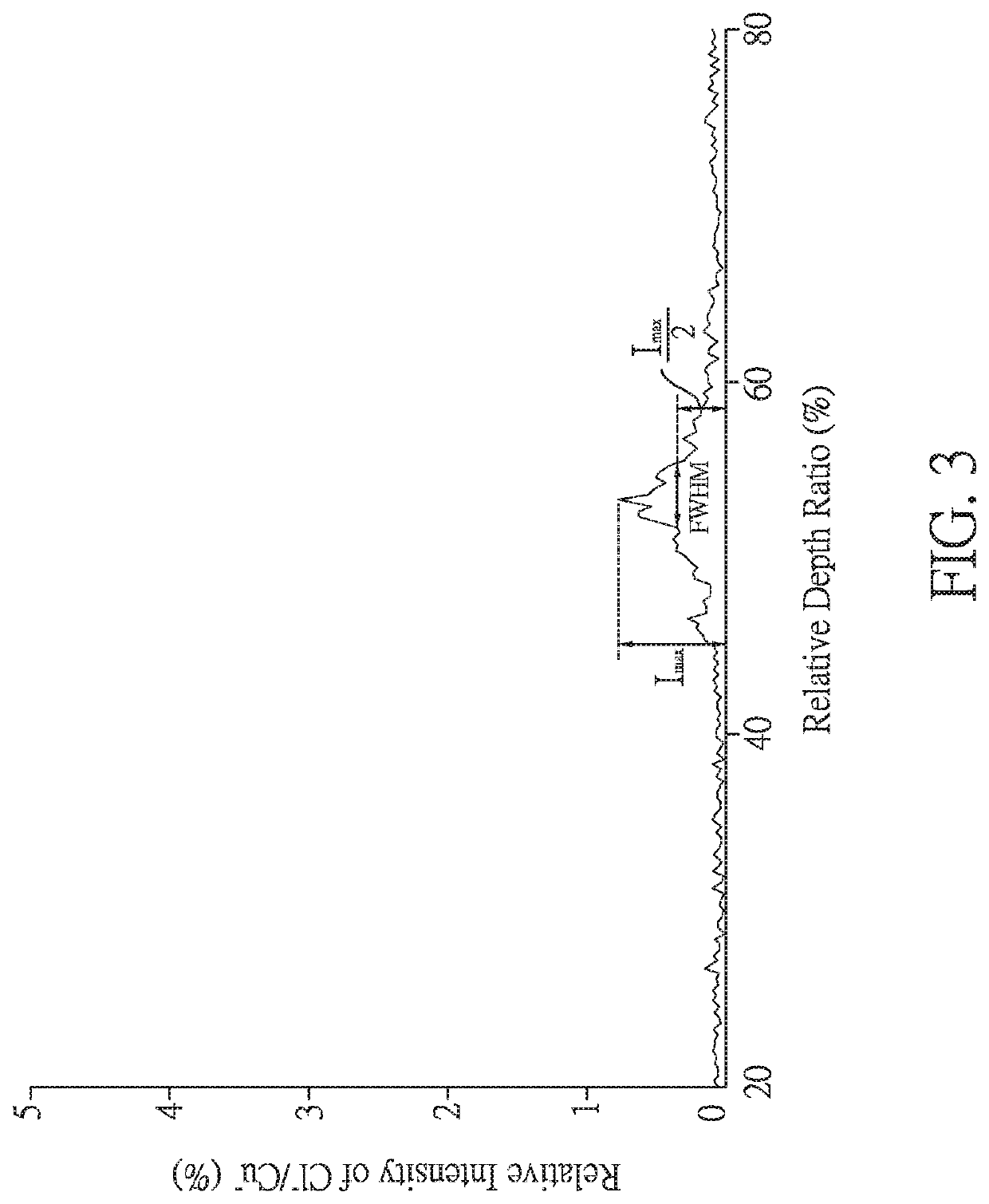

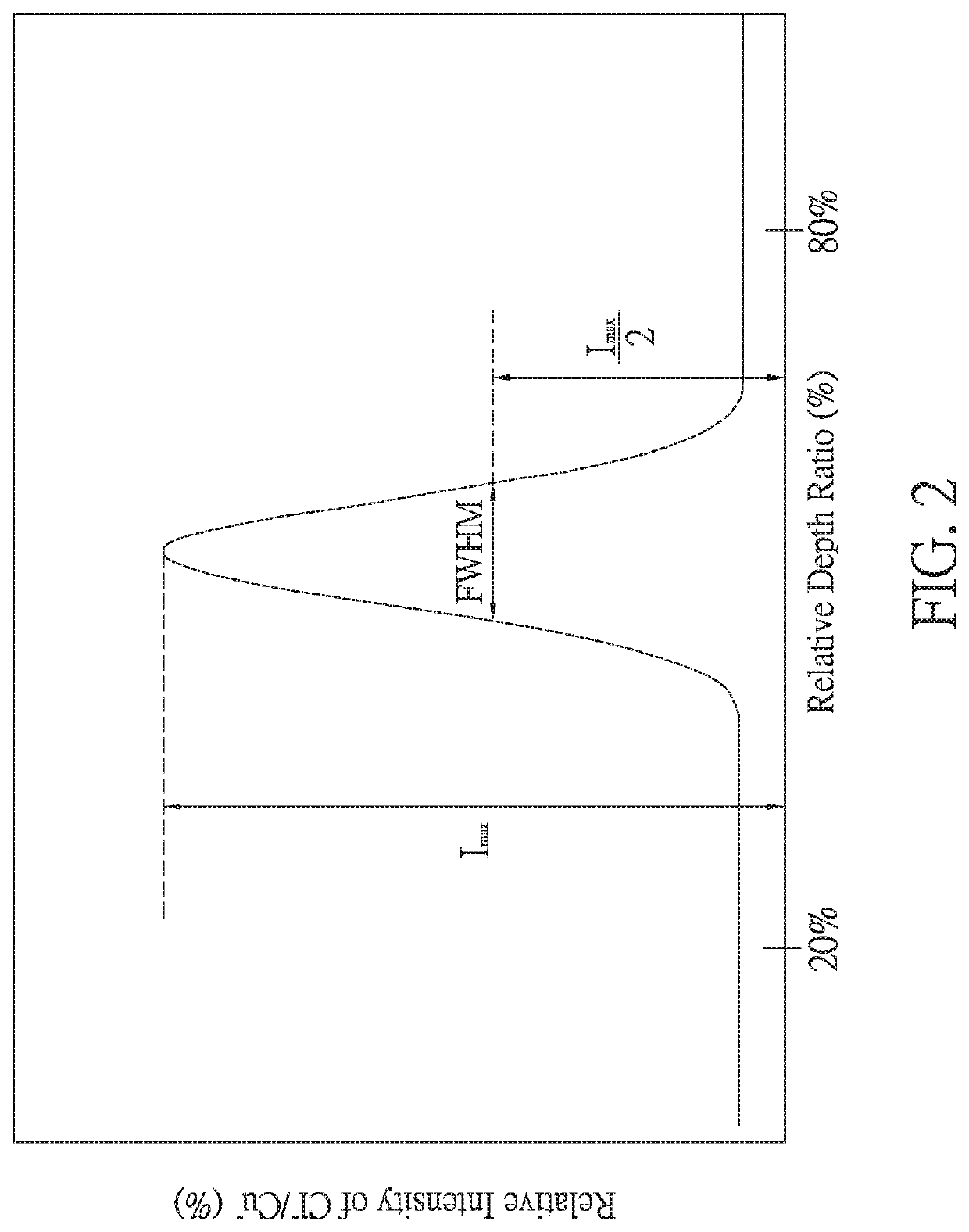

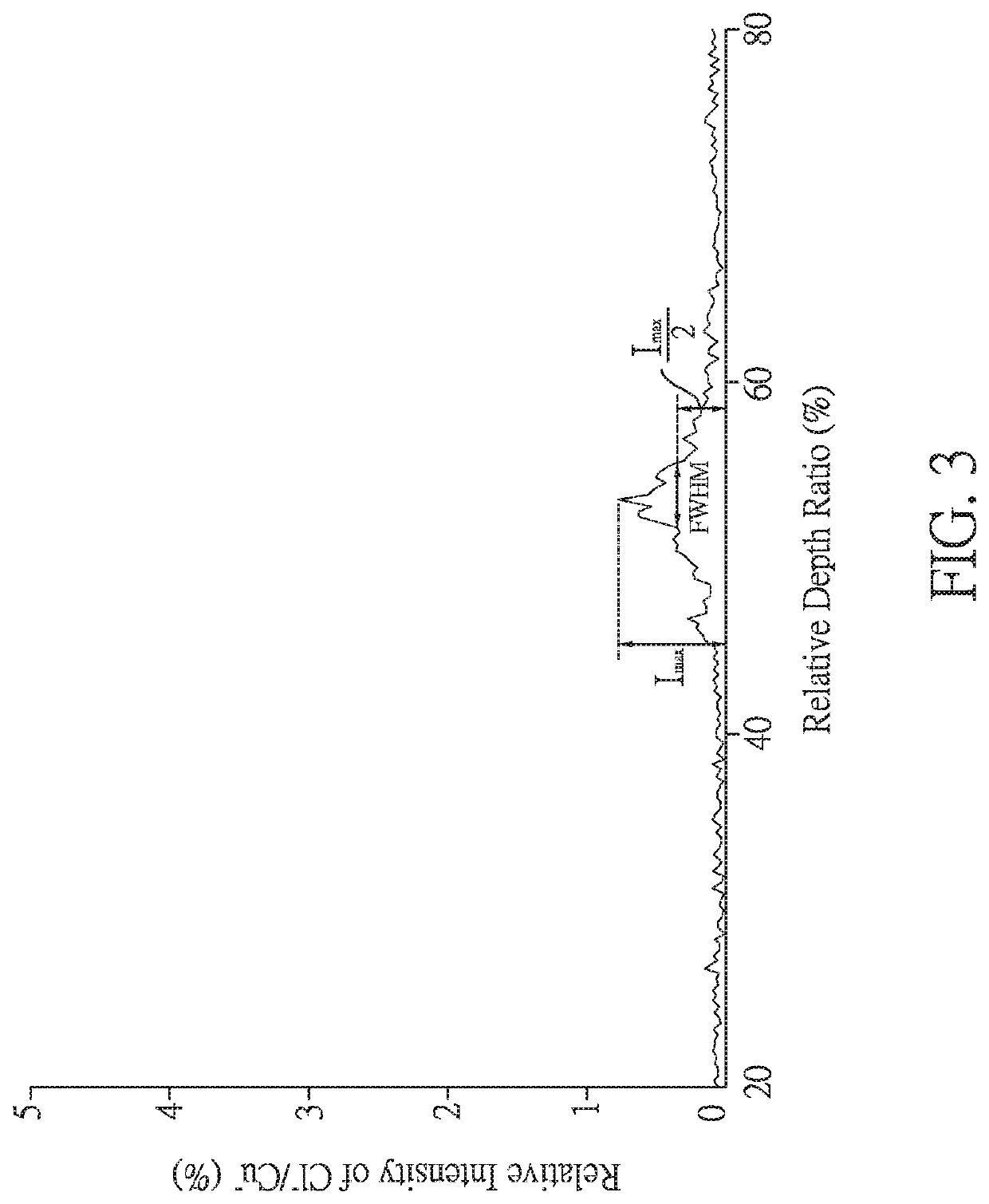

ActiveUS20210226197A1Mitigating and suppressing degree of warpageImprove coating uniformityElectrode carriers/collectorsNegative electrodesElectrolysisCopper foil

Provided are an electrolytic copper foil, an electrode, and a lithium-ion cell. The electrolytic copper foil comprising copper and chloride is analyzed by TOF-SIMS along its thickness direction to obtain a spectrum of a relative depth ratio as X-axis and a relative intensity of chloride versus copper as Y-axis. There is a chloride peak located between 20% and 80% of the relative depth ratio in the spectrum, and the chloride peak is characterized by a maximum relative intensity of chloride versus copper ranging from 0.77% to 5.13% and a full width at half maximum ranging from 2.31% to 5.78%. With above characteristics, the electrolytic copper foil has low density of copper particles, low degree of warpage, and good coating uniformity of the active material applied thereon, thereby optimizing the efficiency of a lithium-ion cell comprising the electrolytic copper foil.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

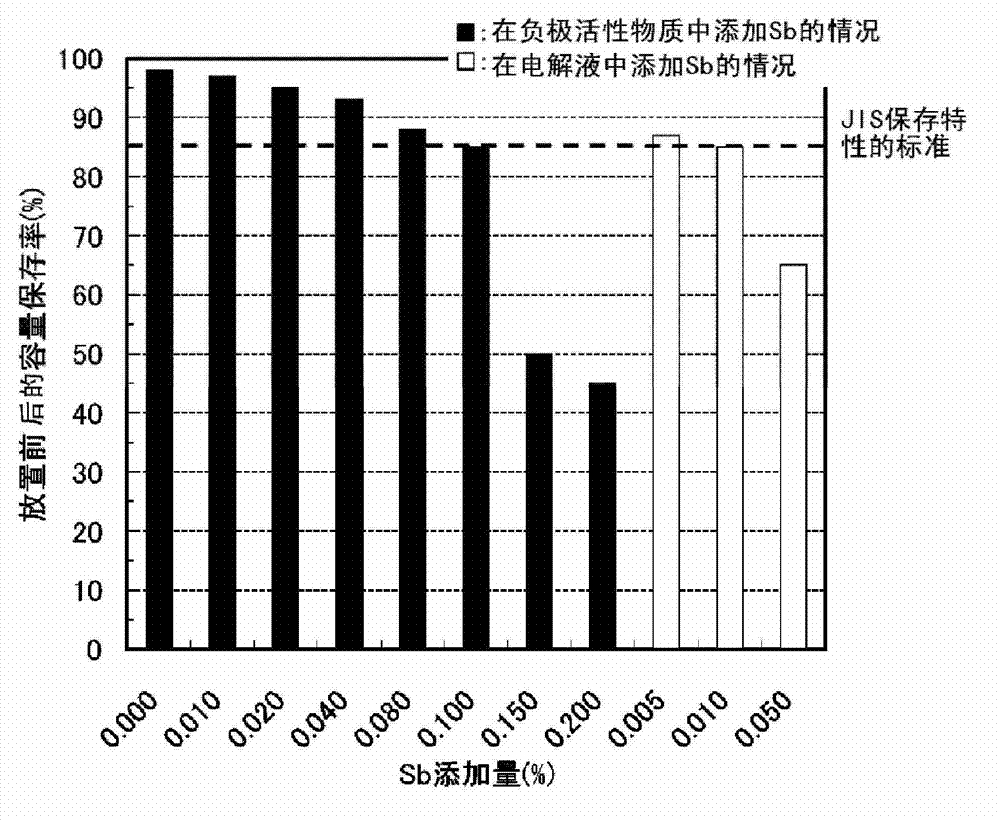

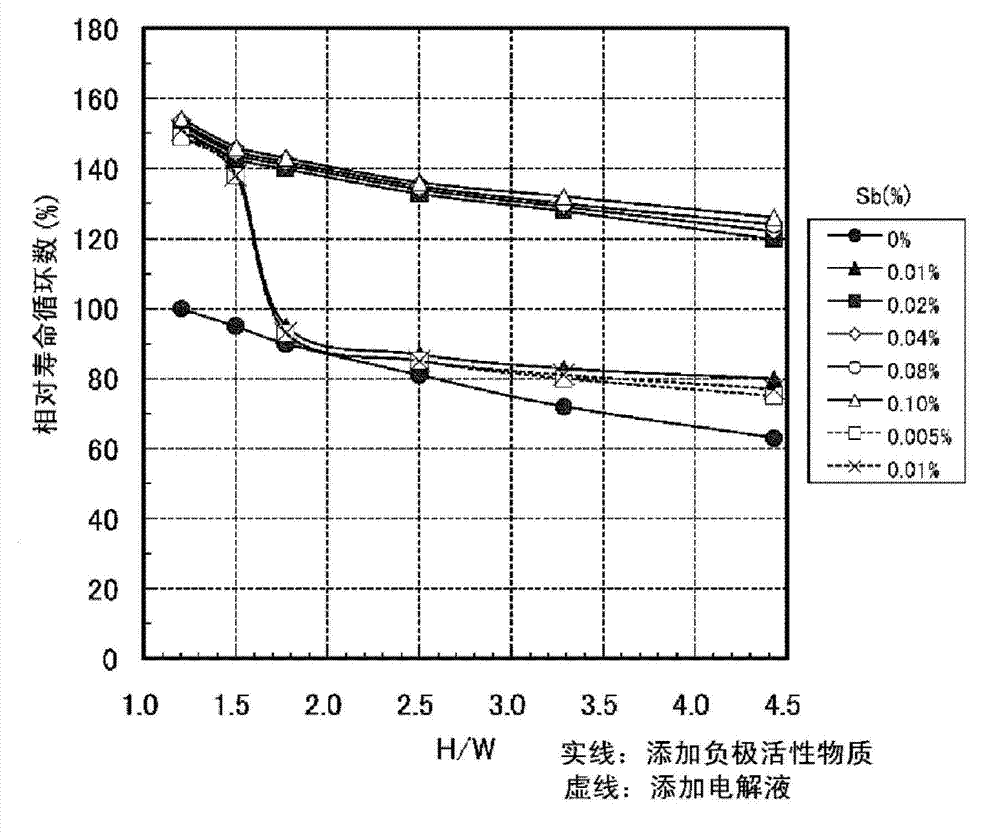

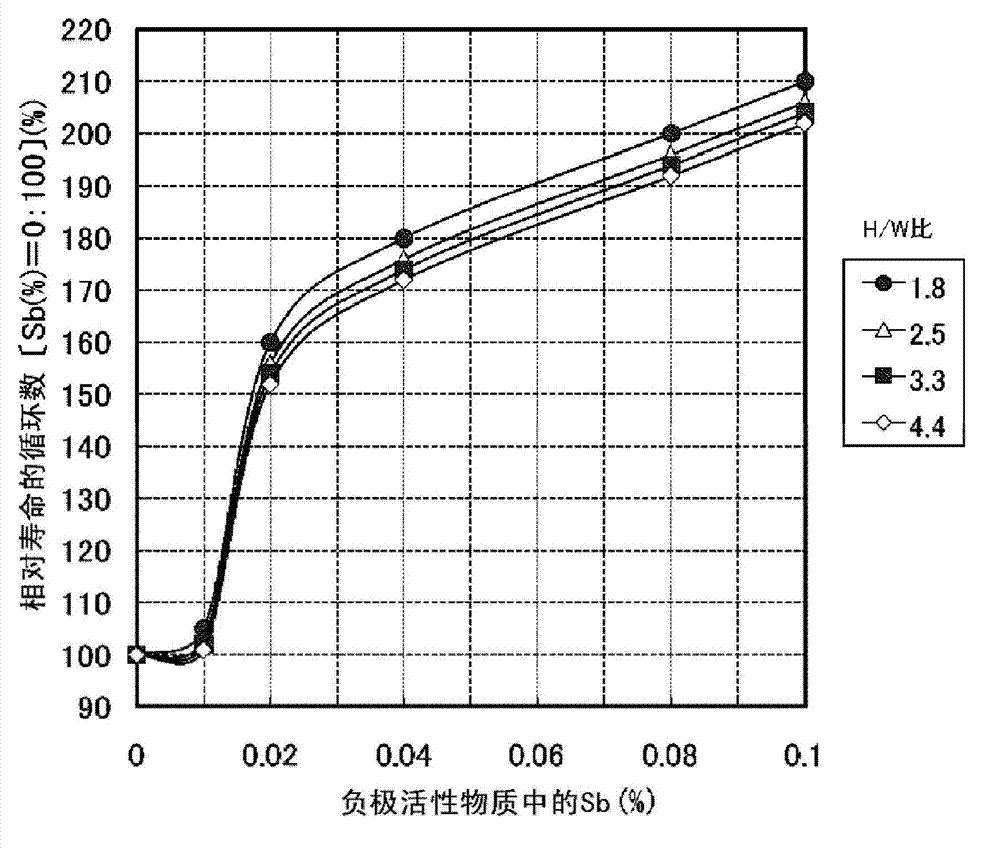

Lead storage battery

InactiveCN102956847AWidely producedImprove the mixing effectLead-acid accumulatorsCell electrodesElectrical batteryEngineering

The invention provides a lead storage battery, which can restrain the layering of an electrolyte very well even though the lead storage battery is a high lead storage battery of which the H / W rate is large, and has an excellent cycle life performance. In the lead storage battery, a battery jar forms an internal space having a more than 1.7 H / W rate of the size H in a height direction and the size W in the width direction parallel with a homopolar panel, and a negative plate possesses a cathode active material containing more than 0.016 mass % of antimony.

Owner:GS YUASA INT LTD

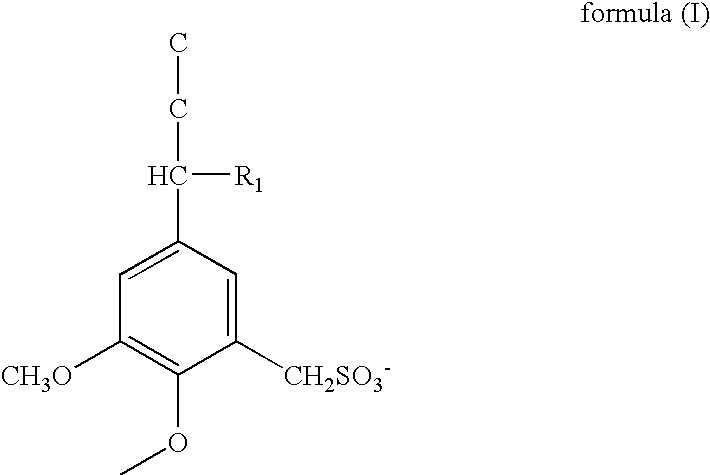

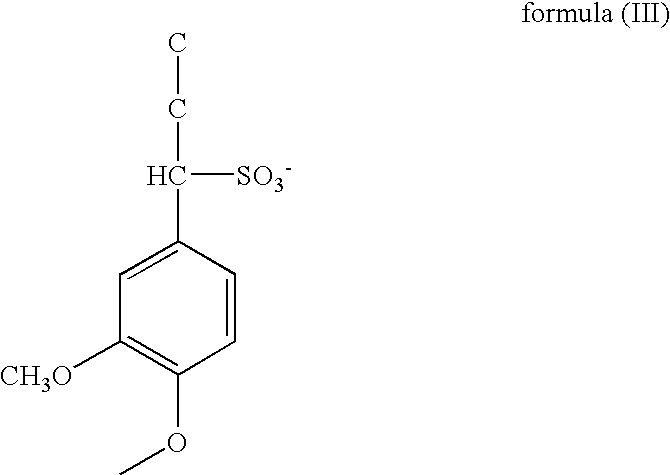

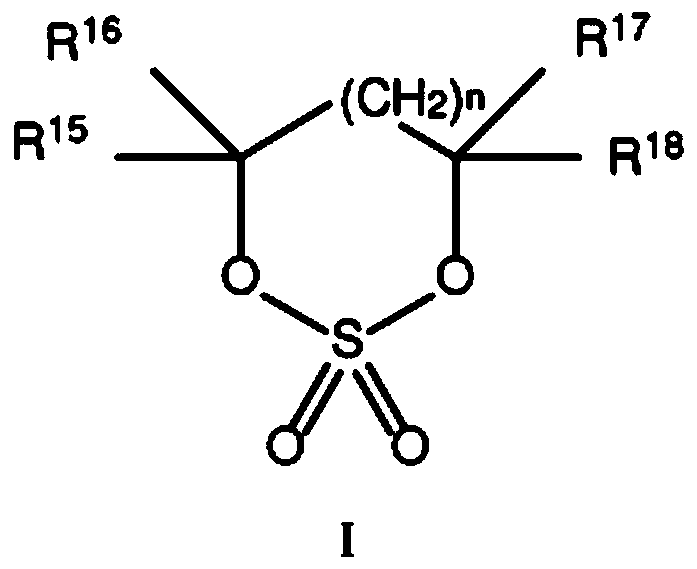

Negative active material, method of manufacturing its material, and lead acid battery

InactiveUS7022433B2Efficiently obtainedEnhanced cycle life performanceLead-acid accumulatorsPrimary cellsMedicineLead oxide

A negative active material is characterized by being prepared by adding a lignin having a unit structure represented by the formula (I) as the main structure to a lead oxide. Since the lignin of the formula (I) is added, the negative active material can be prevented from shrinkage due to charge / discharge. (wherein R1 is H, OH, COOH, SO3H, SH, C6H5, COO−, SO3−, R2C6H4, (R2)2C6H3, or (R2)3C6H2; and R2 is at least one member selected from among OH, COOR, SO3H, and CH2SO3H.)

Owner:GS YUASA INT LTD

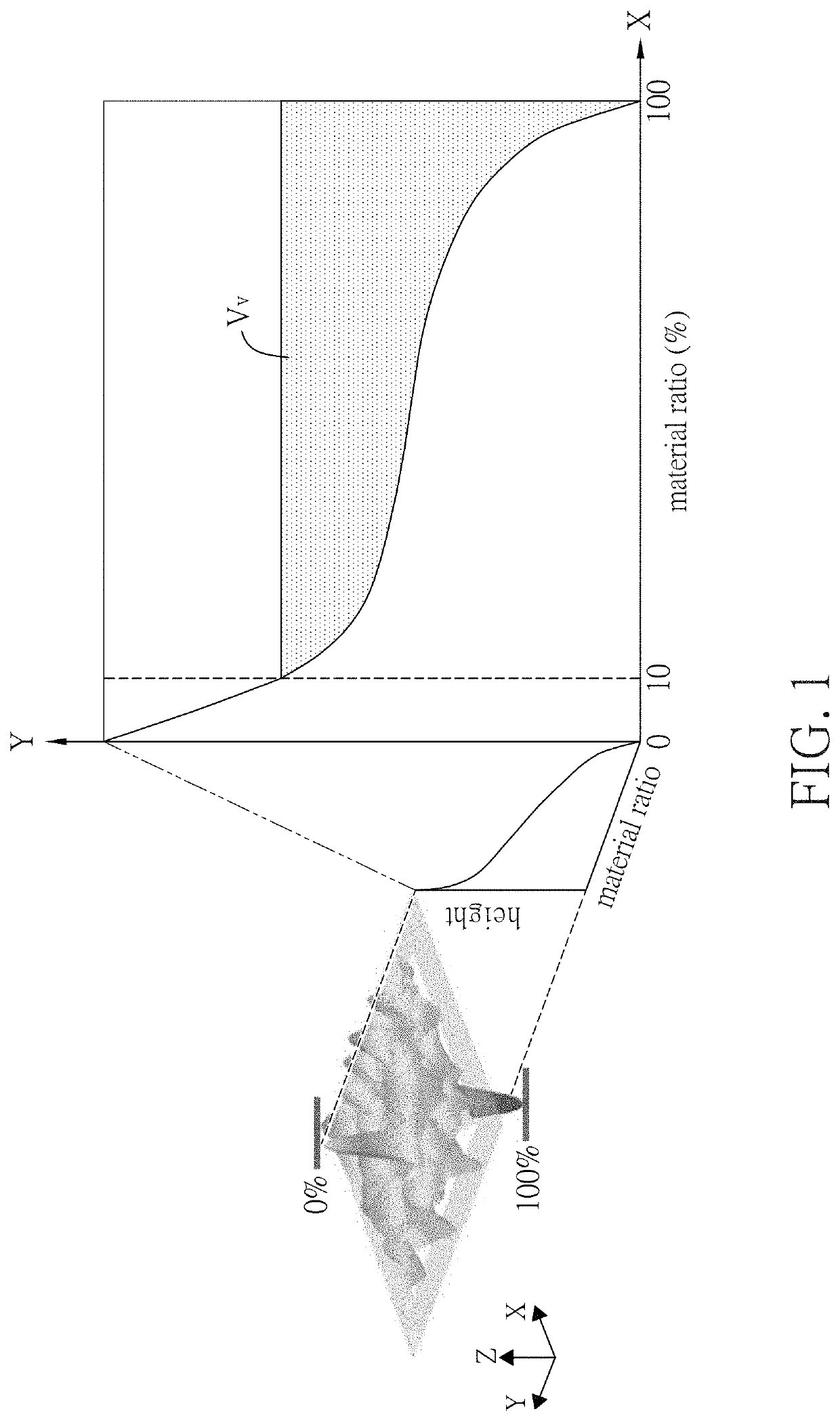

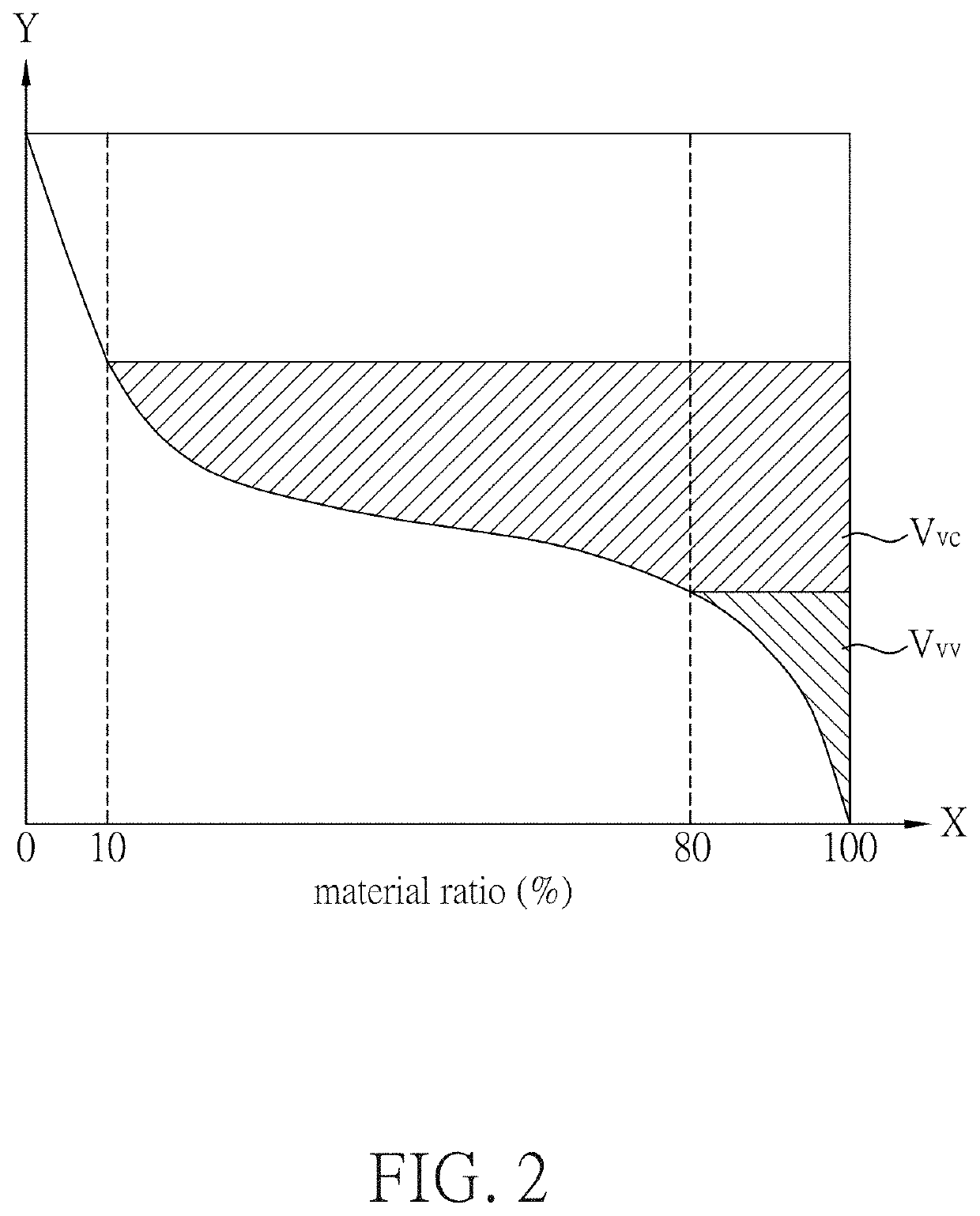

Electrodeposited copper foil and electrode, and lithium-ion secondary battery comprising the same

ActiveUS20210305580A1Maintain good propertiesLarge capacityElectrode manufacturing processesElectrode carriers/collectorsMetallurgyCopper foil

Provided are an electrodeposited copper foil, an electrode comprising the same, and a lithium-ion secondary battery comprising the same. The electrodeposited copper foil has a drum side and a deposited side opposing the drum side, wherein at least one of the drum side and the deposited side exhibits a void volume value (Vv) in the range of 0.17 μm3 / μm2 to 1.17 μm3 / μm2; and an absolute value of a difference between a maximum height (Sz) of the drum side and a Sz of the deposited side is in the range of less than 0.60 μm.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

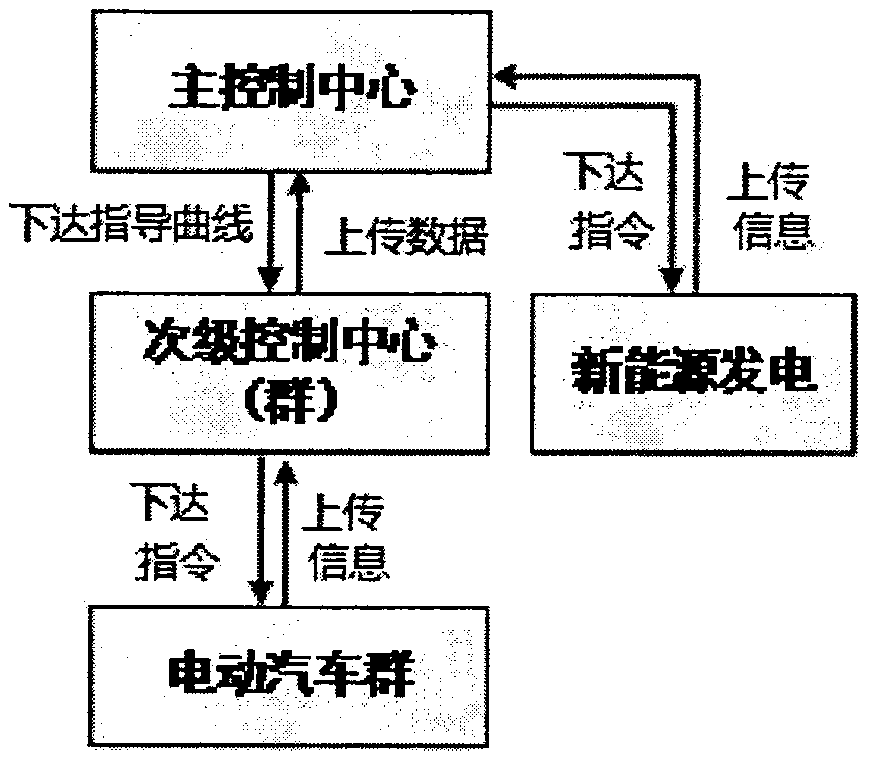

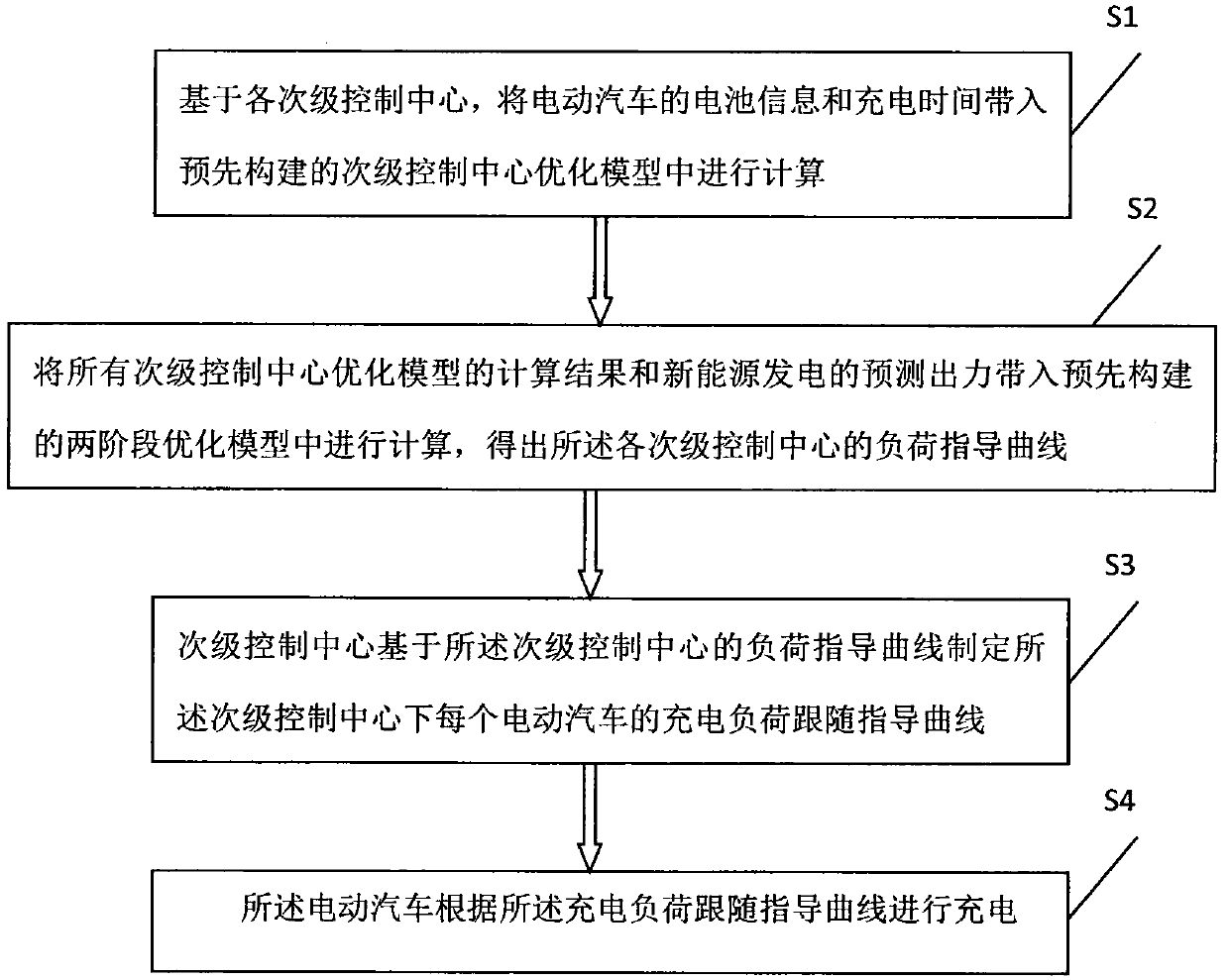

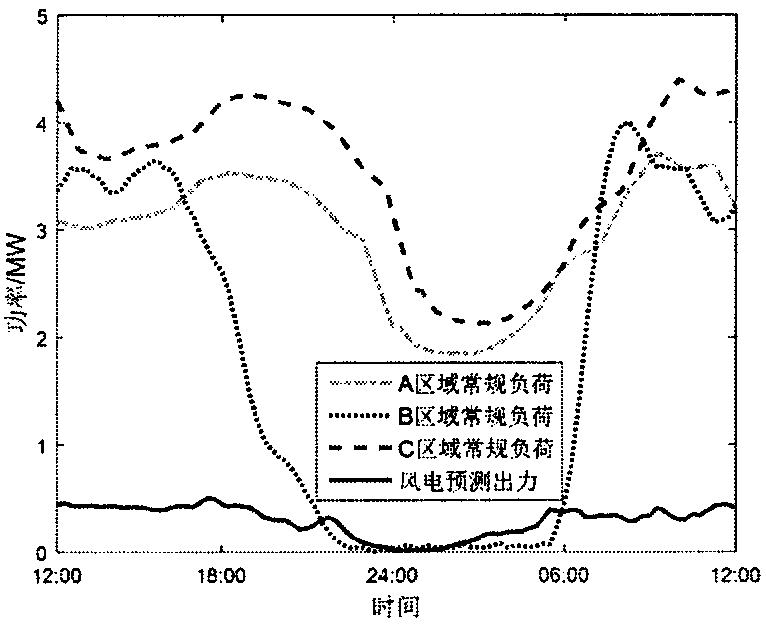

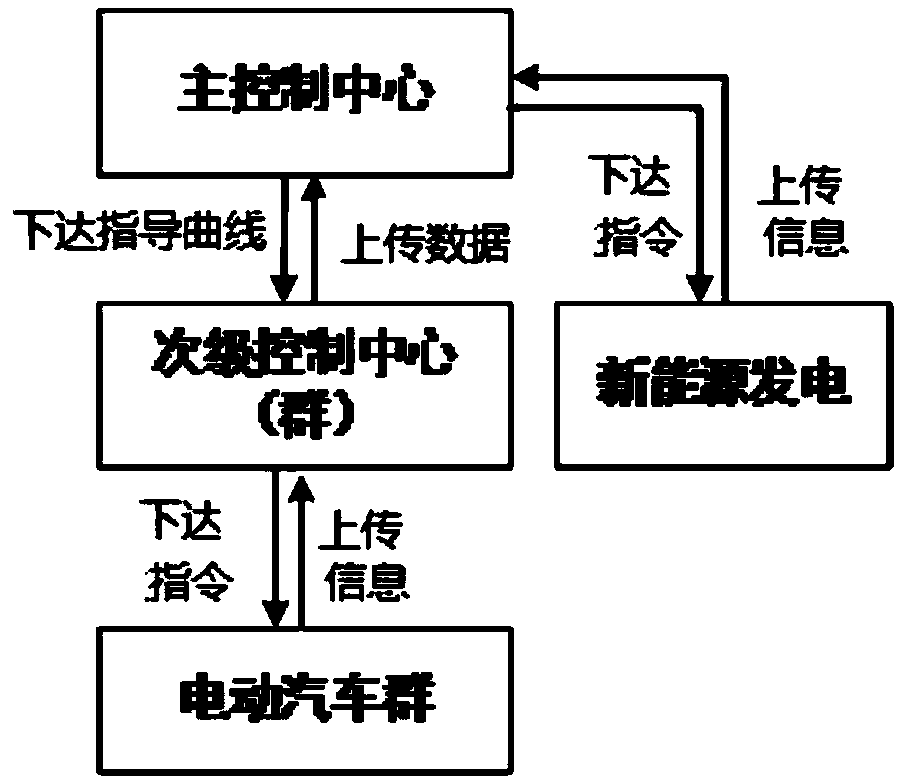

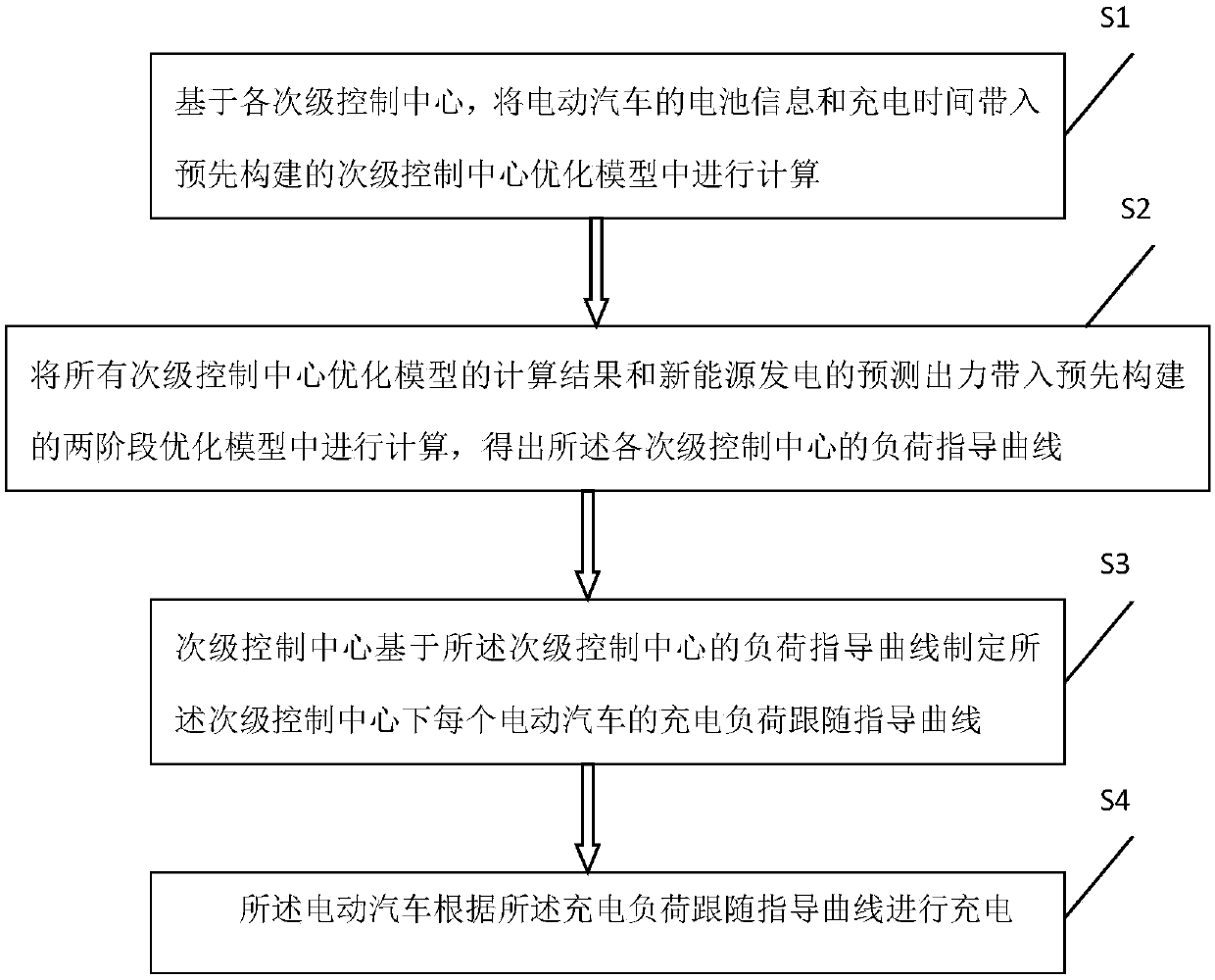

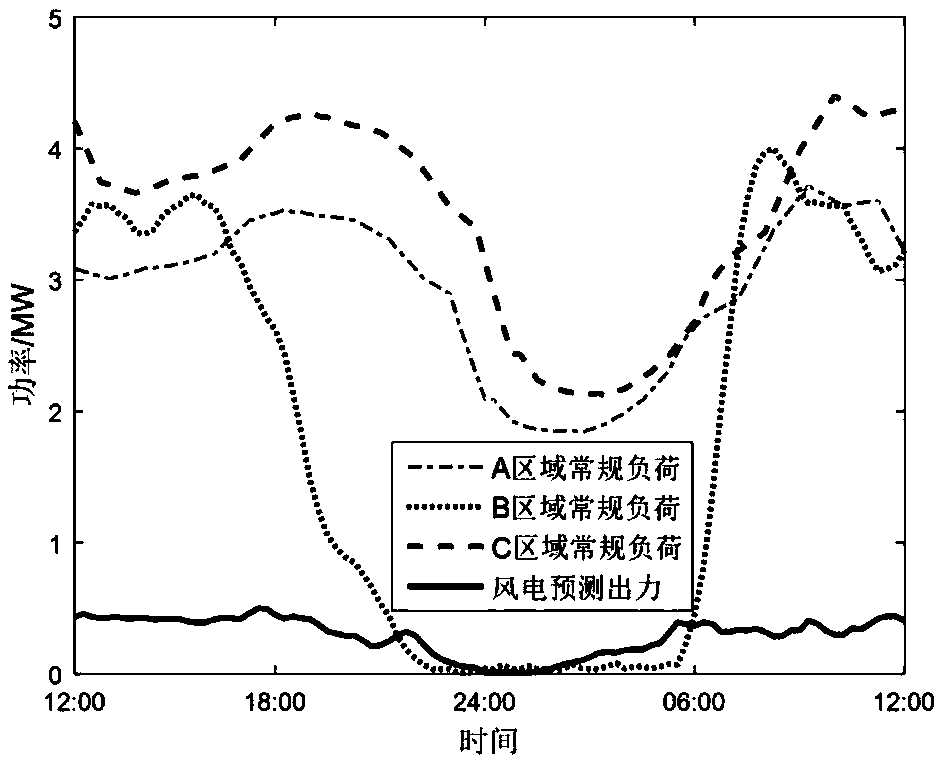

Electric vehicle charging method and system

PendingCN110797931AImprove scalabilityCooperate wellInternal combustion piston enginesFinal product manufactureElectrical batteryNew energy

The invention discloses an electric vehicle charging method and system. The method comprises the steps of substituting battery information and charging time of an electric vehicle into a secondary control center optimization model for calculation based on each secondary control center; substituting the calculation result and the predicted output of new energy power generation into a two-stage optimization model for calculation to obtain a load guidance curve of each secondary control center; formulating a charging load following guidance curve of each electric vehicle under the secondary control center based on the load guidance curve; and charging the electric vehicle according to the charging load following guidance curve. According to the invention, the orderly charging load following method for the electric vehicle can be embedded into a hierarchical control method, and the write control problem of electric vehicle charging and clean energy power generation can be solved by means of the hierarchical control method, so that the charging behavior of the electric vehicle can be better matched with intermittent new energy power generation, and thus economic benefits and social benefits are created for the society, the power grid and electric vehicle operators.

Owner:STATE GRID ELECTRIC VEHICLE SERVICE CO LTD +3

Charging method and system for electric vehicles distributed in wide area

ActiveCN110745030AImprove scalabilityCooperate wellInternal combustion piston enginesForecastingWide areaNew energy

The invention discloses a charging strategy and system for large-scale electric vehicles distributed in a wide area. The charging strategy for the large-scale electric vehicles distributed in the widearea comprises the following steps: battery information and charging time of the electric vehicles are brought into optimization models of secondary control centers and calculated on the basis of thesecondary control centers; calculation results and predicated output of new energy power generation are brought into a two-stage optimization model and calculated to obtain load guidance curves of the secondary control centers; a charging load following guidance curve of each electric vehicle under the corresponding secondary control center is formulated on the basis of the corresponding load guidance curve; and the electric vehicles are charged according to the charging load following guidance curves. According to the charging strategy and system for the large-scale electric vehicles distributed in the wide area, the strategy of ordered charging load following of the electric vehicles can be embedded into a hierarchical control strategy, and through the hierarchical control strategy, thepurpose of writing cooperation control over the large-scale electric vehicles distributed in the wide area during charging, and clean energy power generation can be achieved, so that a charging behavior for the electric vehicles can be better matched with the intermittent new energy power generation, and then economic benefits and social benefits are created for the society, power grid and electric vehicle operators.

Owner:STATE GRID ELECTRIC VEHICLE SERVICE CO LTD +3

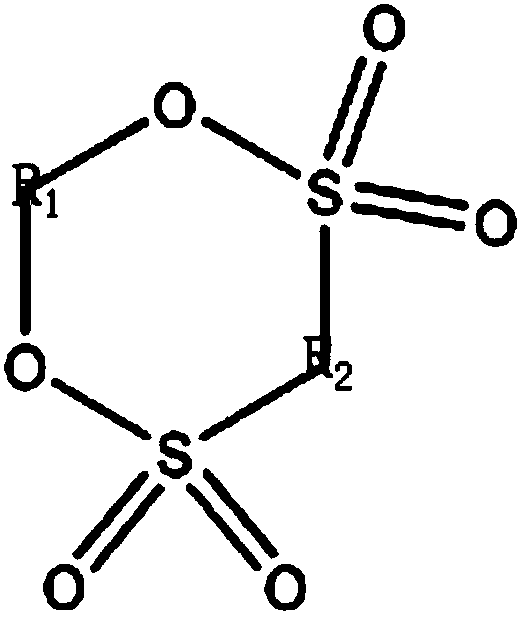

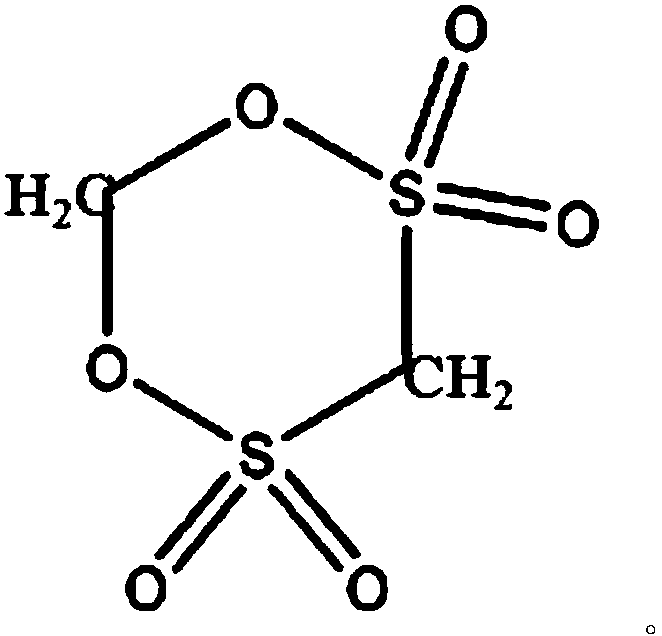

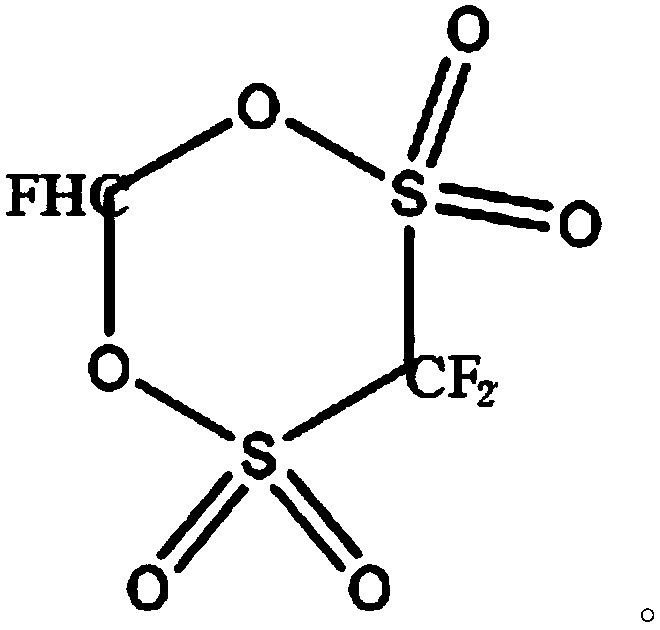

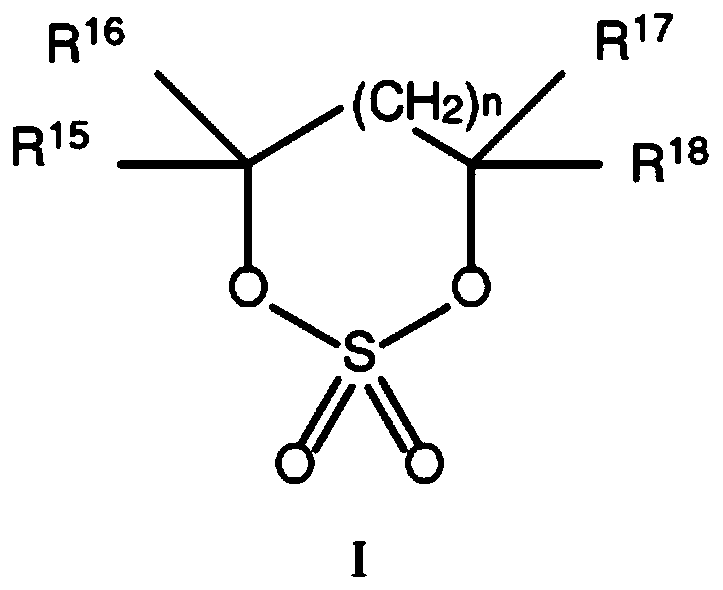

Electrolytes containing six membered ring cyclic sulfates

PendingCN109997258AEnhanced cycle life performanceImprove discharge capacityCell electrodesSecondary cellsCarboxylic acidLithium-ion battery

Disclosed herein are electrolyte compositions comprising at least one electrolyte component comprising a cyclic carbonate, such as a fluoroethylene carbonate, and at least one additive comprising a 6-member ring heterocyclic sulfate, such as a 1,3 propylene sulfate. The disclosed electrolyte compositions can comprise additional electrolyte components, such as fluorinated acyclic carboxylic acid esters, and additional additives, such as lithium boron compounds, and cyclic carboxylic acid anhydrides, such as maleic anhydride. The improved battery performances, which include high temperature cycling conditions and / or room temperature stability, make these electrolyte compositions useful in electrochemical cells, such as lithium ion batteries.

Owner:SOLVAY SA

Electrolytic copper foil and electrode and lithium-ion cell comprising the same

ActiveUS11050050B1Mitigating and suppressing degree of warpageImprove coating uniformityElectrode carriers/collectorsNegative electrodesElectrolysisCopper foil

Provided are an electrolytic copper foil, an electrode, and a lithium-ion cell. The electrolytic copper foil comprising copper and chloride is analyzed by TOF-SIMS along its thickness direction to obtain a spectrum of a relative depth ratio as X-axis and a relative intensity of chloride versus copper as Y-axis. There is a chloride peak located between 20% and 80% of the relative depth ratio in the spectrum, and the chloride peak is characterized by a maximum relative intensity of chloride versus copper ranging from 0.77% to 5.13% and a full width at half maximum ranging from 2.31% to 5.78%. With above characteristics, the electrolytic copper foil has low density of copper particles, low degree of warpage, and good coating uniformity of the active material applied thereon, thereby optimizing the efficiency of a lithium-ion cell comprising the electrolytic copper foil.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com