Method for prolonging cycle life of lithium ion battery

A lithium-ion battery, cycle life technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of rate performance decline, cost control, impedance rise, etc., to achieve cycle life improvement, The effect of low cost and moderate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

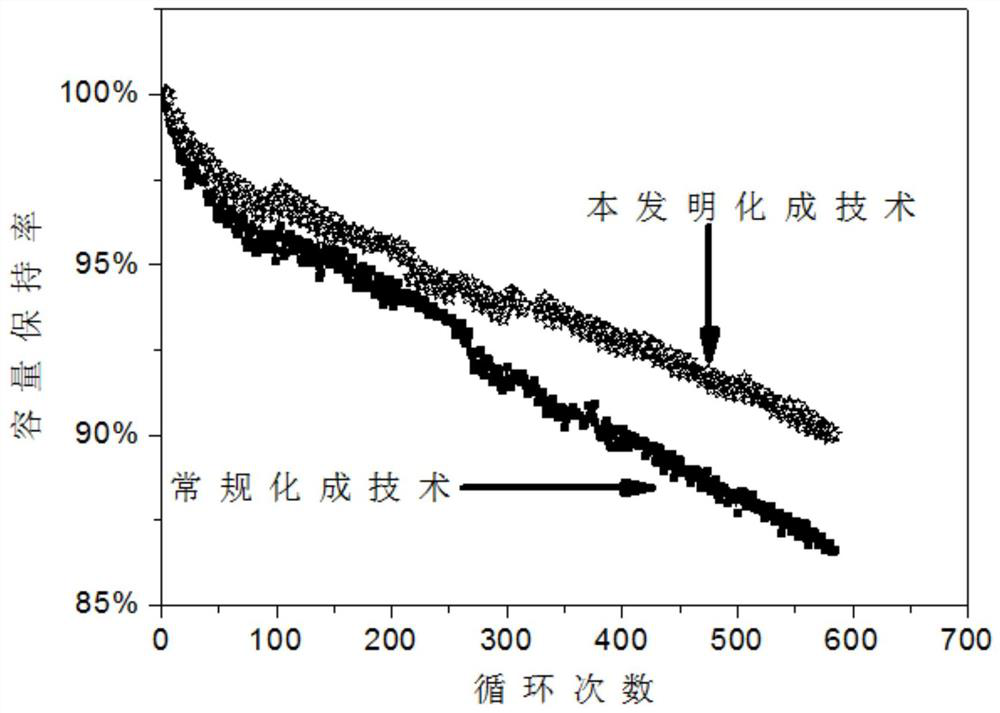

[0049] A method of forming a low-impedance SEI film by adjusting the growth mode of the SEI film to realize the improvement of the cycle life of the aluminum-plastic case soft-packed lithium-ion battery. The ternary positive electrode material used in the lithium battery is nickel-cobalt lithium 0.8 co 0.1 mn 0.1 )O 2 , the negative electrode material is graphite, and the electrolyte in the electrolyte is LiPF 6 , The solvent is the electrolyte system of mixed solvents of EC, DEC and EMC;

[0050] The specific steps are as follows:

[0051] step one

[0052] 1) The rated capacity of the lithium battery is 6Ah, and the lithium battery is left to stand for 22 hours after liquid injection, and a pressure of 0.4Mpa is applied to the lithium battery through a pressure device;

[0053] 2) Connect the lithium battery to the temperature-controllable formation equipment, the formation temperature is 45°C, and use the step charging mode to charge, that is, charge with a constant cu...

Embodiment 2

[0062] A method of forming a low-impedance SEI film by adjusting the growth mode of the SEI film to improve the cycle life of an aluminum-plastic case soft-packed lithium-ion battery. The ternary positive electrode material used in the battery is nickel-cobalt lithium manganate Li (Ni 0.8 co 0.1 mn 0.1 )O 2 , the negative electrode material is graphite, and the electrolyte in the electrolyte is LiPF 6 , The solvent is the electrolyte system of mixed solvents of EC, DEC and EMC;

[0063] The specific steps are as follows:

[0064] step one

[0065] 1) The rated capacity of the lithium battery is 6Ah. After the lithium battery is filled with liquid, let it stand for 20 hours, and apply a pressure of 0.5Mpa to the lithium battery through a pressure device;

[0066] 2) Connect the lithium battery to the temperature-controllable formation equipment, the formation temperature is 50°C, and use the step charging mode to charge, that is, charge with a constant current of 0.3A for ...

Embodiment 3

[0075] A method of forming a low-impedance SEI film by adjusting the growth mode of the SEI film to improve the cycle life of an aluminum-plastic case soft-pack lithium-ion lithium battery. The ternary positive electrode material used in the lithium battery is nickel-cobalt lithium 0.8 co 0.1 mn 0.1 )O 2 , the negative electrode material is graphite, and the electrolyte in the electrolyte is LiPF 6 , The solvent is the electrolyte system of mixed solvents of EC, DEC and EMC;

[0076] The specific steps are as follows:

[0077] step one

[0078] 1) The rated capacity of the lithium battery is 6Ah, and the lithium lithium battery is left to stand for 24 hours after liquid injection, and a pressure of 0.2Mpa is applied to the lithium lithium battery through a pressure device;

[0079] 2) Connect the lithium battery to the temperature-controllable formation equipment, the formation temperature is 55°C, and charge in the step charging mode, that is, charge with a constant curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com