Lithium secondary battery having lithium metal formed on anode and manufacturing method therefor

A lithium secondary battery and positive electrode technology, which is applied in secondary battery, electrolyte storage battery manufacturing, secondary battery repair/maintenance, etc., can solve problems such as difficult preparation and use, and achieve the effect of enhancing cycle life performance and inhibiting formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

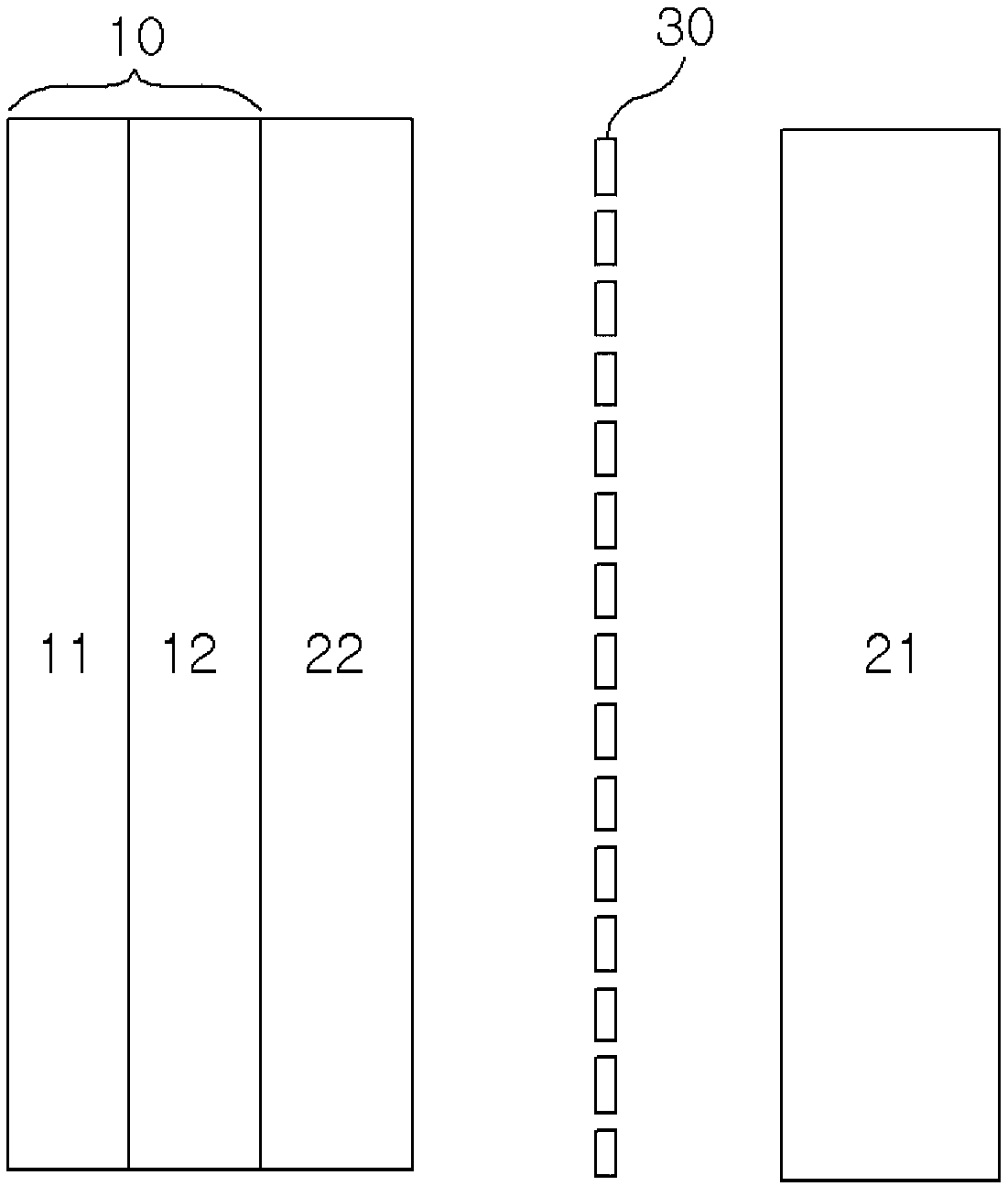

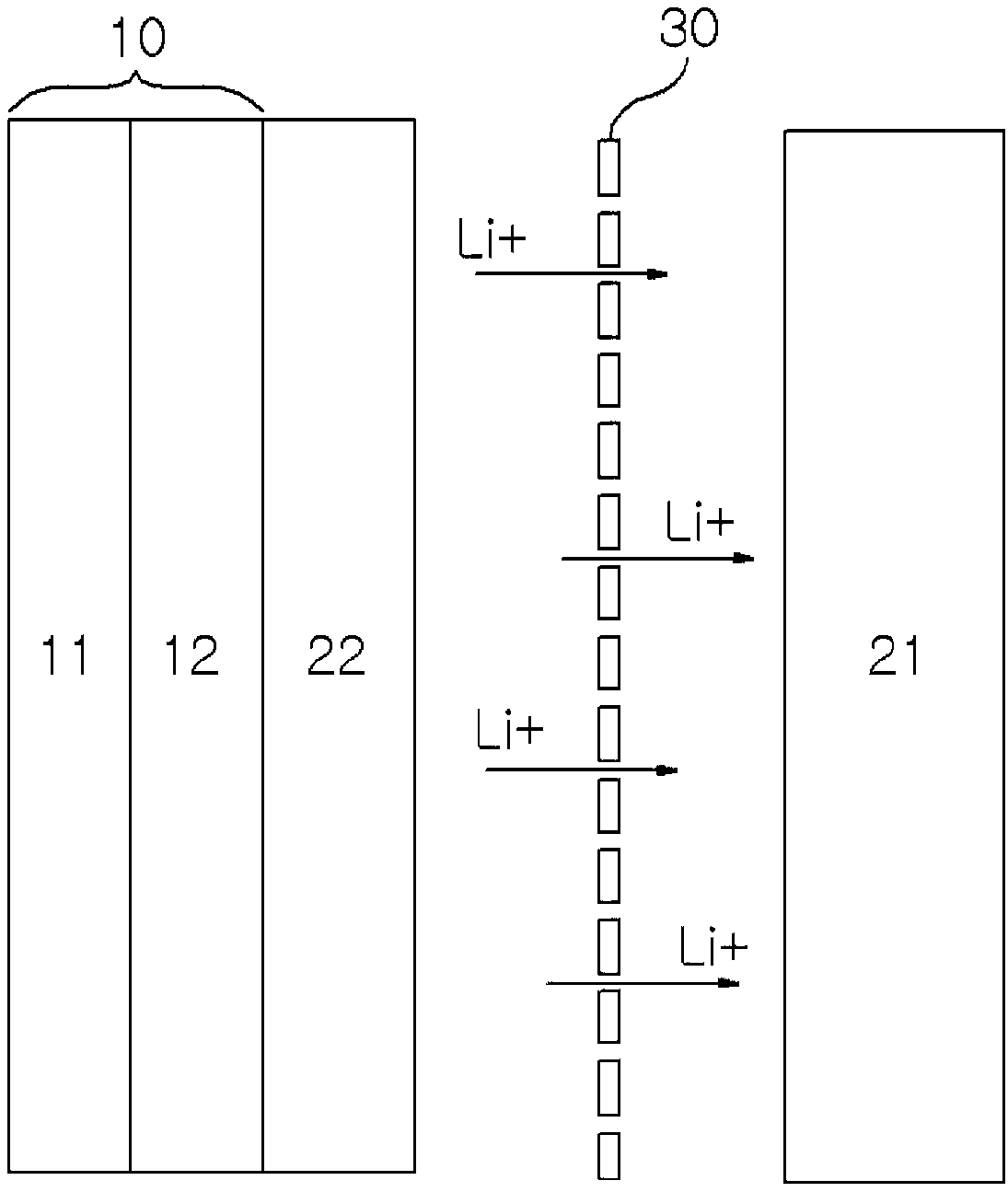

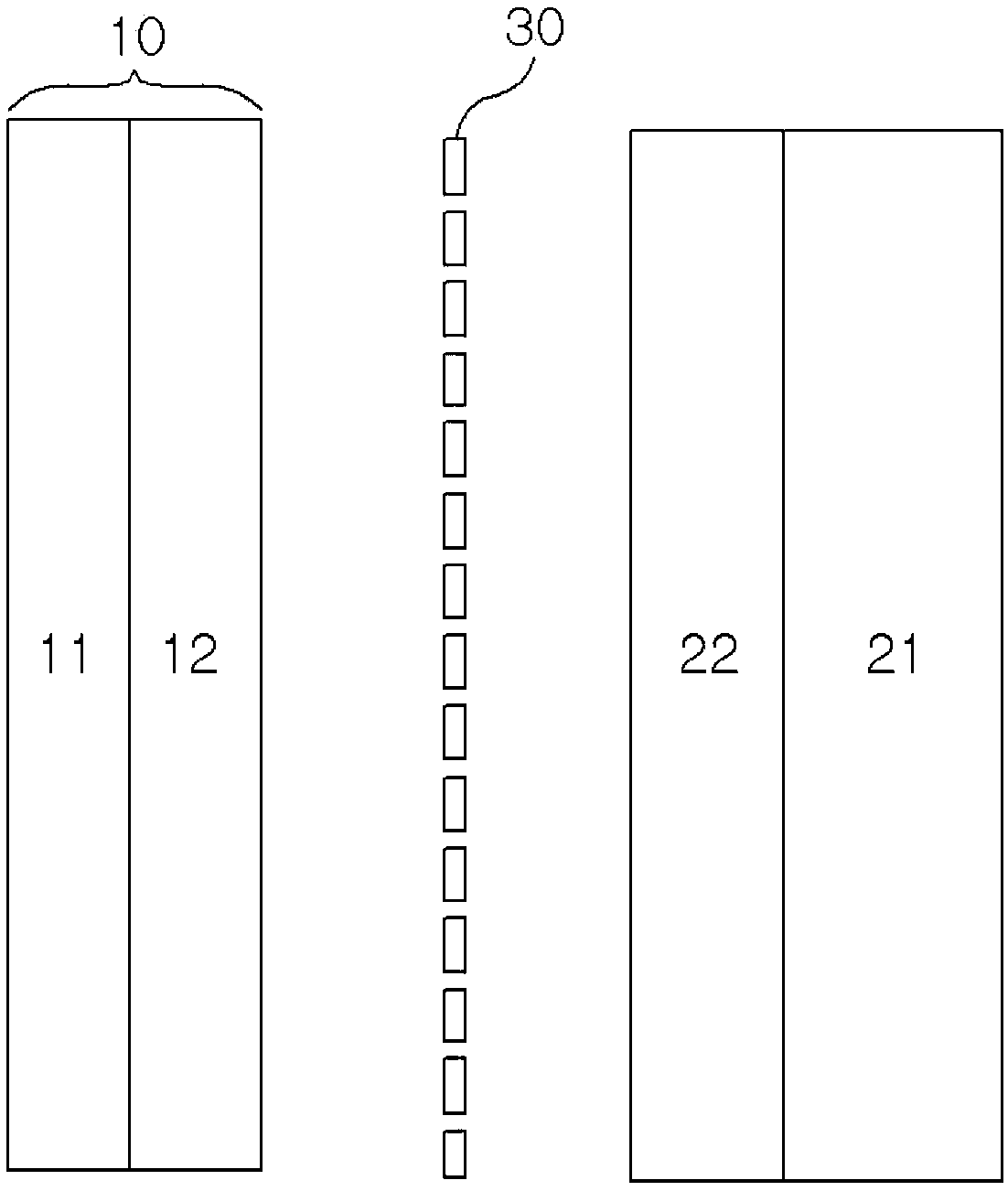

[0067] The LCO-based cathode active material, Super-P (conductive carbon black) and PVdF were mixed in a weight ratio of 95:2.5:2.5, and then coated on an aluminum current collector to form a cathode (load 450mg / 25cm 2 ). A lamination method was used to laminate lithium metal with a thickness of 20 μm thereon.

[0068] On one surface of the copper current collector, a negative electrode formed with a 0.2 μm thick LiPON protective layer was prepared.

[0069] A porous polyethylene separator is disposed between the prepared positive electrode and the negative electrode to prepare an electrode assembly, and after the electrode assembly is placed in the case, an electrolyte is injected therein to manufacture a lithium secondary battery. Here, the electrolyte is prepared as follows: 1M LiPF 6 And 2% by weight of vinylene carbonate (VC) dissolved in fluoroethylene carbonate (FEC): ethylene carbonate (EC): diethyl carbonate (DEC) in a volume ratio of 1:1:2:1 ): In an organic solvent form...

Embodiment 2

[0071] A lithium secondary battery was manufactured in the same manner as in Example 1, except that a LiPON protective layer was not formed in the negative electrode.

Embodiment 3

[0073] A lithium secondary battery was manufactured in the same manner as in Example 1, except that a 0.3 μm-thick PVdF-HFP (HFP content: 5 wt%) protective layer was formed on one surface of the copper current collector instead of the negative electrode LiPON protection layer in the.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com