Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Effective killing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin mucous membrane disinfectants and preparation method thereof

ActiveCN101642449AEasy to prepareReduce manufacturing costAntibacterial agentsBiocideDisinfectantAdditive ingredient

The invention provides various skin mucous membrane disinfectants which are prepared by adopting double-chain quaternary ammonium salt and benzalkonium bromide (C20H40BrN) as main germicidal ingredients and using triclosan (C12H7Cl3O2), polyethylene glycol (HOCH2(CH2OCH2)nCH2OH), glycerol (C3H8O3), Tween 80, menthol, borneol, medical alcohol and the like as adjuvant ingredients, can be used in thefields such as the disinfection of skin and mucosa, the disinfection of surgical hand washing and the disinfection of medical apparatus and instruments in the hospital, the disinfection of tools anddevices in public places and different production industries, the mold prevention of industrial products and agricultural grains, the health disinfection of poultry houses, the aquatic product field,the aquaculture, the killing of alga, the preparation of plastic antibacterial agent, the preparation of compound disinfectant and the like and has effective bactericidal action to staphylococcus aureus, colibacillus, candida albicans, HIV and the like ; in addition, the preparation method is simple and the production cost is lower.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

Special toothpaste containing multiple components from natural sources for children

InactiveCN106420552AReduce wearEffective killing effectCosmetic preparationsToilet preparationsNatural sourcePropolis

The invention discloses special toothpaste containing multiple components from natural sources for children. The toothpaste is prepared from 52-53% of (sorbose) sorbitol, 14-16% of egg shell powder, 1.5-2.5% of glycerinum, 1.2-1.4% of sodium lauryl sulfate, 2.5-3.5% of xylitol, 1.4-1.6% of pulullan, 1-1.5% of propolis extract, 1.8-2.2% of honeysuckle extract, 0.08-0.12% of ethylene diamine tetraacetic acid disodium salt, 0.04-0.06% of sodium benzoate, 0.08-0.12% of nisin and the balance deionized water, and is prepared according to a method for preparing conventional toothpaste. The special toothpaste for children is not only capable of generating rich foams, being wild and having no irritation and having small erosion on teeth of children, but also capable of having a better carries-preventing effect when being used cooperatively with natural extracts capable of inhibiting bacteria inducing caries and a sweetening agent capable of preventing caries.

Owner:FUJIAN MENGJIAOLAN DAILY CHEM

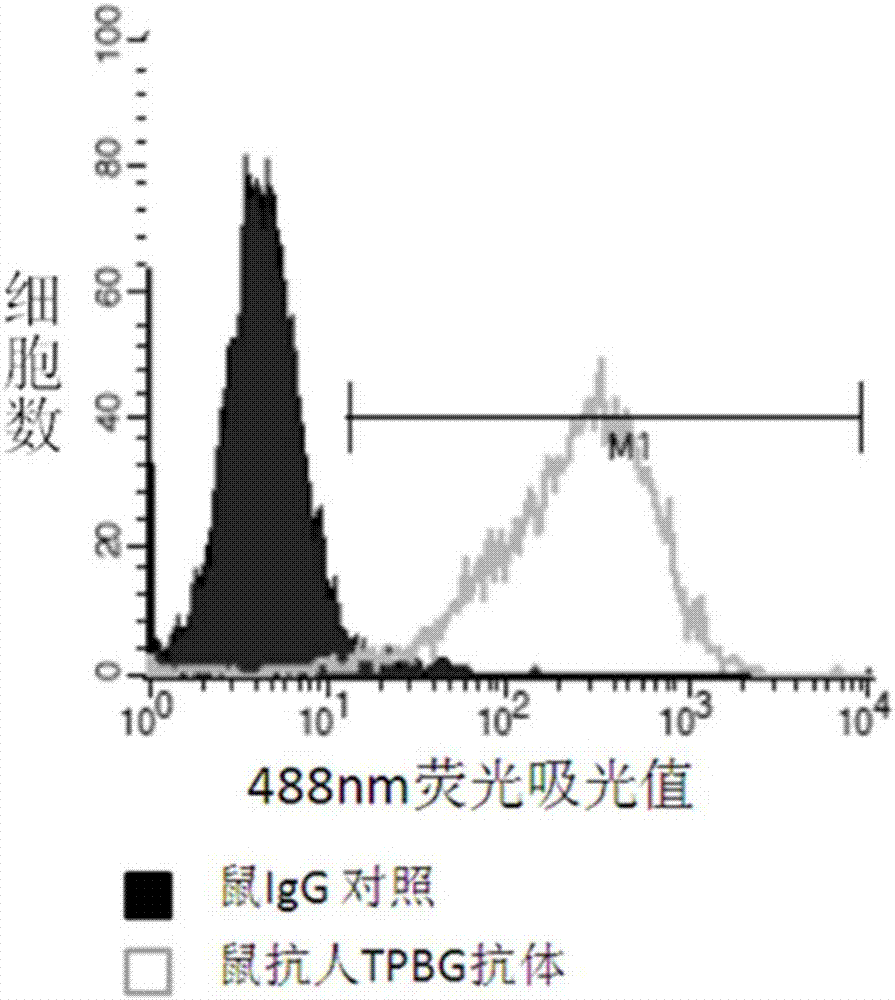

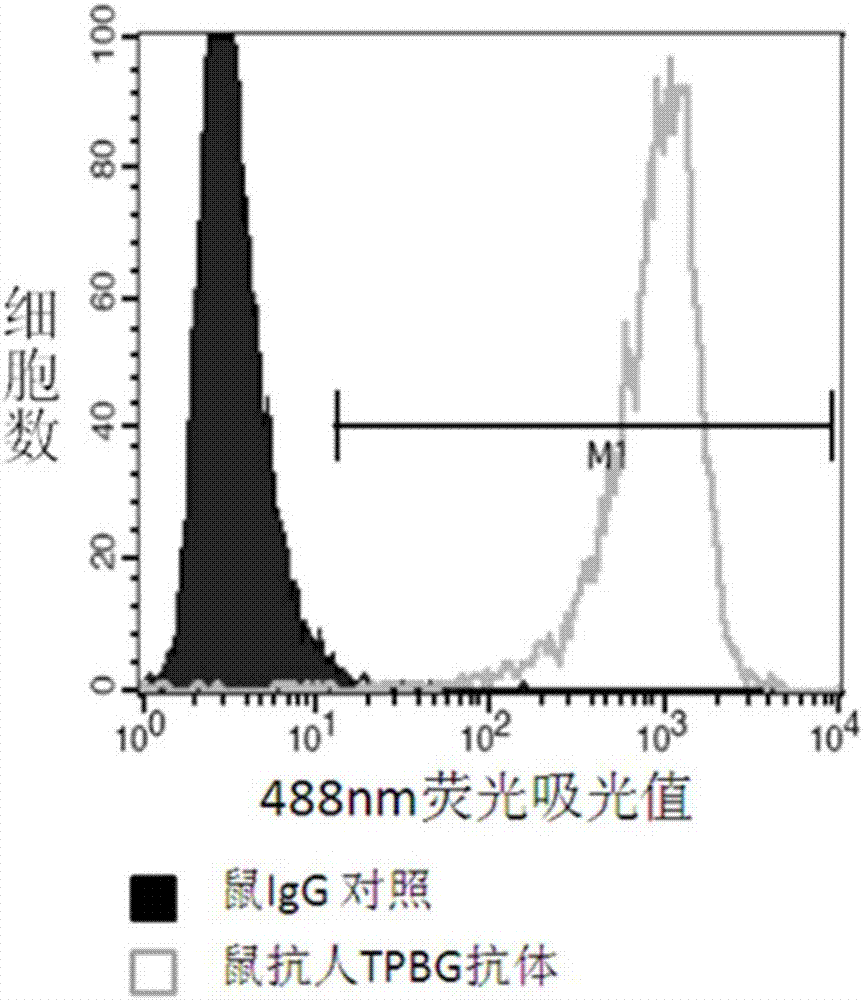

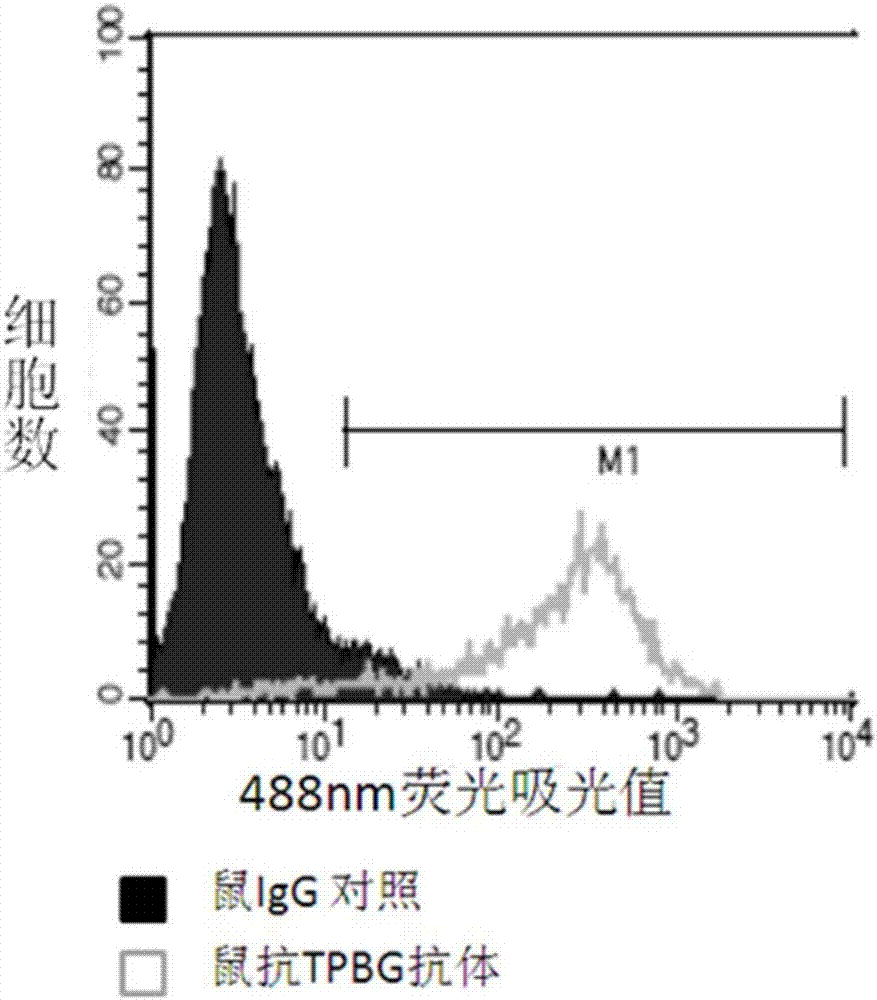

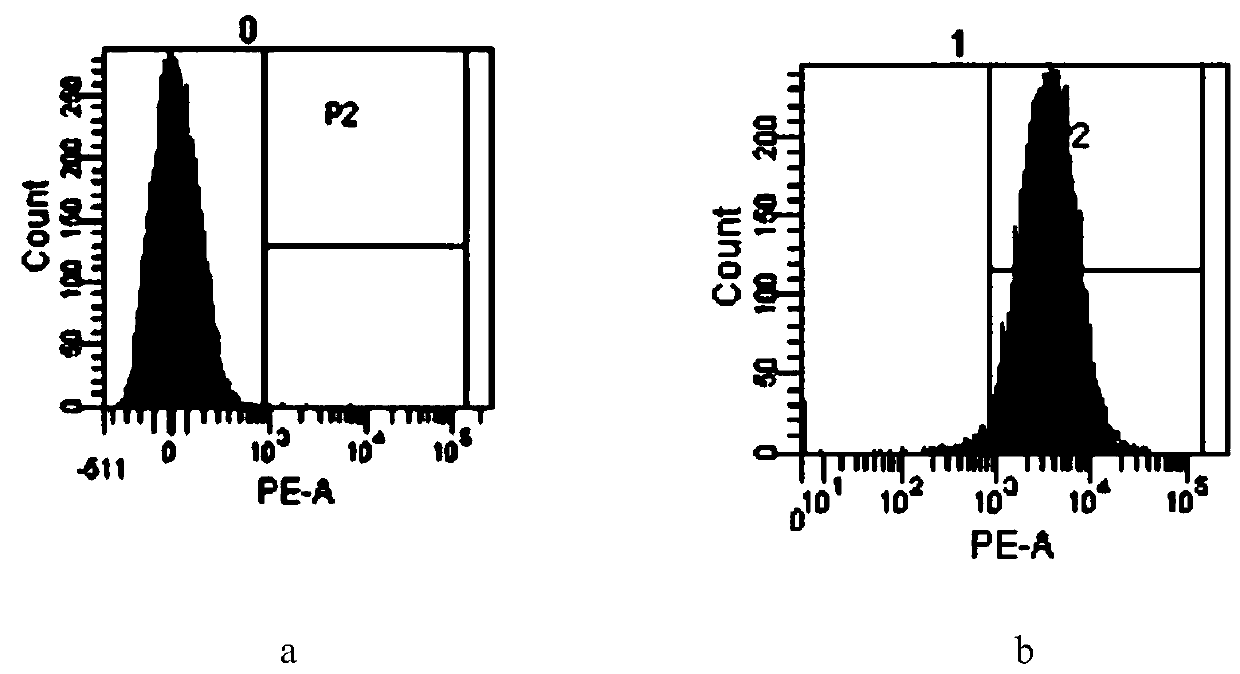

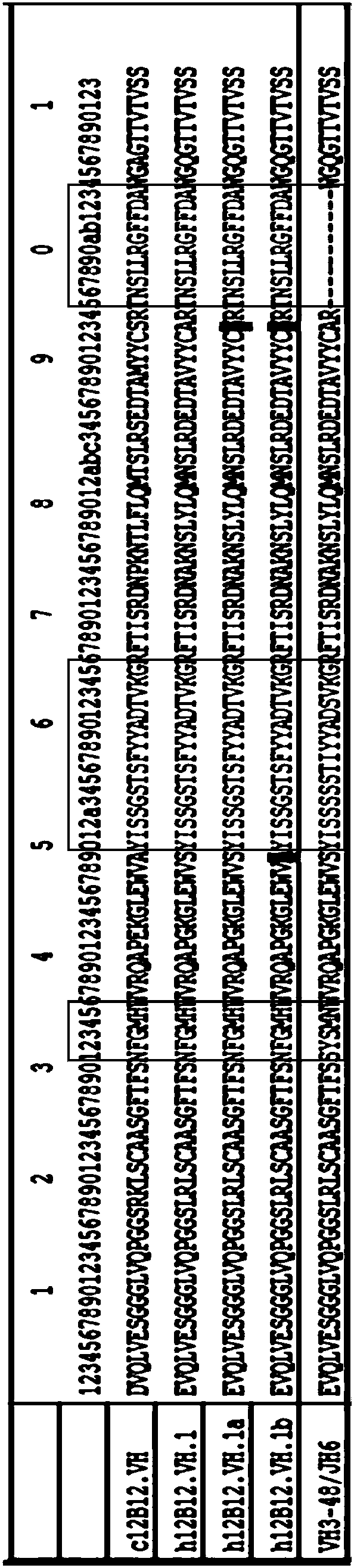

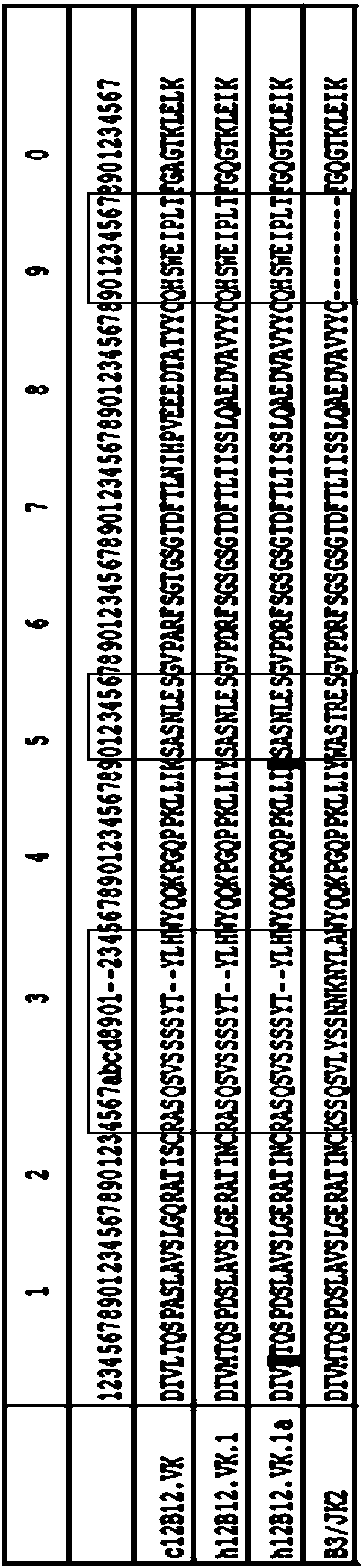

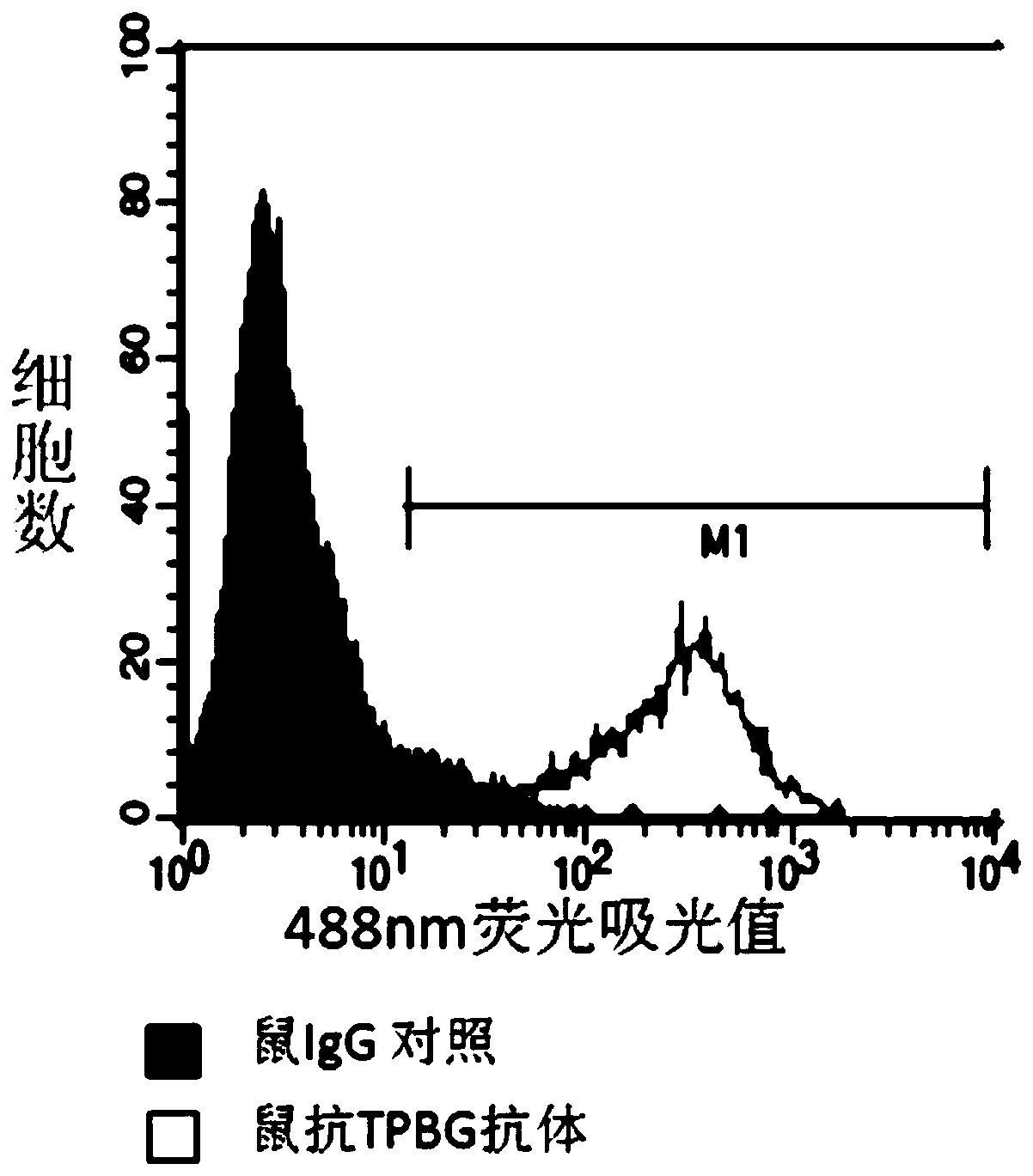

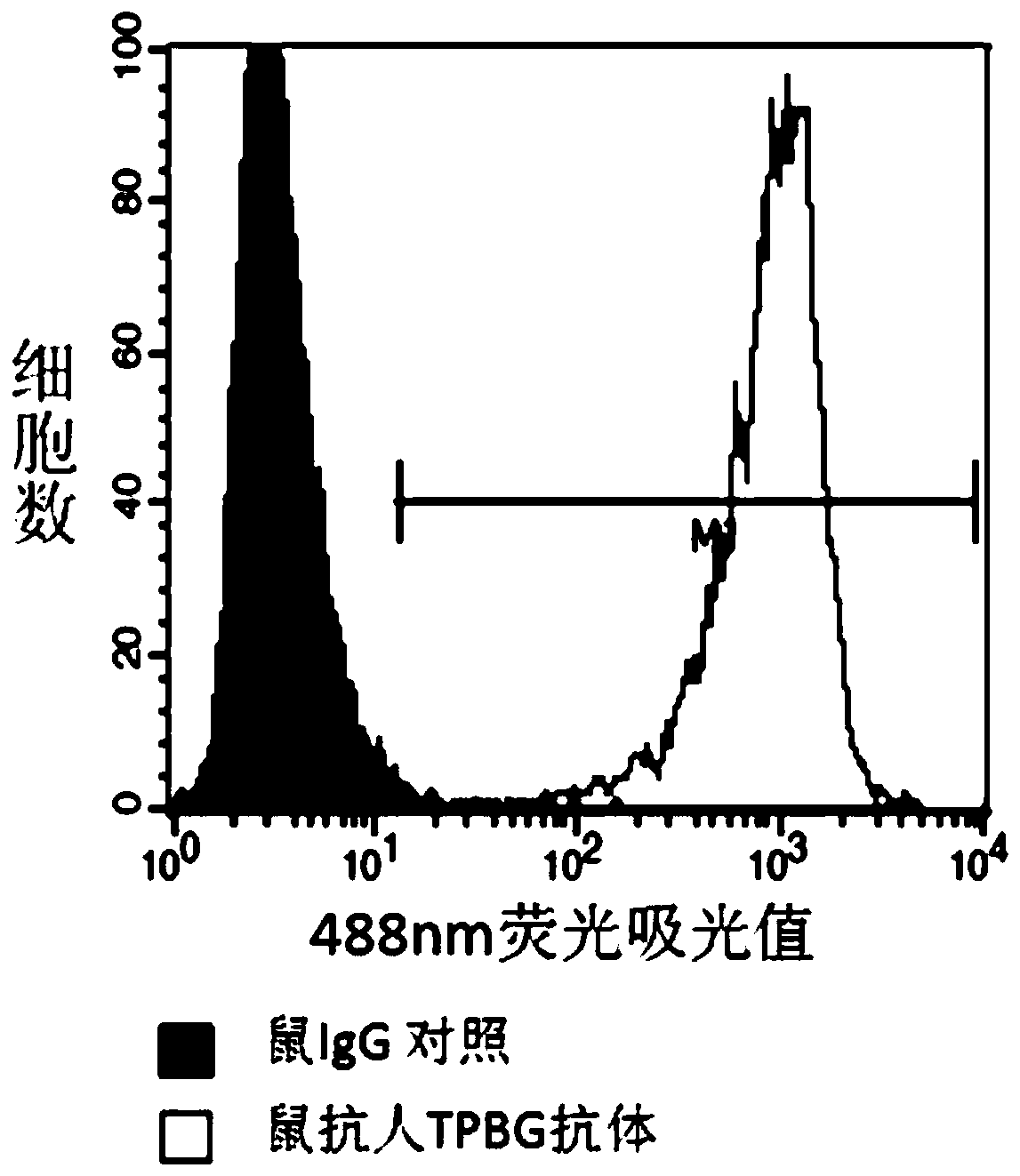

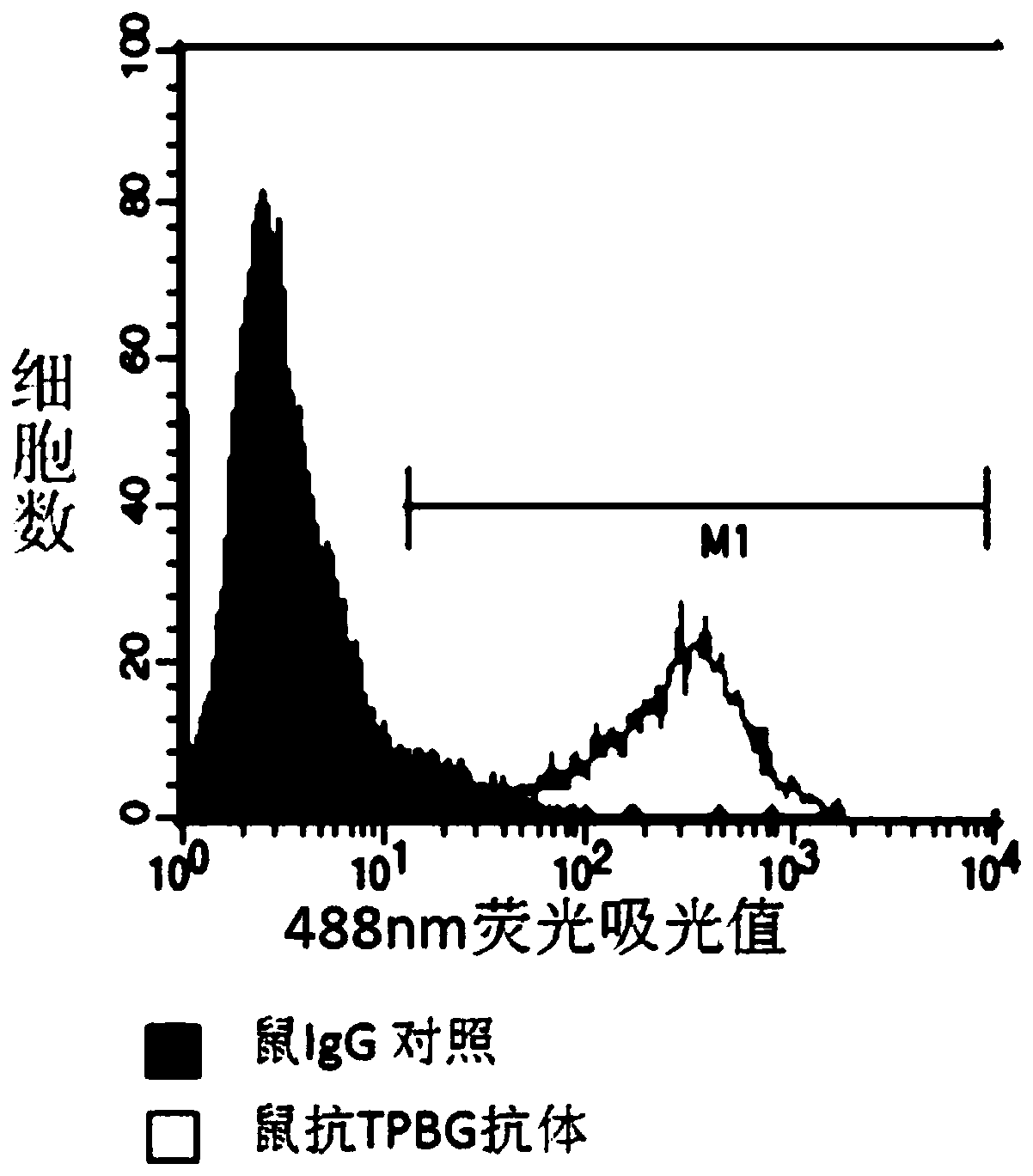

TPBG antibody, and preparation method, conjugate and application thereof

ActiveCN106916227APotent cytotoxicityEffective killing effectOrganic active ingredientsCompound screeningAntiendomysial antibodiesHumanized antibody

The invention discloses a TPBG antibody, and a preparation method, a conjugate and an application thereof. The TPBG antibody comprises one or more of a heavy chain CDR1, a heavy chain CDR2 and a heavy chain CDR3 in the heavy chain variable region of the TPBG antibody, and / or one or more of a light chain CDR1, a light chain CDR2 and a light chain CDR3 of the light chain variable region of the TPBG antibody, and the amino acid sequences of all above heavy chains and light chains are respectively shown in the description. The TPBG antibody is a humanized antibody and has high affinity, and the conjugate prepared by coupling the TPBG antibody with a micro-molecular drug toxin MMAF has a cytotoxin killing effect on TPBG positive cells, so the conjugate can be used in the preparation of tumor treatment drugs.

Owner:KAIHUI SCI & TECH DEV SHANGHAI

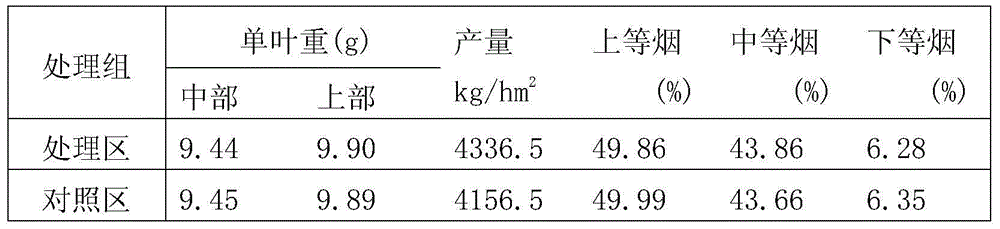

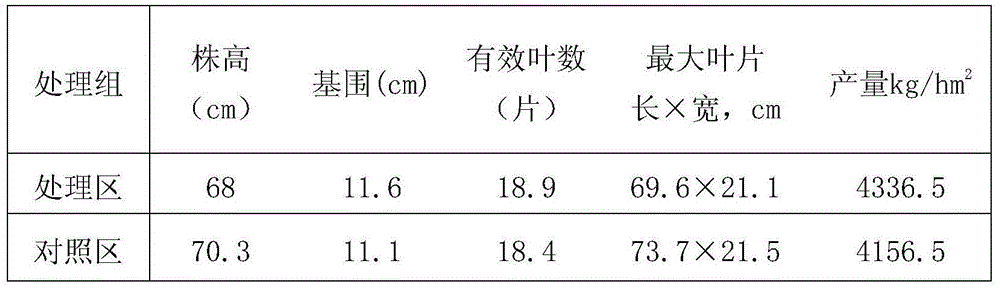

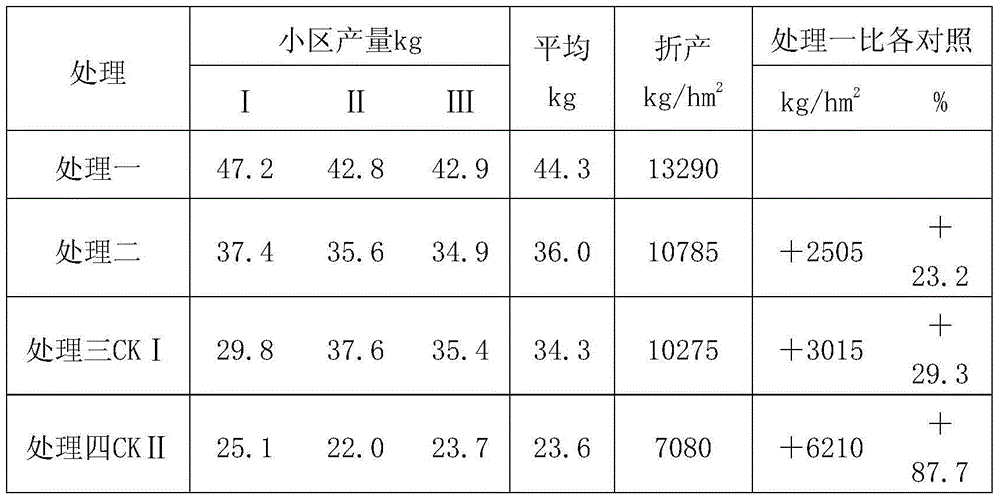

Special organic fertilizer for peppers and preparation method for special organic fertilizer

InactiveCN108083928AGood for healthPromote rapid and healthy growthAnimal corpse fertilisersBioloigcal waste fertilisersSludgeOrganic fertilizer

The invention provides a special organic fertilizer for peppers and a preparation method for the special organic fertilizer, and relates to the technical field of fertilizers. The special organic fertilizer for the peppers is prepared from the following raw materials in parts by weight: 10-20 parts of biogas residues, 7-14 parts of bits of wood, 6-12 parts of grass pond lime sludge, 5-10 parts ofoyster shell powders, 5-10 parts of fermented tea leaf residues, 4-9 parts of disinfection liquid, 2-6 parts of a bactericide and a proper amount of water. The fertilizer provided by the invention solves the problems, which an existing fertilizer cannot solve, that soil compaction causes soil water retention ability and fertility-keeping ability as well as permeability to drop, residual chemical fertilizer in the plant pollutes the environment and the like; when yield increase is promoted, growth quality of the peppers can be further guaranteed; and no harm on soil is caused, so that the greenagriculture purpose is achieved.

Owner:宜州市怀远镇诚信辣椒种植专业合作社

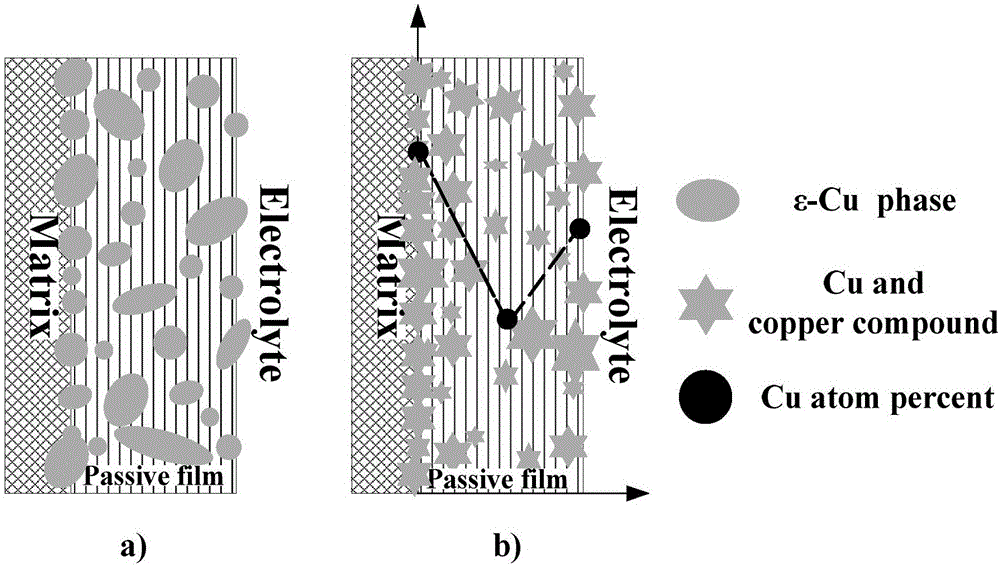

Heat treatment method for antibacterial double-phase stainless steel material

The invention aims to provide a heat treatment method for antibacterial double-phase stainless steel. The antibacterial double-phase stainless steel can have an effective antibacterial function in the condition of single heat treatment. The heat treatment method is characterized in that antibacterial heat treatment is solid solution treatment; the temperature for the solid solution treatment is 1,050 to 1,250 DEG C; and the temperature is preserved for 5 to 20 hours and then is water-cooled to room temperature. Meanwhile, the antibacterial double-phase stainless steel has two phases of stable structures, namely, stable ferrite / austenite, and can be widely applied to the material fields of chemical industry, petroleum energy, power plants, ocean engineering and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Medicine for treating chronic superficial gastritis and peptic ulcer diseases

The present invention relates to a Chinese medicine preparation for curing the diseases of chronic superficial gastritis and peptic ulcer with obvious therapeutic effect. Said Chinese preparation is made up by using 18 Chinese medicinal materials of raw rhubarb, coptis root, notoginseng, dandelion, salvia root, schutellaria root, frankincense, astragalus root and others through a certain preparation process.

Owner:孟宪安

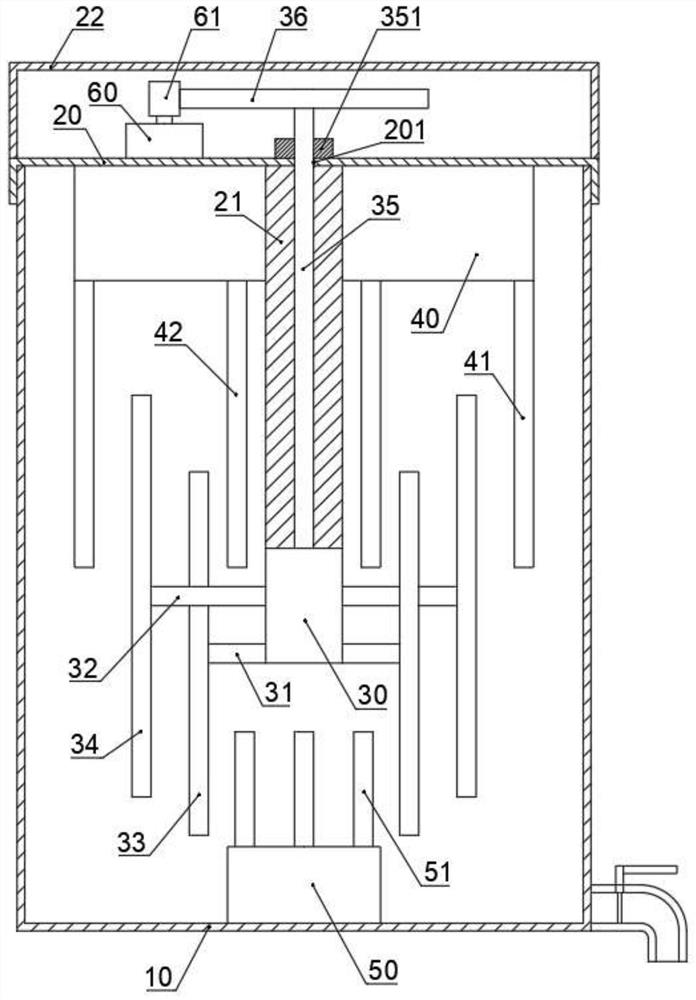

Electric-shock disinsection device

InactiveCN102388849AInsect trap effect is goodImprove purification effectInsect catchers and killersElectricityEngineering

The invention discloses an electric-shock disinsection device, comprising a front cover plate, an electric-shock plate, a rear cover plate and an LED lamp source group, wherein the electric-shock plate and the LED lamp source group are clamped between the front cover plate and the rear cover plate. The LED lamp source group is arranged on the front end surface of the electric-shock plate. The electric-shock plate is printed with a metal wire, and the metal wire has an anode and a cathode. The electric-shock plate is an epoxy resin plate. The LED lamp is used for inducing the winged insects; when the winged insects fly to the electric-shock plate, the metal wire discharges the electricity to kill the winged insects. The invention has the following advantages: the killing effect of the production is improved through inducing the winged insects by the light transmitted by the LED lamp; harmful bacteria in the air can be effectively killed so as to purify the air and improve the air quality; the product can be hung at the high place to preventing the children from touching; in addition, the device is matched with a collecting box, the dead winged insects by electric-shock drops in the box, which is convenient to clean. The invention has a rational design, a simple structure, reliable work, stable performance and safe use.

Owner:安徽虫博士环保科技有限公司

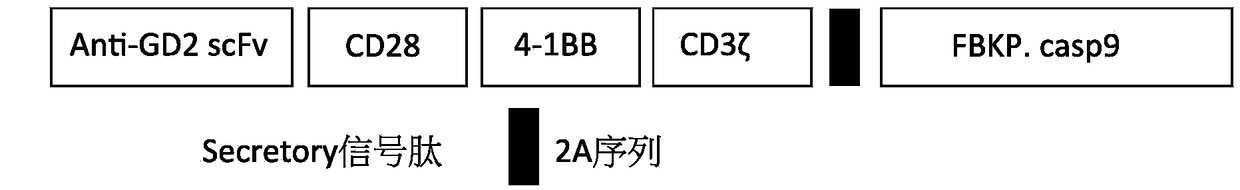

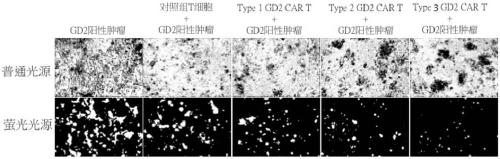

Chimeric antigen receptor based on GD2 and application thereof

ActiveCN108948211AReduce storm riskModerate signal stimulusVirusesHydrolasesAntigenSingle-Chain Antibodies

The invention relates to a chimeric antigen receptor based on GD2. The chimeric antigen receptor is characterized by being prepared from an antigen combined structural domain, a transmembrane structural domain, a costimulatory signal transduction structural domain, a CD3 zeta signal transduction structural domain and a self-destroying structural domain which are connected in series, wherein the antigen combined structural domain is combined with a surface antigen of a tumor, the surface antigen of the tumor is GD2, the antigen combined structural domain is a single chain antibody for the surface antigen of the tumor GD2, and the self-destroying structural domain is a caspase 9 structural domain. The chimeric antigen receptor is actually applied to a patient suffered from phase IV neuroblastoma expressing a specific target point GD2 of the tumor, is smaller in clinical side effect and higher in safety, can reduce the solid tumor foci effectively, and improves the whole survival rate ofthe patient effectively as presence of GD2-CART can be monitored in the body of the patient for a long time.

Owner:BEIJING MEIKANG JIMIAN BIOTECH CO LTD

Application of aspirin in preparation of platelet targeted drug delivery system

InactiveCN111035625ALower levelEffective aggregationOrganic active ingredientsPhotodynamic therapyAspirinPharmaceutical drug

The invention discloses application of aspirin in preparation of a platelet targeted drug delivery system. According to the invention, aspirin is utilized to inhibit platelet aggregation in vitro, prevent platelet deformation and maintain a relatively high proportion of complete platelets, so that relatively high encapsulation efficiency of nanoparticles and antitumor drugs is further realized, aneffective antitumor effect is realized, and the use process is safe and efficient.

Owner:SOUTHEAST UNIV

Traditional Chinese medicinal preparation having advantages of environmental protection, no residual and long-acting sterilization desinsection, and preparation method thereof

InactiveCN103999883AImprove organizational vitalityEasy to transportBiocideFungicidesAconitum carmichaeliInsect pest

The invention relates to a traditional Chinese medicinal preparation having the advantages of environmental protection, no residual and long-acting sterilization desinsection. Raw materials of the traditional Chinese medicinal preparation comprise Herba Taraxaci, Quisqualis indica L., Sophora flavescens, Rhizoma Coptidis, Pericarpium Zanthoxyli, Gleditsia sinensis Lam, Aconitum carmichaeli Debx., Nux Vomica, Fructus Toosendan, Ailanthus altissima leaf, mulberry leaf, Clerodendrum inerme and a synergist. In the invention, all traditional Chinese medicines are mixed, a decoction or extraction process is utilized to obtain the effective components in the traditional Chinese medicines, alkali active substances in all the traditional Chinese medicines can effectively kill fungi, bacteria, viruses and insect pests in root tissues of crops and root soil, can prevent and treat pathogens and insects in fruit trees, vegetables, flowers and grain crops, and the addition of compound sodium nitrophenolate realizes disinfection and desinsection synergy, improves the tissue vitality of the crop roots, and improves the crop nutrition transport and the absorption rate of a fertilizer.

Owner:TIANJIN CHANGQINGTAI AGRI ENVIRONMENTAL PROTECTION SCI & TECH DEV

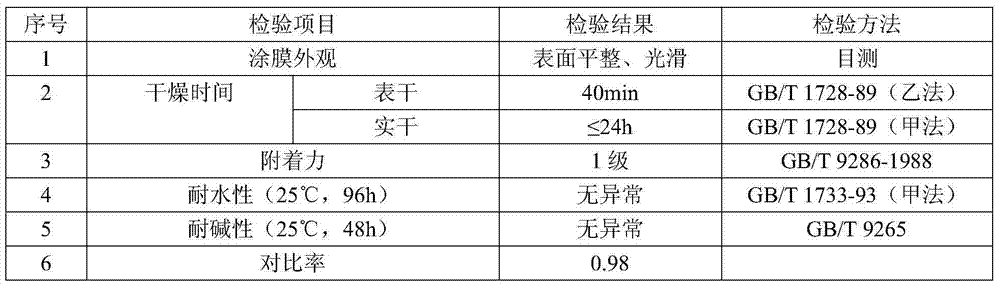

Antibacterial latex paint

InactiveCN104497663ALight smellGood water solubilityAntifouling/underwater paintsPaints with biocidesSolubilityWater based

The invention belongs to the field of a wall coating for indoor decoration, and particularly relates to an antibacterial latex paint. The antibacterial latex paint is characterized by being prepared from the following raw materials in parts by mass: 150-350 parts of water-based acrylic acid, 1-5 parts of defoaming agents, 2-4 parts of preservative agents, 5-10 parts of dispersing agents, 150-300 parts of pigments, 150-350 parts of fillers, 2-9 parts of thickening agents, 1-10 parts of levelling agents, 6-15 parts of nanometer inorganic negative ion antibacterial agents, 50-90 parts of nanometer polymer hollow microspheres, 50-90 parts of bamboo vinegar, 1-5 parts of cosolvents, 10-20 parts of citronella oil and 100-350 parts of water. The antibacterial latex paint disclosed by the invention can be coated on a wall and a wood. A paint film has the advantages of mild smell, good water solubility, low VOC, good covering power, low cost and optimal environment-friendly property. The antibacterial latex paint disclosed by the invention is a product which perfectly combines three themes, namely decoration, functionality and environmental friendliness, and has long-term continuous bacteriostatic effect.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

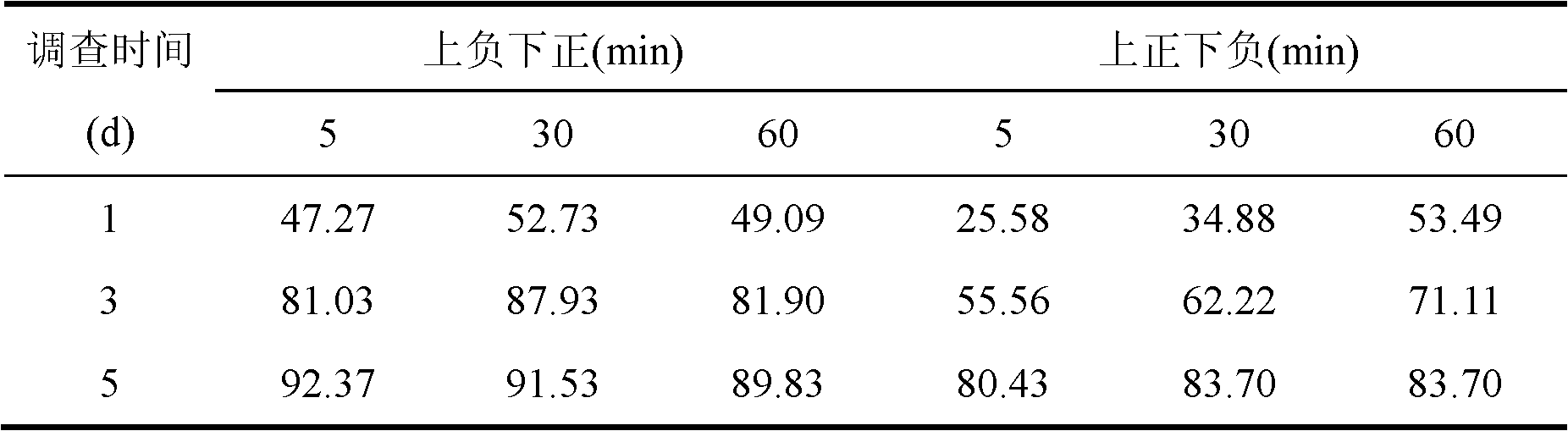

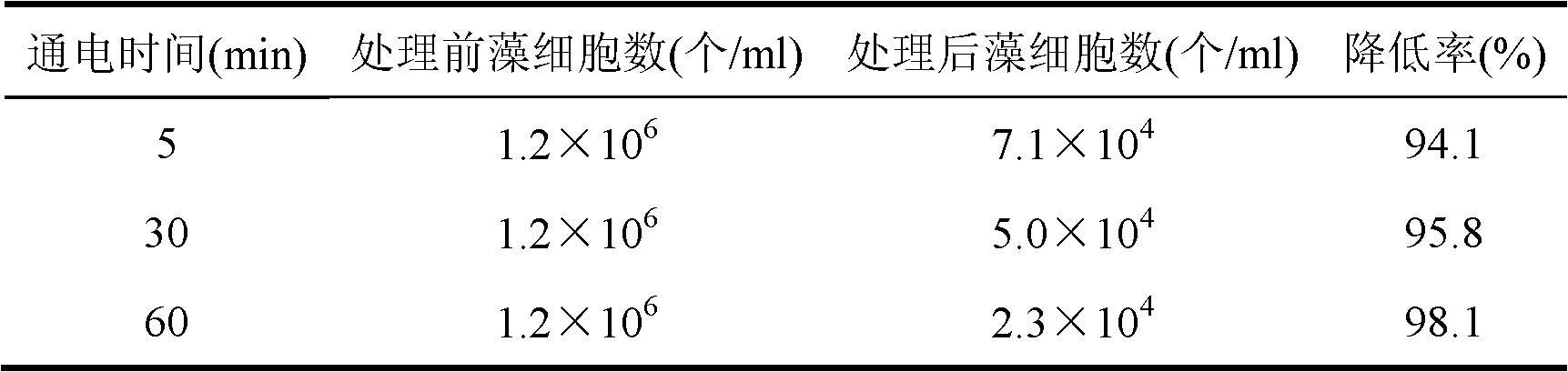

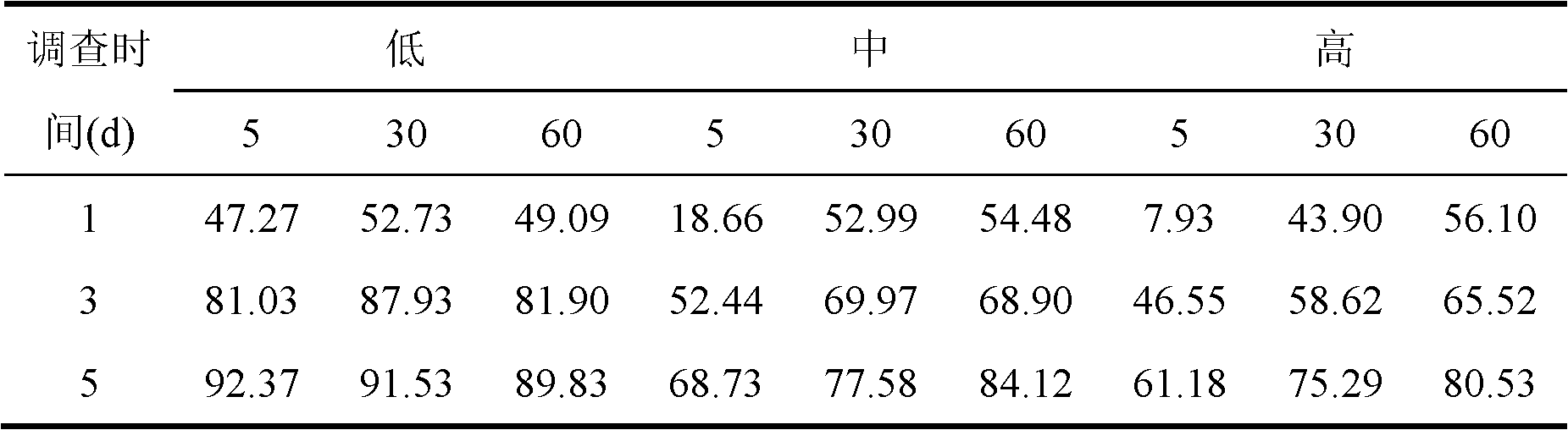

Method for purifying water by killing algae by using micro-current and application thereof

InactiveCN102557206AAchieve purificationReach current densityWater/sewage treatment by magnetic/electric fieldsQuadrigulaAnabaena

The invention belongs to the technical field of water pollution control and particularly relates to a method for purifying water by killing algae by using micro-current and the application of the method. The method is characterized in that two electrodes are put in water with algae and connected with a direct-current motor so that the upper electrode and the lower electrode have a certain current density, and the alga cells are killed after a certain period of time and sunken to the bottom of the water so that the water is purified. The micro-current has the significant function of killing a variety of algae including microcystis, aphanizomenon, anabaena, quadrigula chodatii and scenedesmus and is suitable for lakes, ponds and other water environment.

Owner:NANJING UNIV

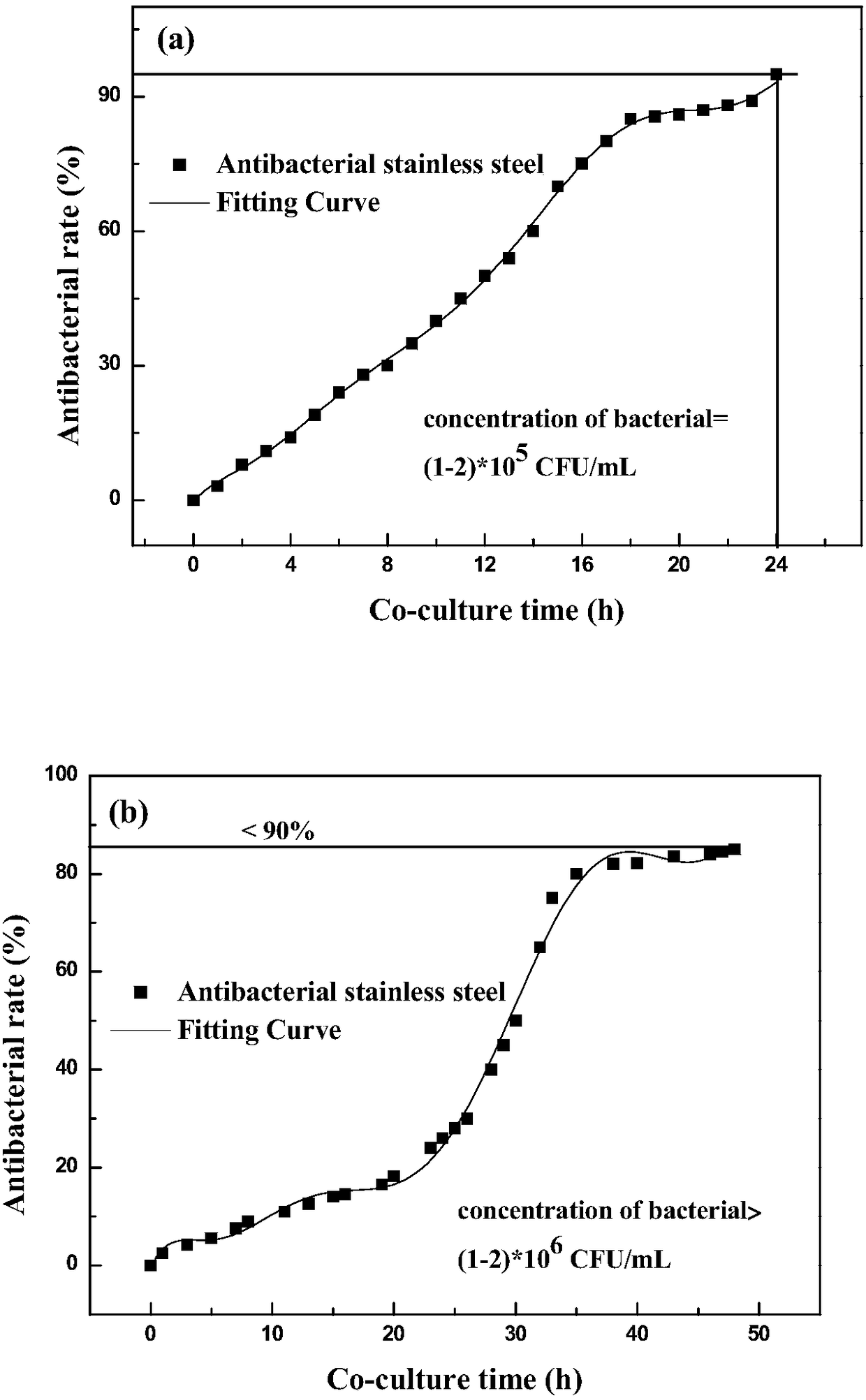

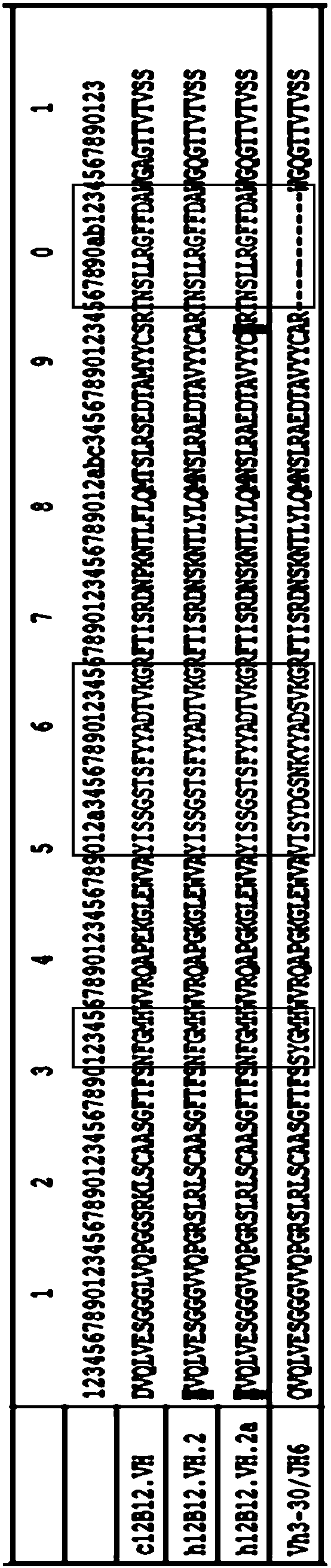

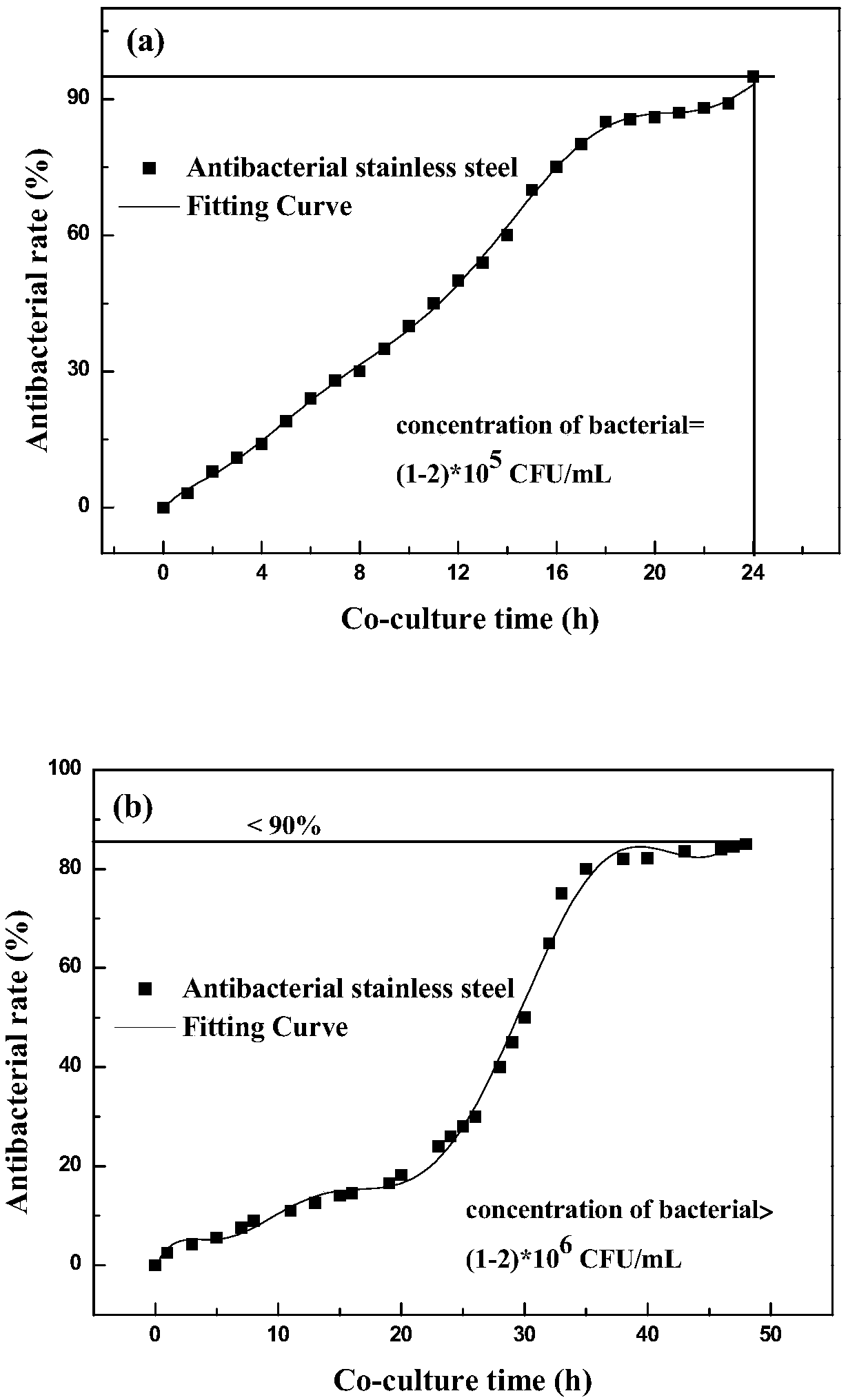

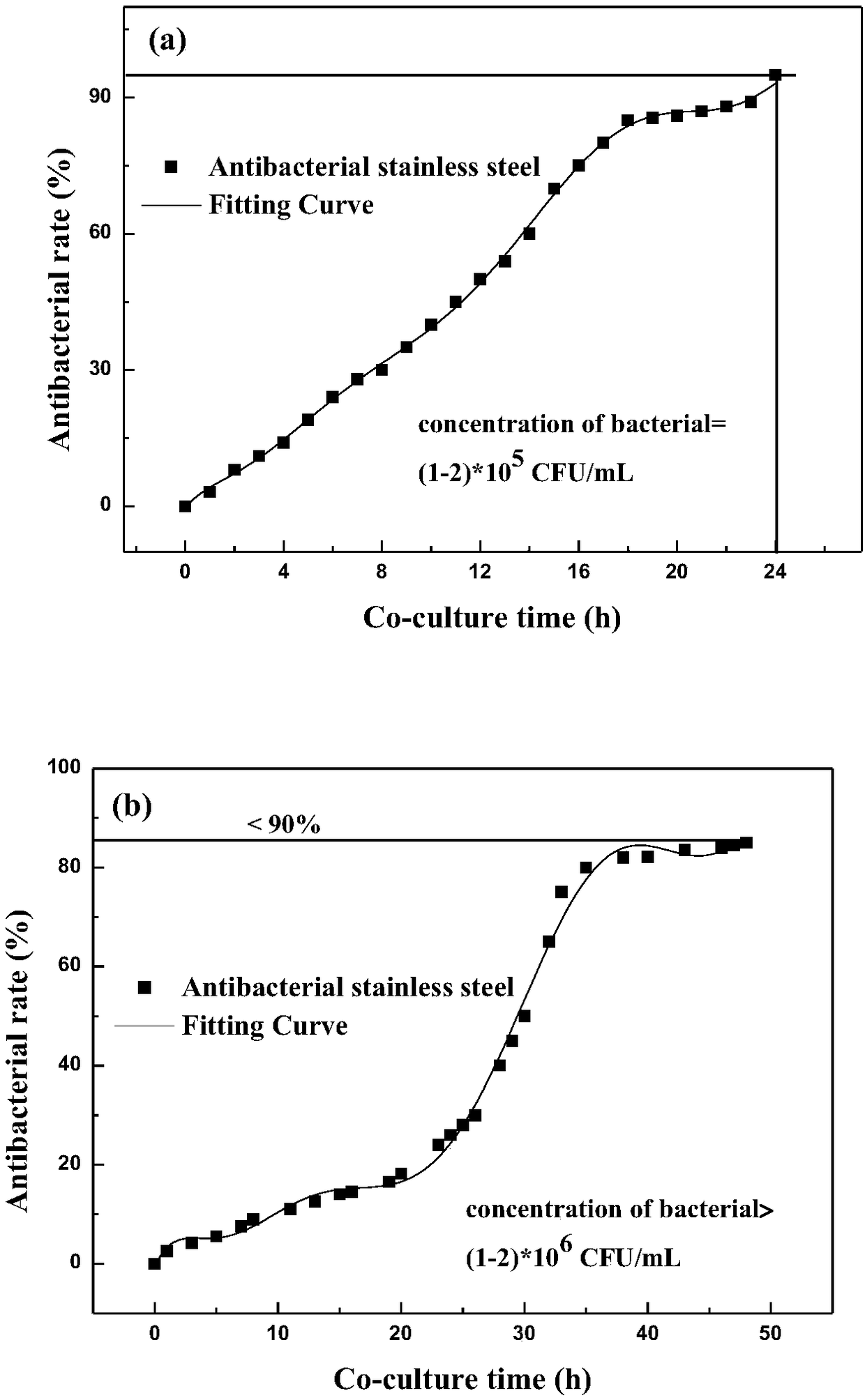

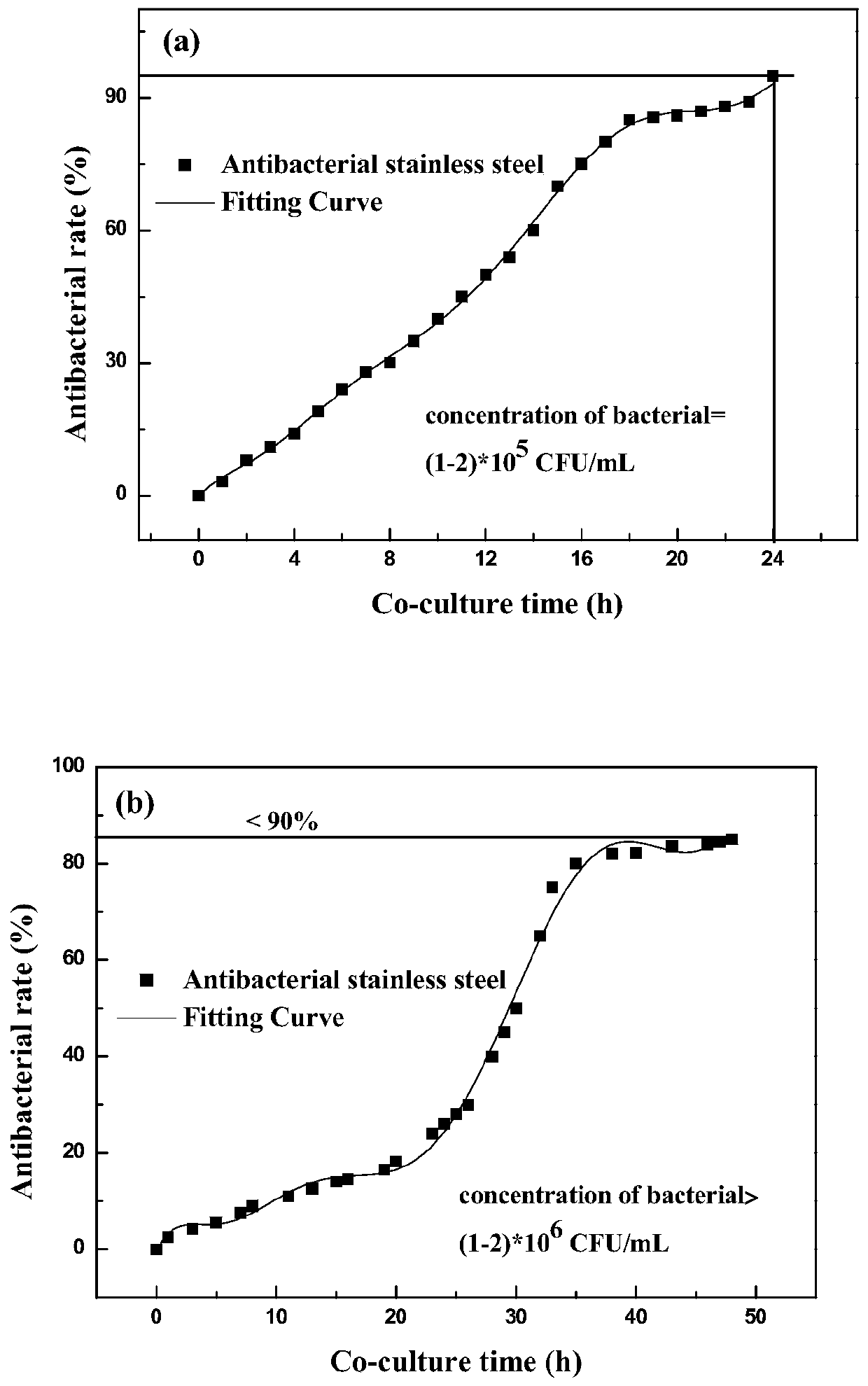

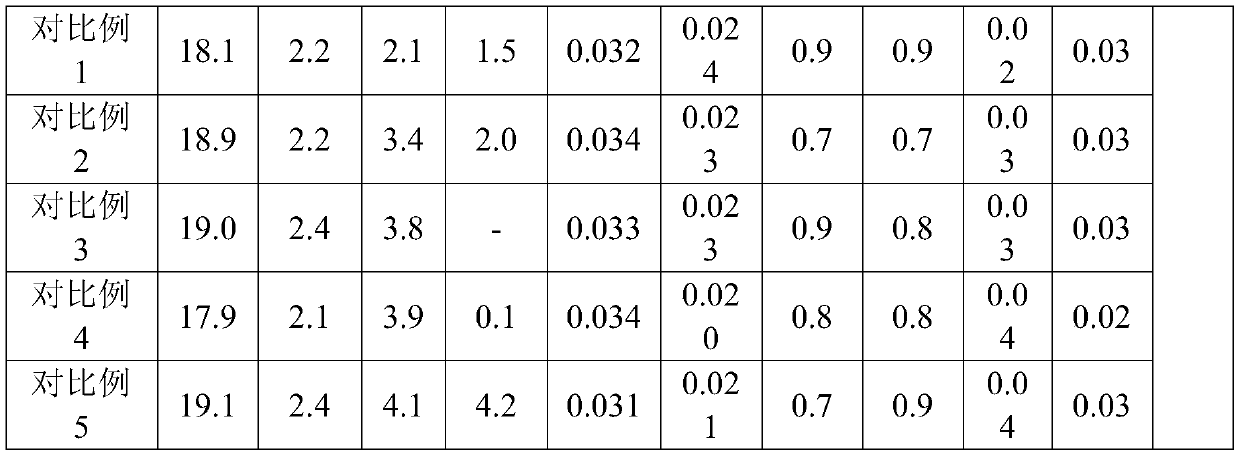

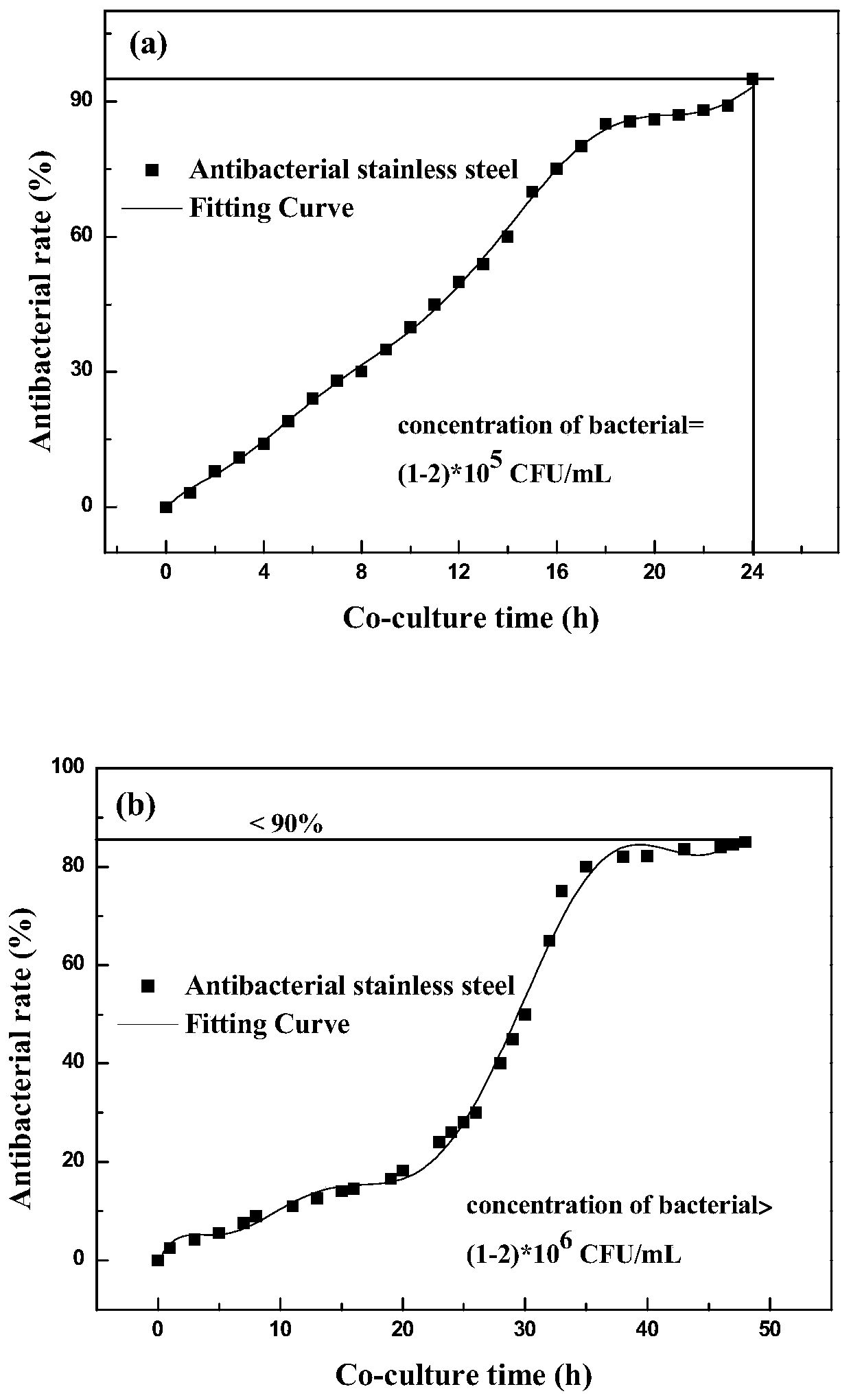

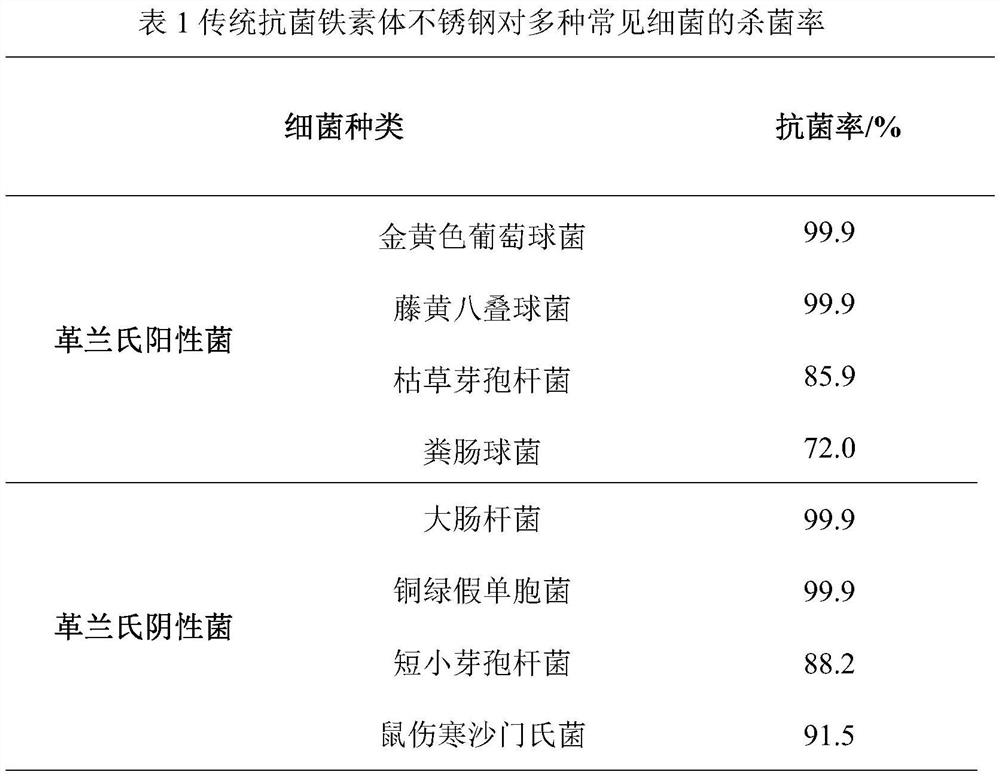

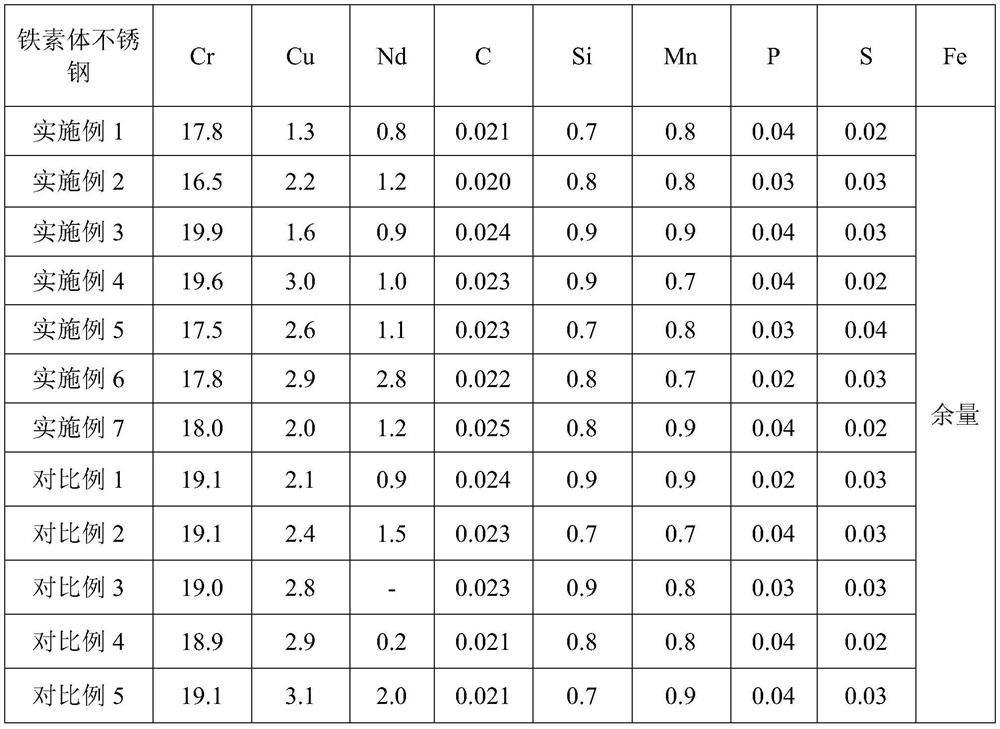

High antibacterial ferritic stainless steel and preparation method thereof

The invention aims to provide a high antibacterial ferritic stainless steel material and a preparation method thereof. The high antibacterial ferritic stainless steel material has the function of effectively resisting high concentration bacteria (more than (1-2)*10<6>CFU / mL) under conditions of solid solution and aging heat treatment, and significantly reduces the risk of corrosion of bacterial microorganisms caused by the use of ferritic stainless steel. The stainless steel comprises the chemical compositions of 17.5-19.5% of Cr, 1.9-2.5% of Mo, 2.0-4.5% of Cu, 1.0-2.5% of Ga, less than or equal to 0.035% of N, less than or equal to 0.025% of C, less than or equal to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.04% of P, less than or equal to 0.03% of S and the balance Fe. The high antibacterial ferritic stainless steel can be widely used in food and chemical industries and civil liquid transportation pipes or storage containers which contain the bacteria.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-efficiency environmental-protection rodenticide

InactiveCN108576076AEffective killing effectNo side effectsBiocidePest attractantsLivestockEnvironmental resistance

The invention discloses a high-efficiency environmental-protection rodenticide. The high-efficiency environmental-protection rodenticide comprises the following raw materials in parts by weight: 2-5 parts of a composition of a traditional Chinese medicine extract, 20-80 parts of megasse, and 500-1000 parts of a bait. The composition is composed of an overground part of aconitum napellus, cynanchumotophyllum schneid, and the traditional Chinese medicine extract of black false hellebore. The rodenticide has effective killing effect, after being eaten by mouse, the mouse died in about 2 days, poisoning individual has no violently discomfort symptom, and is no easy to alert to other mouse, the rodenticide has no toxic and side effect for human body and other livestock, has no pollution on environment, and has characteristic of no generation of resistance on mouse.

Owner:深圳市捷立克卫生服务有限公司

Humanized anti-TPBG antibody, preparation method thereof, conjugate and application thereof

ActiveCN108690136APotent cytotoxicityEffective killing effectImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsAntigenHeavy chain

The invention discloses a humanized anti-TPBG antibody, a preparation method thereof, a conjugate thereof and application thereof. The humanized anti-TPBG antibody comprises (a) a framework region comprising residues of a human antibody framework region; and (b) one or more CDRs in a light chain variable region shown as SEQ ID NO.4 or 8 or one or more CDRs in a heavy chain variable region shown asSEQ ID NO.2 or 6. The humanized anti-TPBG antibody has a binding affinity of at least about 1 * 10<-7> M to about 1 * 10<-12>M for a human TPBG antigen. The humanized anti-TPBG antibody is conjugatedwith a small molecule compound such as MC-MMAF to obtain the conjugate which is effective in cytotoxic killing effect on TPBG positive cells. Therefore, the humanized anti-TPBG antibody is used for preparing an antibody cross-linking drug, which can effectively kill tumor cells and treat tumors.

Owner:KAIHUI SCI & TECH DEV SHANGHAI

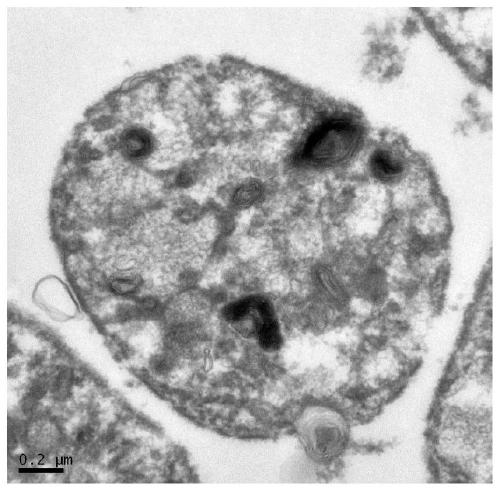

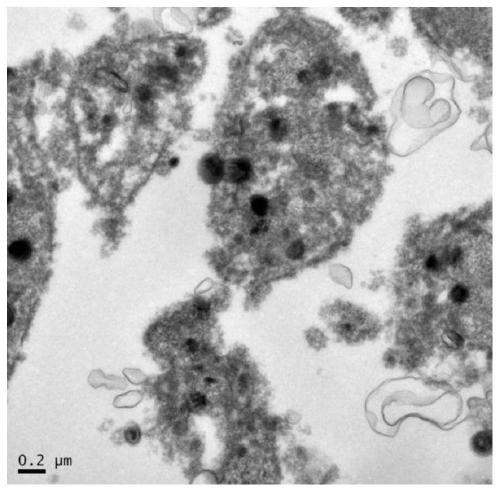

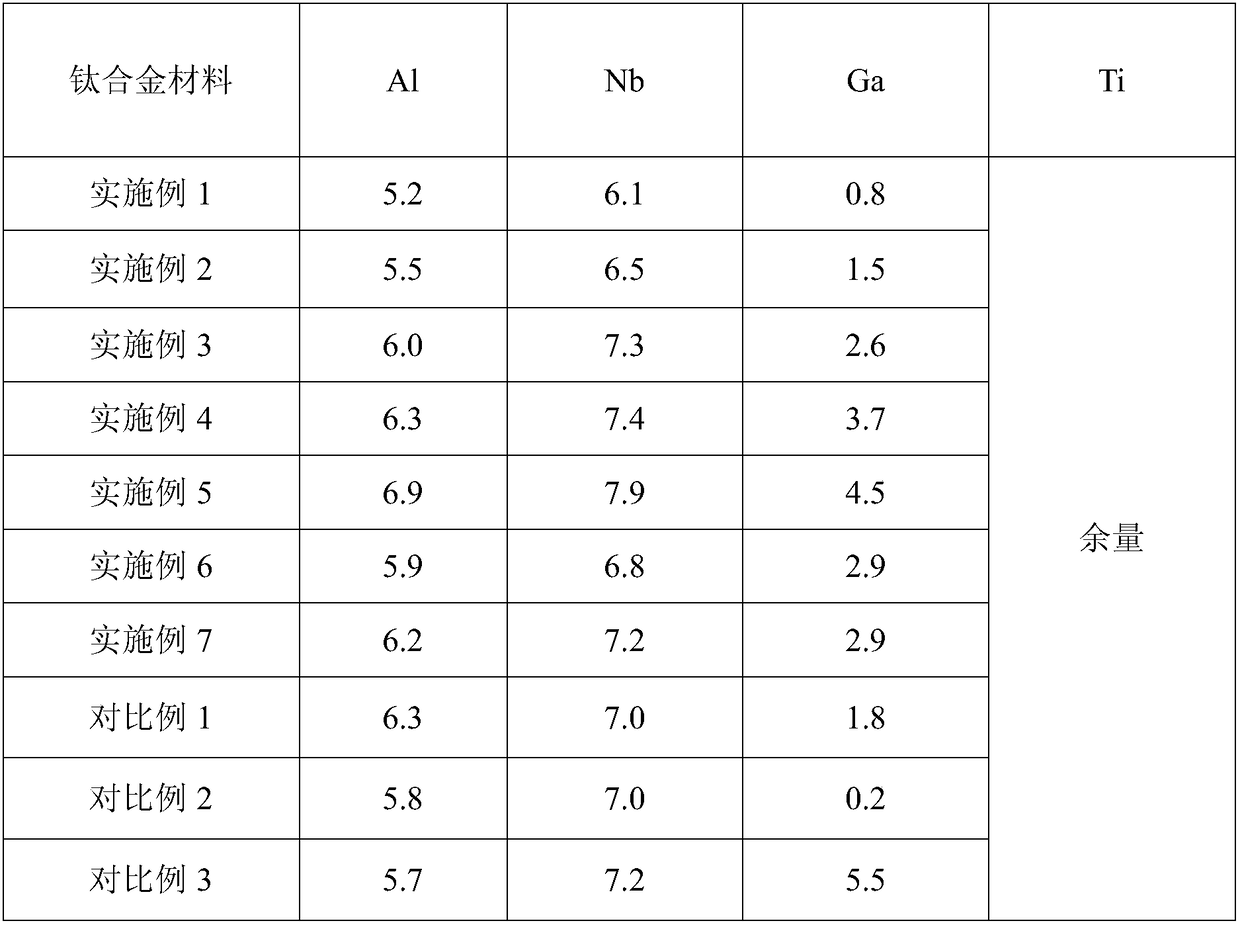

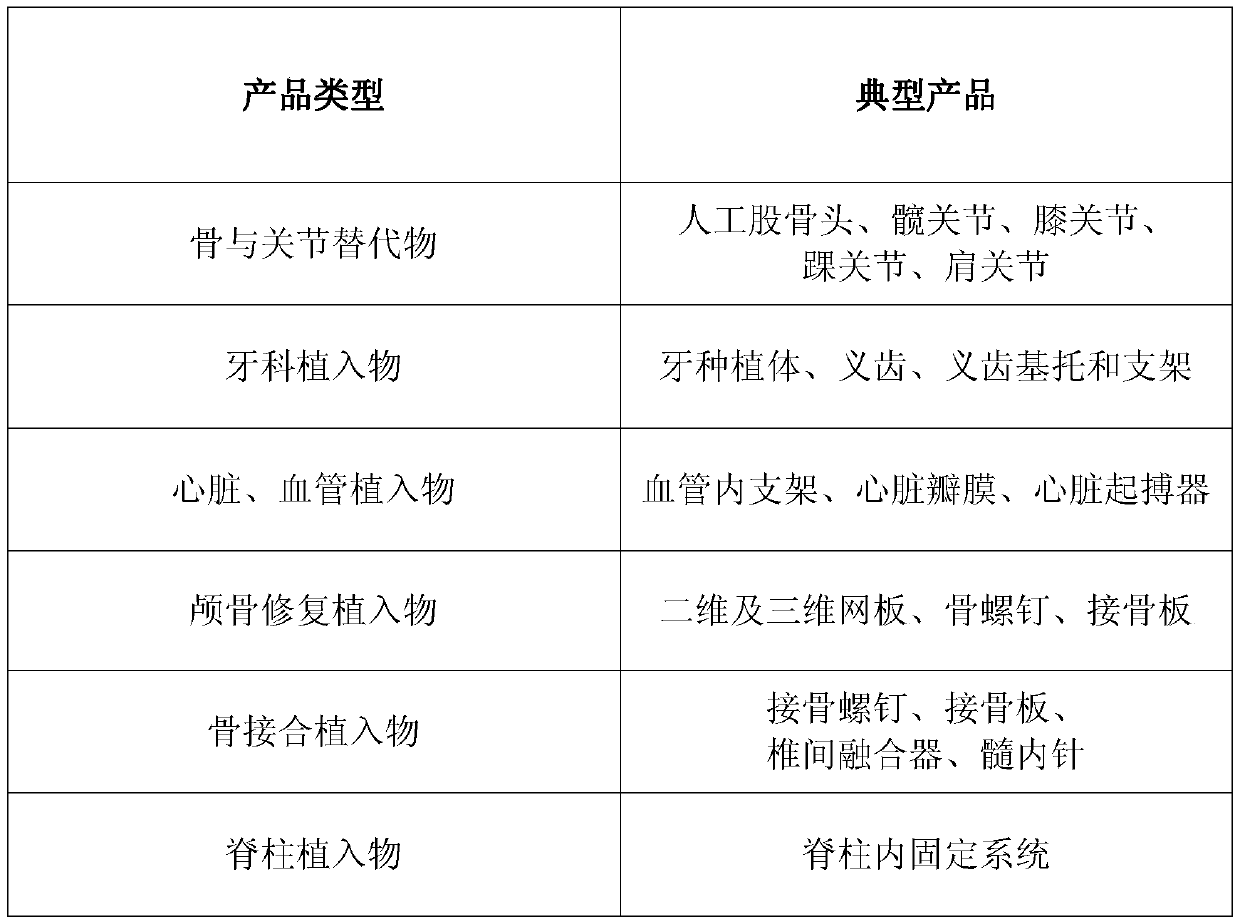

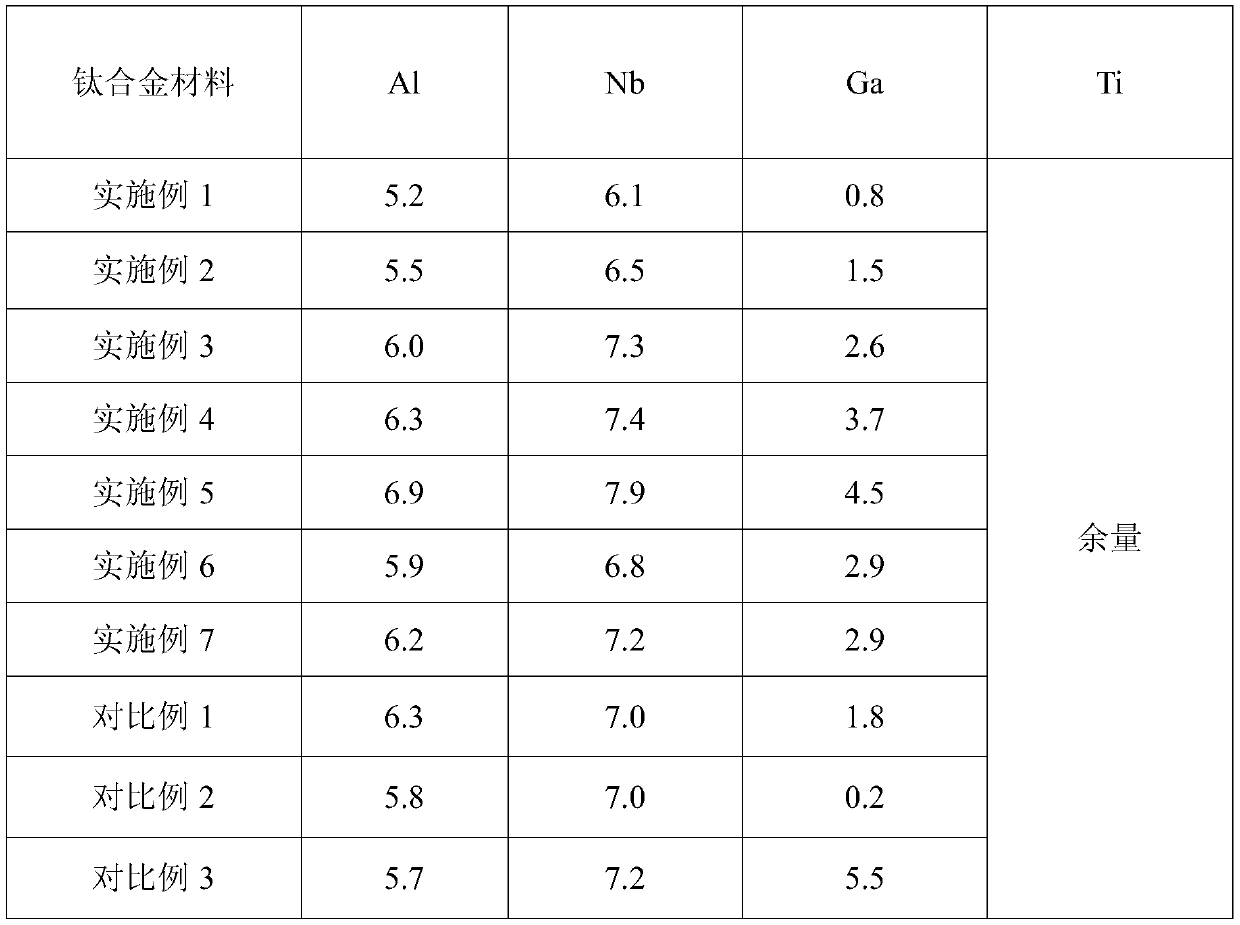

Ultrahigh-antibacterial-performance titanium alloy applied to medical implant and manufacturing method of ultrahigh-antibacterial-performance titanium alloy

ActiveCN108728691AReduce time to killEffective killing effectSurgeryTissue regenerationCorrosionHigh concentration

The invention aims to provide an ultrahigh-antibacterial-performance titanium alloy applied to a medical implant and a manufacturing method of the ultrahigh-antibacterial-performance titanium alloy. The ultrahigh-antibacterial-performance titanium alloy and the manufacturing method of the ultrahigh-antibacterial-performance titanium alloy aim to achieve the effects that under the solid solution and aging heat treatment states of the titanium alloy, a function of effectively resisting high-concentration bacteria (larger than (8-9)*10<6> CFU / mL) is achieved, and the corrosion risk of bacteria microorganisms caused by the use of the titanium alloy is remarkably reduced. The titanium alloy comprises the following chemical components of, by weight, 5.5-6.5% of Al, 6.5-7.5% of Nb, 1.0-3.0% of Gaand the balance Ti. According to the heat treatment mode after material optimization, the temperature of the solid solution treatment is 950-1000 DEG C, heat preservation is carried out for 1.0-2.0 hours, and the temperature is reduced to the room temperature through water cooling. The ultrahigh-antibacterial-performance titanium alloy is widely applied to the multiple kinds of titanium alloy medical implants which are used in the medical clinic fields of a department of stomatology and a department of orthopedics, and the implants particularly refer to the dental implants, bone screws, bonefracture plates, (knee, ankle, shoulder and hip) joints and other common medical surgical implants.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

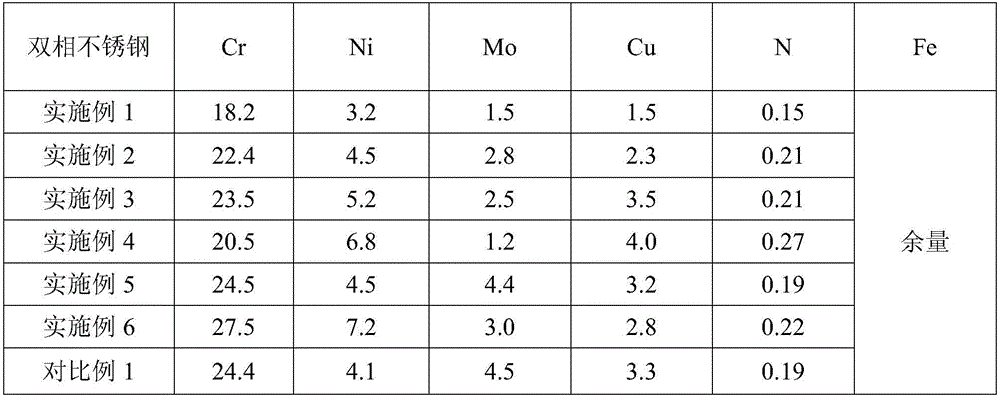

Duplex stainless steel with ultrahigh antibacterial performance and preparation method of duplex stainless steel

The invention aims to provide a duplex stainless steel material with ultrahigh antibacterial performance and a preparation method of the duplex stainless steel material. The duplex stainless steel material can have a function of effectively resisting high-concentration bacteria (>(8-9)*10<6>CFU / mL) in the heat treatment state of solid solution and aging, and the bacterial and microbial corrosion risks caused by duplex stainless steel in use are remarkably reduced. The stainless steel comprises chemical components: 22.0-25.0 of Cr, 4.5-7.5 of Ni, 1.5-3.0 of Mo, 2.0-4.0 of Cu, 1.0-2.5 of Ga, 0.2-0.3 of N, 0.03 or less of C, 1.0 or less of Si, 3.0 or less of Mn, 0.03 or less of P, 0.02 or less of S and the balance Fe. The duplex stainless steel can rapidly restrain bacterial reproduction in the service environment, the destroying risks of microbiological corrosion are relieved, and the duplex stainless steel can be widely applied to the fields of petroleum energy exploitation and oceanographic engineering where ultrahigh-concentration bacteria are contained, and is specifically applied to a storage container and a liquid conveying pipeline.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

TPBG antibody, preparation method of TPBG antibody, conjugate and application of TPBG antibody

ActiveCN110606890APotent cytotoxicityEffective killing effectCompound screeningOrganic active ingredientsCytotoxicityHumanized antibody

The present invention provides a TPBG antibody, a preparation method of the TPBG antibody, a conjugate and application of the TPBG antibody. The TPBG antibody comprises one or more of a heavy chain CDR1, a heavy chain CDR2, and a heavy chain CDR3 of a heavy chain variable region of the TPBG antibody, and / or one or more of a light chain CDR1, a light chain CDR2, and a light chain CDR3 of a light chain variable region of the TPBG antibody, and the amino acid sequences are respectively described in the specification. The TPBG antibody is a humanized antibody with high affinity, the conjugate prepared by coupling the TPBG antibody with a small molecule drug toxin MMAF can have a cytotoxicity effects on TPBG-positive cells, and thus the TPBG antibody can be used in the preparation of drugs fortreating tumors and the like.

Owner:KAIHUI SCI & TECH DEV SHANGHAI

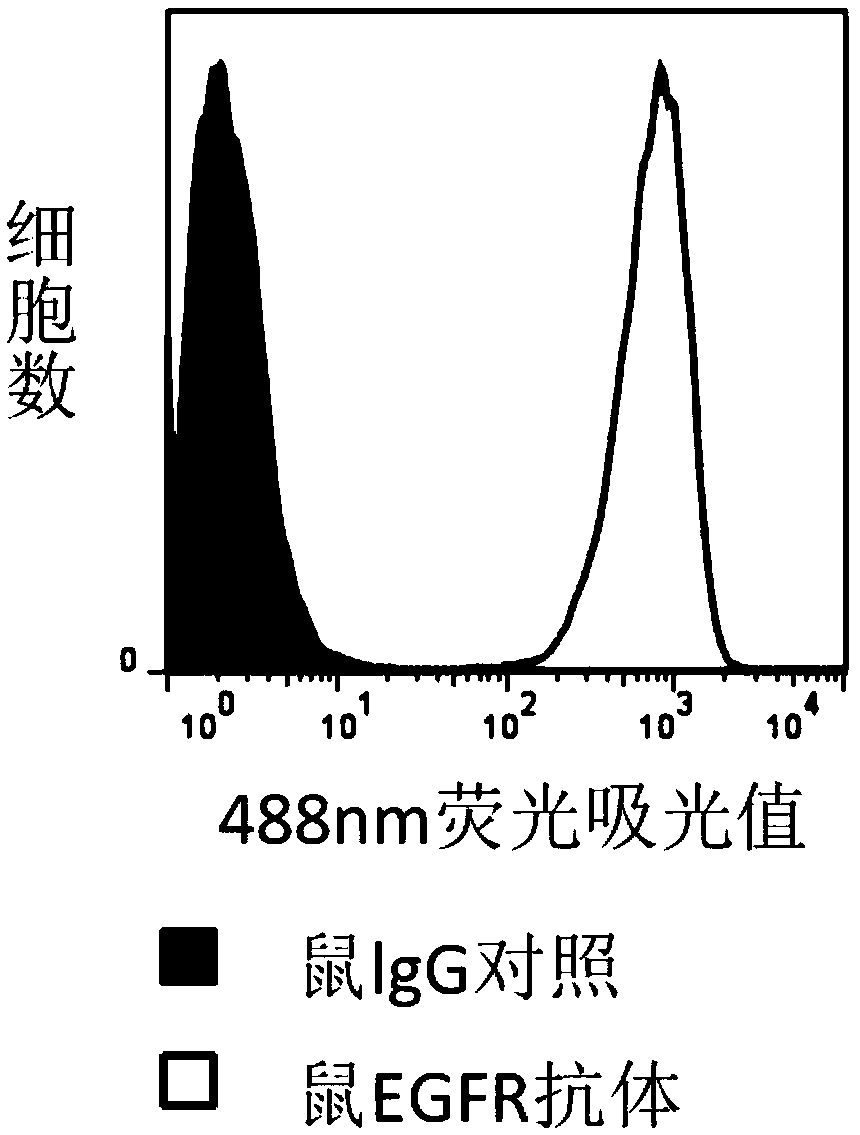

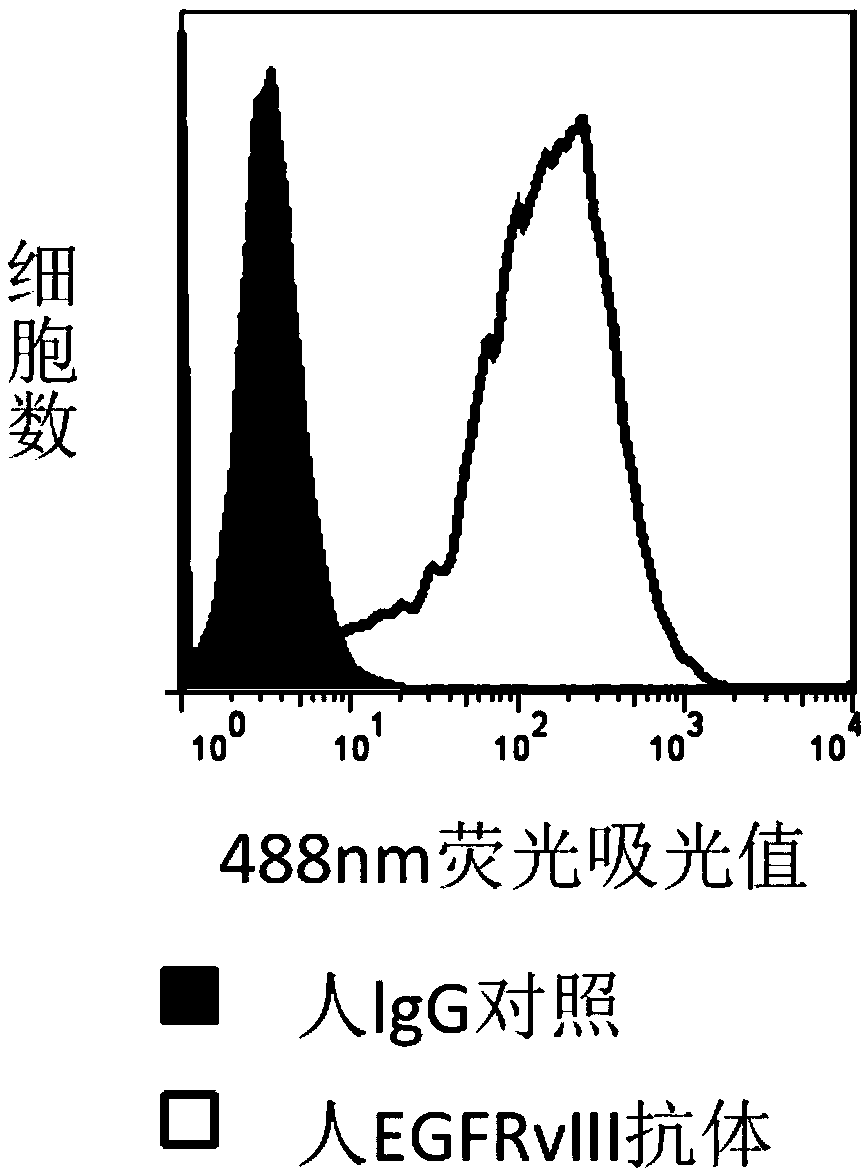

EGFRvIII antibody, conjugate thereof, preparation method and application

InactiveCN109912715APotent cytotoxicityEfficient killingPeptide/protein ingredientsBiological material analysisComplementarity determining regionHeavy chain

The invention discloses an EGFRvIII antibody, a conjugate thereof, a preparation method and application. The antibody comprises complementarity determining regions (CDRs) of the EGFRvIII antibody: oneor more of a heavy chain CDR1, a heavy chain CDR2, and a heavy chain CDR3, and / or one or more of a light chain CDR1, a light chain CDR2 and a light chain CDR3, the amino acid sequences of antibody are described herein. The EGFRvIII antibody has high affinity with an EGFRvIII protein, can enter a cell after being coupled with a small molecule toxin such as MMAE, and performs cytotoxic killing effect on EGFRvIII positive cells. Therefore, the EGFRvIII antibody can be applied to preparation of medicines for treating tumors and the like.

Owner:KAIHUI SCI & TECH DEV SHANGHAI

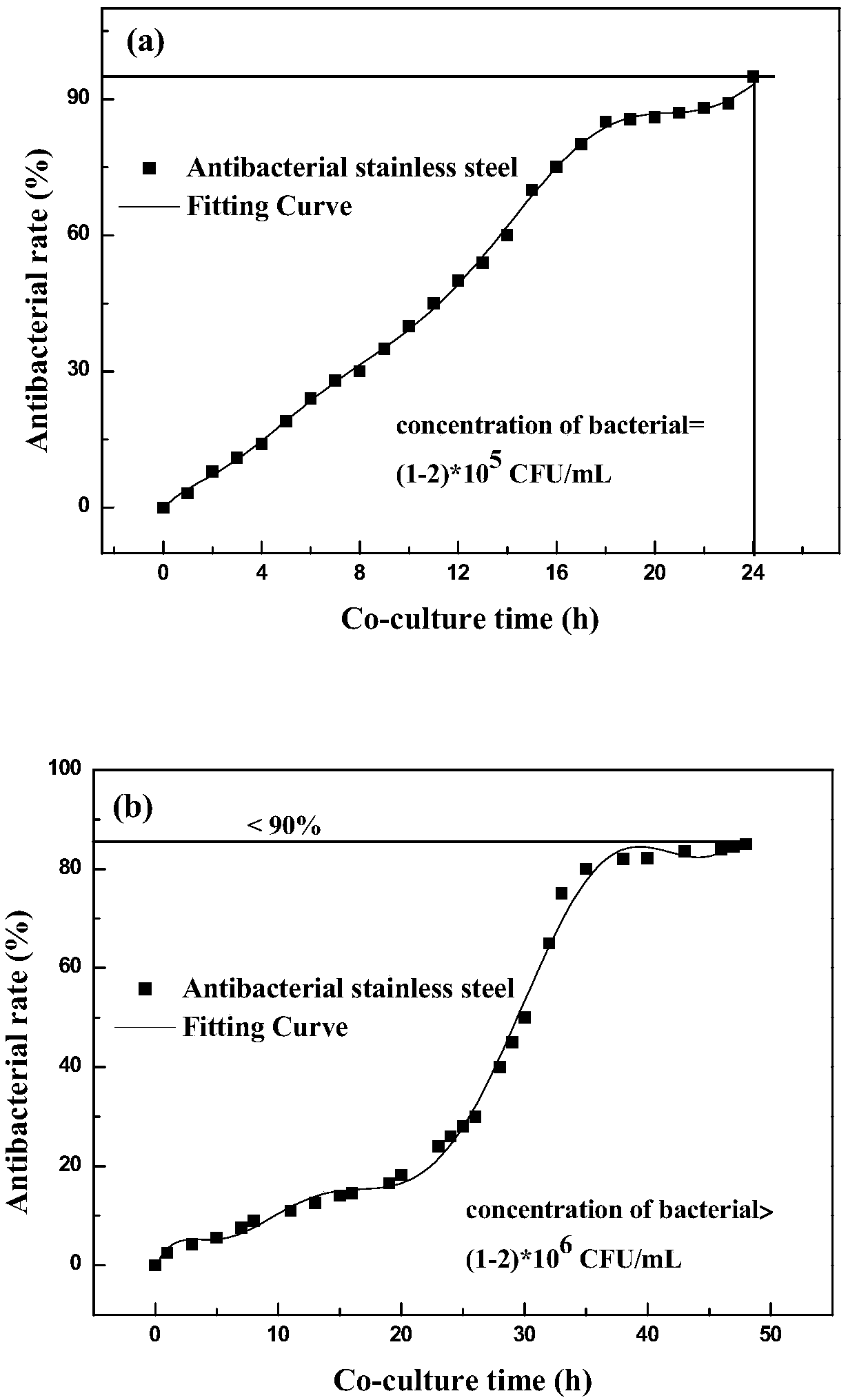

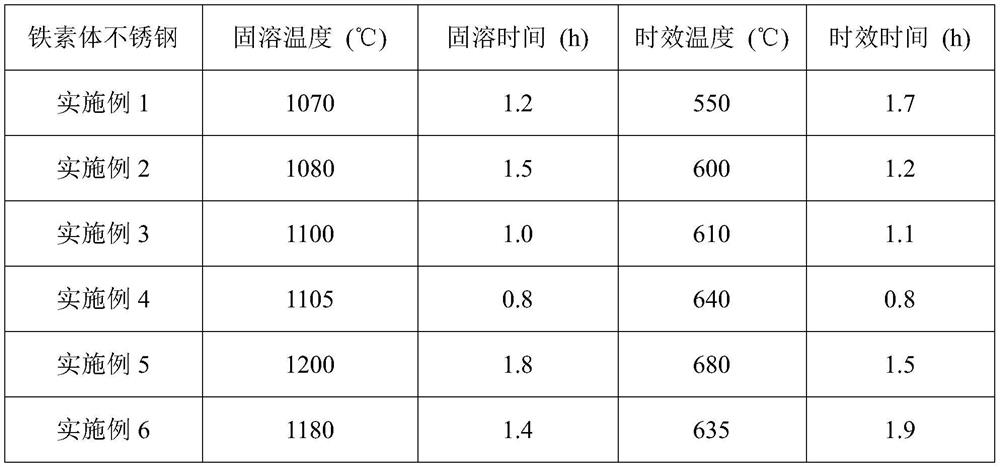

A kind of high antibacterial ferritic stainless steel and preparation method thereof

The invention aims to provide a high antibacterial ferritic stainless steel material and a preparation method thereof. The high antibacterial ferritic stainless steel material has the function of effectively resisting high concentration bacteria (more than (1-2)*10<6>CFU / mL) under conditions of solid solution and aging heat treatment, and significantly reduces the risk of corrosion of bacterial microorganisms caused by the use of ferritic stainless steel. The stainless steel comprises the chemical compositions of 17.5-19.5% of Cr, 1.9-2.5% of Mo, 2.0-4.5% of Cu, 1.0-2.5% of Ga, less than or equal to 0.035% of N, less than or equal to 0.025% of C, less than or equal to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.04% of P, less than or equal to 0.03% of S and the balance Fe. The high antibacterial ferritic stainless steel can be widely used in food and chemical industries and civil liquid transportation pipes or storage containers which contain the bacteria.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Autumn freshwater shrimp breeding control method

InactiveCN104782541ASolve the problem of excessive autumn multiplicationReduce the cost of farmingClimate change adaptationPisciculture and aquariaFresh water organismPrawn

The invention belongs to the technical field of aquaculture and relates to an autumn freshwater shrimp breeding control method. The method comprises the following steps that 1, shrimp bodies are checked, during 20 days after shrimp larvae are thrown, some freshwater shrimps are caught, whether the freshwater shrimps breed eggs is carefully checked, and the development degree is observed; 2, zoaea are checked, and whether a large number of the zoaea exist in a pond is checked 7-10 days when it is found that the shrimp eggs are developed into the eyespot stage; 3, splashing is carried out, and an abamectin solution is dissolved into water and splashed into the pond. Abamectin is agricultural or veterinary-used pesticide widely used, and has an effective effect of killing the zoaea of the freshwater shrimps without influencing the freshwater shrimps, the problem of excessive autumn breeding in the freshwater shrimp cultivation process is effectively solved, the freshwater shrimp cultivation cost is reduced, and the commodity rate and economic benefits of freshwater shrimp cultivation are increased.

Owner:镇江山水湾生态农业开发有限公司

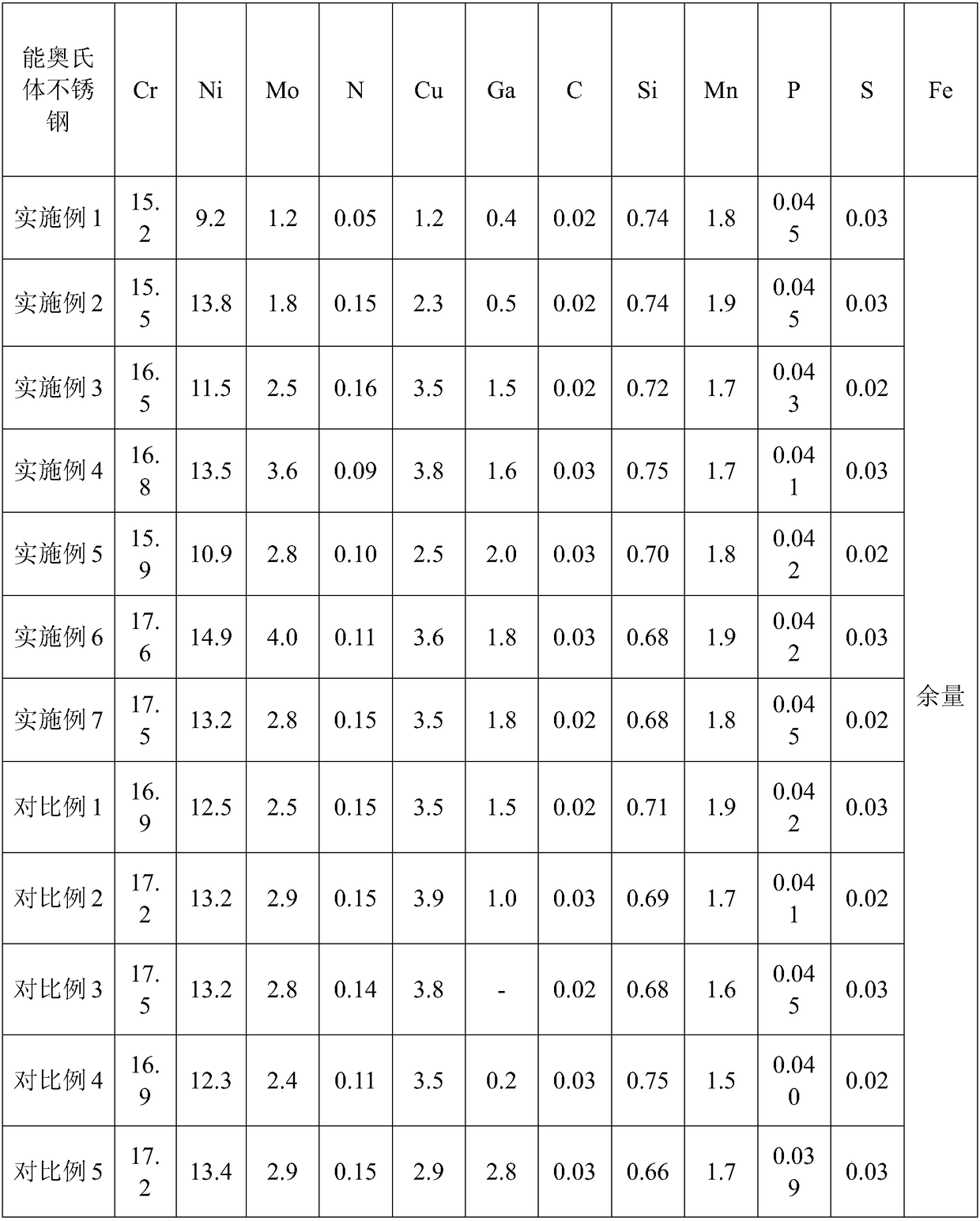

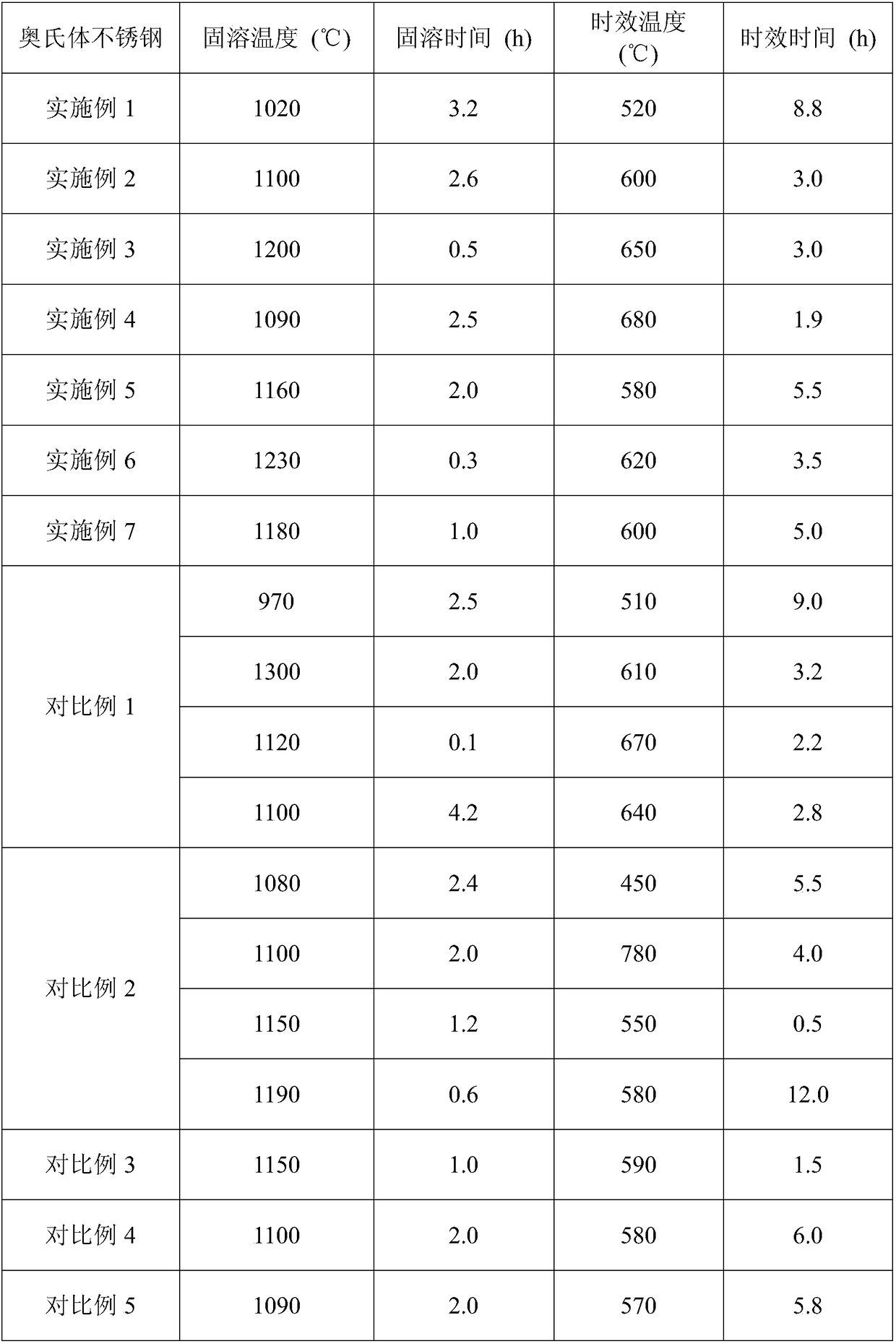

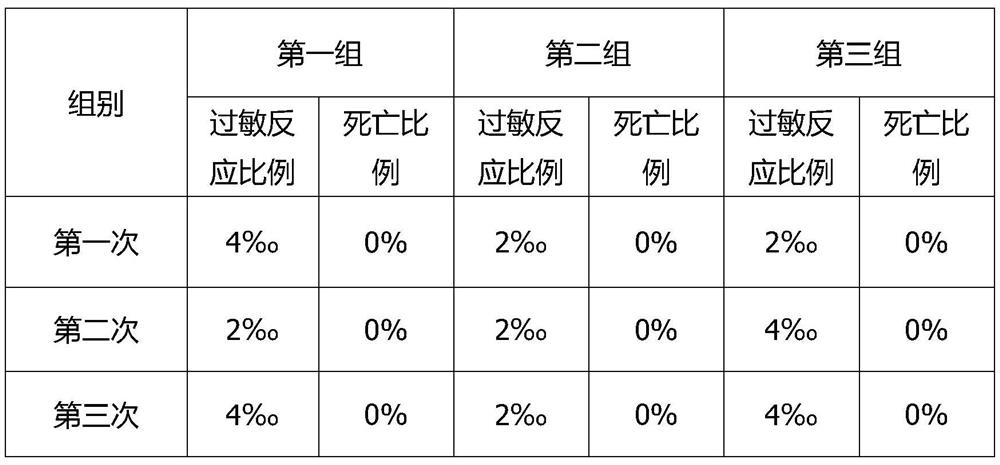

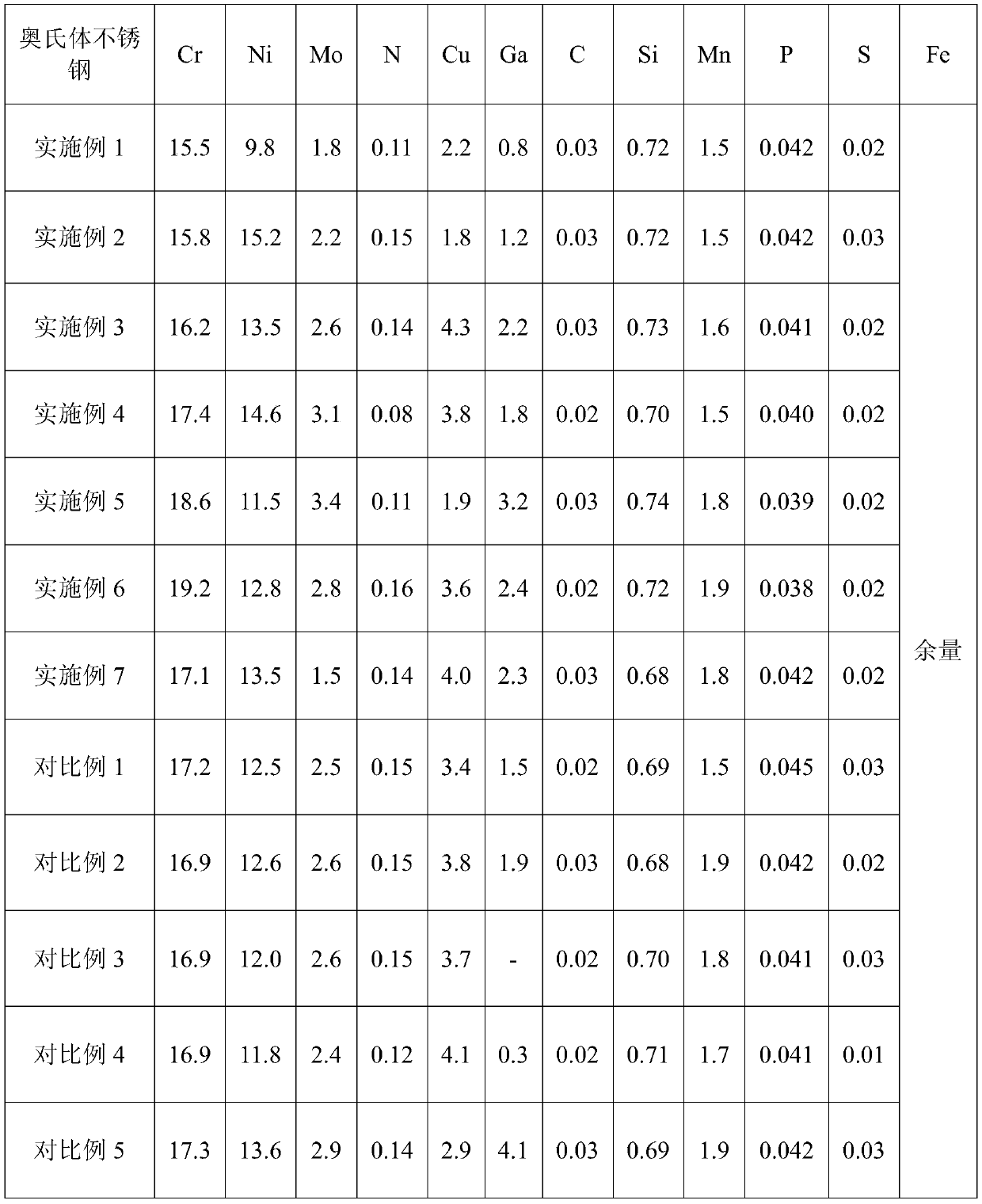

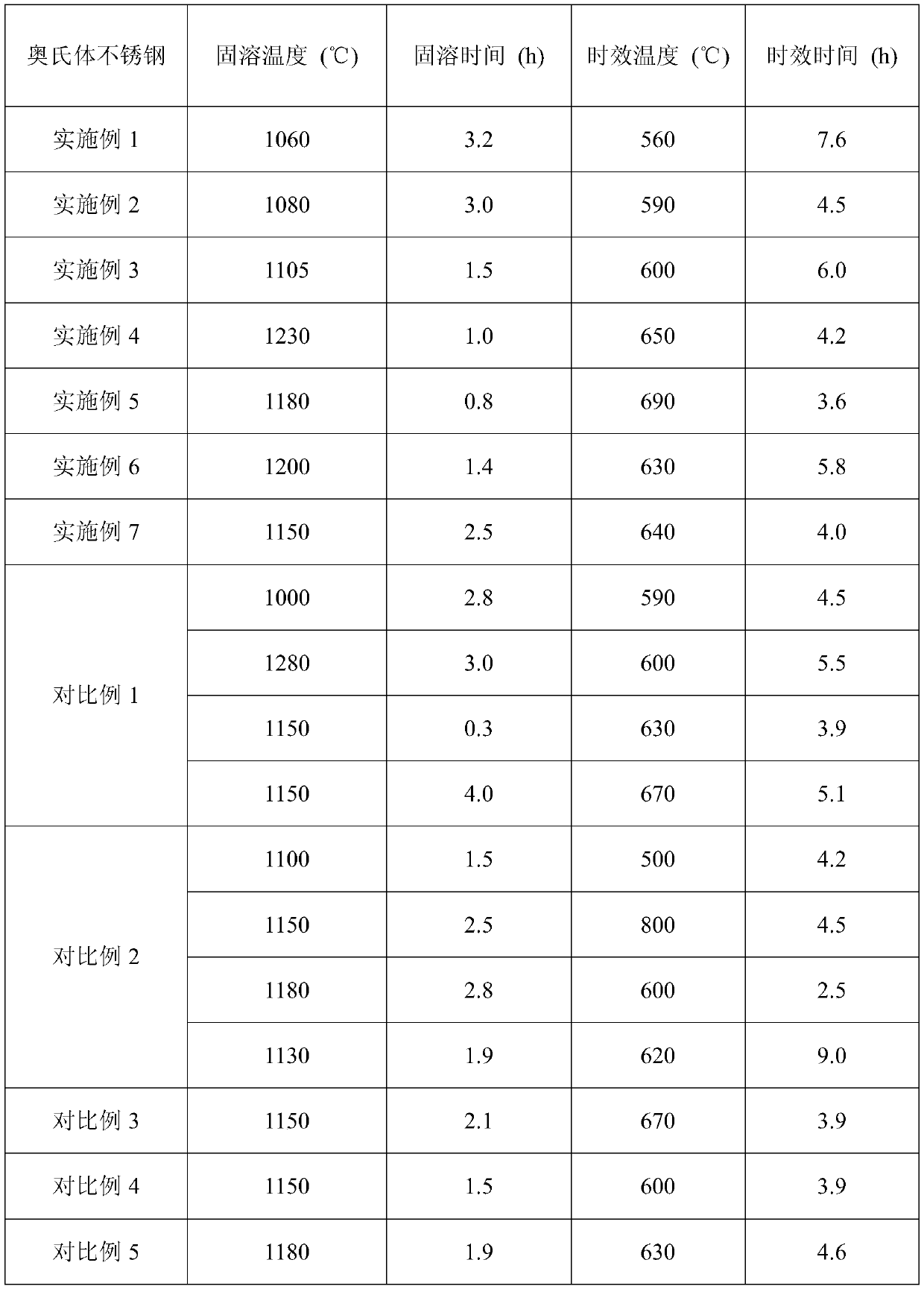

Austenitic stainless steel having ultra-high antibacterial property and applied to chemical industry production

The invention aims to provide an austenitic stainless steel material having the ultra-high antibacterial property and applied to chemical industry production, and a preparation method thereof. The austenitic stainless steel material has the function of effectively resisting high-concentration bacteria under the solution treatment and aging heat treatment states, and the bacterial and microbial corrosion risks caused during using of austenitic stainless steel are lowered remarkably, wherein the concentration is larger than (8-9)*10<6> CFU / mL. The chemical components of the stainless steel comprise 16.0-18.0 of Cr, 10.0-14.0 of Ni, 2.0-3.0 of Mo, 2.0-4.0 of Cu, 0.5-2.0 of Ga, 0.1-0.16 of N, 0.03 or the less of C, 0.75 or the less of Si, 2.0 or the less of Mn, 0.045 or the less of P, 0.03 orthe less of S and the balance Fe. The austenitic stainless steel having the ultra-high antibacterial property is widely applied to chemical industry production containing ultra-high-concentration bacteria and mainly comprises a storage container and a liquid conveying pipeline.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Pingyangmycin-containing nanoemulsion contrast therapeutic agent and preparation process thereof

InactiveCN112316159AReasonable structural designGood effectDispersion deliveryGeneral/multifunctional contrast agentsIodized oilBiomedical engineering

The invention discloses a pingyangmycin-containing nanoemulsion radiography therapeutic agent and a preparation process thereof. The pingyangmycin-containing nanoemulsion radiography therapeutic agentcomprises 70-90 parts of superparamagnetic nanoparticles, 400-500 parts of iodized oil, 135-175 parts of medical composite gelatin, 1-3 parts of pingyangmycin, 15-25 parts of serum albumin and 5-10 parts of an emulsifier, wherein the superparamagnetic nanoparticles are Fe2O3 nanoparticles, and are obtained through a steaming method; the diameter of the superparamagnetic nanoparticles is 3-10 nm;the Fe2O3 nanoparticles are wrapped in the emulsified iodized oil emulsion droplets; the medical composite gelatin comprises gelatin for bone pharmacy and gelatin for skin pharmacy according to a massratio of 10: 3; the iodine content of iodized oil is 100-150 mg / ml; the serum albumin is combined with the emulsion droplets prepared from the medical composite gelatin; and the pingyangmycin is combined on the serum albumin.

Owner:THE AFFILIATED HOSPITAL OF GUIZHOU MEDICAL UNIV

Compound algicide and preparation method thereof

InactiveCN109081406AImprove water qualityReduce ammonia nitrogenWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionCatalytic oxidation

The invention discloses a compound algicide and a preparation method thereof and belongs to the technical field of biological environmental protection. In the method, rhodopseudomonas palustris is activated and cultured under light conditions, dissolved pigment protein active substances are extracted, and the pigment protein active substances are converted to glucose by the aid of CO2 or H2S and water in algae photosynthesis for catalytic oxidation. Long-term effect of algae removal can be played by the aid of tetra-butyl titanate, acetic acid and other substances since the addition of the pigment protein active substances can continuous to grow and propagate to promote photocatalytic reaction; rectorite is taken as a raw material added with sodium silicate and ferric sulfate to generate active substances with fluocculation and turbidity removal functions in situ, certain oxidation capacity and electric neutralization effects are achieved, eutrophic substances and algal toxin are removed, good removal effect on algae cells is achieved, and algae removal efficiency is prompted; problems about short maintain time and poor algae removal effect of an existing algicide are solved.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

Medicine for treating chronic superficial gastritis and peptic ulcer diseases

InactiveCN100364594CEffective killing effectSimple treatmentDigestive systemPlant ingredientsDiseaseSalvia miltiorrhiza

The present invention relates to a Chinese medicine preparation for curing the diseases of chronic superficial gastritis and peptic ulcer with obvious therapeutic effect. Said Chinese preparation is made up by using 18 Chinese medicinal materials of raw rhubarb, coptis root, notoginseng, dandelion, salvia root, schutellaria root, frankincense, astragalus root and others through a certain preparation process.

Owner:孟宪安

A kind of TPBG antibody and its preparation method, its conjugate and application

ActiveCN106916227BPotent cytotoxicityEffective killing effectCompound screeningOrganic active ingredientsAntiendomysial antibodiesHumanized antibody

Owner:KAIHUI SCI & TECH DEV SHANGHAI

An ultra-high antibacterial performance austenitic stainless steel for medical implant stents

ActiveCN108728770BReduce time to killEffective killing effectSurgeryHigh concentrationCardiovascular stent

The invention aims to provide an ultrahigh-antibacterial-performance austenitic stainless steel material applied to a medical implantable stent and a preparation method thereof. The ultrahigh-antibacterial-performance austenitic stainless steel material has an effective function of resisting to high-concentration bacteria (>(8-9)*10<6> CFU / mL) in the heat treatment state of solution treatment andaging, and the risk of corrosion of bacteria microorganisms caused by the use of austenitic stainless steel can be remarkably reduced. The stainless steel comprises the following chemical components of, by weight, 16.0%-17.5% of Cr, 10.0%-14.0% of Ni, 2.0%-3.0% of Mo, 2.5%-4.5% of Cu, 1.0%-2.5% of Ga, 0.1%-0.15% of N, less than or equal to 0.03% of C, less than or equal to 0.75% of Si, less than or equal to 2.0% of Mn, less than or equal to 0.045% of P, less than or equal to 0.03% of S and the balance Fe. The ultrahigh-antibacterial-performance austenitic stainless steel is widely applied to material of the medical implantable stent, and specifically applied to medical implantable stent products such as a cardiovascular stent, a urethra stent, an intestinal stent and a bile duct stent.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Core bio-control bacteria and organic fertilizer containing the core bio-control bacteria

ActiveCN103518781BIncrease protease activityPrevention or mitigation of harmBiocideFungicidesContinuous croppingMicroorganism

Owner:湖南泰谷生态工程有限公司

A titanium alloy with ultra-high antibacterial properties used in medical implants and its preparation

ActiveCN108728691BReduce time to killEffective killing effectSurgeryTissue regenerationHigh concentrationTitanium alloy

The invention aims to provide an ultrahigh-antibacterial-performance titanium alloy applied to a medical implant and a manufacturing method of the ultrahigh-antibacterial-performance titanium alloy. The ultrahigh-antibacterial-performance titanium alloy and the manufacturing method of the ultrahigh-antibacterial-performance titanium alloy aim to achieve the effects that under the solid solution and aging heat treatment states of the titanium alloy, a function of effectively resisting high-concentration bacteria (larger than (8-9)*10<6> CFU / mL) is achieved, and the corrosion risk of bacteria microorganisms caused by the use of the titanium alloy is remarkably reduced. The titanium alloy comprises the following chemical components of, by weight, 5.5-6.5% of Al, 6.5-7.5% of Nb, 1.0-3.0% of Gaand the balance Ti. According to the heat treatment mode after material optimization, the temperature of the solid solution treatment is 950-1000 DEG C, heat preservation is carried out for 1.0-2.0 hours, and the temperature is reduced to the room temperature through water cooling. The ultrahigh-antibacterial-performance titanium alloy is widely applied to the multiple kinds of titanium alloy medical implants which are used in the medical clinic fields of a department of stomatology and a department of orthopedics, and the implants particularly refer to the dental implants, bone screws, bonefracture plates, (knee, ankle, shoulder and hip) joints and other common medical surgical implants.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ferritic stainless steel with strong antibacterial function

InactiveCN111996442AStrong Antibacterial PropertiesBroad-spectrum antimicrobial propertiesAnti bacterialCorrosion

The invention aims to provide a novel ferritic stainless steel material with a strong antibacterial function. Compared with traditional ferritic stainless steel, the antibacterial function of the ferritic stainless steel is further improved in the heat treatment state of solid solution and aging, the antibacterial rate can reach 99.9%, and the risks of corrosion of bacteria and microorganisms andsecondary pollution of water caused in the use process of the ferritic stainless steel are remarkably reduced. The stainless steel is prepared from the following chemical components in percentage by weight: 16.5-20.0% of Cr, 1.0-3.0% of Cu, 0.8-1.5% of Nd, no greater than 0.025% of C, no greater than 1.0% of Si, no greater than 1.0% of Mn, no greater than 0.04% of P, no greater than 0.03% of S andthe balance of Fe. The ferritic stainless steel with the strong antibacterial function can become an excellent substitute product of the existing ferritic stainless steel.

Owner:BEIJING ZHONGKE PUJIN SPECIAL MATERIAL TECHDEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com