Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Avoid precision errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portable ship water gauge automatic detection and identification method based on machine vision

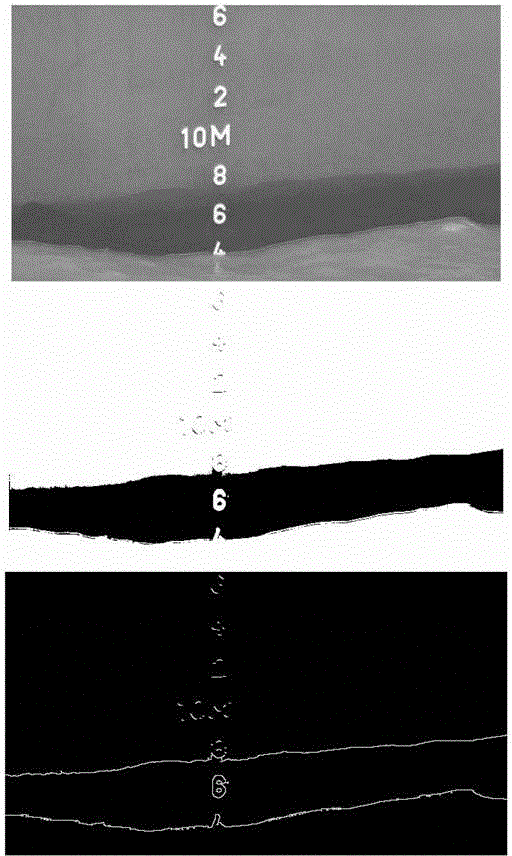

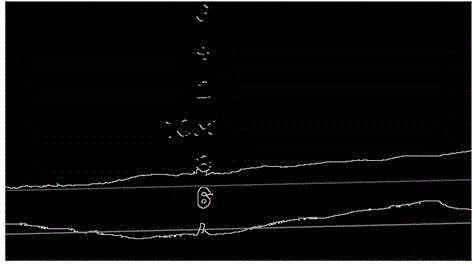

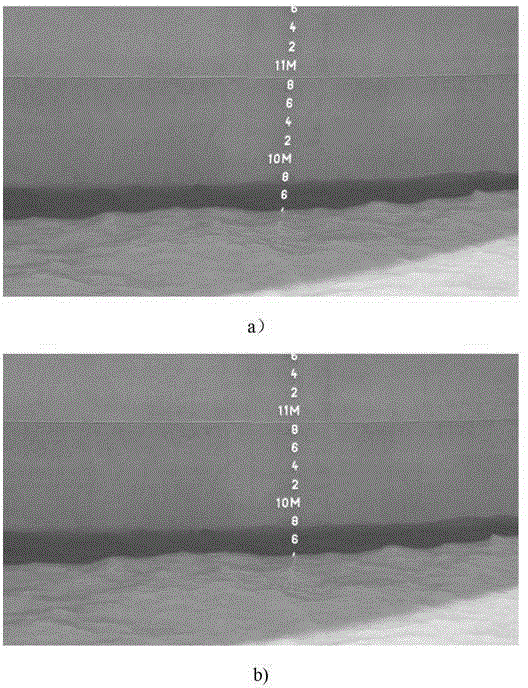

InactiveCN102975826AEasy retrievalEasy data playbackVessel stability improvementMovement controllersMachine visionResearch Object

The invention provides a portable ship water gauge automatic detection and identification method based on machine vision. Video data of a ship water gauge in the overwater environment are used as a main research object, the machine vision and the image processing theory are used as main means, so as to detect and identify the scale of the ship water gauge and perform statistical analysis on detection results of continuous video frames, and finally, a ship draft value is obtained. According to the system, the relatively objective ship draft value can be obtained in accordance with image data, the detection results are visually displayed, the workload of ship draft detection personnel can be reduced, the measurement stability and accuracy of the ship water gauge are increased, and an objective measuring means and reference data are provided for determining ship draft.

Owner:SHANGHAI MARITIME UNIVERSITY

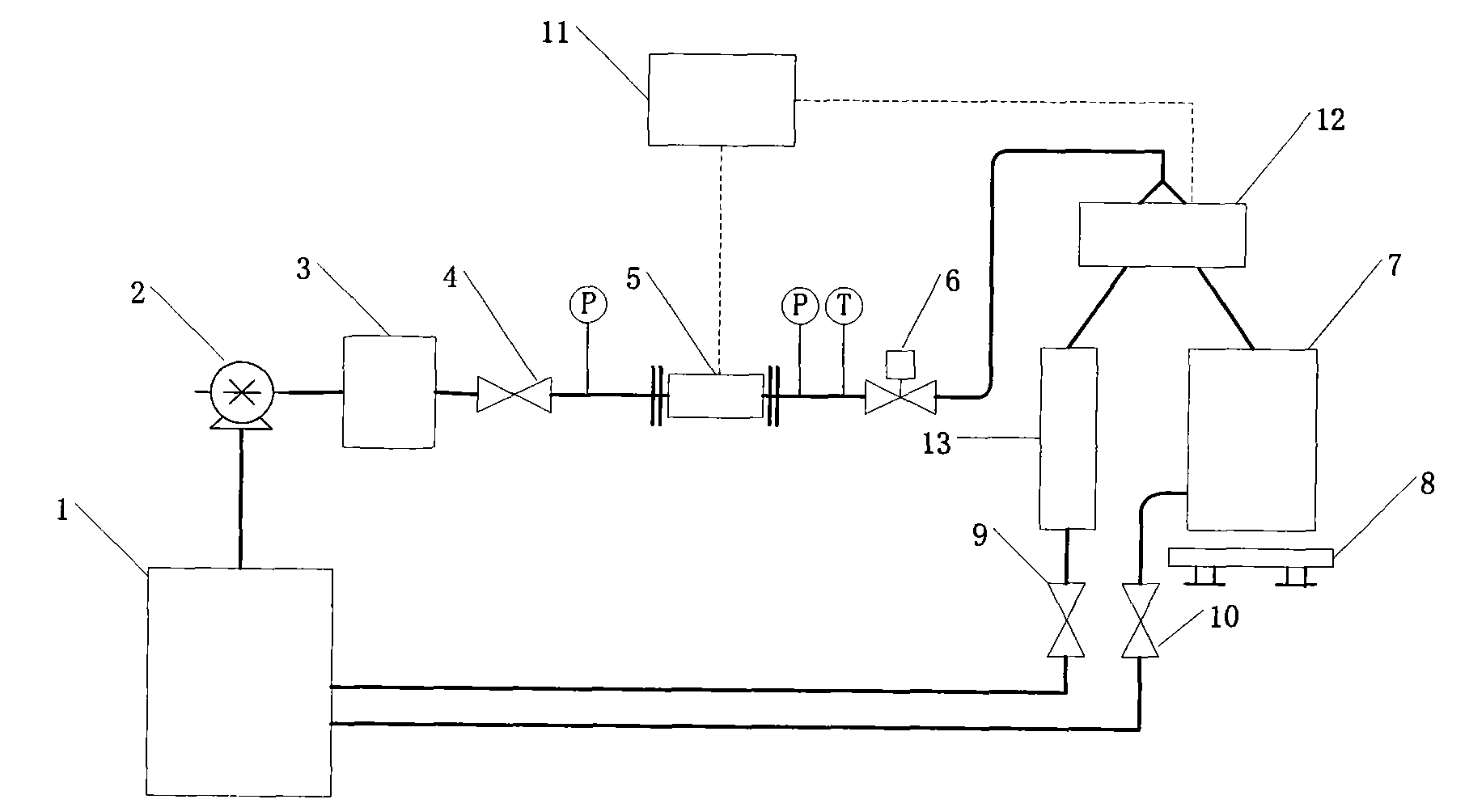

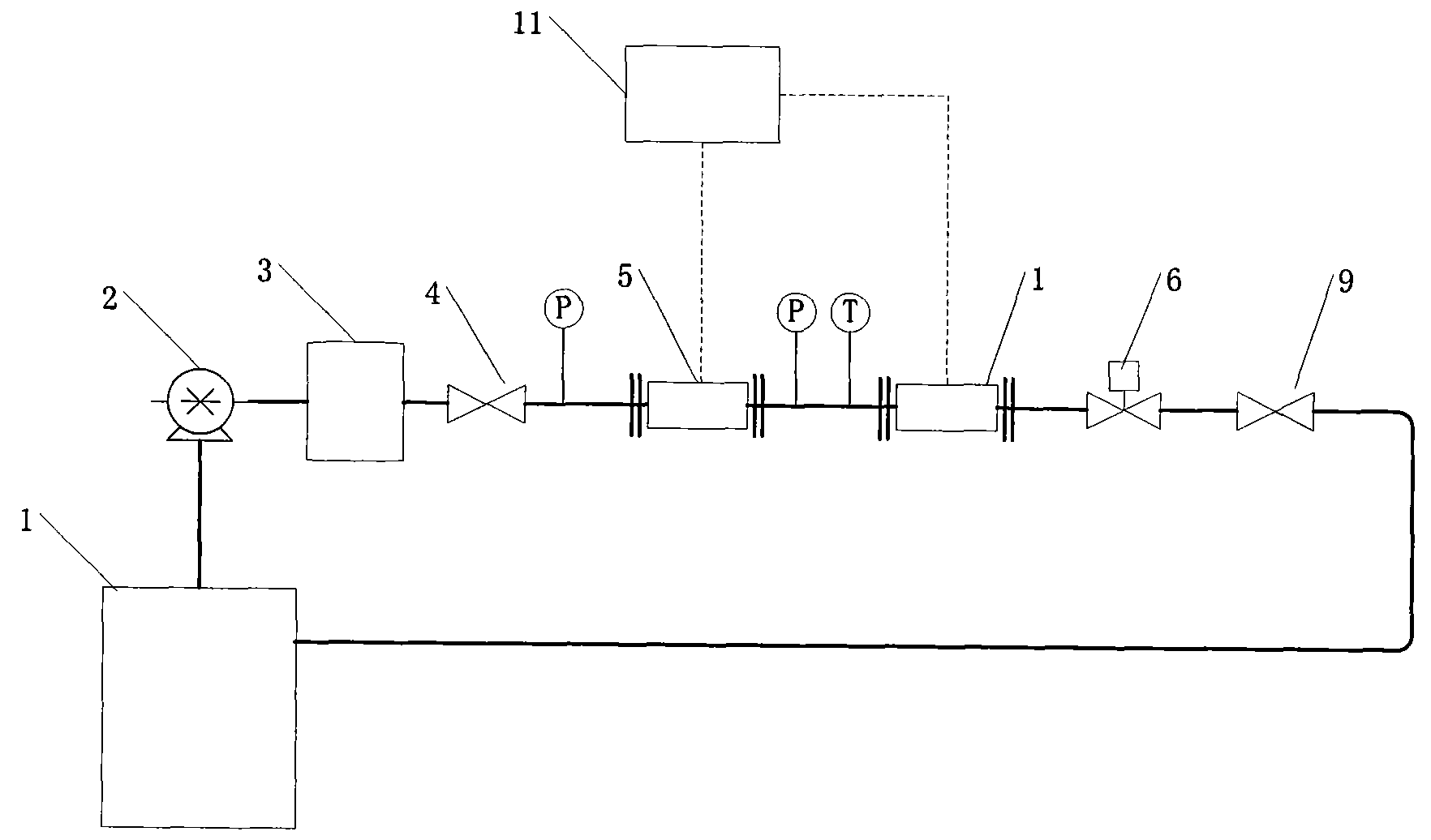

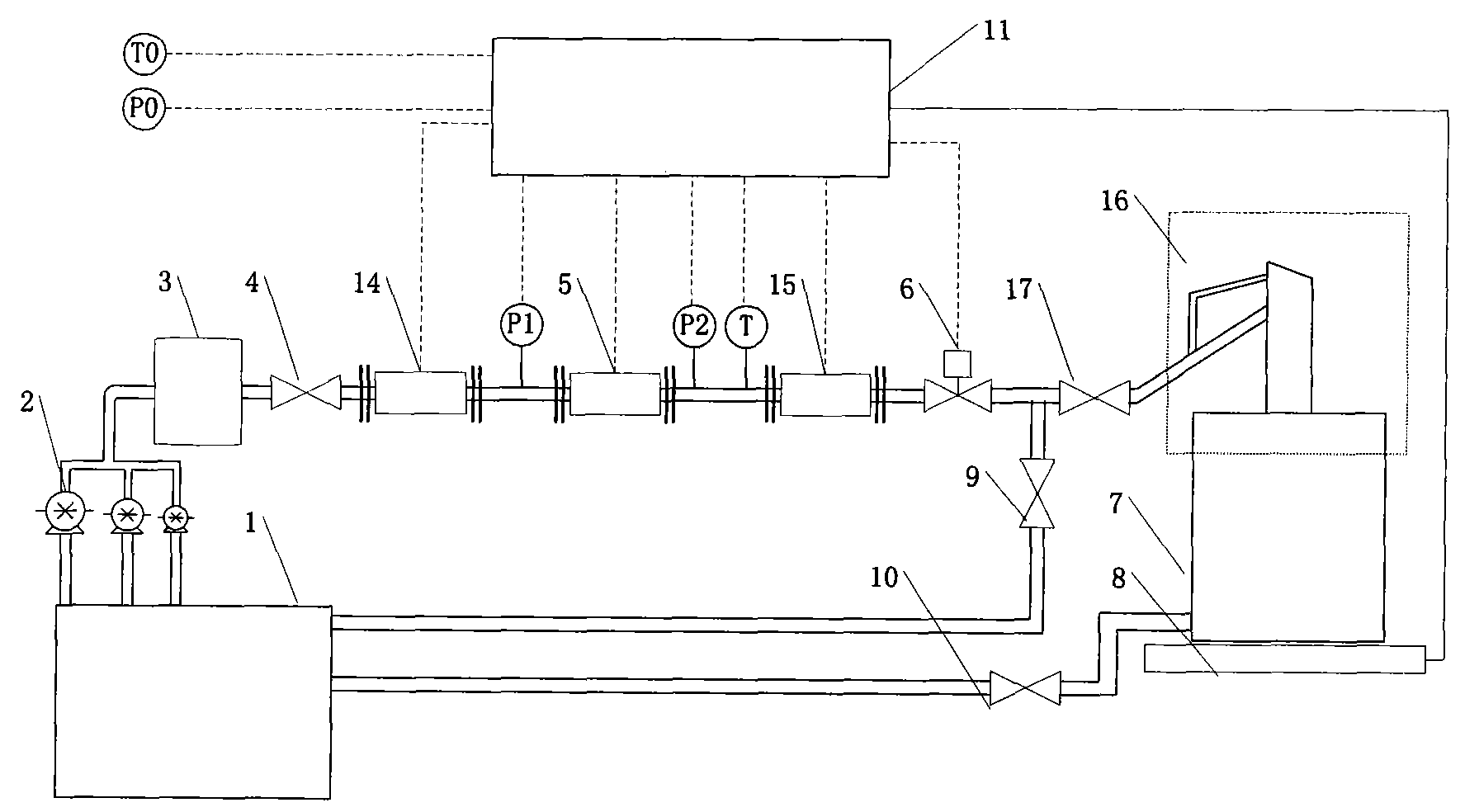

Composite static start-stop method mass flowmeter calibration system

InactiveCN101556181AImprove calibration accuracyImprove work efficiencyTesting/calibration apparatusStart stopEngineering

The invention relates to a composite static start-stop method mass flowmeter calibration system which is used for checking the flow rate of a mass flowmeter, is a calibrating apparatus adopting the mass flowmeter that is nationally and legally prescribed and can check the main characteristics and accuracy index of the mass flowmeter. The calibration system comprises a water tank, a current stabilizer, a regulating valve, stop valves and an electronic scale, and is characterized in that a flow rate pump set is connected between the water tank and the current stabilizer, the two sides of the flowmeter to be measured are respectively connected with standard flowmeter sets, the two ends of the regulating valve are respectively provided with the stop valves, one end thereof is connected with the water tank, and the other end is connected with the current stabilizer which is connected with a weighing container; the standard flowmeter sets, the flowmeter to be measured, the regulating valve and the electronic scale are connected with a computer. The calibration system has the advantages of weighing method and standard scale method, so as to have high accuracy in calibration and working efficiency and the like; furthermore, a static start-stop method is adopted to calibrate the mass flowmeter, so that the accuracy error caused by inconsonant positive and negative strokes of a steering gear can be avoided.

Owner:XIAN DONGFENG MACHINERY & ELECTRONICS

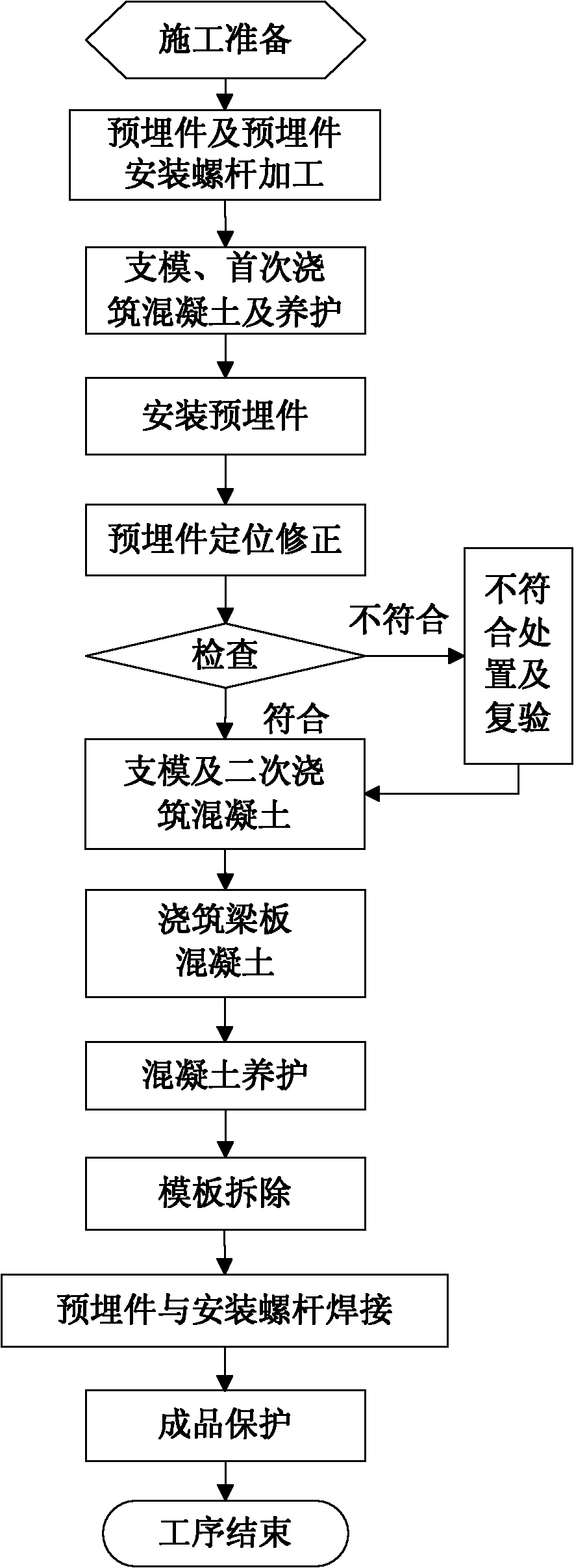

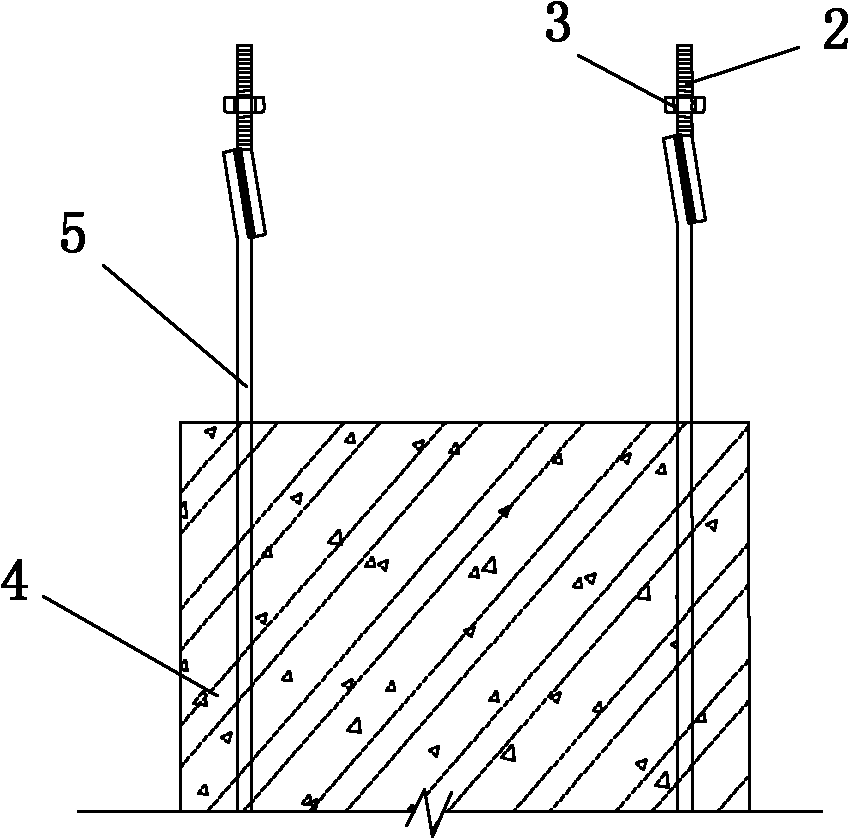

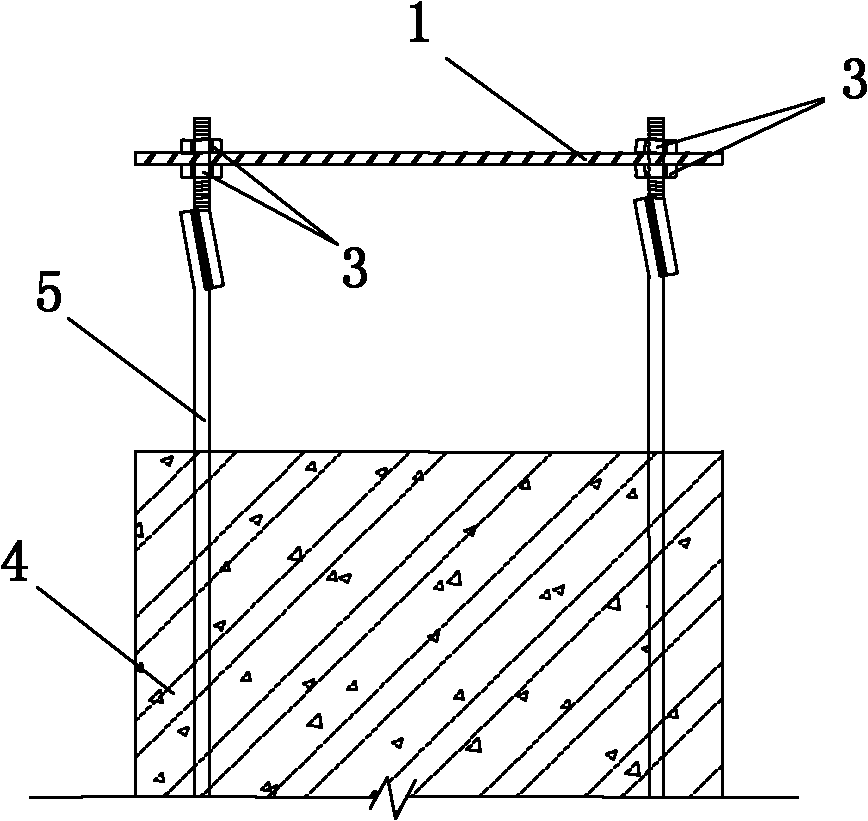

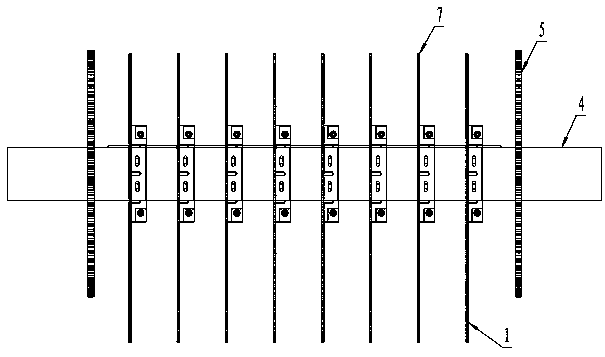

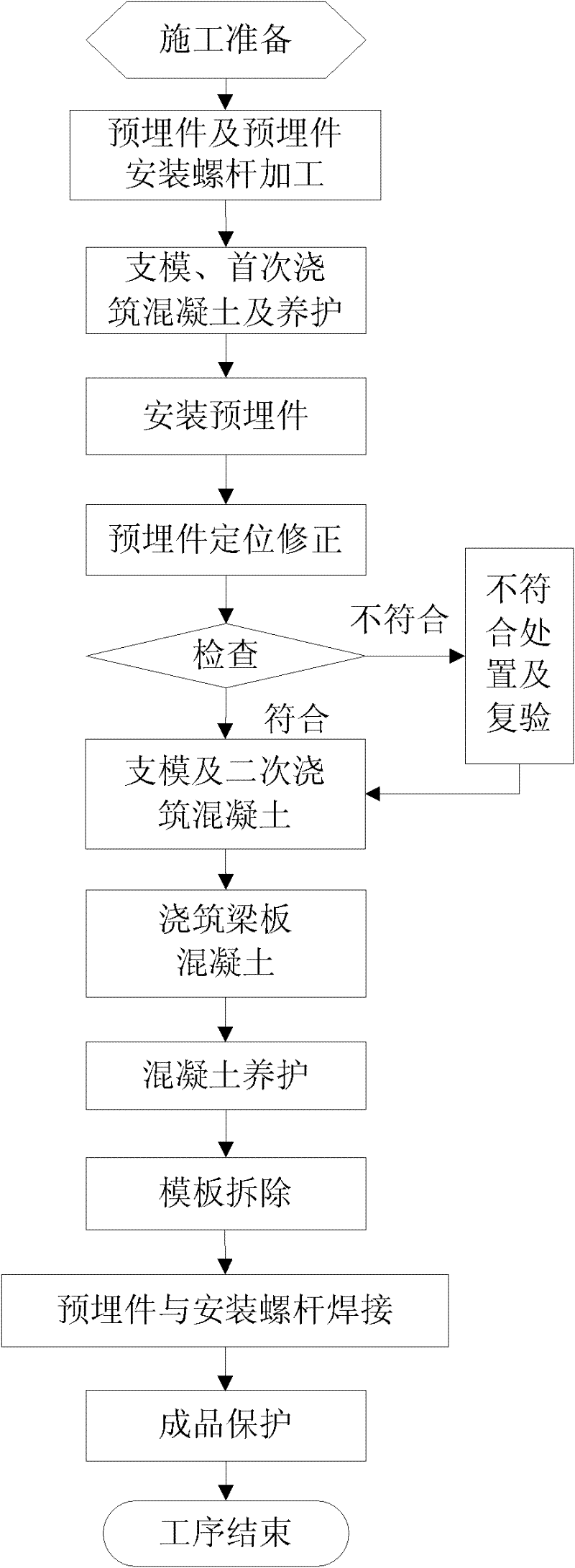

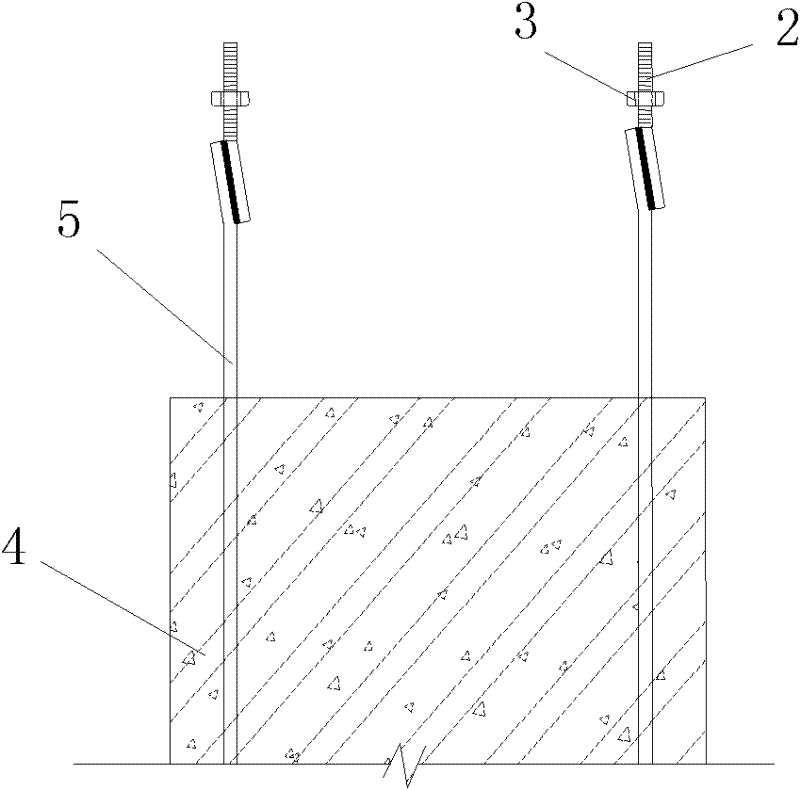

Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

InactiveCN102134879AReasonable designSimple construction stepsFoundation engineeringBuilding constructionsRebarReinforced concrete

The invention discloses an embedding accuracy control construction method for an embedded part of an overlong equipment foundation platform, including the following steps: firstly, processing the embedded part and the installation screw of the embedded part; secondly, molding construction of the lower middle reinforced concrete structure of the foundation platform needing construction: a plurality of vertical reinforcing steel bars extend out from the top of the lower middle reinforced concrete structure under construction of molding and are arranged vertically; thirdly, installing the installation screw of the embedded part; fourthly, installing a nut at the bottom of the threaded section of the installation screw of the embedded part; fifthly, installing and positioning the embedded part; sixthly, installing a nut on top of the threaded section of the installation screw of the embedded par; seventhly, molding construction of the upper reinforced concrete structure of the foundation platform needing construction; and eighthly, subsequent construction treatment. The method has in design, simple construction steps, easy control of construction quality, high construction accuracy and good in use effect, and can solve the problems of the existing embedding construction method of embedding parts that the embedding accuracy is inconvenient to control, the embedding accuracy is low, the construction quality is poor, the investment cost is high, the construction period is long, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

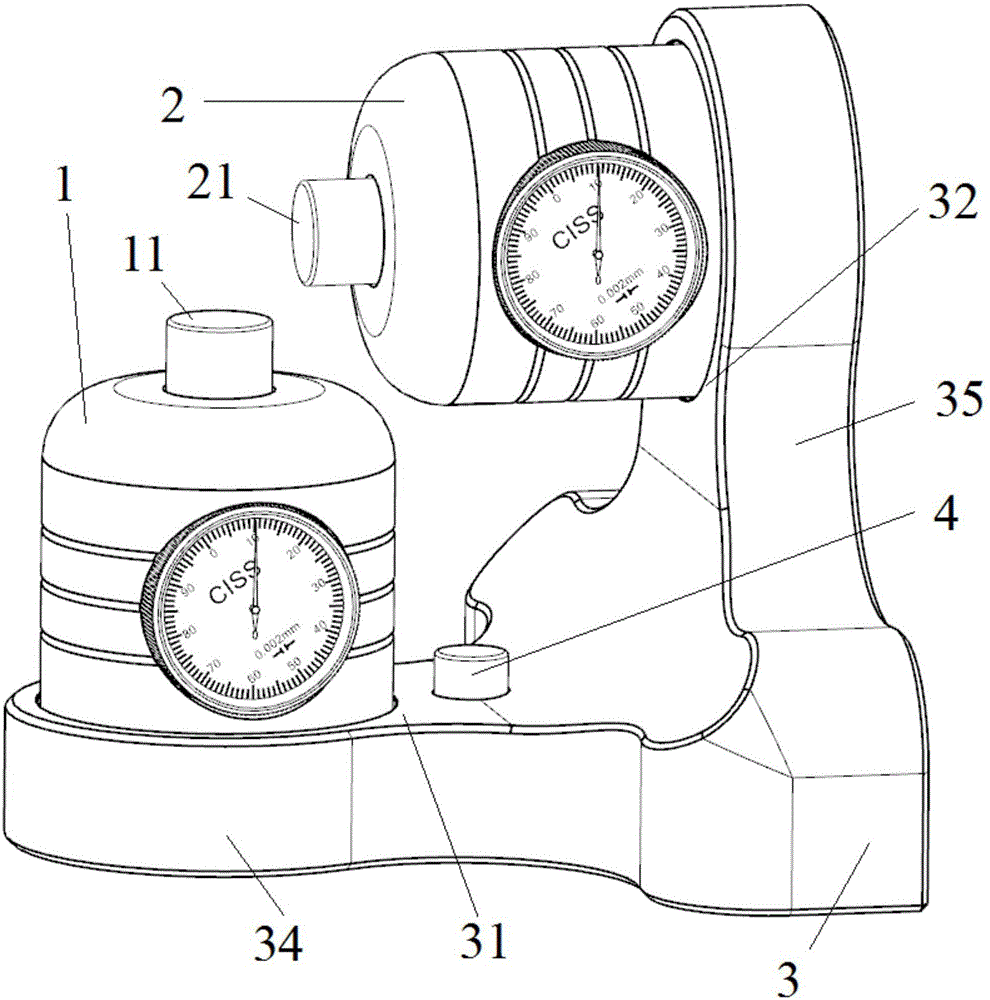

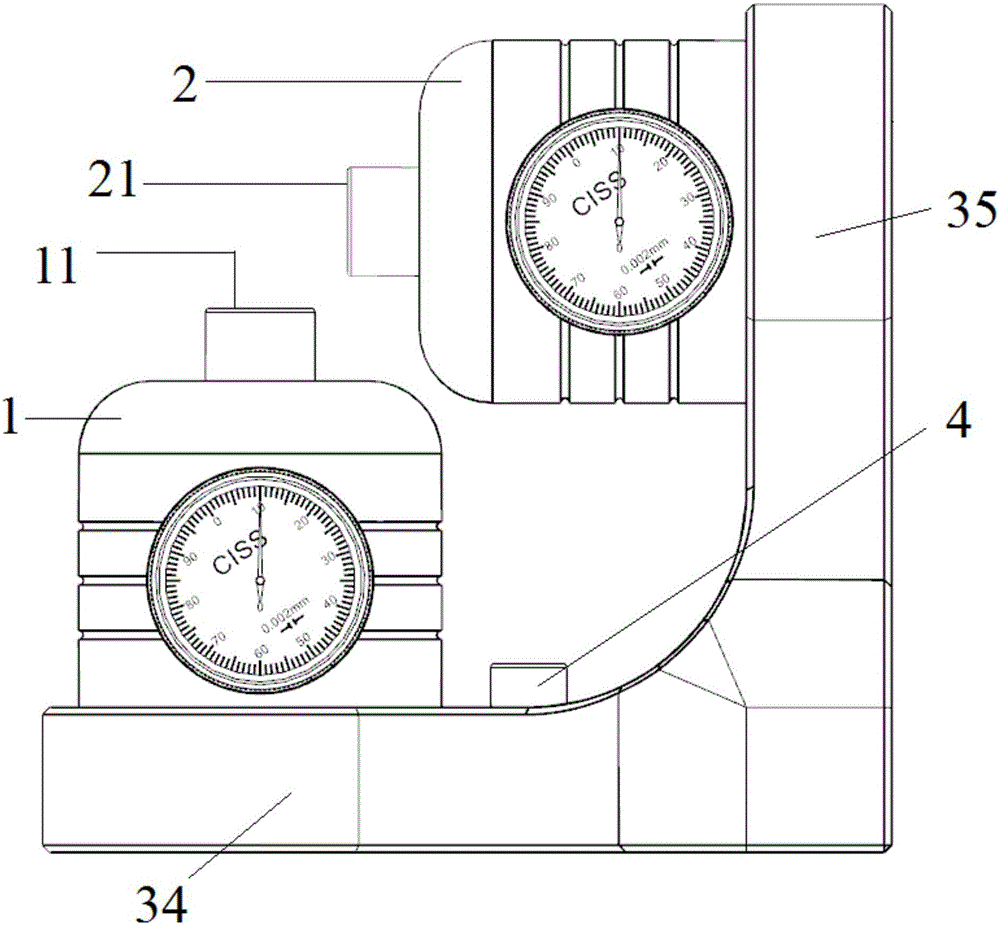

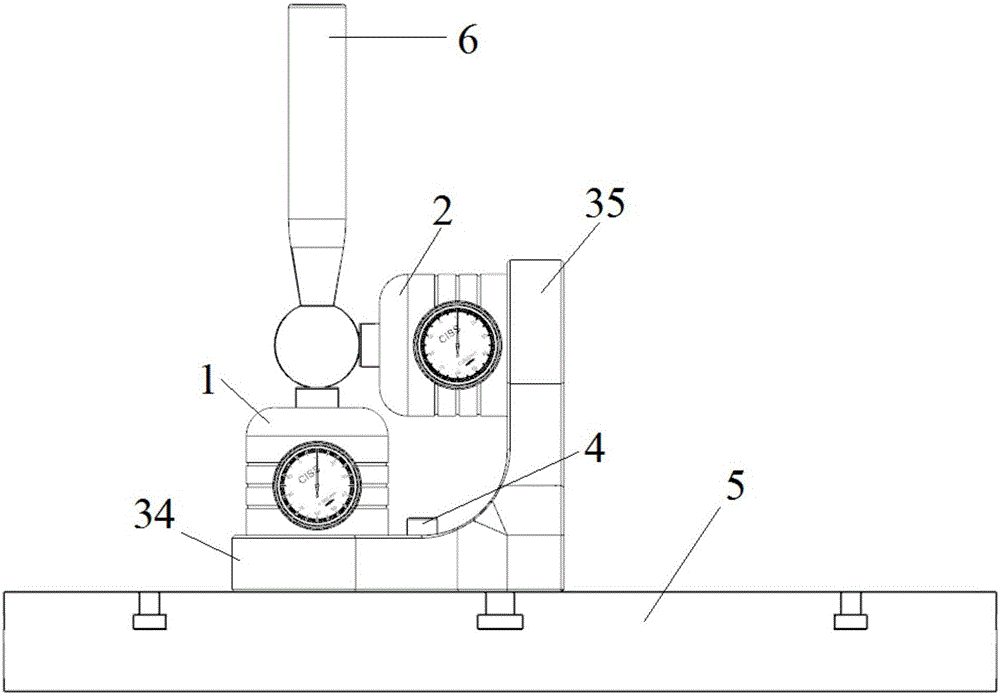

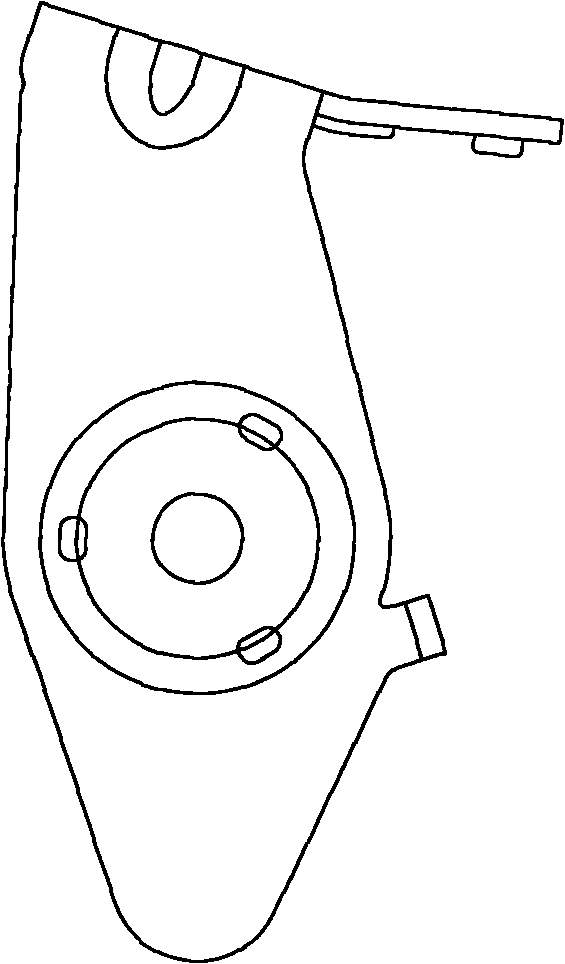

Five-axis linkage machine tool RTCP dynamic precision calibrating apparatus and calibrating method thereof

ActiveCN105043190AEasy to operateImprove calibration accuracyMechanical measuring arrangementsGeometric errorEngineering

The invention discloses a five-axis linkage machine tool RTCP dynamic precision calibrating apparatus and a calibrating method thereof. The apparatus comprises a support, and a first face contact type dial gauge and a second face contact type dial gauge both arranged on the support. The central axes of the two face contact type dial gauges are perpendicular to each other and located in the same plane. The apparatus satisfies the following formula: d1=d2<=r-3mm. d1 is the distance between the measuring end face of the first face contact type dial gauge to the vertically intersecting point of the central axes of the two face contact type dial gauges. d2 is the distance between the measuring end face of the second face contact type dial gauge to the vertically intersecting point of the central axes of the two face contact type dial gauges. r is the bulb radius of a bulb test rod for calibration. By using the two face contact type dial gauges arranged on the support, the apparatus prevents complex equation solving processes, conventional dial gauge calculating errors and measuring geometric errors, and complex operations during a conventional calibration method using process. The calibration efficiency and the calibration precision are thus greatly improved. The invention further discloses a calibrating method for the five-axis linkage machine tool RTCP dynamic precision calibrating apparatus.

Owner:中工科安科技有限公司

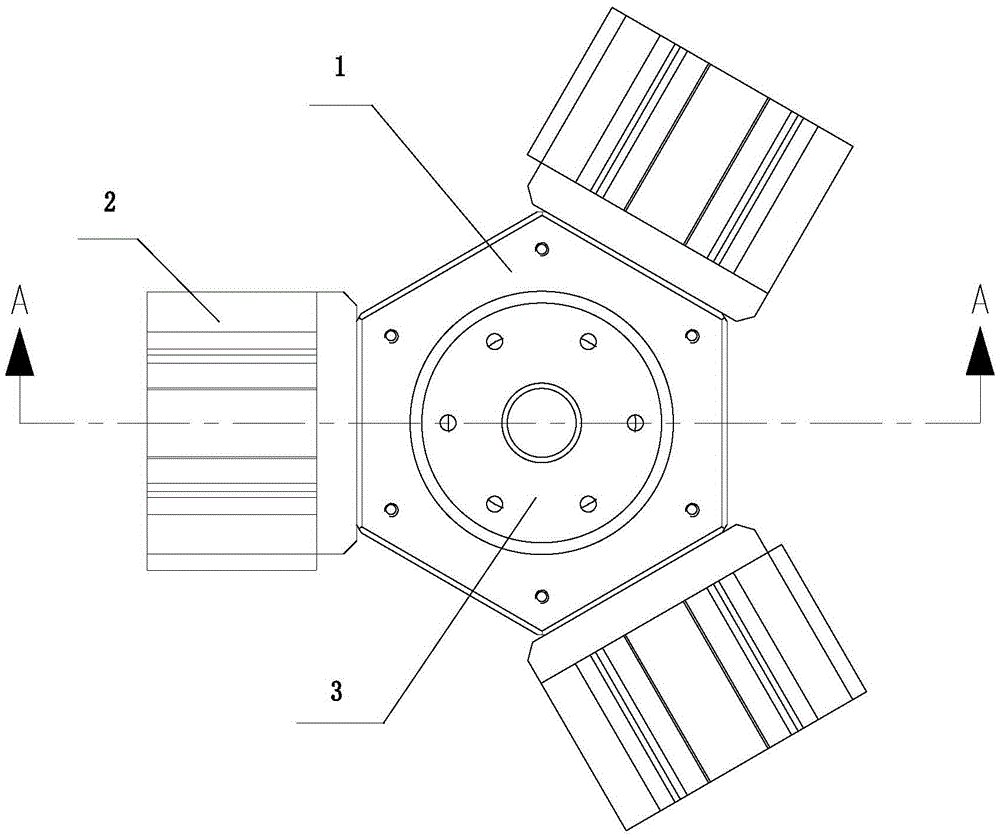

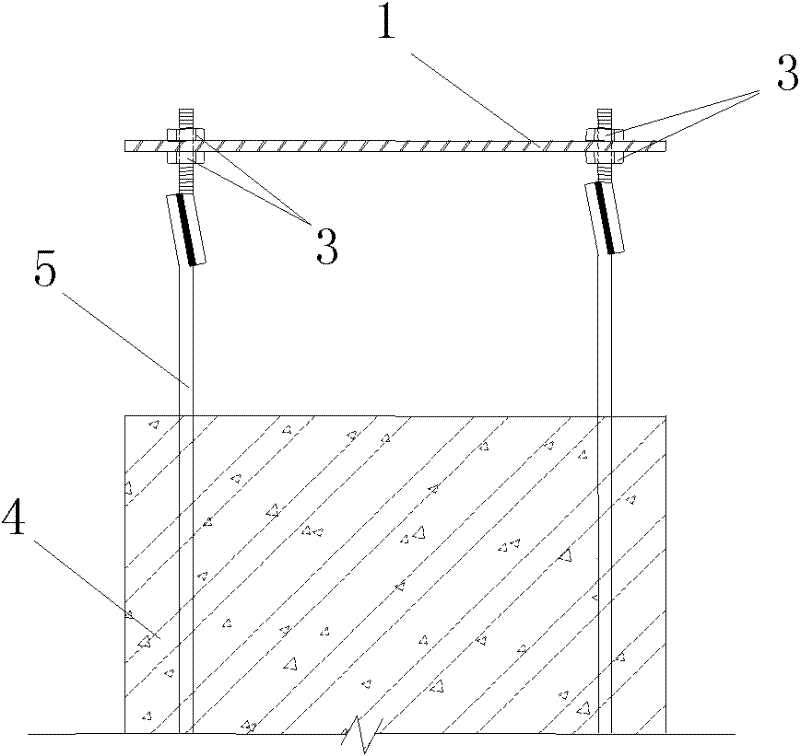

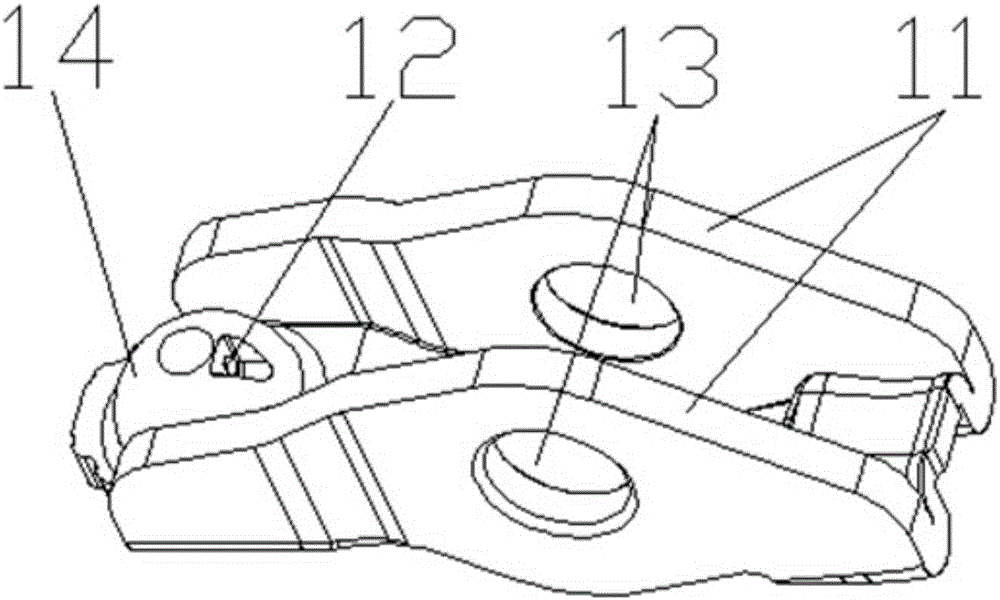

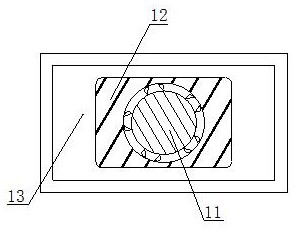

Pose adjusting ball device for airplane assembly

ActiveCN105539876ARealize docking assemblyImprove automationAircraft assemblyNumerical controlEngineering

The invention discloses a pose adjusting ball device for airplane assembly and belongs to the field of airplane manufacturing equipment. The defects that errors are large and the stress of the connecting portion is large exist in the airplane body pose adjustment process due to the adoption of a special fixture or a jack manual operation manner currently. The pose adjusting ball device comprises a ball socket seat and an installation seat used for being connected with and supporting an airplane body. A connecting flange is arranged at the upper portion of the installation seat and the lower portion of the installation seat is fixedly connected with a ball through a connecting rod. An installation seat installation cavity is formed in the center of the ball socket seat. A ball socket corresponding to the ball is arranged at the lower portion of the installation cavity. The installation seat is installed in the ball socket seat. Three clamping devices are evenly arranged on the sides of the ball socket seat in the circumferential direction. An in-position detection switch is arranged at the bottom of the ball socket seat. The pose adjusting ball device is combined with a three-coordinate numerical control locator, accuracy errors existing in manual pose adjustment are effectively avoided, airplane assembly automation and intelligence are improved, and the pose of the airplane body can be better adjusted in six directions.

Owner:ZHEJIANG RIFA AVIATION DIGITAL EQUIP

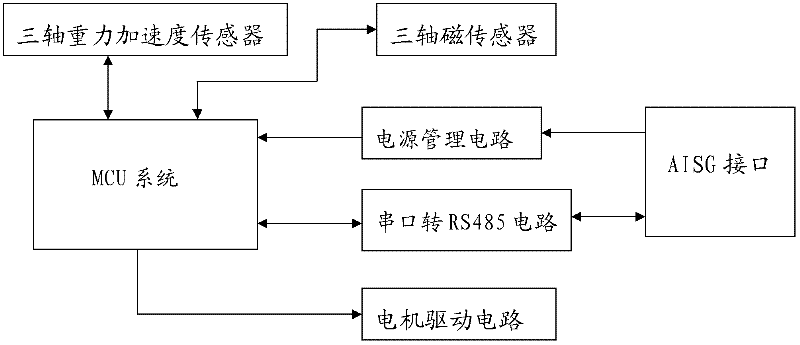

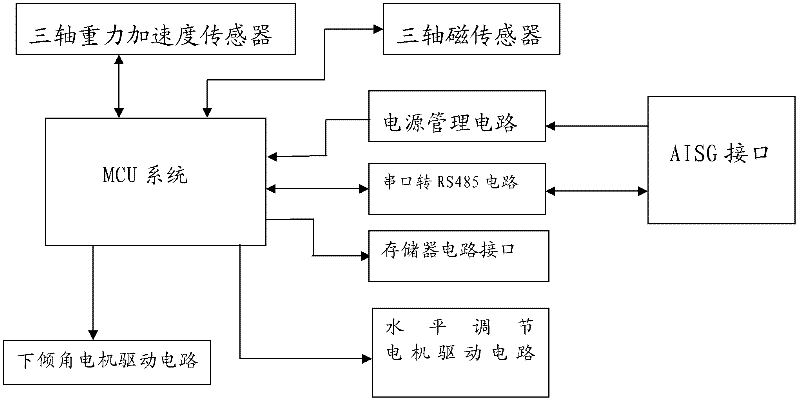

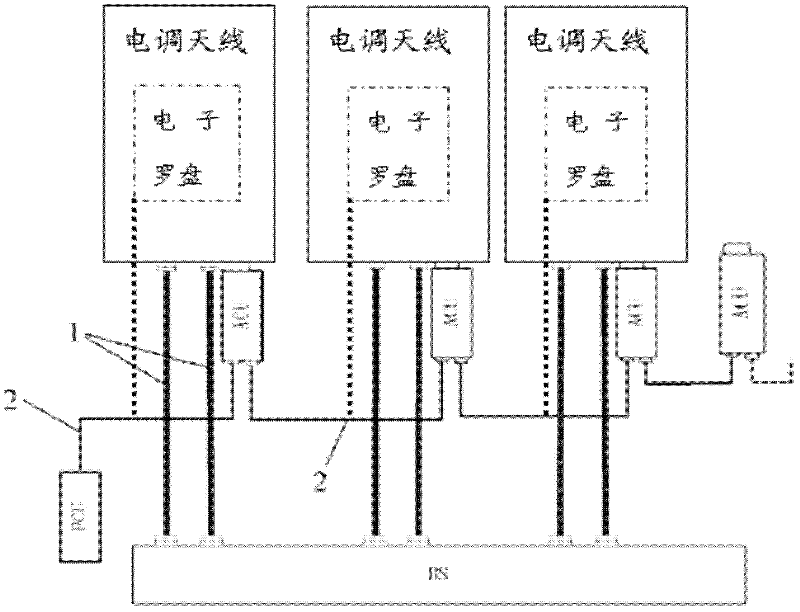

Electrically-regulated antenna based on orientation correction and regulation

InactiveCN102655269ASimple structureImprove stabilityAntenna supports/mountingsAntennas earthing switches associationElectricityTelecommunications link

The invention discloses an electrically-regulated antenna based on orientation correction and regulation, which comprises at least one electrically-regulated antenna body, at least one antenna control unit, at least one terminal control module and a direction sensing device, wherein the downward inclination angle and the azimuthal angle of the electrically-regulated antenna body can be regulated; the at least one antenna control unit is used for regulating the downward inclination angle and the azimuthal angle of the electrically-regulated antenna body and is provided with an input end and an output end, the output end is electrically connected to the electrically-regulated antenna body, and the antenna control unit is corresponding to the electrically-regulated antenna body one by one; the terminal control module controls and is connected to the input end of the antenna control unit, and establishes a communication link with the antenna control unit, and each terminal control module respectively controls one or more antenna control units; and the direction sensing device is fixed on the electrically-regulated antenna body, and used for sensing the physical orientation of the electrically-regulated antenna body, and the direction sensing device is electrically connected to the input end of the antenna control unit.

Owner:TONGYU COMM INC

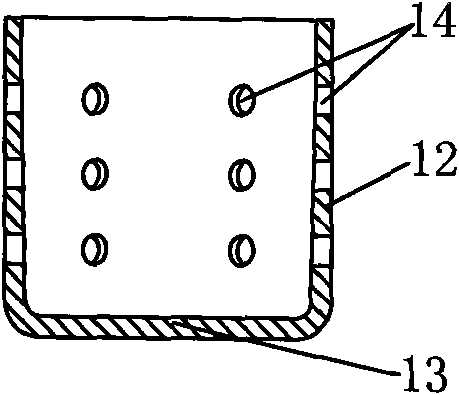

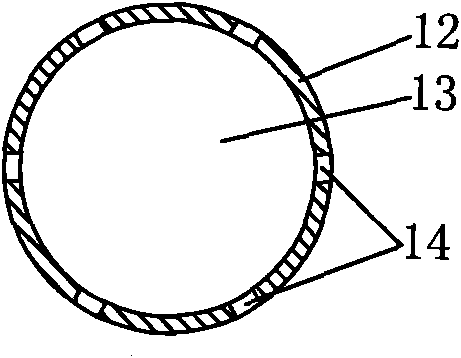

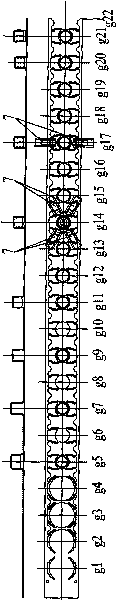

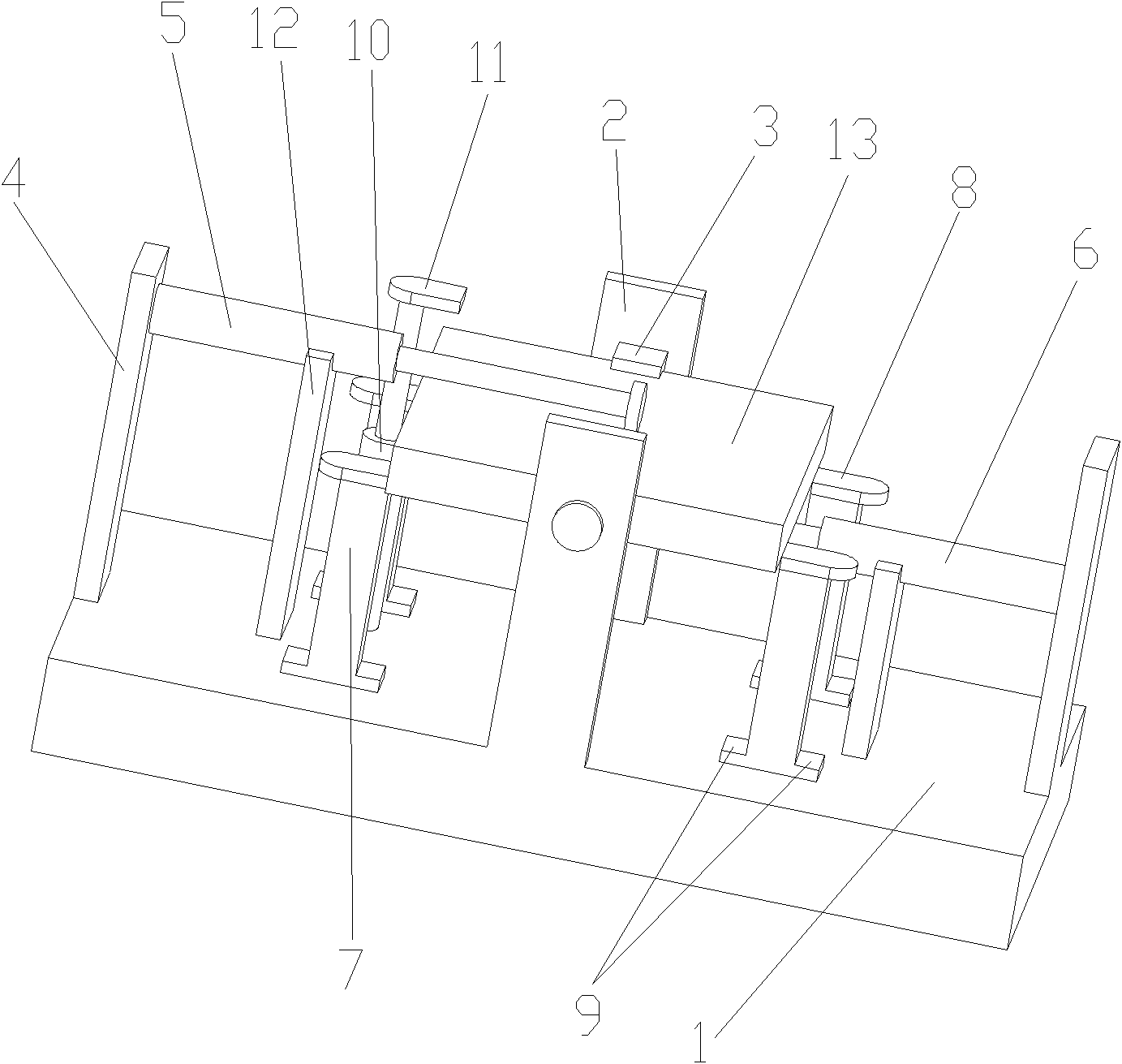

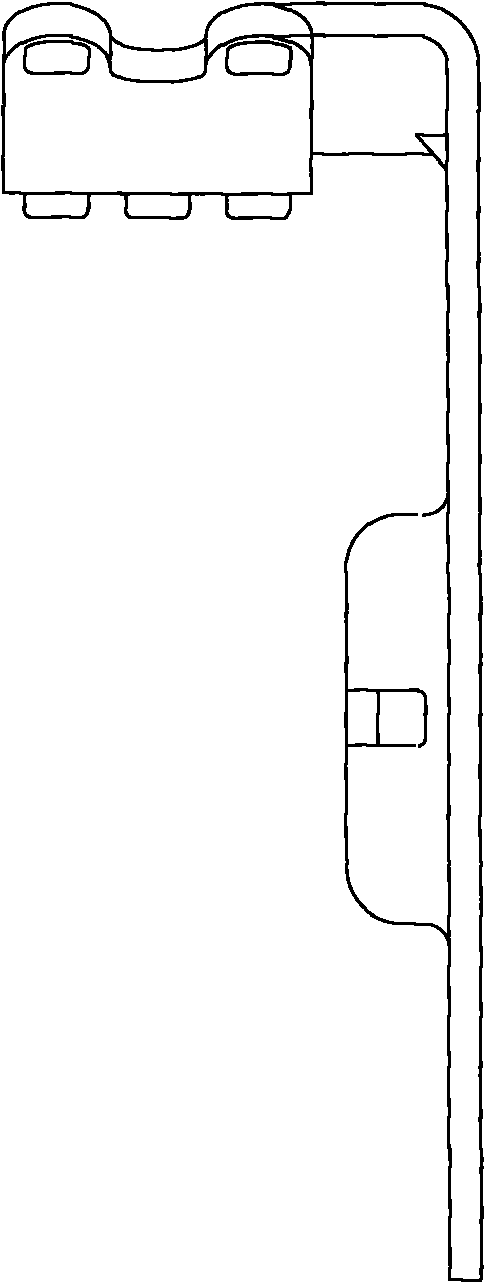

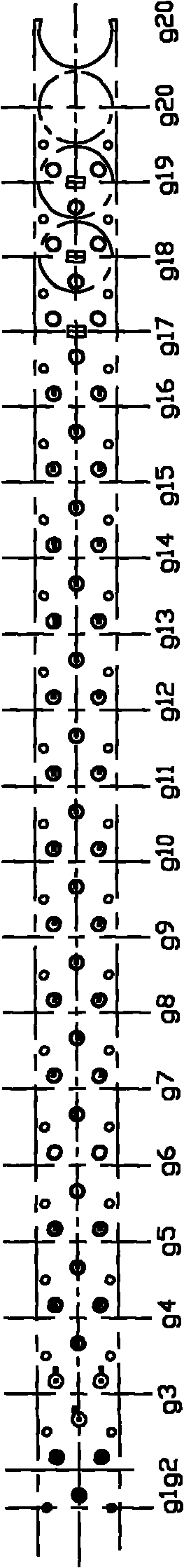

Side hole progressive die

InactiveCN101733325AAvoid precision errorsGood quality and stabilityShaping toolsStripping-off devicesHigh volume manufacturingPunching

The invention discloses a side hole progressive die comprising two sets or more than two sets of deep drawing devices and a side punching device. The side punching device is arranged behind the deep drawing device and comprises an upper die, a lower die, an elastic structure, a side punching structure and a discharge structure; the side punching structure and the discharge structure are arranged between the upper die and the lower die; and the elastic structure is positioned in the upper die and acts on between the discharge structure and the upper die. With the adoption of the technical scheme, the side hole progressive die can well finish deep drawing since two sets or more than two sets of the depth-drawing devices are arranged; the side hole progressive die can greatly improve the processing efficiency and make rapid large-batch production to ensure timely supply compared with the traditional processing mode of adopting multidie single procedure as the deep drawing die and the side punching die are combined together; and meanwhile, the labor cost is greatly reduced, and the labor of operators is lightened. In addition, the side hole progressive die avoids the precision error brought by the moving of a workpiece blank between different working positions, thereby having higher processing precision and better quality stability.

Owner:上海定达机电设备有限公司

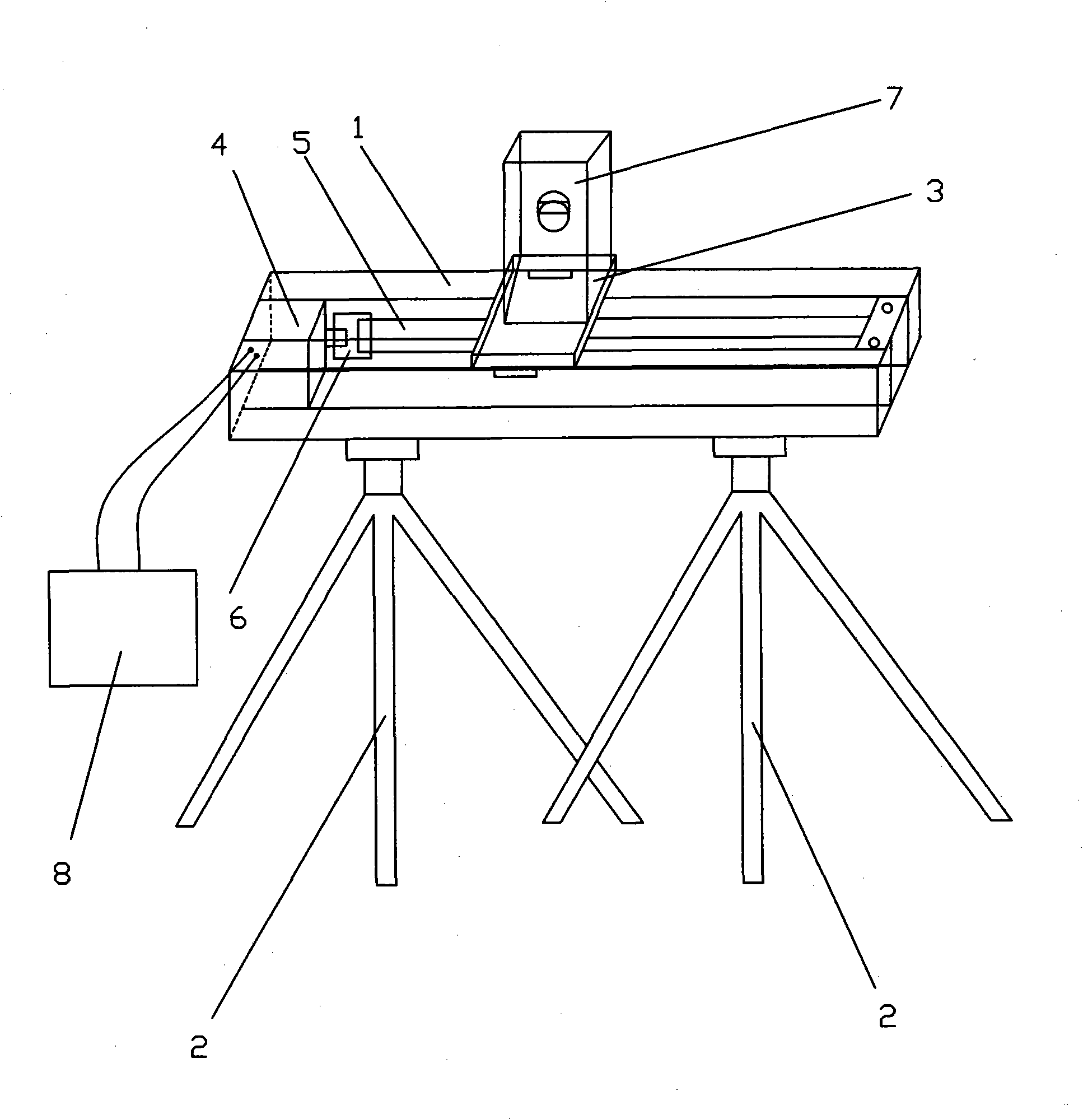

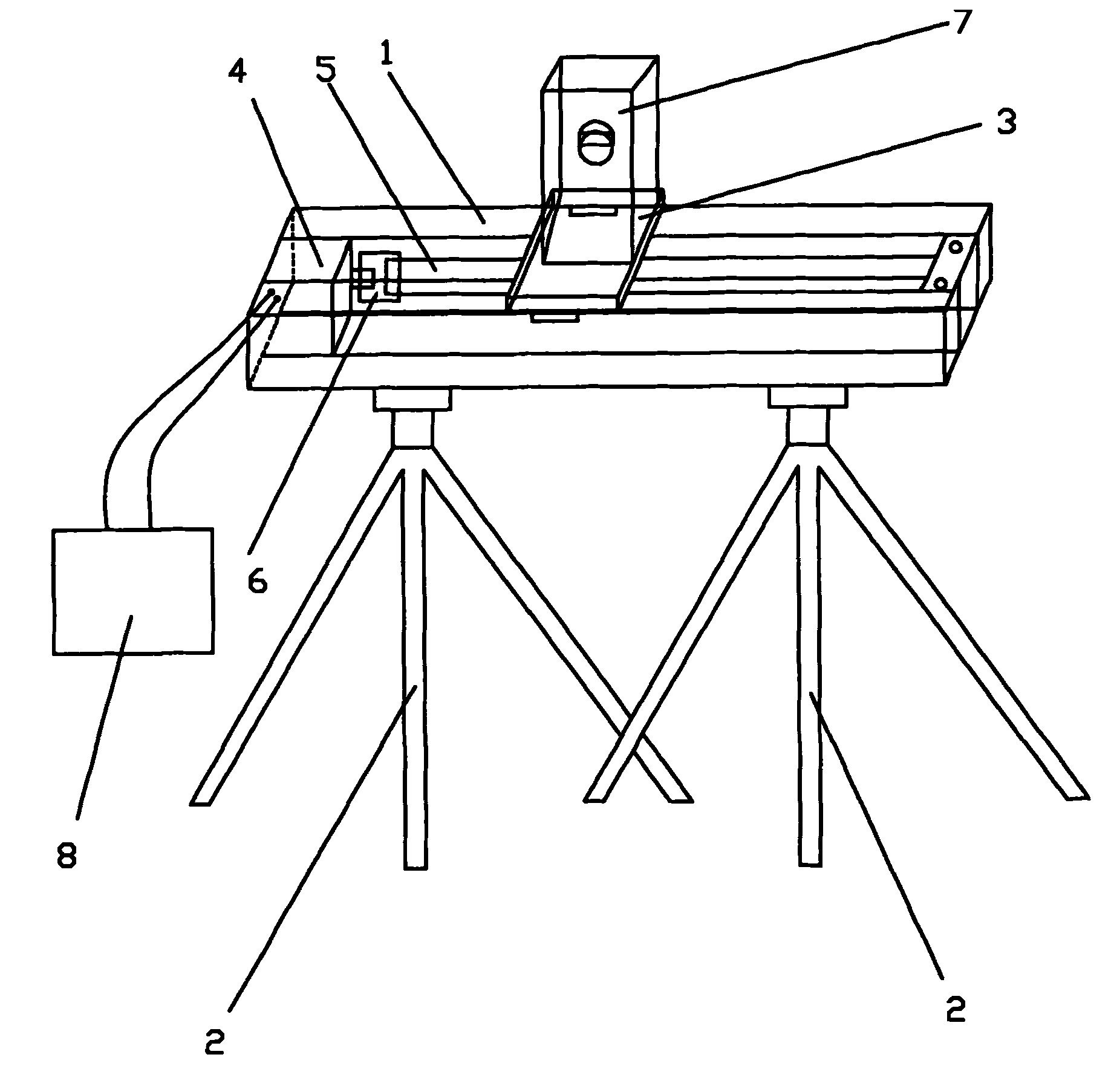

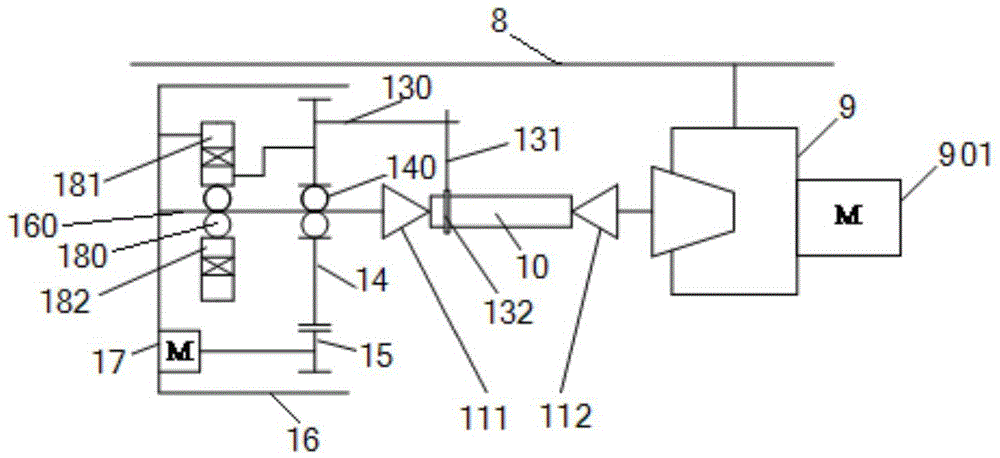

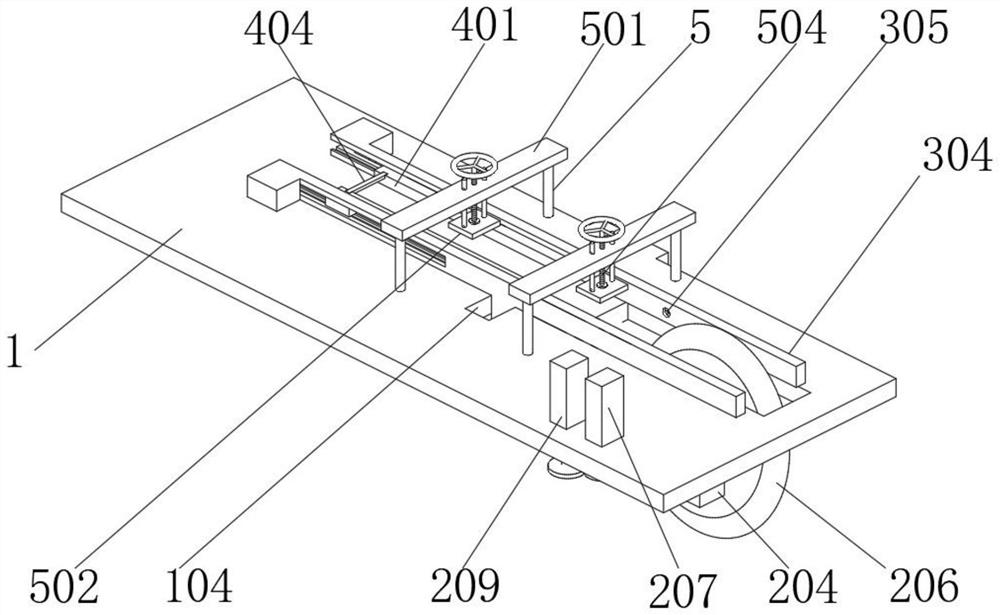

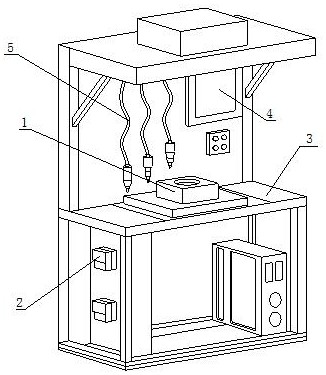

Three-dimensional image shooting device

InactiveCN102062994AImprove the shooting effectLow costStands/trestlesStereoscopic photographyEngineeringDrive motor

The invention discloses a three-dimensional image shooting device comprising a guide rail (1), a bracket (2) for supporting the guide rail, a worktable (3), a driving motor (4), a camera and a controller. The worktable (3) is arranged on the guide rail (1) and can slide along the guide rail (1), the driving motor (4) drives the worktable (3) to slide, the controller (8) is electrically connected with the motor (4), the guide rail (1) is a linear guide rail, and the camera (7) is fixedly connected with the worktable (3). By adopting the three-dimensional image shooting device, the camera slides on the linear guide rail along with the worktable and continuously shots a plurality of images at different angles; the vision angles of the obtained images can be adjusted through software so as to meet the need for combining three-dimensional images; the linear guide rail is adopted to decrease the cost of the shooting device and omit the fine tuning of the angle and the focus as compared with a curve guide rail; and the camera and the worktable are directly fixed to avoid accuracy error and shooting joggling brought by the rotation of a camera in the prior art and ensure good shooting effect.

Owner:李建华

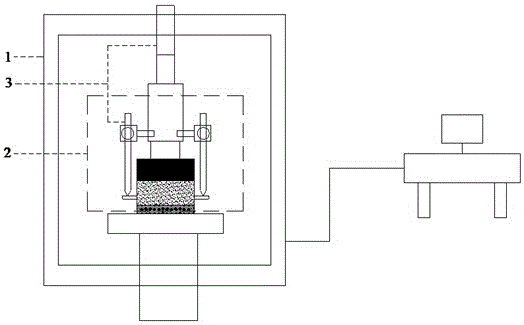

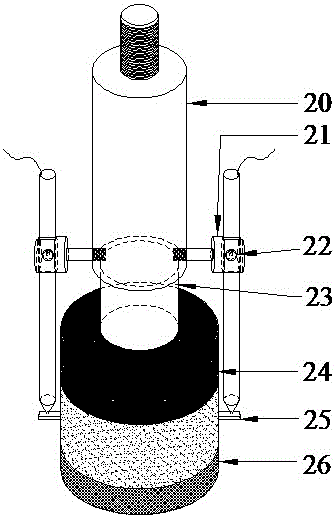

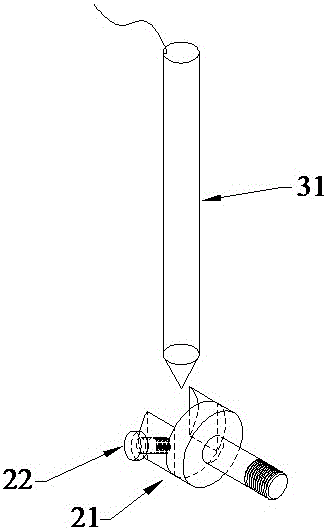

Testing device of rigid and flexible composite test piece asphalt layer rebound modulus and method thereof

ActiveCN106644727AEliminate the effects ofAvoid precision errorsClimate change adaptationMaterial strength using tensile/compressive forcesData acquisitionEngineering

The invention discloses a testing device of rigid and flexible composite test piece asphalt layer rebound modulus and a method thereof; the device comprises a loading system, a clamping system and a data collecting system; the loading system is a MTS hydraulic servo material tester; the clamping system respectively comprises a shaft coupler, a clamp, a rotary button, a pressing head, a blocking base and a rubber cushion from top to bottom; through the shaft coupler, the clamping system is closely meshed with the loading system; a real road structure is simulated through the rigid and flexible composite test piece and the rubber cushion naturally placed beneath the test piece; the composite test piece is loaded through the pressing head, and the clamping data collecting system measures the stress and strain of the composite test piece asphalt layer during the loading process; through processing and calculating the measured stress and strain data, the test of the composite structural asphalt layer rebound modulus can be realized finally.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

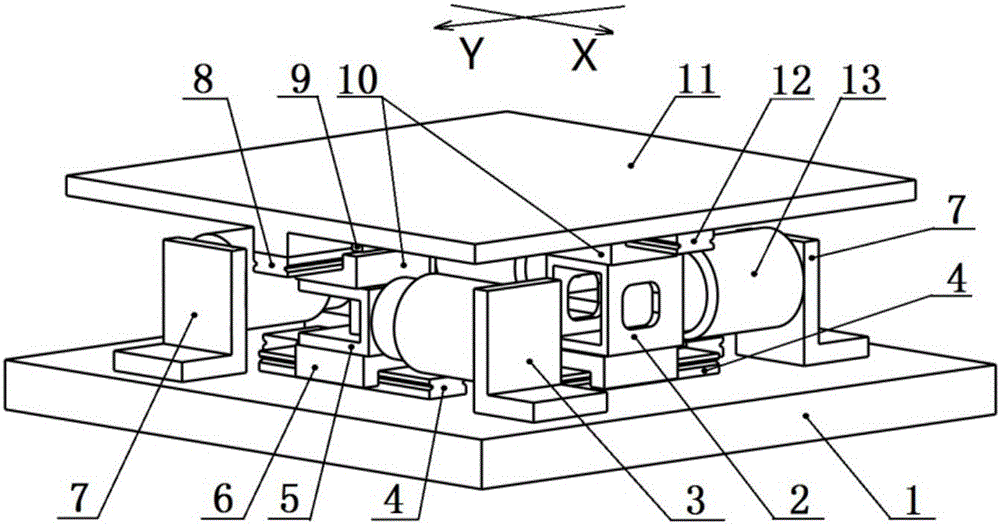

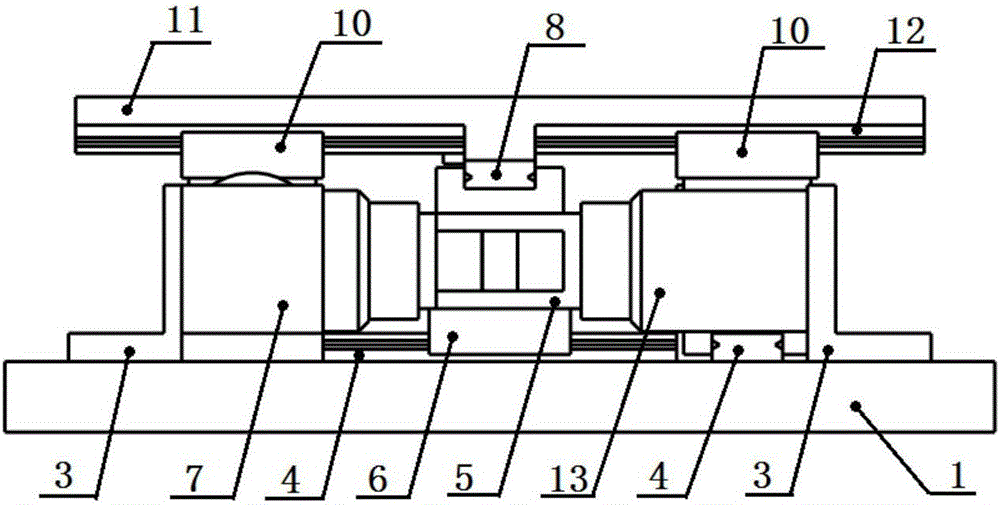

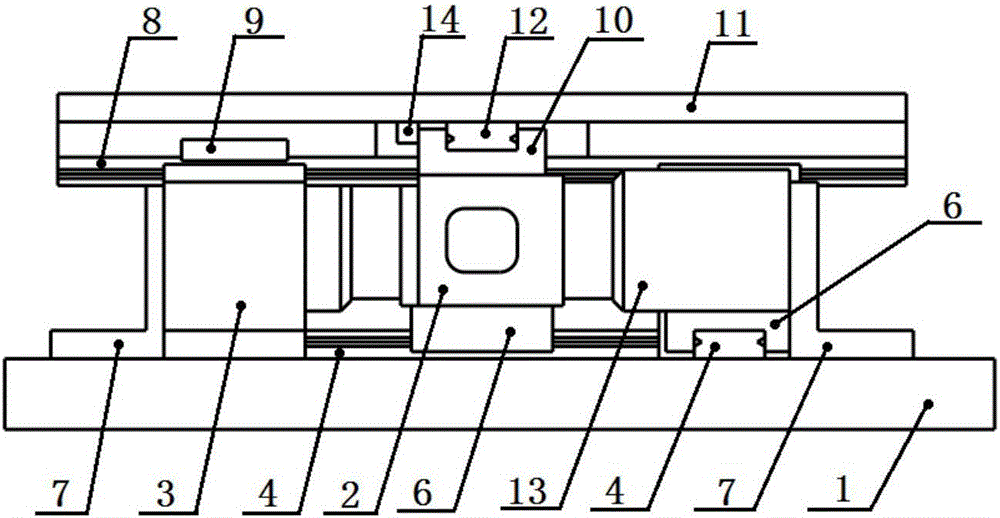

Antisymmetric parallel connection direct drive motion decoupling high-precision servo platform

ActiveCN106393070AGood linear relationshipEasy to controlProgramme-controlled manipulatorLinear driveMotion direction

The invention discloses an antisymmetric parallel connection direct drive motion decoupling high-precision servo platform. The antisymmetric parallel connection direct drive motion decoupling high-precision servo platform comprises a base, a movement flat plate, a first guide rail and a second guide rail; the first guide rail and the second guide rail are both fixed to the movement flat plate and are perpendicular to each other; the base is provided with a first slide rail parallel to the first guide rail and a second slide rail parallel to the second guide rail; the first slide rail and the second slide rail are each provided with a linear driving device in a matched manner; the first slide rail and the second guide rail are connected through a first slider; the second slide rail and the first guide rail are connected through a second slider; the linear driving device on the first slide rail drives the first slider to move so as to drive the movable flat plate to move in the X direction; and the linear driving device on the second slide rail drives the second slider to move so as to drive the movable flat plate to move in the Y direction, and therefore motion decoupling in the two movement directions of X and Y is achieved.

Owner:SHANDONG UNIV

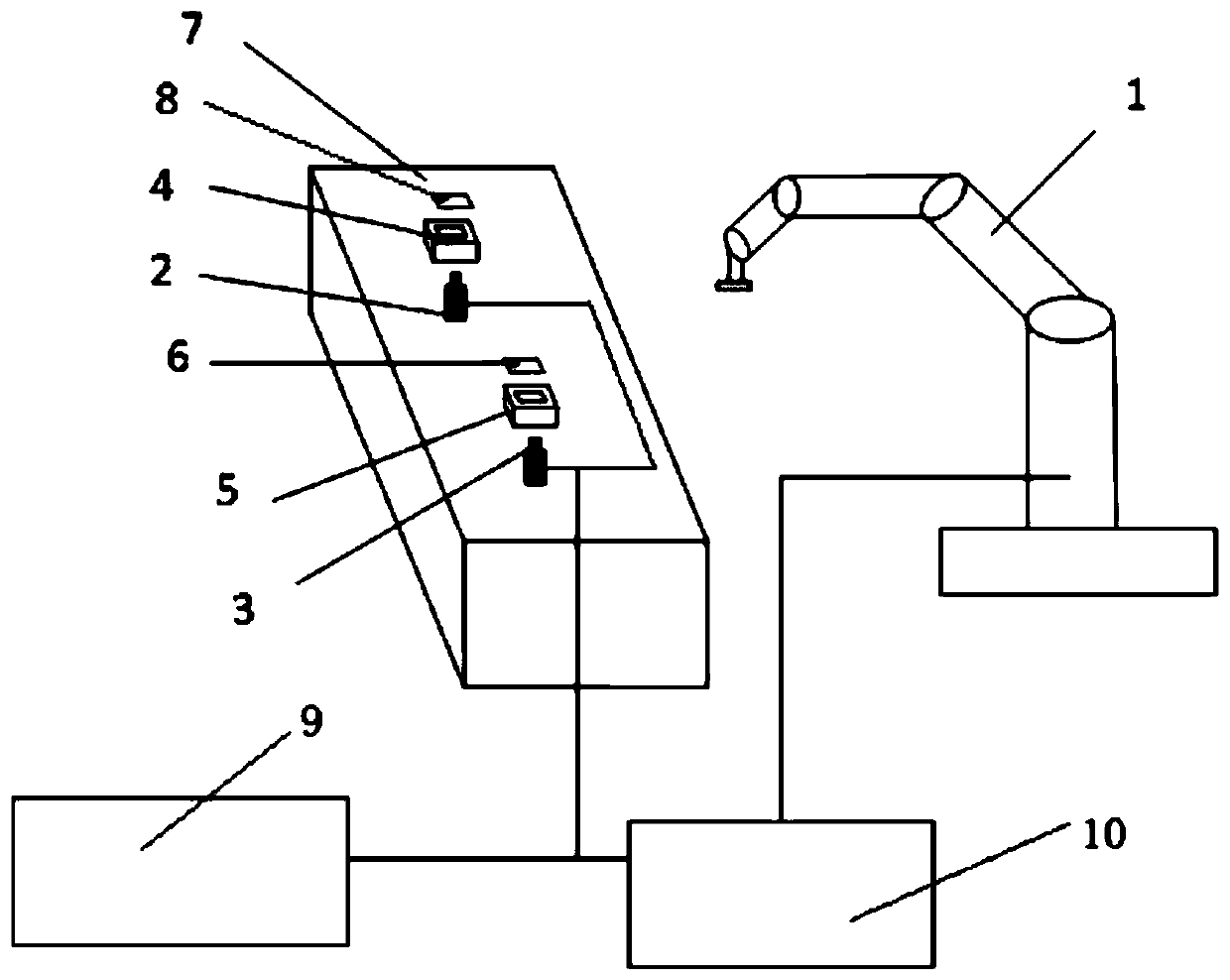

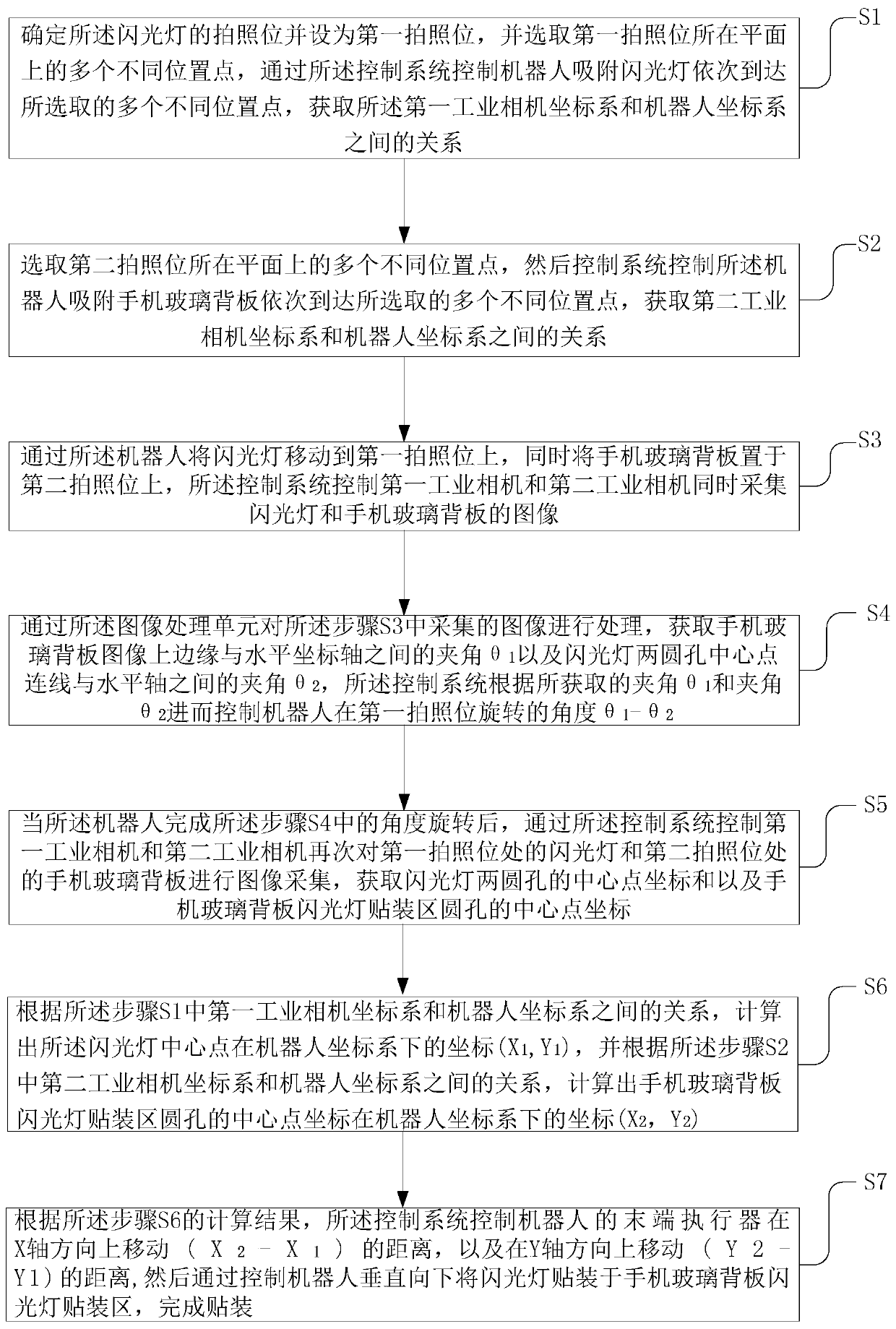

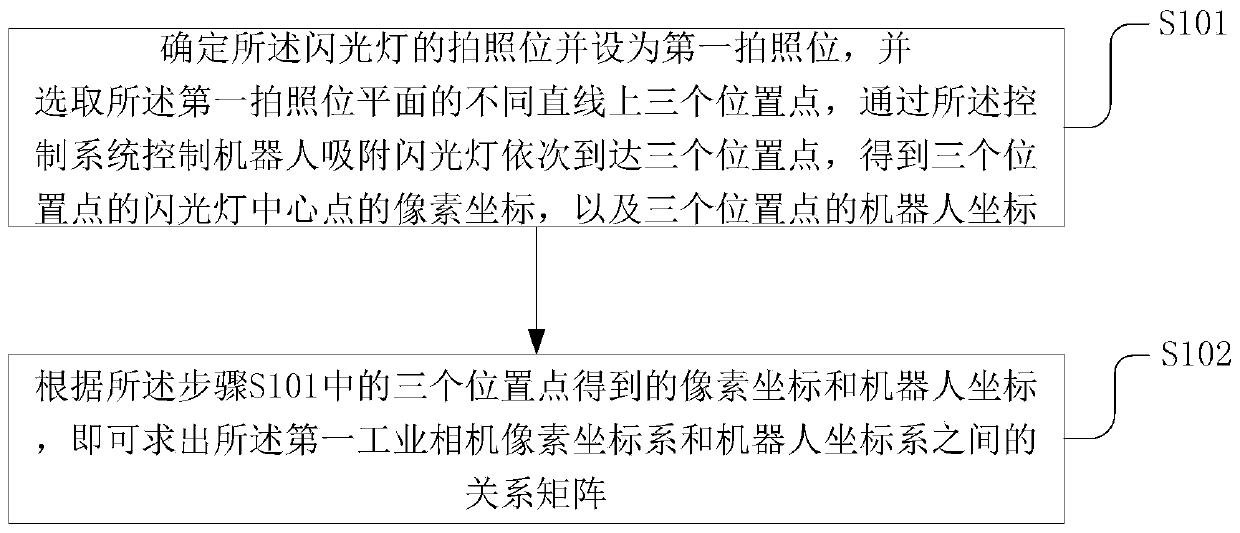

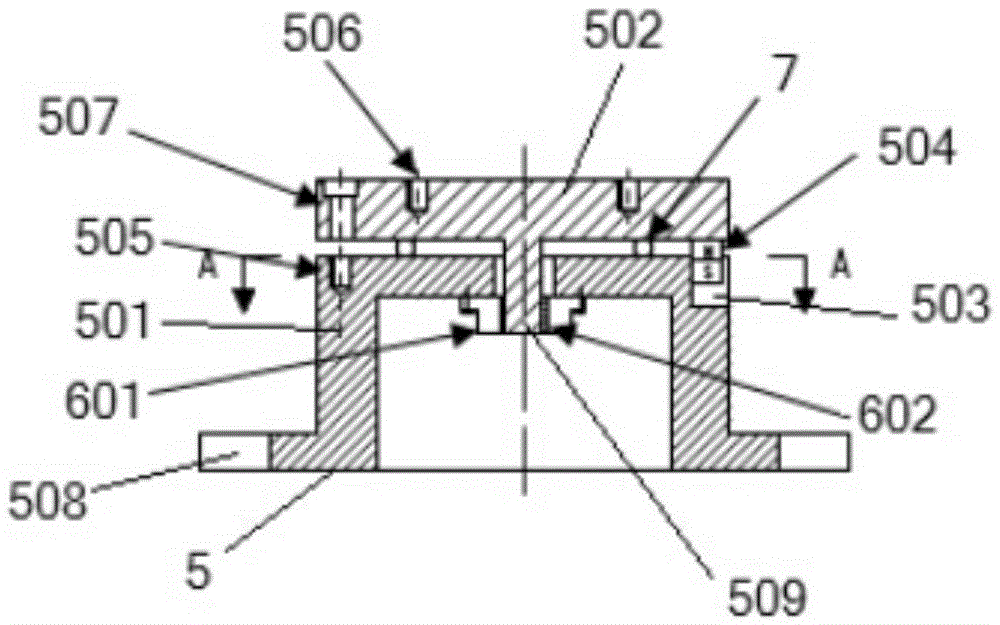

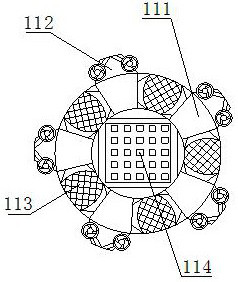

Robot-vision-guided mobile phone flashlight assembling system and method

ActiveCN109719734AOptimize locationConvenient angleProgramme-controlled manipulatorComputer visionRobot vision

The invention discloses a robot-vision-guided mobile phone flashlight assembling system and method. The robot-vision-guided mobile phone flashlight assembly system comprises a worktable, a first industrial camera, a second industrial camera, a robot, a vision system and a control system. The robot-vision-guided mobile phone flashlight assembly method comprises the steps that firstly, the positionsof the industrial cameras and the photographing position are determined, a camera coordinate system and a robot coordinate system are calibrated, then images of a flashlight and a mobile phone glassbackplane are collected by the industrial cameras to complete angle compensation of a robot, then the images of the flashlight and the glass backplane of the mobile phone are collected again by the industrial cameras to complete coordinate compensation of the robot, and finally, the flashlight is mounted on the mobile phone glass backplane in a pasted mode to complete assembling. By collecting theimages of the flashlight and the mobile phone glass backplane, angle compensation and coordinate compensation of the robot are completed, the position change or the angle change possibly generated inthe process of sucking and moving the flashlight is relieved, assembly accuracy is improved, and the characteristics of wide application range and high flexibility are achieved.

Owner:HUNAN UNIV

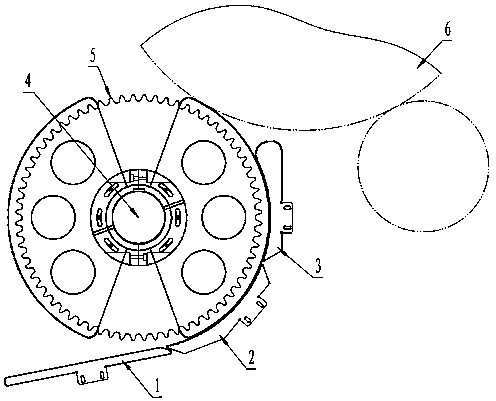

On-machine detection device and detection method of worm gear pair transmission precision

ActiveCN105598534AAvoid installation structuresEasy to measureGear-cutting machinesGear teethAngular degreesEngineering

The invention discloses an on-machine detection device of the worm gear pair transmission precision. The detection device comprises a rotary table for installing a worm gear and a tool for installing a worm, a worm gear angular displacement sensor which detects the rotation angle of the worm gear is installed in the rotary table, a worm angular displacement sensor which detects the rotation angle of the worm is installed on the tool, the worm gear angular displacement sensor and the worm angular displacement sensor are in output connection with a worm gear detector, the tool is provided with a bracket, a sliding plate located above the bracket and a pair of fixed centers for supporting the two ends of the worm, a driving motor is arranged on the bracket and drives a gear transmission set, and a rotor of the worm angular displacement sensor and a tail end gear coaxially and synchronously rotate to measure the rotation angel of the worm; the rotary table comprises an installation table and a base which can rotate relatively, a rotor of the worm gear angular displacement sensor is coaxially installed on a protruding column of the installation table, and a stator of the worm gear angular displacement sensor is fixedly connected with the base. The invention further discloses an on-machine detection method of the worm gear pair transmission precision. By means of the on-machine detection device and detection method of the worm gear pair transmission precision, the on-machine detection problem of the worm gear pair transmission precision is solved.

Owner:CHONGQING UNIV OF TECH

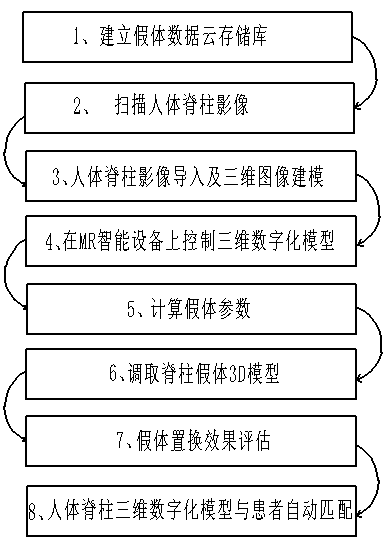

Prosthesis replacement surgery simulation system based on mixed reality technology and construction method

PendingCN110174953AEasy positioningHigh precisionInput/output for user-computer interactionMedical imagesInformatizationHuman body

The invention relates to the technical field of medical informatization, in particular to a spinal prosthesis replacement surgery simulation system based on a mixed reality technology and a construction method, and the method comprises the following steps: (1) establishing a prosthesis data cloud storage library, and recording and storing images and data information of spinal prosthesis models ofvarious parameters; step (2), scanning a human spine image, including a CT scanning image or a nuclear magnetic scanning image; (3) carrying out human body spine image import and three-dimensional image modeling; (4) controlling the three-dimensional digital model of the human body spine image on the MR intelligent equipment; (5) calculating prosthesis parameters; step (6), calling a spinal prosthesis 3D model; step (7), carrying out prosthesis replacement effect evaluation; and (8) automatically matching the human body spine three-dimensional digital model with the patient. The precision andspeed of the prosthesis replacement operation can be improved, the operation time is shortened, and the operation pain is relieved.

Owner:无锡蓝软智能医疗科技有限公司

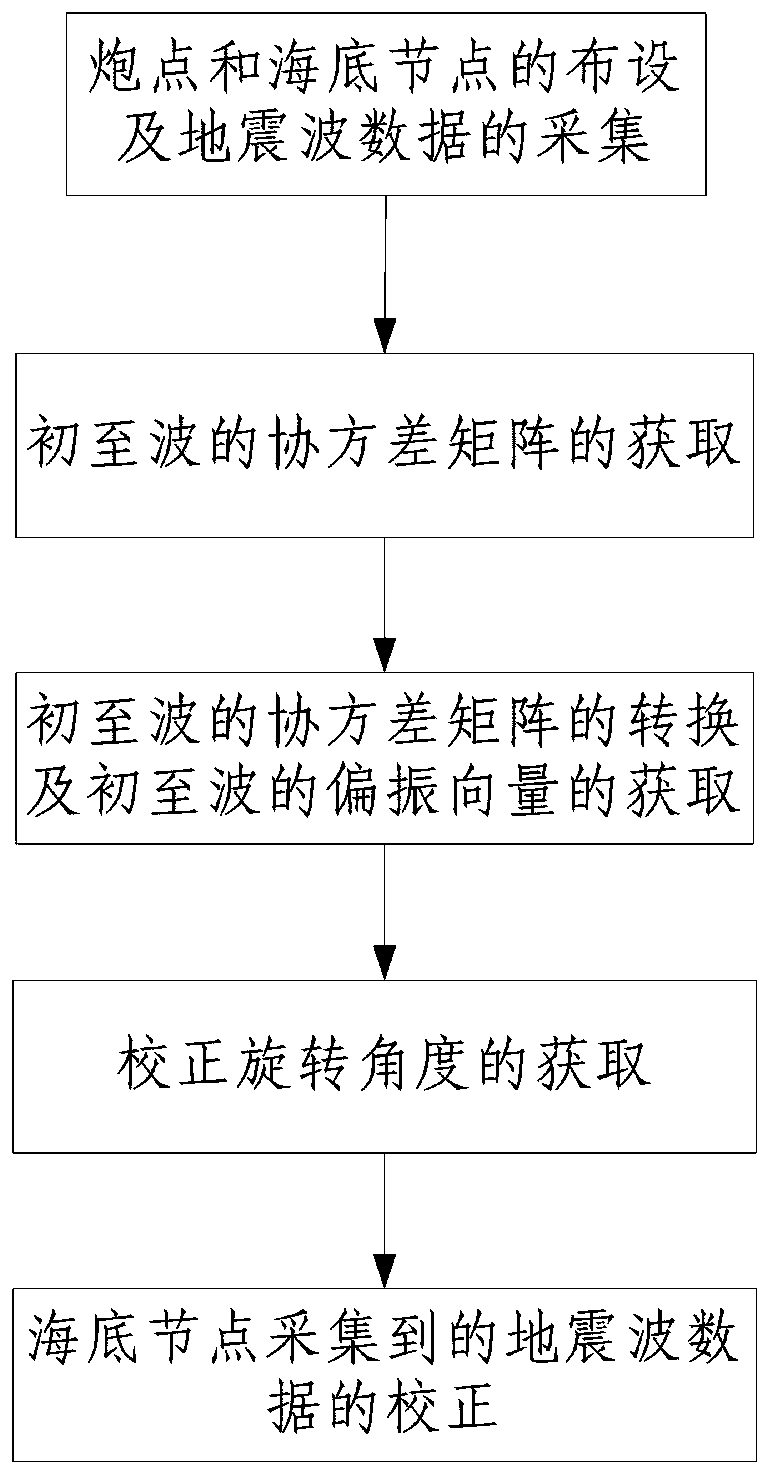

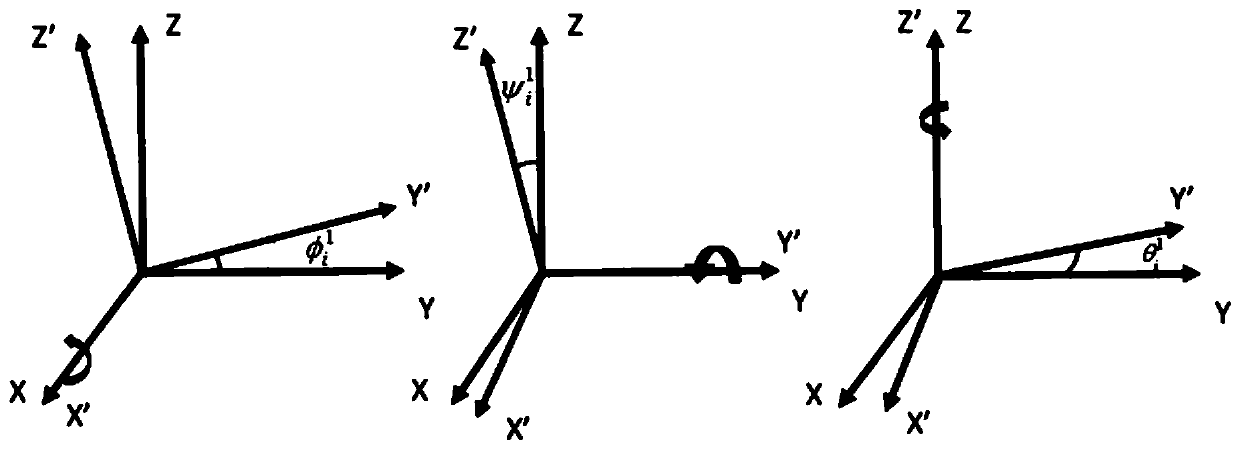

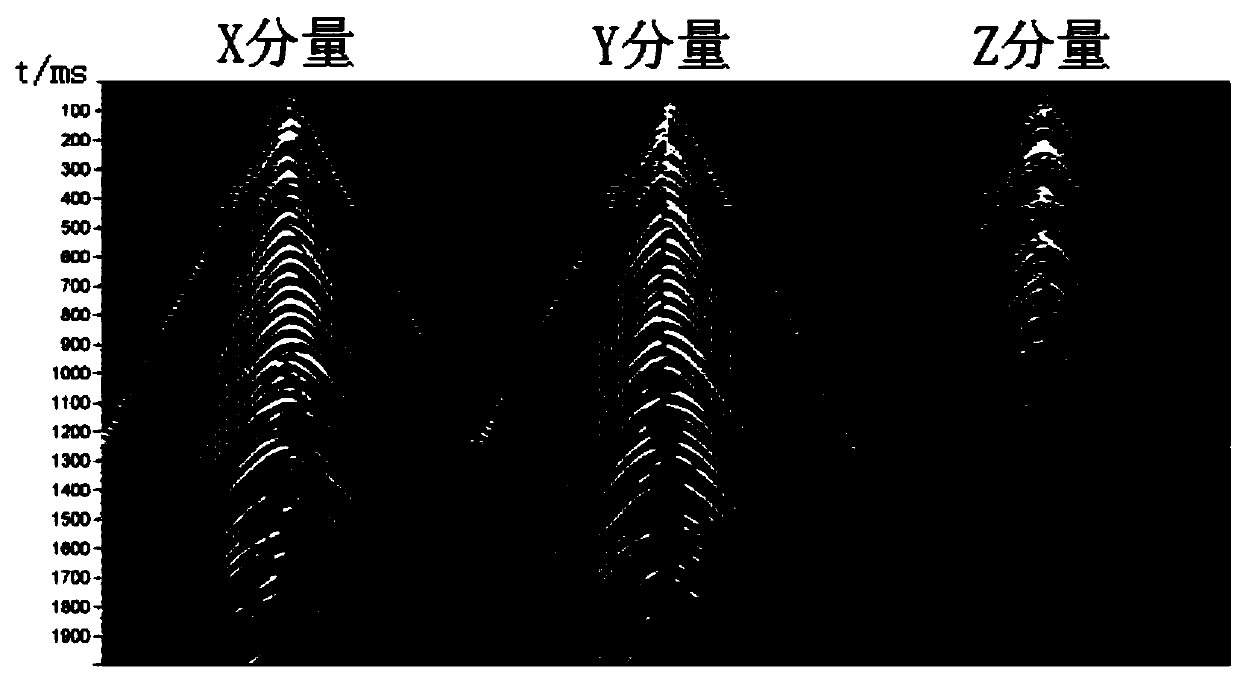

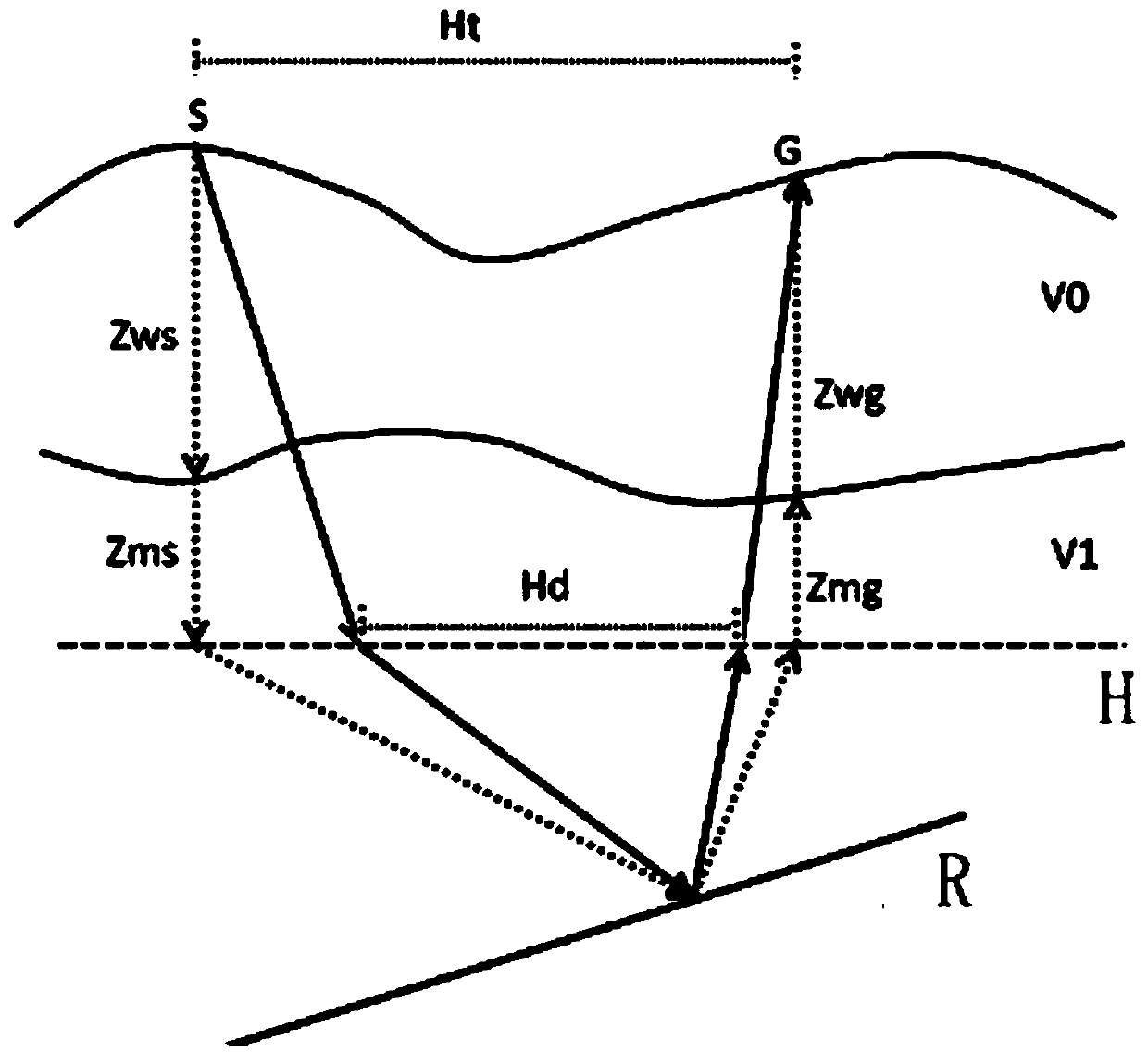

Three-component directional correction method of submarine node seismograph

ActiveCN110687606AHigh precisionSimple stepsSeismic signal processingSeismology for water-covered areasEngineeringStructural engineering

The invention discloses a three-component directional correction method of a submarine node seismograph. The method comprises the following steps: (1) arranging a shot point and a submarine node, andcollecting seismic wave data; (2) obtaining a covariance matrix of a preliminary wave; (3) converting the covariance matrix of the preliminary wave, and obtaining a polarization vector of the preliminary wave; (4) obtaining a correction rotating angle; and (5) collecting the seismic wave data collected by the submarine node. According to the three-component directional correction method disclosedby the invention, the three-component directional correction is performed by using the polarization characteristics of the refracted waves, and the problems of insufficient accuracy and limitation ofthree-component redirection by using direct waves can be solved.

Owner:CHANGAN UNIV

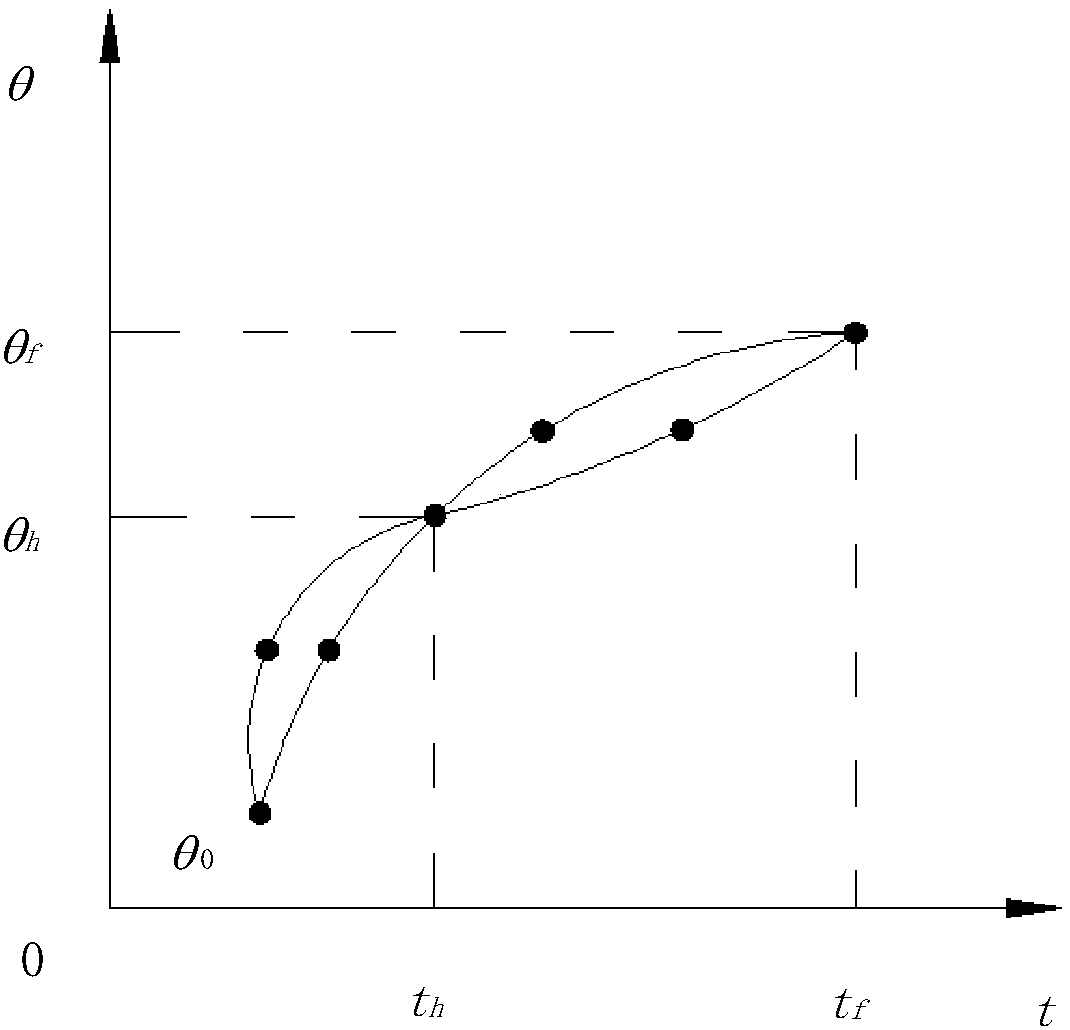

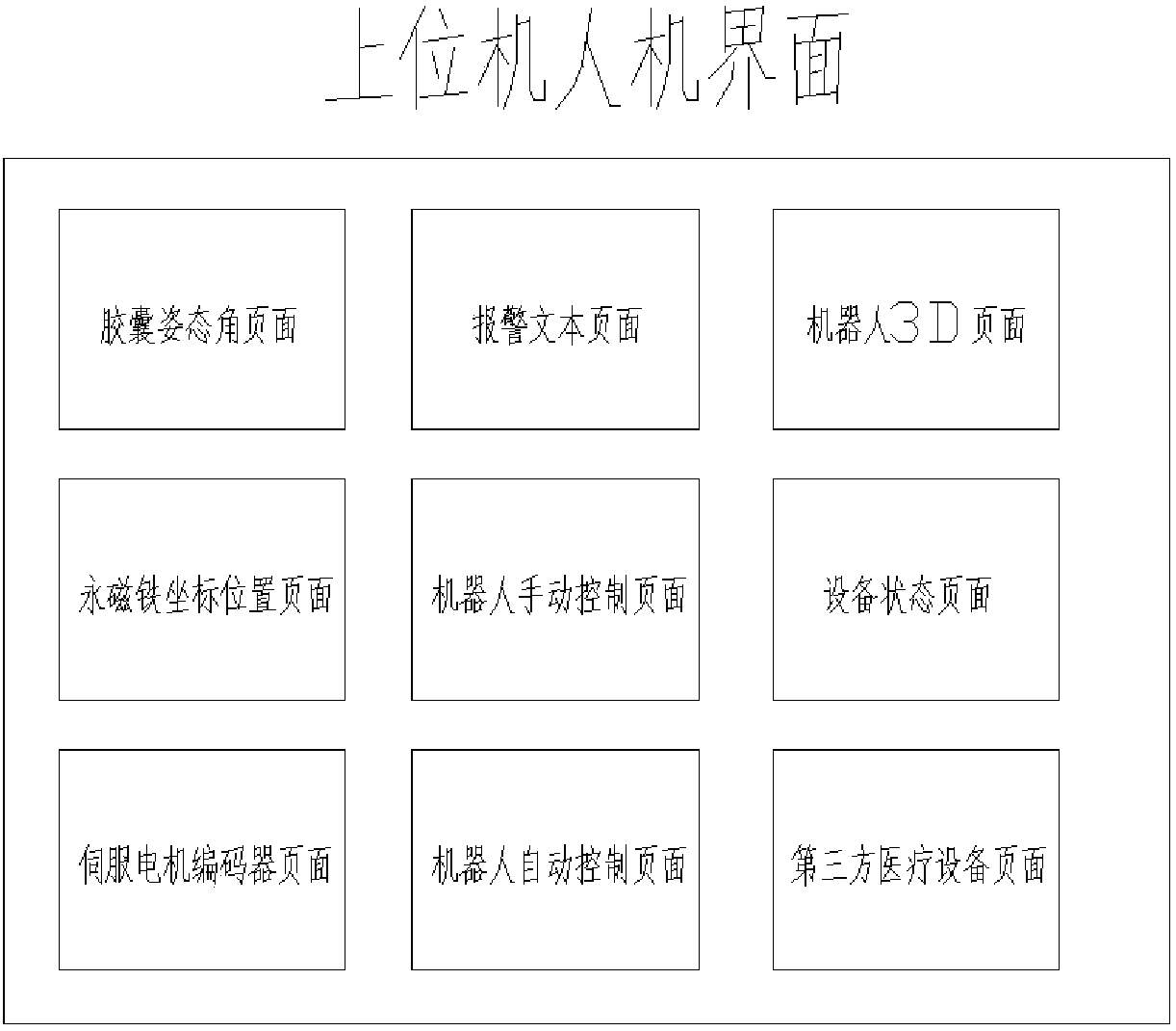

Control system of capsule endoscope

InactiveCN108175368AAvoid precision errorsHigh movement precisionGastroscopesOesophagoscopesCapsule EndoscopesMagnet

The invention discloses a control system of a capsule endoscope. The control system comprises a control end and a robot body. A magnet for pulling the capsule endoscope is fixed to the robot body. Thecontrol end generates a control instruction according to parameters of preset detection position points by means of a robot multi-axis interpolation control algorithm and sends the control instruction to the robot body; the robot body analyzes the control instruction to obtain a movement trajectory curve, and the automatic pulling capsule endoscope automatically goes to all the preset position points according to the movement trajectory curve for multi-angle camera shooting. It can be seen that by means of the system, the automatic pulling capsule endoscope is obtained by controlling the robot body for comprehensive scanning. The robot body is automatically pulled, no fatigue problem can be generated after the robot body operates for a long time, the robot body is pulled according to themovement trajectory curve, the precision errors caused by manual pulling can be avoided, and the movement precision is improved, the robot body can be kept at an ideal adsorption position.

Owner:CHONGQING JINSHAN MEDICAL INSTR CO LTD

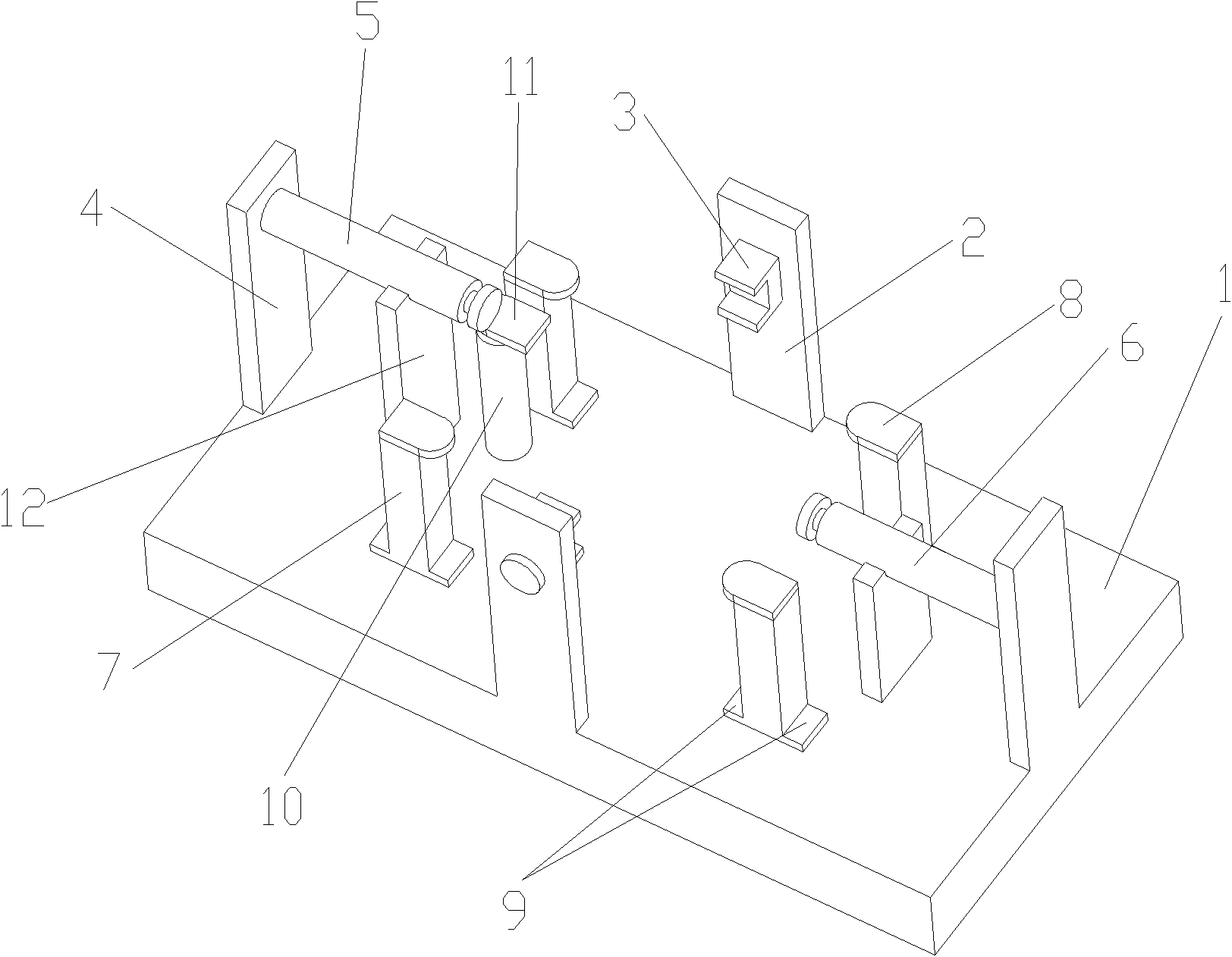

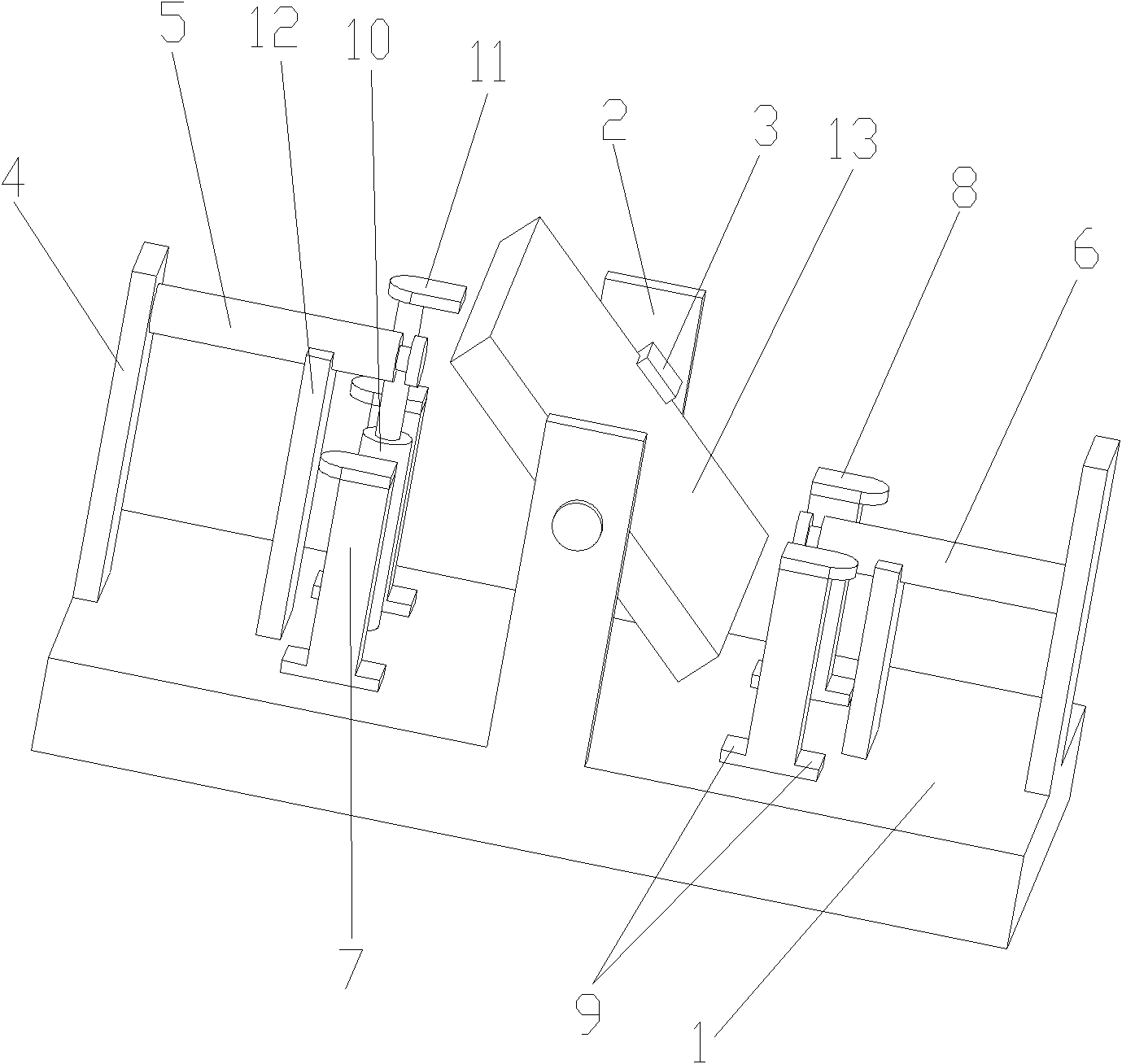

Flat-plate double-side drill jig

InactiveCN102581643AEasy to operateImprove machining accuracyMetal working apparatusPositioning apparatusEngineeringBilateral symmetry

The invention discloses a flat-plate double-side drill jig, which comprises a bottom plate, first mounting plates, fixed blocks, second mounting plates, a first air cylinder, a second air cylinder, vertical posts, rotating disks, sensors, a third air cylinder and a lifting plate. The first mounting plates are disposed on the upper surface of the bottom plate in vertical symmetry, and the second mounting plates are disposed on the upper surface of the bottom plate in bilateral symmetry. One reversible fixed block is mounted at the inner end of each first mounting plate. The first air cylinder and the second air cylinder horizontally mounted are disposed on the second mounting plates. At least two vertical posts are disposed on the bottom plate in bilateral symmetry. One rotatable rotating disk is disposed at the upper end of each vertical post. Two sensors are disposed at the left lower end and the right lower end of each vertical post. The third air cylinder vertically mounted is disposed on the bottom plate. The lifting plate is disposed on the third air cylinder. The flat-plate double-side drill jig is convenient in operation. After a flat plate to be drilled on both sides is set, both-side drilling can be performed without secondary mounting, so that precision errors caused by repeated mounting is avoided and machining precision of the flat plate is improved.

Owner:SUZHOU FUMAI PRECISION MACHINERY

Anti-smearing paper flattening device applicable to quality detection system of dry offset press

ActiveCN103954633ANo bendingNo deformationMaterial analysis by optical meansPulp and paper industrySprocket

The invention discloses an anti-smearing paper flattening device applicable to a quality detection system of a dry offset press. The anti-smearing paper flattening device comprises a hollow spoke type roller of the dry offset press and a plurality of strip-shaped paper flattening sheets, wherein the hollow spoke type roller comprises a plurality of circular spoke sheets which are coaxially and fixedly connected with a central shaft of a paper outlet chain wheel and are distributed along the central shaft at equal intervals; each spoke sheet corresponds to one flattening sheet; each flattening sheet and the corresponding spoke sheet are located on a same plane; each flattening sheet is divided into an upper section, a middle section and a lower section; the arc-shaped sides, matched with the outer edges of the spoke sheets, of the upper sections and the middle sections of the flattening sheets lean against print products on the outer edges of the spoke sheets, and a shooting gap is formed between the arc-shaped sides and the print products; the lower sections of the flattening sheets are used for guiding the print products out to a paper chain channel. According to the anti-smearing paper flattening device applicable to the quality detection system of the dry offset press, moving tracks of paper on the dry offset press are limited by the flattening sheets, so that irregular bend, deformation, floatation and the like of the print products in a detection position are avoided, and the detection accuracy of the print products is further improved.

Owner:石家庄印钞有限公司 +1

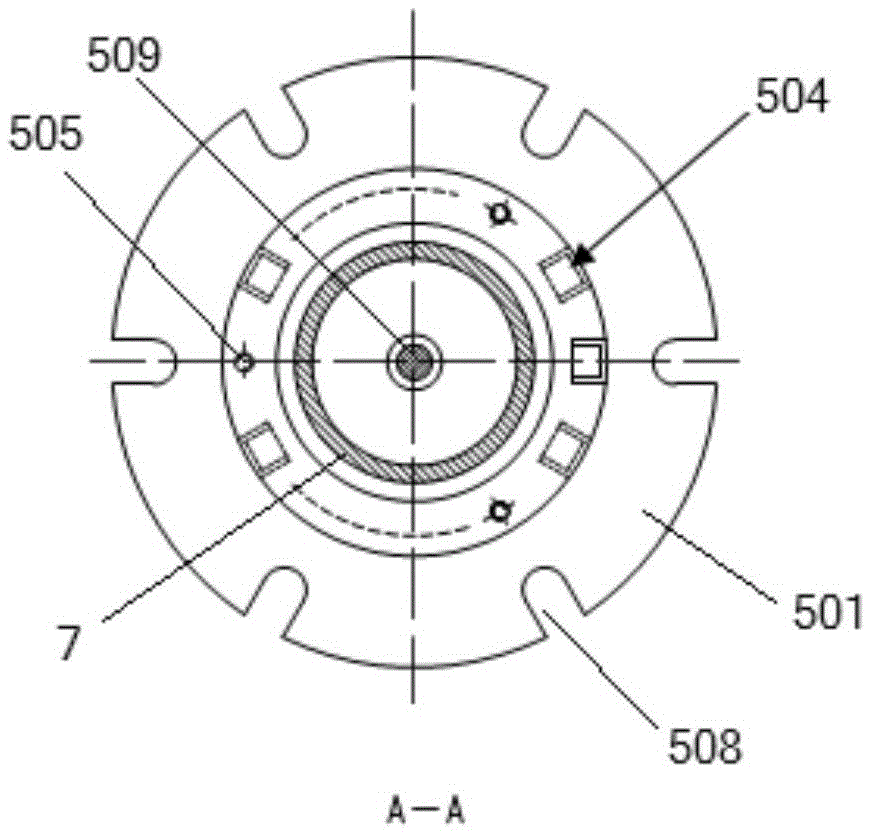

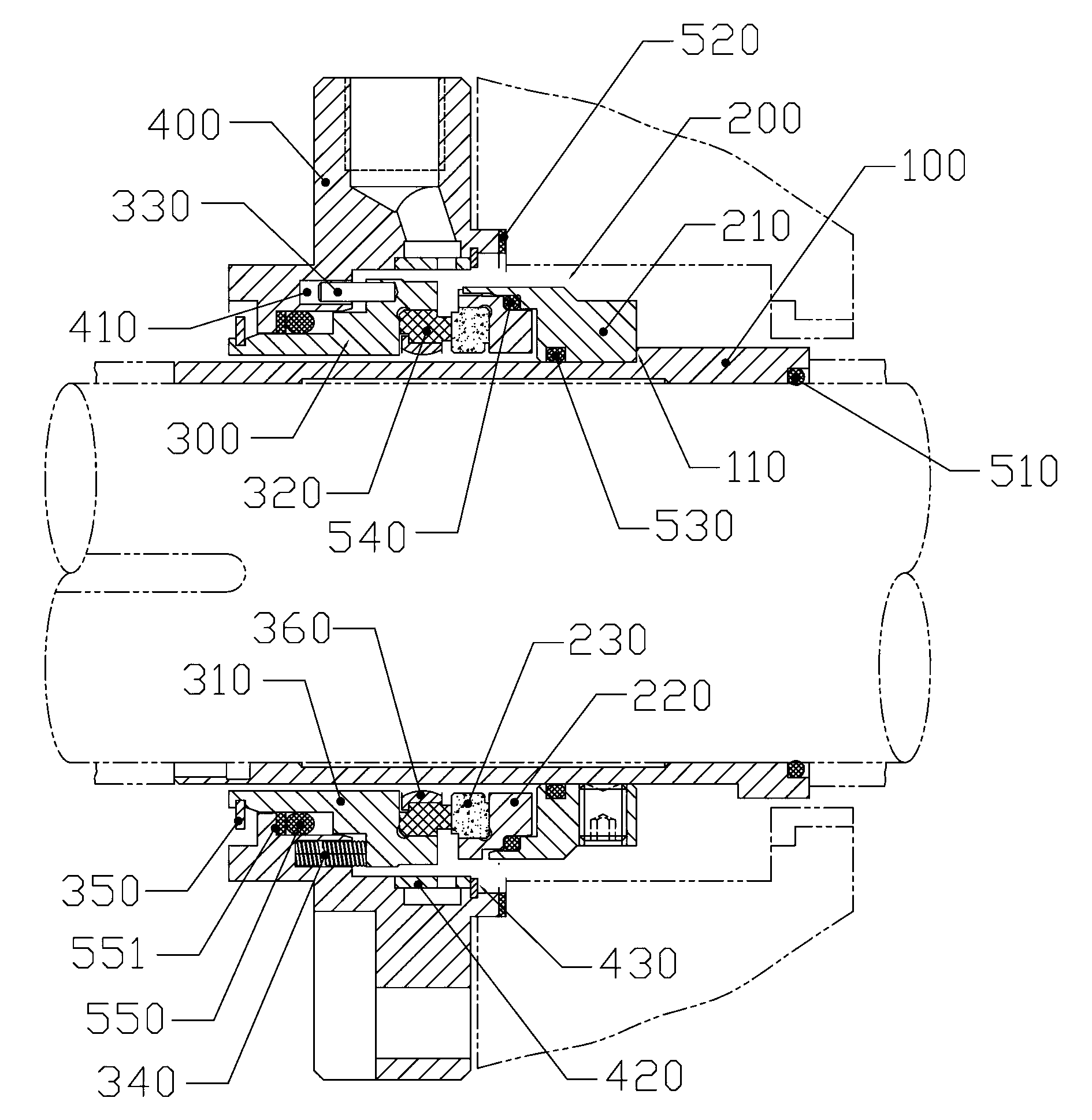

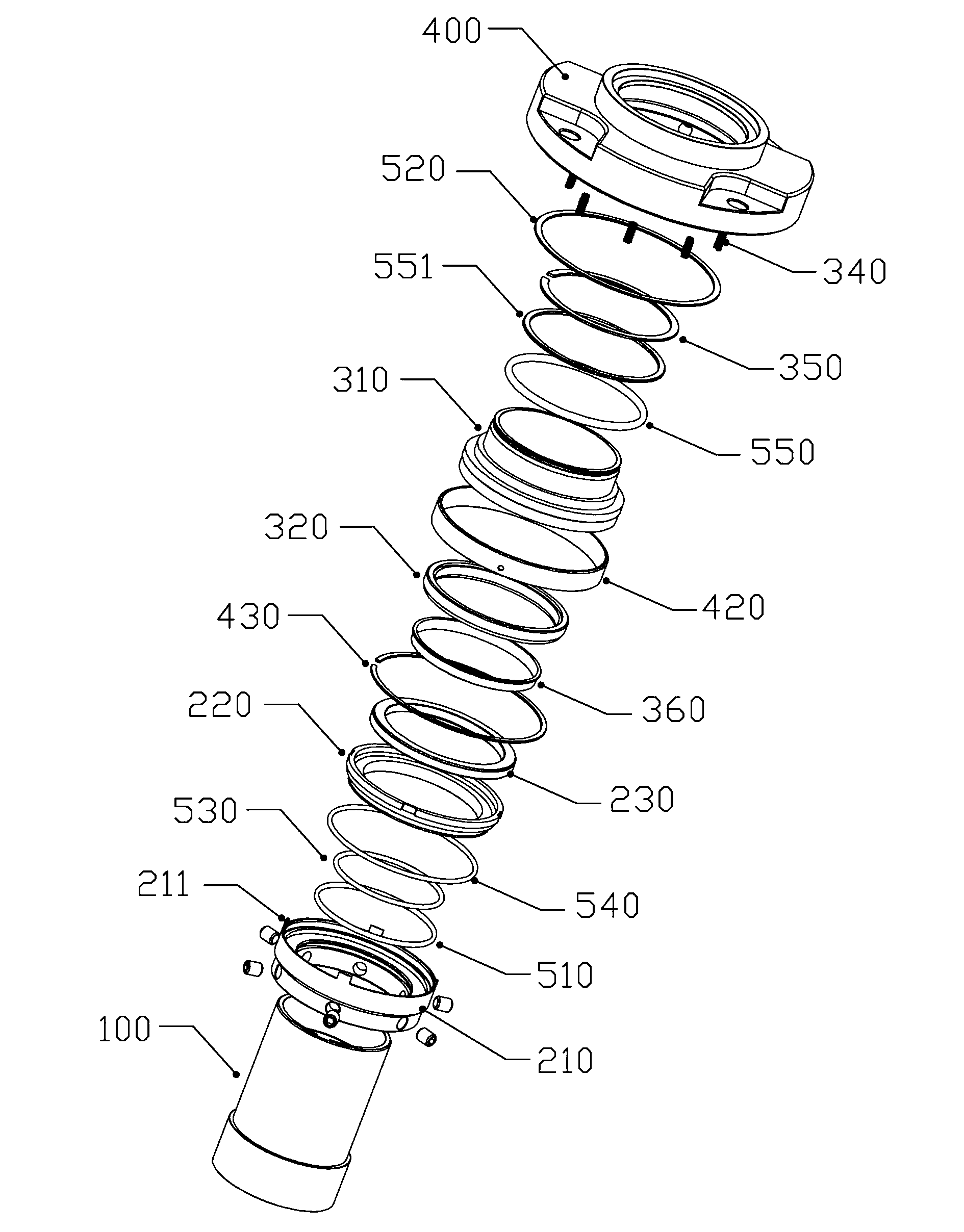

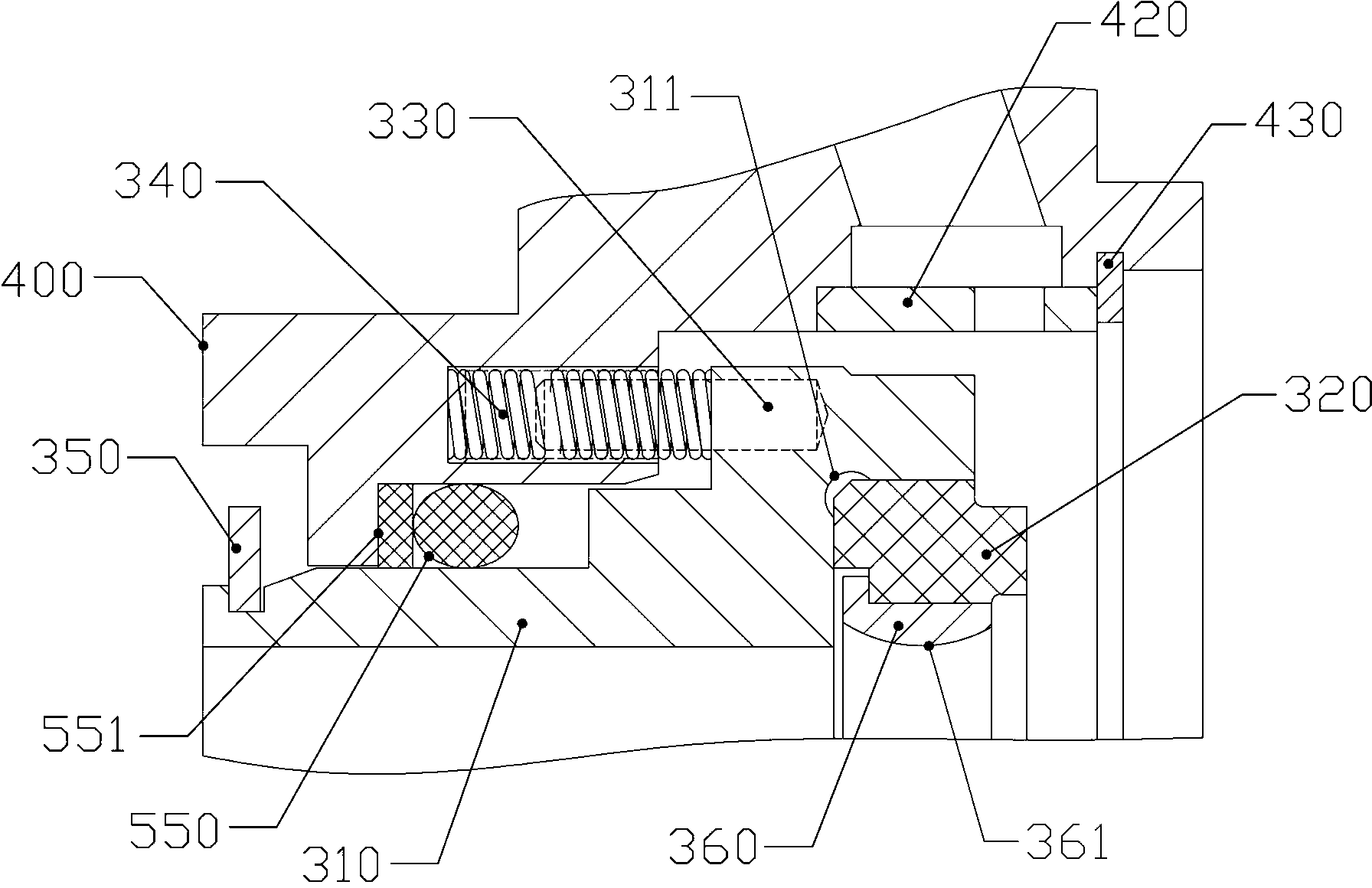

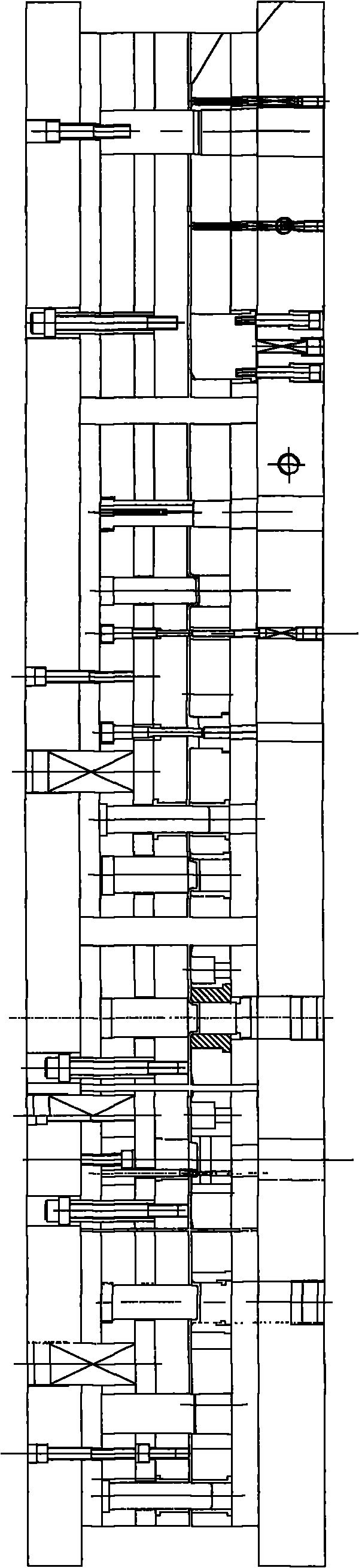

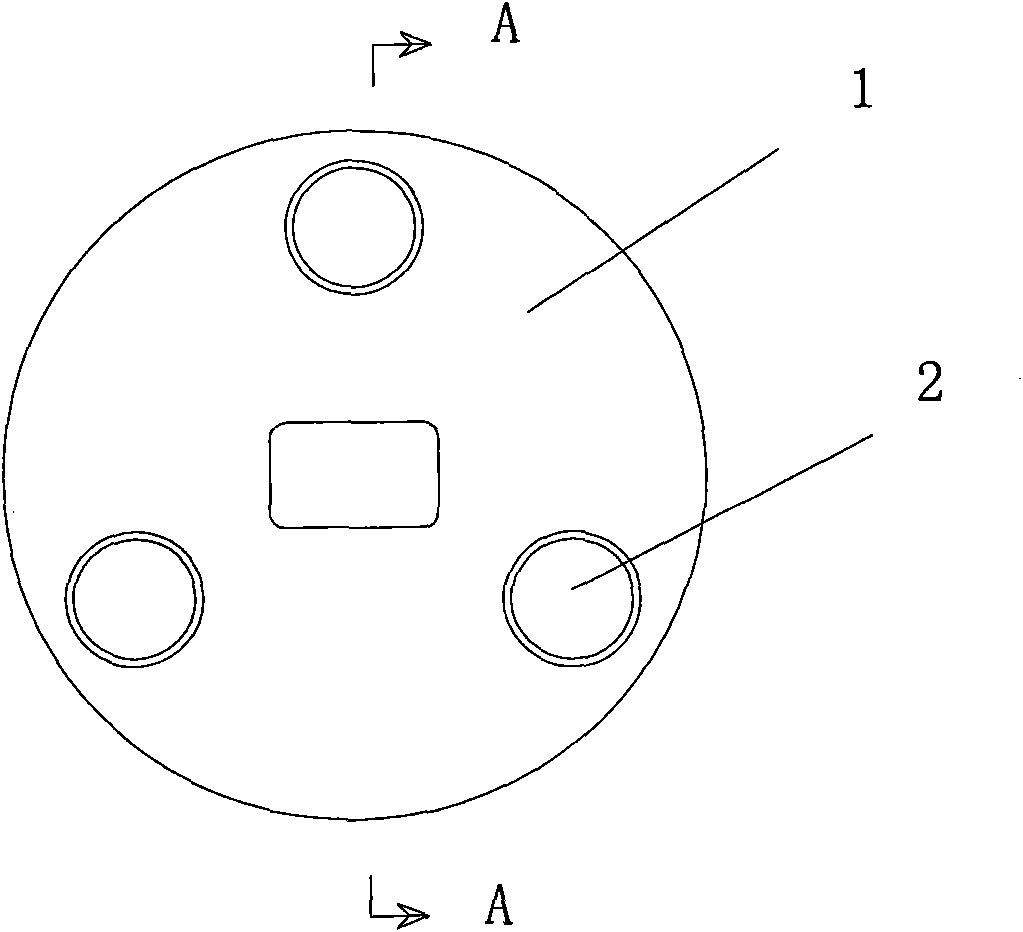

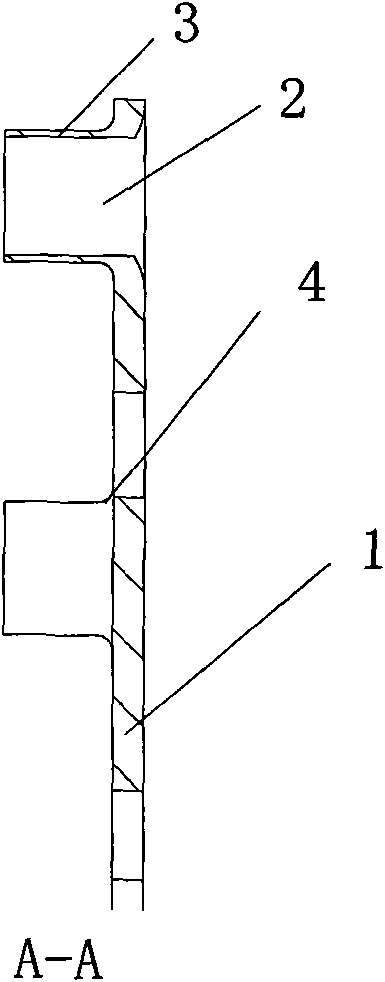

Mechanical sealing device of high-pressure water injection pump

ActiveCN103016391ATo promote floatingReduced stabilityPump componentsPumpsHigh pressure waterEngineering

The invention discloses a mechanical sealing device of a high-pressure water injection pump. A shaft sleeve is provided with a step, a movable ring assembly is fixed on the outer wall of the shaft sleeve, one end of the movable ring assembly is abutted against the step, an elastic compensation assembly comprises a stationary ring seat, a stationary ring which is embedded on the stationary ring seat, an anti-rotation pin which is arranged on the stationary ring seat and a plurality of small springs, a sealing gland bush is provided with an axial accommodating hole, a plurality of spring holes are uniformly distributed on the circumference, the anti-rotation pin is plugged into the accommodating hole and can float in the axial direction, the small springs are arranged inside the spring holes, one end of each small spring is abutted against the stationary ring seat, the tail end of the stationary ring seat stretches out of the sealing gland bush, the tail end of the stationary ring seat is provided with a clamping spring, the elastic compensation assembly is pre-installed on the sealing bland bush, the inner wall of the sealing gland bush is fixedly provided with a distribution ring, and a plurality of injection holes are uniformly distributed on the distribution ring. The elastic compensation assembly is installed in a stationary manner and free from the influence of centrifugal force, the small springs which are uniformly distributed can result in good floatability, the elastic compensation assembly is pre-installed in the sealing gland bush through the clamping ring, and the injection holes which are uniformly distributed can realize multipoint washing, so that uniformity in cooling can be realized.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

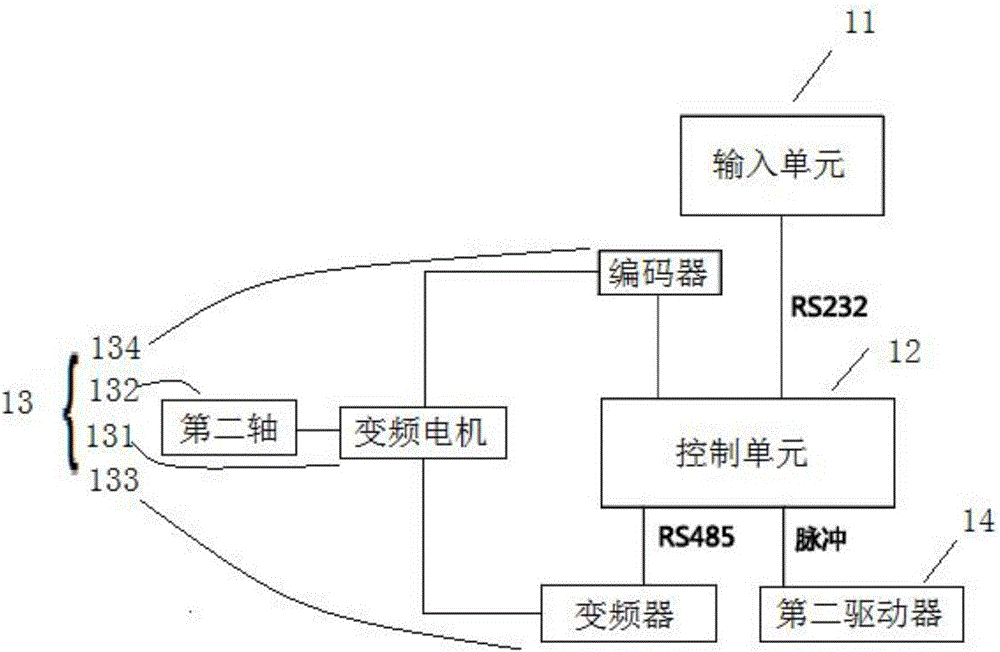

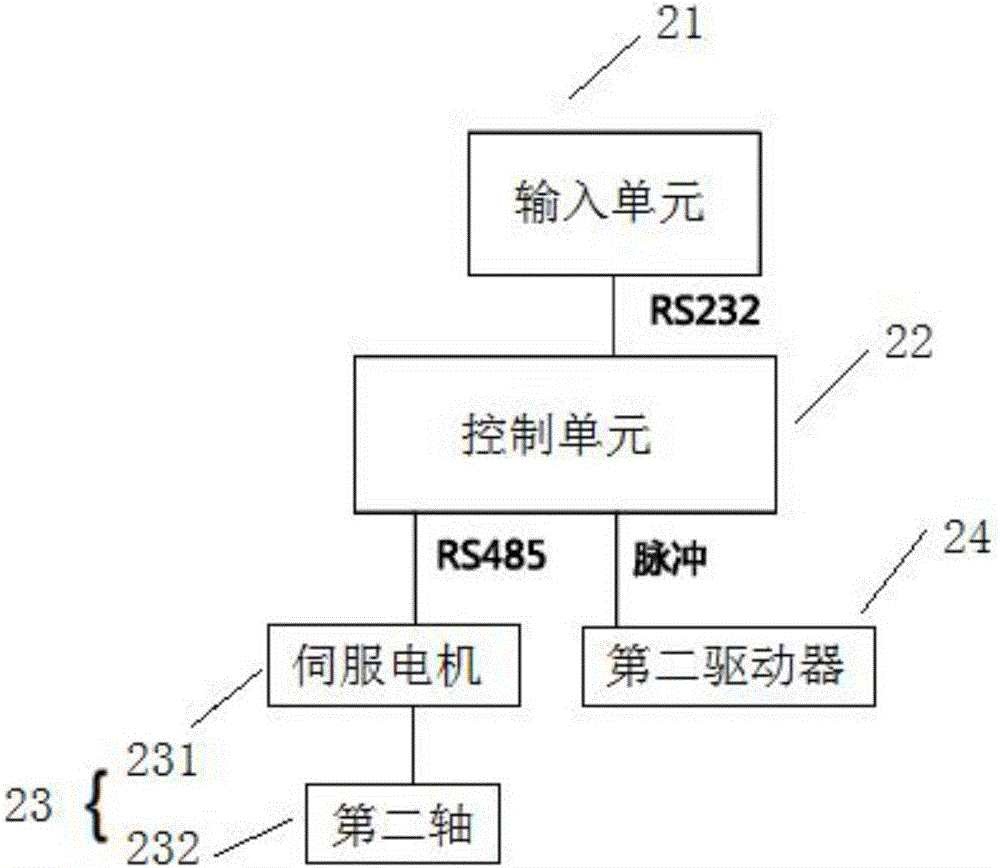

Electronic cam control system and control method

InactiveCN106597987AAvoid precision errorsEasy to manufacture and installProgramme control in sequence/logic controllersControl systemAssembly line

The invention provides an electronic cam control system and a control method. The electronic cam control system is intended for filling an assembly line and includes an input unit, a control unit, a first driver and a second driver. The input unit transmits control parameters to the control unit. The control unit moves the first driver based on the control parameters. The control unit moves the second drive based on the move of the first driver. The first driver and the second driver move linearly. According to the method, the control unit moves the second driver based on the move of the first driver, replaces traditional mechanical cams with electronic motion-controlled cams, thus simplifying the manufacturing, installation, operation and maintenance of devices and reducing mechanical breakdown. The electronic cam control system uses the characteristics of electronic cams to set production scale of choice and obviates the need for the exchanging of mechanical apparatuses.

Owner:DELTA GREENTECH CHINA CO LTD

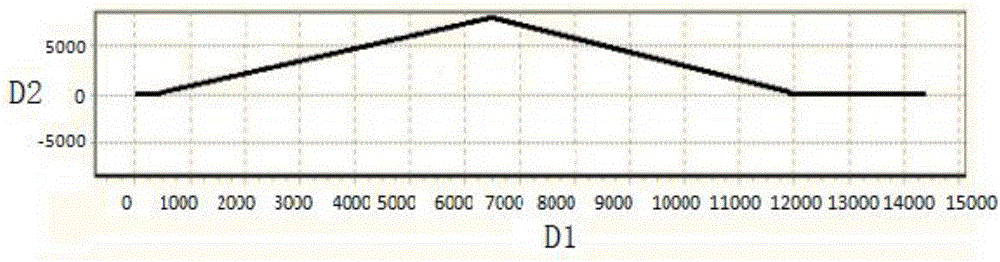

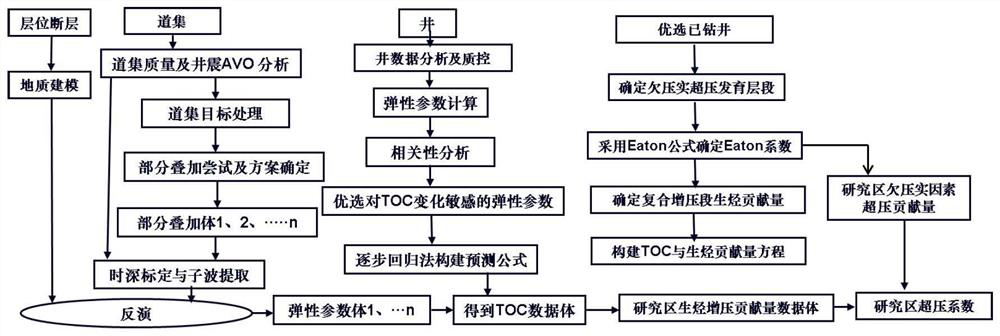

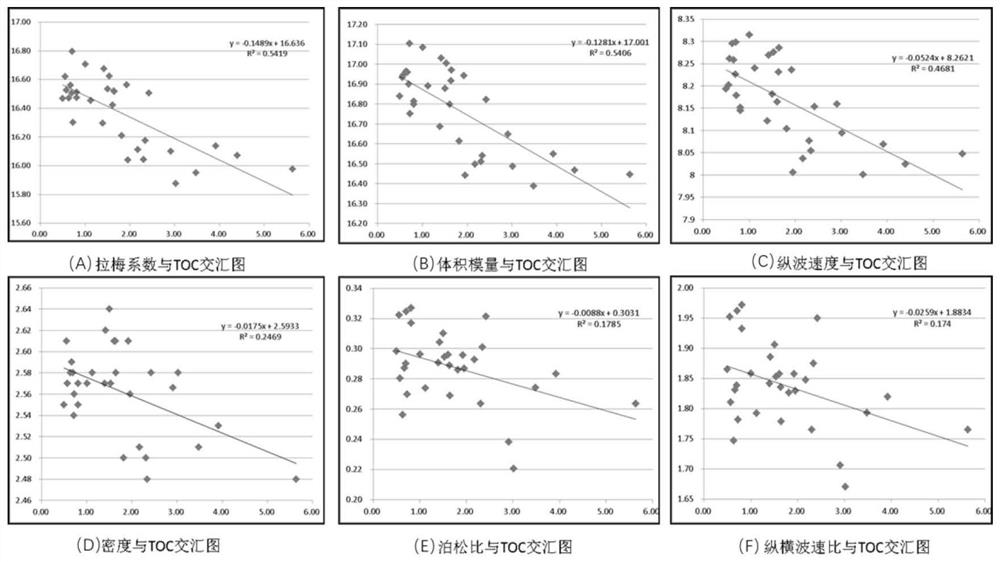

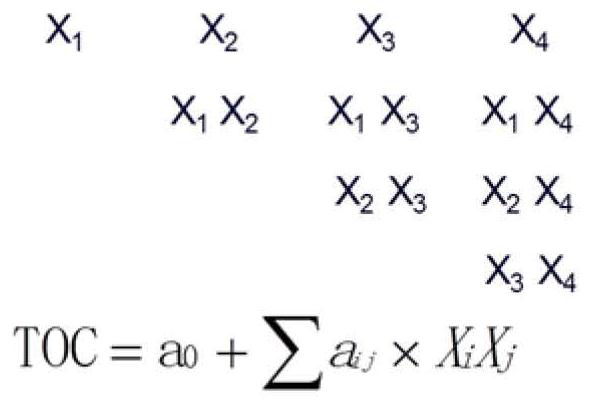

Method for predicting overpressure of undercompaction and hydrocarbon generation mixed cause stratum

ActiveCN112034521AAvoid multiple risks brought about by uncertaintyDecrease in determinationSeismic signal processingSeismology for water-loggingPhysicsGeotechnical engineering

The invention discloses a method for predicting overpressure of an undercompaction and hydrocarbon generation mixed formation cause, and aims to provide a method for carrying out quantitative formation pressure prediction in a development area which has two cause mechanisms of undercompaction and hydrocarbon generation at the same time and jointly causes overpressure of formation pores. Accordingto the new method, stratum TOC content pre-stack earthquake prediction is creatively correlated with hydrocarbon generation pressurization on the basis of calculating the under-compaction factor overpressure contribution by taking speed reduction as the basis by adopting the thought of quantitatively characterizing and finally stacking the under-compaction factor overpressure contribution and thehydrocarbon generation overpressure cause contribution respectively. The invention provides a new hybrid cause overpressure prediction method which is simpler, more convenient and more intuitive thanthe existing methods based on the loading / unloading theory, such as power and the like. According to the method, the risk that the prediction precision is reduced due to the fact that parameters of anunder-compaction or hydrocarbon generation prediction model are adjusted to be approximate to a mixed cause result conventionally is avoided, the complex regional parameter determination step of a power loading / unloading curve overpressure prediction method is also avoided, and a calculation result is more stable.

Owner:CHINA NAT OFFSHORE OIL CORP +1

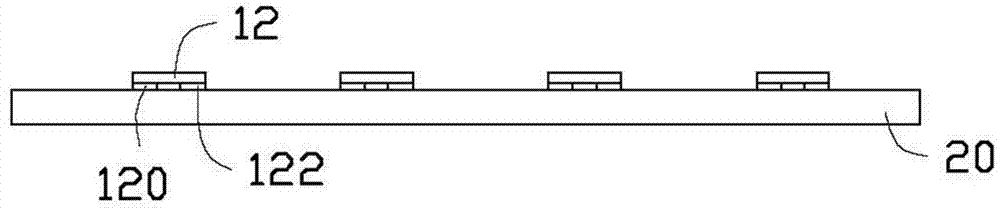

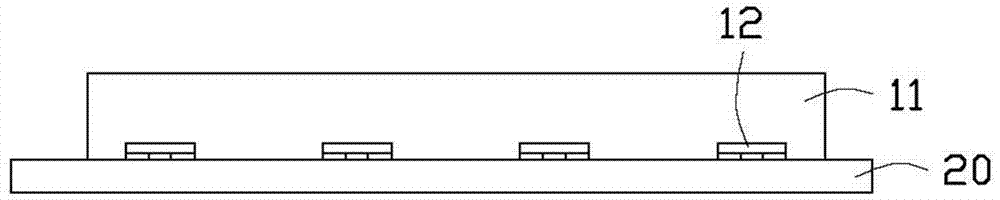

Light emitting diode packaging method

InactiveCN104752582APackage structure is simpleAvoid wasting timeSemiconductor devicesLight-emitting diodeDiode

A light emitting diode packaging method comprises the steps of 1 providing a first viscous film layer and arranging multiple light emitting diode crystal grains on the first film layer; 2 forming a packaging layer on the first film layer and enabling the packaging layer to cover the multiple light emitting diode crystal grains; 3 cutting the packaging layer between every two light emitting diode crystal grains so as to form a cutting way, wherein a light emitting diode unit is formed between every two adjacent cutting ways; 4 providing a second viscous film layer, transferring the light emitting diode units to the second film layer; 5 forming multiple connected optical lenses on the second film layer, wherein each optical lens corresponds to one light emitting diode unit and wraps the light emitting diode unit; 6 removing the film layer; 7 cutting the multiple connected optical lenses so as to obtain multiple light emitting diode packaging bodies.

Owner:ZHANJING TECH SHENZHEN +1

Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

InactiveCN102134879BReasonable designSimplify construction stepsFoundation engineeringBuilding constructionsReinforced concreteRebar

The invention discloses an embedding accuracy control construction method for an embedded part of an overlong equipment foundation platform, including the following steps: firstly, processing the embedded part and the installation screw of the embedded part; secondly, molding construction of the lower middle reinforced concrete structure of the foundation platform needing construction: a plurality of vertical reinforcing steel bars extend out from the top of the lower middle reinforced concrete structure under construction of molding and are arranged vertically; thirdly, installing the installation screw of the embedded part; fourthly, installing a nut at the bottom of the threaded section of the installation screw of the embedded part; fifthly, installing and positioning the embedded part; sixthly, installing a nut on top of the threaded section of the installation screw of the embedded par; seventhly, molding construction of the upper reinforced concrete structure of the foundation platform needing construction; and eighthly, subsequent construction treatment. The method has in design, simple construction steps, easy control of construction quality, high construction accuracy and good in use effect, and can solve the problems of the existing embedding construction method of embedding parts that the embedding accuracy is inconvenient to control, the embedding accuracy is low,the construction quality is poor, the investment cost is high, the construction period is long, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

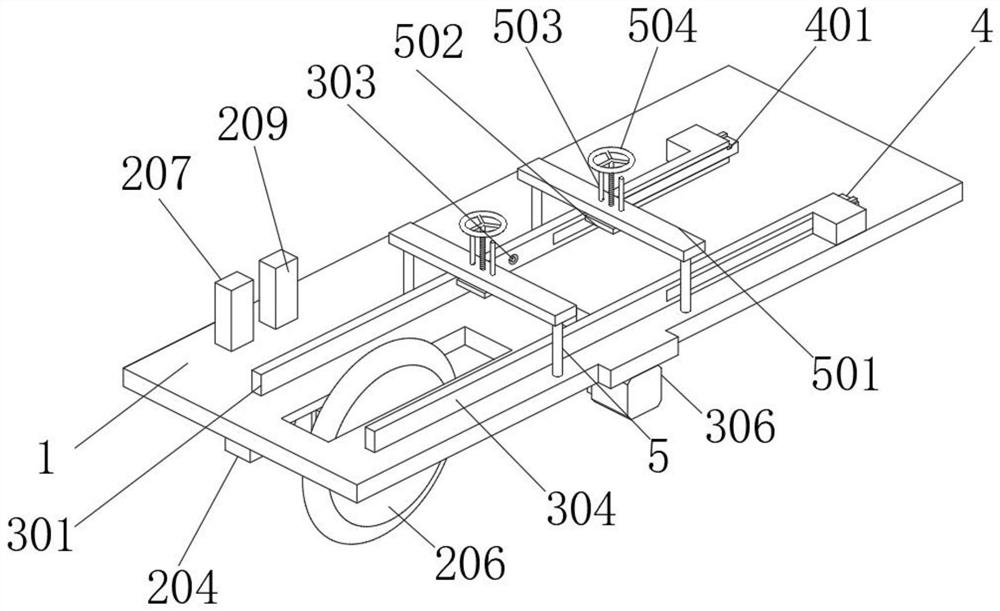

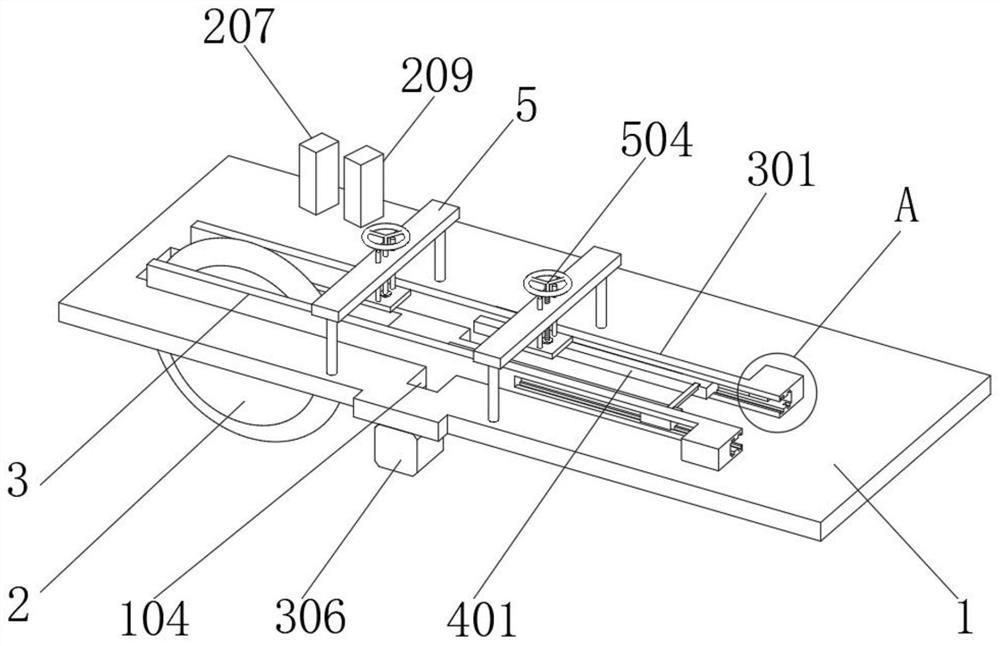

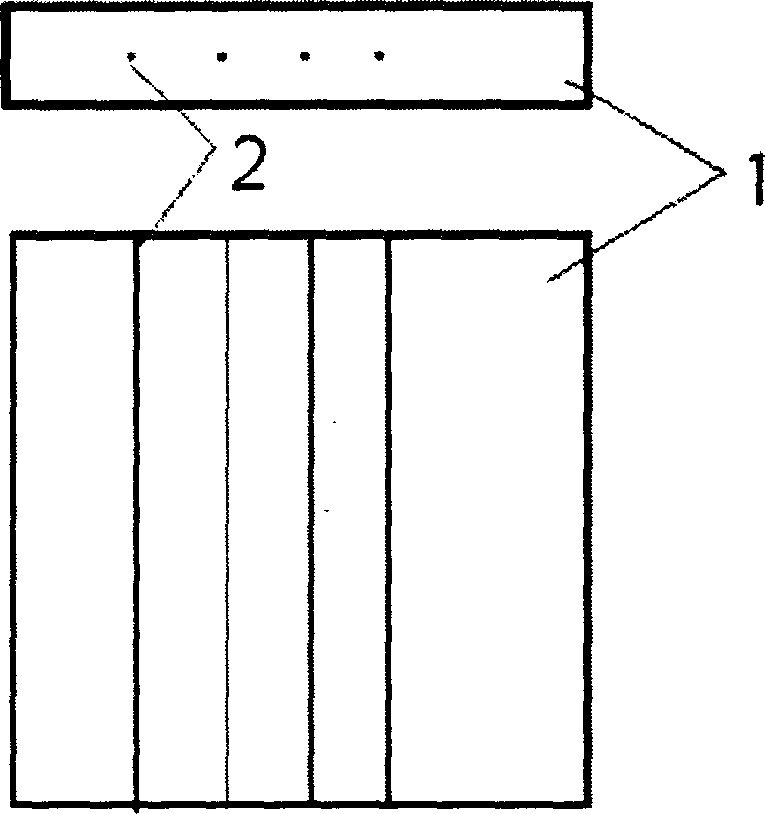

Side hole forming and deep drawing type progressive die

InactiveCN102009101AAvoid precision errorsImprove processing efficiencyShaping toolsPunchingHigh volume manufacturing

The invention discloses a side hole forming and deep drawing type progressive die which comprises a deep drawing device and a side hole forming device, wherein the deep drawing device is arranged in a deep drawing station and is used for deep drawing a material tape; the side hole forming device is used for side hole forming on material tape drawing and a side wall, and the side hole forming device is arranged on a station in the deep drawing device and comprises a station arrangement structure, an elastic structure, an upper die, an lower die, an unloading structure and a punching structure for punching side holes. Because a deep drawing die and a punching die are assembled to form the progressive die of the invention, the invention has greatly improved machining efficiency and can realizes fast and large-scale production and timely product supply compared with the traditional multiple-die single-procedure machining mode; meanwhile, labor cost is greatly reduced, and an operator can be more relaxed. In addition, an accuracy error caused by moving a workpiece blank among different stations is also avoided so that machining accuracy is higher and quality stability is better.

Owner:上海定达机电设备有限公司

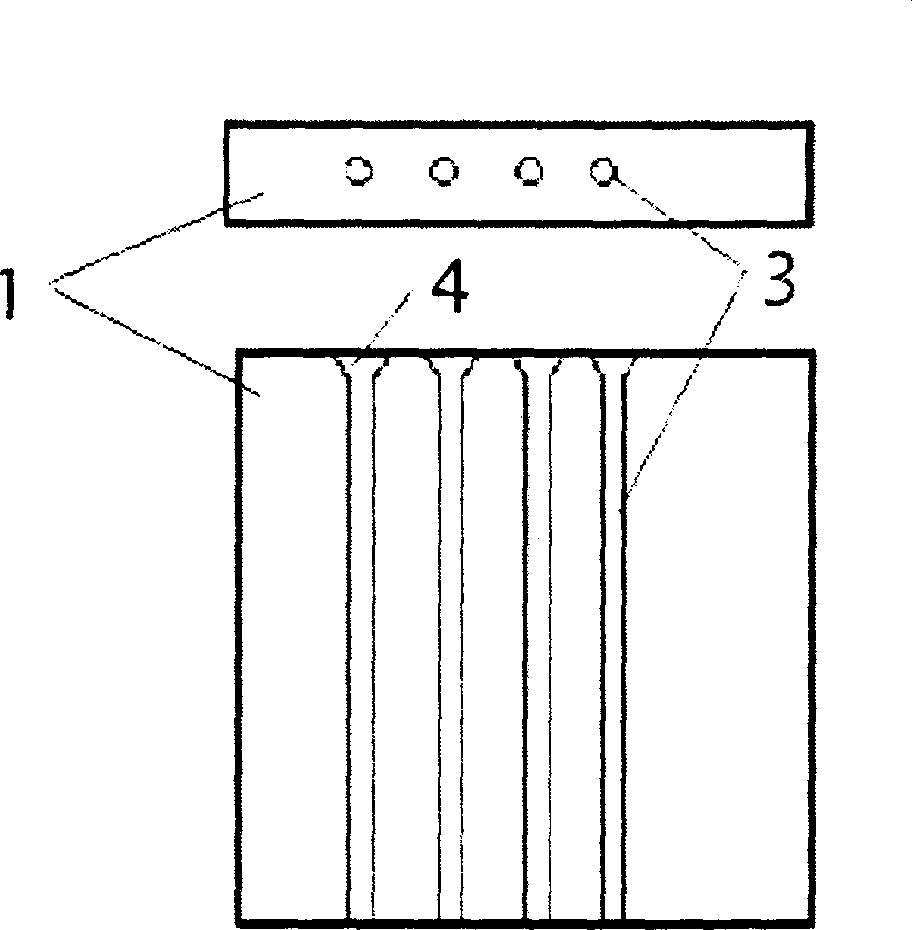

Thinning drawn punching process and die

InactiveCN101966542AImprove processing efficiencyAvoid precision errorsPerforating toolsHigh volume manufacturingPunching

The invention discloses a thinning extrusion drawing process adopted in the moulding of a force output plate product and a force output plate progressive die thereof. The thinning extrusion drawing process comprises processes of drawing, extrusion, end surface moulding, blanking, and the like. The force output plate progressive die comprises a drawing device for drawing a material belt and also comprises a punching device, a multi-thinning extrusion device, a cylindrical end surface moulding device and a blanking delivery plate. By combining the processes of drawing, extrusion, end surface moulding, blanking, and the like in a die, compared with the traditional processing way realized by adopting a single procedure and a plurality of dies, the technical scheme of the invention greatly improves the productivity and is suitable for mass production. In addition, the invention also prevents a precision error brought by shifting workpiece blanks among different stations, therefore, the processing precision is higher, and the quality stability is better.

Owner:上海定达机电设备有限公司

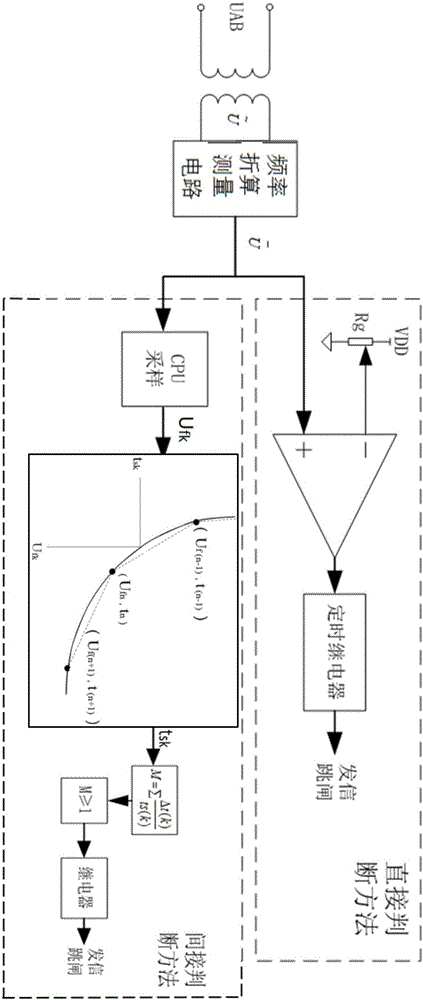

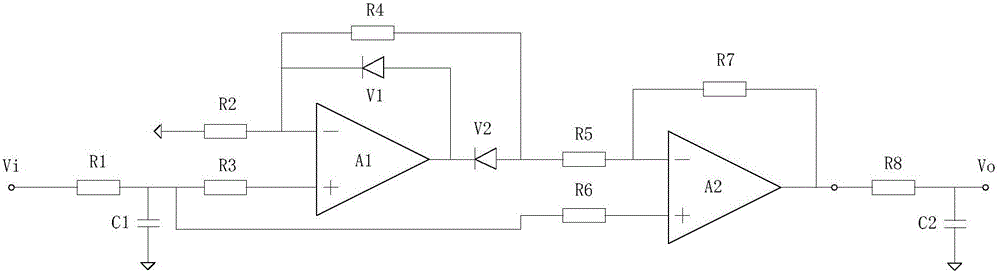

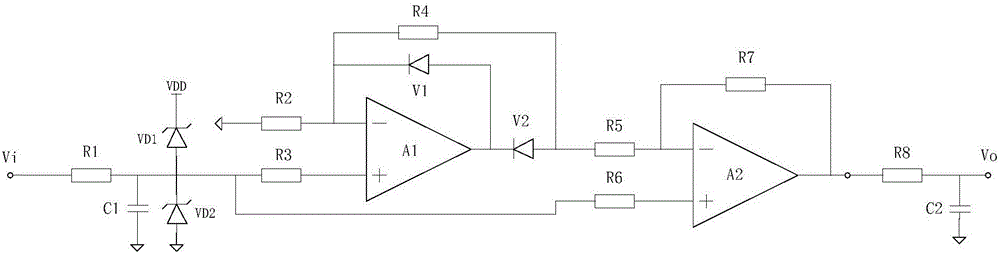

Frequency conversion measurement circuit for over-excitation protection and over-excitation protection method

ActiveCN105891738AFast conversionHigh precisionMagnetic measurement environmental aspectsFrequency conversionEngineering

The present invention provides a frequency conversion measurement circuit for over-excitation protection and an over-excitation protection method. The circuit can measure the multiples of over-excitation in real time, has high conversion speed and high precision, and is just slightly affected by frequency with appropriate circuit parameters provided. Since judgment on a zero crossing point is not required, the inherent delay of the protection is short, and therefore, requirements of the over-excitation protection for action time and return time can be satisfied; and a temperature compensation circuit is adopted, so that accuracy error caused by temperature variation can be effectively prevented. According to the over-excitation protection method, the frequency conversion measurement circuit is adopted to convert signals to be tested into direct current voltage signals, and the direct current voltage signals are outputted; modes for judging whether the protection acts are flexible, hardware can be used to directly judge whether the protection acts, and software can be also used to indirectly judge whether the protection acts; a plurality of parabolas are adopted to fit an inverse-time curve, so that the problem of unsmooth time variation on fitting points can be solved; and a heat effect accumulation discrimination algorithm is adopted, so that the cumulative effect of historical values in an over-excitation value dynamic variation process can be reflected.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

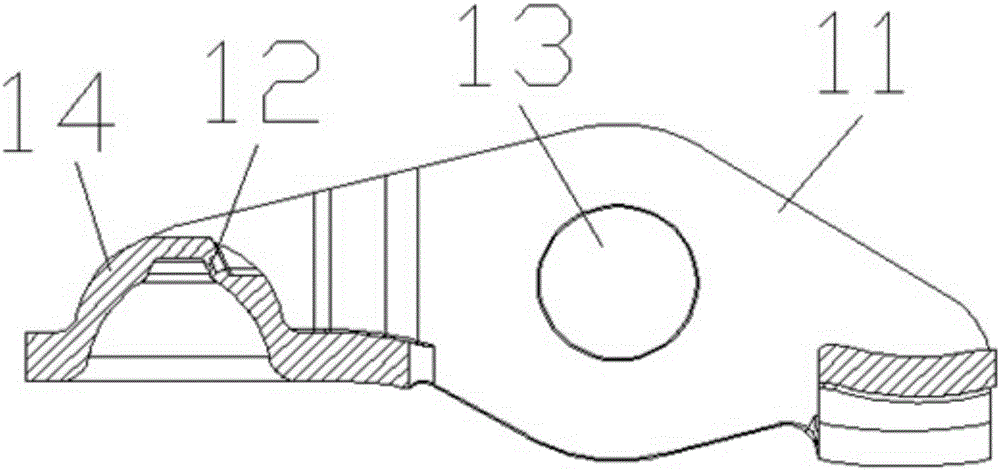

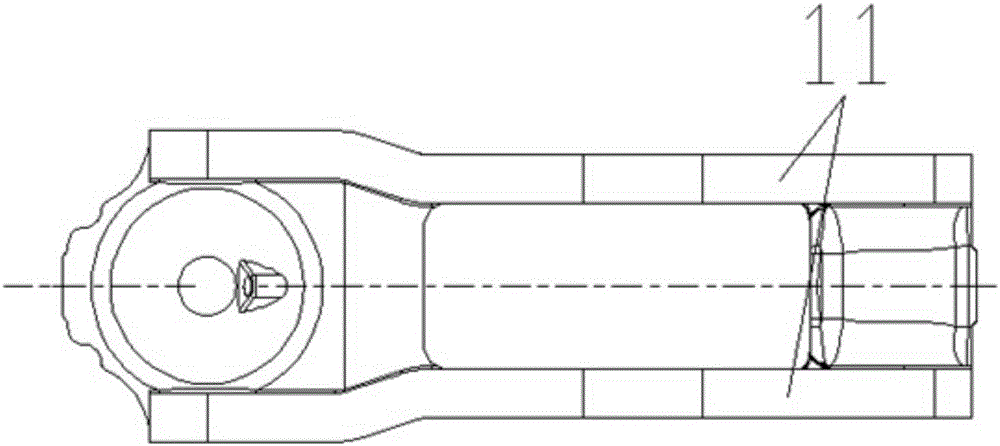

Side punching type progressive die for bending forming of rocker arm body

ActiveCN105710209AAvoid precision errorsImprove processing efficiencyShaping toolsStripping-off devicesSingle processHigh volume manufacturing

The invention discloses a side punching type progressive die for bending forming of a rocker arm body. The side punching type progressive die comprises bending forming devices arranged on a bending forming station for conducting bending forming on a material belt, and a side punching device inclined towards the punching station and arranged behind the bending forming station. At least two sets of bending forming devices are arranged, and two or more steps are needed for bending forming. The side punching device is used for punching symmetric side holes in the side wall of a part blank obtained after bending forming of the material belt and comprises an upper die, a lower die, a discharging structure and a lateral punching structure. Due to the fact that the side punching type progressive die for bending forming of the rocker arm body is formed by combining bending forming dies and lateral punching dies, compared with an existing manner of machining this kind of parts through multiple pairs of dies and a single process, the machining efficiency is greatly improved, and the requirement for mass production can be met; meanwhile, the labor cost is greatly reduced, and an operator conducts operate more easily; and in addition, precision errors caused by carrying of the workpiece blank between among stations are avoided, and therefore the machining precision is higher, and the quality stability is also better.

Owner:上海晨昌精密模具有限公司

Multi-angle adjustable cutting device for mechanical engineering manufacturing

InactiveCN112247240APrecise processingPrecise Control ProcessingShearing machinesShearing machine accessoriesStructural engineeringCutting tool

The invention discloses a multi-angle adjustable cutting device for mechanical engineering manufacturing. The multi-angle adjustable cutting device comprises a cutting plate, a cutting tool adjustingmechanism, a limiting adjusting mechanism, a pushing mechanism and a fixing mechanism; a cutting groove is formed in the cutting plate, and a first penetrating hole and a second penetrating hole are formed in one side of the cutting groove side by side; a first penetrating hole and a second penetrating hole are formed in the cutting plate, two limiting grooves are formed in one end of the cuttinggroove, and limiting grooves are formed in the cutting plate; and the cutting tool adjusting mechanism is arranged below the cutting plate, the limiting adjusting mechanism is arranged above the cutting plate, the pushing mechanism is installed on the limiting adjusting mechanism, the fixing mechanism is arranged on the outer side of the limiting adjusting mechanism, and the fixing mechanism is arranged on the upper surface of the cutting plate. The pushing mechanism is adopted for controlling the movement of the rear half section during raw material cutting, an operator is prevented from making contact with a cutter in a close distance, and the operator is protected.

Owner:NINGBO POLYTECHNIC

Non-surface consistency static correction method based on equivalent speed

InactiveCN110858003AAvoid precision errorsAccurate space-time distance relationshipSeismic signal processingSeismic wavePhysics

The invention discloses a non-surface consistency static correction method based on equivalent speed and belongs to the field of seismic exploration. The method comprises the following steps that: theequivalent speed of seismic waves transmitted from the ground to a static correction surface H is calculated according to a near-surface model; an offset distance mapping relation between an offset distance before static correction and an offset distance after static correction under the condition of the transmission of seismic waves along an actual propagation path is constructed according to the equivalent speed, and a travel time mapping relation between travel time before static correction and travel time after static correction under the condition of the transmission of the seismic wavesalong the actual propagation path is constructed according to the equivalent speed; and the offset distance and travel time of the seismic waves under the condition of the transmission of seismic waves along the actual propagation path are calculated according to the offset distance mapping relation and the travel time mapping relation. With the non-surface consistency static correction method based on the equivalent speed adopted, precision errors caused by the vertical transmission of seismic waves assumed by conventional static correction are avoided. Compared with the conventional staticcorrection, the method has higher precisions, can better keep an accurate space-time distance relation, and meanwhile can better guarantee subsequent imaging precision.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for manufacturing optical fiber array connector

InactiveCN1790074ASimple processHigh precisionCoupling light guidesLaser beam welding apparatusChemical treatmentFiber

The invention discloses a fiber-optical array connector making method of optical communication, which comprises the following steps: combining the femtosecond laser illuminating and chemical disposal method to produce the array through-hole in the base plate; plugging and fixing the optical fiber in the through-hole to prepare the fiber-optical array connector. The method prevents the traditional method from preparing mould and sintering the blank, which simplifies the manufacturing technology and improves the gap precision.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Electronic component mobile test equipment

InactiveCN113189423APromote repairImprove stabilityElectrical testingMeasurement instrument brakingData displayElectronic component

The invention discloses electronic component mobile test equipment, which structurally comprises a detection table, an electric controller, a working bracket, a data display screen and an electric test pen, wherein the lower surface of the detection table is fixedly connected with the surface of the working bracket in an embedded manner, the left side of the working bracket is fixed with the surface of the tail end of the electric controller through a bolt, the inner side of the electric controller is movably matched with the interior of the data display screen, the whole data display screen is connected with the surface of the working supporting frame in a nested mode, the top end of the electric testing pen is in clearance fit with the surface of the detection table, the detection table comprises a testing groove, an equipment sleeve table and a table supporting plate, and the surface of the table supporting plate is connected with the bottom part of the equipment sleeve table in an embedded mode. The electronic component mobile test equipmentimproves the handle holding hand feeling of an operator through using a balance strip, when testing is needed, a user only needs to hold and press the balance strip with a hand to enable an internal movable block to go down a slope inwards to stretch a rope and a stabilizing rod, an internal lead block drives a lower end pressing rod column to movably extrude an internal hook spring in a displacement cavity for pressure decomposition, the stability of the electric testing pen is improved, and the problem of element precision error of the test equipment caused by shaking is effectively avoided.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com