Light emitting diode packaging method

A technology of light-emitting diodes and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the accuracy of packaging components and the difficulty of ensuring accuracy, so as to avoid time consumption and accuracy errors, simplify the packaging structure, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The LED packaging method provided by the embodiment of the present invention includes the following steps.

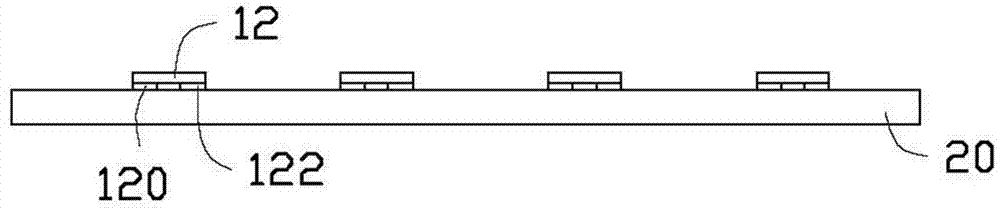

[0014] first step, see figure 1 and figure 2 , providing a viscous and elastic film layer 20 and disposing a plurality of LED chips 12 on the film layer 20 , the two electrodes 120 , 122 of each LED chip 12 are attached to the film layer 20 .

[0015] In this embodiment, the film layer 20 is a UV film or a polyimide (Polyimide) film, and the plurality of LED chips 12 are disposed on the film layer 20 by flip-chip.

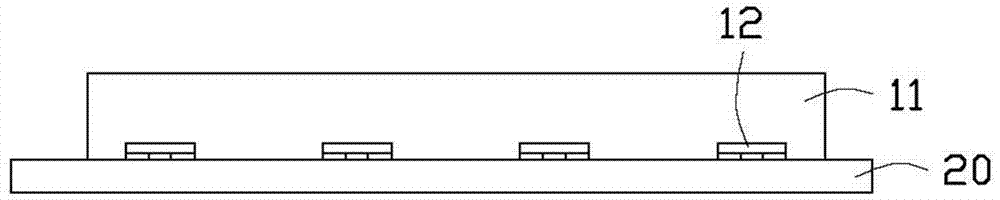

[0016] The second step, see image 3 , forming an encapsulation layer 11 on the film layer 20 and making the encapsulation layer 11 cover the plurality of LED dies 12 .

[0017] Phosphor powder can be mixed in the encapsulation layer 11 , so as to emit light with a wavelength different from that of the light-emitting diode grain 12 under light excitation of the light-emitting diode grain 12 , so as to obtain light of a desired color through light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com