Testing device of rigid and flexible composite test piece asphalt layer rebound modulus and method thereof

A kind of resilience modulus, rigid-flexible composite technology, applied in measuring device, using stable tension/pressure test material strength, instrument and other directions, can solve the problem of not suitable for the resilience modulus of asphalt surface layer, can not accurately reflect the asphalt layer The evolution law of the elastic modulus does not take into account the bonding state between layers and the combination of structural stiffness, so as to avoid the accuracy error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

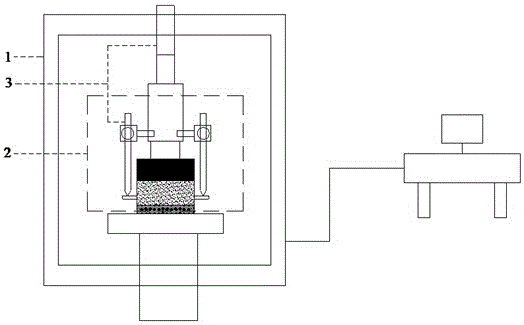

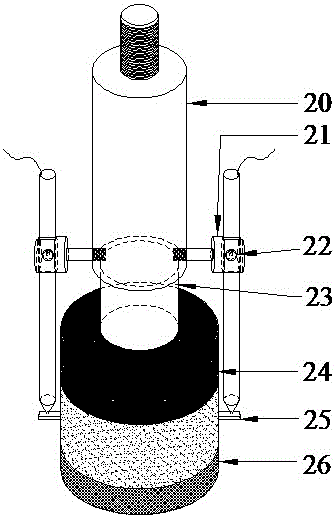

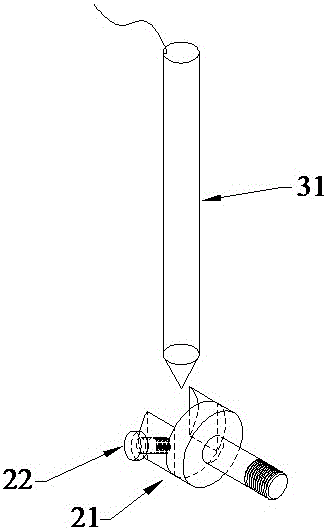

[0031] As shown in Figures 1, 2 and 3, the present invention includes a loading system (1), a clamping system (2), and a data acquisition system (3); its specific implementation steps include:

[0032] Prepare the test piece: process the end of the composite test piece (24) to keep it smooth and flat. Use superglue to paste the holder (25) on the lower 1 / 3 of the rigid-flexible interface of the composite test piece (24). on the device.

[0033] Adjust the cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com