Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

A technology of equipment foundation and construction method, which is applied in the direction of basic structure engineering, architecture, building structure, etc., can solve the problems of inconvenient control and adjustment of pre-embedded precision, high investment cost, and long construction period, so as to shorten the installation and construction period and save investment The effect of low cost and simple construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

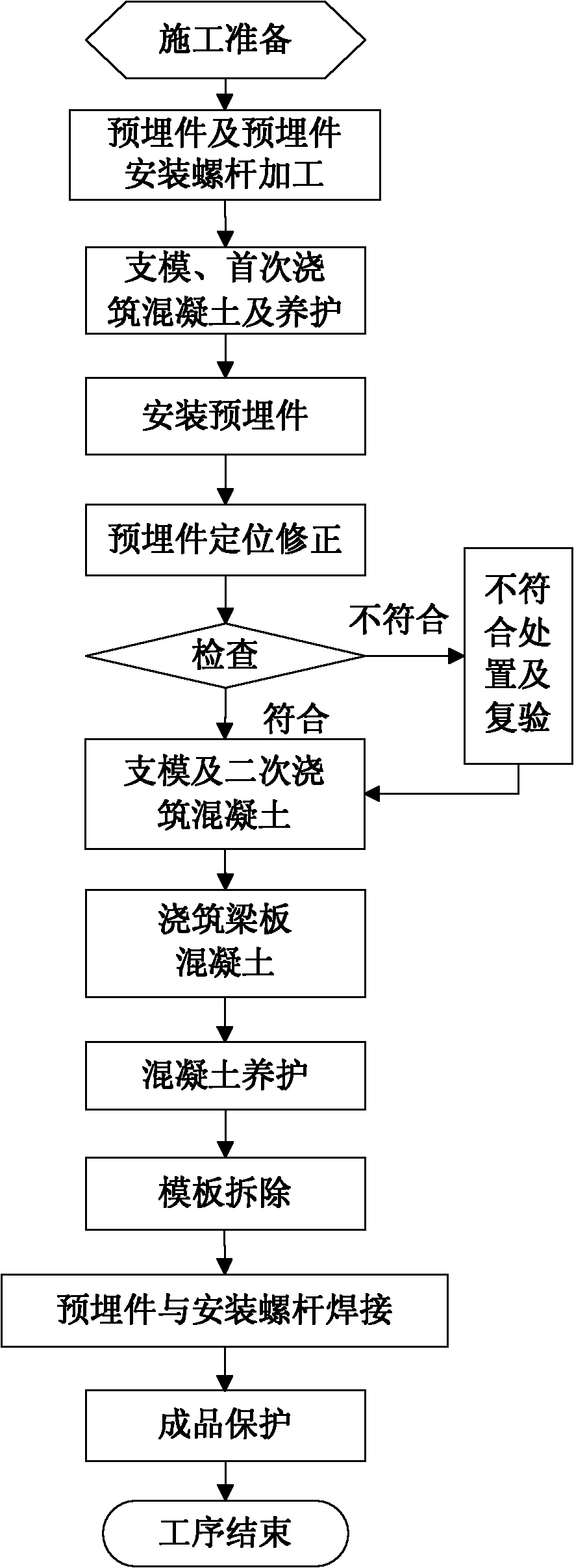

[0044] Such as figure 1 A construction method for controlling the embedding accuracy of embedded parts of an ultra-long equipment foundation platform is shown, including the following steps:

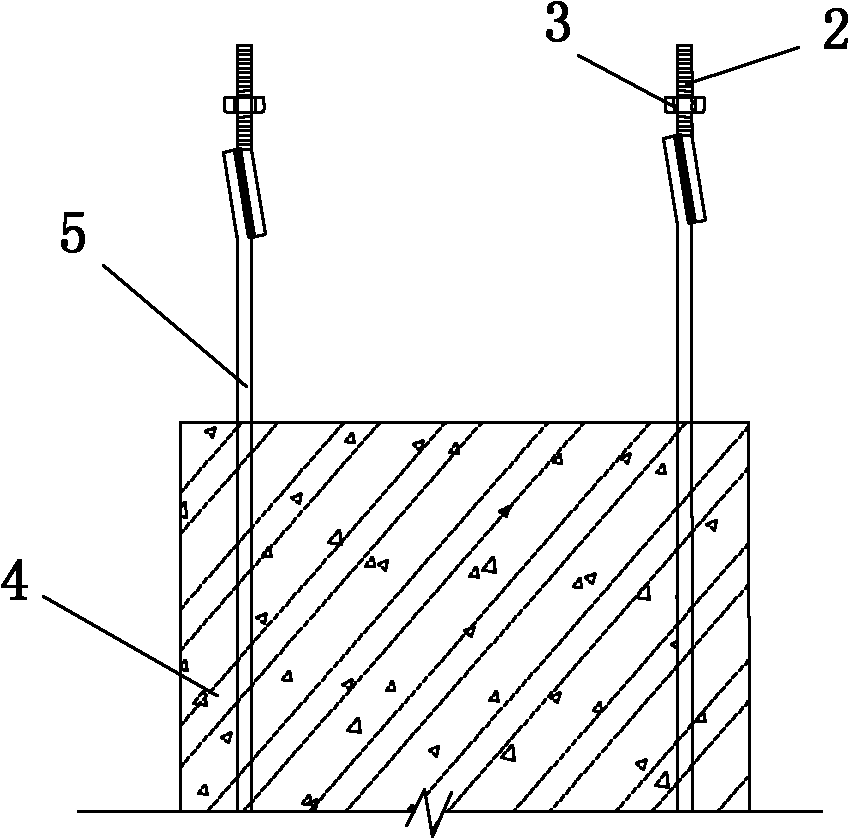

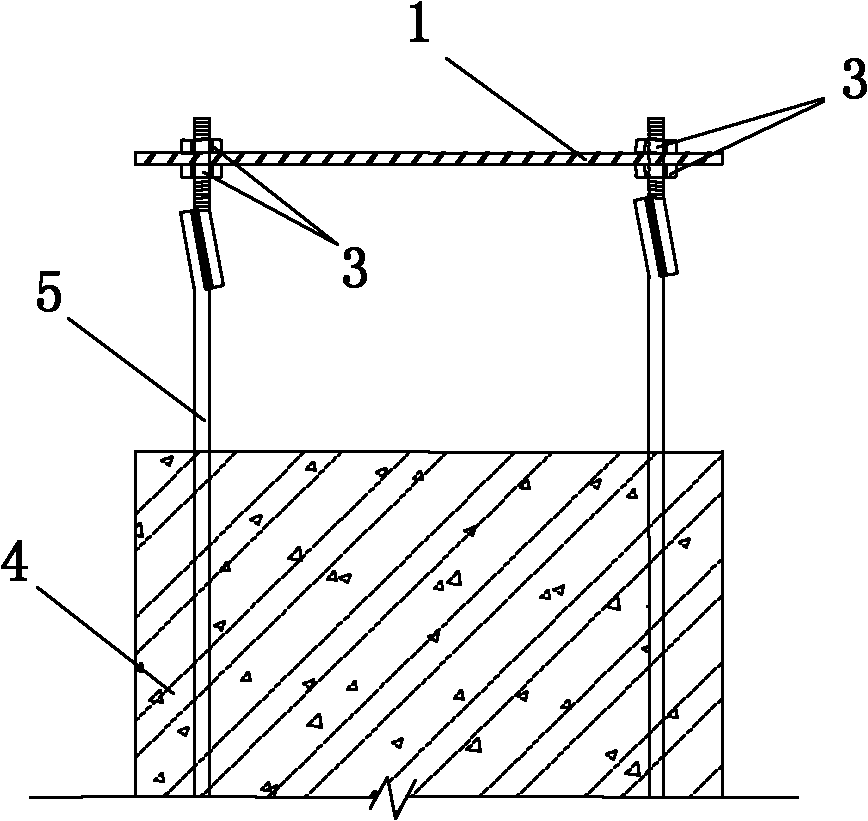

[0045] Step 1. Embedded parts and embedded parts installation screw processing: use machining equipment to process the embedded parts 1, and use drilling equipment to drill multiple holes with the same size and uniformity on the processed embedded parts 1. It is a circular through hole arranged vertically. The embedded part 1 is a horizontal steel plate and is embedded horizontally on the top of the foundation platform to be constructed; at the same time, cutting equipment and thread processing equipment are used to process multiple structures and sizes that are the same The embedded part installation screw 2, and correspondingly process a plurality of nuts 3 used in conjunction with the threaded section of the embedded part installation screw 2. The structure and size of the plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com