Anti-smearing paper flattening device applicable to quality detection system of dry offset press

A technology of detection system and flattening device, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of unusable, dirty printed pictures and texts, dirty printing ink, etc., so as to improve the detection accuracy, The effect of good flattening effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Hollow spoke roller

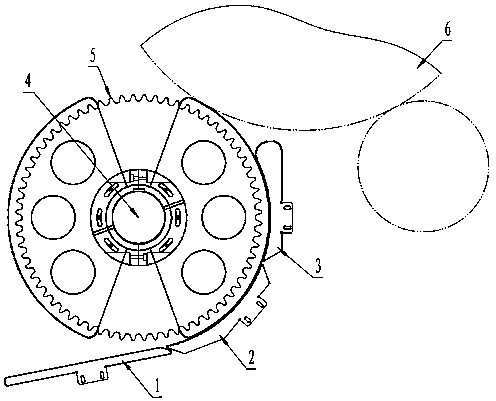

[0022] The dry offset printing machine adopts the front and back one-time printing technology. After the graphic printing is completed on the impression cylinder 6, the paper is handed over to the paper output sprocket 5, and is transported to the paper drop warehouse by the chain gripper. Since the online detection system is used to determine the quality of graphic printing, it must be installed after the printing is completed, so the detection system is designed on the paper output sprocket 5.

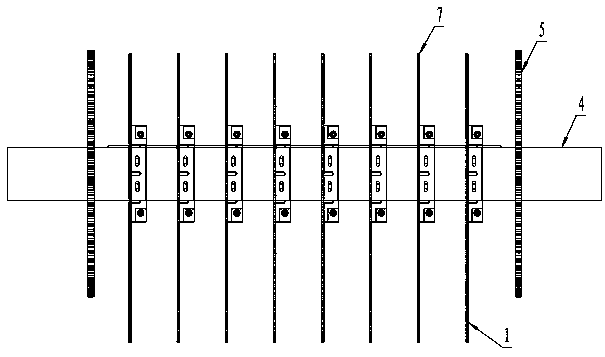

[0023] The paper output sprocket 5 adopts a hollow spoke structure, and several spoke pieces 7 are equally spaced on the central axis 4. In order to prevent the front graphic from being dirty and minimize the contact area with the paper, the thickness of a single spoke piece 7 is 5mm.

[0024] The maximum running speed of the sprocket reaches 2.8 revolutions per second. During the rotation of the paper, it will be randomly shaken by the centrifugal for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com