Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Achieve clear imaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

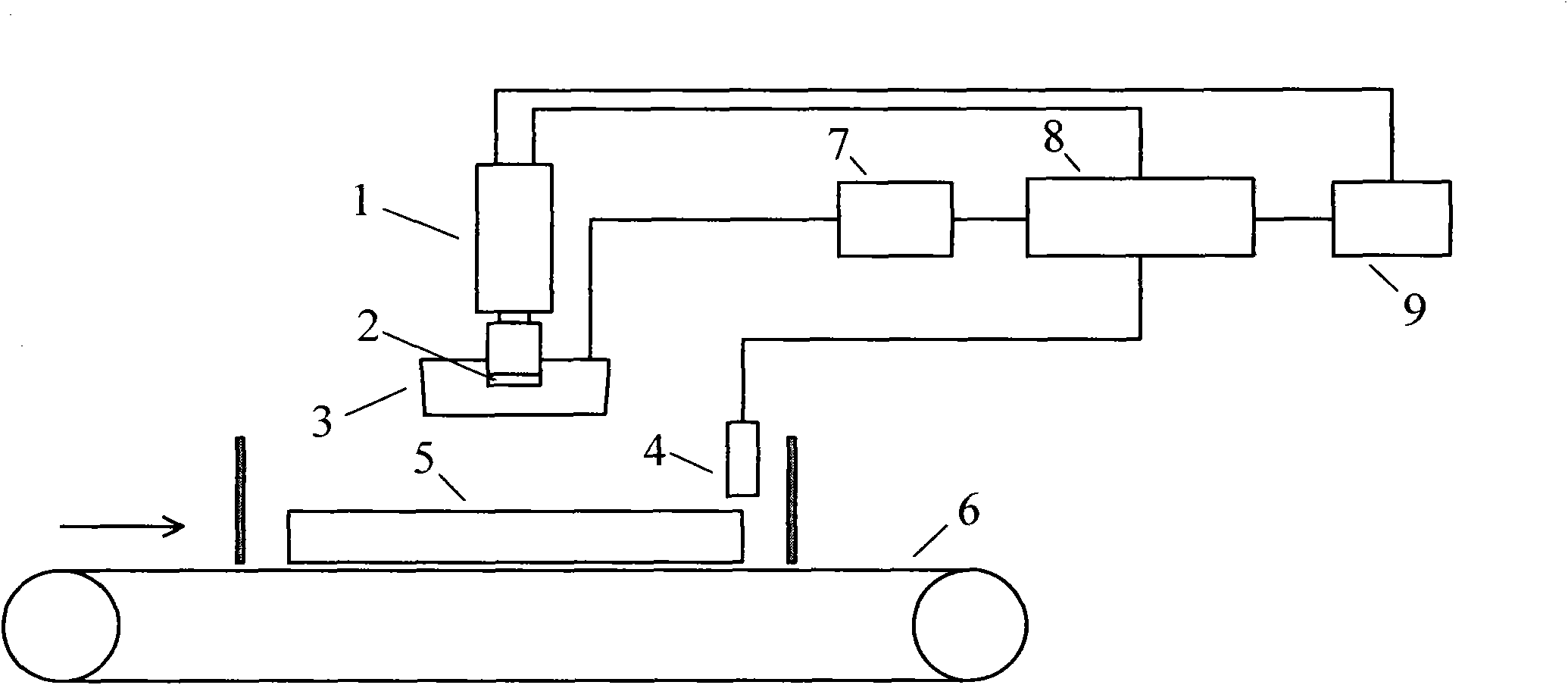

Device and method for acquiring product coded identifier information

ActiveCN101885391AIncrease brightnessImprove recognition rateCharacter and pattern recognitionPackagingOpto electronicImaging equipment

The invention relates to a device and a method for acquiring product coded identifier information. The device comprises a data acquisition unit, a data identification unit and a control unit, wherein the data acquisition unit is positioned above a convey belt and comprises an image device, a lighting device and a position photoelectric switch; the image device is used for photographing product coded identifier to obtain image data; the lighting device is used for irradiating the product coded identifier; the position photoelectric switch is used for sensing the position of the product on the convey belt; the data identification unit is used for identifying and processing the image data acquired by the data acquisition unit to obtain the product coded identifier information and storing the information and is also connected with the image device and the control unit respectively through a data line; and the control unit is used for controlling the data acquisition unit, and connected with the data identification unit, the image device, the lighting device and the position photoelectric switch respectively through data lines. The invention also provides the method for acquiring the product coded identifier information.

Owner:北京赛腾标识系统股份公司

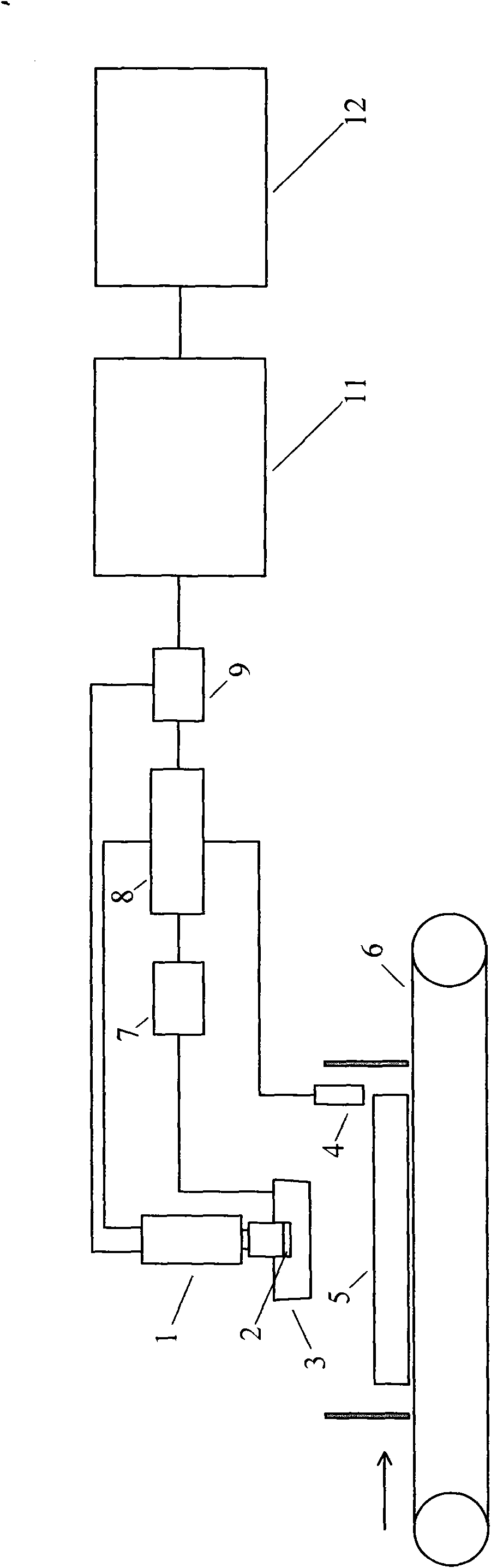

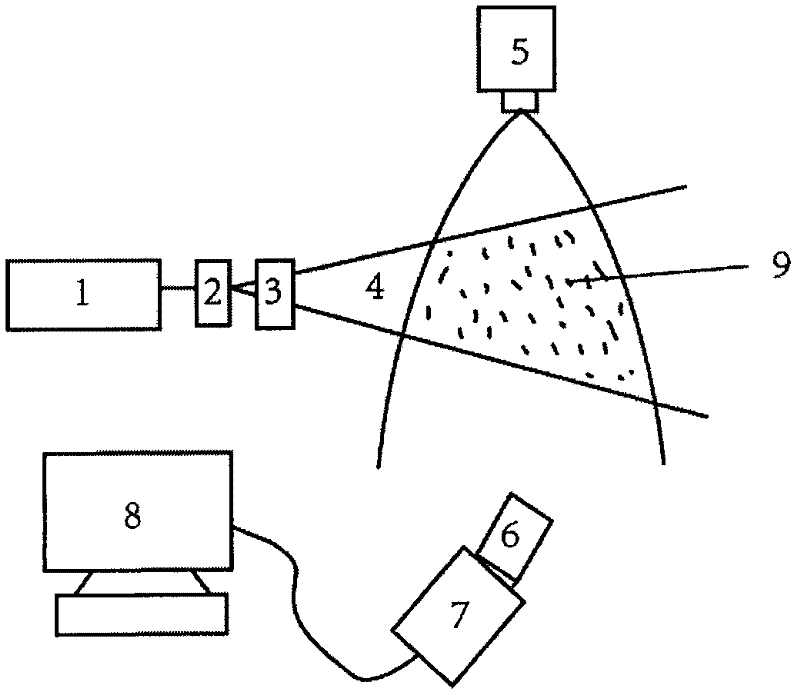

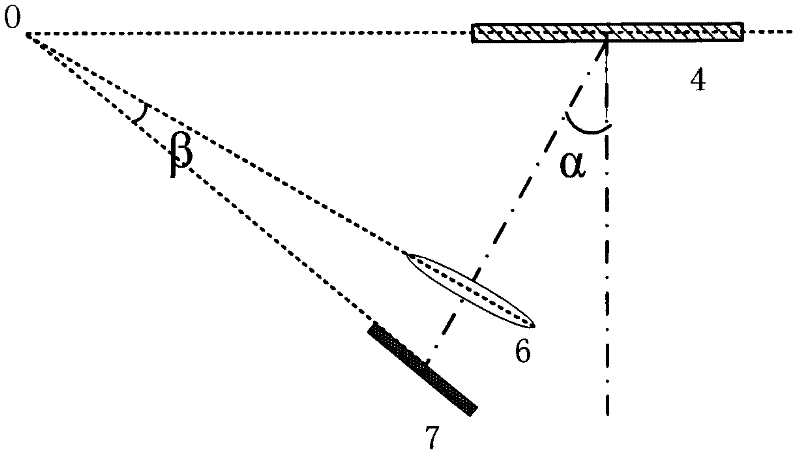

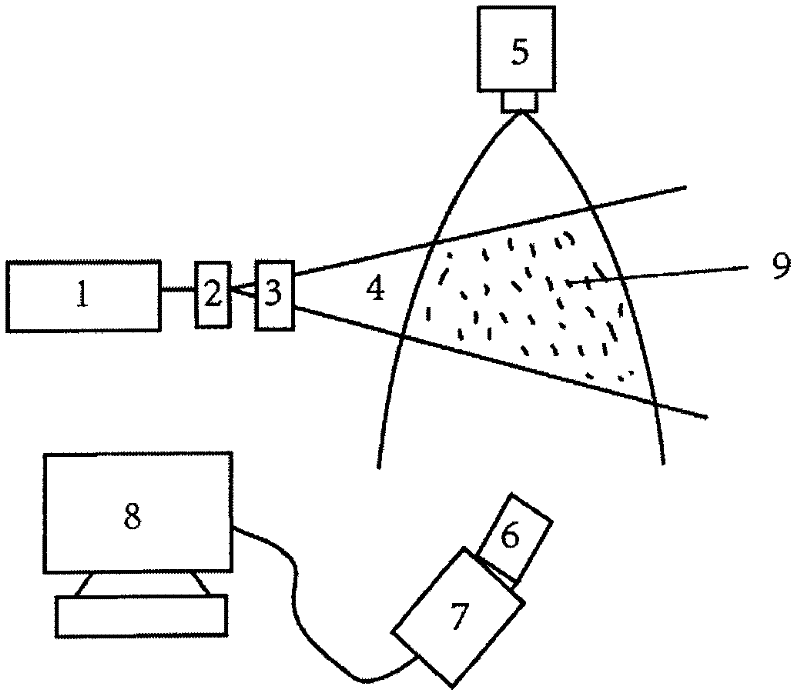

System for testing particle moving speed based on single image

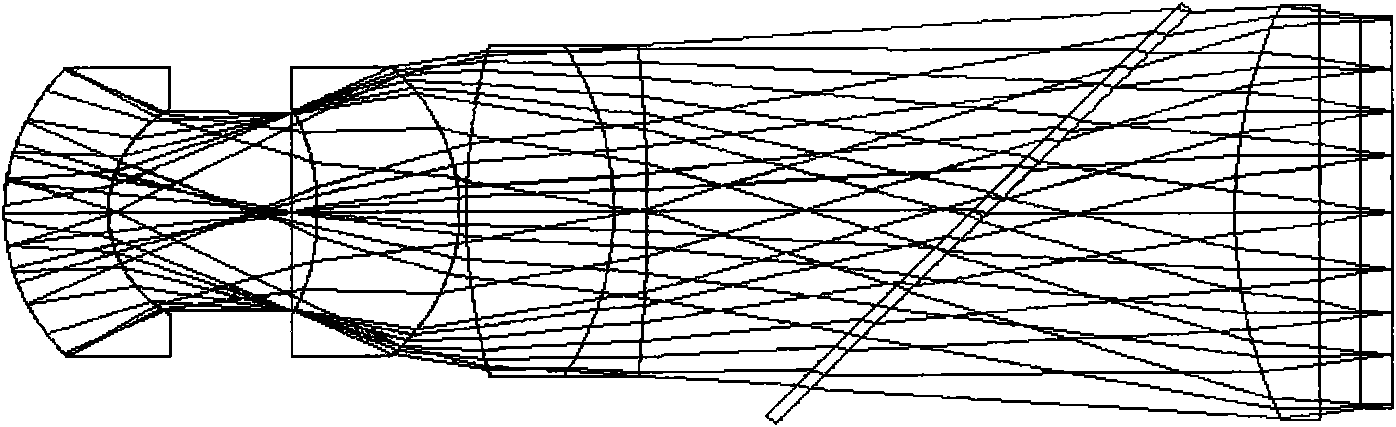

InactiveCN102393473AEnhance exposure intensityAvoid partial blurParticle size analysisFluid speed measurementCamera controlCamera lens

The invention discloses a system for testing the particle moving speed based on a single image. In the system, a continuous laser is taken as a laser light source, and a shift lens is taken as a camera lens; by adjusting the horizontal position of the shift lens, the shift lens is deviated from a sheet light source along the vertical direction by a certain angle, and the exposure intensity of a particle image is remarkably increased; and by adjusting an included angle between the shift lens and a camera sensitive surface, planes where the shift lens, the light sensitive surface of the camera and the sheet light source are intersected on a straight line, and clear imaging of all particles in a testing area is realized. In the invention, the exposure time is controlled by using the camera, changes of the speed and moving direction of the particles within the expose time can be reflected in real time only by acquiring a single image of the particle moving, and parameters such as speed change and distribution of particles in a flow field, particle diameter distribution of the particles and the like can be obtained by processing. The system has low equipment cost and low manufacturing cost, and can be applied to particle parameter testing of various atomization and flow fields.

Owner:NANJING UNIV OF SCI & TECH

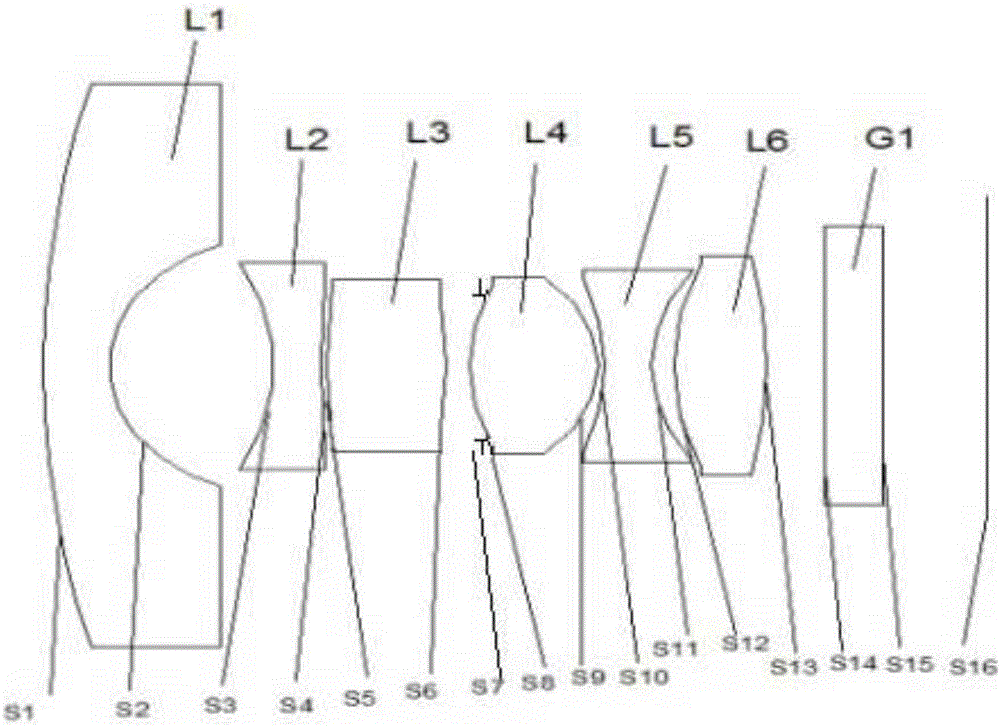

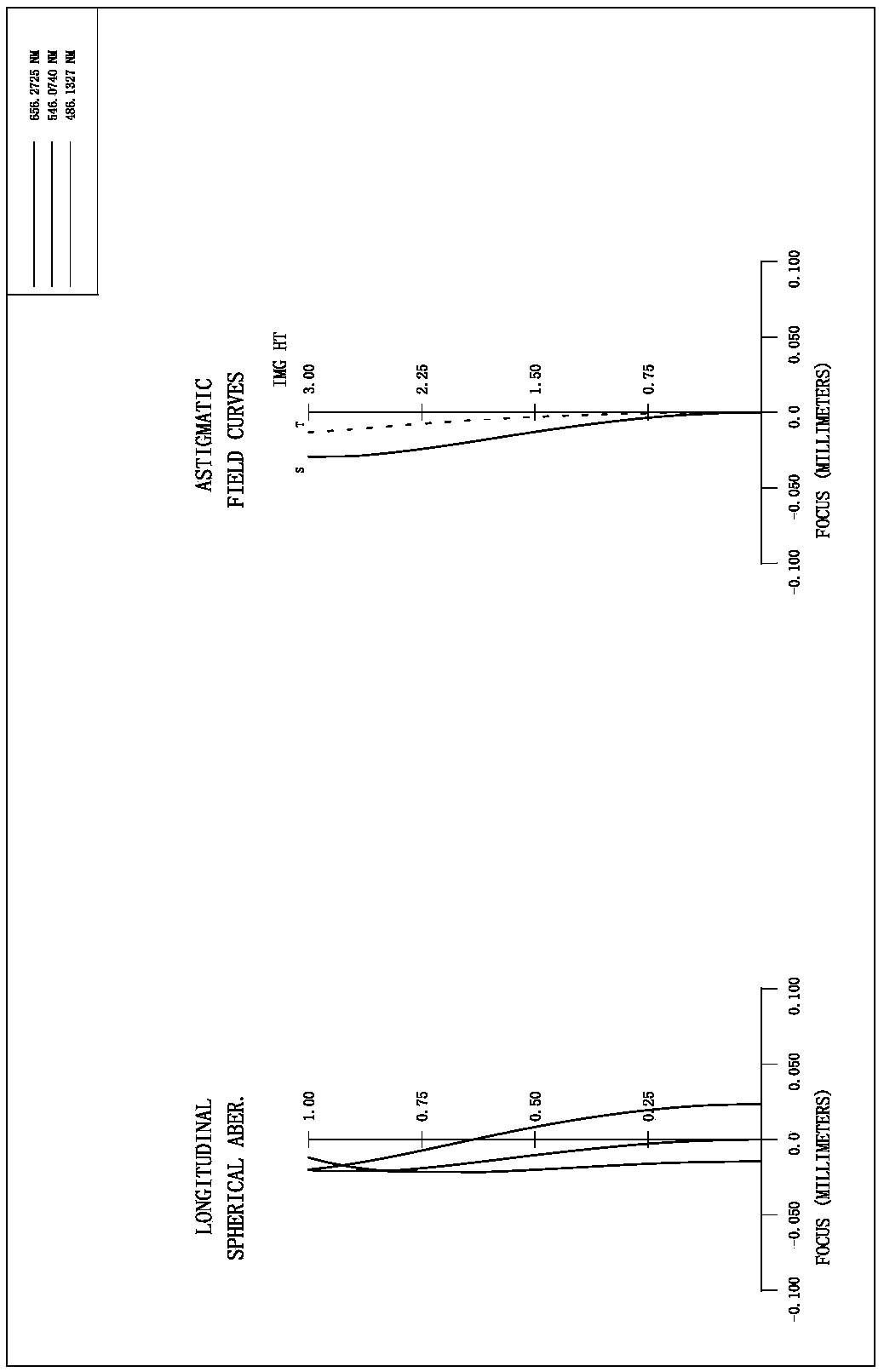

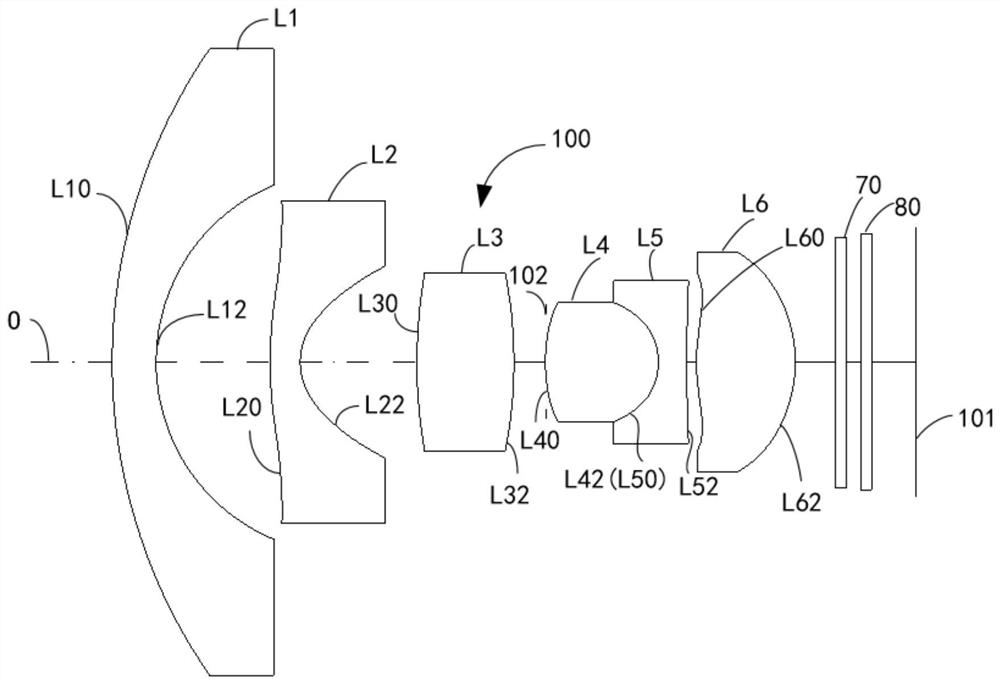

Wide-angle lens

ActiveCN106125258AGood optical performanceMiniaturizationOptical elementsAspheric lensMiniaturization

The invention provides a wide-angle lens, which comprises, from an object side to an imaging plane in sequence, a meniscus-type first lens, which has negative focal power and the concave surface of which faces to the imaging plane; a second lens, which has negative focal power; a third lens has positive focal power; a fourth lens, which has positive focal power, and the double surfaces of which are convex surfaces respectively; a fifth lens, which has negative focal power and the double surfaces of which are concave surfaces respectively; a sixth lens, which has positive focal power and the double surfaces of which are convex surfaces respectively; a diaphragm, which is arranged between the third lens and the fourth lens; and an optical filter, which is arranged between the sixth lens and the imaging plane, wherein each lens is a plastic aspheric lens. Since each lens is the plastic aspheric lens, the wide-angle lens is allowed to have better optical performance; and meanwhile, structure composition between the lenses can help realize miniaturization of the wide-angle lens.

Owner:郑州联创电子有限公司

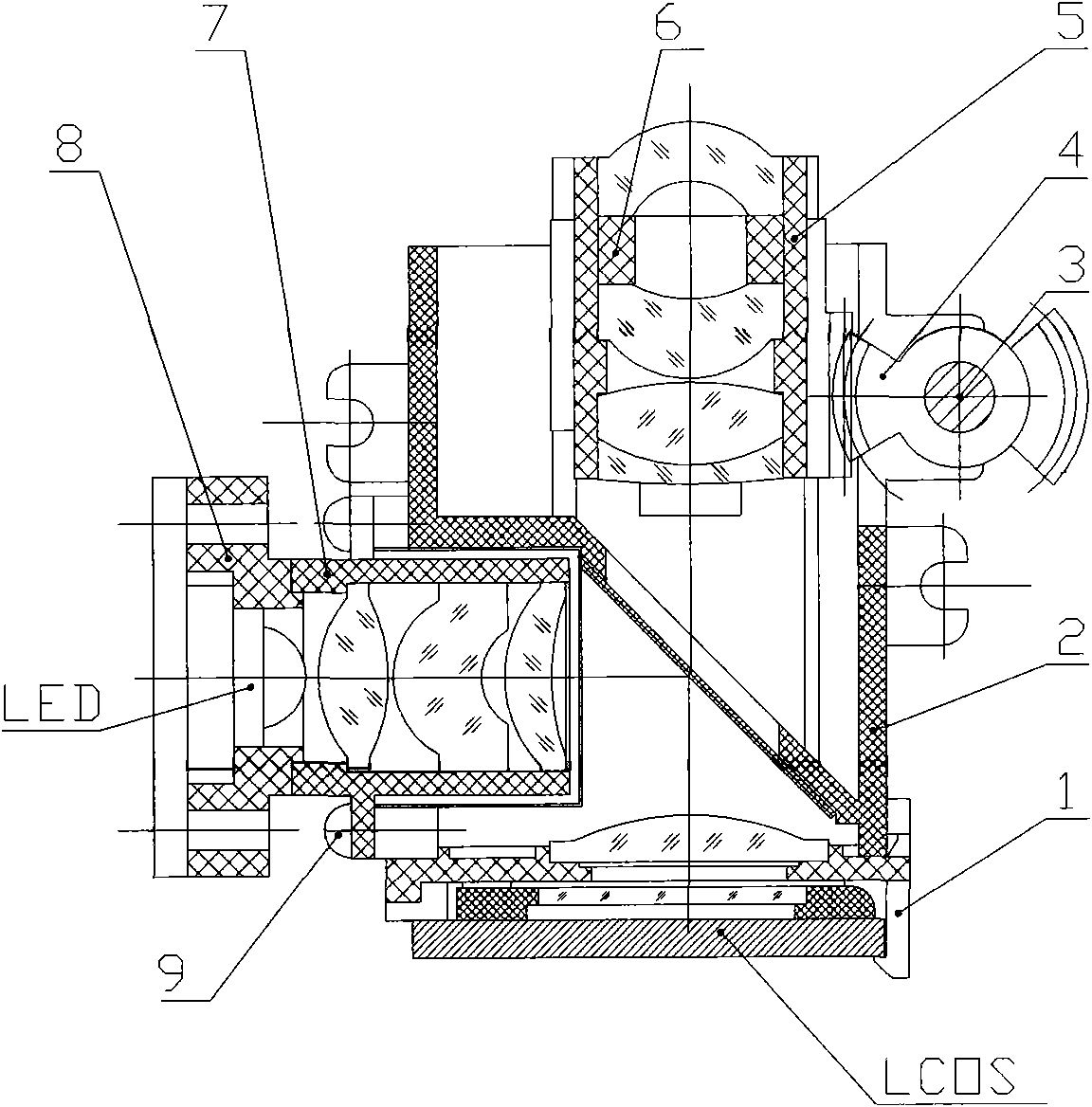

Minitype single-chip LCOS projection optical engine

InactiveCN101666962AMeet the aspect ratioIncrease profitProjectorsOptical elementsCamera lensBeam splitter

The invention relates to a minitype single-chip LCOS projection optical engine which is composed of a projection lens, a PBS beam splitter, a field lens and an LCOS chip which are sequentially arrayedalong a system imaging optical axis from a screen side to an image plane side, the PBS beam splitter and the imaging optical axis form a 45-degree angle, and an illuminating system of an optical engine is formed by an LED light source lens, a first condenser lens, a cylindrical lens and a second condenser lens which are sequentially arrayed along the optical axis of the illuminating system. The optical axis of the illuminating system and the optical axis of an imaging optical path from a 90-degree angle, and the PBS beam splitter, the field lens and the LCOS chip are commonly used by the imaging optical path and an illuminating optical path. An illuminating central beam is vertically radiated on the LCOS chip after being reflected by the PBS beam splitter, the system moves forward and backward to realize focusing along the imaging optical path by the projection lens, so as to ensure to realize to image clearly at different distances. The system has low cost and good process and is suitable for batch production.

Owner:南阳市海科光电有限责任公司

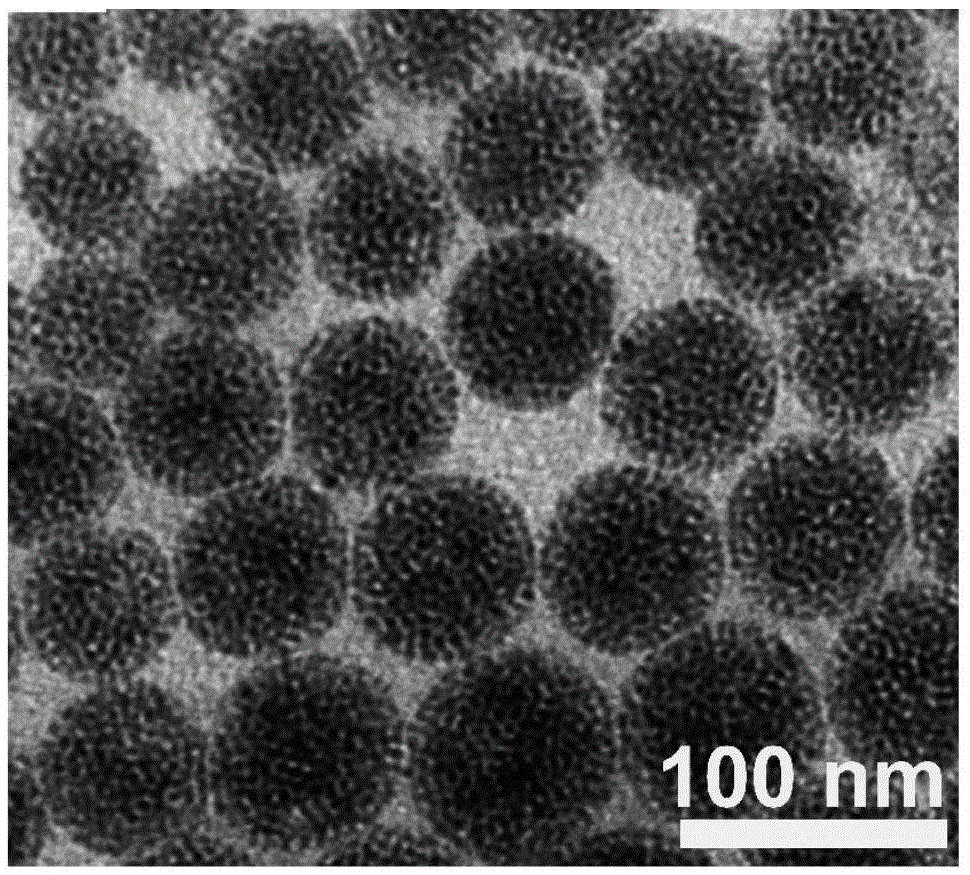

Molecular imaging probe and application thereof

ActiveCN108949147AAchieve high volumeAchieve long-term enrichmentFusions for specific cell targetingIn-vivo testing preparationsLife qualityMolecular imaging

The invention provides a molecular imaging probe which is a polypeptide molecule, including a specific targeted section on one end, a responding assembly-retention section in the middle, and a color developing section on a side chain; wherein the responding assembly-retention section includes a responding sequence as the SEQ ID No.1 and an assembling sequence as the SEQ ID No.2. The molecular imaging probe can recognize a tumor cell through the specific targeted section and achieves assembly retention in a tumor microenvironment through a "responding assembly-retention effect", thereby achieving high-amount and long-acting imaging in a tumor tissue; through near-infrared light excitation, the molecular imaging probe can achieve imaging navigation during a stable and long-acting operation on a tumor focus part, thus achieving visible localization of the tumor. The accuracy of resection of tumors by a doctor is improved, operation success rate is greatly increased and post-operation recurrence rate is reduced; the molecular imaging probe can improve the post-operation life quality of patients.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

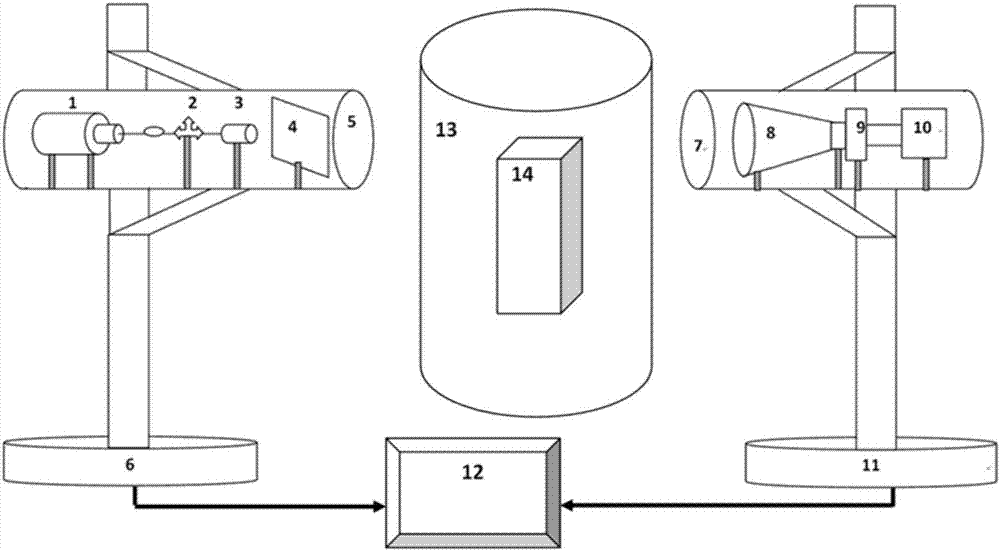

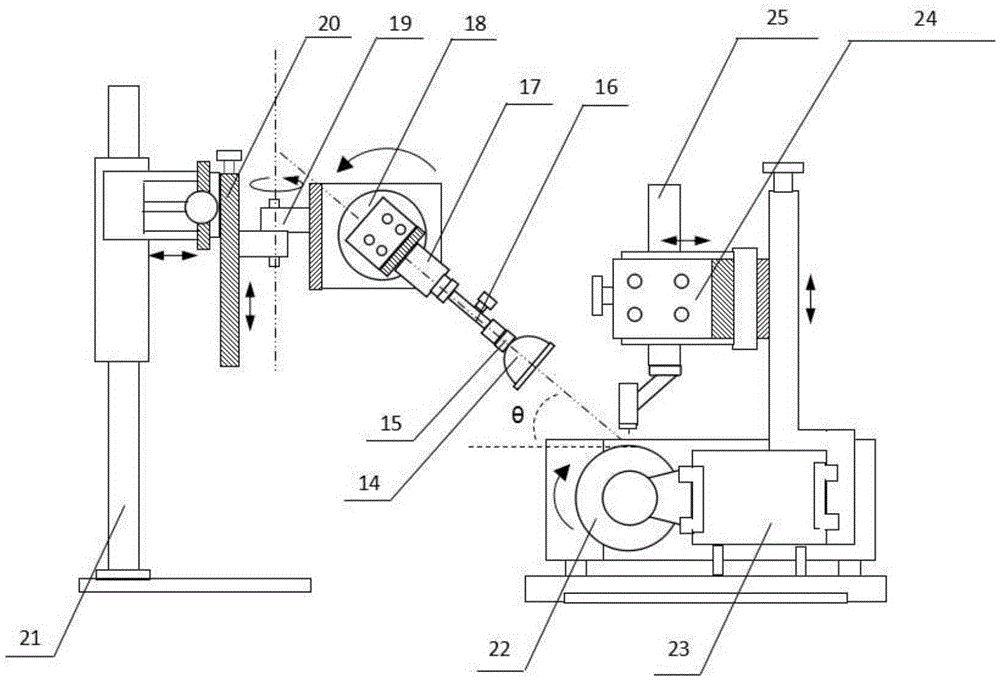

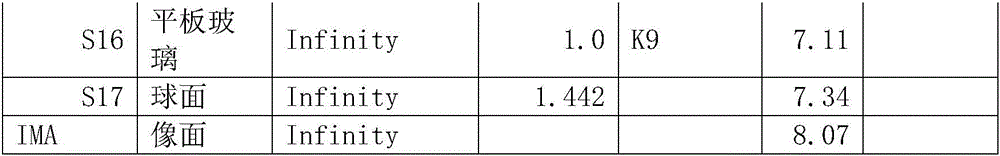

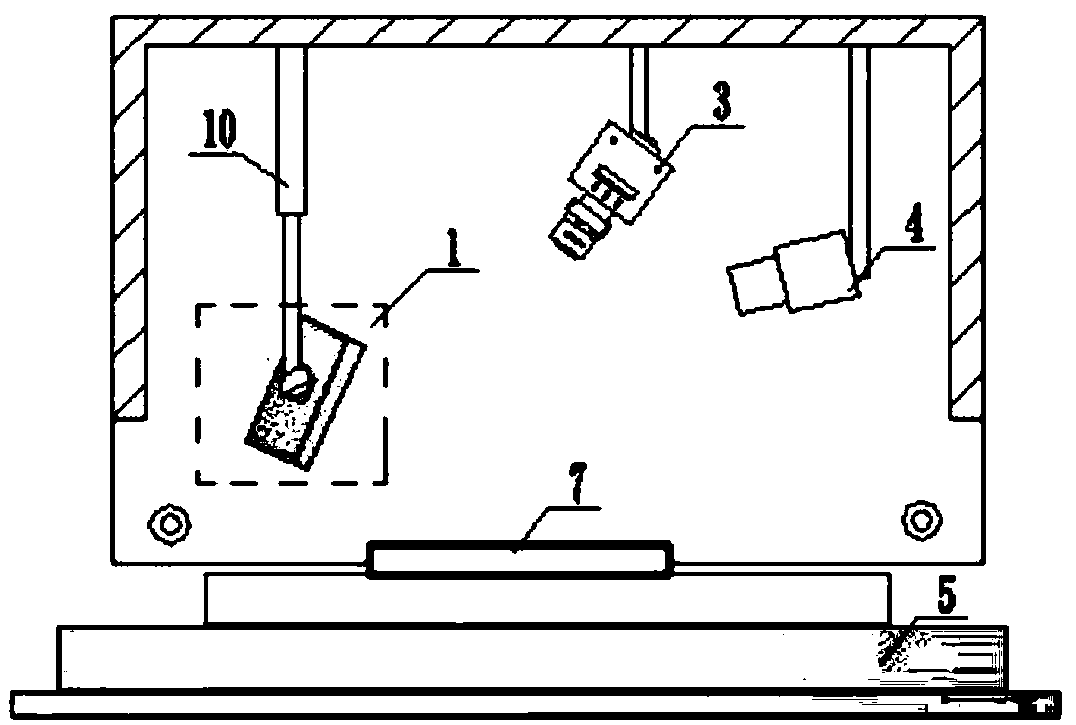

Measuring device for measuring displacement or deformation quantity of parts in high- and low-temperature vacuum glass covers

InactiveCN107957243AImprove image qualityAchieve clear imagingUsing optical meansGlass coverMeasurement device

The invention relates to a measuring device for measuring the displacement or deformation quantity of parts in high- and low-temperature vacuum glass covers and belongs to the measurement field of small displacement or deformation quantity of parts or objects. The measuring device includes a laser, a first cylindrical mounting seat, a first vertical translation frame, a second cylindrical mountingseat, an image sensor, a second vertical translation frame, a computer, a high-temperature vacuum glass cover and a measured object; the high-temperature vacuum glass cover is placed vertically in anaxial direction; the measured object is fixedly installed inside the high-temperature vacuum glass cover; the first vertical translation frame and the second vertical translation frame are respectively arranged at two sides of the high-temperature vacuum glass cover; the first cylindrical mounting seat is fixedly installed on the top of the first vertical translation frame; the second cylindricalmounting seat is fixedly installed at the top of the second vertical translation frame; the laser is fixedly installed inside the first cylindrical mounting seat; and the laser and the image sensor are both communicated with the computer. The measuring device of the present invention directly calculates the displacement or deformation quantity of the measured object, and has the advantages of non-contact measurement, high efficiency, high precision, automated measurement and the like.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

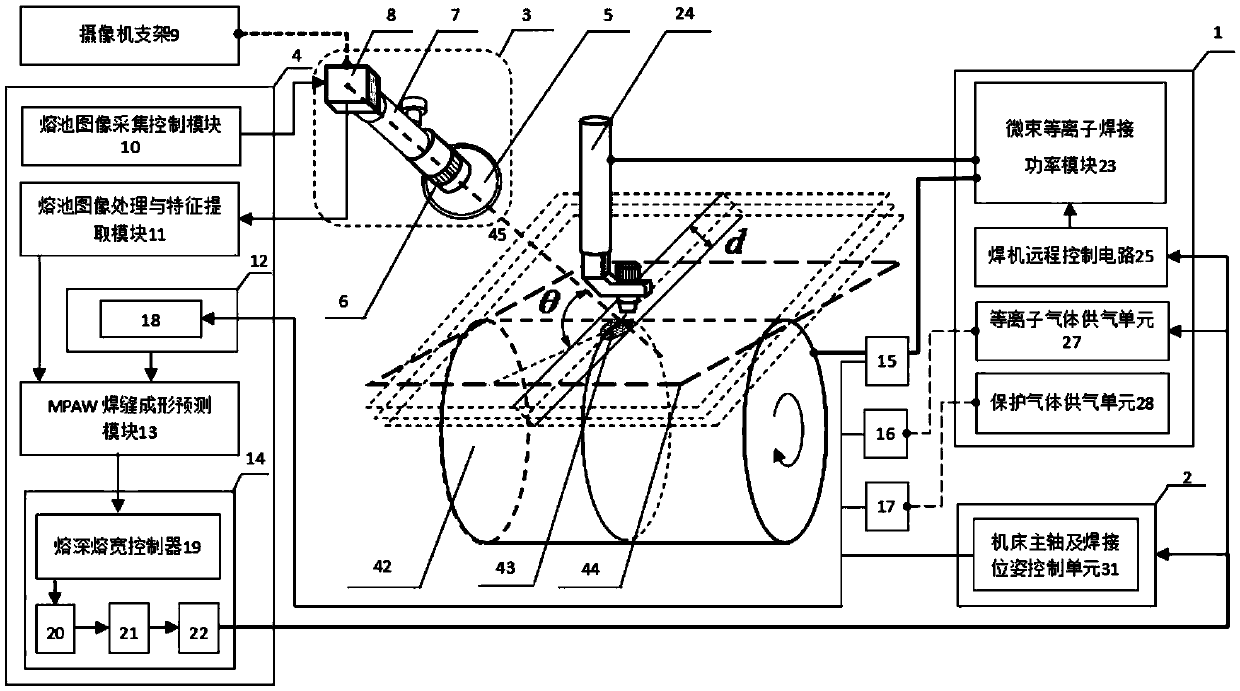

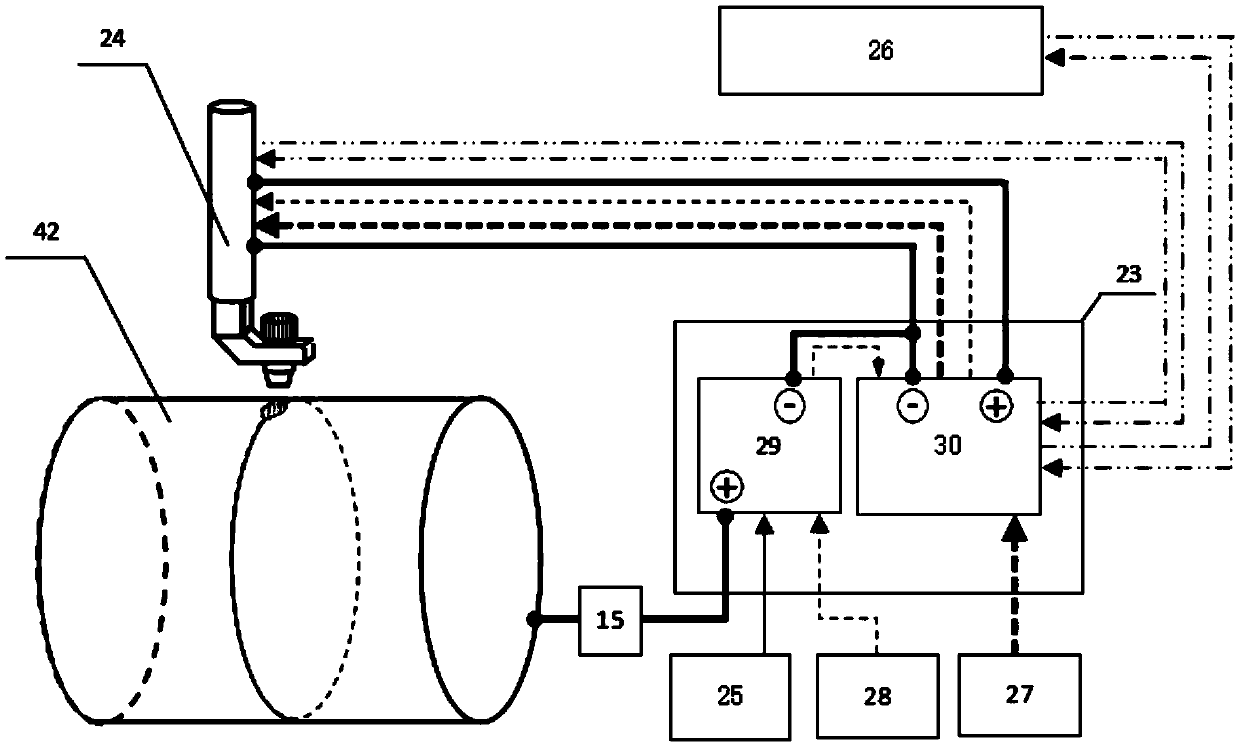

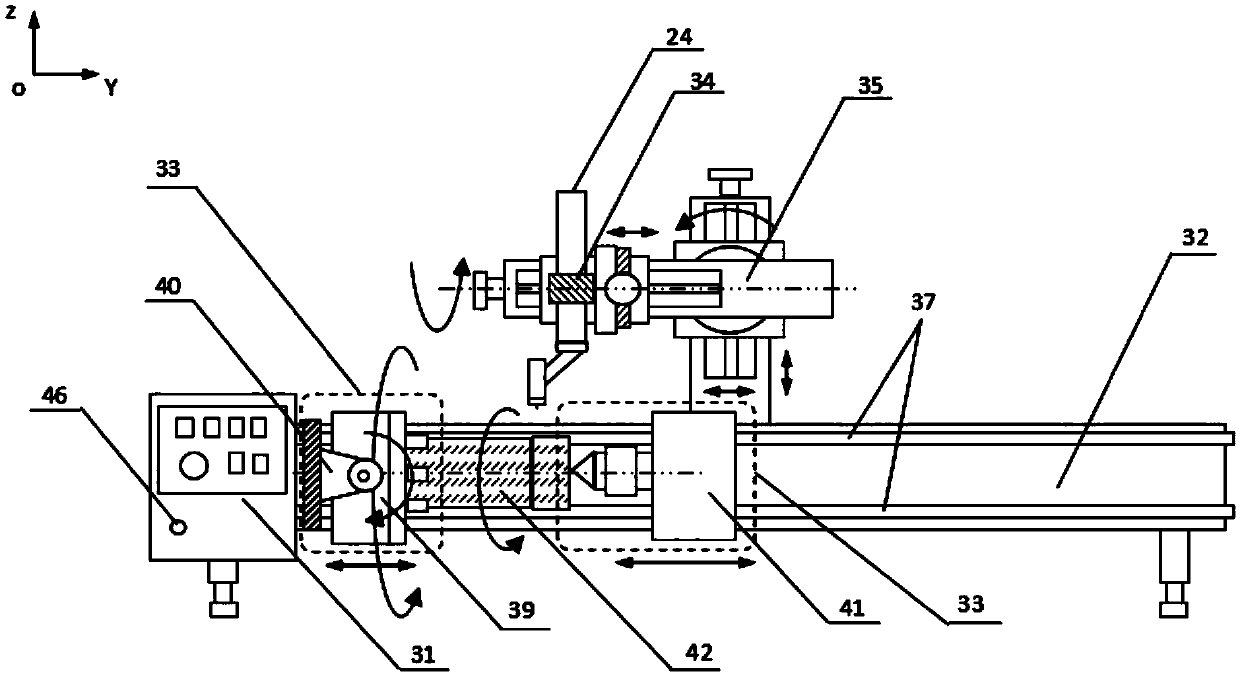

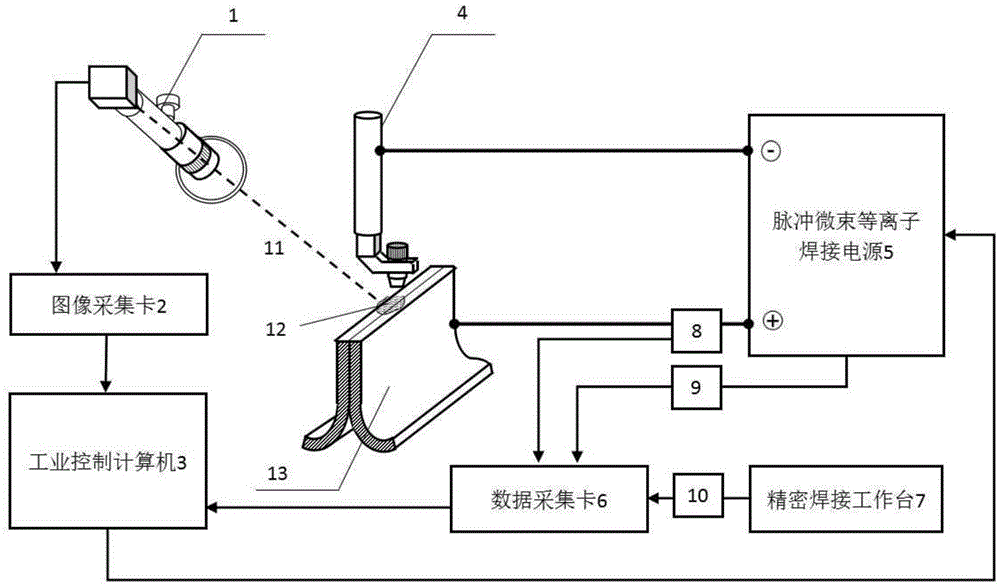

Control system for micro-beam plasma welding formation of thin-wall slit circular longitudinal seam

ActiveCN105499772AAchieve clear imagingImprove quality reliabilityPlasma welding apparatusEngineeringFeature parameter

The invention provides a control system for micro-beam plasma welding formation of a thin-wall slit circular longitudinal seam. The control system comprises a micro-beam plasma welding system, a precision welding workbench, a monocular coaxial telecentric visual sensing system and an MPAW (micro plasma arc welding) formation real-time control unit; the monocular coaxial telecentric visual sensing system is used to acquire a weld pool front transient image for thin-wall slit circular longitudinal seam micro-beam plasma welding, the MPAW formation real-time control unit is used to perform multi-electricity parameter synchronous acquisition of a welding process and online real-time prediction of seam formation feature parameters, and the micro-beam plasma welding system and the precision welding workbench perform real-time adjustment of welding process parameters according to a control command transmitted by the MPAW formation real-time control unit. The system enables an improvement in the quality reliability of welded products and success rate of single welding, is applicable to the micro-beam plasma welding process of thin-wall metal precision members in the fields such as aerospace manufacturing and is particularly applicable to precision welding of elastic elements such as ultrathin-wall membrane boxes and bellows.

Owner:TSINGHUA UNIV

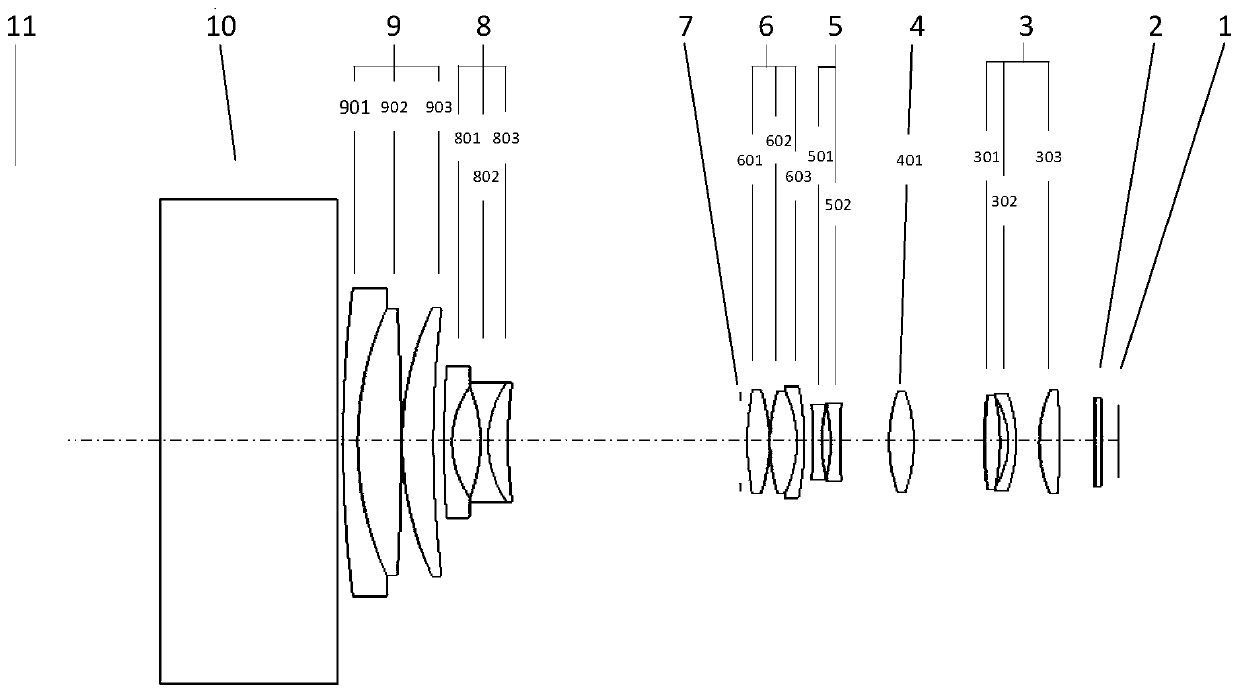

Underwater large-field-of-view continuous zooming optical system

ActiveCN110109237AImprove image qualityRealize continuous zoom functionOptical elementsOptical axisOptoelectronics

The invention provides an underwater large-field-of-view continuous zooming optical system, thereby solving problems of small field of view angle, small zoom ratio, small system size, and complicatedsystem structure of the existing underwater continuous zooming optical systems. The provided underwater large-field-of-view continuous zooming optical system comprises a window, a front fixed mirror group, a zooming mirror group, a diaphragm, an intermediate fixed mirror group, a compensation mirror group, an aberration stabilizing mirror group, a rear fixed mirror group, and a filter that are arranged successively and coaxially in an optical axis direction. The front fixed mirror group includes a first glue mirror group having the positive focal power and a second positive lens. The zooming mirror group includes a second negative lens and a second glue lens group having the negative focal power. The intermediate fixed lens group includes a fourth positive lens group a third glue lens group having the positive focal power. The compensation mirror group includes a fifth negative lens and a sixth negative lens. The aberration stabilizing mirror group includes a sixth positive lens. And the rear fixed mirror group includes a seventh positive lens, a seventh negative lens, and an eighth positive lens. The zooming mirror group, the compensation mirror group, and the aberration stabilizing mirror group can move linearly back and forth in an optical axis direction.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

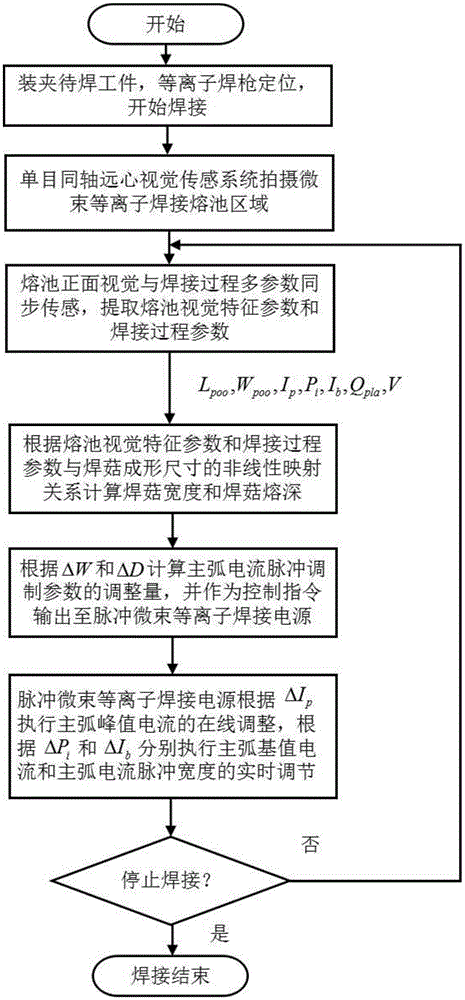

Edge micro-plasma arc welding forming control method based on telecentric vision sensing

ActiveCN105478975AAchieve clear imagingImprove quality reliabilityPlasma welding apparatusEngineeringVisual perception

The invention provides an edge micro-plasma arc welding forming control method based on telecentric vision sensing and belongs to the technical field of welding quality control. Aiming to solve the problems of unstable welding process and non-uniform weld forming caused by energy parameter fluctuation, heat dissipation condition change and the like in a thin-walled edge joint pulsed micro-plasma arc welding process, the method adopts a monocular coaxial telecentric vision sensing system for acquisition of sharp front transient images of a molten pool, performs real-time adjustment on main arc current pulse modulation parameters on the bases of the front transient images of the molten pool and a mapping relation of multiple electric parameters and mushroom weld forming characteristic parameters in a welding process, and realizes accurate control of the edge micro-plasma arc welding mushroom weld forming. The edge micro-plasma arc welding forming control method can improve the quality reliability of welded products and increase the one-time welding qualification rate, can be applied to an edge micro-plasma arc welding process for thin-walled metal precision components in the fields of aerospace manufacture and the like and is particularly applicable to precision welding occasions for elastic components such as ultra-thin-walled capsules, bellows and the like.

Owner:TSINGHUA UNIV

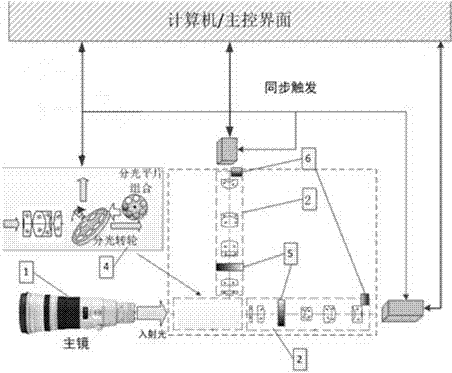

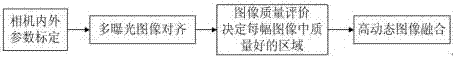

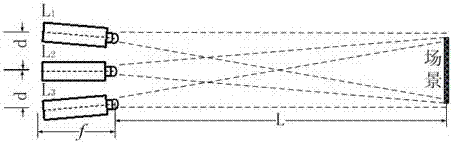

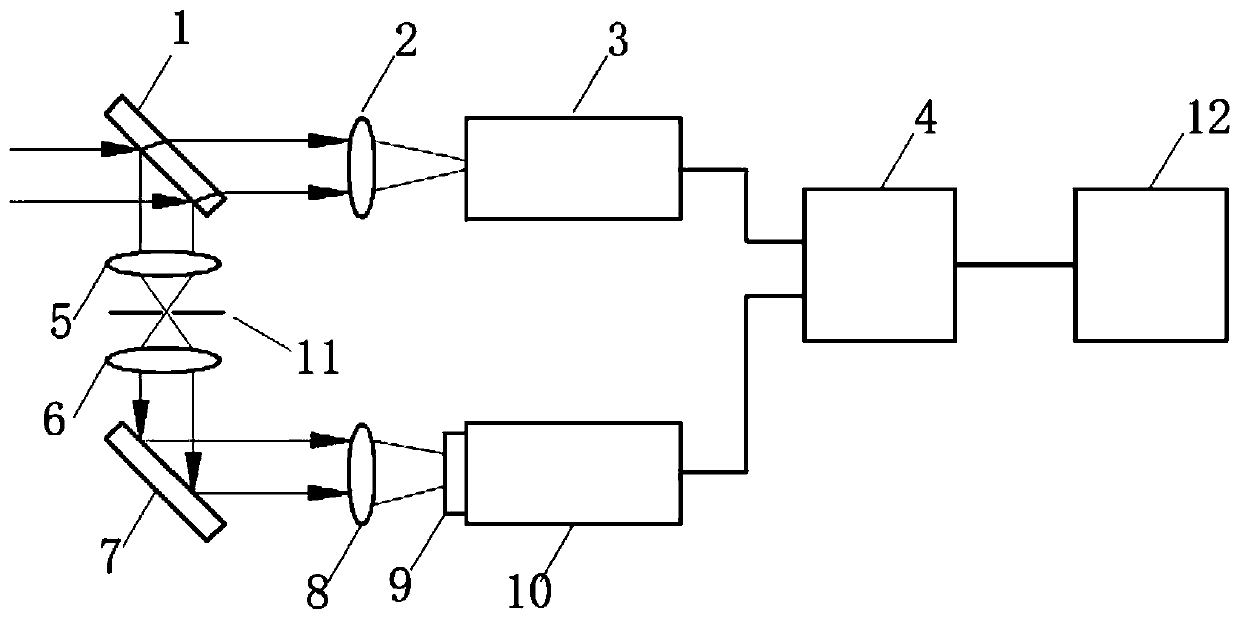

High dynamic range imaging module based on runner dynamic light splitting

InactiveCN107302668AAchieve clear imagingGuaranteed full coverage of linear response dynamic rangeTelevision system detailsImage analysisHigh-dynamic-range imagingTransmittance

The invention relates to a high dynamic range imaging module based on runner dynamic light splitting. Through the combination of a primary mirror, a plurality of adapters and a plurality of cameras, a dynamic adjusting technology of parameters such as light splitting ratio, light intensity transmittance, lens stop and camera exposure time and a multi-source image high dynamic synthesis technology are adopted, and clear imaging in a large dynamic range under scene light intensity extreme change conditions is realized, so that the problem of dynamic exposure adjustment required for high dynamic range imaging is solved, and the module is significant for realizing target high-quality imaging in light measurement.

Owner:NAT UNIV OF DEFENSE TECH

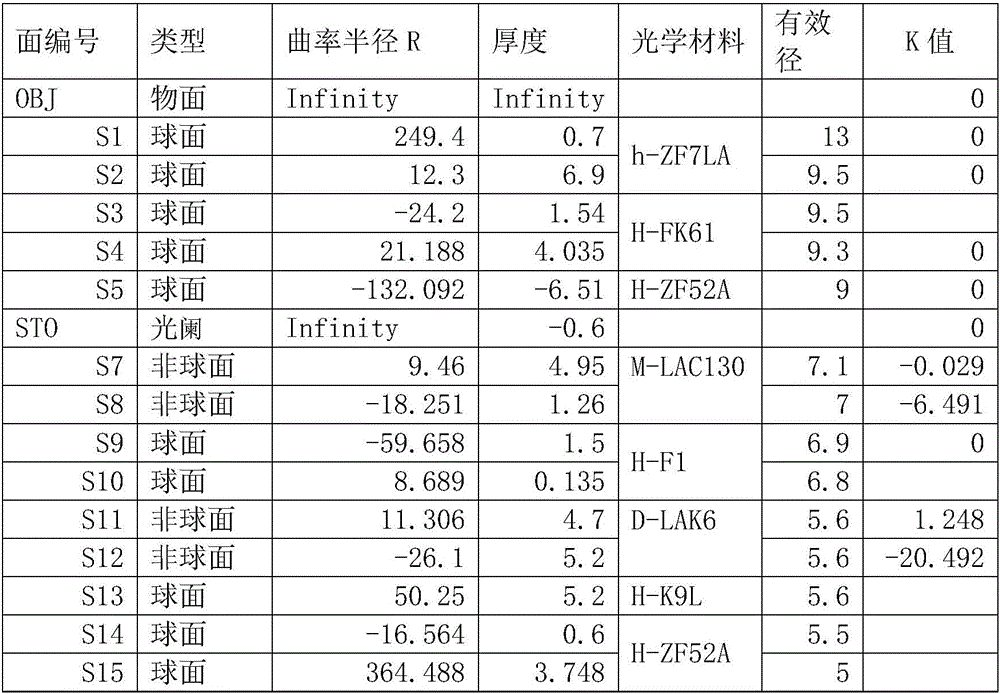

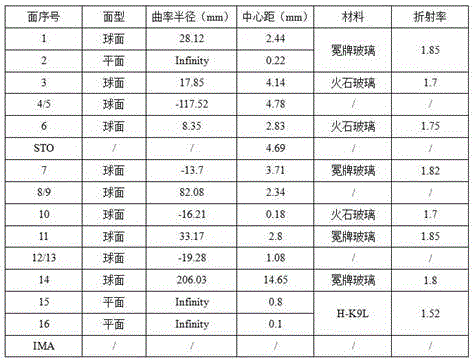

Camera lens used for vehicle-mounted AR-ADAS

The invention provides a camera lens used for a vehicle-mounted AR-ADAS, and belongs to the technical field of imaging of camera lenses. According to the camera lens, the technical problems that the existing camera lens of the vehicle-mounted AR-ADAS is not clear in imaging are solved. The camera lens used for the vehicle-mounted AR-ADAS comprises a first lens with negative power, a second lens with negative power, a third lens with positive power, a fourth lens with negative power, a fifth lens with positive power, a sixth lens with positive power and a seventh lens with positive power in sequence from an object surface to an image surface, wherein a diaphragm is arranged between the third lens and the fourth lens. The camera lens used for the vehicle-mounted AR-ADAS is characterized in that the fourth lens and the fifth lens are combined into a cemented lens; and a cemented surface of the cemented lens bends to an image space. The camera lens used for the vehicle-mounted AR-ADAS hasthe advantage that the imaging is clear.

Owner:平湖动态电子有限公司

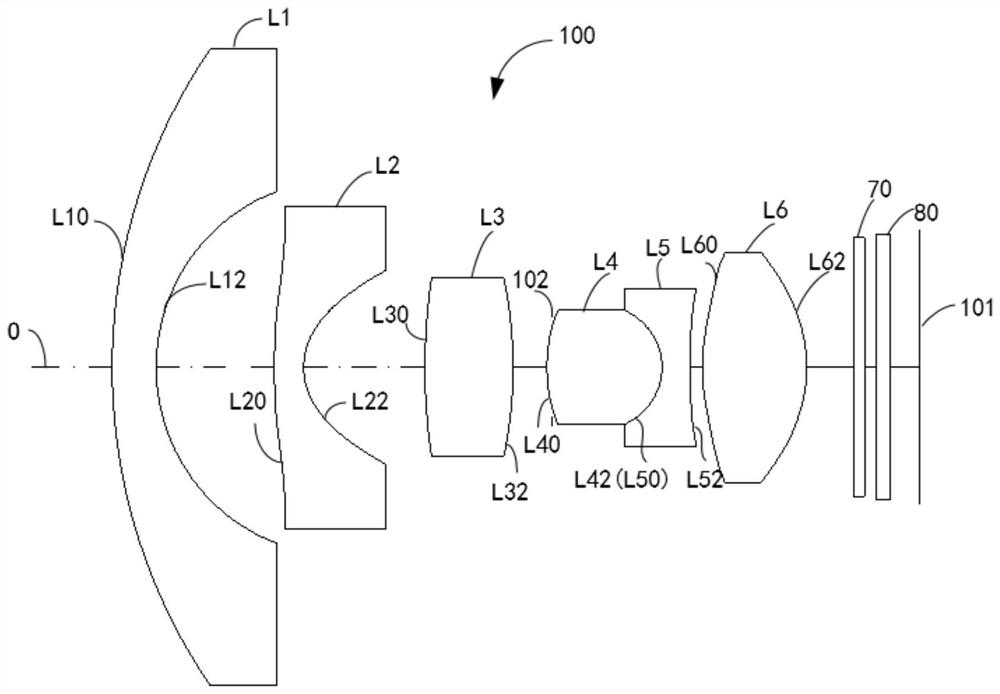

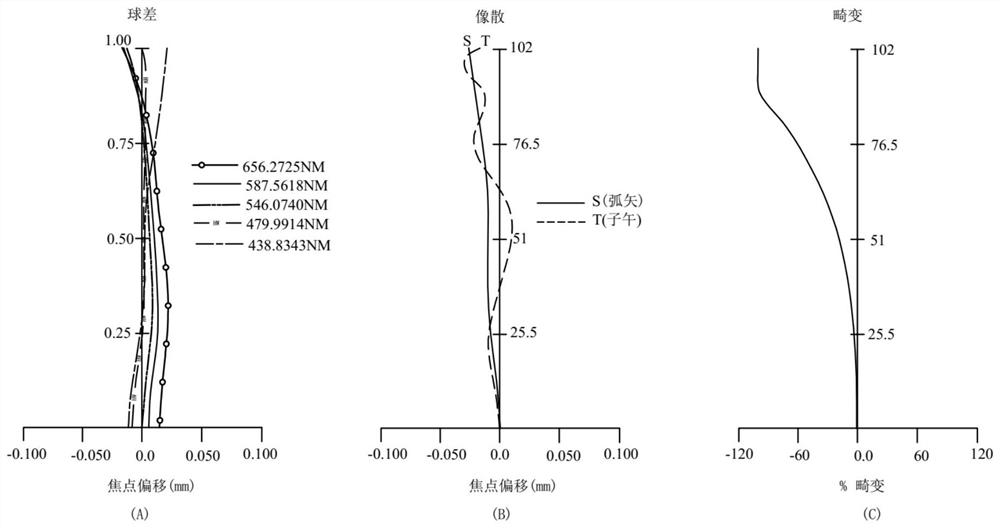

Optical lens, camera module, electronic equipment and automobile

InactiveCN112099197AImprove imaging resolutionCompact structureOptical elementsOptical axisMiniaturization

The invention discloses an optical lens, a camera module, electronic equipment and an automobile. The optical lens comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens anda sixth lens which are sequentially arranged from an object side to an image side along an optical axis; the first lens has negative refractive power, the second lens has negative refractive power, and the third lens has positive refractive power. The fourth lens has positive refractive power, the fifth lens has negative refractive power, the sixth lens has positive refractive power, and the optical lens satisfies the following relation: 3.4 < (D34 + CT4) / (CT5 + D56) < 4. According to the optical lens, the camera shooting module, the electronic equipment and the automobile, due to the fact that the lens has the refraction power and the convex-concave design of the object side face and the image side face, when the relation that 3.4 < (D34 + CT4) / (CT5 + D56) < 4 is met, miniaturization design can be met, and meanwhile large-angle-range shooting and clear imaging can be achieved.

Owner:TIANJIN OFILM OPTO ELECTRONICS CO LTD

Solar blind ultraviolet imaging background light suppression optical system and method

InactiveCN110161374AImprove detection sensitivityReasonable design and structure of the instrumentFault locationOptical elementsLevel fusionOptoelectronics

The invention belongs to the field of weak optical signal detection, and provides a solar blind ultraviolet imaging background light suppression optical system and method for detecting weak ultraviolet signals under the condition of strong sunlight, improving the detection reliability and the measurement sensitivity. The incident light is divided into two paths by using a total reflection total lens A, a visible light imaging light path is arranged on a transmission light path, and the visible light is imaged on a visible light CCD after passing through a visible light imaging objective lens;ultraviolet light is reflected, an ultraviolet light imaging light path is arranged on a reflection light path, the ultraviolet light is incident to a total reflection total lens B, residual visible light in an ultraviolet light path is transmitted out of the ultraviolet light imaging light path from the total reflection total lens B, the ultraviolet light reflected by the total reflection total lens B is imaged on an ultraviolet solar blind CCD after passing through an ultraviolet imaging object lens, and pixel level fusion is carried out on ultraviolet channel signals through an image fusionsystem; and under the condition of larger background light intensity, the detection sensitivity of the solar blind signal is improved.

Owner:SUZHOU MICRONANO LASER PHOTON TECH CO LTD

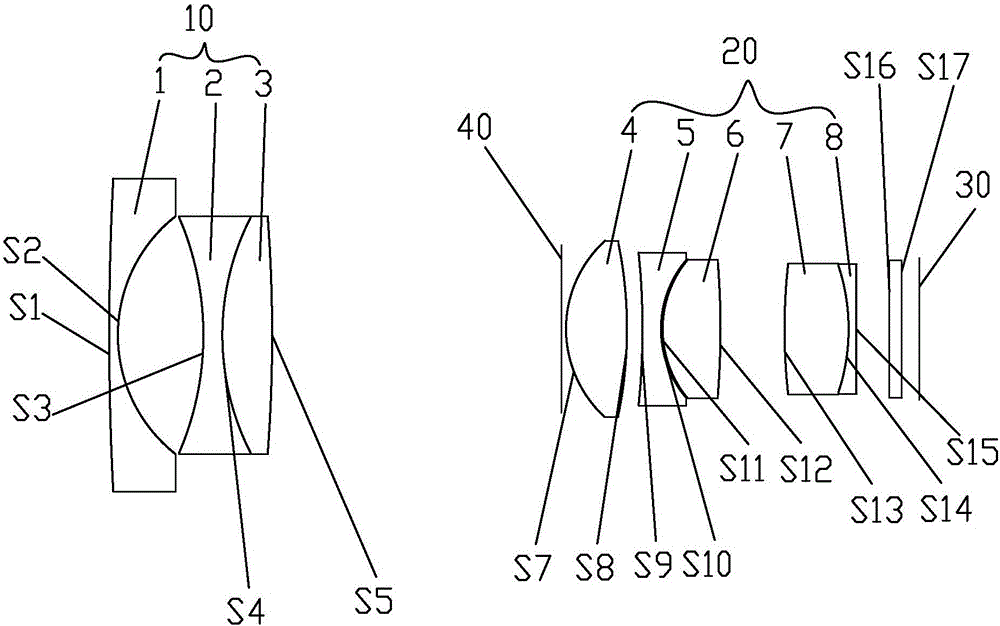

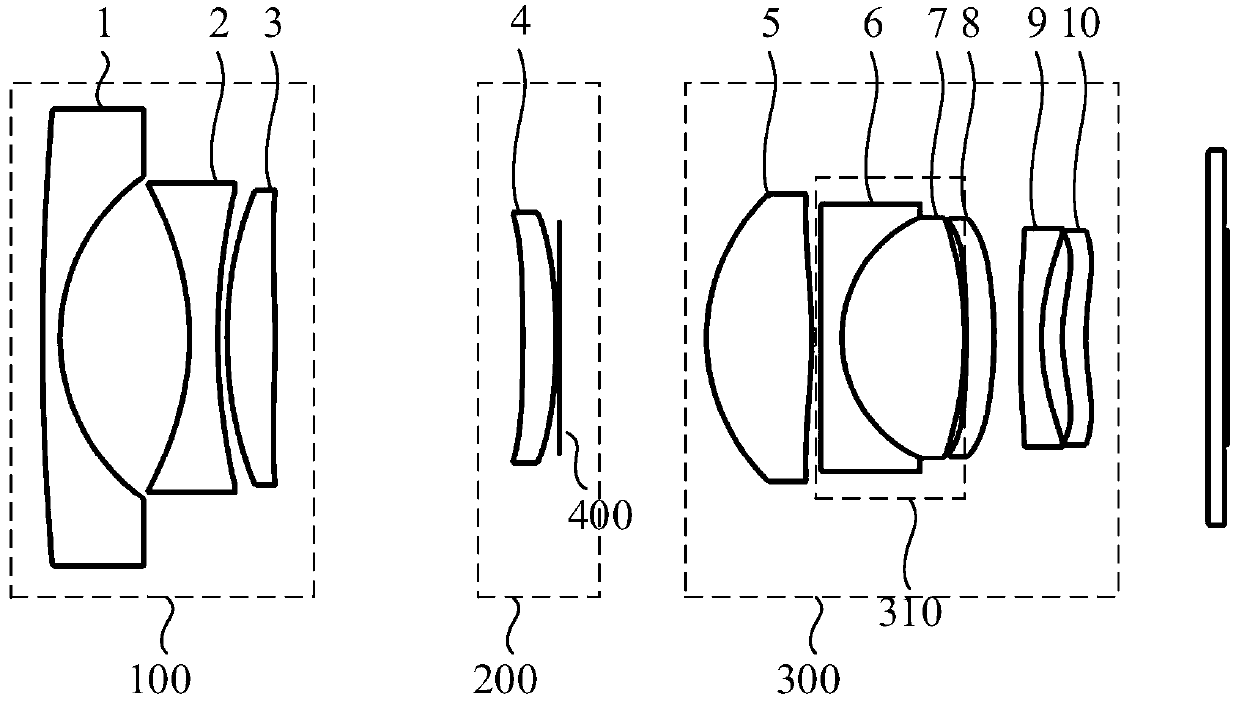

Zoom optical system

The invention discloses a zoom optical system. The zoom optical system comprises a light sensing chip (30), wherein a first lens group (10) capable of moving relative to the light sensing chip is arranged on one side of the light sensing chip (30); a second lens group (20) capable of moving relative to the light sensing chip (30) is arranged between the first lens group (10) and the light sensing chip (30); a diaphragm (40) fixed relative to the position of the light sensing chip (30) is arranged between the second lens group (20) and the first lens group (10); in the changing process of the zoom optical system from a short focal distance to a long focal distance, the first lens group (10) and the second lens group (20) get close towards the diaphragm (40) gradually; and moreover, the integral focal distance of the first lens group (10) is negative, and the integral focal distance of the second lens group (20) is positive. The zoom optical system is small in size, large in image plane and high in resolution ratio.

Owner:UNION OPTECH

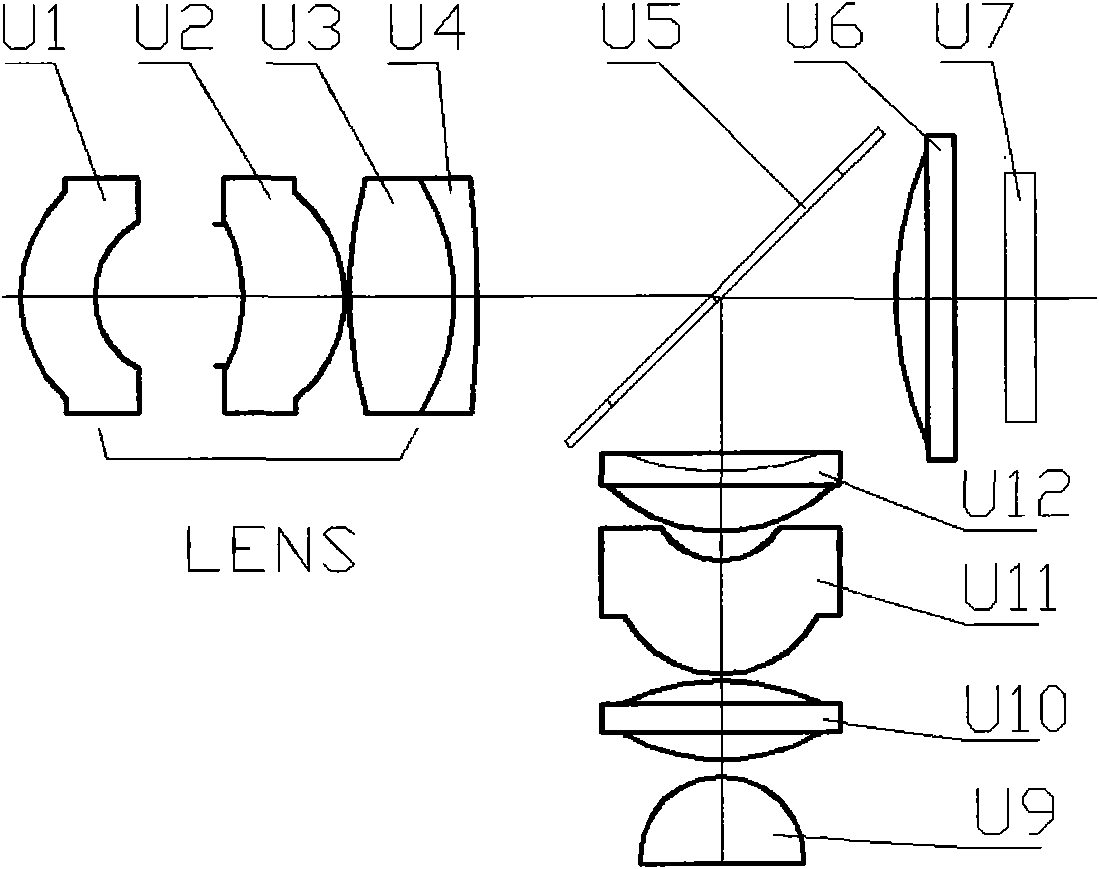

Focus-adjustable retina camera imaging system based on liquid lens

InactiveCN104856643AAchieve clear imagingLow proficiency requirementOthalmoscopesVisibilityLighting system

The invention provides a focus-adjustable retina camera imaging system based on a liquid lens, which comprises an imaging system and an illuminating system, wherein the imaging system comprises an aperture diaphragm, an eye object lens, a spectroscope, an imaging object lens, the liquid lens and an image plane; the components are connected by the respective sequences that the eye object lens, the spectroscope, the imaging object lens and the liquid lens are in sequence disposed behind the aperture diaphragm, and the liquid lens is disposed between the imaging object lens and the image plane. The invention designs the imaging system based on a mechanical focus-adjusting manner, wherein the liquid variable-focus lens is introduced into the imaging system and surface curvature of the liquid lens can be changed continuously by adjusting voltage in order to realize clean human eye imaging with different visibilities. The focus-adjusting manner only needs to adopt a focus-fixed mechanical structure form, has a simple mechanical structure, reduces requirements for proficiency of an operator, and can realize more accurate adjustment by continuously changing the surface curvature of the lens.

Owner:宁波奉化科创科技服务有限公司

Light converter for online detection of surface defects of automobile interior decorative parts, and design method

ActiveCN108693635AAchieve clear imagingReduce complexityMaterial analysis by optical meansMountingsPlane mirrorHigh reflectivity

The invention relates to a light converter for the online detection of surface defects of automobile interior decorative parts, and the light converter is a multiple directional plane mirror group which consists of a plurality of plane reflectors, wherein the number of the plane reflectors is determined by the number of curved surfaces formed by the dividing of the surface of a detected object. The form of each surface of the detected object is corresponding to one independent plane reflector, and the posture of each plane reflector is changed to achieve the focusing of the reflected light ofdifferent surfaces on an imaging plane of a line scanning imaging system. The invention also relates to a design method for the light converter. The light converter can achieve the online detection imaging of the surface quality of a high-reflectivity and multi-curved-surface product.

Owner:DONGHUA UNIV

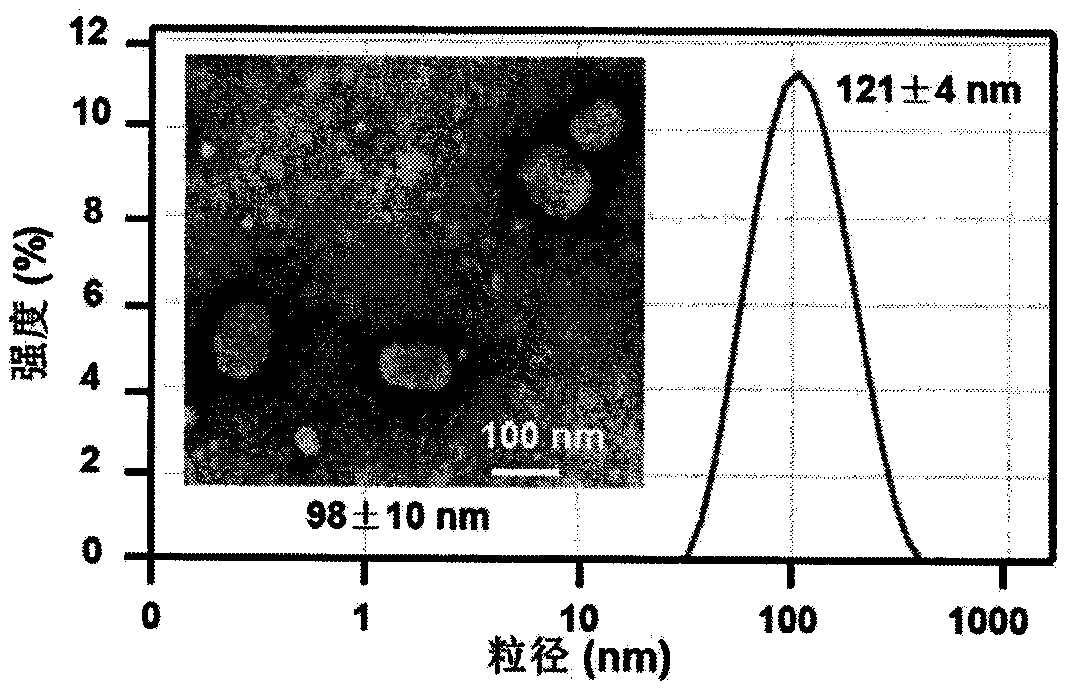

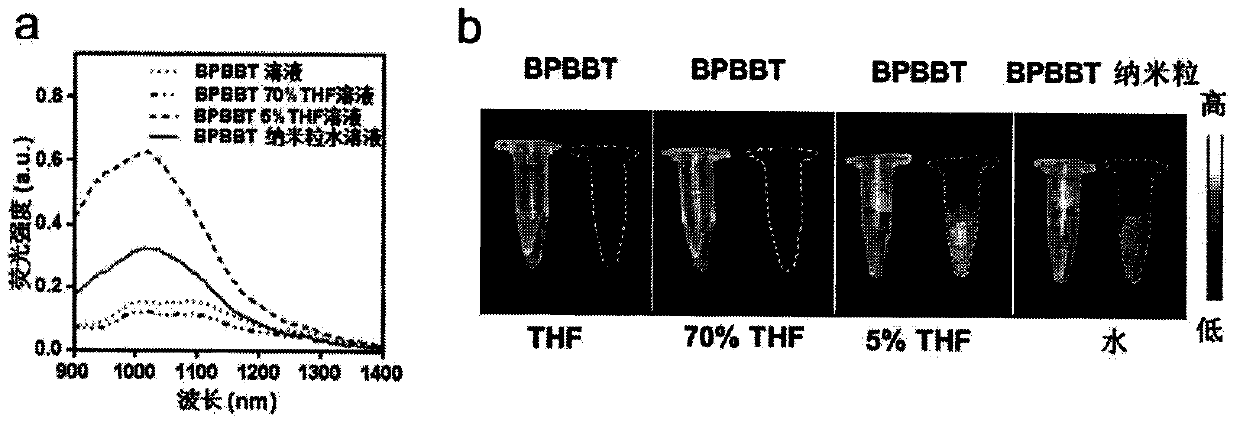

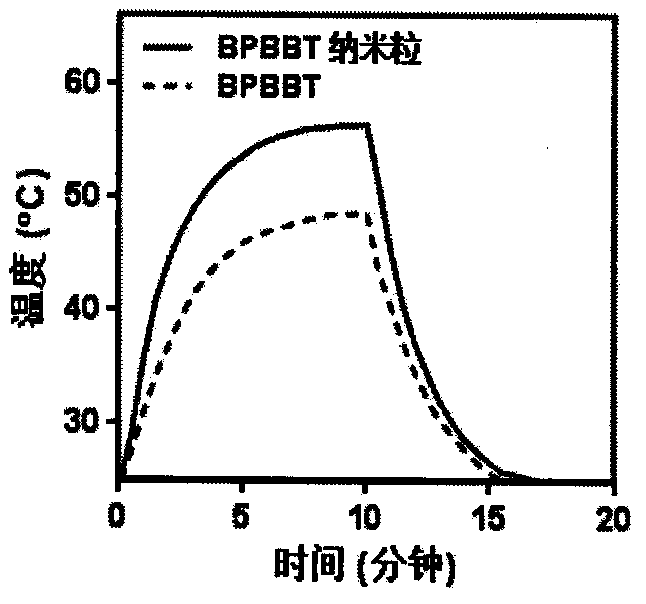

Albumin nano-particle preparation of donor-receptor type fluorescent molecule containing aggregation-induced emission group in near infrared II region

ActiveCN110787305AGood water solubilityEfficient light-to-heat conversion capabilityPowder deliveryEnergy modified materialsInfraredLight energy

The invention belongs to the field of pharmaceutical preparation, and relates to an albumin nano-particle preparation of a donor-receptor type fluorescent molecule containing an aggregation-induced emission group in a near infrared II region. By adopting an emulsifying high-pressure homogenization method, bovine serum albumin, human serum albumin or recombinant human serum albumin and the donor-receptor type fluorescent molecule containing the aggregation-induced emission group are processed so that nano-particles are prepared; albumin is bonded with the fluorescent molecule , so that rotation in the molecule is limited, molecular conformation is changed, and twisted intramolecularcharge transfer and aggregation-induced emission effect are changed, so that the nano-particle preparation having good fluorescence imaging and photothermal conversion is obtained. The nano-particle preparation can emit fluorescence in the near infrared II region under irradiation of infrared light, and a part of light energy is transformed into heat energy, and an image-guided photothermal therapy for cancers is realized. The albumin nano-particle preparation can be used for preparing a medicine for conducting fluorescence imaging and photothermal therapy in the near infrared II region (NIR-II, 1000nm to 1700nm), and the aim of integration of diagnosis and treatment is fulfilled.

Owner:FUDAN UNIV

Vehicle-mounted wide-angle lens

A vehicle-mounted wide-angle lens comprises a first lens of a negative focal power, a second lens of a negative focal power, a third lens of a negative focal power, a fourth lens of a positive focal power, a fifth lens of a negative focal power, a sixth lens of a positive focal power and a seventh lens of a positive focal power successively from the object plane to the image plane; an aperture diaphragm is arranged between the fourth and the fifth lenses; protective glass and an optical filter are configured between the seventh lens and the image plane; the image plane is provided with light reception surfaces of solid shooting components as CCD and CMOS; the first, second and third lenses are falcate lenses which bend towards the image plane; the fifth and sixth lenses are combined into a glued lens, and a gluing side of the glued lens bends towards the image plane; the fourth and fifth lenses are glass lenses of high refractive indexes respectively; and the first, second, third, sixth and seventh lenses are glass lenses of low dispersion.

Owner:JIAXING ZHONGRUN OPTICAL TECH

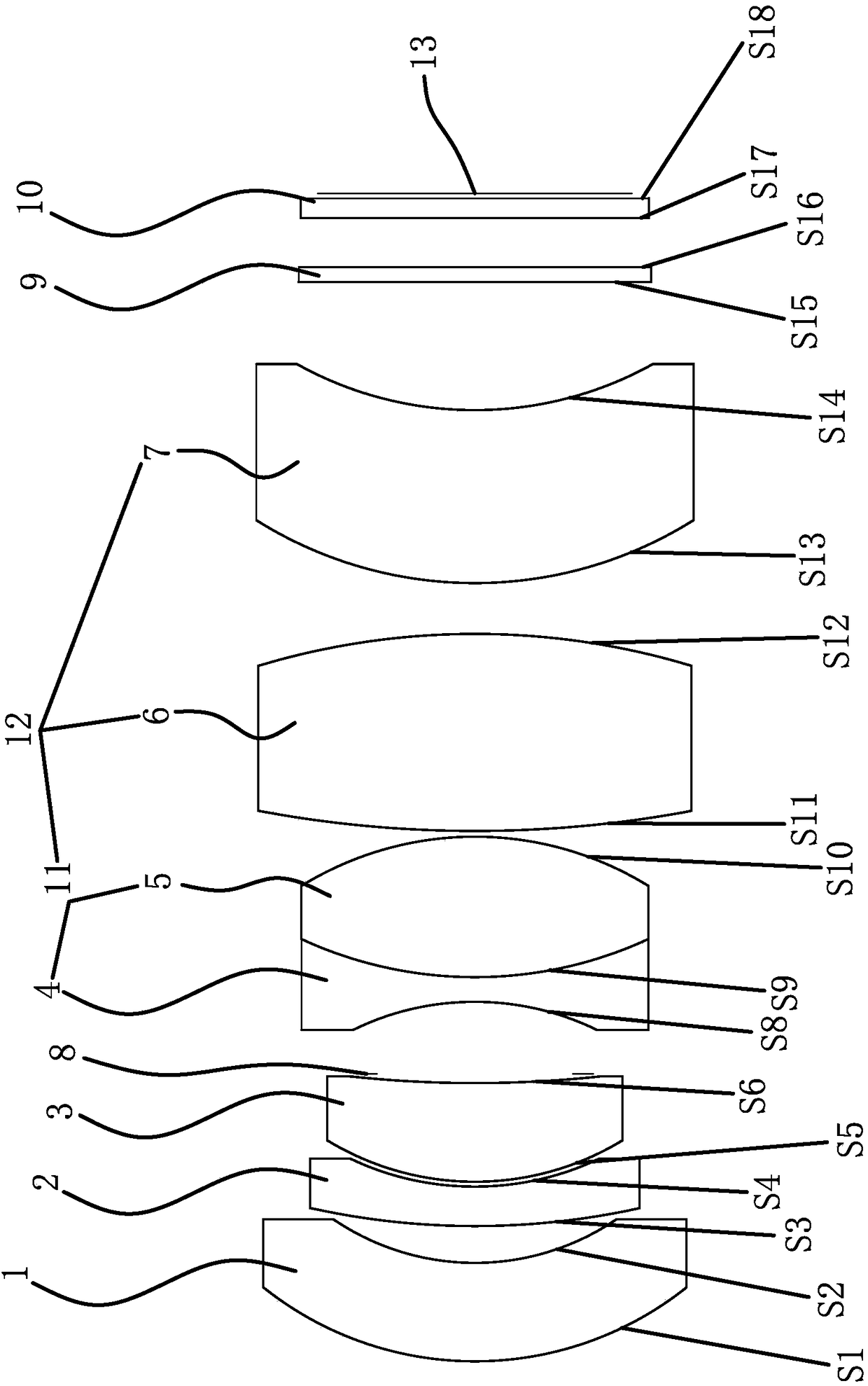

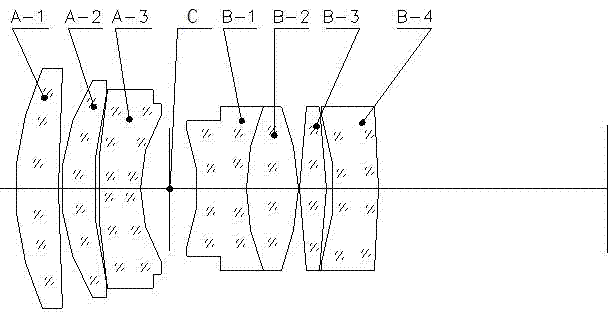

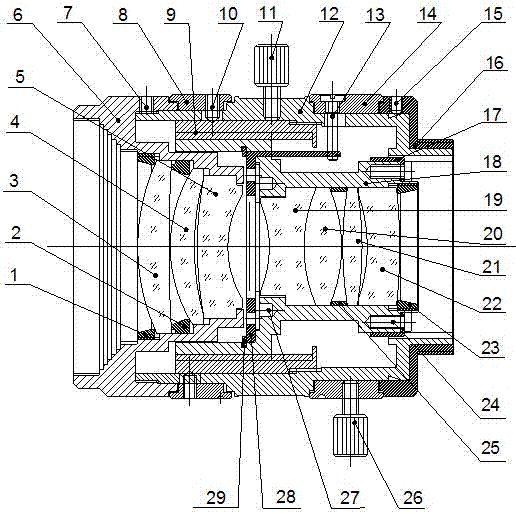

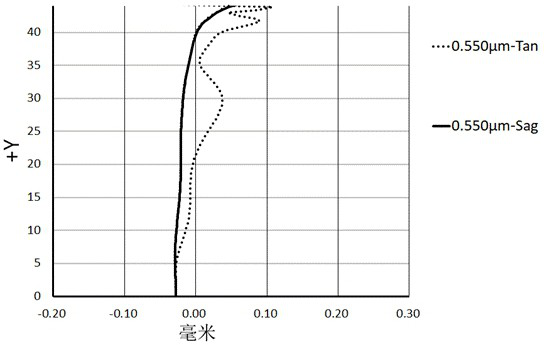

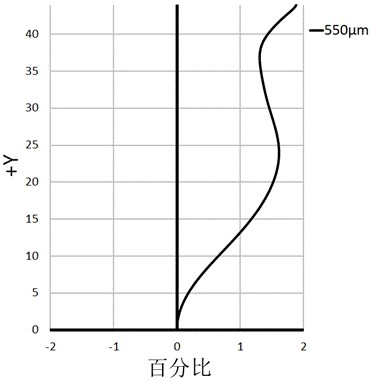

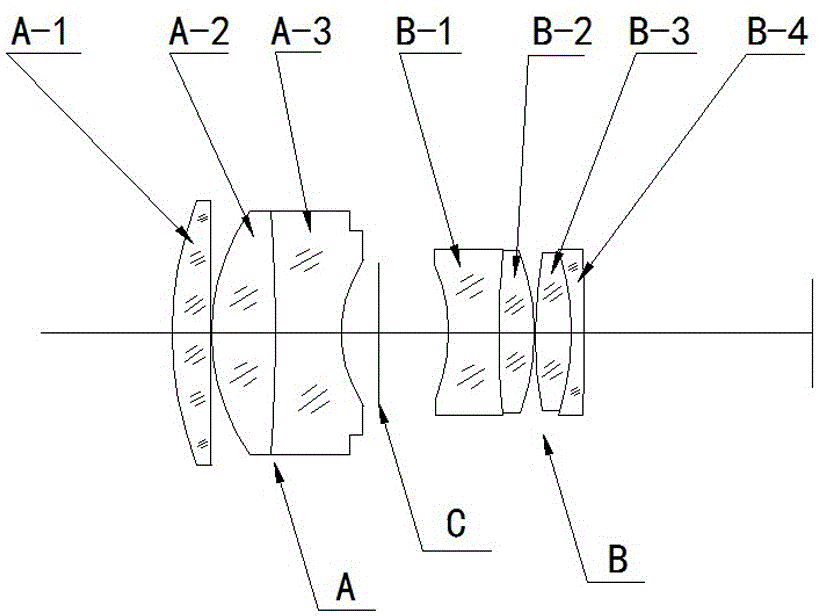

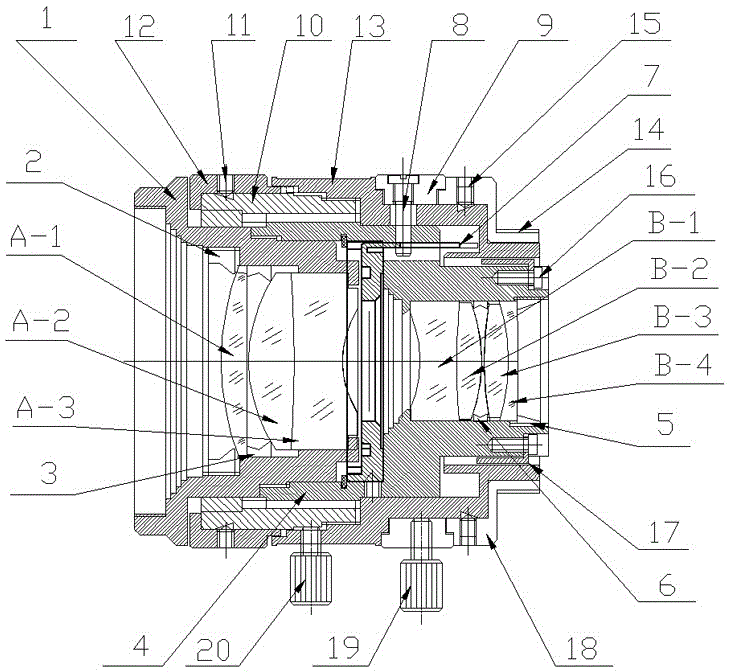

Pick-up lens for high-resolution single group movement industry

The invention relates to a pick-up lens for a high-resolution single group movement industry. A front group A with negative focal power, an iris diaphragm C and a rear group B with positive focal power are sequentially arranged in an optical system of the lens along the incident direction from left to right of light, wherein the front group A is sequentially provided with a positive meniscus lens A-1, a positive meniscus lens A-2 and a negative meniscus lens A-3, and the rear group B is sequentially provided with a glued group with tight joint of a biconcave lens B-1 and a biconvex lens B-2, a biconvex lens B-3 and a positive meniscus lens B-4. The pick-up lens disclosed by the invention has the characteristics of high resolution, large target surface, low distortion, small minimum photographic distance and the like, and can be in adaptation with a high-resolution CCD (charge coupled device) or a CMOS (complementary metal oxide semiconductor) video camera, realize high-resolution videography, simultaneously realize clear imaging with minimum photographic distance of 0.3m and enable the distortion to be lower than 1%.

Owner:FUJIAN FORECAM OPTICS CO LTD

Optical lens

The invention provides an optical lens. From an object side to an imaging surface, the optical lens comprises a diaphragm; a first lens, wherein the object side surface of the first lens is a convex surface, and the image side surface of the first lens is a concave surface; a second lens which has negative focal power; a third lens, wherein the object side surface of the third lens is a convex surface, and the image side surface of the third lens is a concave surface; a fourth lens which has focal power, wherein the image side surface of the fourth lens is a concave surface; a fifth lens, wherein the object side surface of the fifth lens is a concave surface, and the image side surface of the fifth lens is a convex surface; a sixth lens, wherein the object side surface of the sixth lens is a convex surface, and the image side surface of the sixth lens is a concave surface; a seventh lens which has positive focal power; and an eighth lens, wherein the object side surface of the eighth lens is a concave surface, and the image side surface of the eighth lens is a concave surface. The optical lens meets the condition that TTL / ImgH is greater than 1.0 and less than 1.2. According to the invention, the optical lens has the advantages of high pixel, large aperture and high imaging quality.

Owner:JIANGXI LIANYI OPTICS CO LTD

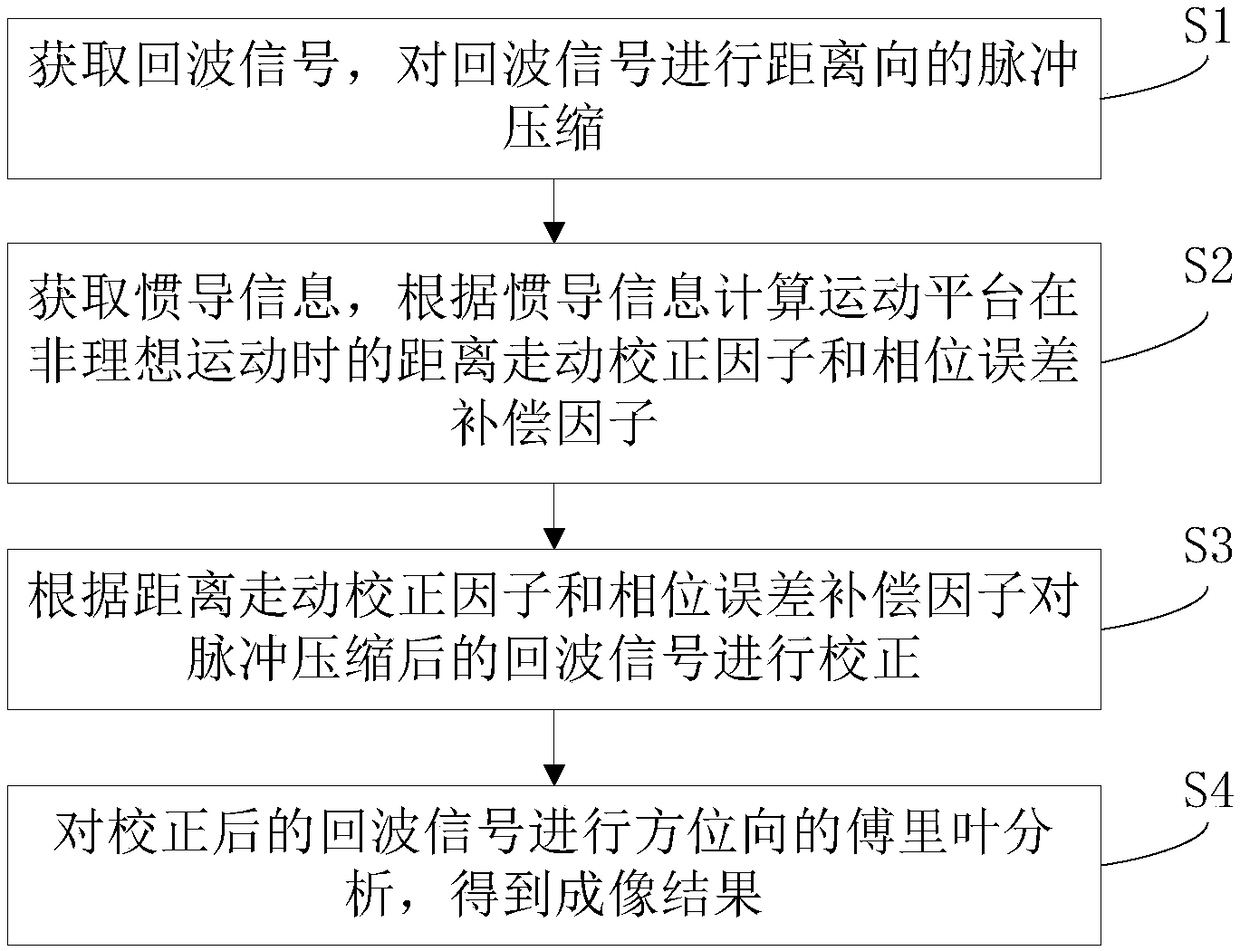

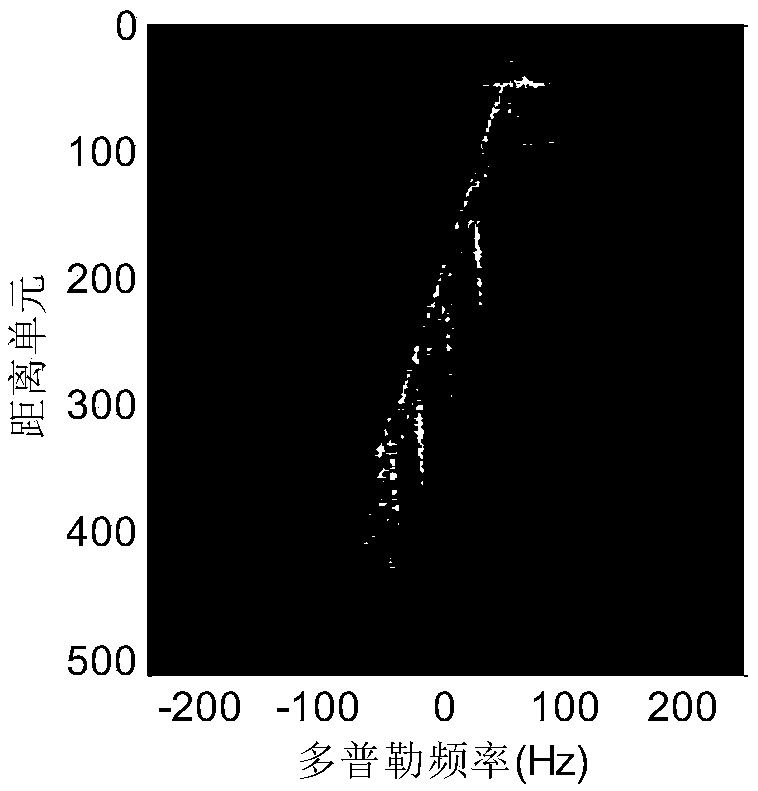

Image method of inverse synthetic aperture radar

InactiveCN109387836AHigh-resolutionSolve the problem of defocus phenomenonRadio wave reradiation/reflectionInterferometric synthetic aperture radarRadar

The invention discloses an imaging method of an inverse synthetic aperture radar, wherein the method relates to the field of the inverse synthetic aperture radar. The method comprises the steps of acquiring an echo signal, performing distance-direction pulse compression on the echo signal; acquiring inertial navigation information, calculating a distance walking correction factor and a phase errorcompensation factor of a moving platform in non-ideal movement according to the inertial navigation information; correcting the echo signal after pulse compression according to the distance walking correction factor and the phase error compensator factor; and performing azimuth-direction Fourier analysis on the corrected echo signal, and obtaining an imaging result. The imaging method according to the invention can realize clear target imaging of the inverse synthetic aperture radar on the condition of the non-ideal movement of the moving platform, thereby improving resolution of the image. Furthermore, the imaging method does not require hardware improvement to existing radar equipment in realization and has high engineering application prospect.

Owner:BEIJING INST OF RADIO MEASUREMENT

High-resolution whole-set mobile industrial photographing camera lens

The invention relates to a high-resolution whole-set mobile industrial photographing camera lens. The high-resolution whole-set mobile industrial photographing camera lens comprises a front set A with negative focal power, a variable light diaphragm C and a rear set B with positive focal power, which are arranged in sequence along light from a left incident direction to a right incident direction, wherein the front set A is composed of a positive crescent-shaped lens A-1, a double-convex lens A-2 and a double-concave lens A-3; the double-convex lens A-2 and the double-concave lens A-3 are tightly connected to form a first gluing set; the rear set B is composed of a double-concave lens B-1, a double-convex lens B-2, a double-convex lens B-3 and a negative crescent-shaped lens B-4; the double-concave lens B-1 and the double-convex lens B-2 are tightly connected to form a second gluing set; the double-convex lens B-3 and the negative crescent-shaped lens B-4 are tightly connected to form a third gluing set. The high-resolution whole-set mobile industrial photographing camera lens provided by the invention is reasonable in optical structure design, and has high resolution, accurate and stable actions including focusing and the like and has a good hand feeling.

Owner:福建福光光电科技有限公司

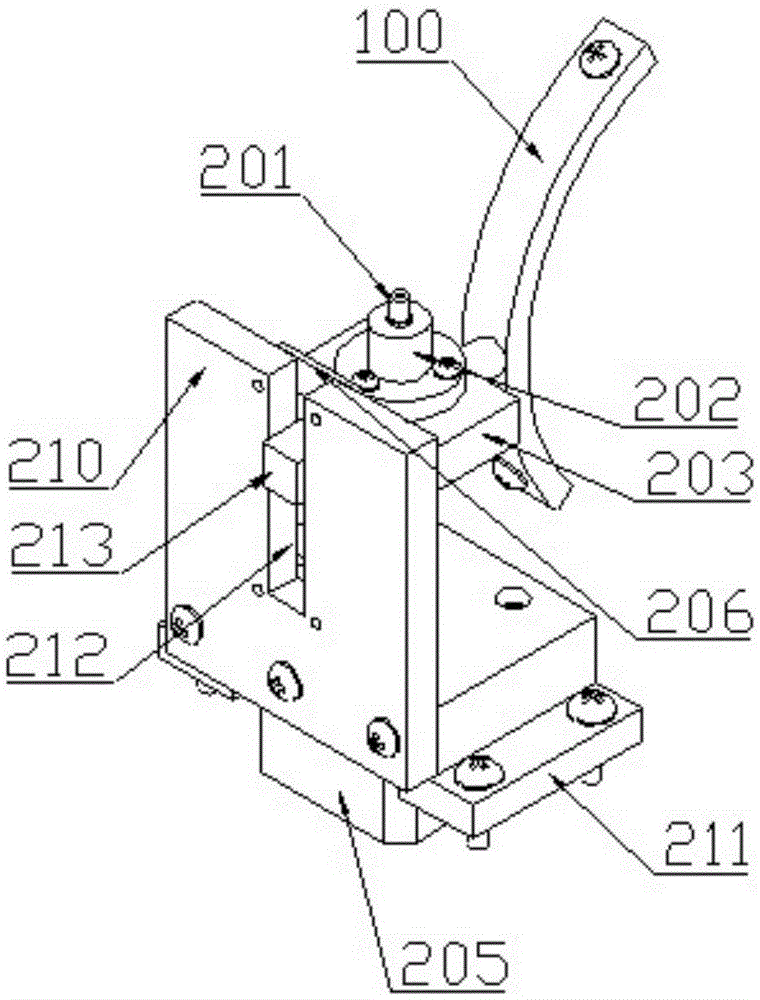

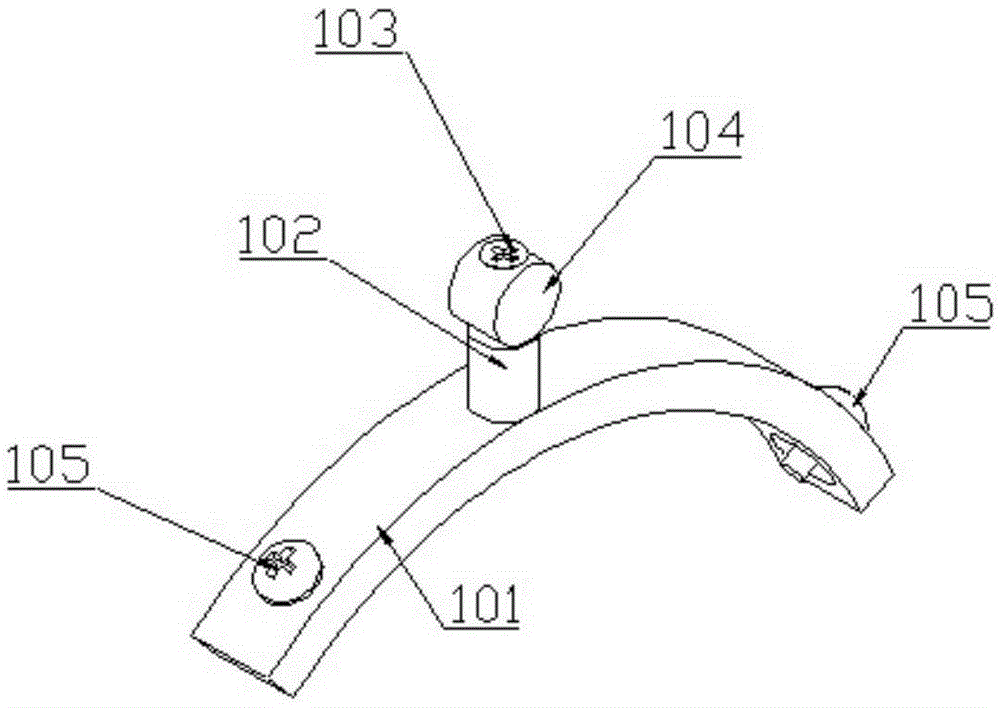

Focusing device and method for satellite remote sensing camera

InactiveCN105334594AAccurate small range focusingClear imagingProjector focusing arrangementCamera focusing arrangementCamera lensSatellite remote sensing

The invention provides a focusing device and method for a satellite remote sensing camera. The focusing device comprises a focusing ring assembly and a motion transmission assembly, wherein the focusing ring assembly and the motion transmission assembly are used for enabling a camera lens focusing ring to conduct small-step-length planar motion. As the focusing ring assembly and the motion transmission assembly which can achieve small-step-length planar motion in orbit are adopted in cooperation with each other, accurate small-range focusing of the camera lens focusing ring is achieved; when the focal plane is out of focus because a satellite is influenced by temperature variation of a space environment, the focal distance of the remote sensing camera can be accurately adjusted through the focusing device, and then clear imaging of the satellite remote sensing camera is achieved. The focusing device has the advantages of being simple in structure, convenient to operate, high in focusing precision and the like, and the excessive focusing problem is avoided.

Owner:NAT UNIV OF DEFENSE TECH

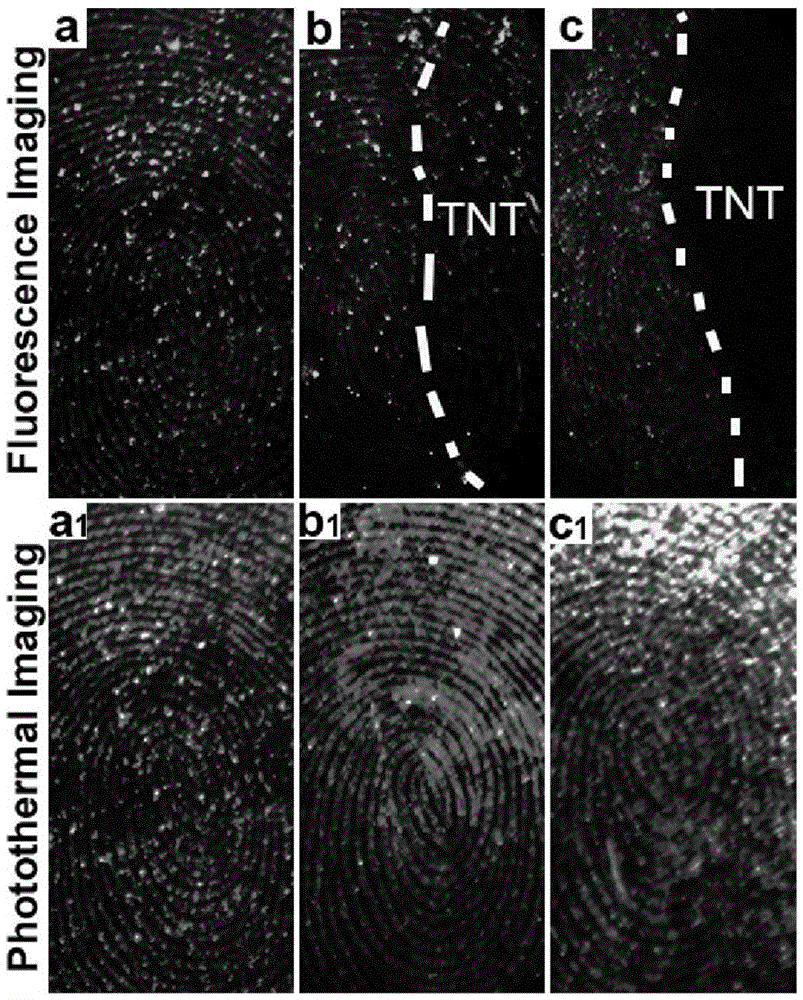

Cu2-xS self-doped semiconductor optothermal material and application thereof to invisible fingerprint imaging

ActiveCN105662425AHigh photothermal conversion efficiencyAchieve clear imagingMaterial nanotechnologyDiagnostic recording/measuringSemiconductor materialsFluorescence

The invention discloses a Cu2-xS self-doped semiconductor optothermal material and application thereof to invisible fingerprint imaging. As polymerization of allyl thiol is used for modifying the surface of the Cu2-xS self-doped semiconductor material with high photothermal conversion efficiency, the Cu2-xS self-doped semiconductor material has amphipathy and can be selectively adsorbed to an invisible fingerprint, and the invisible fingerprint can be imaged clearly under the complicated background by means of near-infrared light radiation and near-infrared imager. In addition, a fluorescence-optothermal bimodal imaging method realized by the Cu2-xS-CdS3@ZnS nanocomposite material is used, residues of 2,4,6-trinitrotoluene and other powerful explosive materials contained in the invisible fingerprint are detected successfully on the condition that fingerprint morphology imaging is complete, a powerful means is provided for scouting crime evidence of criminal offenders, and the Cu2-xS self-doped semiconductor optothermal material can play an important role in judicial expertise and anti-terrorist application.

Owner:BEIJING UNIV OF CHEM TECH

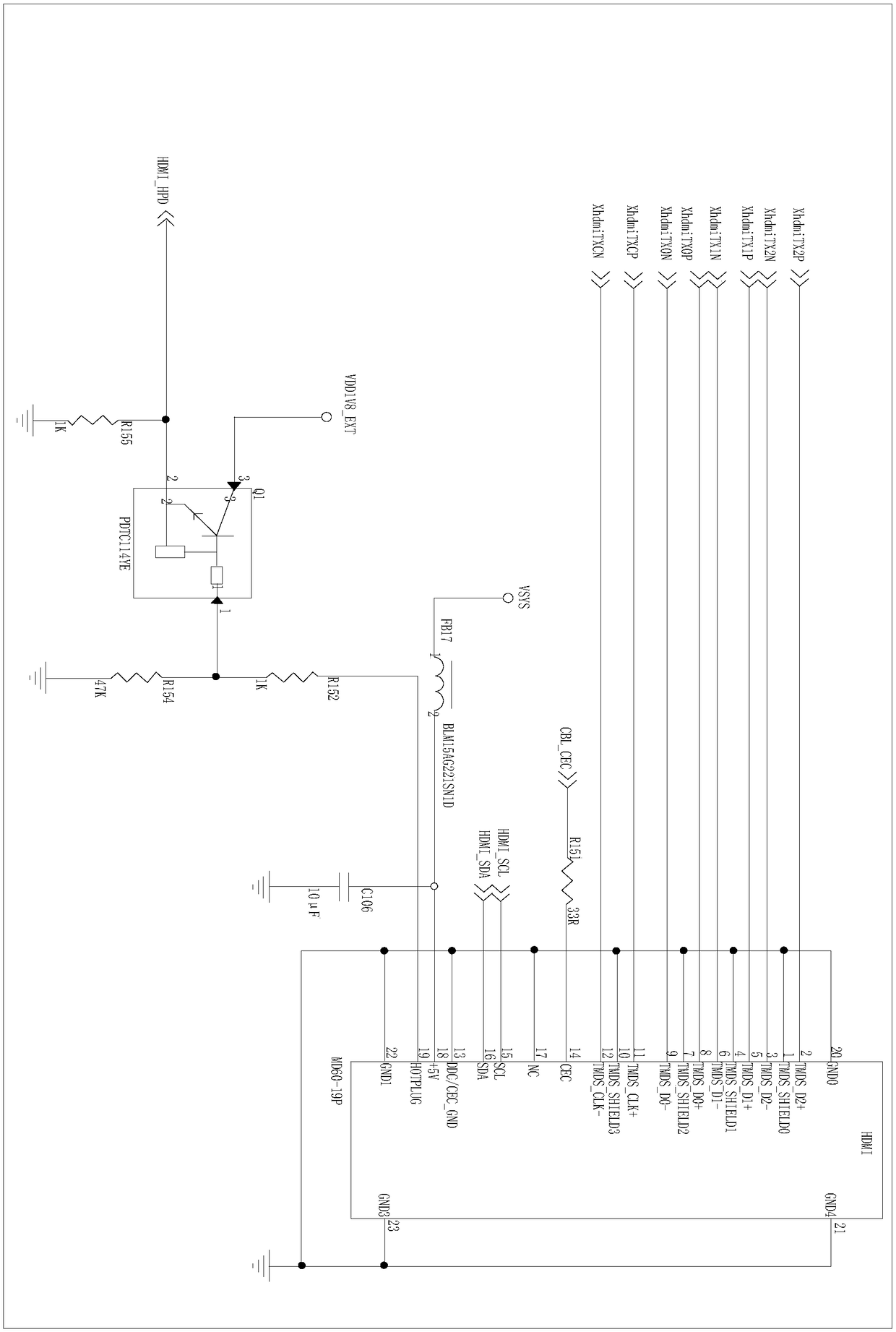

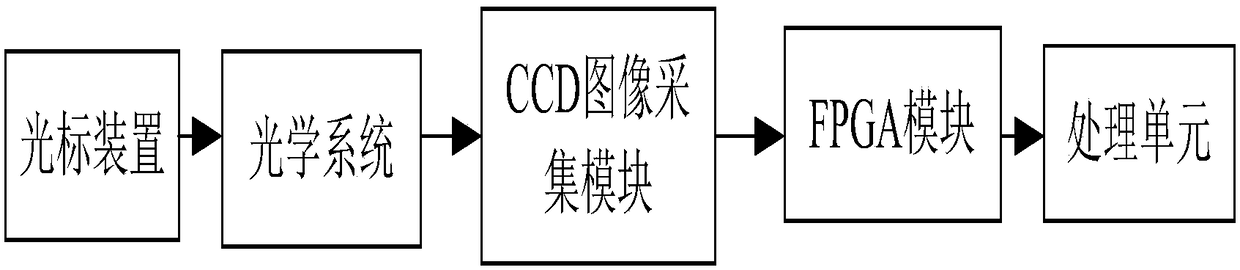

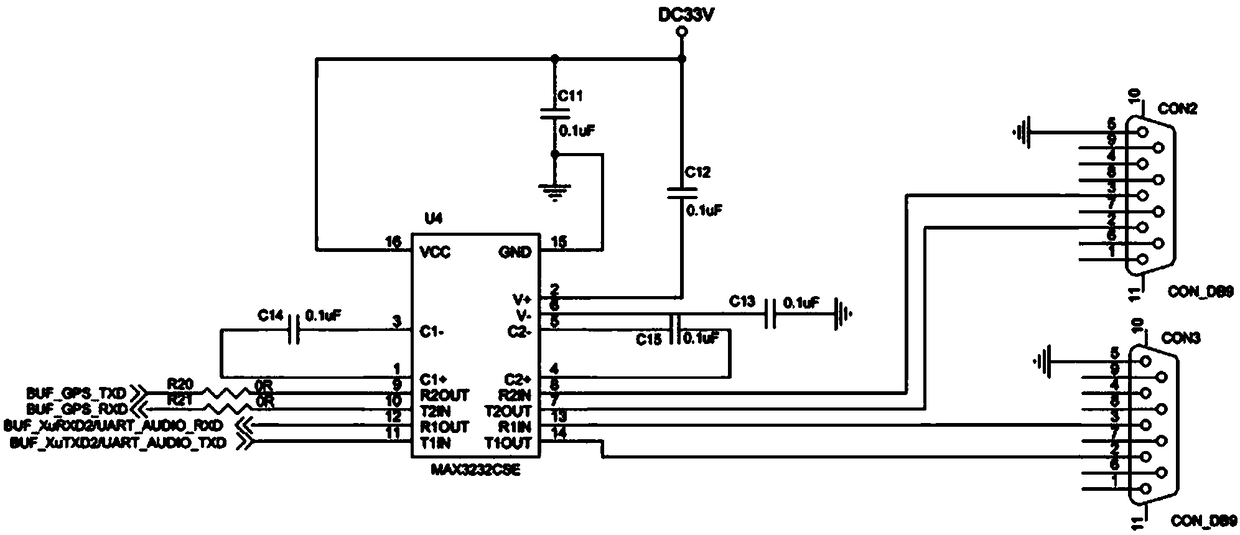

Bridge amplitude real-time monitor

PendingCN108444663AAchieve clear imagingImprove recognition accuracyElasticity measurementField-programmable gate arrayComputer science

The invention discloses a bridge amplitude real-time monitor, comprising a cursor device added to an amplitude point of a bridge, an optical system for imaging the cursor device on a receiving area array of a CCD (Charge Coupled Device) image acquisition module, an FPGA (Field Programmable Gate Array) module for judging the bridge amplitude according to the center movement condition of the cursordevice in an cursor device image before and after the vibration of the bridge, and a processing unit for performing data processing on the output information of the FPGA module and controlling the communication between various modules. The bridge amplitude real-time monitor is based on an image recognition technology; since the optical system is added in front of the receiving area array of the CCD image acquisition module, the image is clearly imaged, the detection range is greatly improved, the recognition accuracy of cursor center can be improved, and the immunity measurement accuracy is improved.

Owner:李自强 +2

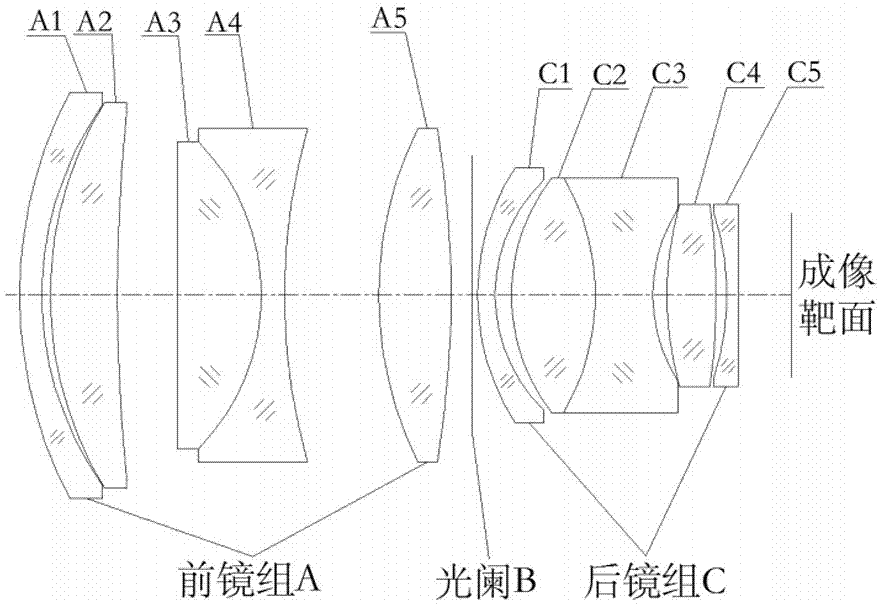

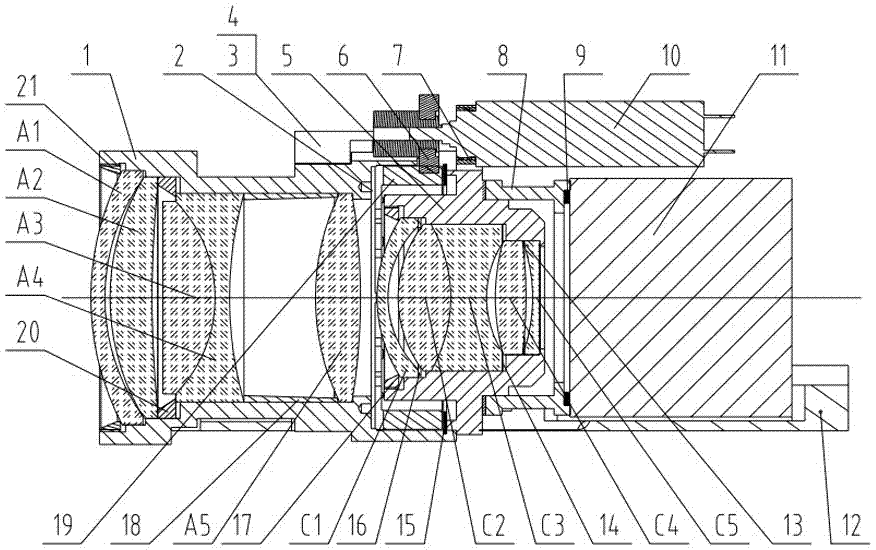

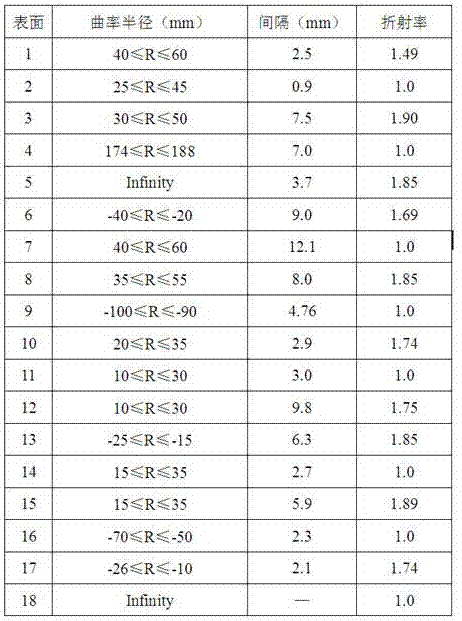

Large-aperture large-target-surface low-light imaging lens

The invention relates to a large-aperture large-target-surface low-light imaging lens. In an optical system of the lens, a front lens group A, a variable diaphragm B and a rear lens group C are arranged successively from left to right along the light incident direction; the front lens group A comprises a negative crescent-shaped lens A1, a positive crescent-shaped lens A2, a first gluing group formed by closely connecting a plano-convex lens A3 with a double-concave lens A4, and a double-convex lens A5 arranged successively from left to right; and the rear lens group C comprises a negative crescent-shaped lens C1, a second gluing group formed by closely connecting a double-convex lens C2 with a double-concave lens C3, a double-convex lens C4 and a plano-convex lens C5 arranged successivelyfrom left to right. The lens uses 10 spherical lenses, F1.0 large-aperture large-target-surface clear imaging is realized, and the detection capability of the lens under a weak illumination conditionis improved effectively; and at the same time, the lens is compact in structure, small in size and low in weight.

Owner:FUJIAN FORECAM OPTICS CO LTD

Zoom lens

The embodiment of the invention discloses a zoom lens. The zoom lens comprises a focusing group, a fixed group and a zoom group which are sequentially arranged from an object space to an image space;in the zooming process, the position of the fixed group is fixed, and the zooming group and the focusing group move along an optical axis; wherein the focal power of each group at the wide-angle end relative to the zoom lens satisfies a certain relational expression; the focusing group comprises a first lens, a second lens and a third lens, the fixed group comprises a fourth lens, and the zoom group comprises a fifth lens, a sixth lens, a seventh lens, an eighth lens, a ninth lens and a tenth lens; the sixth lens and the seventh lens form a cemented lens group, and the focal power of each lensrelative to the corresponding group is set to satisfy a certain relational expression. According to the embodiment of the invention, the zoom lens can be formed by mixing four glass lenses and six plastic lenses, the manufacturing cost of the zoom lens can be properly reduced, light weight is realized, meanwhile, the visible light aberration is well corrected, and a confocal effect of visible light and infrared light is ensured.

Owner:DONGGUAN YUTONG OPTICAL TECH

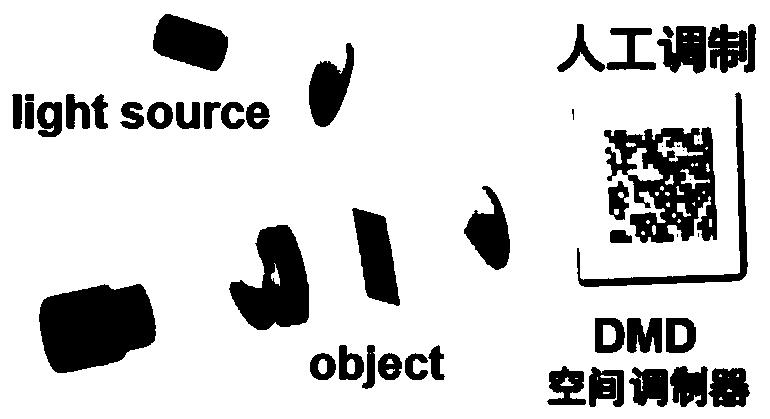

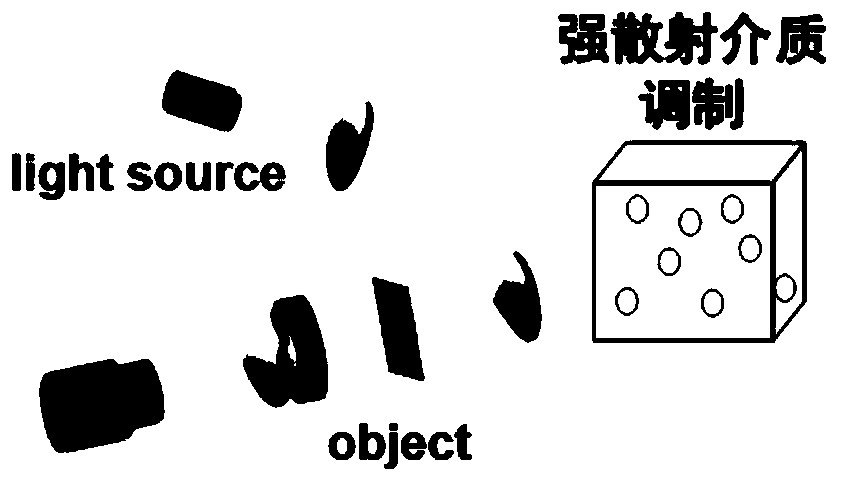

Single-pixel imaging method based on atmospheric scattering medium modulation

ActiveCN111352126AImproving Optical Imaging CapabilitiesAchieve clear imagingElectromagnetic wave reradiationModulation patternImage reconstruction algorithm

The invention discloses a single-pixel imaging method based on atmospheric scattering medium modulation, and the method comprises the steps: enabling a laser beam to enter an atmospheric scattering medium, taking the atmospheric scattering medium as a spatial modulator, and calculating a single modulation pattern of the atmospheric scattering medium under a current condition; in the modulation mode, enabling light in the atmospheric reflection direction to reach a target through the lens, and enabling the barrel detector to collect all light signals from the target to obtain a detection value;randomly changing the transmission direction of the laser beam entering the atmosphere to obtain a series of different modulation patterns of the atmosphere for light field modulation; taking the single modulation pattern as a row vector, and forming an atmospheric scattering medium measurement matrix by row vectors corresponding to a series of different modulation patterns; obtaining a measurement vector composed of a series of detection values corresponding to a series of different modulation patterns; and recovering the target signal by using an image reconstruction algorithm. According tothe method, an atmospheric scattering medium is used as a spatial modulator for single-pixel imaging, and clear imaging of a target surrounded by the scattering medium is realized.

Owner:NAT SPACE SCI CENT CAS

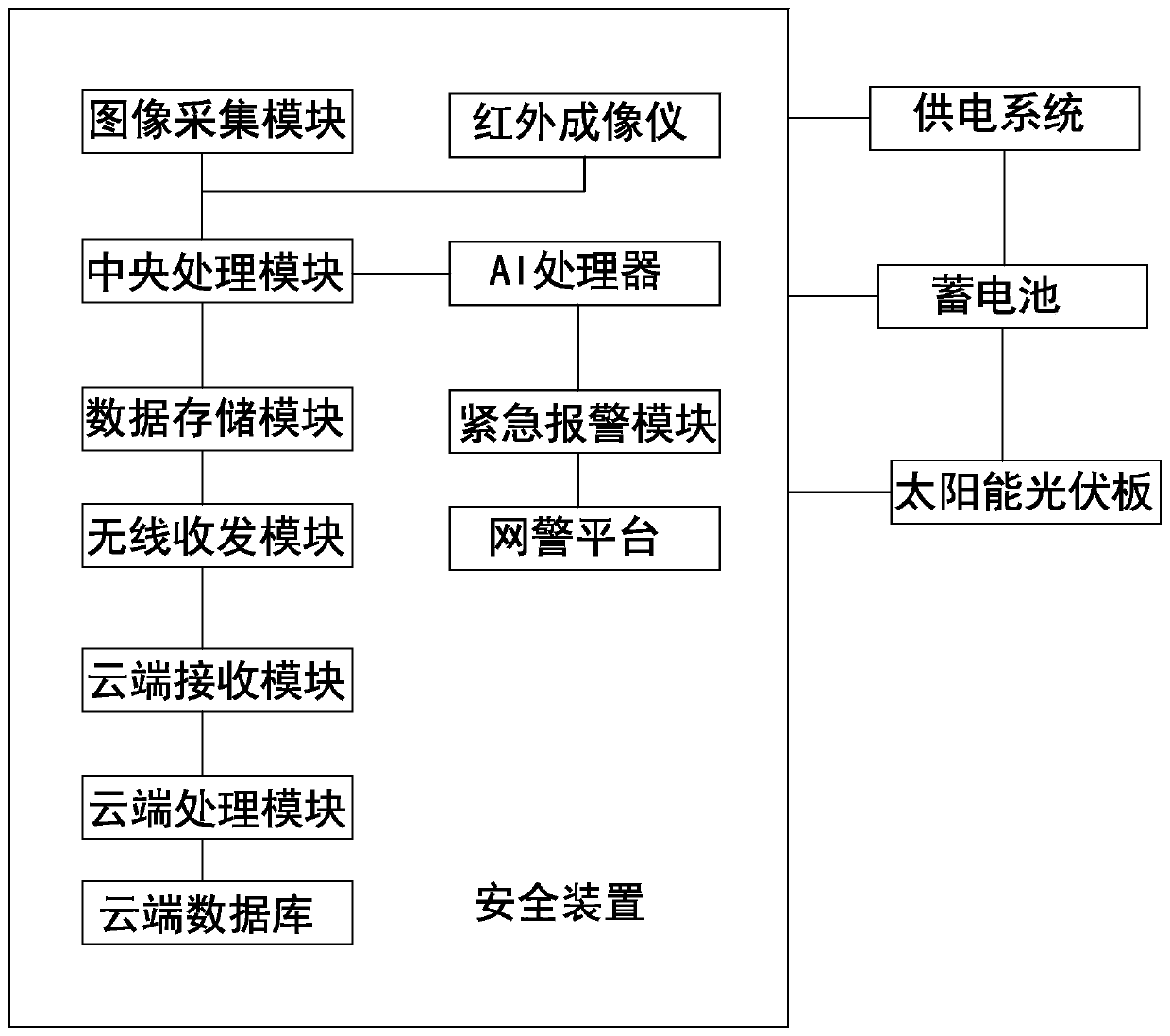

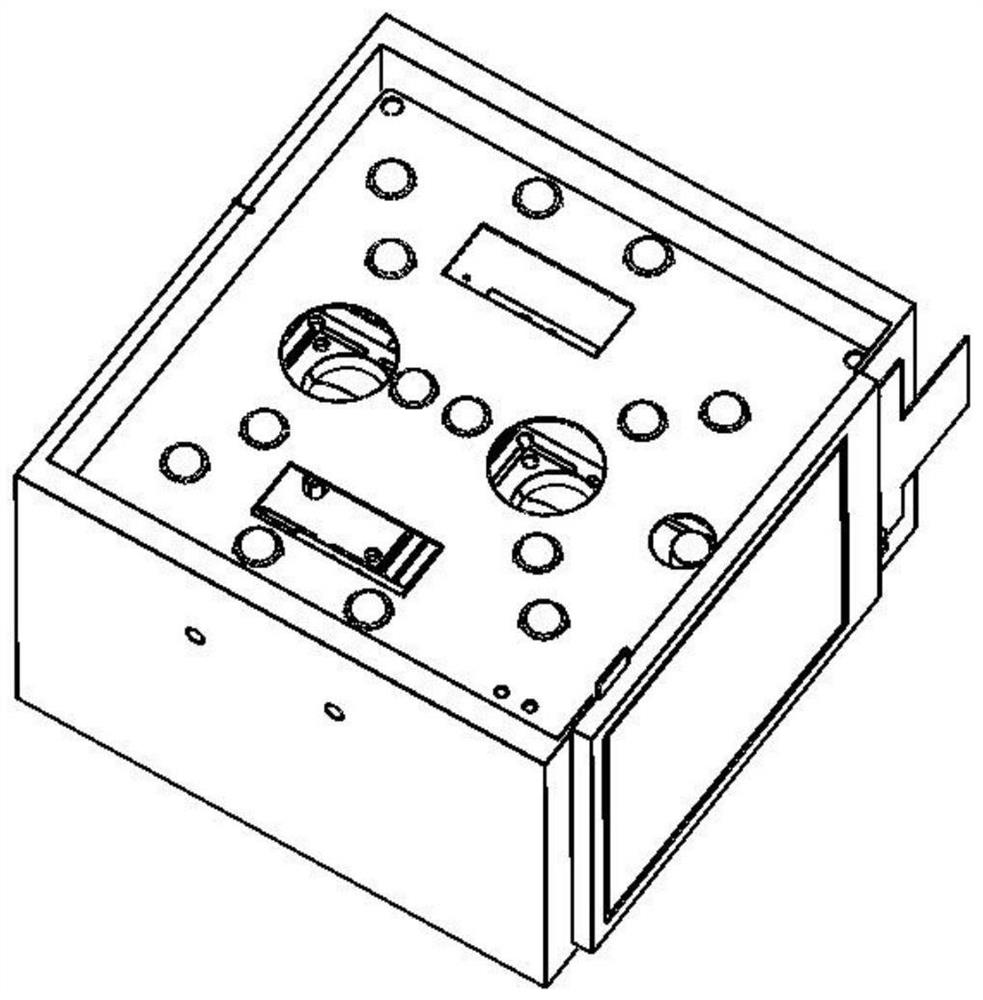

Smart street lamp provided with infrared imaging module

InactiveCN110410743AEasy to viewEasy to identifyMechanical apparatusElectric circuit arrangementsEngineeringInformation transfer

The invention discloses a smart street lamp provided with an infrared imaging module. The smart street lamp comprises a street lamp body and a safety device installed on the street lamp body, whereinthe safety device comprises an image collection module, infrared imagers, a central processing module, a data storage module and a wireless receiving and transmitting module; a plurality of cameras are arranged on the image collection module, one infrared imager is arranged above each camera, the cameras are used for shooting real-time images of surroundings of the street lamp, and the shot real-time images are sent to the central processing module; the infrared imagers collect infrared information of the surroundings of the street lamp and send the infrared information to the central processing module; the central processing module synthesizes the real-time images and the infrared information to generate clear image information, and the image information is stored in the data storage module; and the wireless receiving module transmits the image information in the storage module to a cloud platform, so that it is convenient to look up in case of a problem later and to view in the ordinary using process.

Owner:JIAXING QUANWEI PHOTOELECTRIC TECH

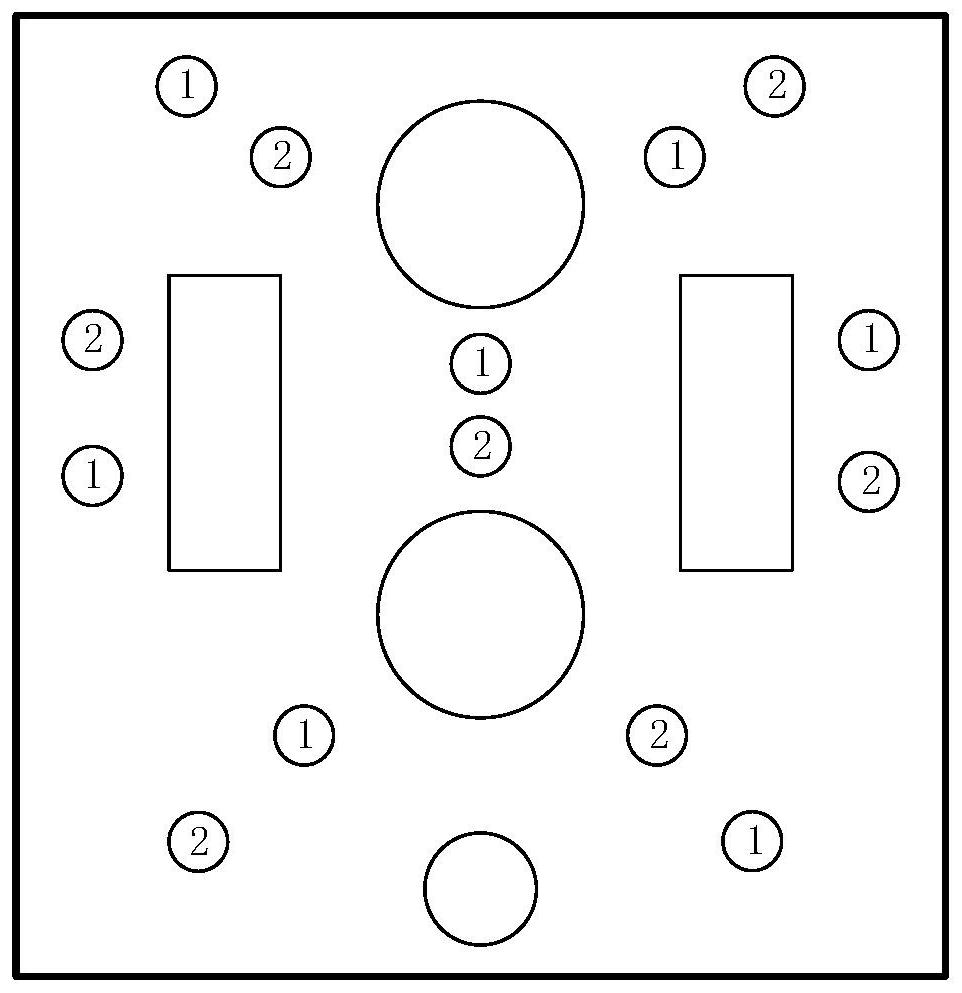

Non-contact gesture, palm print and palm vein fused identity recognition system and method

PendingCN114220130AImprove accuracyImprove robustnessDigital data authenticationNeural architecturesComputer hardwarePalm print

The invention discloses a non-contact gesture, palm print and palm vein fused identity recognition system and method. The non-contact gesture, palm print and palm vein fused identity recognition system comprises a shell, an imaging system and a control system, the imaging system comprises a light source module, an acquisition module and a photoelectric switch; the control system comprises a processing and control module; the light source module comprises a light source circuit board; the acquisition module comprises a camera provided with an optical filter; the light source circuit board and the camera are started through the photoelectric switch, when the photoelectric switch detects an object, the light source is turned on, and the camera starts to acquire an image; the processing and control module comprises an interface circuit board, an embedded core board, a temperature sensor and a touch screen.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com