Edge micro-plasma arc welding forming control method based on telecentric vision sensing

A micro-beam plasma and visual sensing technology, applied in the field of welding quality control, to achieve the effect of clear imaging, improving quality reliability and first-time welding pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

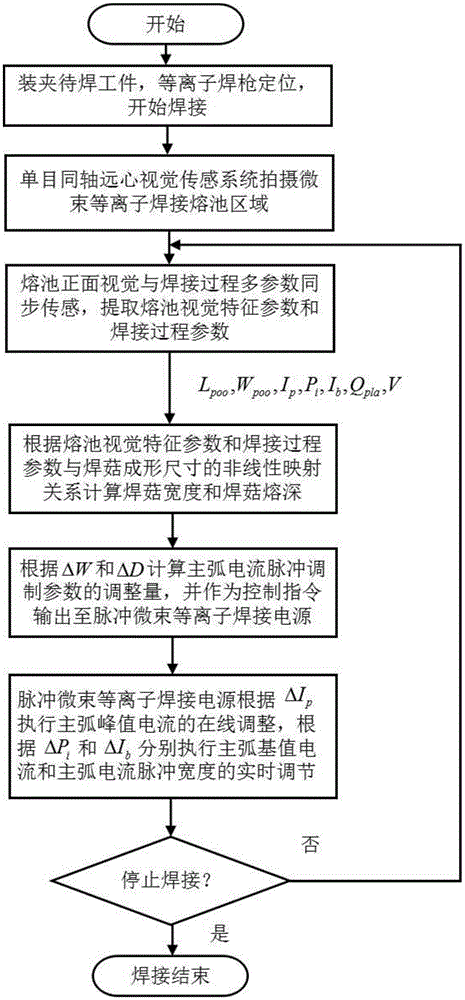

[0036] The principle and working process of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

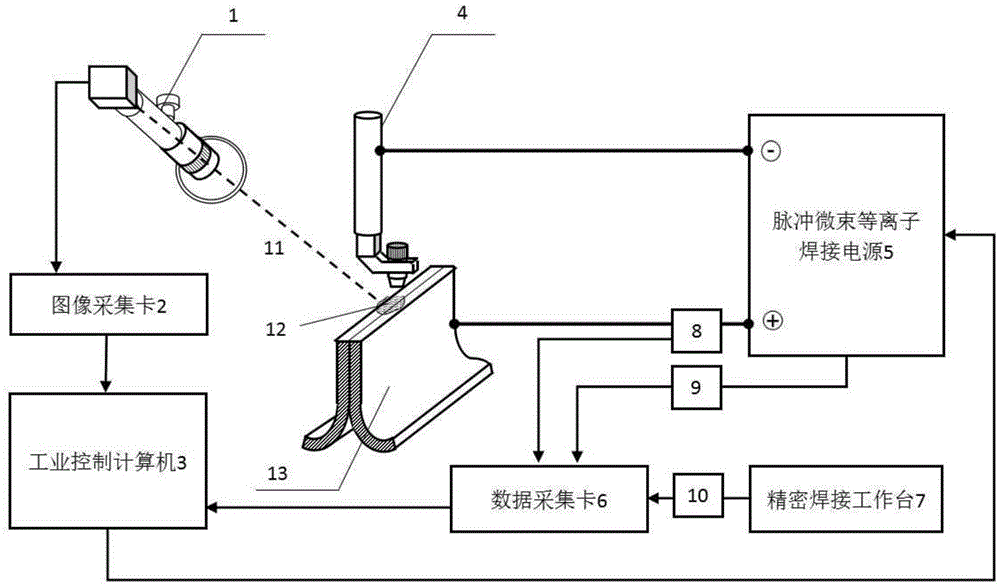

[0037] figure 2 Shown is the structure diagram of the micro-beam plasma welding forming control system for realizing the method of the present invention, the system includes a monocular coaxial telecentric vision sensor system 1, an image acquisition card 2, an industrial control computer 3, a plasma torch 4, a pulse Micro-beam plasma welding power supply 5, data acquisition card 6, precision welding workbench 7, Hall current sensor 8, gas flow sensor 9, photoelectric code disc speed sensor 10; the plasma torch 4 is connected to the micro-beam plasma through a welding cable The negative pole of the welding power supply 5, the positive pole of the pulsed micro-beam plasma welding power supply 5 is connected with the weldment through the Hall current sensor 8 through the welding cable; the monocular coaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com