Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Acceptable strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

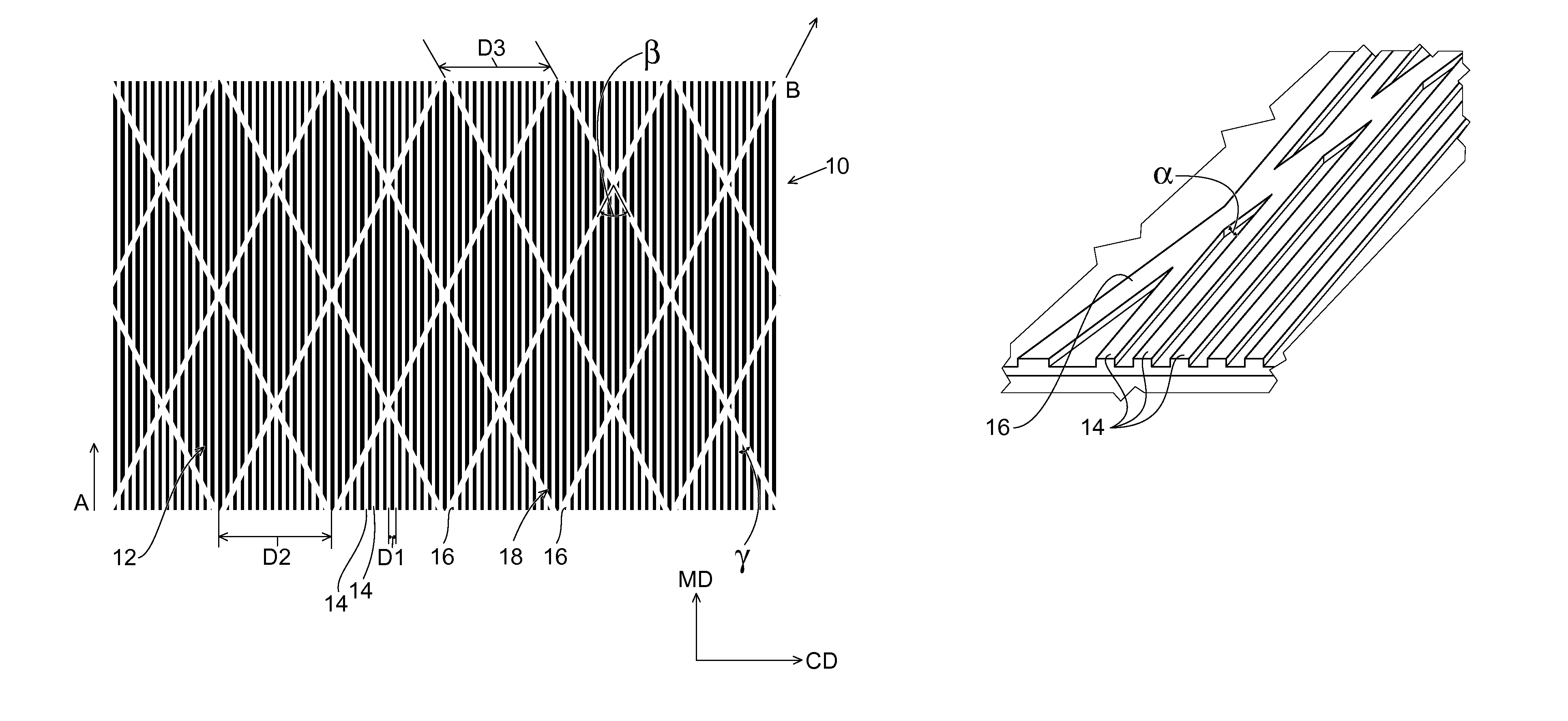

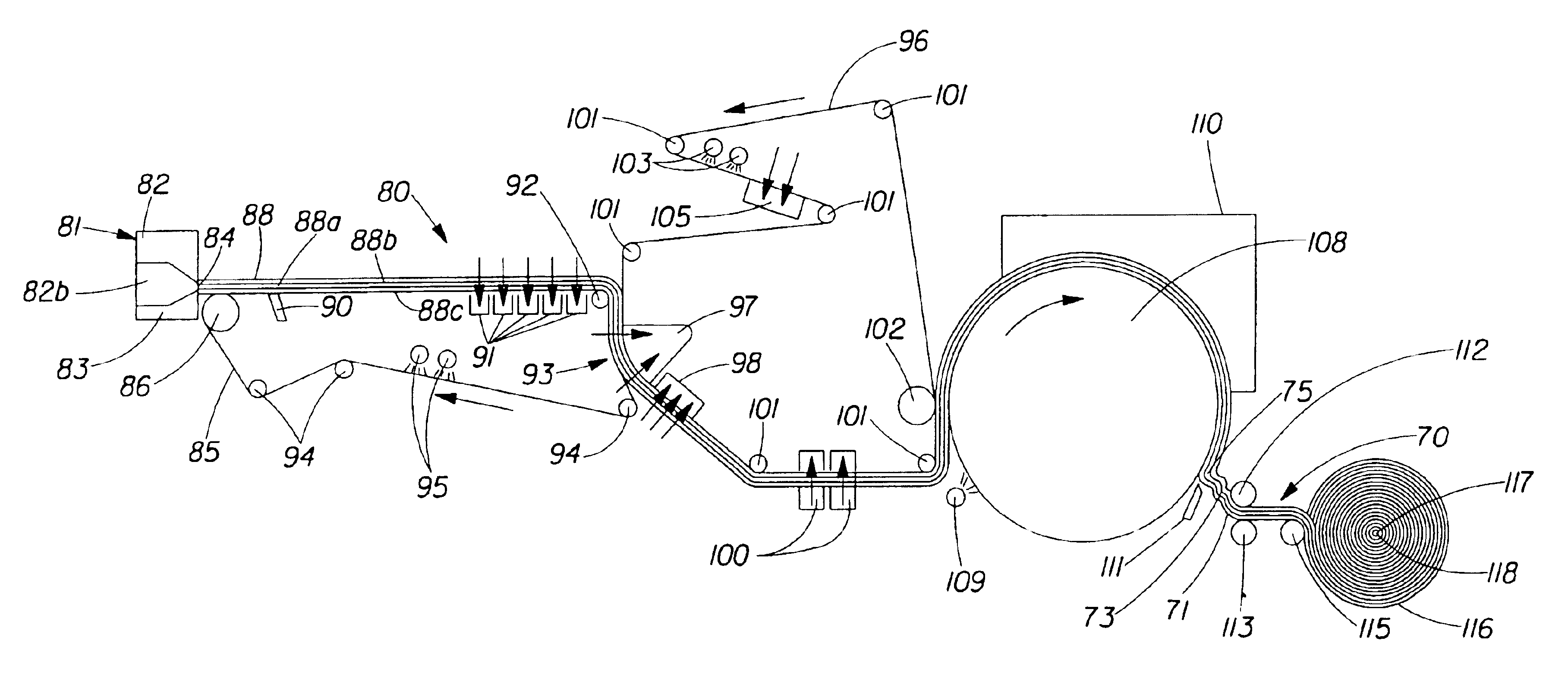

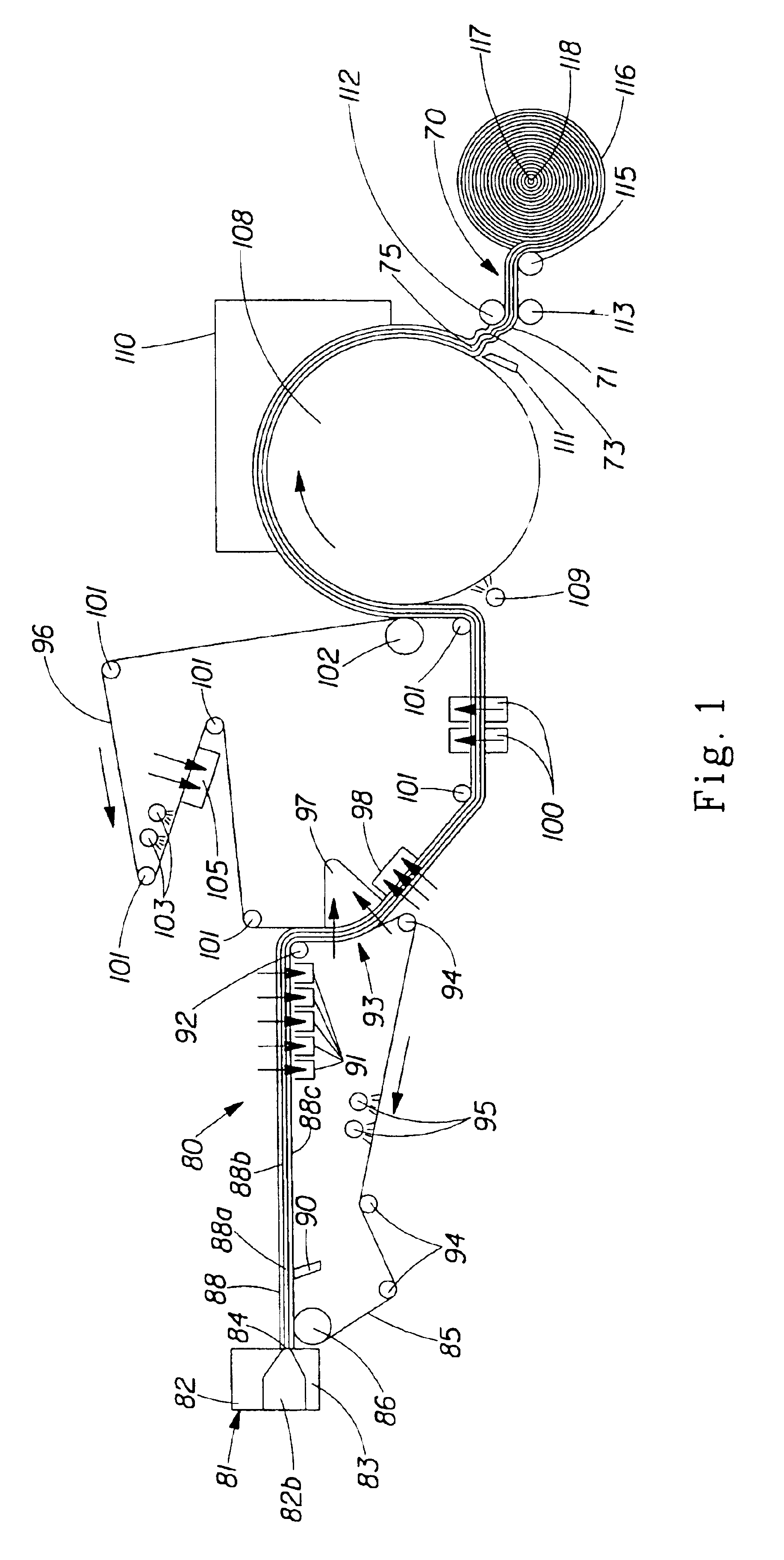

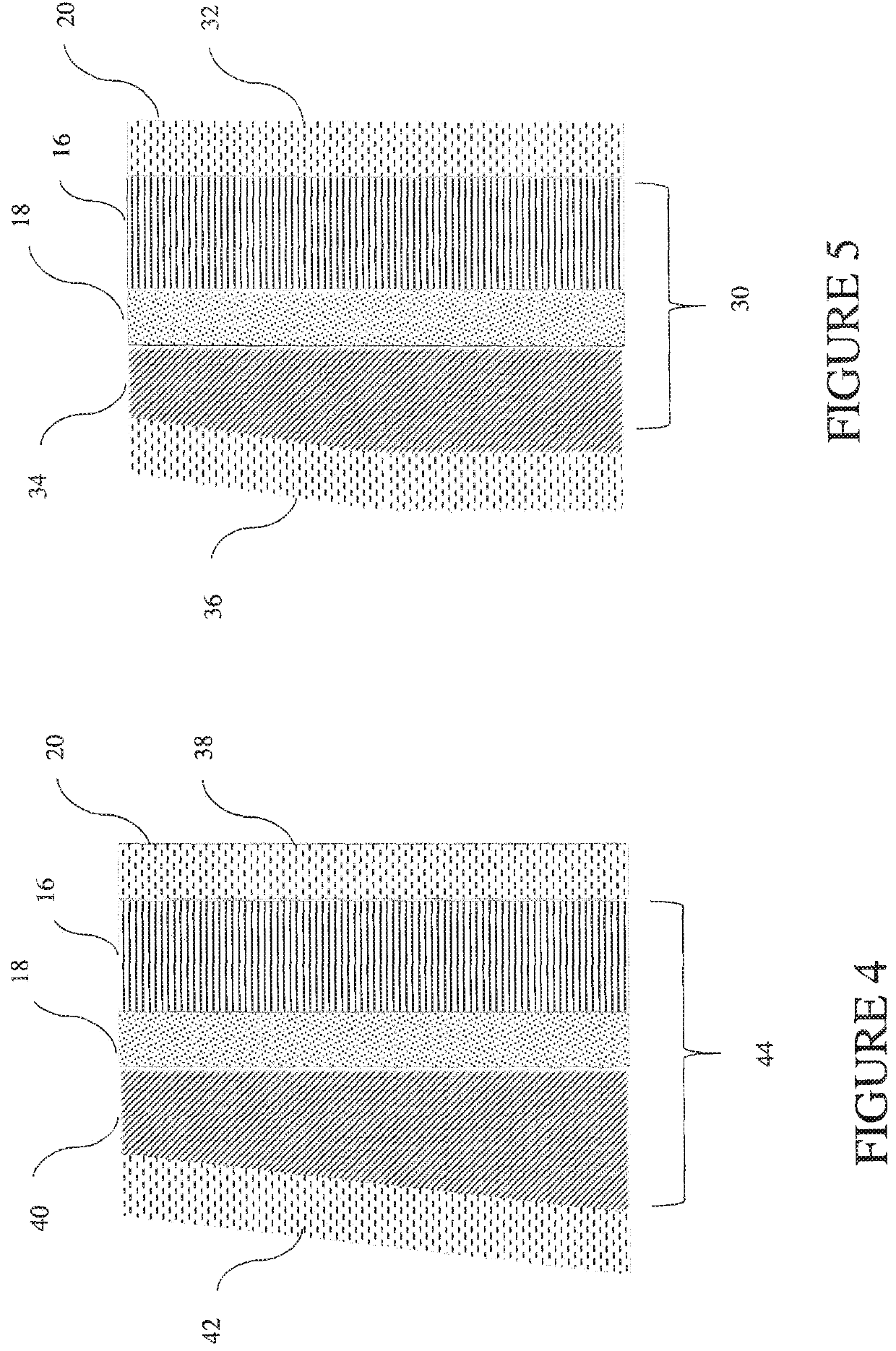

Fibrous structures and methods for making same

ActiveUS20120107568A1Increase flexibilityConsumer acceptable strengthMachine wet endPaper/cardboard layered productsEngineeringFiber structure

Owner:THE PROCTER & GAMBLE COMPANY

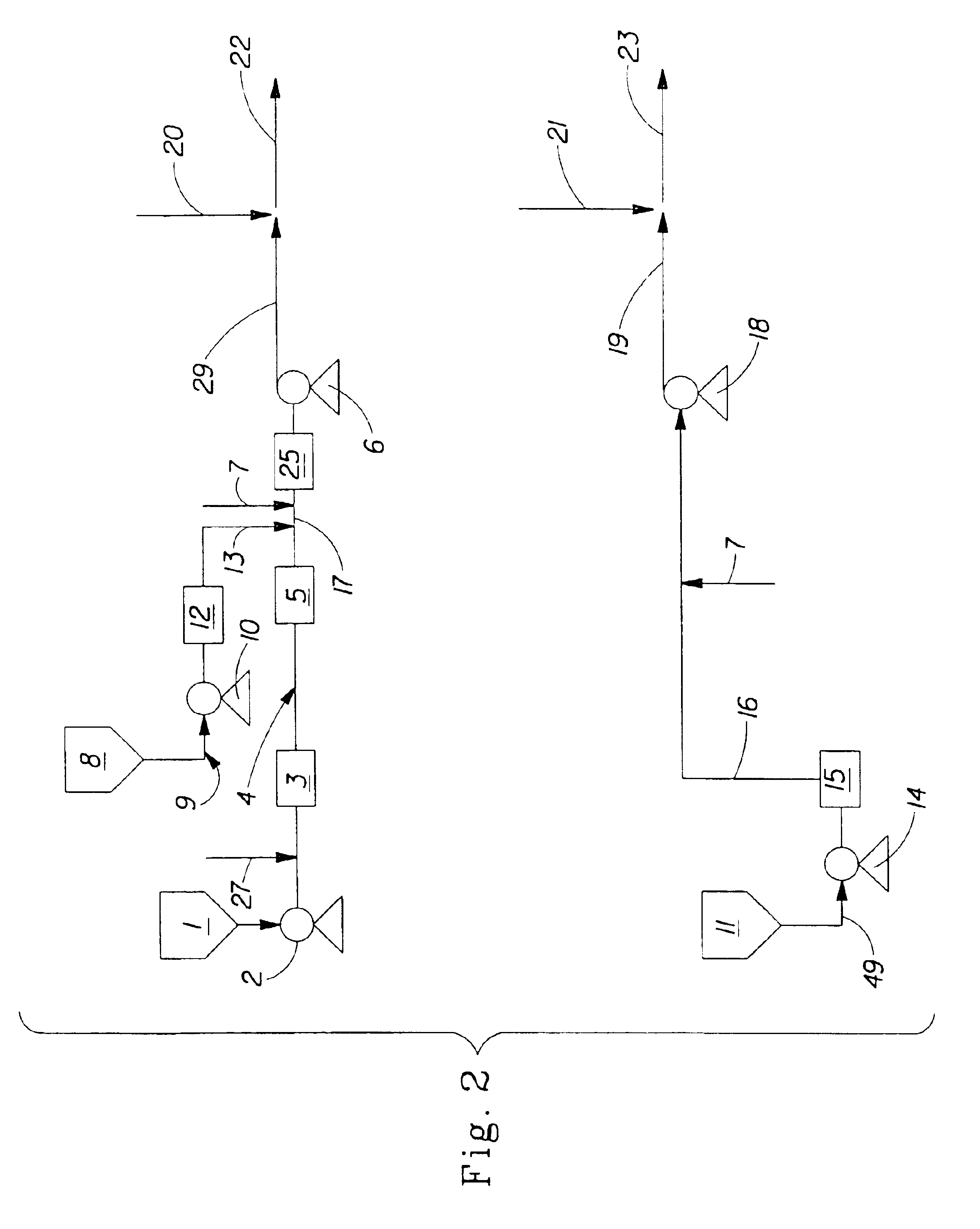

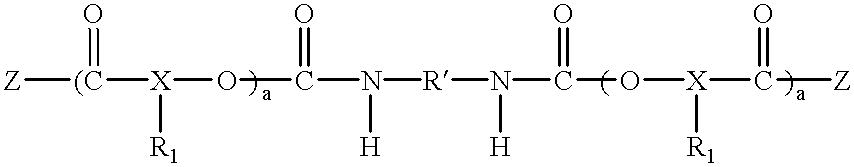

Low viscosity bilayer disrupted softening composition for tissue paper

InactiveUS6855229B2Good flexibilityAcceptable strengthNatural cellulose pulp/paperSpecial paperCelluloseAmmonium compounds

Disclosed is a composition for softening a wet laid cellulosic structure. A particularly preferred structure is an absorbent tissue. Further disclosed are tissue structures softened using the composition. The composition includes an effective amount of a softening active ingredient; a vehicle in which the softening active ingredient is dispersed; an electrolyte dissolved in the vehicle; and a bilayer disrupter. The electrolyte and the bilayer disrupter cooperate to cause the viscosity of the composition to be less than the viscosity of a dispersion of the softening active ingredient in the vehicle alone. Preferably, the softening active ingredient is a quaternary ammonium compound with the formula:(R1)4-m—N+—[(CH2)n—Y—R3]mX−the vehicle is water, the electrolyte is calcium chloride, and the bilayer disrupter is a nonionic surfactant. Also disclosed is a method of using the compound by adding it at a use concentration to the wet end of a papermaking process.

Owner:THE PROCTER & GAMBLE COMPANY

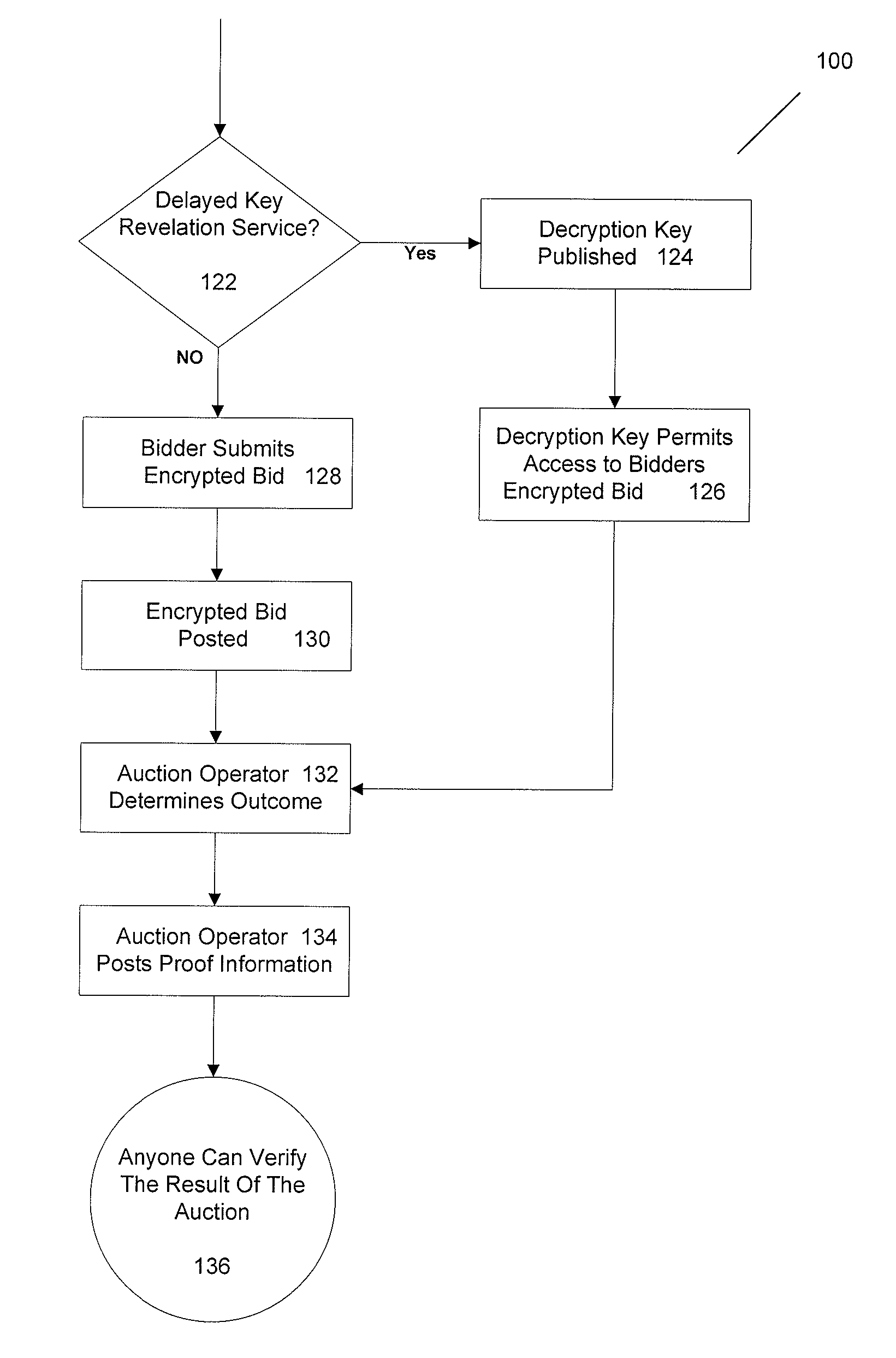

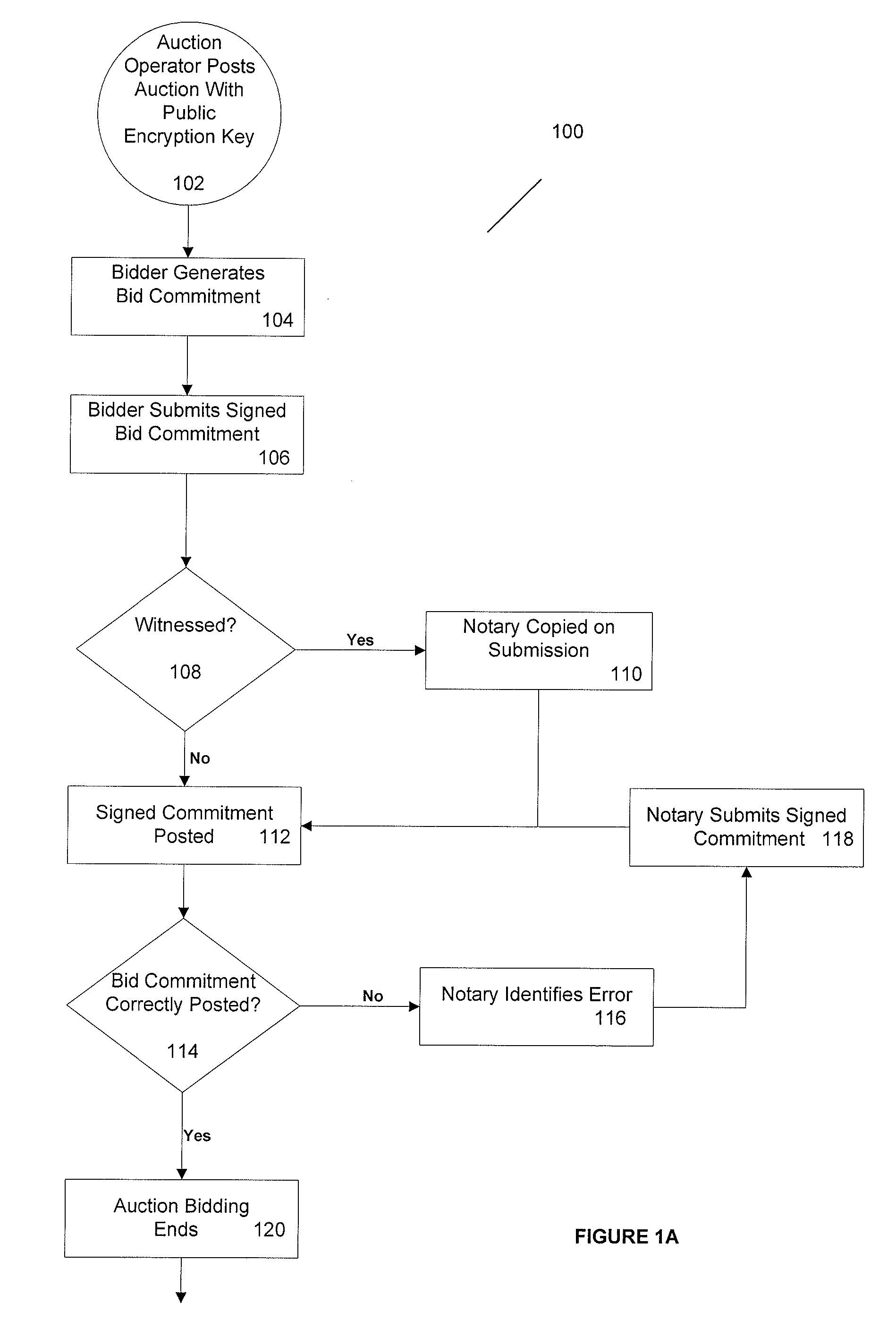

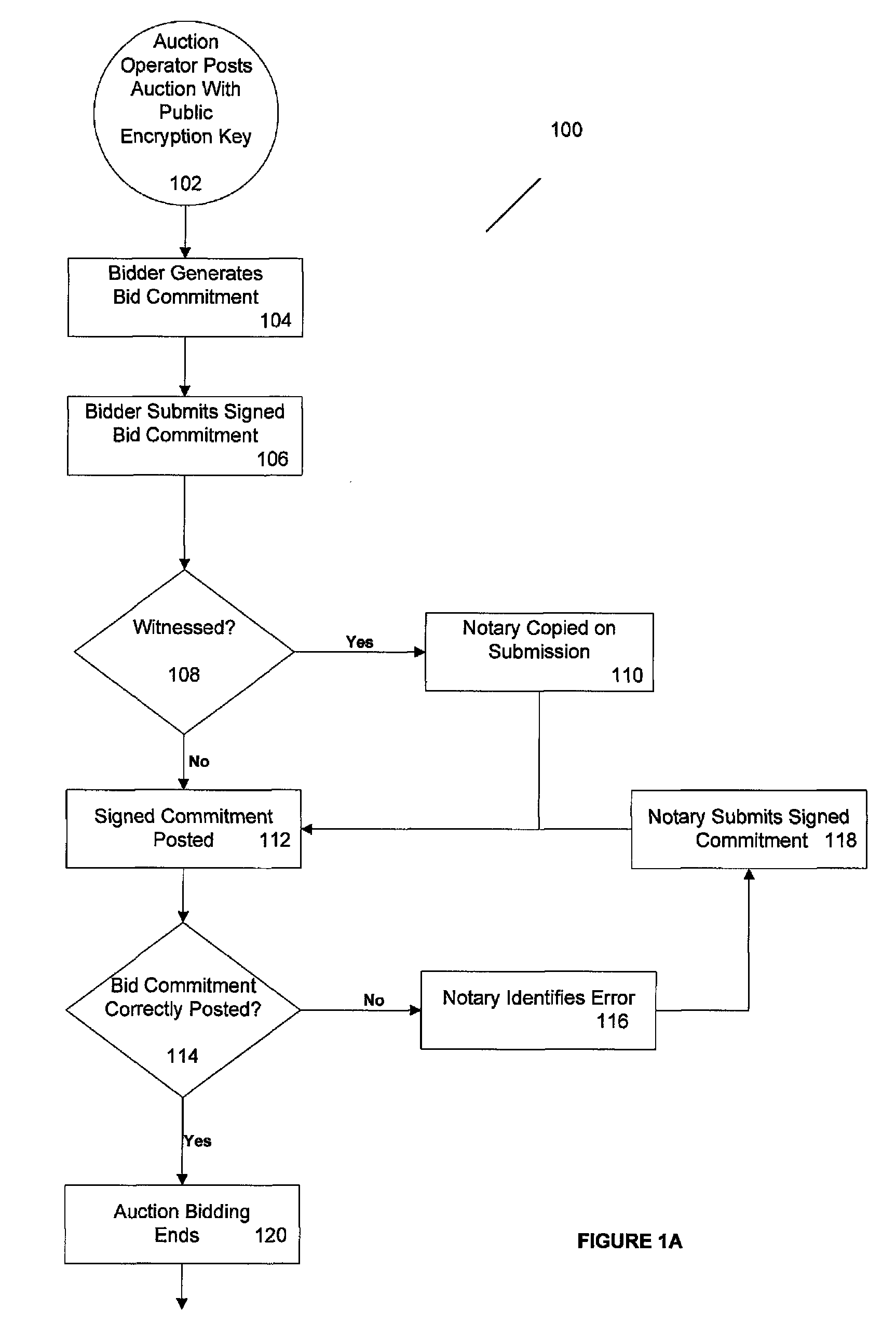

Practical secrecy-preserving, verifiably correct and trustworthy auctions

ActiveUS20090182667A1Ensure safetyImprove simplicityMultiple keys/algorithms usageUser identity/authority verificationCorrectness proofsTheoretical computer science

A system and method for conducting verifiably correct auctions that preserves the secrecy of the bids while providing for verifiable correctness and trustworthiness of the auction is disclosed. Some of the elements of the method and apparatus are that the auction operator accepts all bids submitted and follows the published rules of the auction. In one embodiment, the bids are maintained secret from the auctioneer and all bidders until the auction closes and no bidder is able to change or repudiate her bid. In another embodiment, the auction operator computes the auction results and publishes proofs of the results' correctness. In yet another embodiment, any party can check these proofs of correctness via publicly verifiable computations on encrypted bids.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Novel polymeric compositions

The present invention relates to novel bioabsorbable polymeric compositions based upon AB polyester polyether or related diblocks and triblocks. Compositions according to the present invention may be used in medical applications, for example, for reducing or preventing adhesion formation subsequent to medical procedures such as surgery, for producing surgical articles including stents and grafts, as coatings, sealants, lubricants, as transient barriers in the body, for materials which control the release of bioactive agents in the body, for wound and bum dressings and producing biodegradable articles, among numerous others.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

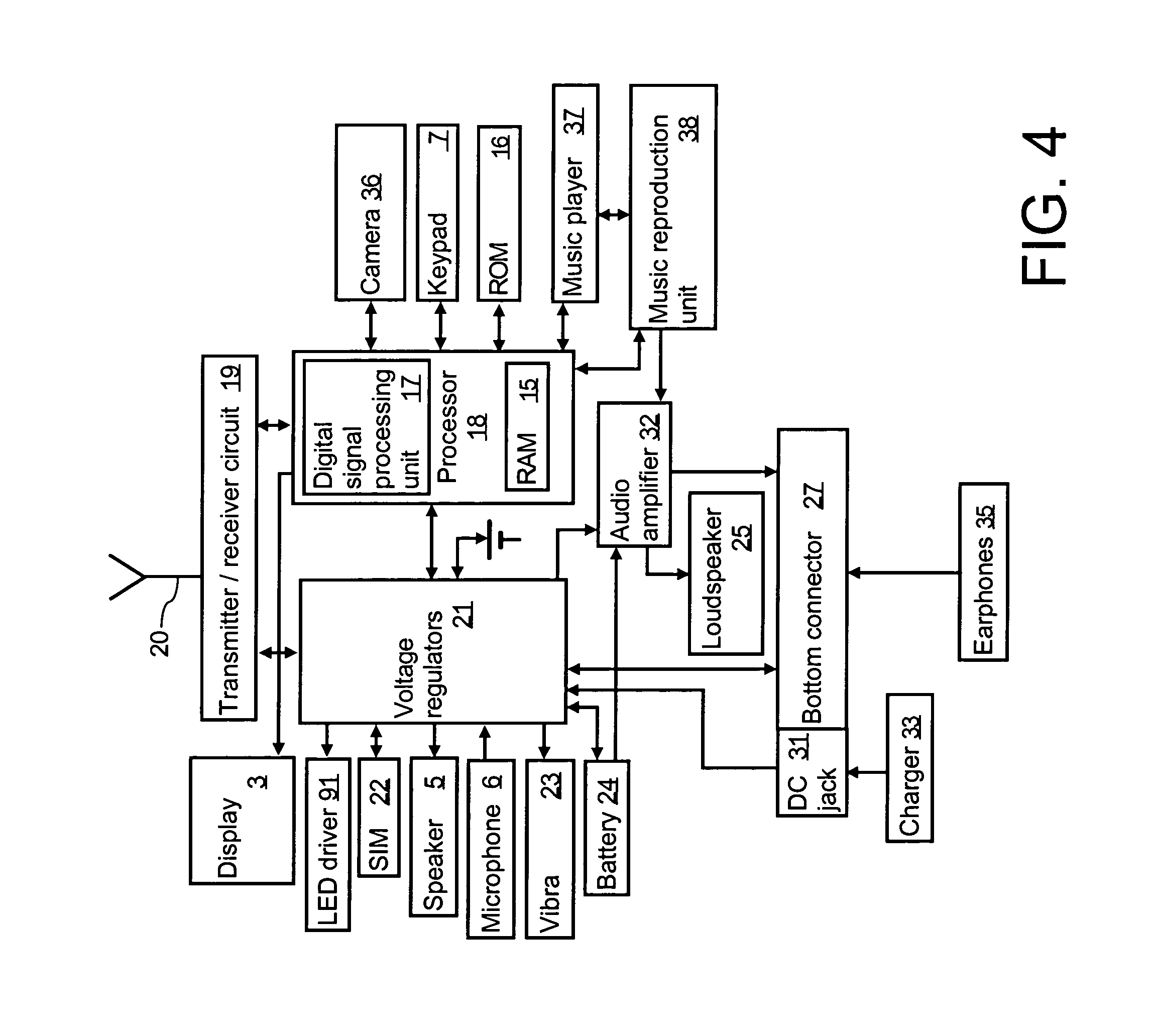

Magnetic Shield

InactiveUS20100304796A1Acceptable external magnetic field level strengthImprove overall strengthShielding materialsTransducer detailsLoudspeakerEngineering

A mobile apparatus includes an internal hands-free loudspeaker and a magnetic shielding plate that protects external objects sensitive to magnetic fields from the high-level magnetic field generated by the loudspeaker.

Owner:NOKIA CORP

Pelletizing of broad molecular weight polyethylene

InactiveUS6454976B1Increased effect on polymer temperatureLow costFlat articlesPolymer scienceProduct gas

Polyethylene having a broad molecular weight distribution is extruded in pellet form using a pelletizing extruder having one or more zones essentially filled with the polyethylene and two or more zones partially filled with the polyethylene. The polyethylene is fed into the extruder at a temperature sufficient to melt the polyethylene, and a mixture of an inert gas and oxygen is fed into at least one partially filled zone of the extruder with the exception of the feed zone. The mixture contains about 1 to about 21% by volume oxygen based on the volume of the gas mixture.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

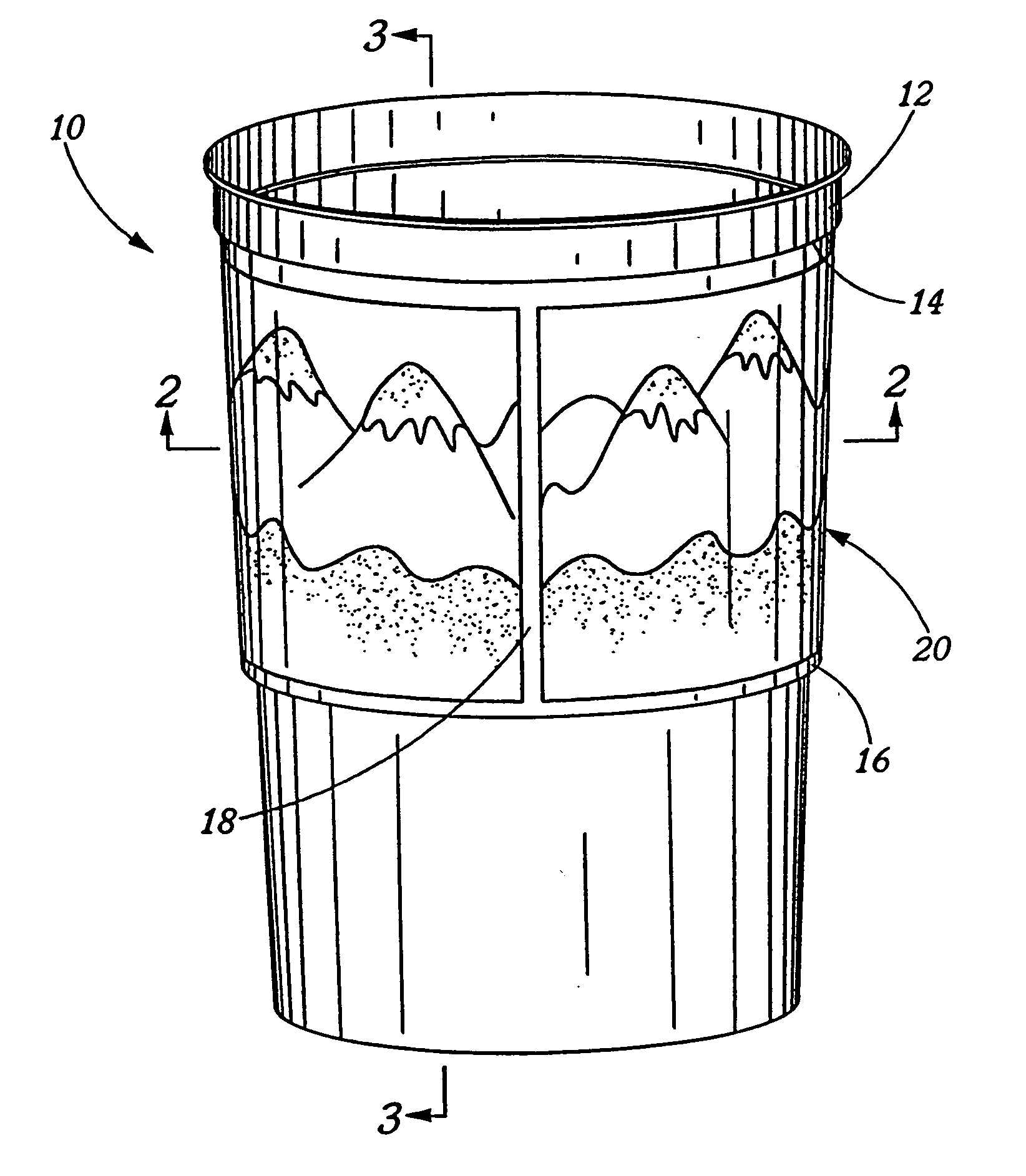

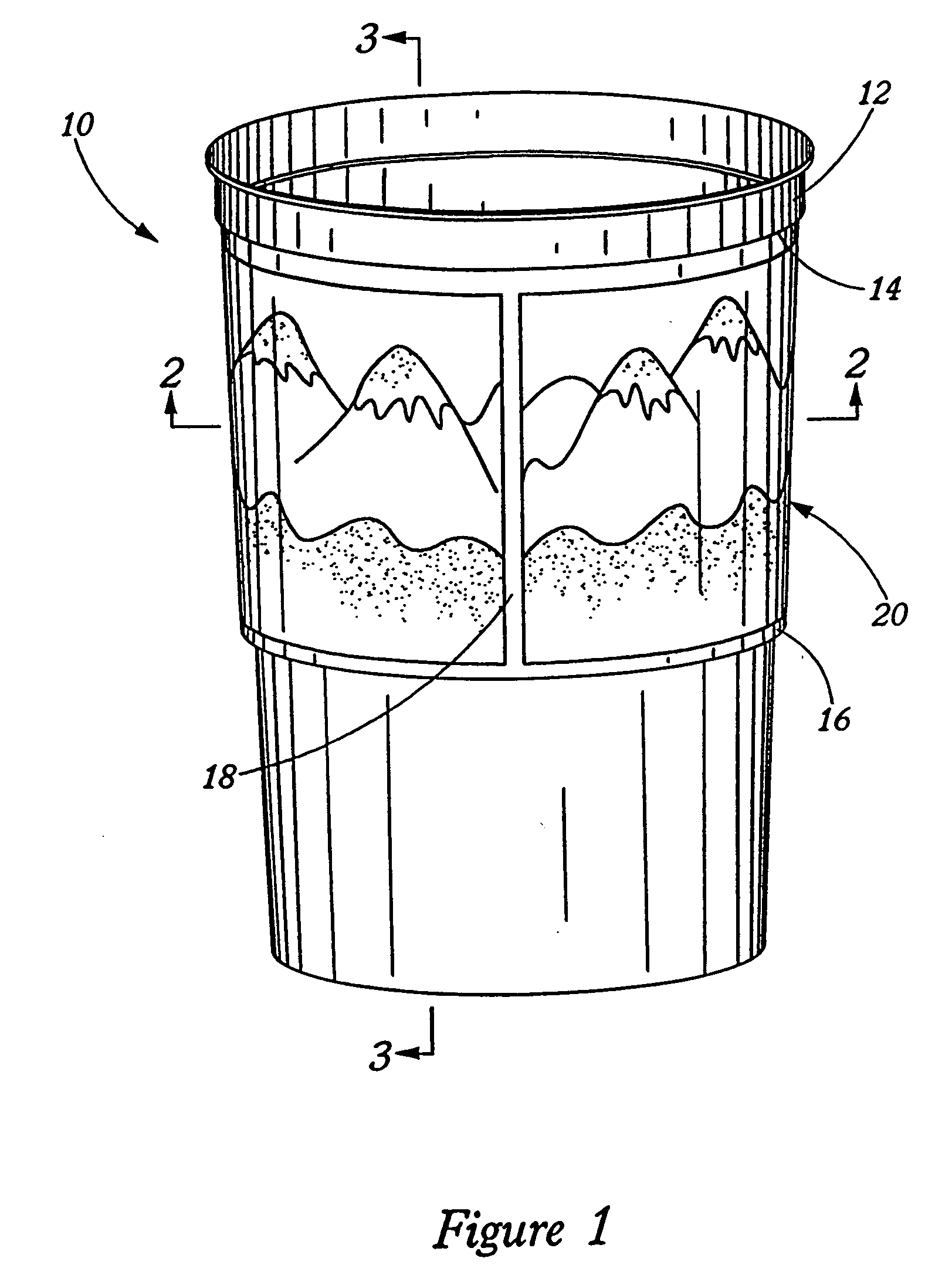

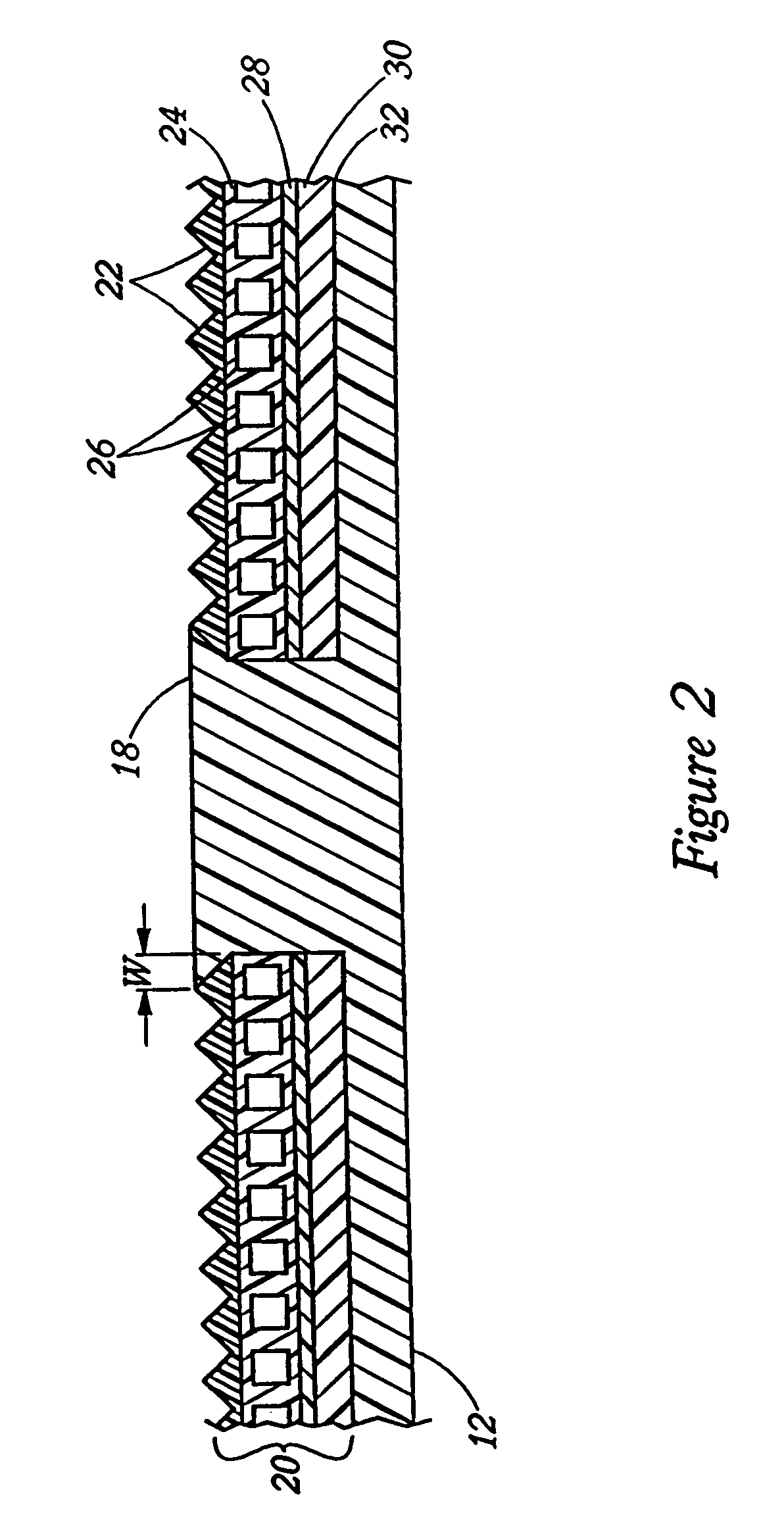

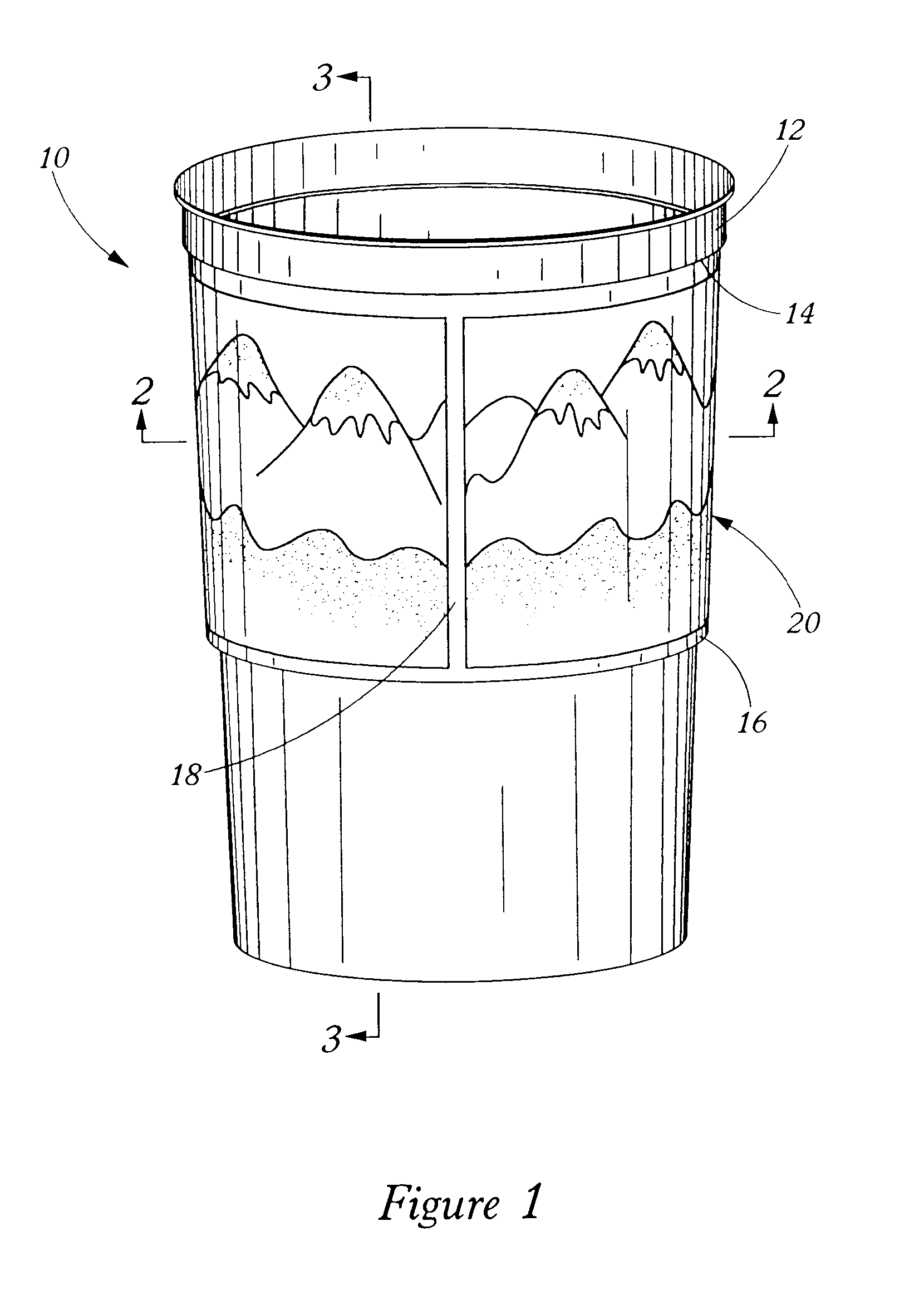

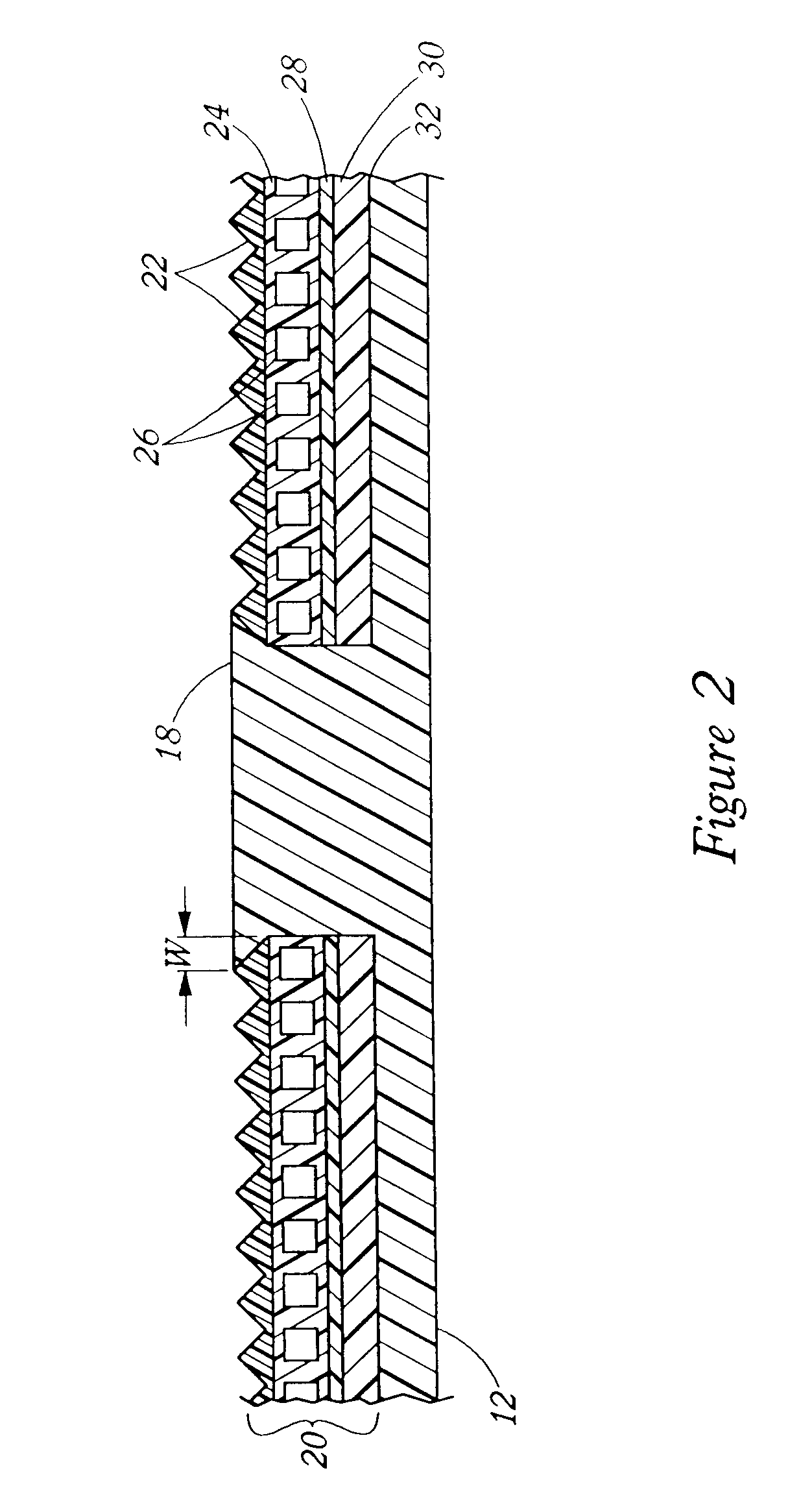

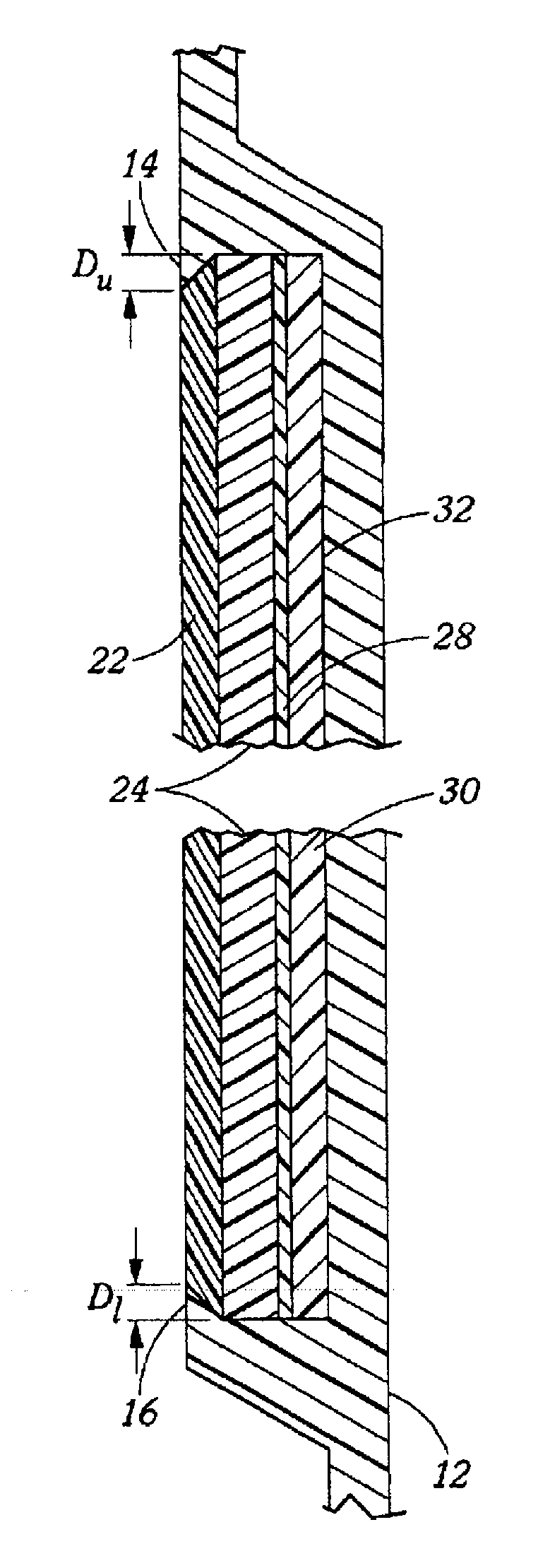

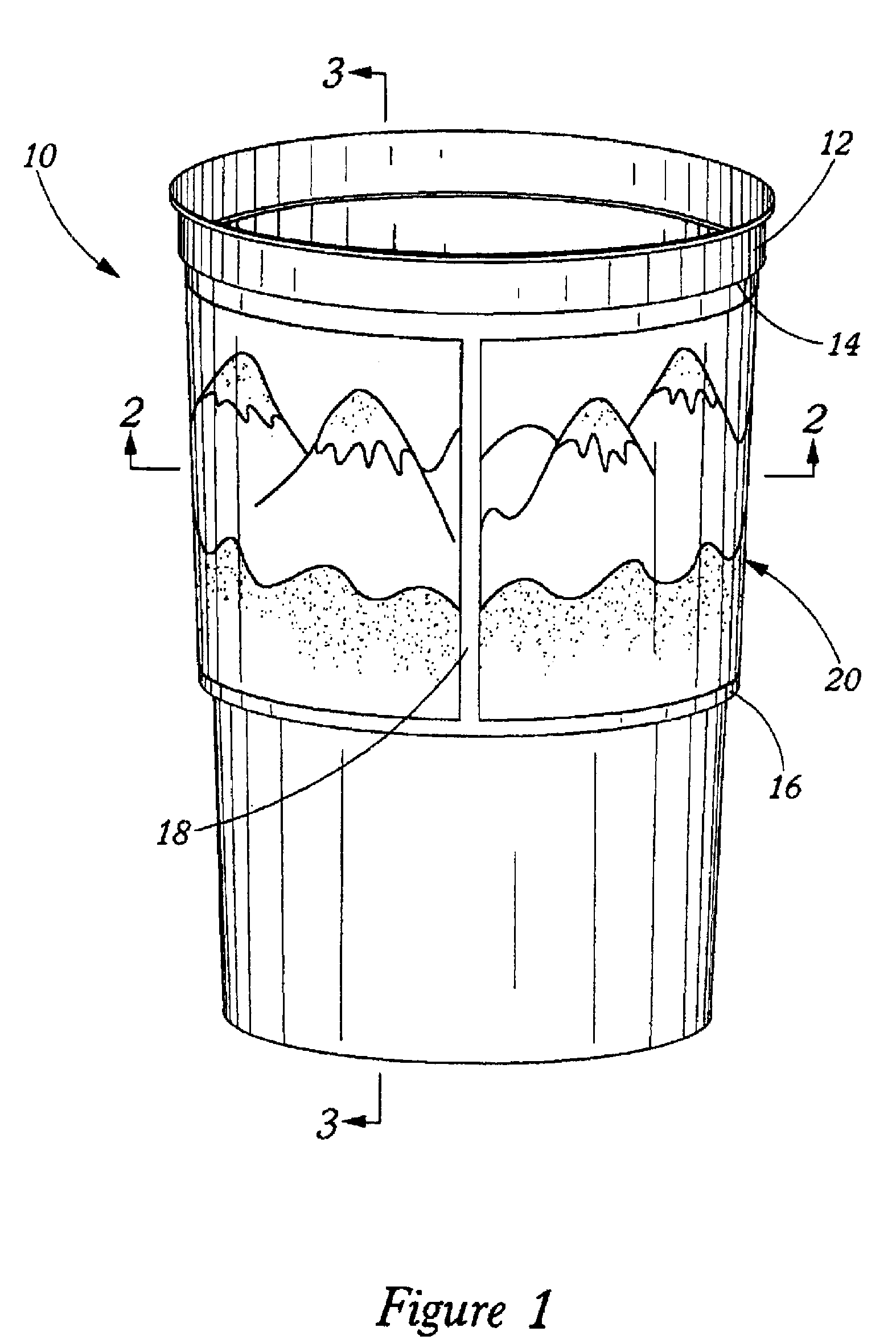

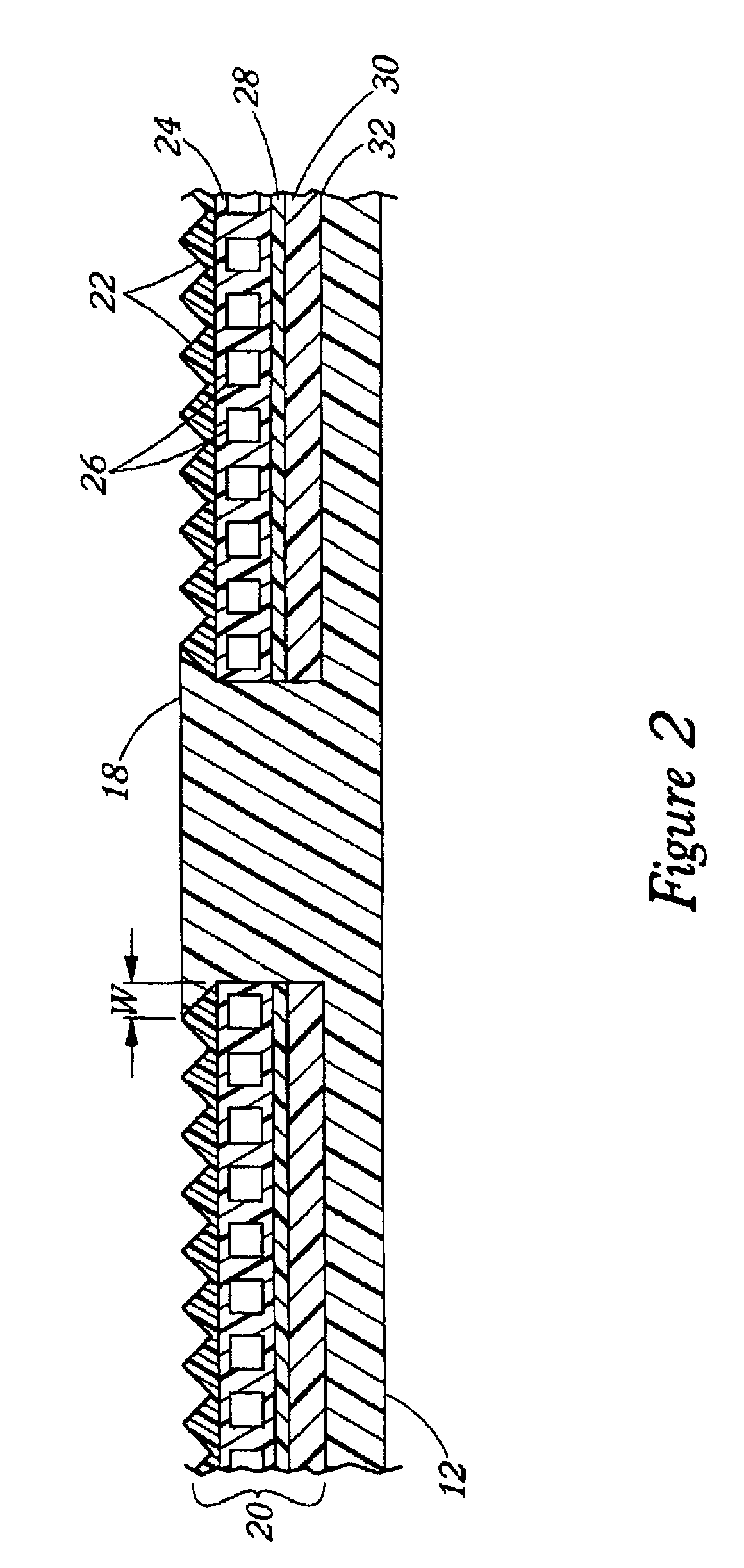

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

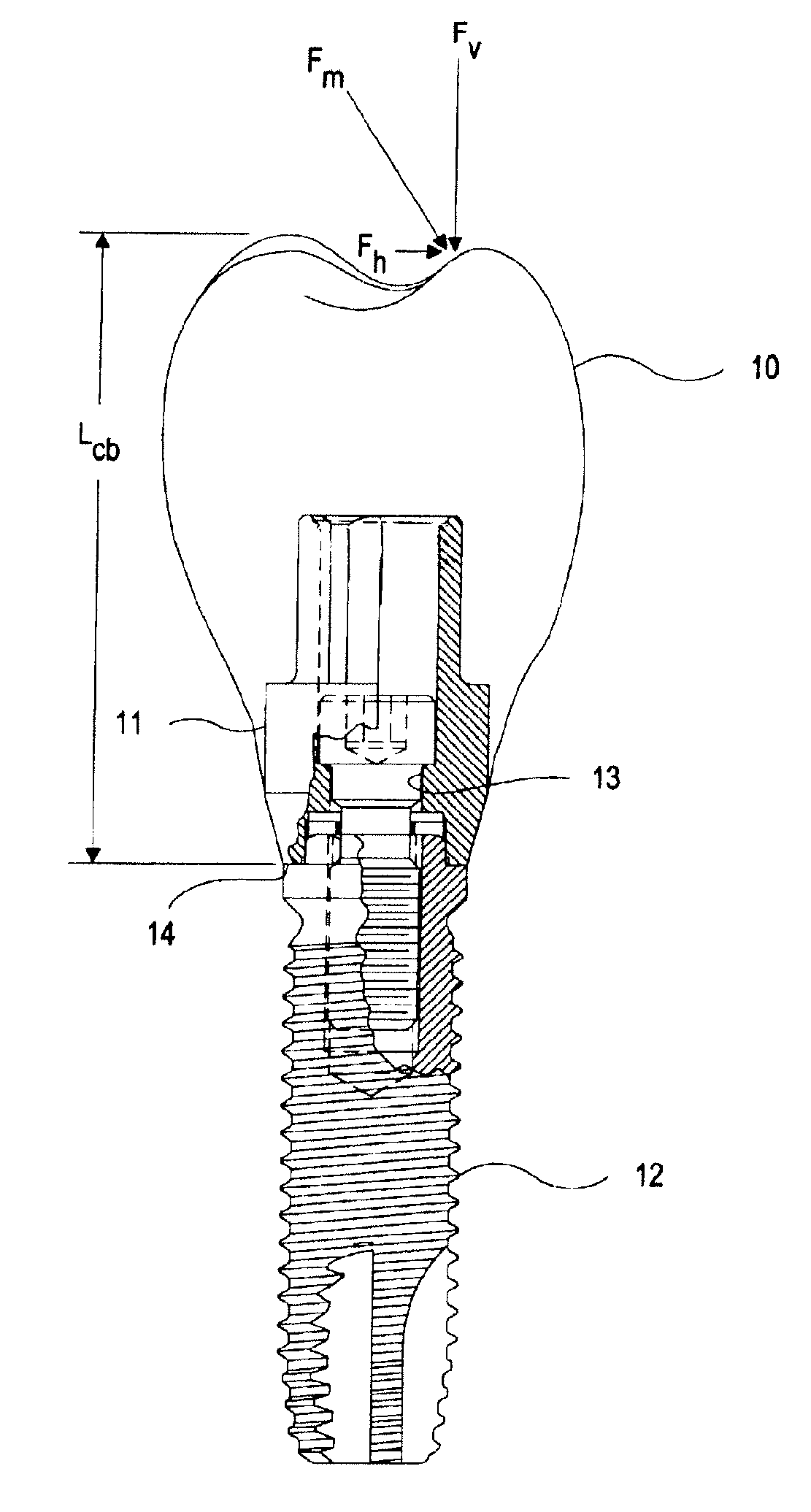

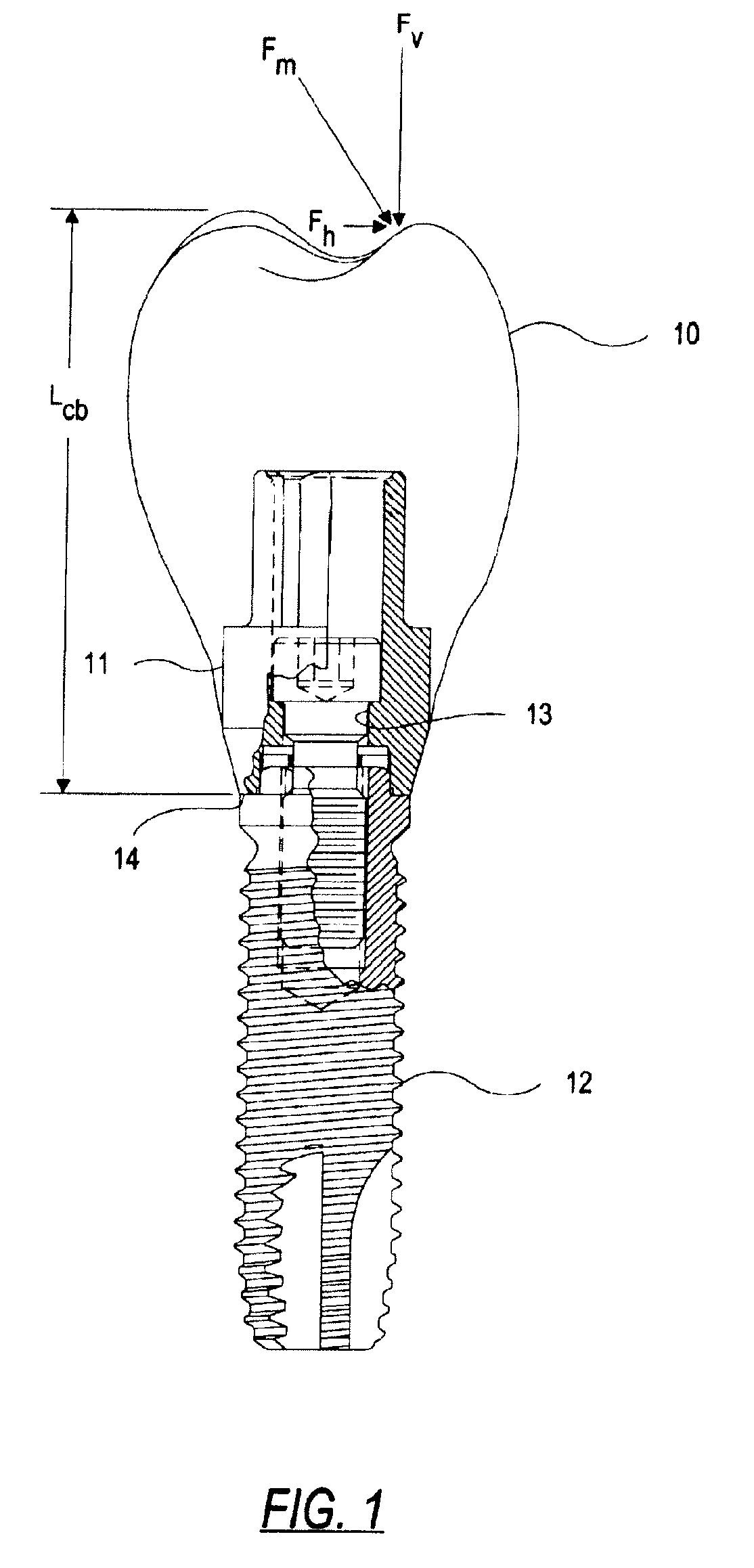

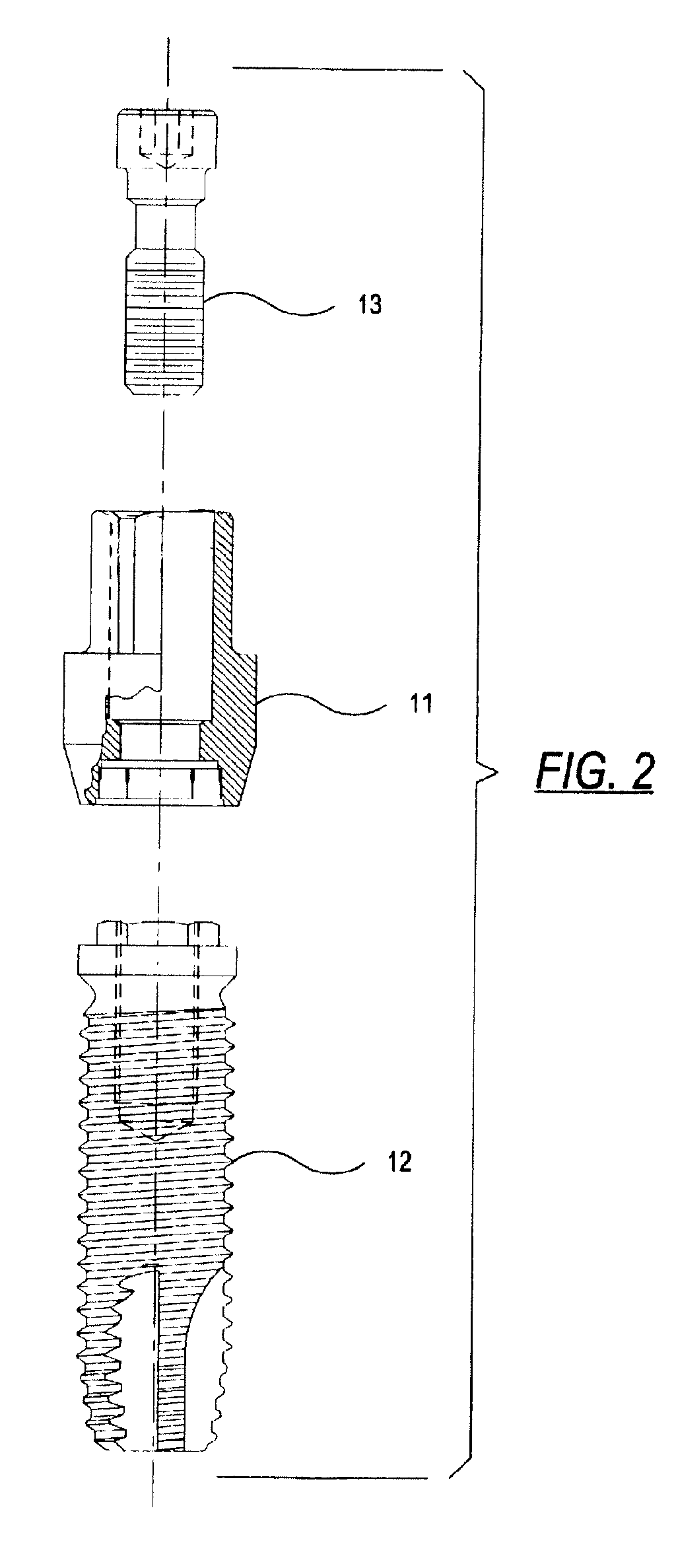

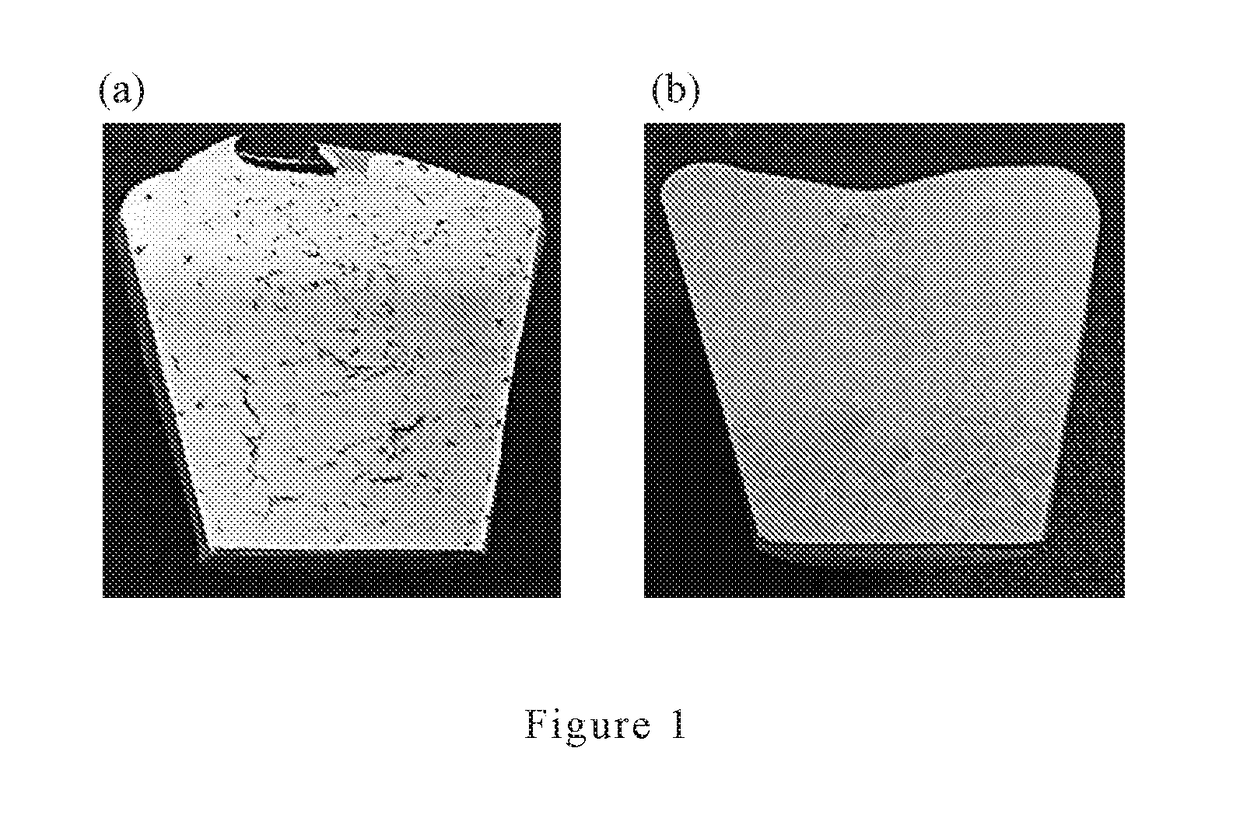

Dental implant having improved stability

InactiveUS20090075236A1Improve screw preloadLow coefficient of frictionDental implantsTeeth fillingAbutment ScrewCorrosion

A dental implant system employs an improved abutment screw with acceptable biocompatibility, corrosion, strength, and preload characteristics. In particular, embodiments provide a dental implant system having an artificial implant and an abutment which are fastened with a screw formed from stainless steel, such as surgical grade 316L stainless steel. In some embodiments, the stainless steel screw is coated with a malleable material, such as gold, silver, or polytetraflouroethylene, to improve screw preload. Alternatively, the stainless steel screw may be coated with a harder material, such as diamond like carbon (DLC), amorphous diamond, crystalline diamond, or a combination thereof, which provides a low coefficient of friction providing improved preload properties.

Owner:BIOMET 3I LLC

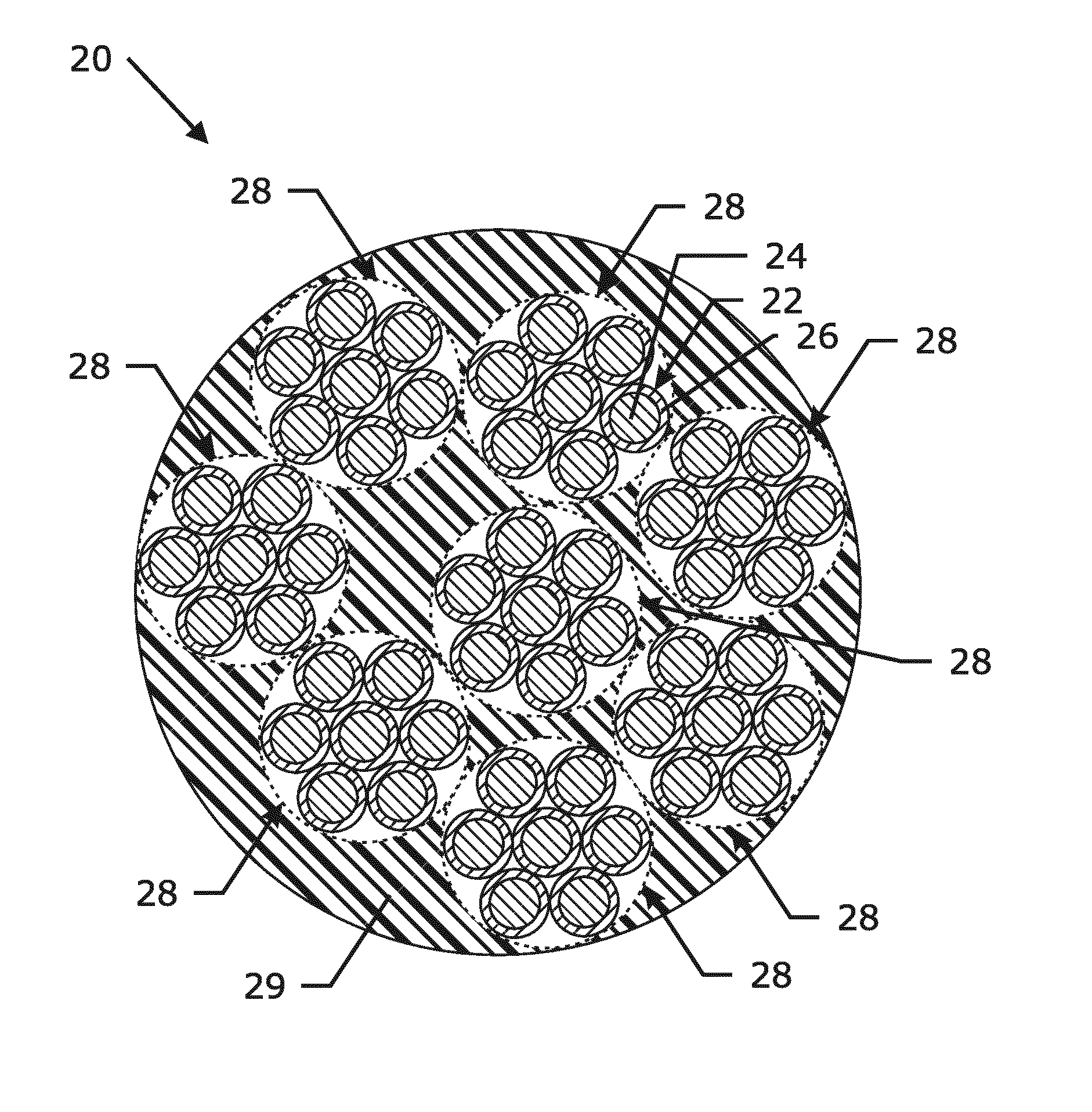

Hydrogel composites

InactiveUS20050287191A1Acceptable strengthImprove integritySynthetic resin layered productsWoven fabricsFibrous compositesUltimate tensile strength

A method for producing a hydrogel / fibre composite comprises: impregnating fibres of a fibrous material with a precursor solution comprising at least one polymerisable, and optionally also crosslinkable, monomer such that at least partial swelling of the fibres takes place; and polymerising, and optionally also crosslinking, the at least one monomer after impregnation and at least partial swelling of the fibres such that the integrity of the fibrous material is at least partially preserved in the resulting hydrogel / fibre composite, provided that the crosslinking is not initiated solely by cation release from the fibres of the fibrous material. The invention provides a hydrogel / fibre composite prepared or preparable by the said method. The hydrogel / fibre composite may be adhesive to human skin with good properties of performance and subsequent painless removal. The composite is found to maintain acceptable strength and structural integrity on hydration or across one or more hydration / dehydration cycle, and thus finds use in, for example, biomedical products where this property is required.

Owner:FIRST WATER

Novel polymeric compositions exhibiting reverse thermal gellation properties

InactiveUS20030187148A1High viscosityEfficient deliveryPeptide/protein ingredientsAntibody ingredientsPolyesterRoom temperature

The present invention relates to novel polymeric compositions based upon An(BCB)An polyester / polyether multi-blocks. Compositions according to the present invention exhibit unexpectedly exceptional reverse thermal gellation properties and in certain cases, relatively low viscosities at approximately room temperature and extremely high viscosities at temperatures above room temperature (preferably at approximately physiological or body temperature, i.e., within a temperature range of about 32-40° C.). Compositions according to the present invention may be used advantageously in applications which make use of their reverse thermal gellation properties. Preferred applications for use of the present compositions include, for example, medical applications which make advantageous use of the inherent composition characteristic of being of relatively low viscosity at room temperature and much higher viscosity at elevated temperatures, especially body temperature.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Polyurethane foams co-blown with a mixture of a hydrocarbon and a halogenated olefin

This invention relates to rigid polyurethane foams which are co-blown with a mixture of a hydrocarbon blowing agent and a halogenated olefin blowing agent. This invention also relates to a process for preparing these rigid polyurethane foams, and to an isocyanate-reactive component containing a polyol blend and the mixture of blowing agents. Phase stable isocyanate-reactive blends are also described.

Owner:COVESTRO LLC

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20040157011A1Efficient and economicalHigh qualityEnvelopes/bags making machineryWrappers shrinkageLens materialsPolyester

Abstract of the Disclosure A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:REIL JENNIFER +4

Practical secrecy-preserving, verifiably correct and trustworthy auctions

InactiveUS8024274B2Preserve secrecyAccurately determineMultiple keys/algorithms usageComputer security arrangementsCorrectness proofsTheoretical computer science

A system and method for conducting verifiably correct auctions that preserves the secrecy of the bids while providing for verifiable correctness and trustworthiness of the auction is disclosed. Some of the elements of the method and apparatus are that the auction operator accepts all bids submitted and follows the published rules of the auction. In one embodiment, the bids are maintained secret from the auctioneer and all bidders until the auction closes and no bidder is able to change or repudiate her bid. In another embodiment, the auction operator computes the auction results and publishes proofs of the results' correctness. In yet another embodiment, any party can check these proofs of correctness via publicly verifiable computations on encrypted bids.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

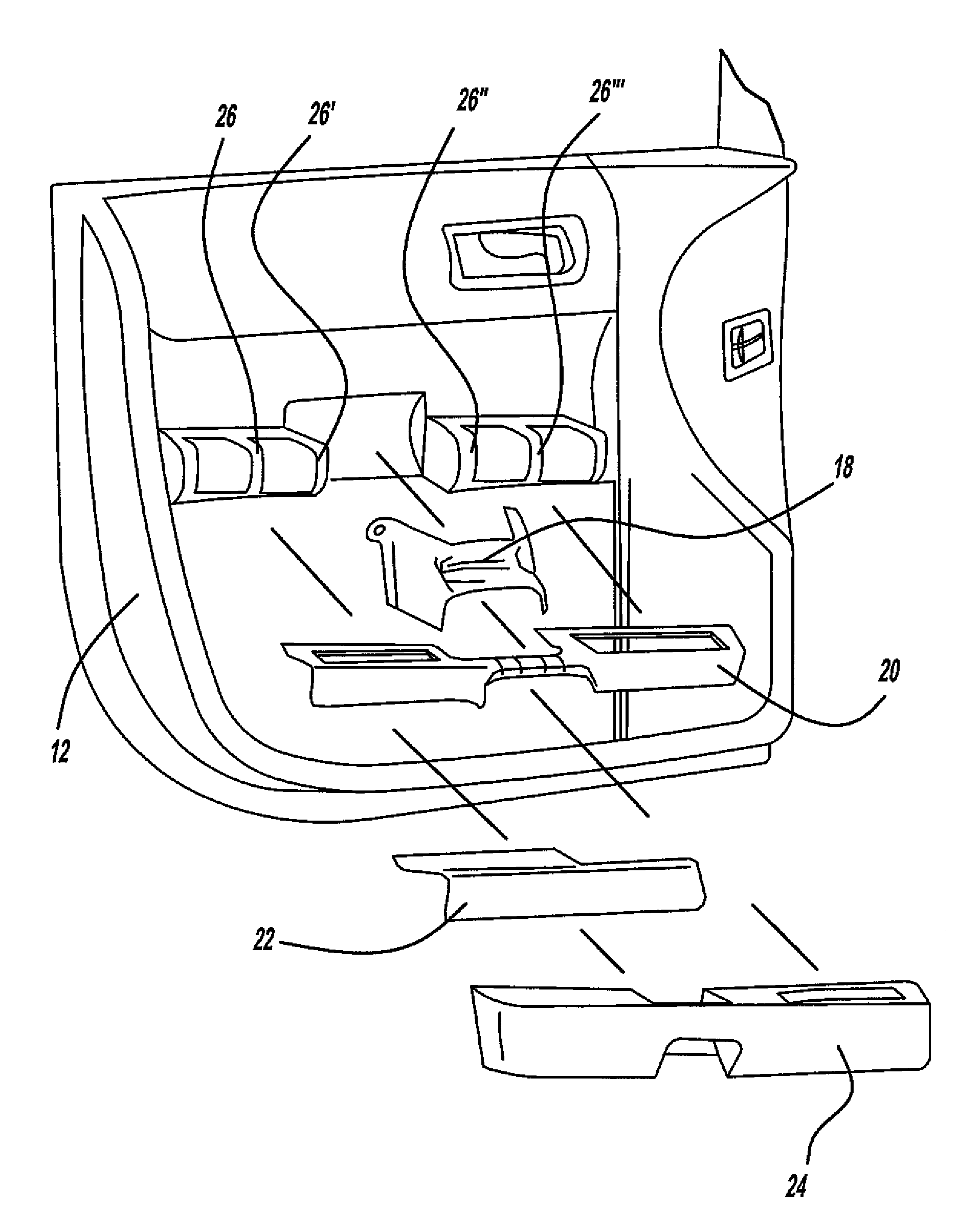

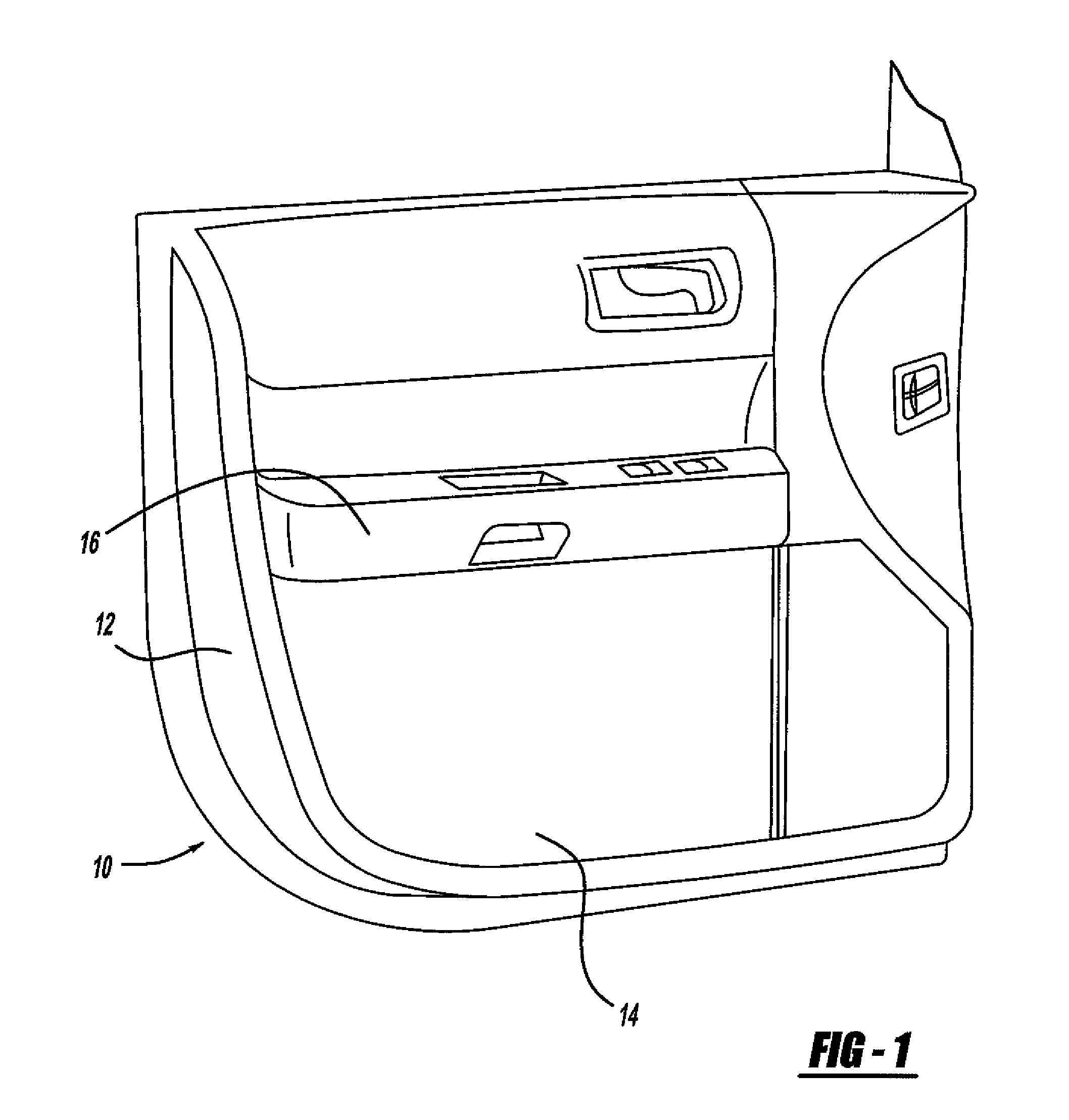

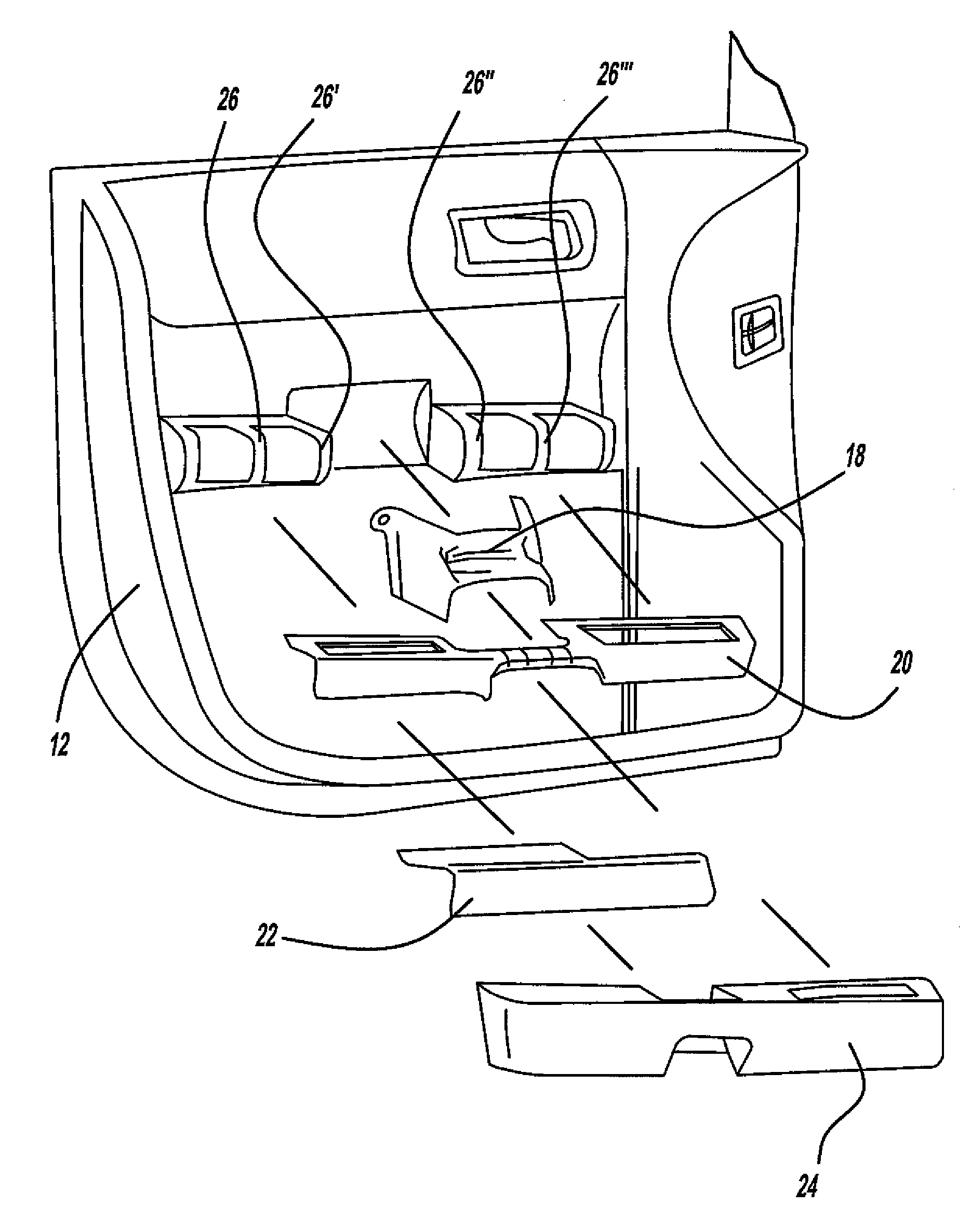

Side impact door trim buckle initiatory design in armrest and grab handle region

InactiveUS7794009B2Acceptable durabilityAcceptable strengthArm restsMonocoque constructionsTrim tabEngineering

A side impact door trim buckle initiator design is provided in a vehicle armrest and grab handle region. The disclosed support structure design induces buckling in the door handle supports while continuing to provide acceptable durability and strength. Two modifications to the door armrest and grab handle structures are made. First, an angled section is added to the material flow strap of the armrest supporting structure to promote buckling. This approach overcomes the difficulty of known material flow straps which tend to be horizontal, thus introducing a strong compressive load path. By adding an angle to the flow straps the vertical motion is forced upon a lateral impact. Second, vertical components of the door handle support structure are removed while a buckle initiator in the door handle support is added.

Owner:FORD GLOBAL TECH LLC

Methods of manufacturing plastic objects having bonded lenticular lens-sheets

InactiveUS20070132122A1Quality improvementEfficient and economicalOptical articlesContainer/bottle contructionPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

Side impact door trim buckle initiator design in armrest and grab handle region

InactiveUS20090134660A1Acceptable durabilityAcceptable strengthArm restsMonocoque constructionsEngineeringSide impact

A side impact door trim buckle initiator design is provided in a vehicle armrest and grab handle region. The disclosed support structure design induces buckling in the door handle supports while continuing to provide acceptable durability and strength. Two modifications to the door armrest and grab handle structures are made. First, an angled section is added to the material flow strap of the armrest supporting structure to promote buckling. This approach overcomes the difficulty of known material flow straps which tend to be horizontal, thus introducing a strong compressive load path. By adding an angle to the flow straps the vertical motion is forced upon a lateral impact. Second, vertical components of the door handle support structure are removed while a buckle initiator in the door handle support is added.

Owner:FORD GLOBAL TECH LLC

Practical secrecy-preserving, verifiably correct and trustworthy auctions

InactiveUS20110295752A1Preserve secrecyAccurately determineMultiple keys/algorithms usagePayment architectureCorrectness proofsTheoretical computer science

A system and method for conducting verifiably correct auctions that preserves the secrecy of the bids while providing for verifiable correctness and trustworthiness of the auction is disclosed. Some of the elements of the method and apparatus are that the auction operator accepts all bids submitted and follows the published rules of the auction. In one embodiment, the bids are maintained secret from the auctioneer and all bidders until the auction closes and no bidder is able to change or repudiate her bid. In another embodiment, the auction operator computes the auction results and publishes proofs of the results' correctness. In yet another embodiment, any party can check these proofs of correctness via publicly verifiable to computations on encrypted bids.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Fibrous structures and methods for making same

ActiveUS9752281B2Increase flexibilityAcceptable strengthLayered productsMachine wet endEngineeringFiber structure

Owner:PROCTER & GAMBLE CO

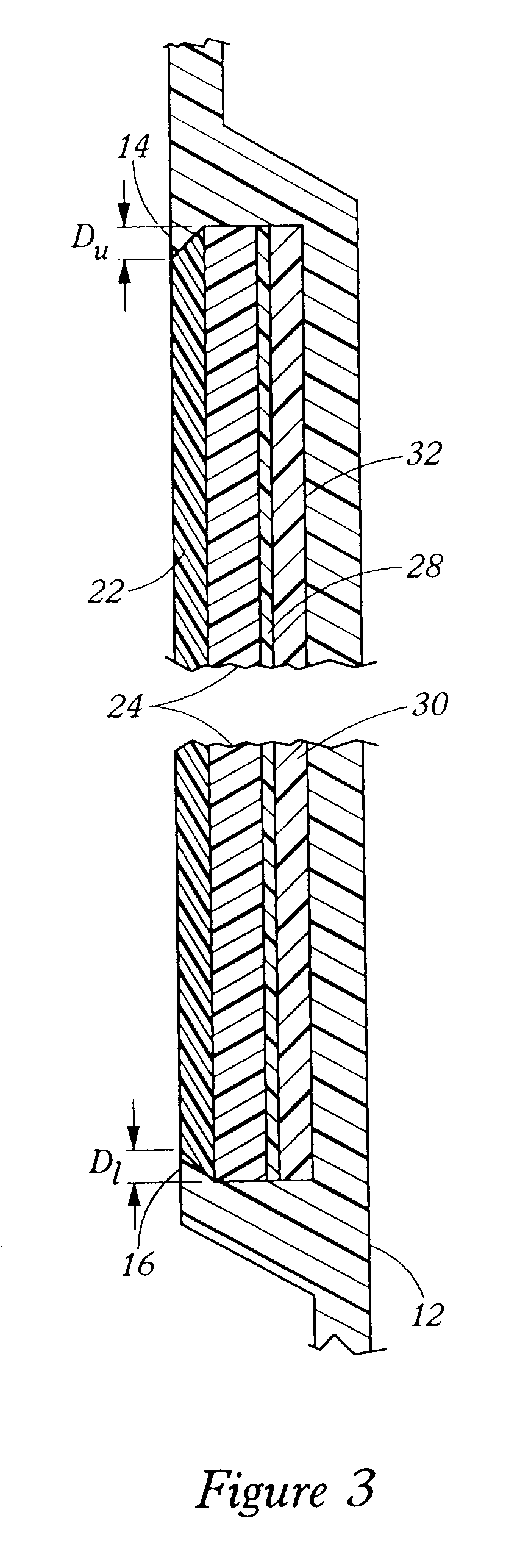

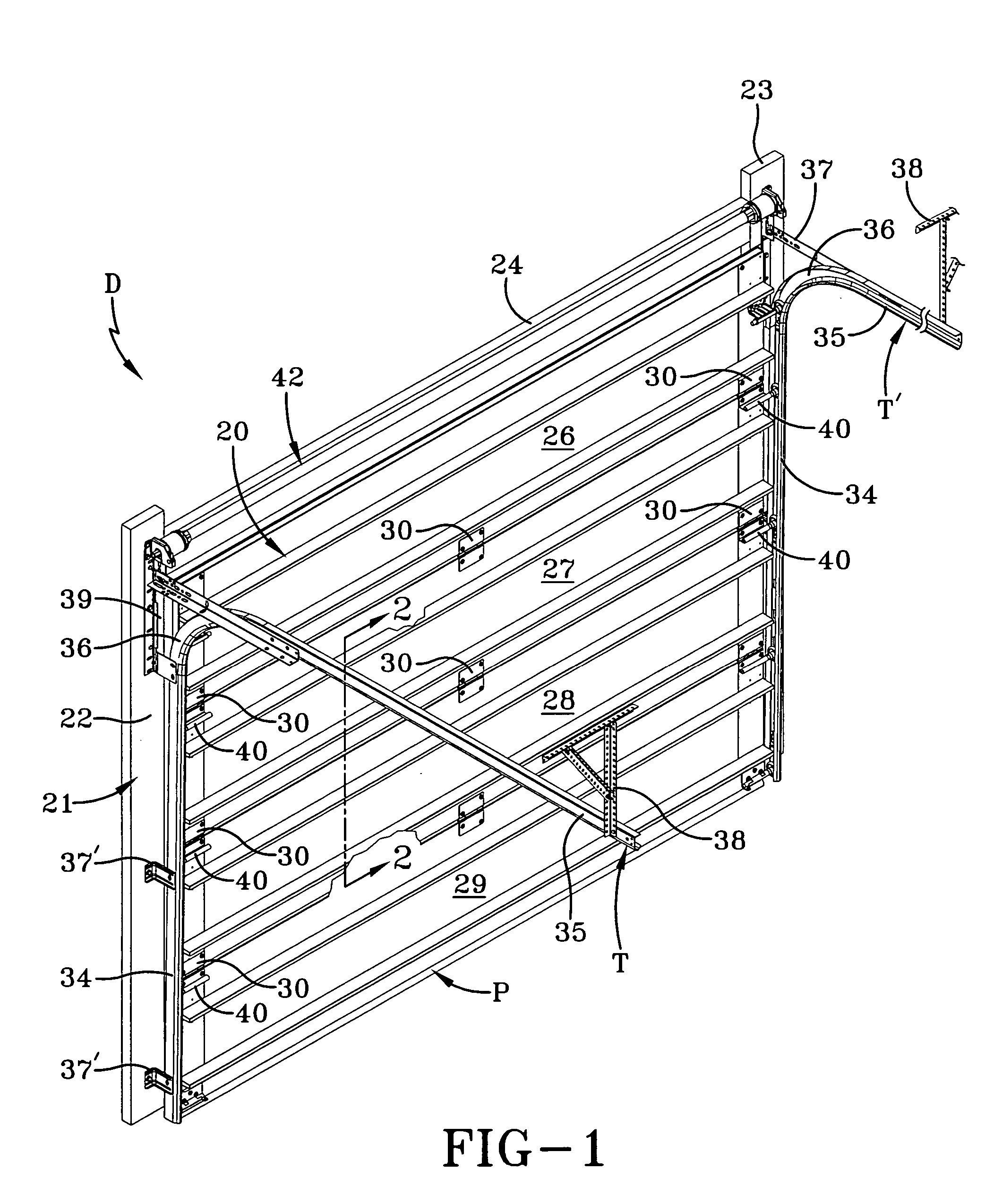

Reinforced sectional door panels

InactiveUS20060137835A1Acceptable strengthCost-effectivelyDoor/window protective devicesWing framesSurface plateEngineering

Owner:OVERHEAD DOOR

Process for extrusion

InactiveUS20020074682A1Increased effect on polymer temperatureReduce capacityWood working apparatusDomestic articlesPolymer scienceProduct gas

A process for the extrusion of polyethylene having a broad molecular weight distribution wherein the polyethylene is prepared in pellet form, said extrusion taking place in a pelletizing extruder having one or more zones essentially filled with polyethylene and two or more zones partially filled with polyethylene including a feed zone comprising (i) introducing the polyethylene into the extruder at a temperature sufficient to melt the polyethylene; (ii) introducing a mixture of an inert gas and oxygen into at least one partially filled zone with the exception of the feed zone, said mixture containing about 1 to about 21 percent by volume oxygen based on the volume of the gaseous mixture; (iii) passing the molten polyethylene through each zone at melt temperature; and (iv) extruding the polyethylene into pellets and cooling same.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Heating cable comprising steel monofilaments

ActiveUS20140008351A1Acceptable diameterAcceptable strengthOhmic-resistance heating detailsHeating element shapesElectrical conductorMaterials science

A new heating cable is described. The heating cable is comprising between seven and two hundred metallic monofilaments of a first type which are acting as electrical conductors to generate heat. The metallic monofilaments of a first type are having a diameter ranging from 30 μm to 100 μm. The metallic monofilaments of a first type are having a substantially round cross section. The metallic monofilaments of a first type are comprising a steel layer with a chromium content of less than 10% by weight. The heating cable is having an electrical resistance ranging between 0.1 Ω / m and 20.0 Ω / m when measured at 20° C.

Owner:NV BEKAERT SA

Non-asbestos friction material

InactiveUS6838161B2Increased shear strengthExcellent characteristicsOther chemical processesSynthetic resin layered productsPorosityShell molding

A non-asbestos friction material is obtained by molding and curing a composition which includes a fibrous base other than asbestos, a binder and a filler wherein the fibrous base contains no inorganic fibers having a length of at least 5 μm, a diameter of up to 3 μm and an aspect ratio greater than 3, and the binder includes a resin having a flow of at most 27 mm at 125° C. The friction materials having a porosity of 8 to 20% exhibit a good braking performance and stability, are endowed with good resistance to fade and wear, provide enhanced safety and hygiene during production, and have minimal impact on the human body from dust generated during use.

Owner:NISSHINBO IND INC

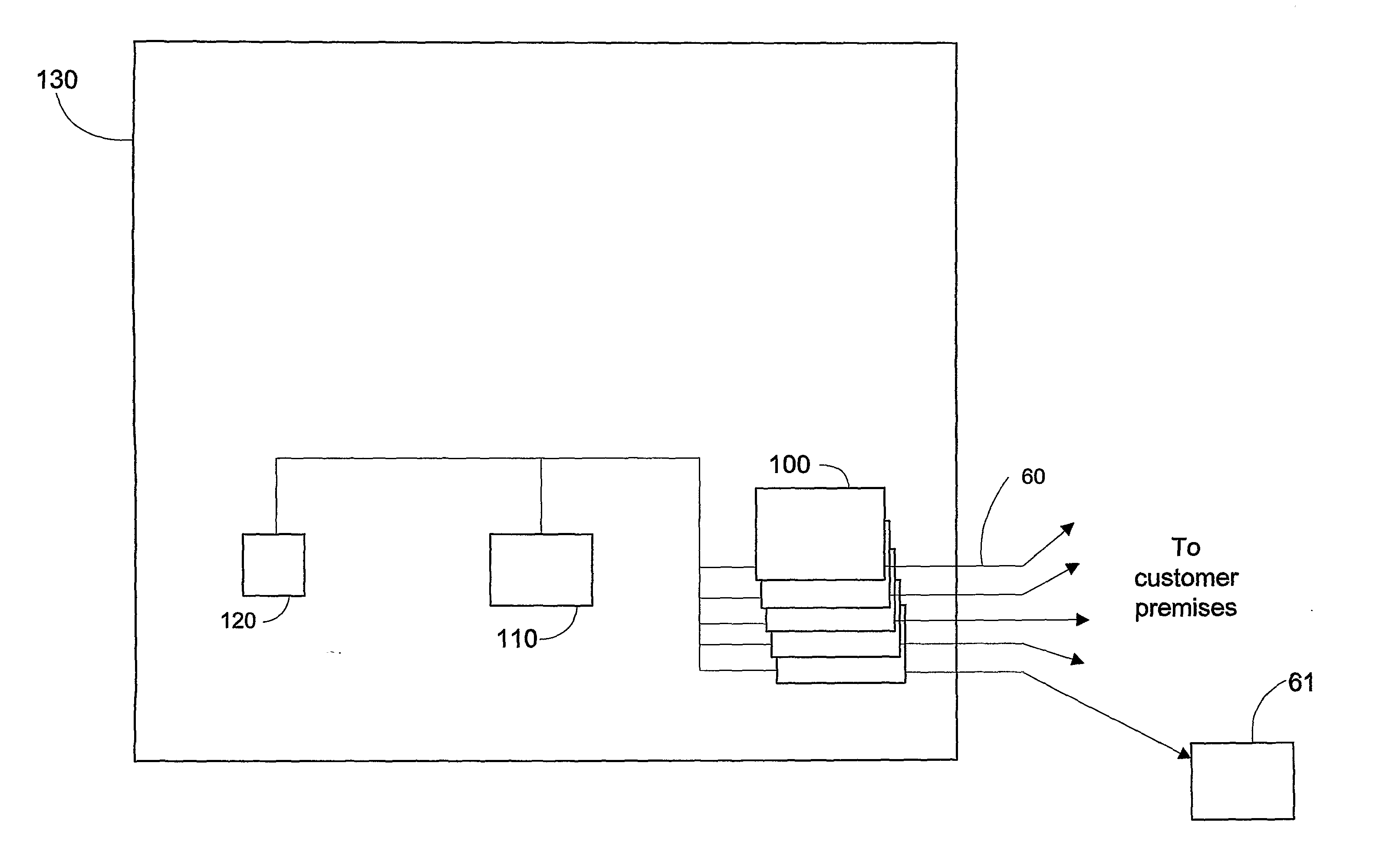

Method and device for estimating properties of a telecommunication transmission line

ActiveUS20090213998A1Acceptable strength of received signalLong lineSupervisory/monitoring/testing arrangementsSubstation equipmentTransmission propertiesLine length

A method and device for estimating one or more transmission properties of a telecommunication transmission line. At least one signal is sent on the line, the at least one signal including at least two frequencies for which the absolute value of the line propagation constant times the line length is less than π, and a resulting signal is received. An estimate of at least one transmission line property is then determined by examining the relationship between the sent and resulting signal or signals. The process may be repeated, if necessary. The estimate determination may also be repeated one or more times, with each successive estimate preferably using for the determination only those frequencies for which, as previously estimated, the absolute value of the line propagation constant times the line length is less than π.

Owner:TELEFON AB LM ERICSSON (PUBL)

Unleaded free-cutting brass alloys with excellent castability, method for producing the same, and application thereof

The present invention is directed to an unleaded free cutting brass alloy with excellent machinability, leak-tightness, reca stability, and mechanical properties, wherein the brass alloy comprises 65 to 75 weight % of copper, 22.5 to 32.5 weight % of zinc, 0.5 to 2.0 weight % of silicon, and other unavoidable impurities; wherein the total content of copper and zinc in the brass alloy is 97.5 weight % or more.

Owner:FORTUNE MFG

Heating cable comprising steel monofilaments

ActiveUS9439244B2Acceptable strengthOhmic-resistance heating detailsHeating element shapesElectrical conductorMaterials science

A new heating cable is described. The heating cable is comprising between seven and two hundred metallic monofilaments of a first type which are acting as electrical conductors to generate heat. The metallic monofilaments of a first type are having a diameter ranging from 30 μm to 100 μm. The metallic monofilaments of a first type are having a substantially round cross section. The metallic monofilaments of a first type are comprising a steel layer with a chromium content of less than 10% by weight. The heating cable is having an electrical resistance ranging between 0.1 Ω / m and 20.0 Ω / m when measured at 20° C.

Owner:NV BEKAERT SA

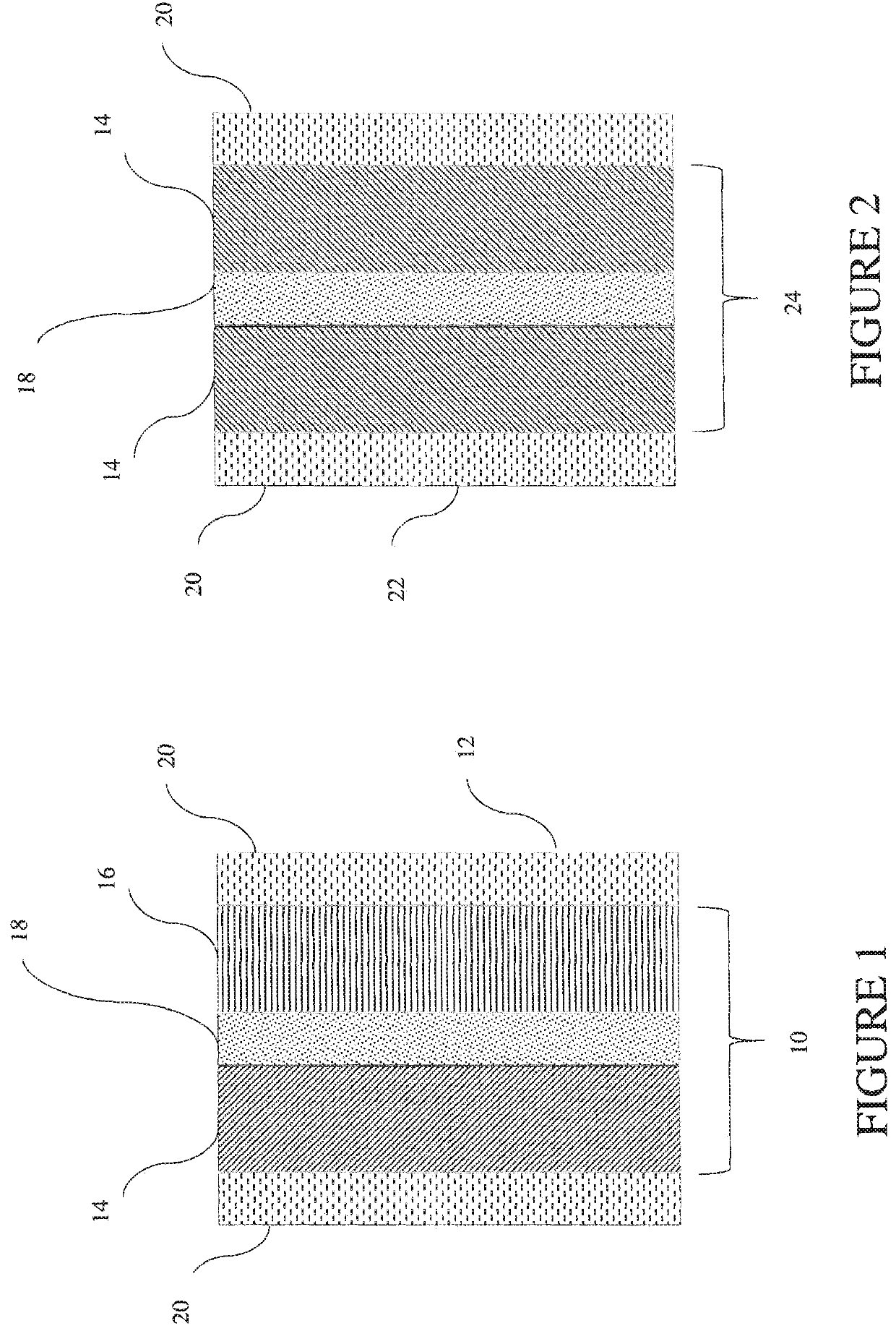

Construction panel having improved fixing strength

ActiveUS10731343B2Improve abilitiesStrong plasterboardConstruction materialSolid waste managementFiberPolymer science

A plasterboard comprises a gypsum matrix having a polymeric additive distributed therein in an amount of at least 1 wt % relative to the gypsum, the gypsum matrix further having a first group of fibres and a second group of fibres embedded therein, wherein the fibres of the first group of fibres have an average length that is at least three times the average length of the fibres of the second group of fibres.

Owner:SAINT GOBAIN PLACO SAS

Construction Panel Having Improved Fixing Strength

ActiveUS20170306623A1Improve fire resistanceImprove abilitiesConstruction materialSolid waste managementFiberUltimate tensile strength

A plasterboard comprises a gypsum matrix having a polymeric additive distributed therein in an amount of at least 1 wt % relative to the gypsum, the gypsum matrix further having a first group of fibres and a second group of fibres embedded therein, wherein the fibres of the first group of fibres have an average length that is at least three times the average length of the fibres of the second group of fibres.

Owner:SAINT GOBAIN PLACO SAS

Method and device for estimating properties of a telecommunication transmission line

ActiveUS8290122B2Reduce signalingAcceptable strengthSupervisory/monitoring/testing arrangementsSubstation equipmentEngineeringTransmission properties

Owner:TELEFON AB LM ERICSSON (PUBL)

Secondary battery with hydroxide-ion-conducting ceramic separator

ActiveUS10483596B2Increasing the thicknessReduce thicknessSolid electrolytesFuel and secondary cellsPorous substrateInternal resistance

Provided is a secondary battery including a hydroxide-ion-conductive ceramic separator. The secondary battery includes a positive electrode; a negative electrode; an alkaline electrolytic solution; a ceramic separator that is composed of a hydroxide-ion-conductive inorganic solid electrolyte and separates the positive electrode from the negative electrode; a porous substrate disposed on at least one surface of the ceramic separator; and a container accommodating at least the negative electrode and the alkaline electrolytic solution, wherein the inorganic solid electrolyte is in the form of a membrane or layer densified enough to have water impermeability, and the porous substrate has a thickness of 100 to 1,800 μm. According to the secondary battery of the present invention, the thickness and resistance of the ceramic separator are decreased without concern for reduced strength, and a reduction in energy density and an increase in internal resistance are effectively prevented.

Owner:NGK INSULATORS LTD

Multilayer interlayer and glass laminate

ActiveUS10538063B2Improve featuresAcceptable stiffnessSynthetic resin layered productsConstructions elementsIonomerInter layer

A multilayer interlayer containing a specified ionomer skin layer and an acoustic damping intermediate layer, and laminate containing such interlayer are provided, wherein the laminate has a desirable combination of sound insulating, flexural strength and optical properties suitable for use in transportation and architectural end uses.

Owner:KURARAY EURO GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com