Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

452results about "Shaping soap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressed, self-solidifying, solid cleaning compositions and methods of making them

ActiveUS8889048B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineeringAdhesive bonding

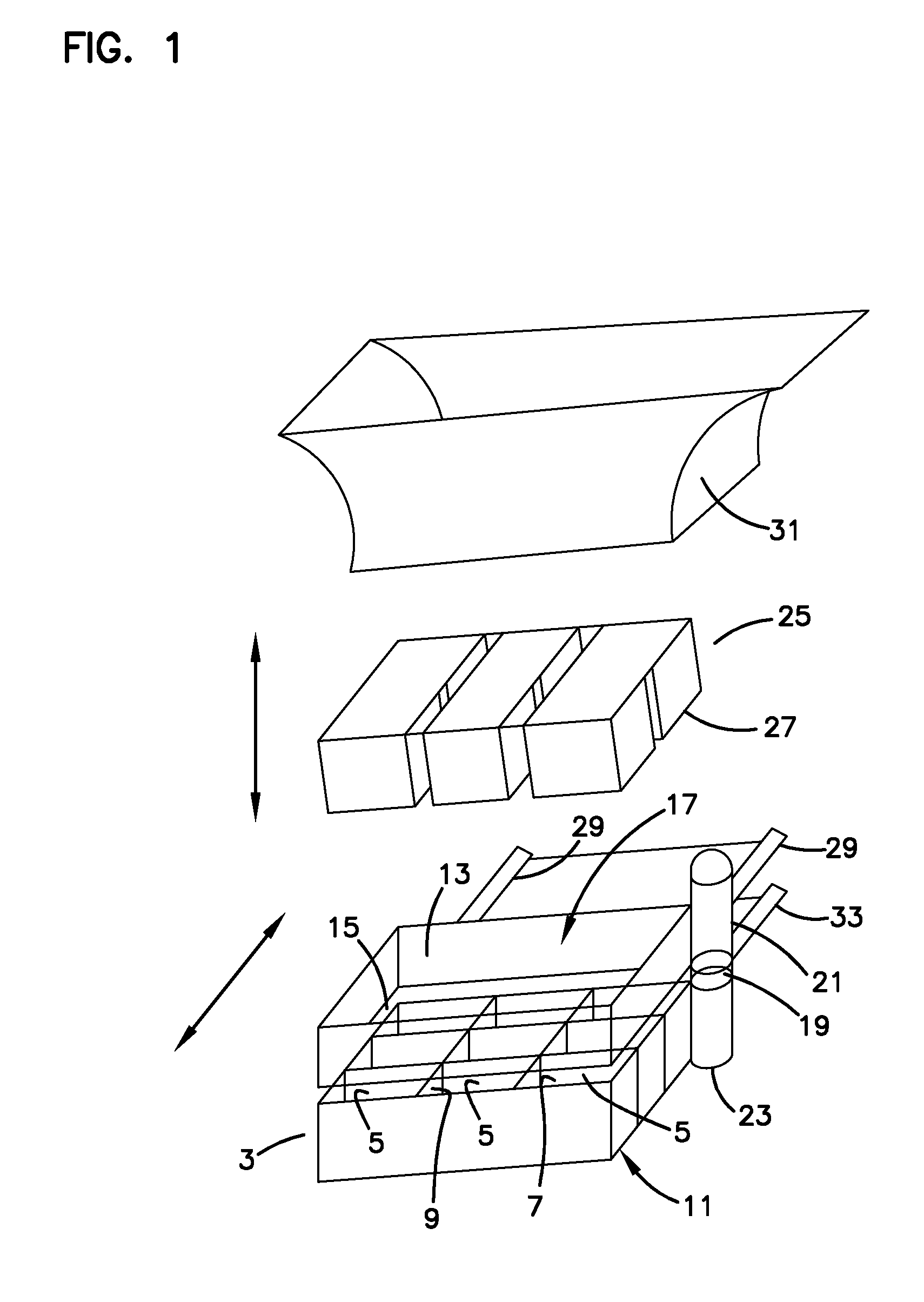

The present invention relates to a method of making a solid cleaning composition. The method can include pressing and / or vibrating a flowable solid of a self-solidifying cleaning composition. For a self-solidifying cleaning composition, pressing and / or vibrating a flowable solid determines the shape and density of the solid but is not required for forming a solid. The method can employ a concrete block machine for pressing and / or vibrating. The present invention also relates to a solid cleaning composition made by the method and to solid cleaning compositions including particles bound together by a binding agent.

Owner:ECOLAB USA INC

Multiphase soaps

Owner:SYMRISE GMBH & CO KG

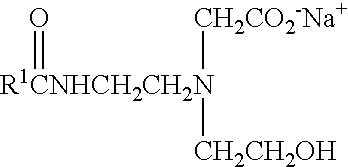

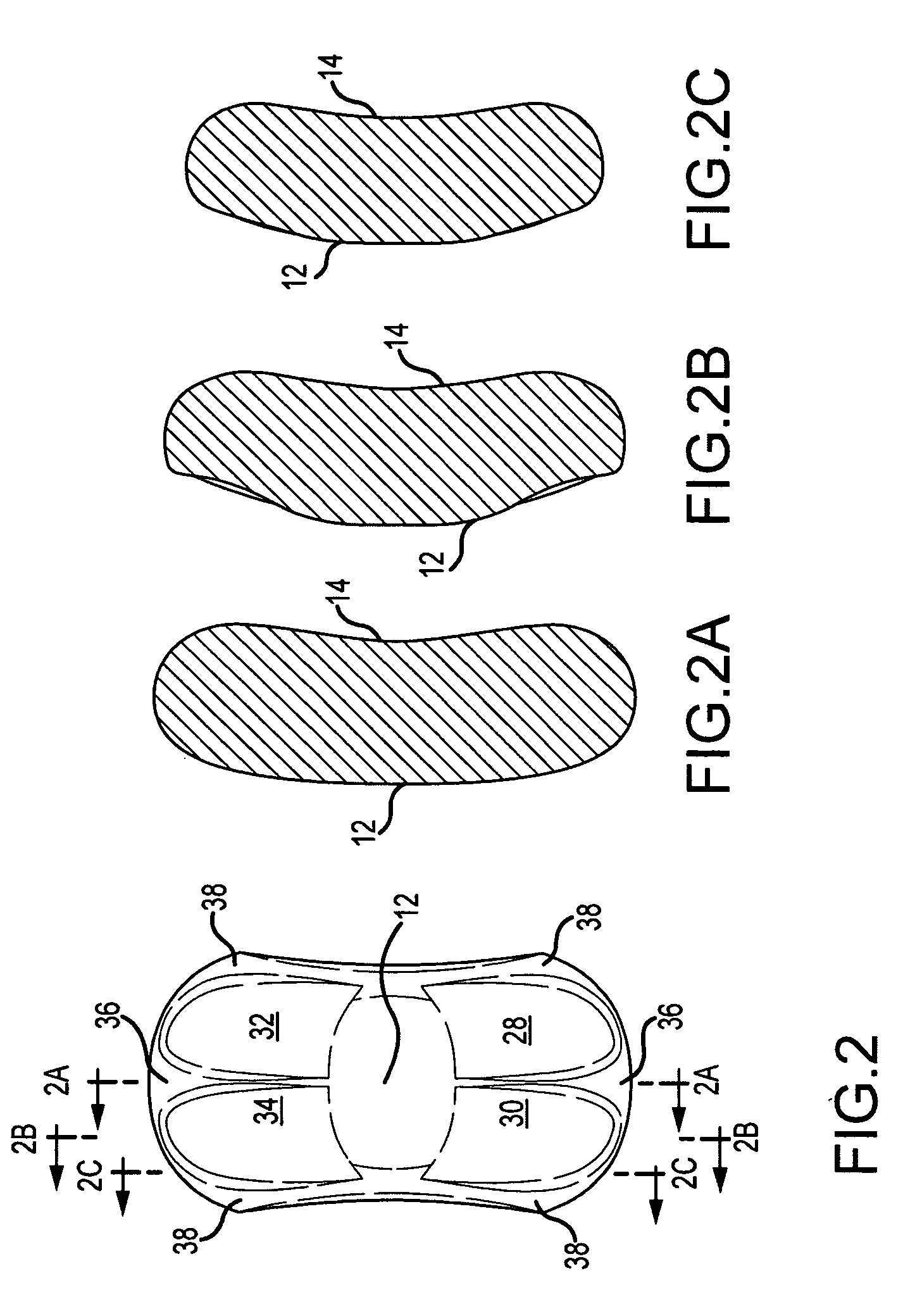

Multi-phase toilet articles and methods for their manufacture

A multi-phase solid toilet article whose phases are separated by a membrane, and processes for making the article are described. Each phase is reproducibly fabricated to form an article allowing the user to sequentially or simultaneously derive benefits from the different materials contained in the article's layers. The membrane is either at least partially water soluble or dispersible in the case of a product used with water, or shearable in the case of a cosmetic product which is applied directly to or rubbed on the skin. The membrane material is selected to dissolve or disintegrate with product use, so as to accomplish its intended function of separating the different cosmetic materials until they are consumed. The flowable toilet or cosmetic formulations are simultaneously or separately transferred into the mold, simultaneously or separately allowed to harden, where the membrane divider is not removed and becomes a part of the finished product. The hardened multi-phase article is finally ejected from the mold.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

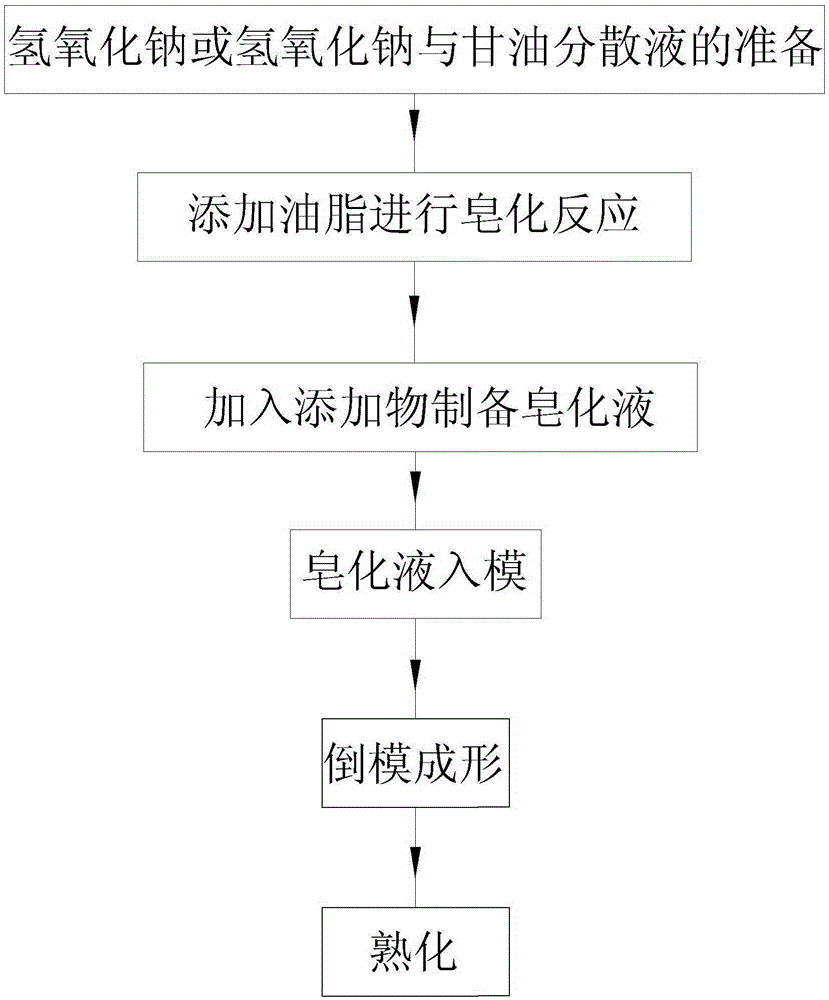

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

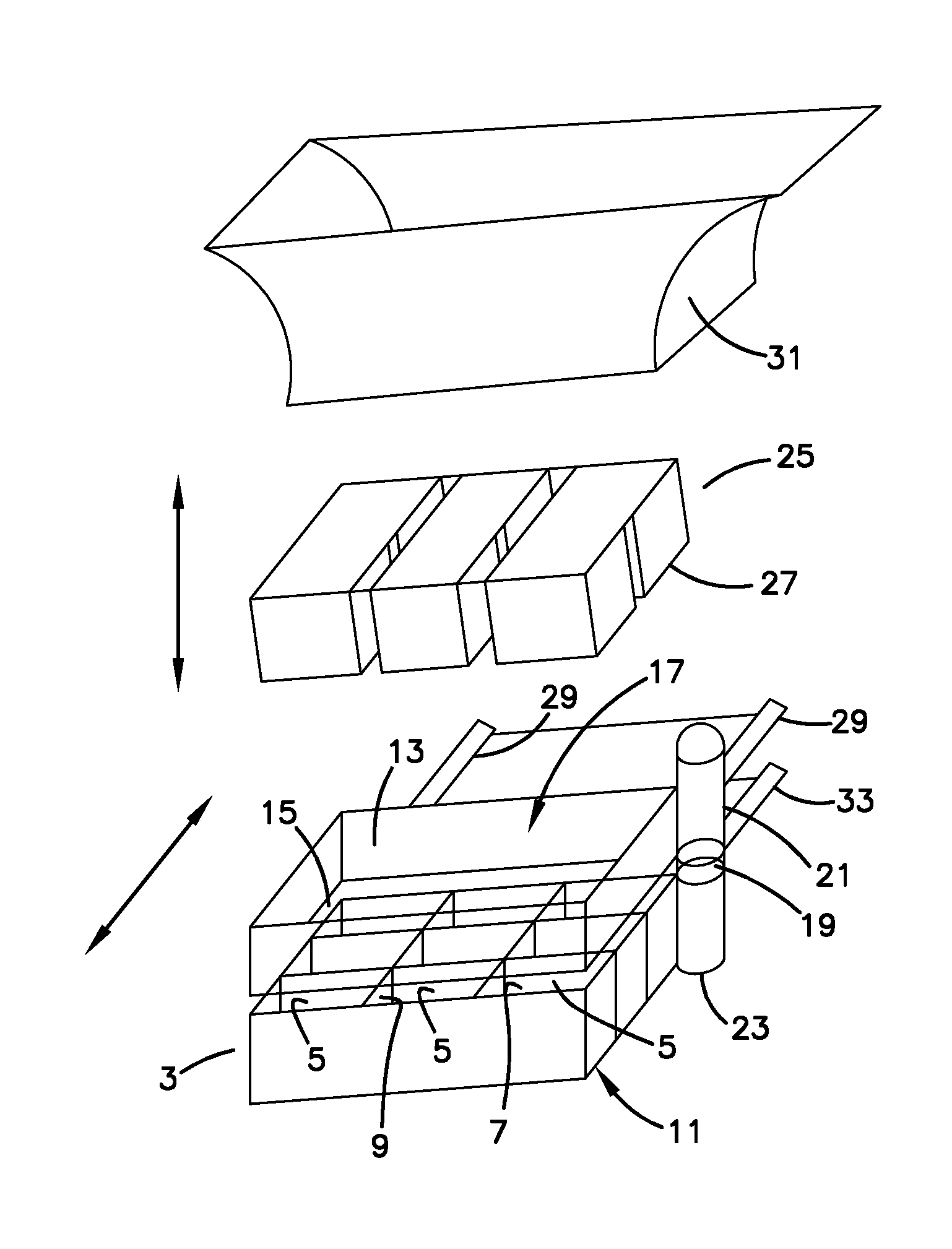

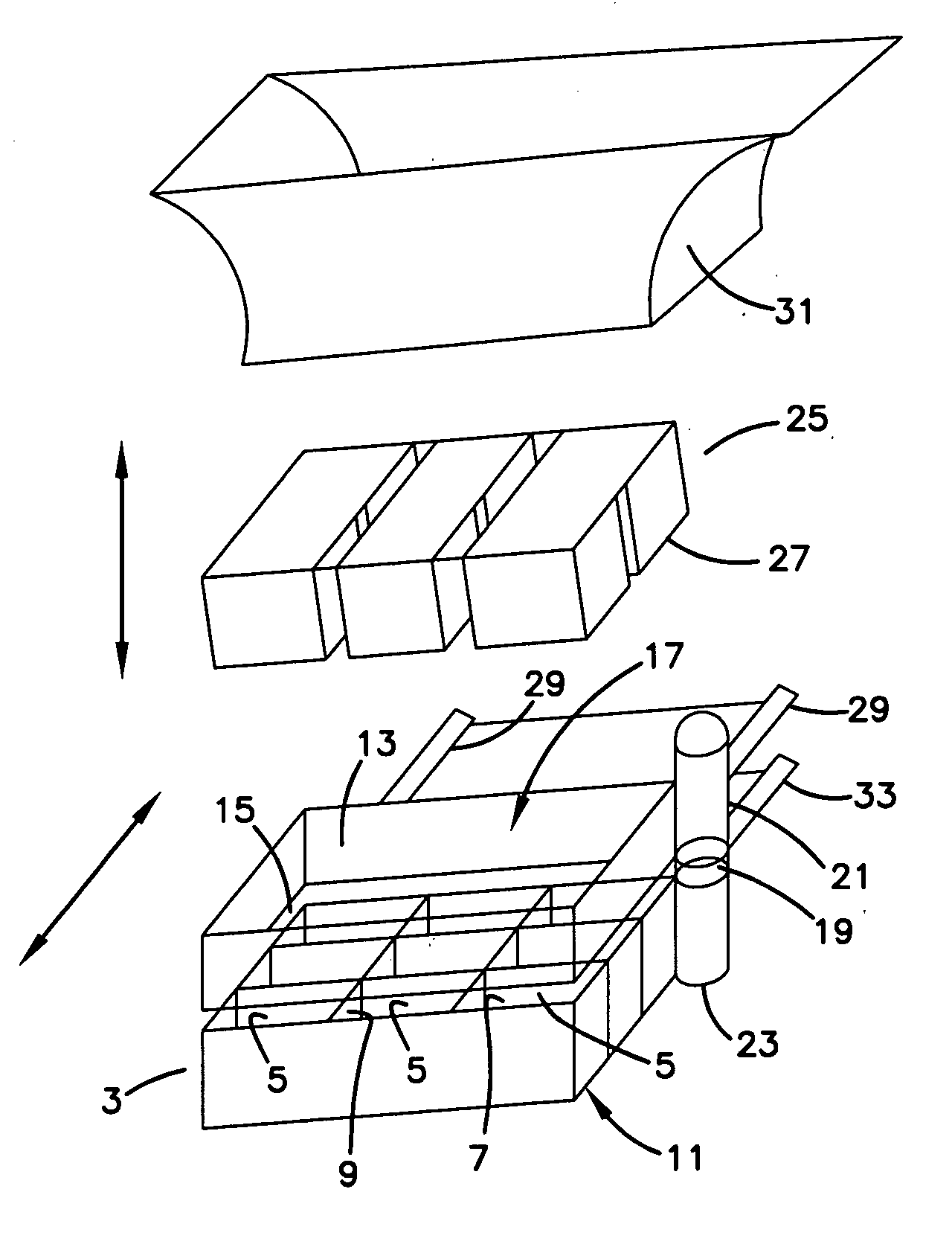

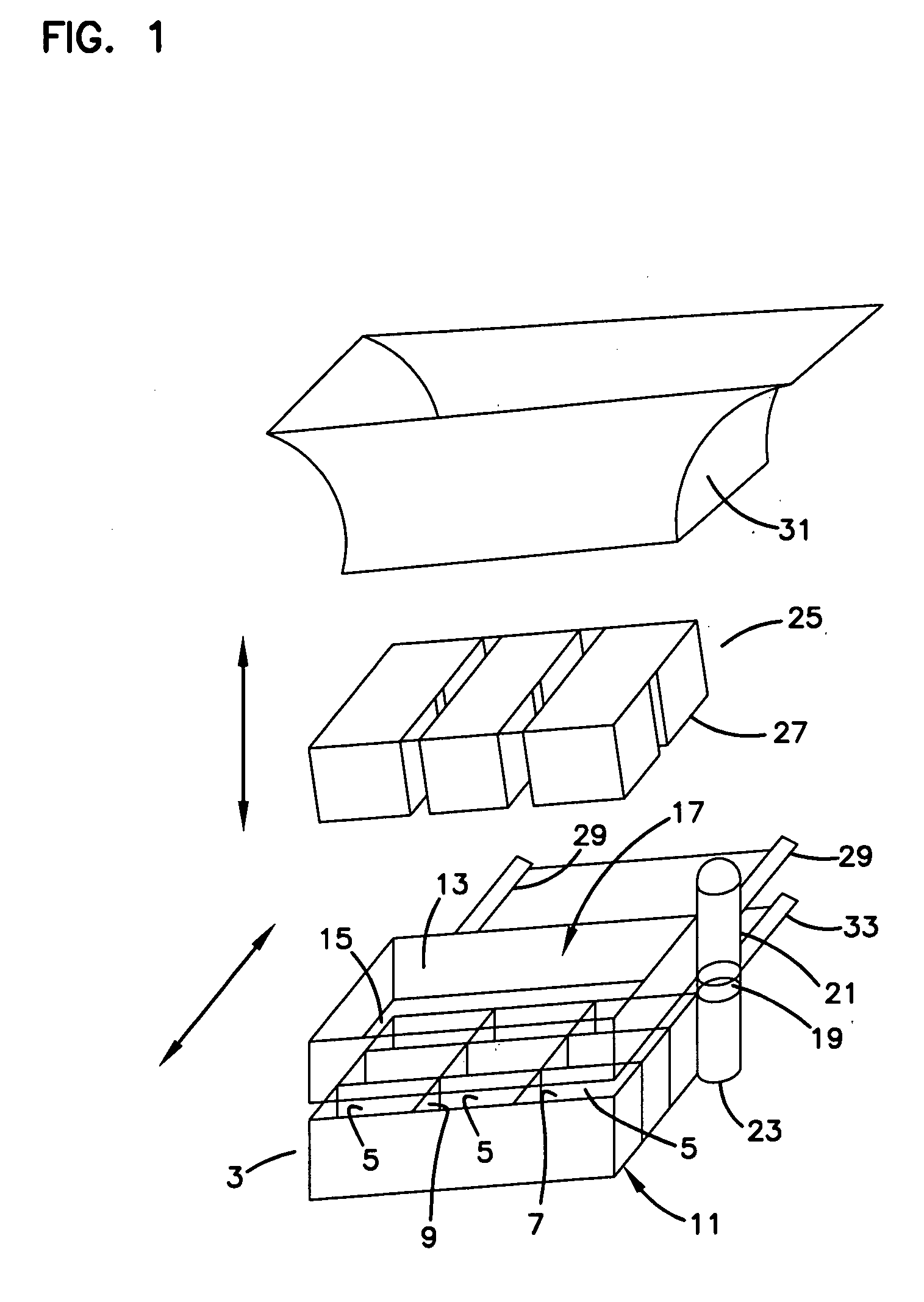

Pressed, self-solidifying, solid cleaning compositions and methods of making them

ActiveUS20090105114A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsVolumetric Mass DensityEngineering

The present invention relates to a method of making a solid cleaning composition. The method can include pressing and / or vibrating a flowable solid of a self-solidifying cleaning composition. For a self-solidifying cleaning composition, pressing and / or vibrating a flowable solid determines the shape and density of the solid but is not required for forming a solid. The method can employ a concrete block machine for pressing and / or vibrating. The present invention also relates to a solid cleaning composition made by the method and to solid cleaning compositions including particles bound together by a binding agent.

Owner:ECOLAB USA INC

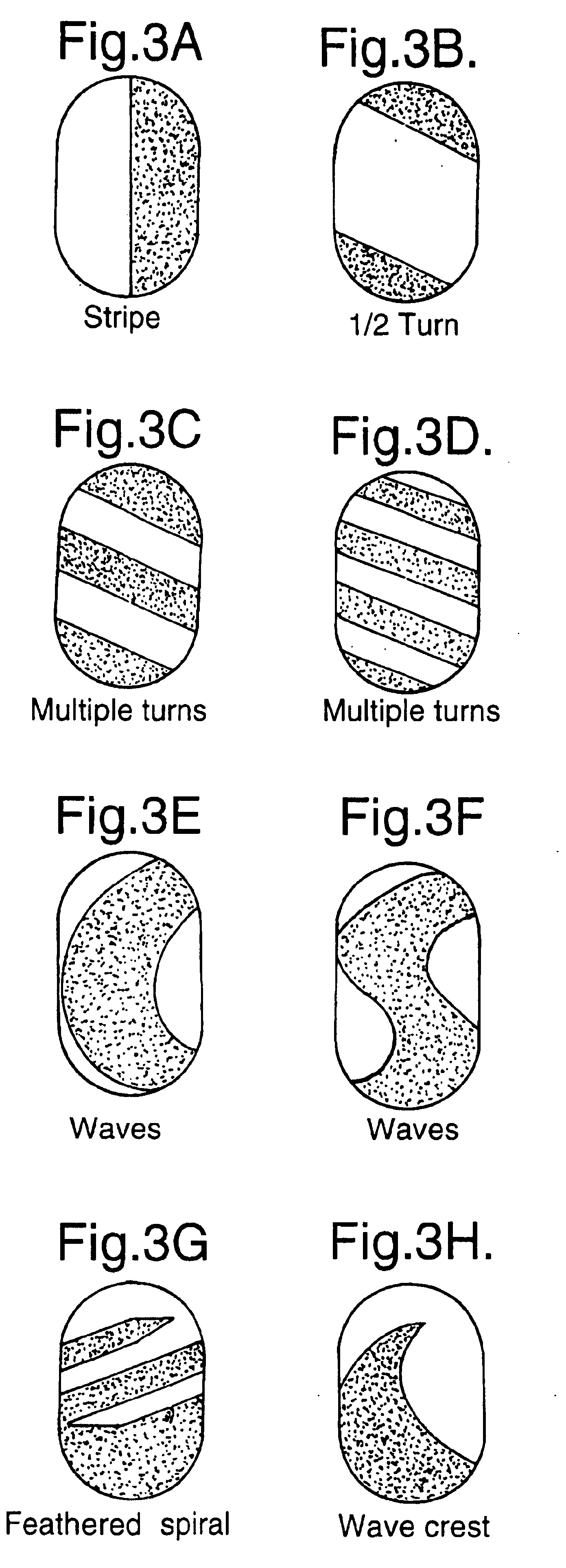

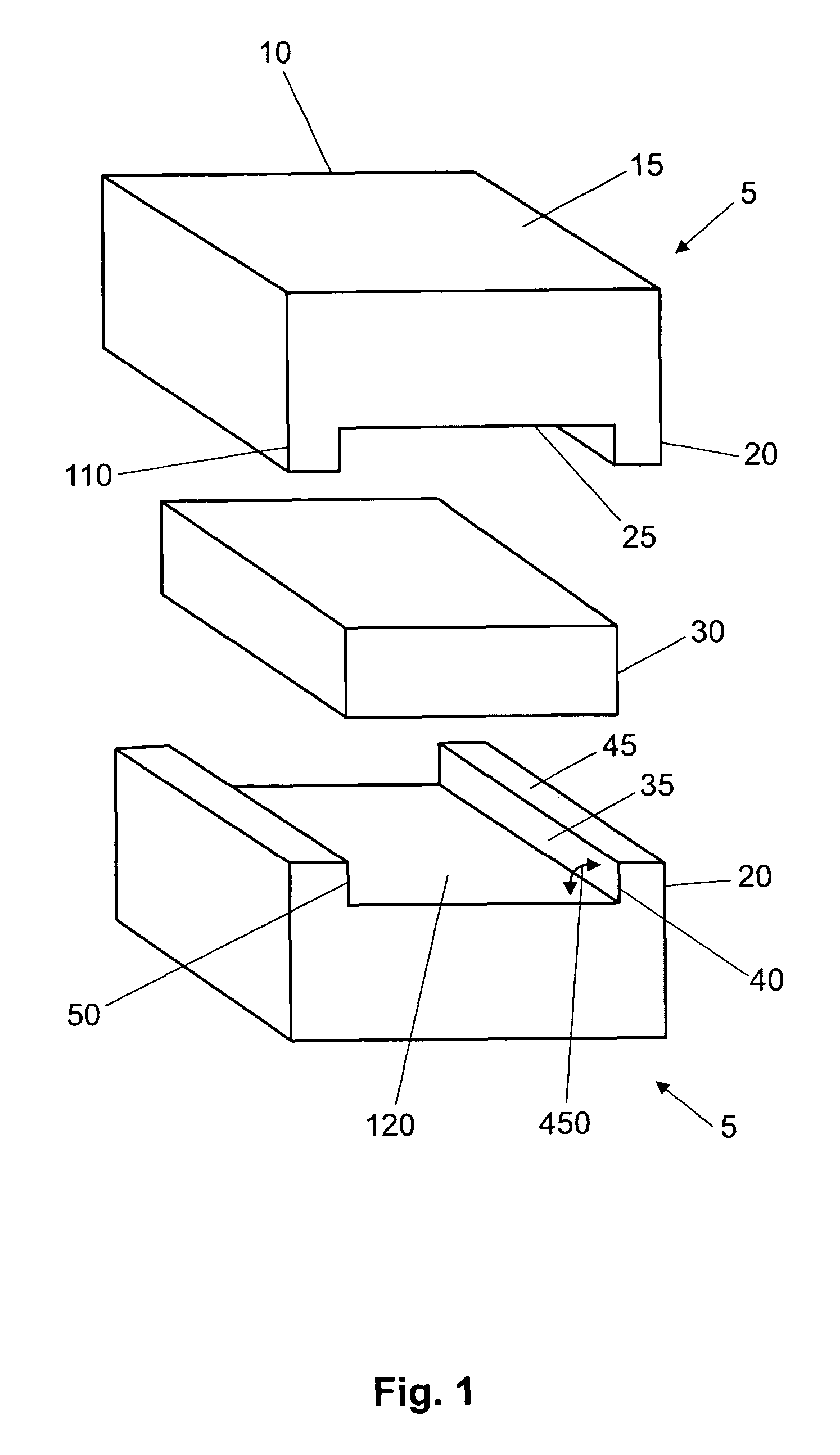

Multi-phase melt cast toilet bar and a method for its manufacture

A multi-phase melt cast toilet bar which has at least one interface along a plane perpendicular to the plane formed by the x and y-axis of said bar, and a process of making the bar is described. Each phase, containing a cleansing agent, is reproducibly positioned in the bar to be used simultaneously thereby allowing the user to simultaneously derive benefits from the use of the cleansing agents contained in the bar's layers. The process for making the bar is a continuous one, whereby the molten cleansing agents are simultaneously or separately poured into the mold, simultaneously or separately allowed to harden, and where the mold divider is not removed or removed either after hardening of the adjacent molten cleansing agent but before the pouring of the next molten cleansing agent, or removed while at least one phase remains flowable. The hardened multi-phase toilet bar is finally ejected from the mold.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Pressed, waxy, solid cleaning compositions and methods of making them

ActiveUS20090105111A1Organic detergent compounding agentsSurface-active detergent compositionsVolumetric Mass DensityAdhesive bonding

The present invention relates to a method of making a solid cleaning composition. The method can include pressing and / or vibrating flowable waxy particles of a waxy cleaning composition. For a waxy cleaning composition, pressing and / or vibrating flowable waxy particles determines the shape and density of the solid but is not required for forming a solid. The method can employ a concrete block machine for pressing and / or vibrating. The present invention also relates to a solid cleaning composition made by the method and to solid cleaning compositions including particles bound together by a binding agent.

Owner:ECOLAB USA INC

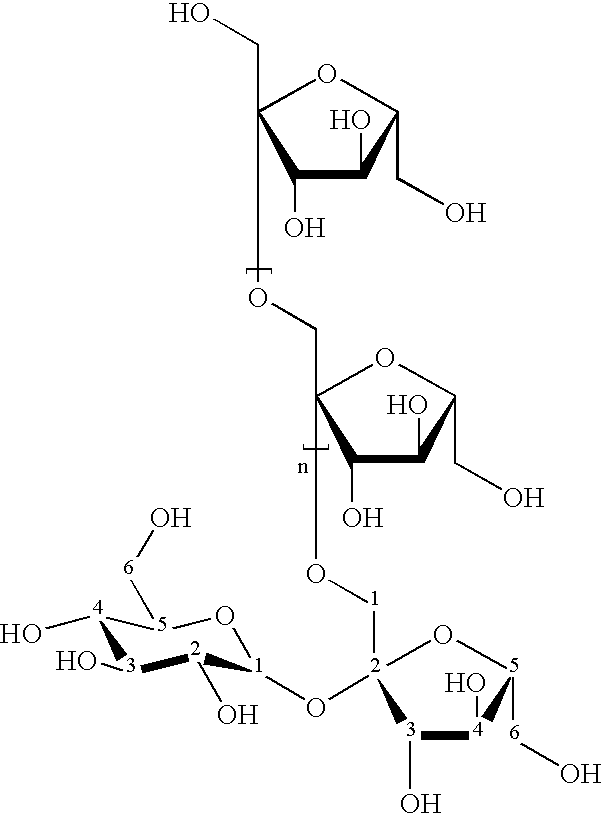

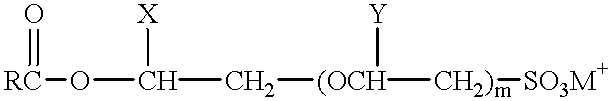

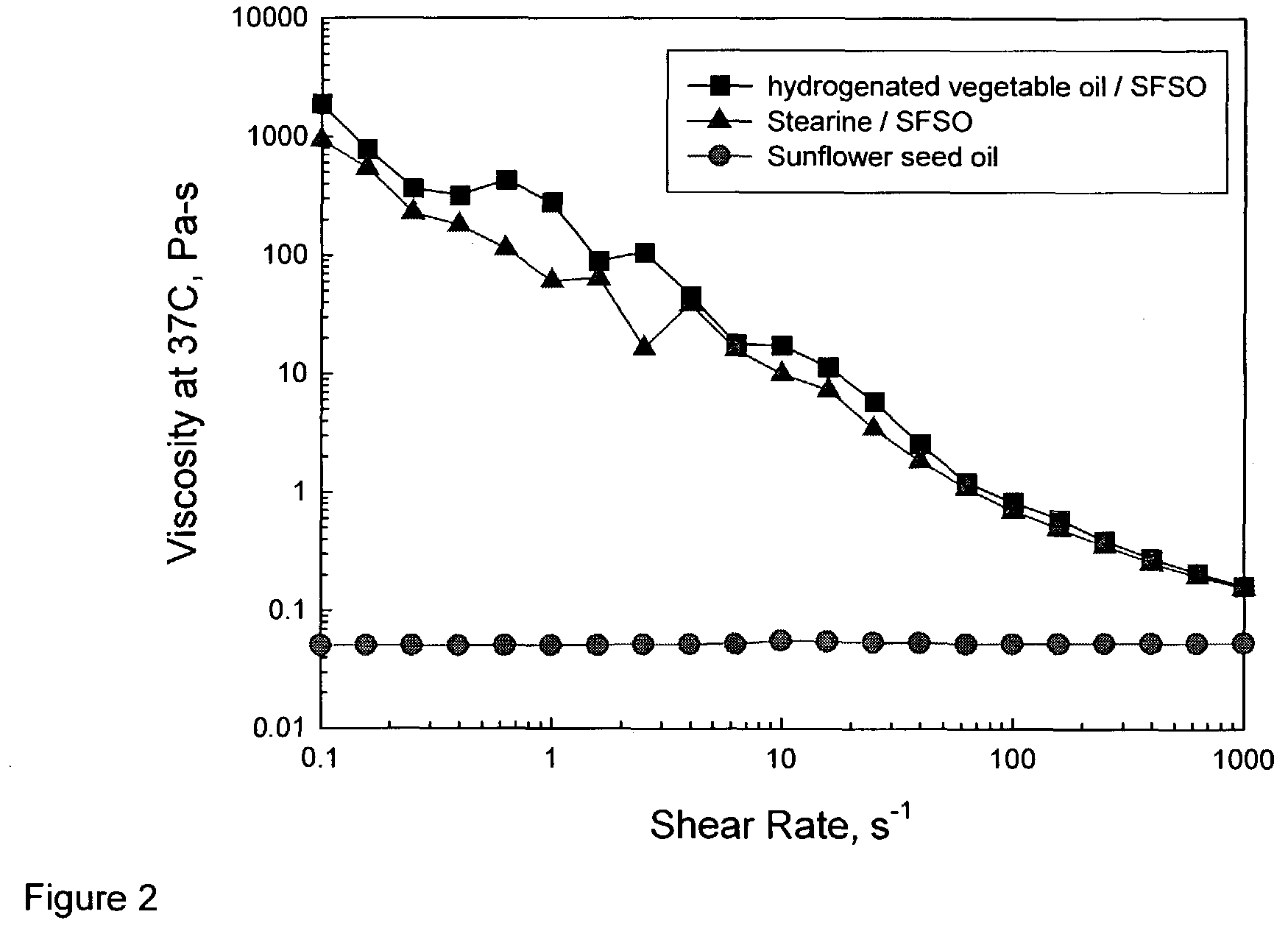

Personal product compositions comprising structured benefit agent premix or delivery vehicle

The present invention relates to compositions comprising a structured benefit agent pre-mix or delivery vehicle comprising benefit agent structured with crystalline materials, as defined, which when separately prepared and combined after preparation, provides enhanced delivery of benefit agent to a carrying composition into which the premix is added.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

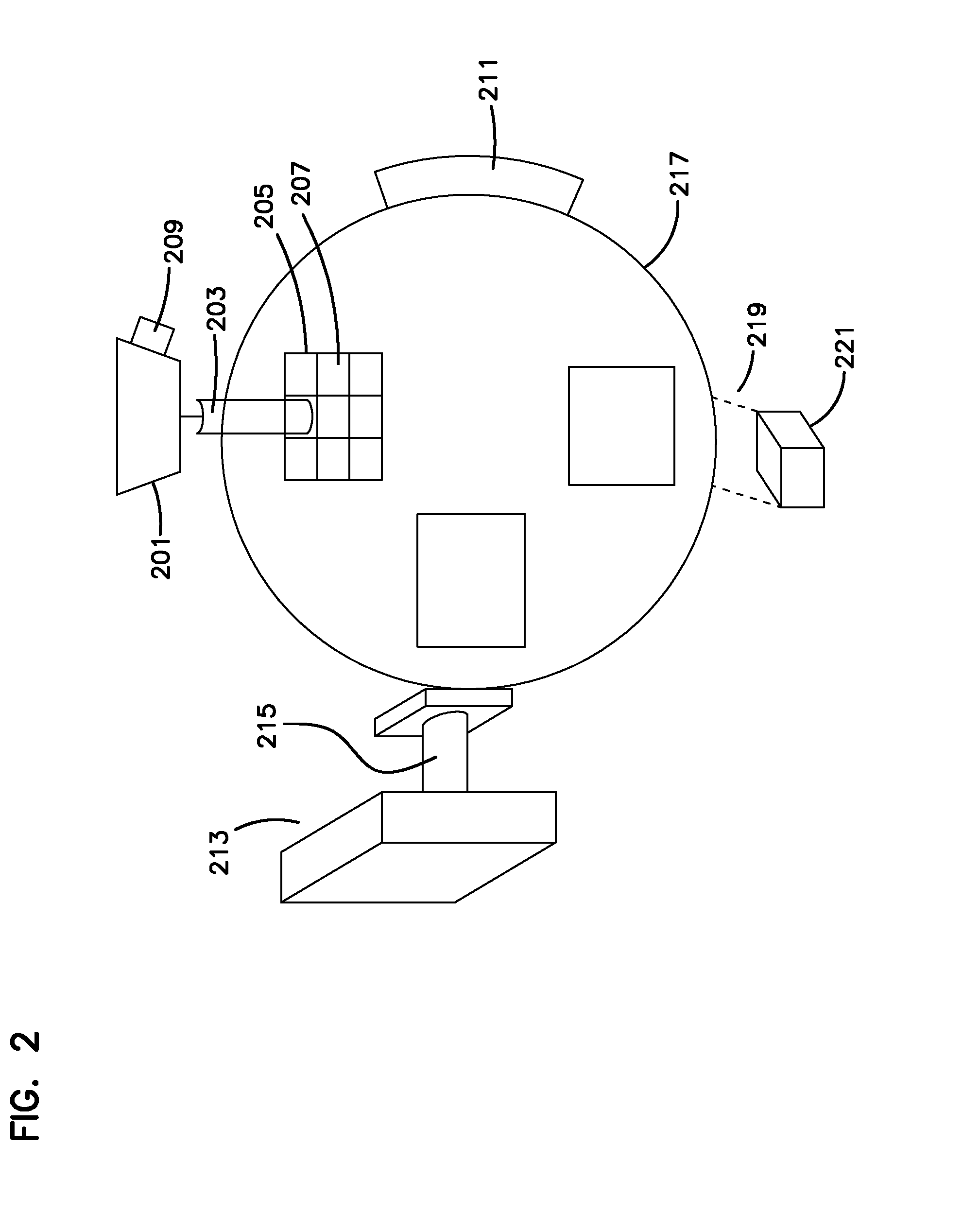

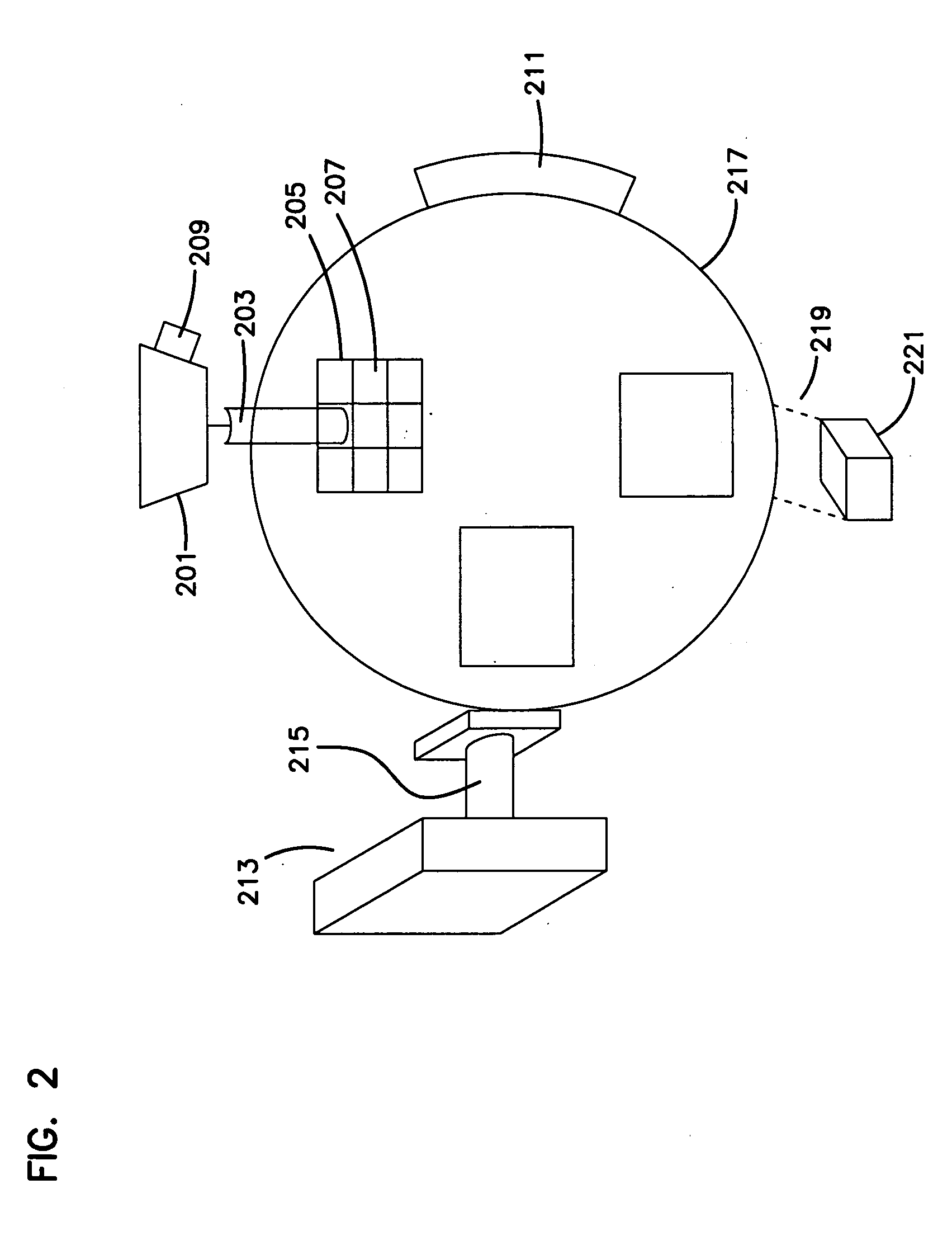

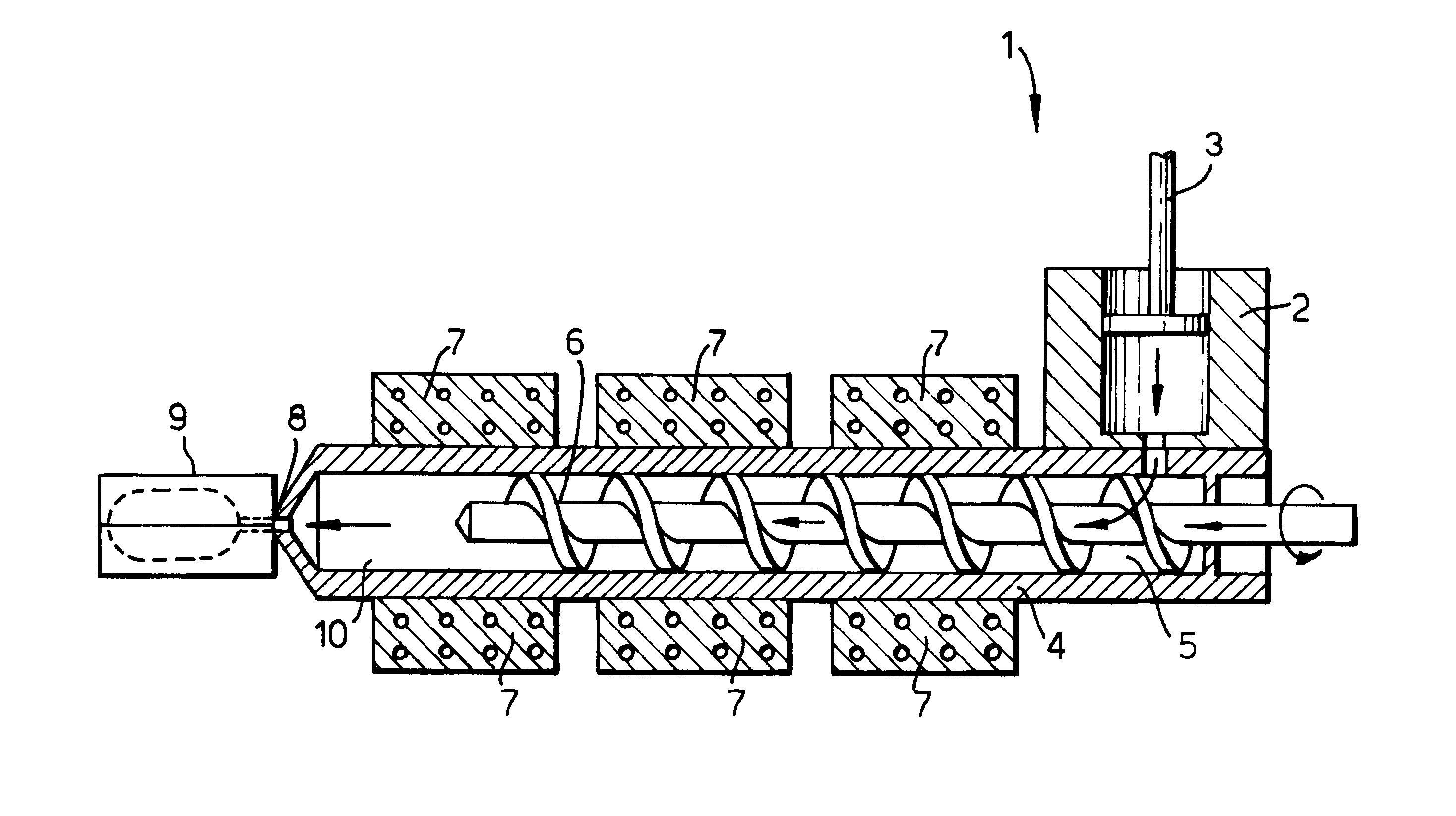

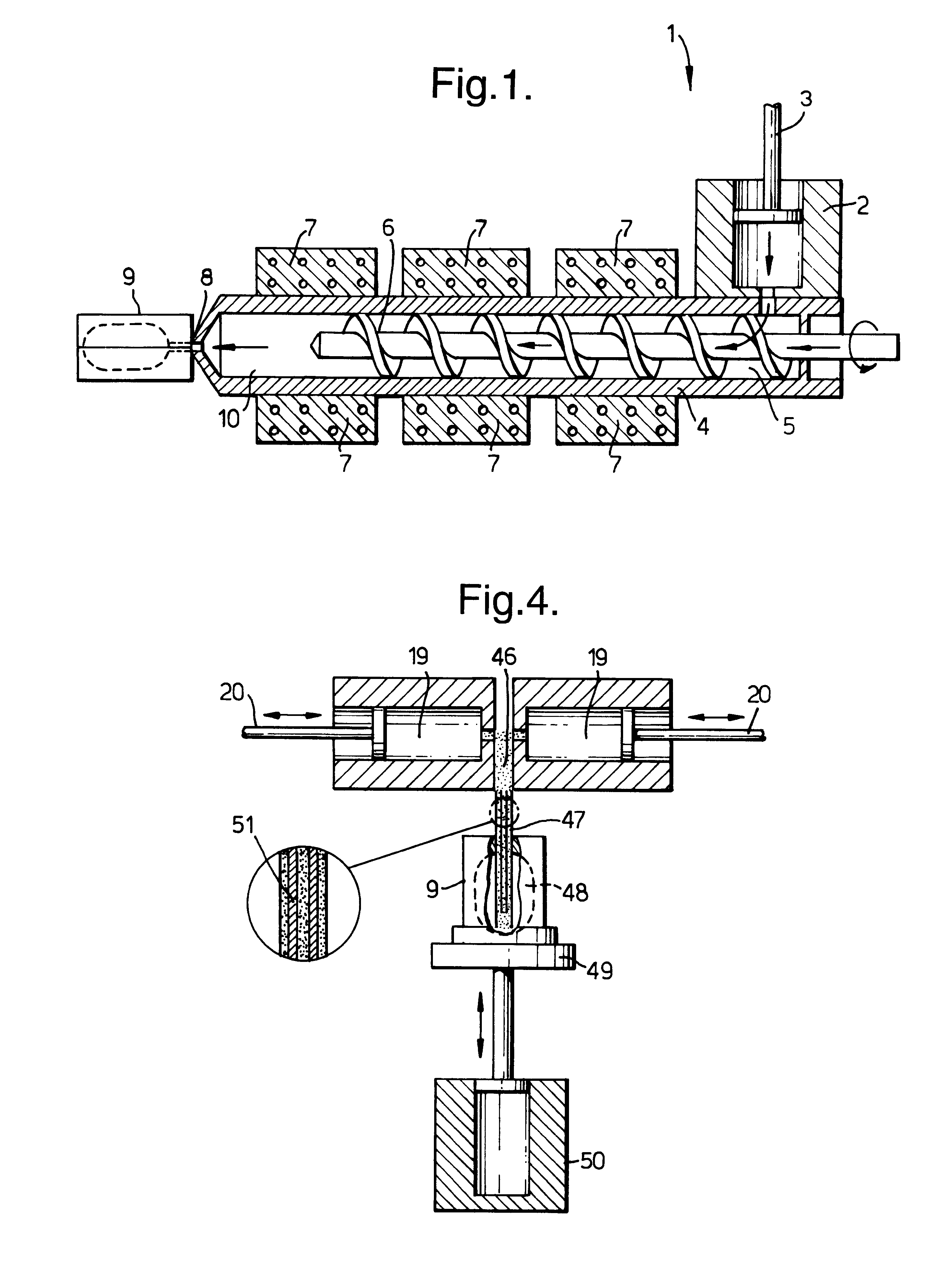

Process for molding of a detergent composition

InactiveUS6224812B1Reduce operating costsLower operating temperatureButtonsRecord carriersShell moldingSemi solid

A process for forming detergent bars by injection moulding in which a pressure is applied to a partially structured detergent composition to deliver it to a mould. The detergent composition can be delivered to the mould in a substantially semi-solid state, at a temperature below 70° C. and at a pressure at the point of injection of greater than 20 psi. Apparatus for forming detergent bars according the invention are also described

Owner:LEVER BROTHERS

Method for preparing beautifying perfumed soap

The invention relates to the field of cleaning products, in particular to a method for preparing beautifying perfumed soap. The beautifying perfumed soap comprises the following components in parts by mass: 6-7 parts of olive oil, 1 part of palm oil, 1 part of sodium hydroxide, 4-5 parts of water and 0.065-0.26 part of pearl powder or essential oil, wherein the olive oil, the palm oil, the sodium hydroxide and the water are used as main raw materials; and the pearl powder and the essential oil are used as auxiliary raw materials for adding as required. The method comprises the following steps of: filling olive oil and palm oil into a stainless steel container or a heat resistant glass container, heating by insolating water and cooling to 45-50 DEG C; slowly adding sodium hydroxide into water; after the sodium hydroxide is completely dissolved into water, cooling to 40-50 DEG C; slowly pouring an alkali solution into a container loaded with oil and rapidly stirring until soap liquid is thick; adding the pearl powder and the essential oil and uniformly stirring; pouring the stirred soap liquid into a die and demoulding after 24 hours; and then placing the soap liquid at normal temperature environment for saponifying for 4-8 weeks. The handmade soap prepared by the invention has the advantages of high grade of adopted grease, simple and safe preparation process and no any additive and can be used for washing the face and the hair and bathing; and because glycerol is still retained in the perfumed soap, the beautifying perfumed soap not only can have the effect of cleaning but also can protect the skin and hair.

Owner:朱鹏龙

Scrub soap and preparation process and formula thereof

InactiveCN102041205AImprove maintenance effectNo adverse effectsShaping soapAlkali/ammonium soap compositionsOyster shellsBULK ACTIVE INGREDIENT

The invention discloses a solid cleaning product, which is prepared by the following steps of: grinding natural plant peel, pericarp, husk and shell materials such as shells, durian shells, litchi pericarp, oyster shells, pineapple peels, buckwheat husks, aloe peels, orange peels and cinnamon bark into particles with 20 to 600 meshes serving as scrub materials, and adding one or more scrub materials into a soap base by adopting low temperature saponification technology to prepare the scrub soap. In the process of preparing the scrub soap, surfactants and chemical additives are not added at all, and byproducts are not generated at all, so the scrub soap cannot have any adverse effect on the skin and environment. The pericarp, husk or shell scrub material in the scrub soap can peel off or remove dead skin cells, contains rich natural active ingredients such as polysaccharides, vitamins, tartaric acid and pectin, which have good effects of sterilizing, beautifying, moistening, repairing and resisting ageing on the skin, and has great market application prospect.

Owner:王世范

Preparation method for manually ground soap

InactiveCN103756817AImprove processing efficiencySolve the low saponification rateShaping soapAlkali/ammonium soap compositionsSolubilityMineralogy

The invention discloses a preparation method for a manually ground soap, which comprises the following steps: after a soap base is prepared, feeding the soap base into a three-roller mill to carry out primary grinding so as to obtain a flaky soap base; detecting the pH of the flaky soap base obtained after primary grinding and if the pH value is greater than 9, adding weak acid into the flaky soap base obtained after primary grinding to regulate the pH value; after the weak acid is added, carrying out grinding again, confirming that the pH value is reduced into the use range, and feeding the soap base subjected to pH value regulation into a soap plodder for extrusion molding; after extrusion molding, printing by a soap cold printing machine to obtain the manually ground soap and packaging to obtain the finished product. According to the invention, the pH value of the soap is regulated in the grinding process, thus, after the soap preparation process is finished, the obtained manually ground soap can be immediately used; in the grinding process, all or most of soap crystal phases are transformed into beta crystal phases by grinding and pressing through mechanical force, thus, compared with an unground soap, the prepared soap has high solubility, strong foaming capacity and fine washing feeling.

Owner:夏程

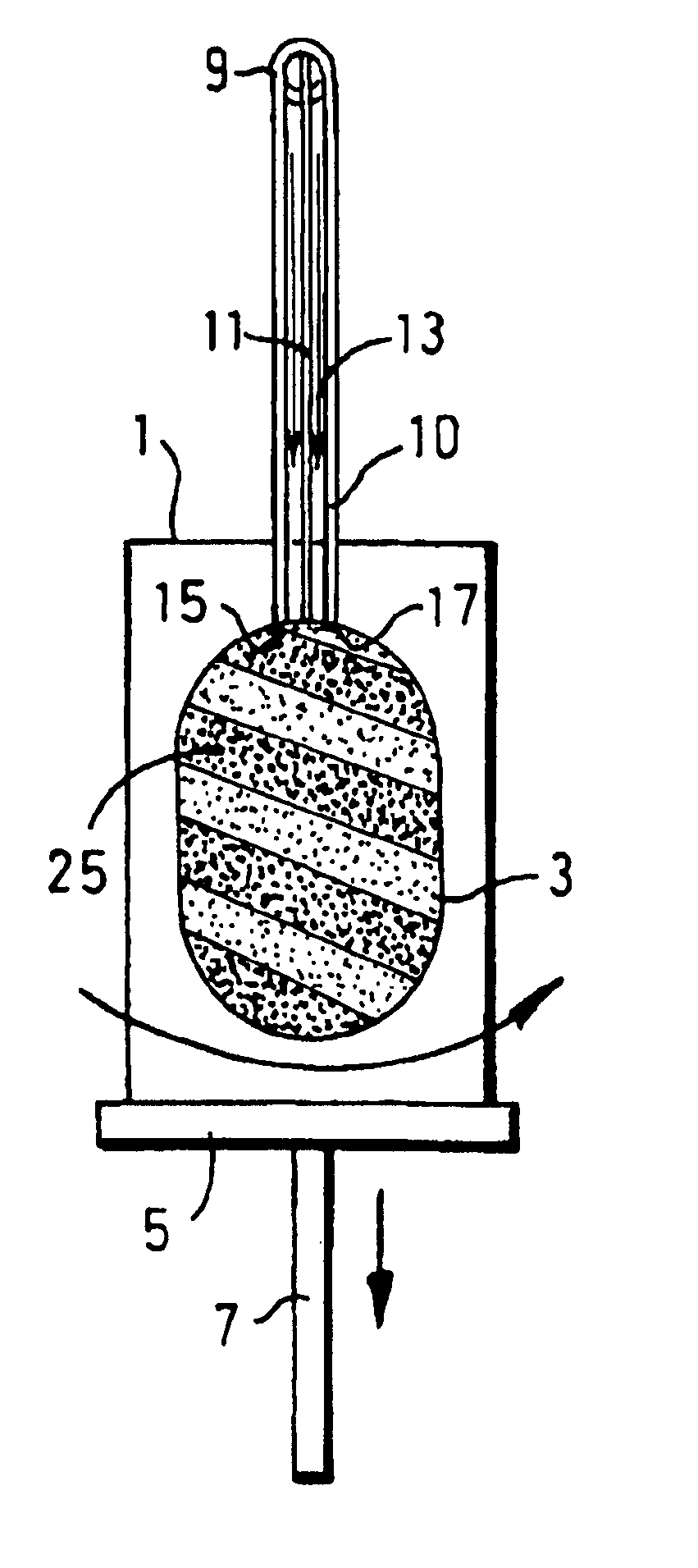

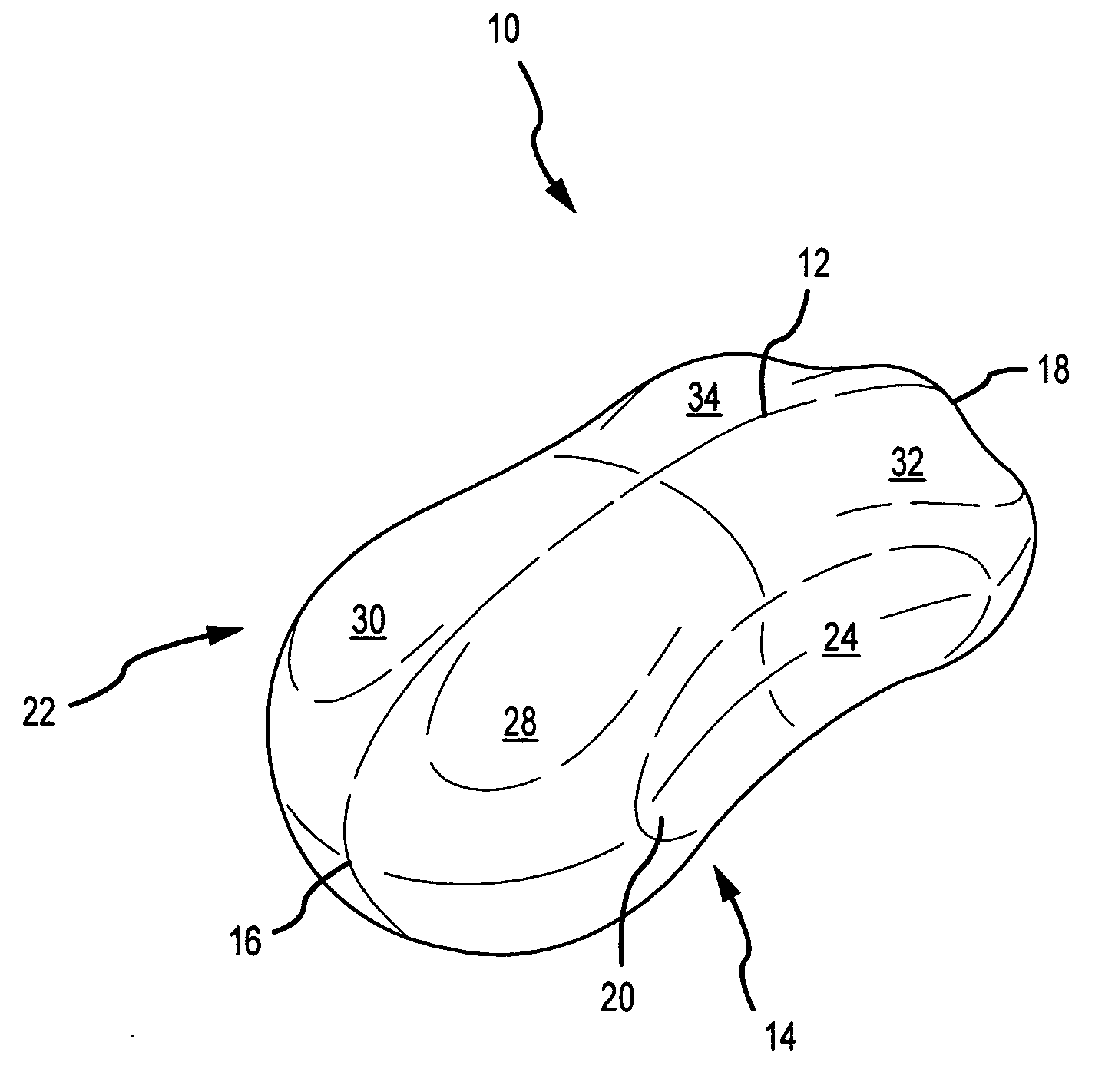

Composite transparent bar soap containing visible soap insert(s)

A composition and a method of preparing a solid, transparent / translucent moisturizing / cosmetic / personal cleansing bar having one or more visible soap inserts, wherein a transparent soap matrix surrounding the soap insert has an increased melting temperature of at least 55° C. to prevent melting the soap insert during manufacture, and to reduce deformation during storage and handling, increasing its hardness and durability, and substantially reducing the tendency of the bar to lose weight over time by evaporation of water by exposure to room temperature. The soap insert can have the same composition as the surrounding transparent matrix soap, having less water to provide at least a 3° C. higher melting point, and / or a small percentage of pigment or dye, for easy recycling of defective bars, without the need to separate the soap insert from the surrounding matrix soap.

Owner:HENKEL KGAA

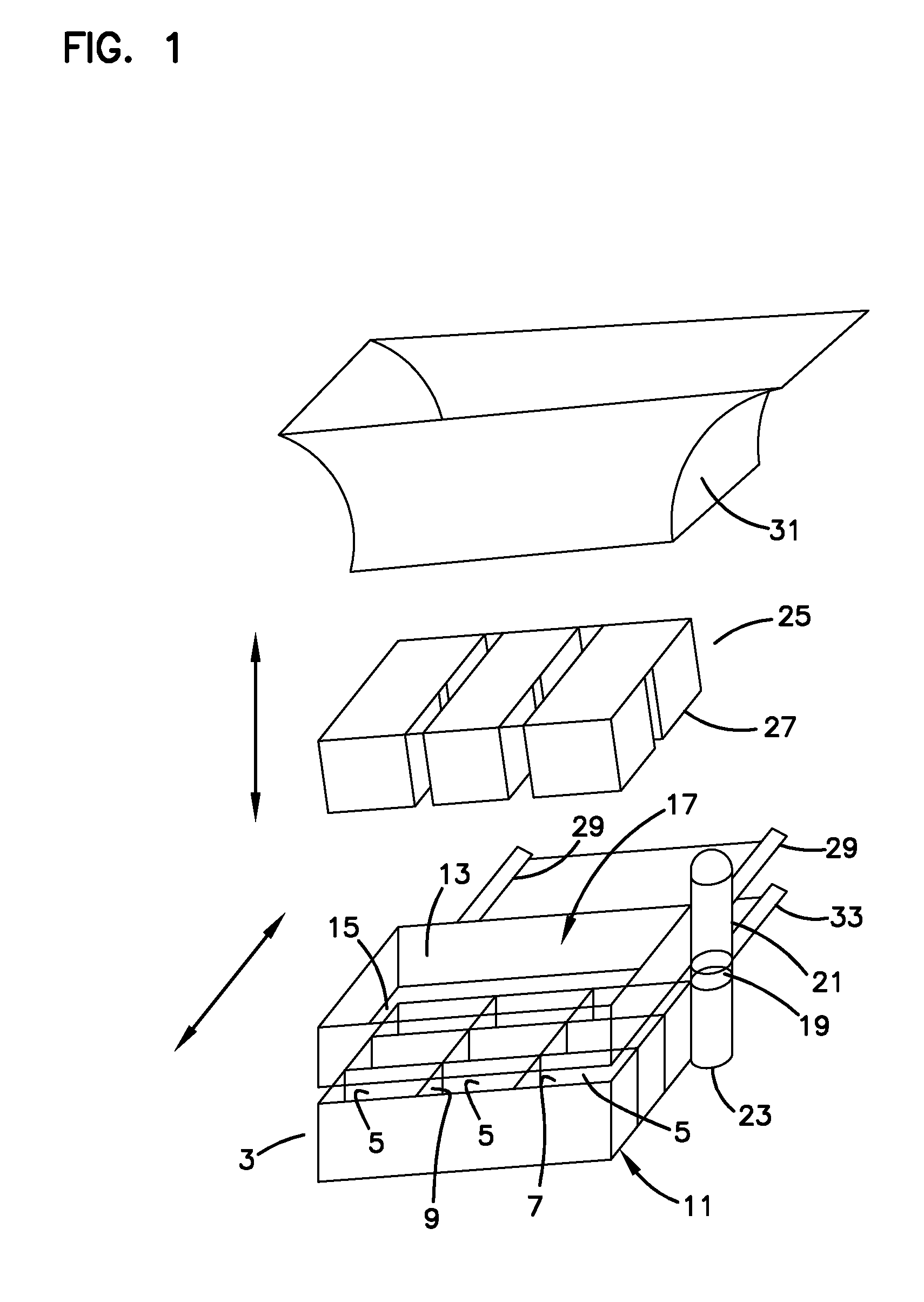

Process and apparatus for the production of a detergent composition

InactiveUS20010011067A1Lower operating temperatureReduce operating costsCosmetic preparationsButtonsSemi solidInjection moulding

A process for forming detergent bars by injection molding in which a pressure is applied to a partially structured detergent composition to deliver it to a mold. The detergent composition can be delivered to the mold in a substantially semi-solid state, at a temperature below 70° C. and at a pressure at the point of injection of greater than 20 psi. Apparatus for forming detergent bars according the invention are also described.

Owner:LEVER BROTHERS

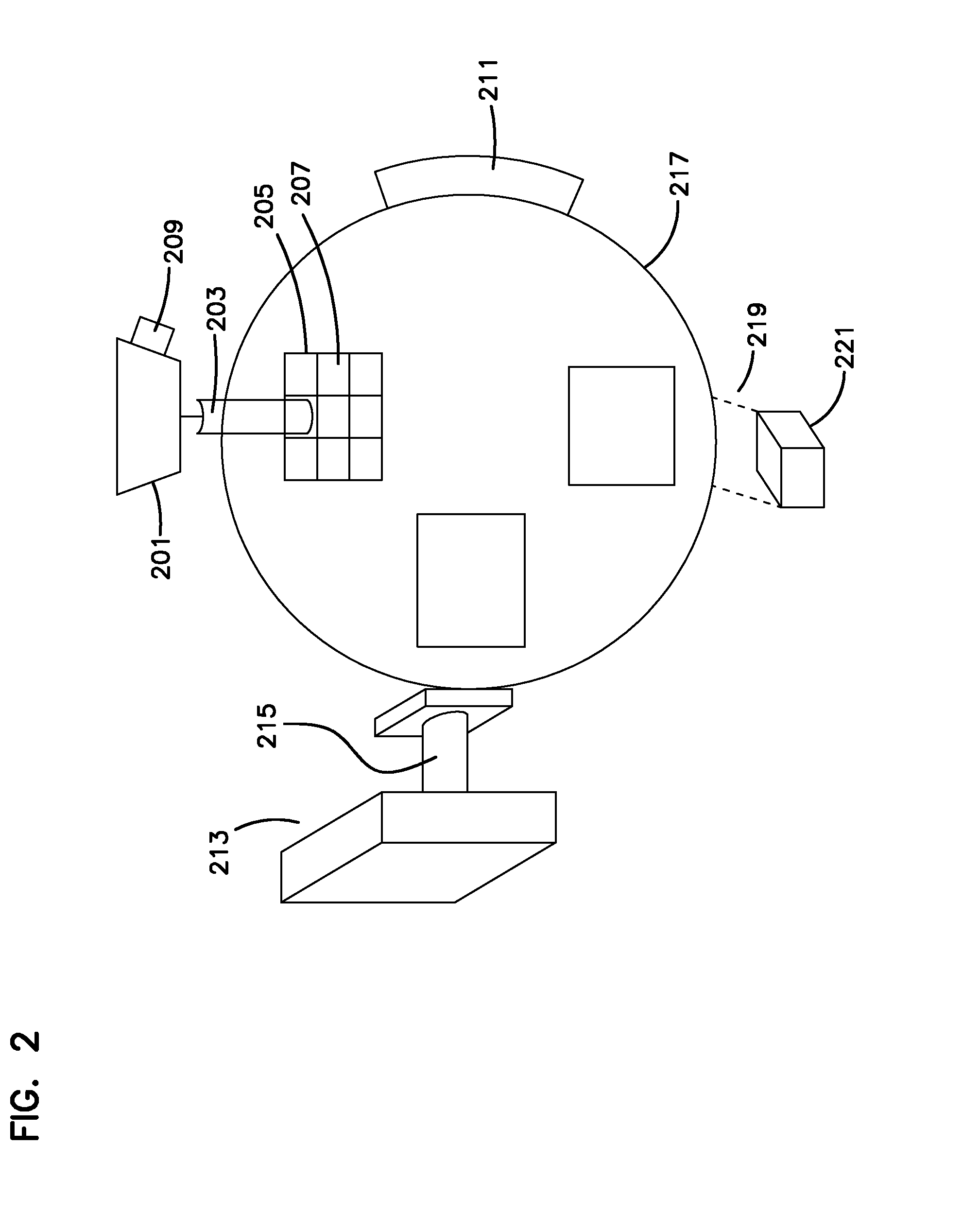

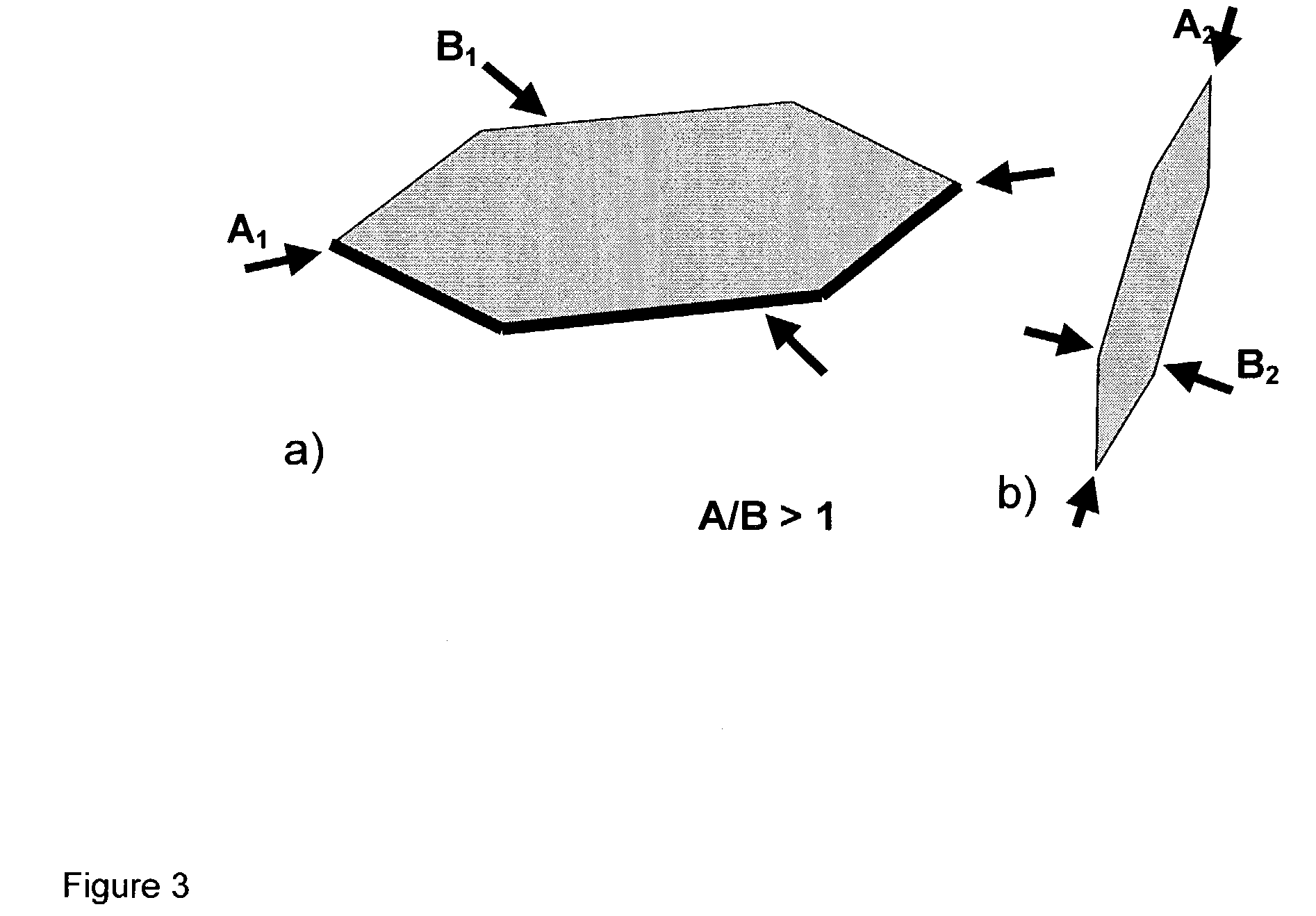

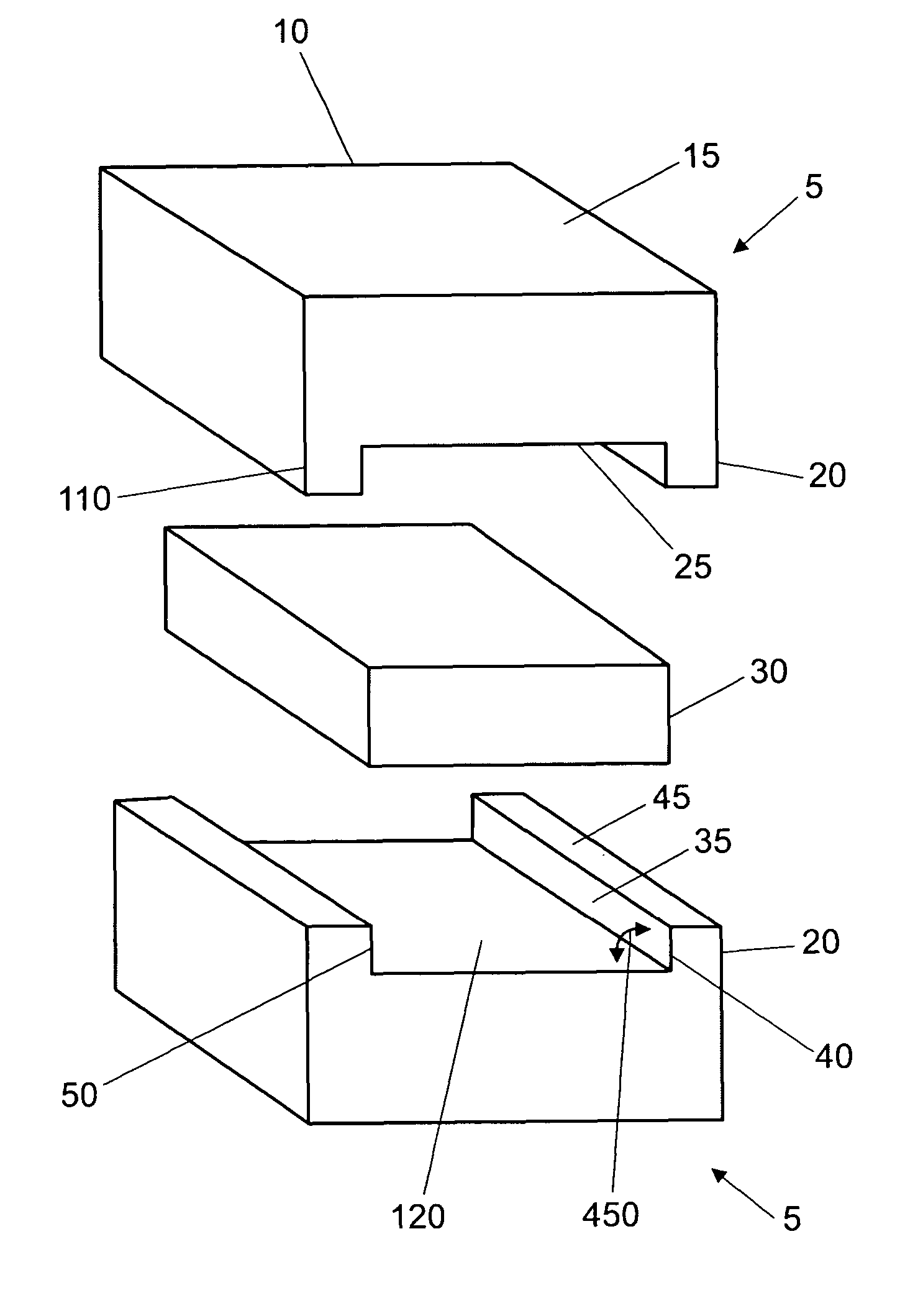

Process for the production of a detergent bar

InactiveUS6878319B2Inhibition formationOther chemical processesMouldsEngineeringMechanical engineering

In an apparatus and process for manufacturing a detergent bar, the bar comprises a first distinct zone comprising a first component and at least a second distinct zone comprising a second component. In an injection step, the first and second components are injected into the mold cavity via nozzle means having a first orifice through which the first component is injected. The second component is injected through a second orifice of the nozzle means. The first and second components solidify in the cavity to form the bar. The interface between the zones may be non-planar and / or such that the zones cannot be separated by a unidirectional cut. The first and second zones may respectively comprise detergent and a benefit agent. The first and second zones may differ in texture.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

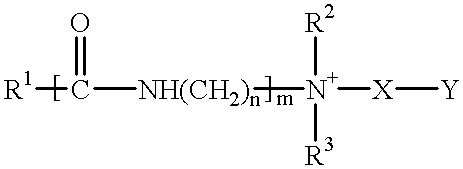

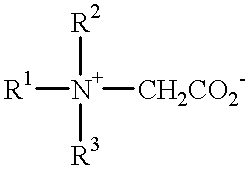

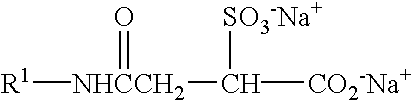

Process for Manufacturing Glass Substrate for Magnetic Recording Medium, Glass Substrate for Magnetic Recording Medium Obtained by the Process, and Magnetic Recording Medium Obtained Using the Substrate

ActiveUS20080028793A1Reduce surface roughnessFew surface defectMagnetic materials for record carriersBase layers for recording layersWear particleMetallurgy

A process for manufacturing a glass substrate for a magnetic recording medium comprising polishing a crystallized glass substrate using abrasive grains, and then washing the substrate using an aqueous organic carboxylic acid solution; a glass substrate for a magnetic recording medium which is manufactured by the process; and a magnetic recording medium obtained using the substrate. A glass substrate for a magnetic recording medium is manufactured, whereby the surface roughness is low and the surface defects are minimal for washing after polishing of a crystallized glass substrate, and wherein the Read-Write performance are not impaired when a recording layer including a magnetic film is formed on the magnetic recording medium substrate for manufacturing a magnetic recording medium.

Owner:RESONAC CORP

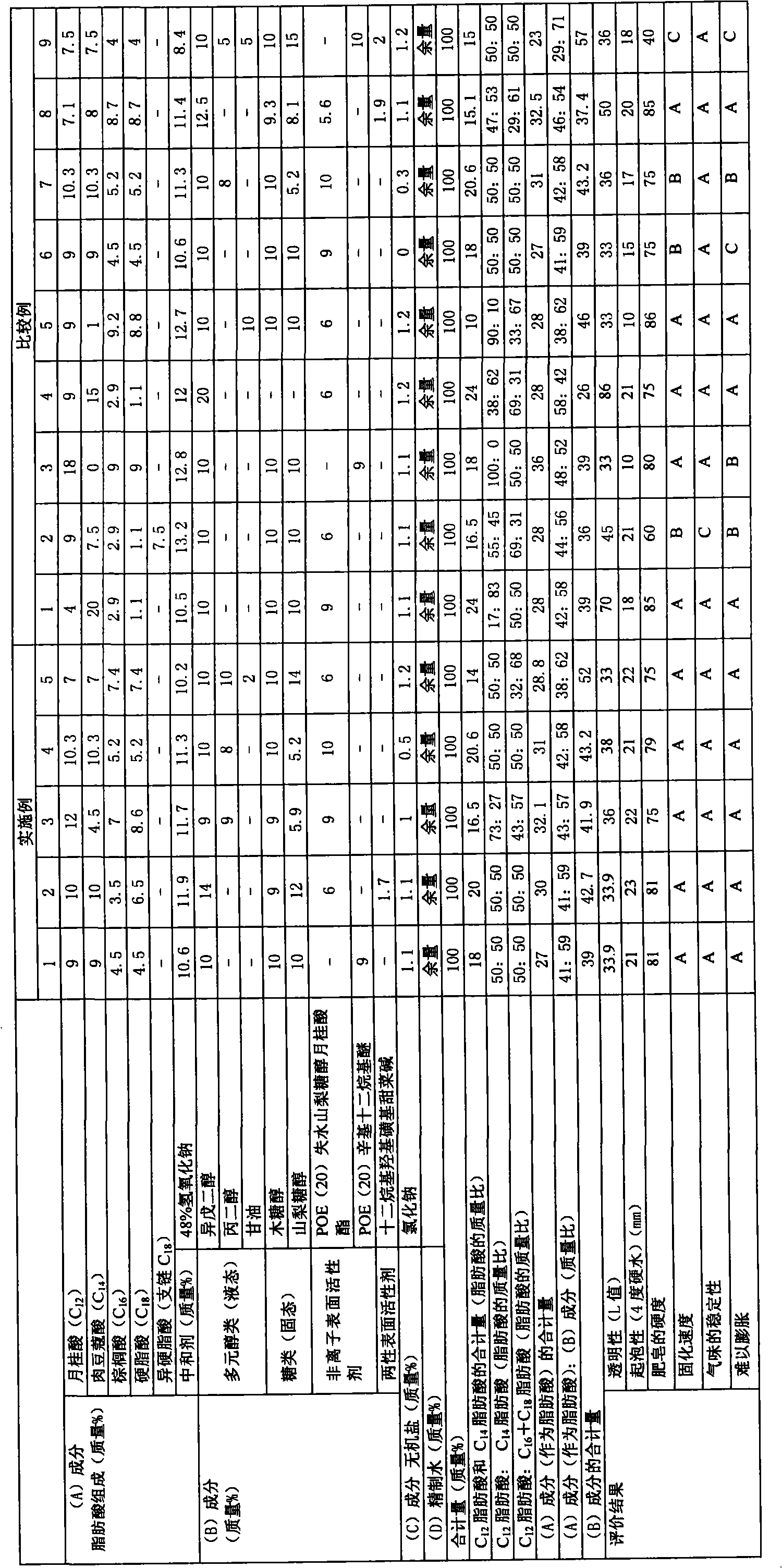

Transparent solid soap

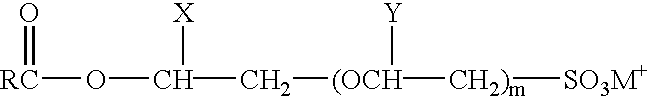

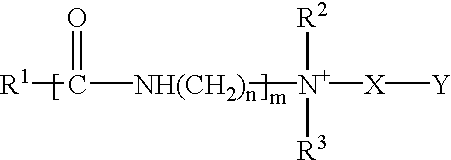

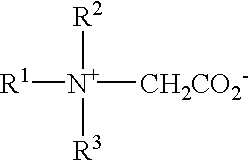

InactiveCN101679924AHigh transparencyFine foamCosmetic preparationsSoap detergents with organic compounding agentsAdditive ingredientSOAP

The invention provides a transparent solid soap which contains (A) C12-18 linear saturated fatty acids and / or salts thereof and contains substantially neither any branched fatty acid salt nor any unsaturated fatty acid salt. The transparent solid soap further contains (B) one or more members selected among nonionic surfactants, amphoteric surfactants, polyhydric alcohols which are liquid at ordinary temperature, and saccharides, (C) an inorganic salt, and (D) water. The content of the fatty acids constituting the ingredient (A) is 20-40 mass% based on the whole solid soap, and the proportion of the fatty acids constituting the ingredient (A) to the ingredient (B) is from 30 / 70 to 45 / 55 by mass. The content of the ingredient (C) is 0.5-5 mass%, and the ingredient (D) constitutes the remainder. In the ingredient (A), the proportion of the C12 fatty acid to the sum of the C16 fatty acid and the C18 fatty acid is from 30 / 70 to 60 / 40 by mass, and the proportion of the C12 fatty acid to theC14 fatty acid is from 20 / 80 to 80 / 20 by mass. The total amount of the C12 fatty acid and the C14 fatty acid is 14-22 mass% based on the whole solid soap. This transparent solid soap is highly transparent and lathers well especially in hard water. It has the moderate hardness required of solid soaps, is free from problems concerning deterioration in odor with time and sogginess. The solid soap has high productivity and can be easily molded into a desired shape.

Owner:KAO CORP

Detergent Composition

InactiveUS20090286706A1Readily availableEasy to mergeInorganic/elemental detergent compounding agentsCosmetic preparationsAdditive ingredientZinc

A detergent composition comprising 40 to 80% by weight soap, 2 to 10% by weight Zinc oxide, and balance of other conventional ingredients, wherein at least 25% by weight of said soap is a salt of Lauric acid.

Owner:CONOPCO INC D B A UNILEVER

Moisture-retaining whitening handmade soap

The invention relates to a moisture-retaining whitening handmade soap. The soap is prepared from the following raw materials by weight: 5 to 10 parts of an aloe extract, 2 to 3 parts of olive oil, 2 to 3 parts of palm oil, 3 to 5 parts of Shikakai Powder, 0.3 to 0.5 part of rose essential oil, 3 to 5 parts of glycerin, 5 to 7 parts of higher fatty acid and 4 to 5 parts of deionized water. The moisture-retaining whitening handmade soap can be directly used for skin cleaning and has the effects of moisture retention, whitening and skin color brightening. The soap is prepared from natural plants, so the soap has no irritation on the skin and is a washing product for long-term use.

Owner:TAIYUAN AOYI MEDICAL BIOLOGICAL TECH

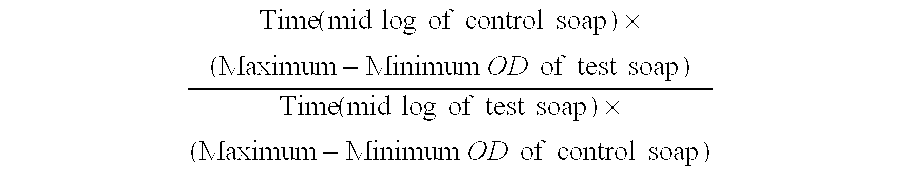

Pure-natural multifunctional handmade soap and preparation method thereof

InactiveCN104403842AAntioxidantWith whiteningSoap detergents with organic compounding agentsShaping soapActive componentFatty acid

The invention discloses a pure-natural multifunctional handmade soap and a preparation method thereof. The pure-natural multifunctional handmade soap is prepared from the following components in parts by weight: 0.02-2 parts of a plant active composition, 10-30 parts of fatty acid, 5-10 parts of oil, 15-30 parts of a humectant, 1.0-3.0 parts of sodium hydroxide and the balance of water. The pure-natural multifunctional handmade soap disclosed by the invention has the advantages that the added plant active component has the effects of resisting oxidization, whitening the skin, diminishing inflammation, inhibiting bacteria and the like; by combination of the plant active component, multiple effects can be achieved; meanwhile, in a soap making process, by selection on other auxiliary agent components for matching the plant active component, the auxiliary agent components are selected to guarantee effective release of the plant active component, so that the mixing relation for achieving the effects of the plant active component can be obtained. The pure-natural multifunctional handmade soap is conveniently used and has the effects of whitening and moistening the skin, diminishing inflammation, retaining the moisture, resisting oxidization and the like.

Owner:AESTHETIC TECH BEIJING

Ergonomic bar soap

Owner:HENKEL KGAA

Soap bar or substance application bar

ActiveUS8303203B2Easy to masterAvoid wastingCosmetic preparationsWriting connectorsEngineeringMechanical engineering

The substance application bar includes an application portion having an exterior surface and an interior surface and configured for applying a substance to a receiving surface and at least one blocking extension extending adjacent the interior surface of the application portion to define a retaining recess therebetween. The blocking extension and the interior surface are associated to cooperatively substantially block movement of an object received in the retaining recess in a direction generally along the interior surface against the blocking extension. The substance application bar may also include at least one bar-preserving extension associated with the interior surface to maintain a portion of the recess open to the atmosphere. This facilitates air flow through and drying of the recess for resisting deterioration of the bar. An assembly of application bars in stacked association also is included.

Owner:4MULA

Sweet-scented osmanthus and honey Handmade soap

InactiveCN104845764AGood moisturizing effectMoisturizing and powerfulShaping soapSkin careJojoba oilSkin color

The present invention discloses a sweet-scented osmanthus and honey handmade soap and relates to the technical field of daily wash supplies. The sweet-scented osmanthus and honey handmade soap is prepared from the following components in parts by weight: 20-30 parts of sweet-scented osmanthus oil, 0.5-1.5 parts of dry sweet-scented osmanthus, 15-20 parts of honey, 5-10 parts of aloe, 200-250 parts of olive oil, 100-150 parts of glycerin, 100-150 parts of jojoba oil, 80-120 parts of sweet apricot kernel oil, 70-100 parts of sodium hydroxide and 230-300 parts of goat milk. The sweet-scented osmanthus and honey handmade soap disclosed by the invention solves the problems that facial soaps in the present market are strong in stimulation and seriously damage skins and the like, has the functions of whitening and diluting speckles, lightening the skin color and the like, and can improve dry, rough, dark and oily skins and the like. The scent of the sweet-scented osmanthus can calm down anxious and dispirited emotions, relieve pressure and recover clam mentality.

Owner:GUANGXI UNIV

Floating soap and preparation method thereof

ActiveCN105861202AImprove uniformityEfficient use ofShaping soapAlkali/ammonium soap compositionsWaxArginine

The invention discloses a floating soap. The floating soap comprises, by weight, 10 to 60% of fat, wax or aliphatic acid, 1 to 40% of an alkaline substance and 0 to 20% of an additive, with the balance being water, wherein fat is one or more than one selected from a group consisting of animal fat, plant fat and synthetic fat, and the alkaline substance is one or more than one selected from a group consisting of sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, triethanolamine and arginine. According to the invention, soap preparation and foaming are integrated, so production efficiency is improved, cost is saved, uniformity of a soap body is improved, and product production is more stable. The floating soap provided by the invention meets common cleaning demands, can be made into a personal care product with efficacy, and is floatable, convenient to carry and full of fun; and even if the size of the floating soap is small, the floating soap does not slip into water, so waste is avoided, resources are better used, and better environmental protection performance is obtained.

Owner:杭州稞恩生物科技有限公司

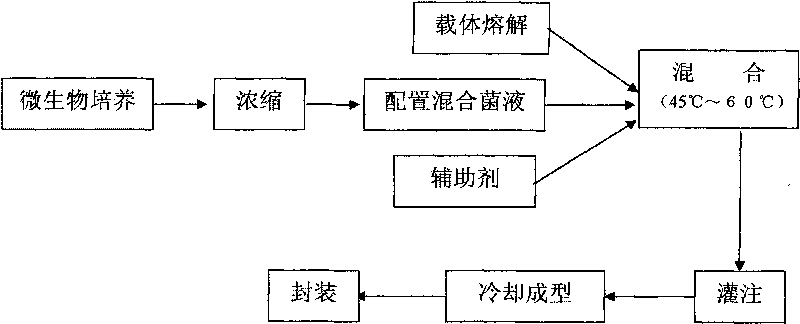

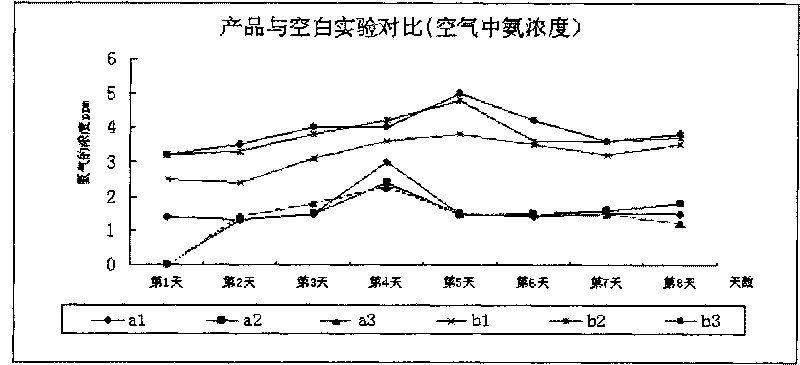

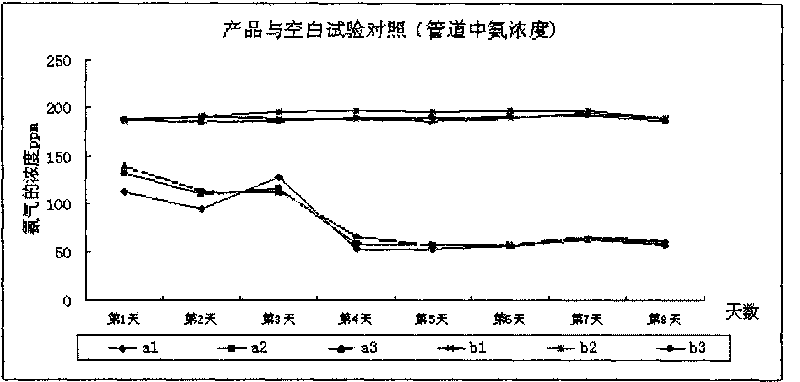

Microbial deodorant soap for cleaning urinal and preparation method thereof

InactiveCN101691530AInhibition formationAvoid blockingShaping soapAlkali/ammonium soap compositionsChemistryDeodorant

The invention discloses a microbial deodorant soap for cleaning a urinal and a preparation method thereof. A product of the microbial deodorant soap comprises at least two of bacterium lacticum, acetobacter, beer yeast, rhodotorula, bacillus licheniformis and bacillus subtilis; and under the condition of being protected by a protective agent, the product is prepared by the steps of soap base vector fixation, an auxiliary agent addition and the like. The microbial deodorant soap can utilize microbes to decompose organic matters capable of blocking a pipeline of the urinal in a toilet and generating odor, prevent corruptive microbes from growing, reduce the production of ammonia and simultaneously, reduce the frequency of flushing the toilet and water consumption so as to achieve the aims of saving water resources, preventing and controlling stink pollution and improving air quality.

Owner:BEIOUTAI TECH SUZHOU

Method for producing industrial flaked soap by using drainage oil

InactiveCN102504986ASolve the way outIn line with the circular economy modelShaping soapAlkali/ammonium soap compositionsFiltrationColloid

Owner:SUZHOU H&H ENVIRONMENTAL TREATMENT

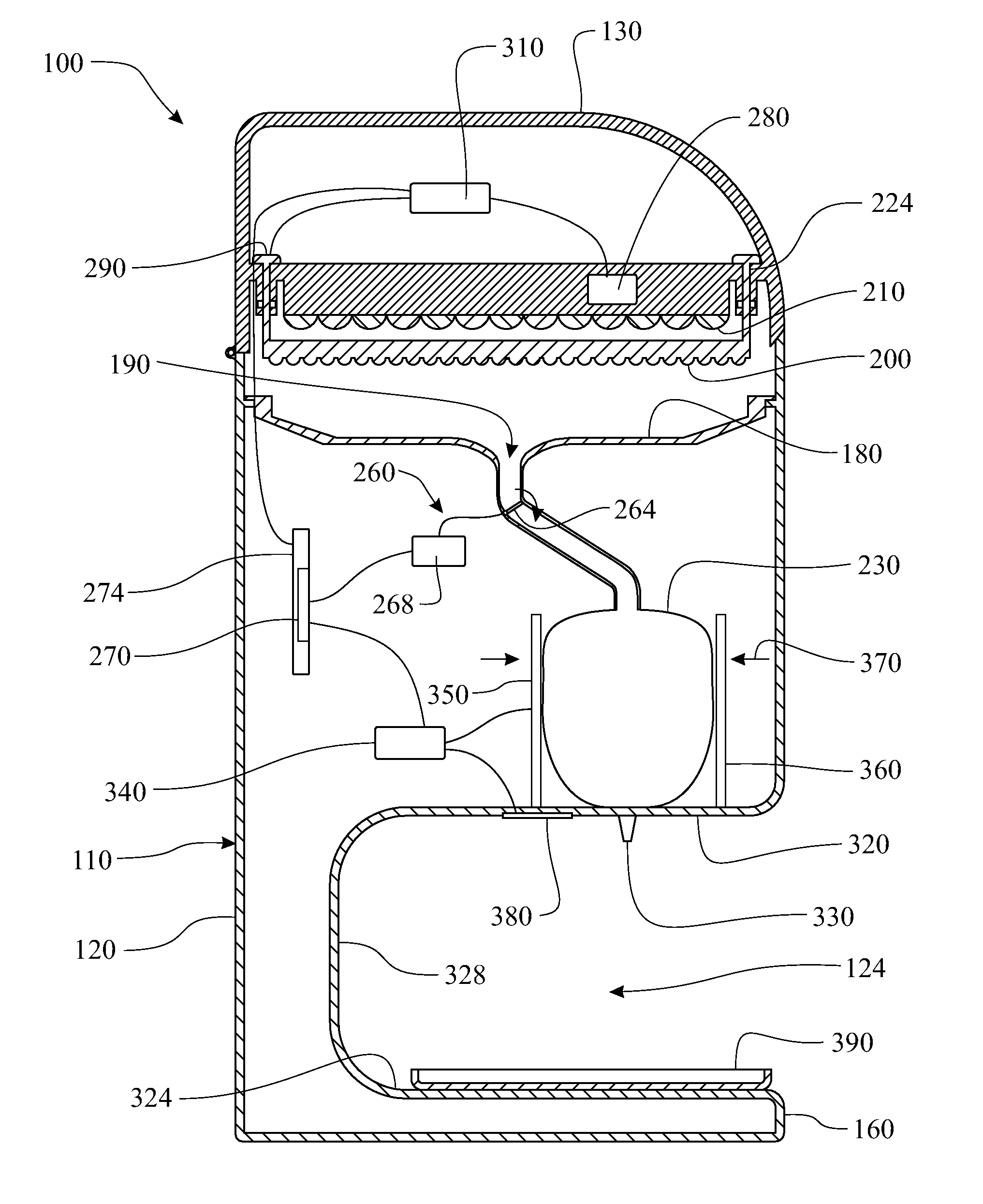

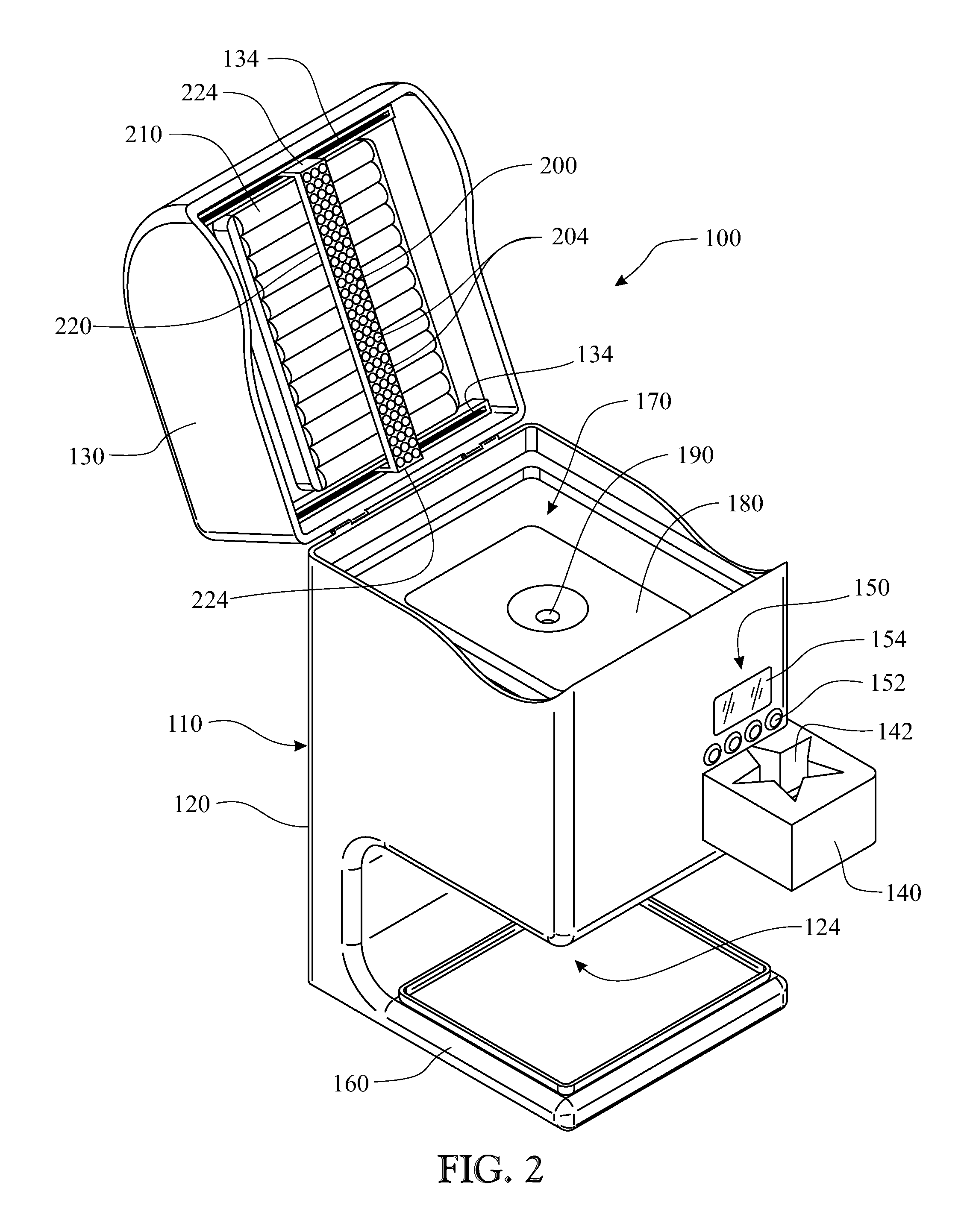

Soap recycling device and method of operation

InactiveUS20150216368A1Save moneyAvoid wastingOpening closed containersBottle/container closureEngineeringOperation mode

The invention refers to a soap recycling device that recycles solid soap bar remnants into purified liquid soap or purified reconstituted solid soap bars, depending on a user's selected mode of operation of the device. The soap recycling device includes a heat source that melts the solid soap remnants, a UV emitter that sterilizes the solid soap remnants, and a directional valve that selectively delivers the molten soap fluid to a first receptacle capable of storing the soap in liquid form and delivering it for direct usage, for instance for hand washing, and a second receptacle where the molten soap fluid solidifies and turns into a reconstituted solid soap bar. The device includes a user interface that allows selecting the desired operation mode to either liquid or solid soap formation. The device according to the invention is compact and versatile.

Owner:MCCLENDON FREDERICK

Detergent composition for removing fish soil

ActiveUS20130239995A1Inorganic/elemental detergent compounding agentsSoap detergents with organic compounding agentsSoil scienceRaw fish

A detergent composition as described which can be utilized in a variety of applications for cleaning surfaces and objects, removing suspended soils, and rinsing easily. The detergent composition is particularly effective at removing soils caused by raw fish soil.

Owner:ECOLAB USA INC

Ginseng cosmetic fancy soap

InactiveCN102242027AGood curative effectPromote wound healingShaping soapAntiviralsLedebouriella seseloidesWound healing

The invention discloses a ginseng cosmetic fancy soap, belonging to daily articles for cleaning. The ginseng cosmetic fancy soap is prepared by mixing a Chinese medicine composition and a soap base in the mass ratio of 1:1 and then pressing, wherein the Chinese medicine composition is prepared by pulverizing and mixing ginseng, fritillary bulb, ledebouriella seseloides, angelica root, chrysanthemum, moutan bark, common peony root, talcum powder and rhizoma typhonii powder. The ginseng cosmetic fancy soap can be used for treating diseases, such as acnes, flat warts, chloasma, freckles, xerosis cutis and crack and the like and can solve the problems of acne wound healing indolence, face itches due to wind blowing, rugged faces caused by scars due to healing of chicken pox and acnes and the like and is a real multipurpose cosmetic fancy soap.

Owner:尤廷帅

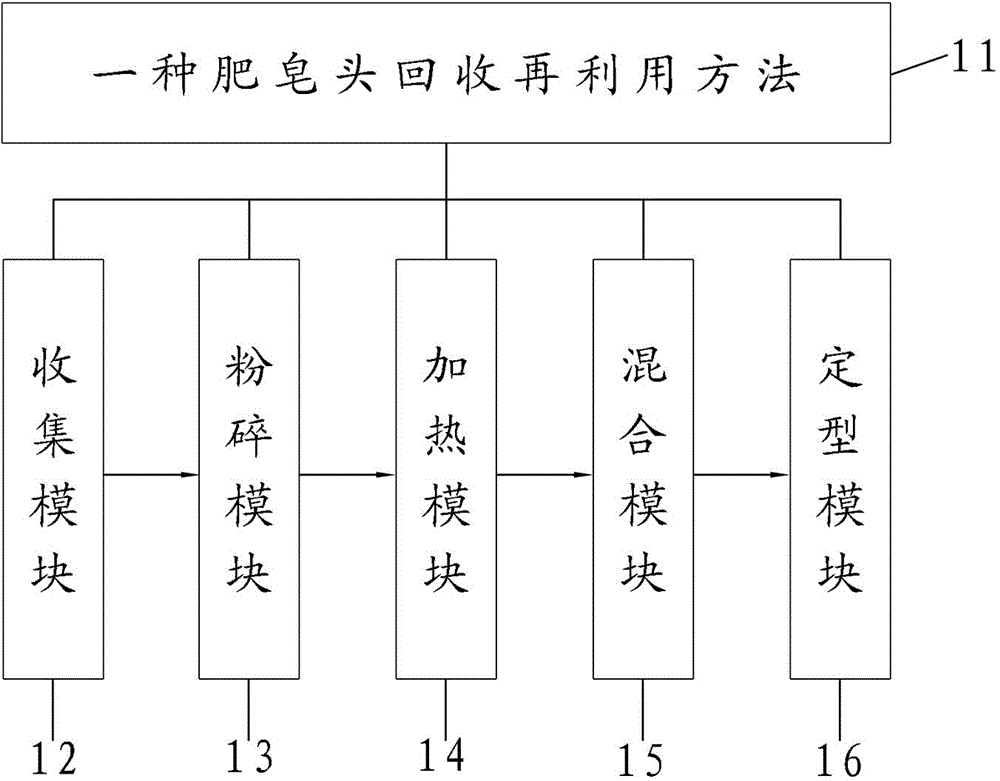

Method of recycling and reusing soap head

The invention discloses a method of recycling and reusing a soap head. Soap is an indispensable washing product when daily sanitation and hygiene are carried out in every family. Usually, people, using the soap, can have such an experience that the soap can become particularly slippery after being soaked with water and can become a very small soap head after being used for a period of time, and thus being inconveniently used and only thrown away. Such wasteful behavior runs counter to the traditional virtue of Chinese nation of industry and thrift. The invention aims at providing a method of recycling and reusing the soap head. According to the method disclosed by the invention, equipment comprises a collecting module, a crushing module, a heating module, a mixing module and a sizing module are used, so that the purposes of saving resources and protecting environment are achieved.

Owner:朱焱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com