Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about "Soap recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

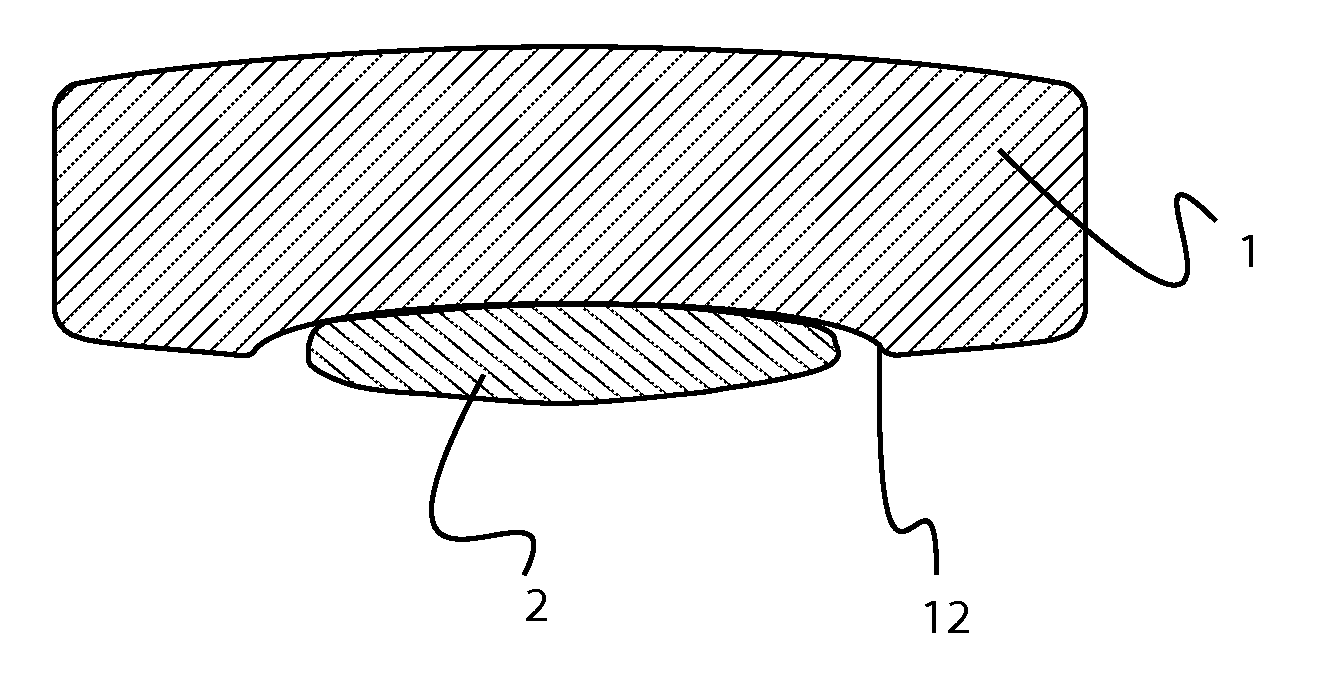

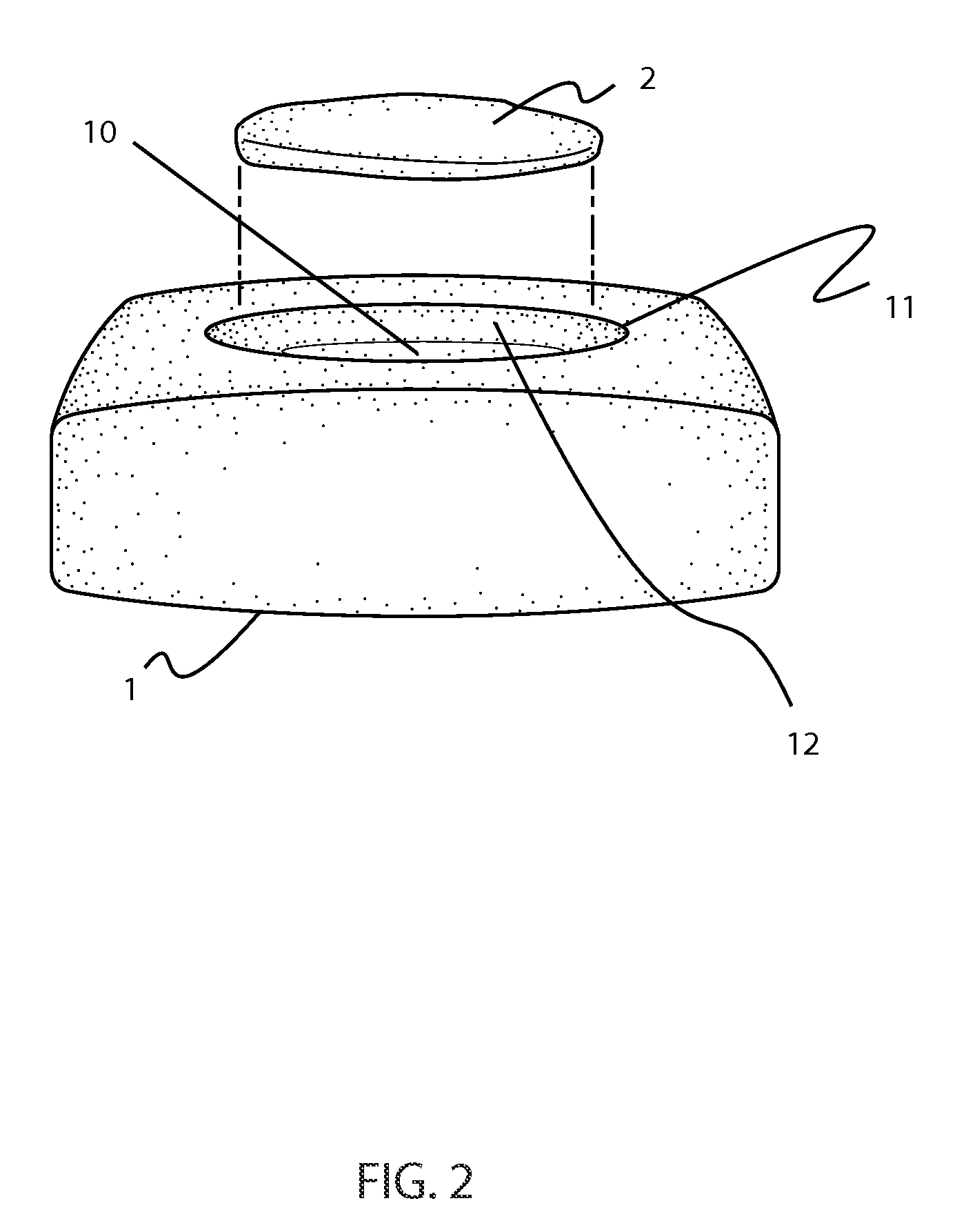

Soap Saver

A soap saver comprises an original soap bar and a soap fragment. The original soap bar comprises a cavity. The cavity comprises a predetermined shape, a cavity wall, and a cavity bottom surface. The cavity wall will be a continuous wall and will be connected to the cavity bottom surface. The cavity wall will have a smooth surface around the wall. The cavity bottom surface will not be a smooth surface. The soap fragment will be inserted into the cavity so the soap fragment can be reused with the original soap bar. Water will combined both the soap fragment and the original soap bar together.

Owner:AESCH JR HAROLD WALTER

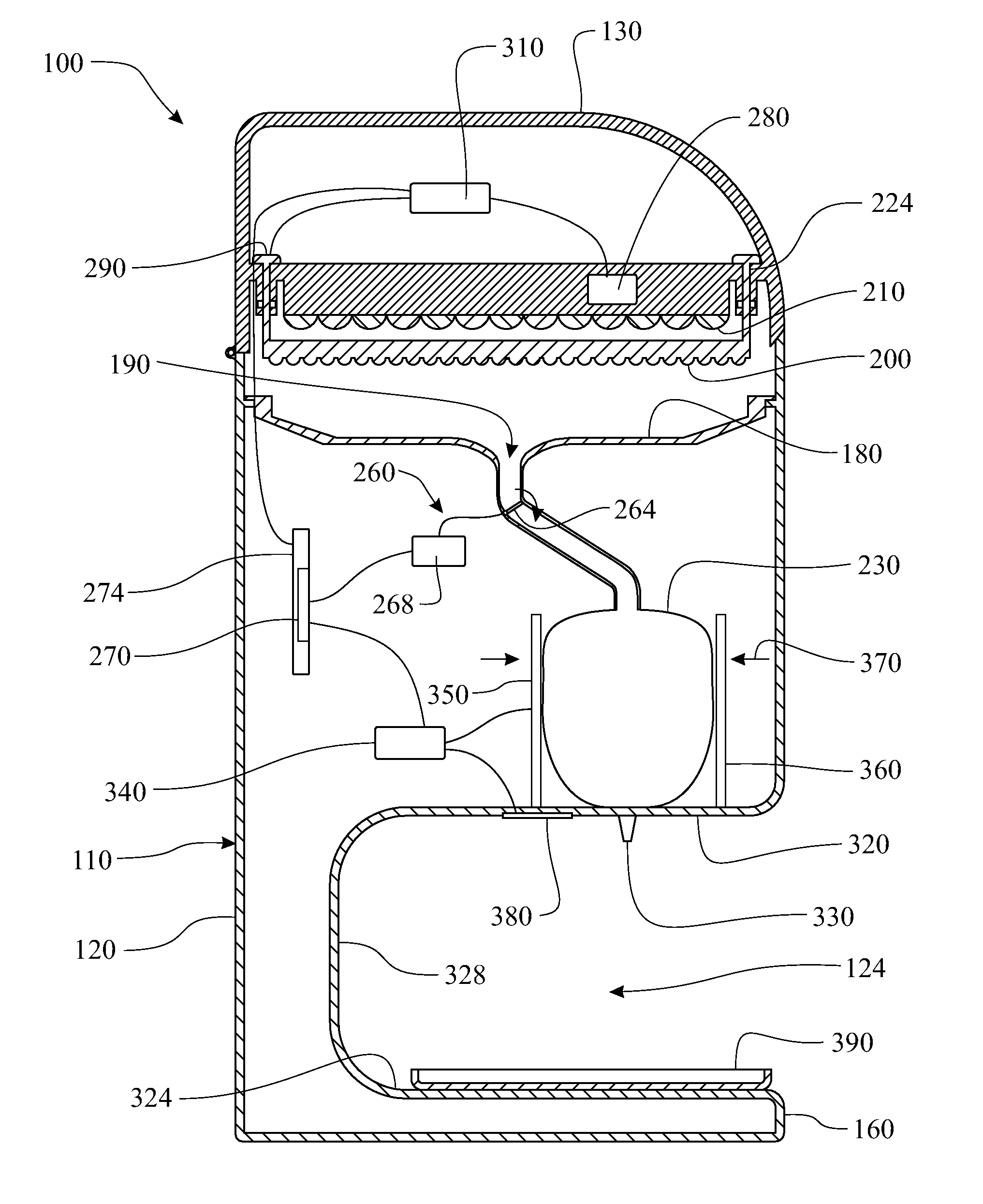

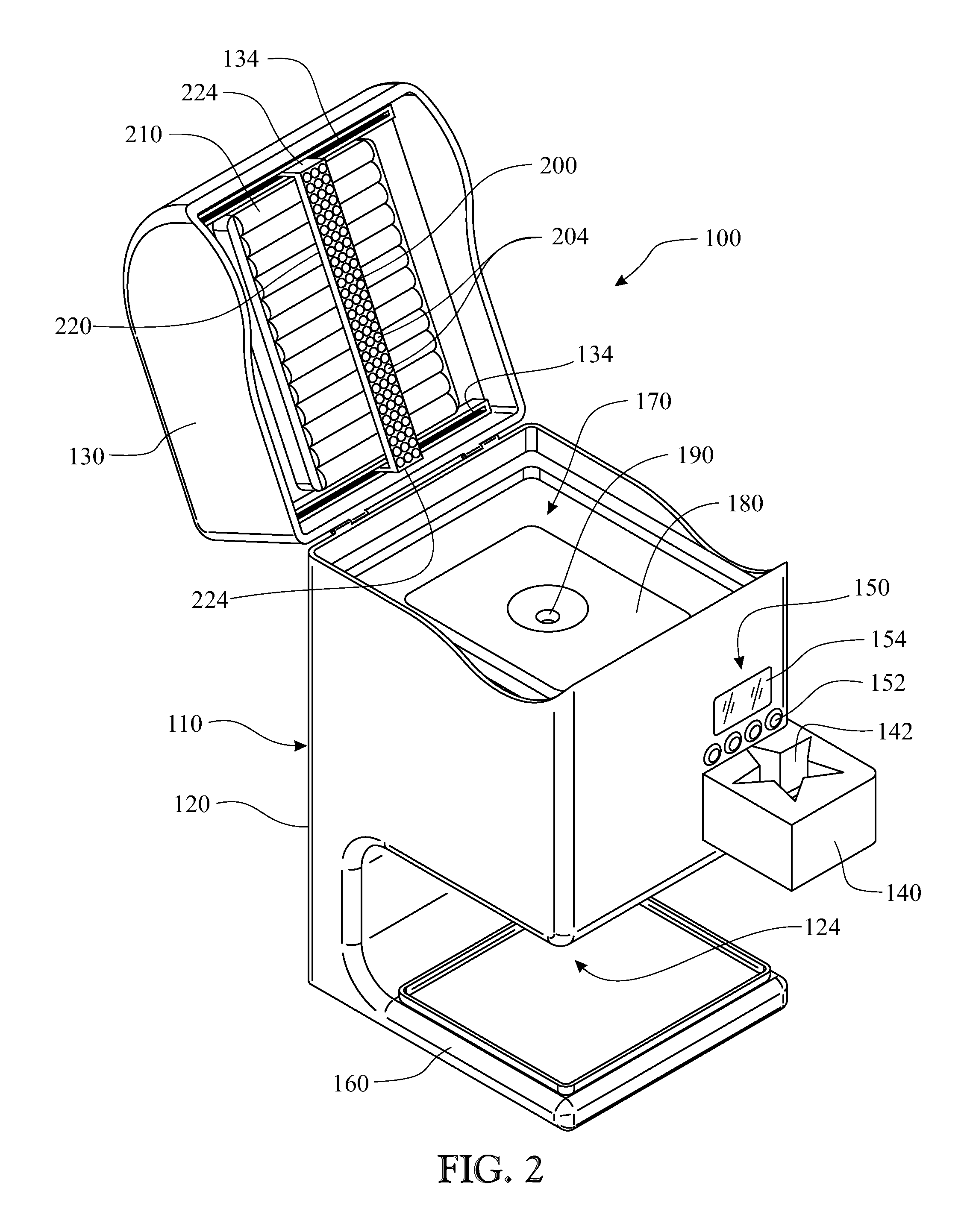

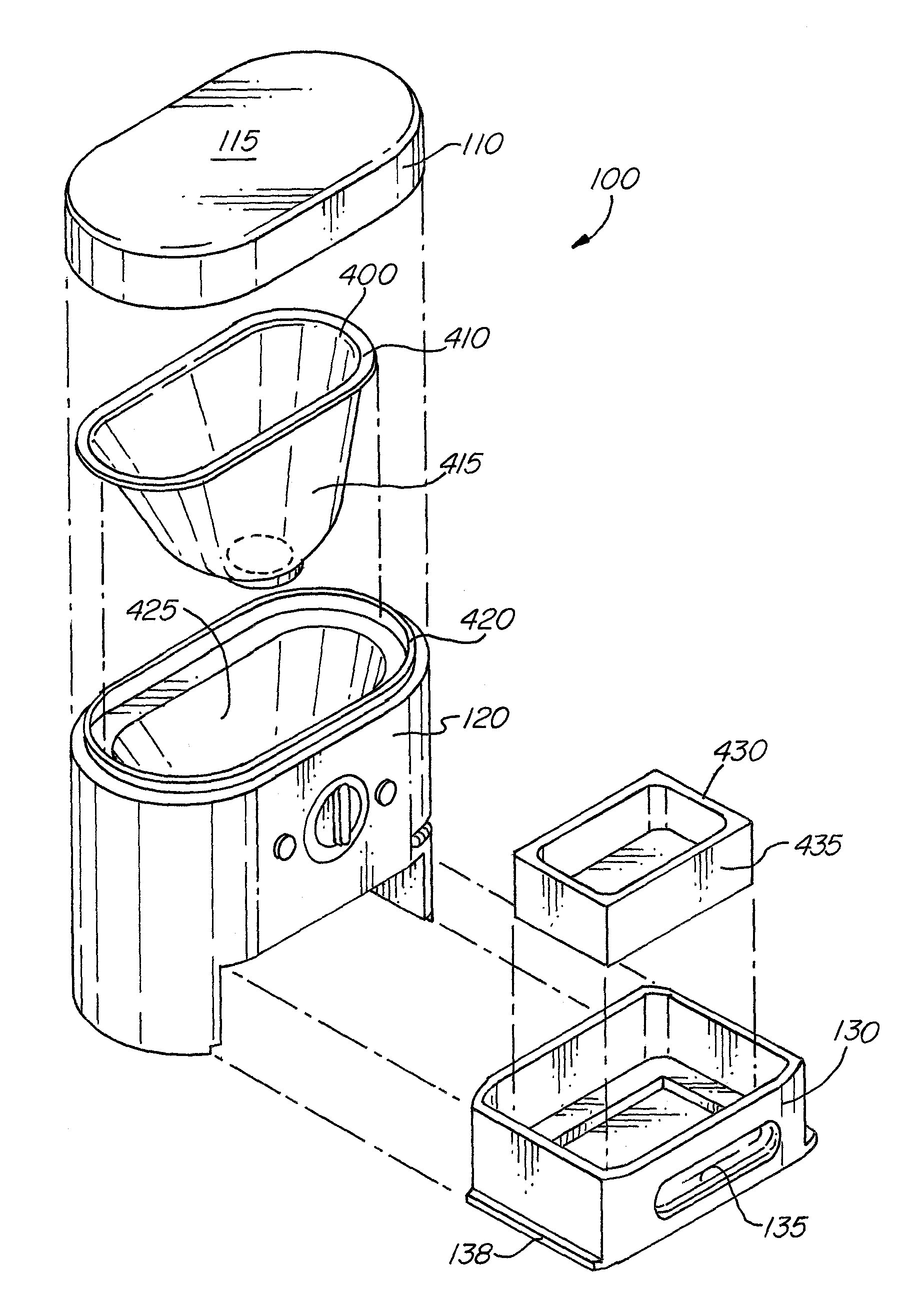

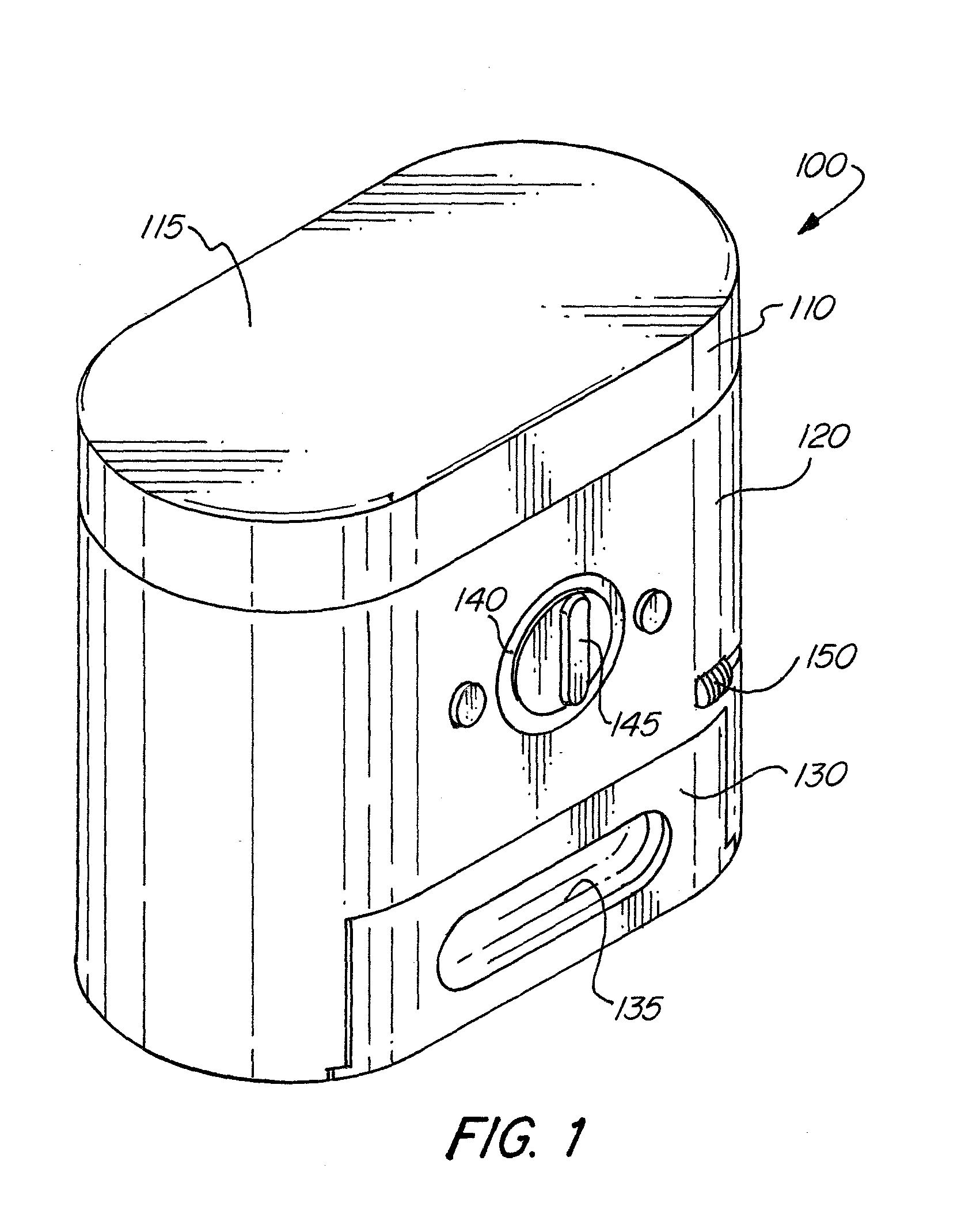

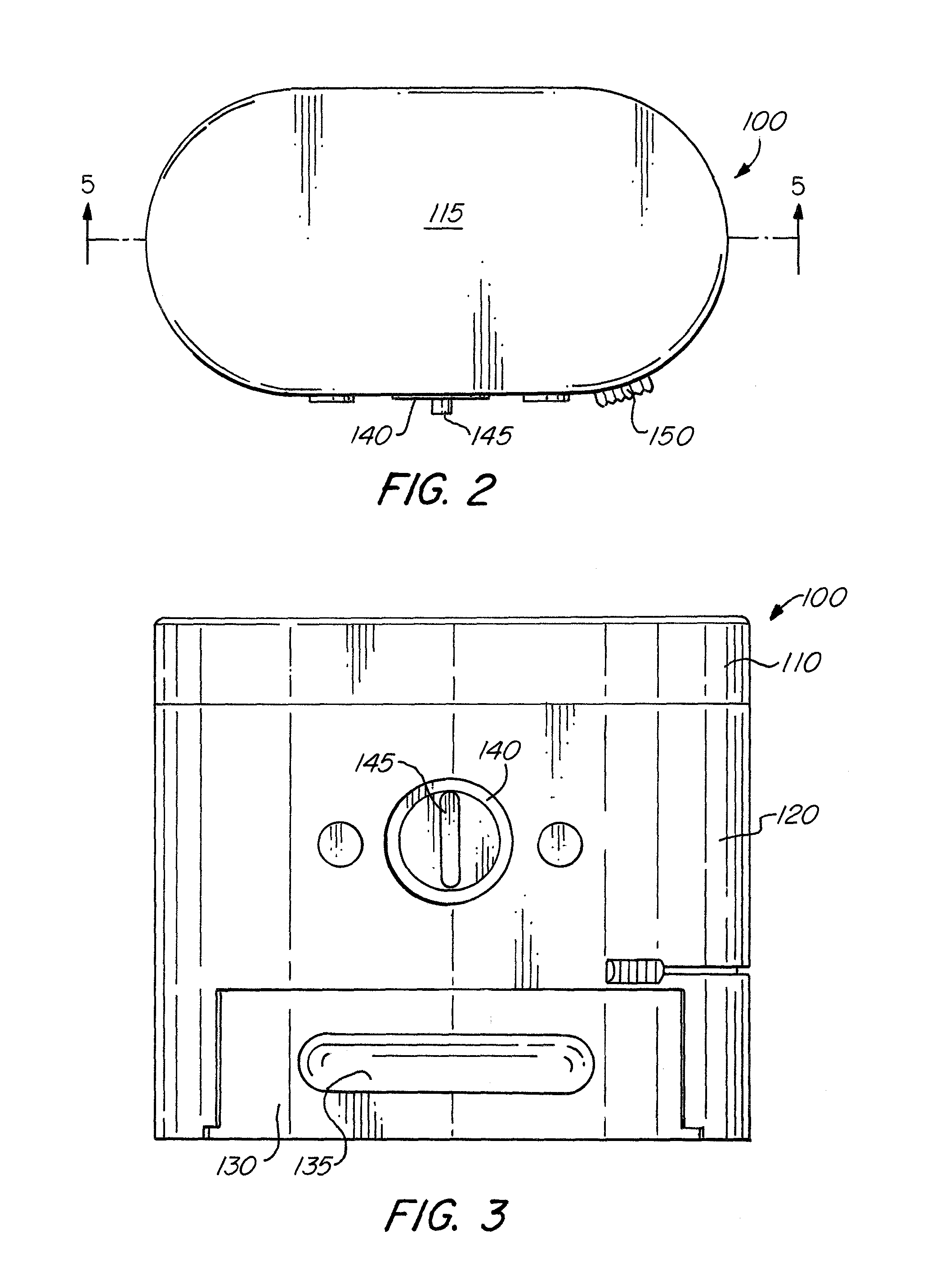

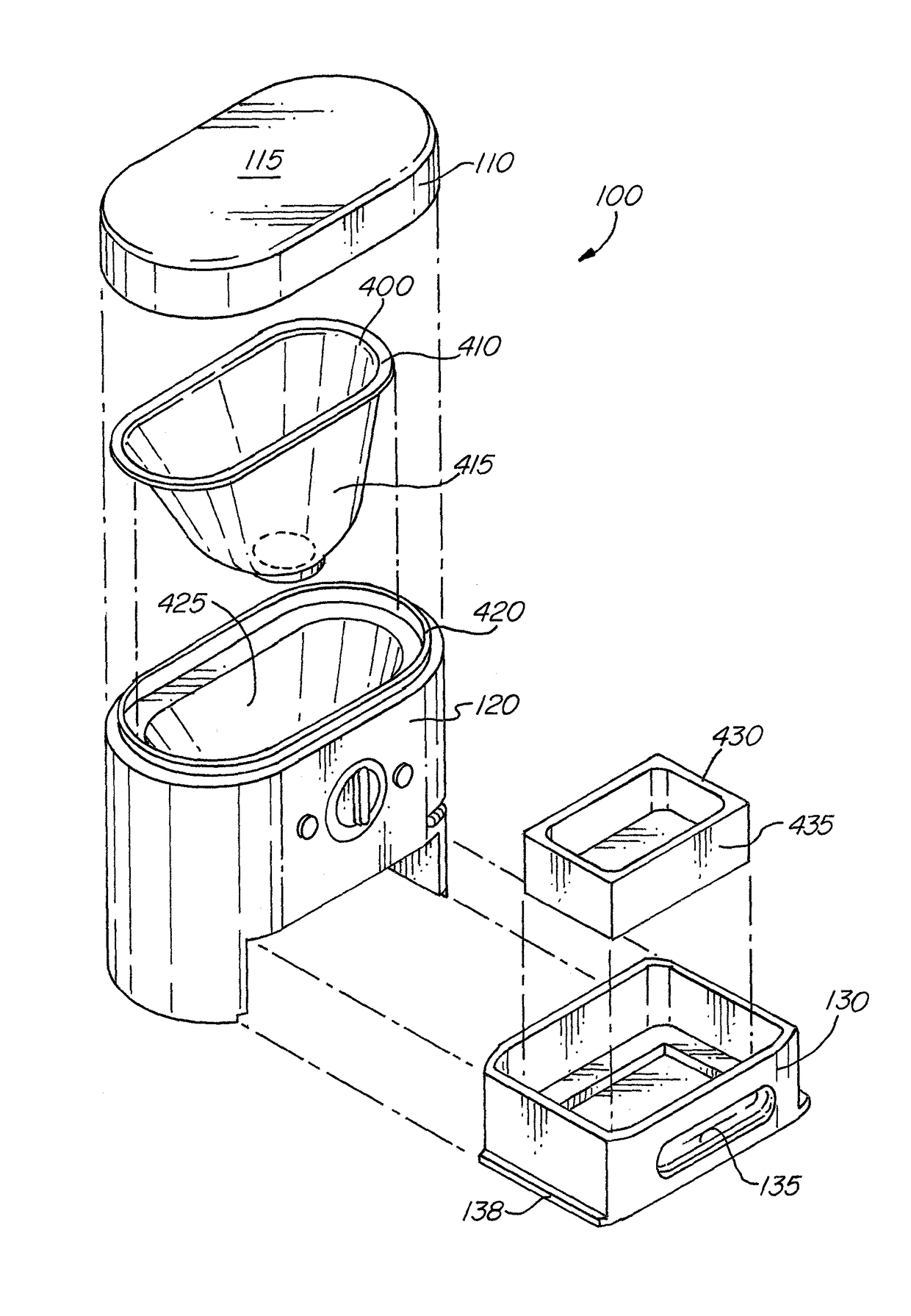

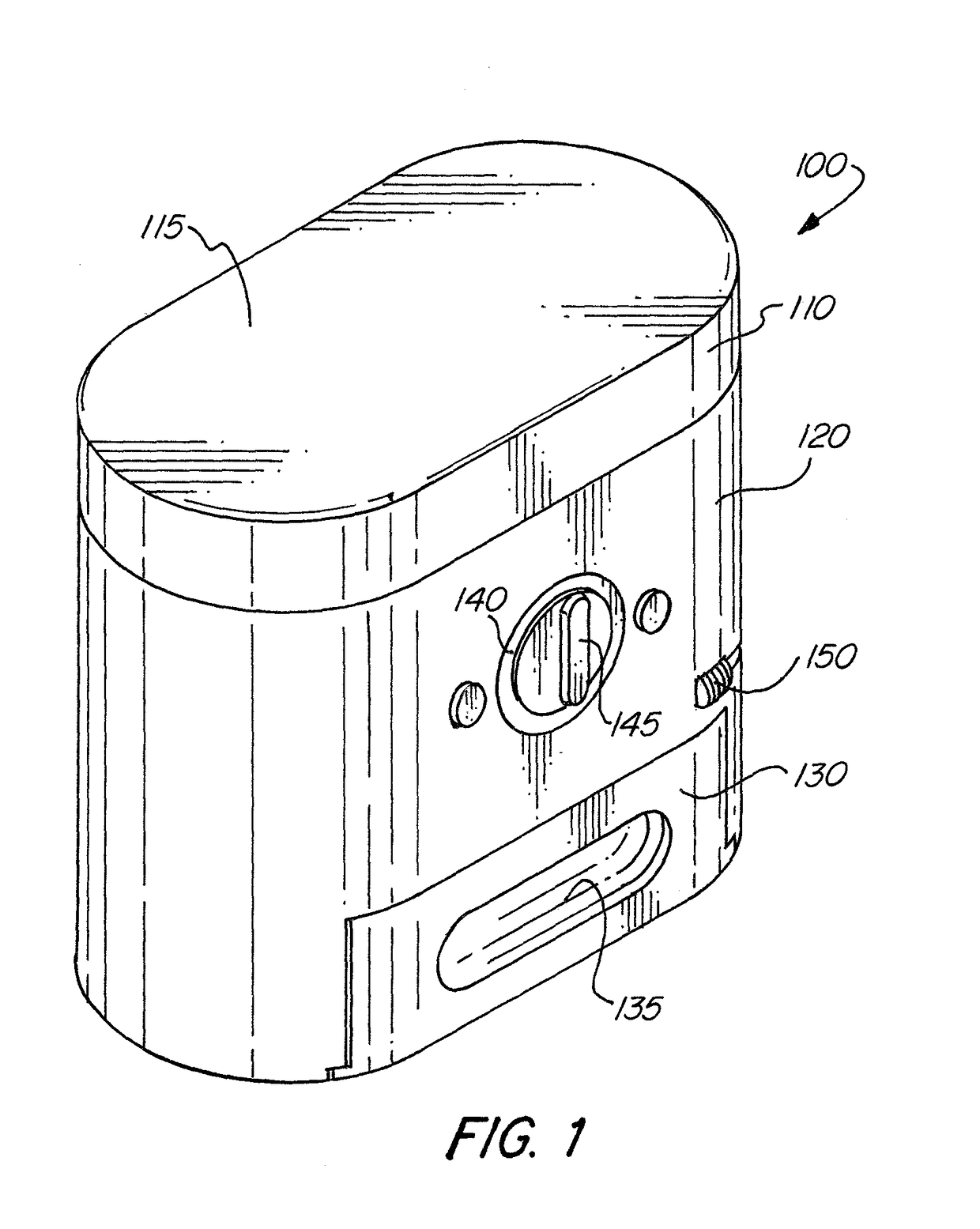

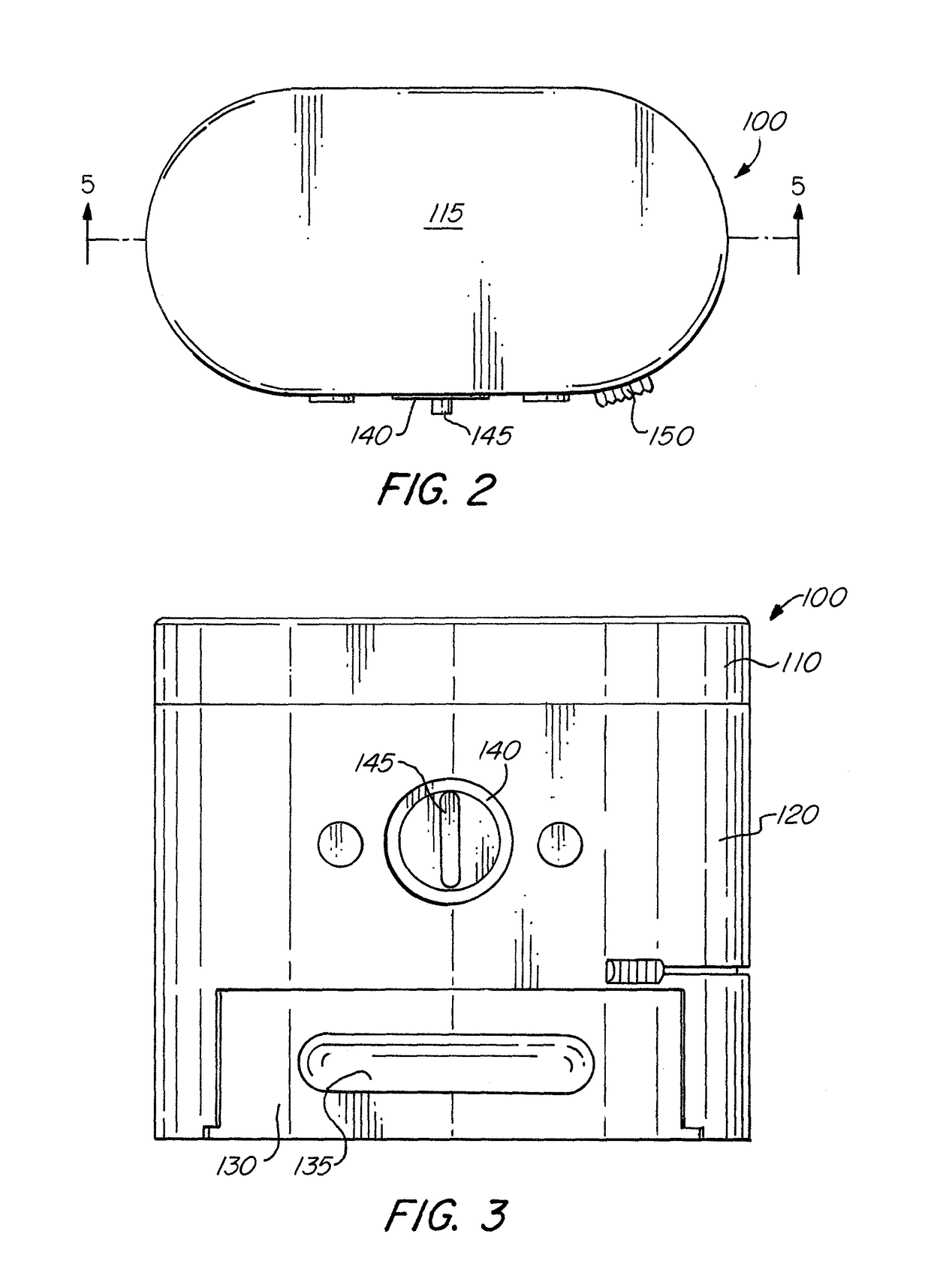

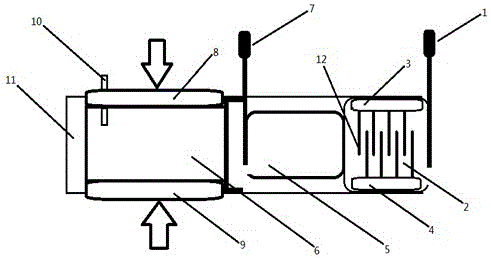

Soap recycling device and method of operation

InactiveUS20150216368A1Save moneyAvoid wastingOpening closed containersBottle/container closureEngineeringOperation mode

The invention refers to a soap recycling device that recycles solid soap bar remnants into purified liquid soap or purified reconstituted solid soap bars, depending on a user's selected mode of operation of the device. The soap recycling device includes a heat source that melts the solid soap remnants, a UV emitter that sterilizes the solid soap remnants, and a directional valve that selectively delivers the molten soap fluid to a first receptacle capable of storing the soap in liquid form and delivering it for direct usage, for instance for hand washing, and a second receptacle where the molten soap fluid solidifies and turns into a reconstituted solid soap bar. The device includes a user interface that allows selecting the desired operation mode to either liquid or solid soap formation. The device according to the invention is compact and versatile.

Owner:MCCLENDON FREDERICK

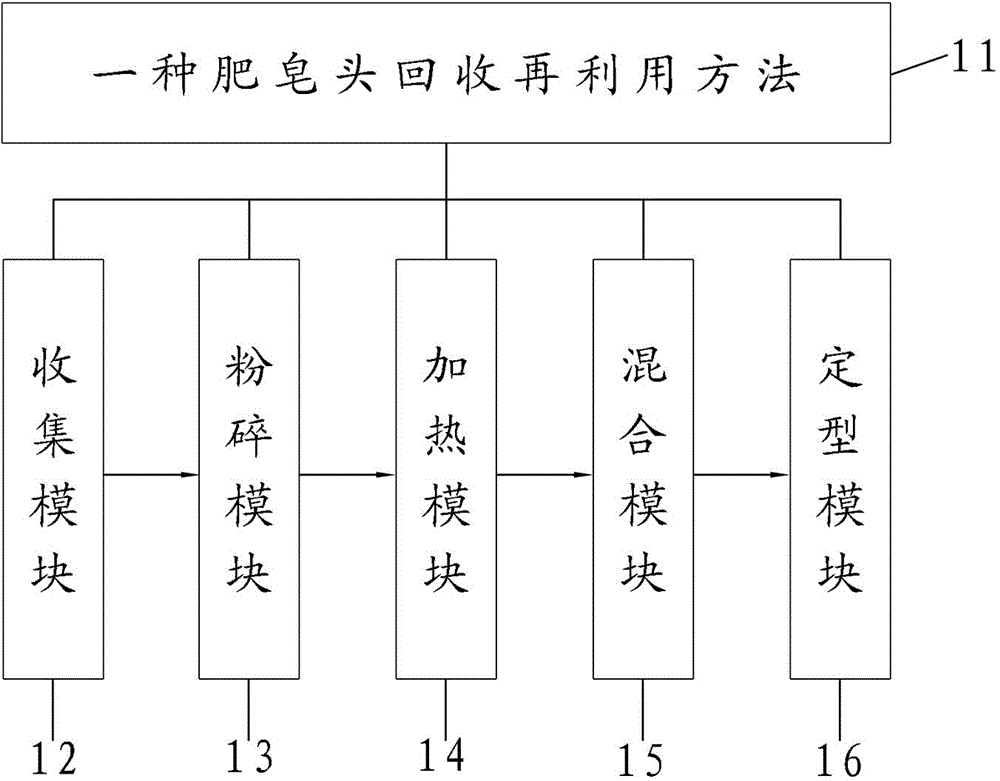

Method of recycling and reusing soap head

The invention discloses a method of recycling and reusing a soap head. Soap is an indispensable washing product when daily sanitation and hygiene are carried out in every family. Usually, people, using the soap, can have such an experience that the soap can become particularly slippery after being soaked with water and can become a very small soap head after being used for a period of time, and thus being inconveniently used and only thrown away. Such wasteful behavior runs counter to the traditional virtue of Chinese nation of industry and thrift. The invention aims at providing a method of recycling and reusing the soap head. According to the method disclosed by the invention, equipment comprises a collecting module, a crushing module, a heating module, a mixing module and a sizing module are used, so that the purposes of saving resources and protecting environment are achieved.

Owner:朱焱

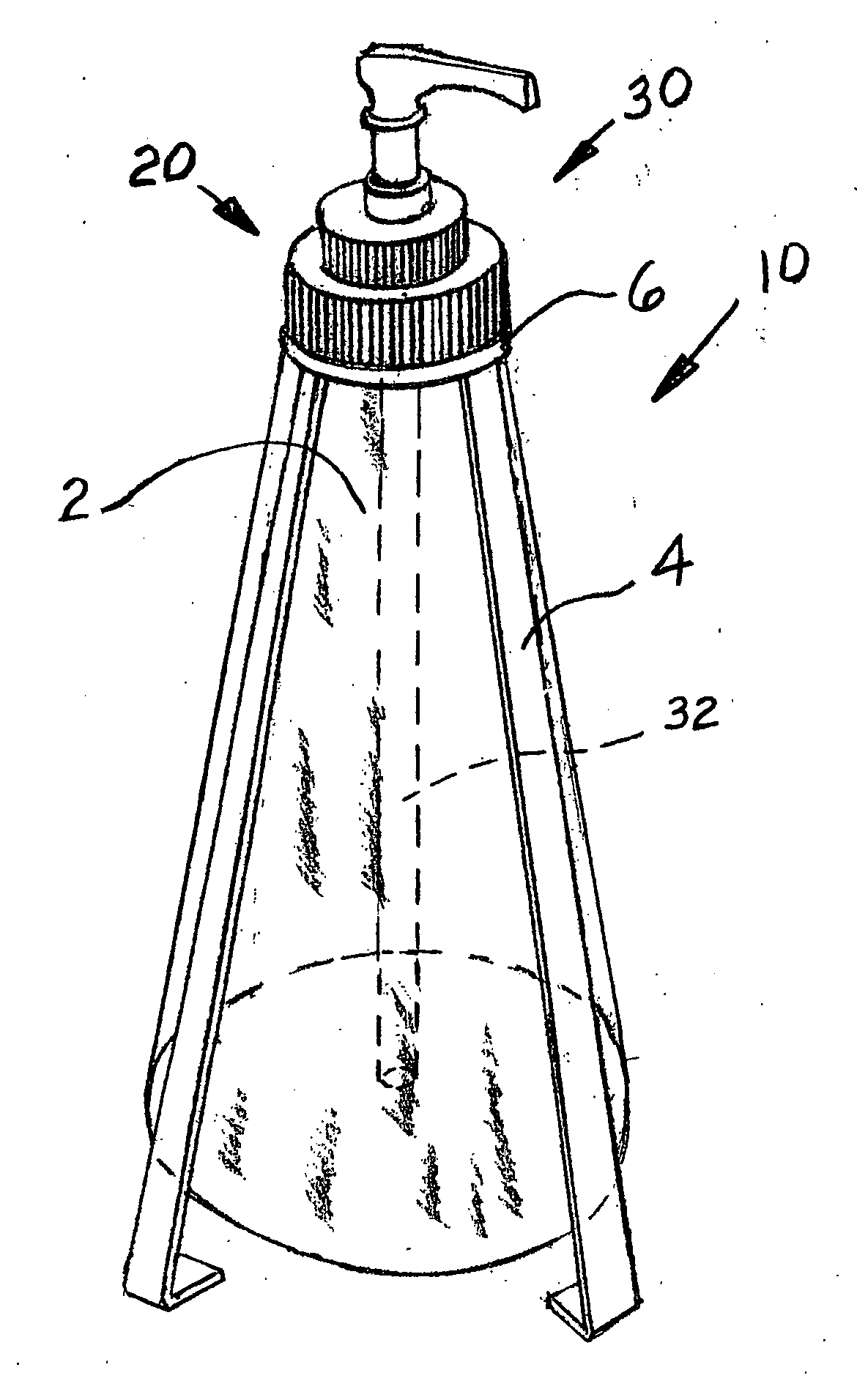

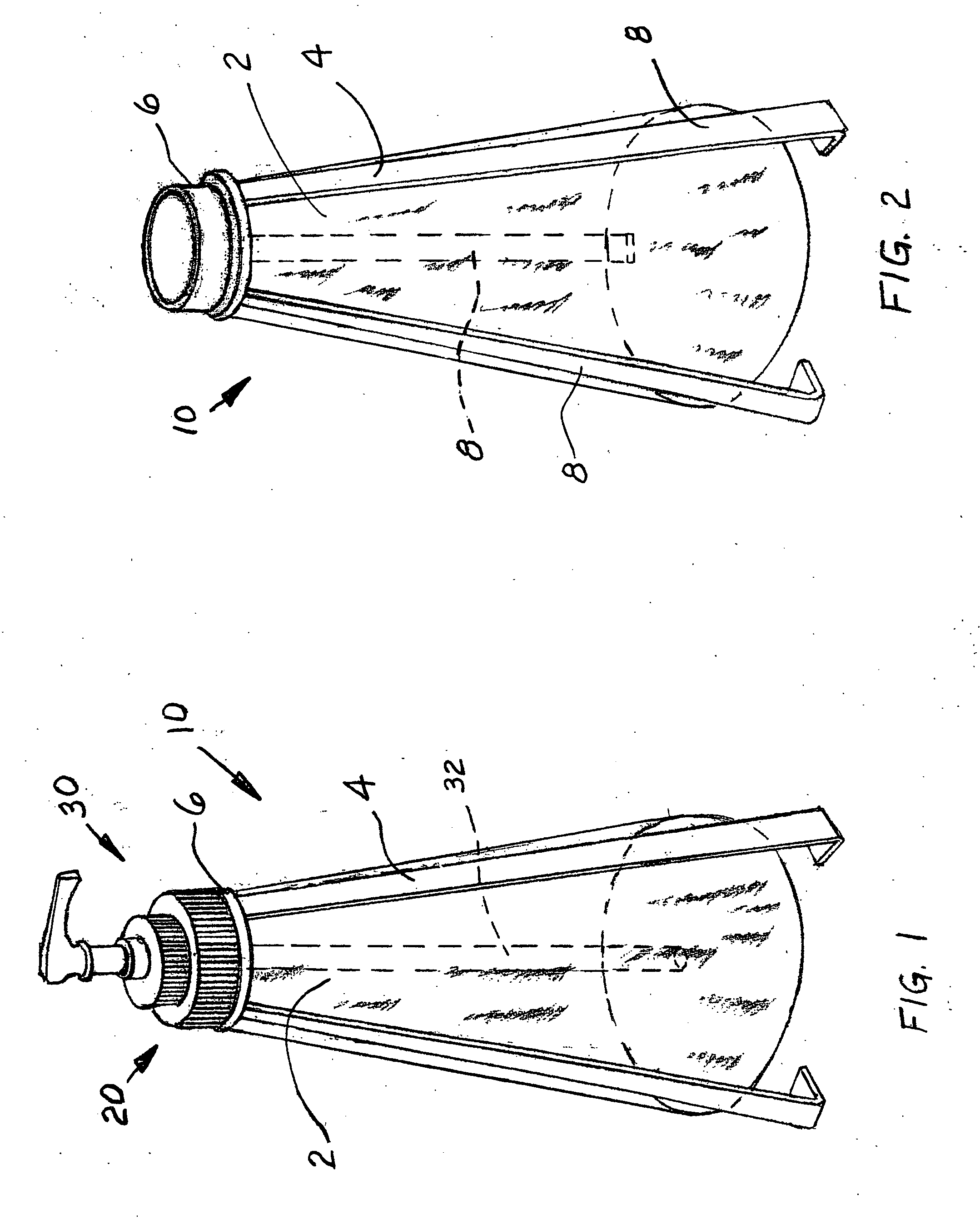

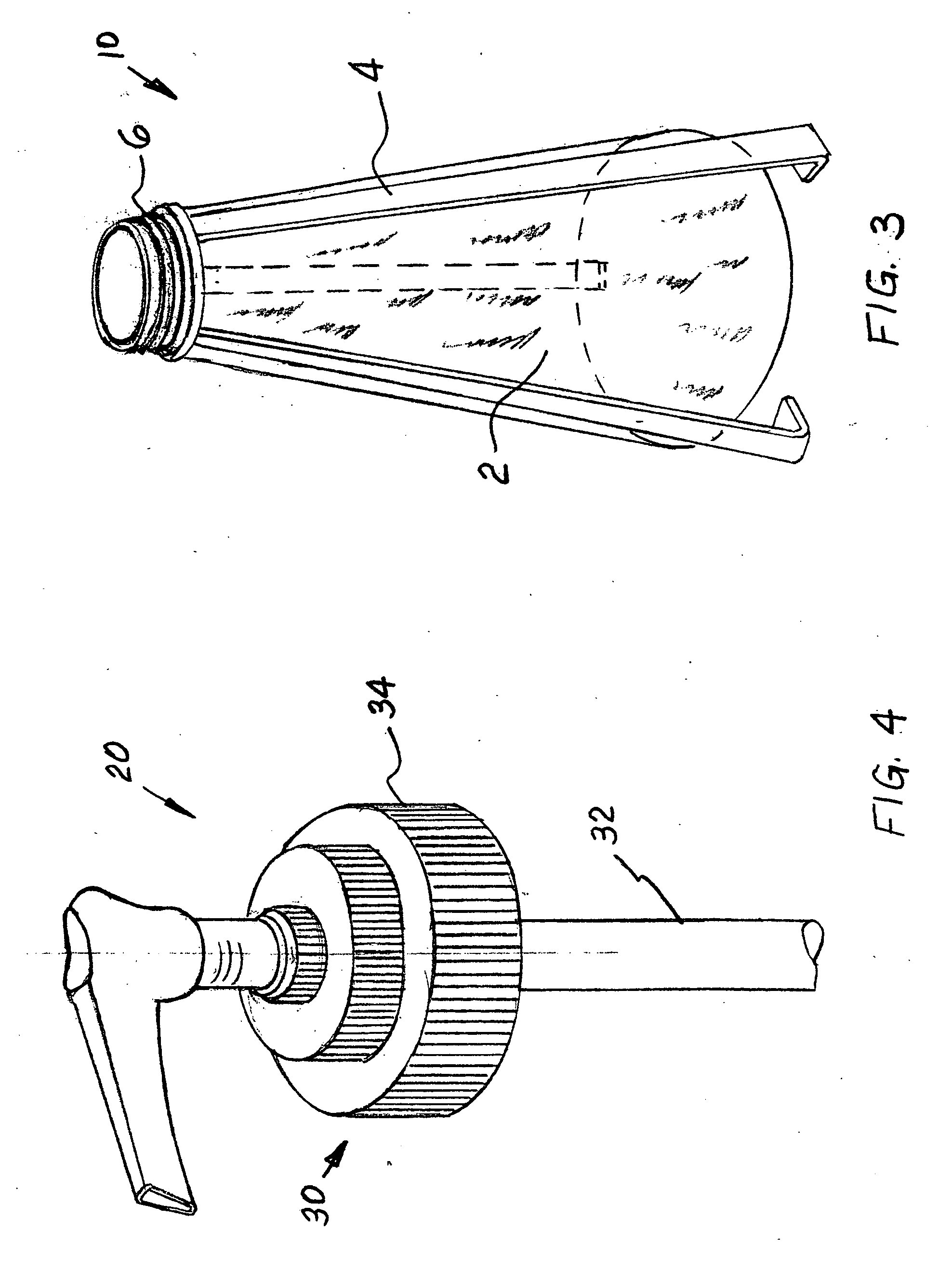

Soap saver

An apparatus for using small leftover pieces of bar soap. The apparatus comprises a container member having a first predetermined shape and formed of a first predetermined material for holding such small leftover pieces of bar soap and mixing such small leftover pieces of bar soap with a predetermined fluid. There is a frame for retaining such container in an upright position. The frame having a second predetermined shape and formed of a second predetermined material. The invention includes pump mechanism for dispensing the liquid soap formed in the container member from such small pieces of bar soap and such predetermined fluid.

Owner:MOORE SINGLETON C

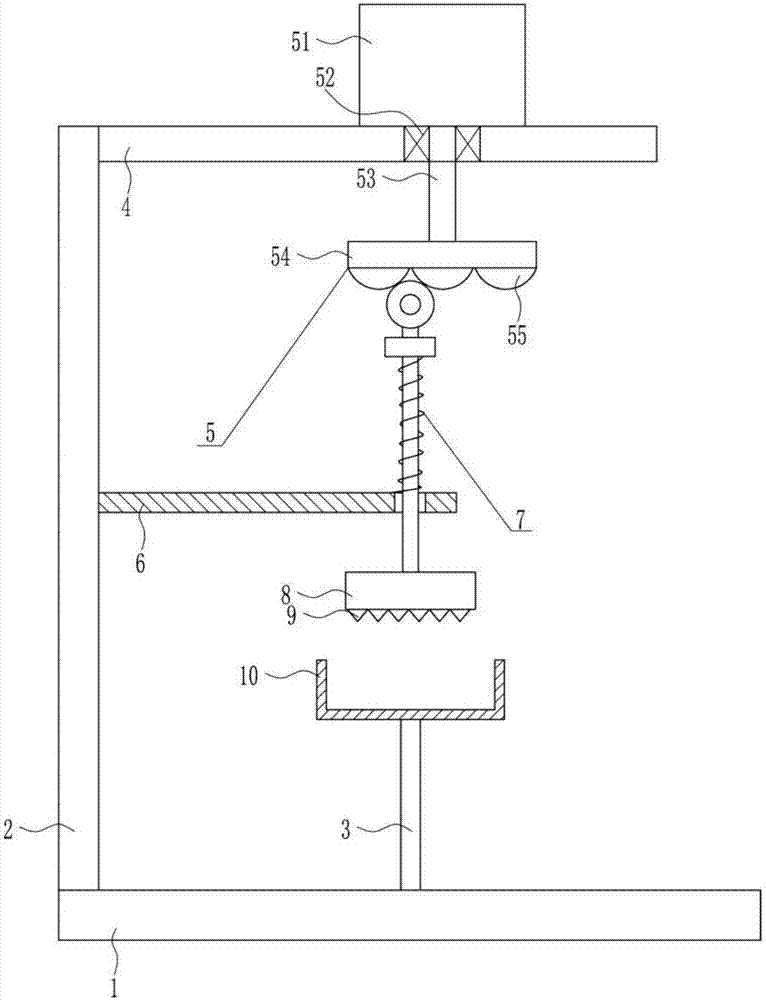

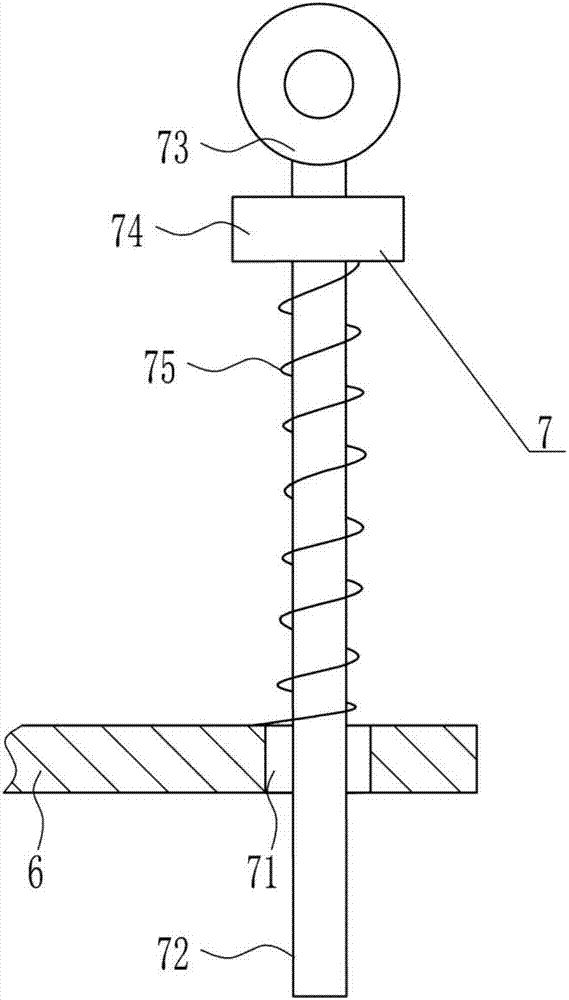

Environment-friendly soap recycling device

InactiveCN107495879AUniform and comprehensive crushingImprove work efficiencyHolders and dispensersSoap recoveryEngineeringSOAP

The invention relates to a soap recycling device, in particular to an environment-friendly soap recycling device. The environment-friendly soap recycling device achieves the technical purposes that soap can be recycled, the soap can be repeatedly utilized, environmental protection is achieved, and resources are saved. In order to achieve the technical purposes, the environment-friendly soap recycling device comprises a base plate, a support, a supporting rod, a top plate, a driving device, a guiding plate, a lifting device and the like. The top of the base plate is vertically connected with the support and the supporting rod in a bolt connection mode, the support is located on the left side of the supporting rod, the top of the supporting rod is connected with a processing frame in a bolt connection mode, the top of the right side face of the support is horizontally connected with the top plate in a bolt connection mode. The effects that the soap can be processed, the soap can be repeatedly utilized, environmental protection is achieved, and resources are saved are achieved.

Owner:虞温乐

Soap reclaiming device

The invention relates to a soap recovery device, which is composed of a soap mold with a mold cavity in the soap shape and a heater fixed below the soap mold. The soap mold consists of an upper mold housing and a lower mold housing, wherein one side of the upper mold housing is hinged with one side of the lower mold housing, and an overflow hole is provided on the upper mold housing. The heater is composed of a housing, a heating filament arranged in the housing, and a switch, a transformer and a power plug sequentially connected with the heating filament. The soap recovery device has the advantages of simple structure as well as prevention soap waste by recovering residual small soaps and making into a large soap.

Owner:SHANGHAI YANAN HIGH SCHOOL

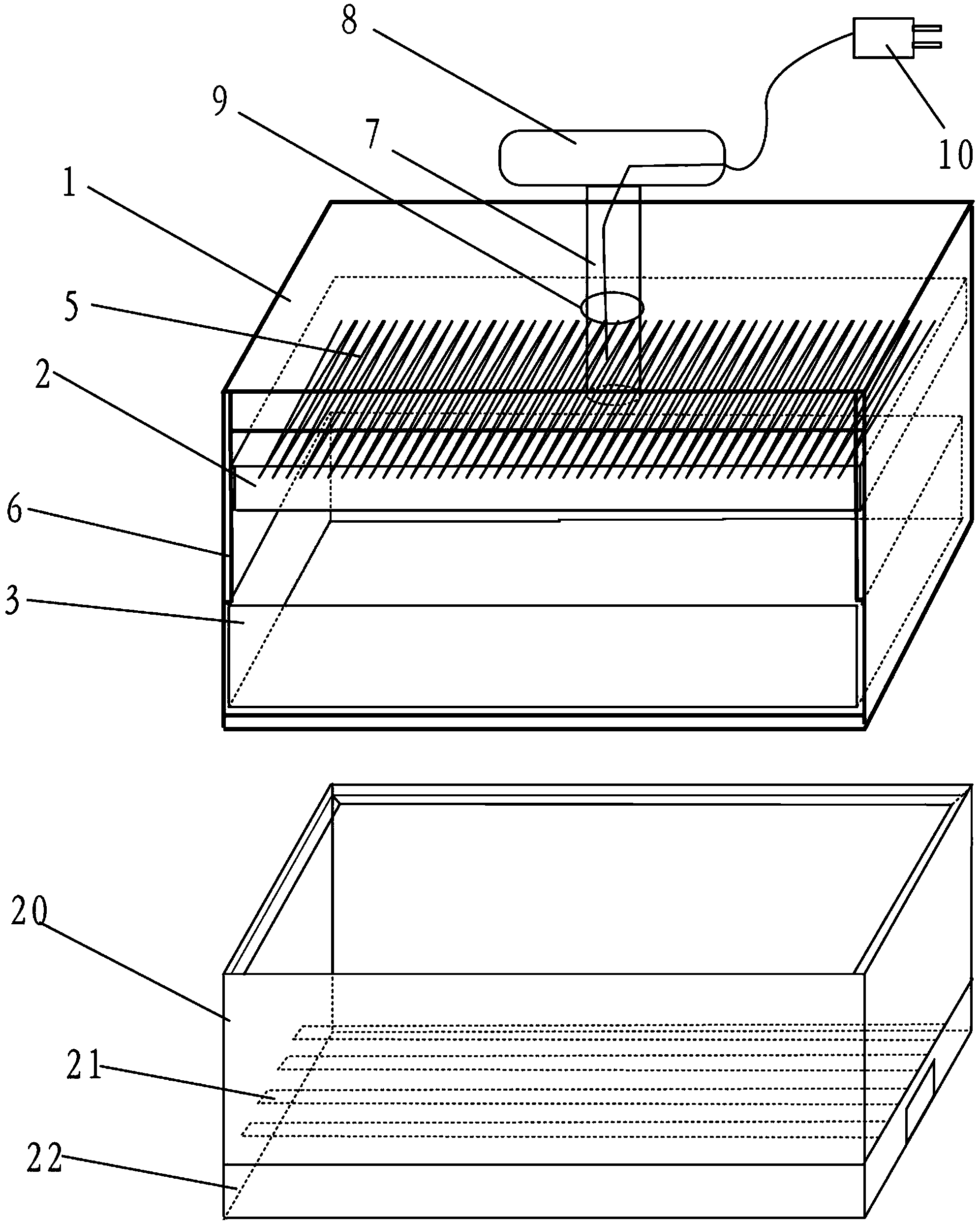

Soap leftover reutilization combination set

The invention discloses a soap leftover reutilization combination set which comprises a soap forming device and a soap box, wherein the soap forming device is arranged on the upper side of the soap box; at least one side surface of the soap forming device is open; a forming pressure plate and a mold are arranged in the soap forming device; the forming pressure plate is arranged on the upper side of the mold, and a heating wire is arranged in the forming pressure plate; the top of the soap forming device is provided with a connecting hole; the forming pressure plate is provided with a connecting rod and a grip connected with the connecting rod; the connecting rod penetrates through the connecting hole; and the grip is connected with a power supply which is electrically connected with the heating wire. The soap forming device can be utilized to heat and soften a plurality of small soap leftovers and perform extrusion forming to form new soap for continuous use, thereby reducing the waste.

Owner:SUZHOU VOCATIONAL UNIV

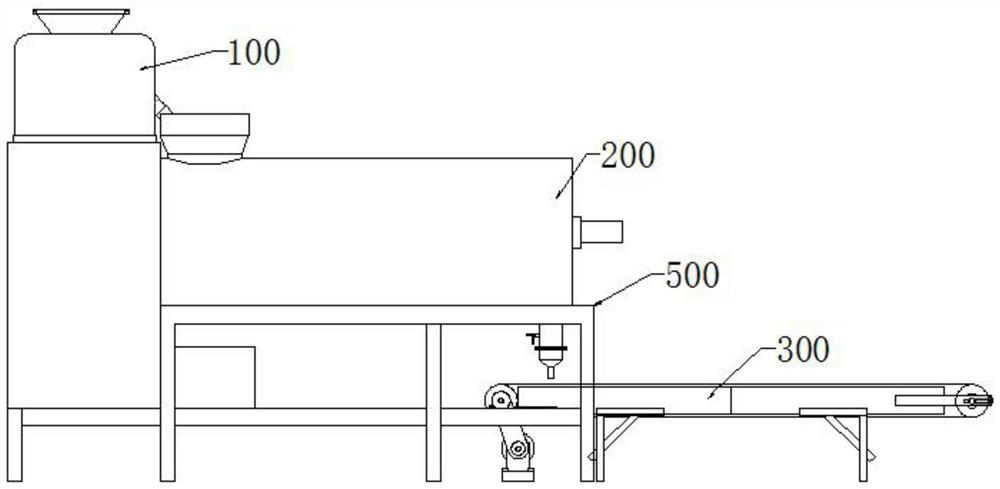

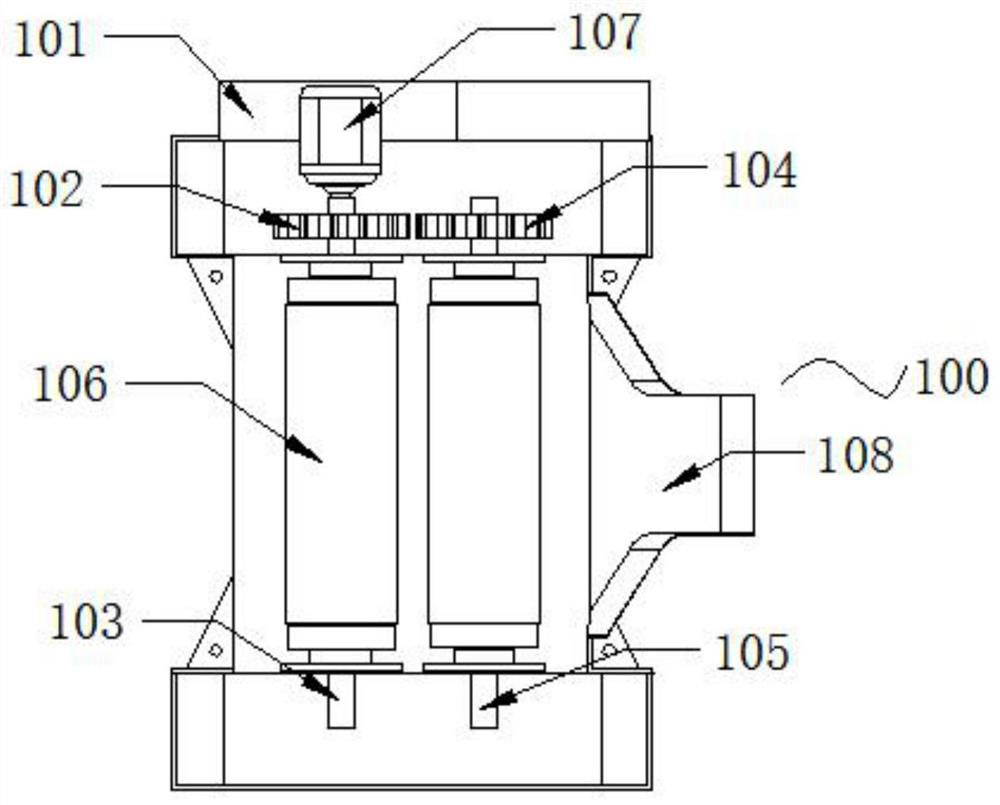

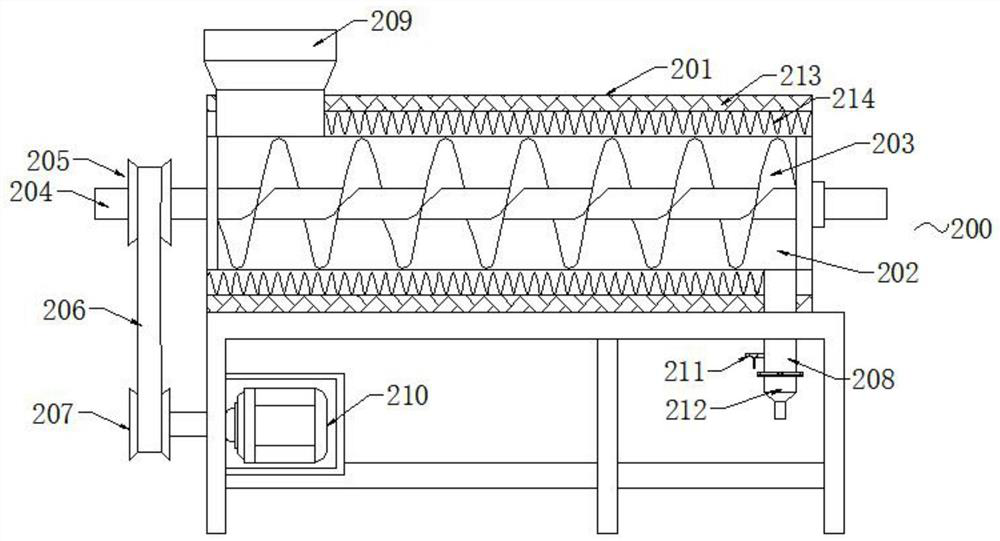

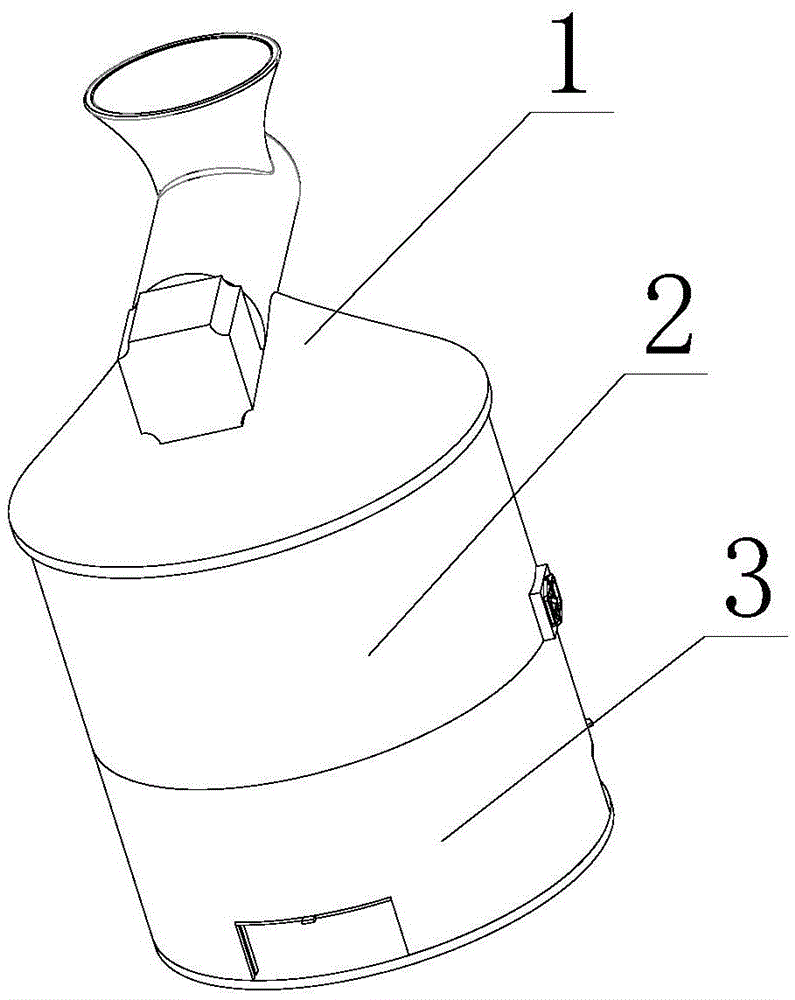

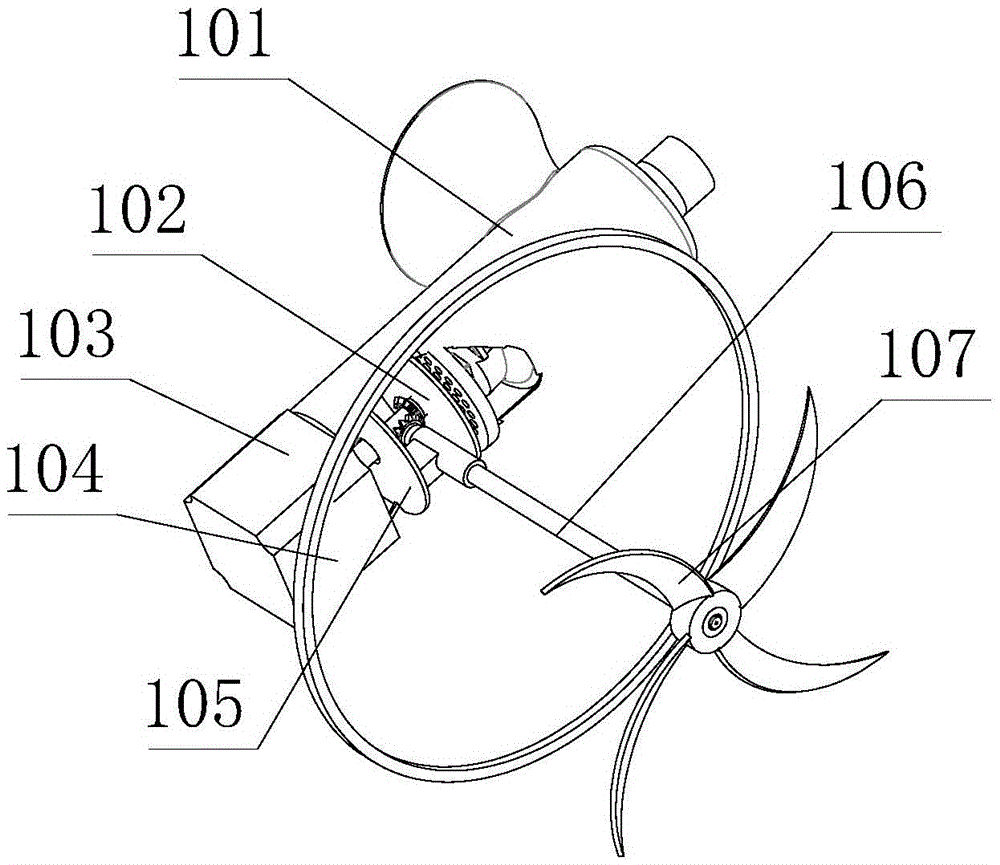

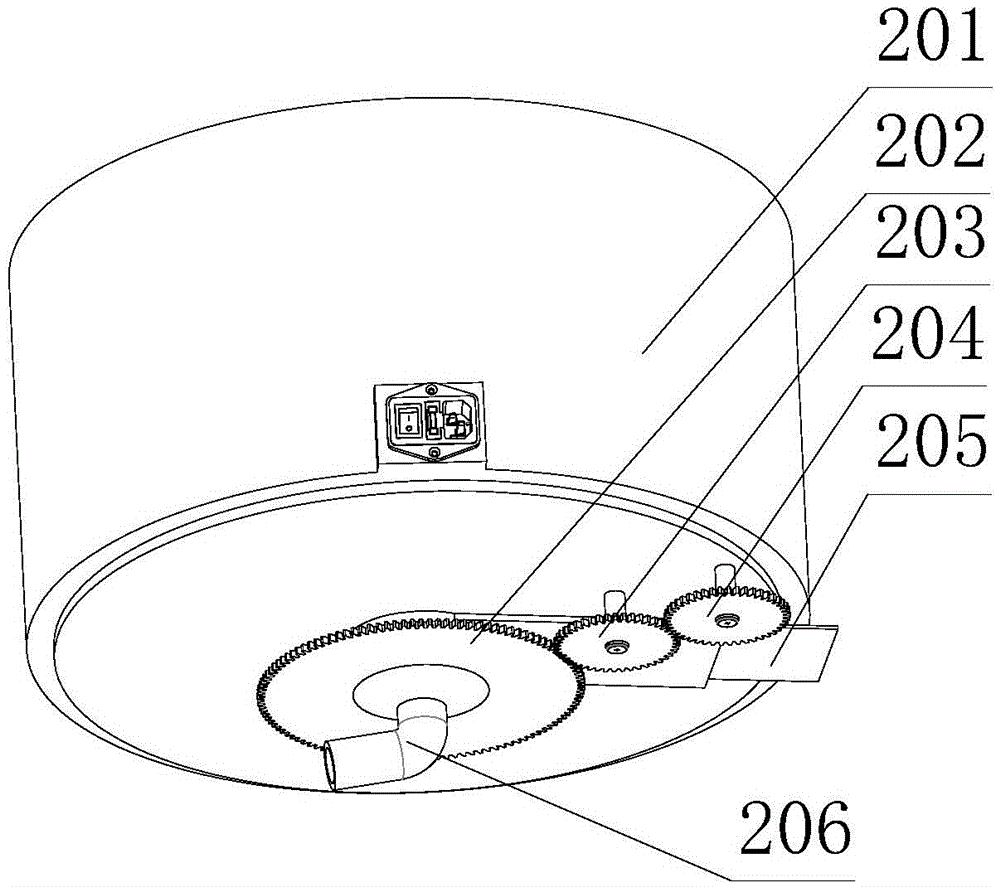

Broken soap collecting and reprocessing device

InactiveCN112625817AImprove processing efficiencyEfficient crushingShaping soapSoap recoveryRotational axisElectric machinery

The invention discloses a broken soap collecting and reprocessing device, which comprises a grinding mechanism, wherein the grinding mechanism comprises a shell, the top of the shell is communicated with a first feeding pipe, a grinding motor is arranged in the shell, an output shaft of the grinding motor is connected with a first rotating shaft, the first rotating shaft is sleeved with a first gear, and the first gear is engaged with a second gear. According to the invention, crushed soap is poured into the first feeding pipe at the top of the shell, the grinding motor is started, the output shaft of the grinding motor drives the first rotating shaft to rotate, the first rotating shaft drives the first gear to rotate, the first gear is meshed with the second gear to drive a second rotating shaft to rotate, the first rotating shaft and the second rotating shaft drive two grinding rollers to oppositely rotate, the two grinding rollers crush and grind the broken soap, large solid particles existing in the broken soap are effectively crushed, and the technical problem that forming is affected by the large solid soap in the prior art is solved.

Owner:淮南市雅洁洗涤用品有限公司

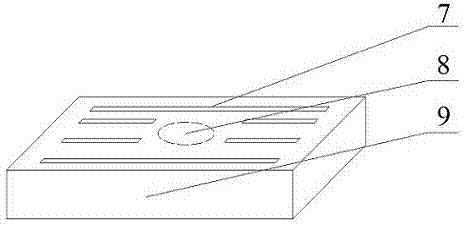

Soap molding device

InactiveCN104651100ASolid shapeSave and reduce pollutionShaping soapSoap recoveryTemperature controlEngineering

The invention discloses a soap molding device and relates to the technical field of molding device manufacture. The soap molding device comprises a lower die and an upper die, wherein the working surface of the lower die 1 is provided with a molding recessed cavity, the bottom part of the molding recessed cavity in the lower die is provided with a heating tube; the heating tube is connected with a temperature control inductive switch; the working surface of the lower die is correspondingly provided with a left jack socket and a right jack socket; the working surface of the upper die is provided with a left plug and a right plug corresponding to the left jack socket and the right jack socket. Compared with the prior art, the soap molding device is simple in structure; the residual small soaps are extruded to form a tough monoblock, so that the environment pollution of the waste can be saved and reduced.

Owner:黎雅伟

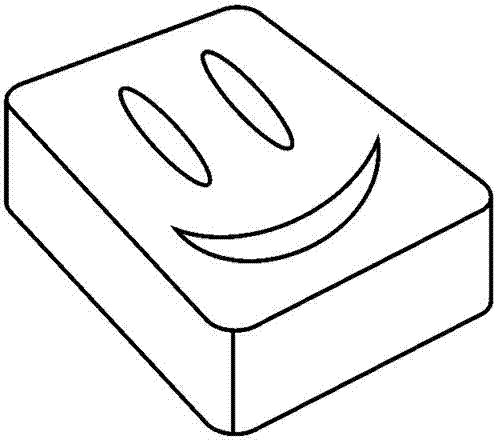

Method for recycling residual soap part with soap

InactiveCN102408960AAdd artistryIncrease attractivenessSoap recoveryDetergent materialsEngineeringMechanical engineering

The invention discloses a method for recycling residual soap part with soap; the method comprises: disposing several holes vertical to the plane in the front side or side face of the soap, wherein the cross section of the hole is the graph having a length and width ratio more than one, namely a prolate hole. The invention has the following beneficial effect: because the prolate hole in the front side or side face of the soap can tightly hold the used residual soap part, the vast majority of the surface of the residual soap part is contacted with the new soap, then the residual soap part is integrated with the new soap as one, which does not drop when using and is very convenient; no additional accessory is needed to complete the operation. Simultaneously, if a beautiful hole shape is used, like cartoon shape, the artistic quality of the soap can be largely increased, so as to increase the attractiveness to consumer.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

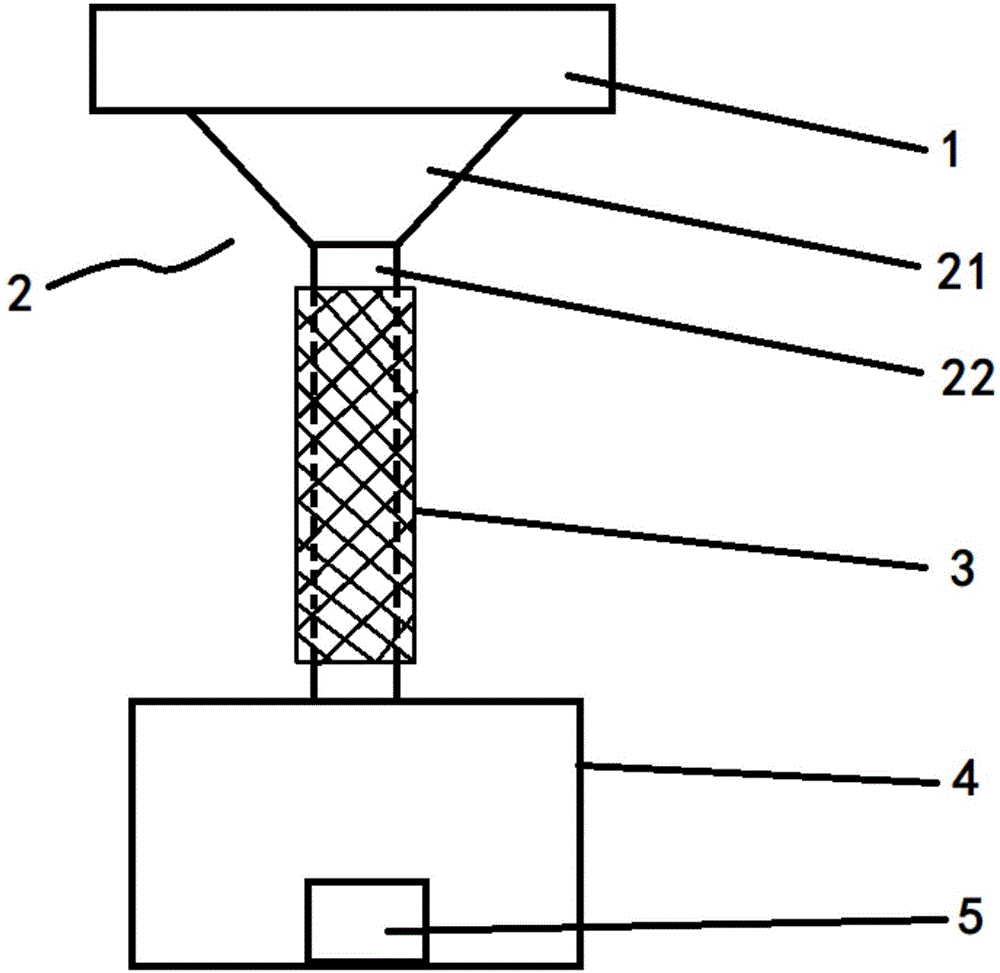

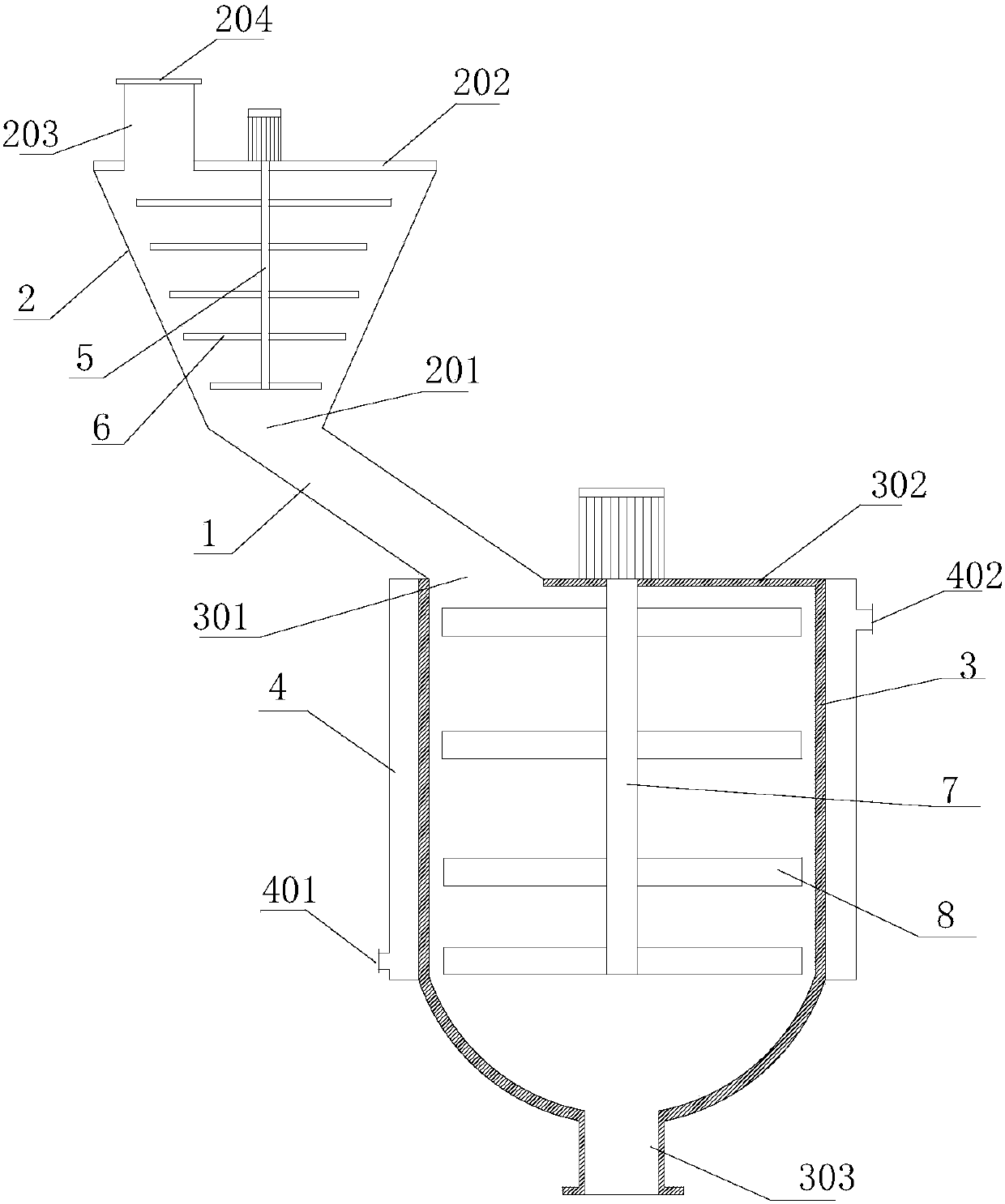

Soap recycling device

InactiveCN105062733AFacilitate subsequent heating and meltingEasy to heat and meltSoap recoverySOAPMechanical field

The invention relates to the mechanical field and discloses a soap recycling device. The soap recycling device comprises a smashing device, a melting vessel, a heating screen, a base bracket and a molding die, wherein the smashing device is positioned above the melting vessel; the lower surface of the smashing device is tightly adhered to the upper surface of the melting vessel; the smashing device is provided with a feed inlet and a feed outlet; the melting vessel is in a funnel-shaped structure and comprises a funnel cavity and a funnel neck; the lower end face of the funnel cavity is seamlessly connected with the upper end face of the funnel neck; the upper end face of the funnel cavity is a lead inlet while the lower end face of the funnel neck is a lead outlet; the feed inlet of the smashing device falls into a plane of the lead outlet of the funnel cavity; the heating screen is arranged around the funnel neck; the base bracket is positioned below the melting vessel; the molding die is placed in the base bracket; the molding die is placed right below the lead outlet of the funnel neck. The soap recycling device disclosed by the invention can be used for smashing, melting and secondarily molding small block soaps to avoid material waste. The device is delicate in structure, convenient to use, comprehensive in function and convenient to operate.

Owner:韦江华

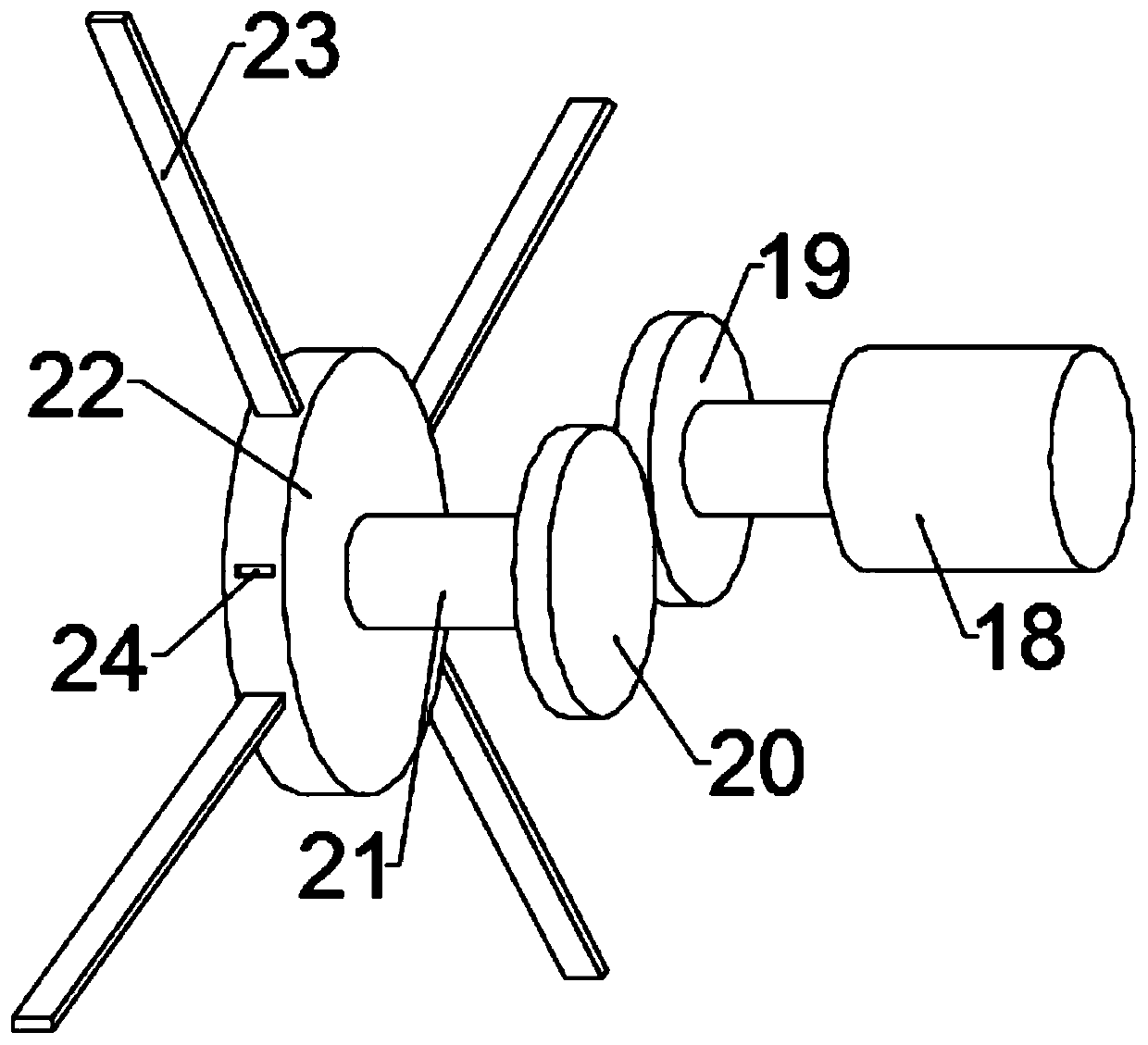

Soap reformer

ActiveCN105567482ASolve wasteSolve the reuse problemShaping soapSoap recoveryEngineeringShipping container

The invention discloses a soap reformer which comprises a crushing assembly, a melting device assembly and a mould assembly. The crushing assembly comprises a motor and a spiral stirring and crushing machine, and a discharging protection cover is arranged at a discharging opening of the spiral stirring and crushing machine; the melting device assembly comprises a heating container, and a heating wire is arranged on an inner wall shaft of the heating container; the heating container is covered by the discharging protection cover through a thread structure, and a longitudinal shaft and a blade can extend into the heating container through the discharging protection cover; a liquid stopping plate is arranged at a discharging opening of the heating container, and the flow of the discharging opening of the heating container can be adjusted through the liquid stopping plate; and the mould assembly comprises a mould cabin and a mould plate; the mould cabin is covered by the heating container through a thread structure; the mould plate is arranged under the mould cabin through a thread structure; more than one mould are arranged on the mould plate, and a discharging opening of a rotary rubber pipe can be arranged right above each mould when the rotary rubber pipe is rotated. The soap reformer can solve the problems of soap waste and recycling.

Owner:SOUTHEAST UNIV

Soap waste processing device

PendingCN108018140APreventing situations that leave the shredderAdjustable temperatureSoap recoveryWaste processingTemperature control

Owner:TIANJIN RUIHAI PENGXIANG TRADING

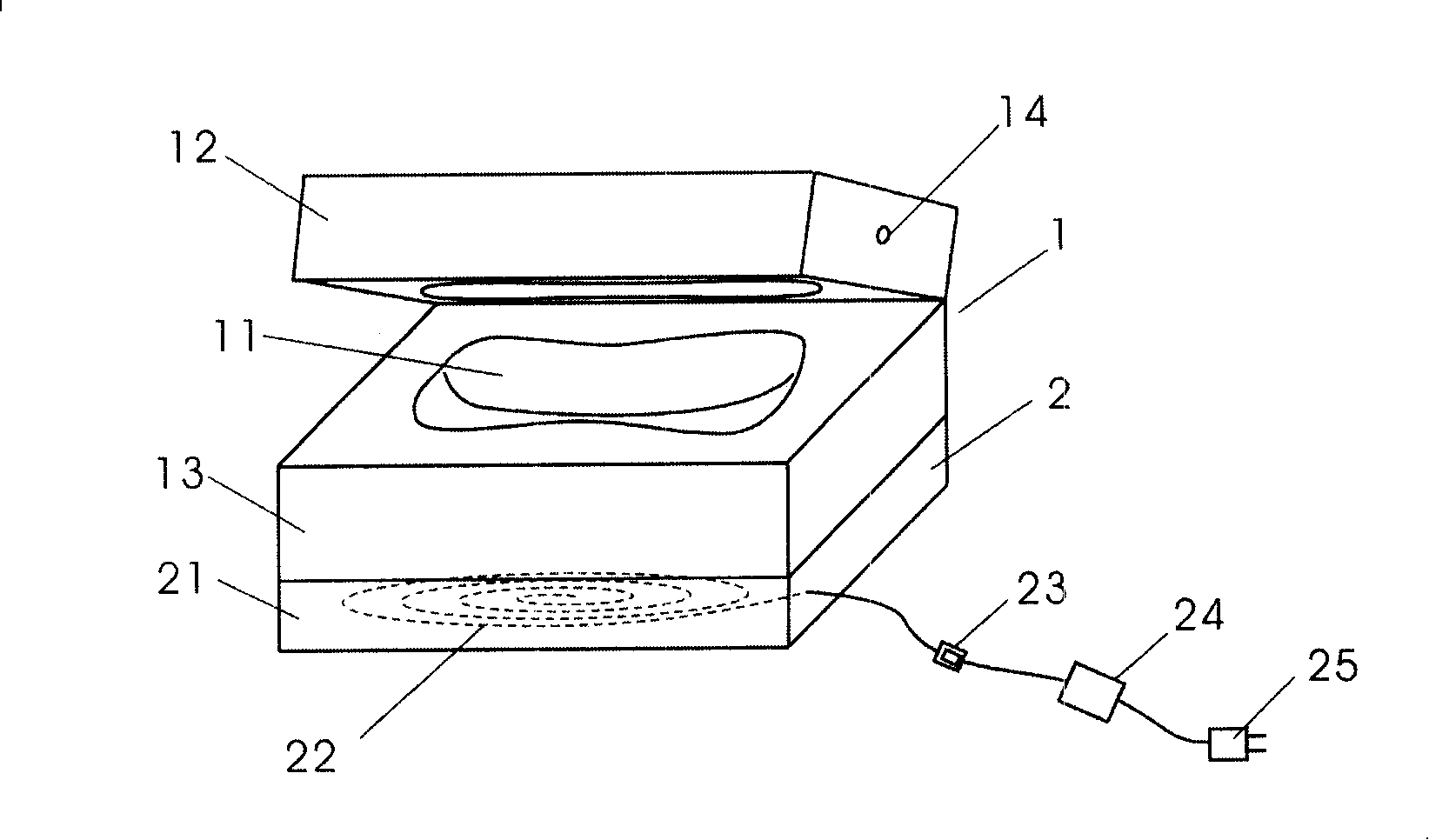

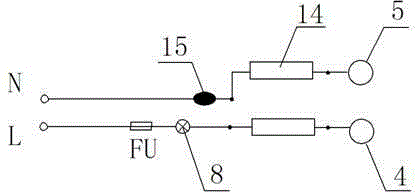

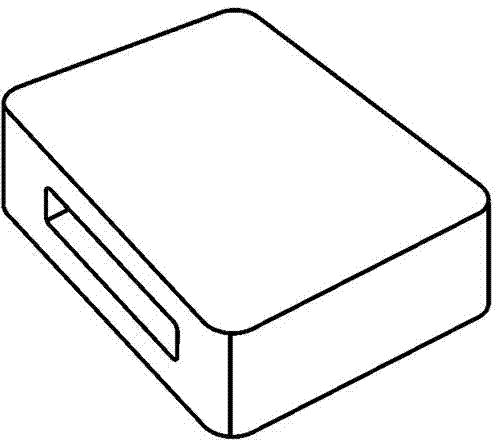

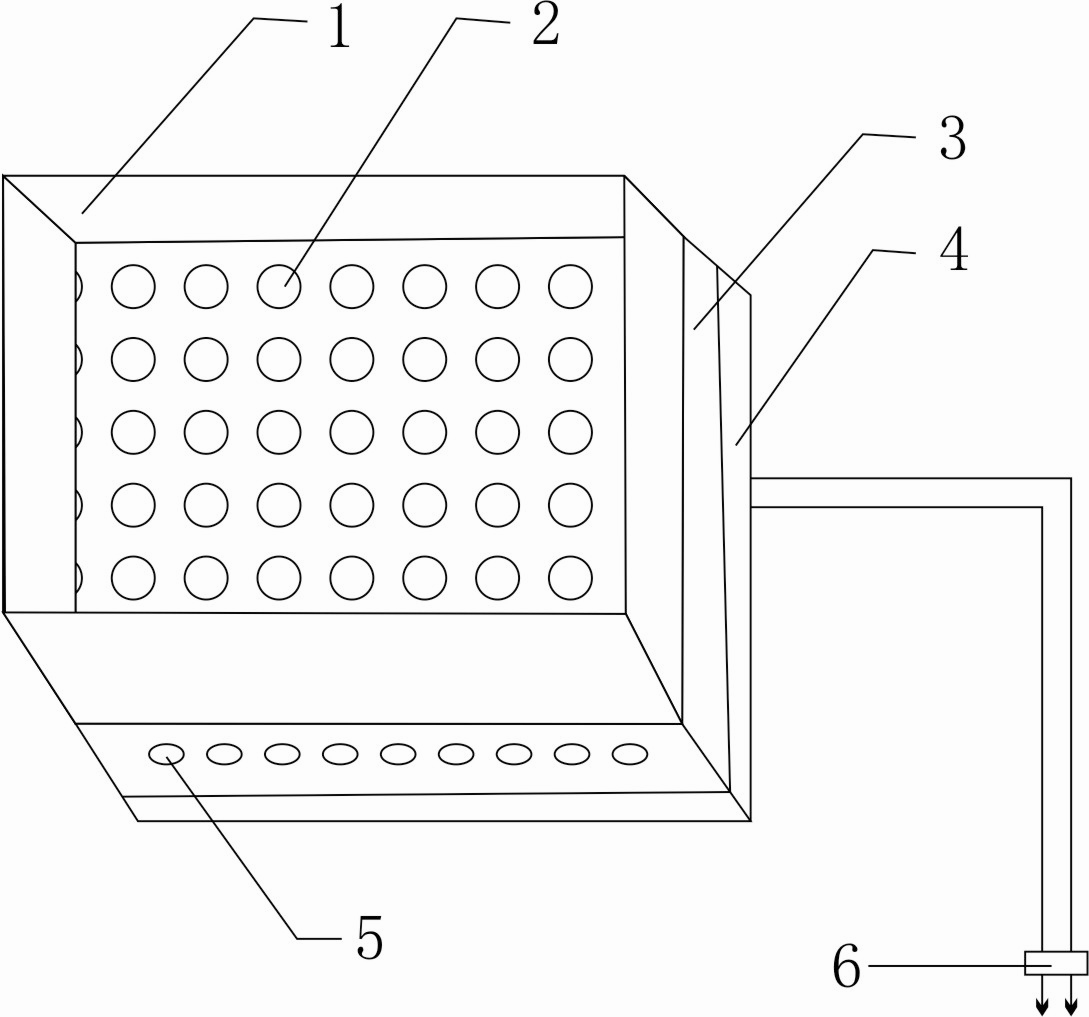

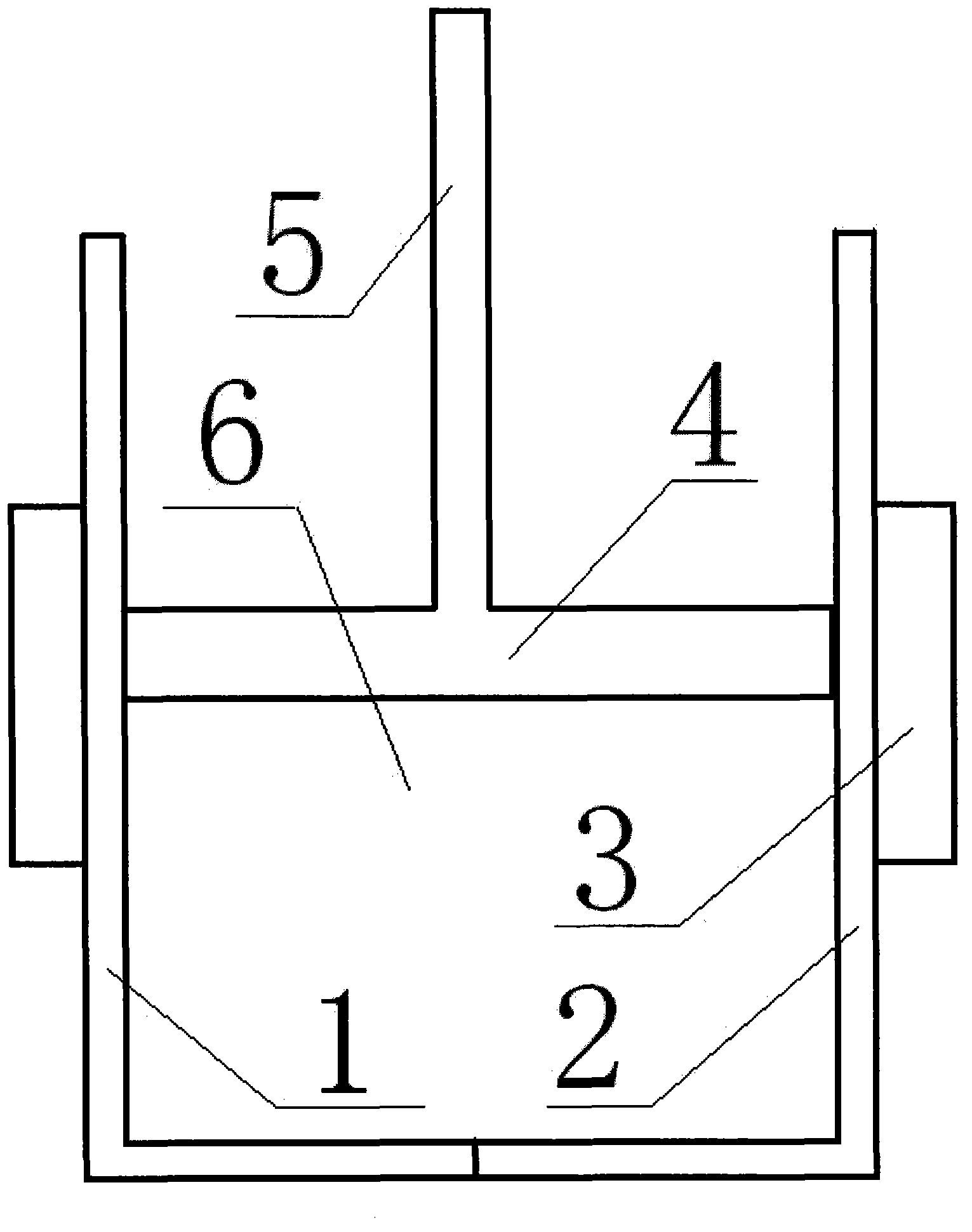

Soap flow-back and solidification device

The invention discloses a soap flow-back and solidification device. The soap flow-back and solidification device consists of a soap box, flow-back holes, a collection tank, a heating device, evaporation holes and a plug, and is characterized in that: the soap box is arranged on the collection tank which is arranged on the heating device; the heating device is connected with the plug by a guide line; flow-back holes are reserved on the interlayer of the soap box; and the evaporation holes are formed around the collection tank. The used soap is placed in the soap box, and soapy water flows into the collection tank through the flow-back holes; moisture is evaporated through the evaporation holes under the action of the heating device, and the solidified soap can be taken out by opening the collection tank and can be recycled; and therefore, the soap can be collected and recycled.

Owner:庄梅兰

Household washing powder preparation method

InactiveCN106867726AAvoid stimulationAvoid harmSurface-active non-soap compounds and soap mixture detergentsSoap recoverySlurrySOAP

The purpose of the present invention is to provide a preparation method of household washing powder, which includes the following steps: (1) raw material preparation: crushed soap, edible soda ash, water; (2) crushed soap and water in a weight ratio of 1:1.5-2.5 After mixing, heat in a container and stir evenly until the crushed soap is completely melted; (3) Add edible soda ash to the melted soap liquid, the weight ratio of edible soda ash to crushed soap is 1:1-1:3, Stir evenly; (4) spread the evenly stirred slurry in the air until the washing powder becomes agglomerated; (5) grind the agglomerated washing powder evenly for later use. The method can use household soap scum, not only realizes waste utilization, but also avoids stimulation and damage to human bodies from washing powders on the market.

Owner:烟台鑫海耐磨胶业有限公司

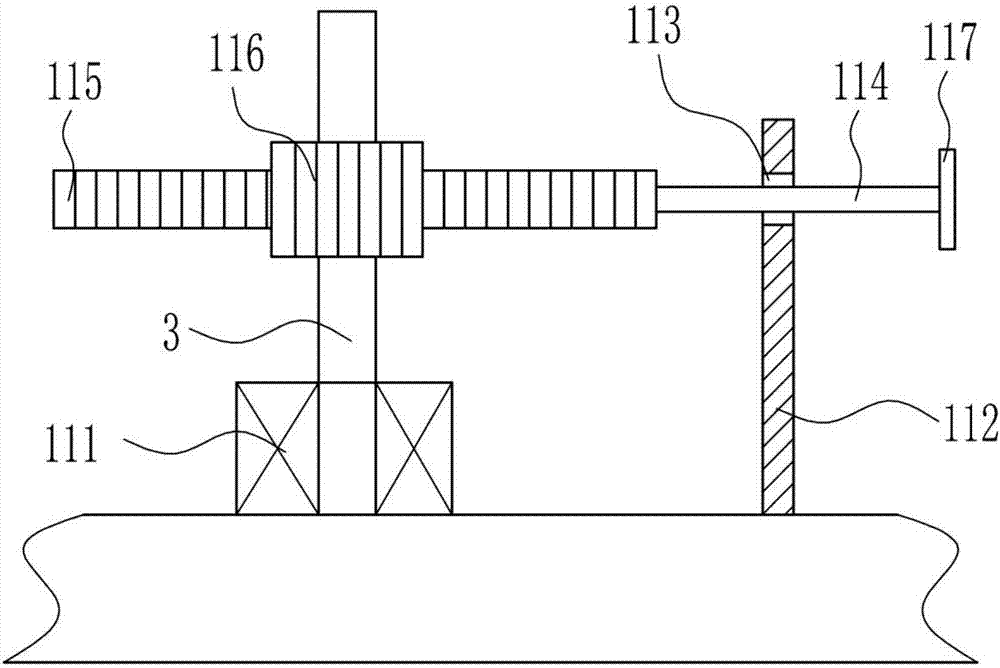

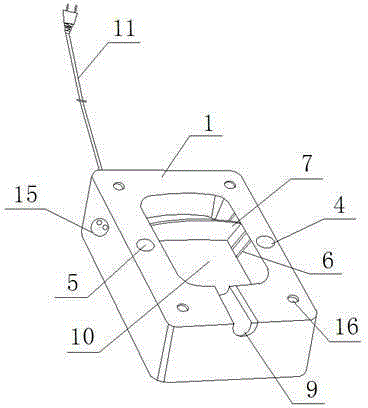

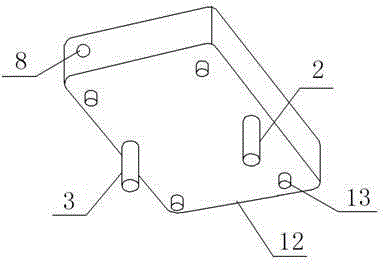

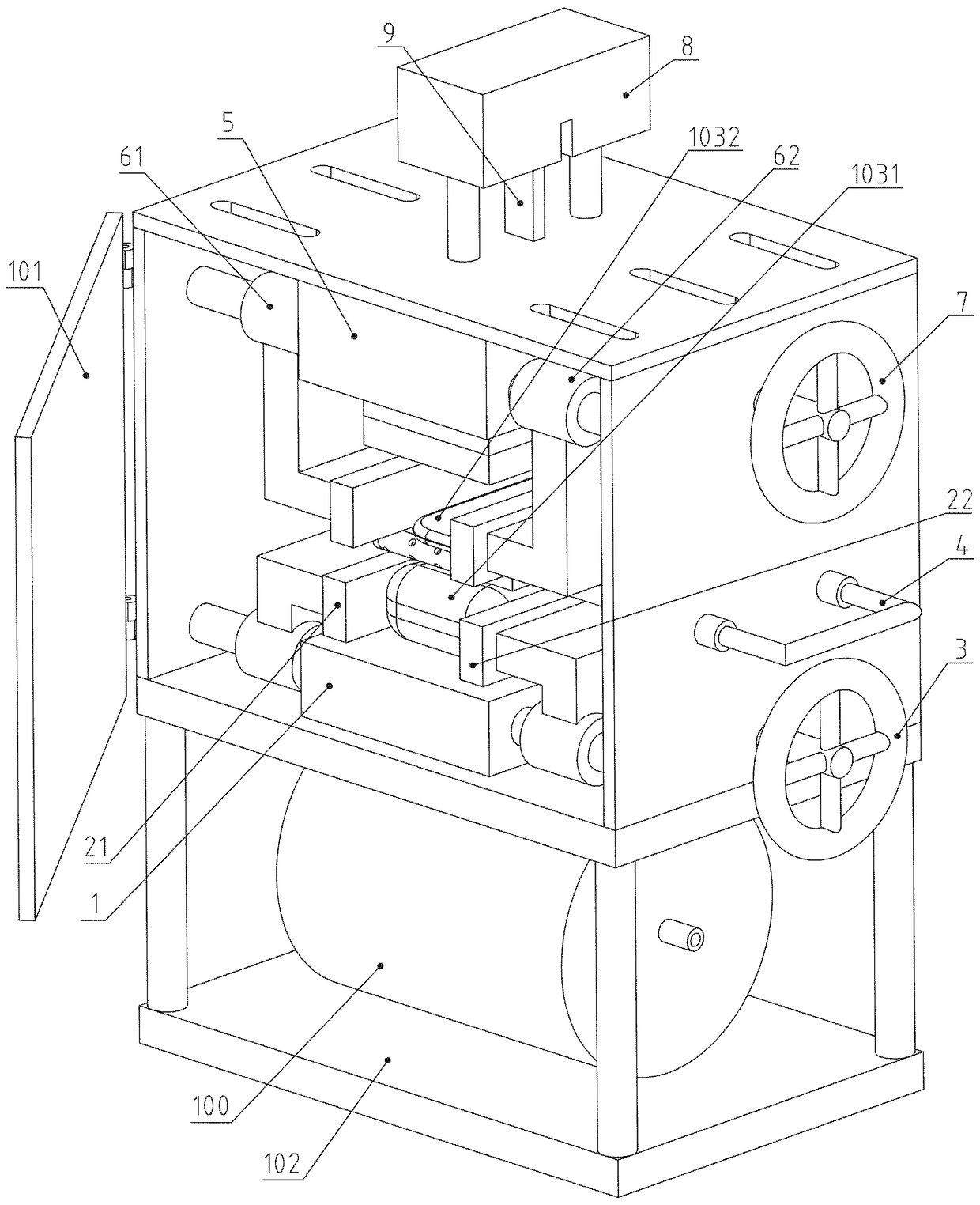

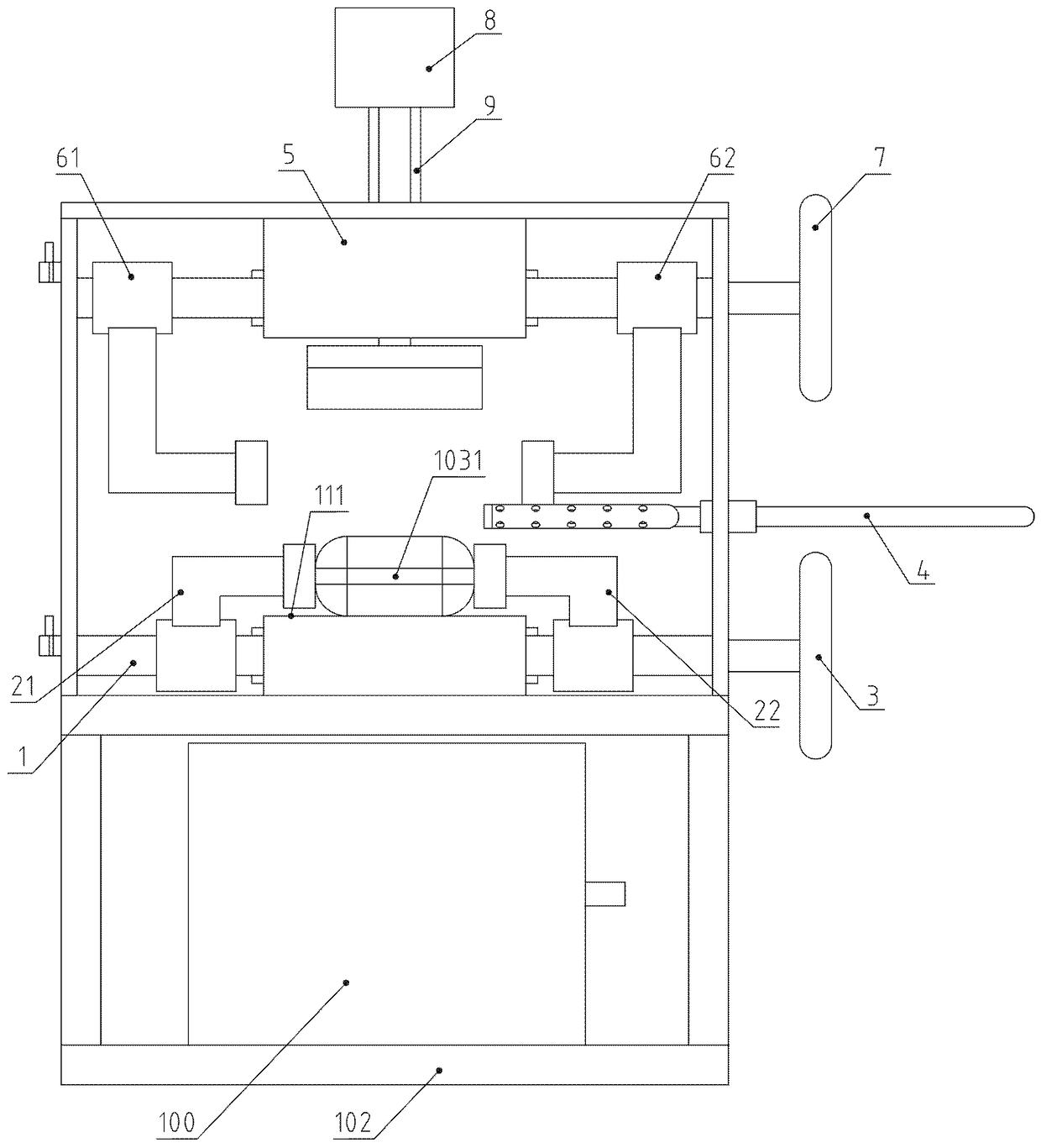

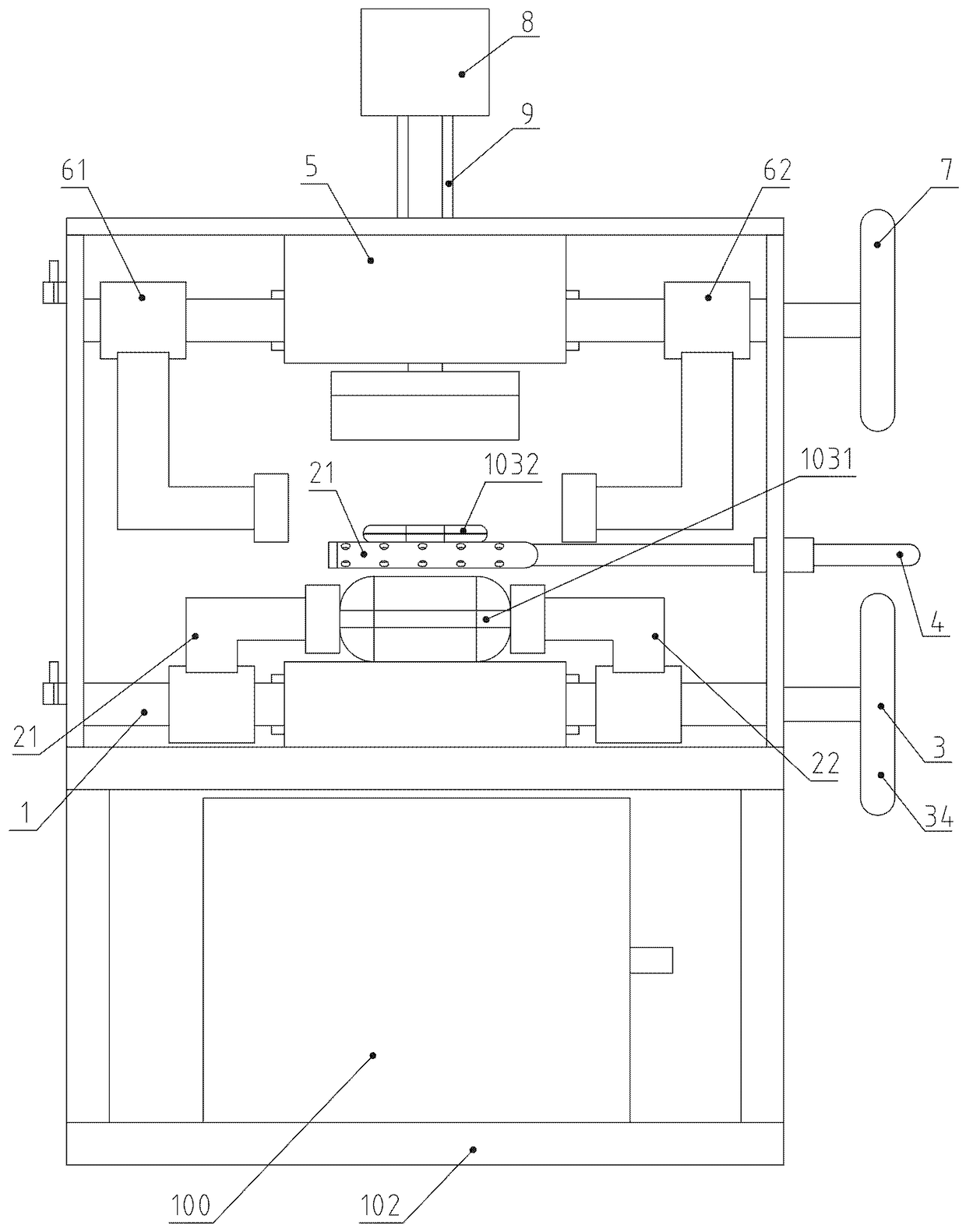

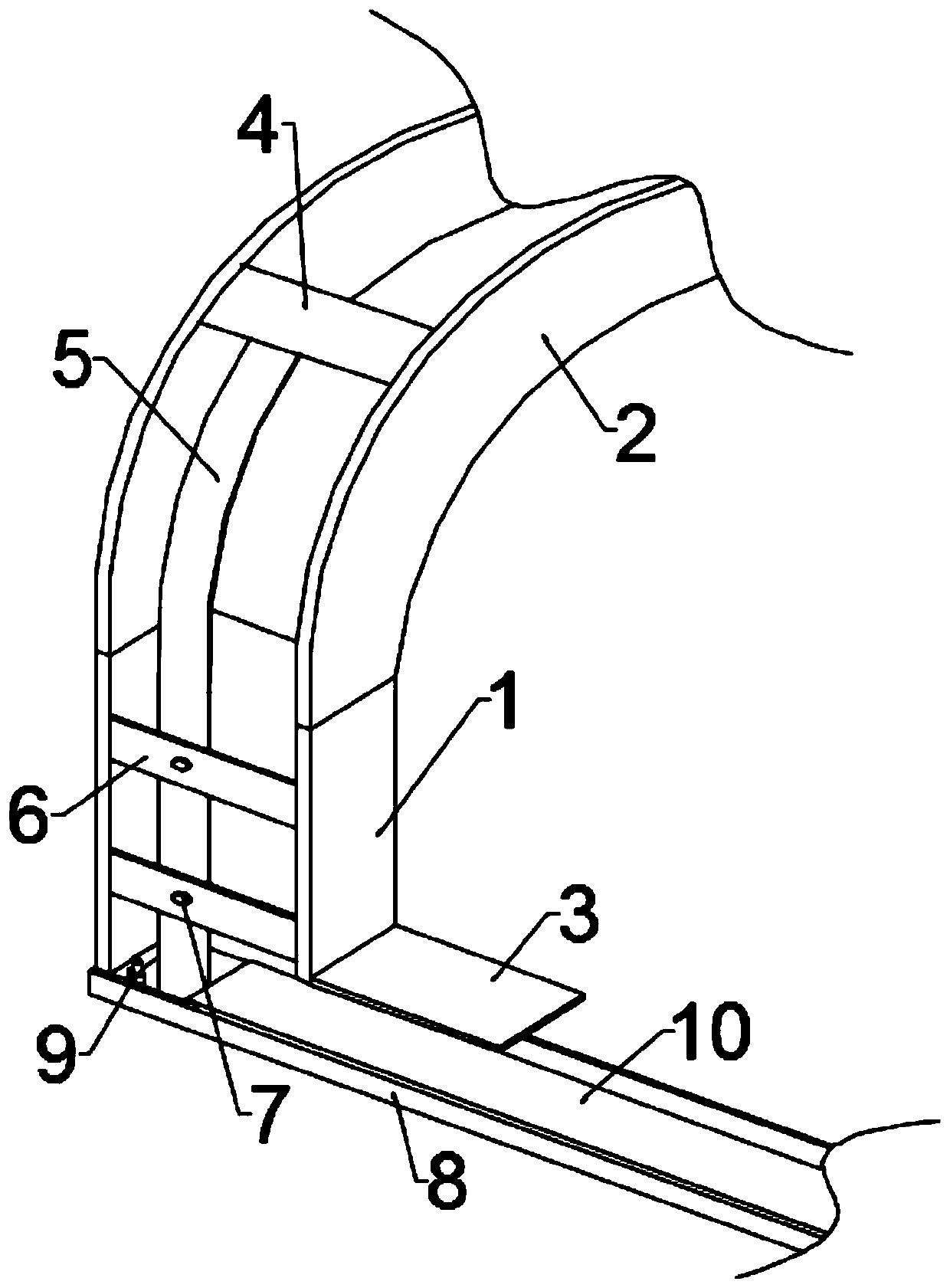

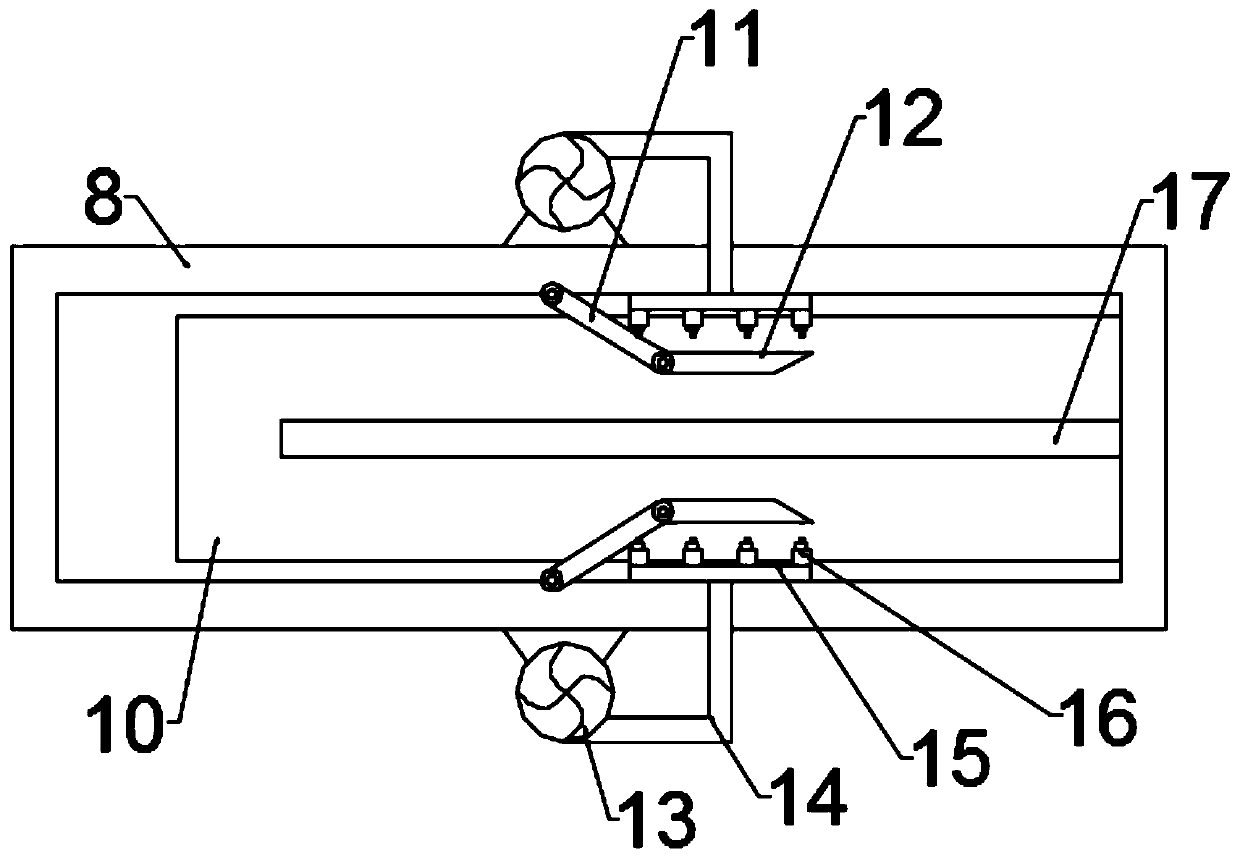

Device for quick hot melt combination of soap residue and new soap

The invention belongs to the technical field of daily life appliances, and particularly relates to a device for quick hot melt combination of a soap residue and a new soap. The new soap to be combinedis placed flat in the center of the upper table, clamped and fixed with the lower left push plate and the lower right push plate; a tweezers component is translated directly above the new soap; the soap head is placed flat on the molars, the soap head is clamped and fixed with the upper left push plate and the upper right push plate; hot wind is generated by a hot air component to blow and melt the soap head and the new soap surface; the tweezers component is translated outward; the soap residue is fallen on the new soap; the soap residue is pressed by the top board; and the soap residue is tightly attached to the new soap; cold wind is blew by the hot air component, and the soap residue and the new soap surface are solidified and bonded. In the invention, the soap residue and the new soap is quickly combined to save the soap and to make the operation convenient, which saves the space for storing the soap residue and saves time.

Owner:伯希和户外运动集团股份有限公司

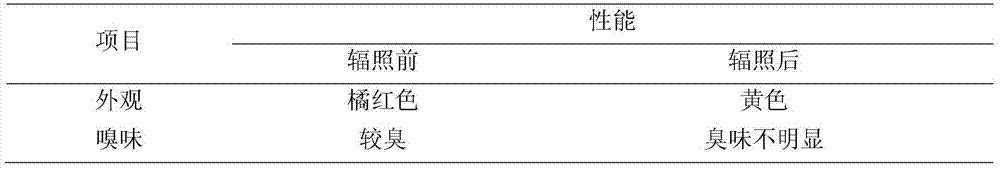

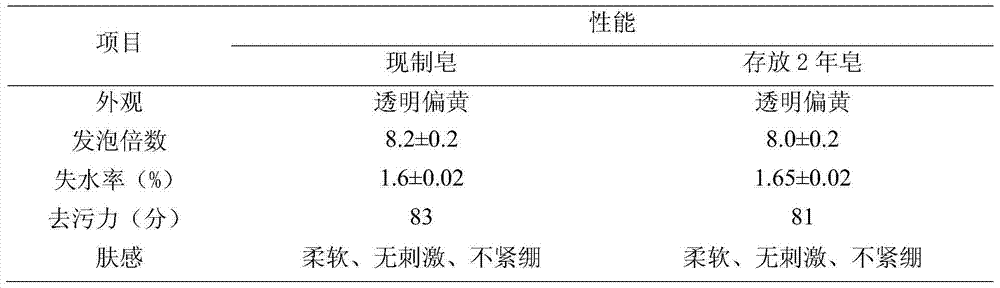

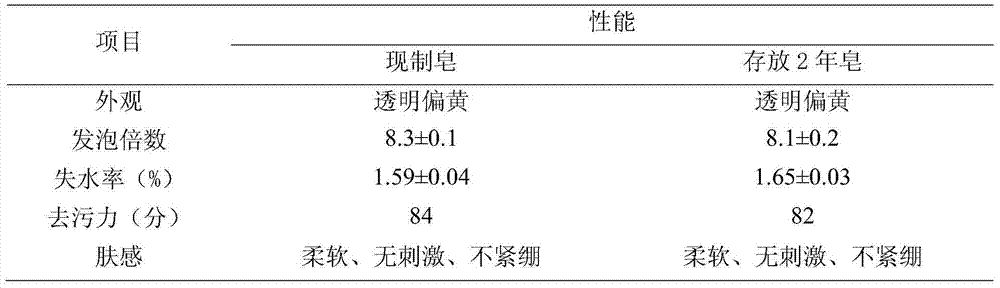

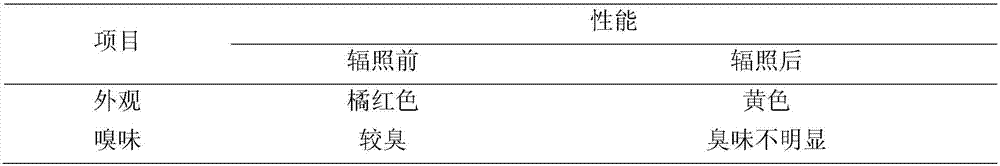

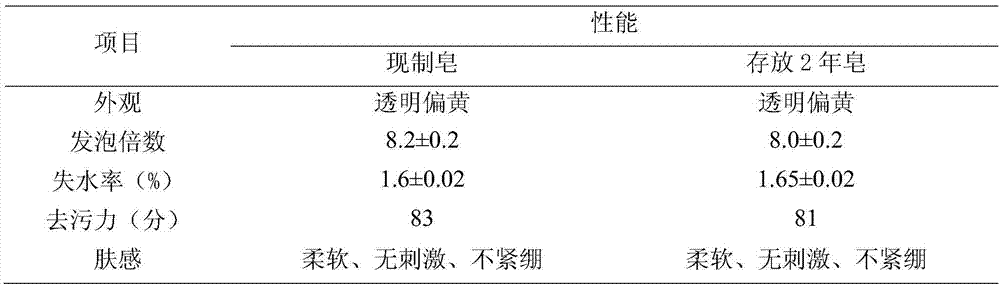

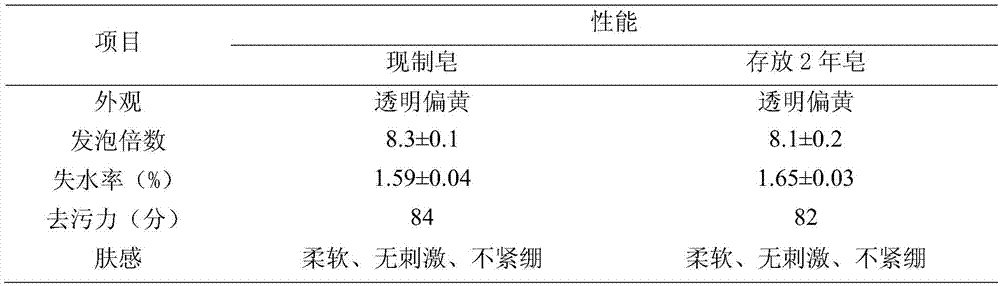

Method for preparing transparent soap by performing irradiation treatment on illegal cooking oil

InactiveCN104762146ARealize harmless resource utilizationUniform structureSoap detergents with organic compounding agentsSoap recoveryResource utilizationProtein structure

The invention relates to a method for preparing transparent soap by performing irradiation treatment on illegal cooking oil. The method comprises the following steps: firstly, performing centrifugal separation on the illegal cooking oil to remove impurities, and sealing by using a sealing bottle; uniformly irradiating the sealing bottle filled with the illegal cooking oil by using cobalt source rays for 5-10 minutes with the auxiliary dosage of 1-5KGy at the room temperature; filtering the irradiated illegal cooking oil, adding sodium hydroxide ethanol solution to be saponified to obtain soap paste; adding ethanol, crane sugar, distilled water and waste soap into the soap paste to be fully stirred until the soap paste is saponified; pouring the saponified soap paste into a mould to be cured and dried to obtain the transparent soap. According to the method, the illegal cooking oil is irradiated by using the cobalt rays, a DNA sequence, a protein structure and the like in bacteria tissue in the illegal cooking oil can be destroyed to cause the death of the bacteria; meanwhile, volatile odor substances in the illegal cooking oil can be modified; the prepared transparent soap has the characteristics of shallow color, asepsis, no odor and long expiration date; the soap body has a uniform crystal structure, and is high in transparency and high in foaming capability; moreover, the harmless resource utilization of the illegal cooking oil can be realized.

Owner:YULIN UNIV

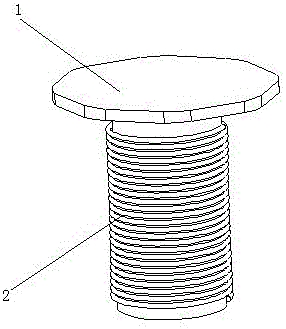

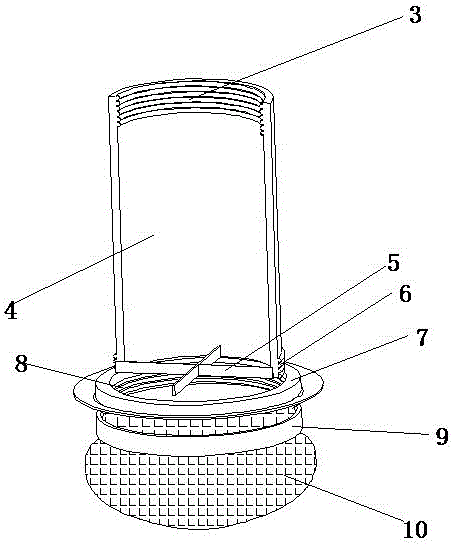

Recycling-type toilet soap piece container

The invention provides a recycling-type toilet soap piece container. The recycling-type toilet soap piece container comprises a pressing column, a tubular body and porous screen cloth, wherein the internal wall, close to the upper end face of the tubular body, of the tubular body has first internal threads, the external wall of the pressing column has first external threads adapted to the first internal threads, and the pressing column can extend into the tubular body from the upper end face of the tubular body; the porous screen cloth is located on the lower end face of the tubular body and completely covers the lower end face of the tubular body, a cross cutter blade is arranged in the tubular body close to the lower end face of the tubular body, and end parts of the cross cutter blade are fixed on the internal wall of the tubular body. The recycling-type toilet soap piece container has the beneficial effects that small pieces of toilet soap can be effectively integrated and reused, so that wasting is avoided; the recycling-type toilet soap piece container is energy-saving and environmentally friendly.

Owner:天津华都佳业科技有限公司

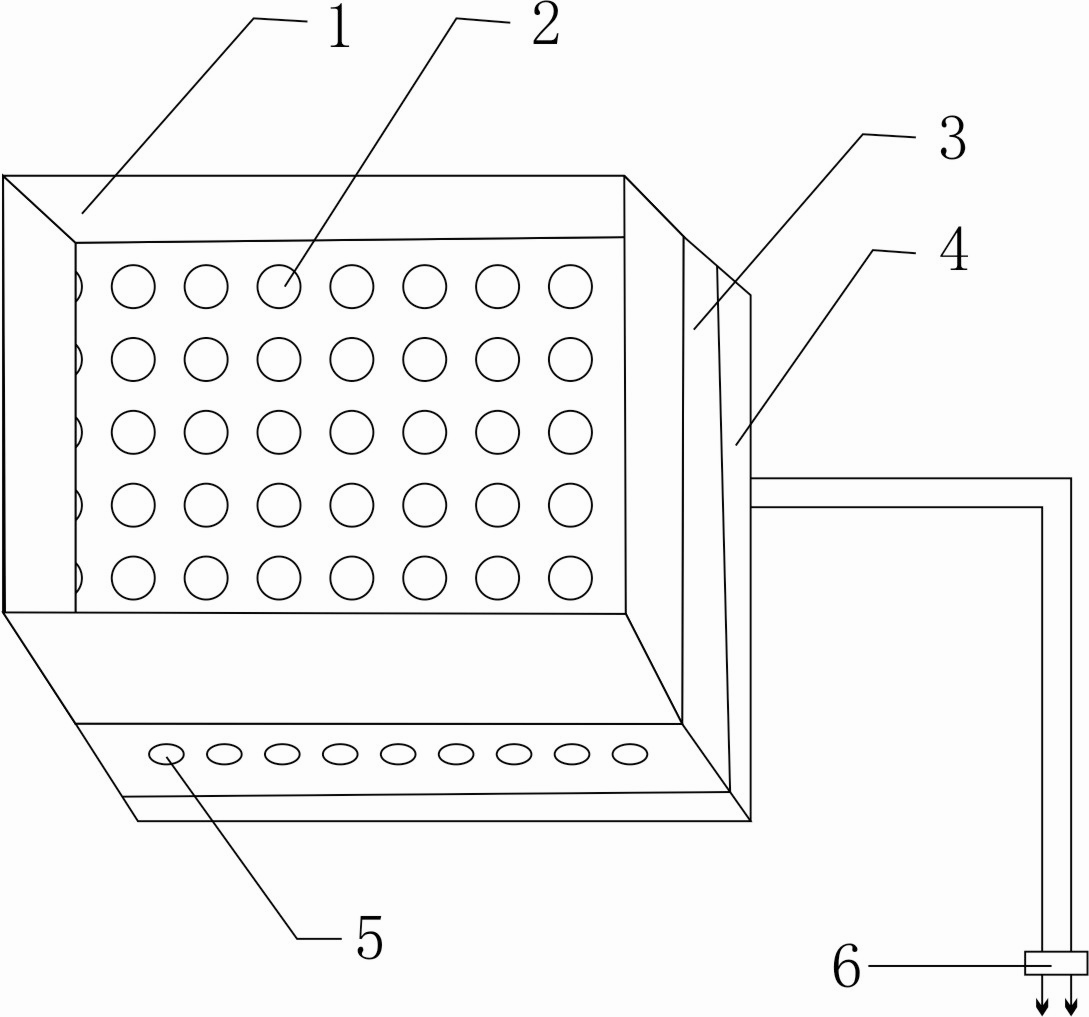

Feeding and conveying device of soap packaging machine

InactiveCN110902018AEasy to packControl distanceCooling soapShaping soapProcess engineeringWaste material

The invention relates to the technical field of soap processing, and particularly discloses a feeding and conveying device of a soap packaging machine. The feeding and conveying device comprises a soap collecting mechanism and a soap conveying mechanism, wherein the soap conveying mechanism is located right below the soap collecting mechanism, the soap collecting mechanism comprises a square groove and an arc groove which are connected, a clamping assembly is arranged on the square groove, the soap conveying mechanism comprises a conveying groove and a conveying belt installed in the conveyinggroove, a position clamping assembly is arranged in the conveying belt, and a cutting assembly and a waste collecting mechanism are arranged on two sides of the conveying groove. Different from an existing conveying device with a single function, the feeding and conveying device is particularly provided with the cutting assembly so that redundant soap can be cut, the soap with consistent size specification can be obtained, the soap connected together can be separated through the position clamping assembly to facilitate packaging, then, the waste collecting mechanism is used for collecting waste chips cut in the cutting process, and cleaning and sanitation of the feeding and conveying device are guaranteed.

Owner:安徽华谊日新科技有限公司

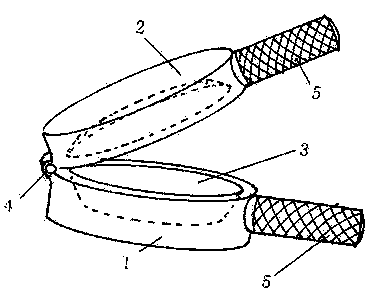

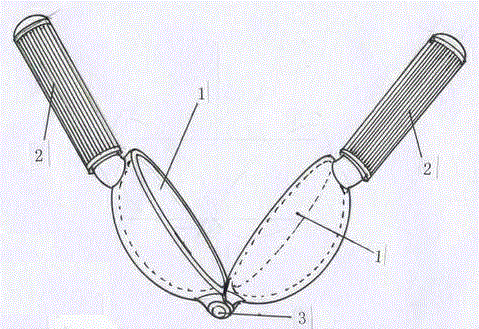

Broken soap former

InactiveCN103773640AFavorable forming and reuseReduce wasteShaping soapSoap recoveryMechanical engineeringSOAP

The invention provides a broken soap former. An extrusion seat and an extrusion plate are connected through a hinge shaft. Correspondingly matched grooves are formed in the opposite inner surfaces of the extrusion seat and the extrusion plate. A handle is connected to each of the extrusion seat and the extrusion plate. When the broken soap former is used, broken soap blocks can be placed in the correspondingly matched grooves, and the handles are held and closed to extrude the broken soap blocks into a whole, so that small broken soap blocks can be favorably formed for reutilization, and waste is reduced.

Owner:ZHUGELIANG MIDDLE SCHOOL

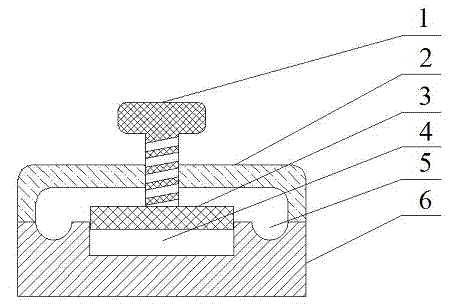

Device for recycling smashed and waste soap head

InactiveCN104711138ASuitable for useNo energy consumptionShaping soapSoap recoverySOAPEnergy consumption

The invention discloses a device for recycling a smashed and waste soap head. The wet soft soap is pressed, shaped, taken out, dried and then recycled, and the soap liquor spilled from the upper layer is utilized. The device is composed of a base in which a soap head recycling cavity and a discharge groove are arranged, and an upper cover which comprises a squeezing plug cock and a pressing piece. The specific using method comprises the steps of putting the smashed waste soap head into a soap head recycling cavity, adding proper water to soften, pressing and shaping the smashed waste soap head according to the squeezing effect of the squeezing plug cock on the pressing piece, spilling the soap liquor from the upper layer to the discharge groove through a pressing piece hole groove, pouring out to reuse, taking the soap block out and drying to obtain the product. The device is safe without energy consumption, simple to operate, low in cost and suitable for popularization.

Owner:闫皙

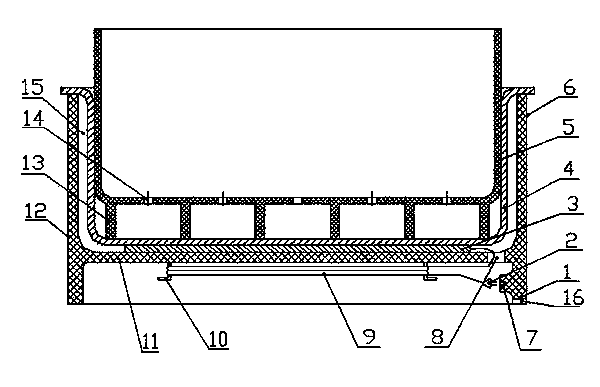

Reshaped soap box

InactiveCN103829857AAvoid softeningExtended service lifeShaping soapHolders and dispensersWater storageEngineering

The invention discloses a reshaped soap box and belongs to living goods. The reshaped soap box structurally comprises a soap box body and a water storage box. The bottom face of the soap box body is provided with a plurality of water penetrating holes, and the soap box body is arranged on the upper portion of the water storage box through a supporting device. The water storage box is arranged above a base which comprises a left baffle, a right baffle, a front baffle, a rear baffle and a middle partition layer. The middle partition layer divides the base into an upper cavity and a lower cavity, and a heating plate is arranged between the water storage box and the middle partition layer of the base. A wire is arranged on the heating plate, and the middle partition layer of the base is provided with a wire extending hole. The lower portion of the middle partition layer of the base is provided with a wire winder, and the wire is wound around the wire winder. The other end of the wire is provided with a plug, and a jack matched with the plug is formed in the inner side of the right baffle of the base. The bottom of the right baffle is provided with a notch. The reshaped soap box has the advantages that the problem of softening of soap is solved, residual soap tail blocks are used for being heated and melted through the heating plate and condensed to form new soap, and waste is reduced.

Owner:蒋佳音

Sticking utilization method of soap residue

InactiveCN103387897AAvoid troubleNo changes to the production processSoap recoveryMixing/kneading soapWhole bodyEngineering

The invention provides a sticking utilization method of a soap residue, relating to the field of utilization methods of articles for daily use. Sticky and slippery liquid generated by wetting soap is used for sticking the soap residue with a piece of new soap to form a whole body and be commonly used, so that the previous soap residue can be utilized completely. When the new soap residue is generated again, the operation is continually carried out by the same method so that the trouble of remaining the soap residues is solved. According to the sticking utilization method disclosed by the invention, the very simple method is adopted under conditions that a production process of the soap is not changed, structures and components of products are not changed, any tool is not used, any expenditure is not increased and the cost is not increased, so that the trouble that the soap residues cannot be used completely in daily lives of people is solved; the method is simple and feasible and can be mastered by everyone so that the method is applicable to being popularized in the public.

Owner:崔广荣

Broken soap molding device

InactiveCN104371867AReduce wasteAvoid pollutionShaping soapSoap recoveryEngineeringMechanical engineering

The invention provides a broken soap molding device, one sides of two correspondingly arranged button boxes are connected together by a hinge shaft to form a movable overall body capable of closely extruding soap for molding, and the other sides of the two button boxes are connected respectively with handles. When in use, multiple broken soap blocks which cannot be used are placed into the button boxes, the two button boxes are closely extruded for molding the broken soap into a block shape by the two handles, and the broken soap molding device is in favor of saving, utilizing waste and reducing waste.

Owner:ZAOYANG NO 2 EXPERIMENTAL ELEMENTARY SCHOOL

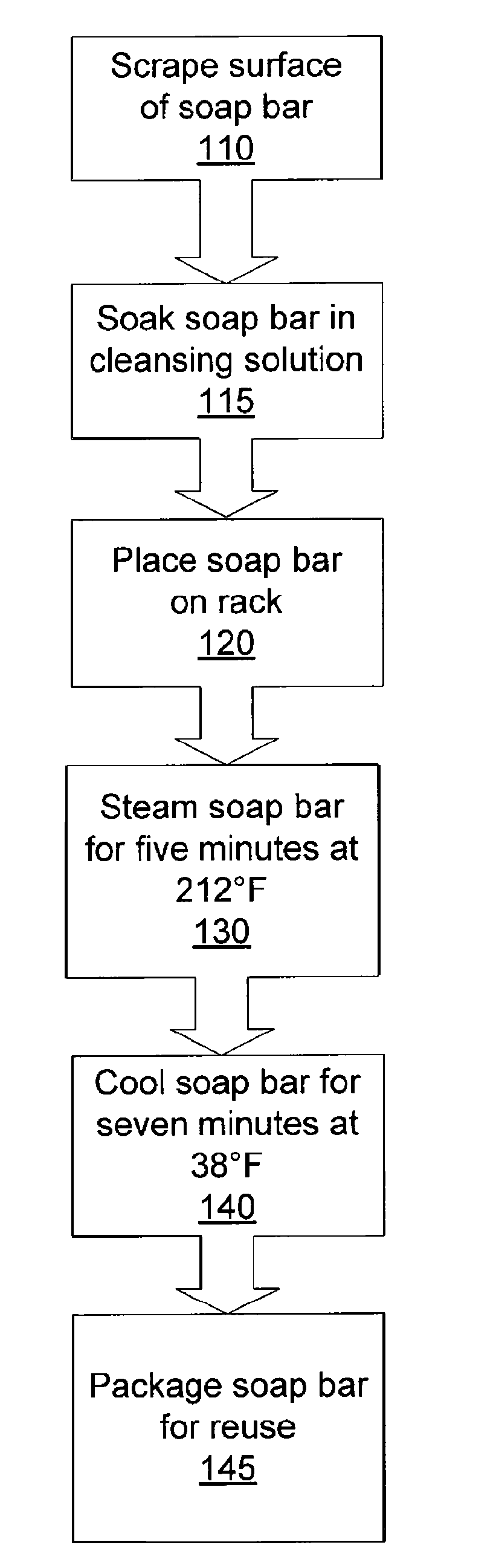

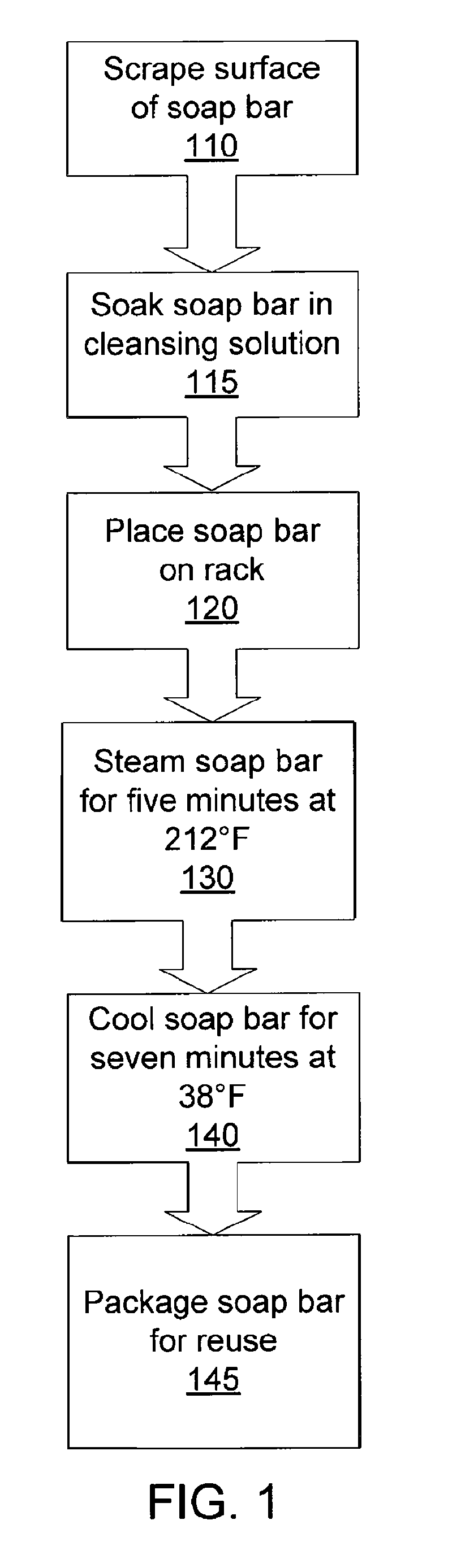

Soap recycling system and method

In one embodiment, a method for recycling soap includes scraping the surface of a soap bar using a bladed implement; soaking the soap bar in a cleansing solution including dimethyl benzylammonium chlorides monohydrate; placing the soap bar on a rack in a Rational Clima Plus Combi unit; placing a pan under the rack; steaming the soap bar using the Rational Clima Plus Combi unit for five minutes at 212° F.; cooling the soap bar in a refrigerator unit at 38° F. for at least seven minutes; and packaging the soap for reuse.

Owner:CLEAN THE WORLD FOUND

Fragmentary soap integrating device

The invention relates to a fragmentary soap integrating device, consisting of a left semi-cylinder, a right semi-cylinder, a hoop, a piston, a piston rod and a compression chamber, wherein the left semi-cylinder and the right semi-cylinder can be merged to be an entire body; the hoop is arranged outside the entire body and is used for fixing the entire body; the piston can move in the entire body freely and is connected with the piston rod; the compression chamber consists of the left semi-cylinder, the right semi-cylinder and the piston; fragmentary soap is placed in the compression chamber; and when the piston rod applies pressure to the piston, the fragmentary soap is compressed into an entire body. Due to adoption of the scheme of the invention, the fragmentary soap can be recycled and limited resources are saved.

Owner:任禹蒙

Soap recycling remodeling tool

InactiveCN106010846AAchieve reuseAchieve the purpose of reuseShaping soapSoap recoveryEngineeringMechanical engineering

A soap reuse remodeling appliance, which is composed of No. 1 switch, crushing area, No. 1 pressure applicator, No. 2 pressure applicator, accumulation area, forming area, No. 2 switch, No. 3 pressure applicator, pressure applying It is composed of device No. 4, water pipe, soap outlet and sheet cutter group. The appliance utilizes the pounding area to crush the waste small soap, and accumulates it in the accumulation area. When the soap reaches a certain amount, it is pressed into new soap in the forming area by presser No. 3 and presser No. 4. The appliance has Simple operation, saving soap, environmental protection and other advantages.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for preparing transparent soap by irradiating waste oil

InactiveCN104762146BRealize harmless resource utilizationUniform structureSoap detergents with organic compounding agentsSoap recoveryResource utilizationProtein structure

The invention relates to a method for preparing transparent soap by performing irradiation treatment on illegal cooking oil. The method comprises the following steps: firstly, performing centrifugal separation on the illegal cooking oil to remove impurities, and sealing by using a sealing bottle; uniformly irradiating the sealing bottle filled with the illegal cooking oil by using cobalt source rays for 5-10 minutes with the auxiliary dosage of 1-5KGy at the room temperature; filtering the irradiated illegal cooking oil, adding sodium hydroxide ethanol solution to be saponified to obtain soap paste; adding ethanol, crane sugar, distilled water and waste soap into the soap paste to be fully stirred until the soap paste is saponified; pouring the saponified soap paste into a mould to be cured and dried to obtain the transparent soap. According to the method, the illegal cooking oil is irradiated by using the cobalt rays, a DNA sequence, a protein structure and the like in bacteria tissue in the illegal cooking oil can be destroyed to cause the death of the bacteria; meanwhile, volatile odor substances in the illegal cooking oil can be modified; the prepared transparent soap has the characteristics of shallow color, asepsis, no odor and long expiration date; the soap body has a uniform crystal structure, and is high in transparency and high in foaming capability; moreover, the harmless resource utilization of the illegal cooking oil can be realized.

Owner:YULIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com