Method for recycling residual soap part with soap

A residual and soap head technology, applied in the field of structural design of fragrance (soap) soap for daily household products, can solve the problems of rising soap production cost, increase of garbage, inconvenient grip, etc., and achieve the effect of increasing artistry and increasing attractiveness

Inactive Publication Date: 2012-04-11

CHENGDU UNIVERSITY OF TECHNOLOGY

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Many people have such an experience that when the scented (soap) soap is used up to the last bit of residual scented (soap) soap, it becomes very inconvenient to hold and pinch, and even slips from the hand, making it impossible to continue to use it. If you throw it away It's a waste not to use it, but in the end it has to be wasted

People often use one of the simplest methods, which is to dip the residual scented (soap) soap head in some water and stick it on a new piece of scented (soap) soap to continue using, but in fact it can't stick firmly, and generally it will fall off as soon as it is used. Falling

[0003] In order to use the residual fragrance (soap) soap head, people are thinking about various methods. For example, the invention patent specification with the publication number CN1277990 discloses a kind of sandwich soap, and the sandwich soap is arranged at the center of the soap. A sandwich core has a certain volume and is easy to hold. It should be said that this technology has certain value for the use of residual fragrance (soap) soap, but it also has many shortcomings. Disadvantage 1: The production process is complicated and the production efficiency is low. Low; Disadvantage 2: The sandwich itself needs to consume certain materials, and the sandwich can only be thrown away in the end, which increases garbage and may even cause environmental pollution; Disadvantage 3: Due to the existence of Disadvantage 1 and Disadvantage 2, it may lead to the production of soap The cost rises; Disadvantage 4: The residual soap head that is finally attached to the core can hardly be fully utilized

For another example, the invention patent specification with the publication number CN101210216A discloses a soap recovery device, which can gather the residual soap heads that are used many times at ordinary times and remake a bar of soap. It should be said that this technology can also be used to a certain extent It solves the problem of soap waste above all, but it also has very obvious disadvantages. Disadvantage 1: the products of this technology have certain complexity and high cost, but the utilization rate is very low, which is very likely to cause consumers to buy the products of this technology. Far beyond the value of the saved soap, thus losing the value of its existence; Disadvantage 2: It is not convenient to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

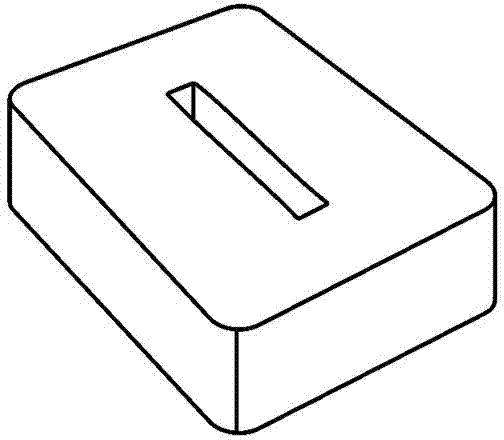

Embodiment 1

[0018] Opening position --- side;

[0019] The cross-sectional shape of the hole---rectangular;

[0020] Number of holes---1.

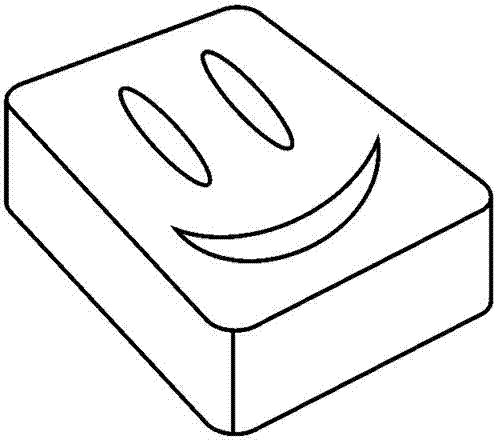

Embodiment 2

[0022] Opening position --- side;

[0023] The cross-sectional shape of the hole --- ellipse;

[0024] Number of holes---1.

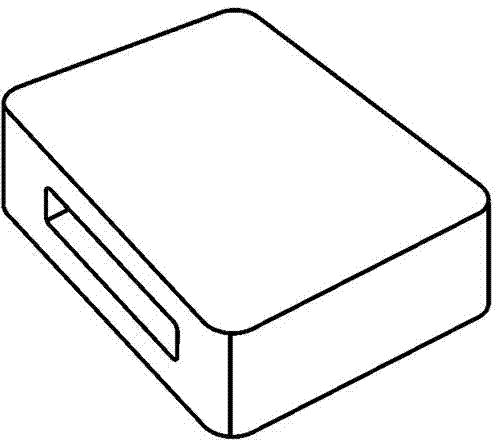

Embodiment 3

[0026] Opening position --- front;

[0027] The cross-sectional shape of the hole---rectangular;

[0028] Number of holes---1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for recycling residual soap part with soap; the method comprises: disposing several holes vertical to the plane in the front side or side face of the soap, wherein the cross section of the hole is the graph having a length and width ratio more than one, namely a prolate hole. The invention has the following beneficial effect: because the prolate hole in the front side or side face of the soap can tightly hold the used residual soap part, the vast majority of the surface of the residual soap part is contacted with the new soap, then the residual soap part is integrated with the new soap as one, which does not drop when using and is very convenient; no additional accessory is needed to complete the operation. Simultaneously, if a beautiful hole shape is used, like cartoon shape, the artistic quality of the soap can be largely increased, so as to increase the attractiveness to consumer.

Description

technical field [0001] The invention relates to a structural design method of daily household product fragrance (soap) soap. Background technique [0002] Many people have such an experience that when the scented (soap) soap is used up to the last bit of residual scented (soap) soap, it becomes very inconvenient to hold and pinch, and even slips from the hand, making it impossible to continue to use it. If you throw it away It is a waste not to use it, but in the end it has to be wasted. People often use one of the simplest methods, which is to dip the residual scented (soap) soap head in some water and stick it on a new piece of scented (soap) soap to continue using, but in fact it can't stick firmly, and generally it will fall off as soon as it is used. Falling. [0003] In order to use the residual fragrance (soap) soap head, people are thinking about various methods. For example, the invention patent specification with the publication number CN1277990 discloses a kind ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D13/00C11D13/30C11D17/00

Inventor 邹俐均郑仁华

Owner CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com