Photo chromic ceramic glaze and preparation method thereof

A photochromic and ceramic glaze technology, applied in the field of ceramics, can solve problems such as unsatisfactory effects, limited application range, and lack of multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

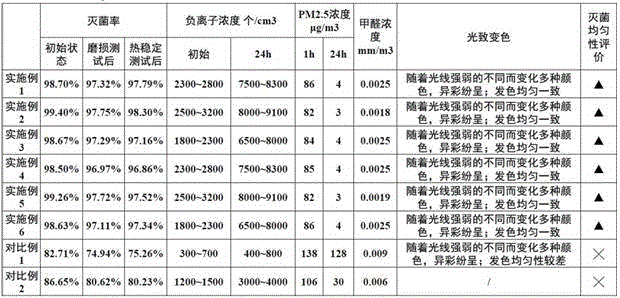

Examples

Embodiment 1

[0033] A photochromic ceramic glaze and a preparation method thereof, the preparation method comprising the steps of:

[0034] Step A, preparing low-temperature frit: by mass percentage, 10% potassium nitrate, 7% quartz, 12% potassium feldspar, 5% albite feldspar, 10% spodumene, 30% boric acid, 5% barium carbonate, 8% fluorite, 3% kaolin, 2% sodium fluoride and 8% functional agent are mixed evenly, sieved, ground and mixed, then calcined at 1250-1300°C and then rapidly quenched to obtain a melting temperature of 650-800°C Low temperature frit;

[0035] Step B, preparing photochromic glaze slurry: by mass percentage, 30% low-temperature frit, 30% potassium feldspar, 10% quartz, 5% calcite, 8% talc, 4% calcium phosphate, 5% kaolin, 8 % Calcined soil is mixed to obtain mixed powder, add functional agent to the mixed powder and mix evenly, finely grind to 300~350 mesh, then add water to obtain glaze slurry and adjust the specific gravity of glaze slurry to 1.6~1.7g / cm 3 , to obt...

Embodiment 2

[0048] A photochromic ceramic glaze and a preparation method thereof, the preparation method comprising the steps of:

[0049] Step A, preparing low-temperature frit: by mass percentage, 8% potassium nitrate, 8% quartz, 10% potassium feldspar, 6% albite feldspar, 11% spodumene, 35% boric acid, 4% barium carbonate, 7% fluorite, 2% kaolin, 4% sodium fluoride and 5% functional agent are mixed evenly, sieved, ground and mixed, then calcined at 1250-1300°C and then rapidly quenched to obtain a melting temperature of 650-800°C Low temperature frit;

[0050] Step B, preparing photochromic glaze slurry: by mass percentage, 25% low-temperature frit, 35% potassium feldspar, 15% quartz, 3% calcite, 5% talc, 4% calcium phosphate, 3% kaolin, 10 % Calcined soil is mixed to obtain mixed powder, add functional agent to the mixed powder and mix evenly, finely grind to 300~350 mesh, then add water to obtain glaze slurry and adjust the specific gravity of glaze slurry to 1.6~1.7g / cm 3 , to obt...

Embodiment 3

[0063] A photochromic ceramic glaze and a preparation method thereof, the preparation method comprising the steps of:

[0064] Step A, preparing low-temperature frit: by mass percentage, 6% potassium nitrate, 10% quartz, 15% potassium feldspar, 8% albite feldspar, 11% spodumene, 33% boric acid, 3% barium carbonate, 5% fluorite, 1% kaolin, 5% sodium fluoride and 3% functional agent are mixed evenly, after sieving, grinding and mixing, they are calcined at 1250-1300°C and then rapidly quenched to obtain a melting temperature of 650-800°C. Low temperature frit;

[0065] Step B, preparing photochromic glaze slurry: by mass percentage, 20% low-temperature frit, 40% potassium feldspar, 20% quartz, 1% calcite, 3% talc, 5% calcium phosphate, 3% kaolin, 8 % Calcined soil is mixed to obtain mixed powder, add functional agent to the mixed powder and mix evenly, finely grind to 300~350 mesh, then add water to obtain glaze slurry and adjust the specific gravity of glaze slurry to 1.6~1.7g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com