Feeding and conveying device of soap packaging machine

A conveying device and packaging machine technology, applied in packaging, cooling soap, forming soap, etc., can solve the problems that the conveyor belt is not easy to separate, the quality of packaging soap is uneven, and achieve the effect of convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

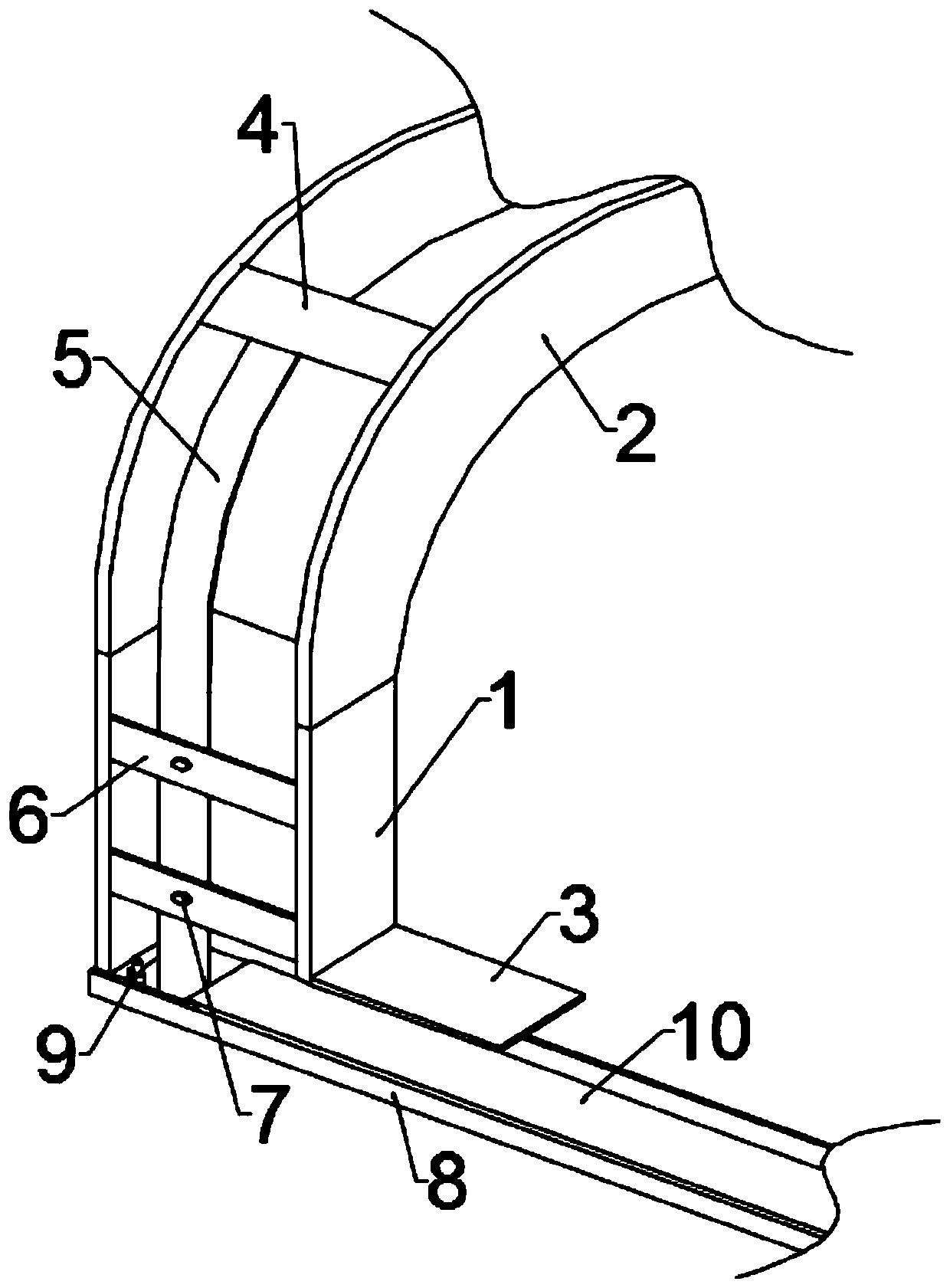

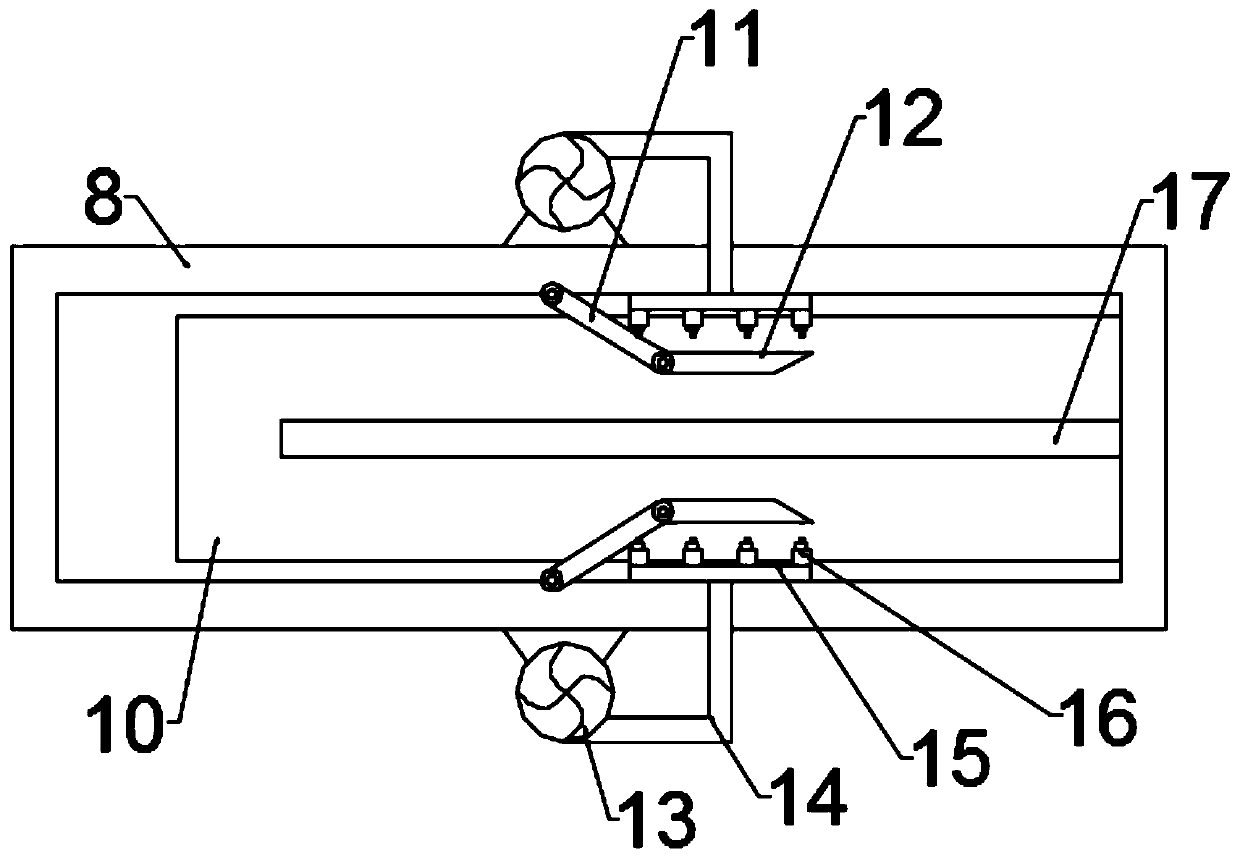

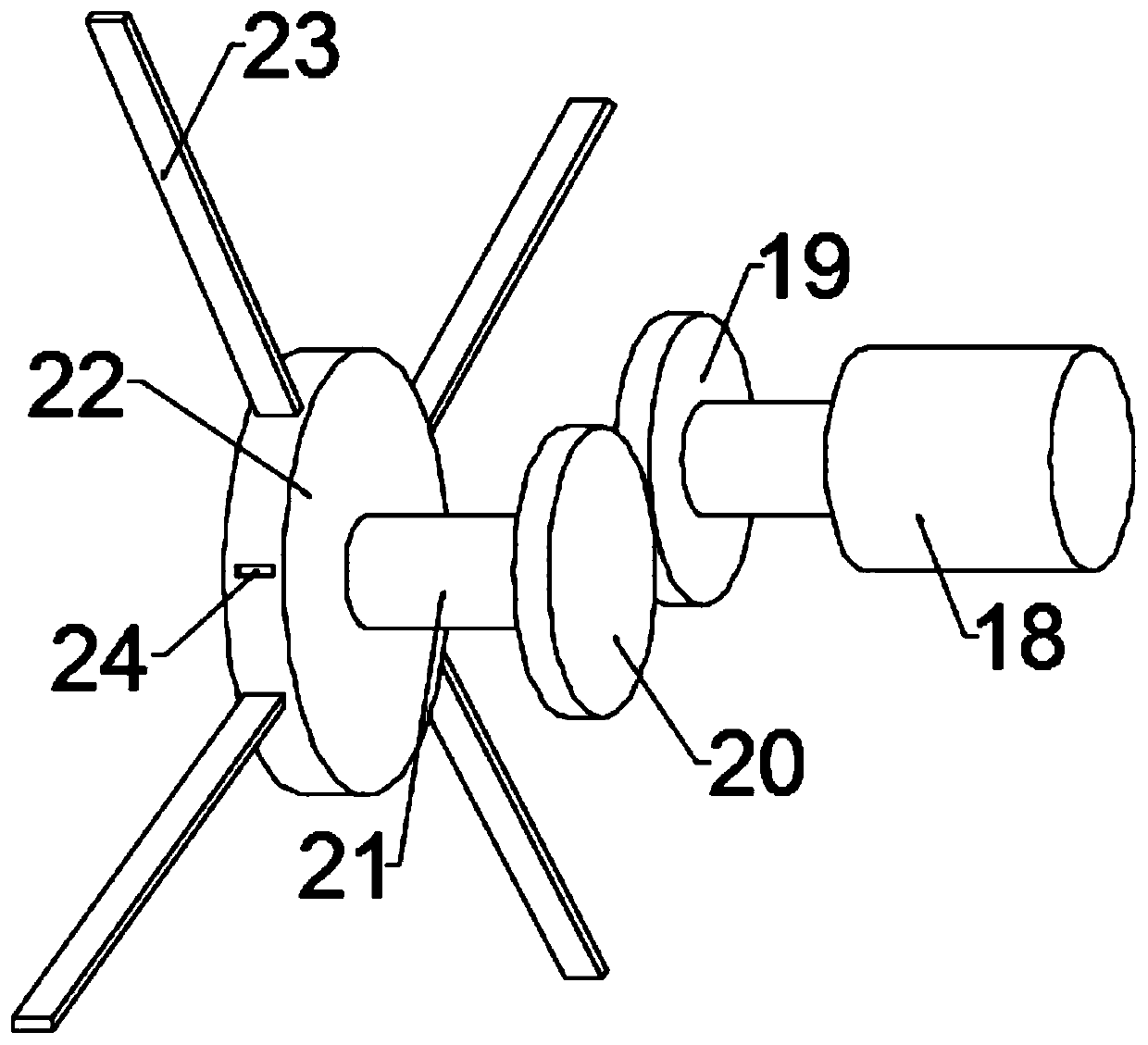

[0039] see Figure 1~2 , in an embodiment of the present invention, a kind of soap packaging machine feeding and conveying device comprises a soap collecting mechanism and a soap conveying mechanism, and the soap conveying mechanism is located directly below the soap collecting mechanism; the soap collecting mechanism includes a connected Square groove 1 and arc groove 2, described square groove 1 is provided with clamping assembly; Described soap delivery mechanism comprises transmission groove 8 and the transmission belt 10 that is installed in described transmission groove 8, in the transmission belt 10 A clamping component is provided; a cutting component and a waste collection mechanism are provided on both sides of the transmission slot 8 .

[0040] The feeding and conveying device of the soap packaging machine is different from the existing conveying device with a single function. It is specially equipped with a cutting assembly, which can cut excess soap to obtain fert...

Embodiment 2

[0056] see Figure 6 , in the embodiment of the present invention, a water tank 31 is provided at the bottom of the collection box 30, a heating wire 32 is installed inside the water tank 31, and a box cover 33 is installed at the top of the collection box 30, and the box cover 33 The lower surface of the electric push rod 34 is provided with a pressing plate 35 fixed on the bottom end of the electric push rod 34 .

[0057] After soap is collected in the inside of collecting box 30, open heating wire 32, the water in the tank 31 is heated, the soap in collecting box 30 inside softens after preheating, and case lid 33 is covered on the top of collecting box 30 again, starts electric motor The push rod 34, the electric push rod 34 controls the pressure plate 35 to push down until it is pressed on the soap, which is beneficial to repress the crumb-like soap into an available block, then close the heating wire 32, the water gradually cools, and the collection box 30 The soap in i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com