Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

487results about "Machine composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

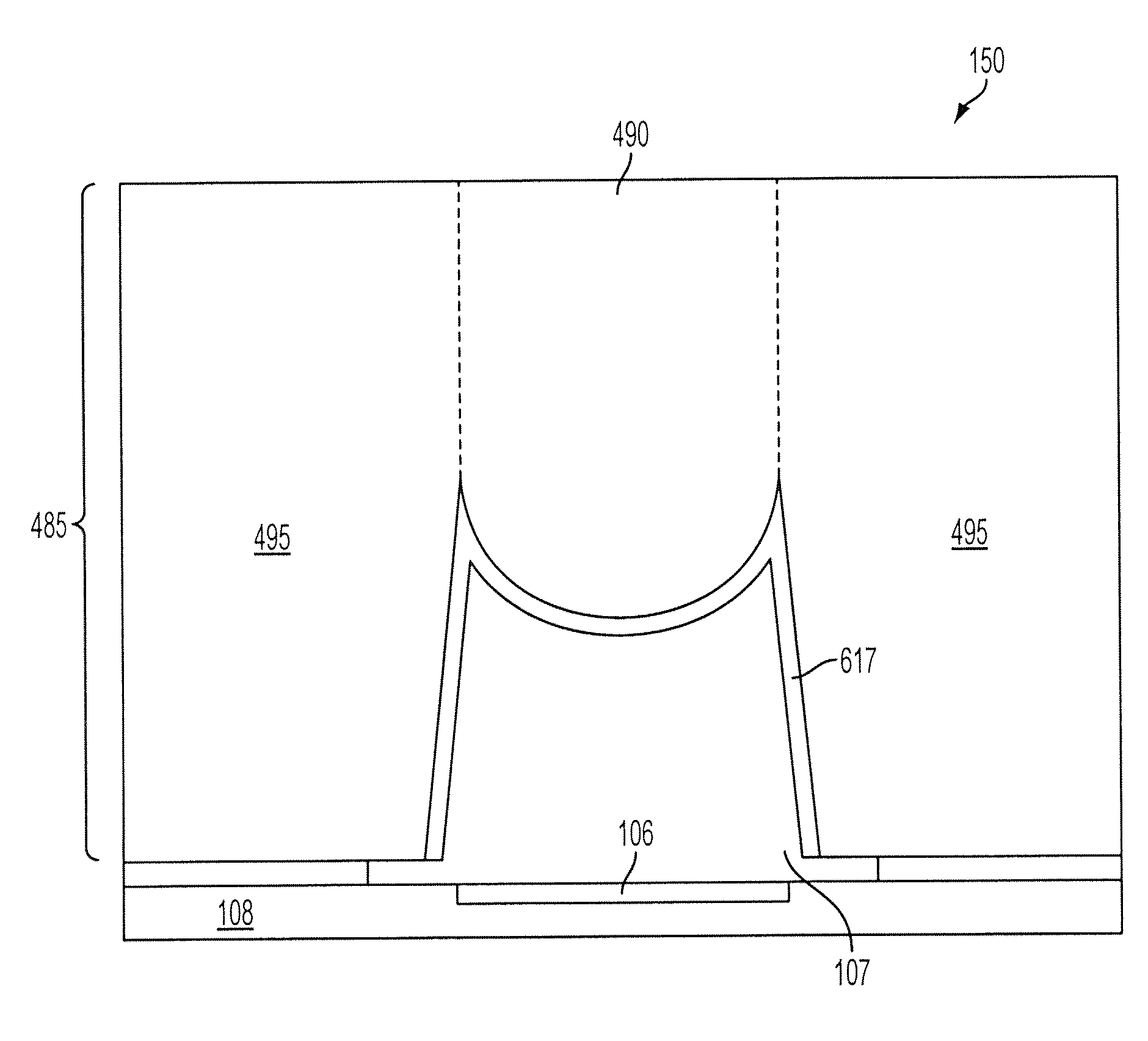

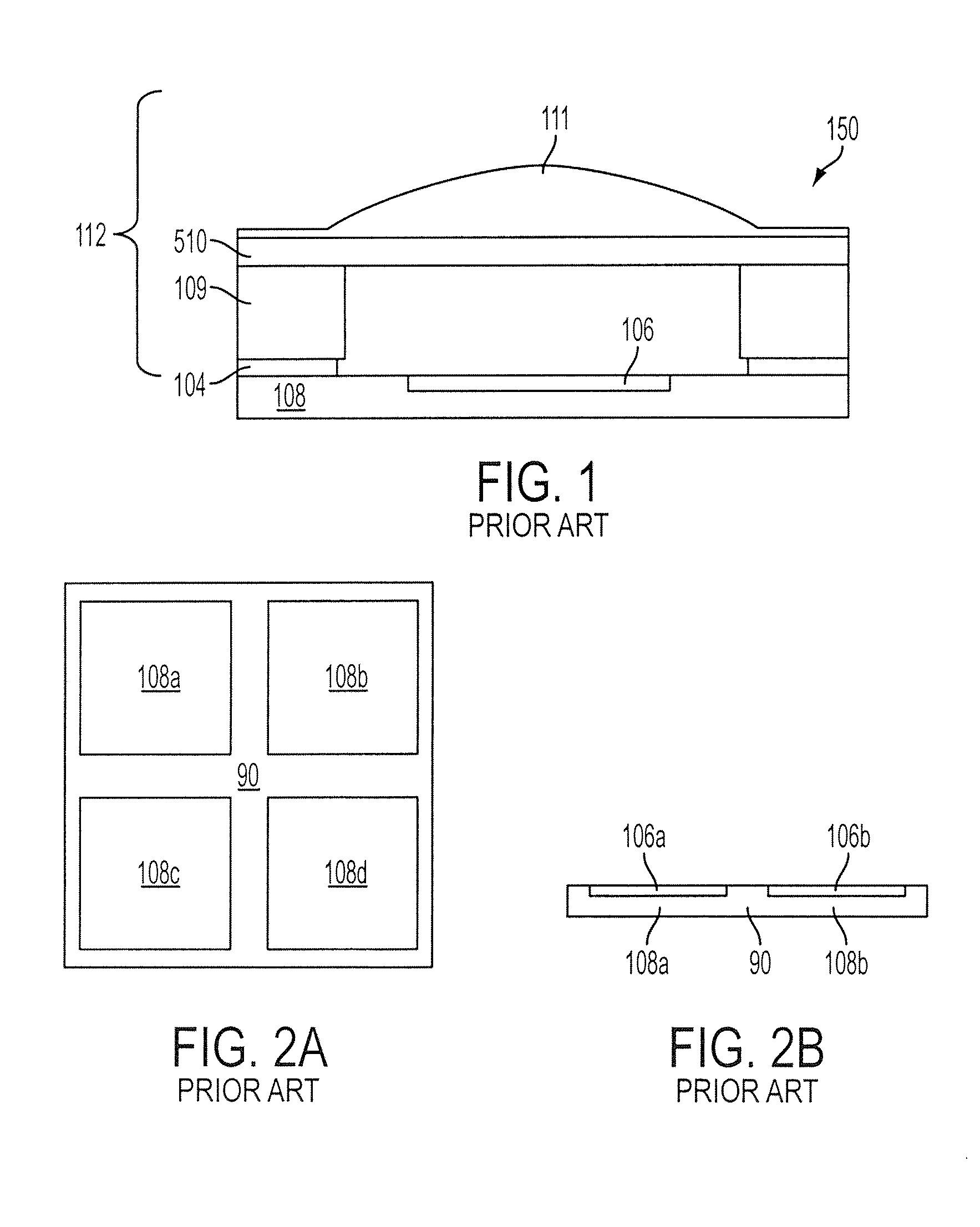

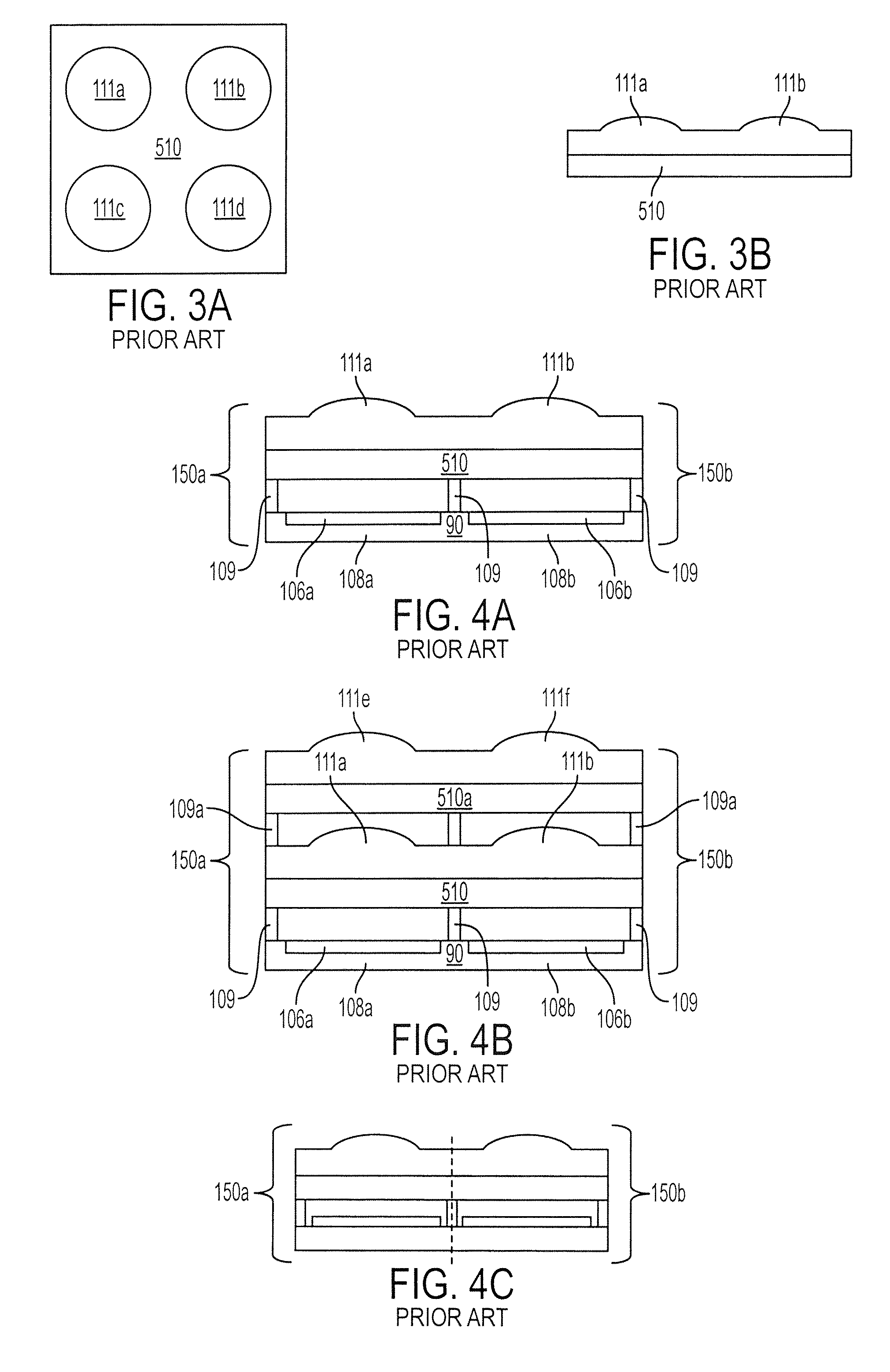

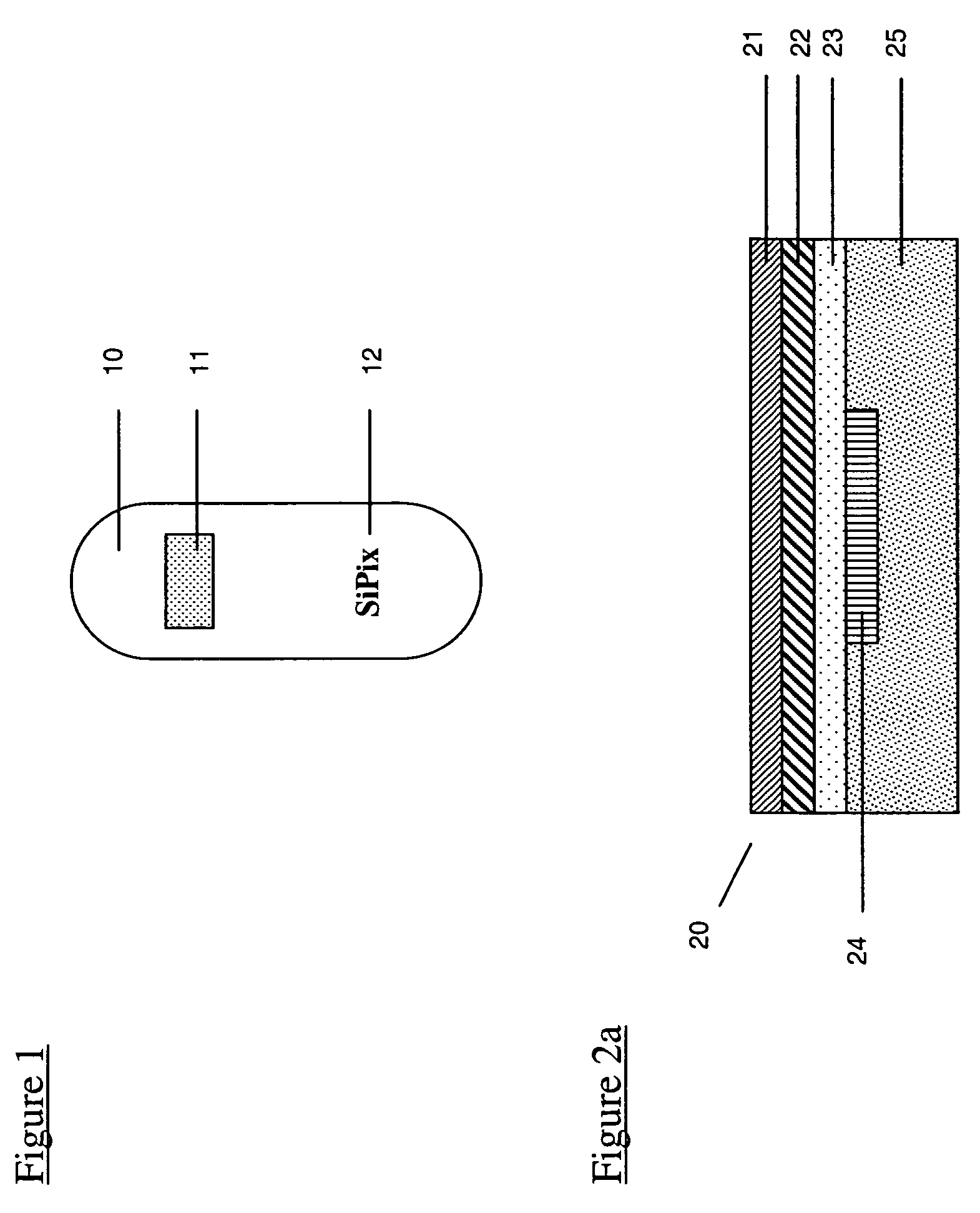

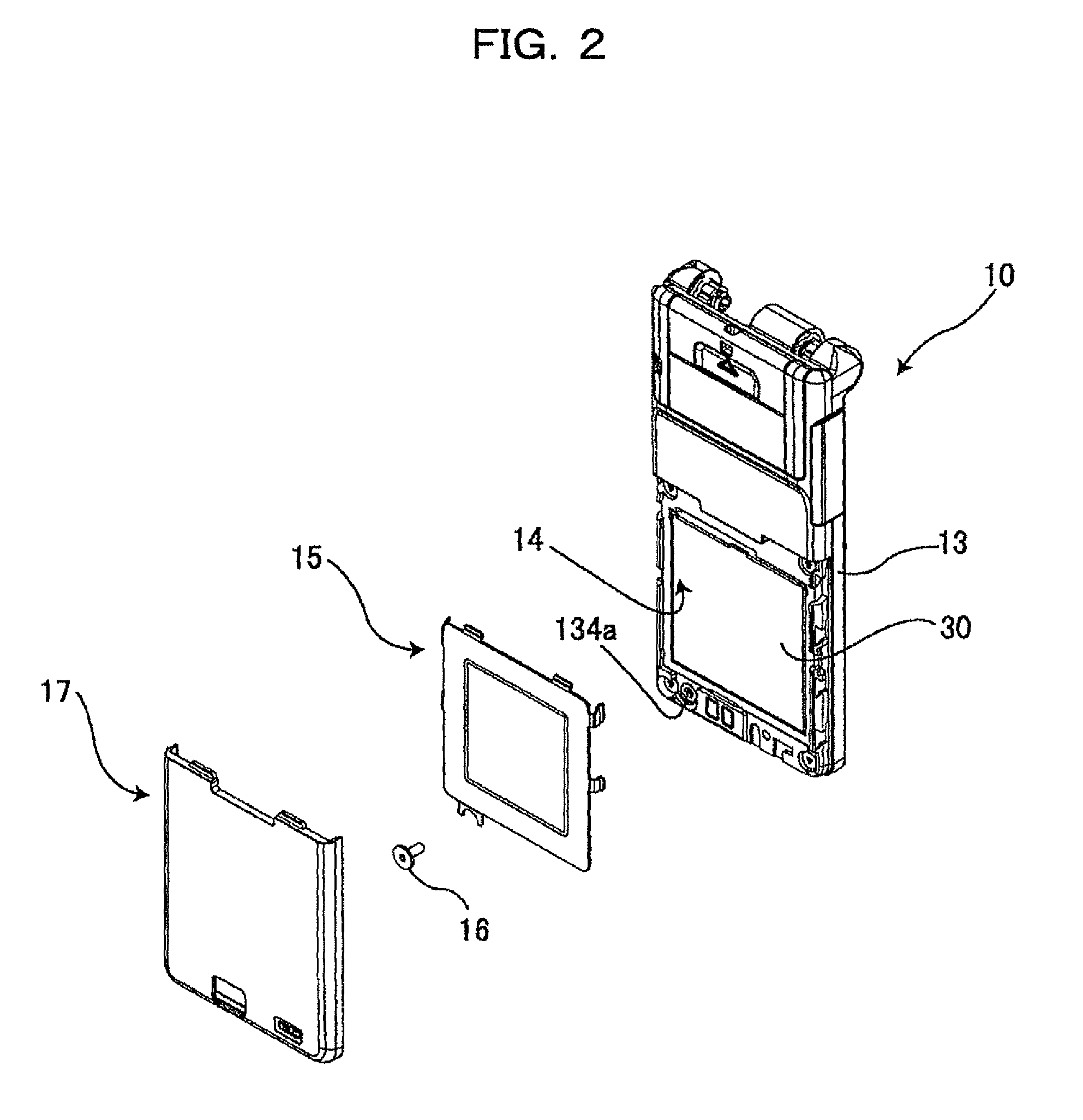

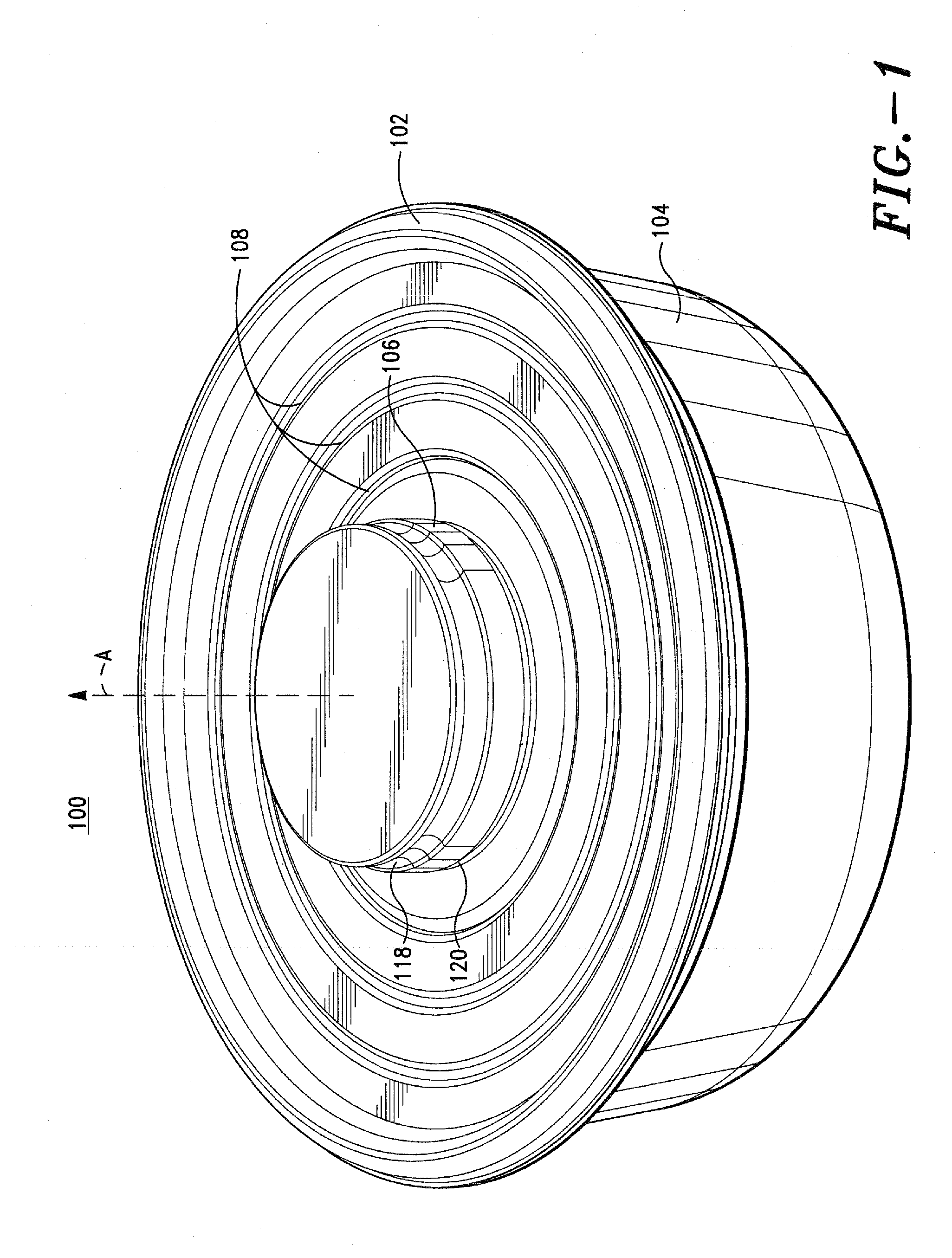

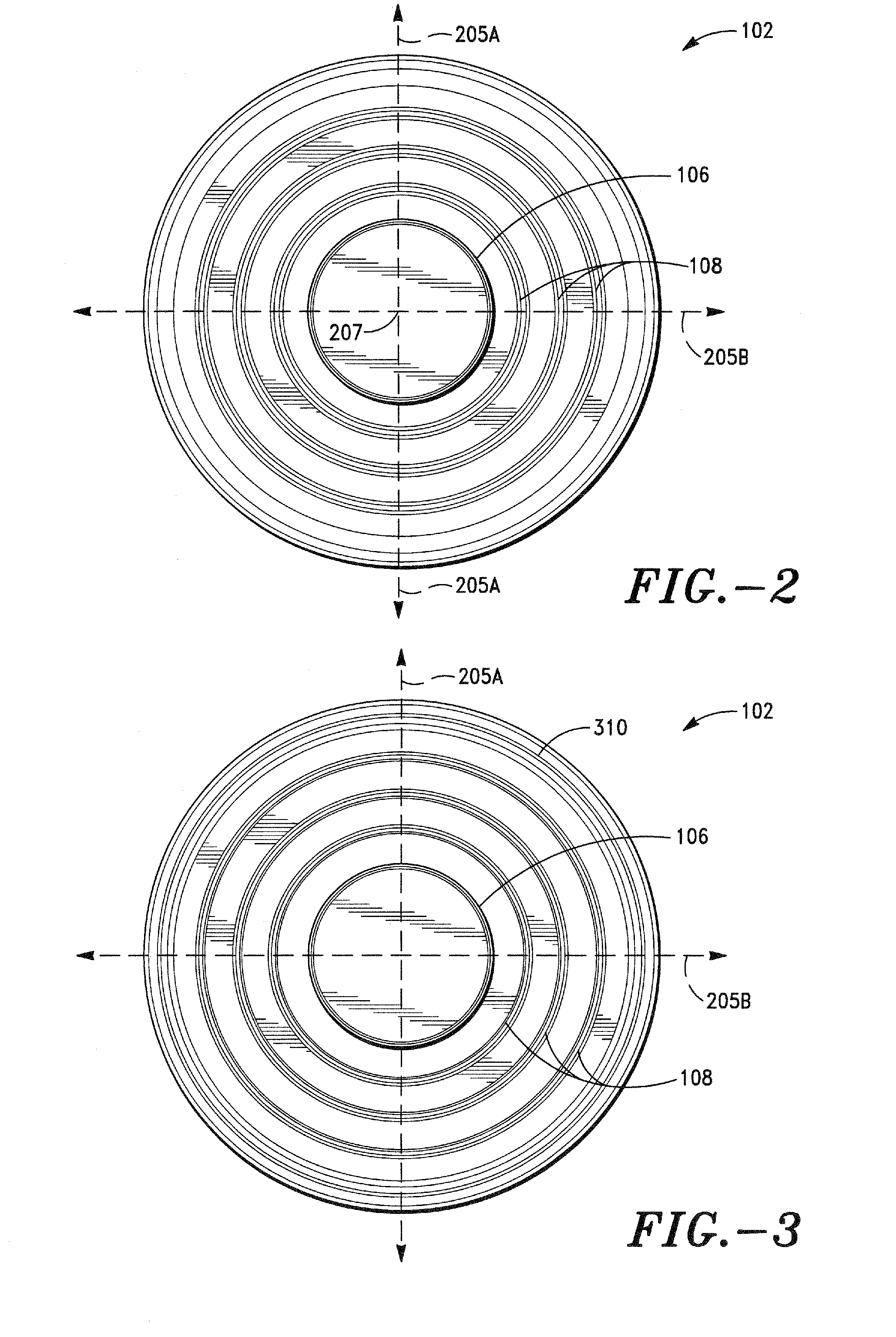

Method and apparatus providing combined spacer and optical lens element

ActiveUS20100244165A1Solid-state devicesSemiconductor/solid-state device manufacturingComputer moduleEngineering

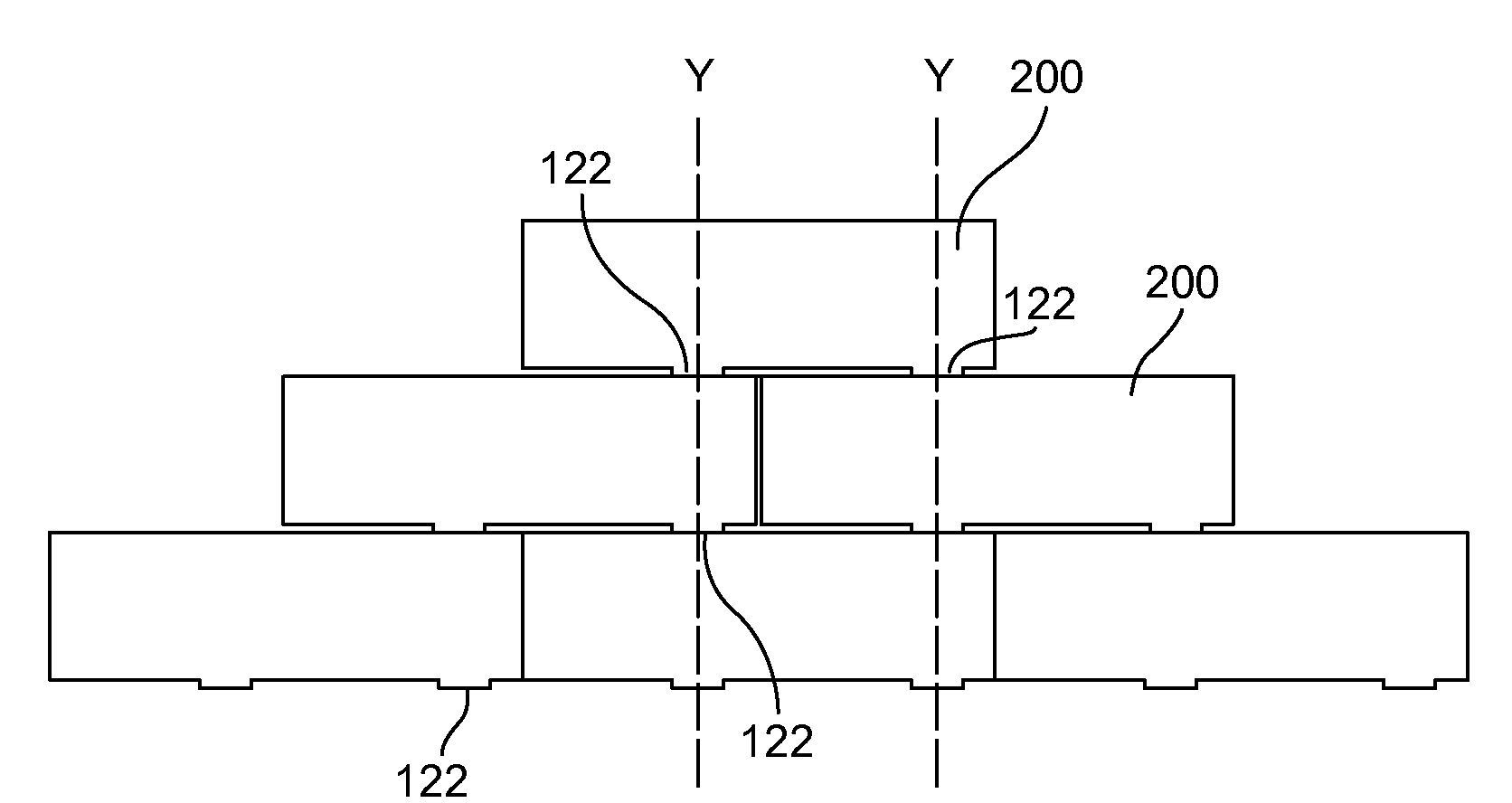

A method and apparatus used for forming a lens and spacer combination, and imager module employing the spacer and lens combination. The apparatus includes a mold having a base, spacer section, and mold feature. The method includes using the mold with a blank to create a spacer that includes an integral lens. The spacer and lens combination and imager modules can be formed on a wafer level.

Owner:MICRON TECH INC

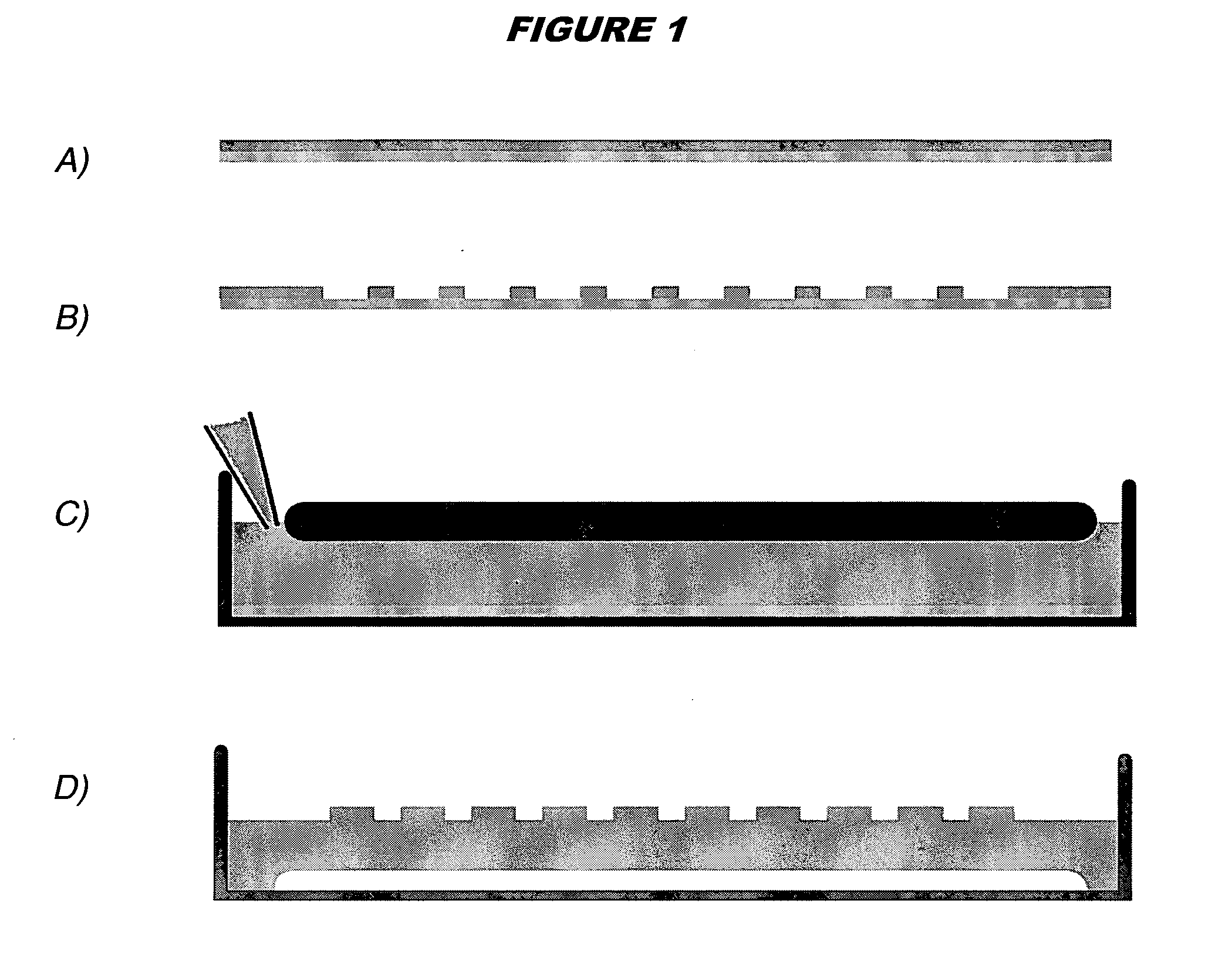

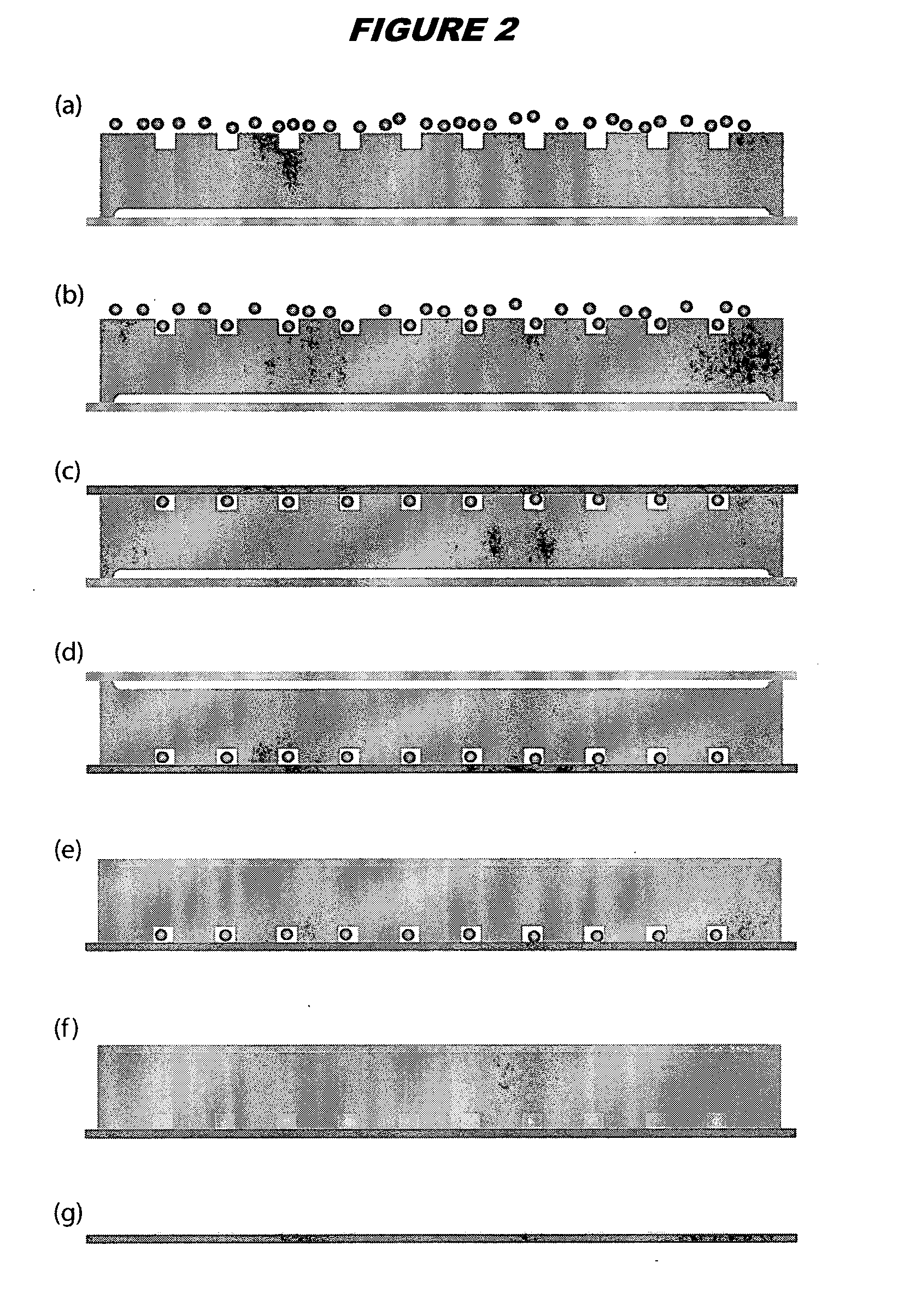

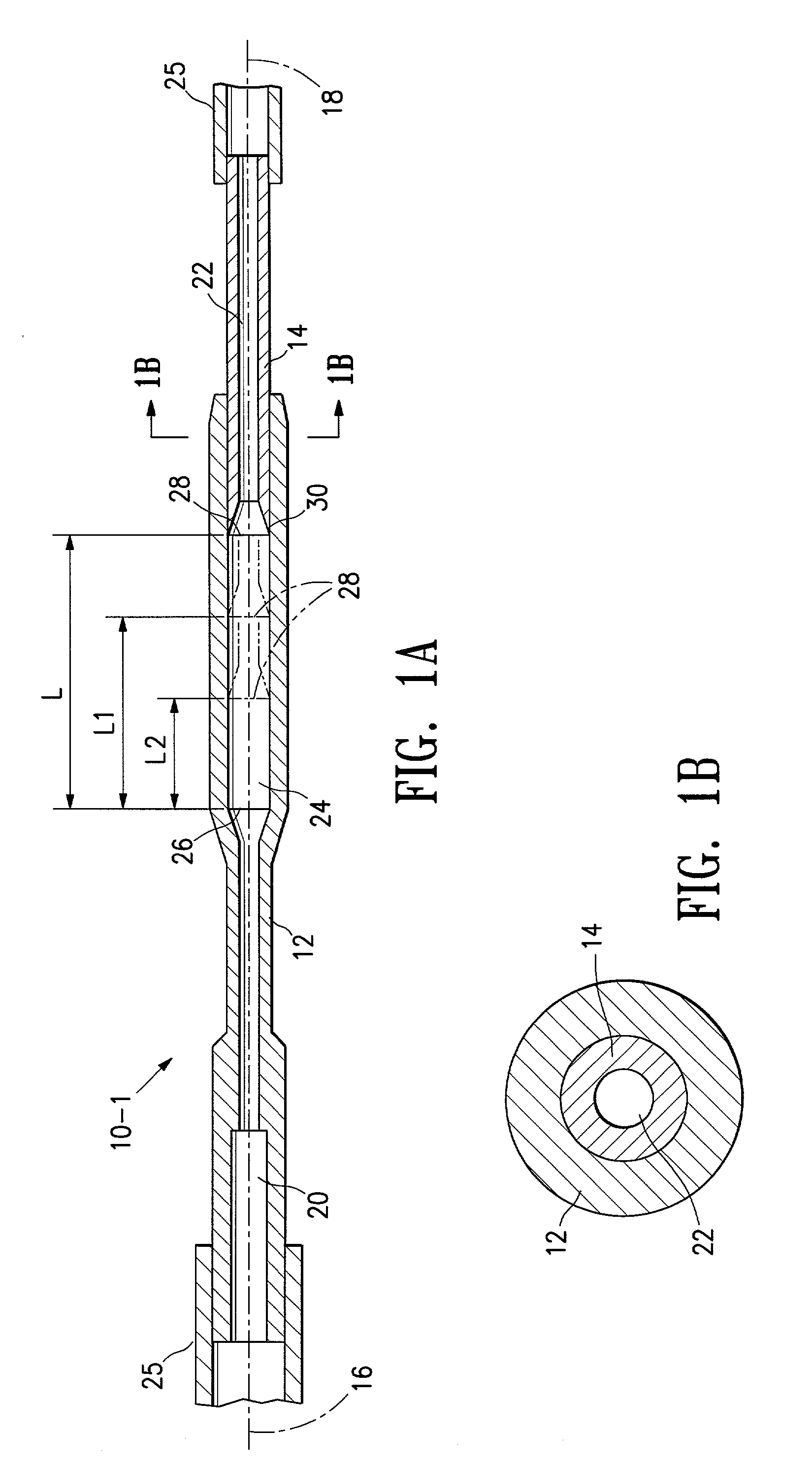

Picowell capture devices for analysing single cells or other particles

InactiveUS20120156675A1Easy to adaptCompared rapidly and convenientlyBioreactor/fermenter combinationsBiological substance pretreatmentsIndividual analysisBiopolymer

Owner:OXFORD GENE TECH IP

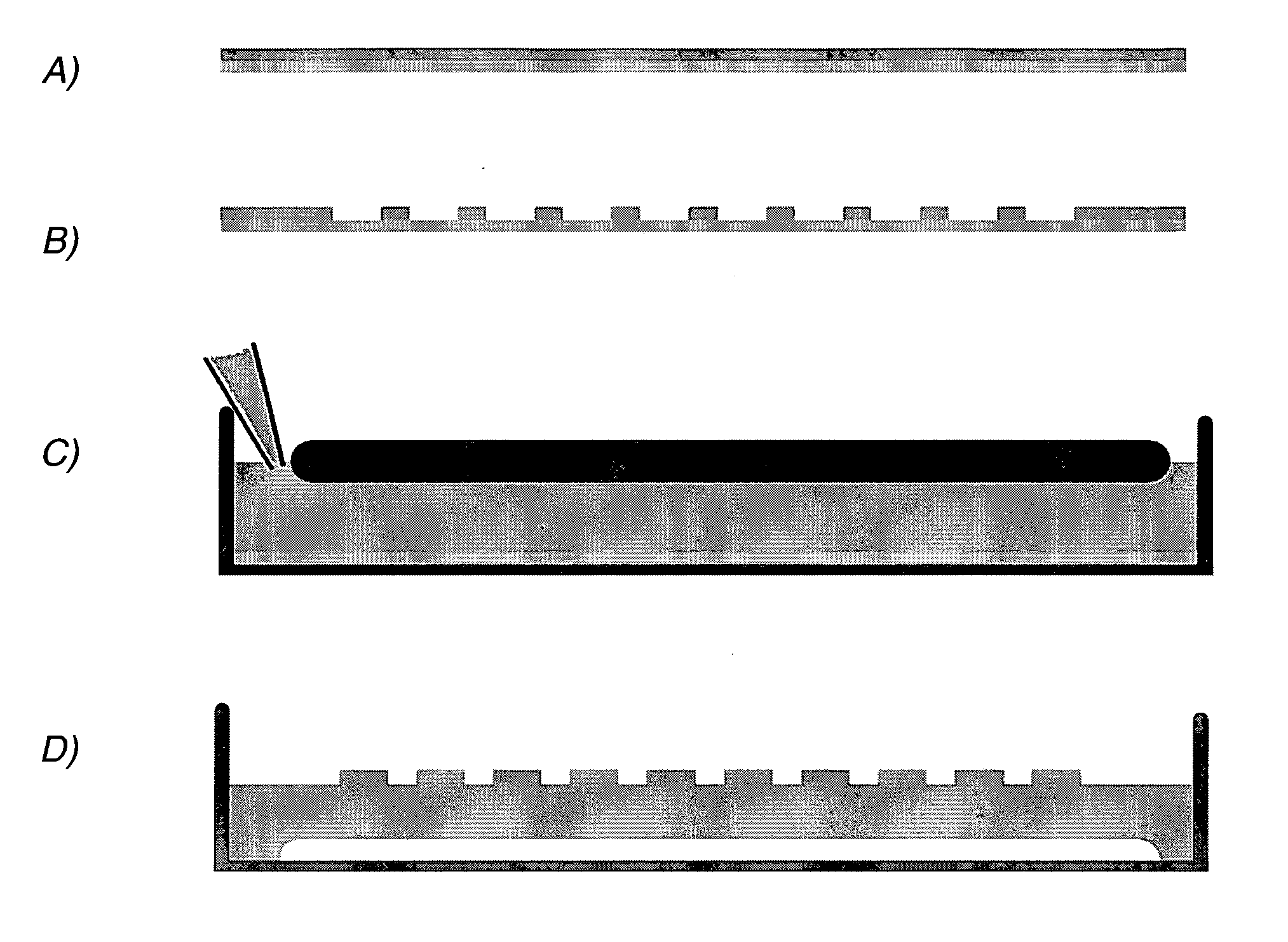

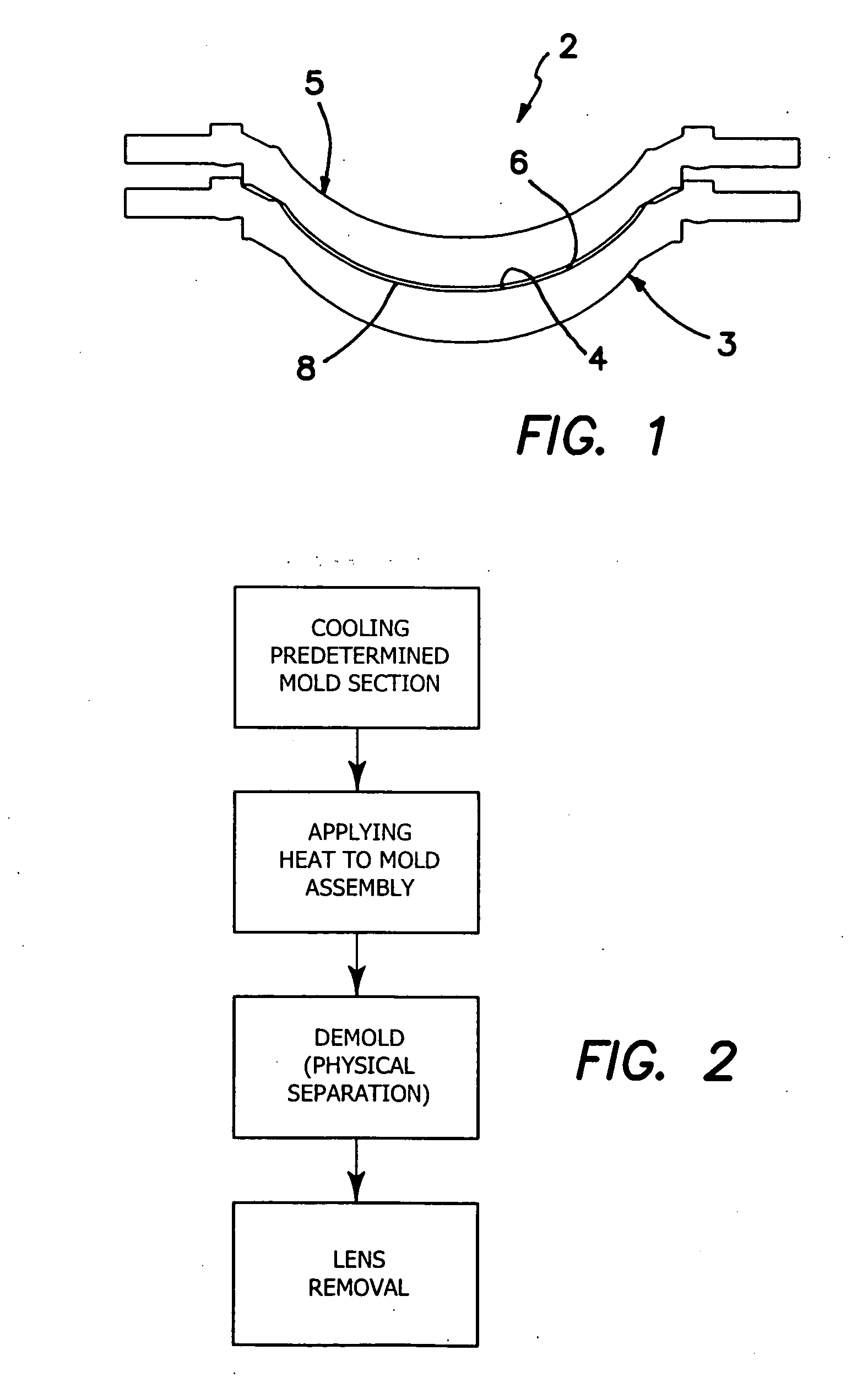

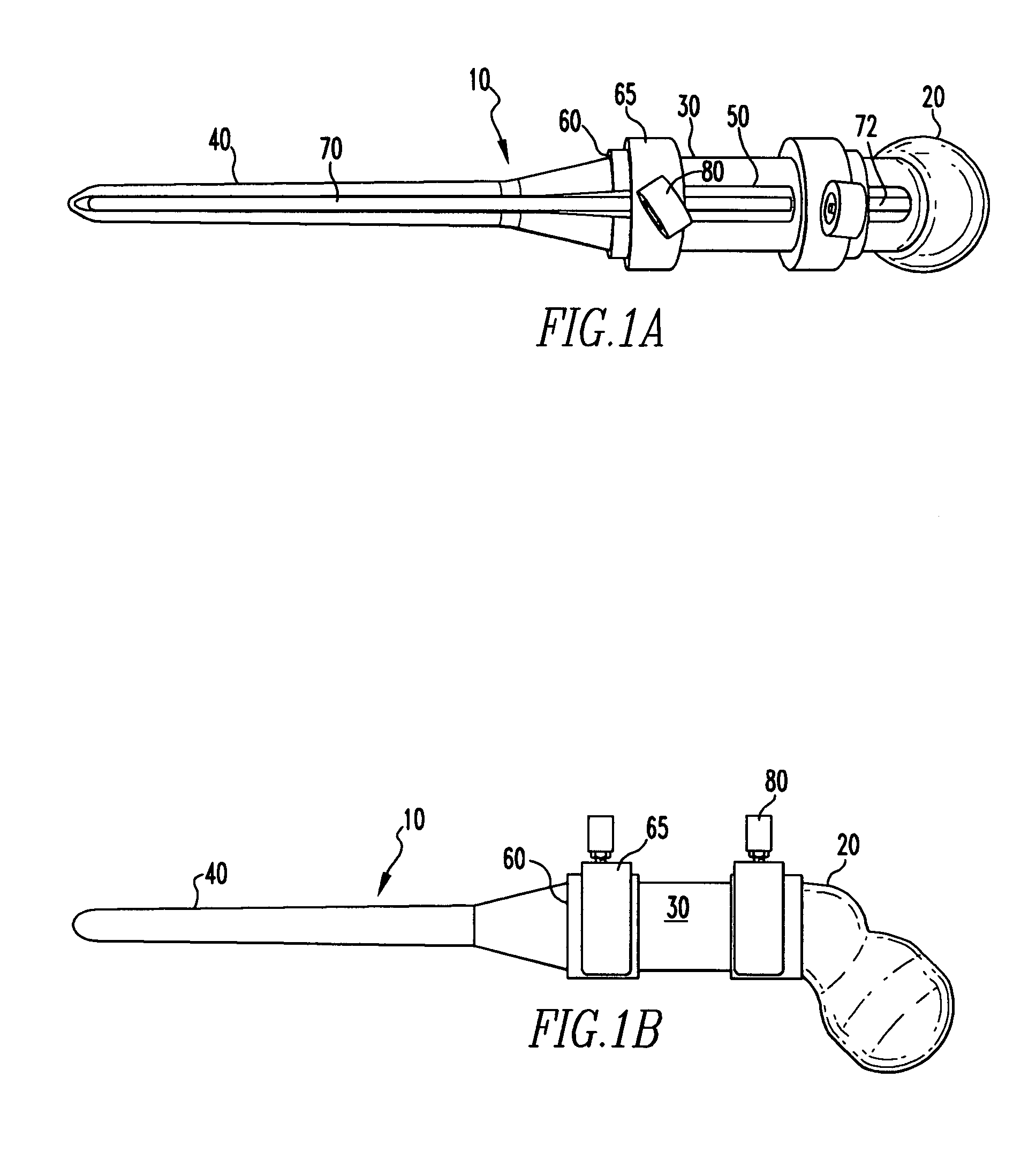

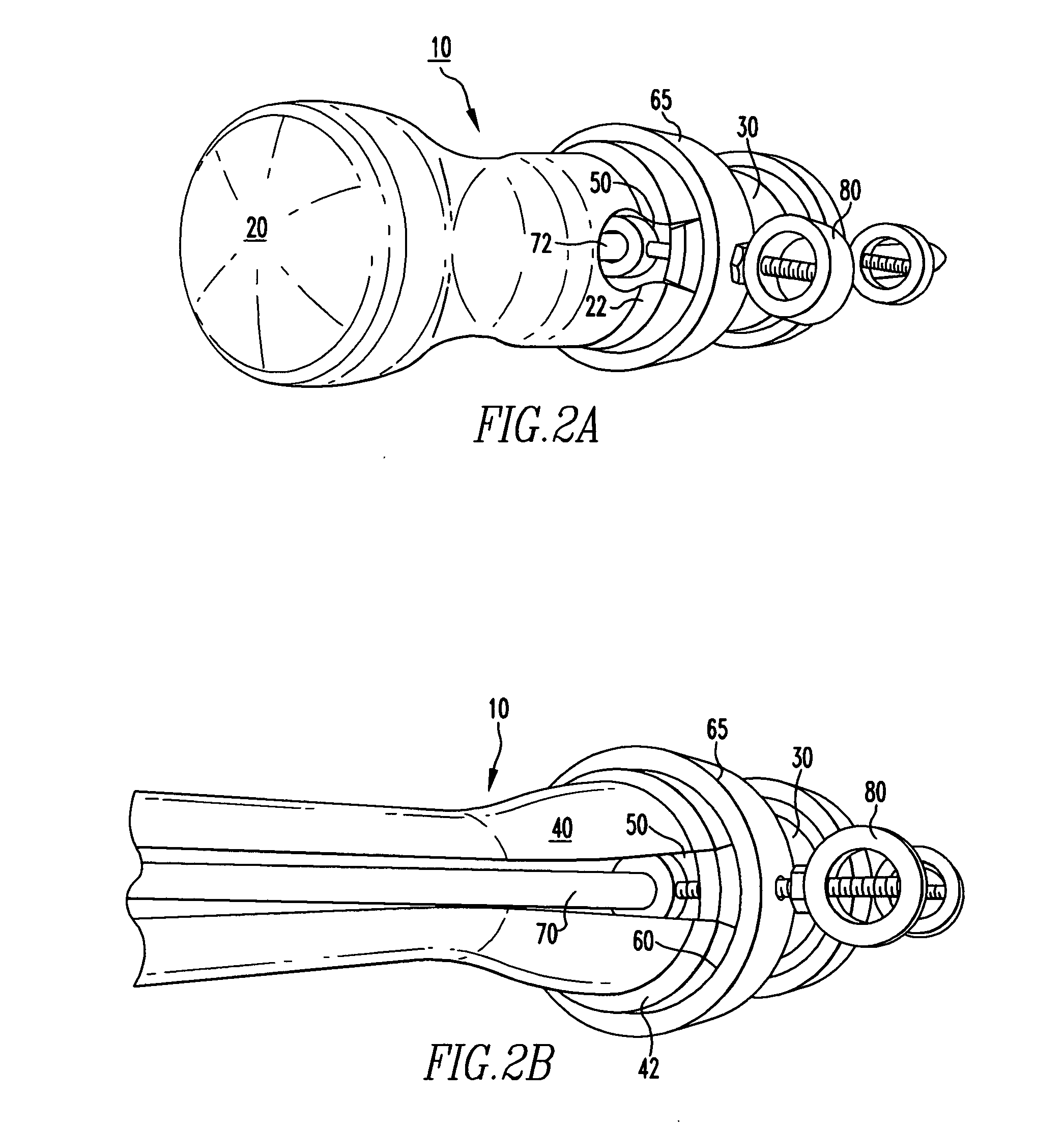

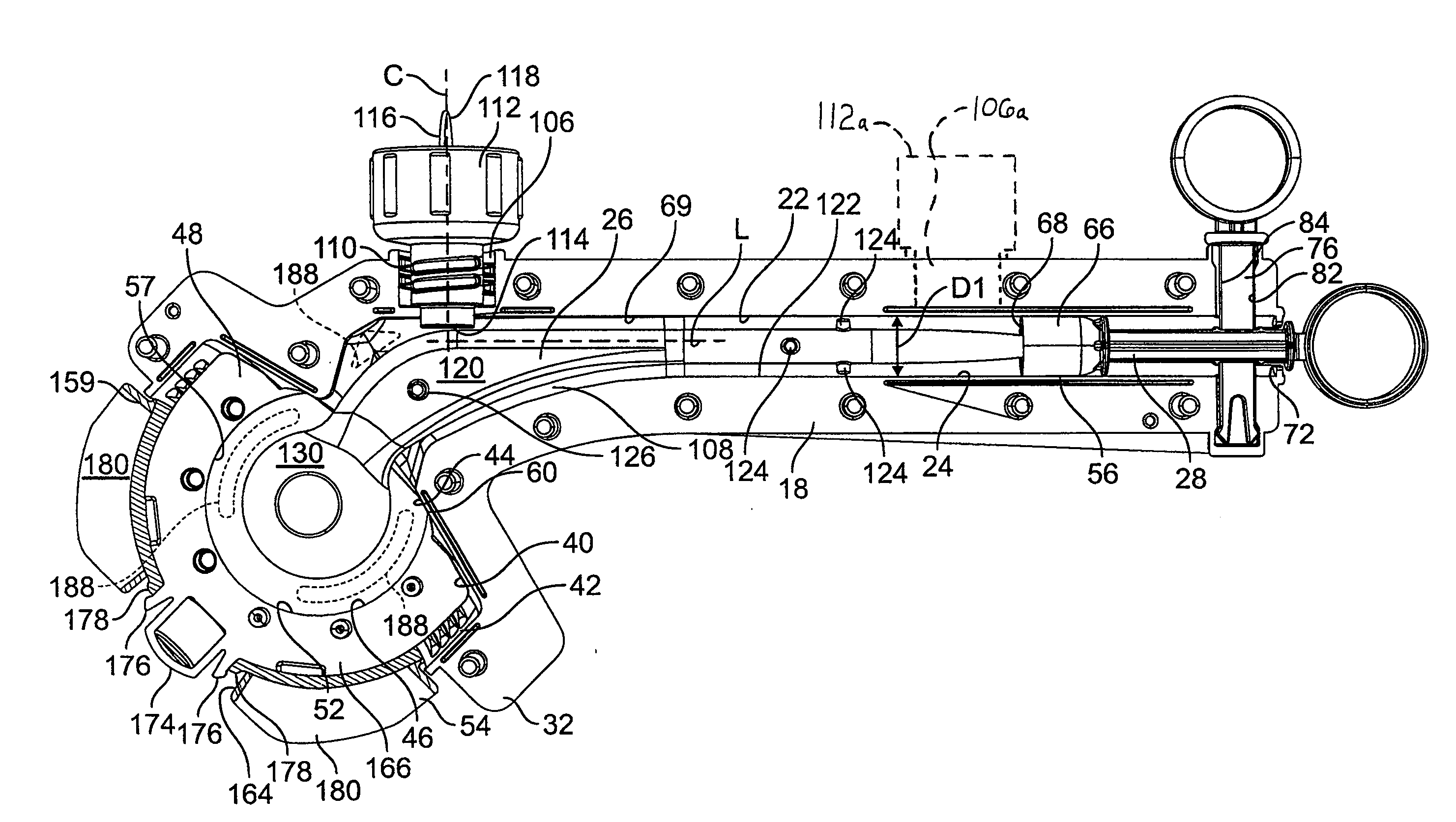

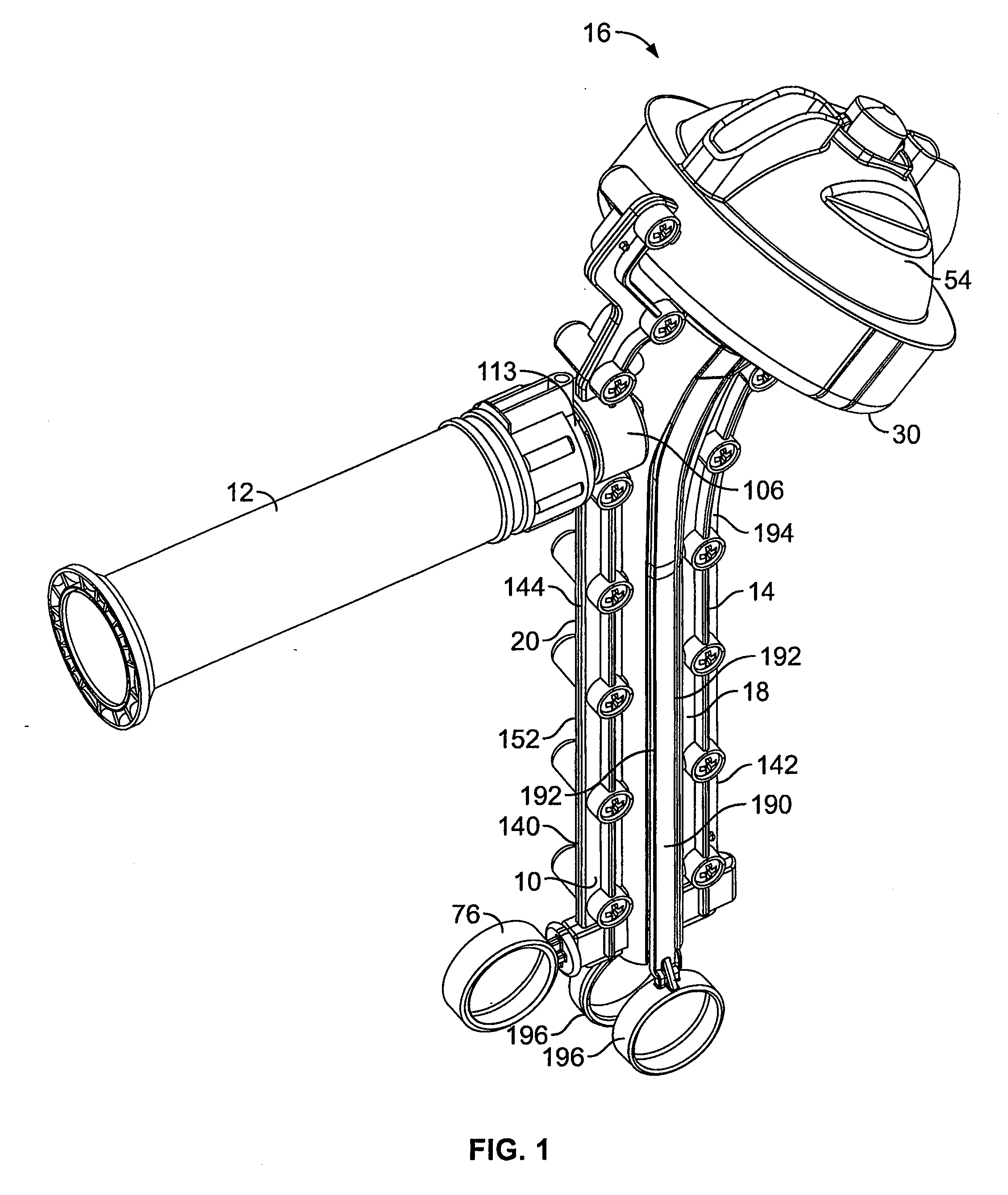

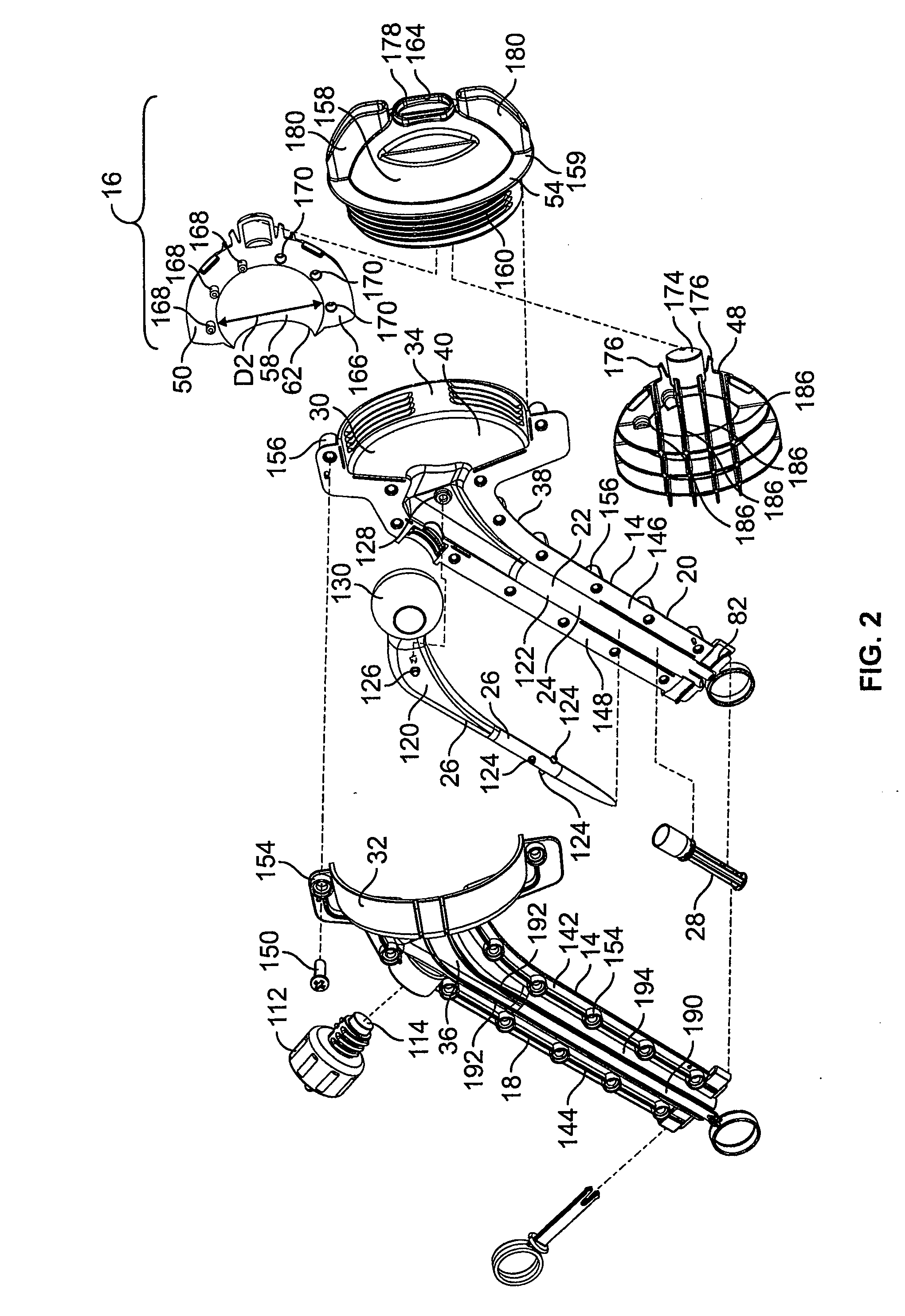

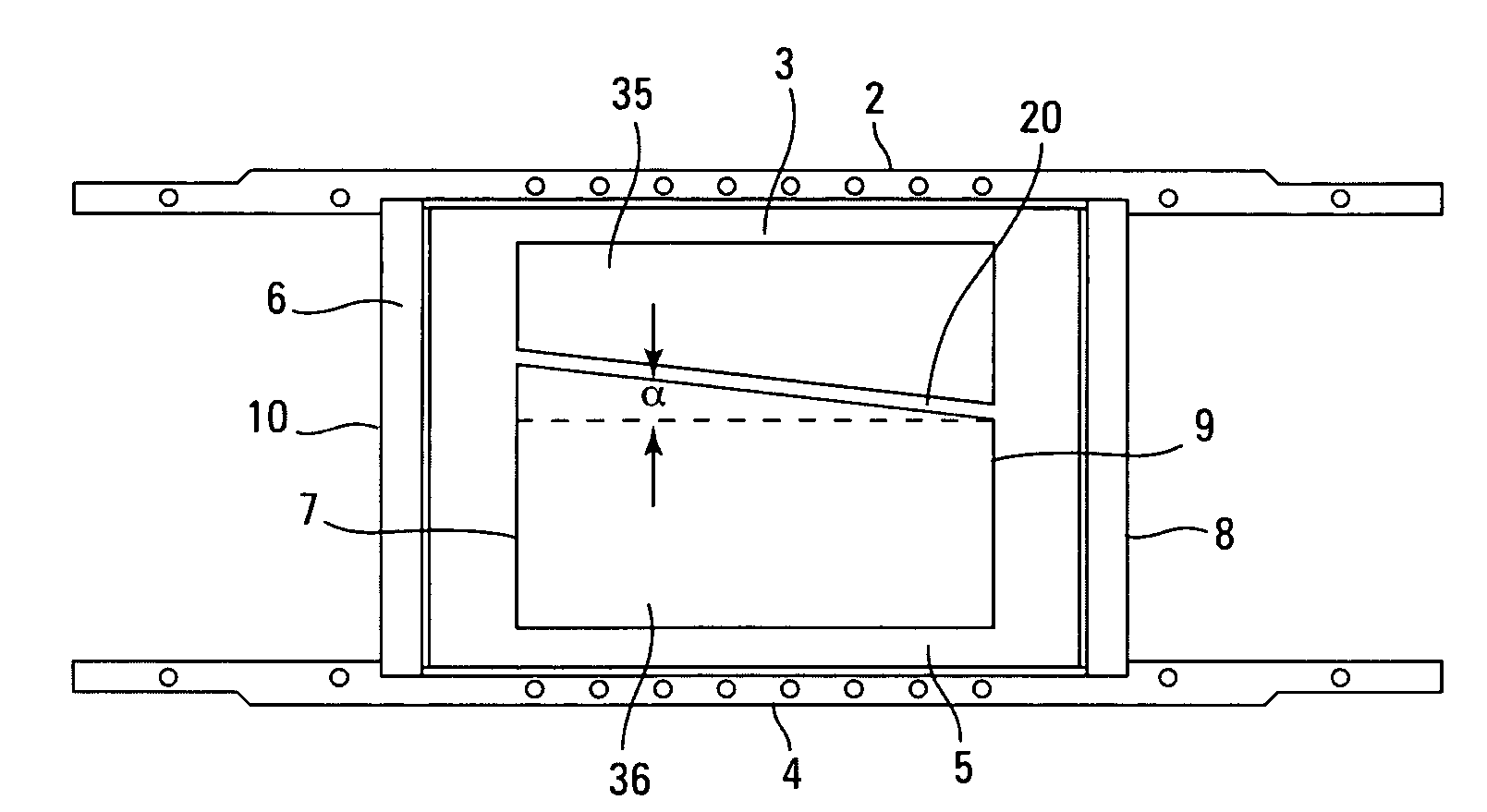

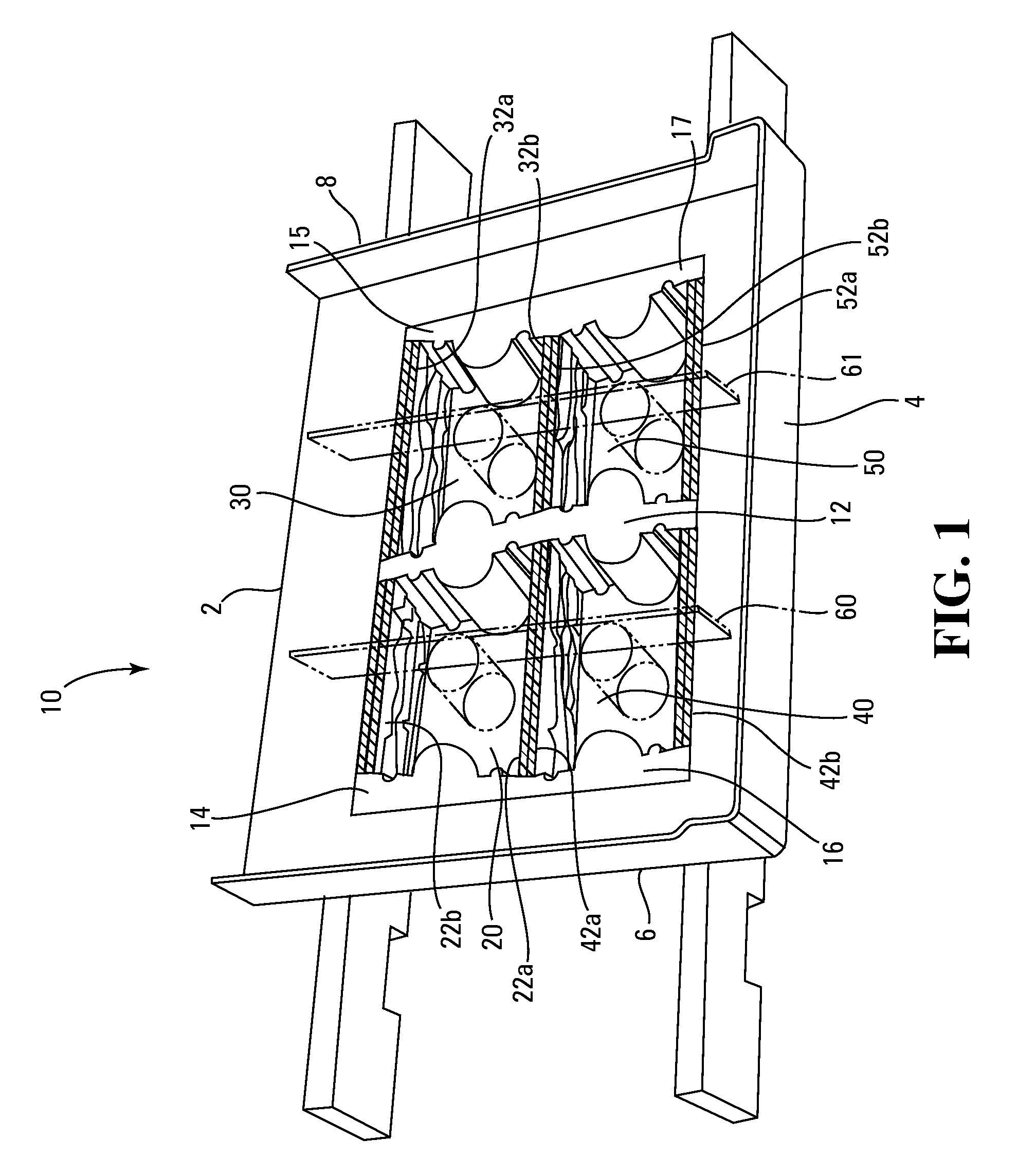

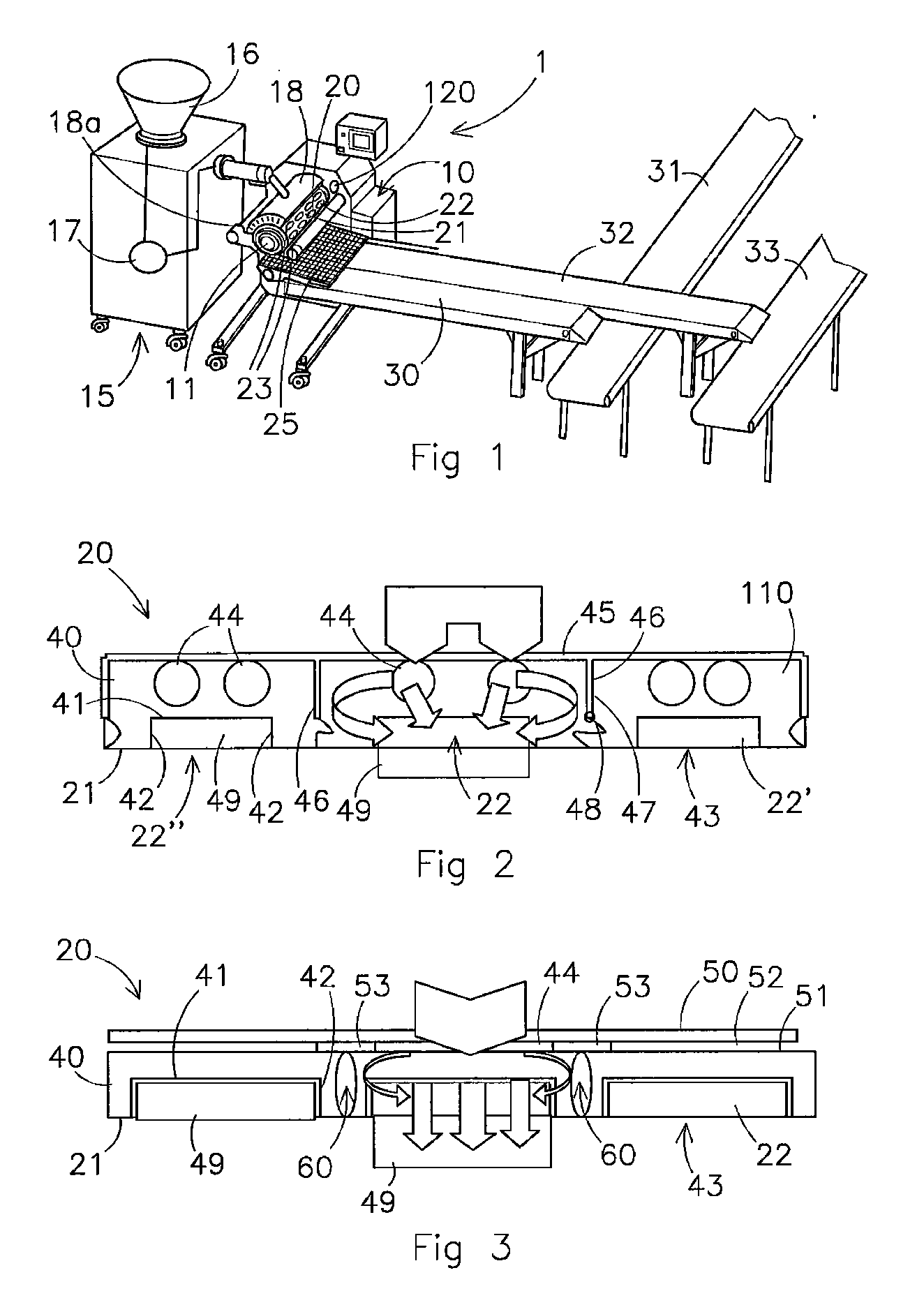

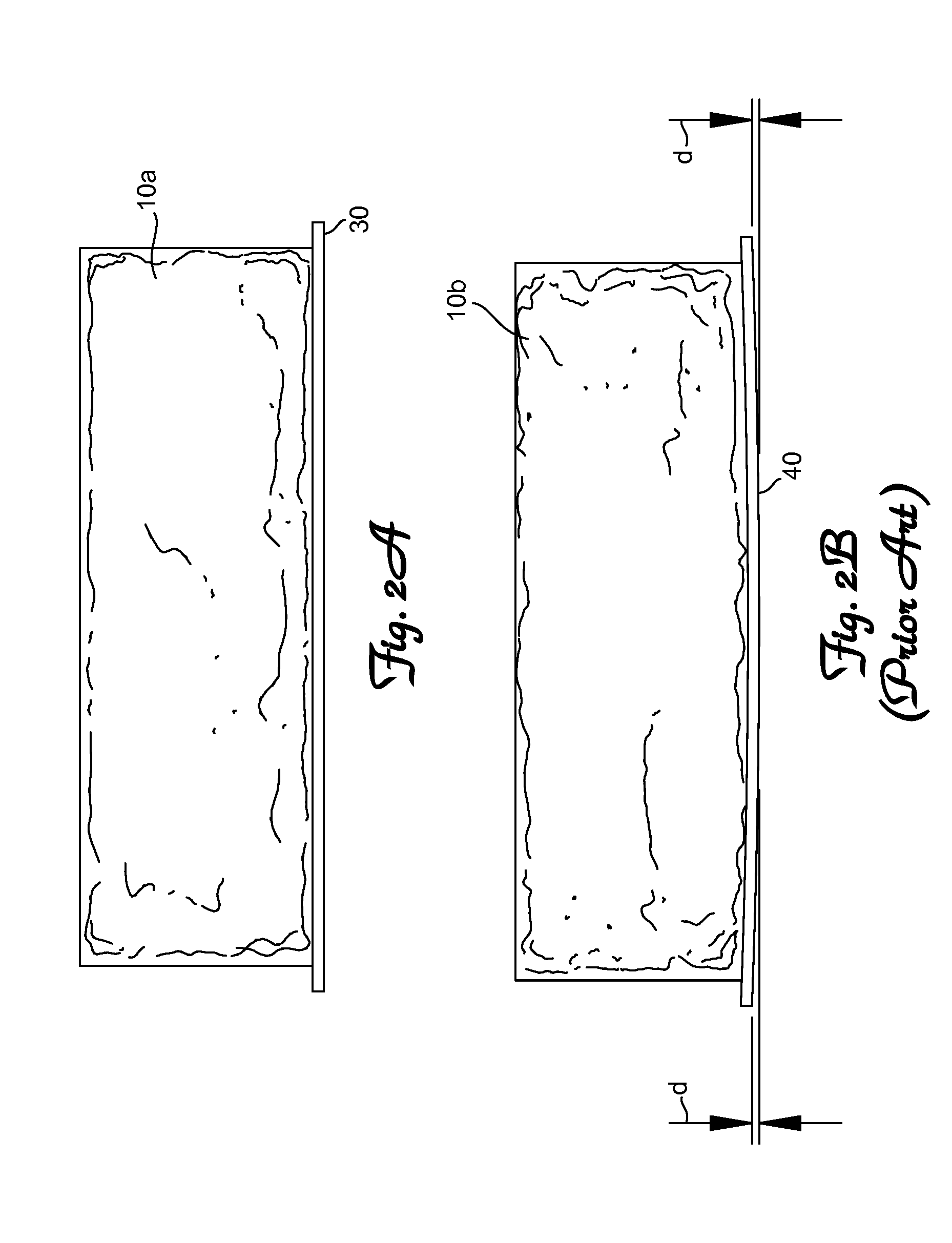

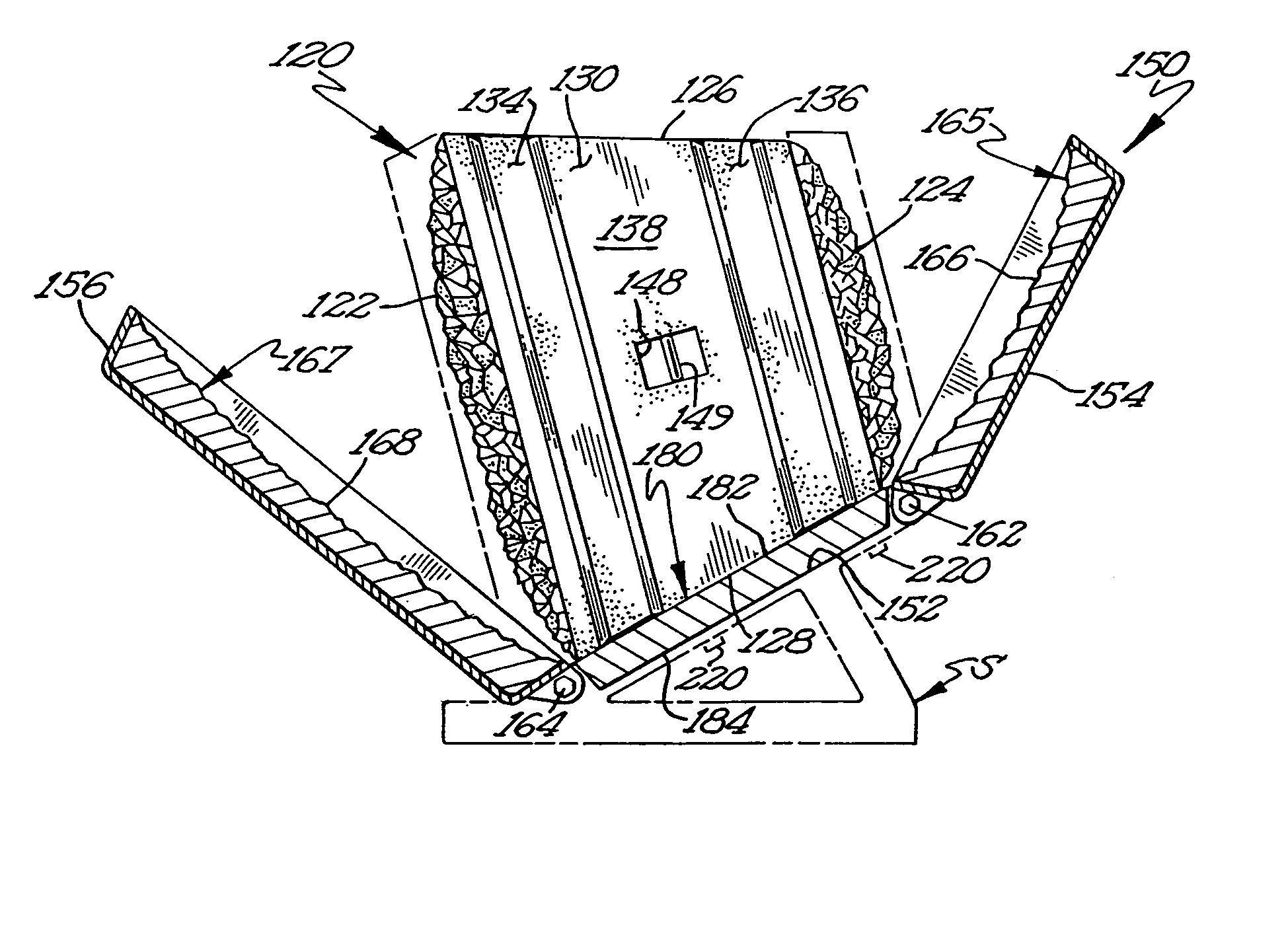

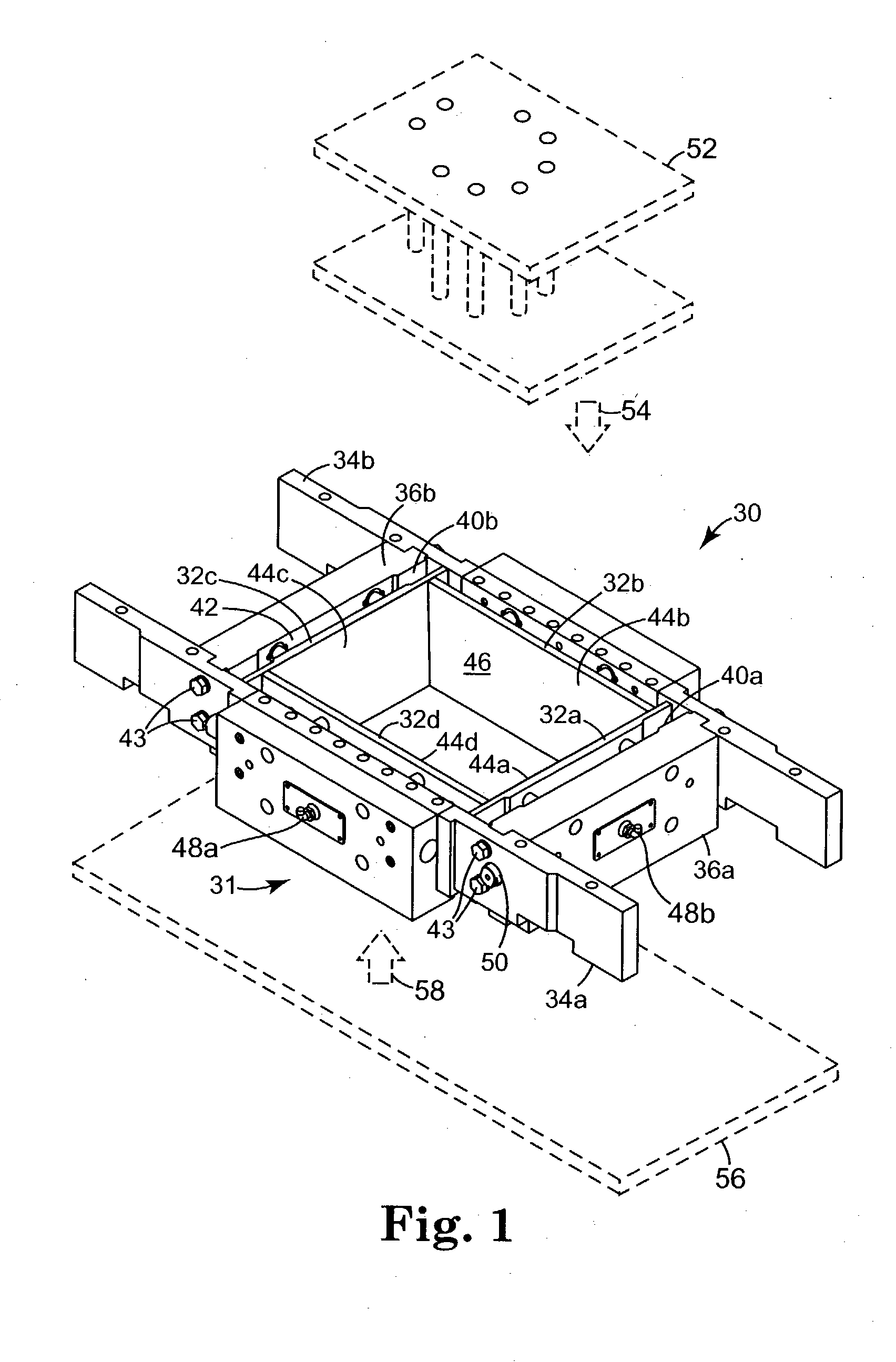

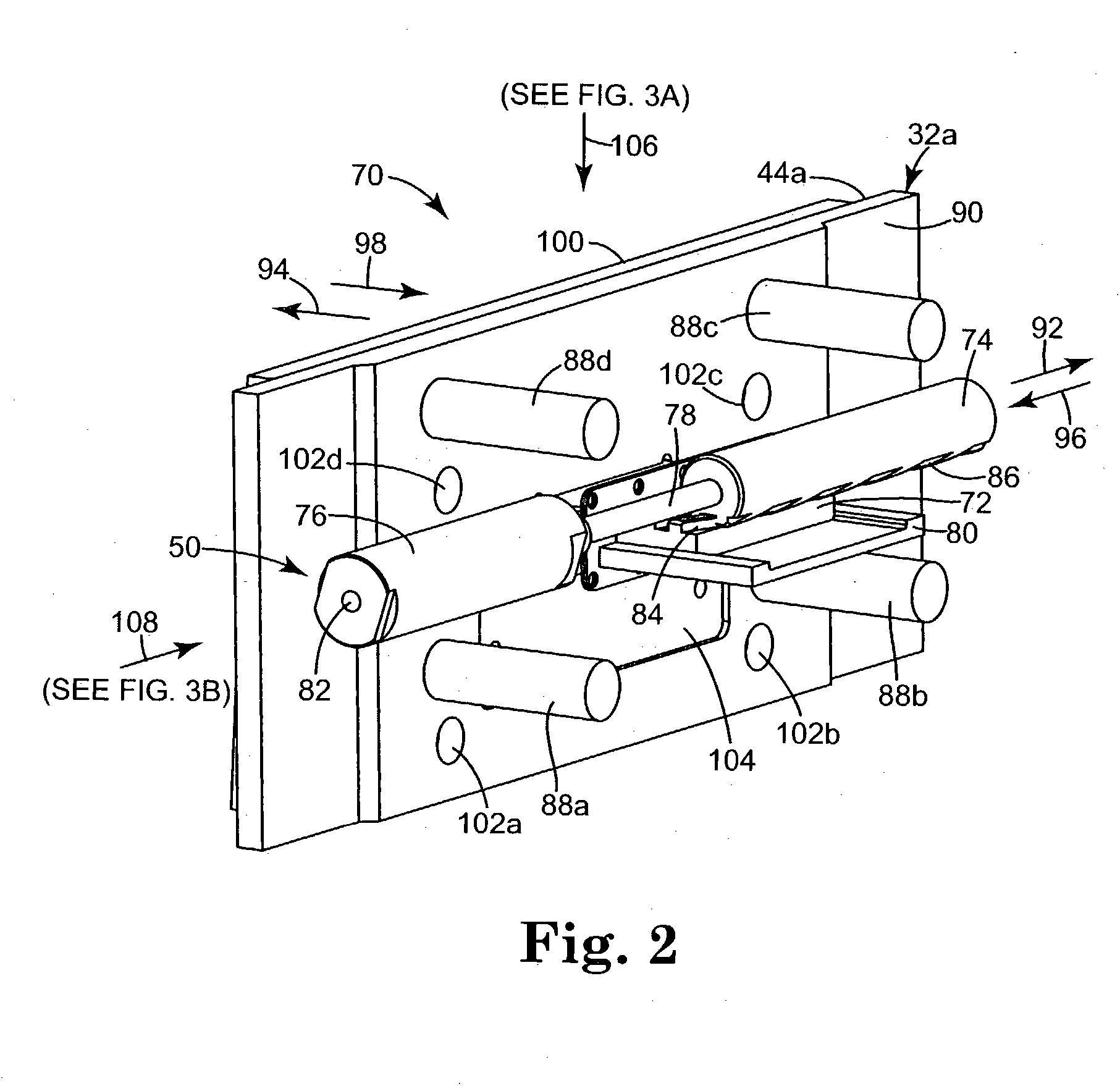

Systems and methods for removing lenses from lens molds

ActiveUS20070035049A1Efficient heatingFacilitate agitationMould separation apparatusConfectioneryEngineeringWedge shape

Methods and apparatus for separating mold sections, removing a lens product from the separated mold sections, and transferring the lens product to a processing tray are provided and include contacting assembled mold sections with a warm fluid to break fused portions between the mold sections, and using one or more wedge shaped elements to pry apart and separate the mold sections, one from the other. A vacuum head having multiple vacuum ports is employed for lifting the newly molded lens product from a mold section and for releasing the lens from the vacuum head into a processing tray. A cylinder of flowing air directed around the circumference of the lens is effective to maintain the lens in an unfolded position as the lens is being released into the processing tray. A tray set including multiple trays holding multiple lenses is provided and includes features for enabling visual and / or mechanical distinction of the trays and lenses held thereby.

Owner:COOPERVISION INT LTD

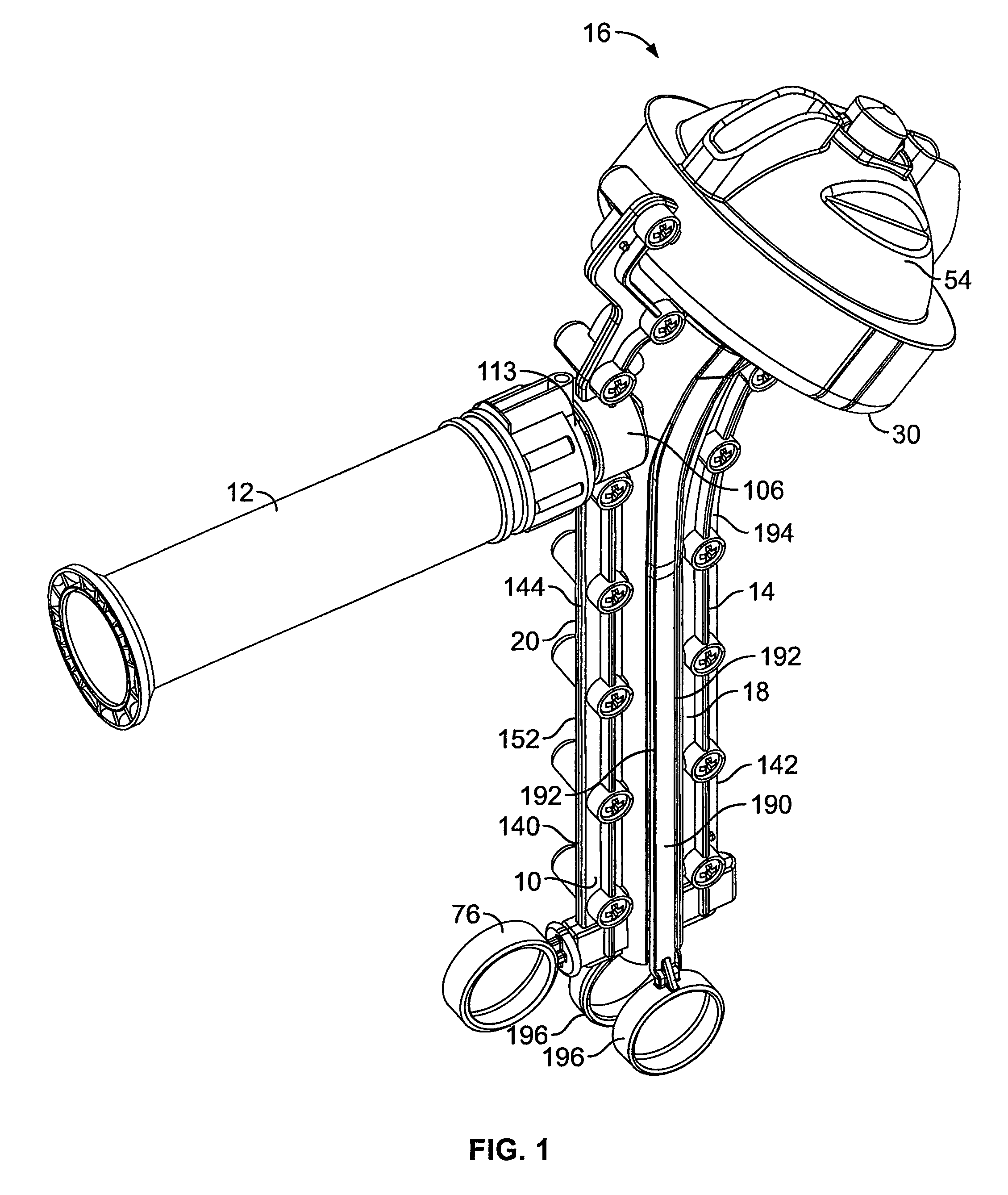

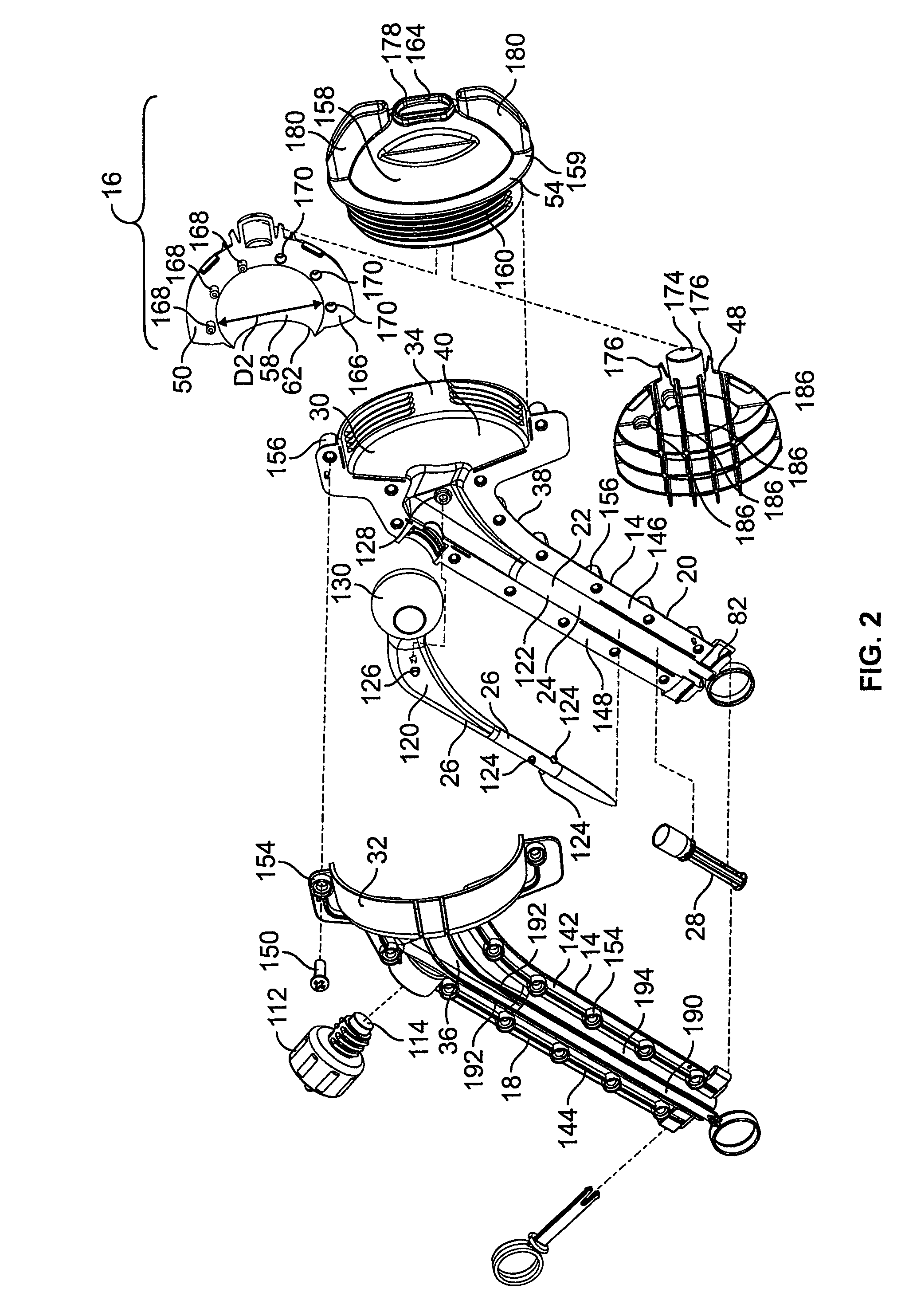

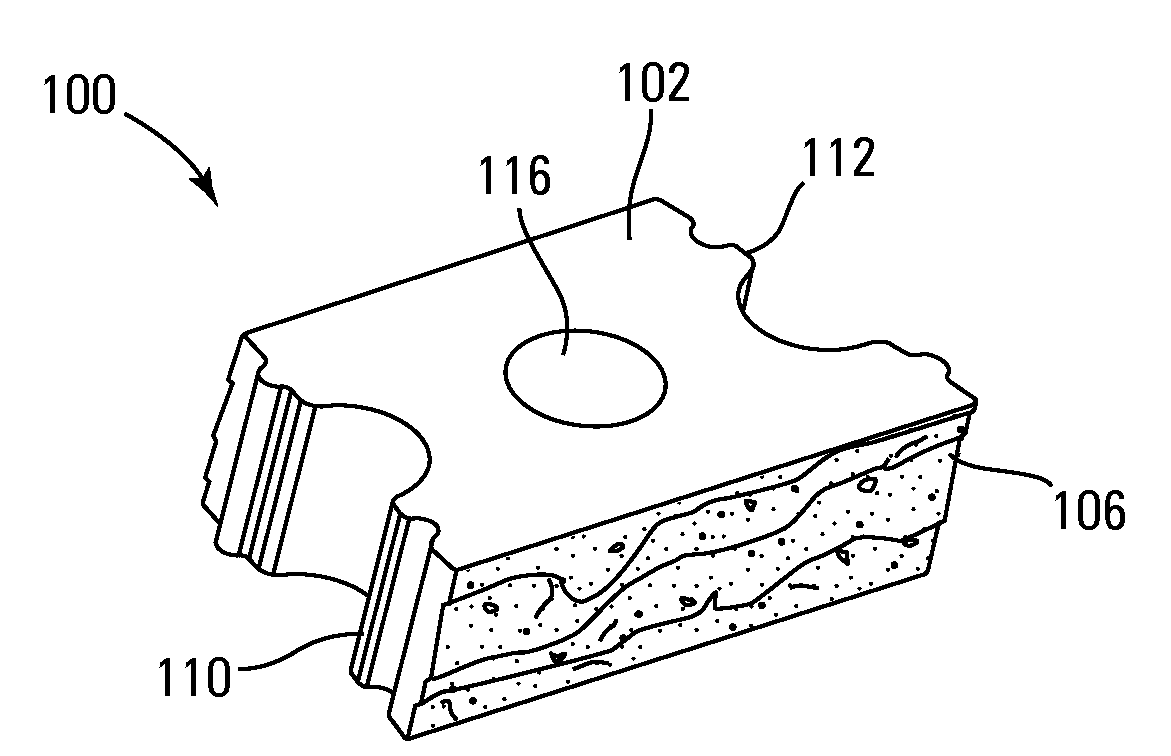

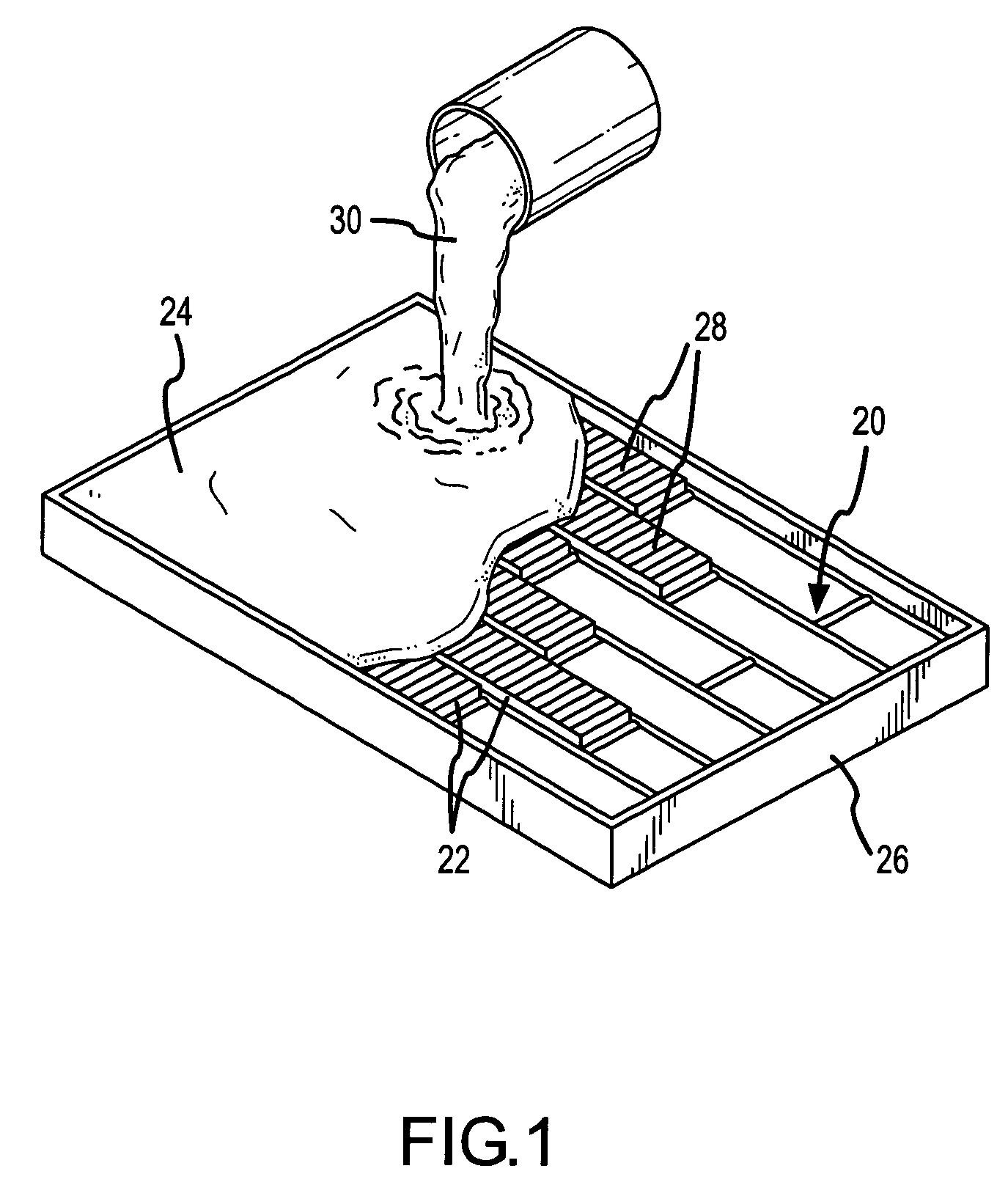

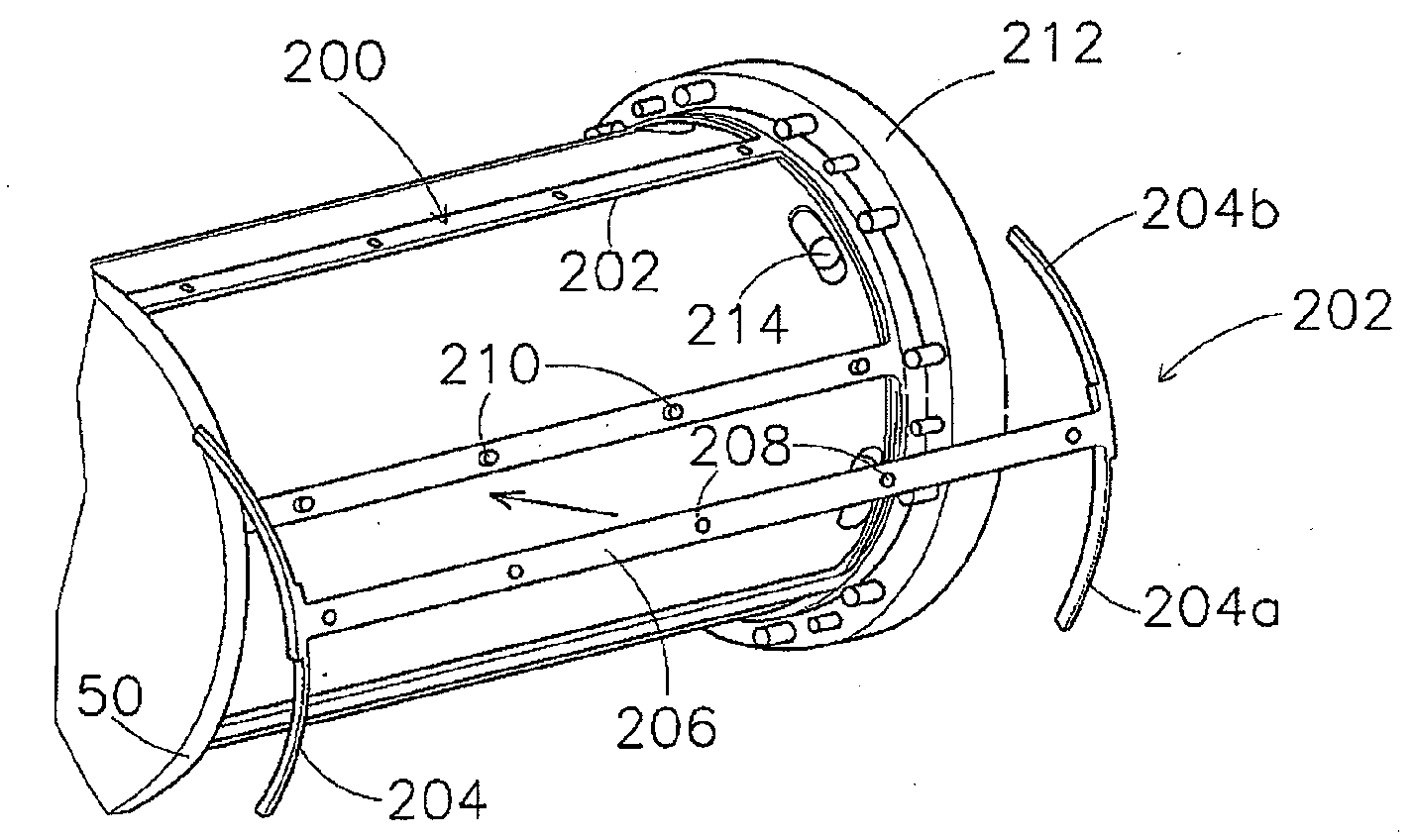

Method of forming a temporary implant and mold assembly for same

InactiveUS20070222114A1Risk of separationArtificial flowers and garlandsJoint implantsBone cementMaterials science

A mold assembly and method of forming a surgical implant from bone cement. The method has the steps of connecting a plurality of mold segments to approximate the size of a patient implant. Each mold segment has an open channel. The method may further include aligning the channels of connected mold segments, positioning a centralizing holder on a reinforcement member, mixing bone cement, pouring at least some bone cement through the channels and into connected mold segments, fitting the reinforcement member into the mold segments, curing the bone cement; and removing the cured surgical implant.

Owner:ZIRAN BRUCE H +1

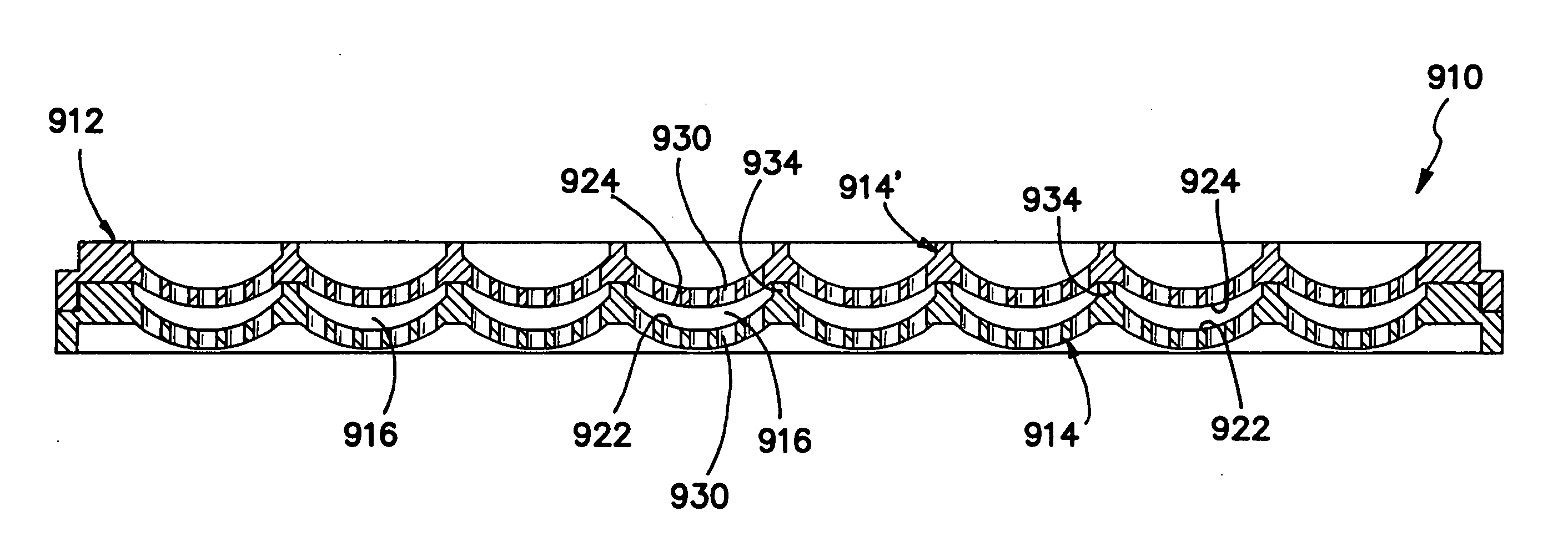

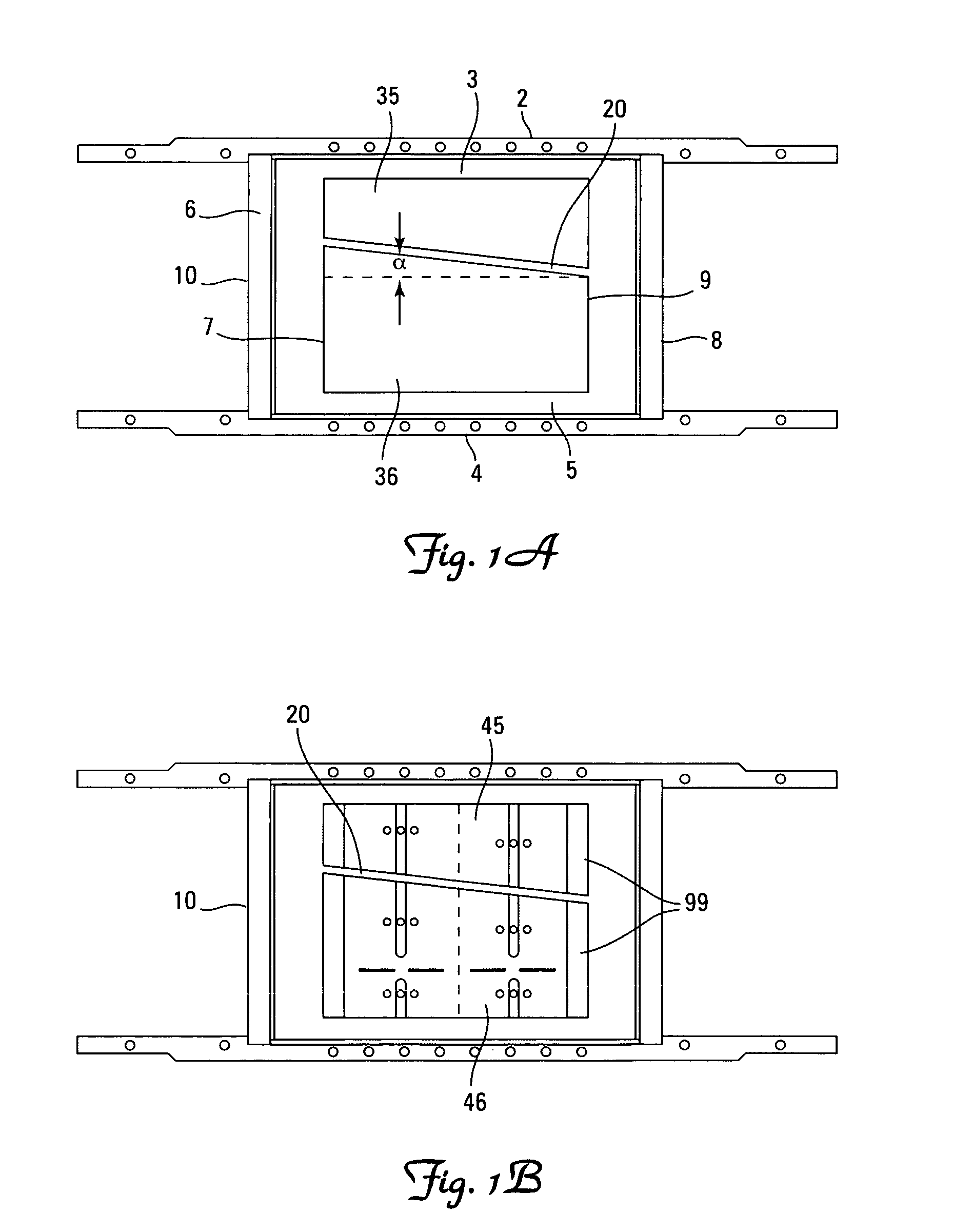

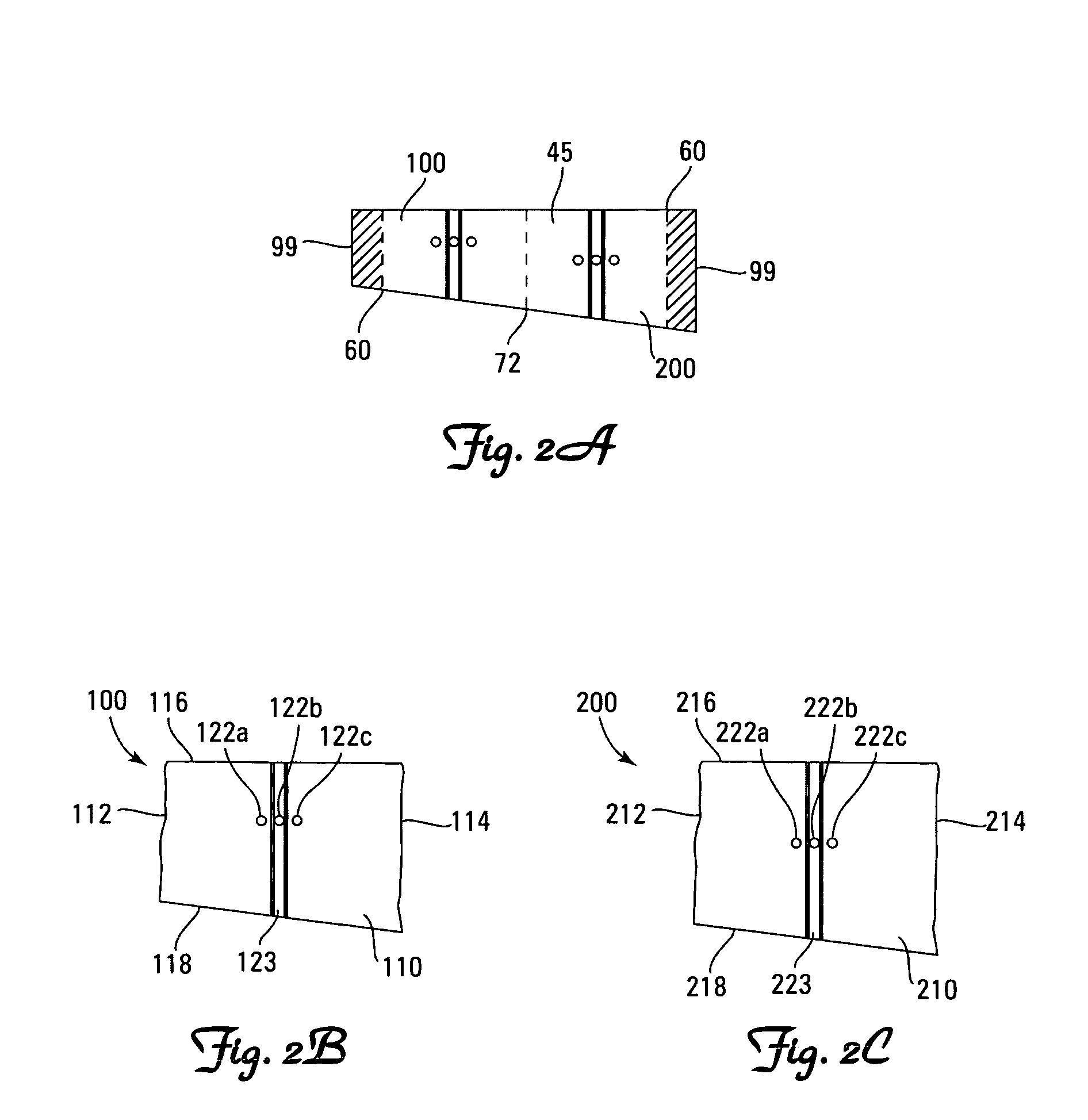

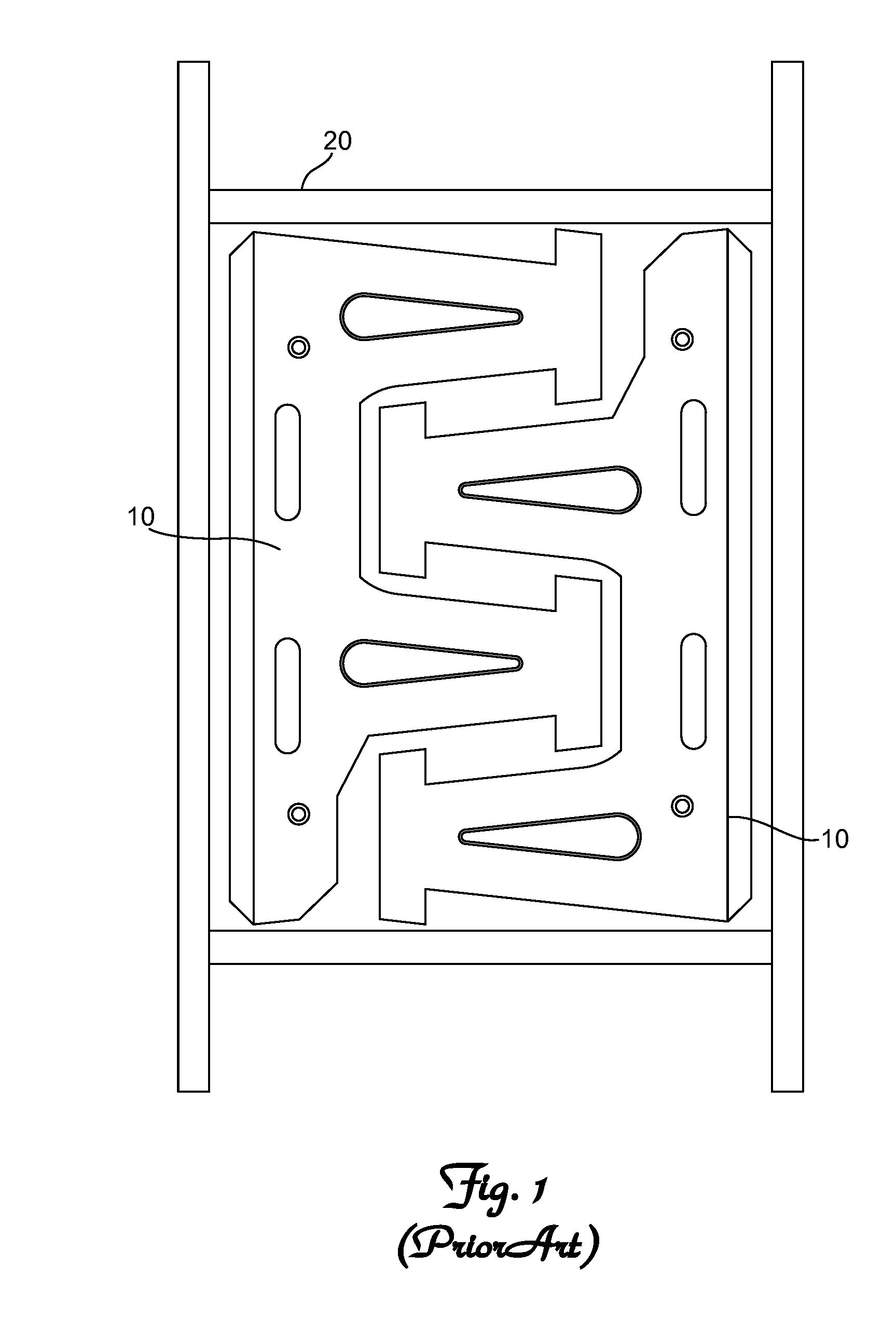

Contact lens mold assemblies and systems and methods of producing same

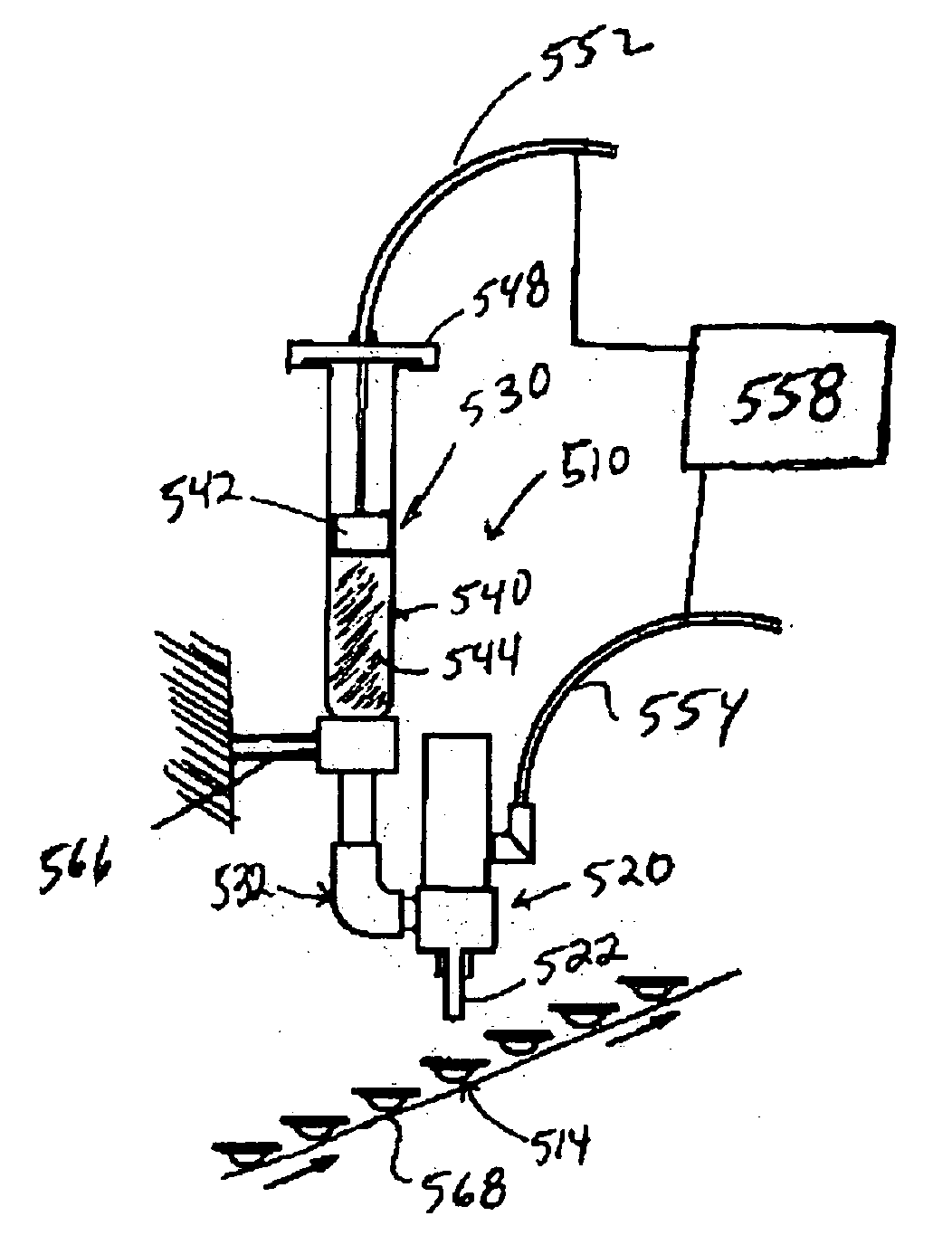

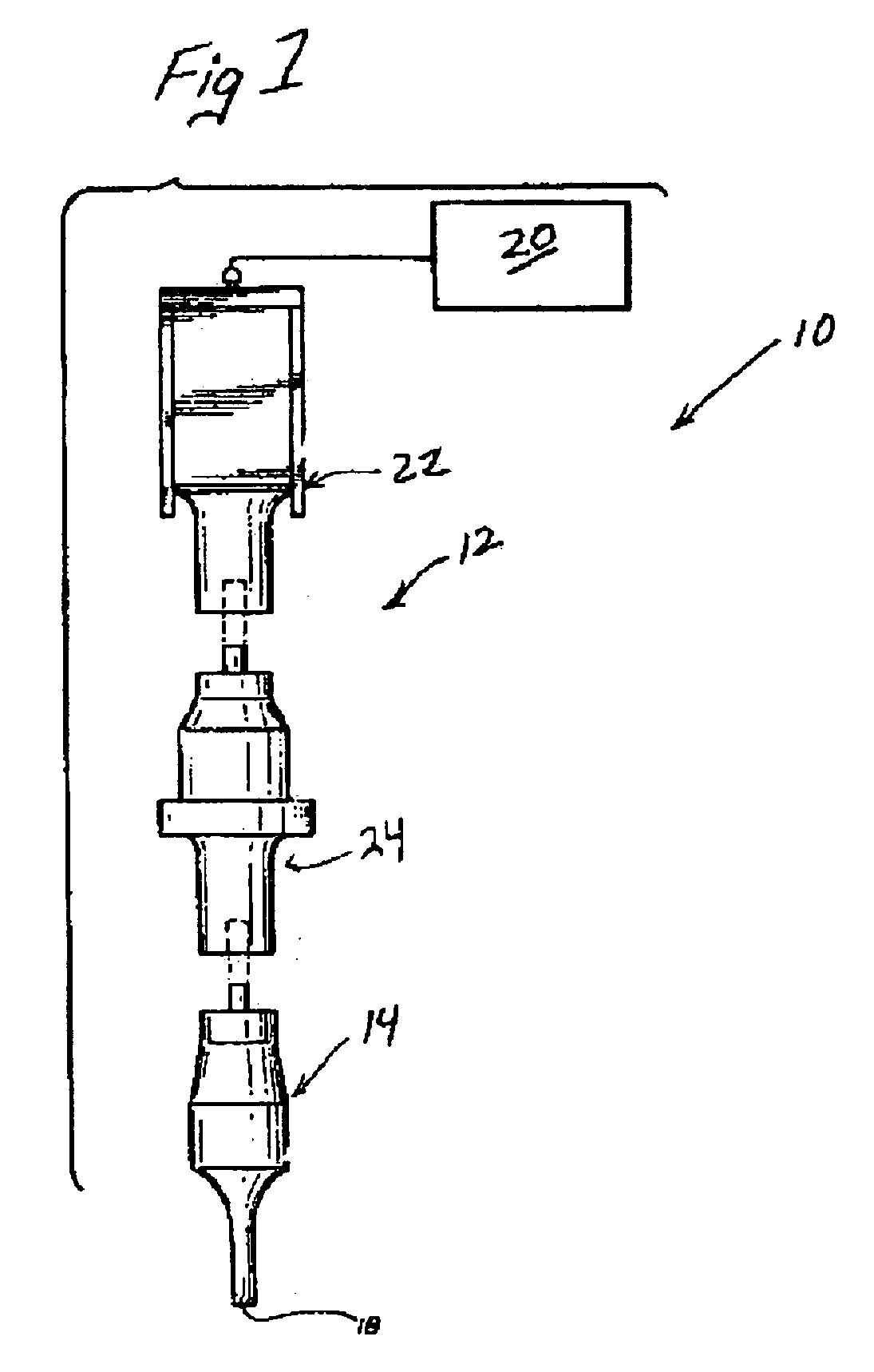

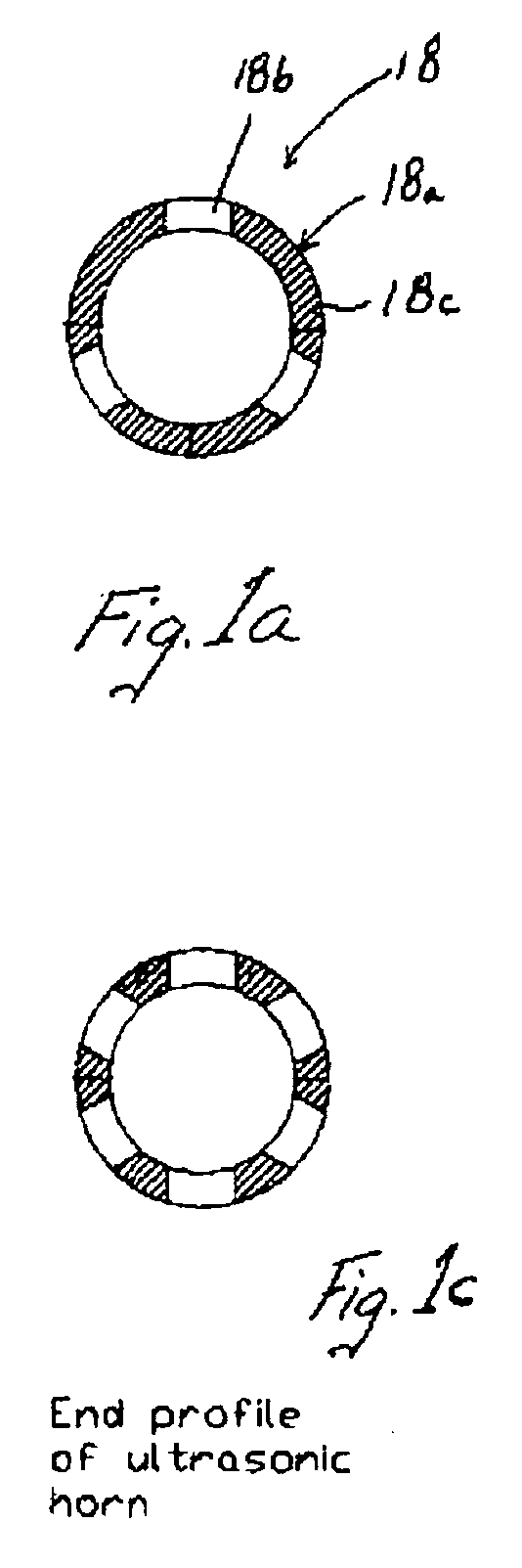

ActiveUS20070035051A1Prevent materialEnhanced cavitationOptical articlesStereotype platesEngineeringContact lens

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which when coupled together are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by means of focused ultrasound energy.

Owner:COOPERVISION INT LTD

In mold manufacture of an object with embedded display panel

This invention relates to an object having a display panel embedded in its top surface and processes for its manufacture. This invention also relates to an in-mold display transfer film or foil, which comprises a temporary carrier film, a release layer, a display panel, an adhesive or tie layer and optionally a durable layer.

Owner:E INK CORPORATION

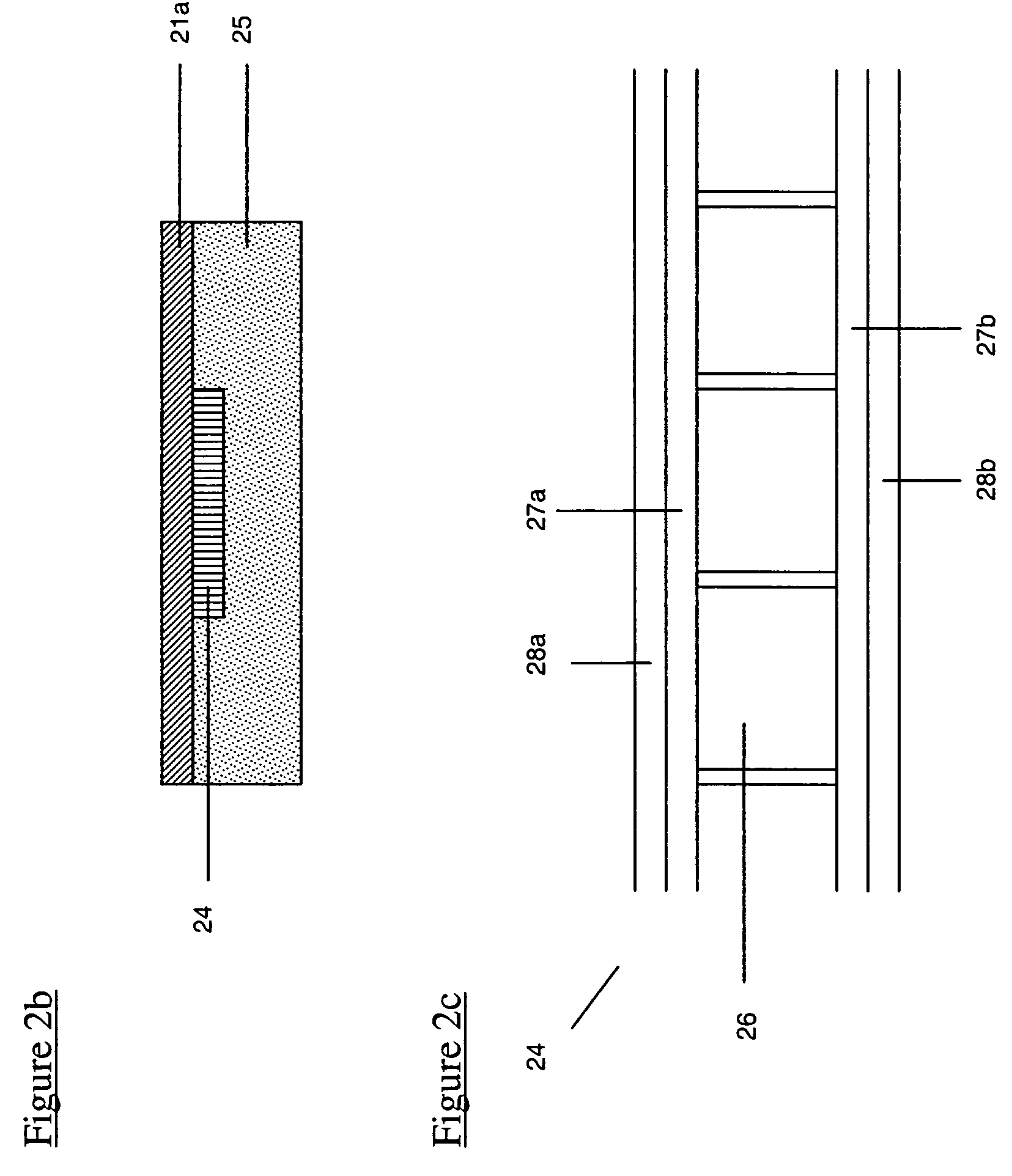

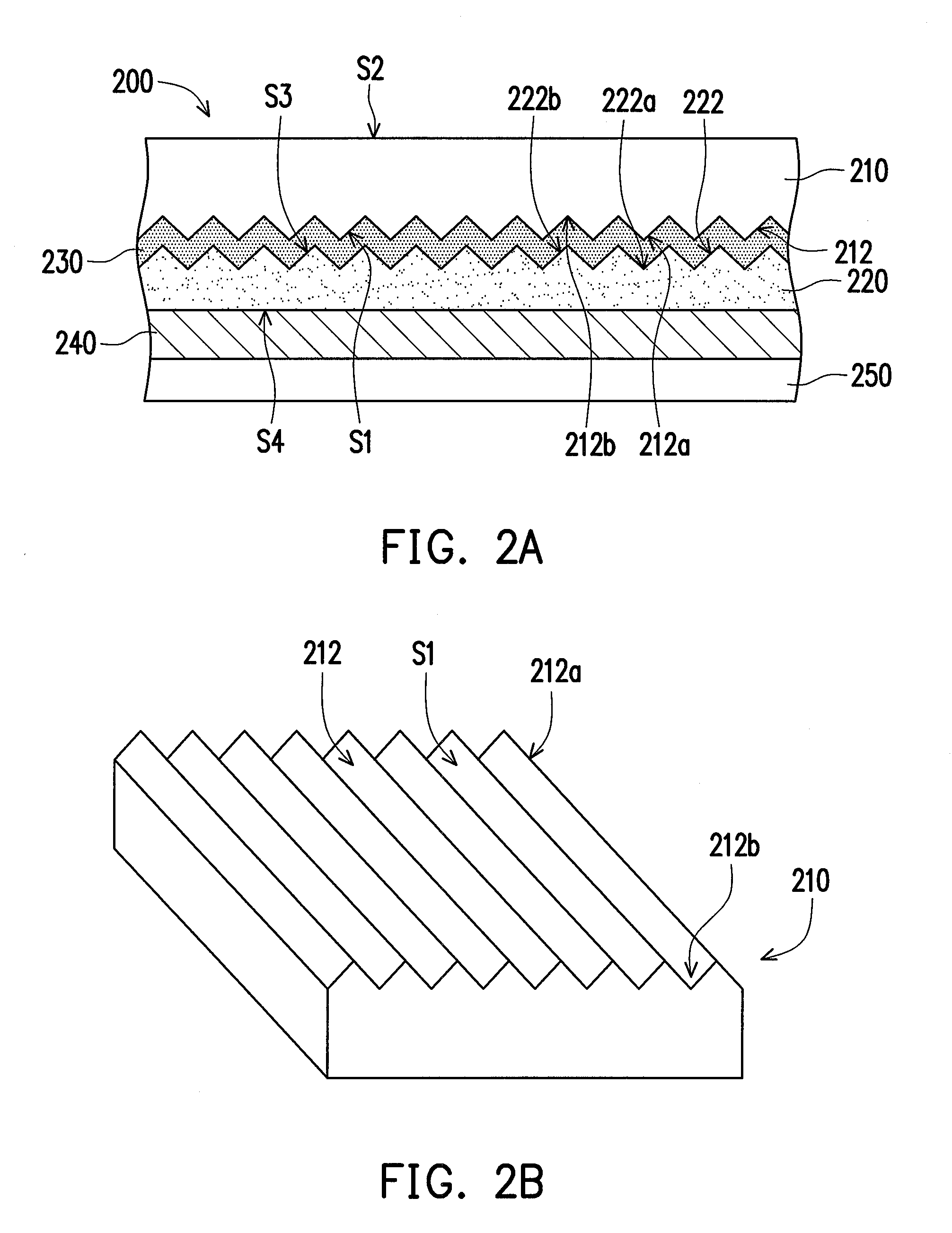

Transfer film, method of manufacturing the same, transfer method and object surface structure

A transfer film including a protection layer and a substrate is provided. The substrate has a first surface with a first three-dimensional pattern and a second surface. The first three-dimensional pattern has at least one protrusion portion or at least one recess portion. The protection layer is disposed on the substrate and has a third surface and a fourth surface. The third surface contacts the first surface and has a second three-dimensional pattern complementary to the first three-dimensional pattern. The second three-dimensional pattern of the third surface is formed by covering the first three-dimensional pattern of the first surface. The protection layer and the substrate are separated after transfer, so as to expose the second three-dimensional pattern.

Owner:COMPAL ELECTRONICS INC

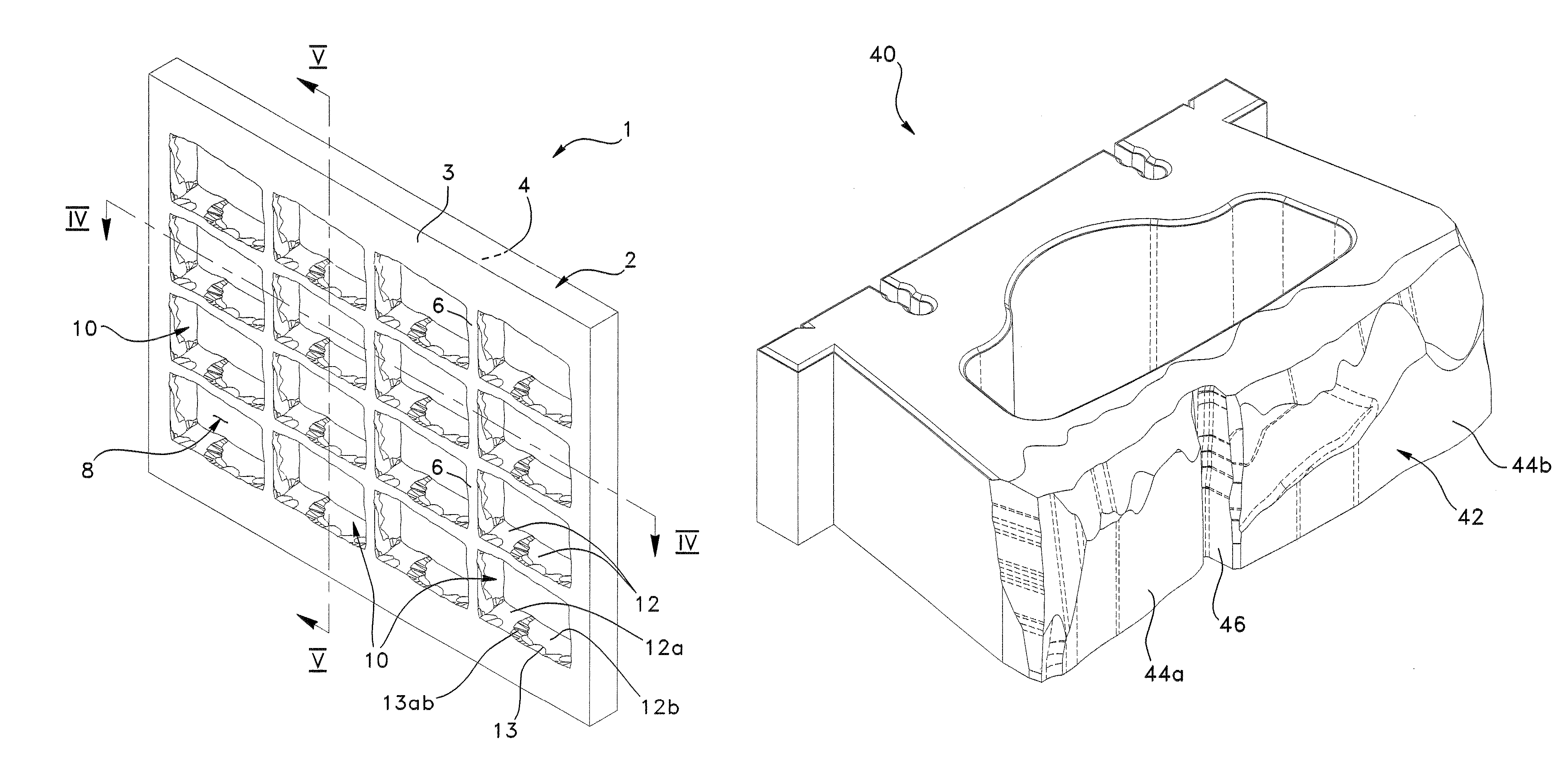

Spacer mold and methods therefor

Owner:ZIMMER ORTHOPAEDIC SURGICAL PRODS

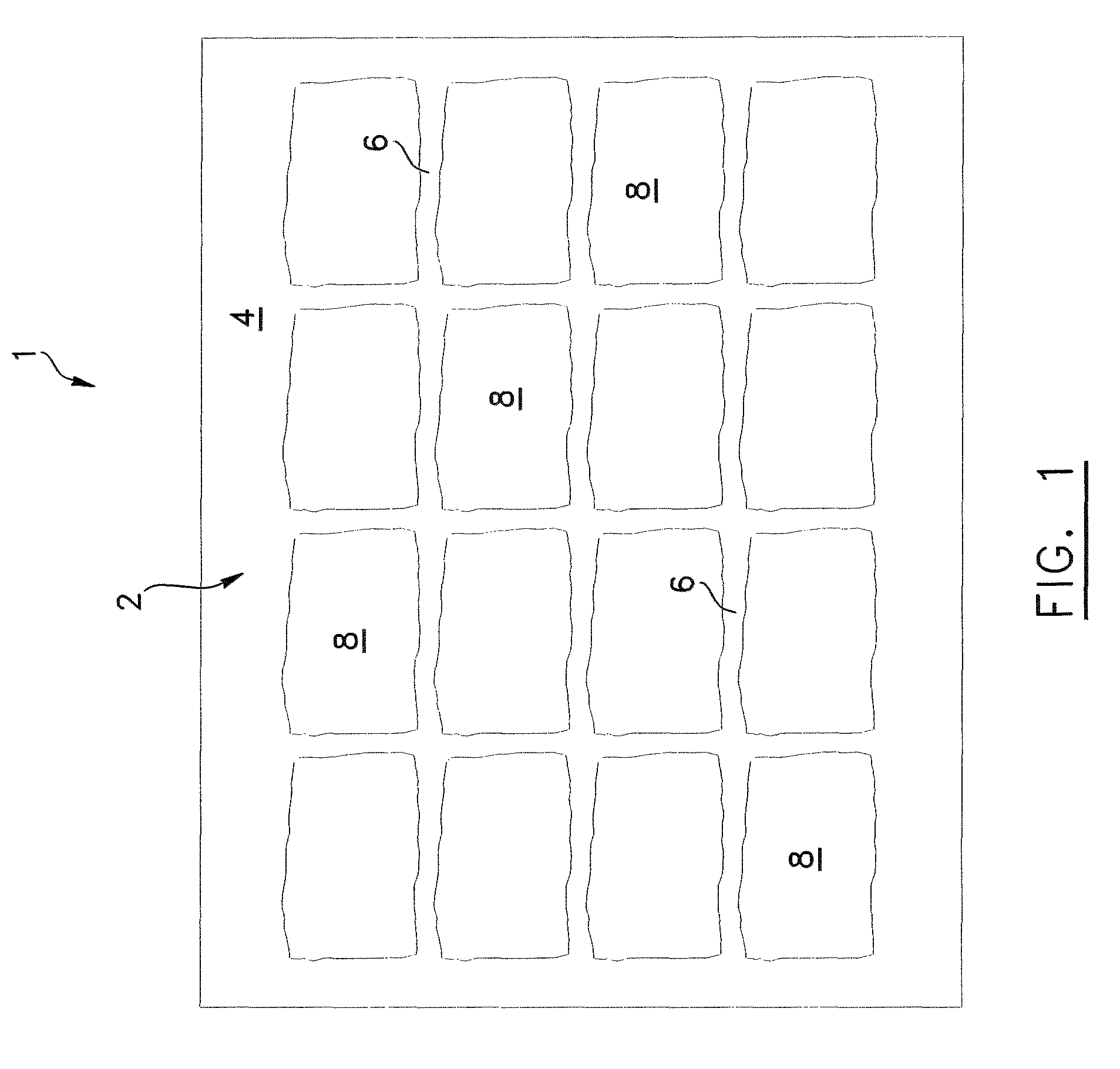

Mold box and method of manufacturing multiple blocks

Owner:KEYSTONE RETAINING WALL SYST

Spacer mold and methods therefor

Owner:ZIMMER ORTHOPAEDIC SURGICAL PRODS

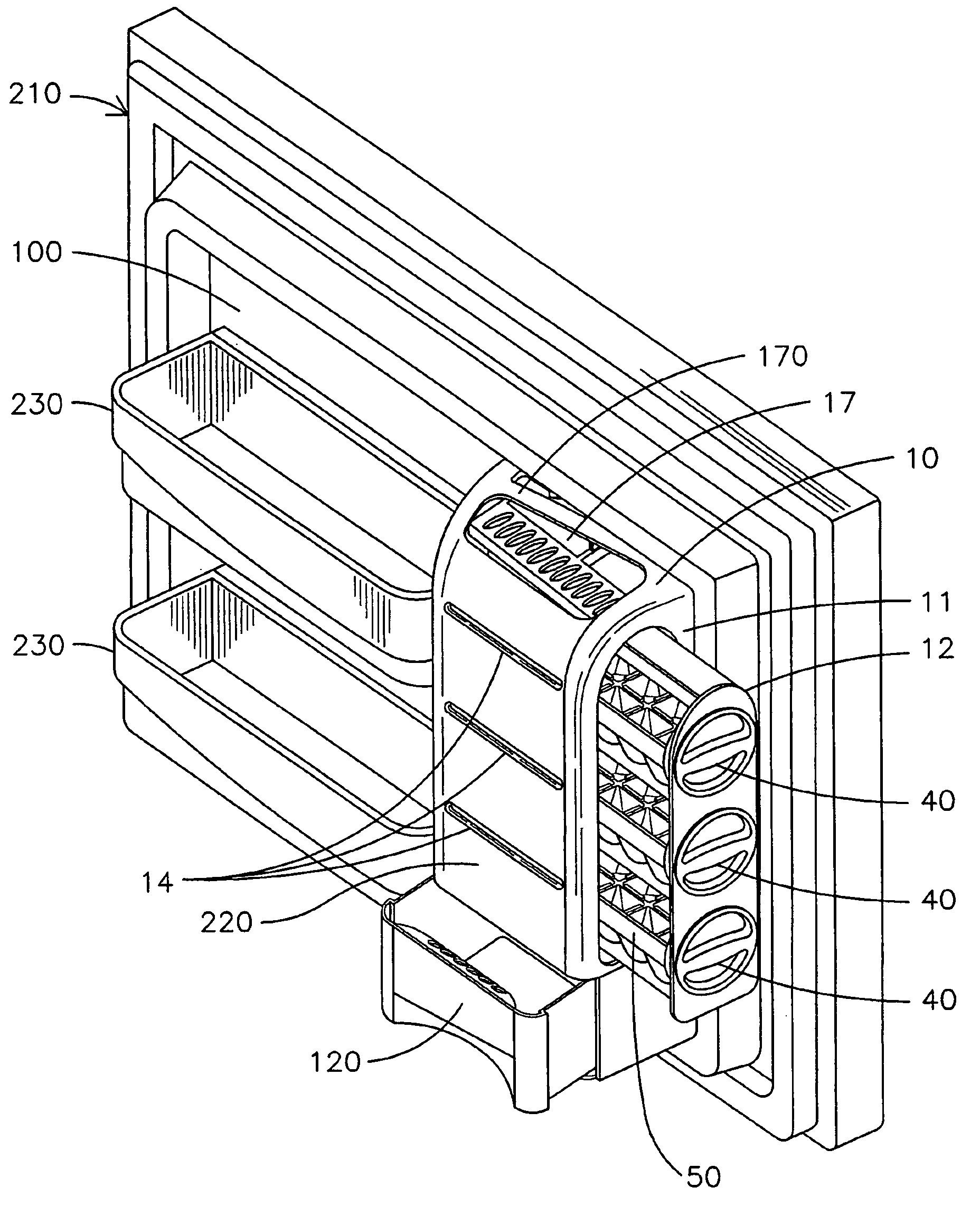

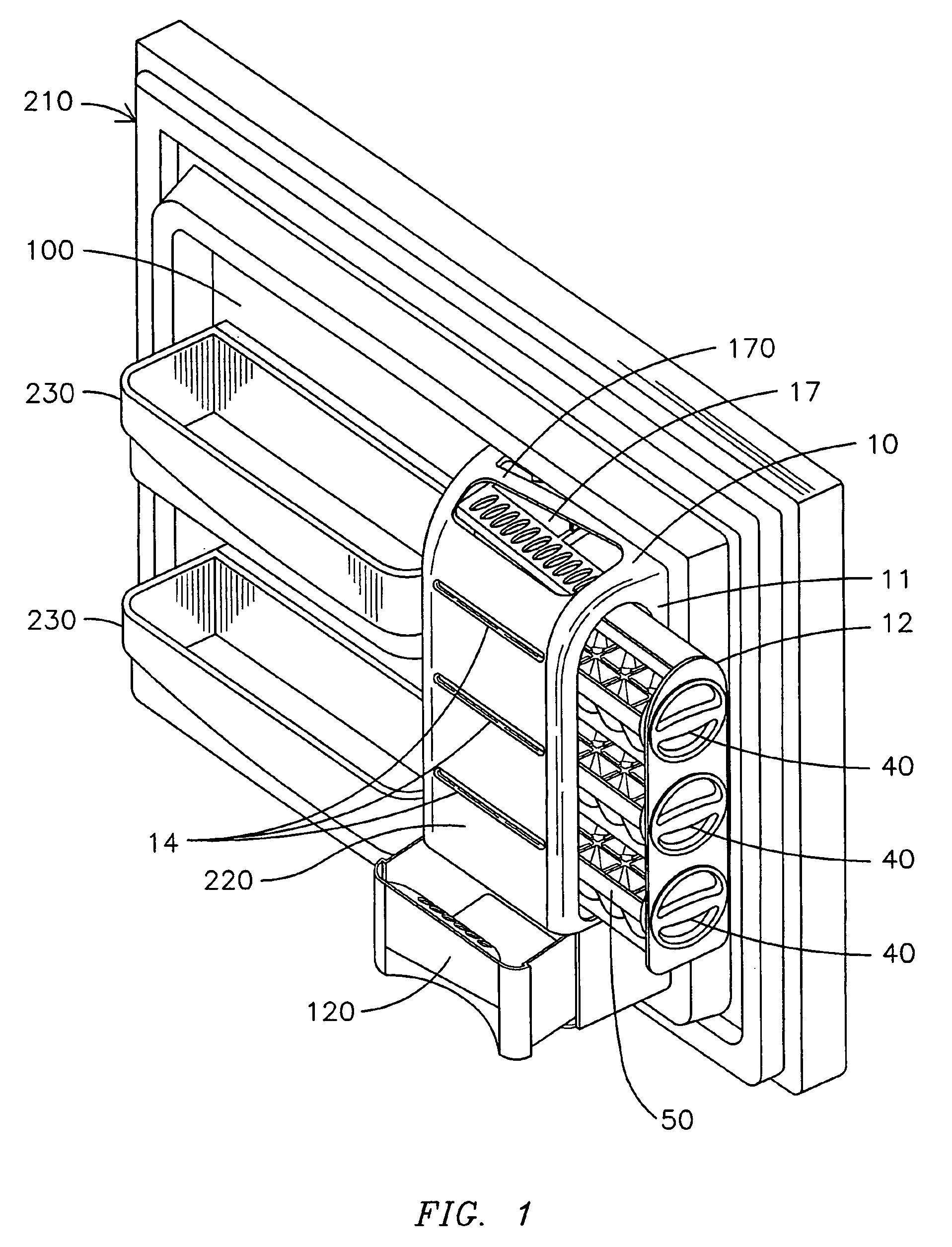

Ice cube making device for refrigerators

InactiveUS7204092B2Mould separation apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:MABE MEXICO S DE R L DE

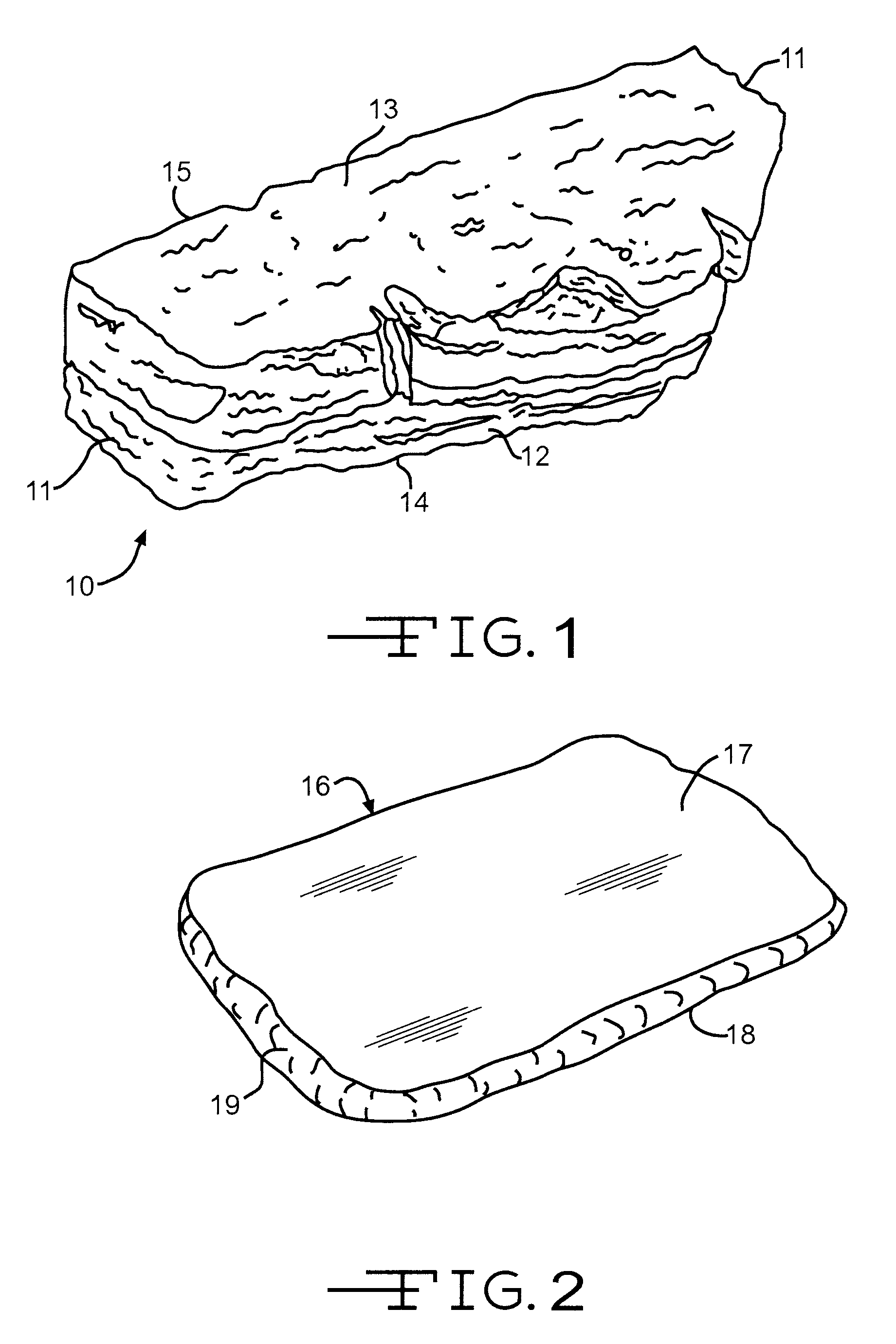

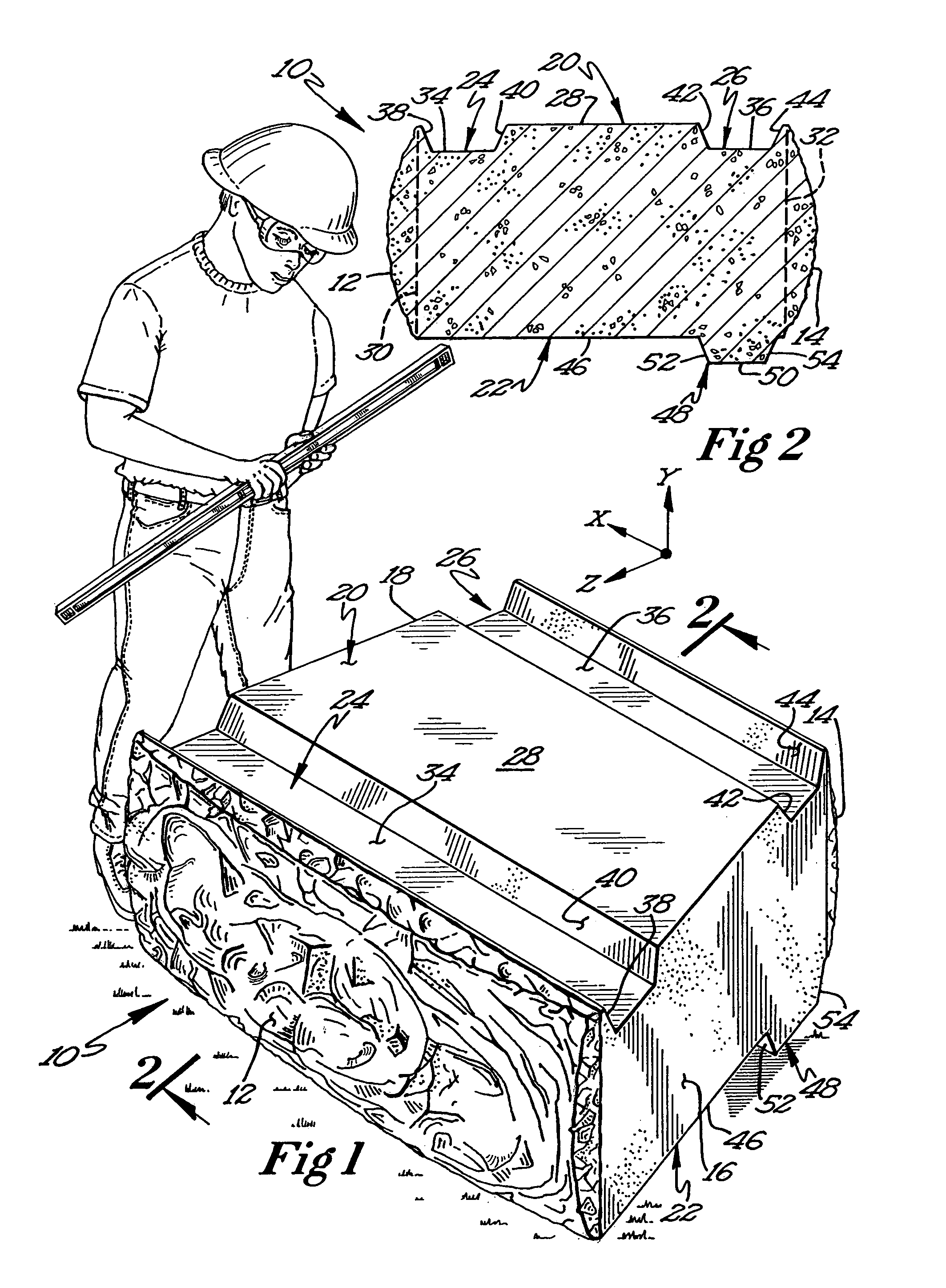

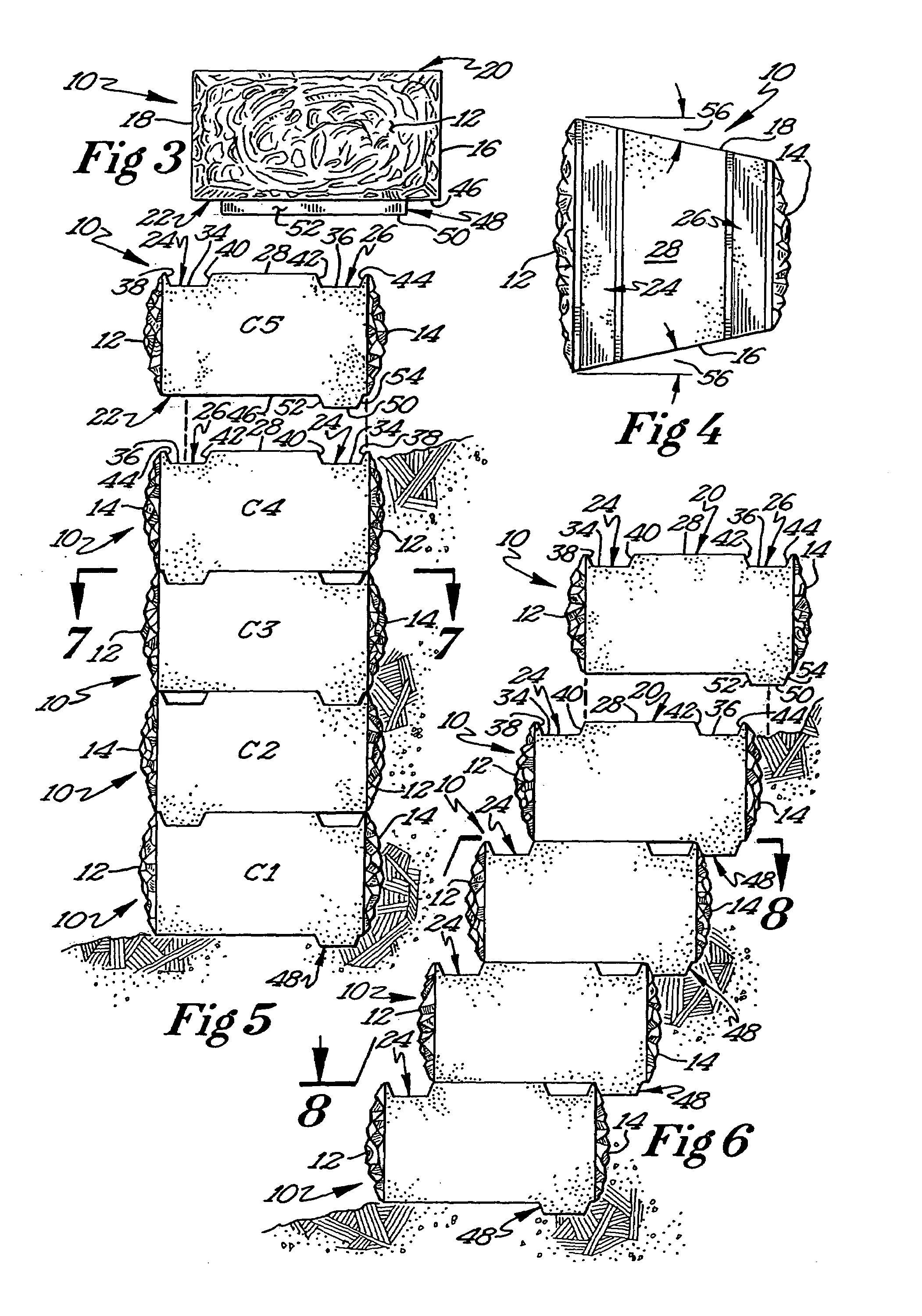

Mold box and method of manufacturing a block

The present invention relates a mold box method of manufacturing a block, and a wall block with a stepped-back strata and ledges imprinted on one or more faces of the block. A mold box is provided with a block face liner that is machine cut to create a particular strata and ledge pattern that is widest at the top of the liner and steps back over a plurality of planes to a narrower width at the bottom of the liner. Masonry material is allowed to form in the mold box around the liner to produce the strata and ledges imprint onto one or more faces of the block. The invention also relates to the mold box, multiple embodiments of the block face liner with differing strata and ledge patterns, and to blocks formed in the mold box and methods of constructing walls with the blocks.

Owner:KEYSTONE RETAINING WALL SYST

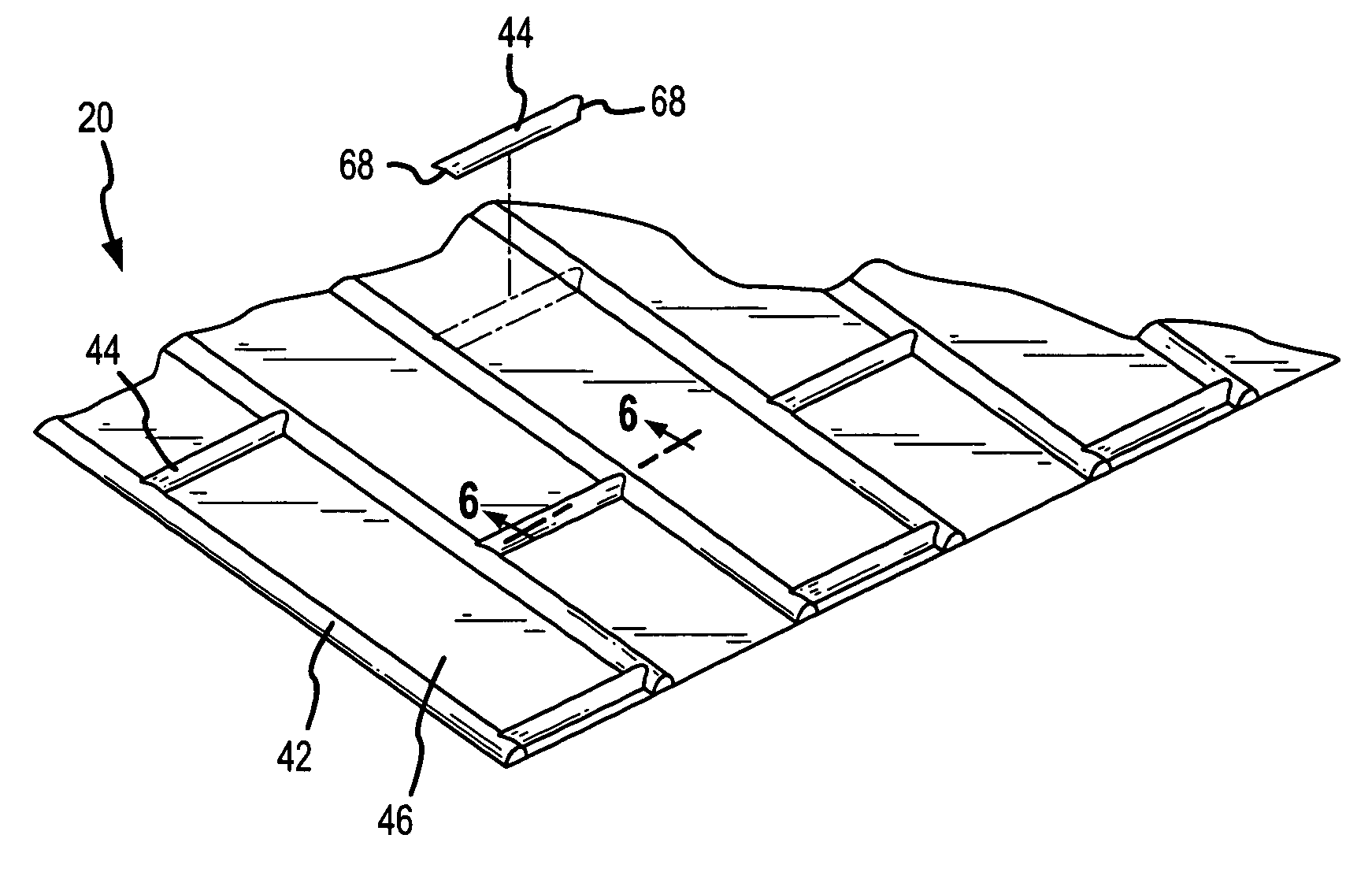

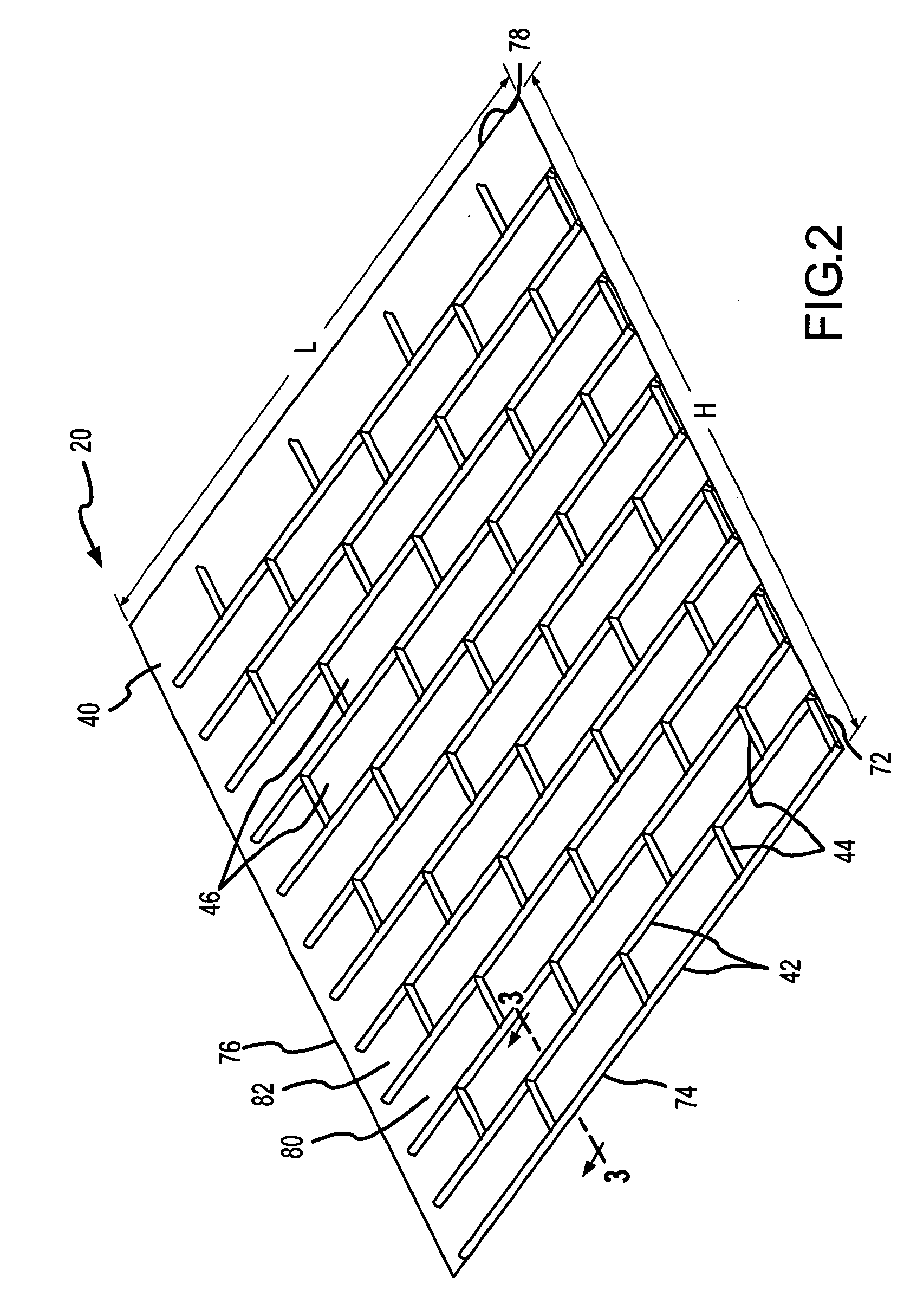

Foam liner for casting objects in poured walls

A liner holds objects in place within a form for a poured wall. The liner includes a backing sheet and a plurality of foam bed joints arranged in a substantially parallel fashion along a length dimension. A plurality of separate foam head joints are attached along a height dimension, wherein opposing ends of the foam head joints engage adjacent bed joints to define a plurality of regions on the backing sheet for receiving the objects to be cast in the poured wall. Each foam joint has a rounded cross section to form a curved grout line between the objects cast in the poured wall. The foam joints include an outer protective skin to prevent the poured wall material from bonding with the foam cells. A method of forming the liner includes aligning the separate foam bed joints and head joints in a grid and then pressing an adhesive-backed paper sheet against the foam joints.

Owner:SCOTT WILLIAM CLARE +1

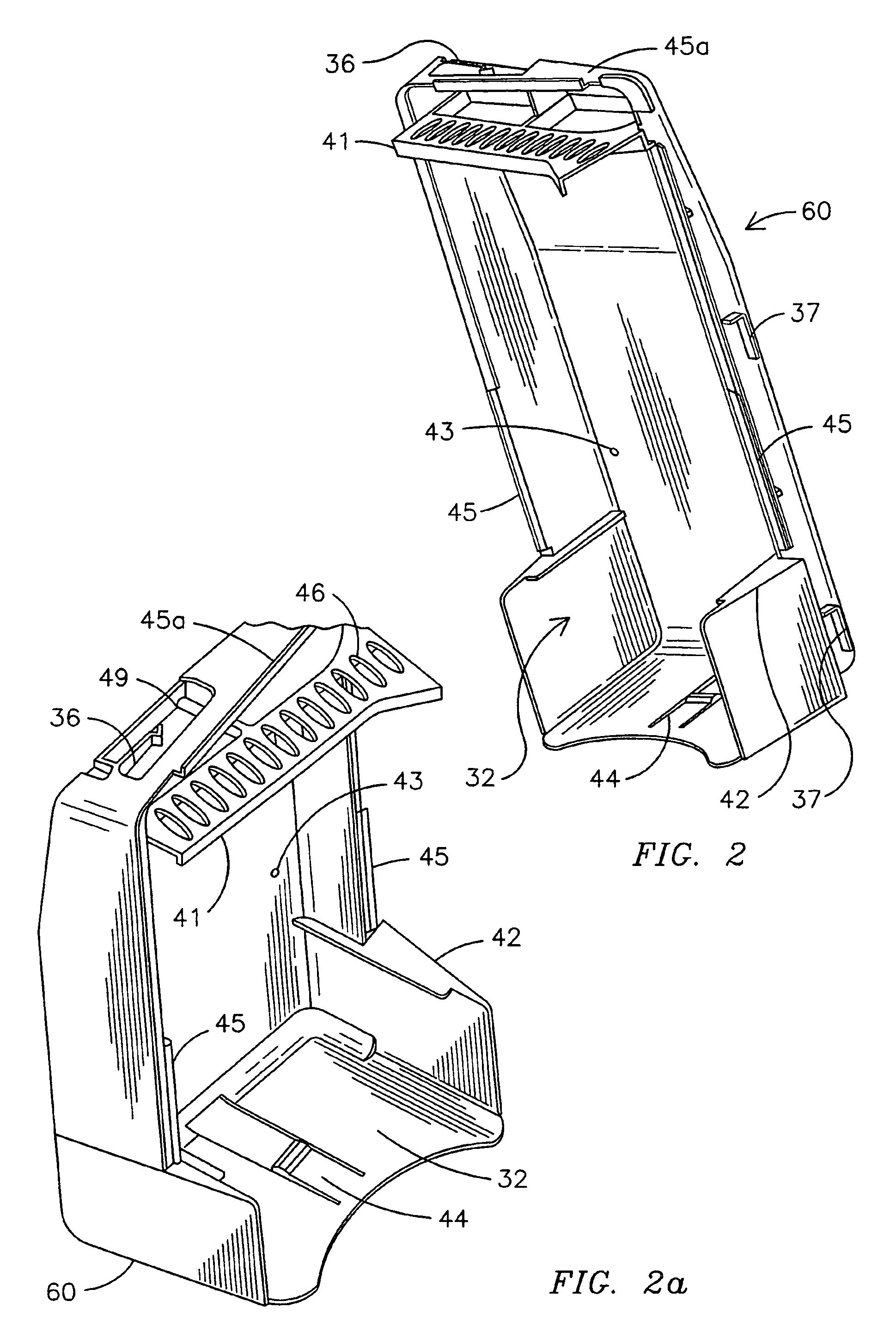

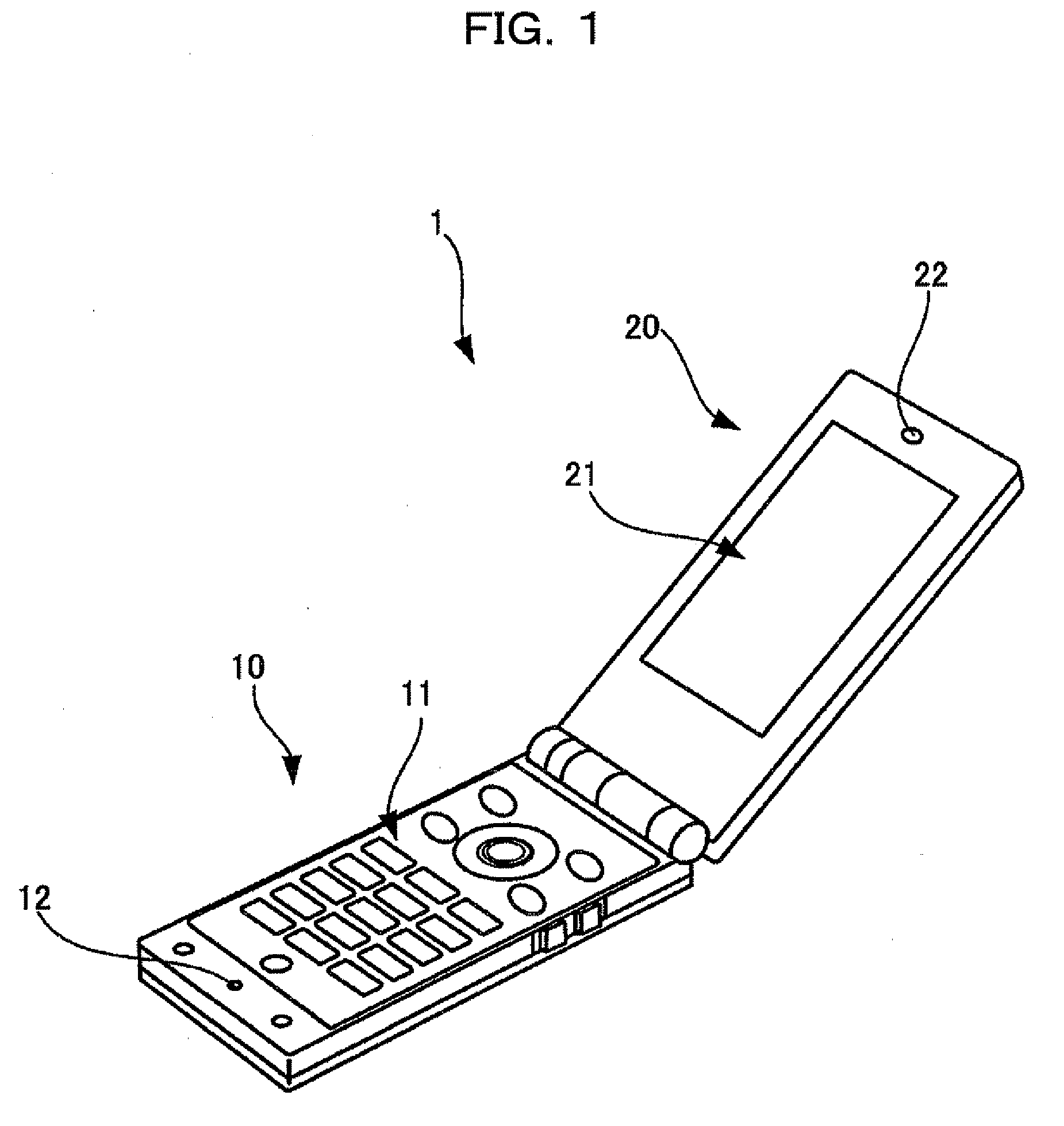

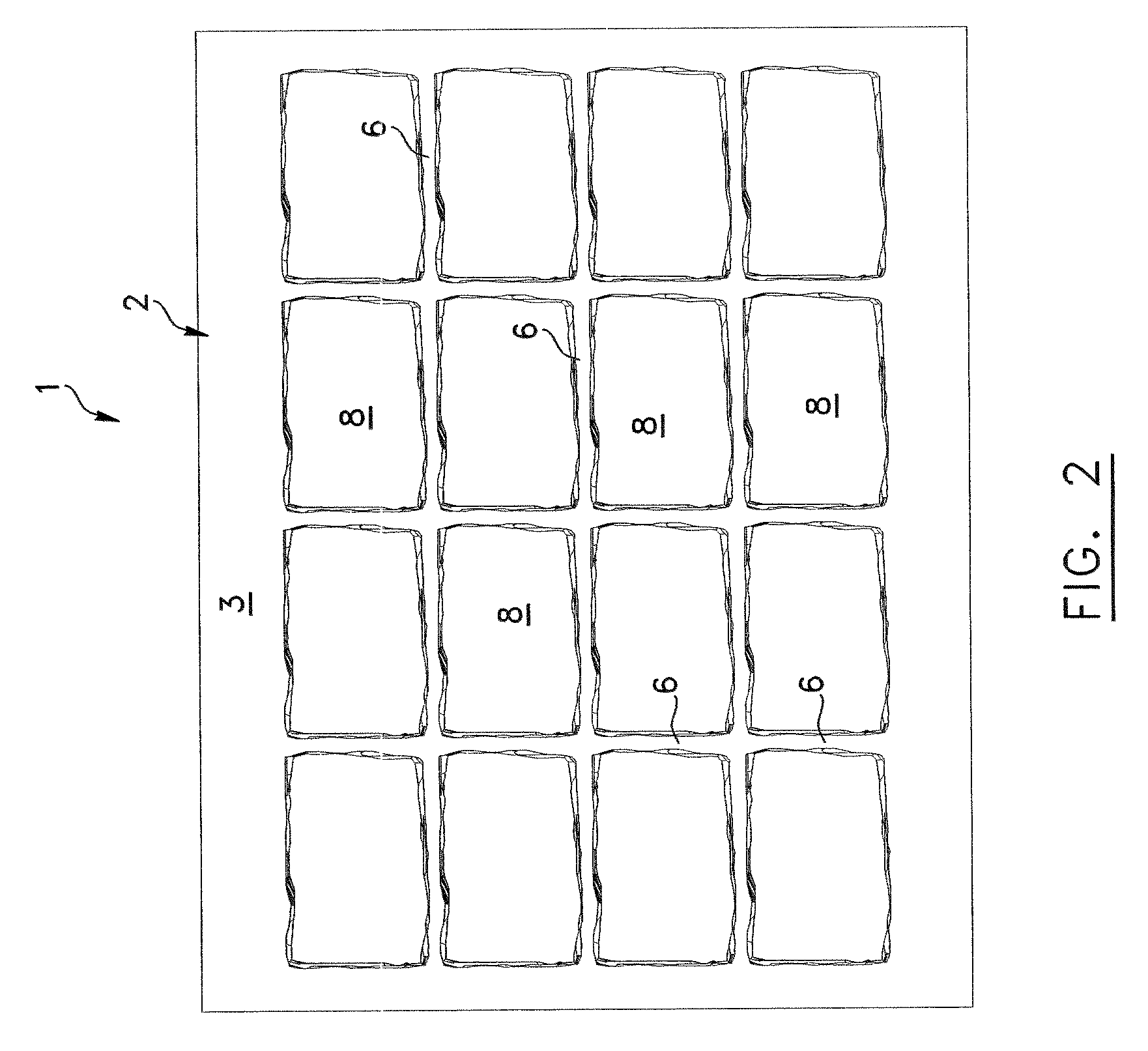

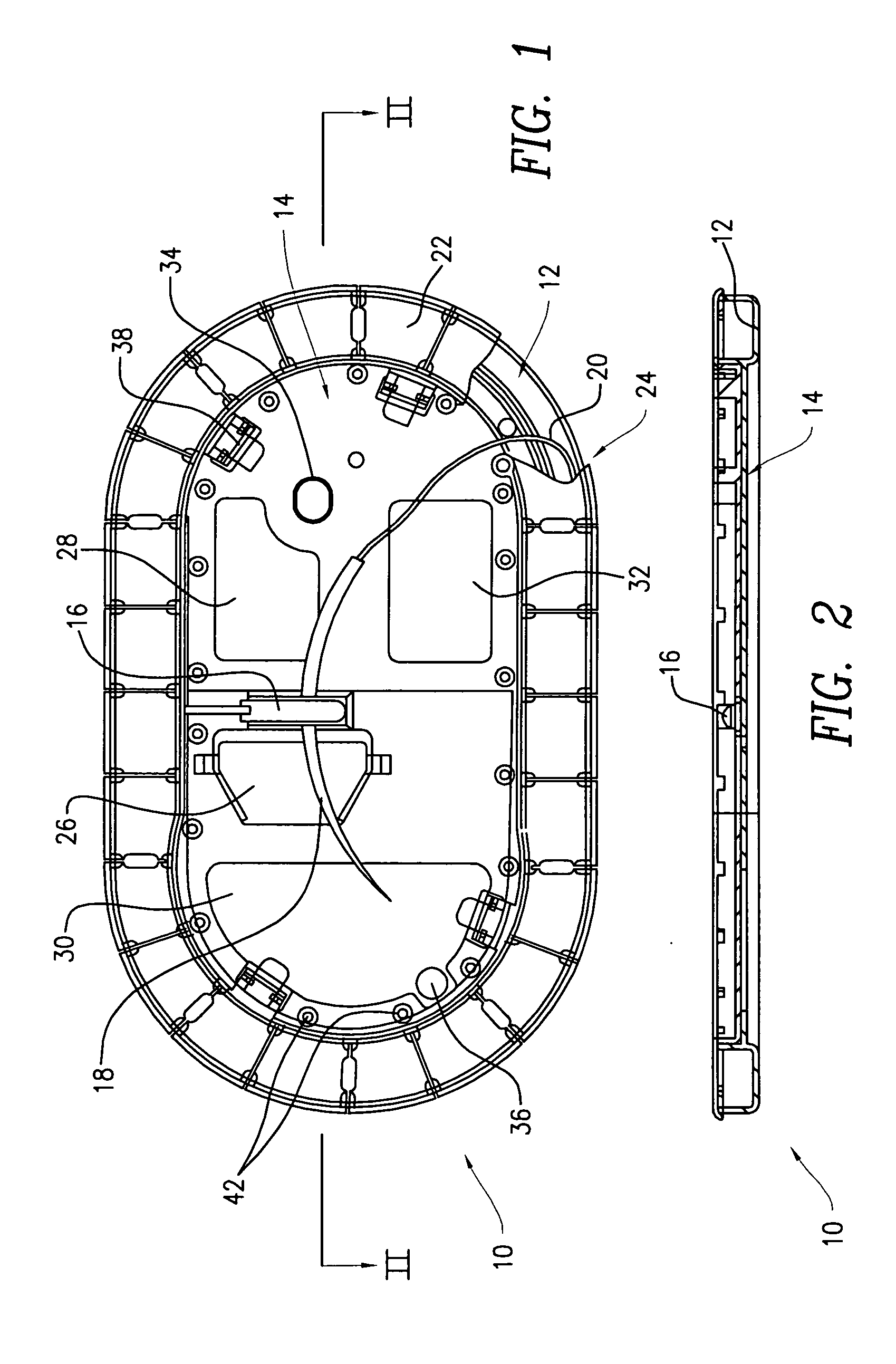

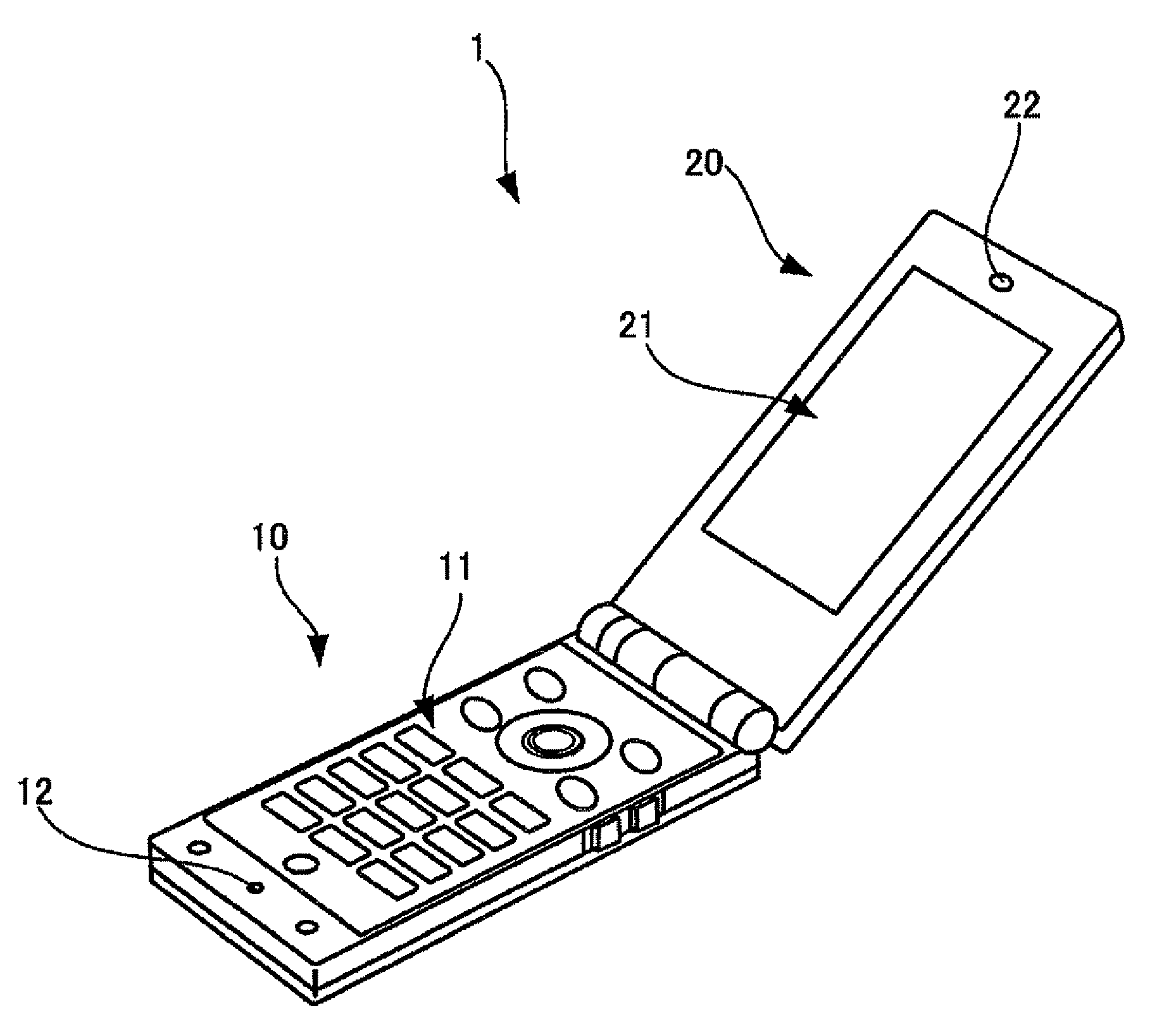

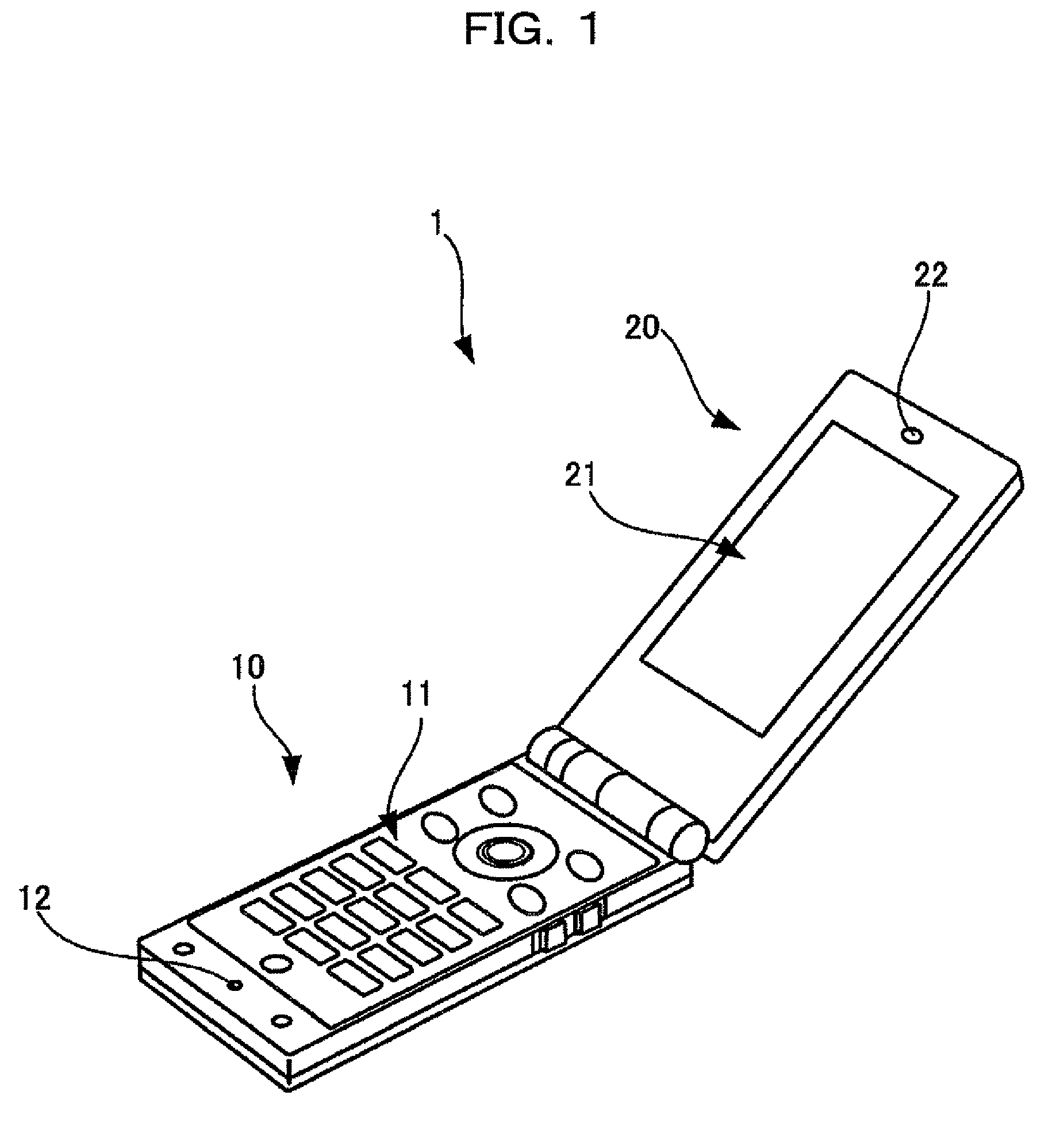

Mobile device

A mobile device having a housing and operating on power supplied from the battery loaded in the battery chamber including: a pair of walls of the housing having hook receiving portions formed a groove; a battery lid covering the battery chamber so as to be freely detached; a pair of positioning hooks serving to position the battery lid by entering the grooves of the corresponding hook receiving portions; overhanging edges serving to regulate position of the cover lid; and a waterproof gasket fixed to the battery chamber side of the cover lid so as to be in contact with all sides of the battery chamber.

Owner:FUJITSU CONNECTED TECH LTD

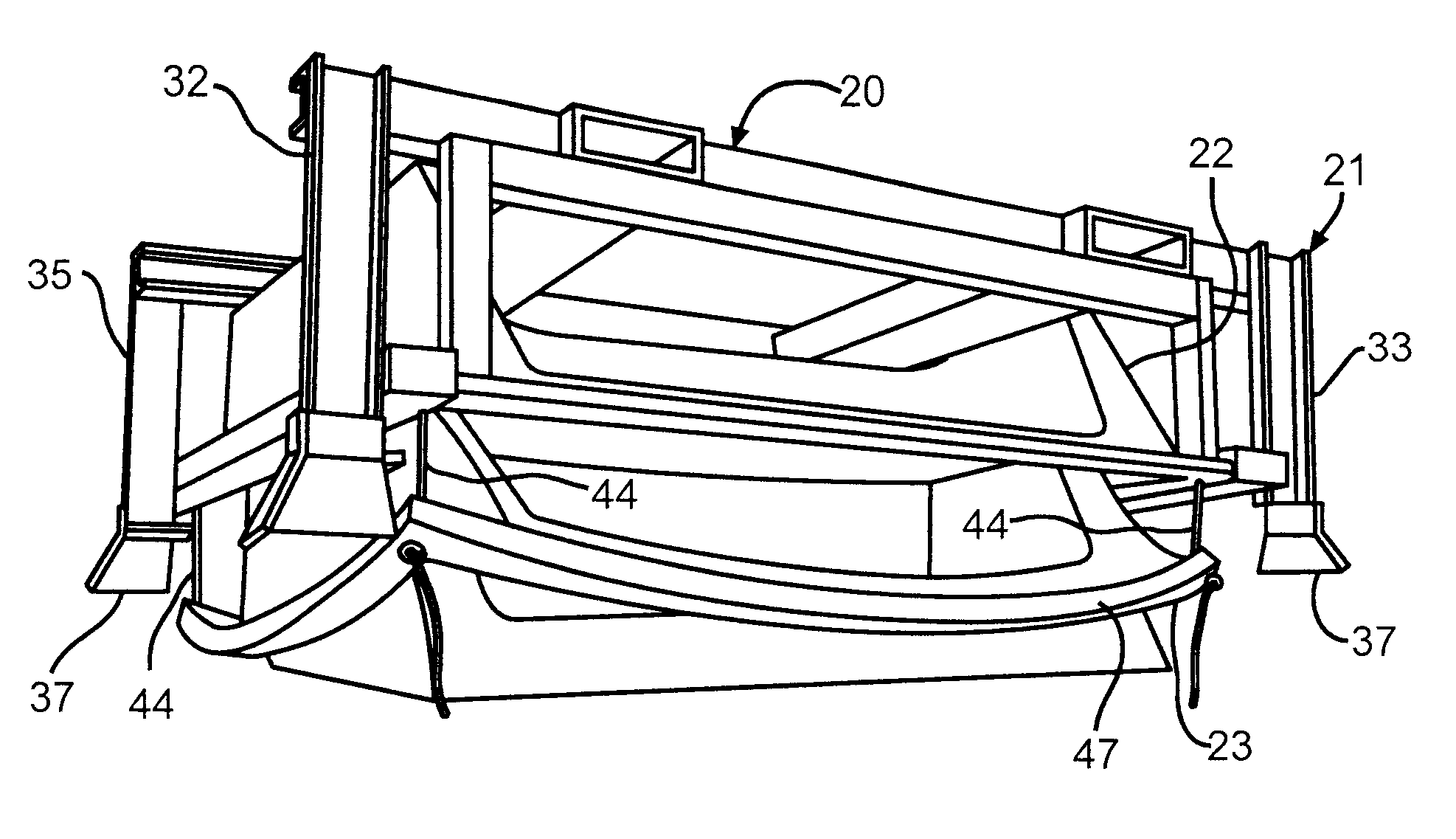

Molding apparatus for producing dry cast products having textured side surfaces

ActiveUS8101113B2Easy to demouldConstruction materialMould separation apparatusEngineeringMechanical engineering

Owner:OLDCASTLE BUILDING PROD CANADA INC

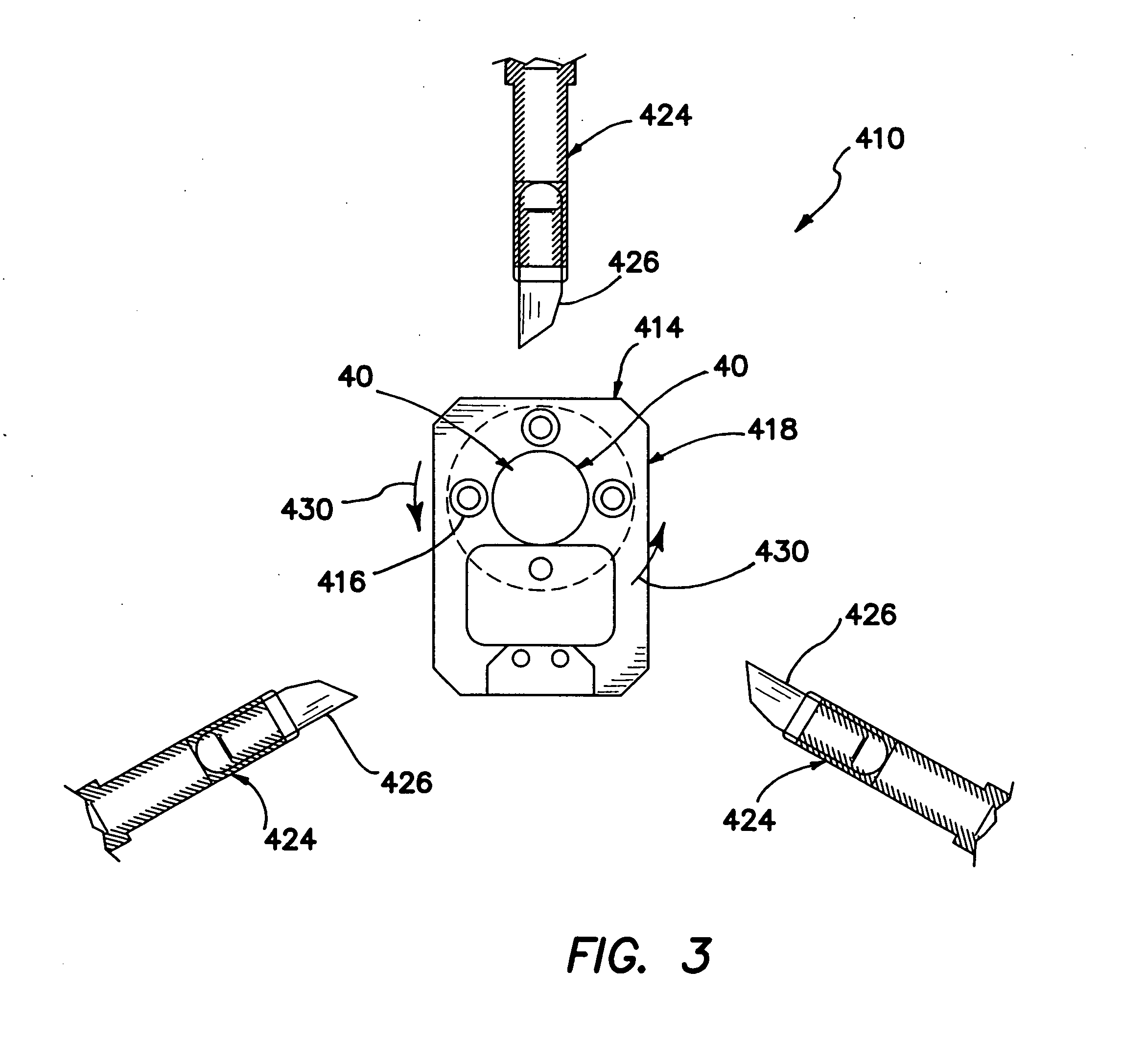

Apparatus and method for making suture packages

ActiveUS20080185752A1Overcome disadvantagesOvercome problemsSuture equipmentsConfectioneryMaterials science

Apparatus and method for making a plurality of different types of suture packages employ a mold with first and second opposing mold parts partially defining a mold cavity, at least one of the opposing mold parts has an opening therein communicating with the mold cavity. An insert is removeably inserted into the opening, to complete the mold cavity in a form suitable for molding a first type of suture package. An alternative insert is interchangeable with the first insert for completing the mold cavity in a form suitable for molding a second type of suture package. To make different suture packages, the mold is initially configured and used with one of the inserts to thereby make one type of suture package. The first insert is then replaced with the second, changing the mold cavity to form another type of suture package.

Owner:ETHICON INC

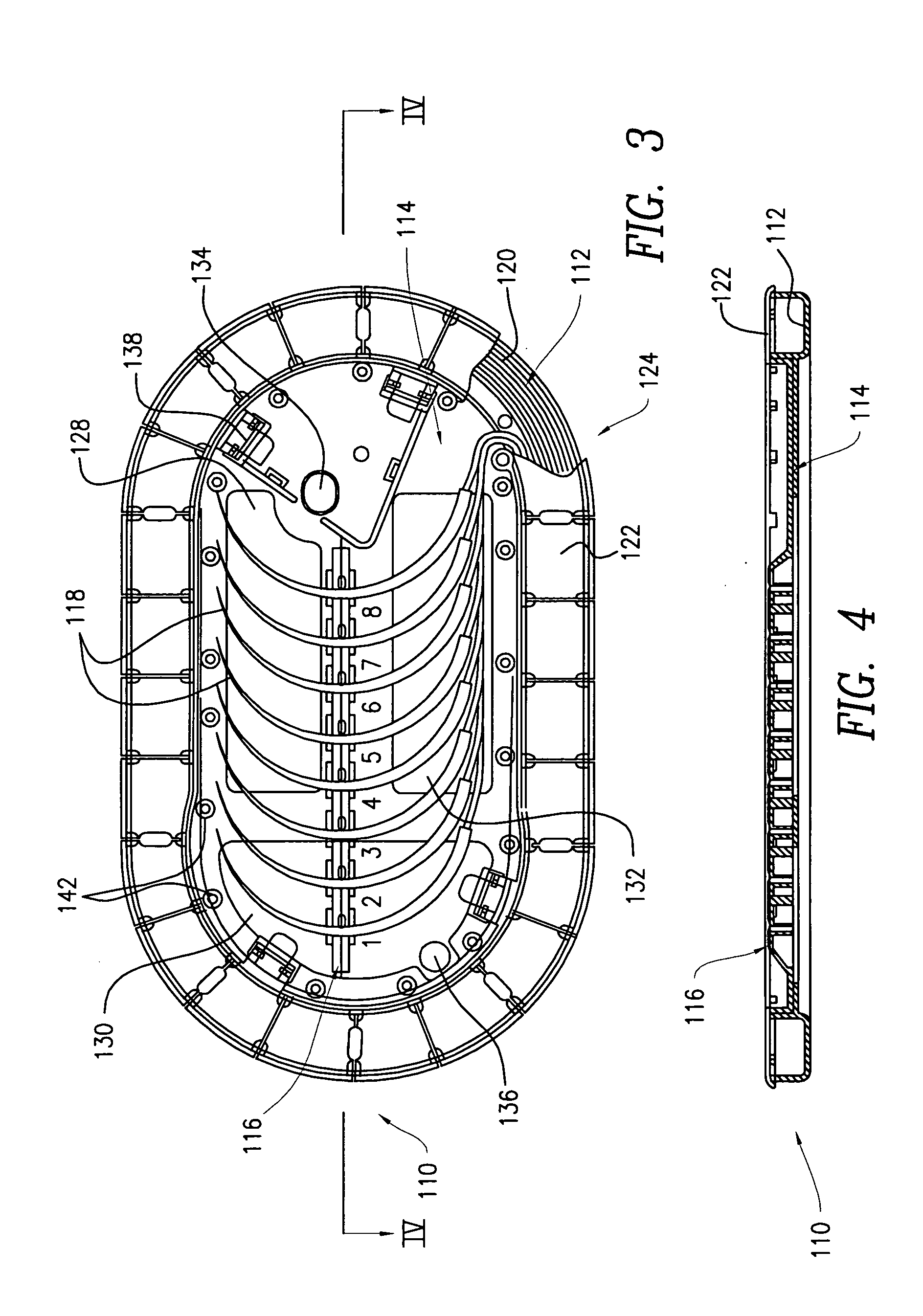

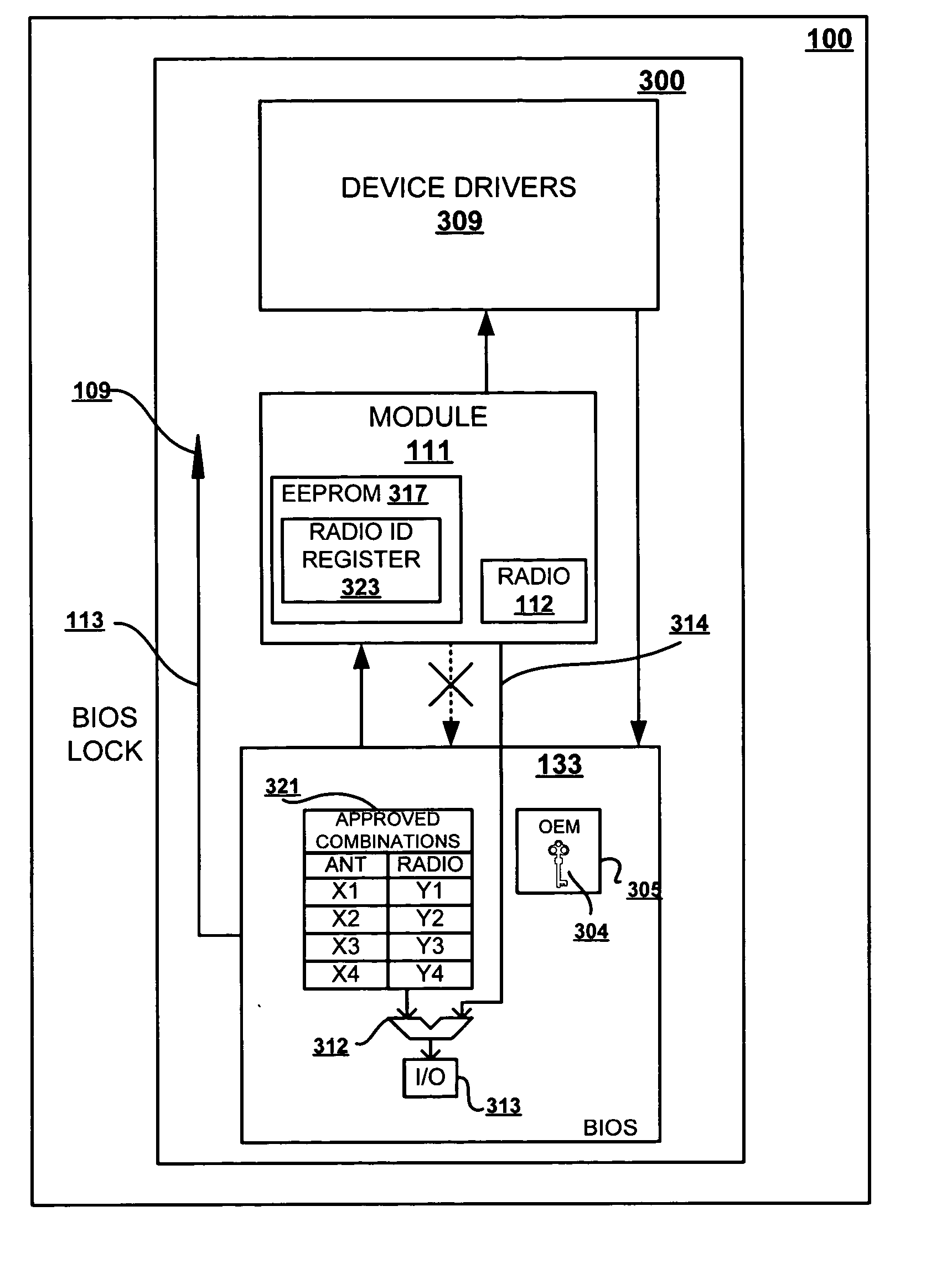

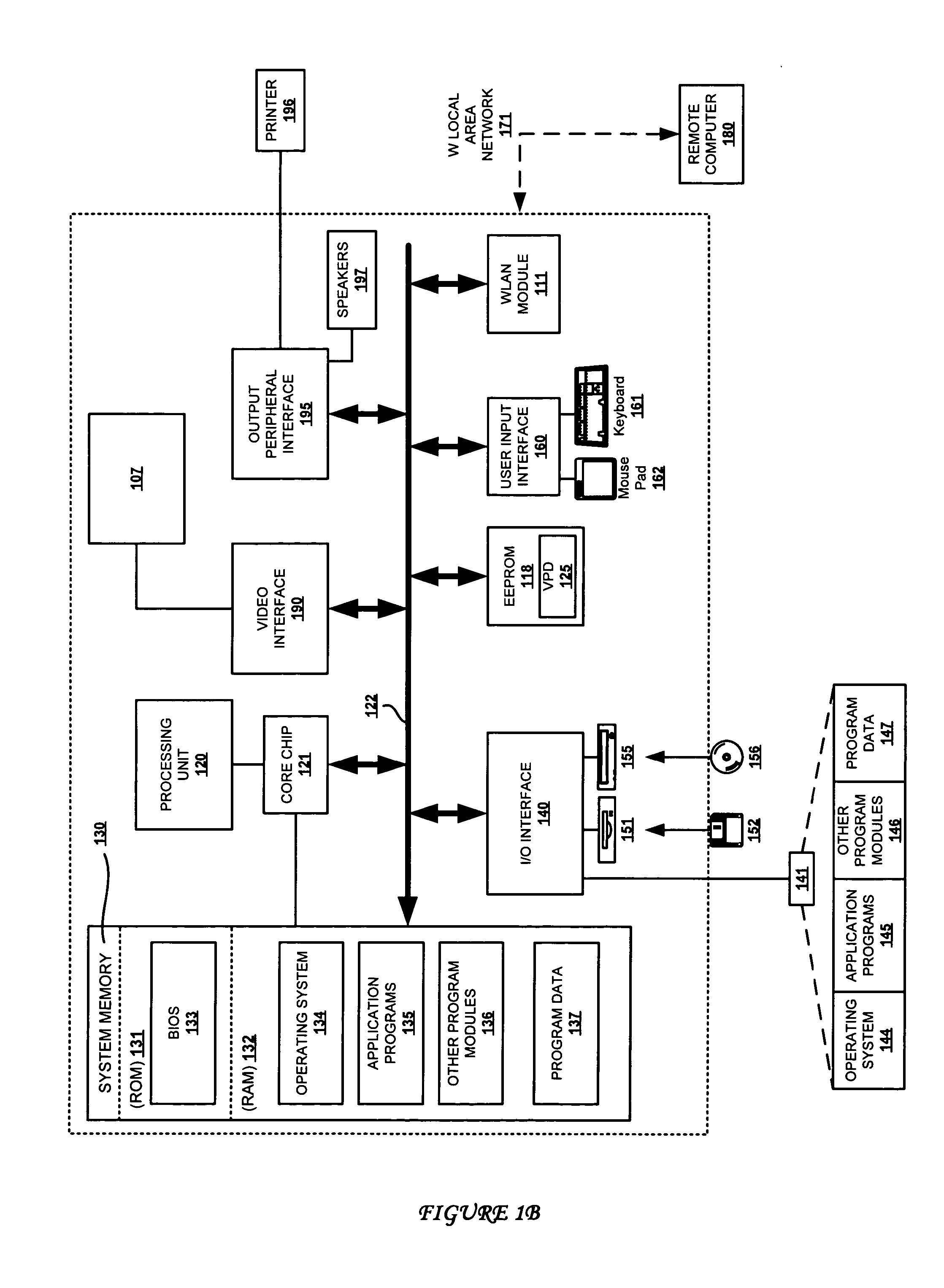

Cruable U-NII wireless radio with secure, integral antenna connection via SM BIOS in U-NII wireless ready device

ActiveUS20050074123A1Avoid modificationAntenna supports/mountingsUser identity/authority verificationBIOSEmbedded system

A method that utilizes software and hardware mechanisms to meet the FCC requirement for a U-NII antenna to be an integral part of the device in which it operates, while providing wireless ready U-NII devices and CRUable U-NII radios. Enhancements are made to the software BIOS, including the inclusion of a table of approved radio-antenna PCI ID pairs to create an authentication scheme that verifies and authenticates the radio and antenna combination as being an FCC-approved unique coupling during boot-up of the system. The BIOS also comprises an OEM field that stores an encrypted secret key utilized to complete a second check of the radio model placed in the device. During boot up of the device, the PCI ID pairs from the BIOS are compared against the PCI ID of the radio and the secret key is checked against the radio model. Only a system with an approved combination of radio and antenna is allowed to complete the boot process, indicating an FCC approved device-antenna-radio combination under the “integral” requirement.

Owner:LENOVO PC INT

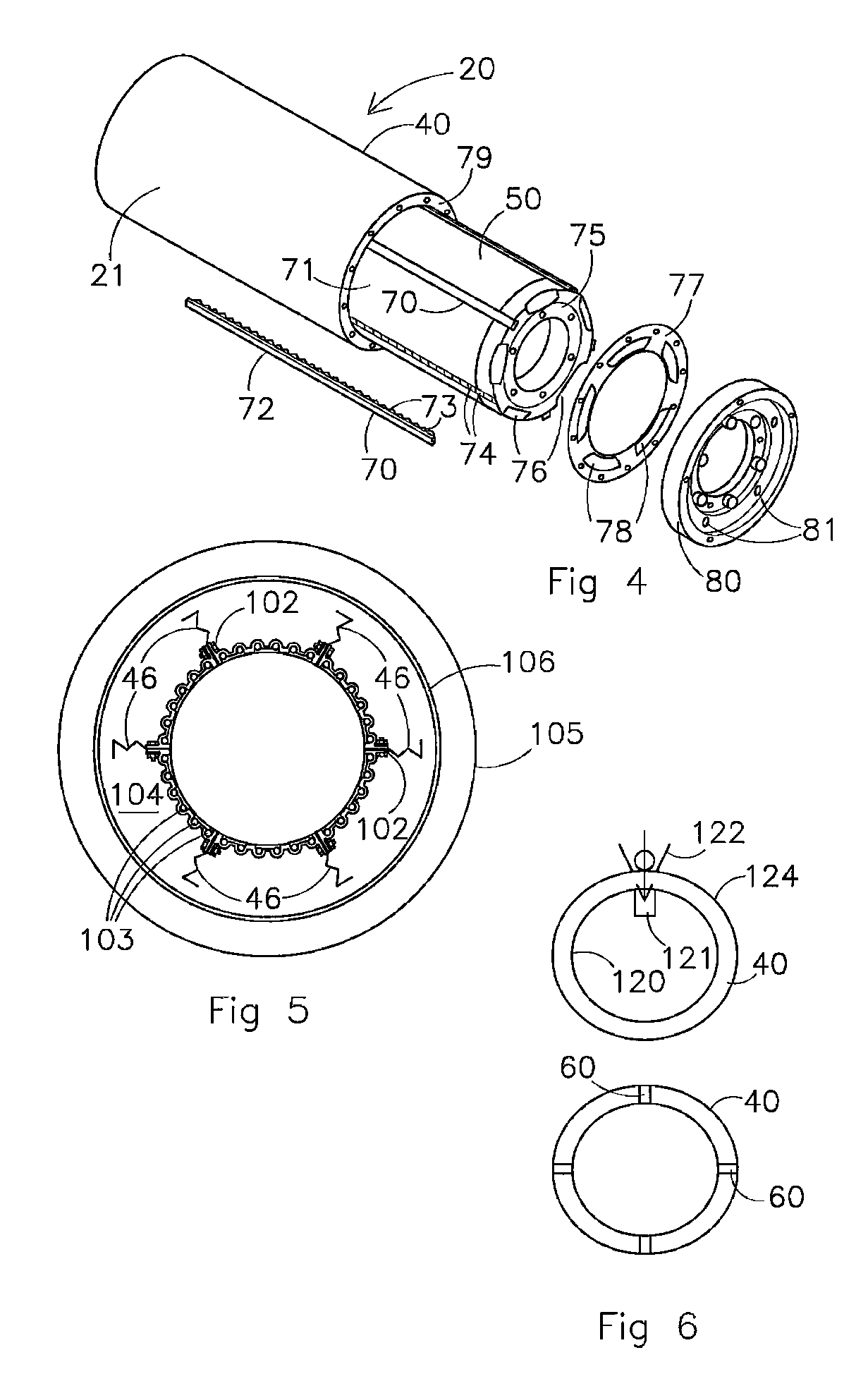

Mould member for moulding three-dimensional products, system and methods of manufacturing a mould member

ActiveUS20090134544A1Difficult to processReduce riskMouldsArtificial flowers and garlandsCavity wallMaterials science

A mould member for moulding three-dimensional products from a mass of one or more food starting materials, which are suitable for consumption, in particular human consumption, comprises a body having a porous structure and a plurality of mould cavities, which mould cavities each have a mould cavity wall defined by the body and an opening in a surface of the body, wherein the body comprises at least one essentially fluid tight barrier.

Owner:STORK TITAN

Radio frequency identification (RFID) solution to lost time spent on instrument inventory

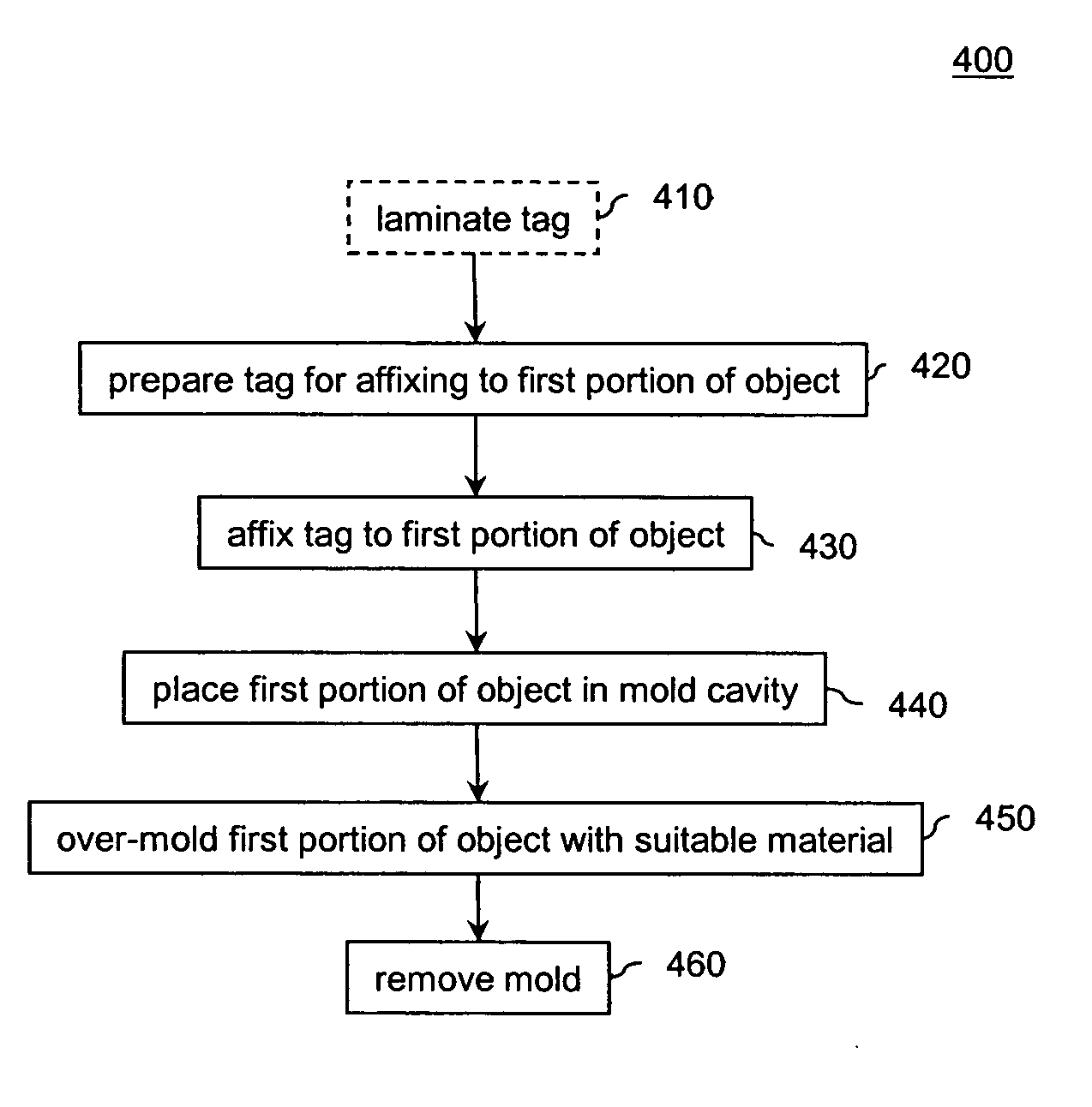

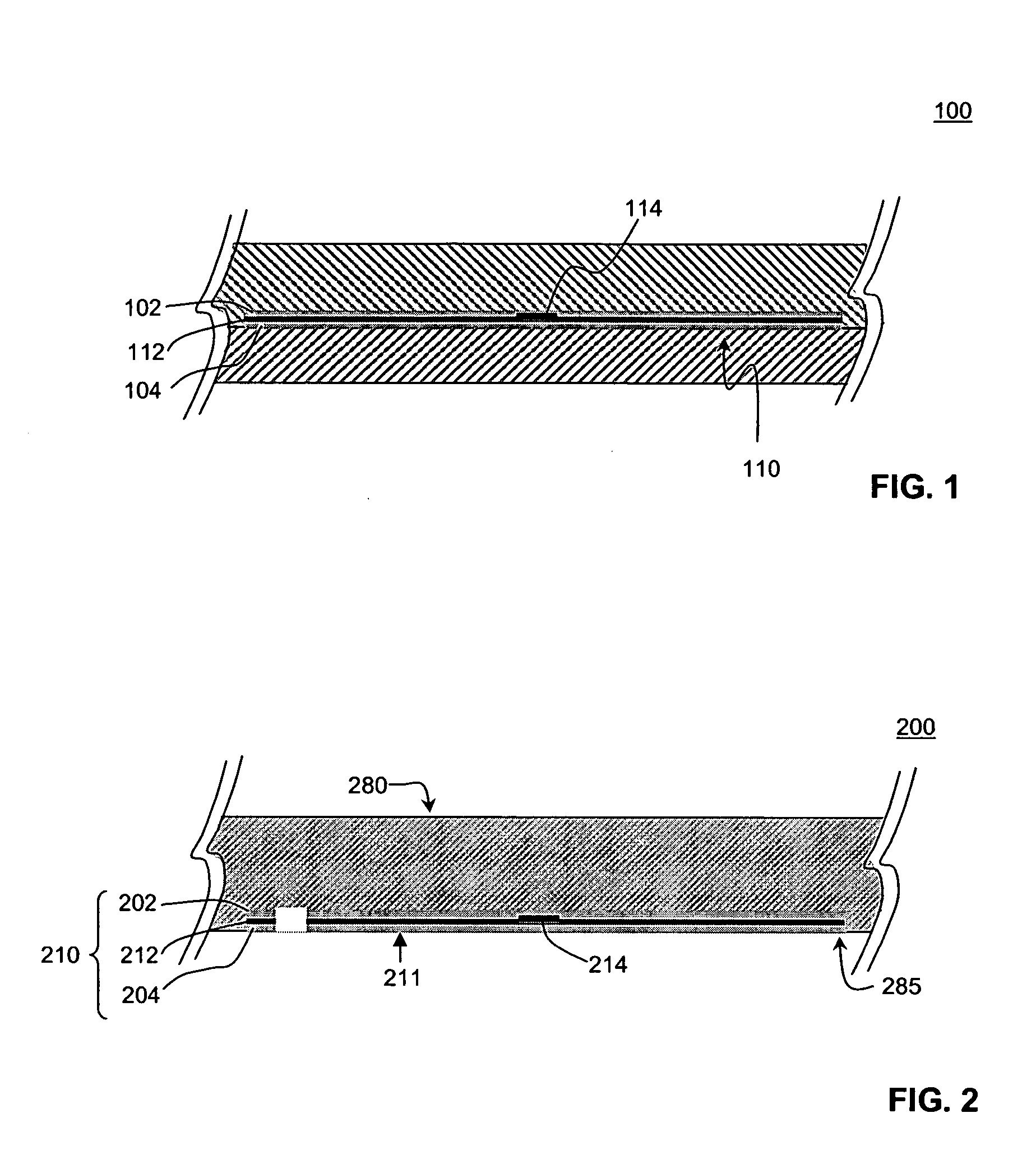

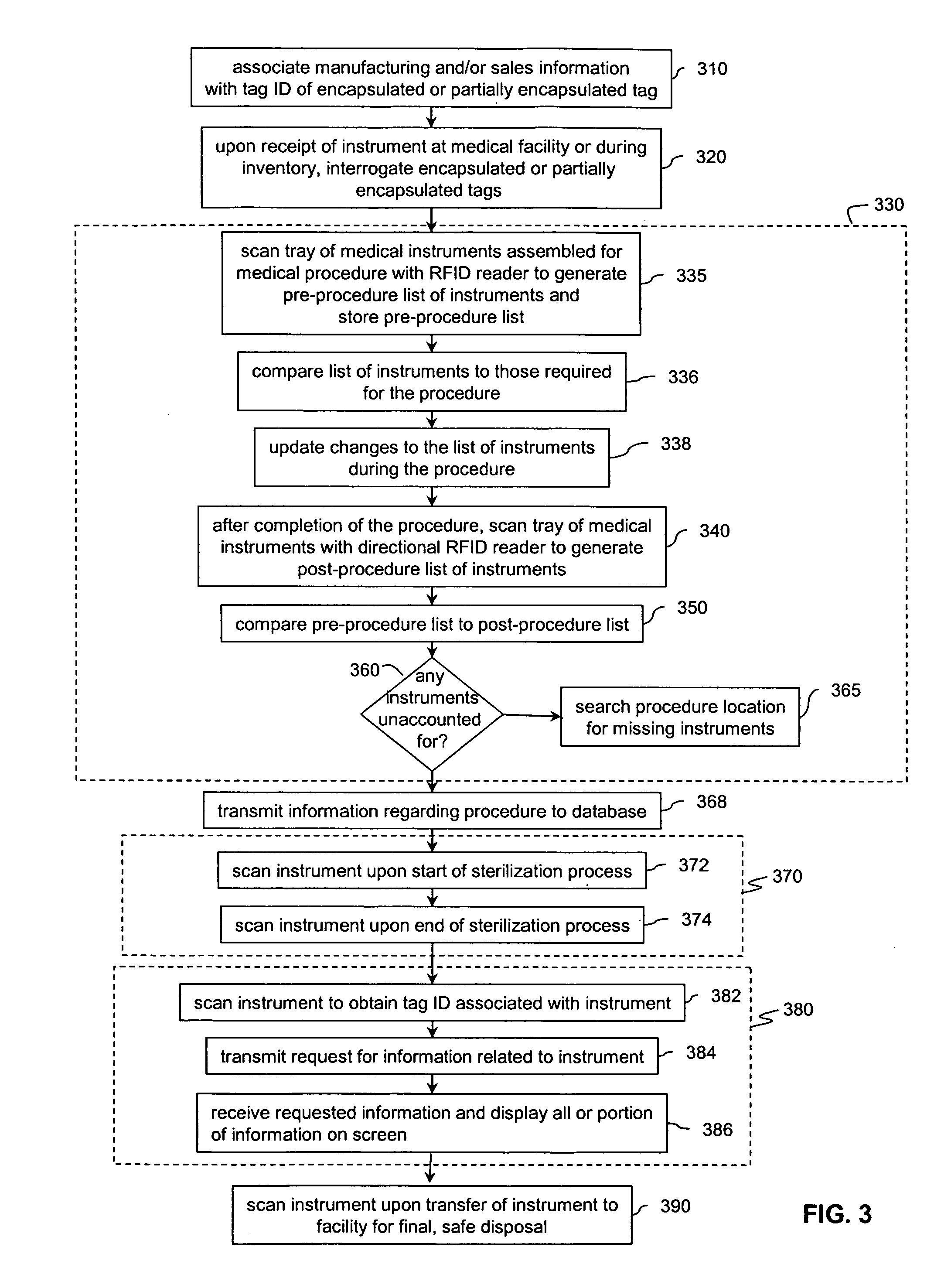

A method for manufacturing an object having an encapsulated radio frequency identification (RFID) tag is provided. An RFID tag is mechanically or chemically affixed to a first portion of the object being manufactured. The first portion of the object, with the RFID tag affixed is placed in a cavity of a mold. The first portion is then over-molded with a first material such as high temperature thermoplastic or low temperature thermoset to generate a seamless object. A method for manufacturing an object having a partially encapsulated RFID tag is also provided. An RFID tag is laminated with a lamination material, such as high temperature thermoplastic. The laminated RFID tag is affixed to a mold. The laminated RFID tag is then over-molded with a first material to generate a seamless object. Methods for tracking medical instruments having encapsulated or partially encapsulated RFID tags are also provided.

Owner:SYMBOL TECH INC

Wall block with weight bearing pads and method of producing wall blocks

A wall block having at least one weight bearing pad on an upper or lower surface of the block and a compression head and methods of making the block and making walls with the block.

Owner:KEYSTONE RETAINING WALL SYST

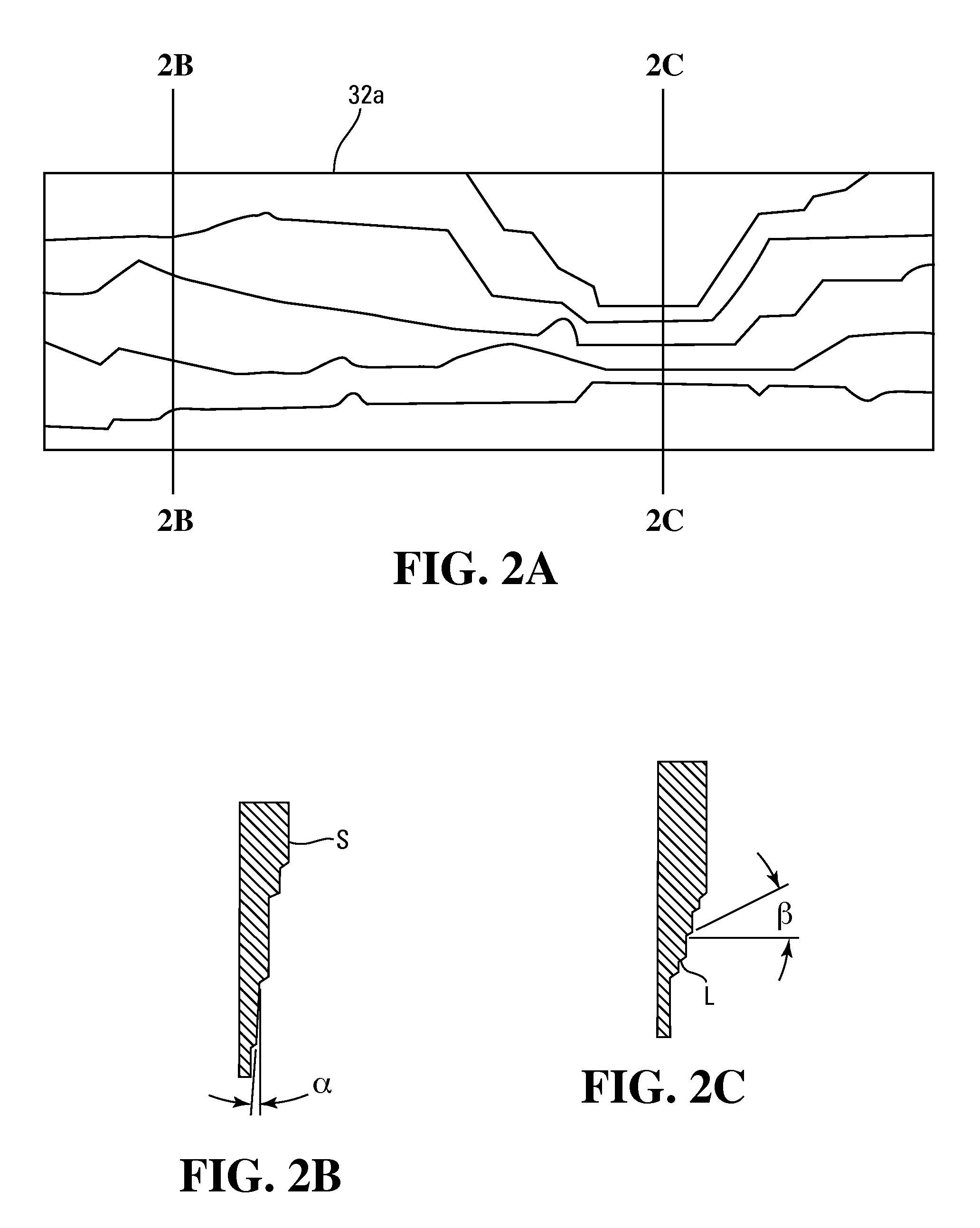

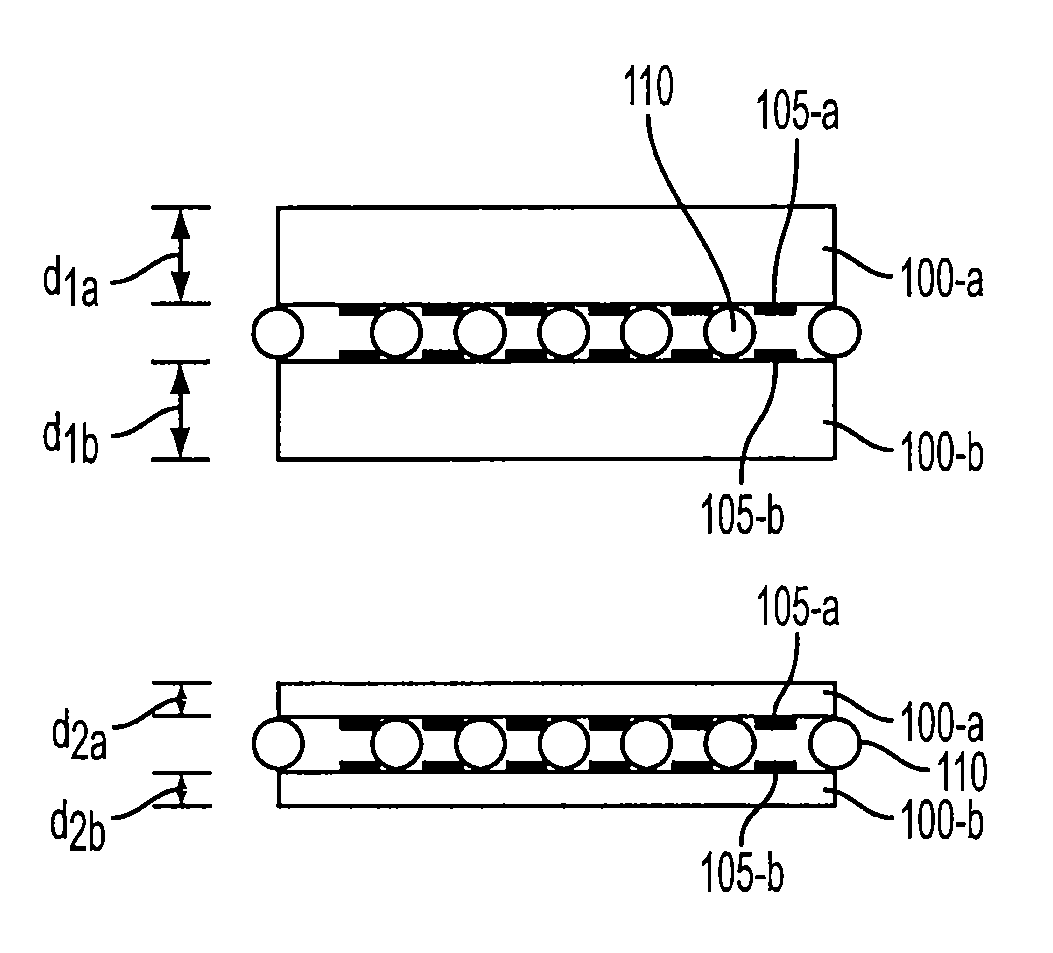

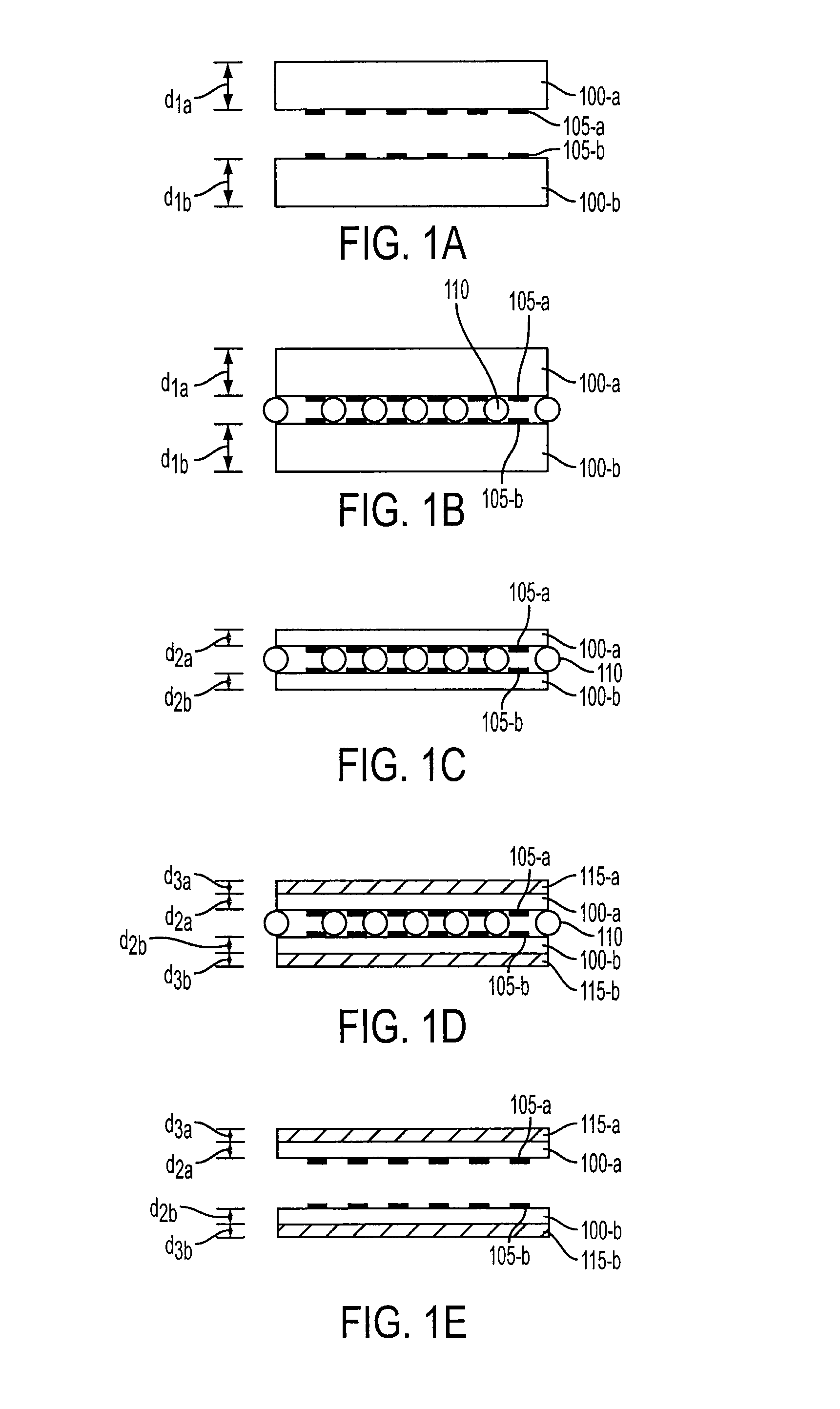

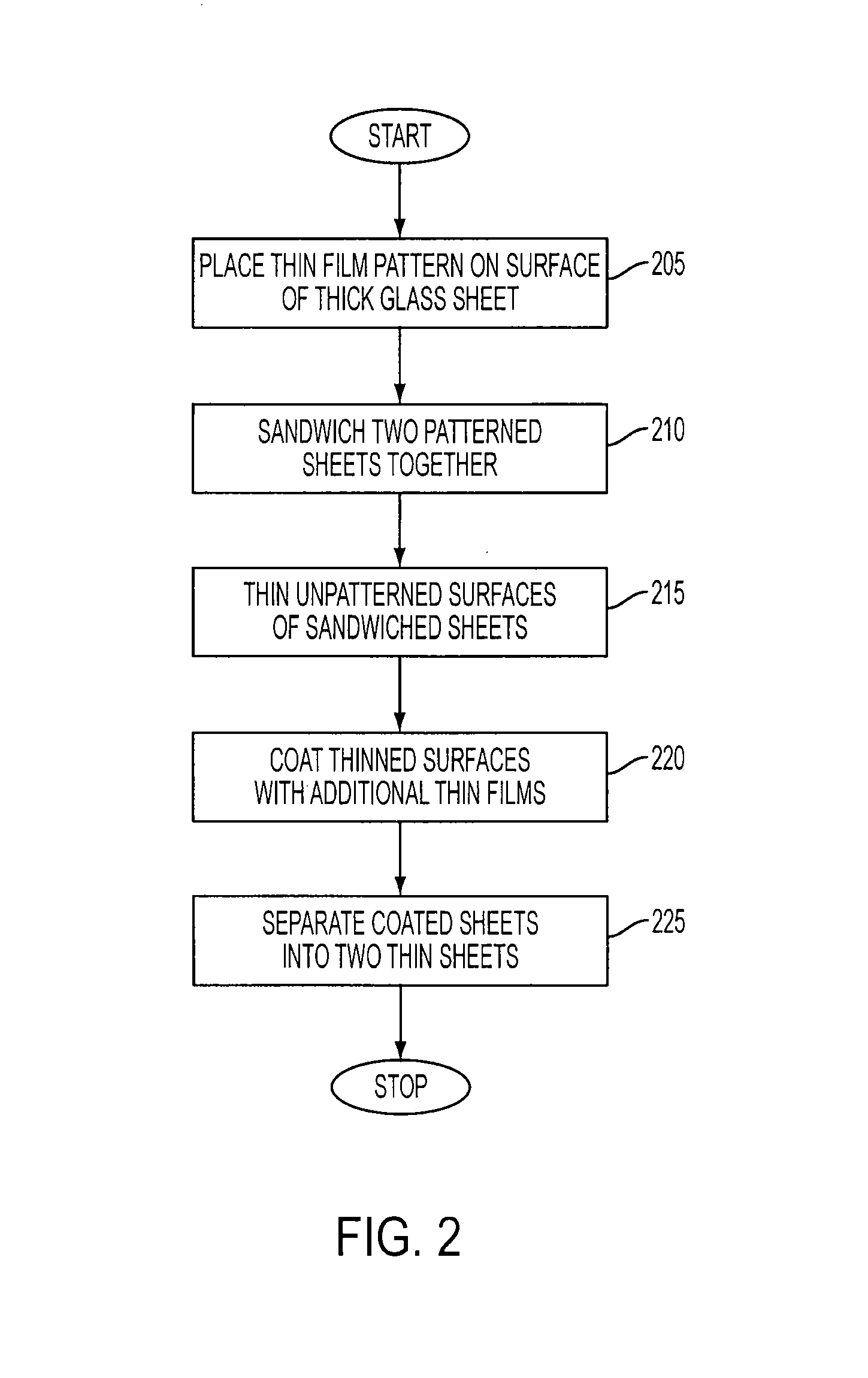

Method for fabricating thin sheets of glass

Fabrication of thin sheets of glass or other substrate material for use in devices such as touch sensor panels is disclosed. A pair of thick glass sheets, typically with thicknesses of 0.5 mm or greater each, may each be patterned with thin film on a surface, sealed together to form a sandwich with the patterned surfaces facing each other and spaced apart by removable spacers, either or both thinned on their outside surfaces to thicknesses of less than 0.5 mm each, and separated into two thin glass sheets. A single thick glass sheet, typically with a thickness of 0.5 mm or greater, may be patterned, covered with a protective layer over the pattern, thinned on its outside surface to a thickness of less than 0.5 mm, and the protective layer removed. This thinness of less than 0.5 mm may be accomplished using standard LCD equipment, despite the equipment having a sheet minimum thickness requirement of 0.5 mm.

Owner:APPLE INC

Method and apparatus for forming concrete blocks

A method and apparatus for forming a concrete block in form having a resilient insert forming a cavity in which the block is cast and a rigid support for the resilient insert. After the block has cured, the form is inverted. One or more areas of the insert are tethered to the support so that at least a portion of the insert can fall a short distance from the support. The weight of the cast block sufficiently deforms the insert to allow the block to fall free from the insert. When the form is again inverted to its upright position, the insert falls back into the support and returns to its original shape.

Owner:ROSETTA HARDSCAPES

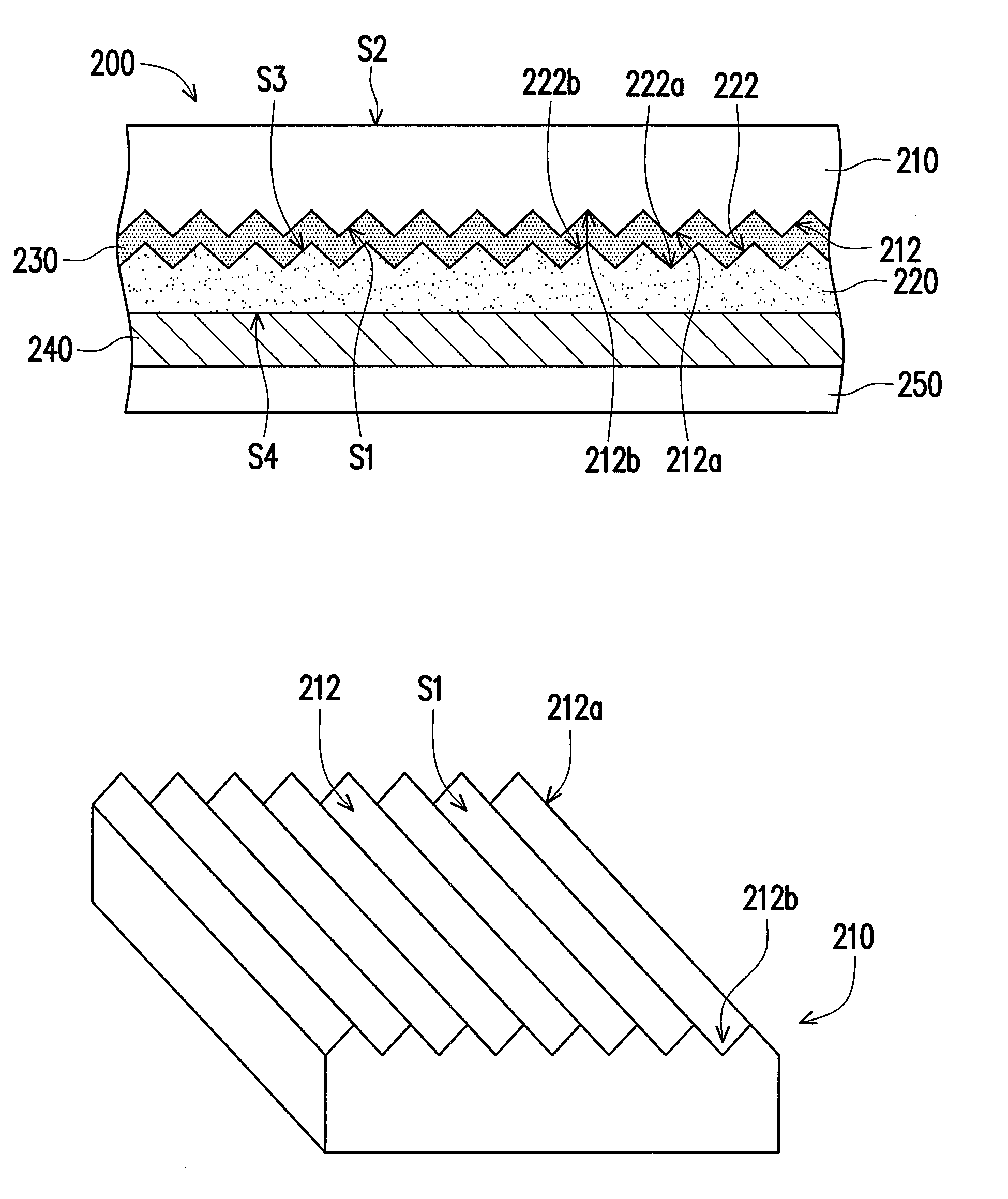

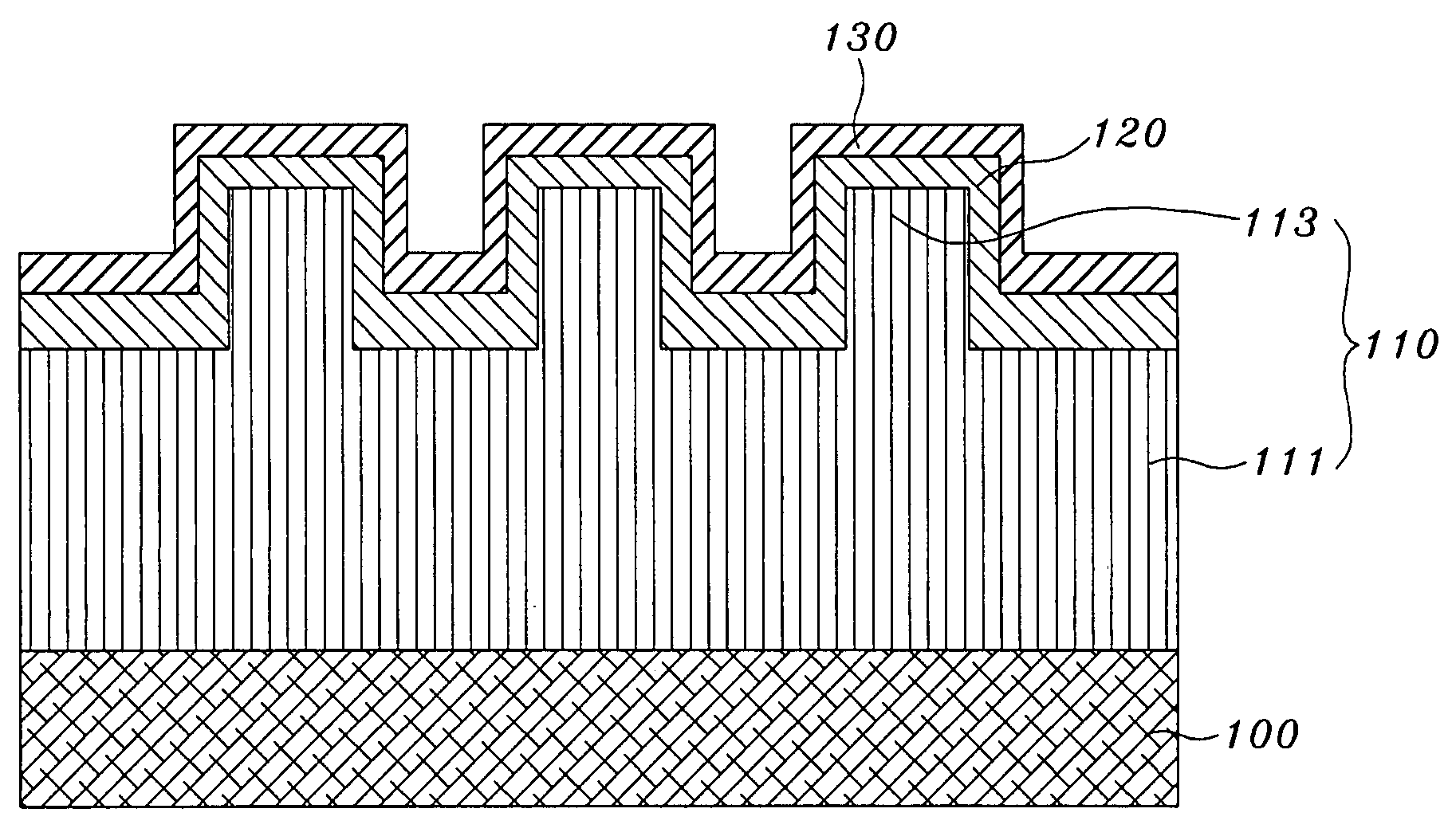

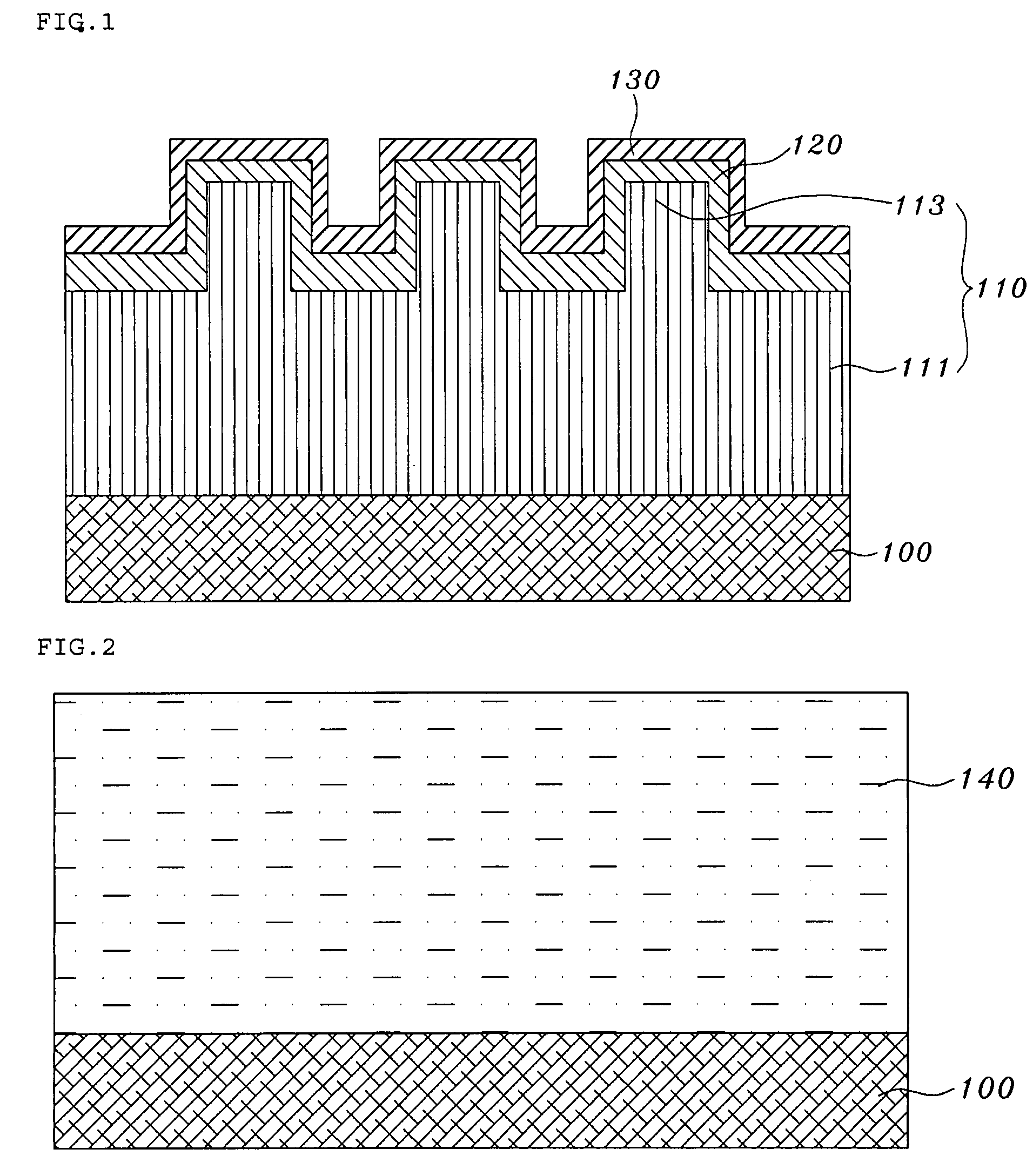

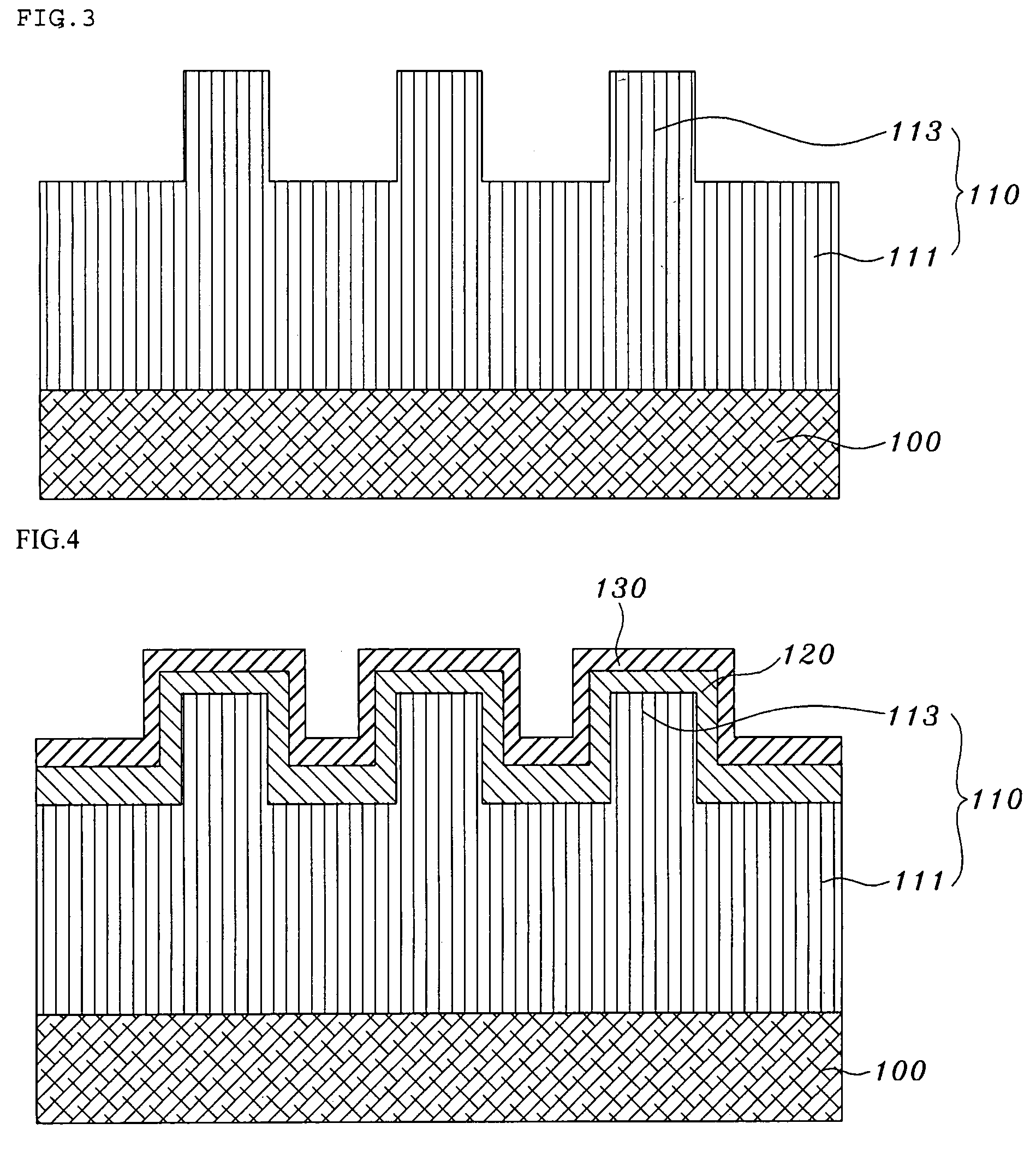

Mold for nano-imprinting and method of manufacturing the same

InactiveUS20080061214A1Increased durabilityAvoid damageNanostructure manufactureConfectioneryScale structureOptoelectronics

A nano-imprint mold and a method of manufacturing the same are provided, which can be used for replicating a nano-scaled structure to a polymer layer. The nano-imprint mold comprises: a substrate; a pattern portion having a prominence and depression pattern formed on the substrate; a hard layer formed of a material with a hardness higher than the pattern portion on a surface of the pattern portion; and a separation layer formed on a surface of the hard layer. In the nano-imprint mold of the present invention, an original pattern can be uniformly replicated even on a substrate with an irregular surface. Further, the pattern can be prevented from being damaged by pressure and being contaminated by synthetic resin, resulting in better accuracy and durability of the pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Wall block mold

A system and method of forming differently sized and / or textured construction blocks from a single mold. The system includes a mold having a base and movable side walls that cooperate with the base to form a mold cavity, and one or more inserts that are configured to be positioned in the mold. The mold is arranged and oriented so that its side walls form the top, bottom, front, and rear surfaces of each block. The inserts may be used individually or grouped together into predetermined sets to form different blocks, such as interior and end blocks, as well as cap stones.

Owner:MORRELL KELLY J

Concrete block mold with moveable liner

One aspect of the present invention provides a mold assembly for manufacturing concrete blocks that is adapted for use in a concrete block machine. The mold assembly comprises a plurality of liner plates and a gear drive assembly. Each liner plate has a major surface and the liner plates are configured such that the major surfaces form a mold cavity, wherein at least one of the liner plates is moveable. The gear drive assembly is selectively coupled to the at least one moveable liner plate and is configured to move the at least one moveable liner plate in a first direction toward an interior of the mold cavity by applying a force in a second direction different from the first direction, and to move the liner plate in a direction away from the interior of the mold cavity by applying a force in a direction opposite the second direction.

Owner:NESS INVENTIONS

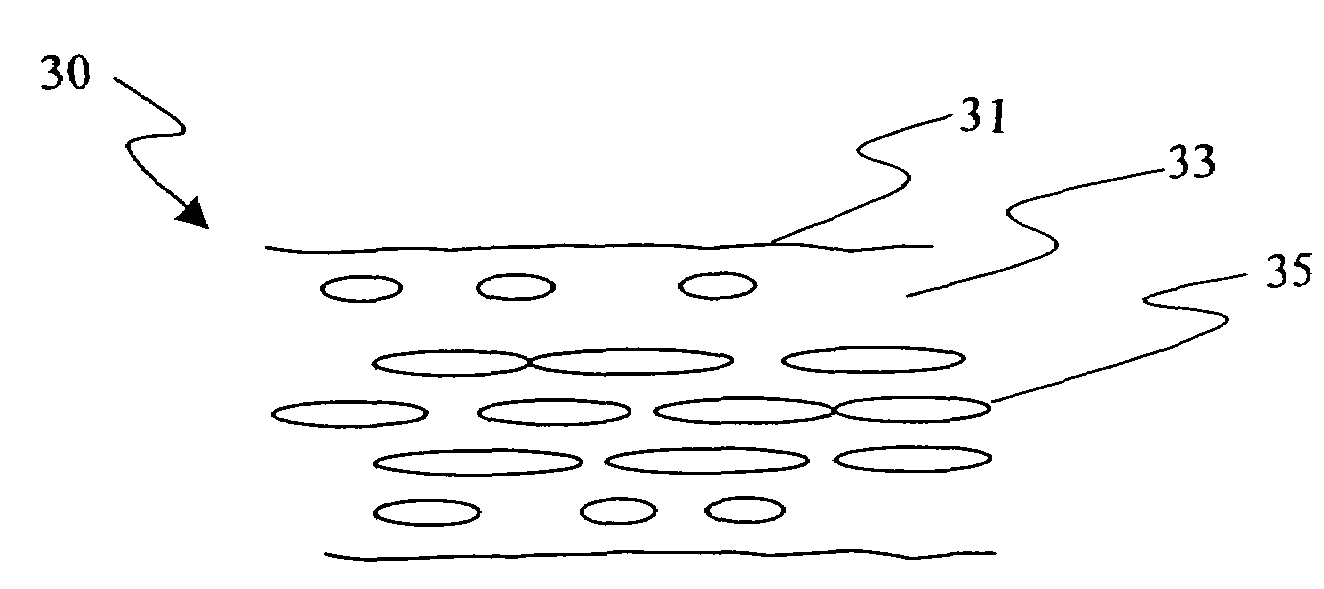

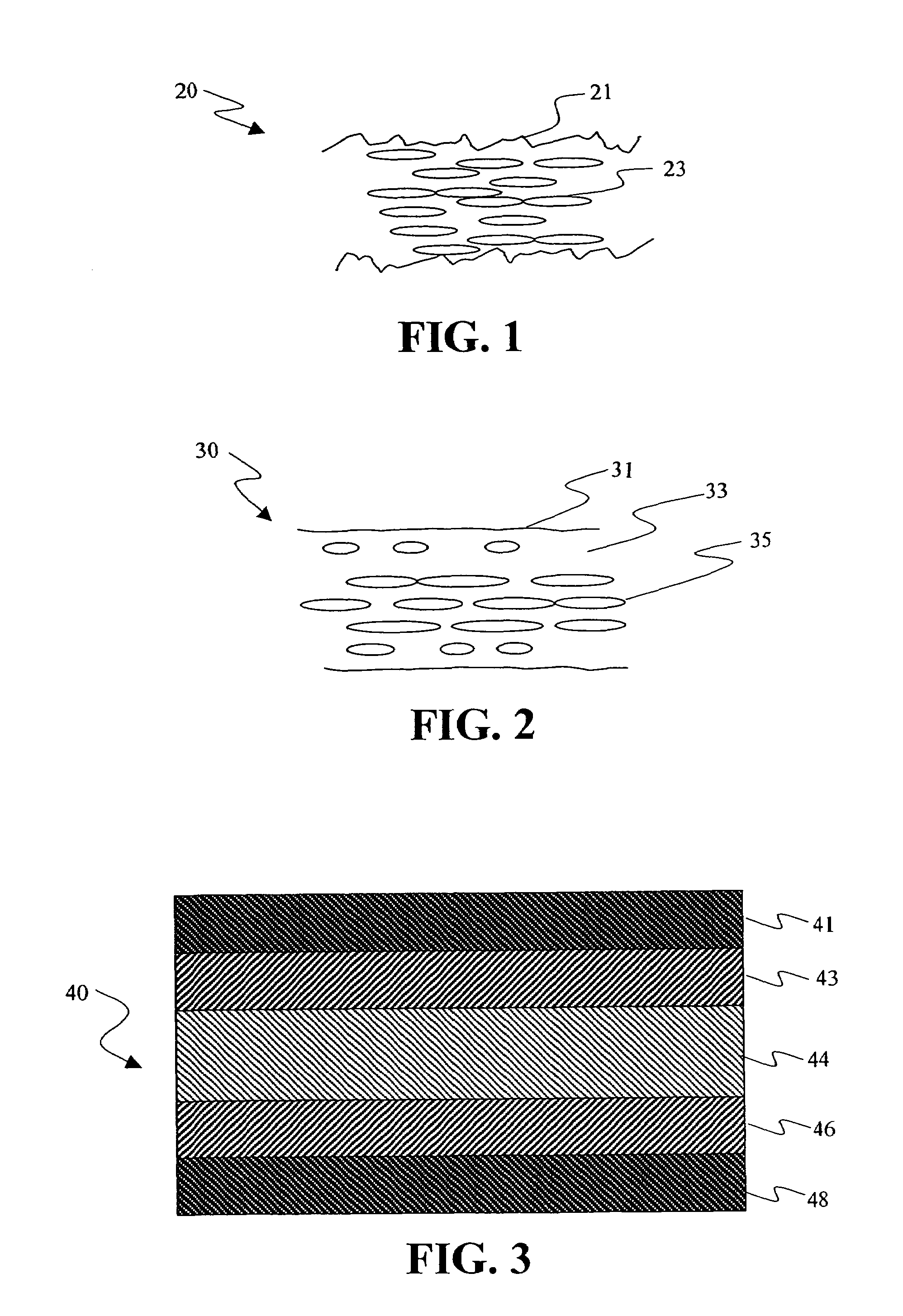

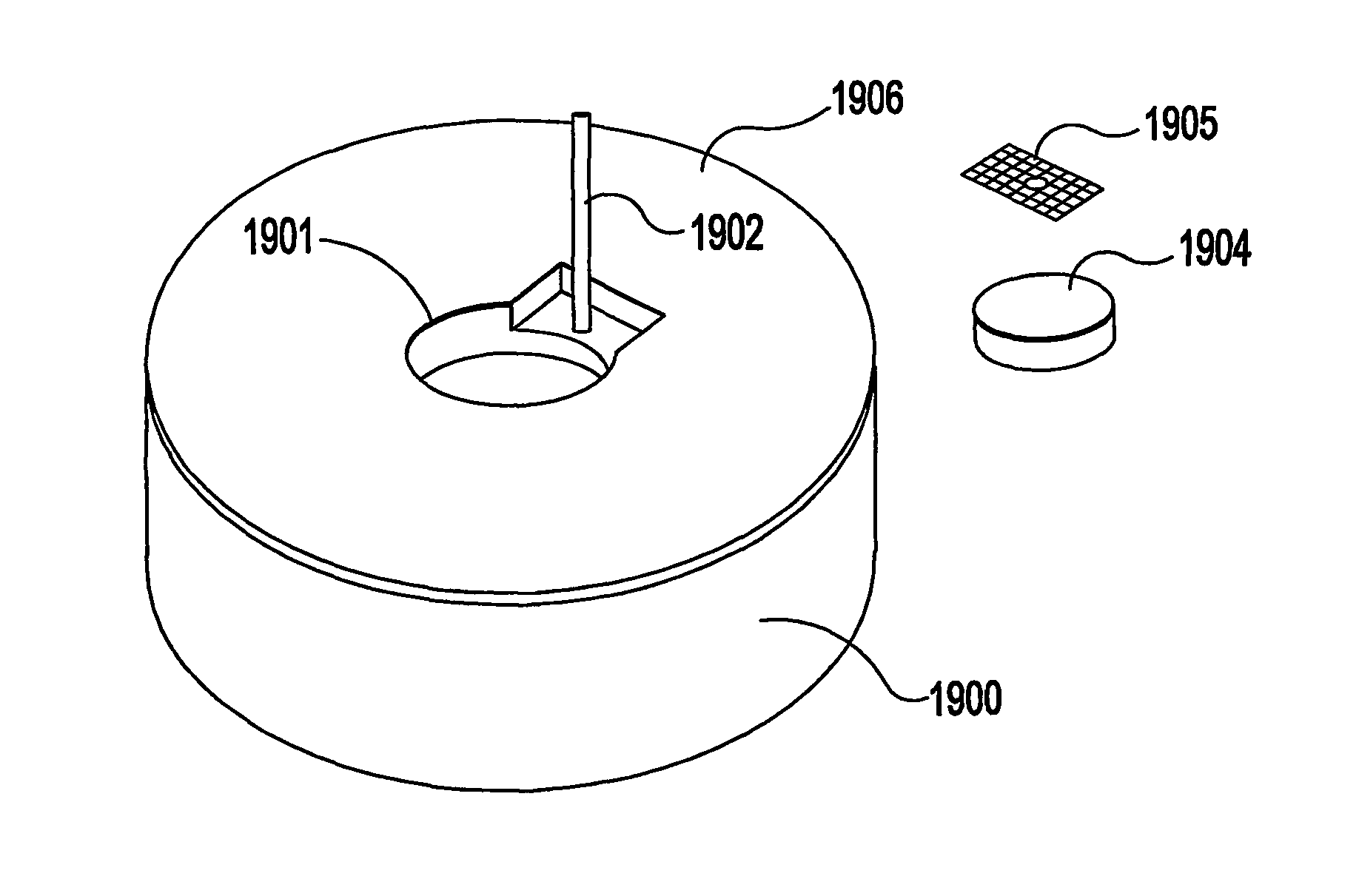

Foam core imaging element with gradient density core

InactiveUS7585557B2Increase stiffnessImprove smoothnessNatural cellulose pulp/paperDecorative surface effectsFoaming agentVolumetric Mass Density

The invention relates to a base comprising a closed cell foam core sheet having a closed cell foam layer with a density gradient between the center of the core and the surfaces of the core. The invention also relates to a method of making such a base by adding a first concentration of a first blowing agent to a first polymer to form a first mixture, adding a second concentration of a second blowing agent to a second polymer to form a second mixture, and extruding the mixtures to form the closed cell foam core sheet. The invention also relates to a method of making such a closed cell foam core sheet base comprising the steps of adding a blowing agent to a polymer to form a mixture, melting the mixture, extruding the mixture from a die, and rapidly quenching the mixture against a high heat transfer surface.

Owner:EASTMAN KODAK CO

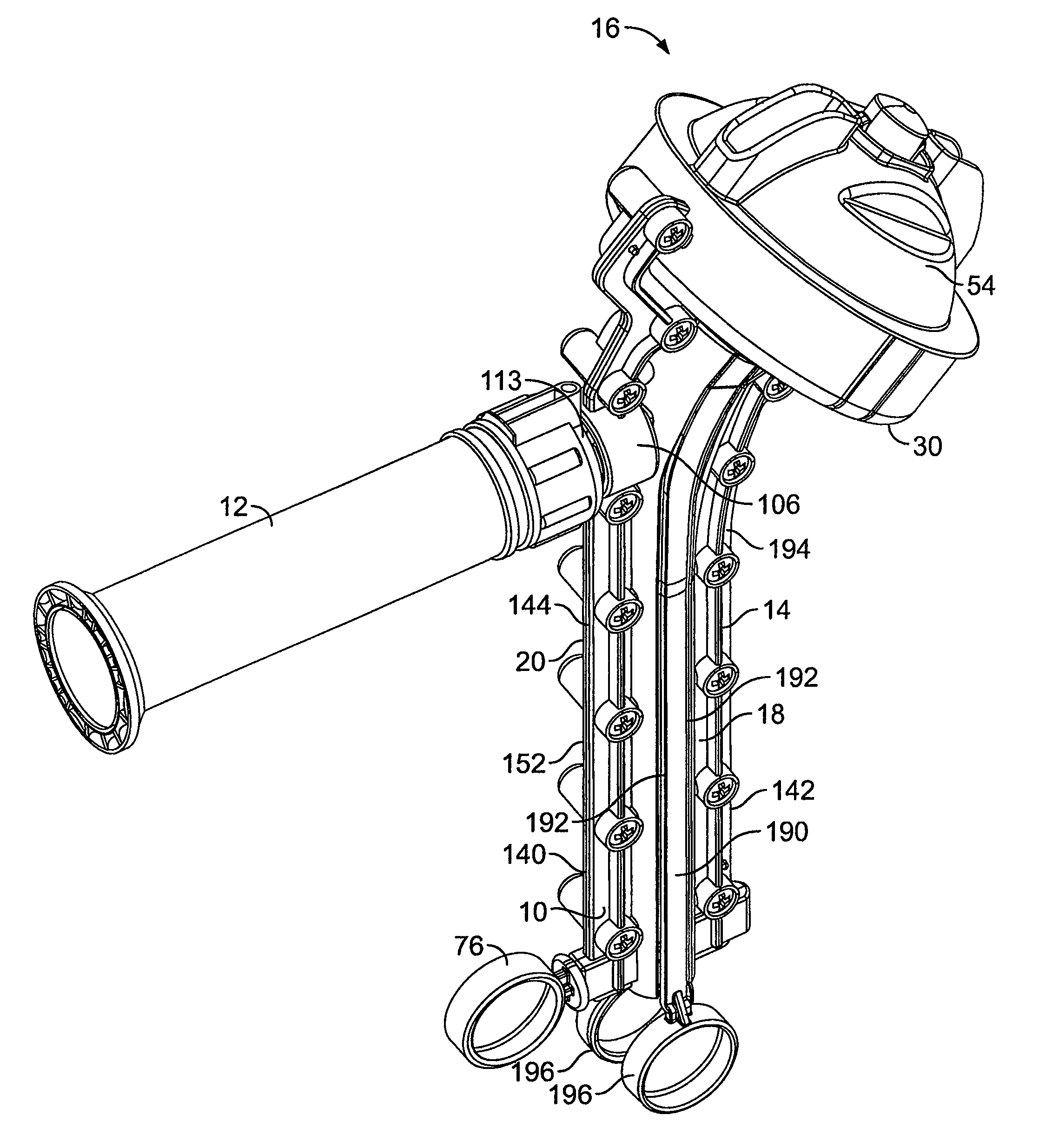

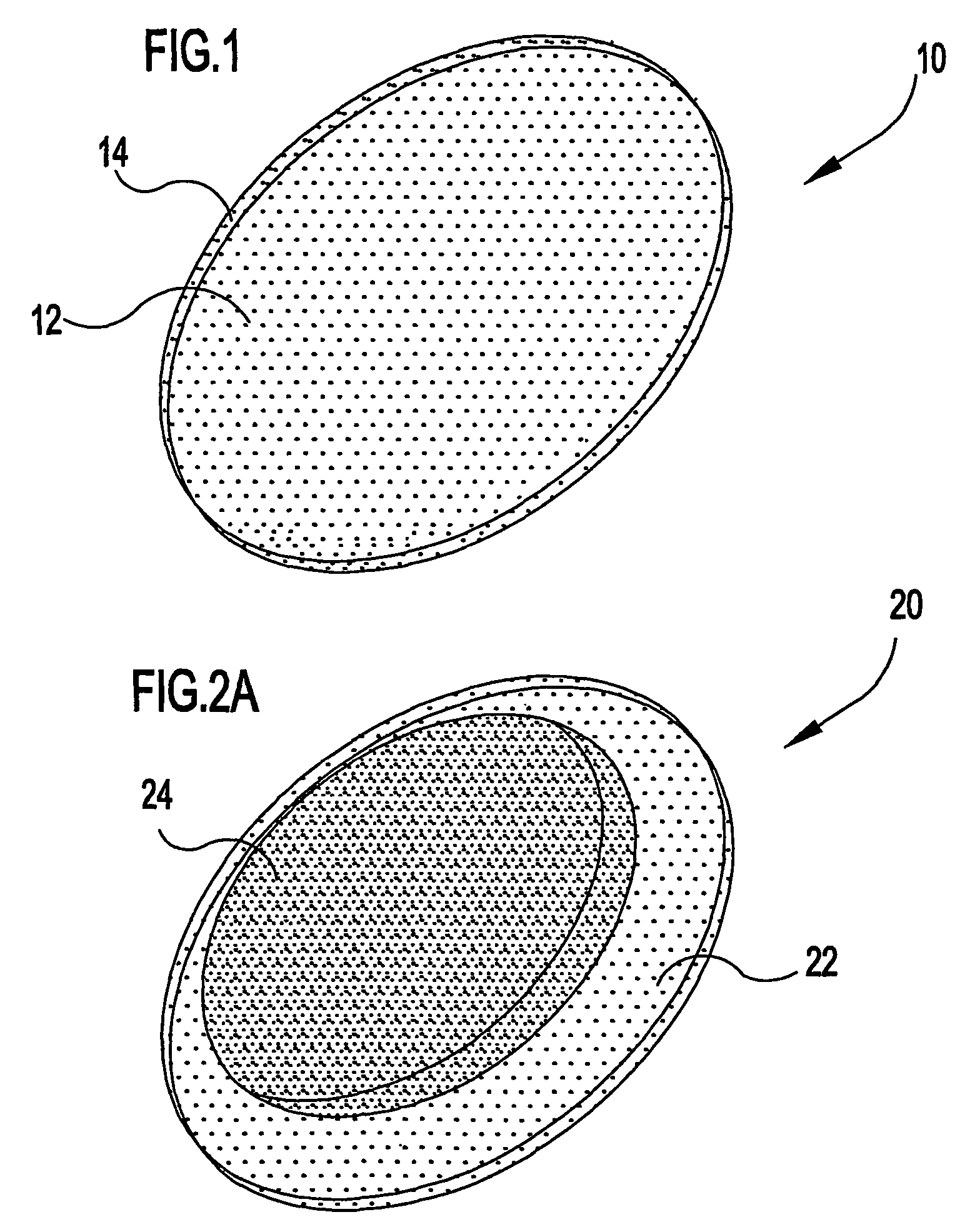

Ocular therapeutic agent delivery devices and methods for making and using such devices

ActiveUS7658364B2Increase release rateReached efficientlyOrganic active ingredientsSenses disorderDual modeOcular implant

Owner:UNITED STATES OF AMERICA

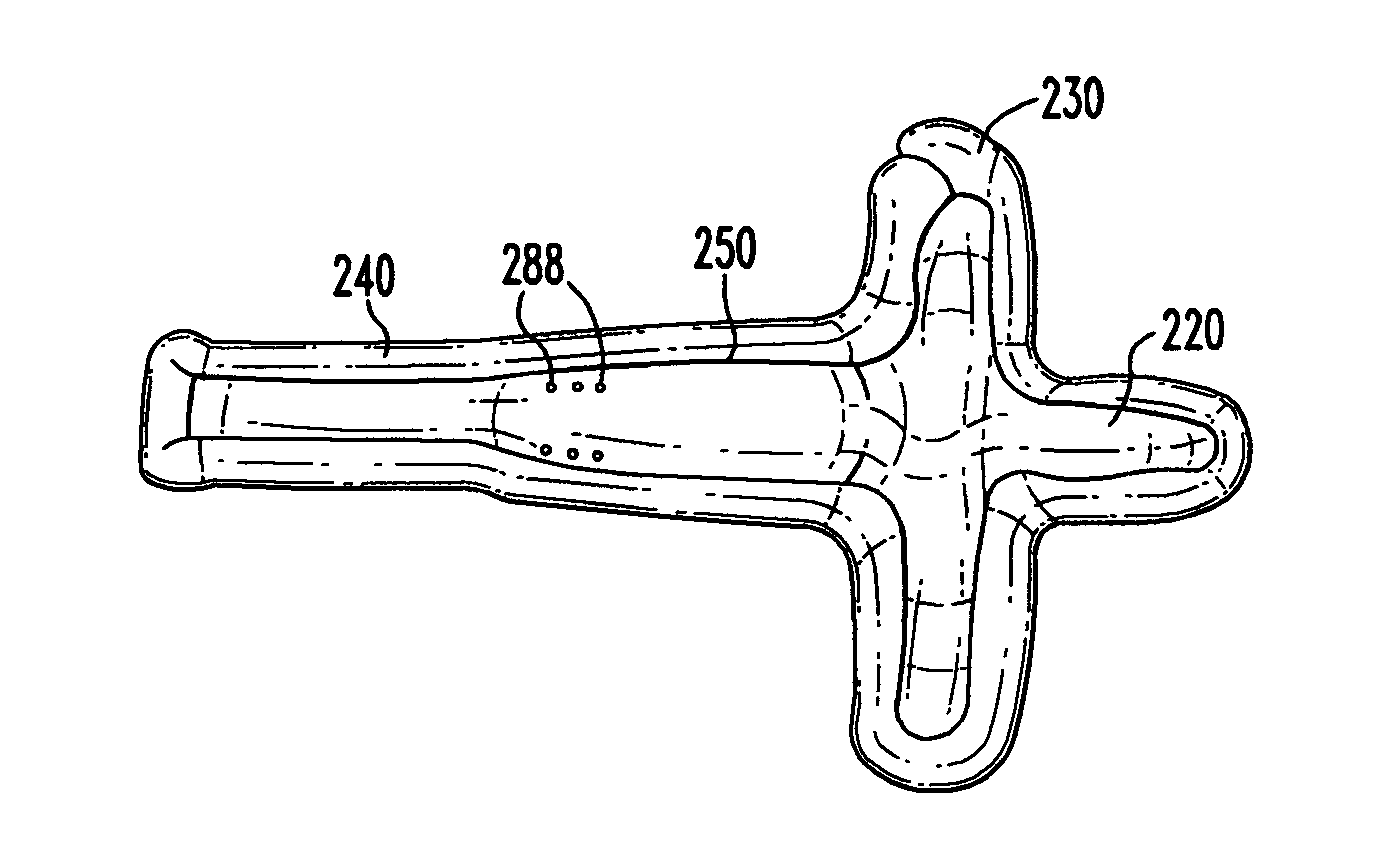

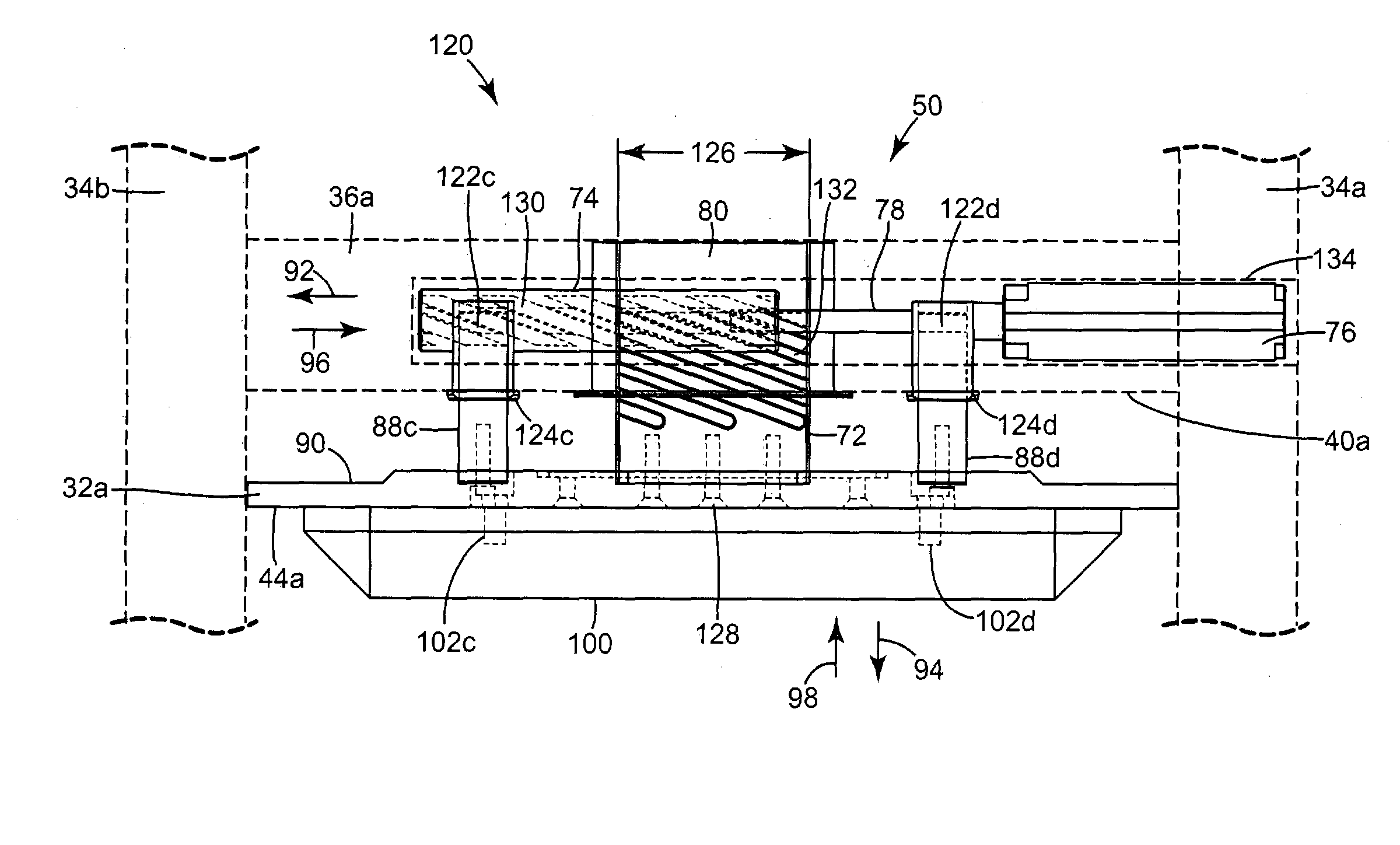

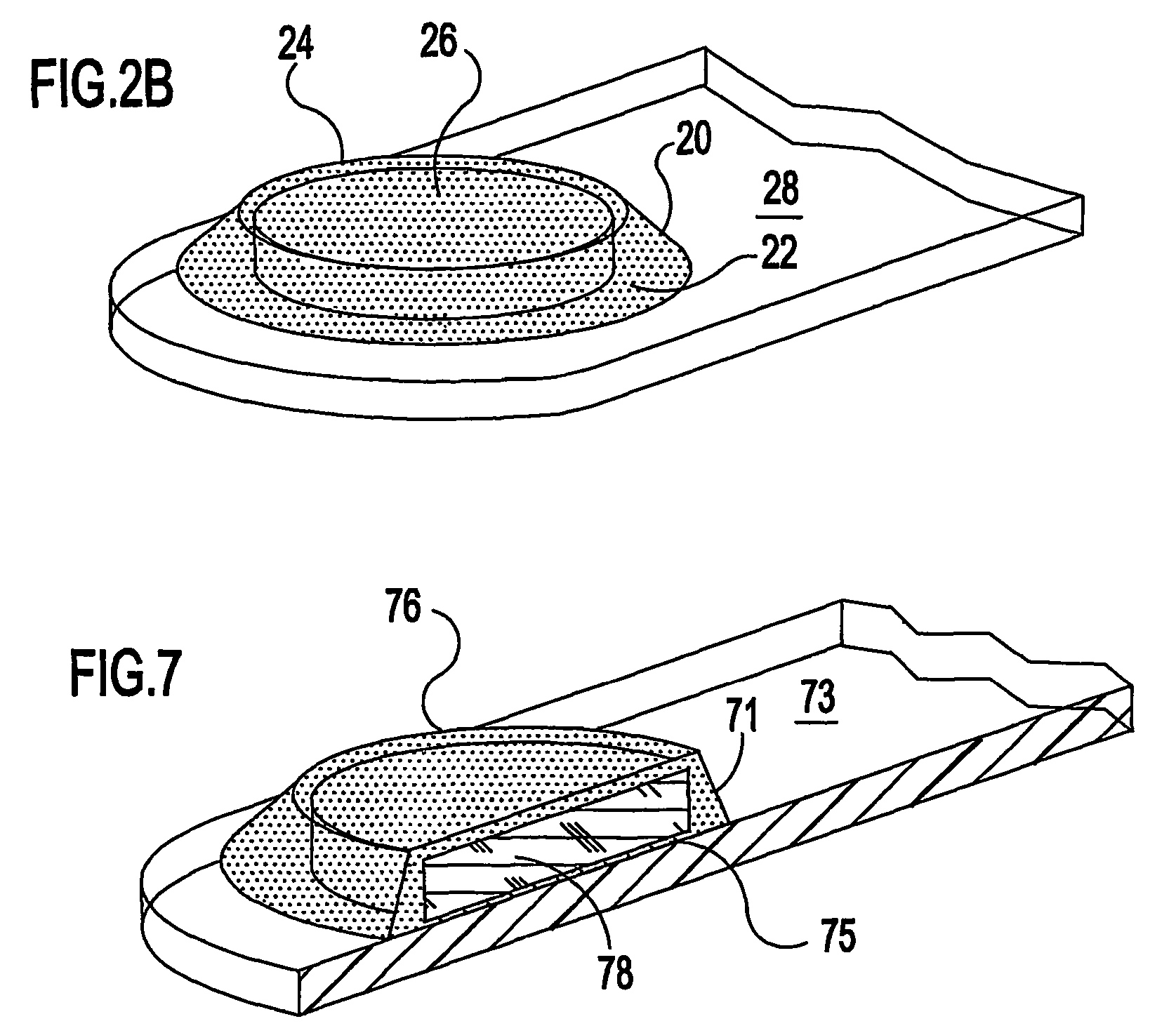

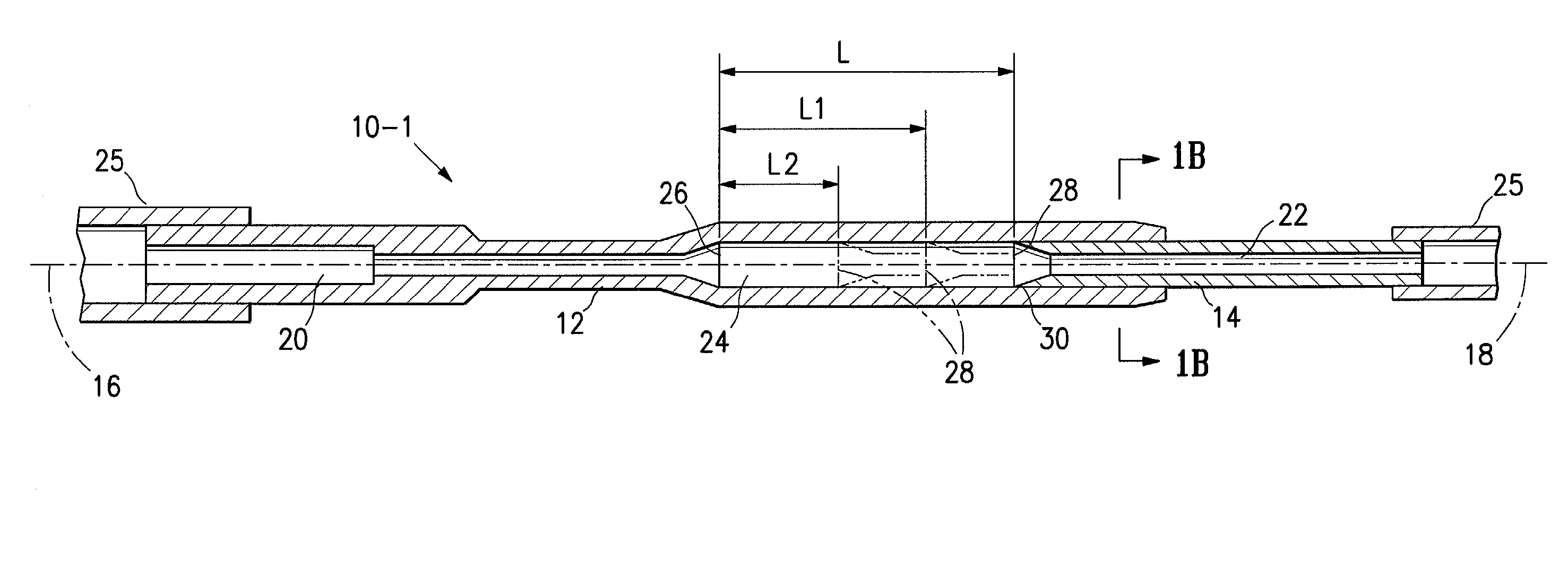

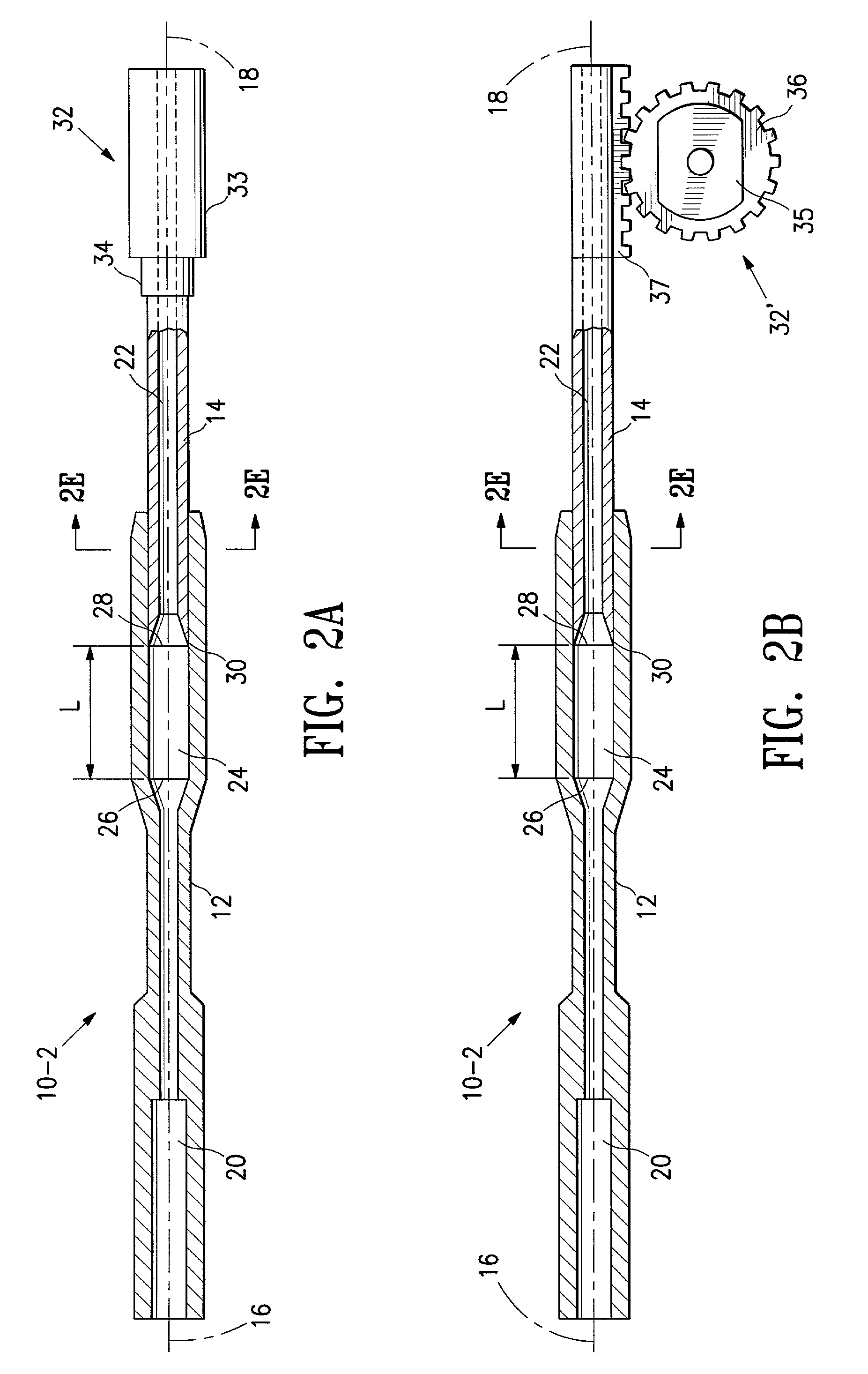

Adjustable length mold assemblies

InactiveUS20020125617A1Quality improvementIncrease temperatureMouldsConfectioneryLocking mechanismEngineering

The invention is directed to adjustable length mold assemblies for forming inflatable members and methods for using adjustable length mold assemblies for forming inflatable members, such as, for example, balloons for use with balloon catheters and stent delivery systems. The adjustable length mold assemblies comprise at least two mold pieces adapted to fit together, one mold piece having a surface configured to be slidably received by a bore of the other mold piece, the placement of one piece within the other defining a chamber of variable length which forms the mold. Each adjustable length mold assembly of the present invention is effective to form balloons, where if desired different balloons formed by a single mold may have different lengths. The adjustable length mold assemblies may also comprise a positioner to put a mold piece in a desired position relative to the other, and a locking mechanism to secure a mold piece in a desired position.

Owner:ABBOTT CARDIOVASCULAR

Mobile device

InactiveUS8024015B2Increase in sizeMouldsMachine compositionMobile deviceElectrical and Electronics engineering

Owner:FUJITSU CONNECTED TECH LTD

Container having an articulated cover

InactiveUS20090166369A1Sufficient structural rigiditySolve the lack of rigidityMould separation apparatusFoundry mouldsMechanical engineeringStructural rigidity

The covers stack together in two different ways. First, the covers can be stacked into an “aligned” stack. The aligned stack provides structural rigidity for bulk handling during manufacturing. Second, the covers can be stacked into a “locked” stack. The locked stack provides even more structural rigidity than does the aligned stack and is useful when storing unused covers. The cover includes a first closure portion, an engagement portion, and an alignment portion. The base includes a second closure portion. The first closure portion of the cover is sealingly engageable with the second closure portion of the base to define a sealed storage area. The alignment portion of the cover is engageable with the alignment portion of a second cover to form an aligned cover stack. The engagement portion of the cover is engageable with the engagement portion of a second cover to form a locked cover stack. The cover further includes at least one articulation element circumscribing the engagement portion of the cover and that provides flexibility to the cover allowing the engagement portion of the cover to easily articulate upwardly or downwardly.

Owner:SAVICKI ALAN F

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com