Soap recycling device

A soap and crushing device technology, applied in the field of machinery, can solve the problems of unusable, waste of materials, inconvenient control of soap, etc., and achieve the effect of convenient use, high efficiency and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

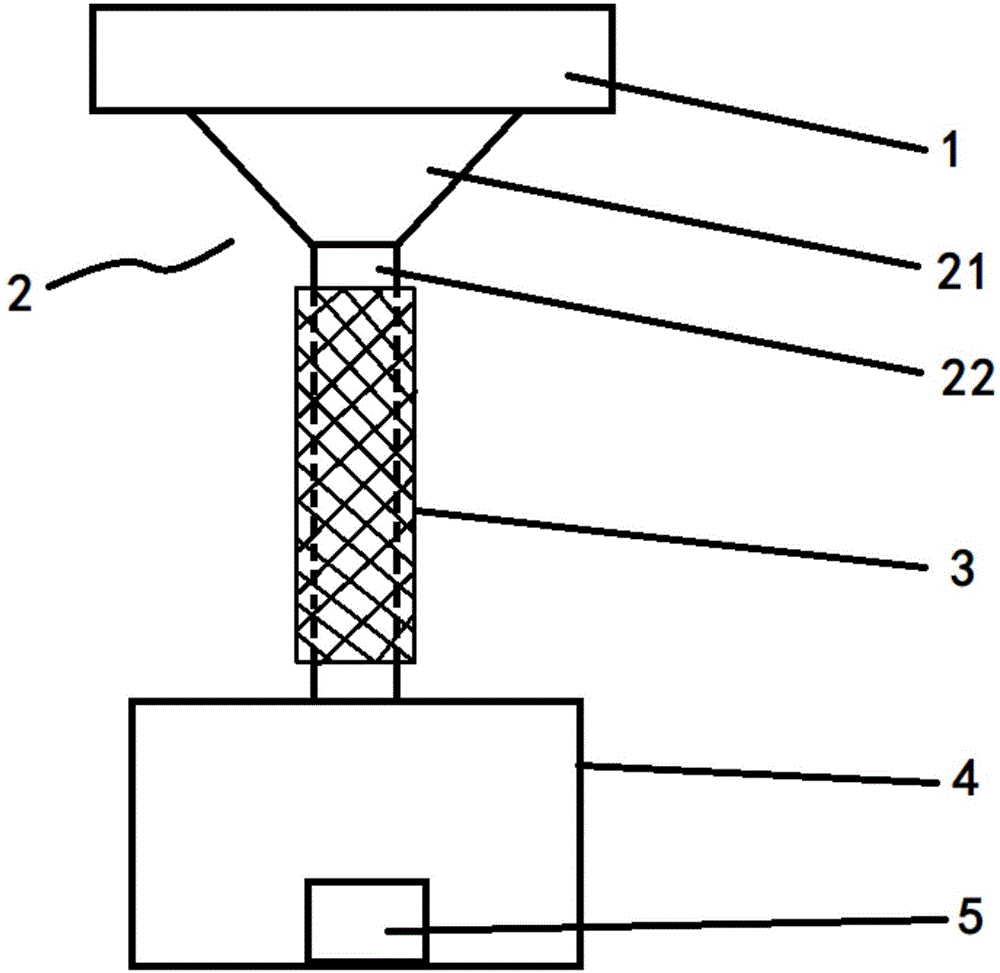

[0024] Such as figure 1 As shown, the present invention provides a soap recycling device, comprising a crushing device 1, a melting vessel 2, a heating screen 3, a base support 4 and a molding die 5, the crushing device 1 is located above the melting vessel 2, and the The lower surface of the crushing device 1 is in close contact with the upper surface of the melting vessel 2, the crushing device 1 has a material inlet and a material outlet, the melting vessel 2 has a funnel-shaped structure, and the melting vessel 2 includes a funnel cavity 21 and funnel neck 22, the lower end surface of the funnel cavity 21 is seamlessly connected with the upper end surface of the funnel neck 22, the upper end surface of the funnel cavity 21 is the inlet, the lower end surface of the funnel neck 22 is the outlet, and the pulverized The material inlet of the device 1 falls into the plane where the inlet of the funnel cavity 21 is located, the heating wire mesh 3 is set around the funnel neck ...

Embodiment 2

[0032] Such as figure 1 As shown, the present invention provides a soap recycling device, comprising a crushing device 1, a melting vessel 2, a heating screen 3, a base support 4 and a molding die 5, the crushing device 1 is located above the melting vessel 2, and the The lower surface of the crushing device 1 is in close contact with the upper surface of the melting vessel 2, the crushing device 1 has a material inlet and a material outlet, the melting vessel 2 has a funnel-shaped structure, and the melting vessel 2 includes a funnel cavity 21 and funnel neck 22, the lower end surface of the funnel cavity 21 is seamlessly connected with the upper end surface of the funnel neck 22, the upper end surface of the funnel cavity 21 is the inlet, the lower end surface of the funnel neck 22 is the outlet, and the pulverized The material inlet of the device 1 falls into the plane where the inlet of the funnel cavity 21 is located, the heating wire mesh 3 is set around the funnel neck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com