Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Shell matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microcapsules

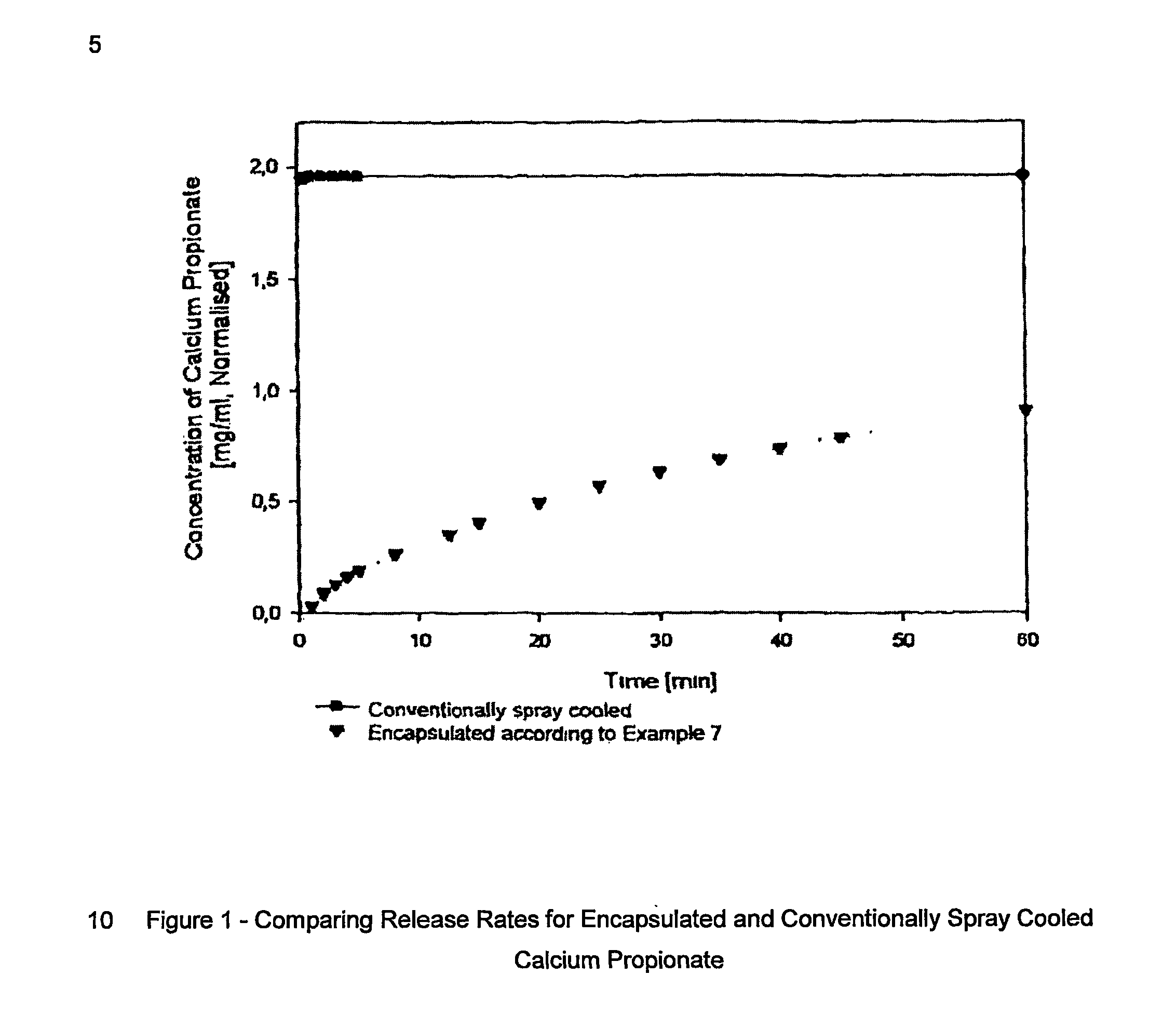

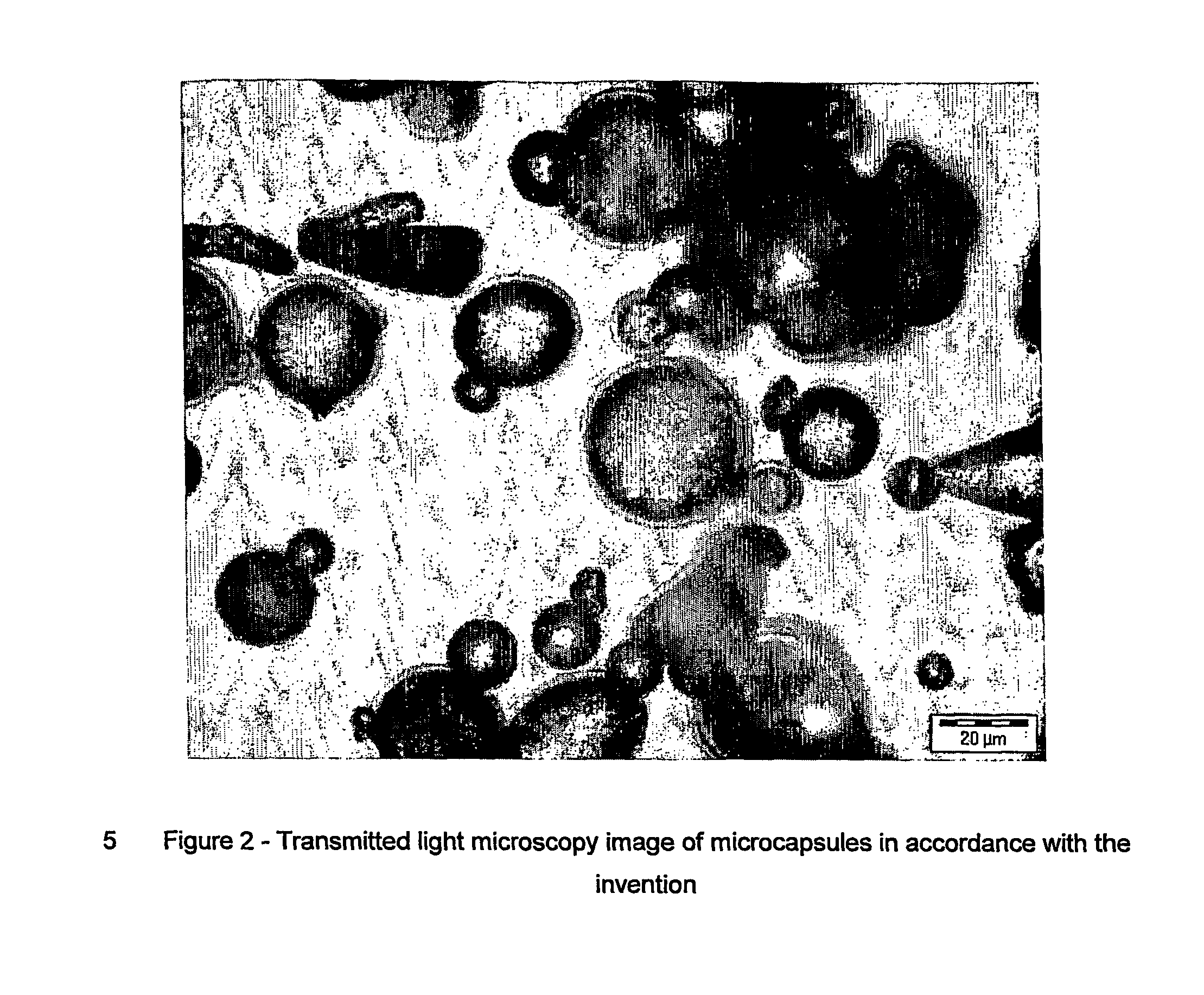

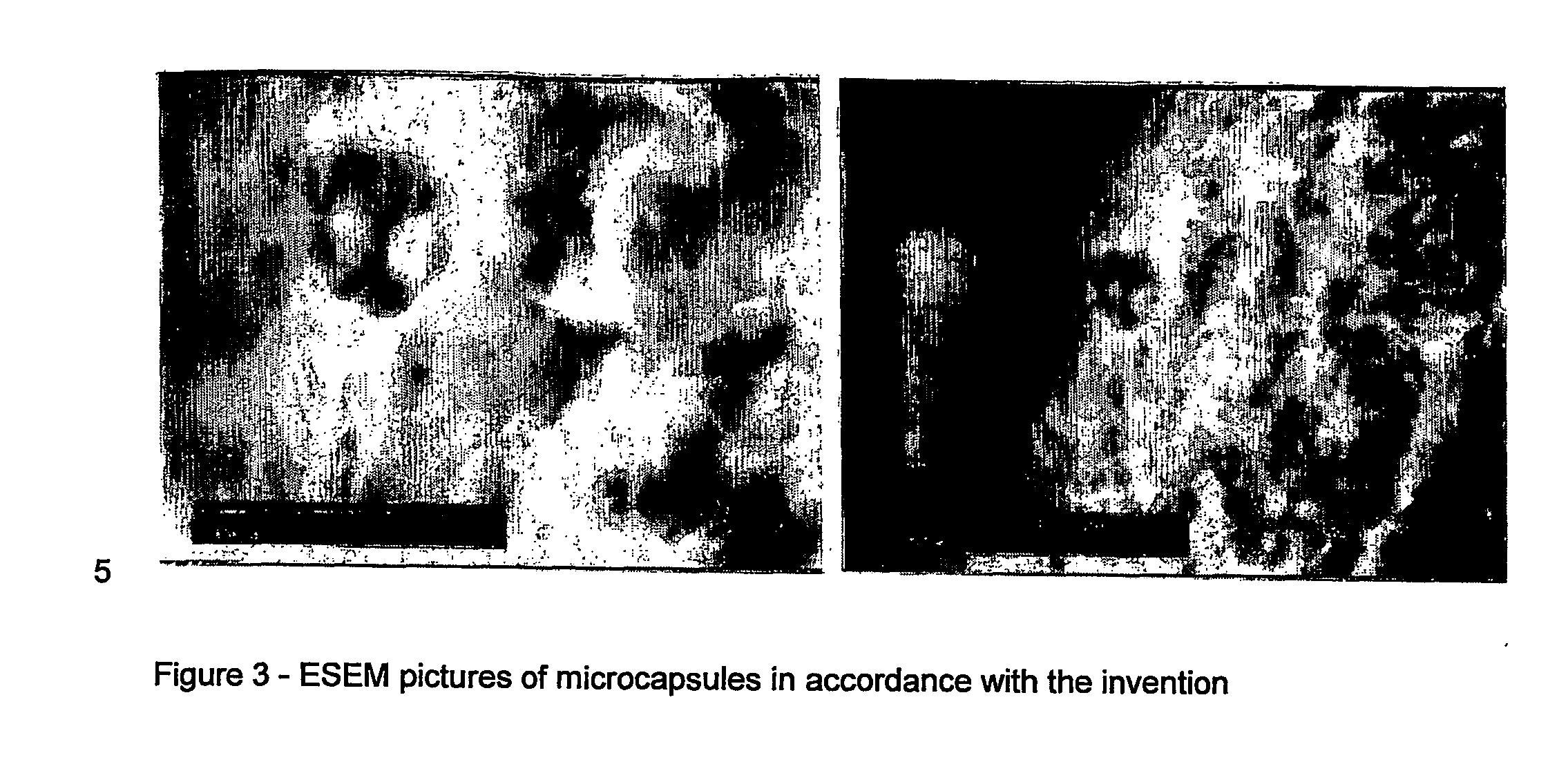

InactiveUS20070042184A1Increase release rateControl releaseBiocideEggs preservation by coatingBULK ACTIVE INGREDIENTActive ingredient

The present invention relates to microcapsules, and more particularly to microcapsules where an aqueous bead or beads comprising the active ingredient is encapsulated in or by a hydrophobic shell matrix. The present invention relates also to novel methods for preparing the microcapsules according to the invention, as well as to the use of the microcapsules of the present invention. A microcapsule of the present invention comprises a solidified hydrophobic shell matrix, an encapsulated aqueous bead or beads which is / are encapsulated in or by the solidified hydrophobic shell matrix, and an active ingredient or active ingredients dissolved or incorporated in the encapsulated aqueous bead or beads.

Owner:DUPONT NUTRITION BIOSCIENCES APS

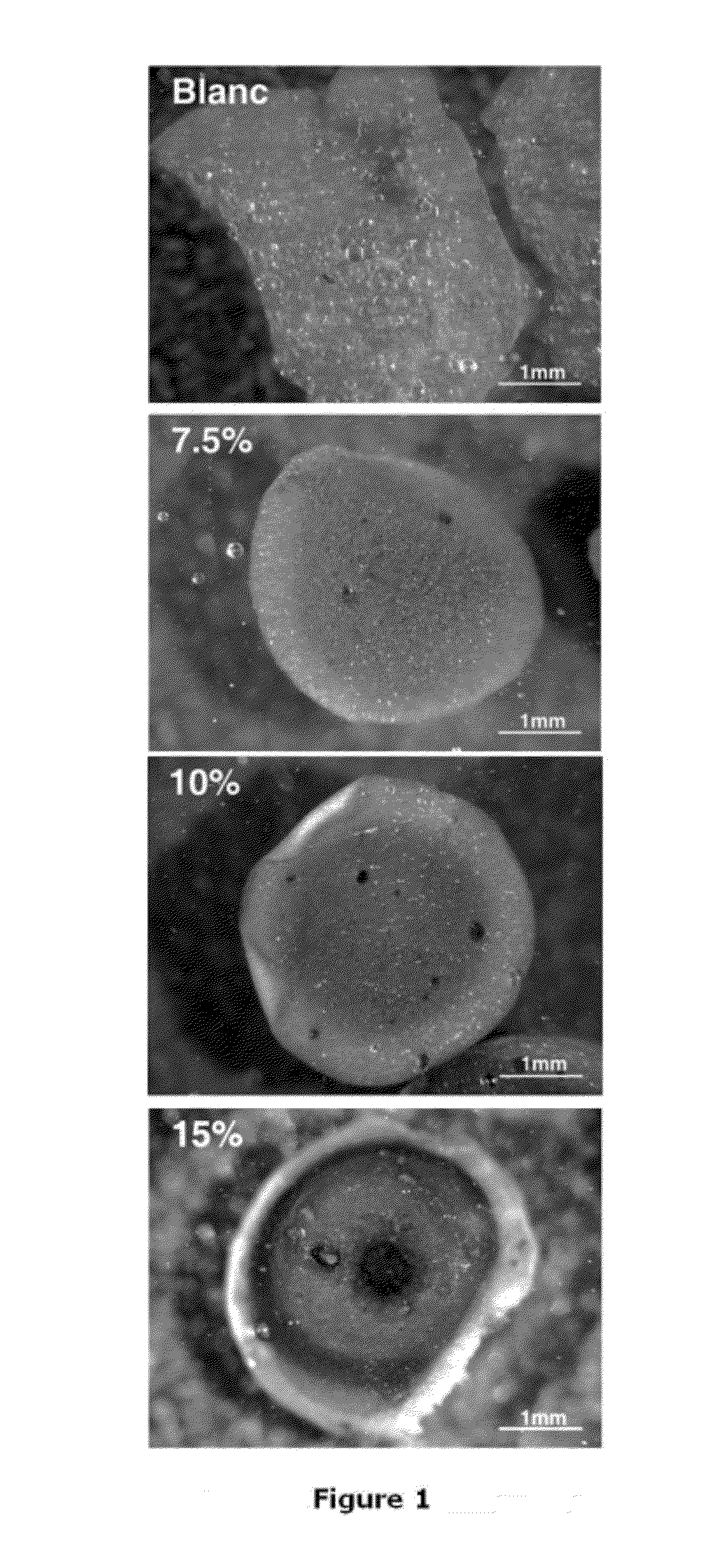

Microcapsules containing salts for food products

InactiveUS20120156288A1Keep shapeMaintain sizeBiocideInorganic phosphorous active ingredientsPolysaccharideOsteoporosis

A composition for delivering edible salts into food products via microcapsules having a protein-polysaccharide shell matrix and an edible salt-containing active material. A method of treating osteoporosis is also disclosed.

Owner:LIPOFOODS

Double-loaded core-shell hydrogel, preparation method and application thereof

ActiveCN109734174AAchieve the effect of removing ammonia nitrogenWide variety of sourcesWater contaminantsTreatment with aerobic and anaerobic processesFreeze-dryingNutrient solution

The invention discloses a double-loaded core-shell hydrogel, a preparation method and an application thereof. The method includes, firstly, mixing natural polymer with adsorption functional groups anda polyacrylic acid aqueous solution, adding denitrifying bacteria, a nutrient solution and a pH regulator to obtain a core matrix after complete mixing; then adding Ca2+-containing salt and gluconicacid lactone into the nuclear matrix to obtain a mixed solution; secondly, pouring the mixed solution into a mold, dripping a hydrophilic natural polymer solution, and foaming to obtain a porous foaming shell matrix; thirdly, preforming physical crosslinking gelation forming on the porous foamed core-shell matrix to obtain a porous core-shell wet gel; placing the porous core-shell wet gel in deionized water, dialyzing and freeze drying to obtain a single-load core-shell hydrogel; and finally, soaking the single-loaded core-shell hydrogel in nitrobacteria solution and freeze-drying to obtain the double-loaded core-shell hydrogel; The preparation method has simple process operation, no pollution and wide source of raw materials, and the prepared double-loaded core-shell hydrogel has the effect of removing ammonia nitrogen.

Owner:SHAANXI UNIV OF SCI & TECH

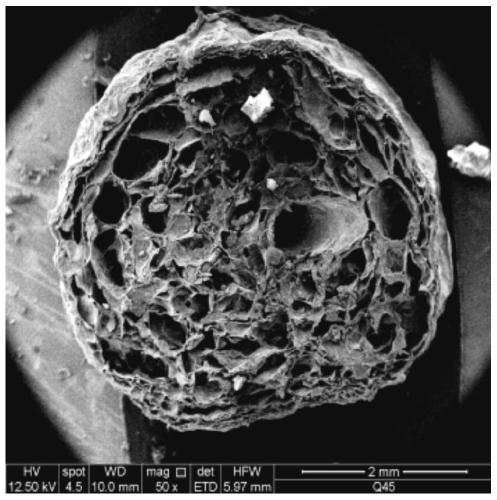

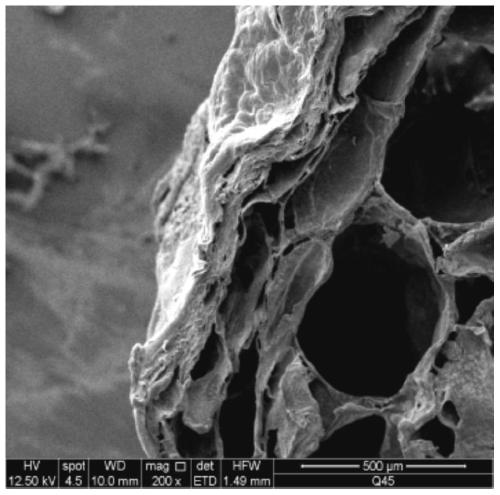

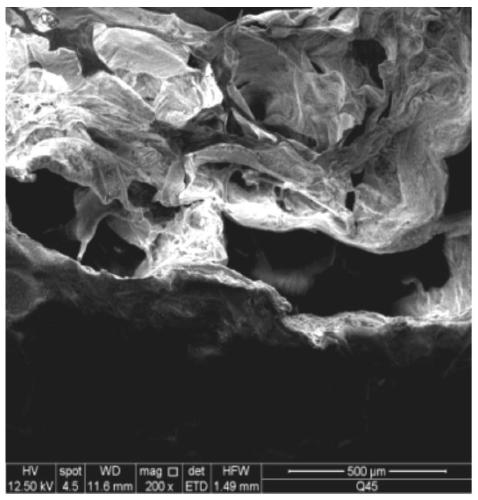

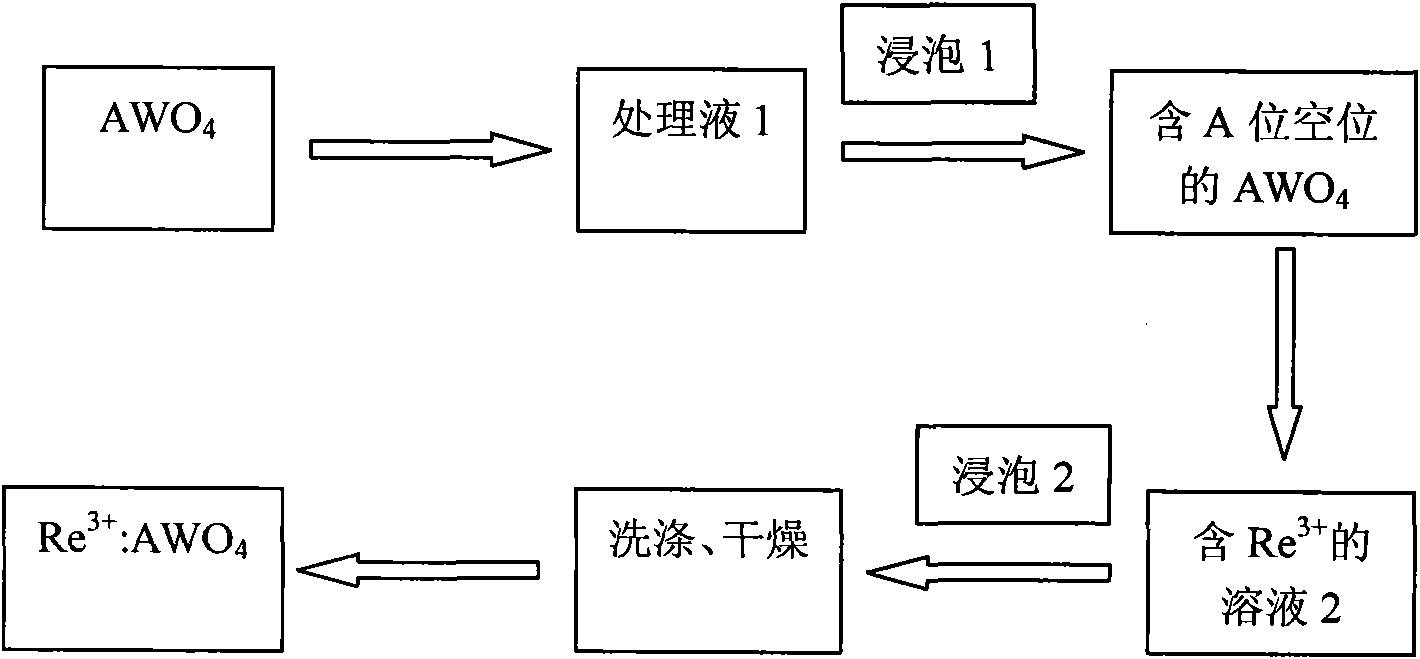

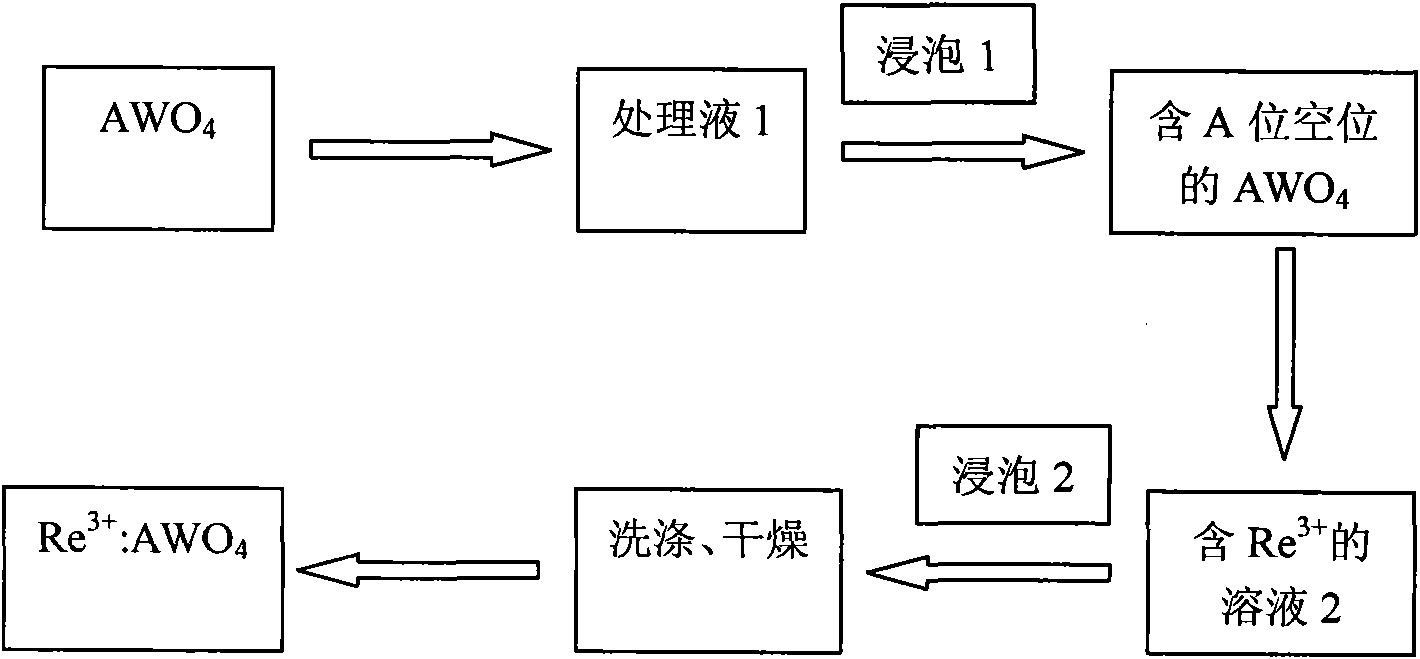

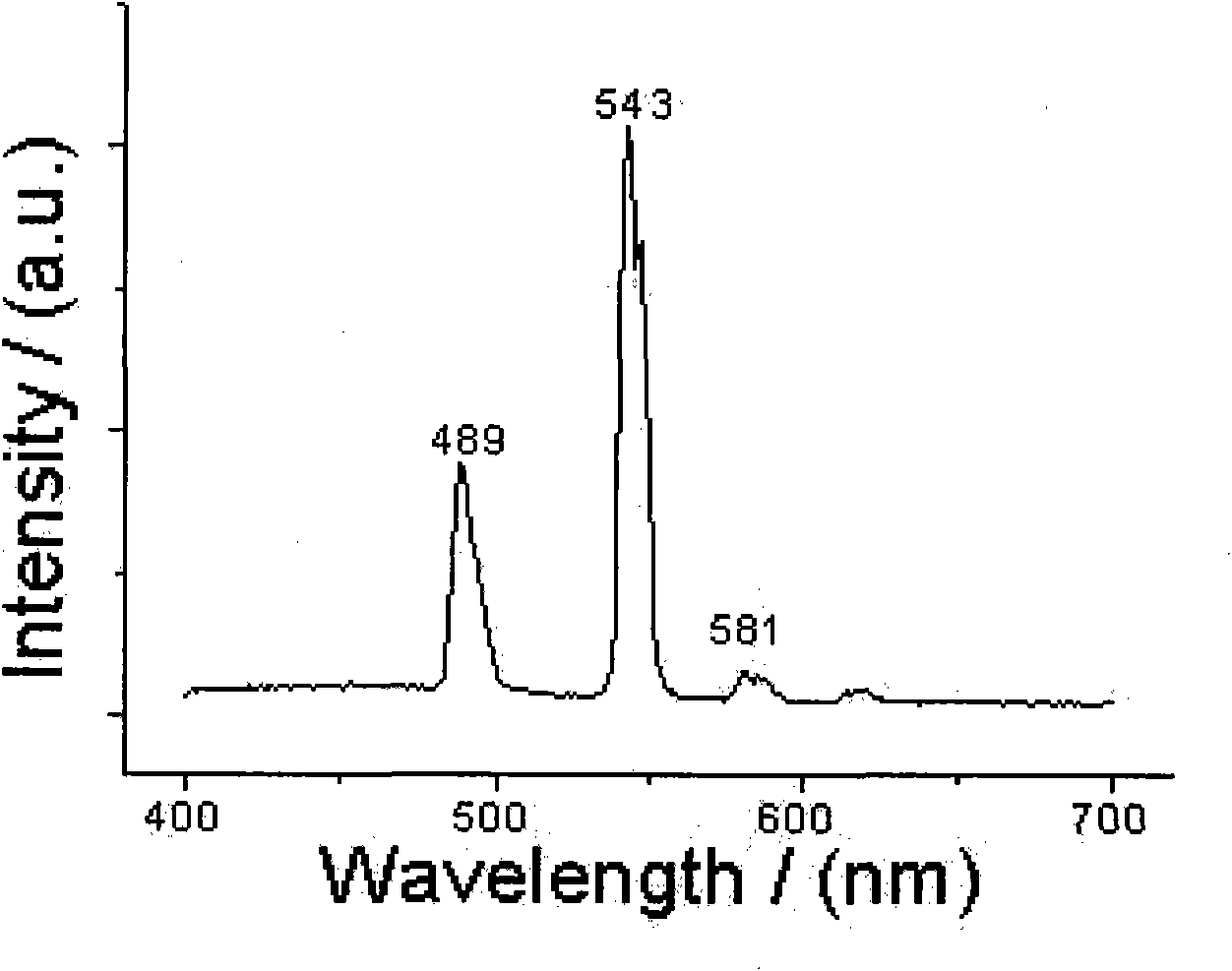

Doping method of scheelite luminescent material

InactiveCN101805611ASimple and fast operationLuminescent compositionsMaterials preparationRare earth ions

The invention discloses a doping method of a scheelite luminescent material, belonging to the technical of material preparation. The doping method is characterized by comprising the steps of: manufacturing an A vacancy in a luminous matrix surface through the posttreatment, and recovering by rare-earth ions so as to synthesize a material with a luminous shell / nuclear structure, wherein the variety and the content of rare earths in Re<3+>:AMO4(A=Mg, Ca, Sr, Ba and Pb; M=W and Mo; Re=rare earth) can be controlled by changing the variety and the concentration and the treatment time of a treating liquid. The doping method is carried out under a room temperature environment without heat treatment; and the synthesized material has a rare earth luminous shell-matrix nuclear structure and excellent luminous property. Therefore, compared with the traditional doping method, the doping method has remarkable advantages of zero energy consumption, rare earth raw material saving, simple and convenient operation and the like.

Owner:陈连平

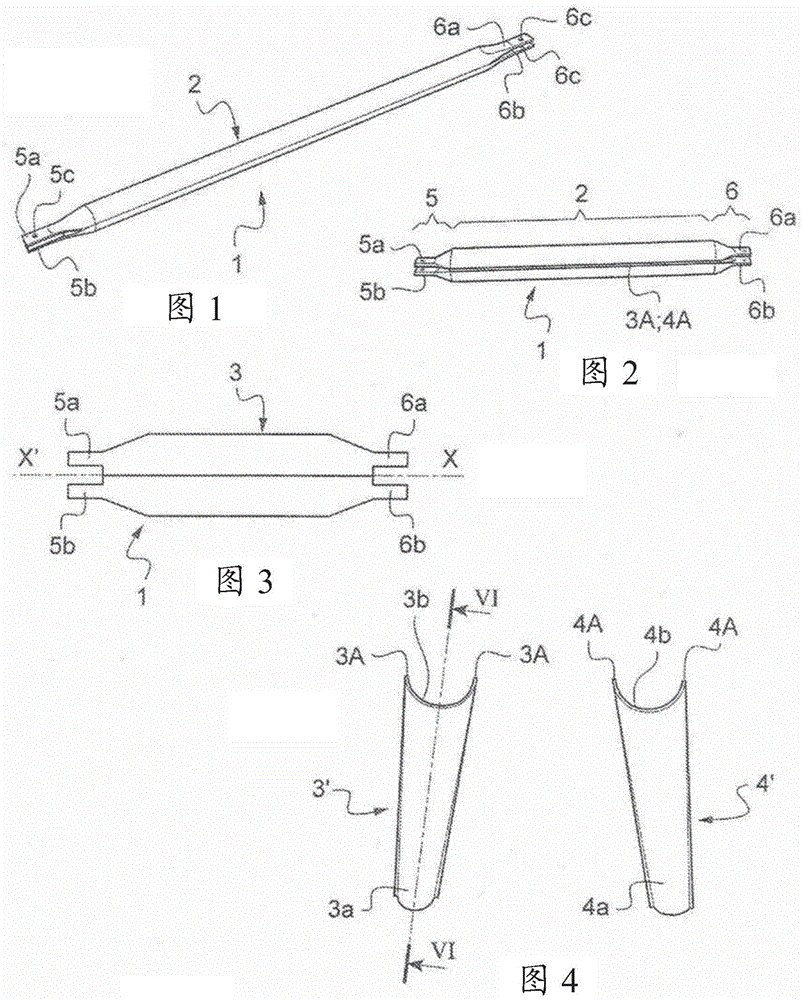

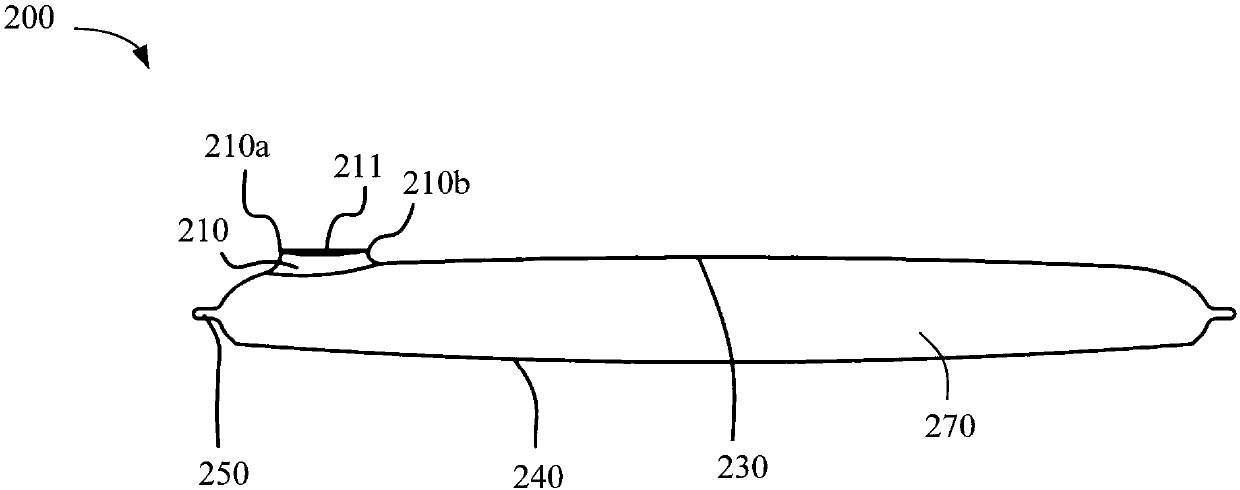

Composite connecting rod, method for producing same and aircraft ceiling or floor structure including same

ActiveCN105431645AReduce quality problemsExcellent mechanical propertiesConnecting rodsWeight reductionFiberAviation

The invention relates to a composite structural connecting rod, an aircraft ceiling or floor structure including same and a method for producing said connecting rod. The invention is intended to take-up mainly axial loads, in particular in the field of aeronautics. The connecting rod includes an elongate body that is convex about a longitudinal axis of symmetry (X'X) and two ends (5a, 5b and 6a, 6b) for connecting to adjacent structures, and comprises two shells (3 and 4) having two longitudinal edges which are assembled at said edges and which are each made up of at least one shell layer having continuous shell fibres which are mostly parallel to said axis of symmetry and impregnated with a thermoplastic shell matrix (7b). According to the invention, the connecting rod includes means for assembling the shells including at least one assembly layer (14, 15) wound around and along the shells on said body and having assembly fibres that are mostly at an angle relative to said axis and impregnated with a molten thermoplastic assembly matrix (14b, 15b) in contact with the shell matrix.

Owner:HUTCHINSON SA

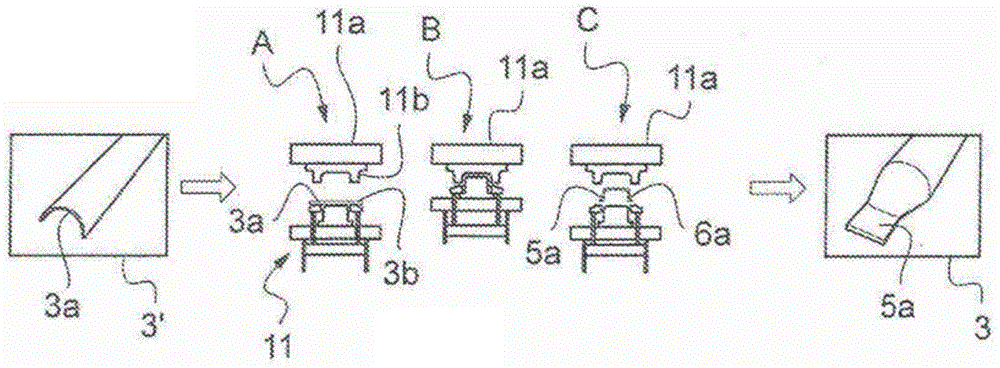

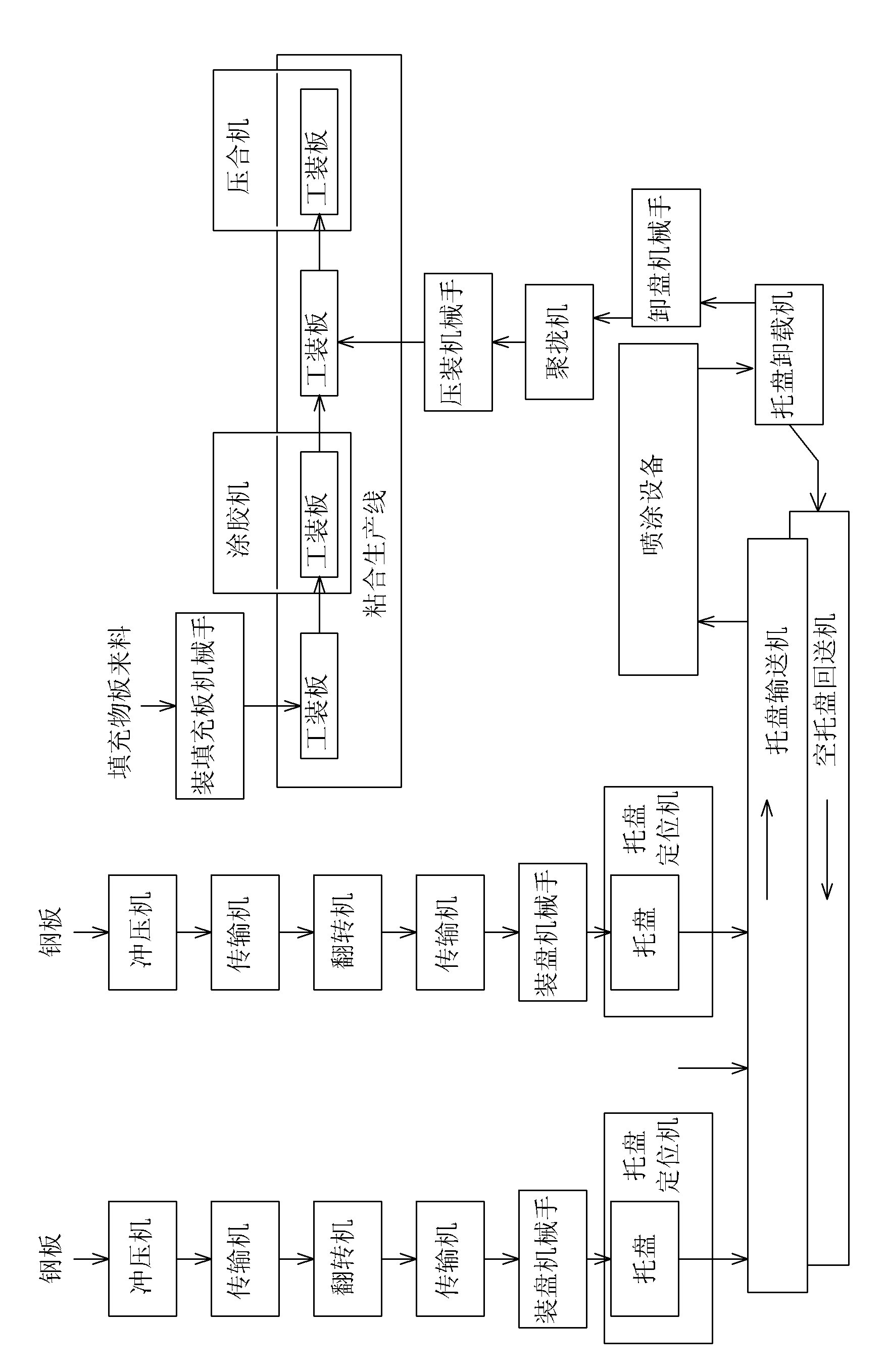

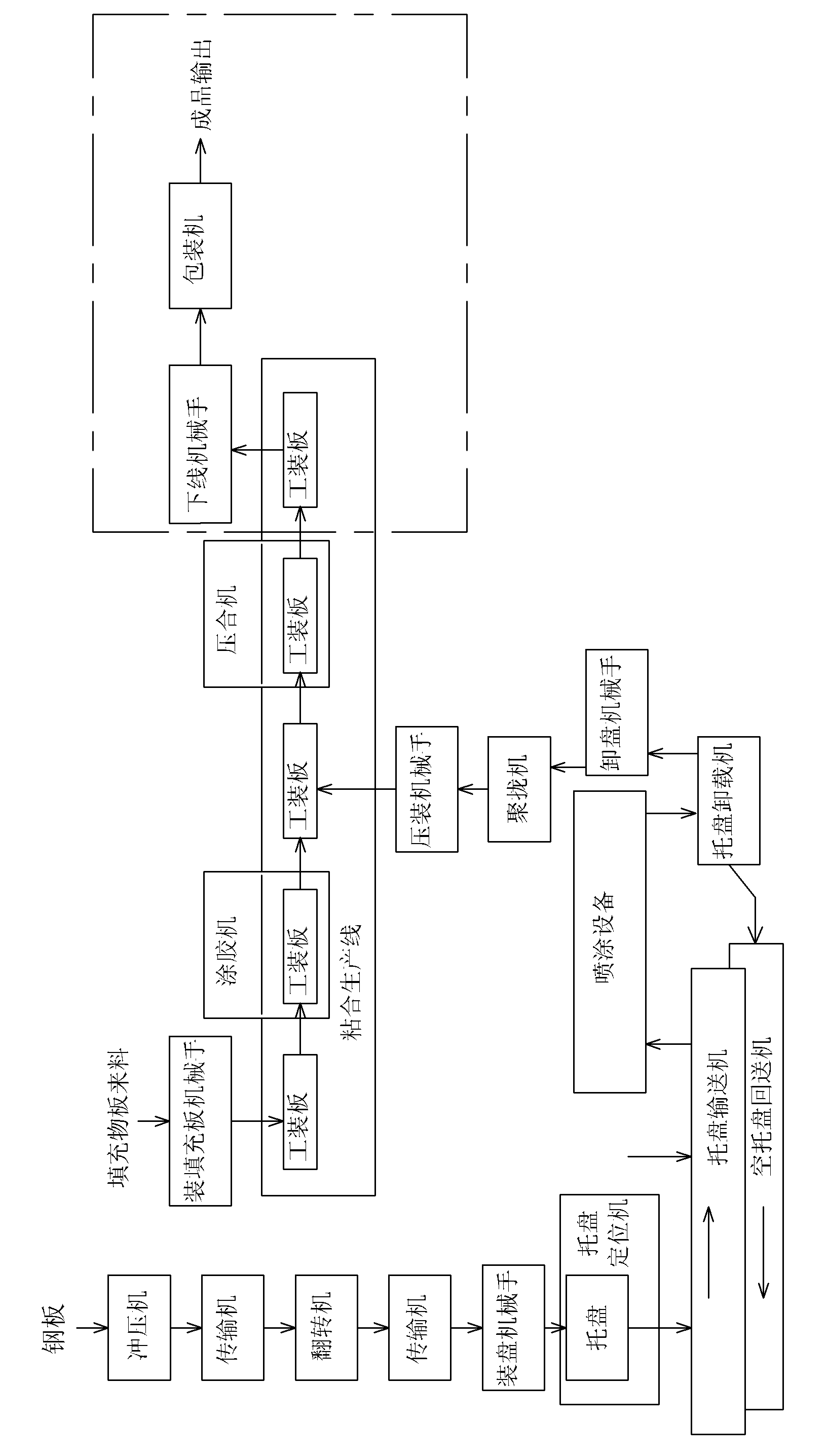

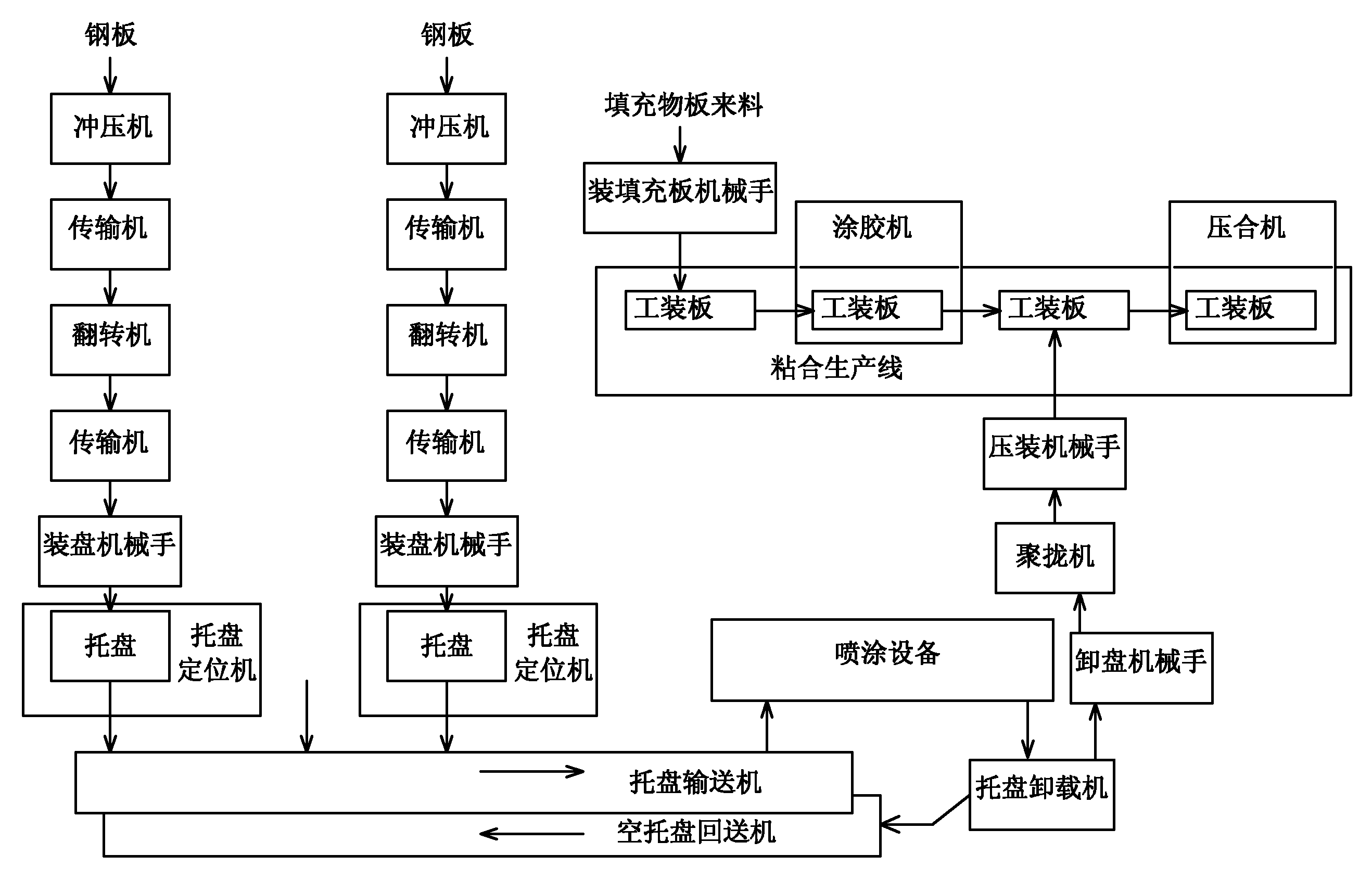

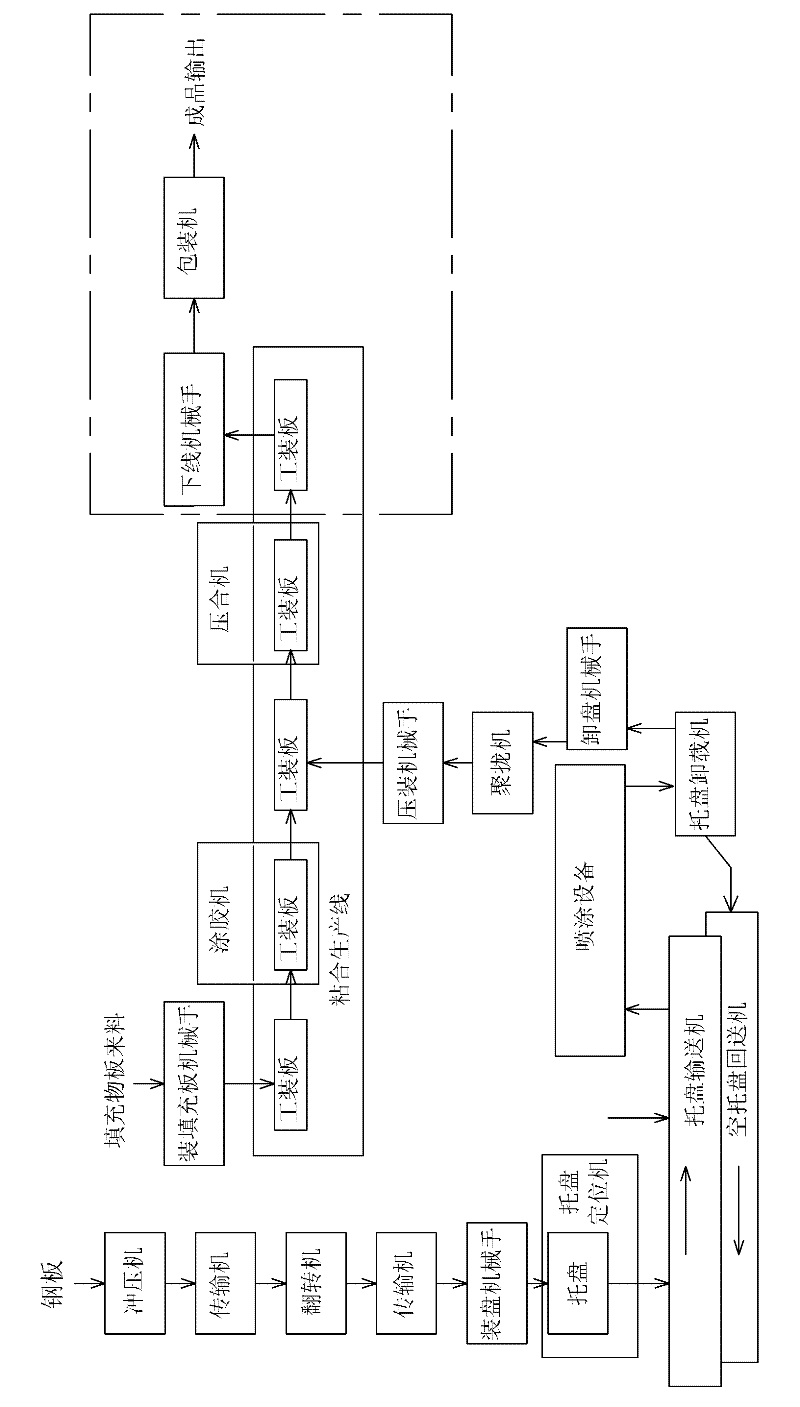

Batch production method for color steel brick

InactiveCN102071783AImprove consistencyThe manufacturing process is compactCovering/liningsLaminationBrickPunching

Owner:HARBIN INST OF TECH

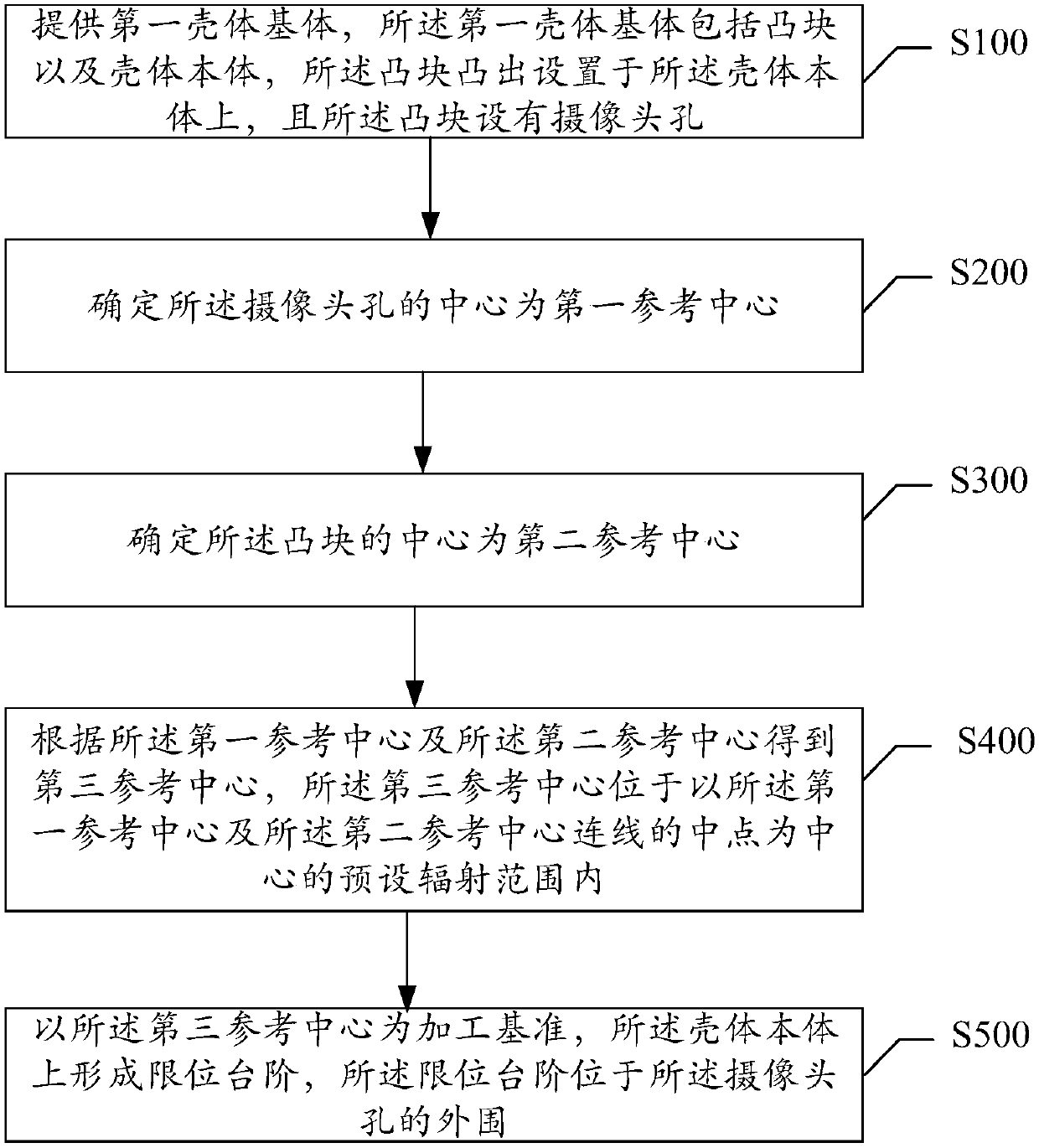

Shell manufacturing method

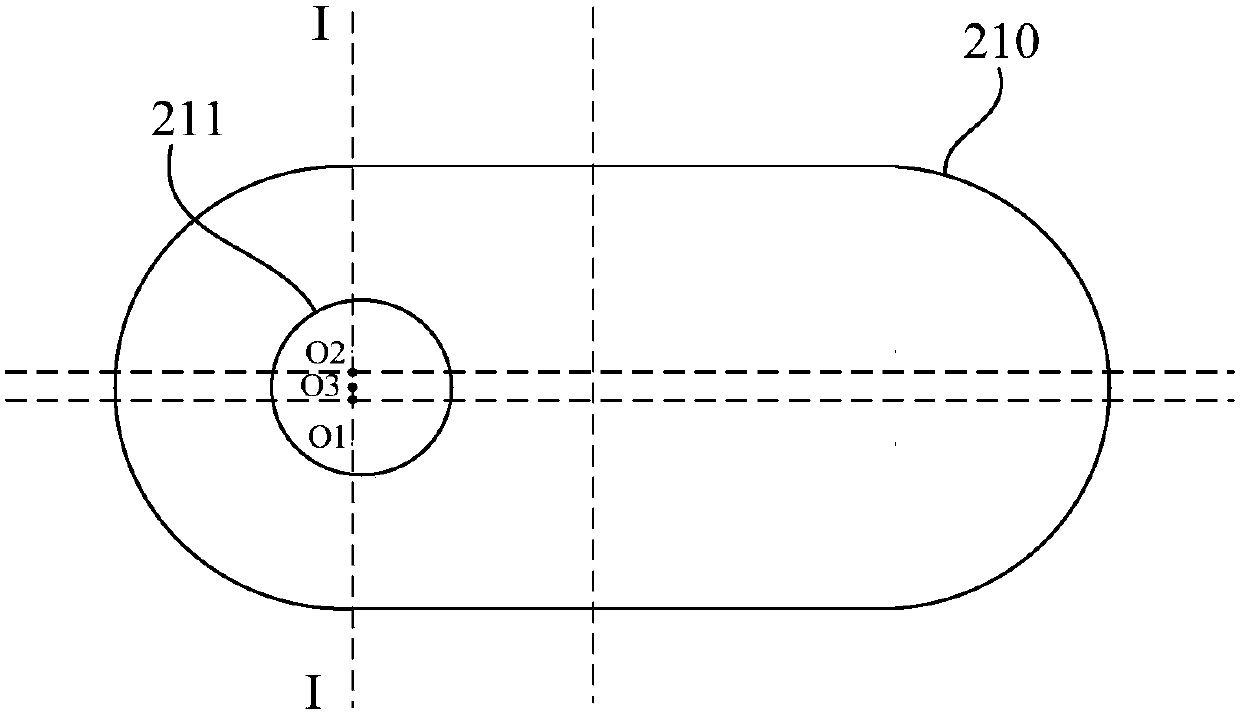

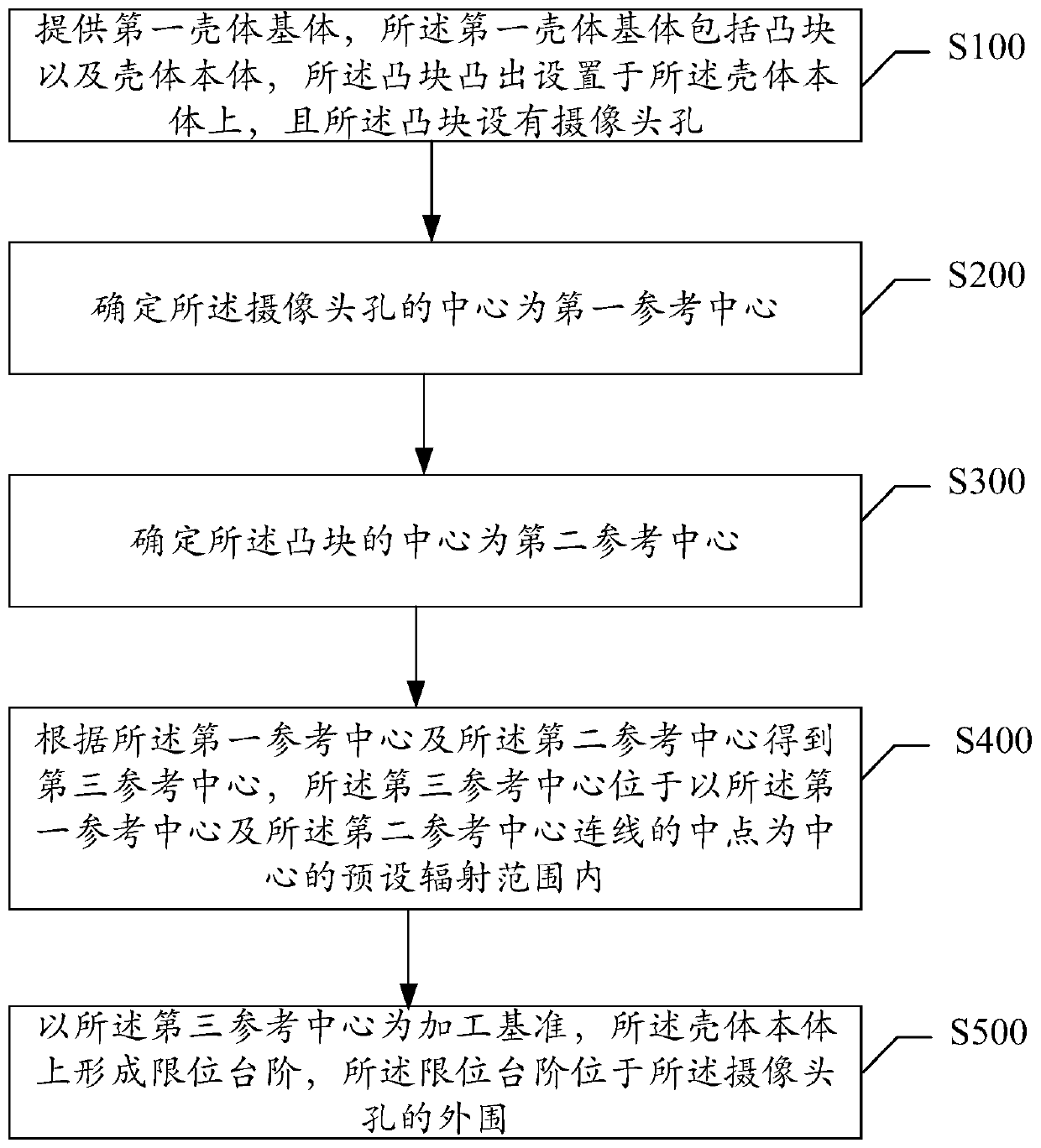

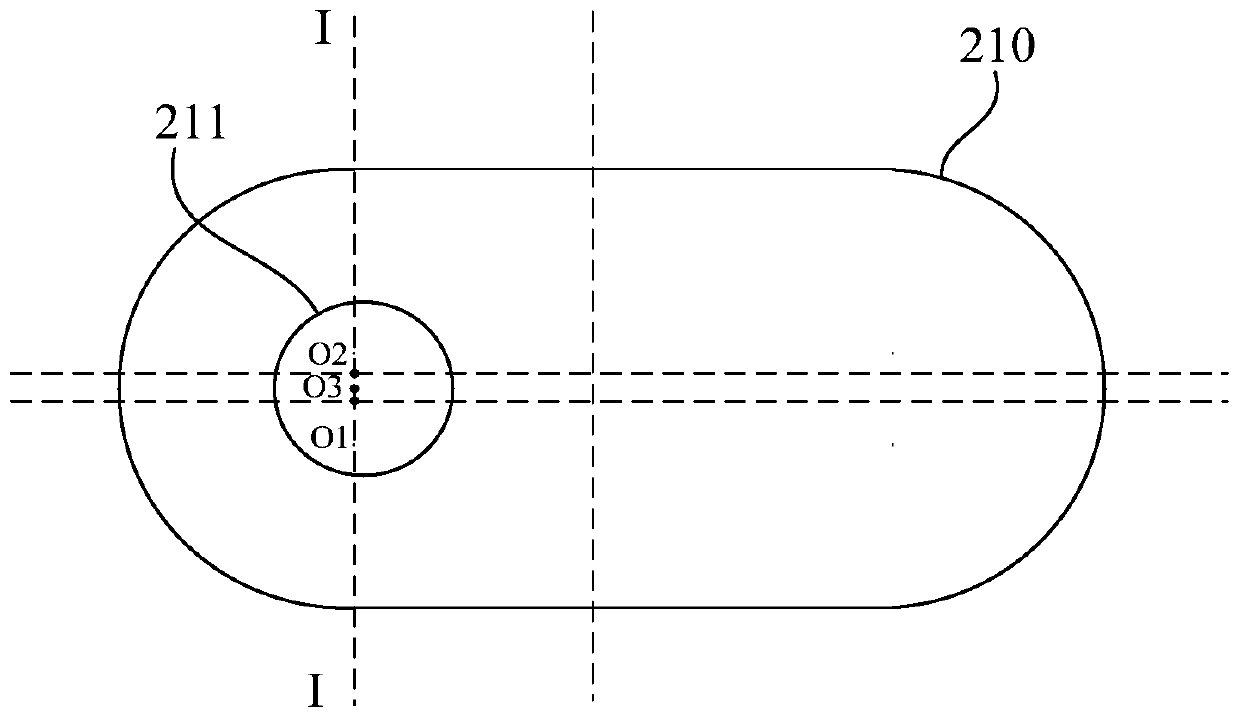

ActiveCN107666805ALarge size deviationCasings/cabinets/drawers detailsForging/hammering/pressing machinesEngineeringRadiation

The invention provides a shell manufacturing method. The shell manufacturing method comprises the following steps of providing a first shell matrix, wherein the first shell matrix comprises a convex block and a shell body, and the convex block provided with a camera hole is arranged on the shell body in a protruding mode; determining the center of the camera hole as a first reference center; determining the center of the convex block as a second reference center; according to the first reference center and the second reference center, obtaining a third reference center, wherein the third reference center is located in a preset radiation range taking the midpoint of the connecting line of the first reference center and the second reference center as the center thereof; taking the third reference center as a processing reference, and forming a limiting step on the shell body, wherein the limiting step is located on the periphery of the camera hole. According to the shell manufacturing method, the size deviation of machined edges on the two sides of the convex block is prevented from being large. Meanwhile, the eccentricity of the camera on the shell is prevented from being large.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for preparing calcium alginate nerve conduit and nerve scaffold

InactiveCN107929808AGood biocompatibilityLow costTissue regenerationProsthesisNerve structureCylindroma

The invention belongs to the field of biomedicine, and particularly relates to a method for preparing a calcium alginate nerve conduit and nerve scaffold. Raw materials include shell powder and sodiumalginate. The shell matrix / calcium alginate nerve conduit is prepared by treating a mixture of shell powder and sodium alginate with hydrochloric acid. The nerve scaffold is obtained by filling the middle of the nerve conduit with a cylinder containing microchannels, and the microchannels are prepared through biofilaments. The preparation method can be used for preparing a nerve conduit with pores of different sizes in the wall and a nerve scaffold containing microchannels of different diameters and numbers. The nerve conduit and nerve scaffold can be used for preparing a model for evaluatingthe repair effect of peripheral nerve defects, thereby providing a reference basis for the design of artificial neural structures and achieving a better effect of promoting repair of peripheral nervedefects.

Owner:SOUTHWEST UNIVERSITY

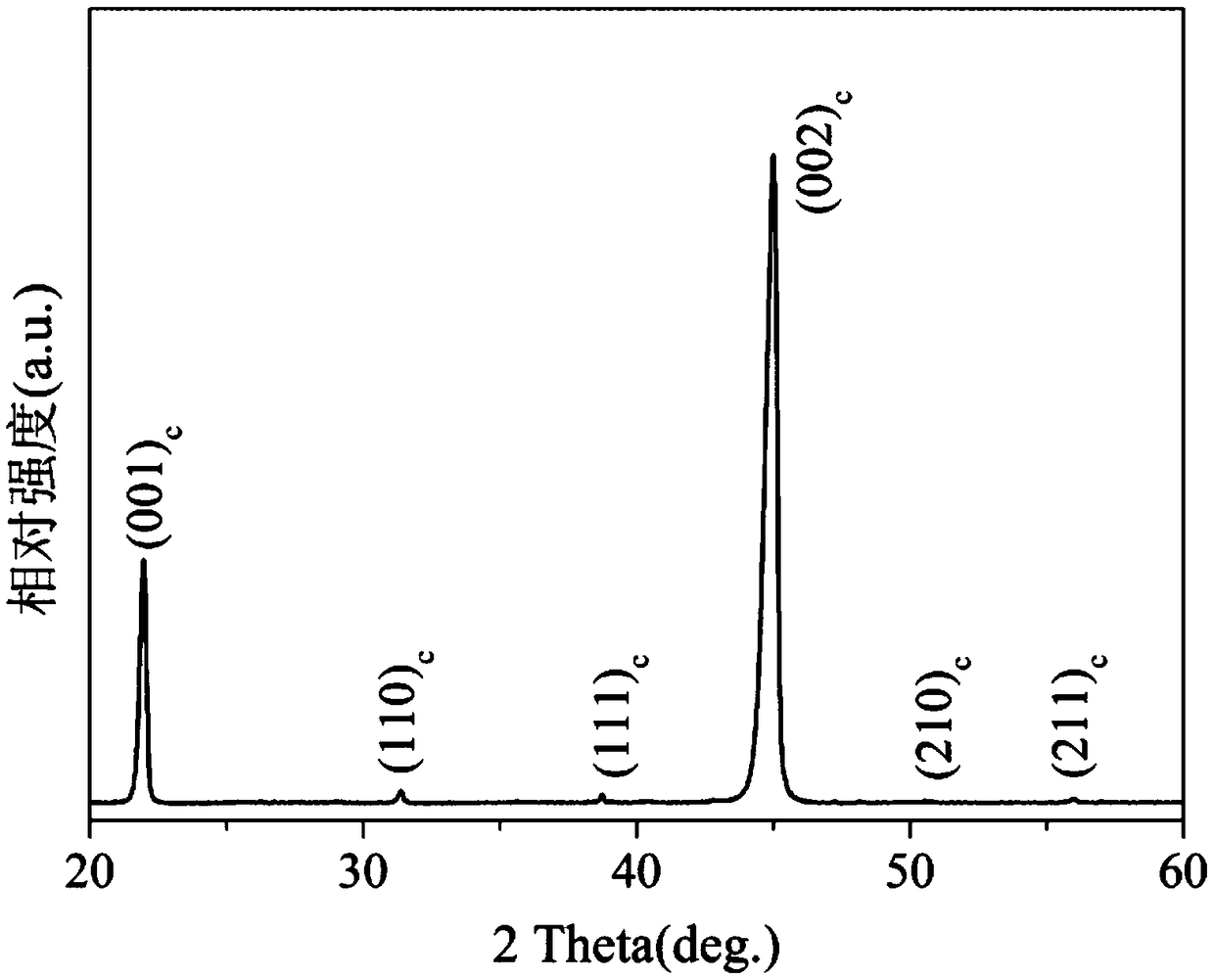

Lead-free piezoelectric texture composite material applied in high-power-density energy collection device and preparation method and application thereof

ActiveCN109400147AMeet power requirementsNovel grainPiezoelectric/electrostriction/magnetostriction machinesElectricityEnergy harvester

The invention relates to a lead-free piezoelectric texture composite material applied in a high-power-density energy collection device and a preparation method and application thereof. The problem that improving amplitude of energy collection performance of a material is very limited on the basis of conventional solid solution or random doping concept due to the fact that existing lead-free piezoelectric ceramic is low in energy density is solved. A chemical general formula of the lead-free piezoelectric texture composite material is (1-x)(Ba1-yCay)(Ti1-zMz)O3 / xBaTiO3. The preparation method includes: 1, preparing fine grain shell matrix powder; 2, preparing casting slurry; 3, preparing ceramic biscuit; 4, preparing texture composite ceramic; 5, preparing highly-compact texture composite ceramic; 6, preparing high-performance texture composite ceramic. The application of the composite material refers to using the composite material in an environment-friendly high-power-density mini energy collector.

Owner:HARBIN INST OF TECH

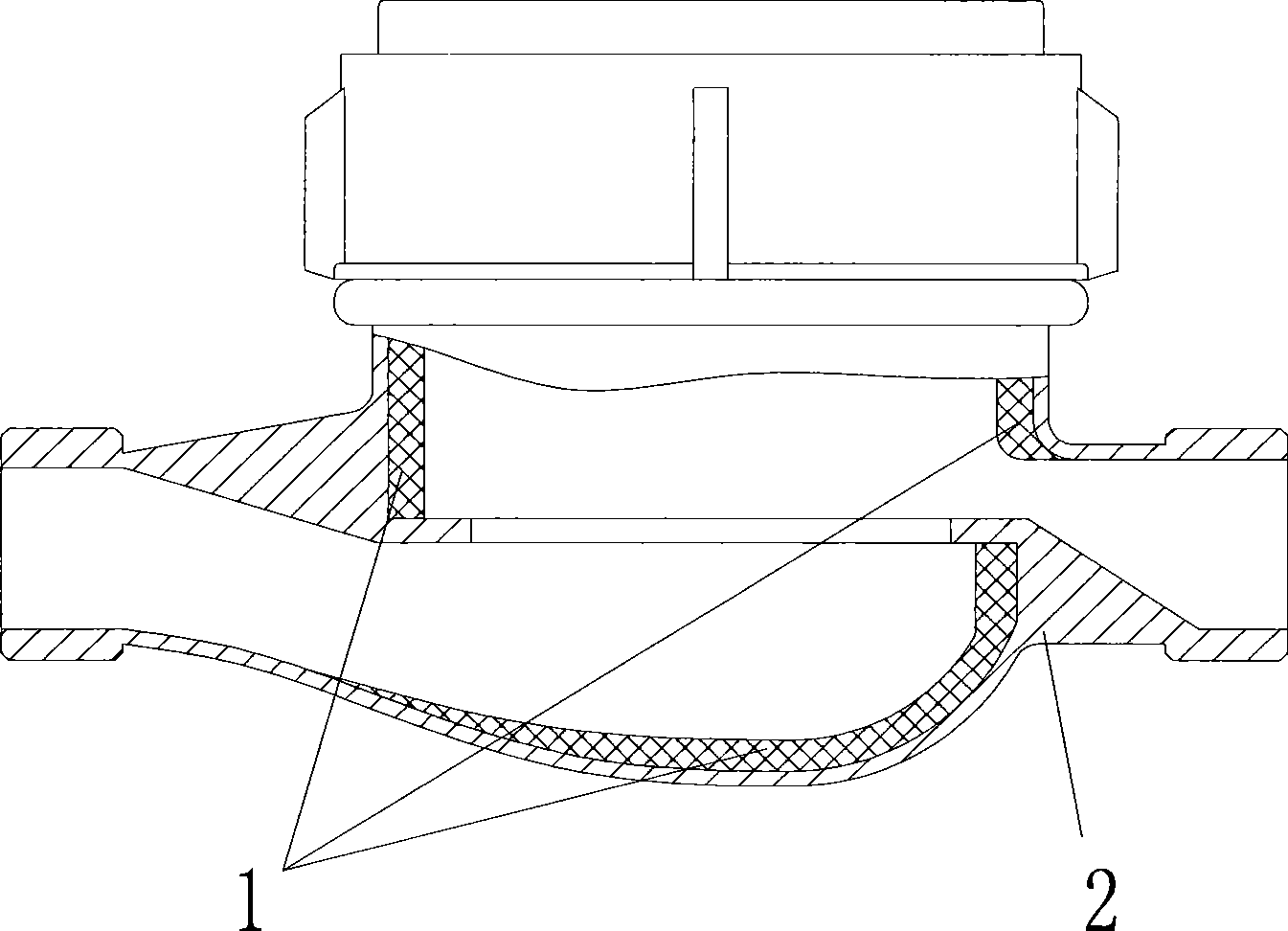

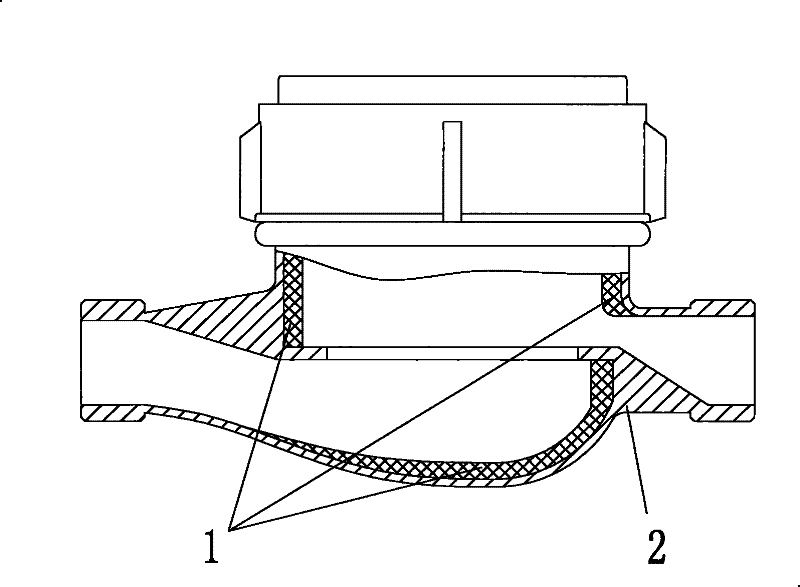

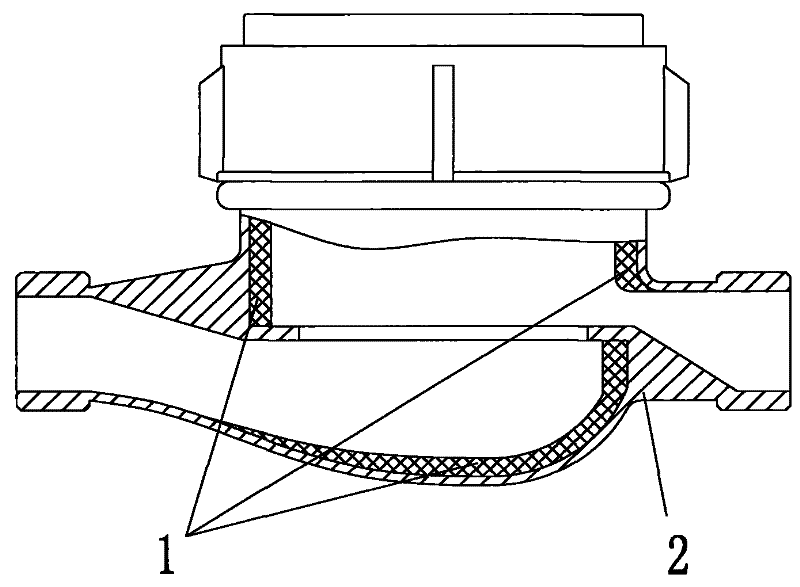

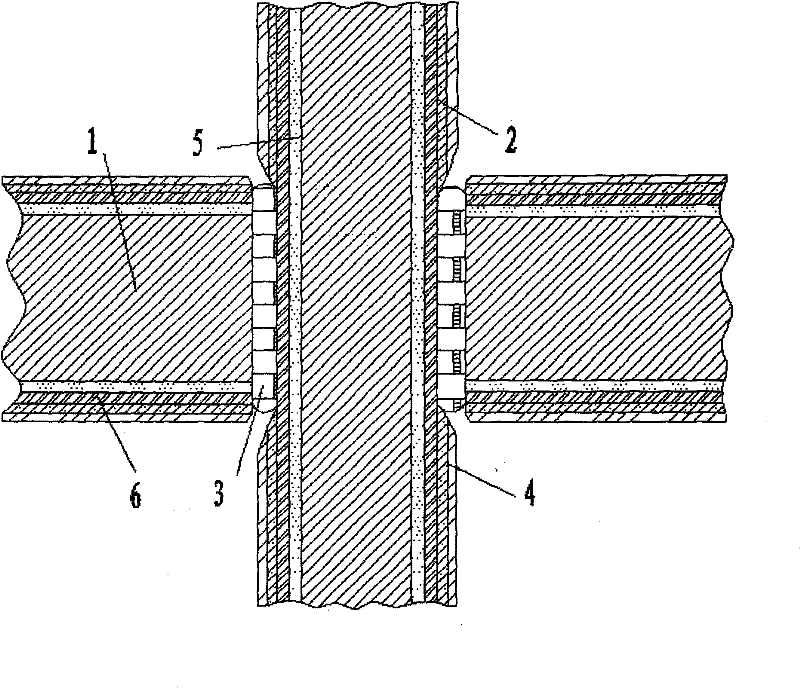

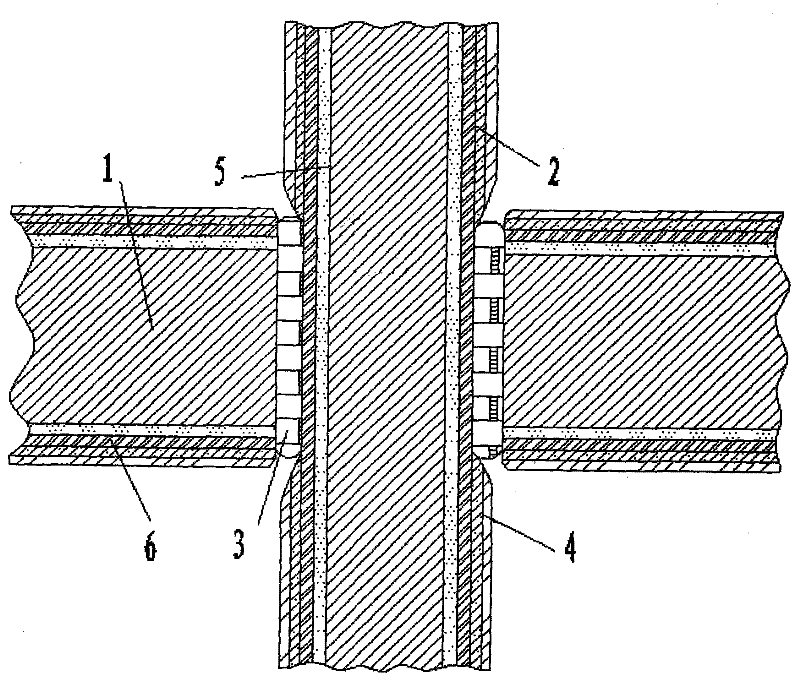

Anti-crack water gauge shell structure

ActiveCN101532860ASolve the problem of antifreeze and explosion protectionVolumetric apparatus damage preventionEngineeringShell matrix

The invention provides an anti-crack water gauge shell structure, comprising a shell matrix; the bottom surface and side inside the shell matrix are both provided with elastic layers, thus realizing overall protection of the shell matrix and effectively solving the problems of freeze and crack prevention when the water gauge is frozen.

Owner:GUANGDONG LIANSU TECH INDAL

Anti-crack water gauge shell structure

ActiveCN101532860BSolve the problem of antifreeze and explosion protectionVolumetric apparatus damage preventionEngineeringShell matrix

The invention provides an anti-crack water gauge shell structure, comprising a shell matrix; the bottom surface and side inside the shell matrix are both provided with elastic layers, thus realizing overall protection of the shell matrix and effectively solving the problems of freeze and crack prevention when the water gauge is frozen.

Owner:GUANGDONG LIANSU TECH INDAL

Doping method of scheelite luminescent material

InactiveCN101805611BSimple and fast operationLuminescent compositionsMaterials preparationRare earth ions

The invention discloses a doping method of a scheelite luminescent material, belonging to the technical of material preparation. The doping method is characterized by comprising the steps of: manufacturing an A vacancy in a luminous matrix surface through the posttreatment, and recovering by rare-earth ions so as to synthesize a material with a luminous shell / nuclear structure, wherein the variety and the content of rare earths in Re<3+>:AMO4(A=Mg, Ca, Sr, Ba and Pb; M=W and Mo; Re=rare earth) can be controlled by changing the variety and the concentration and the treatment time of a treating liquid. The doping method is carried out under a room temperature environment without heat treatment; and the synthesized material has a rare earth luminous shell-matrix nuclear structure and excellent luminous property. Therefore, compared with the traditional doping method, the doping method has remarkable advantages of zero energy consumption, rare earth raw material saving, simple and convenient operation and the like.

Owner:陈连平

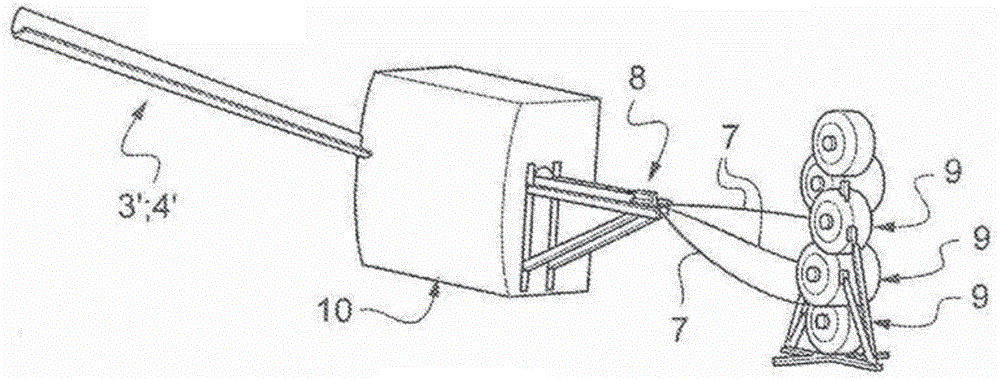

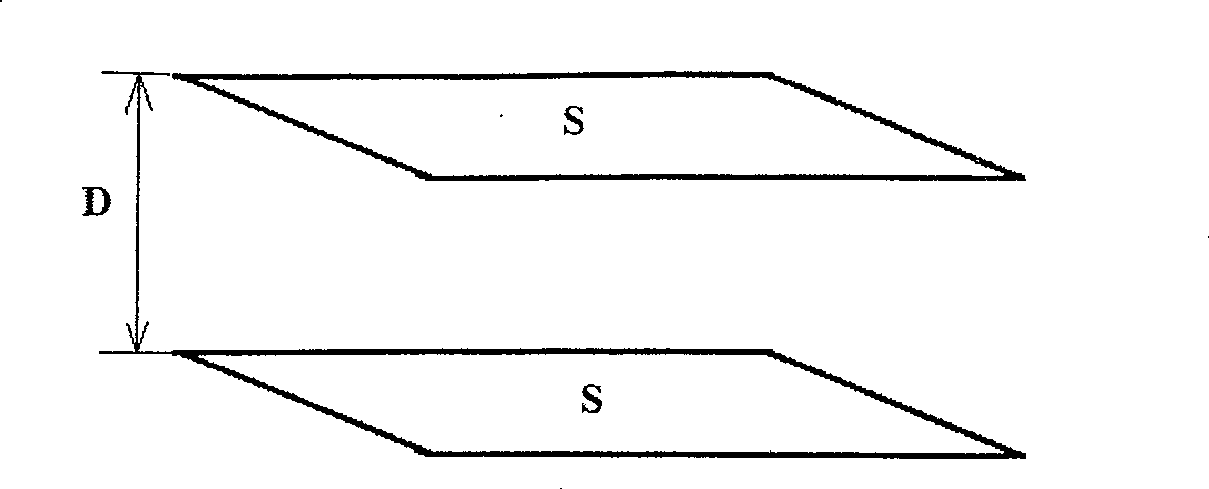

Plates for producing multi-layer composite bearing shells and machining technology and machining system of such plates

PendingCN107776118AUniform spray coatingUniform curingLamination ancillary operationsPretreated surfacesAutomatic controlCarbon steel

The invention provides plates for producing multi-layer composite bearing shells and a machining technology and a machining system of such plates. The plates for producing the multi-layer composite bearing shells can be used for producing the multi-layer composite bearing shells with elasticity, embedability and resistance to wear up to the standard through punch forming by a punch press. A material for producing the multi-layer composite bearing shells consists of a polymer layer, an alloy layer and a low-carbon steel layer sequentially from to top to bottom. The machining system is automatically controlled from sintering and roller forming of dual-alloy plates to preparation of a self-lubricating coating through plate plane spraying and adopts a multistage temperature control curing technology, a cooling technology and a stepless speed-regulating conveyance technology. After those technologies are employed, polymer coating and one bearing shell matrix are higher in bonding strength than curved surface bearing shell spraying, other subsequent treatment is unneeded when the material for producing the multi-layer composite bearing shells is formed prior to forming of the bearing shells, and the coating is less prone to shedding during punch forming and actual use, so that production efficiency is improved and production cost is saved.

Owner:上海涟屹轴承科技有限公司

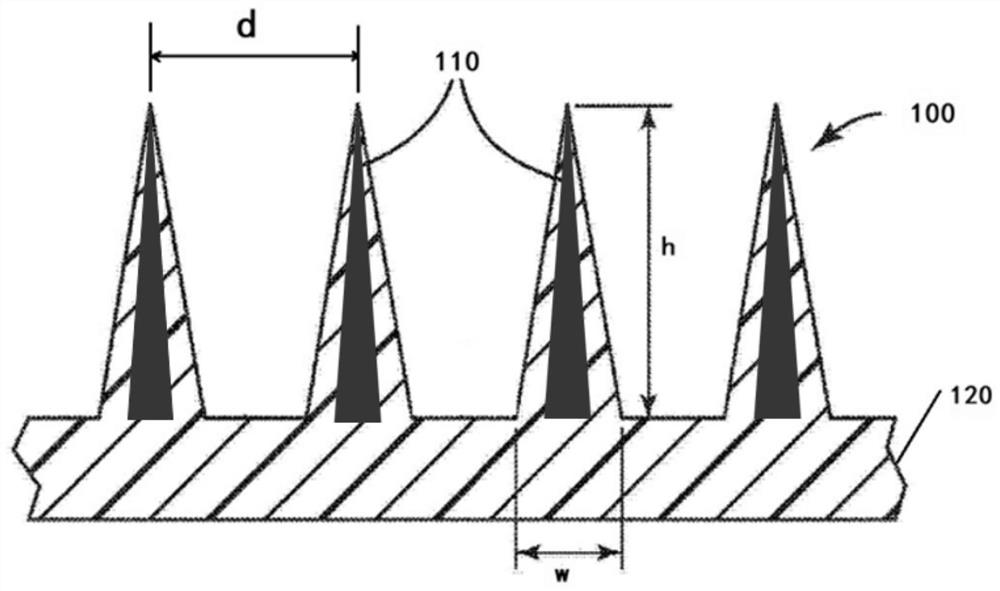

Anti-hair loss and hair growth integrated core-shell microneedle patch and preparation method thereof

PendingCN113713088APromote regenerationPromote growthPeptide/protein ingredientsMicroneedlesMesenchymal stem cellEngineering

The invention discloses an anti-hair loss and hair growth integrated core-shell microneedle patch and a preparation method thereof. The anti-hair loss and hair growth integrated core-shell microneedle patch comprises a backing and a core-shell microneedle array attached to one side of the backing, the core-shell microneedle array comprises a plurality of microneedles arranged on the backing in an array mode, each microneedle comprises a shell matrix material and an inner core, the shell matrix material is loaded with a nano-enzyme for removing excessive active oxygen. According to the anti-hair loss and hair growth integrated core-shell microneedle patch and the preparation method thereof, the shell matrix material is rapidly degraded after the microneedle patch is applied to the skin, and the loaded nano-enzyme can passively release and remove active oxygen and promote the generation of blood vessels in the microenvironment around hair follicles, exosome derived from mesenchymal stem cells is loaded in the inner core of the microneedle, and the inner exosome is released and conveyed to a hair follicle ecological niche after the shell matrix material is degraded, so that the pigmentation can be improved, and the hair regeneration is promoted.

Owner:TANGYI HLDG(SHENZHEN) LTD +1

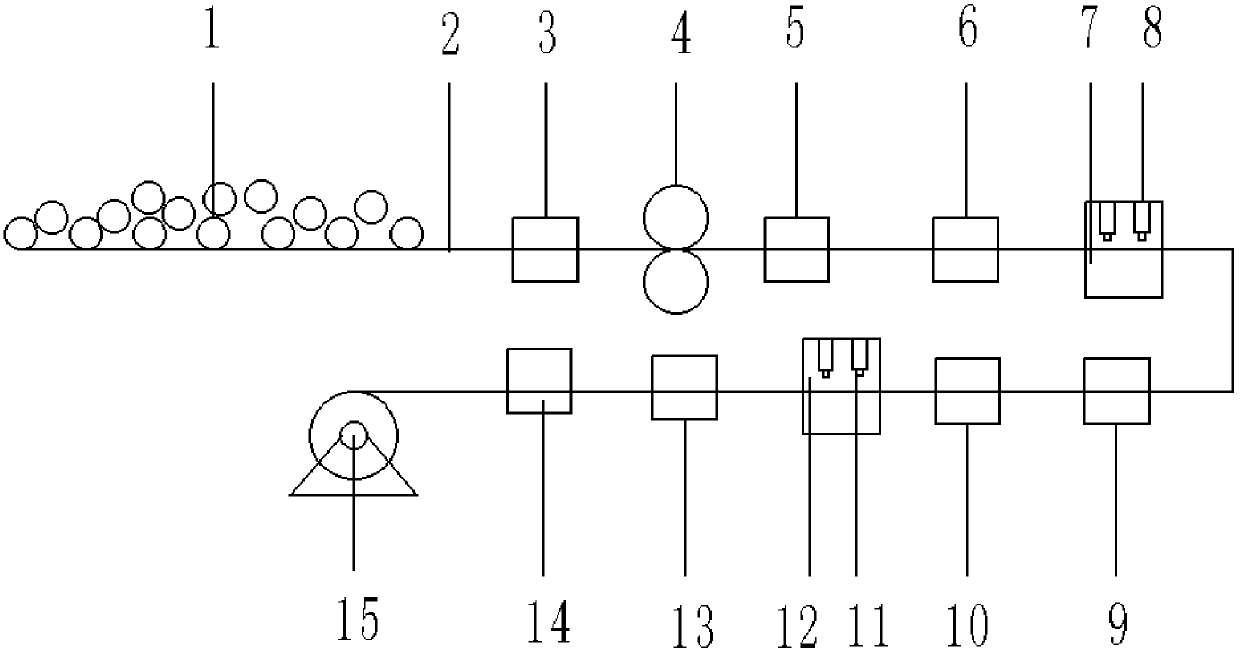

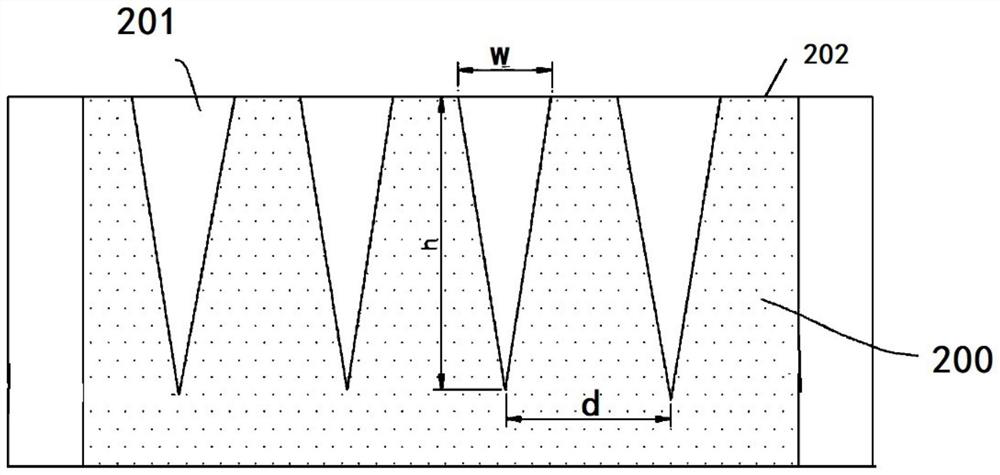

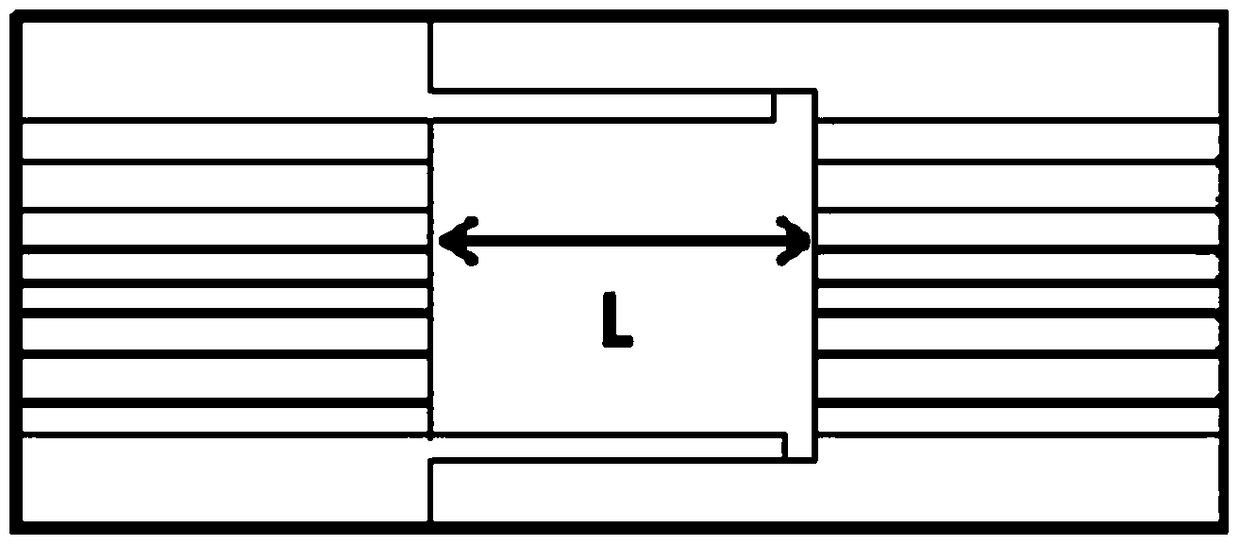

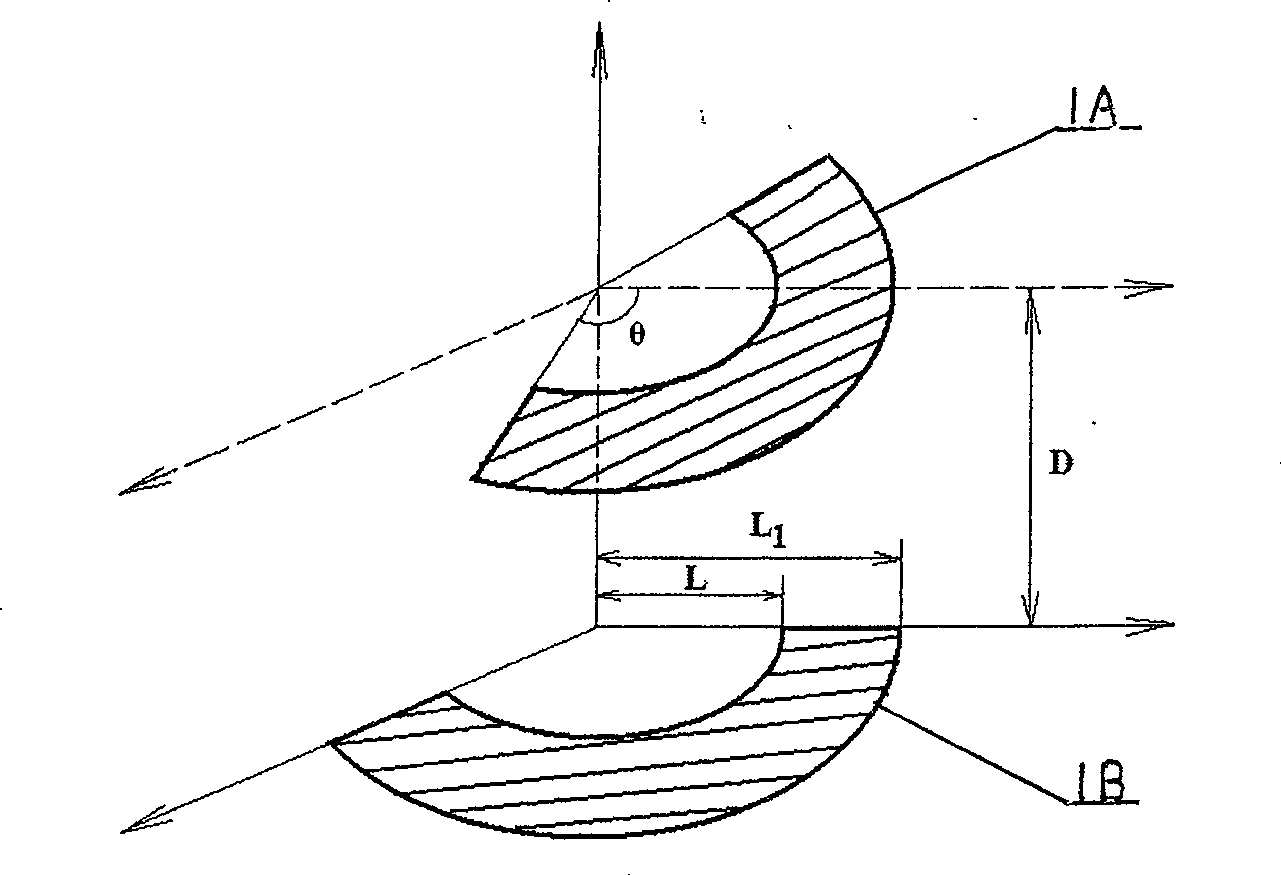

Preparation method of adjustable waveguide system for X-ray nano-scale focusing

ActiveCN109166644AMake up for focus performance lossPrecise positioningHandling using diffraction/refraction/reflectionX-rayWaveguide

The invention relates to the processing technology of ionizing radiations, in particular to X-ray focusing apparatuses applying diffraction, refraction or reflection, and specifically to a preparationmethod of an adjustable waveguide system for X-ray nano-scale focusing. The waveguide system comprises an adjustable shell matrix, the adjustable shell matrix consists of a first shell matrix and a second shell matrix, the first shell matrix and the second shell matrix can be driven to carry out relative movements, the interiors of the first shell matrix and the second shell matrix are both fixedly provided with multi-layer thin film waveguide structures with a same structure, and the adjustable shell matrix is integrally arranged in a temperature-adjustable cavity. Compared with the prior art, the adjustable waveguide system can use two waveguide structures to perform regulatory focusing on X-ray, and the problem that the expected focusing effect cannot be achieved in a traditional focusing apparatus is solved, because after the traditional focusing apparatus is produced and formed, errors existing in a manufacturing process of the traditional focusing apparatus can cause parameter differences comparing with parameters determined by a simulation calculation process, so that a novel idea for further improving the focusing performance of X-ray waveguides is provided.

Owner:萧县众科电磁检测有限公司

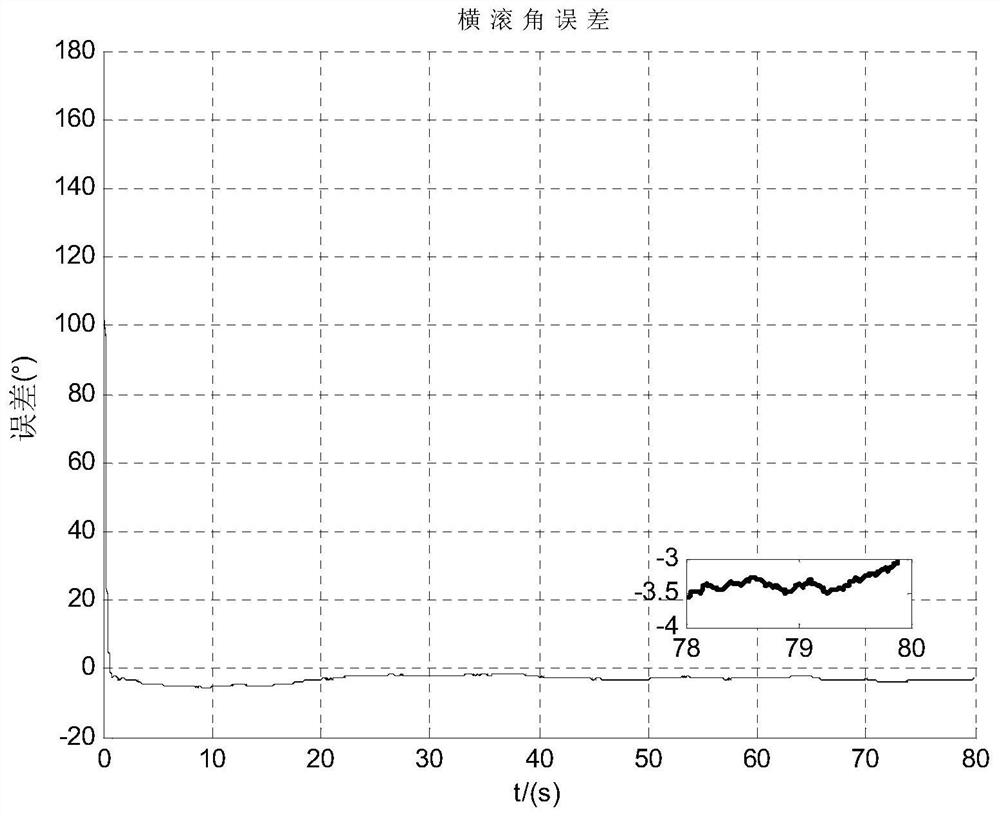

An Estimation Method of Projectile Roll Angle Based on GPS and Least Square Filter

ActiveCN109059914BHigh precisionNavigational calculation instrumentsNavigation by speed/acceleration measurementsGyroscopeClassical mechanics

The invention discloses a method for estimating the roll angle of a projectile based on GPS and least squares filtering. The method includes the following steps: (1) Calculate the inertial frame i of the carrier at time t according to the velocity and position of the projectile provided by the gyroscope and GPS b system is relative to the shell attitude matrix of the carrier system b, the navigation system n is relative to the navigation inertial system i n The shell attitude matrix (2) calculates the shell in the carrier inertial frame i b and navigation inertial frame i n The speed value under the system and (3) the speed ratio provided by GPS to calculate the initial heading angle Y 0 and pitch angle P 0 , set the state variable X according to the initial roll angle; (4) estimate X according to the least squares filter and calculate it as i n system relative to i b (5) Calculate the roll angle of the shell according to the sum at time t; where is the attitude matrix of the n system relative to the b system at the time t.

Owner:SOUTHEAST UNIV

Batch production method for color steel brick

InactiveCN102071783BImprove consistencyThe manufacturing process is compactCovering/liningsLaminationBrickPunching

The invention discloses a batch production method for a color steel brick, which relates to a production method for an exterior wall brick, and aims to solve the problems that the conventional production method for the color steel brick has scattered process steps and is not suitable for mass production. The production process of the invention comprises the following steps that: steel plates are punched into steel shells on a punching machine; the steel shells are turned over for 180 degrees by using a turnover machine, so that openings of the steel shells are downward; the steel shells are arranged in a row and are positioned; a plurality of steel shells are sucked up by a manipulator and are placed on a tray with a positioning boss; the tray is conveyed to a spray-coating station to spray the outer surfaces of the steel shells; the steel shells are taken down by the manipulator and the steel shells are arranged on a gathering machine and gathered into closely adjacent matrixes; filler is filled on a tool plate in a circular pipeline; the upward surface of the filler is uniformly glued; the closely adjacent steel shell matrixes prepared on the gathering machine are simultaneouslysucked up; the steel shells are pressed and assembled on the filler; further the steel shells and the filler are pressed out by a pressing machine; the steel shells are combined with a glue layer on the filler, so that the color steel brick is formed. The method is suitable for the production of the color steel brick.

Owner:HARBIN INST OF TECH

Method for producing line output transformer shell with high thermal diffusivity

The invention discloses a method for producing a line output transformer shell with a high thermal diffusivity. The method comprises the following steps: melting ABS resin and polypropylene to obtaina mixture a; mixing and grinding negative ion powder, tourmaline, ferric acetylacetonate, talcum powder, sodium gluconate and carboxymethylcellulose sodium to obtain a mixture b; mixing the mixture awith the mixture b, and uniformly stirring the mixture a and the mixture b in order to obtain a mixture c; melting, molding and cooling the mixture c to obtain a green body d; homogenizing the green body, and cooling the homogenized green body with water to obtain a line output transformer shell matrix; and smearing a thermal diffusion material on the surface of the line output transformer shell matrix, and drying the surface to obtain the line output transformer shell, wherein the thermal diffusion material comprises modified viscose-based carbon fibers, nanometer silicon nitride, a couplingagent, naphthenic oil and ethanol. The method is simple, is friendly to the environment and is suitable for industrial production, and the produced line output transformer shell has excellent thermaldiffusivity, excellent insulating property and excellent ageing resistance.

Owner:天长市富柏特电子有限公司

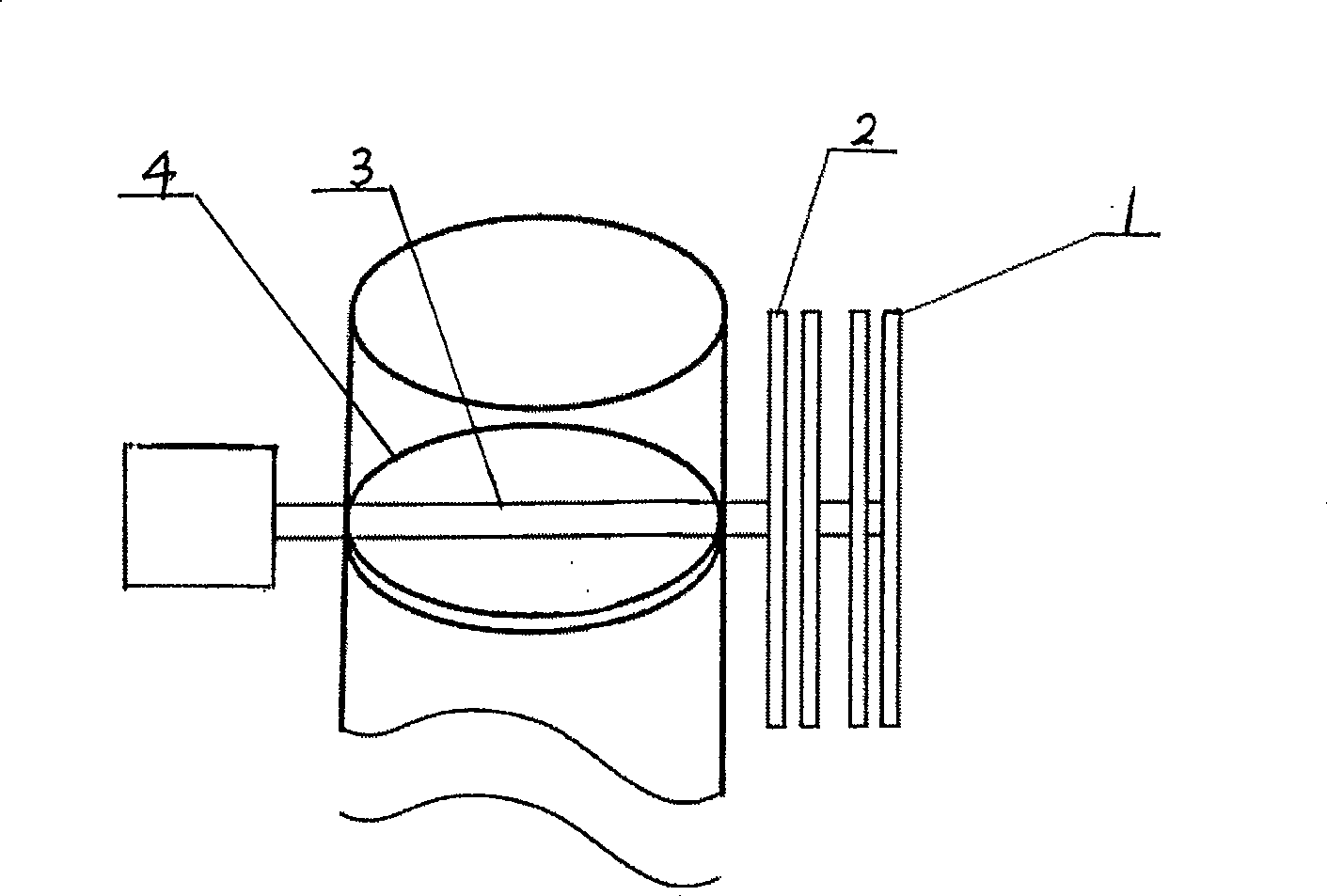

Engine throttle position sensing method and sensor

InactiveCN100460821CRealize sensingRealize measurementConverting sensor output electrically/magneticallyCapacitanceParallel plate

The invention relates to a sensing method of engine's throttle plate place .It uses two parallel plate capacitor separately used as measure capacitance and reference compensation capacitor .One wafer of the measure capacitance is fixed connected to throttle plate's rotating shaft , the other wafer is fixed installed on the shell matrix of the capacitance on the throttle plate , and two wafers keep the same distance in axial direction .Two wafers forming the capacitance's effective area changes with the jaw opening of the throttle plate .The reference compensation capacitor and the measure capacitor are installed in the same environment ,and the former capacitor compensates the latter one gain accurate change value of the measure capacitor .Measure the linear relationship between the changing value and rotating angle of capacitor , through circuit processing ,then obtain the accurate angle of unlocking the throttle plate to realize the measurement of the place of throttle plate .The invention can realize high resolution and high degree of accuracy measurement under large scale , and it's useful to extend the sensor's useful time .Its structure is simple ,and it is inexpensive ,the requirement of its craft is not high .

Owner:CHONGQING RUIYANG TECH DEV

Shell manufacturing method, shell and mobile terminal

InactiveCN107864259BReduce processImprove processing efficiencyTelephone set constructionsWireless communicationMechanical engineeringElectrical and Electronics engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Shell making method

InactiveCN107666805BLarge size deviationCasings/cabinets/drawers detailsForging/hammering/pressing machinesEngineeringRadiation

The invention provides a shell manufacturing method. The shell manufacturing method comprises the following steps of providing a first shell matrix, wherein the first shell matrix comprises a convex block and a shell body, and the convex block provided with a camera hole is arranged on the shell body in a protruding mode; determining the center of the camera hole as a first reference center; determining the center of the convex block as a second reference center; according to the first reference center and the second reference center, obtaining a third reference center, wherein the third reference center is located in a preset radiation range taking the midpoint of the connecting line of the first reference center and the second reference center as the center thereof; taking the third reference center as a processing reference, and forming a limiting step on the shell body, wherein the limiting step is located on the periphery of the camera hole. According to the shell manufacturing method, the size deviation of machined edges on the two sides of the convex block is prevented from being large. Meanwhile, the eccentricity of the camera on the shell is prevented from being large.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A preparation method of a tunable waveguide system focusing on x-ray nanoscale

ActiveCN109166644BMake up for focus performance lossPrecise positioningHandling using diffraction/refraction/reflectionX-rayWaveguide

The invention relates to the processing technology of ionizing radiations, in particular to X-ray focusing apparatuses applying diffraction, refraction or reflection, and specifically to a preparationmethod of an adjustable waveguide system for X-ray nano-scale focusing. The waveguide system comprises an adjustable shell matrix, the adjustable shell matrix consists of a first shell matrix and a second shell matrix, the first shell matrix and the second shell matrix can be driven to carry out relative movements, the interiors of the first shell matrix and the second shell matrix are both fixedly provided with multi-layer thin film waveguide structures with a same structure, and the adjustable shell matrix is integrally arranged in a temperature-adjustable cavity. Compared with the prior art, the adjustable waveguide system can use two waveguide structures to perform regulatory focusing on X-ray, and the problem that the expected focusing effect cannot be achieved in a traditional focusing apparatus is solved, because after the traditional focusing apparatus is produced and formed, errors existing in a manufacturing process of the traditional focusing apparatus can cause parameter differences comparing with parameters determined by a simulation calculation process, so that a novel idea for further improving the focusing performance of X-ray waveguides is provided.

Owner:萧县众科电磁检测有限公司

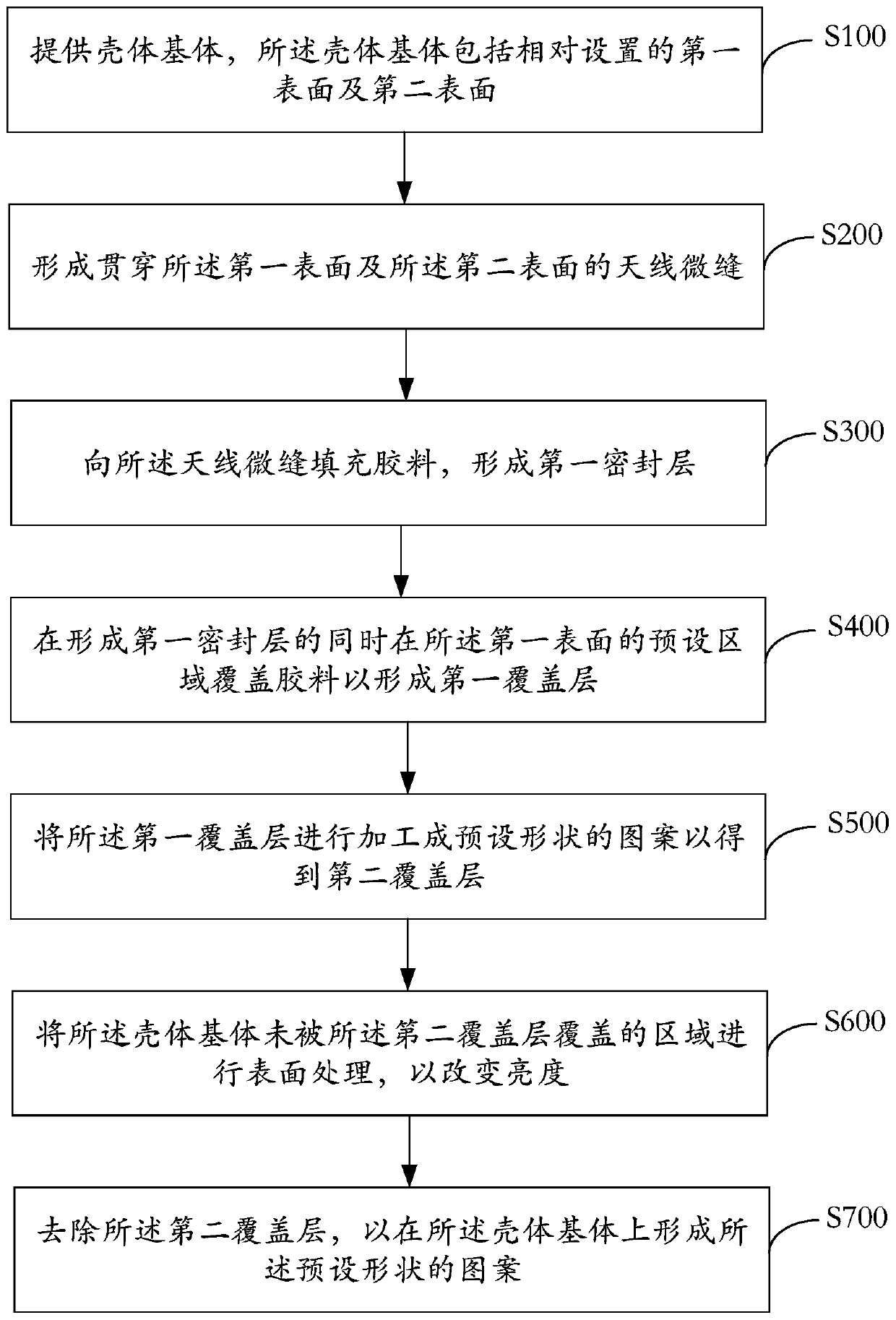

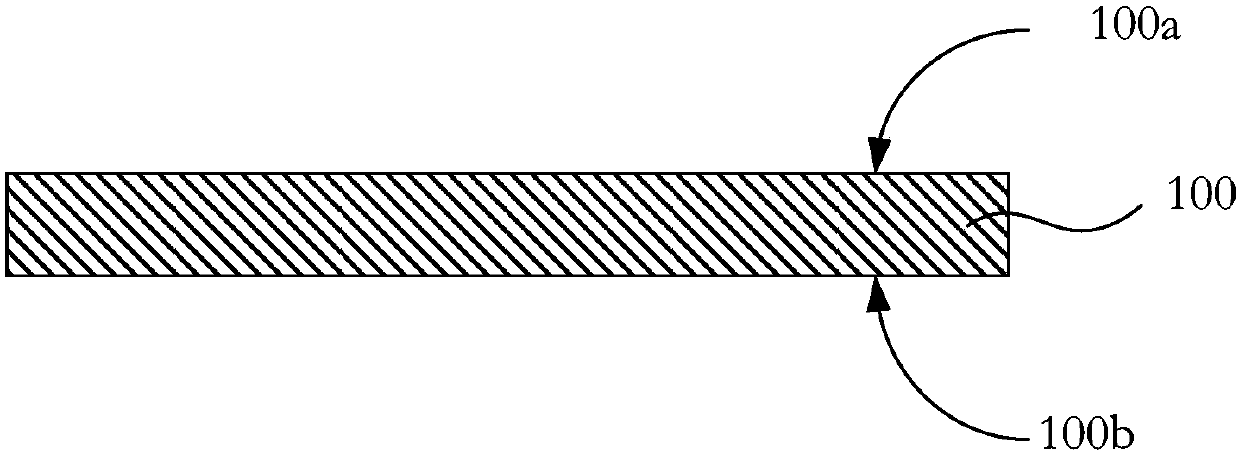

Shell manufacturing method, shell and mobile terminal

ActiveCN107864259AReduce processImprove processing efficiencyTelephone set constructionsComputer terminalEngineering

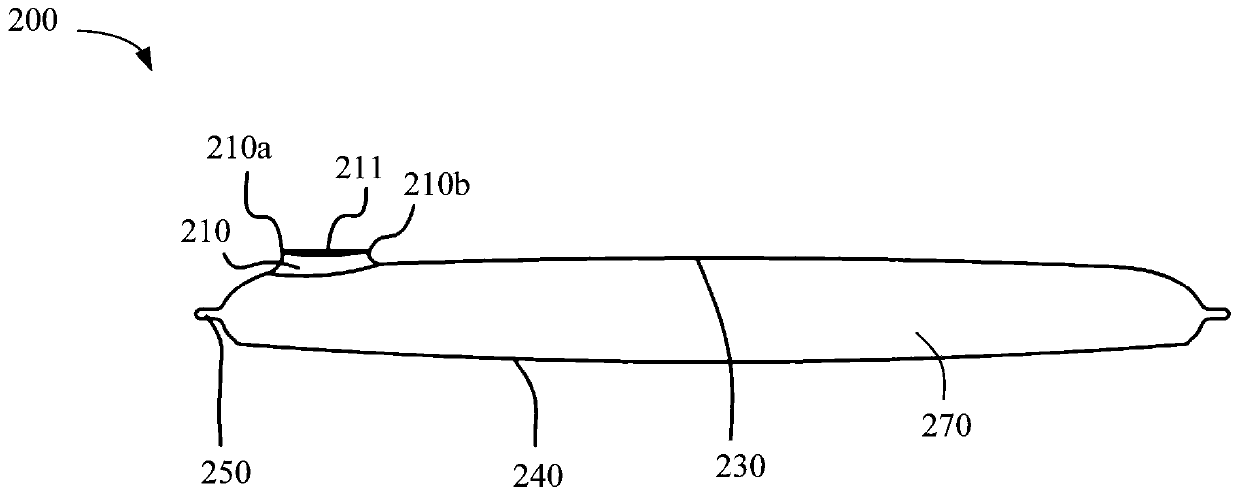

The application provides a shell manufacturing method, a shell, a mold and a mobile terminal. The shell manufacturing method comprises the following steps: providing a shell matrix, wherein the shellmatrix comprises a first surface and a second surface opposite to each other; forming an antenna slit penetrating the first surface and the second surface; filling the glue in the antenna slit to forma first sealing layer; covering the glue at the preset region of the first surface while forming the first sealing layer, thereby forming a first coverage layer; processing the first coverage layer into a pattern with the preset shape so as to obtain a second coverage layer; performing surface processing on the region which is uncovered by the second coverage layer on the shell matrix, thereby changing the brightness; and removing the second coverage layer so as to form the pattern with the preset shape on the shell matrix.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

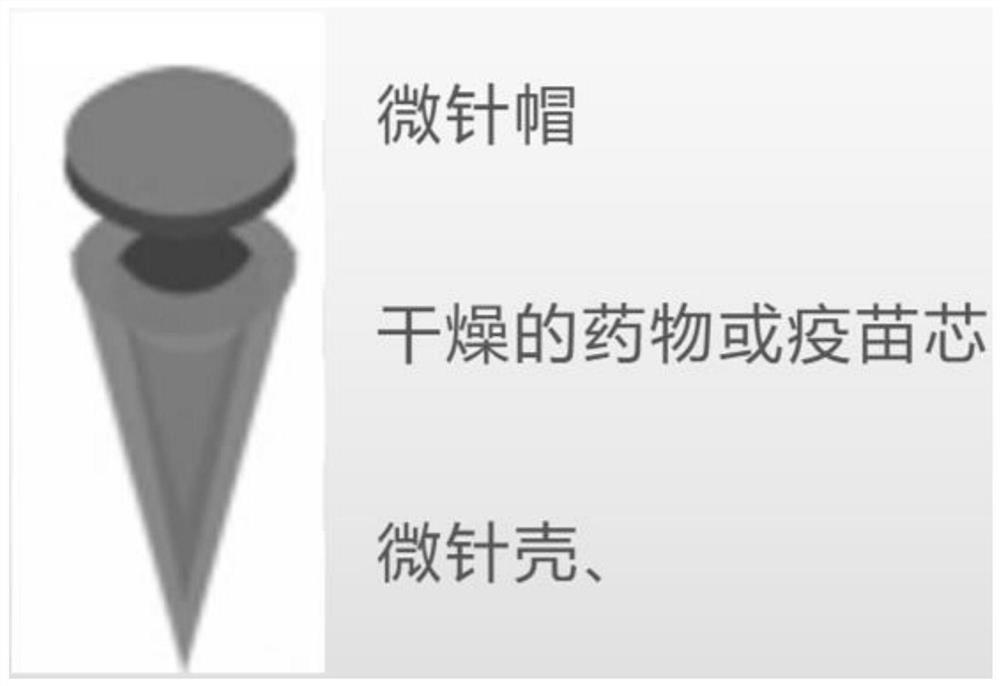

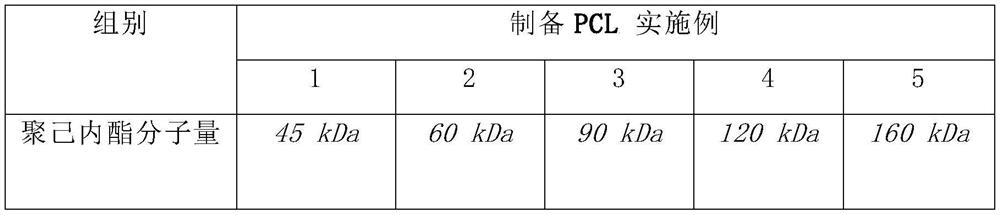

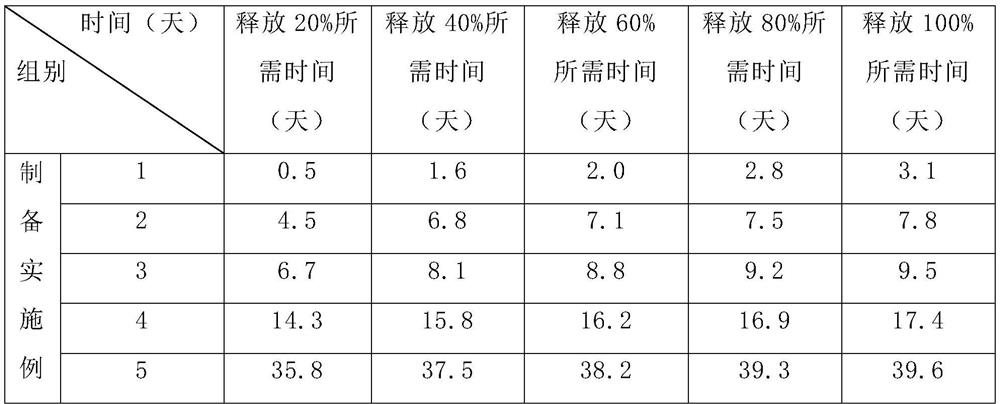

Multi-administration core-shell microneedle patch and preparation method thereof

The invention relates to a multi-administration core-shell microneedle patch and a preparation method thereof. The core-shell microneedle patch comprises a core-shell microstructure generated by a 3D manufacturing process that assembles together three different components of the microneedle, including a microneedle shell, a microneedle cap and a dry drug or vaccine core. The microneedle patch which is inserted at one time and released by delayed rupture is applied to the skin at different controllable time points, the microneedle shell matrix material is unequally biodegraded by the human body from several days to several months, the medicine or vaccine is released, and an immune response similar to injection of the same antigen vaccine for multiple times is initiated. The microneedle is loaded with a large number of protein antigens, can be easily inserted into the skin in a minimally invasive manner, does not cause obvious skin irritation during long-term implantation, and reduces the biohazard of a needle / syringe and the risk of disease transmission. In addition, the obtained microneedle patch administration system also shows good biocompatibility, and shows good potential in transformational medicine.

Owner:TIANJIN UNIV

Plating layer for electrochemistry corrosion resistant electronic encapsulation shell

InactiveCN101649456BSacrificial corrosionEffective protectionSemiconductor/solid-state device manufacturingMetallic material coating processesSurface layerElectrochemistry

The invention relates to a plating layer for an electrochemistry corrosion resistant electronic encapsulation shell, which comprises the following step: sequentially plating an inert metal-plating layer, a ferronickel-plating layer, a nickel-plating layer and a gold-plating layer on a surface layer of a shell matrix and a surface layer of a lead from the inner part to the outer part, wherein the ferric content of the ferronickel-plating layer is from 15 to 65 percent by weight. The invention can prevent and retard the electrochemistry corrosion of the electronic encapsulation shell.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Battery steel belt, battery steel shell using steel belt and manufacturing method for steel shell

ActiveCN106367789ASolve the bonding problemReduce wasteCell component detailsElectrical batteryDissolution

The invention relates to a battery steel belt, a battery steel shell using the steel belt and a manufacturing method for the steel shell. The battery steel belt is characterized in that nickel electroplated layers are separately formed on the surfaces, wherein the thickness of the nickel plated layer on the inner surface is greater than that of the nickel plated layer on the outer surface; the plated layers on the surfaces of the steel belt are subjected to thermal treatment to interpenetrate with matrix to form Fe-Ni alloy layers; and the Fe-Ni alloy layers formed by thermal treatment are compact in structure, are good in corrosion resistance; bonding force between the Fe-Ni alloy layers and Fe matrix is much greater than that between regular electroplated layers and the Fe matrix, so that the possibility of generating cracks during steel shell punching is reduced, and conditions can be provided for forming post-electroplated Ni layers with good bonding force on surfaces. After being subjected to nickel pre-plating and nickel post-plating, the steel shell has the characteristic that the nickel layer on the inner surface is thick, so that power storage of a battery is improved, compactness and corrosion resistance of the battery are much better than those of a battery with a single electroplated nickel layer, and therefore, the battery leakage problem caused by dissolution of steel shell matrix iron during long-term storage of the battery is solved.

Owner:宁波堇山新材料有限公司

Shell manufacturing method, shell and mobile terminal

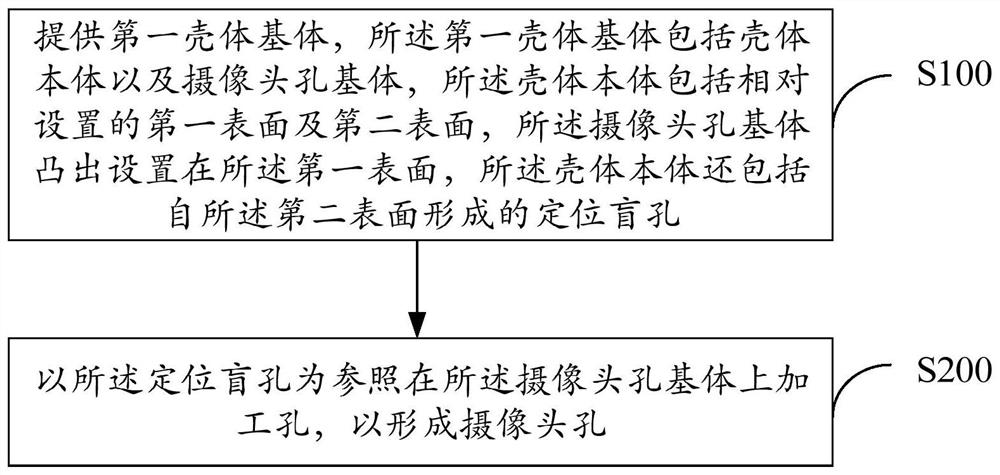

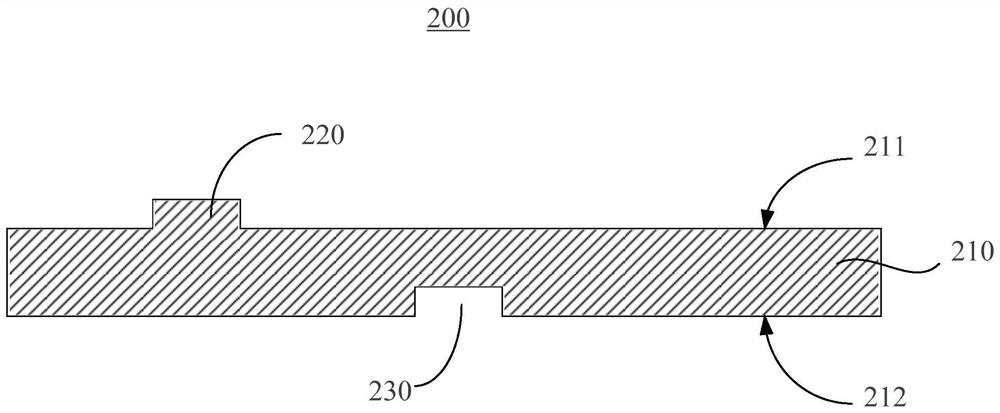

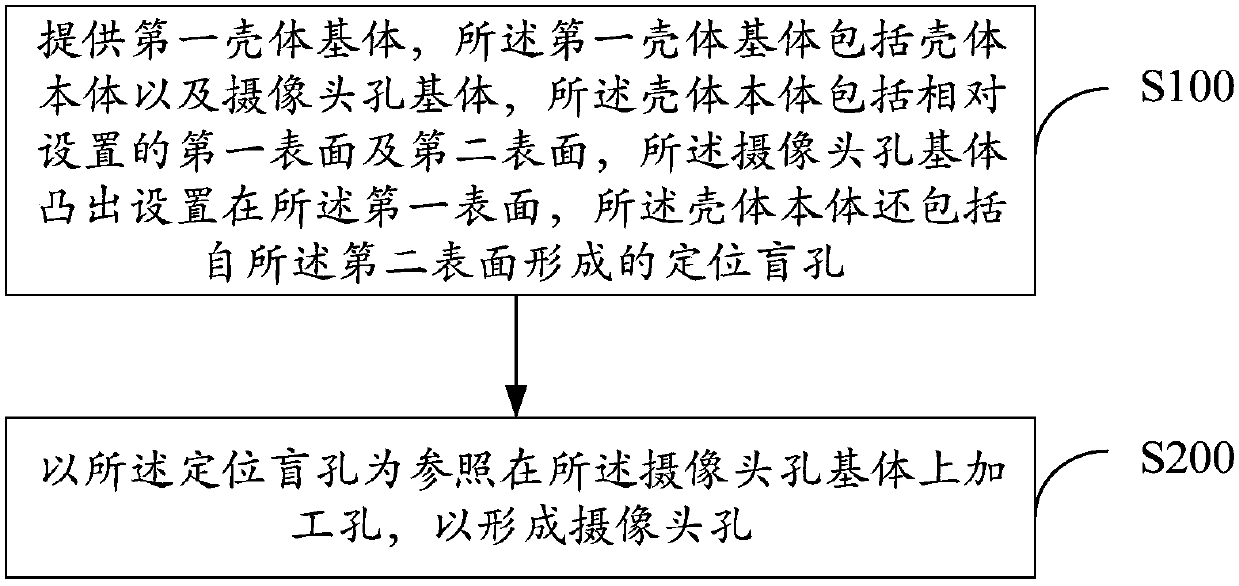

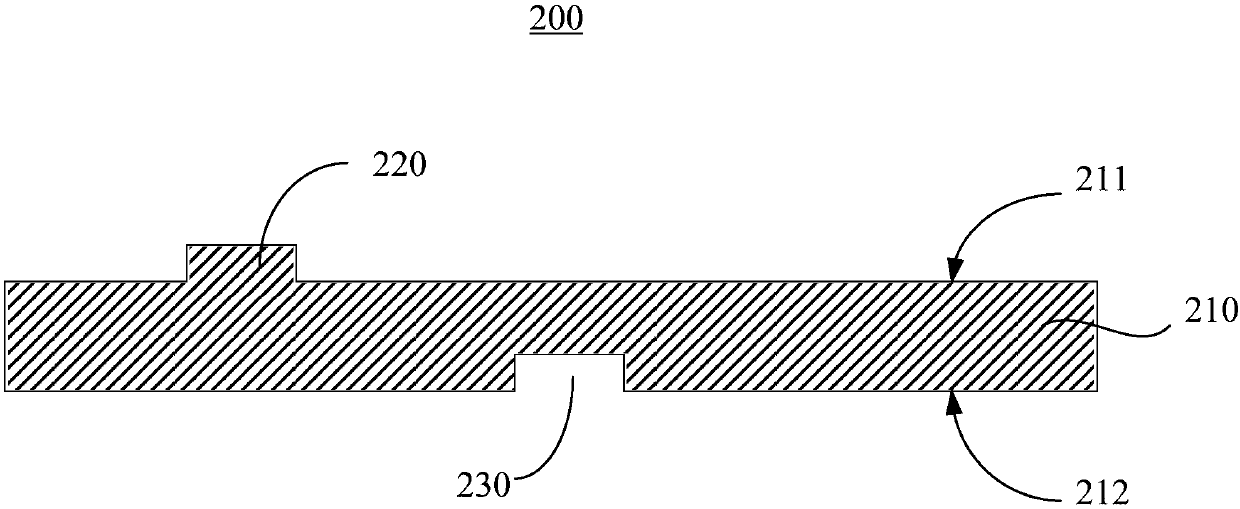

The application provides a shell production method, a shell and a mobile terminal. The shell production method comprises the steps of: providing a first shell matrix, wherein the first shell matrix comprises a shell body and a camera hole matrix, the shell body comprises a first surface and a second surface which are arranged oppositely, the camera hole matrix is arranged in a protruding mode on the first surface, and the shell body further comprises a positioning blind hole formed from the second surface; and machining a hole on the camera hole matrix with reference to the positioning blind hole so as to form a camera hole. The shell production method provided by the application has reference when machining the camera hole so as to avoid deviation of the camera hole on the camera hole matrix and promote yield of a produced shell.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Drug Delivery with Orally Dissolving Capsules

InactiveUS20180318226A1Reduce hepatic first effectSustained releaseOrganic active ingredientsGranular deliveryWhole bodyTherapeutic effect

A slow-release orally dissolving capsule has been described, which releases medicaments in the mouth cavity up to 1 hour. The medicaments may have a therapeutic effect in the mouth cavity and a portion of the drug is delivered to stomach. Thus, the medication may have a local action in the oral cavity and / or have a systemic effect. Mainly, the orally dissolving capsule is administered without an aid of water. Also, large capsules such as size “000” can be administered allowing delivery of large amounts (800 to 1600 mg) of medicament. The medicament can be absorbed through mouth cavity to blood stream bypassing hepatic first pass metabolism. In some instances, a drug(s) is incorporated in the capsule shell matrix and no drug composition is filled inside the capsule shell core.

Owner:JOSHI HEMANT N +1

Shell production method, shell and mobile terminal

ActiveCN107592387AImprove yieldReduce processTelephone set constructionsComputer graphics (images)Computer terminal

The application provides a shell production method, a shell and a mobile terminal. The shell production method comprises the steps of: providing a first shell matrix, wherein the first shell matrix comprises a shell body and a camera hole matrix, the shell body comprises a first surface and a second surface which are arranged oppositely, the camera hole matrix is arranged in a protruding mode on the first surface, and the shell body further comprises a positioning blind hole formed from the second surface; and machining a hole on the camera hole matrix with reference to the positioning blind hole so as to form a camera hole. The shell production method provided by the application has reference when machining the camera hole so as to avoid deviation of the camera hole on the camera hole matrix and promote yield of a produced shell.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

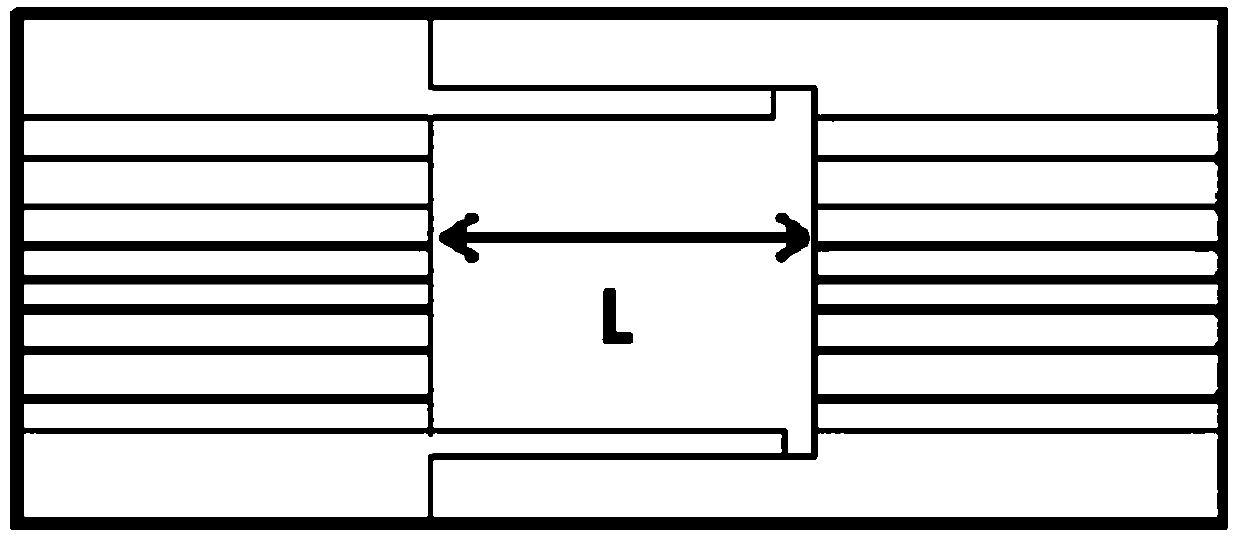

Shell manufacturing method, shell and mobile terminal

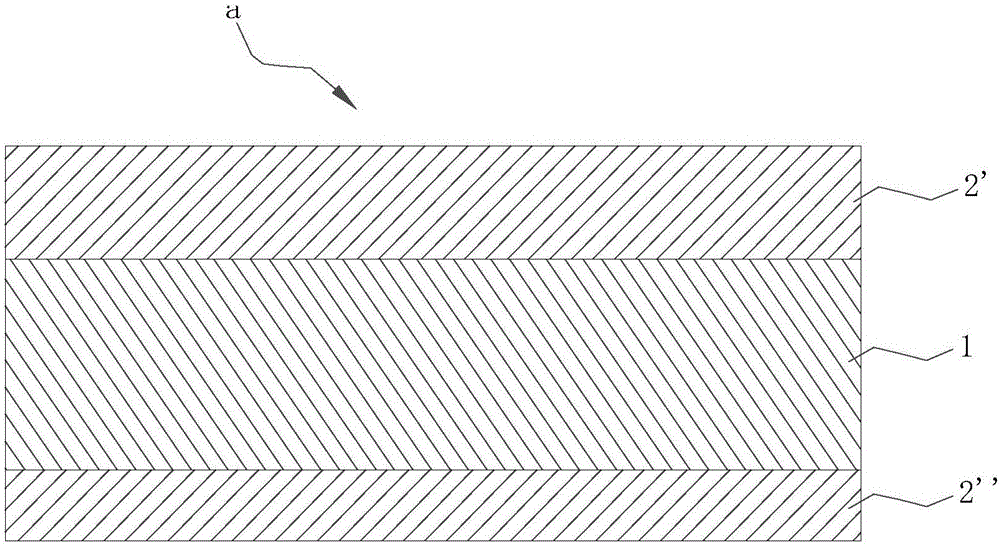

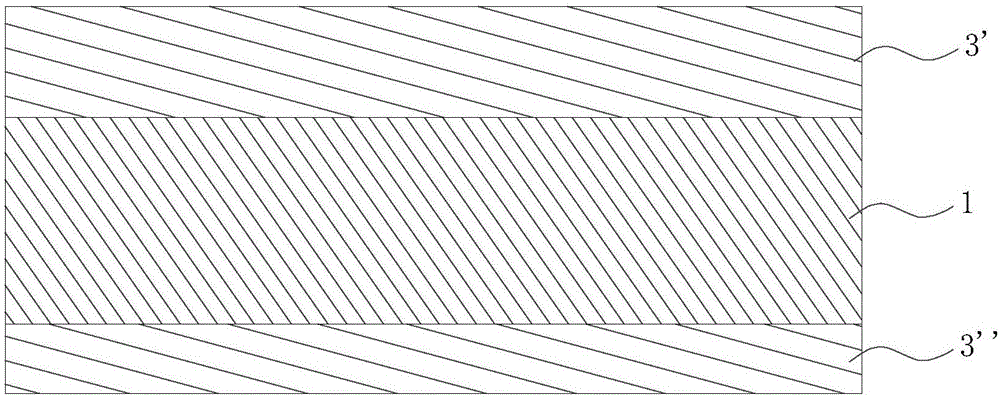

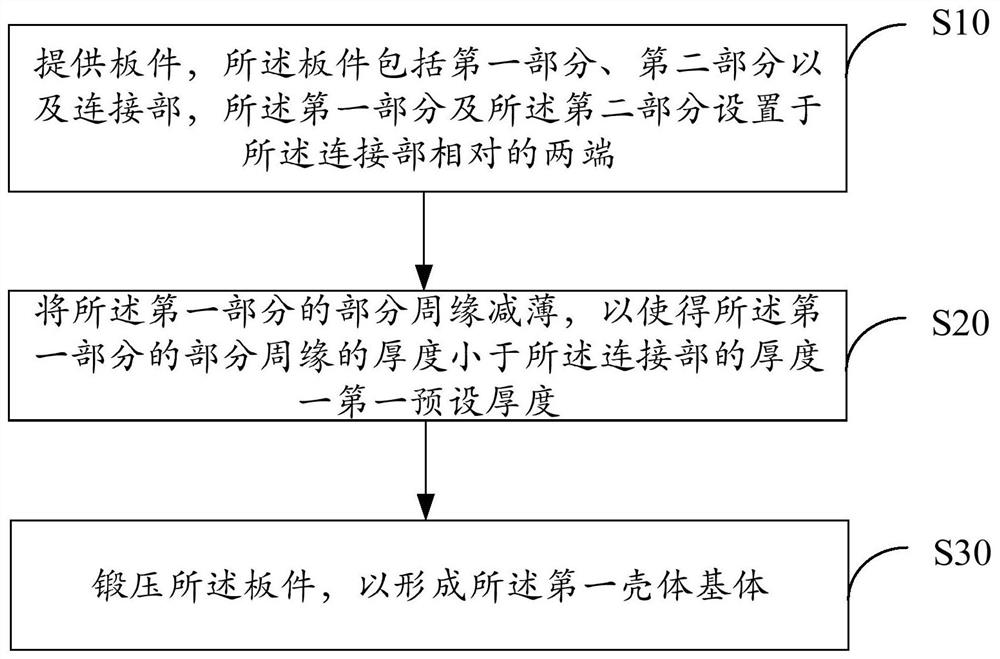

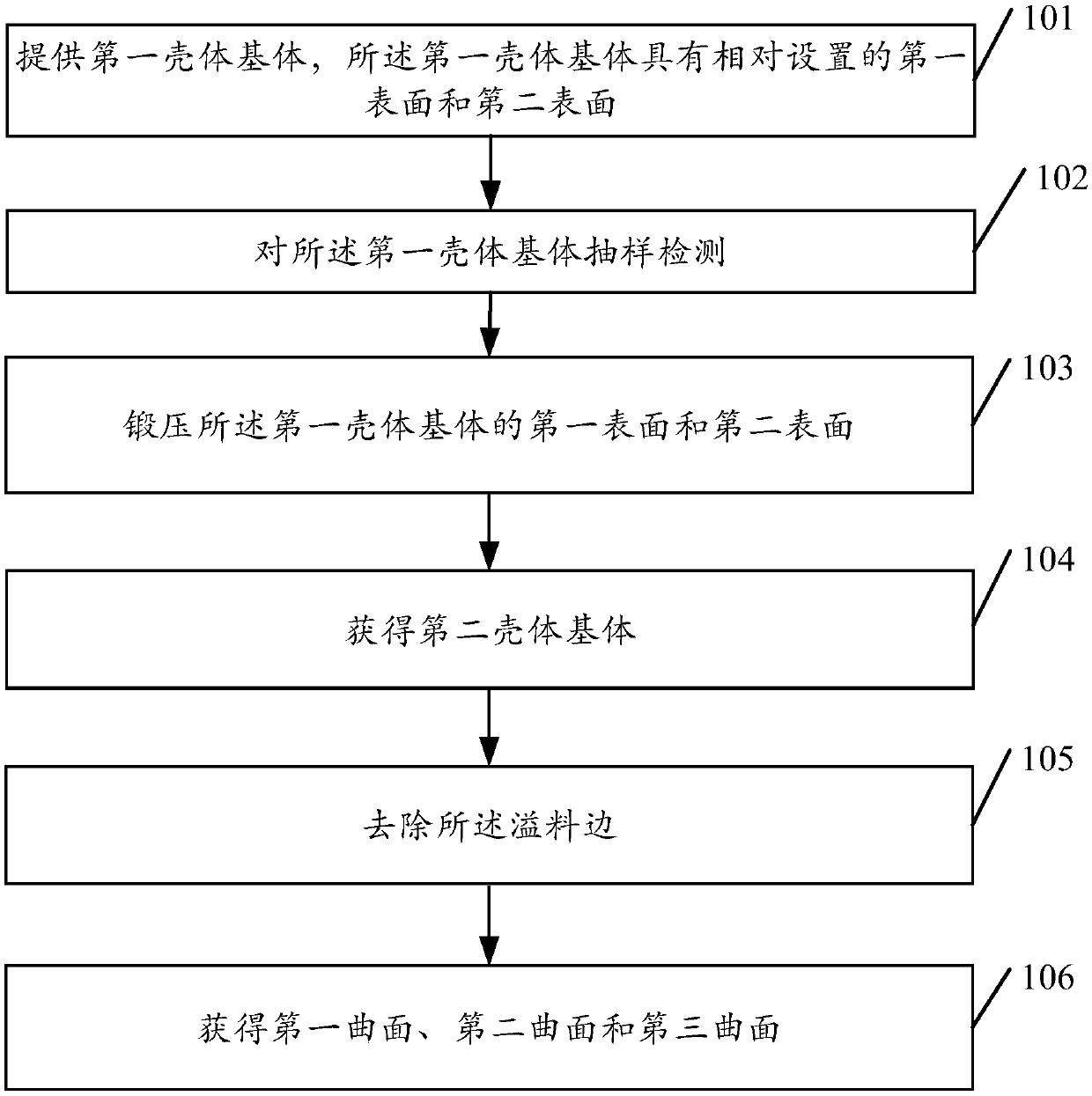

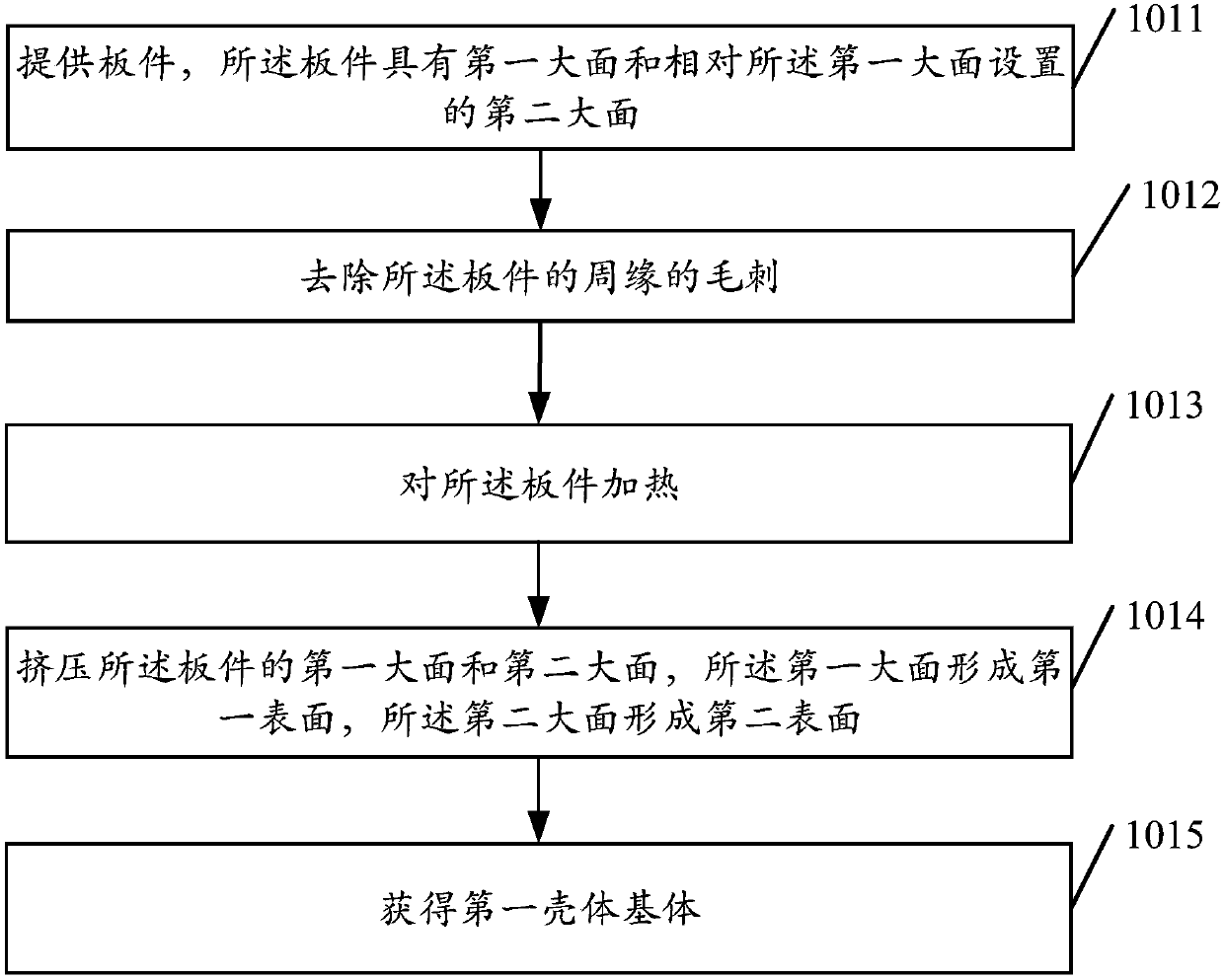

ActiveCN107716820AImprove molding qualityMeet margin requirementsForging/hammering/pressing machinesTelephone set constructionsEngineeringShell matrix

The invention provides a shell manufacturing method, a shell and a mobile terminal. The shell manufacturing method comprises the following steps that a first shell matrix is provided, wherein the first shell matrix is provided with a first surface and a second surface which are oppositely arranged; the first surface and the second surface of the first shell matrix is forged and pressed; a second shell matrix is obtained, wherein the second shell matrix is provided with a first allowance part, a second allowance part which is arranged opposite to the first allowance part, and a molding flash located between the first allowance part and the second allowance part, the allowance size of the first allowance part is smaller than the allowance size of the second allowance part, a third allowancepart is further connected between the first allowance part and the molding flash, and the allowance size of the third allowance part is larger than the allowance size of the first allowance part; andthe molding flash is removed. Therefore, the third allowance part can meet the allowance requirement of a complex structure, and the forming quality of the shell manufacturing method is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com