Method for preparing calcium alginate nerve conduit and nerve scaffold

A nerve conduit and sodium alginate technology, applied in the field of biomedicine, can solve the problem of no pore size description, achieve low raw material cost, simple operation, and promote the effect of repairing peripheral nerve defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Influence of the pores in the nerve conduit (NC) wall on its ability to promote the repair of peripheral nerve defects

[0077] 1) Preparation of shell powder with gradient particle size

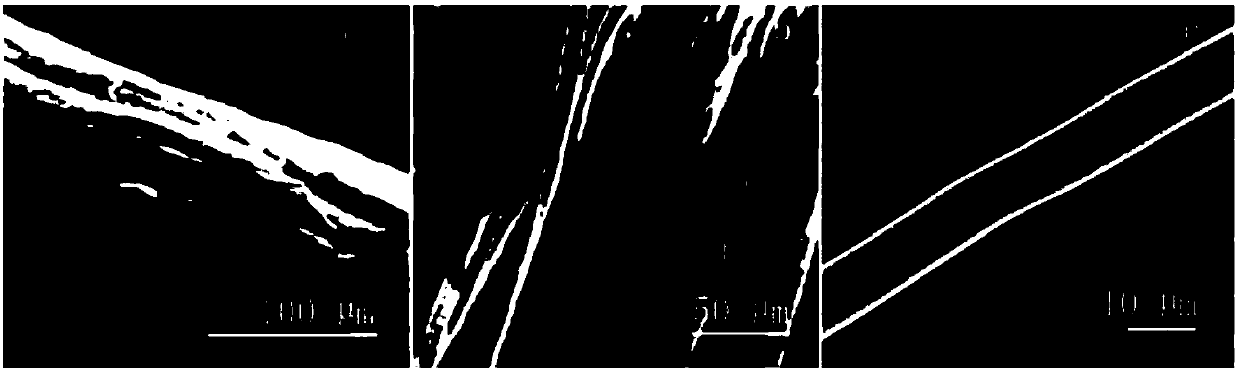

[0078] Rinse the shell of Anodonta dorsalis with clean water, and dry it. The structure is shown in figure 2 . The superficial layers of the exfoliated layer and the nacre layer were polished separately, and the remaining part was regarded as the prismatic layer, which was used as a material for subsequent research. Mechanically pulverize and sieve (n mesh) for later use. Select a standard sieve according to Table 1 to prepare shell powder with a particle size ranging from 25 to 150 μm.

[0079] Table 1 Imperial Standard Sieve / Particle Size / Expected Pore Comparison Table

[0080] British standard sieve (mesh)

100

150

200

240

300

350

400

500

Particle size (μm)

150

105

75

63

53

45

37

25

Expected porosity (μm)

...

Embodiment 2

[0101] Effects of microchannels inside artificial nerves on its effect on promoting the repair of peripheral nerve defects

[0102] 1) Preparation of a cylinder (AS) with microchannels inside

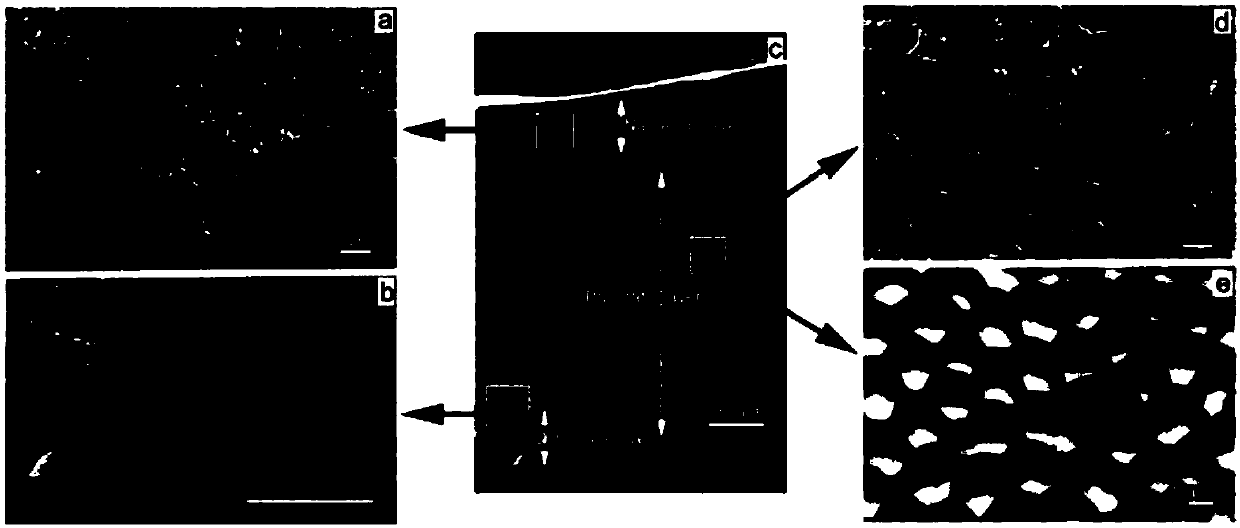

[0103] use Figure 4 device to prepare microchannels. That is, prepare two disks ( Figure 4 a), 80 grooves with a width of 1.5mm are arranged radially on it ( Figure 4 d), 100 circular holes with a diameter of 1mm are distributed on each groove ( Figure 4 e). These 2 disks are fixed against each other, and the two are spaced 1m apart. According to the number of microchannels in Table 2, n silks are arranged on the disk in parallel and evenly (n=microchannel quantity) ( Figure 4 c). In the middle of the fiber, two rings ( Figure 4 b) Limit the outer diameter of the tow in between to 18mm. Install a tubular mold with an inner diameter of 18mm, add sodium alginate shell powder colloid to it, dry it naturally, and place it in two rings ( Figure 4 b) Cut the silk at a position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com