Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

177 results about "Oxygen equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

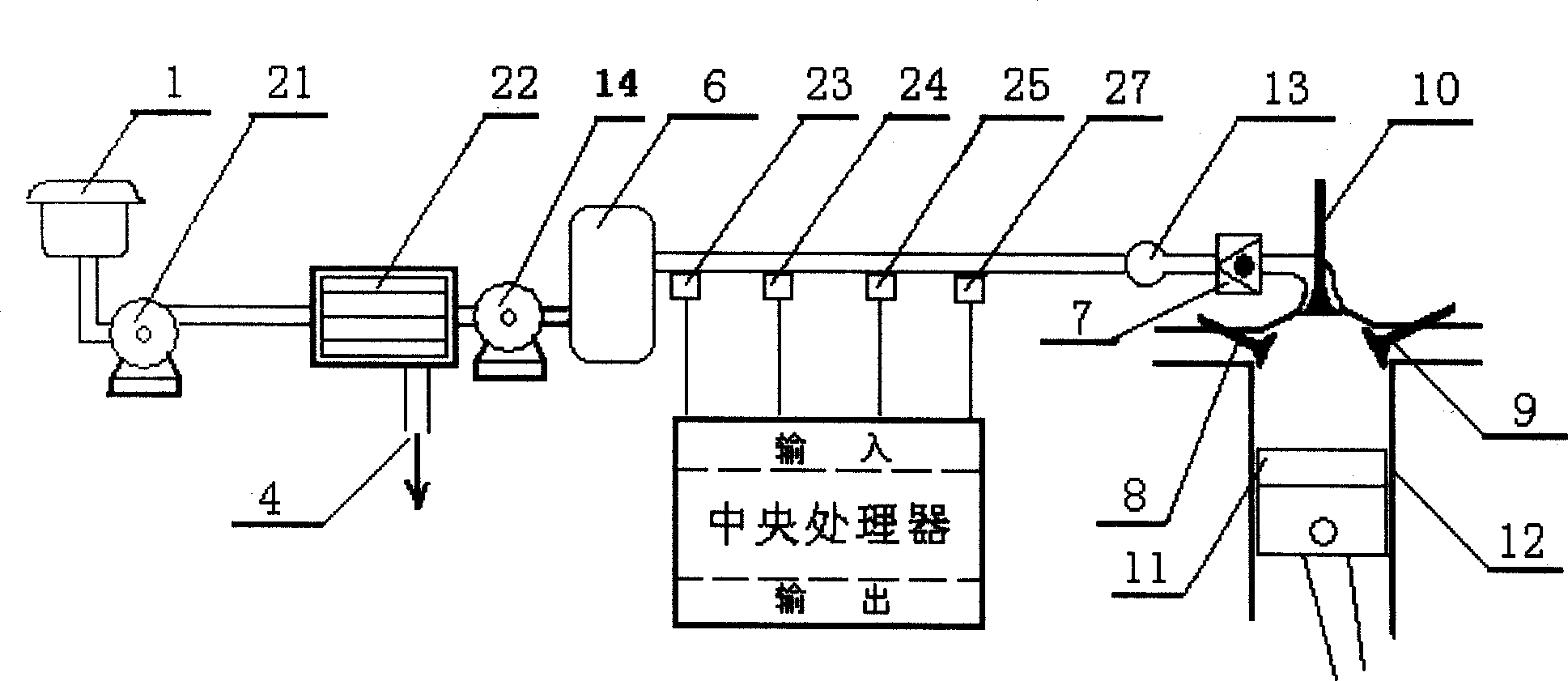

IC engine with oxygen jet in cylinder and oxygen-enriched combustion control

InactiveCN1746478AReduce demandReduce injection volumeElectrical controlNon-fuel substance addition to fuelCombustion chamberGas exchange

This is an invention of an inside cylinder oxygen injection internal combustion engine and its oxygen rich combustion control method. On each cylinder's combustion chamber installs at least one oxygen rich inlet port, the outlet of the port links to the combustion chamber, and the inlet of the port links to the outlet of a back flow valve, the inlet of the back flow valve links to the main pipe of the oxygen rich supply. The main pipe links to an oxygen generation device. By controlling the open and close of the port, injecting oxygen rich gas during the stage of inspiration or gas exchange, compressing, combustion to increase the fuel's combustion and so increase power output and decrease the exhaustion of NOx, CH, PM. This inversion consumes only 30% of oxygen rich gas of traditional engine under the same oxygen level. The oxygen generation device is of small size, light in weight, low energy consumption and low cost. It can be used in any kinds of two strokes and four strokes internal combustion engine.

Owner:贺长宏

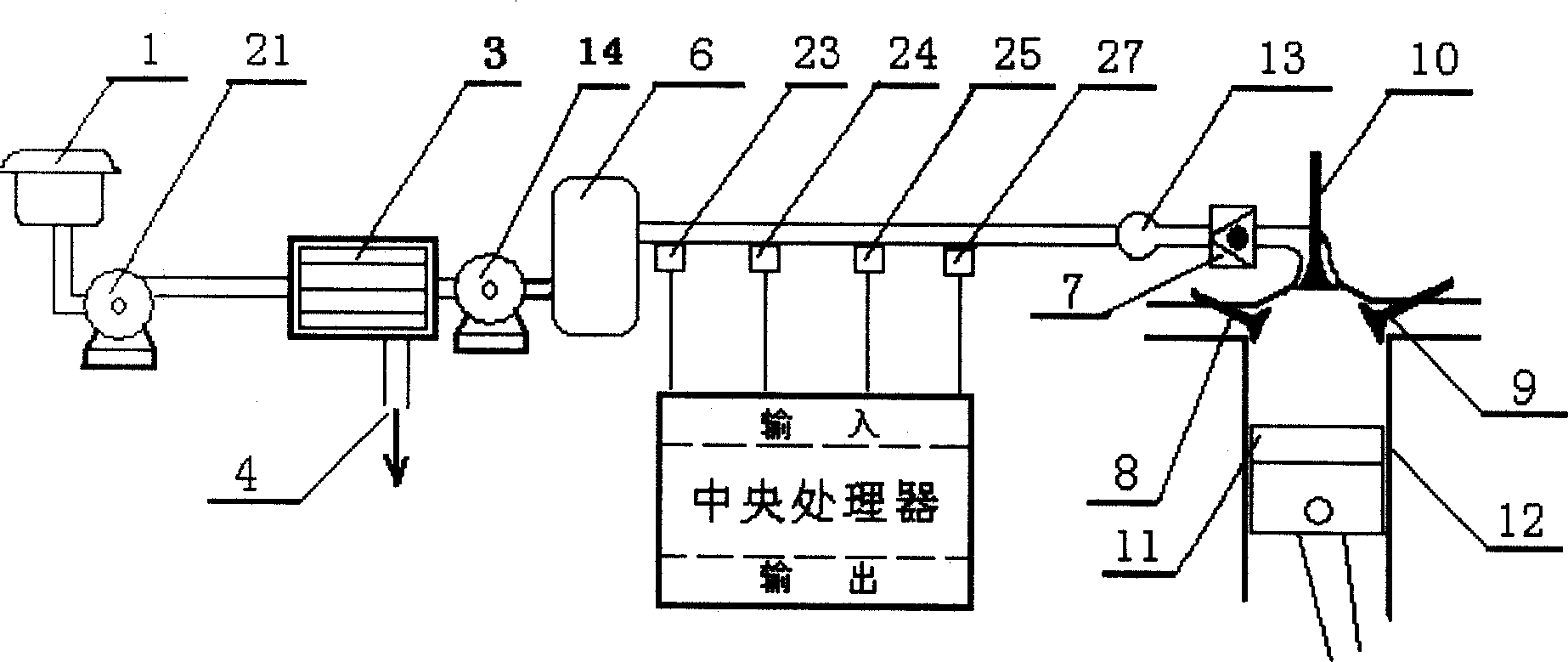

Method and equipment for producing liquid sulfur dioxide through sulfur trioxide and sulphur

ActiveCN103626135AImprove product qualityRaw materials are cheap and easy to getSulfur compoundsInorganic ChemicalSulfur trioxide

The invention belongs to the technical field of inorganic chemical industry, and particularly relates to a method and equipment for producing liquid sulfur dioxide through sulfur trioxide and sulphur. The method comprises the following steps: concentrated sulfuric acid or fuming sulphuric acid is fed into a reaction kettle, then liquid sulfur trioxide and liquid sulphur are fed into the reaction kettle, and stirring for reaction is performed; mixed gas generated through reaction enters a packing reaction tower filled with blocky solid sulphur for reaction, then mixed gas generated through reaction sequentially enters a purification tower and a pickling tower for purification absorption, and then is cooled to be liquid sulfur dioxide through a condenser. The equipment comprises the reaction kettle, wherein the reaction kettle, the packing reaction tower, the purification tower, the pickling tower, the condenser and a liquid sulfur dioxide storage tank are sequentially connected with one another; the reaction kettle is connected with a blow-down pump. Compared with the conventional pure-oxygen sulphur-burning method, the method has the advantages that multiple complex filtering equipment and oxygen generating equipment with relatively high cost are not required, the raw materials are cheap and easy to obtain, and are not required to be processed, the processes are simple, the technology is stable and reliable, the production running cost is reduced greatly, the product quality is high, and the method is suitable for industrial production of the liquid sulfur dioxide.

Owner:SHANDONG KAISHENG NEW MATERIALS

Process for preparing malolactic fermentation complex flavor distilled white liquor

The invention provides a process for preparing malolactic fermentation complex flavor distilled white liquor. The process comprises the following steps: (1) squeezing apple juice; (2) fermenting, namely diluting the concentrated apple juice in the step (1) into fruit juice with the sugar degree of 16-20 percent, feeding the fruit juice into a fermentation tank, adding a wine-brewing yeast to ferment into apple raw wine at low temperature; (3) sealing and storing, namely clarifying and filtering the apple raw wine, inputting the apple raw wine into an oak barrel for sealing and storing; (4) distilling; (5) inputting the raw distilled wine in the step (4) into a micro oxygen equipment for ageing; (6) inputting the distilled wine in the step (5) into a freezing tank for freezing; and (7) blending to prepare the finished wine. The white liquor is prepared by apple juice, stored in the oak barrel after fermentation, distilled and aged in the micro oxygen equipment, the content of methanol and fusel oil is greatly reduced, and due to the process for sequentially storing and distilling, the brewed white liquor is pleasant in taste, and people do not feel dizzy after drinking the white liquor.

Owner:YANTAI GISBELLE WINE

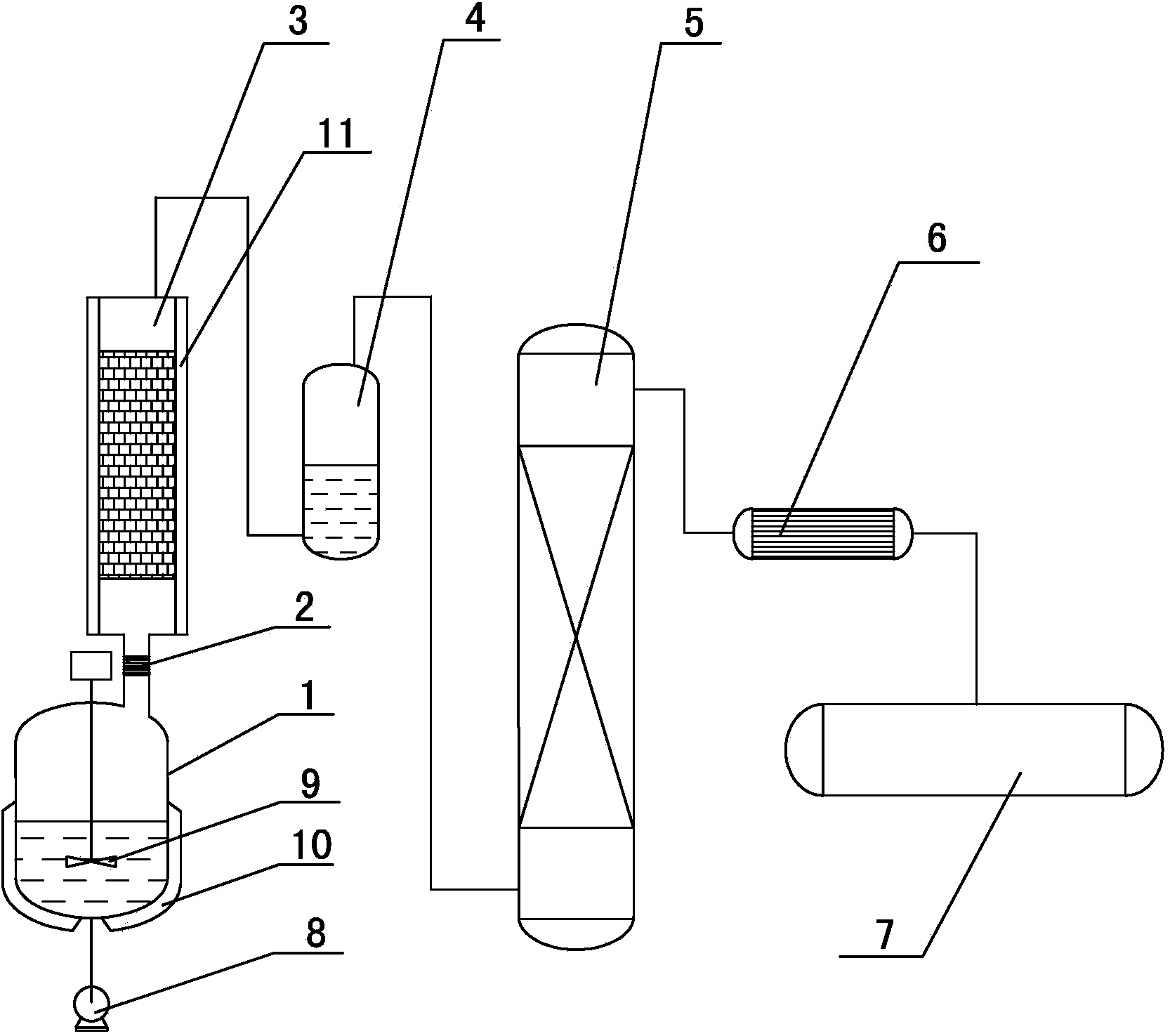

Client-based oxygen production equipment remote fault diagnosis system and fault diagnosis method

PendingCN107037800AProtect physical and mental healthImprove reliabilityTotal factory controlProgramme total factory controlReliability engineeringExpert system

A client-based oxygen production equipment remote fault diagnosis system and a fault diagnosis method are provided. The system comprises field oxygen production stations and a remote technology service center communicating with the field oxygen production stations through a network. The field oxygen production stations are field oxygen production stations distributed in different regions and at different positions. The remote technology service center comprises a service center router connected with the field oxygen production stations through a network, a data server used for receiving, analyzing and storing data of the field oxygen production stations, a WEB server used for extracting the data in the data server and releasing the data on the web, a switch used for data sharing, and a remote client used for carrying out remote monitoring and fault diagnosis and feeding the diagnosis result back to the field oxygen production stations, wherein the service center router, the data server, the WEB server, the switch and the remote client are connected in sequence. The operation status of field oxygen production equipment can be monitored in real time by an expert system of the remote technology service center or professional maintenance engineers, fault diagnosis and analysis can be carried out according to acquired data, and a solution can be given. The maintenance efficiency is improved.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA +1

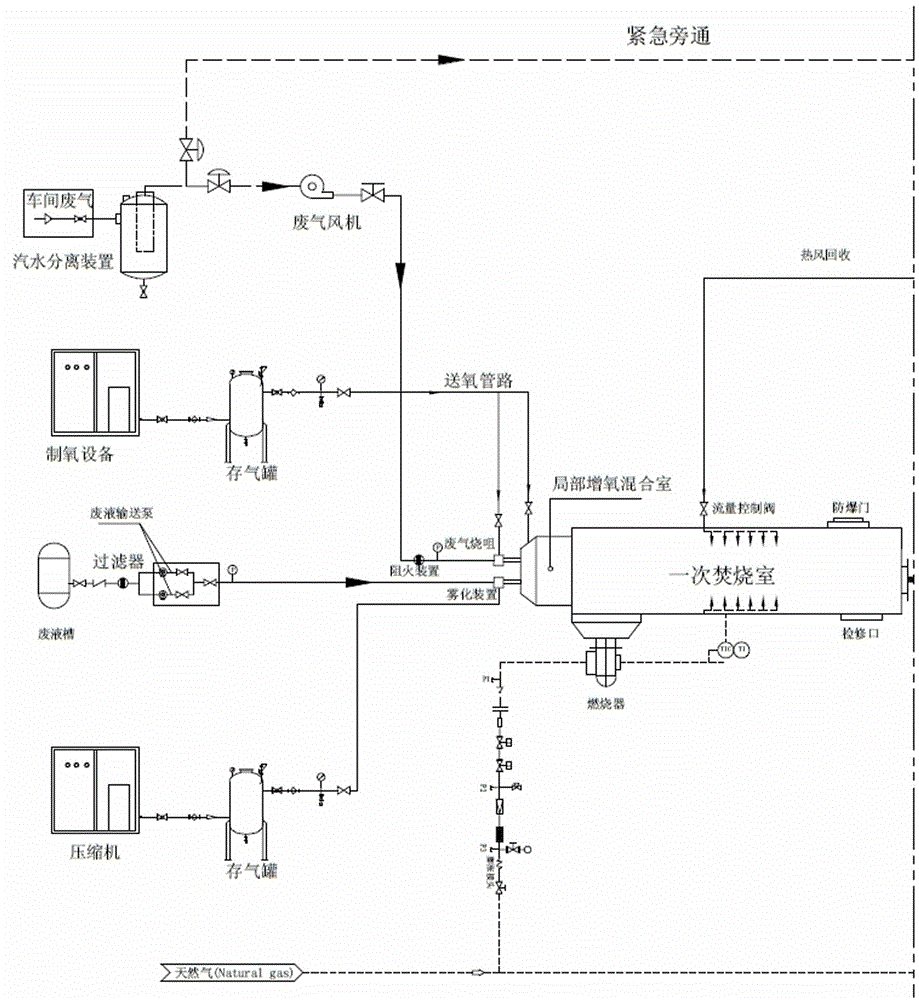

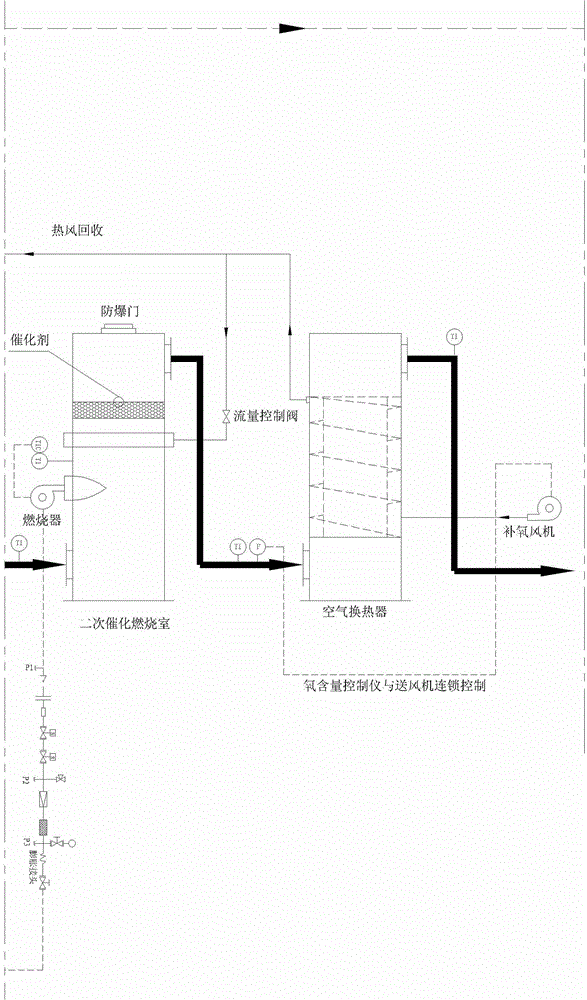

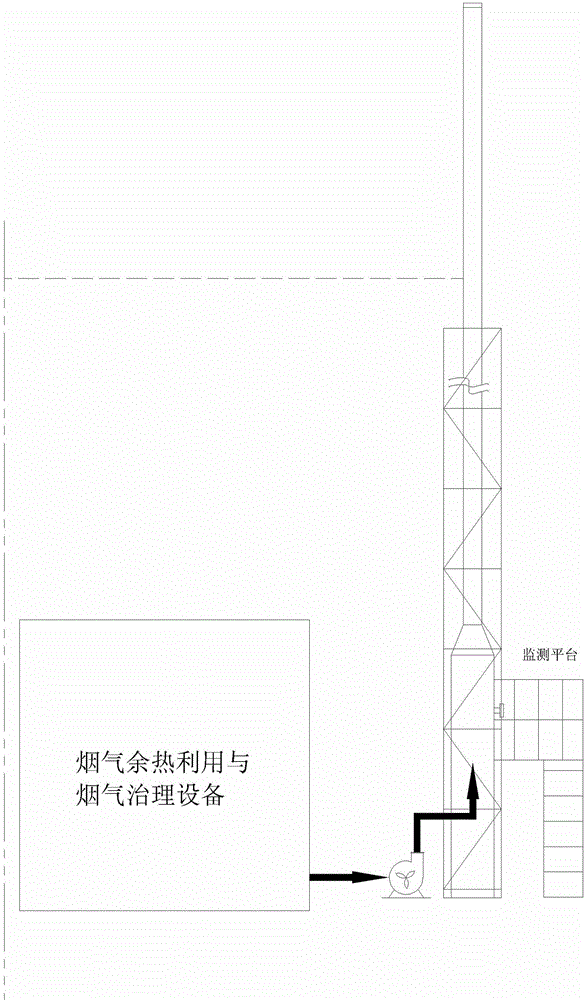

Waste gas and waste liquid incineration system and method

ActiveCN104359113AIncrease contentReduce exhaustIncinerator apparatusAir quality improvementPtru catalystPollution

The invention discloses a waste gas and waste liquid incineration system. The system comprises oxygen production equipment, a local oxygen increasing, combustion and mixing chamber, a primary incineration chamber, a secondary catalytic incineration chamber, an air heat exchanger and a waste heat utilization and smoke purification device which are sequentially connected; harmful waste gas or atomized waste liquid, compressed air and pure oxygen are proportionally mixed in the mixing chamber and then are fed into the primary incineration chamber for incineration. The waste gas and waste liquid incineration system has the advantages that the content of oxygen is locally improved in the primary incineration chamber for waste gas and waste liquid, the combustion speed is accelerated, the complete combustion is facilitated, the smoke exhaust amount after combustion is reduced, and the heat utilization ratio is improved; smoke after primary incineration enters the secondary catalytic incineration chamber and reacts with catalyst, toxic gases such as ammonia and hydrogen cyanide produced after primary incineration is decomposed into N2, H2 and CO2, the problem of environmental pollution caused by smoke exhaust is solved, and the energy saving and emission reduction are facilitated.

Owner:宜兴市智博环境设备有限公司

Air distribution process and air distribution system for rotary kiln

ActiveCN102853654AReduce involvementReduce consumptionRotary drum furnacesIncreasing energy efficiencyLow oxygenEnvironmental geology

The invention provides an air distribution process and an air distribution system for a rotary kiln. The air distribution process comprises smoke purification, smoke recirculation, smoke powder feeding, smoke adjustment, oxygen enrichment preparation and enriching oxygen conveying. Smoke passing through a pre-heater or a waste heat boiler is subjected to particle and dust removal through a de-duster, and the smoke passing through a smoke recirculation fan is used for conveying coal powder for a kiln head combustor or a decomposing furnace, and is used as smoke gas at the center of the combustor to adjust flame shape and the position of a flame high-temperature area; air with high oxygen concentration is prepared by oxygen preparing equipment, and is conveyed to the kiln head combustor or is supplied into an air duct of the decomposing furnace after the air with high oxygen concentration is mixed with the air to obtain the air with relatively low oxygen concentration. According to the air distribution process provided by the invention, the oxygen enrichment air combustion supporting and the smoke recirculation can be comprehensively used on the rotary kiln, so that the involvement amount of cold air is reduced; the fuel coal consumption amount is reduced; the flame shape and the position of the high-temperature area can be adjusted; the generation of nitric oxides is reduced; the selection range of fuel is widened; and the system use ratio is improved. The air distribution process and system are simple, are convenient to use, and have good utilization effect.

Owner:徐州燃烧控制研究院有限公司

Oxygen cabin type gym air-conditioning system and working method thereof

ActiveCN102759152AImprove impactReasonable structureSpace heating and ventilation safety systemsLighting and heating apparatusCO2 contentProcess engineering

The invention provides an oxygen cabin type gym air-conditioning system and a working method thereof. The oxygen cabin type gym air-conditioning system comprises an oxygen cabin type gymnasium, a central air-conditioning new air supplying main air channel, an air source purifying system, an air sterilization filtering device, an oxygen generator, an oxygen supplying device, a carbon dioxide lower air suction system and a negative oxygen ion generator. When an oxygen measuring instrument measures that oxygen content in the gymnasium is smaller than or equal to 22%, the oxygen generator starts to work to deliver oxygen into the gymnasium. When the oxygen measuring instrument measures that oxygen content in the gymnasium is greater than or equal to 30%, the oxygen generator does not work. When a carbon dioxide measuring instrument measures that CO2 content in the gymnasium is smaller than or equal to 3%, the carbon dioxide lower air suction system does not work. When the carbon dioxide measuring instrument measures that the CO2 content in the gymnasium is greater than or equal to 3%, greater than or equal to 5% or greater than or equal to 6%, an exhaust fan of the carbon dioxide lower air suction system respectively work at a low gear, a middle gear and a high gear. The oxygen cabin type gym air-conditioning system has the advantages of being reasonable in structure, simple in operating step, economic in cost and strong in practical applicability, thoroughly changes air property in the gymnasium and further changes physical function of a sporter.

Owner:李洪均

Method and device for simulating pure oxygen iron-making and blast furnace gas recycling

ActiveCN111485044AHigh volume loadEasy to separateBlast furnace componentsBlast furnace detailsCo2 storageDust control

The invention discloses a method and a device for simulating pure oxygen iron-making and blast furnace gas recycling. The device comprises oxygen production equipment, a hot blast stove, a blast furnace, dust removal equipment, pressurizing equipment, CO2 separating equipment, a CO2 compressor, a CO2 storage tank, a CO storage tank and a valve component. In an original blast furnace iron-making process, oxygen is prepared by adding the oxygen production equipment and CO2 is separated from CO by adding the CO2 separating equipment; part CO2 obtained by separating is mixed with the oxygen in a certain proportion to serve as a combustion-supporting gas for the blast furnace iron-making, so that a large amount of N2 in a blast furnace gas is avoided; the difficulty in purifying the CO is reduced; the utilization value of the blast furnace gas is improved; the consumption of coke and coal for the blast furnace iron-making is reduced; and therefore, the purposes of saving energy and reducingthe emission of the CO2 are achieved.

Owner:BEIJING PEKING UNIV PIONEER TECH

Electromechanical combination preparation process and apparatus for hydrogen by spray method

The invention provides a process and equipment for producing electromechanical hydrogen by a spray method, and relates to a technique and equipment for producing hydrogen with water as the raw material. The technique sprays water mist into a spray decomposition chamber through an atomizing nozzle, ionizes and decomposes water molecules by the combination of mechanical force and electric field force, and generates hydrogen and oxygen. The equipment mainly comprises a spray decomposition chamber, an atomizing nozzle, a hydrogen-catching electrode, a hydrogen-collection chamber, an oxygen-catching electrode and an oxygen-collection chamber. The hydrogen-collection chamber is arranged at the upper part, the spray decomposition chamber is arranged at the middle part, and the oxygen-collection chamber is arranged at the lower part; the atomizing nozzle is arranged at the lateral side of the spray decomposition chamber; the nozzle of the atomizing nozzle points to the center of the spray decomposition chamber; the hydrogen-catching electrode and the oxygen-catching electrode are arranged in the internal space of the spray decomposition chamber. The process and equipment adopt the spray method to produce the hydrogen through the electromechanical combination, thus reducing the power consumption and increasing the reaction speed. The process and equipment adopt water as the raw material to produce the hydrogen with no consumption of fossil energy, take water as energy, and can be used as a gasifying agent generation device of gasifying equipment, hydrogen-producing equipment or oxygen-producing equipment taking water as raw material.

Owner:周开根

Oxygen generating equipment system and process flow thereof

ActiveCN104192807AGuaranteed adsorption effectGuaranteed service lifeOxygen preparationMolecular sieveActivated carbon filtration

The invention discloses an oxygen generating equipment system and a process flow thereof. The oxygen generating equipment system comprises an air compressor, a high-efficiency degreaser, a precision filter, a micro heat regeneration drier, a dust fine filter A, an active carbon filter, a buffer air storage tank, oxygen generating equipment, a dust fine filter B, an oxygen storage tank and a sterilizing filter which are sequentially connected. The oxygen generating equipment system disclosed by the invention reduces the requirements on installation and using environments by adopting the micro heat regeneration drier, thereby being high in safety. According to the oxygen generating equipment system, compressed air is clean by utilizing a multi-purification device, so that the adsorption capacity and service life of a zeolite molecular sieve are effectively ensured, and resources are saved; oxygen with the purity of 90%-93% can be continuously produced through the alternate adsorption of two adsorption towers, the output of the oxygen is 12 Nm<3> / h, and the delivery pressure of the oxygen is 0.3 MPa.

Owner:HANGZHOU CHENRUI AIR SEPARATION EQUIP MFG

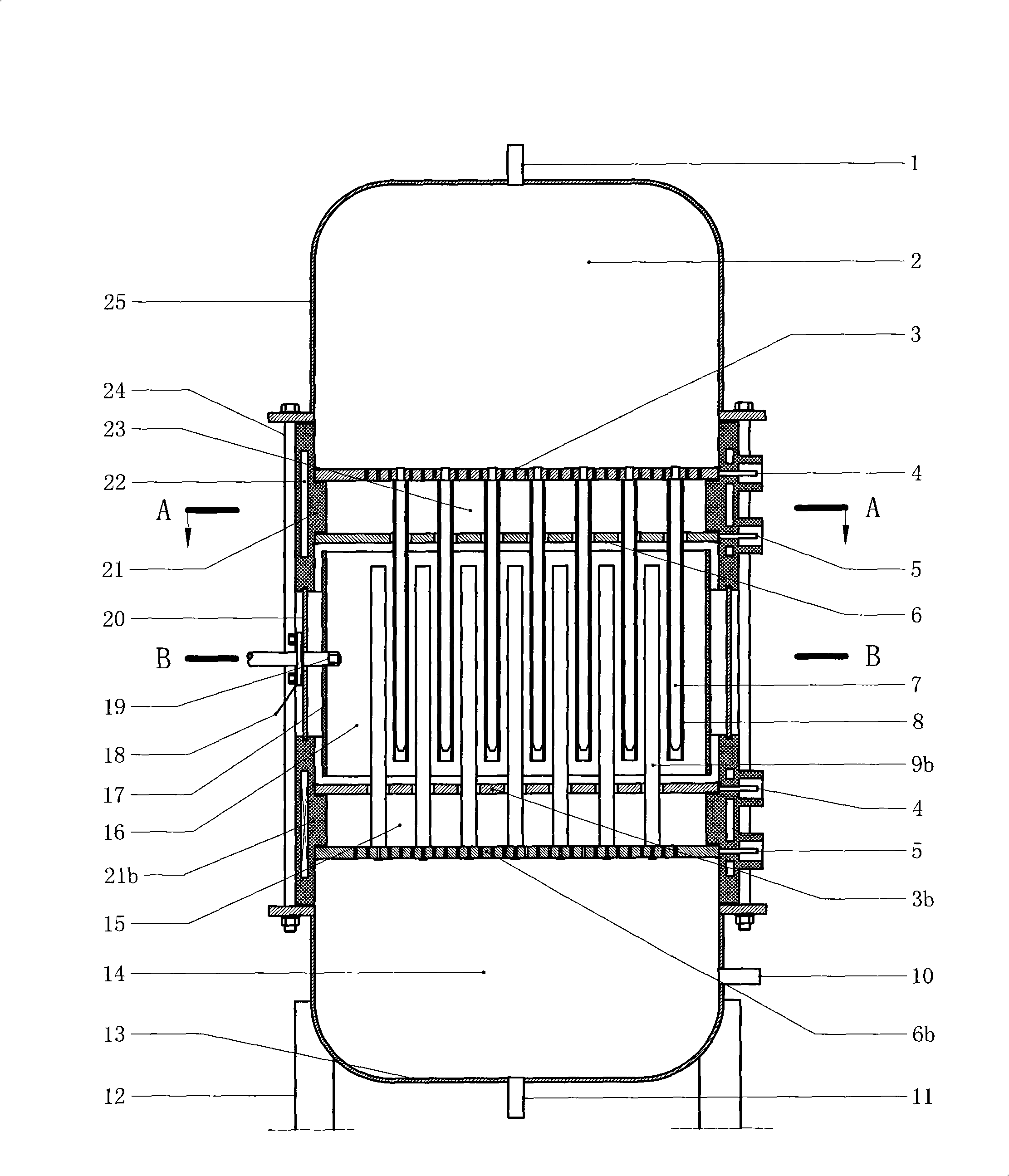

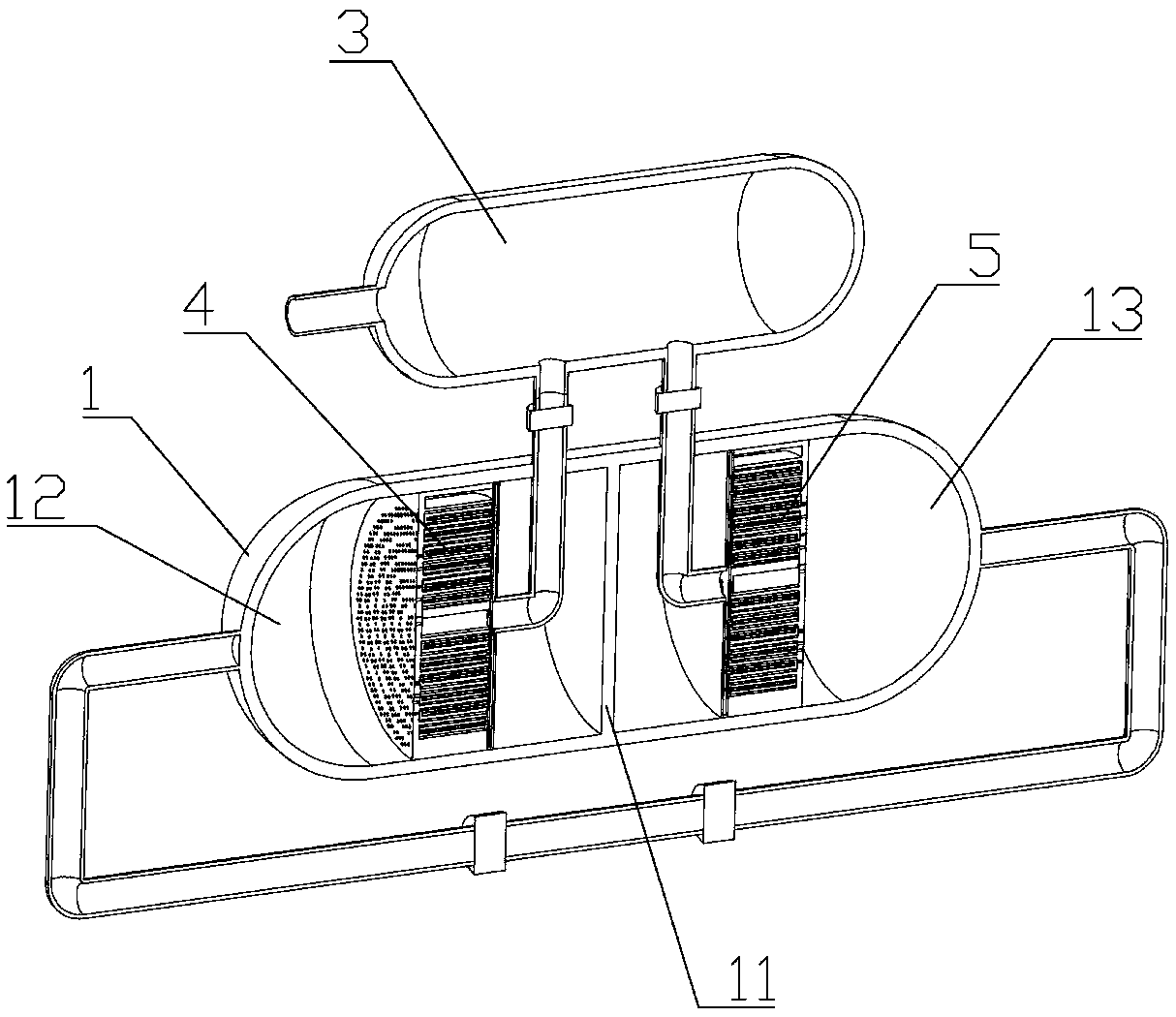

Oxygen generating equipment

ActiveCN109160490AIncrease the adsorption areaSmall footprintGas treatmentDispersed particle separationMolecular sieveBuffer tank

The invention belongs to the technical field of gas purification equipment and mainly relates to oxygen generating equipment. The oxygen generating equipment comprises an air compressor, a filter, a degreaser, a dryer, a molecular sieve adsorption tower, a membrane separator and an oxygen storage tank connected in sequence, wherein the molecular sieve adsorption tower comprises an adsorption tankand a buffer tank; the adsorption tank is communicated with the buffer tank; the buffer tank is communicated with the membrane separator; a separating board is integrally formed in the adsorption tankand divides the adsorption tank into a left cavity and a right cavity; a first molecular sieve filter is arranged in the left cavity; a second molecular sieve filter is arranged in the right cavity;screening filtering layers are spirally arranged in the first molecular sieve filter and the second molecular sieve filter. The oxygen generating equipment has the advantages of being smaller in occupied area, larger in molecular sieve adsorption area, convenient to use and suitable to popularize and use; two filters can be alternately used for adsorption and regeneration.

Owner:杭州博大净化设备有限公司

Diffuse type intelligent oxygen-enriched air circulation system and air purifying method

ActiveCN108954524AAvoid secondary pollutionImprove air purification effectDucting arrangementsMechanical apparatusCo2 absorptionEngineering

The invention discloses a diffuse type intelligent oxygen-enriched air circulation system which comprises oxygen generation equipment arranged outdoors and indoor air circulation purifying equipment arranged indoors. The indoor air circulation purifying equipment comprises a purifying disinfection section with an air return port and an air supply section with an air supply port, and a fan sectionis arranged between the purifying disinfection section and the air supply section. A carbon dioxide absorption / adsorption device is detachably connected with the interior of the purifying disinfectionsection relative to the air return port, and therefore carbon dioxide gas of air entering a room from the air return port can be filtered away. The oxygen generation equipment conveys oxygen to the purifying disinfection section of the indoor air circulation purifying equipment through an oxygen-enriched pipe. The invention further provides an air purifying method. By adopting the diffuse type intelligent oxygen-enriched air circulation system, oxygen-enriched air with low-concentration carbon dioxide is obtained. The technical problem that secondary pollution of air purified in the prior artin the conveying process is serious is solved.

Owner:海润新风(重庆)智能技术有限公司

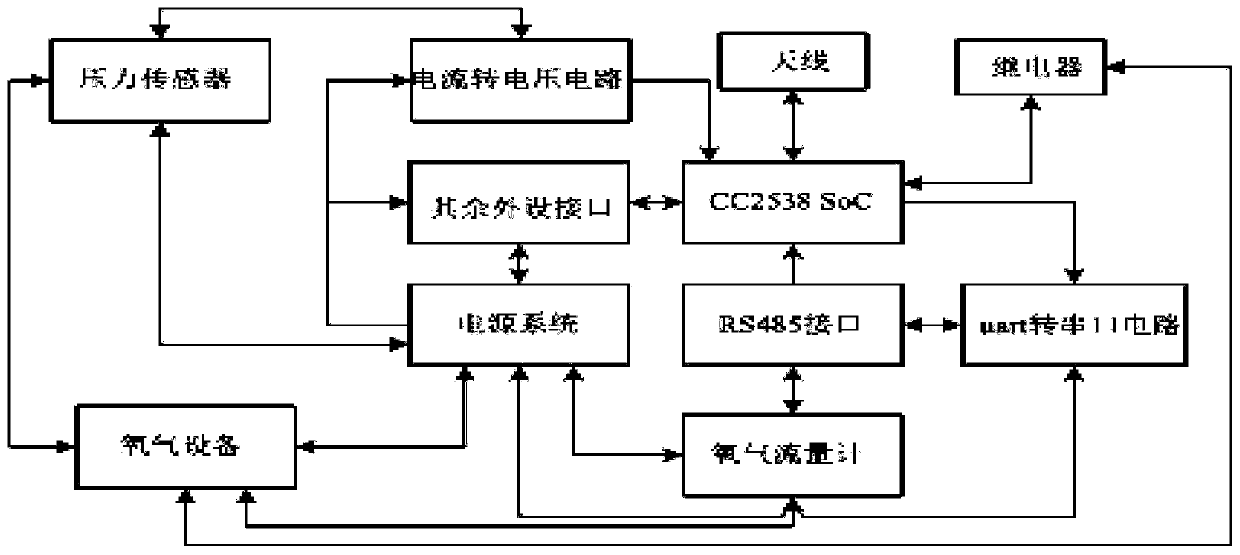

Intelligent medical oxygen equipment monitoring system based on MQTT protocol

InactiveCN110535953ARealize remote monitoringReduce loadRespiratorsMedical devicesTraffic capacitySafety index

The invention discloses an intelligent medical oxygen equipment monitoring system based on an MQTT protocol. The system comprises an oxygen equipment control node used for controlling on-off of oxygenequipment, switching an oxygen bottle, monitoring real-time oxygen flow data and sending an MQTT data packet containing oxygen equipment flow, oxygen equipment pressure information and an IPv6 address of the oxygen equipment control node; a MQTT proxy server used for connecting each oxygen equipment control node and storing the content of the MQTT data packet sent by each oxygen equipment controlnode; a database system used for receiving and storing the oxygen equipment information and the IPv6 address of the oxygen equipment control node; and a client which acquires state information of alloxygen equipment by accessing the MQTT proxy server and the database system. The system has the beneficial effects that the network load is effectively reduced, the client realizes a comprehensive log function and an alarm function, the safety index of a patient is greatly increased, doctor-patient disputes are reduced, the medical cost is saved, and the modernization level of gas management is improved.

Owner:NANTONG UNIVERSITY +1

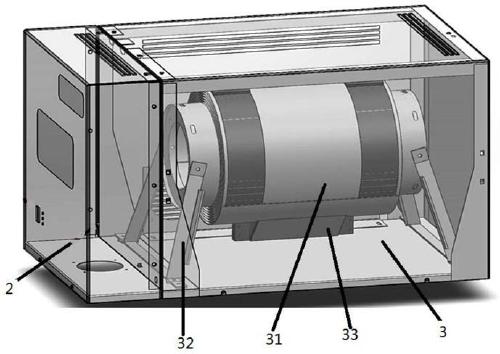

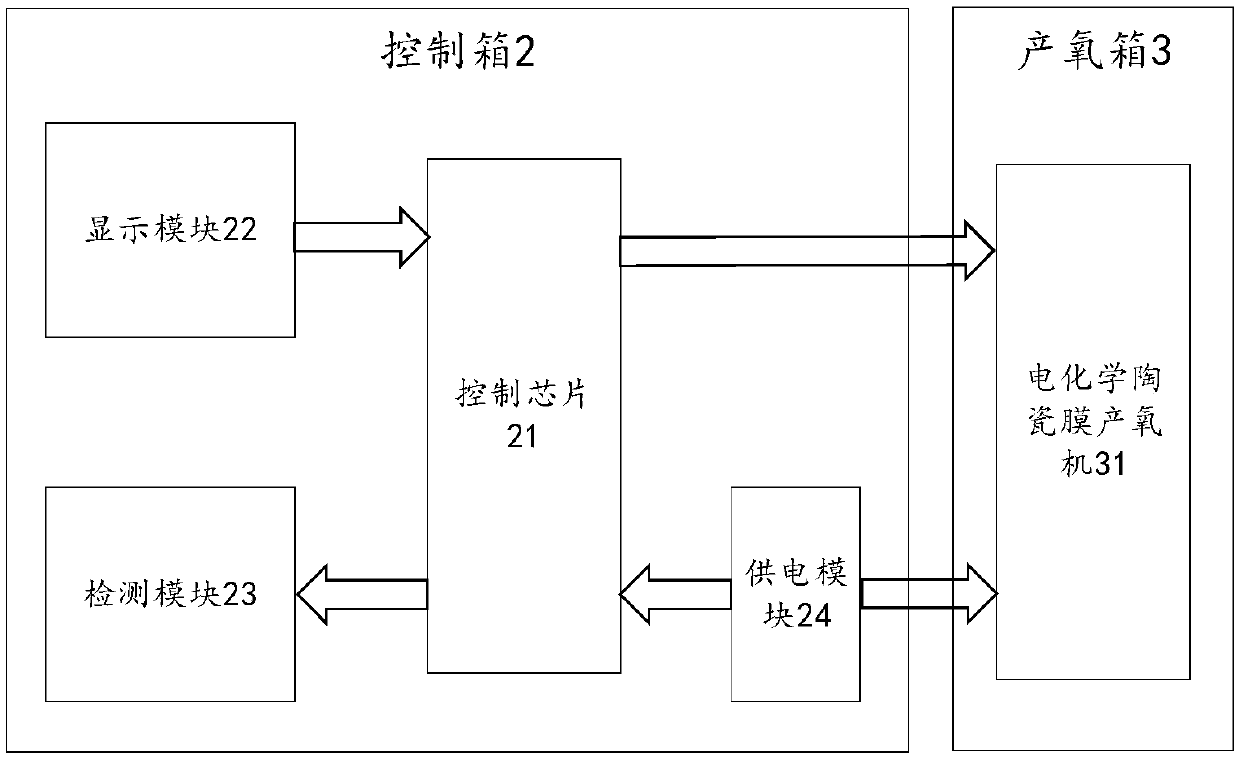

Electrochemical ceramic membrane oxygen producing machine and oxygen producing equipment thereof

ActiveCN109626333ANo noiseNo pollution in the processGas treatmentDispersed particle separationThermal isolationCeramic membrane

The invention discloses an electrochemical ceramic membrane oxygen producing machine and oxygen producing equipment thereof, and relates to the technical field of oxygen production. The electrochemical ceramic membrane oxygen producing machine comprises a ceramic membrane stack, an airflow distributor, a heater, double helical exchangers and thermal isolation sleeves; the ceramic membrane stack comprises electrochemical ceramic membrane pieces vertically stacked parallelly, the sides of the electrochemical ceramic membrane pieces are closed to form vertical cavities, the other sides of the electrochemical ceramic membrane pieces are connected with oxygen outputting pipes through ceramic pipes, the bottom of the ceramic membrane stack closely fits the upper surface of the airflow distributor, and a heater is arranged at the lower end of the airflow distributor; the outer sides of the ceramic membrane stack, the airflow distributor and the heater are wrapped by the double helical exchangers, and the thermal isolation sleeves sleeve the two ends of each double helical exchanger and converge on a double helical interaction device. The electrochemical ceramic membrane oxygen producing machine and the oxygen producing equipment thereof can prepared pure oxygen, high-purity oxygen and hyperpure oxygen on site, and are small in size, light in weight, low in cost and suitable for quickdeployment.

Owner:北京汉华元生科技有限公司

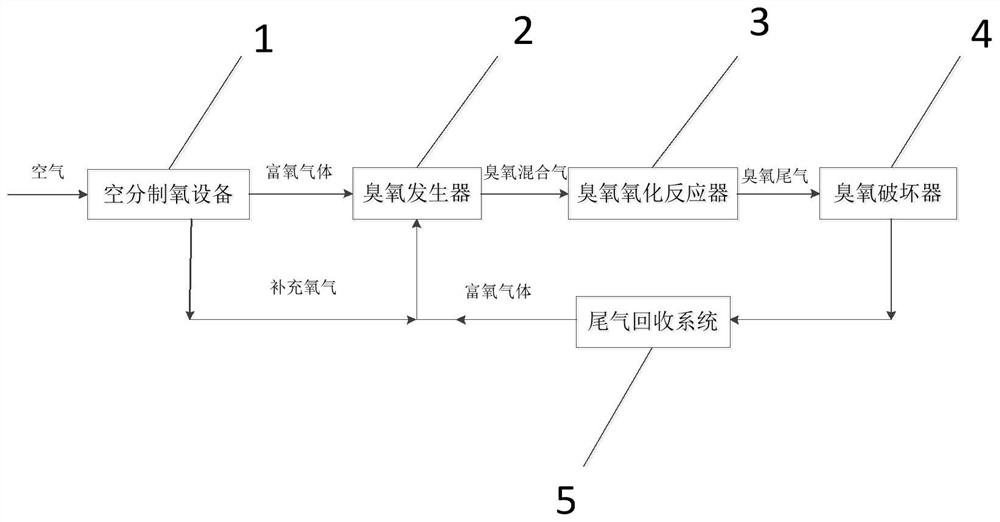

Wastewater advanced treatment system and treatment method

PendingCN111646562ALow costGuarantee continuous and stable operationWater/sewage treatment apparatusWater/sewage treatment by oxidationSewageAir separation

The invention relates to the technical field of advanced wastewater treatment processes, and provides advanced wastewater treatment system and method. The treatment system comprises an ozone preparation system, an oxidation system and a tail gas recovery system, wherein the ozone preparation system comprises air separation oxygen production equipment and an ozone generator; the oxidation system comprises an ozone oxidation reactor and an ozone destructor; the tail gas recovery system is used for purifying tail gas mixed gas and providing oxygen to the ozone generator together with the air separation oxygen production equipment. The treatment method comprises the following steps: treating air into oxygen-enriched gas through the air separation oxygen generation equipment, and feeding the oxygen-enriched gas into the ozone generator to generate ozone mixed gas; enabling the ozone mixed gas to enter an ozone oxidation reactor to degrade sewage, and enabling the oxidized ozone mixed gas toenter an ozone destructor to generate tail gas mixed gas; and sending the tail gas mixed gas to the tail gas recovery system to be purified to obtain oxygen-enriched gas, wherein the oxygen-enrichedgas and oxygen generated by the air separation oxygen generation equipment are supplemented to the ozone generator.

Owner:GREENTECH ENVIRONMENTAL CO LTD

Ozone production method and sewage treatment method

InactiveCN101921041AImprove removal efficiencyImprove ozone production efficiencyMultistage water/sewage treatmentOzone preparationSewageAir separation

The invention relates to the technical field of environment-friendly sewage treatment and discloses an ozone production method and a sewage treatment method. Through an air separation and oxygen production technology and discharge process-combined ozone production process, high-purity dry oxygen is produced by a high-efficiency pressure swing adsorption air separation and oxygen production device, and ozone is produced by an ozone generator. The process has the characteristics of high ozone generating efficiency, high concentration and the like; and the equipment is combined with a manual rapid infiltration system device to be applied to the field of advanced sewage treatment, so the efficiency of removing main pollutants in the sewage can be effectively improved.

Owner:SHENZHEN HONGKONG INSTITUTION OF IND EDUCATION & RES ENVIRONMENTAL ENG TECH CO LTD

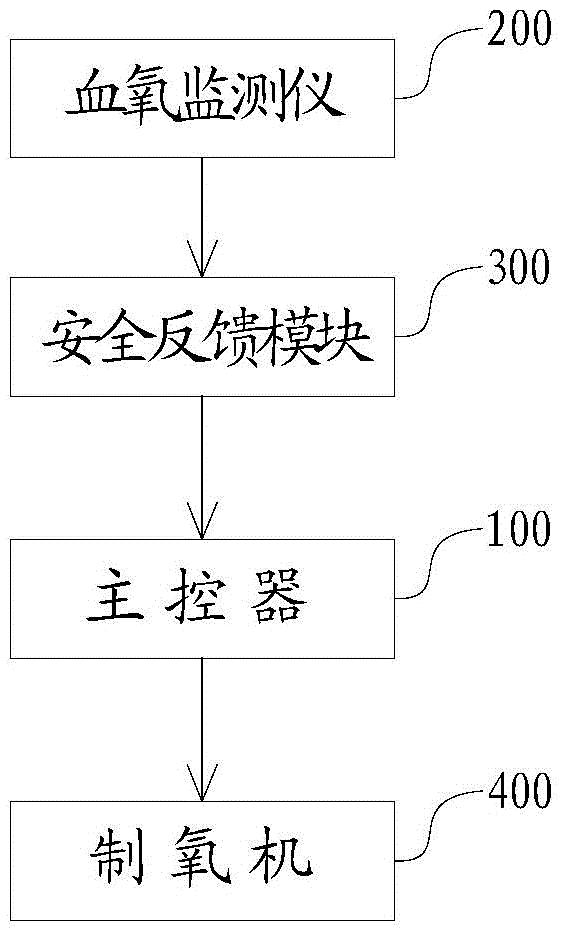

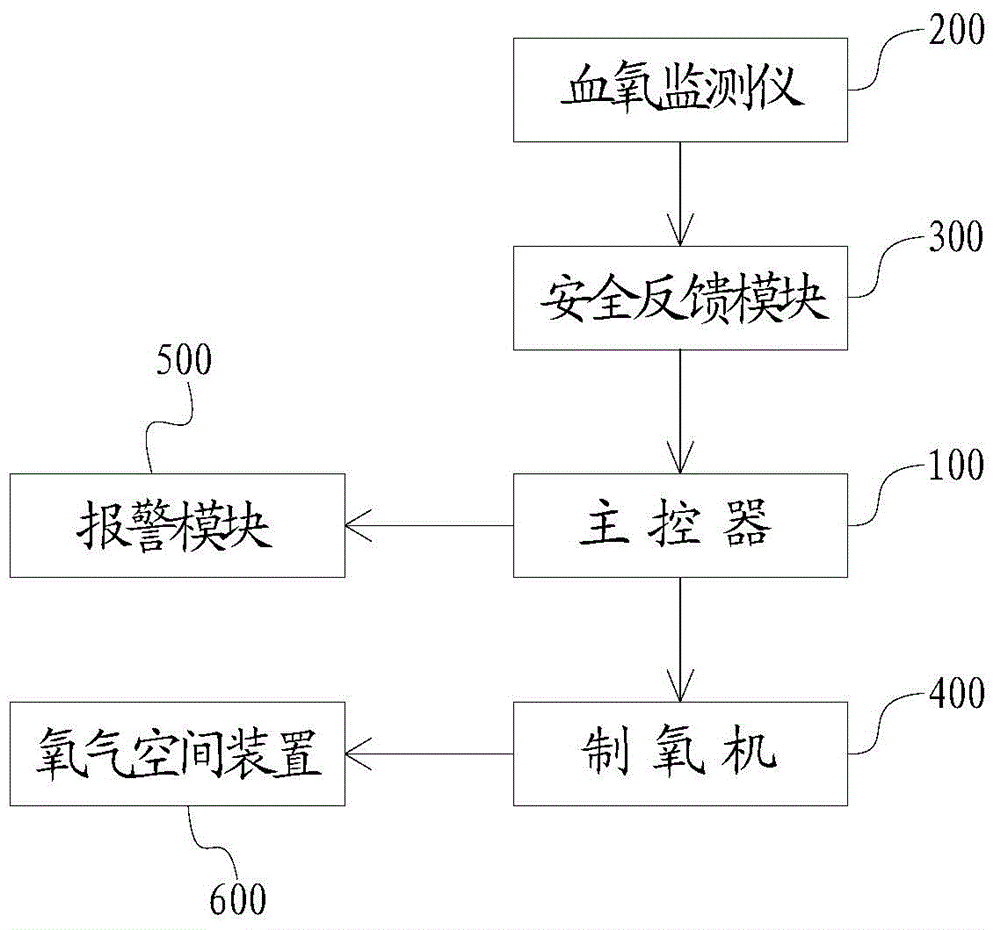

Human body oxygen supply equipment

ActiveCN104667399AAvoid accidents such as oxygen poisoningPrevent oxygen poisoning accidentsRespiratorsMaster controllerOxygen monitors

The invention provides human body oxygen supply equipment, which comprises a master controller, an oxygen generator, a safety feedback module and a blood oxygen monitor, wherein the blood oxygen monitor is used for monitoring a blood oxygen parameter of a human body in real time in an oxygen supply process, and transmitting the parameter to the safety feedback module in a wired or wireless manner; the safety feedback module is used for receiving the parameter, judging the change of the parameter, and transmitting a transferred oxygen amount regulation instruction to the master controller according to the change; the master controller is used for receiving the transferred oxygen amount regulation instruction, and notifying the oxygen generator to correspondingly increase or decrease the generated oxygen amount. According to the equipment, the technical problem that the transferred oxygen amount cannot be accurately regulated in real time by conventional oxygen generation equipment is solved.

Owner:于泓

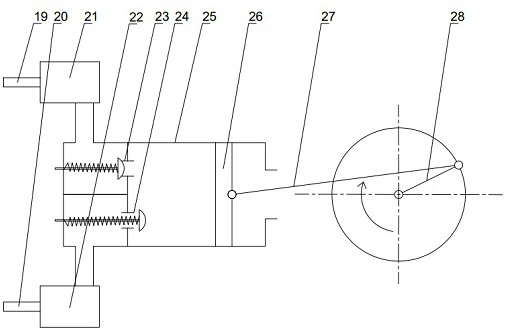

Energy-saving and environment-friendly household movable atomization oxygen inhalation machine

PendingCN113599660AEasy to breatheAvoid uncomfortable conditions such as itchingRespiratorsMedical devicesEngineeringOxygen inhalation

The invention relates to the technical field of oxygen production equipment, and discloses an energy-saving and environment-friendly household movable atomization oxygen inhalation machine. The machine has the advantages that purified and dry oxygen is cooled and humidified, a user can breathe better, the situation that the mouth and the nose of the user are dry and cracked and lack water due to dry air, and consequently uncomfortable states such as pain, itching and intolerance are caused is avoided, and the oxygen machine can automatically walk. According to the energy-saving and environment-friendly household movable atomization oxygen inhalation machine, a strong magnetic stator drives a rotating coil to rotate, the rotating coil drives an eccentric rotating disc to rotate, the eccentric rotating disc drives a synchronous rotating disc to rotate, the synchronous rotating disc drives a compression rod to rotate, the compression rod drives a compression piston to move, the compression piston drives air to enter compressed air, the air is purified and compressed through a separation filter screen in a concentric-square-shaped frame, and therefore the effects that the purified and dry oxygen is cooled and humidified, the user can breathe better, and the situation that the mouth and the nose of the user are dry and cracked and lack water due to dry air, and consequently uncomfortable states such as pain, itching and intolerance are caused is avoided are achieved.

Owner:JILIN UNIV

Pressure swing adsorption oxygen production radial flow adsorption tower

PendingCN112619366AFast adsorption rateReduce PSA Oxygen Operation Cycle TimeDispersed particle separationOxygen preparationEngineeringMechanical engineering

The invention belongs to the field of oxygen production equipment, and particularly relates to a pressure swing adsorption oxygen production radial flow adsorption tower. The tower comprises an air inlet pipe flange, an oxygen outlet pipe flange, a butterfly-shaped end socket, a splitter plate, a tank body, a first screen plate, a first internal supporting piece, a second screen plate, a third screen plate, a second internal supporting piece, a first feeding port, a second feeding port, an inner end socket supporting piece, a first adsorbent and a second adsorbent. According to the invention, the adsorption rate is improved, the pressure swing adsorption oxygen production operation cycle time is shortened, the system operation energy consumption is reduced, and the production efficiency is improved.

Owner:昆山易氧空分科技有限公司

Wearable oxygen production garment

InactiveCN111689473AEasy to wearReduce weightRespiratory masksGarmentsAir compressorSaturation oxygen

The invention provides a wearable oxygen production garment which is characterized in that the garment includes a wearable waistcoat and a breathing mask, and an oxygen supply system, a control systemand a power supply system are integrated on the waistcoat. The whole oxygen supply system comprises an oxygen generation system and an oxygen storage system, wherein the oxygen generation system is composed of a filter, a positive and negative pressure integrated small air compressor and a molecular sieve filled with LiA type zeolite, and the oxygen storage system is composed of four rectangularoxygen bags connected in series. The control system is composed of a CPU, an air pressure detection sensor and an oxygen saturation detection sensor, and the control system controls the air compressorto change the working state of the system through information fed back to the CPU by the air pressure detection sensor and the oxygen saturation detection sensor. The wearable oxygen production garment solves the problems that traditional PSA type oxygen production equipment is large in size, heavy in weight and difficult to carry.

Owner:中船(海南)科技发展有限公司

Medical oxygen production equipment

InactiveCN112456446AReduce work intensityImprove cleanlinessGas treatmentDispersed particle filtrationMolecular sieveEngineering

The invention discloses medical oxygen production equipment which comprises a primary oxygen production box, a cooling dehumidification box, a secondary oxygen production box and an oxygen storage box, the oxygen storage box is communicated with a first oxygen outlet pipeline through a mixing pipeline, an adjusting valve is fixedly arranged in the end, close to the first oxygen outlet pipeline, ofthe mixing pipeline, a cooling elastic plate is fixedly connected to the interior of the cooling dehumidification box, a porous elastic film is movably arranged in the through hole, a pull rope is fixedly connected to the end, extending out of the open groove, of the extension rod, and the end, away from the extension rod, of the pull rope is fixedly connected to the porous elastic film. In use,the oxygen-rich membrane and the molecular sieve are cooperatively used so that the working strength of the molecular sieve is reduced, meanwhile, the cleanliness of the molecular sieve is guaranteed,oxygen with different concentrations is obtained through the mixing pipeline and the adjusting valve, the tensile deformation degree of the cooling elastic plate and the porous elastic film is increased through the oxygen inlet pipe, the screw rod, the toothed plate, the pull rope and other structures, and the cooling and dehumidifying effects are improved.

Owner:蚌埠冠鑫达医疗科技有限公司

Petroleum coke powder full oxygen combustor

ActiveCN102635856ABurn fullyImprove burnout ratePulverulent fuel combustion burnersCombustorEngineering

The invention relates to a petroleum coke powder full oxygen combustor. The petroleum coke powder full oxygen combustor comprises an outer pipe, a combustor support used for sleeving the outer pipe, an inner pipe sleeved in the outer pipe, a coke powder gun which is sleeved in the inner pipe and stretches into a combustion kiln, as well as a Venturi pipe arranged on the head ends of the inner pipe and the outer pipe, wherein the Venturi pipe comprises a venturi inner pipe arranged on the head of the inner pipe and a venturi outer pipe arranged on the inner wall of the outer pipe; the inner wall of the outer pipe and the outer wall of the inner pipe form an oxygen gas channel in a surrounding manner, and the tail end of the oxygen gas channel is connected with outside oxygen equipment through an oxygen gas interface arranged on the outer pipe; the head end of the oxygen gas channel forms a jet orifice through a venturi channel of the venturi pipe; and the tail end of the coke powder gun is connected with an outside coke powder supplying device and is provided with an atomizer, and a gun nozzle at the head end of the coke powder gun extends out from the jet orifice to be inserted into the combustion kiln. The petroleum coke powder full oxygen combustor provided by the invention has the advantages of reasonable structure, energy conservation and environmental protection, and can ensure coke powder to fully burn, and can greatly improve coke powder utilization ratio.

Owner:虞上海

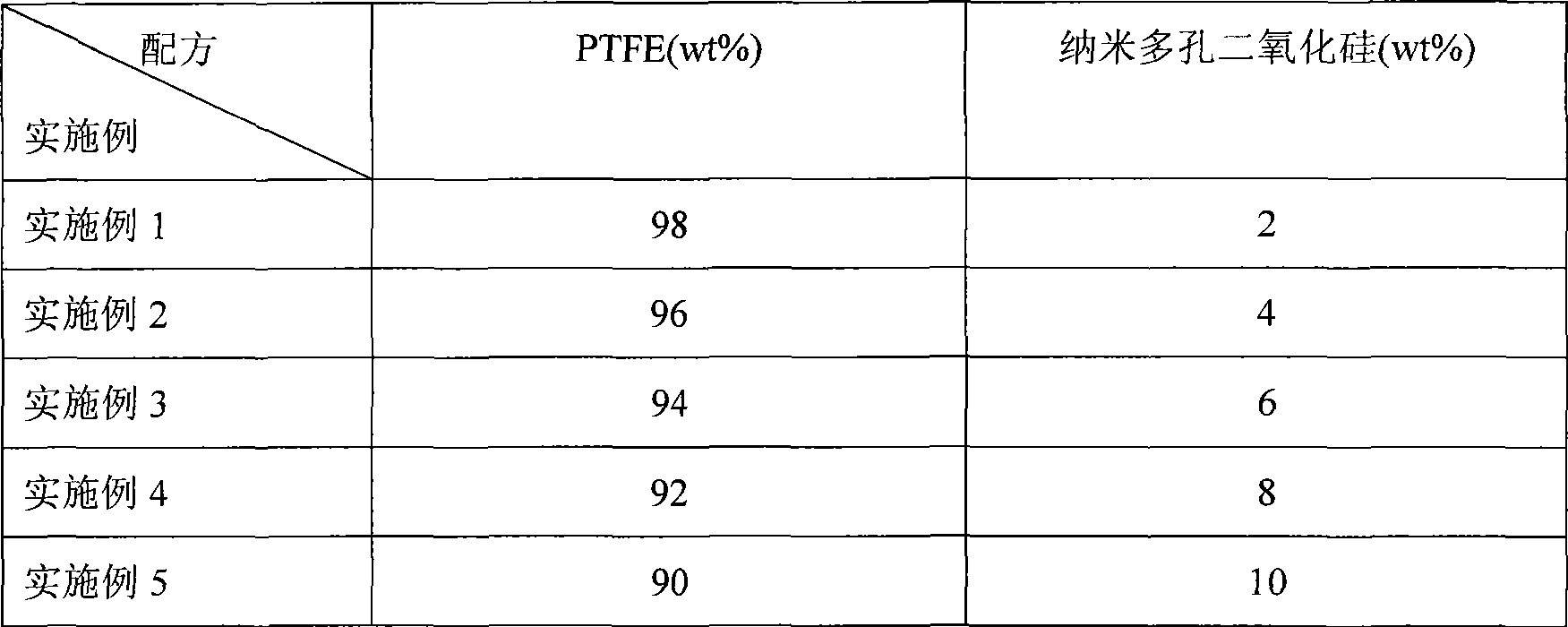

Abrasion-proof self-lubricating composite material and its preparation method

InactiveCN101386699AImprove high temperature resistanceSmall loss of toughnessLiquid fuelProduct gas

The invention relates to an abrasion resistant self-lubricating composite material and a preparation method thereof. The raw materials in weight percentage of the material are: 1 to 15 percent of nano-porous silicon dioxide and 85 to 99 percent of suspended PTFE resin moulding powder. The material can be widely applied to the fields of lubricating, sealing and so on, is made into various parts such as bushes, sealing rings, guiding rings and so on, and is suitable for the working occasions at ultralow temperature and ultrahigh temperature, such as oil forbidden self-lubricating abrasion resistant parts of ultralow temperature refrigerating machines, liquid fuel pumps, high pressure pumps, oxygen generating devices, high temperature driers, conveyor belts inside furnaces, medicines and foods and so on, and dynamic seals of liquid or gas of an engine.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

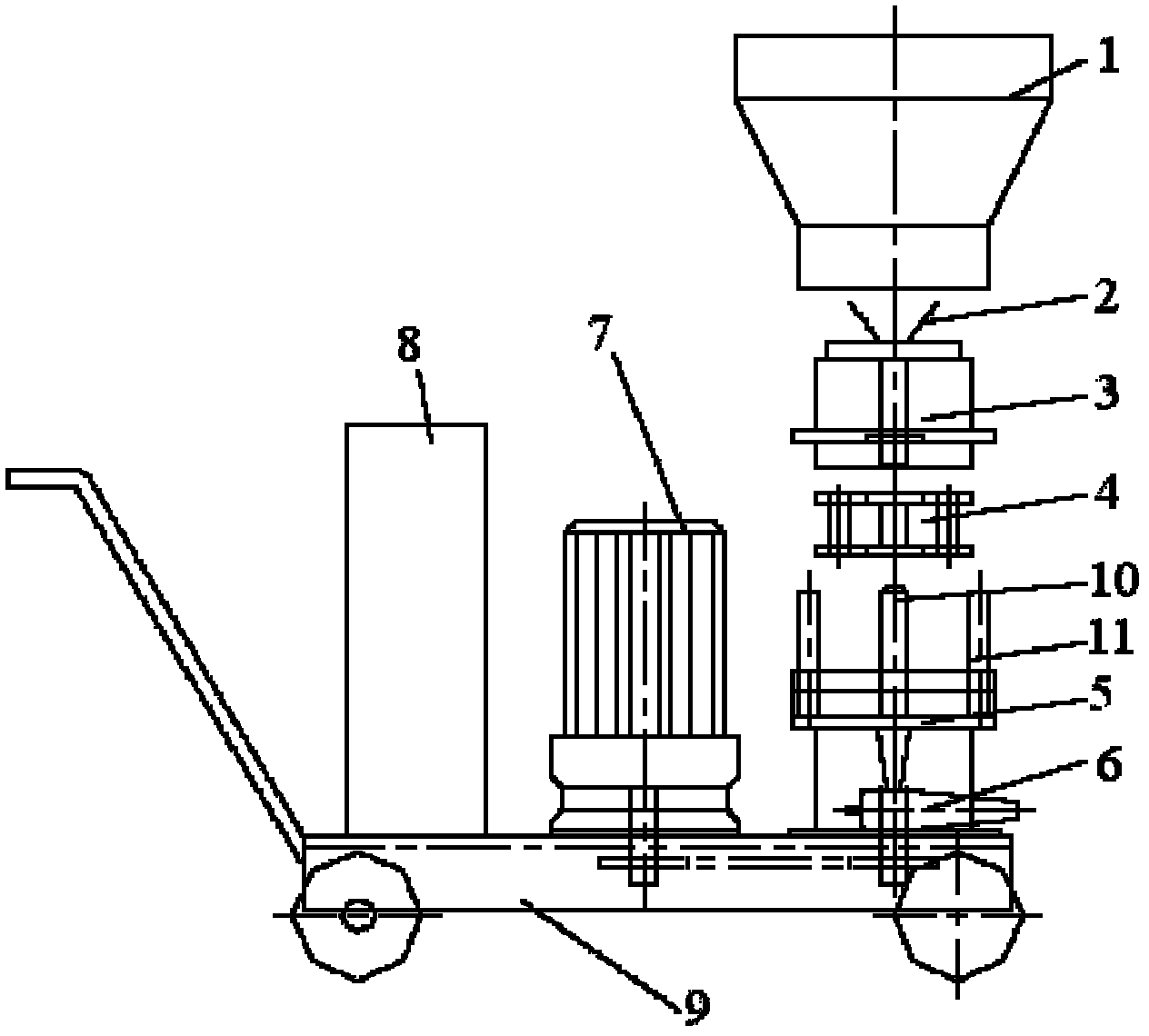

Industrial furnace repair equipment

InactiveCN102200391AImprove spraying effectShorten repair timeLinings repairProcess engineeringCoke oven

The invention discloses industrial furnace repair equipment, which comprises a flame ceramic repair-welding machine, wherein the flame ceramic repair-welding machine is provided with a feeding hopper (1) and a mixer (6); the mixer (6) is provided with a feeding hole (15), an air inlet (16) and a mixed outlet (17); the feeding hole (15) is communicated with the feeding hopper (1); and the air inlet (16) is communicated with oxygen equipment. By adoption of the technical scheme, temperature reduction is not required in a repair process, and repair working time is shortened; the industrial furnace repair equipment is simple in structure, convenient to operate, fast and high-efficiency; the spraying capacity of a repair-welding material is high; flow quantity is controllable; spraying is uniform; the temperature of a sprayed part is about 800 DEG C; different spraying materials are selected for repairing corresponding parts and repairing and spraying broken parts of an oven wall of a coke oven; and a good effect is obtained.

Owner:WUHU XINXING DUCTILE IRON PIPES

Multifunctional waterborne lifesaving protection equipment

This is a multi-functional water lifesaving protective equipment belonging to the technological field of water lifesaving articles. It consists of waterproof breathing device and floating clothing, among which the floating clothing for man to wear and breathing device is put on people's head. The water- repellent and breathing device includes waterproof cover, breathing waterproof implement and breathing straw. The intracavity of the waterproof cover is connected with the breathing straw, which is linked with the breathing waterproof implement. The floating clothing is one-piece undershirt, including waterproof cold-proof clothes and the one-piece undershirt. The water cold-proof clothes is of elastic one-piece style, with the one-piece undershirt tightly fixed outside. This invention can prevent from being choked, drowned, frozen, and can keep the drowned warm and alive to win the valuable time for the succour's arrival. This Invention is especially suitable for salvage by perils of the sea, and for the divers who works underwater in short of oxygen equipments.

Owner:宫生铭

Oxygen generator convenient to adjust and move

ActiveCN112794287AEasy to adjustEasy to moveDispersed particle filtrationStands/trestlesHydraulic cylinderEngineering

The invention discloses an oxygen generator convenient to adjust and move. The oxygen generator comprises a supporting mechanism, a damping mechanism and a noise reduction mechanism. The supporting mechanism comprises a base, universal self-locking wheels and a hydraulic cylinder, the universal self-locking wheels are symmetrically arranged at the bottom of the base, and the hydraulic cylinder is fixedly connected to the top of the base. The damping mechanism is arranged above the supporting mechanism. Limiting mechanisms are arranged on the left side and the right side of the noise reduction mechanism, an air inlet is formed in the front side of a sound insulation box, a compressor is arranged in the sound insulation box, and a filtering mechanism and a humidifying bottle are arranged on a partition plate. According to the oxygen generator convenient to adjust and move, the hydraulic cylinder is arranged and can move the compressor, the filtering mechanism, the humidifying bottle and other oxygen generating equipment upwards through the damping mechanism, so that a user can adjust the height of the oxygen generator according to the requirement of the user conveniently; and a user can move the device conveniently through the universal self-locking wheels, so that the flexibility of the device is improved.

Owner:艾洣科技(江苏)有限公司

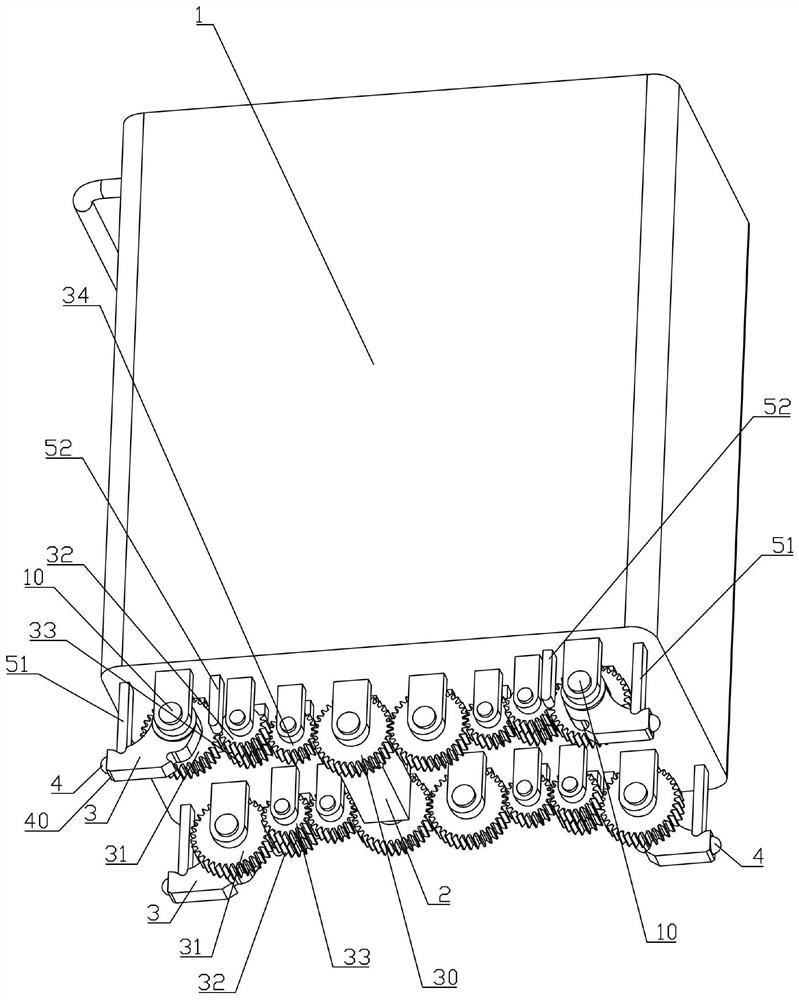

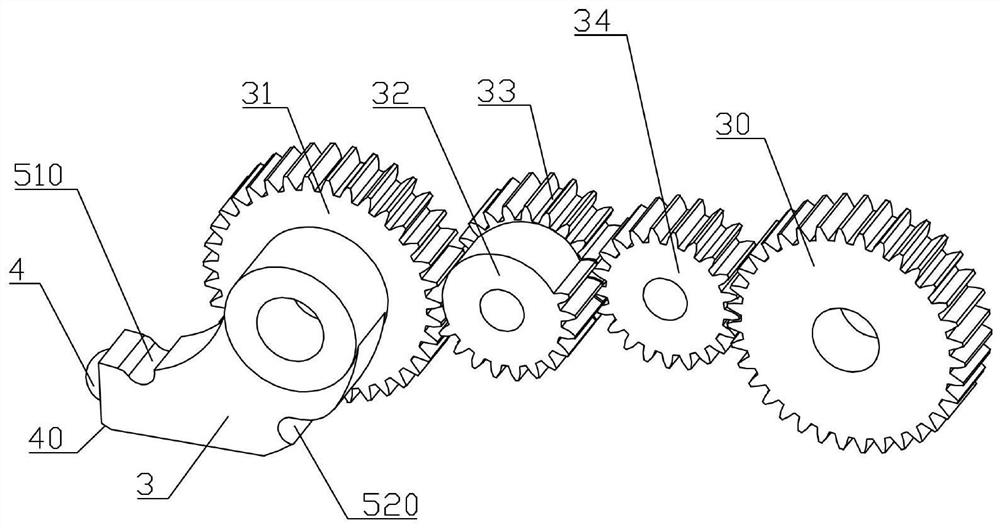

Portable medical oxygen generator

ActiveCN112344132AAvoid damageExtended service lifeMachine framesNon-rotating vibration suppressionGear driveElectric machinery

The invention belongs to the technical field of oxygen production equipment, and particularly relates to a portable medical oxygen generator. The portable medical oxygen generator comprises an oxygengenerator body, a controllable double-head motor is fixedly installed on the lower end face of the oxygen generator body, and four symmetrical supporting sets are further installed on the lower end face of the oxygen generator body; each supporting set comprises a rotating shaft which is rotationally installed on the oxygen generator body, an L-shaped supporting block, a first rotating gear, a second rotating gear, a third rotating gear and a main gear, wherein the L-shaped supporting block is fixedly connected with the first rotating gear, the first rotating gear is meshed with the second rotating gear, the second rotating gear is fixedly connected with the third rotating gear, the third rotating gear is in transmission connection with the main gear, and the second rotating gear is an incomplete gear; four first supporting blocks and four second supporting blocks are further fixedly installed on the lower end face of the oxygen generator body; and each first supporting block and the corresponding second supporting block are located on the two sides of each L-shaped supporting block. The portable medical oxygen generator aims to solve the problem of short service life caused by structural defects of a conventional oxygen generator.

Owner:杭州博大净化设备有限公司

Carbon dioxide concentration detection and oxygen regeneration system

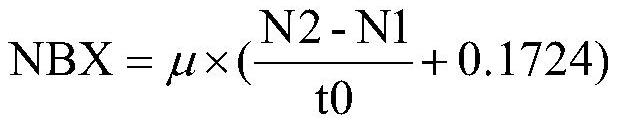

PendingCN113687027AImprove accuracyImprove efficiencyGas analyser calibrationOxygen preparationData acquisitionProcess engineering

The invention discloses a carbon dioxide concentration detection and oxygen regeneration system, and belongs to the technical field of gas detection. The carbon dioxide concentration detection and oxygen regeneration system comprises: a data acquisition module, wherein the data acquisition module, comprises an equipment acquisition unit and an environment acquisition unit, the equipment acquisition unit is used for acquiring operation information of detection equipment, and the environment acquisition unit is used for acquiring environment information of a detection environment; a processing and marking module used for processing and marking the operation information and processing and marking the environment information; a calculation and analysis module used for calculating the processed operation information to obtain a concentration coefficient and a set operation value, calculating the processed environment information to obtain a human migration coefficient and an environment matching value, and calculating and analyzing an equipment operation value and the environment matching value to obtain an analysis matching set; and an oxygen production regulation and control module which carries out oxygen production and early warning prompt on oxygen production equipment according to the analysis matching set. The carbon dioxide concentration detection and oxygen regeneration system solves the technical problem that the detection effect of the carbon dioxide concentration in an existing scheme is poor.

Owner:ANHUI ZHONGNAN AIR DEFENCE WORKS PROTECTIVE EQUIP

Auxiliary medical molecular sieve center oxygen generation equipment

InactiveCN102674257AImprove reliabilityGuaranteed stabilityRespiratorsOxygen preparationMolecular sieveOxygen balance

The invention relates to auxiliary medical molecular sieve center oxygen generation equipment which comprises a main air supply source and auxiliary air supply sources, wherein the main air supply source and the auxiliary air supply sources commonly use one air balance tank, one oxygen balance tank and one oxygen distribution cylinder with a pressure and flow equalizing function, and the auxiliary air supply sources are arranged adjacent to the main air supply source side by side and complementarily supply air to the main air supply source.

Owner:珠海市精钰科技设备有限公司

Double-stage oxygen making system

InactiveCN101293164AIncrease oxygen contentImprove the desorption effectDispersed particle separationOxygen preparationTowerOxygen content

The invention discloses a secondary adsorption type oxygen generation system, by adopting a third molecule sieve absorption tower and a fourth molecule sieve absorption tower as main secondary oxygen generation equipment, the oxygen obtained by primary oxygen generation equipment is further purified so as to obtain a finished gas with high oxygen content; in addition, the invention adopts a vacuum pump to draw off a waste gas from a first molecule sieve absorption tower and a second molecule sieve absorption tower; due to a lower pressure generated by the vacuum pump, an adsorption effect of each molecule sieve absorption tower is good, which is convenient for improving the work efficiency and improving the oxygen content of the finished gas at the same time. The invention has the advantage of high oxygen generating efficiency and higher oxygen content of the finished gas.

Owner:张文权

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com