Oxygen generating equipment

An oxygen production equipment, the first technology, applied in the fields of oxygen preparation, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problems of large area, large equipment design, large selection, etc. Small footprint, easy to use, and the effect of large adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

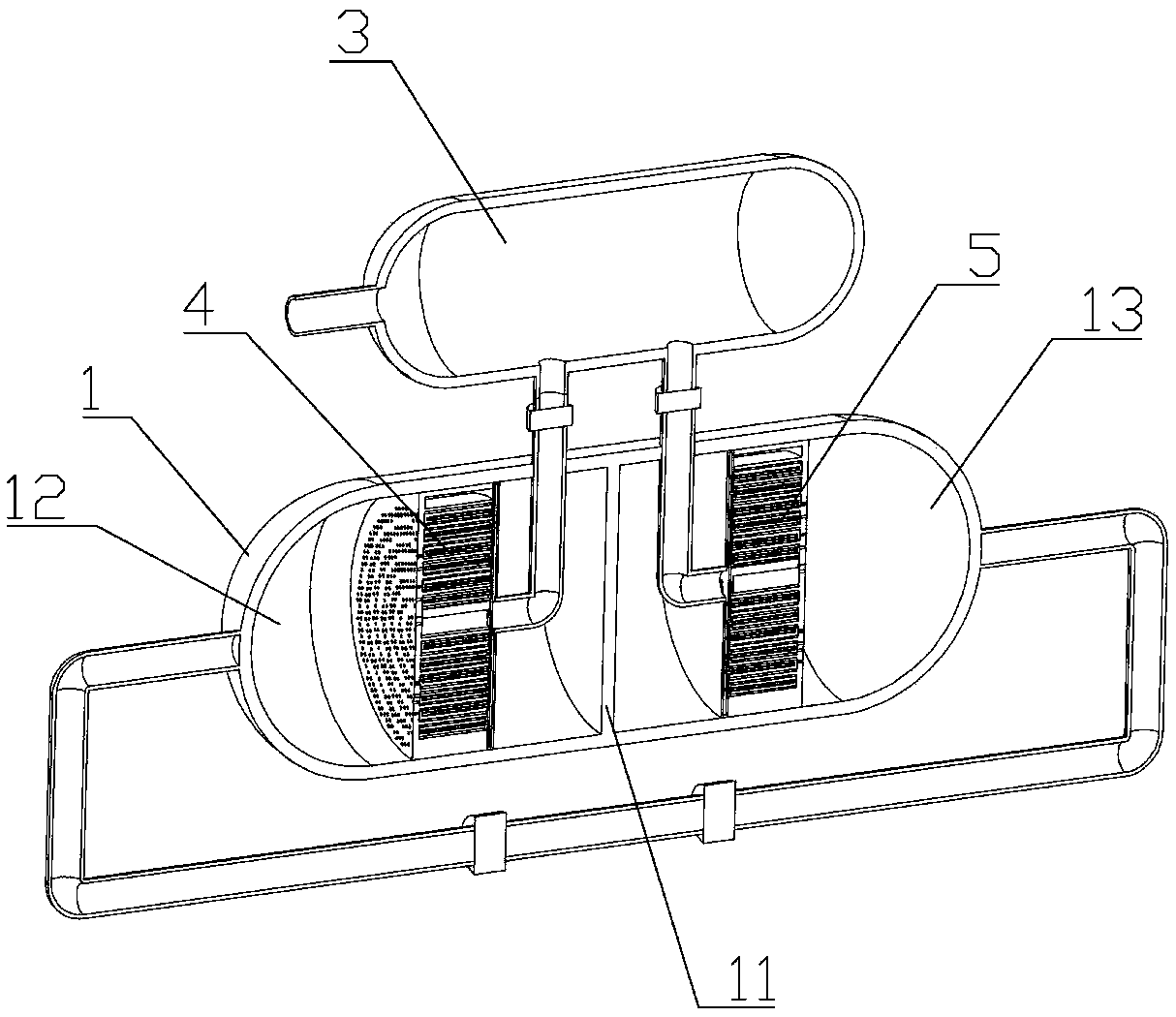

[0028] Such as Figure 1-7 As shown, an oxygen production equipment includes a connected air compressor, filter, degreaser, dryer, molecular sieve adsorption tower, membrane separator and oxygen storage tank, the filter is connected to the degreaser, and the degreaser is connected to the compressor , the compressor is connected to the drier, the drier is connected to the molecular sieve adsorption tower, the molecular sieve adsorption tower is connected to the membrane separator, and the membrane separator is connected to the oxygen storage tank, wherein the molecular sieve adsorption tower includes an adsorption tank 1 and a buffer tank 3, and the buffer tank 3 is equipped with Exhaust pipe 31, the exhaust pipe 31 communicates with the membrane separator, the exhaust valve is installed on the exhaust pipe 31, the adsorption tank 1 communicates with the buffer tank 3, the buffer tank 3 communicates with the membrane separator, and the adsorption tank 1 is integrally formed The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com