Multi-stage porous carbon-based material based on reaction template, and preparation method and application thereof

A technology of carbon-based materials and hierarchical pores, which is applied in the fields of chemical instruments and methods, carbon compounds, hybrid/electric double-layer capacitors, etc., can solve the problems of difficult large-scale production, limitations in the preparation of porous carbon materials, and high preparation costs. Achieve the effect of improving the electron transmission rate, increasing the electron adsorption area, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

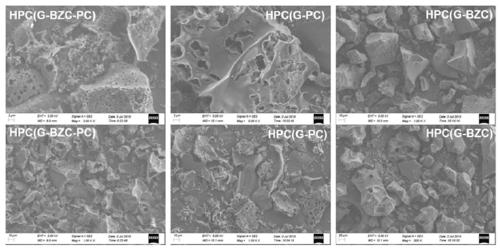

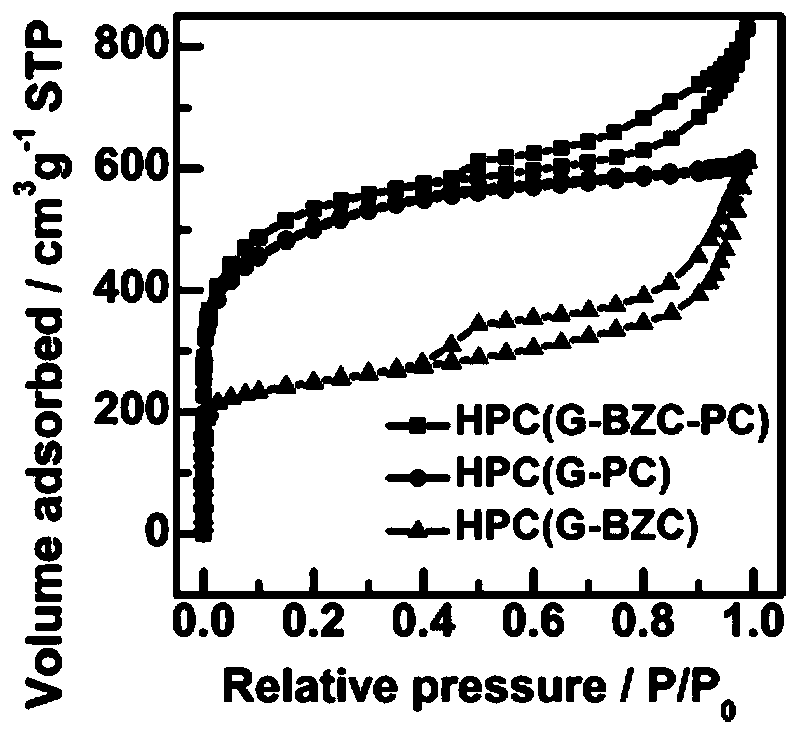

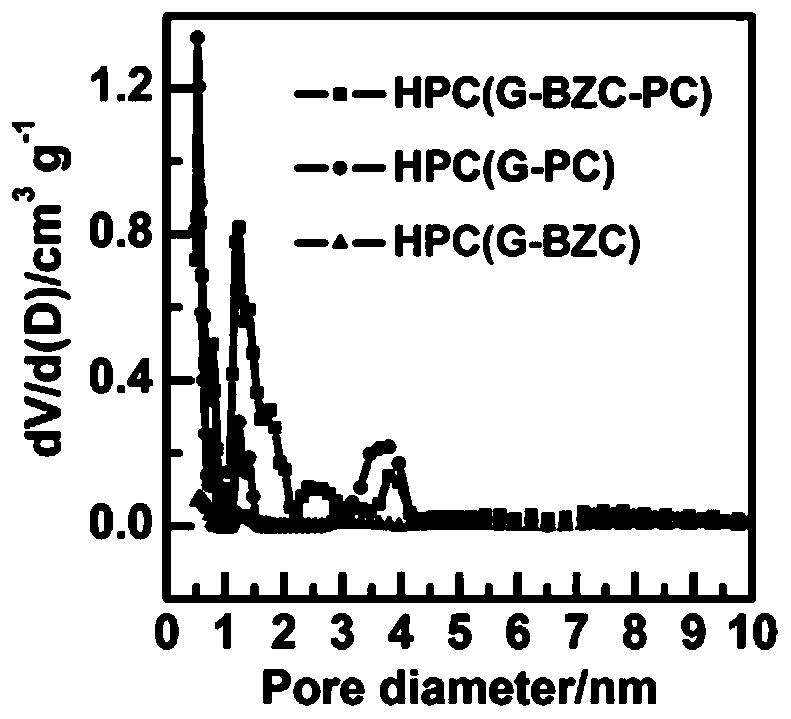

Image

Examples

Embodiment 1

[0043] 1) First take 2g of glucose, 1g of basic zinc carbonate, and 1g of potassium carbonate and add them into an agate mortar for sufficient solid-phase mixing to obtain solid powder A;

[0044] 2) A obtained in step 1) was mixed in 200mL min -1 Under the protection of flowing inert gas, the temperature was raised to 750°C at 5°C / min and kept for 1.5h, then naturally cooled to room temperature and ground evenly to obtain catalyst precursor B;

[0045] 3) The catalyst precursor B obtained in step 2) was treated with an aqueous acid solution at room temperature for 20 h, then suction filtered and dried to obtain a carbon-based material from which the template and impurities were removed, labeled as HPC.

Embodiment 2

[0047] 1) Take 1g of disodium EDTA, 1g of basic magnesium carbonate, and 1g of potassium carbonate and add them into an agate mortar for sufficient solid-phase mixing to obtain solid powder A;

[0048] 2) A obtained in step 1) was mixed in 180mL min -1 Under the protection of flowing inert gas, the temperature was raised to 800°C at 7°C / min and kept for 1h, then naturally cooled to room temperature and ground evenly to obtain catalyst precursor B;

[0049] 3) Treat the catalyst precursor B obtained in step 2) with an aqueous acid solution at room temperature for 12 hours, and then perform suction filtration and drying to obtain a carbon-based material from which the template and impurities have been removed, which is marked as HPC;

Embodiment 3

[0051] 1) Take 2g of chitosan, 0.5g of basic nickel carbonate, and 2g of potassium carbonate and add them into an agate mortar for sufficient solid-phase mixing to obtain solid powder A;

[0052] 2) A obtained in step 1) was mixed in 250mL min -1 Under the protection of flowing inert gas, the temperature was raised to 1000°C at 4°C / min and kept for 1h, then naturally cooled to room temperature and ground evenly to obtain catalyst precursor B;

[0053] 3) Treat the catalyst precursor B obtained in step 2) with an aqueous acid solution at room temperature for 5 hours, and then perform suction filtration and drying to obtain a carbon-based material from which the template and impurities have been removed, which is marked as HPC;

[0054] 4) With the HPC obtained in step 3), in 180mL min -1 Flow reactive gas NH 3 Under protection, the temperature was raised to 900°C at 5°C / min and kept for 0.5h, and then naturally cooled to room temperature to obtain the further improved hierarc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com