Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Nozzle geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

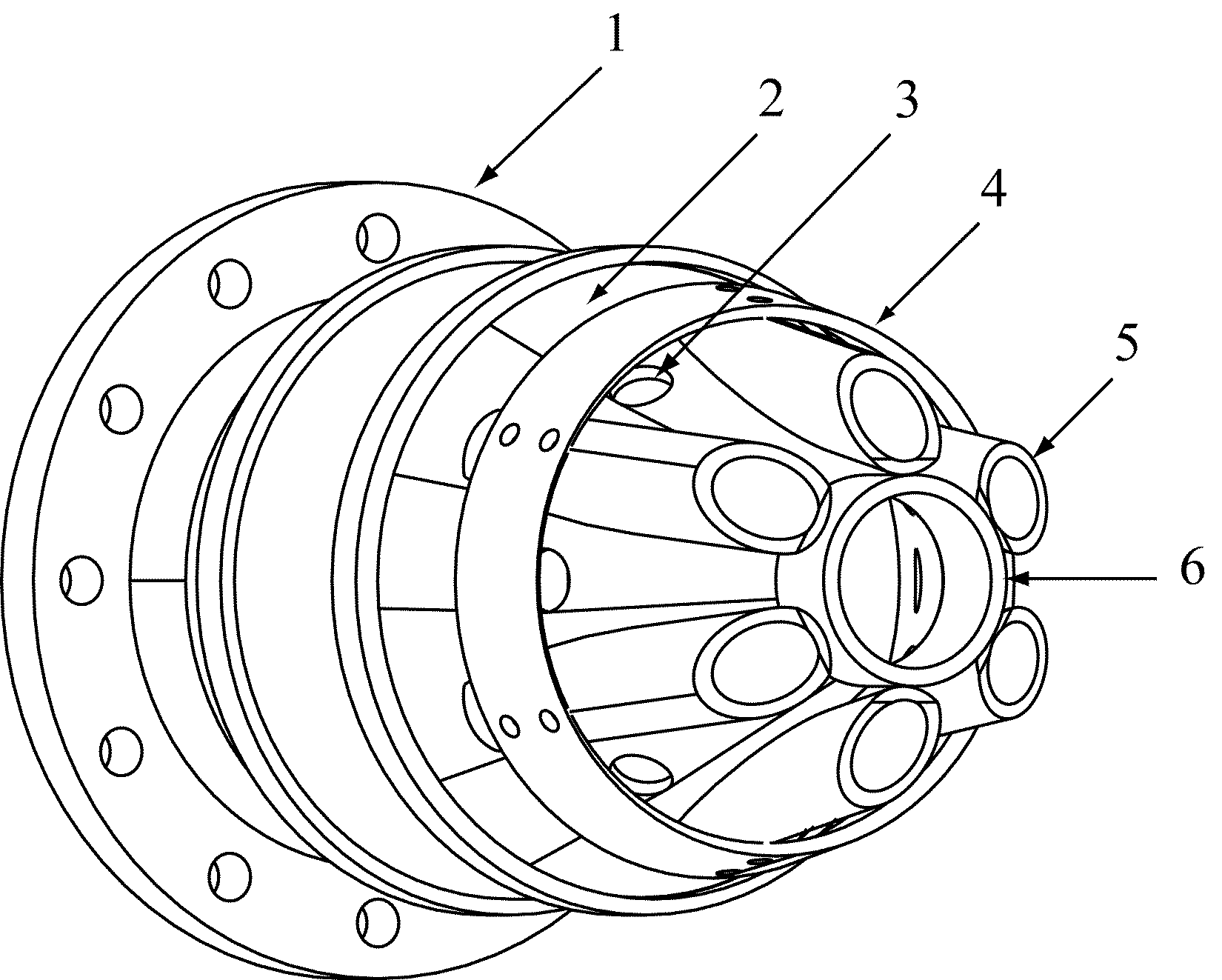

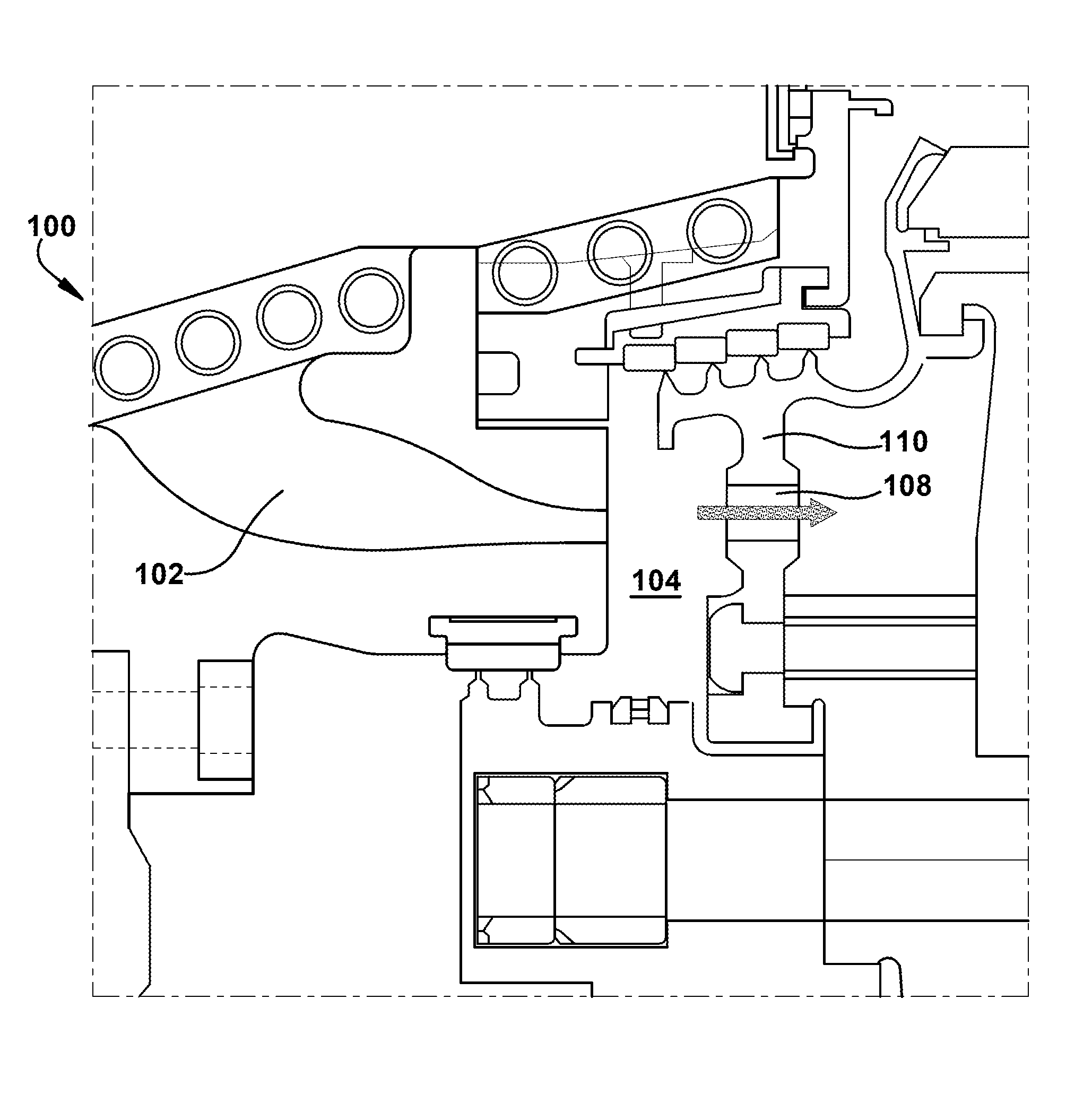

Ejector Nozzle

InactiveUS20060027679A1Reduce noiseEfficient constructionDust removalFire preventionEngineeringNozzle geometry

A multi-lobed ejector nozzle of economical construction and simple form is described. The lobes are formed by a plurality of short tubes that intersect with a central jet. Coanda jets upstream of the ejector formed by a collar and multiple apertures further assist the induction of an external flow to the primary ejector. Shaping of the tube nozzles aid in forming the ejector lobes. The nozzle geometry and the Coanda ring contribute to a reduction in the noise of the ejector assembly.

Owner:GRATTEAU MR JACK EDWARD

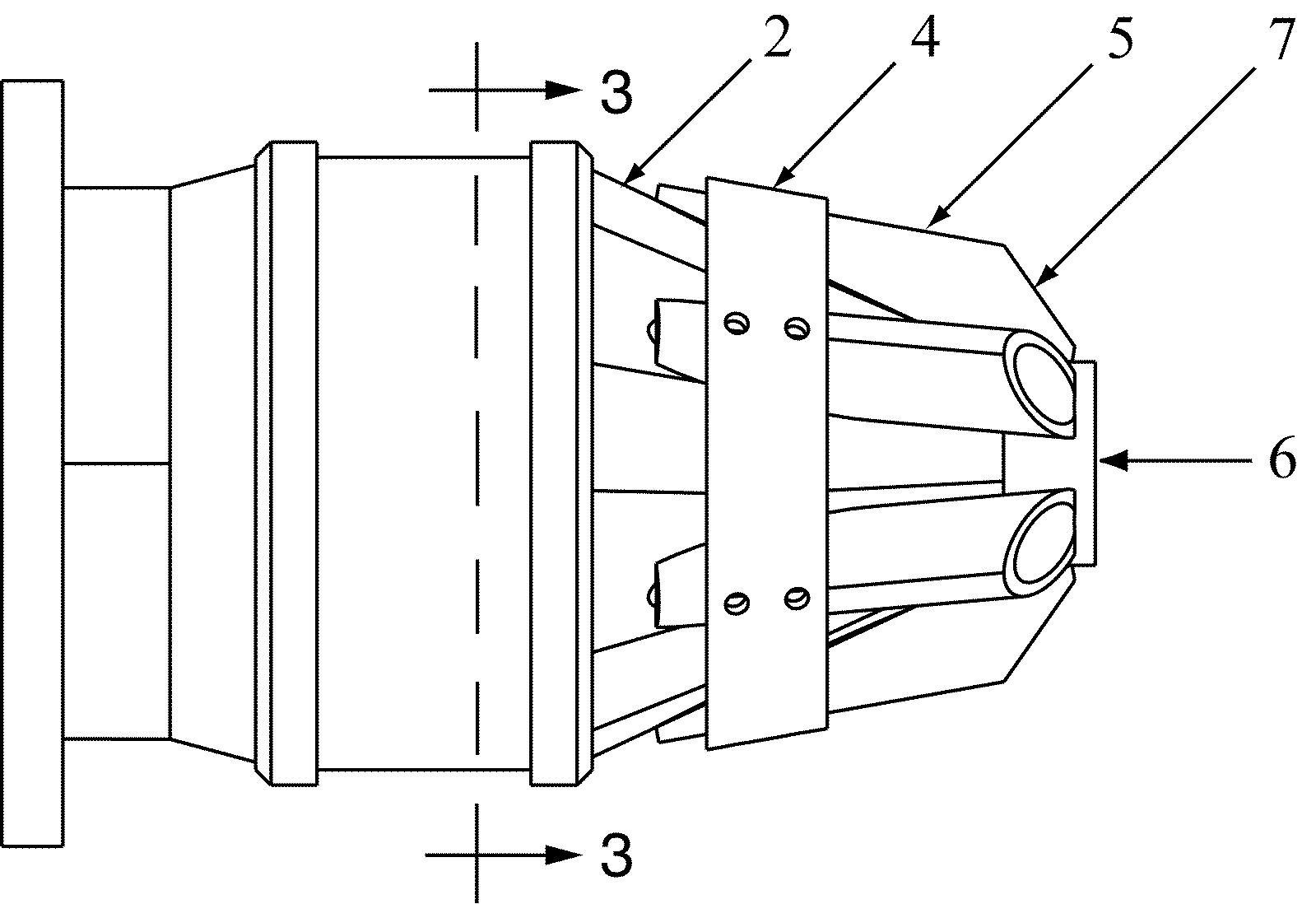

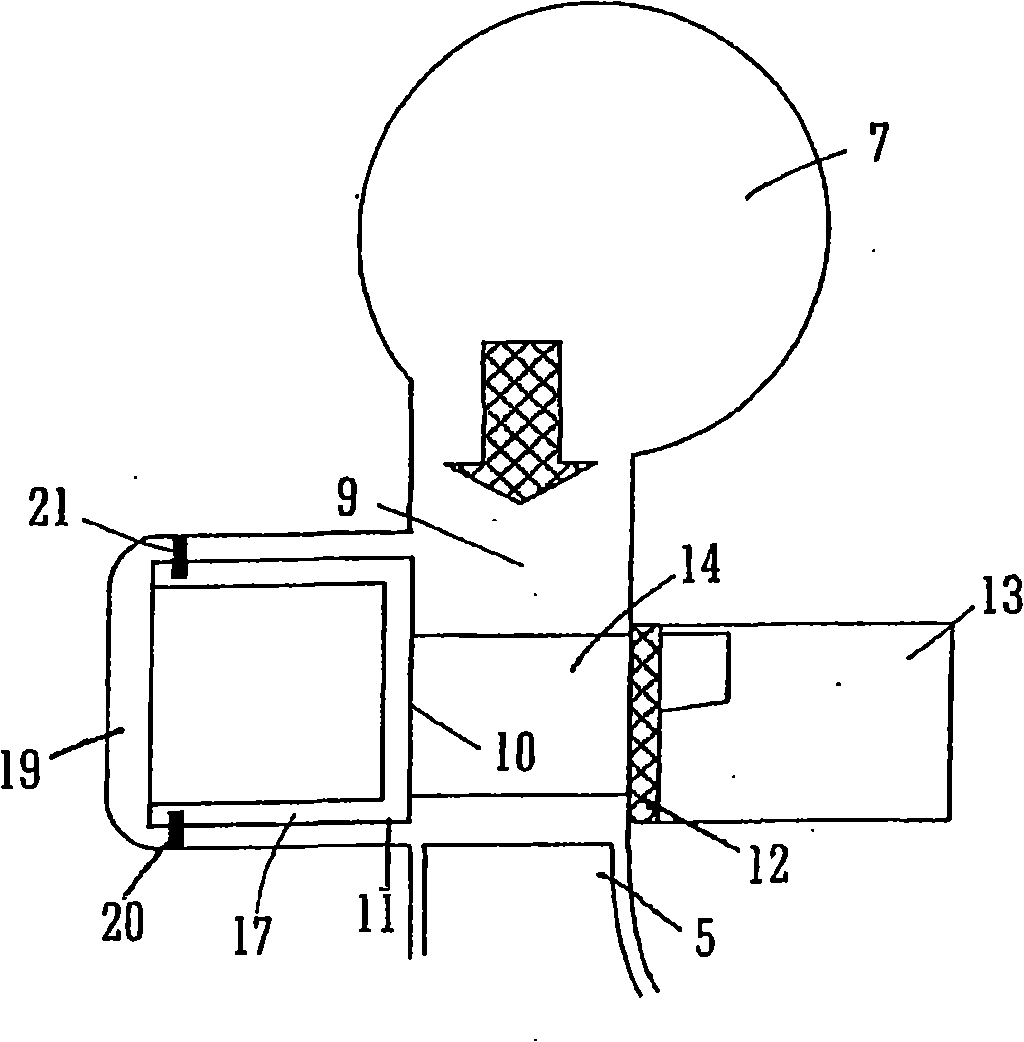

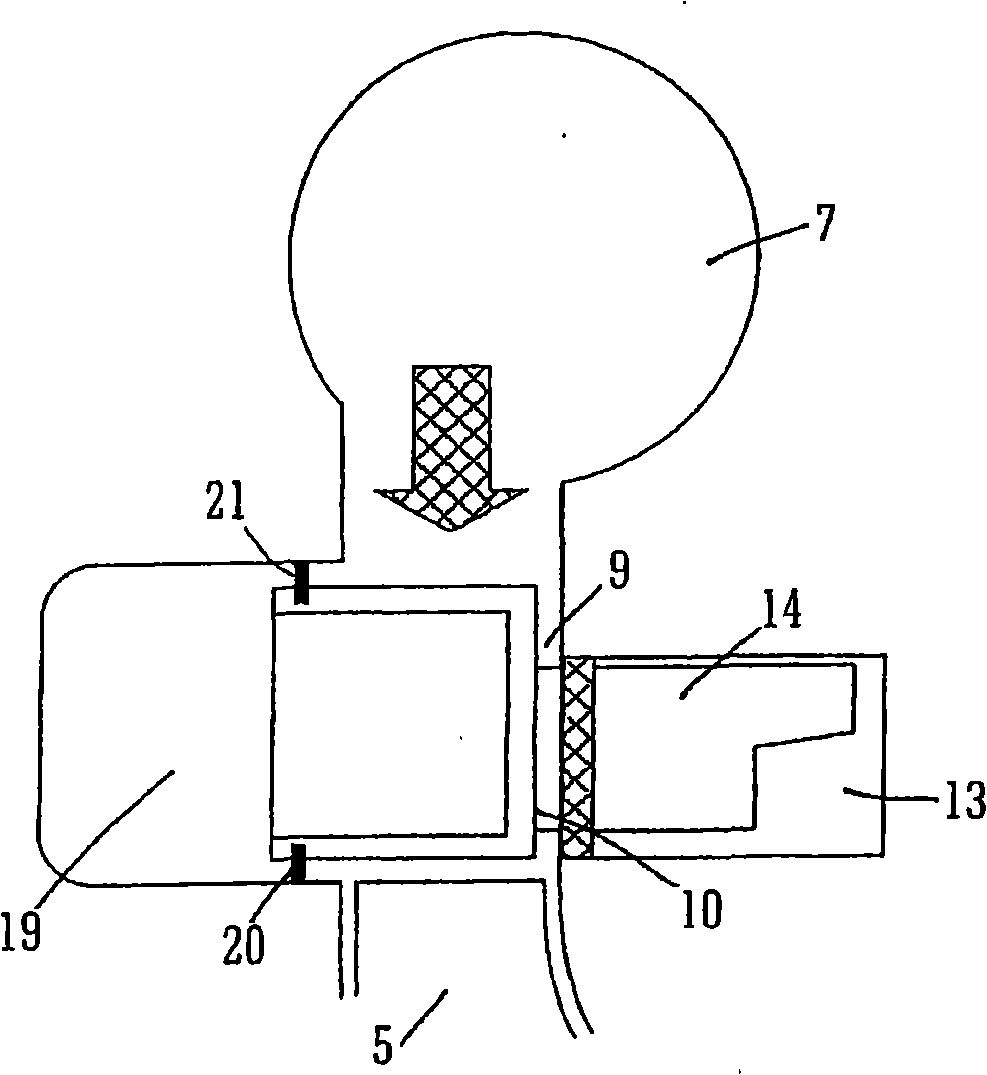

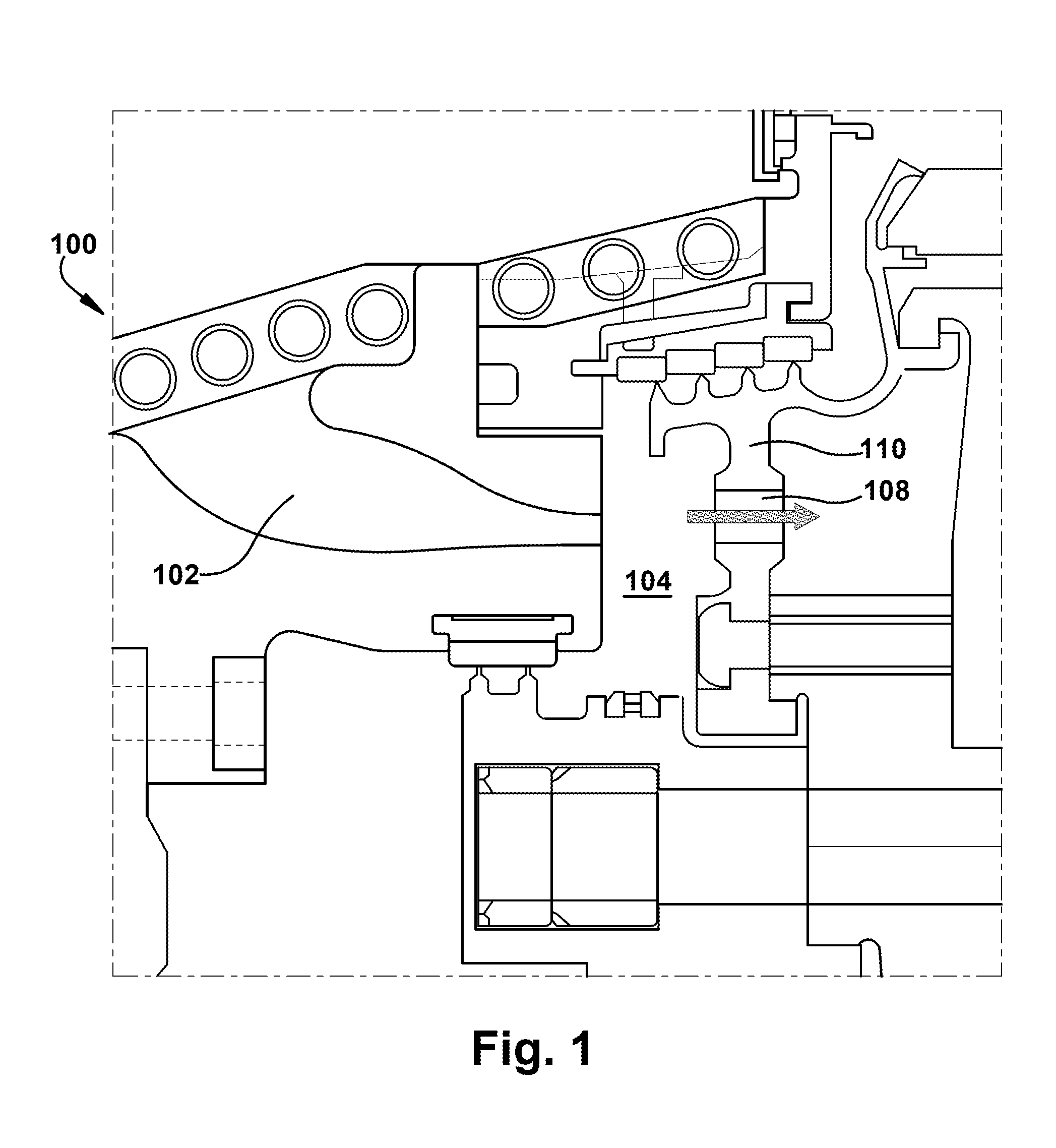

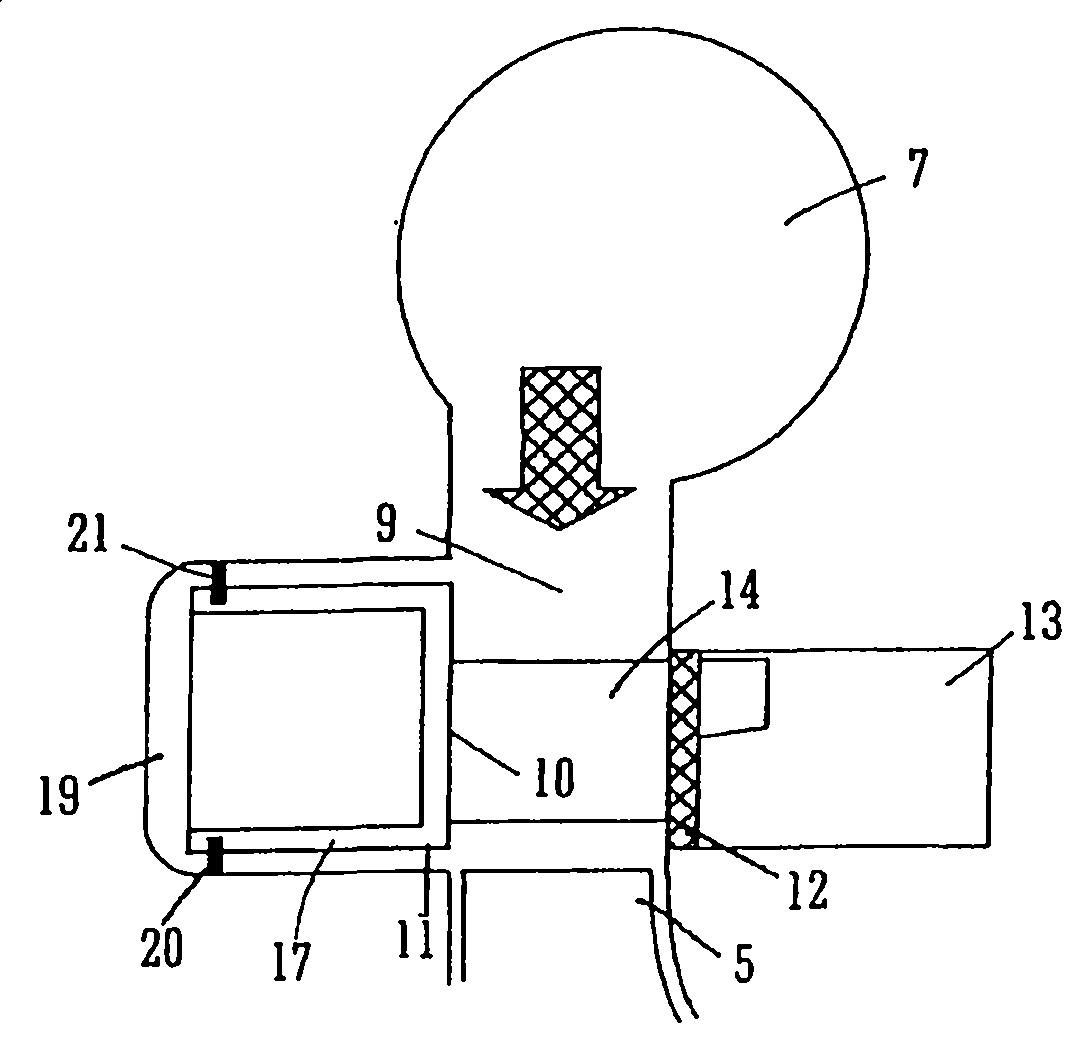

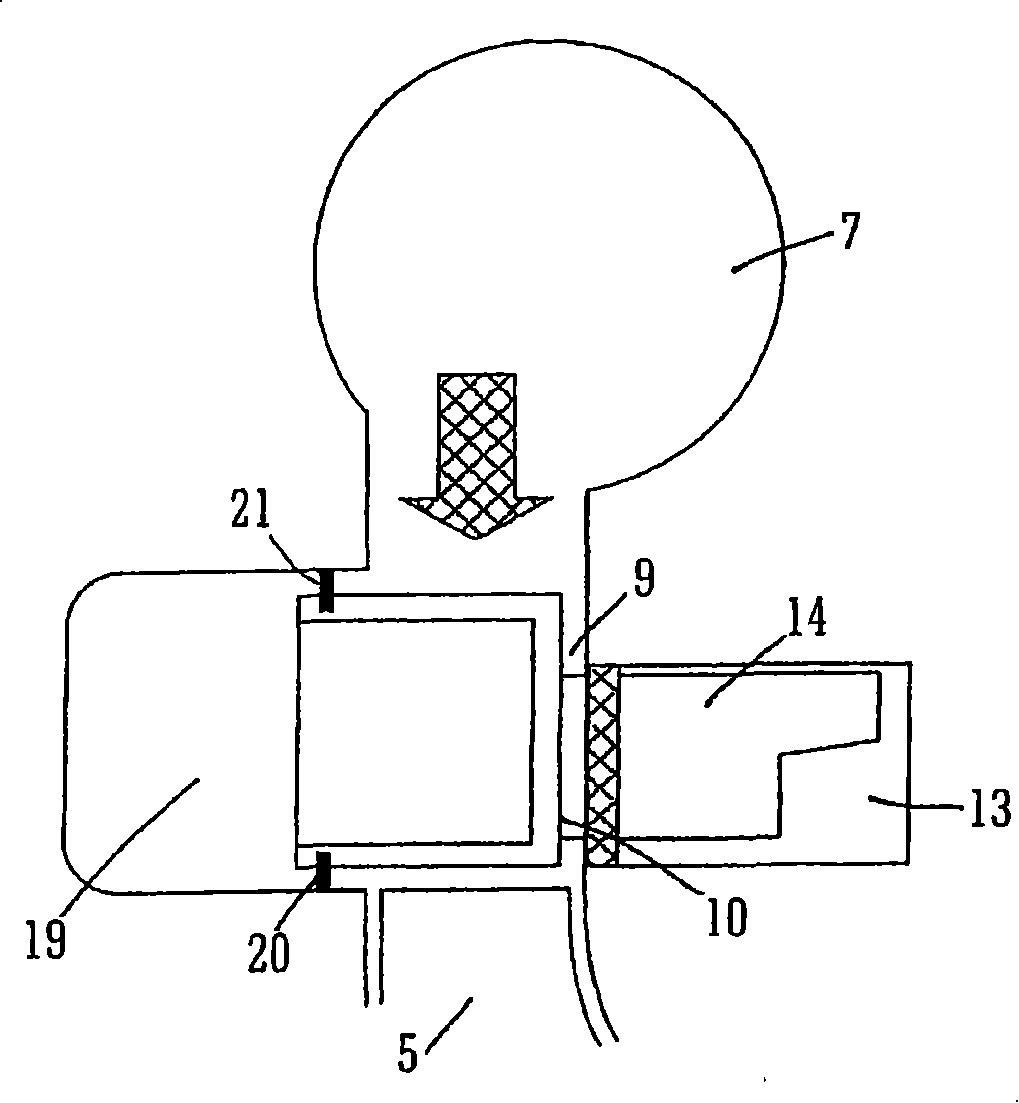

Multiple Fuel Circuits for Syngas/NG DLN in a Premixed Nozzle

InactiveUS20100319353A1Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemSyngas

A fuel / air premixer for use in a burner in a combustion system of an industrial gas turbine includes an air inlet, a fixed nozzle geometry, and an annular mixing passage. The fuel / air premixer mixes fuel and air in the annular mixing passage for injection into a combustor reaction zone. A plurality of fuel sources are connected with the fixed nozzle geometry, and each of the fuel sources is cooperable with the fixed nozzle geometry to effect multiple fuel flow variations including variations in fuel type, fuel blend, volumetric flow, and pressure ratios.

Owner:GENERAL ELECTRIC CO

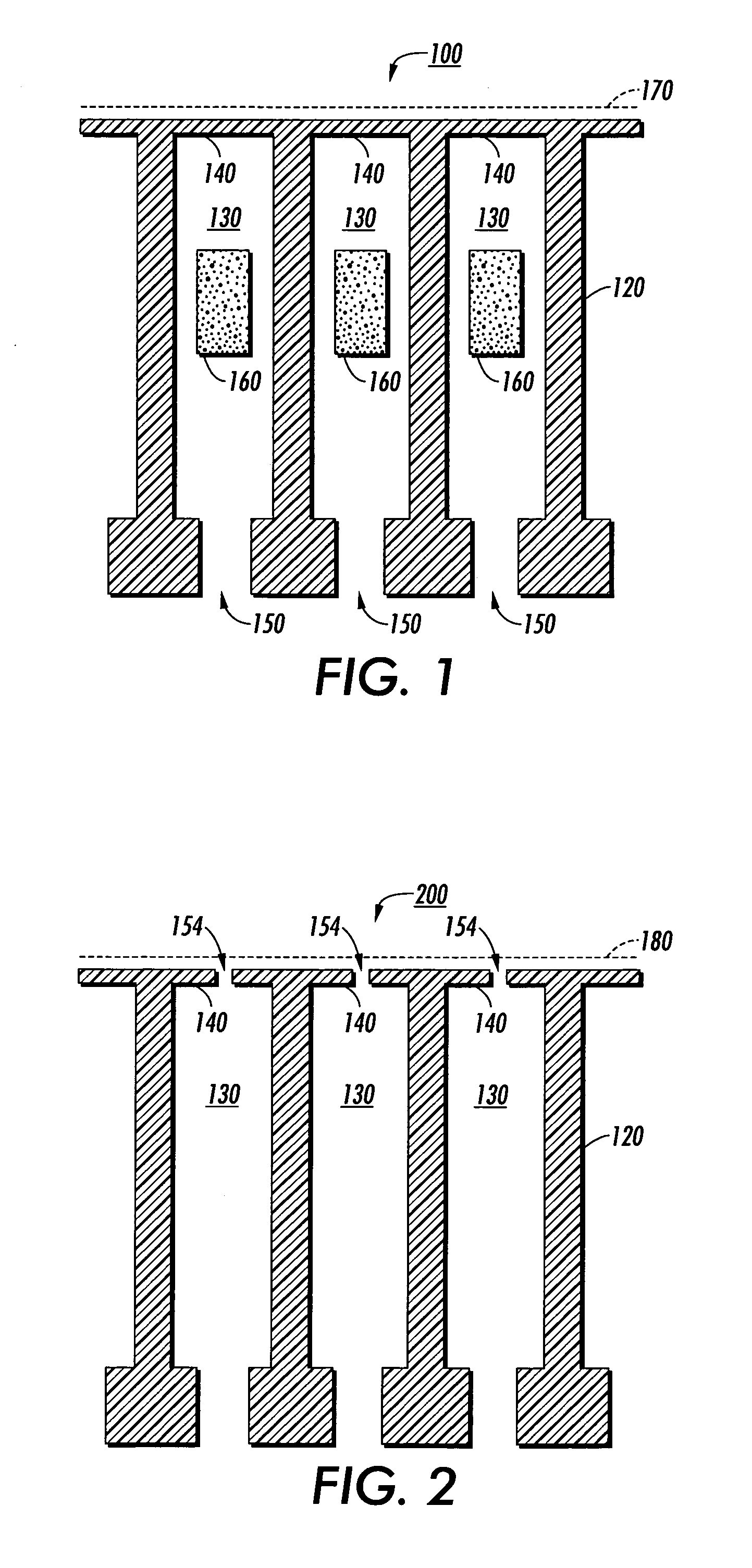

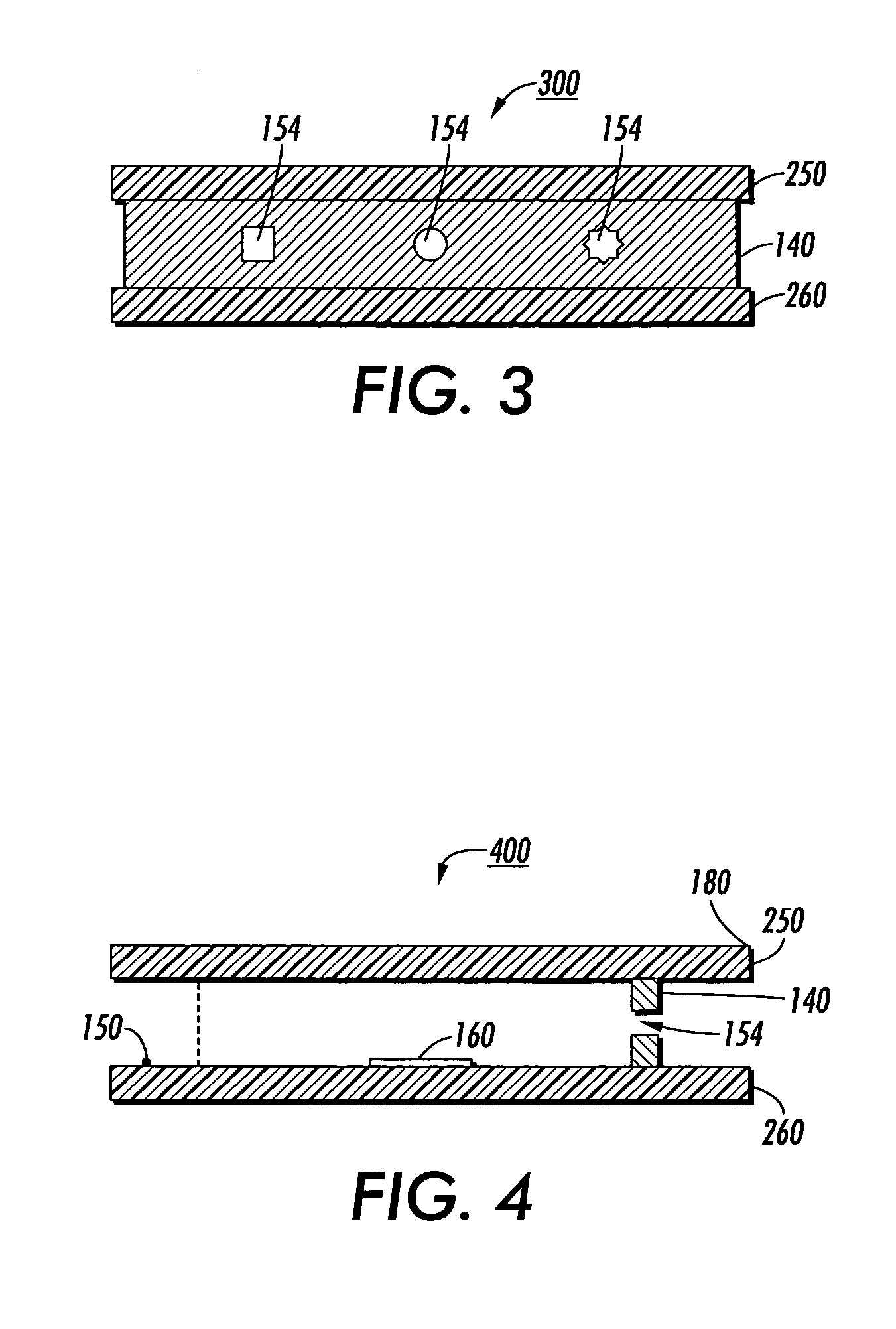

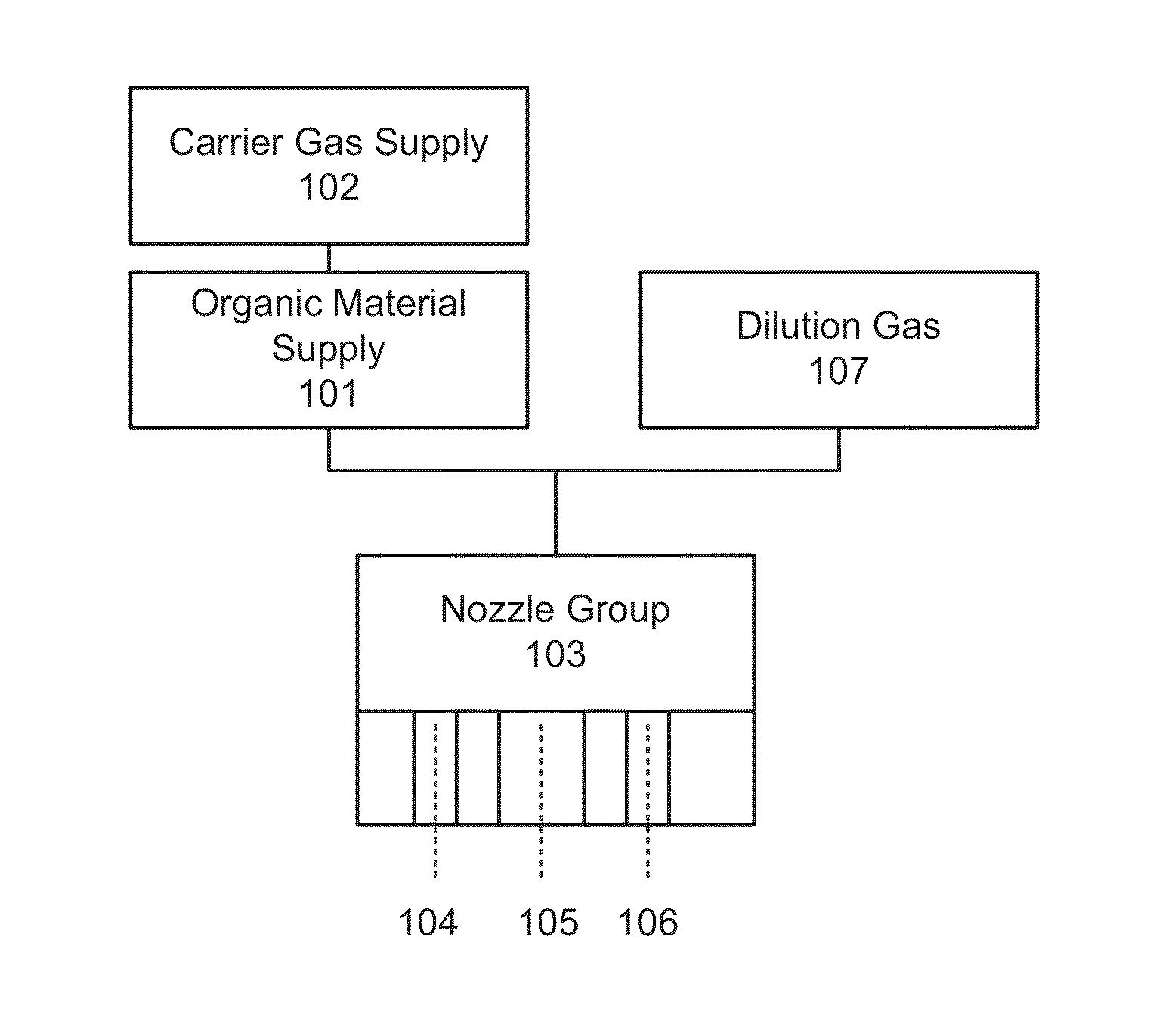

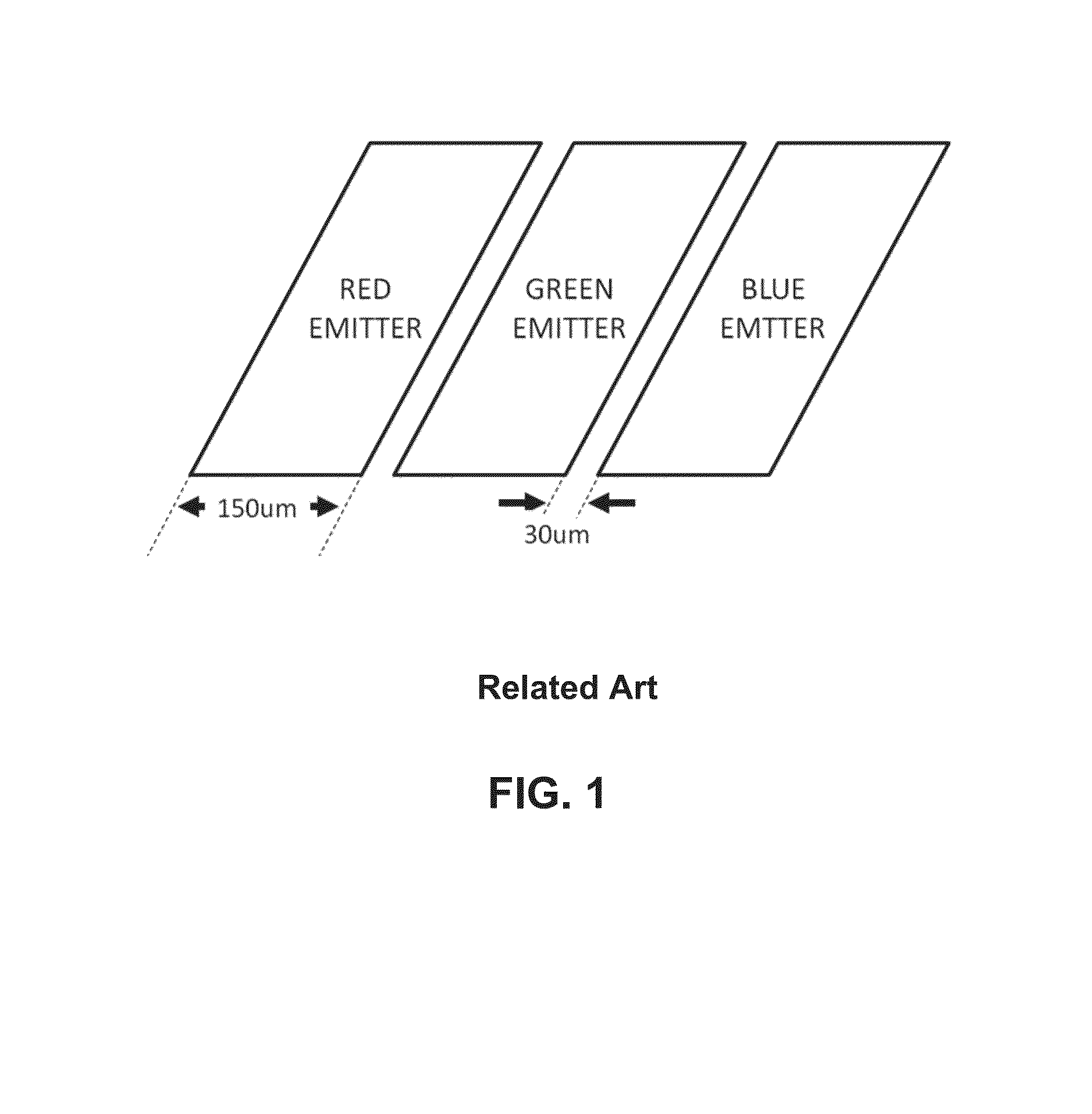

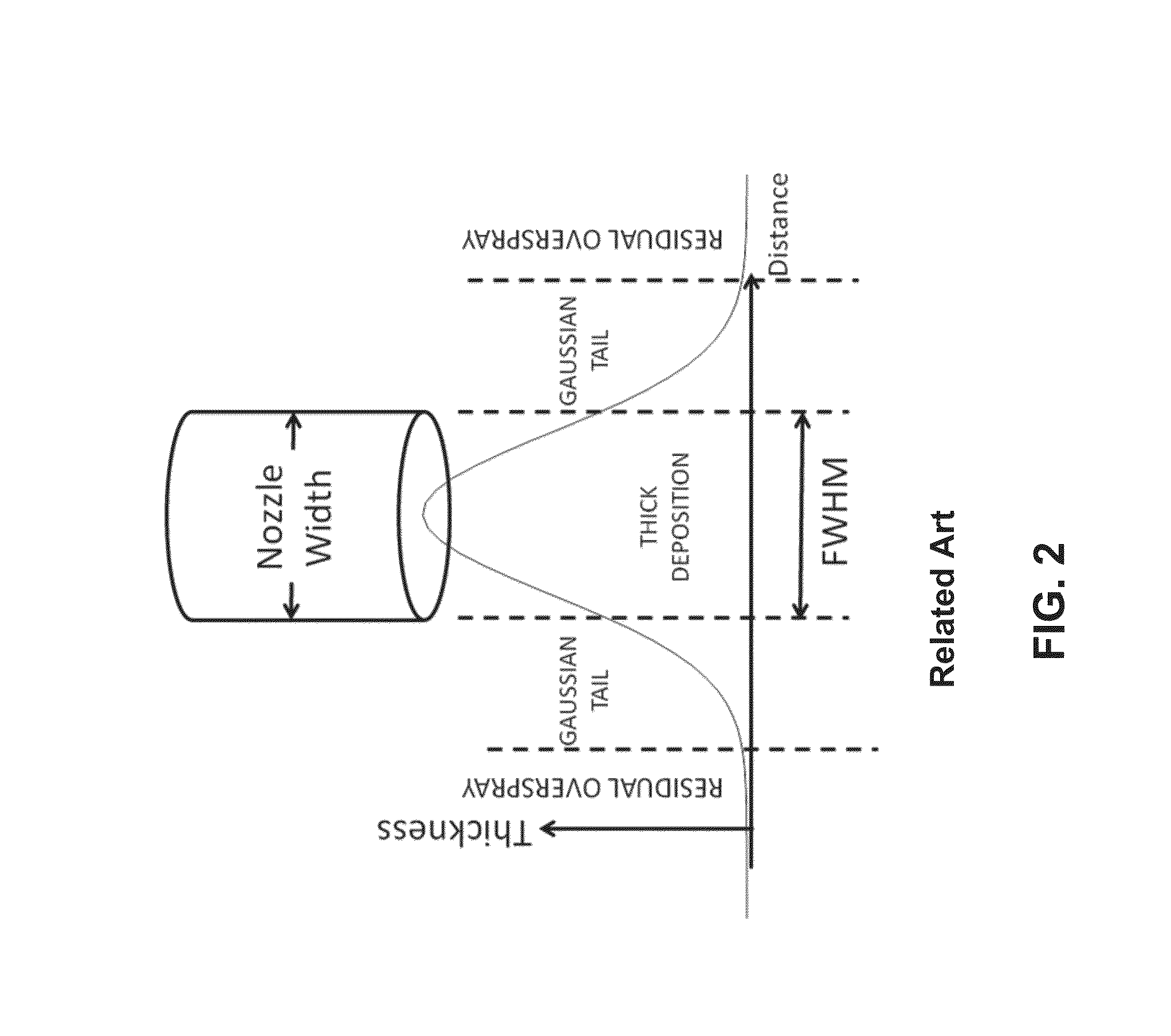

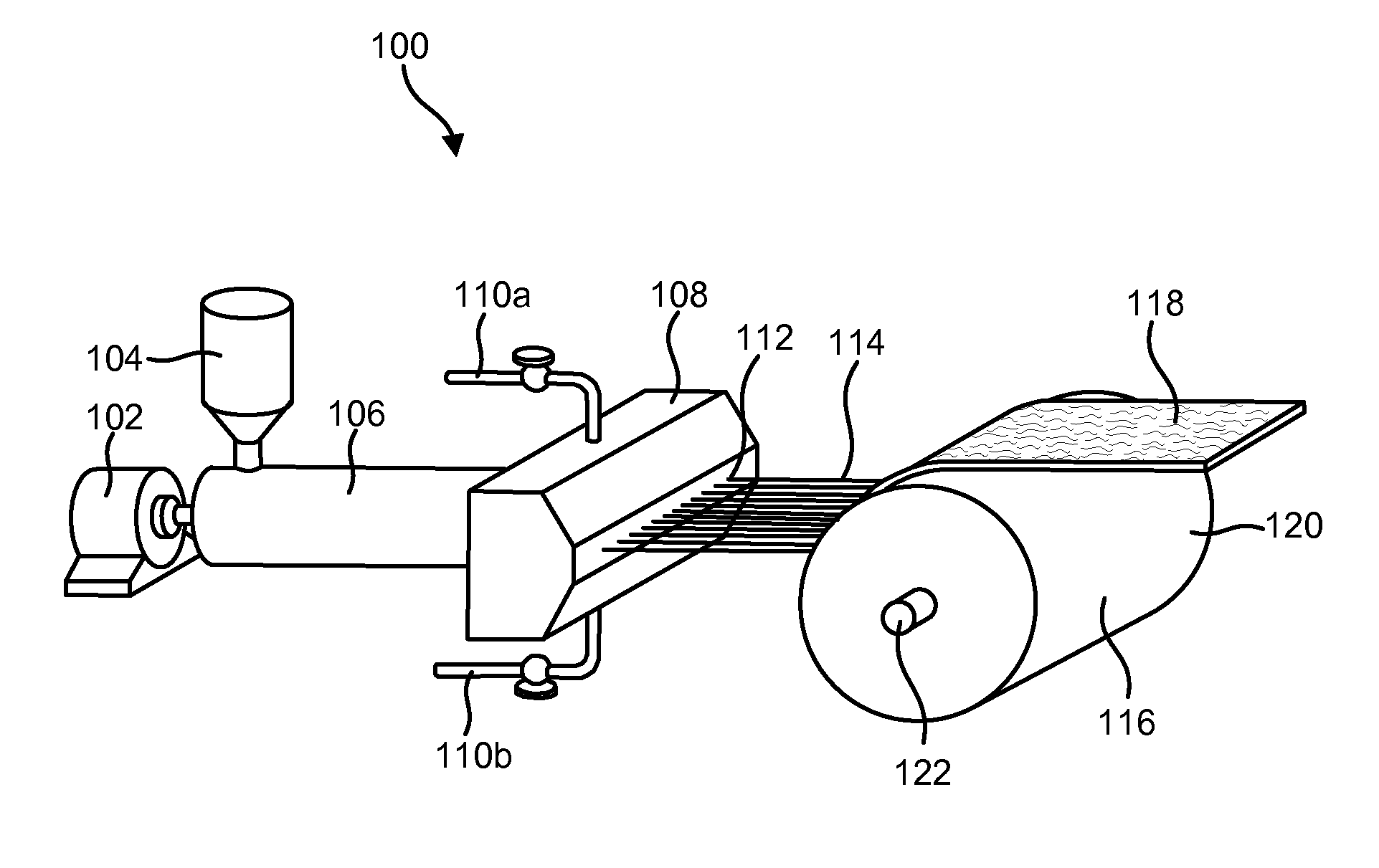

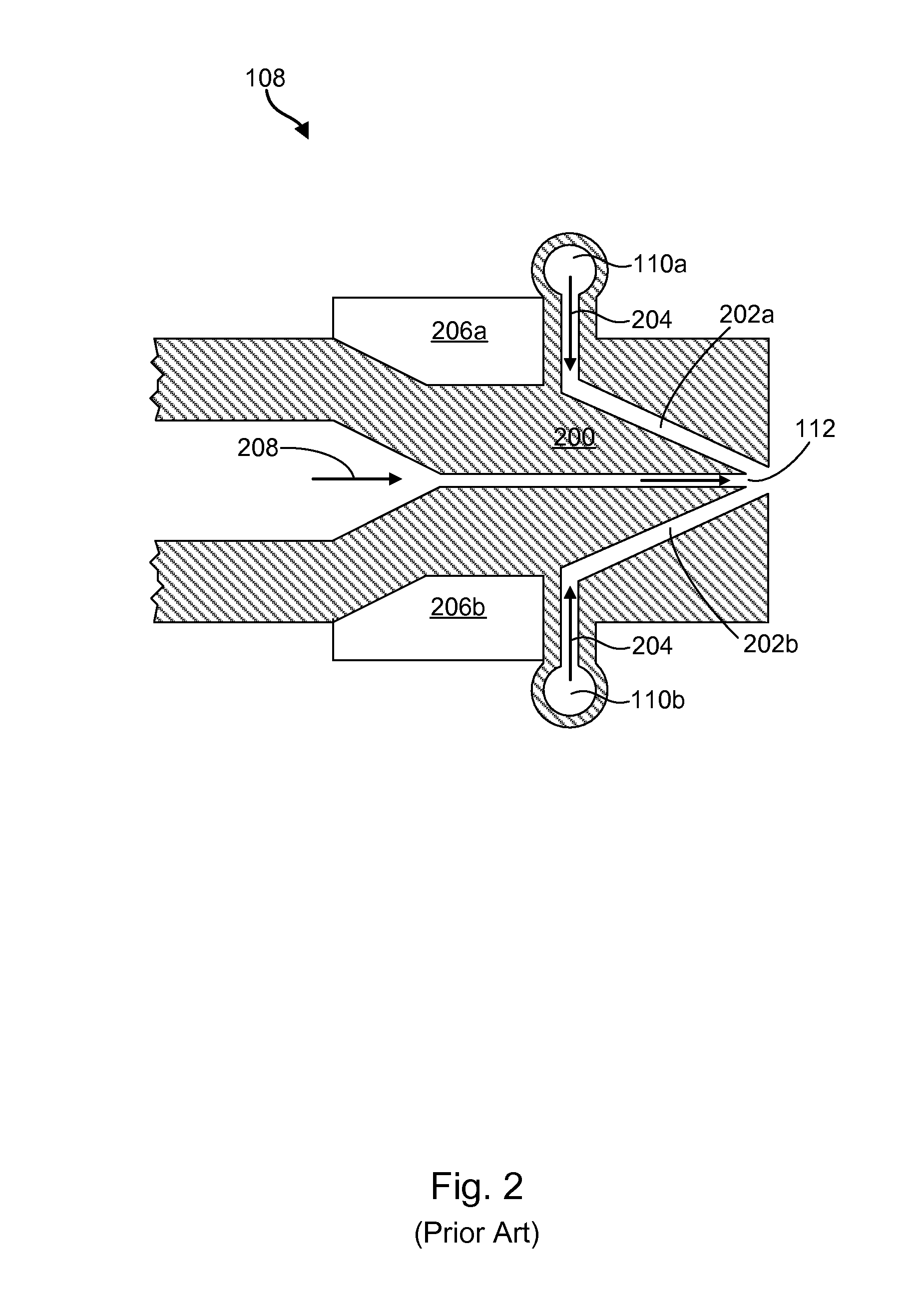

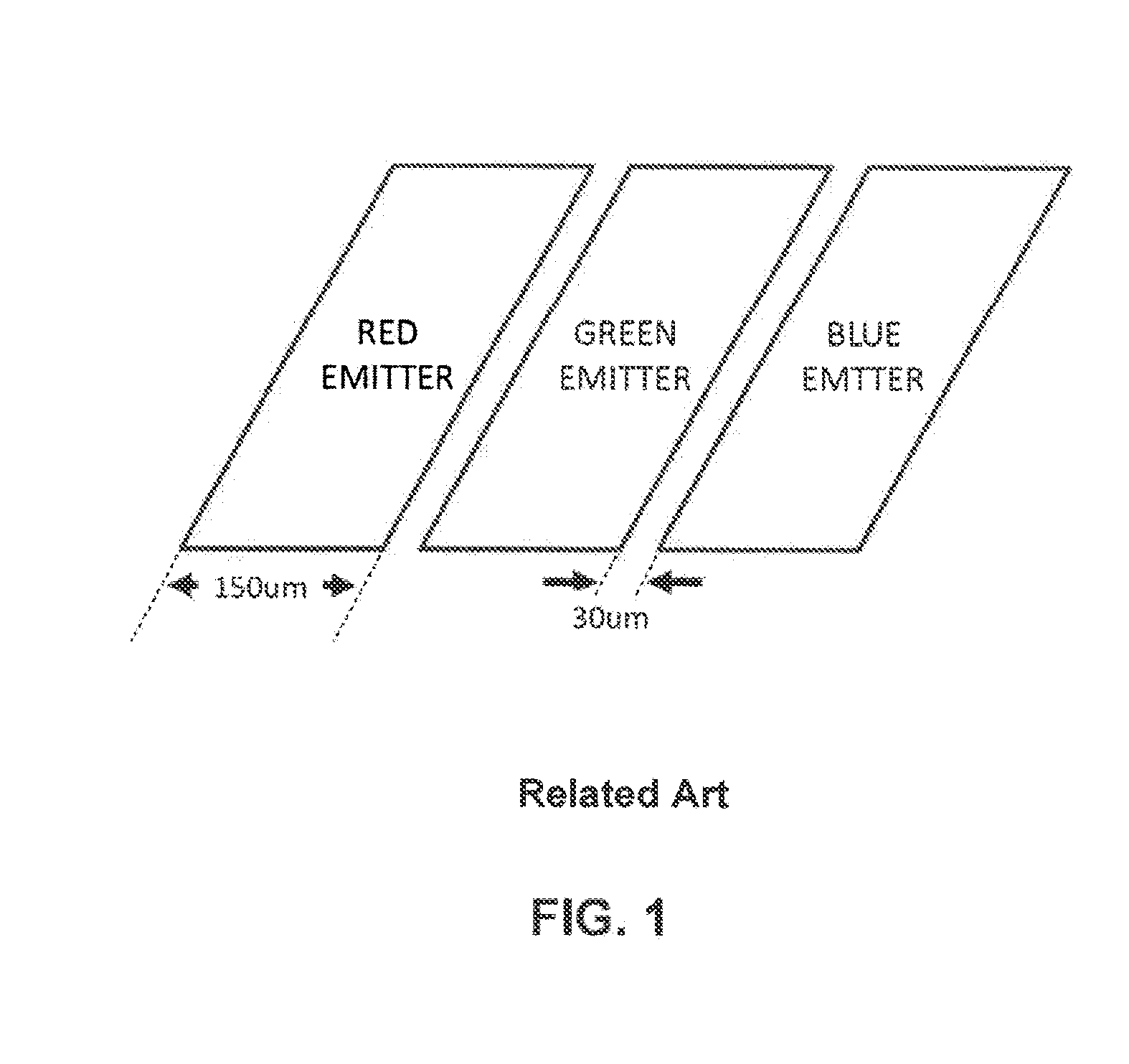

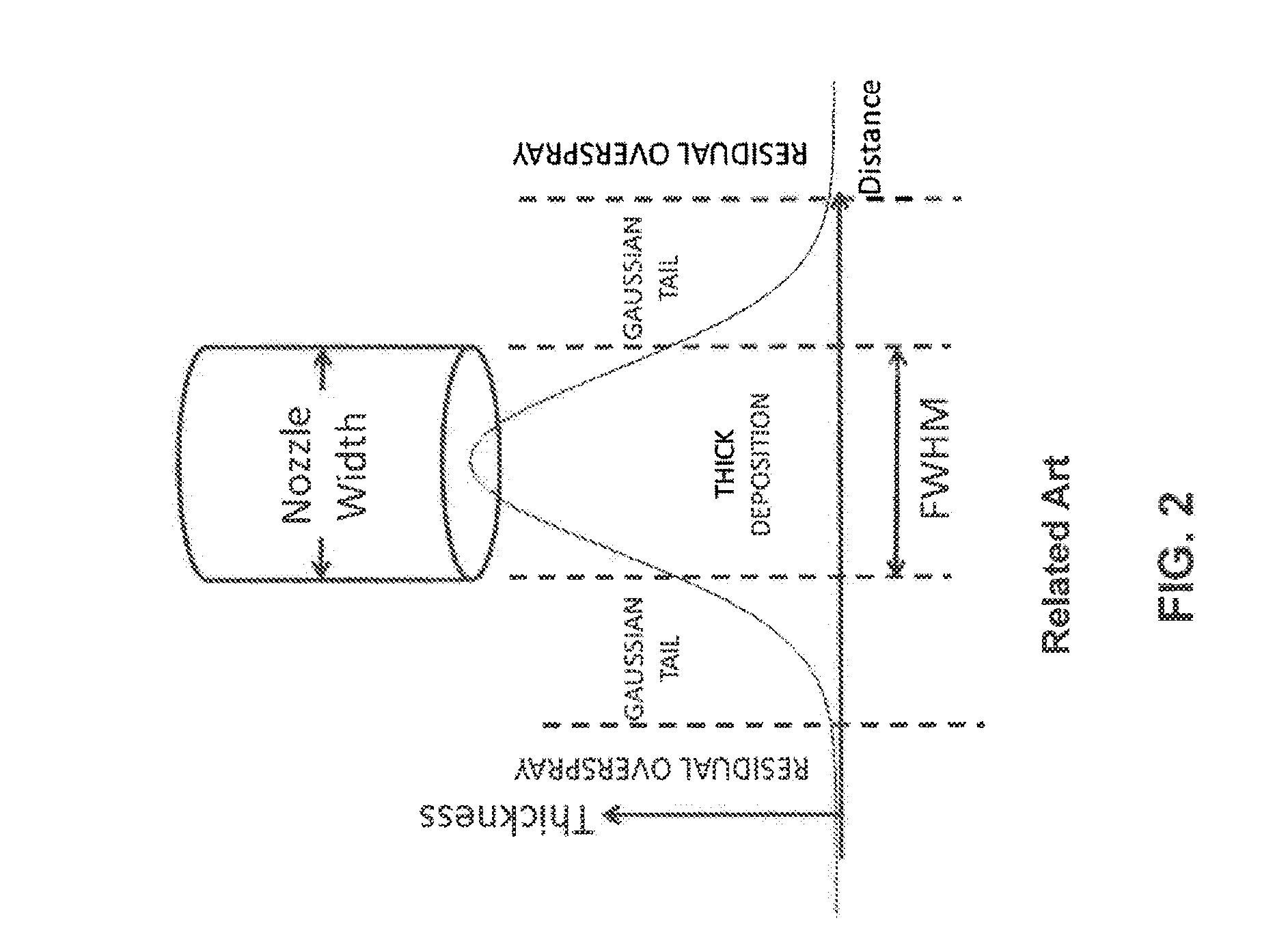

Multi-nozzle organic vapor jet printing

ActiveUS8728858B2High resolutionReducing undesirable “overspray”Liquid surface applicatorsSemiconductor/solid-state device testing/measurementLeading edgeSpray nozzle

Owner:UNIVERSAL DISPLAY

Ink jet nozzle geometry selection by laser ablation of thin walls

A novel method of fabricating the channel ends of an ink jet printhead: lithographically fabricating channels in photopolymer having the channel end blocked by a thin layer of photopolymer; sandwiching the photopolymer between two parallel substrates, one of which has an actuator for each channel; dicing through the substrates on a line perpendicular to the channels and leaving the channels and solid wall at the end of the channels intact; optionally coating the diced face including the polymer wall blocking the channel ends with a hydrophobic material; and forming nozzles in the end of the channels by laser ablating through the polymer layer at the end of the channel. Forming the nozzles after dicing and the optional coating prevents contamination of the interior of the printhead. The nozzles can be recessed from the diced edges of the substrate. Photolithographic formation of the end of the channel insures an accurate distance is maintained between the nozzle and the actuator. Improved jetting stability, directionality of the ejected drops, and drop size result from this novel fabrication method.

Owner:XEROX CORP

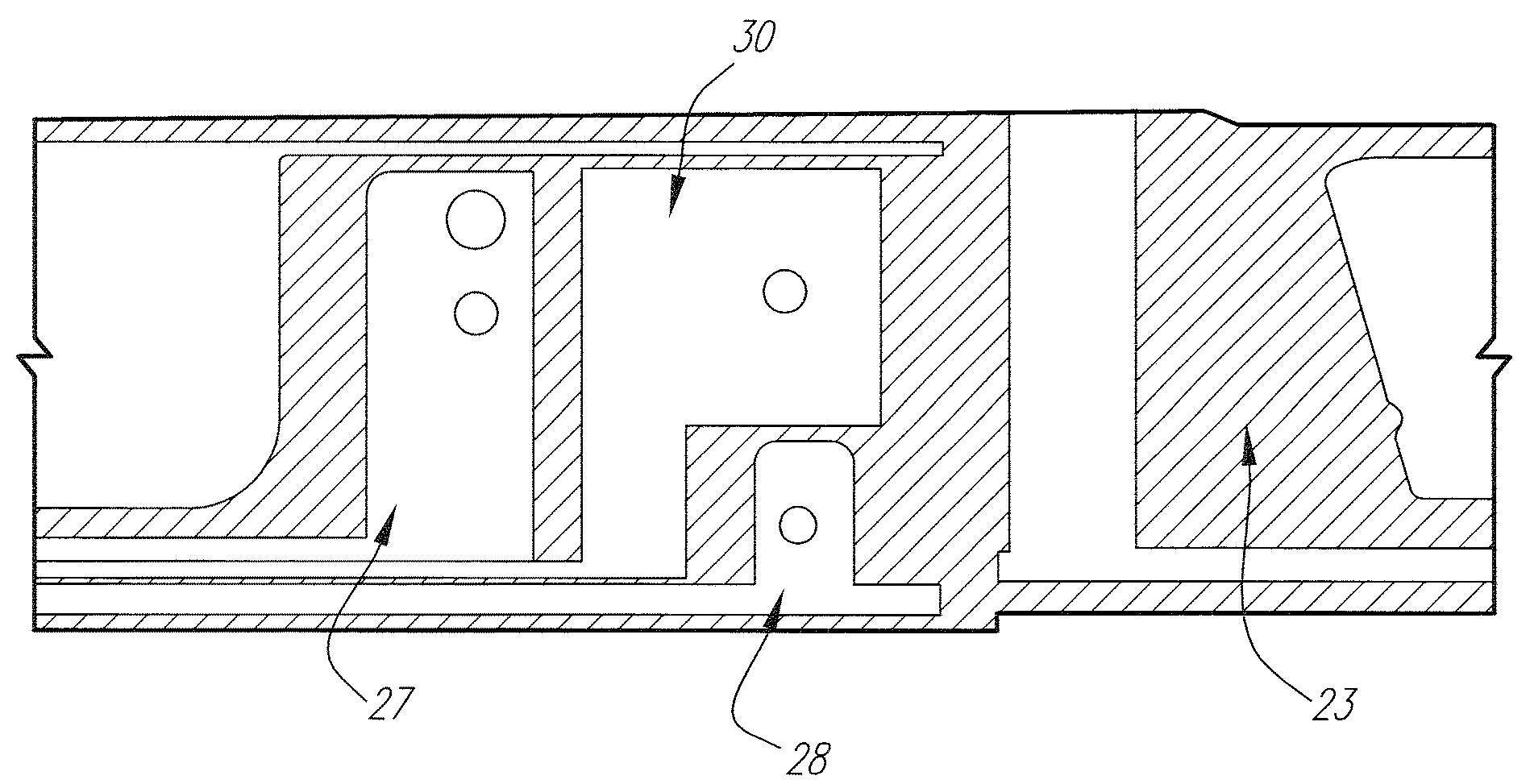

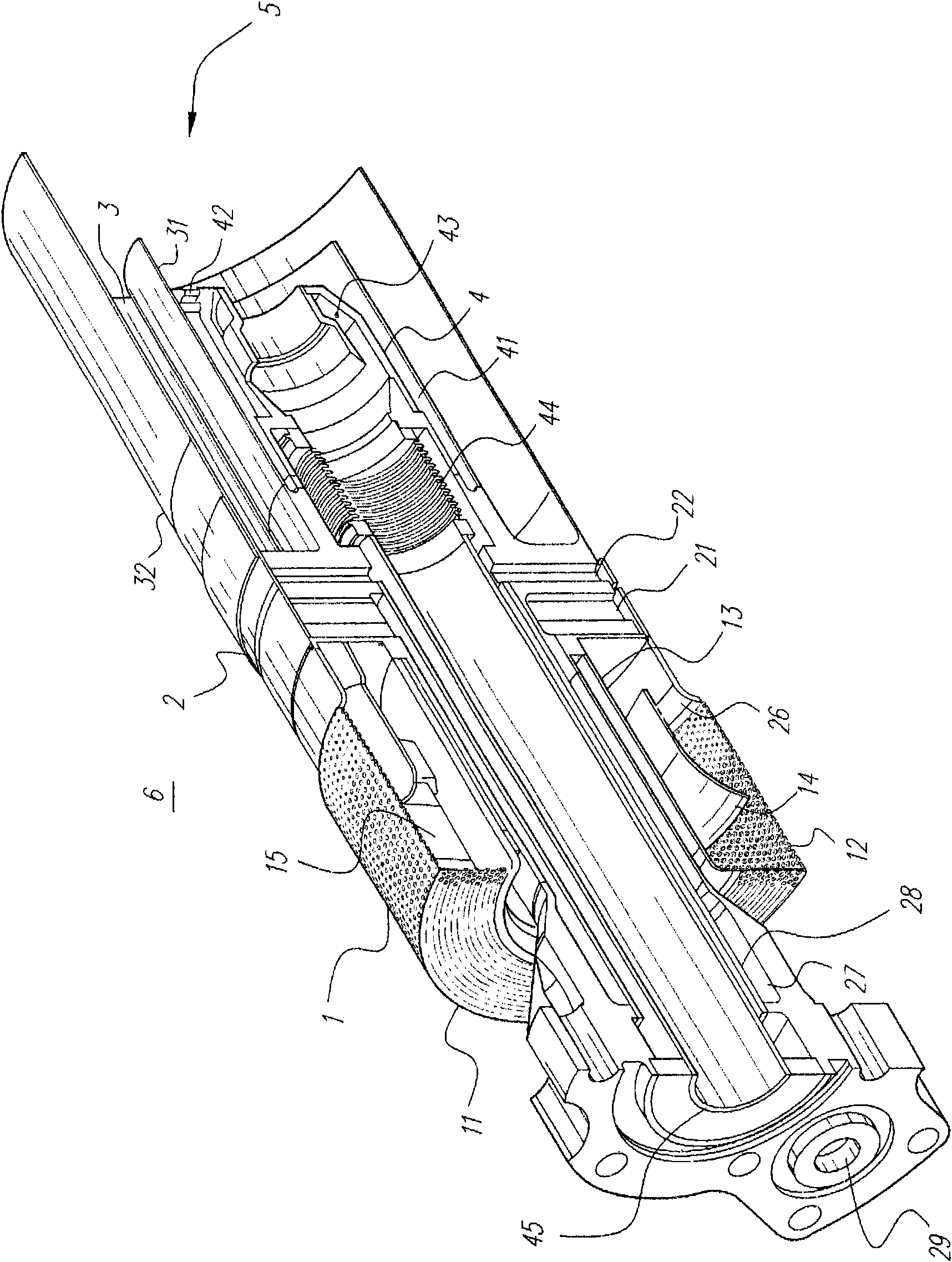

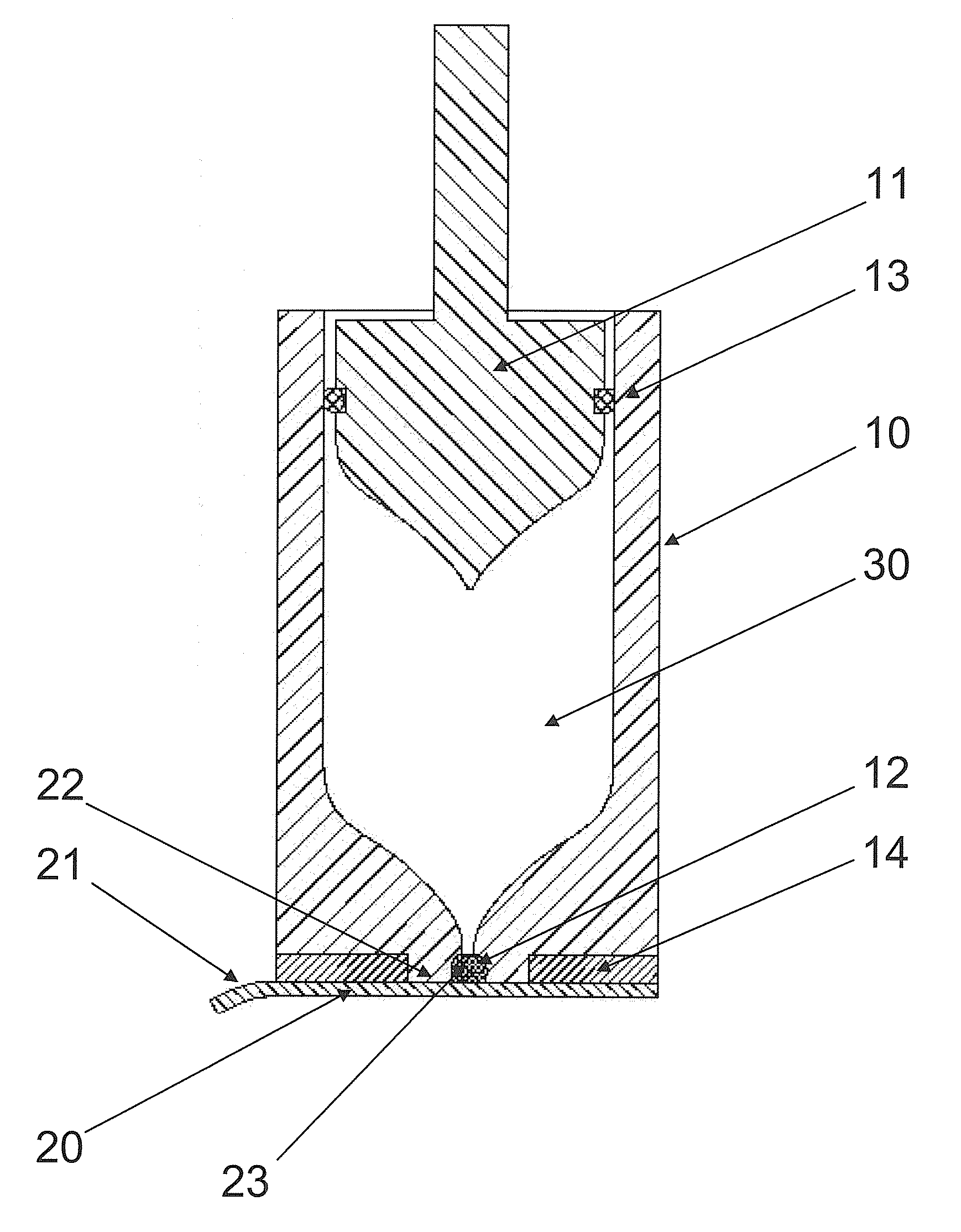

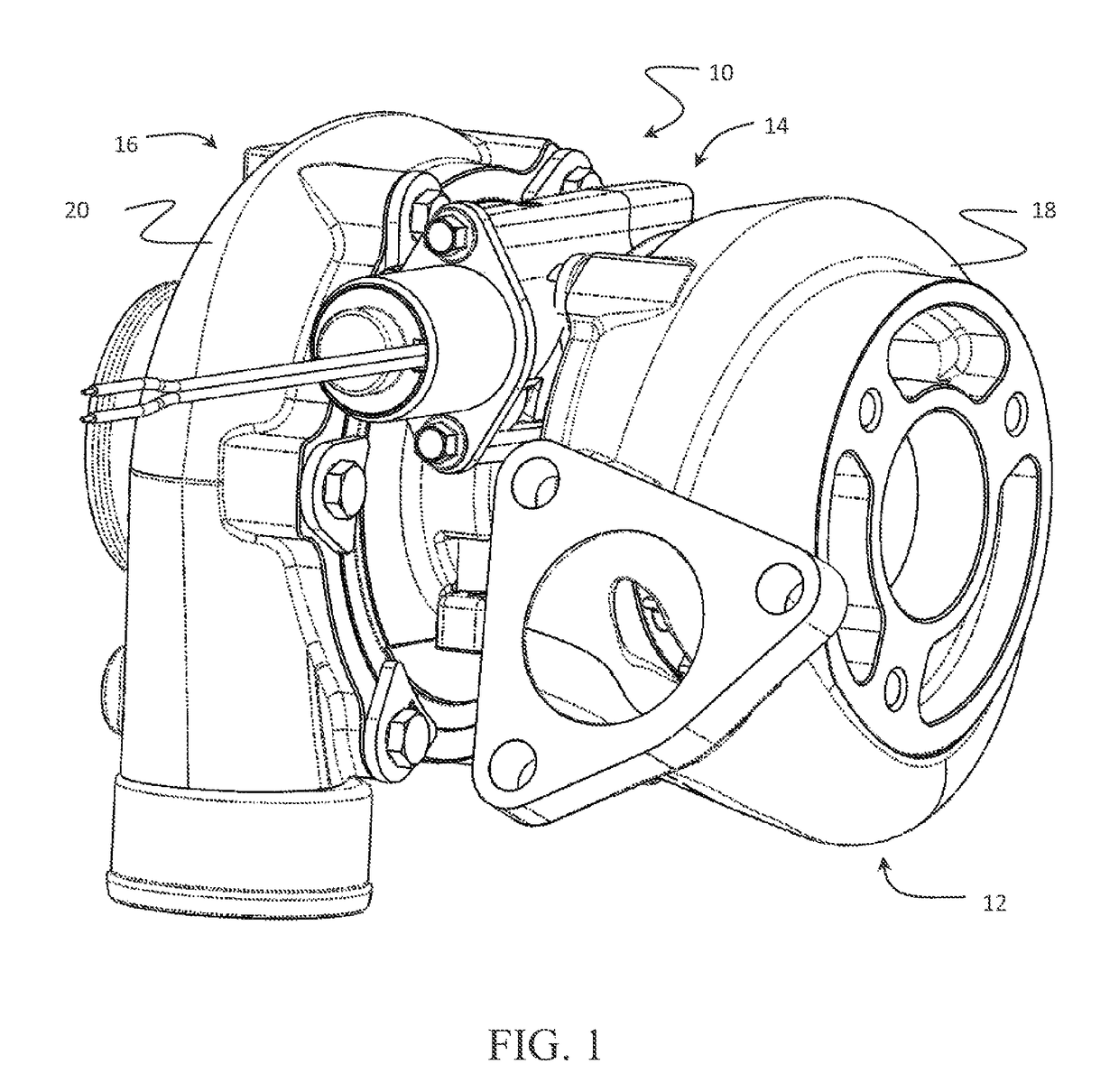

Turbine with variable inlet nozzle geometry

The invention provides a variable turbine. The variable turbine comprises a turbine wheel supported in a housing for rotation about a turbine axis with an annular inlet passageway defined between a radial face of a movable nozzle ring and a facing wall of the housing. The nozzle ring is movable along the turbine axis to vary the width of the inlet passageway. A substantially annular rib is provided either on the face of the nozzle ring (such that the minimum width of the inlet passageway is defined between the rib and a the facing wall of the housing) or on the facing wall of the housing (such that the minimum width of the inlet passageway is defined between the rib and the nozzle ring).

Owner:CUMMINS TURBO TECH

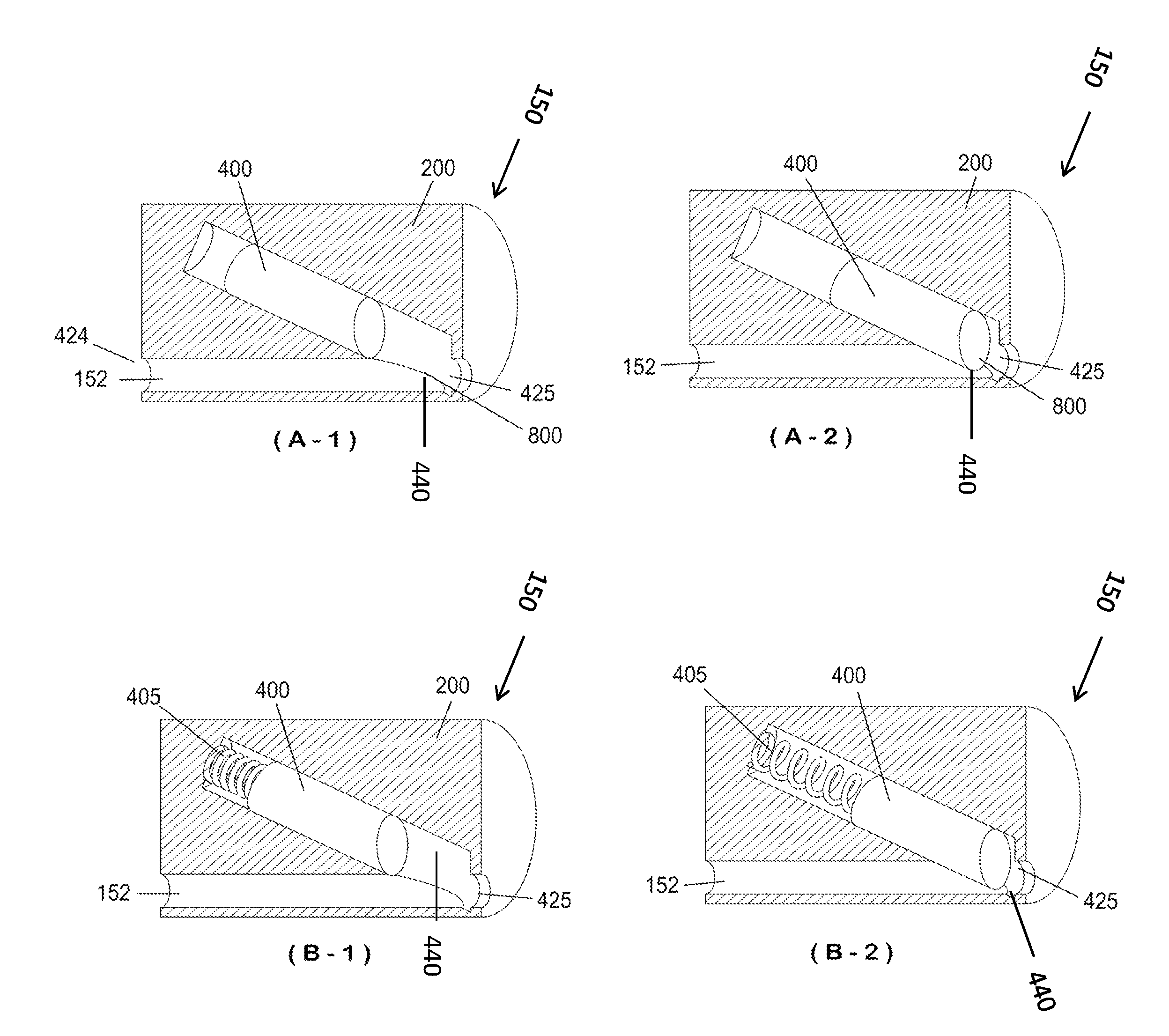

Multi-nozzle organic vapor jet printing

ActiveUS20140057390A1High resolutionReducing undesirable “overspray”Solid-state devicesVacuum evaporation coatingLeading edgeGobio gobio obtusirostris

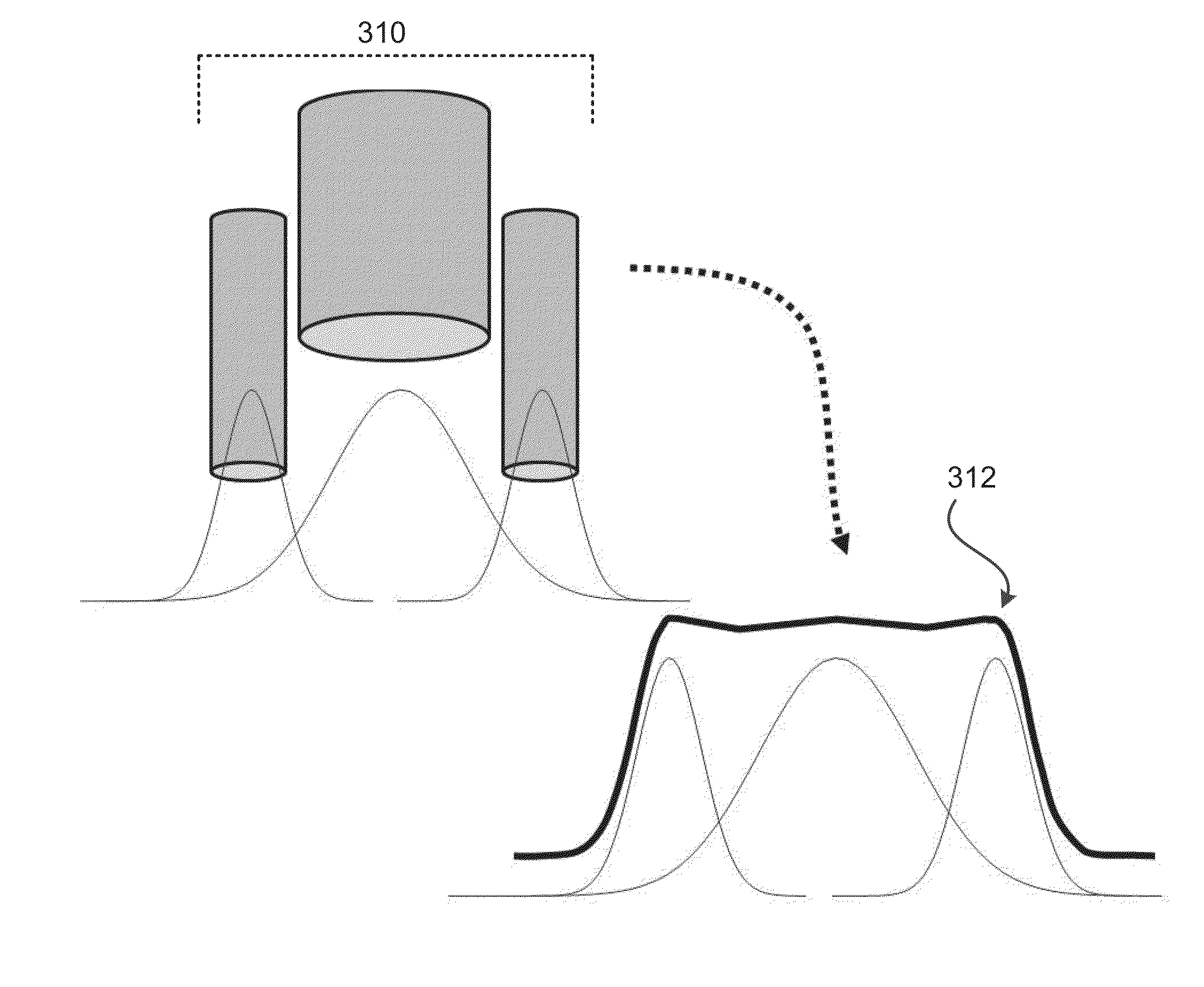

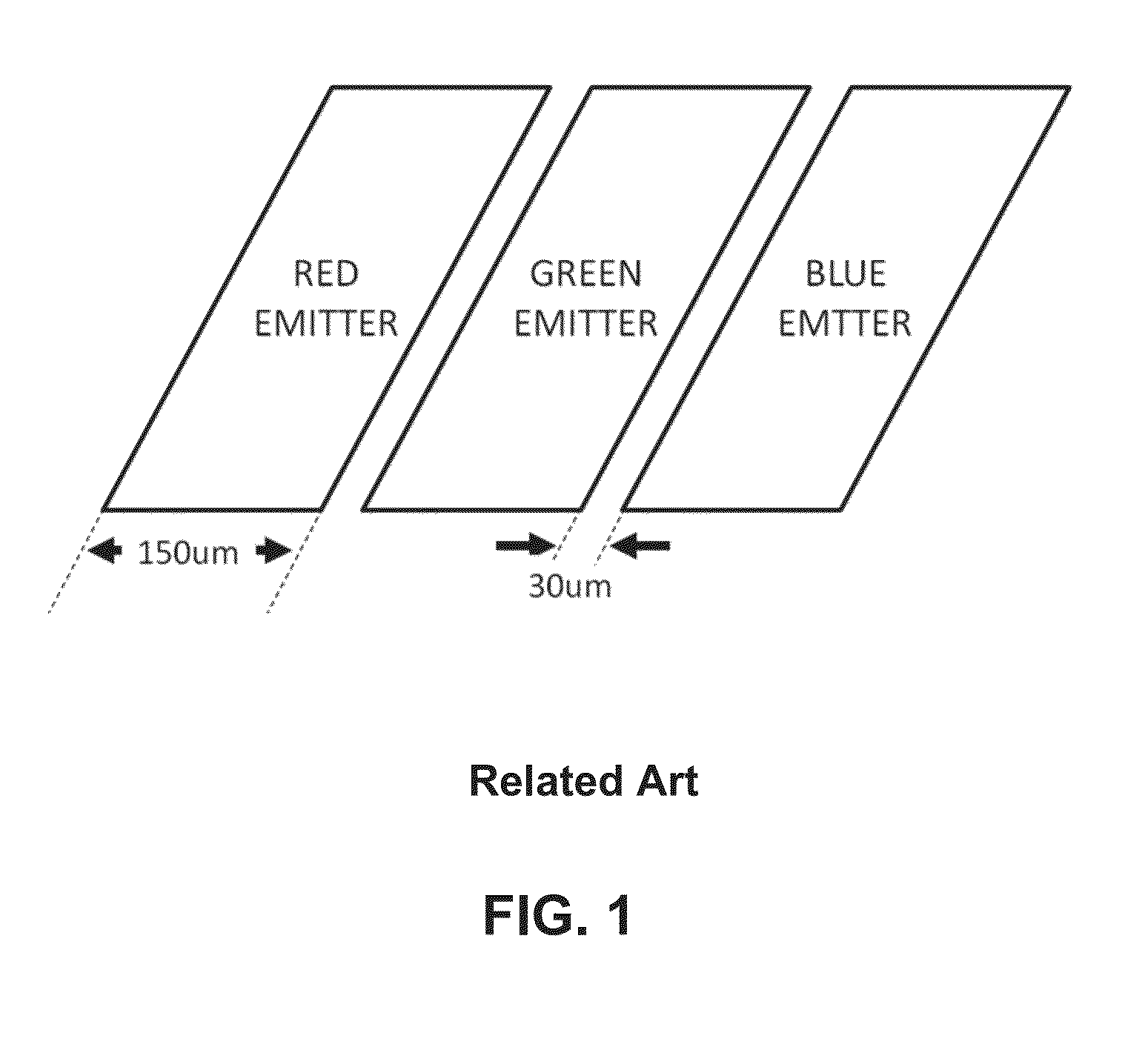

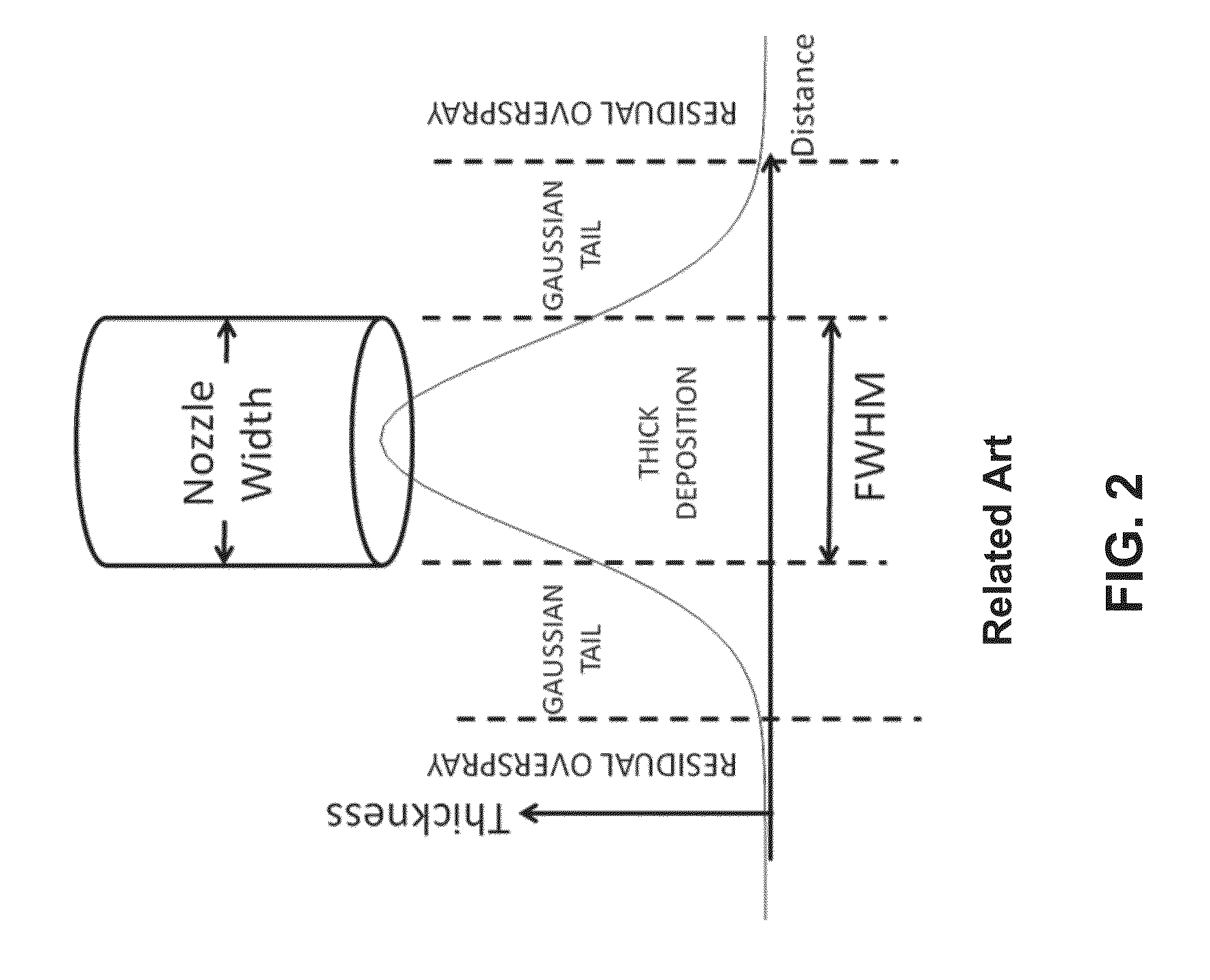

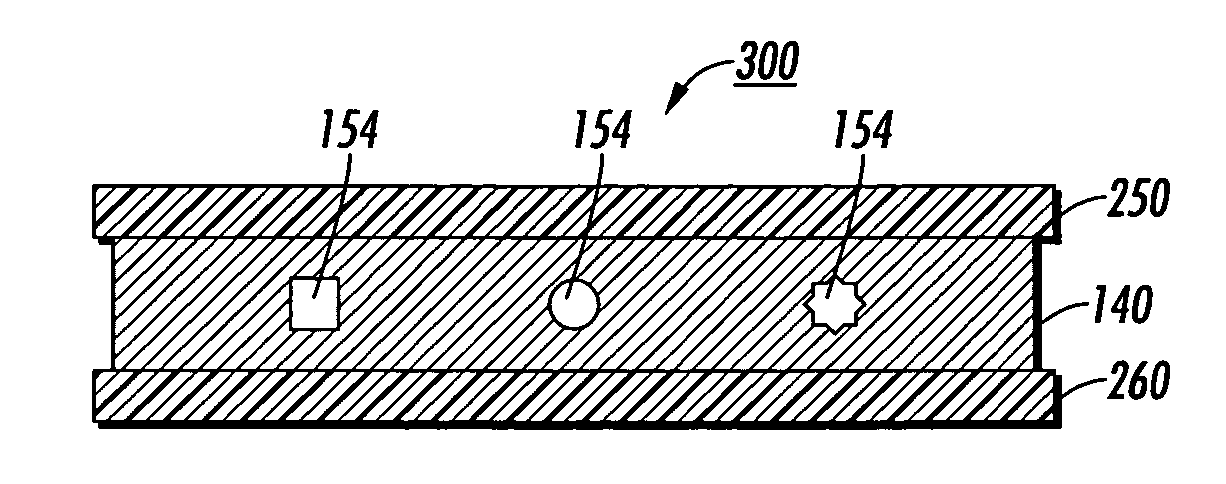

Systems and methods are provided in which individual elements of a thin patterned film are deposited by two or more nozzles having different geometries. The different nozzle geometries may include one or more of different throttle diameters, different exhaust diameters, different cross-sectional shapes, different bore angles, different wall angles, different exhaust distances from the substrate, and different leading edges relative to the direction of movement of the nozzles or the substrate. Methods may include steps of ejecting a carrier gas and a material from a plurality of nozzles and depositing the material on the substrate in a plurality of laterally spaced elements, each of the elements deposited by a separate nozzle group. At least one of the nozzles in a group of nozzles depositing an element may be configured to deposit the material on the substrate in a width that is smaller than the width of the element.

Owner:UNIVERSAL DISPLAY

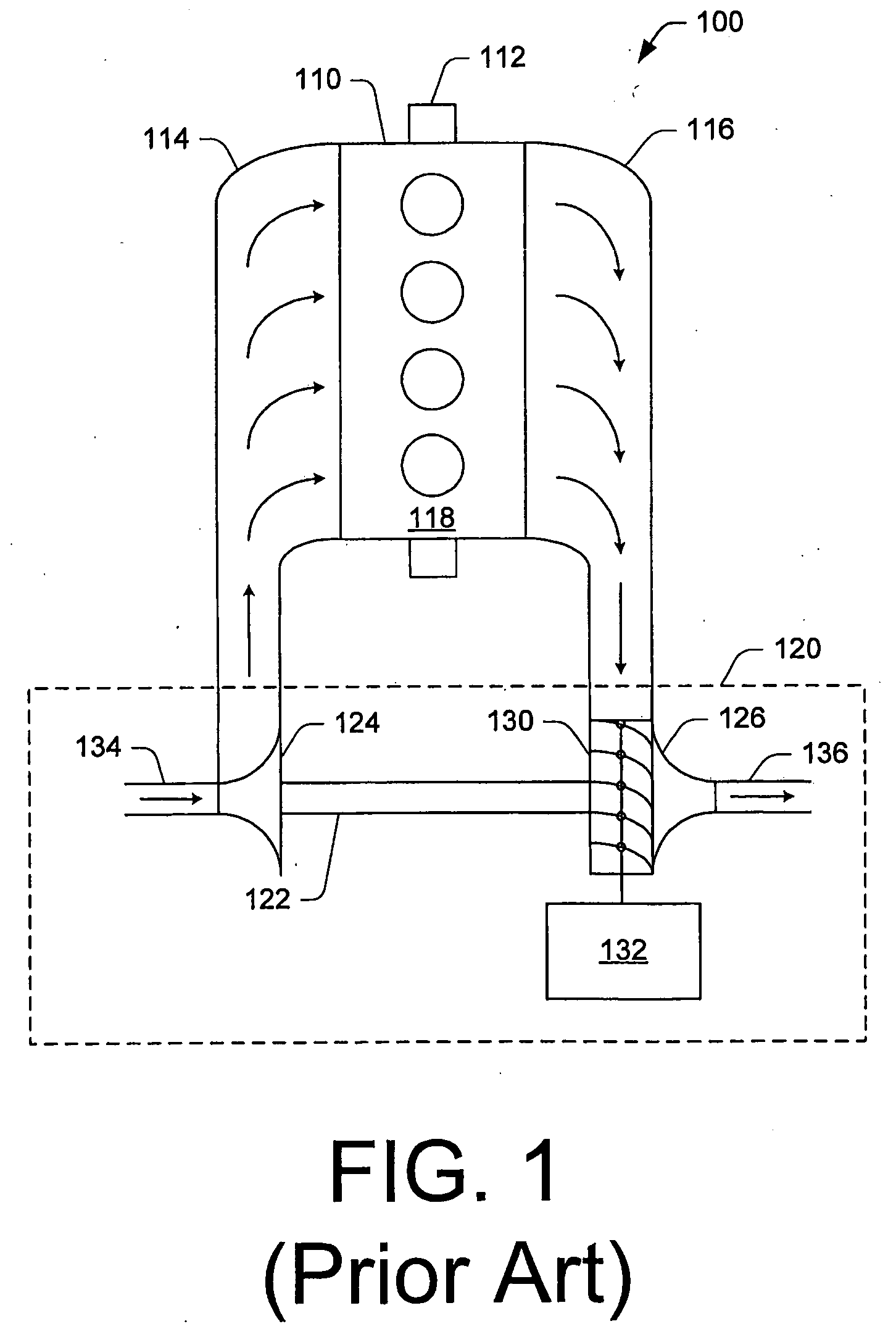

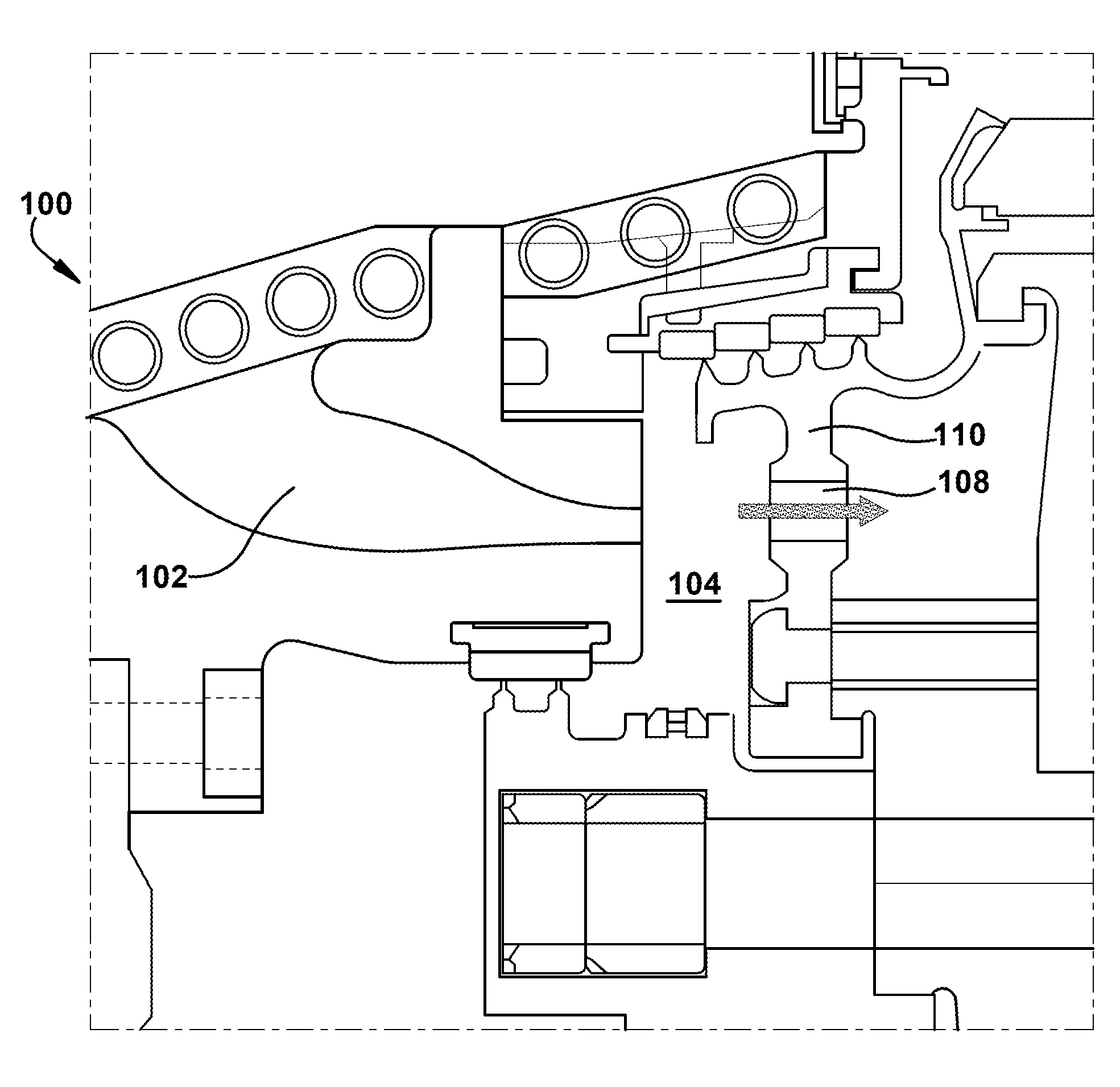

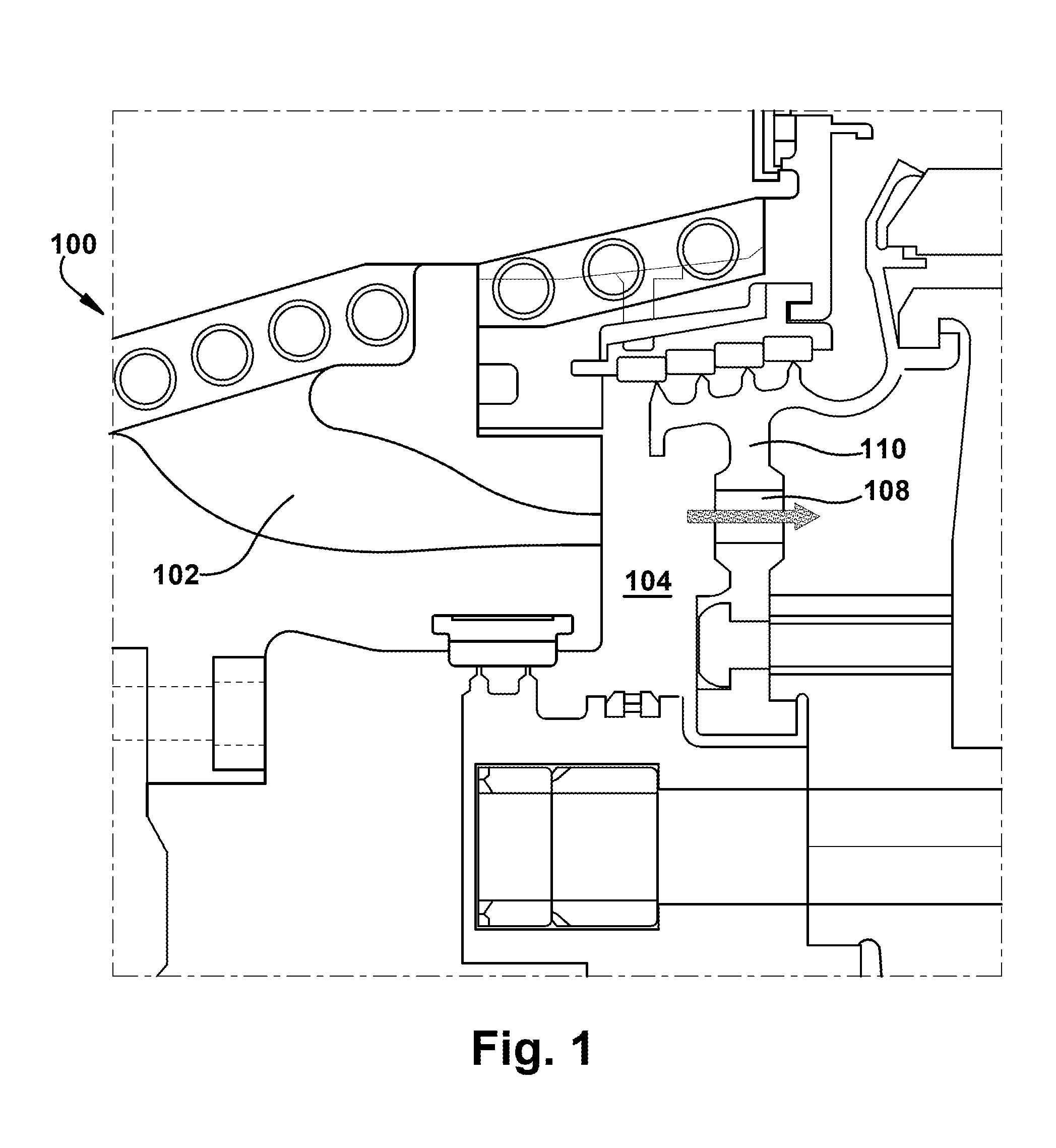

Methods, systems and/or apparatus relating to inducers for turbine engines

An inducer that includes a profiled throat. In some embodiments, the inducer includes a conical shape upstream of the profiled throat with a relatively large circular inlet that narrows to the profiled throat and, downstream of the profiled throat, a downstream section that broadens from the profiled throat. The profiled throat may include an approximate convergent-divergent nozzle geometry.

Owner:GENERAL ELECTRIC CO

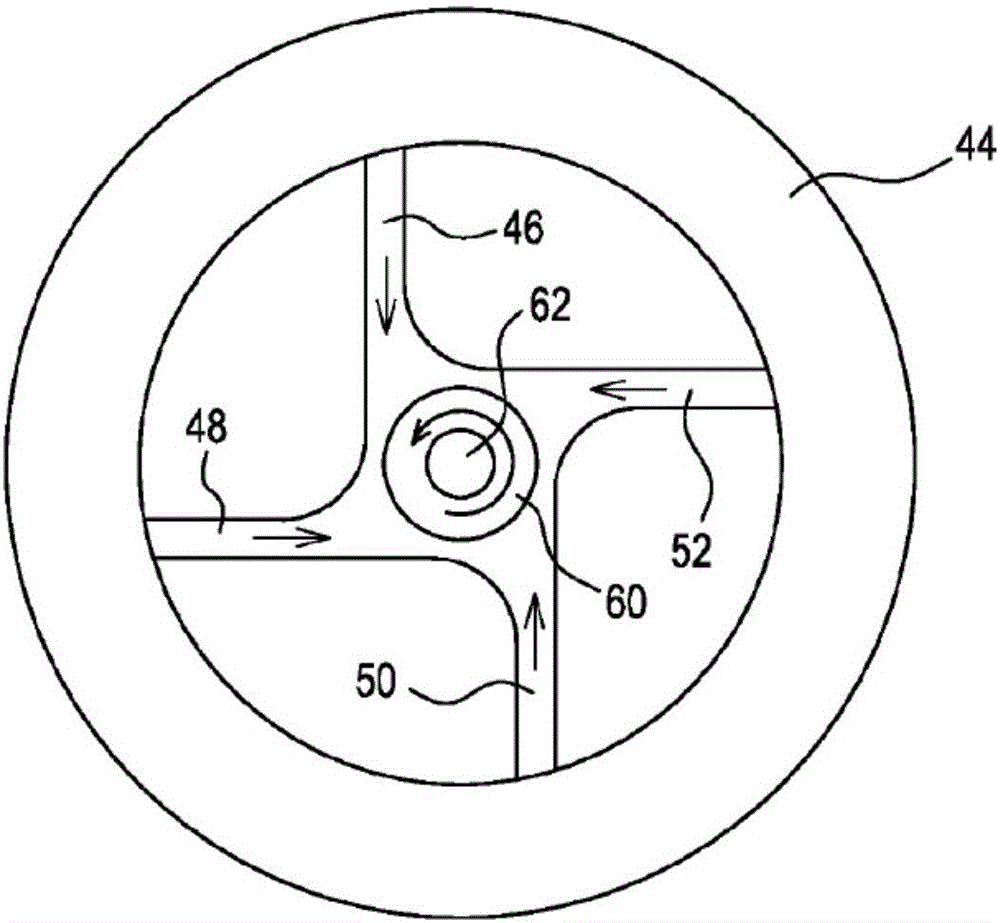

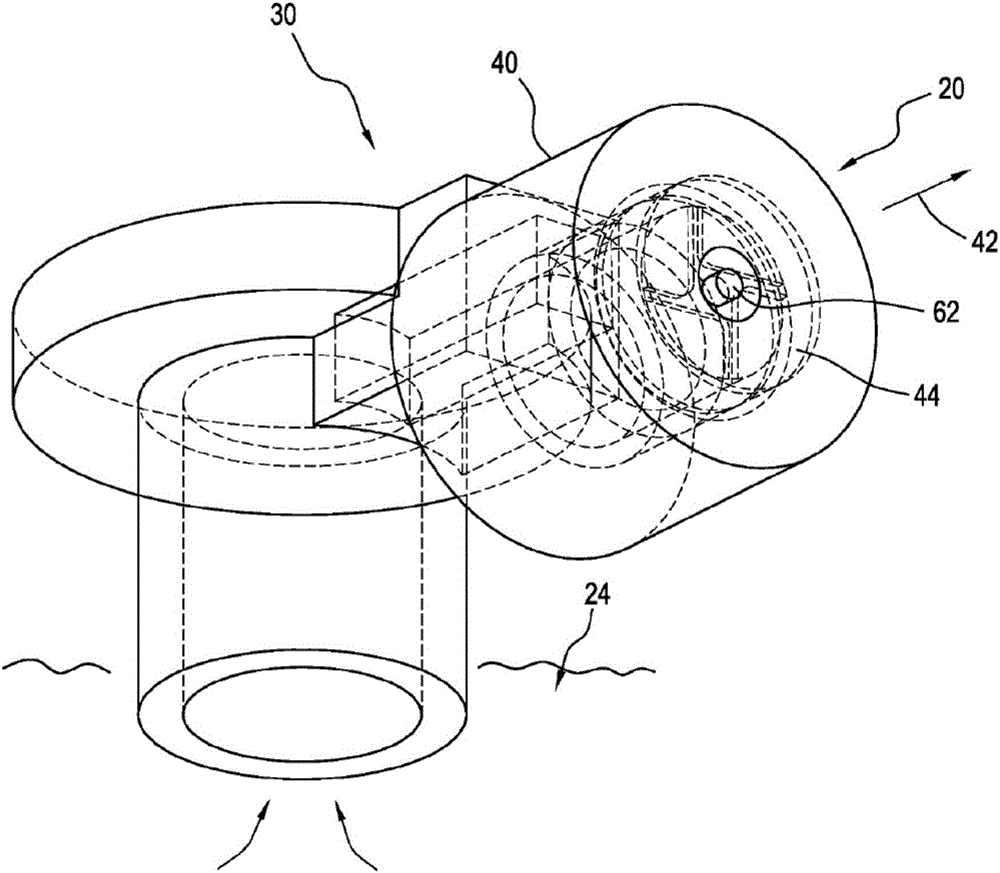

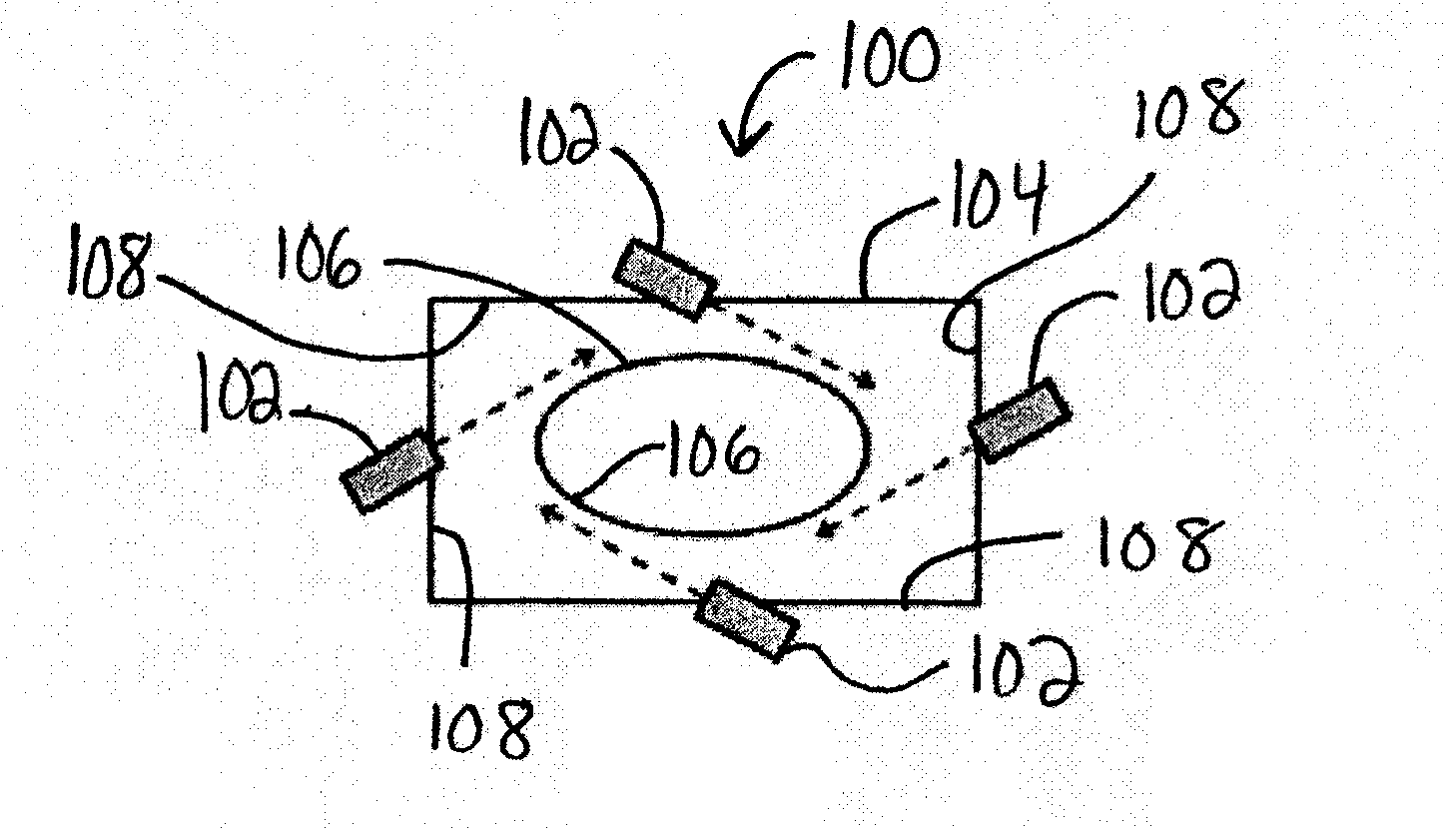

Multi-inlet, multi-spray fluidic cup nozzle with shared interaction region and spray generation method

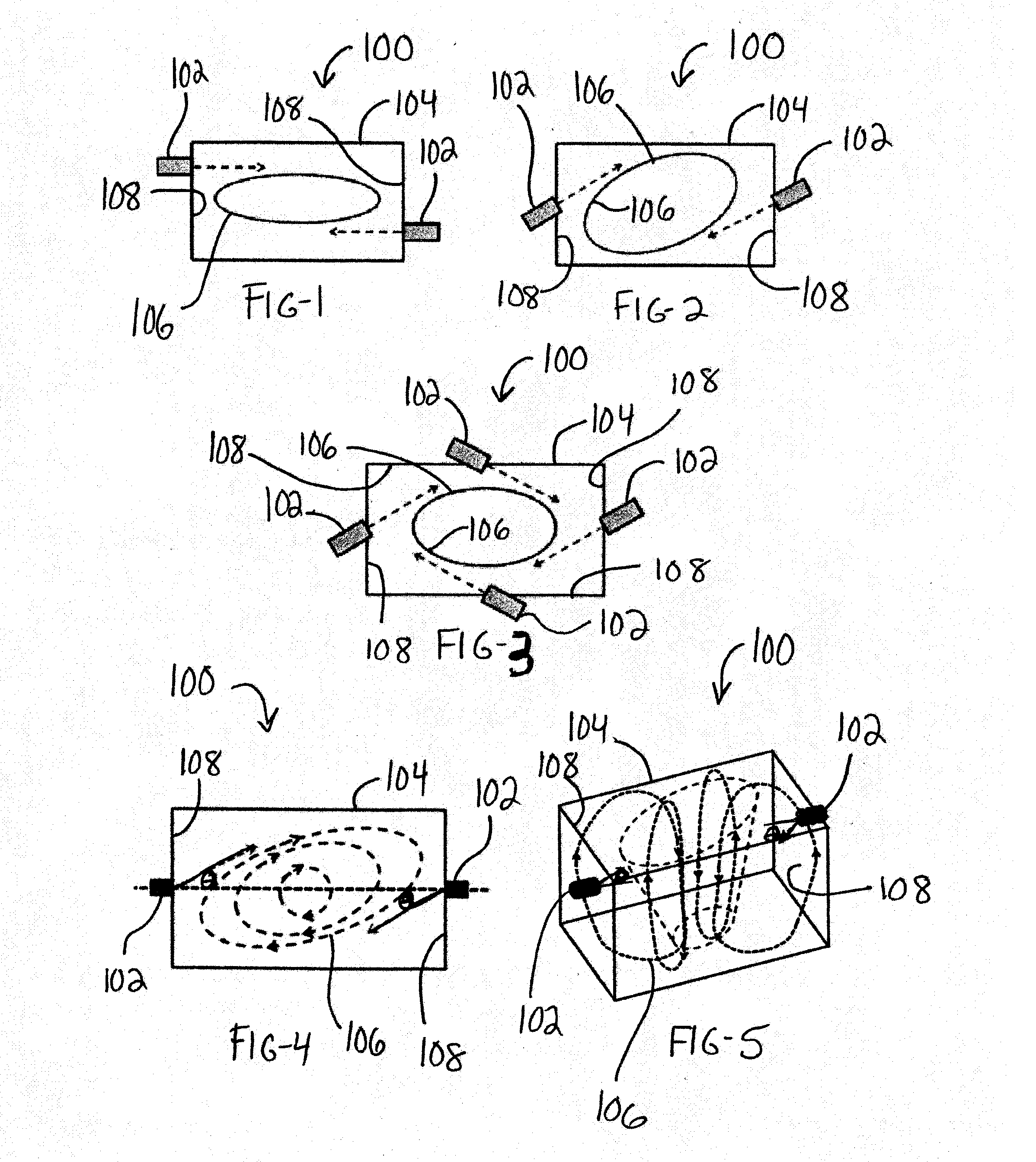

A conformal, cup-shaped fluidic oscillator spray nozzle member (100, 200, 300, 400, 500) is configured to generate one or more oscillating sprays from fluid flowing into a substantially open proximal end and distally into a substantially closed distal end wall with one or more centrally located orifices defined therein. A multi-input, multi-output cup-shaped fluidic oscillator ( 200, 300, 400) is configured to generate a selected fluid spray from a plurality of (e.g., 2-8) fluid product inlets which are configured in interacting pairs and feed into a common interaction region of the fluidic nozzle geometry. Optionally, an outlet "A" can be positioned in the interaction region and allow for air entrainment into the interaction region or external oscillating spray streams to generate a foamed spray of fluid product.

Owner:DLHBOWLES INC

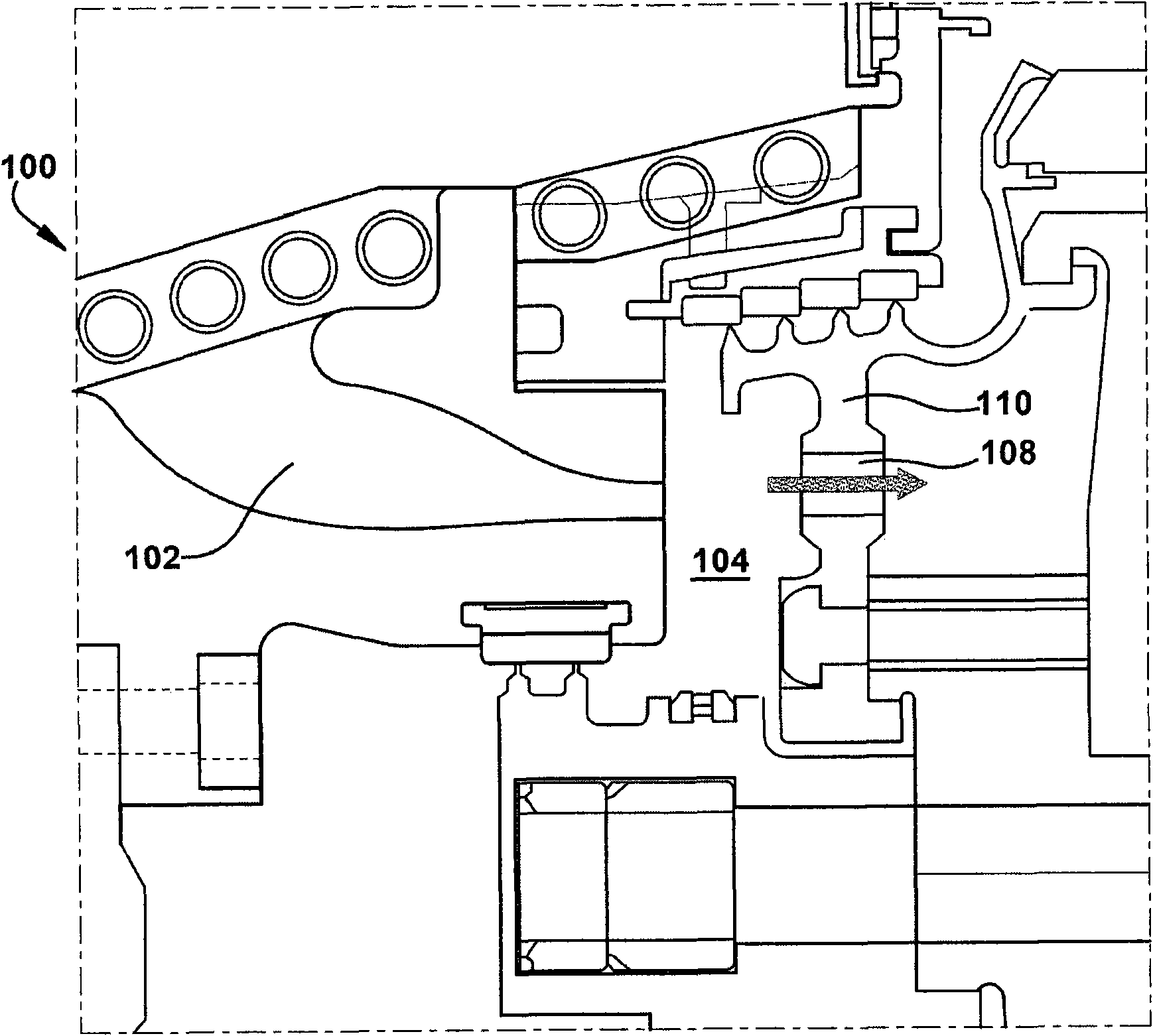

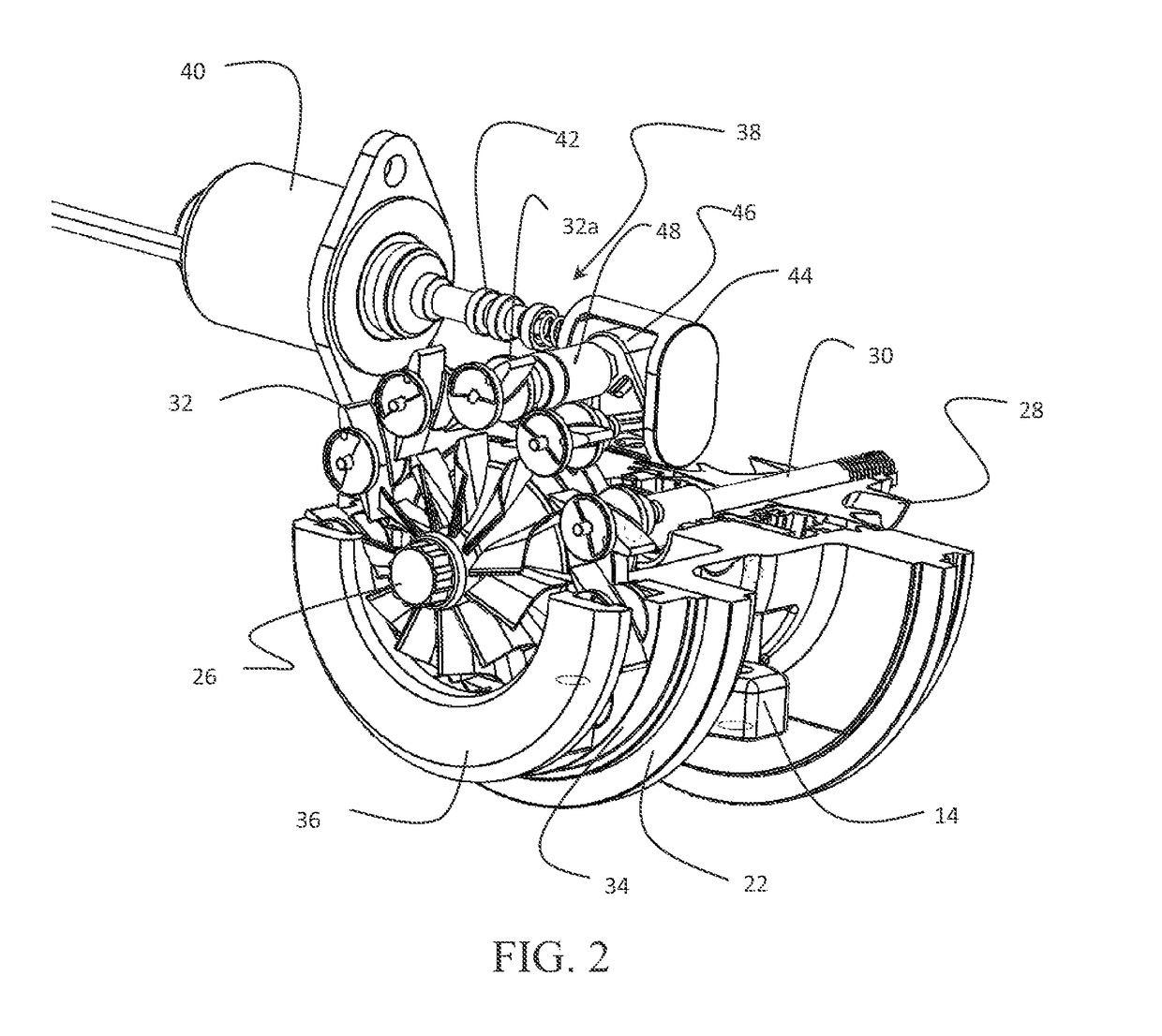

Axial loading management in turbomachinery

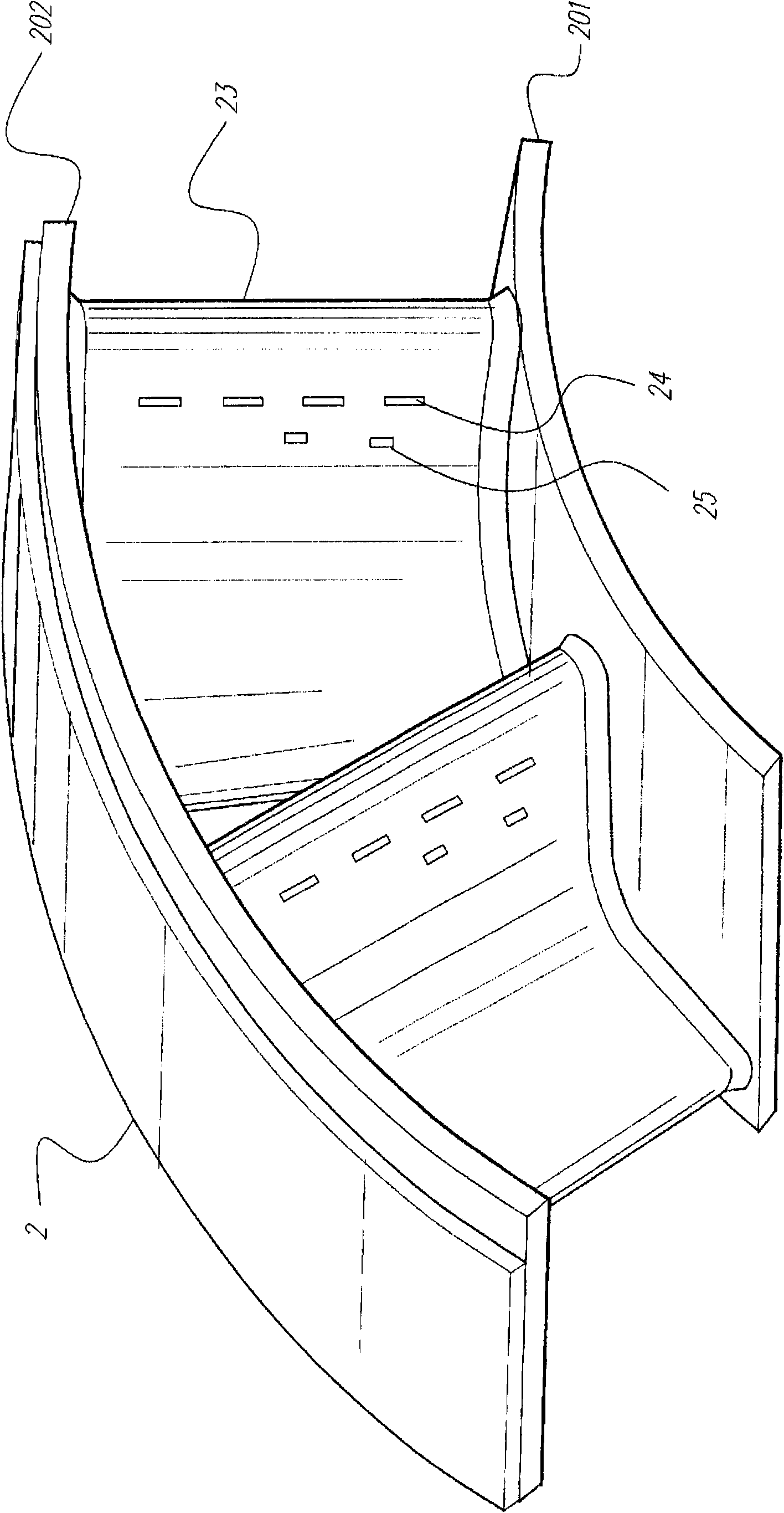

ActiveUS7305826B2Reduce loadUniform pressureWind motor controlPump componentsTurbochargerNozzle geometry

Exemplary vanes for a turbocharger having variable nozzle geometries are disclosed. In one aspect, each of the vanes includes two axial surfaces that are on opposite sides of the vane. The opposite axial surfaces include two corresponding chambers. These chambers are partially exposed to each other through an aperture. Such an aperture allows for some degree of equalization of the pressures in the chambers and, thereby, reduces the axial load exerted by a vane, for example, on the unison ring. In another aspect, each of the vanes includes two opposite airfoil surfaces. At least one of the airfoil surfaces includes a notch that allows a chamber in the nozzle to be pressurized by the exhaust gas. The pressure in the chamber creates a counteracting force that reduces the axial load exerted by a vane.

Owner:GARRETT TRANSPORATION I INC

Multi-fuel-loop used for premixing synthetic gas/ng dln in nozzle

The invention relates to a multi-fuel-loop used for premixing synthetic gas / NG DLN in nozzle. Concretely, a fuel / air premixer used for a burner in a combustion system of a gas turbine comprises an air inlet (1 and 6), a fixed nozzle geometry structure (4) and a annular mixing channel (3). The fuel / air premixer mixes fuel and air in the annular mixing channel to inject the mixture in a burner reaction area (5). A plurality of fuel sources (21 and 22) are connected with the fixed nozzle geometry structure, and cooperate with the fixed nozzle geometry structure to realize various fuel flow changes such as fuel type change, fuel doping change, volume flow change and pressure ratio change.

Owner:GENERAL ELECTRIC CO

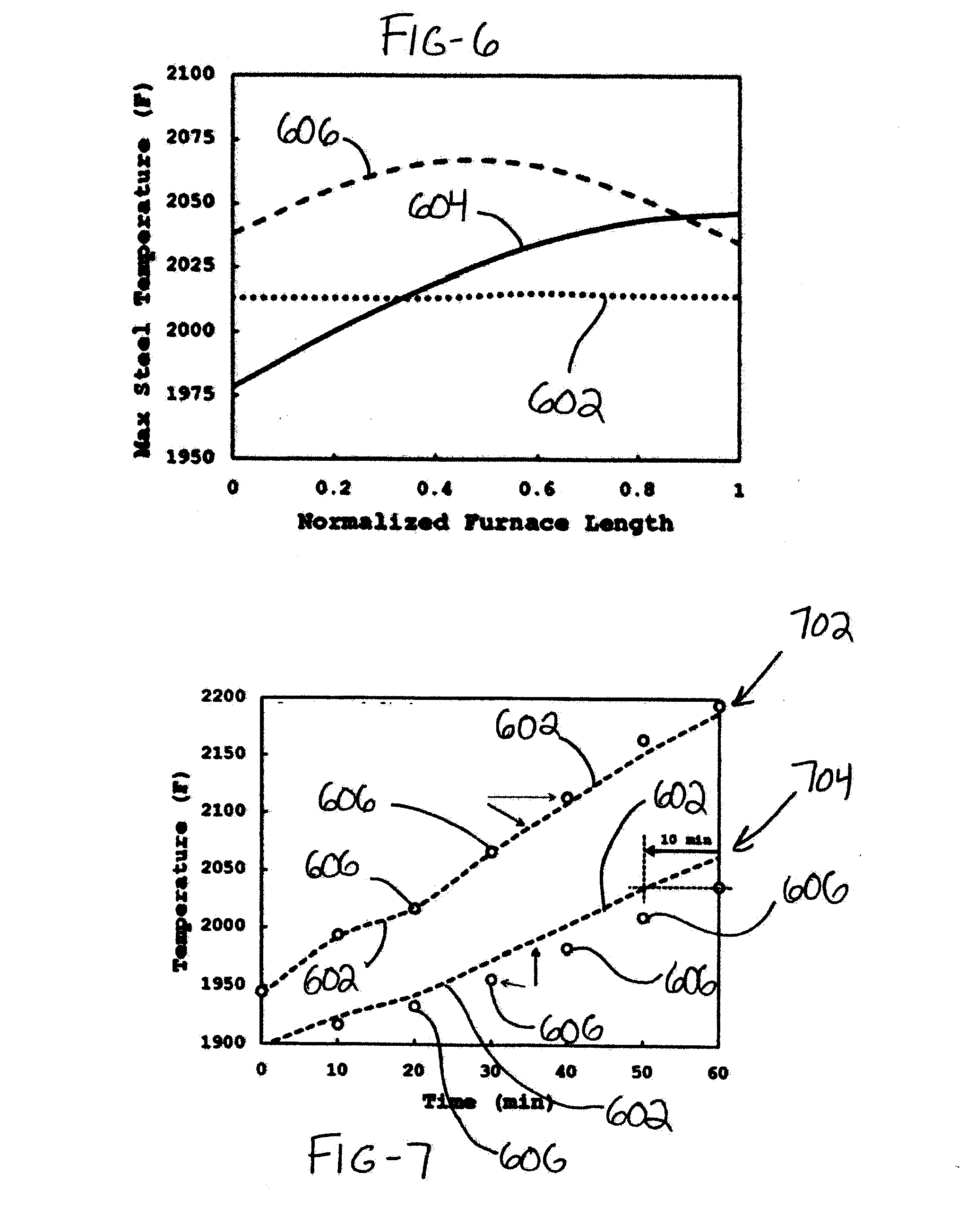

Oxy-Fuel Furnace and Method of Heating Material in an Oxy-Fuel Furnace

InactiveUS20130095437A1Increase convective heatingImprove form factorCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAngular velocityEngineering

An oxy-fuel furnace and method of heating material in an oxy-fuel furnace are disclosed. The method includes combusting oxygen and fuel with an oxy-fuel burner arrangement in the oxy-fuel furnace forming combustion gases, and maintaining a vortex including the combustion gases within a central region of an enclosure of the oxy-fuel furnace. The oxy-fuel burner arrangement includes a plurality of high momentum oxy-fuel burners arranged at an angle to generate the vortex, the angle being greater than 15 degrees but less than 75 degrees with respect to a furnace wall boundary of the enclosure, an angular velocity of greater than 0.07 radians per second, or a combination thereof. The furnace includes an oxy-fuel burner arrangement including at least two high momentum oxy-fuel burners having high shape factor nozzle geometries, and an enclosure. The vortex increases convective heating within the enclosure and uniformity of heating within the enclosure.

Owner:AIR PROD & CHEM INC

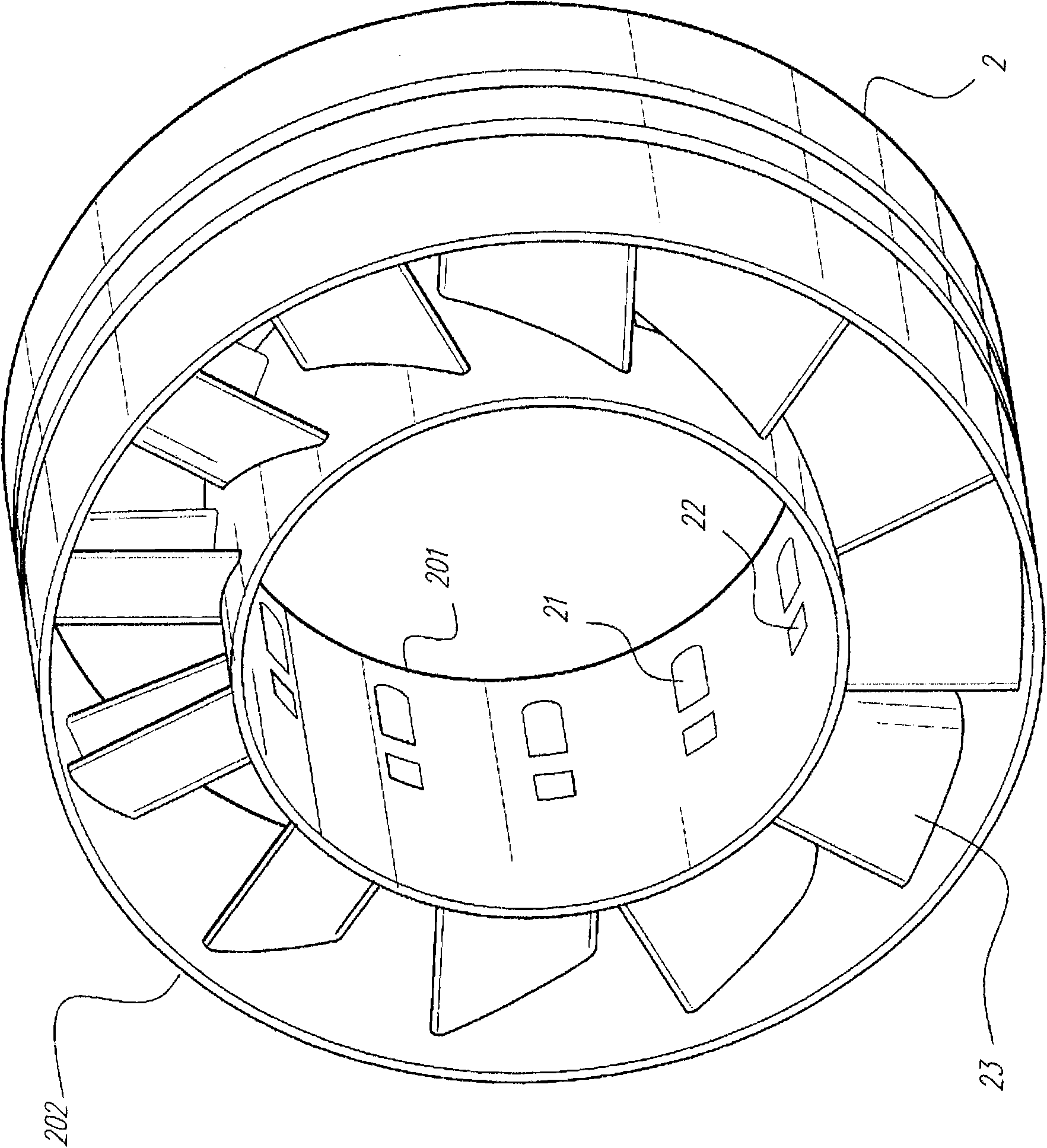

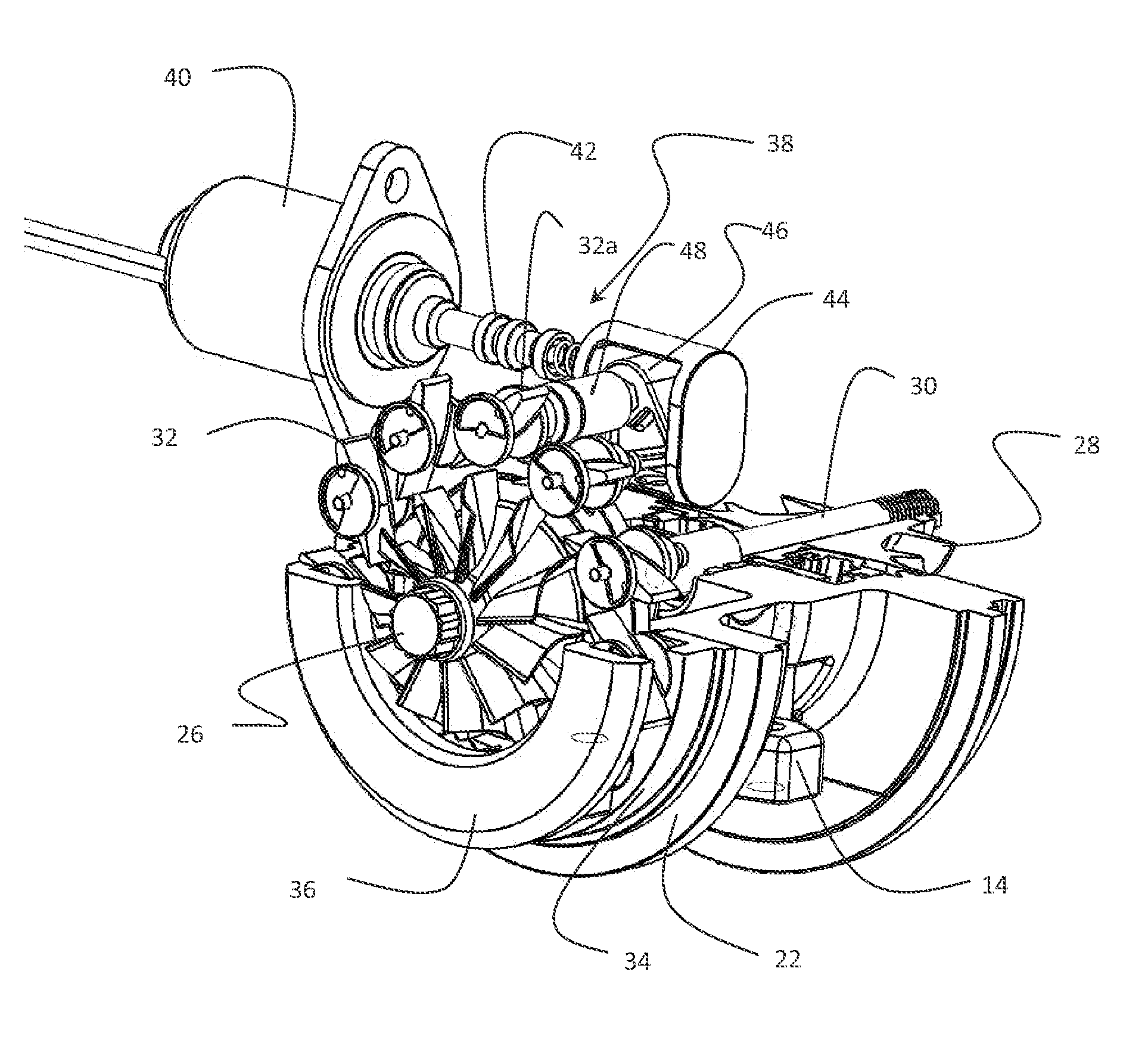

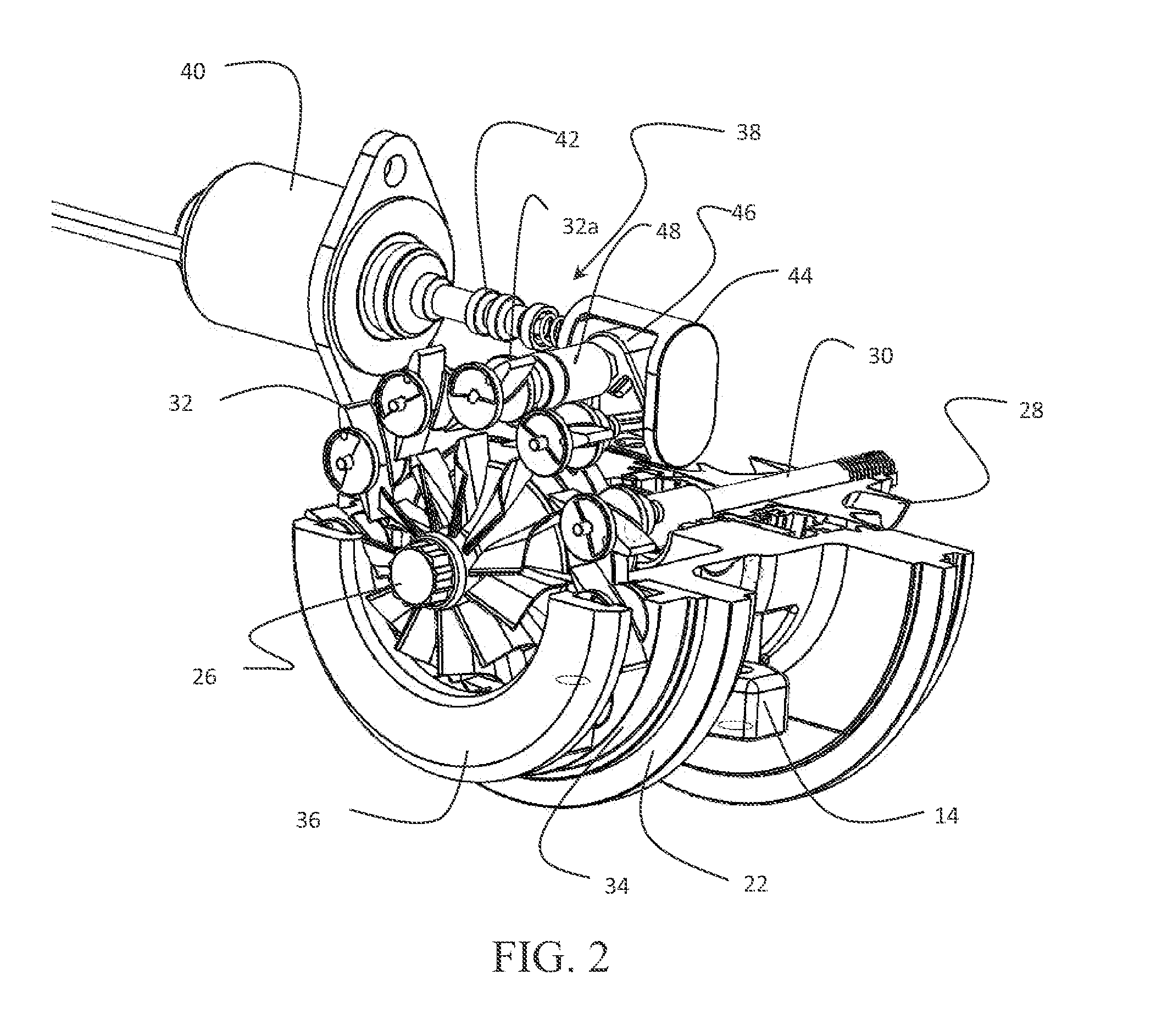

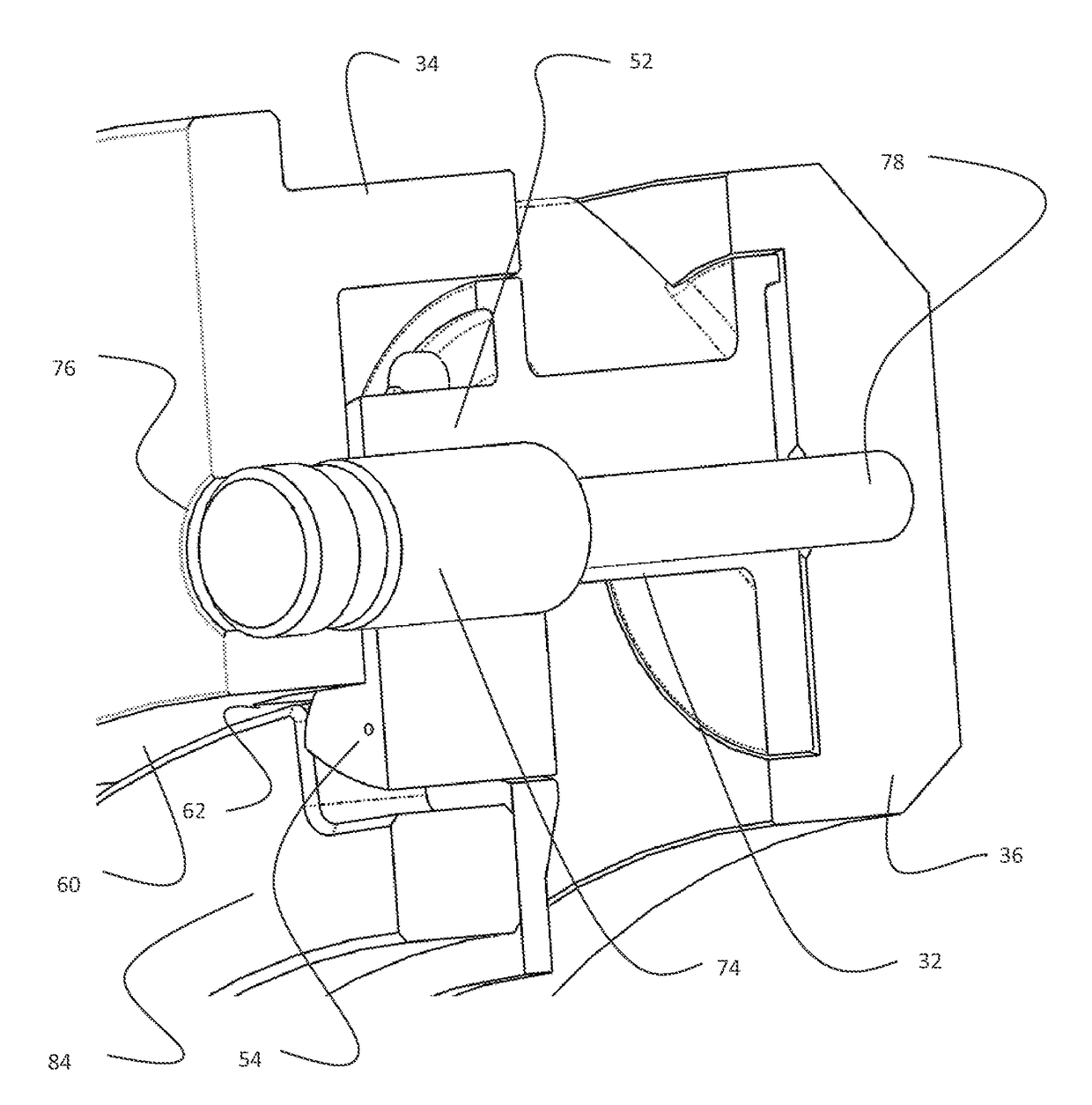

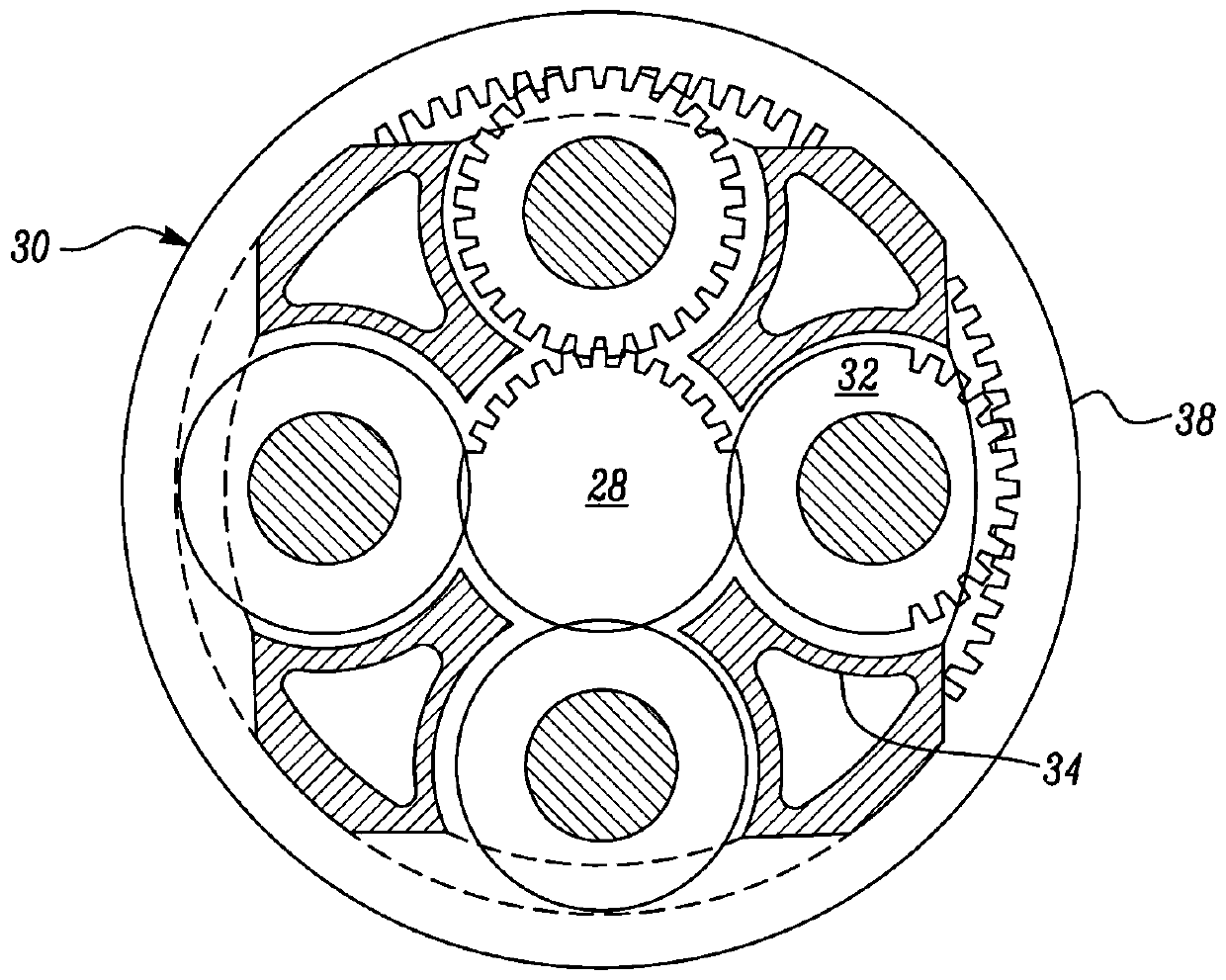

Balanced vanes and integrated actuation system for a variable geometry turbocharger

ActiveUS20170009645A1Internal combustion piston enginesPump controlVariable geometry turbineSpray nozzle

A variable geometry turbine (VGT) for turbochargers incorporates a turbine nozzle having a plurality of vanes, each vane having an airfoil with an inner disc and an outer disc. A first nozzle plate incorporates pockets to receive the inner discs with the inner discs substantially flush with a nozzle surface on the first nozzle plate. A second nozzle plate has pockets to receive the outer discs with outer discs substantially flush with a second nozzle surface. An integral actuation system rotates the plurality of vanes for variation of the nozzle geometry.

Owner:KANGYUE TECH

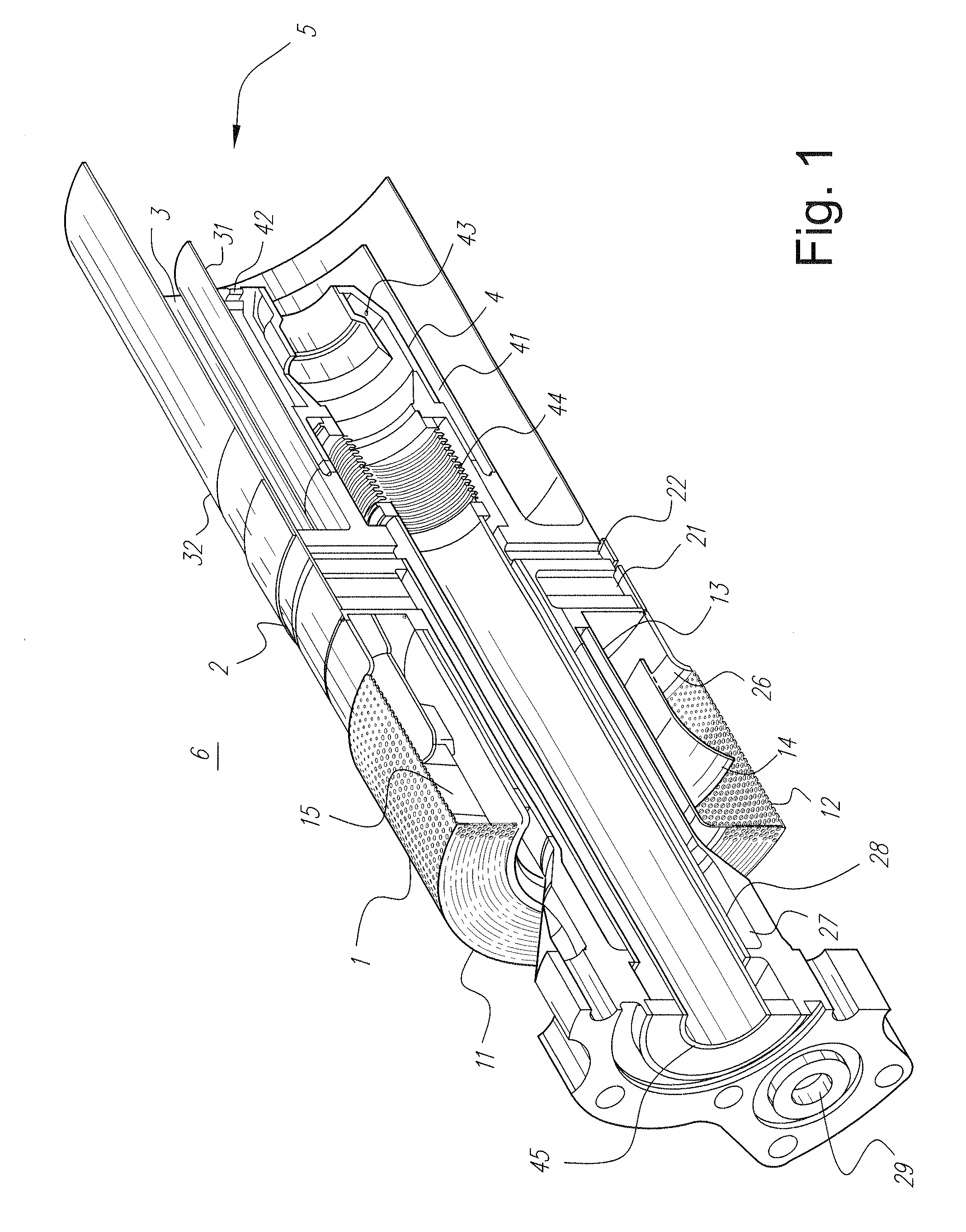

Seal for a Prefilled Medical Jet Injection Device

InactiveUS20090099510A1Easy to operateAvoid pollutionJet injection syringesIntravenous devicesAdhesiveJet injection

A sealing membrane 20 on a nozzle 10 for a jet injection device is adapted to seal off the nozzle orifice 12 by having a sealing rim 22 surrounding the nozzle orifice 12, which ensures a distinct closure of the nozzle orifice 12 to protect the nozzle geometry against damage and dirt and to protect the drug 30 contained in the cartridge 10 against contamination. The sealing rim 22 can narrowly enclose the nozzle orifice 12, or in case an adhesive 14 is applied to the nozzle face to ensure skin retention during injection, the sealing rim 22 can run in the middle of the adhesive covered area or entirely outside the adhesive covered area to protect the adhesive as well. A third sealing member 23 can also be provided to give a third distinct closure assurance in case the primary and secondary sealing membrane 20 is damaged. The third sealing member 23 can be one or more plug(s) adapted to press fit inside the nozzle orifice.

Owner:NOVO NORDISK AS

Axial loading management in turbomachinery

ActiveUS20060179839A1Reduce loadUniform pressureWind motor controlPump componentsTurbochargerEqualization

Exemplary vanes for a turbocharger having variable nozzle geometries are disclosed. In one aspect, each of the vanes includes two axial surfaces that are on opposite sides of the vane. The opposite axial surfaces include two corresponding chambers. These chambers are partially exposed to each other through an aperture. Such an aperture allows for some degree of equalization of the pressures in the chambers and, thereby, reduces the axial load exerted by a vane, for example, on the unison ring. In another aspect, each of the vanes includes two opposite airfoil surfaces. At least one of the airfoil surfaces includes a notch that allows a chamber in the nozzle to be pressurized by the exhaust gas. The pressure in the chamber creates a counteracting force that reduces the axial load exerted by a vane.

Owner:GARRETT TRANSPORATION I INC

Apparatus, system, and method for maximizing ultrafine meltblown fiber attenuation

InactiveUS20080122143A1Restricting flow of gasMaximize ultrafine meltblown fiber attenuationSpinnerette packsCeramic shaping apparatusUltrasound attenuationFiber

An apparatus, system and method to maximize ultrafine meltblown fiber attenuation. The nozzle apparatus includes a polymer streaming channel, at least one gas delivery channel, a restricted throat area, and a bounded expansion area. In some embodiments, the nozzle comprises a two-dimensional converging-diverging Laval nozzle geometry. The gas delivery channels may provide the gas under a pressure exceeding critical pressure, such that the gas achieves supersonic speeds at the restricted throat area. The bounded expansion area may stabilize such supersonic speeds, thus maximizing ultrafine meltblown fiber attenuation while minimizing the formation of fly and other defects.

Owner:CUMMINS FILTRATION IP INC

Multi-nozzle organic vapor jet printing

ActiveUS20140295615A1High resolutionReducing undesirable “overspray”Vacuum evaporation coatingSolid-state devicesLeading edgeEngineering

Systems and methods are provided for depositing thin patterned films of materials in which individual elements of the patterned film are deposited by two or more nozzles having different geometries. The different nozzle geometries may include one or more of different throttle diameters, different exhaust diameters, different cross-sectional shapes, different bore angles, different wall angles, different exhaust distances from the substrate, and different leading edges relative to the direction of movement of the nozzles or the substrate. Methods may include steps of ejecting a carrier gas and a material from a plurality of nozzles and depositing the material on a substrate in a plurality of laterally spaced elements.

Owner:UNIVERSAL DISPLAY

Methods, systems and/or apparatus relating to inducers for turbine engines

An inducer that includes a profiled throat. In some embodiments, the inducer includes a conical shape upstream of the profiled throat with a relatively large circular inlet that narrows to the profiled throat and, downstream of the profiled throat, a downstream section that broadens from the profiled throat. The profiled throat may include an approximate convergent-divergent nozzle geometry.

Owner:GENERAL ELECTRIC CO

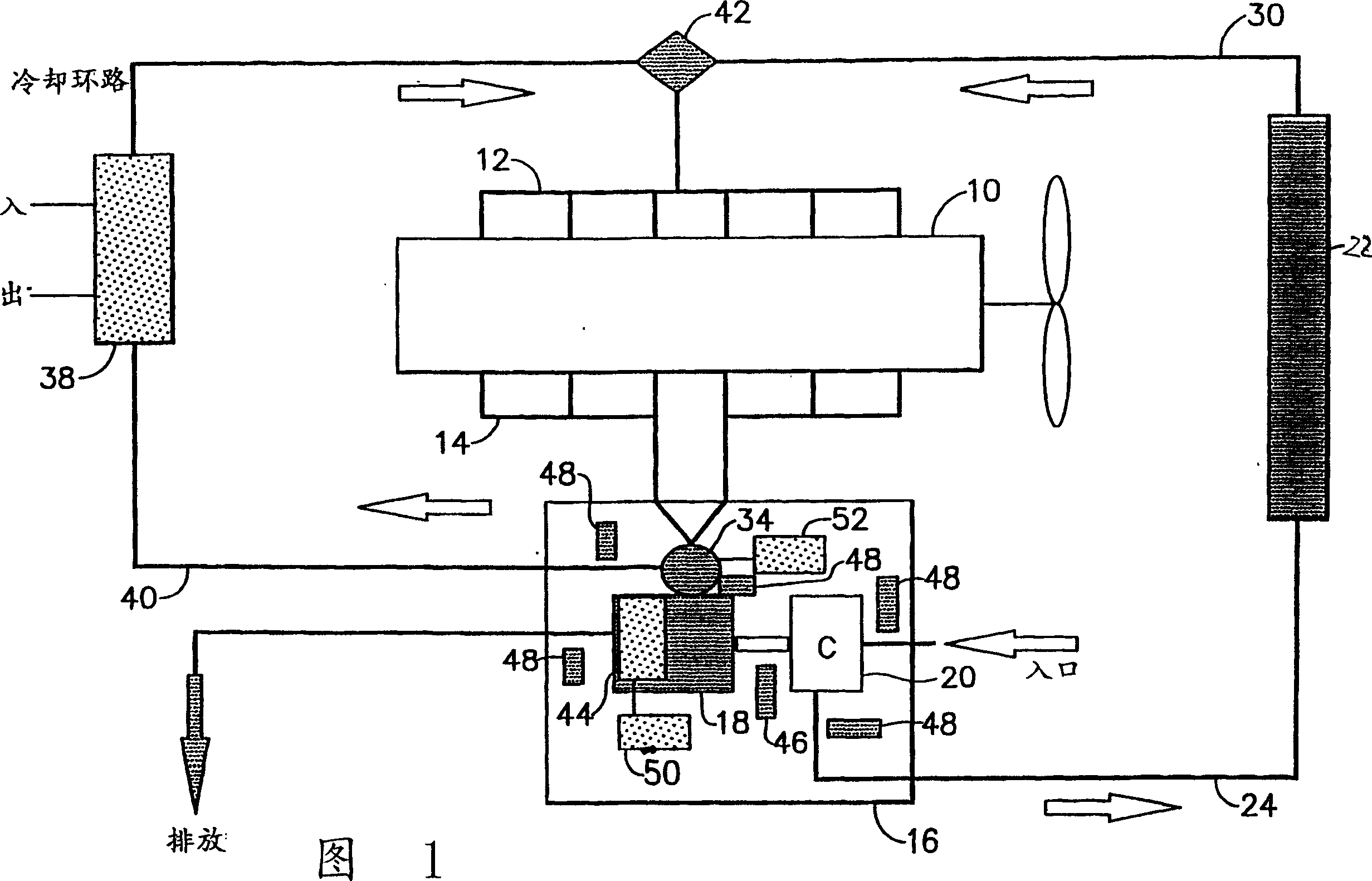

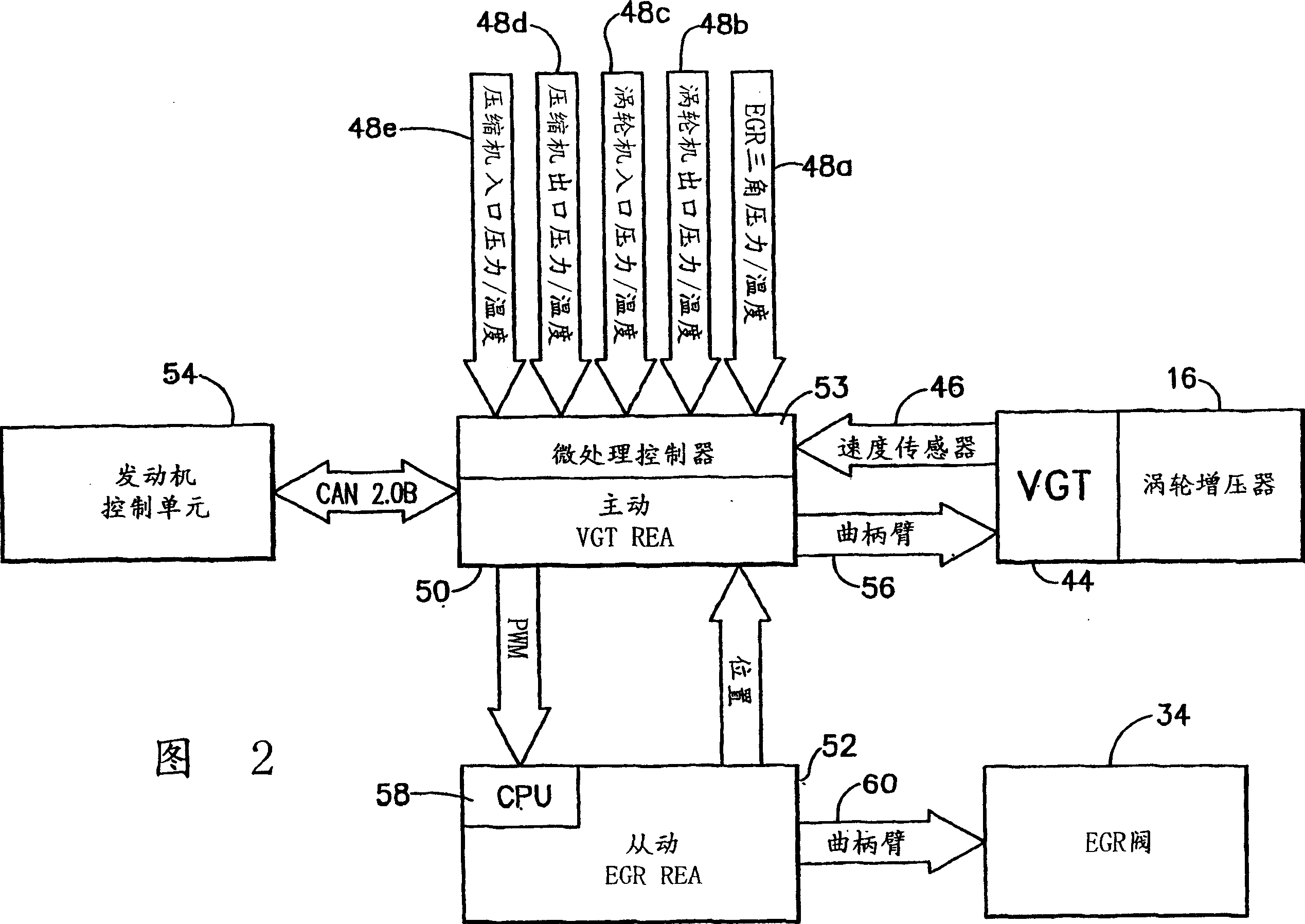

Integrated exhaust gas recirculation system for internal combustion engine

InactiveCN1263948CElectrical controlNon-fuel substance addition to fuelTurbochargerMicroprocessor controller

An exhaust gas recirculation (EGR) system for an engine with a variable geometry turbocharge (18) incorporates a master rotary electric actuator (REA) (50) with a microprocessor controller (53) receiving condition signals (46, 48a-e) from sensors (48) associated with the turbocharger and the engine control unit (ECU) (54) and positioning the turbine inlet nozzle geometry of the turbocharger in response to a predetermined matrix of the condition signals. A slave REA (52) is connected through an internal processing unit (58) to the controller to position an EGR valve (34). The processing unit provides an actual position signal to the controller which responds with a desired position signal based on the predetermined condition signal matrix. The processing unit engages the slave REA to position the EGR valve.

Owner:HONEYWELL INT INC

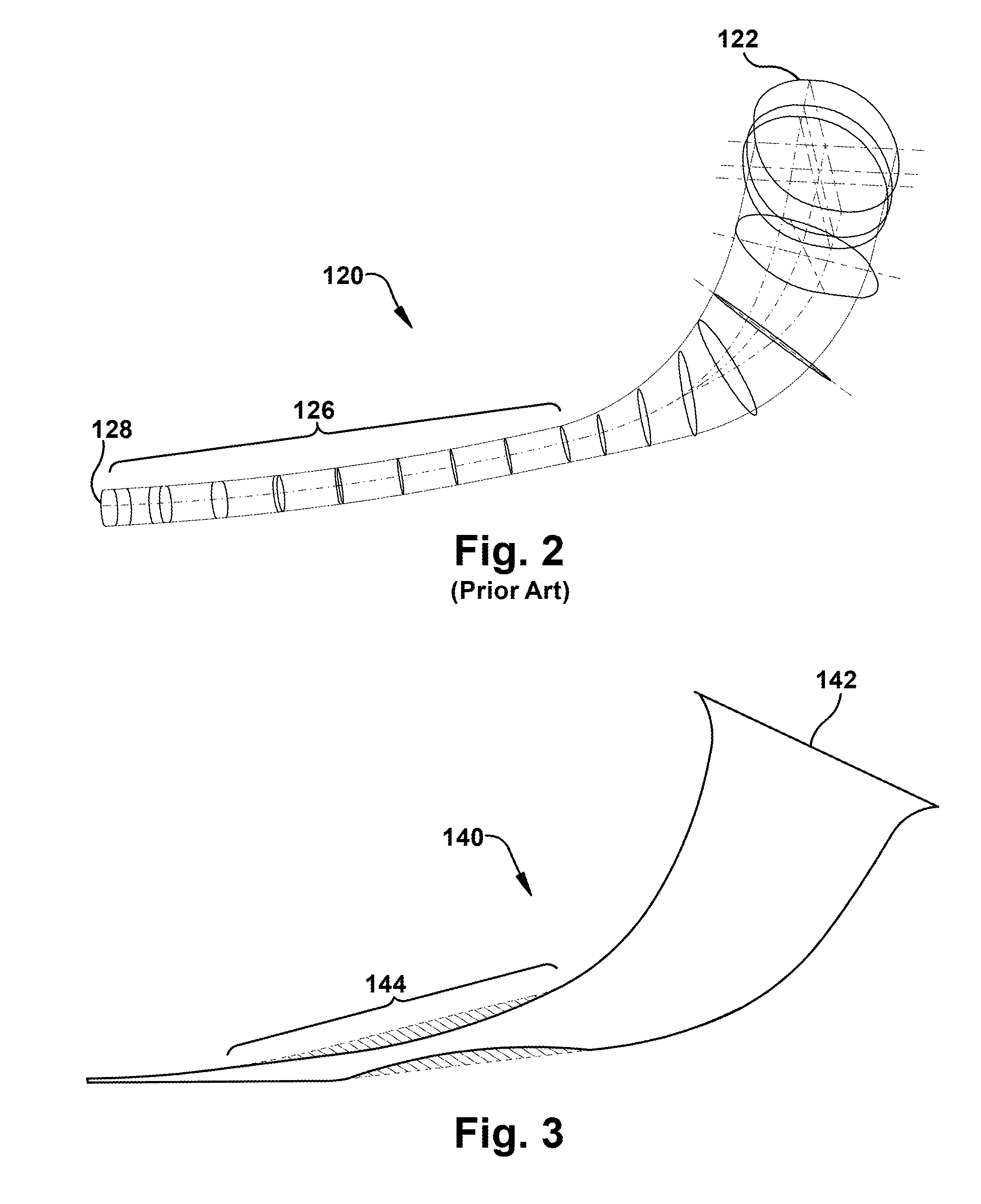

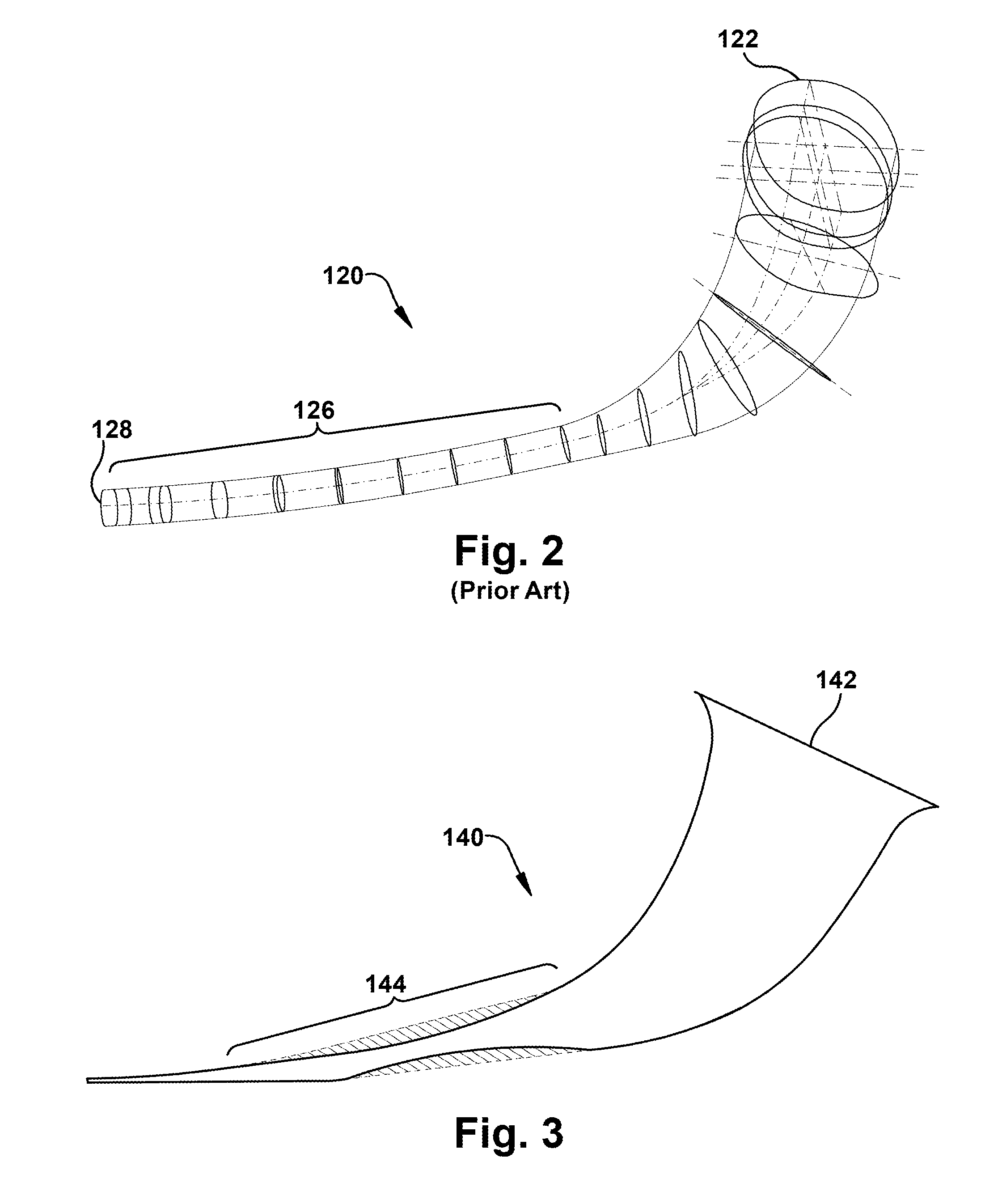

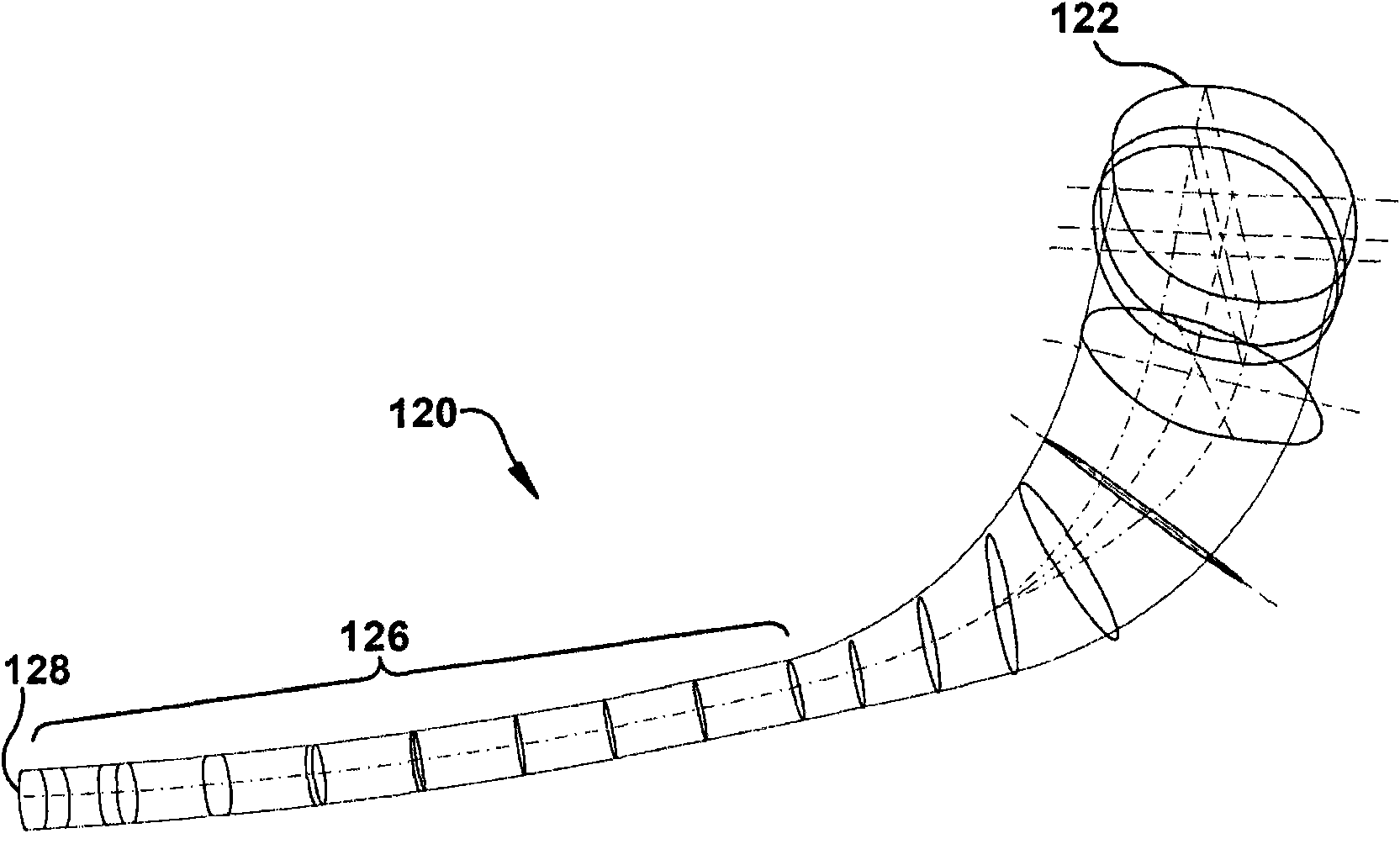

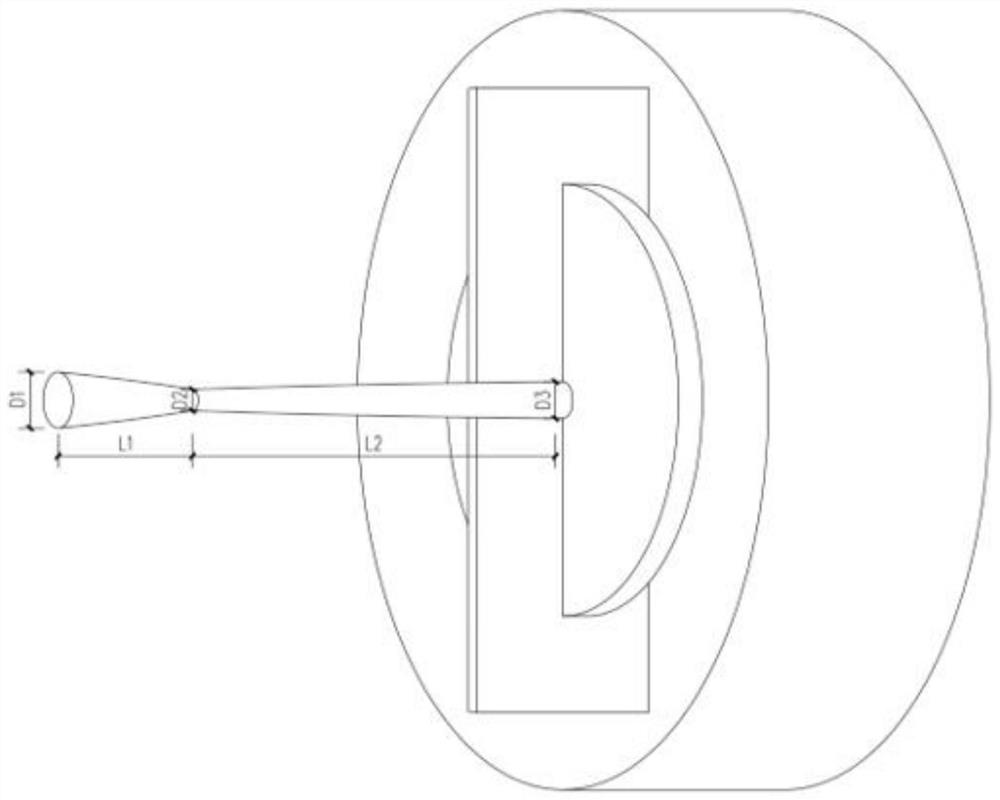

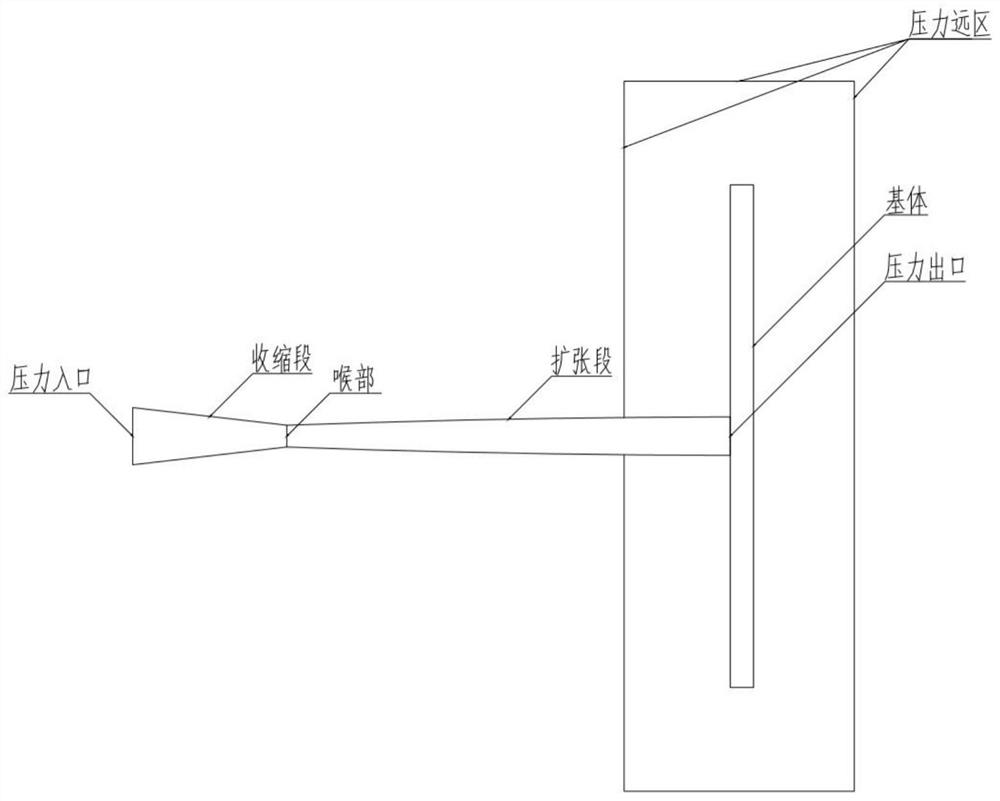

Methods, systems and/or apparatus relating to inducers for turbine engines

The invention relates to methods, systems and / or apparatus relating to inducers for turbine engines. An inducer (140) that includes a profiled throat (144). In some embodiments, the inducer (140) includes a conical shape upstream of the profiled throat (144) with a relatively large circular inlet (142) that narrows to the profiled throat (144) and, downstream of the profiled throat (144), a downstream section that broadens from the profiled throat (144). The profiled throat (144) may include an approximate convergent-divergent nozzle geometry.

Owner:GENERAL ELECTRIC TECH GMBH

Compressor blade with nozzle

A compressor blade having at least one nozzle for ejecting fluid, in particular for ejecting water, is provided. The at least one nozzle is produced as a laminar structure in which, in particular, individual layers such as metal sheets are laid on top of each other, and has differently orientated channel sections of a channel between an inlet and an outlet, wherein the metal sheets have cutouts corresponding to the channel sections. The nozzle geometry makes it possible to prevent the formation of droplets as water exits a compressor blade.

Owner:SIEMENS AG

Method and apparatus for remotely changing flow profile in conduit and drilling bit

InactiveUS20150136489A1High speedNozzle area is reducedDrill bitsDrilling rodsControl flowSection plane

The present invention relates to apparatus and methods for remotely adjusting the drill bit hydraulic horse power per square inch (HSI). Varying the nozzle geometry remotely without the need to pull the drill string outside the hole has obvious advantage. Changing the nozzle flow geometry results in changing the nozzle HSI, which is beneficial to optimize drilling a well having different rock formations. The drill bit nozzle geometry of the present invention can be varied by causing a change of at least one physical property of the environment. The variable geometry nozzle is not limited to drill bit, it can be placed within the inner flow passage or between the inner flow passage and annular flow passage for controlling flow profile within a wellbore, a tubular string or a flow conduit.

Owner:MIT INNOVATION

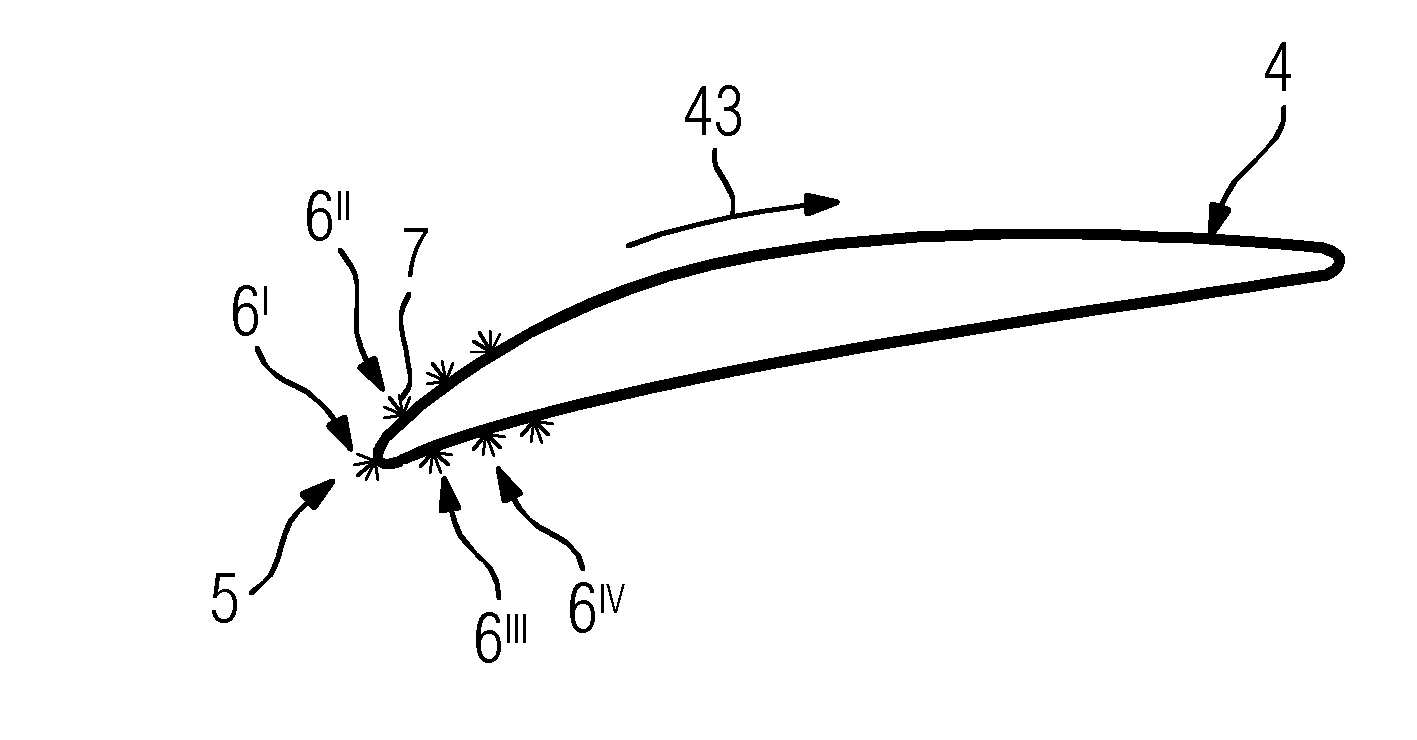

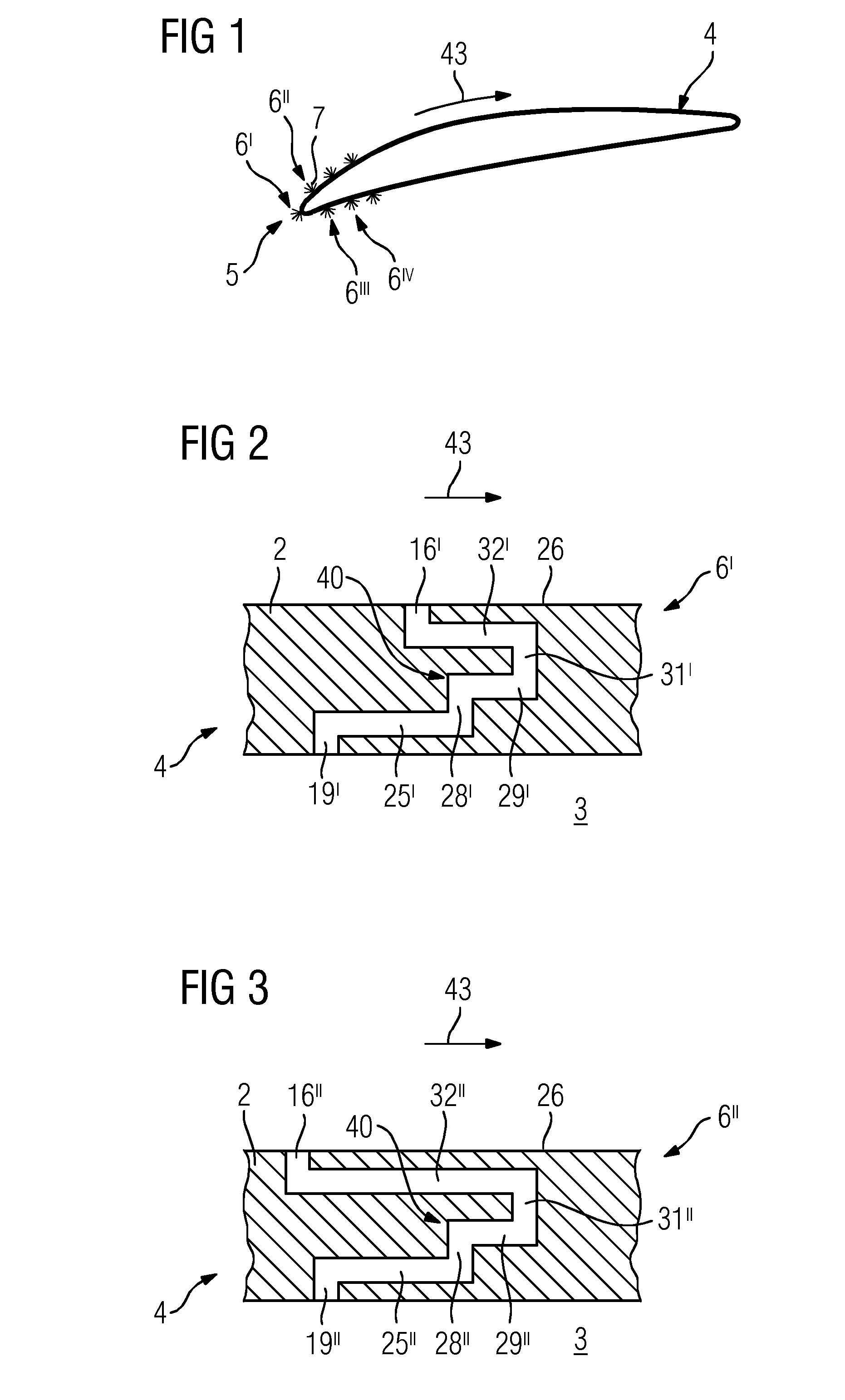

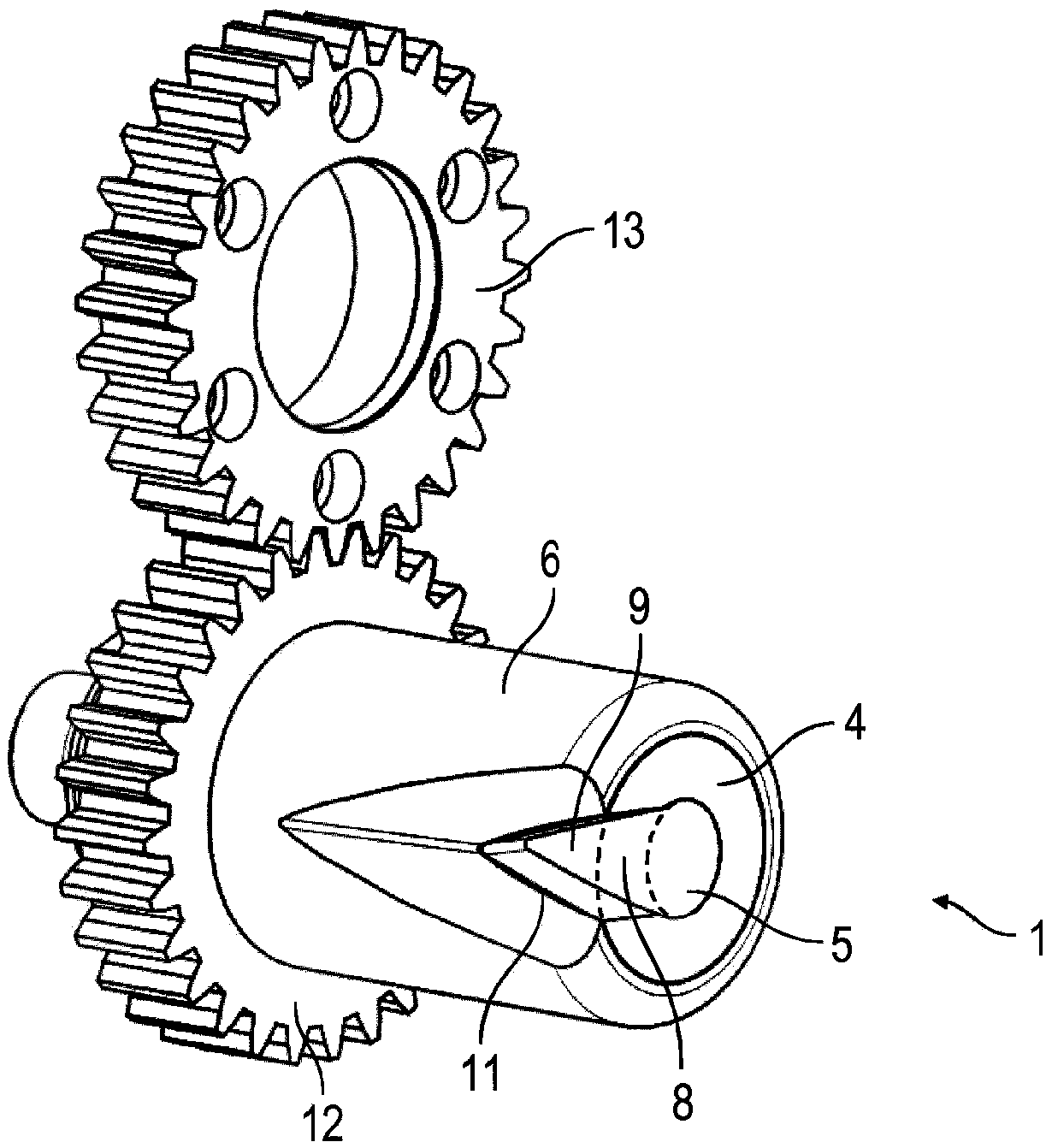

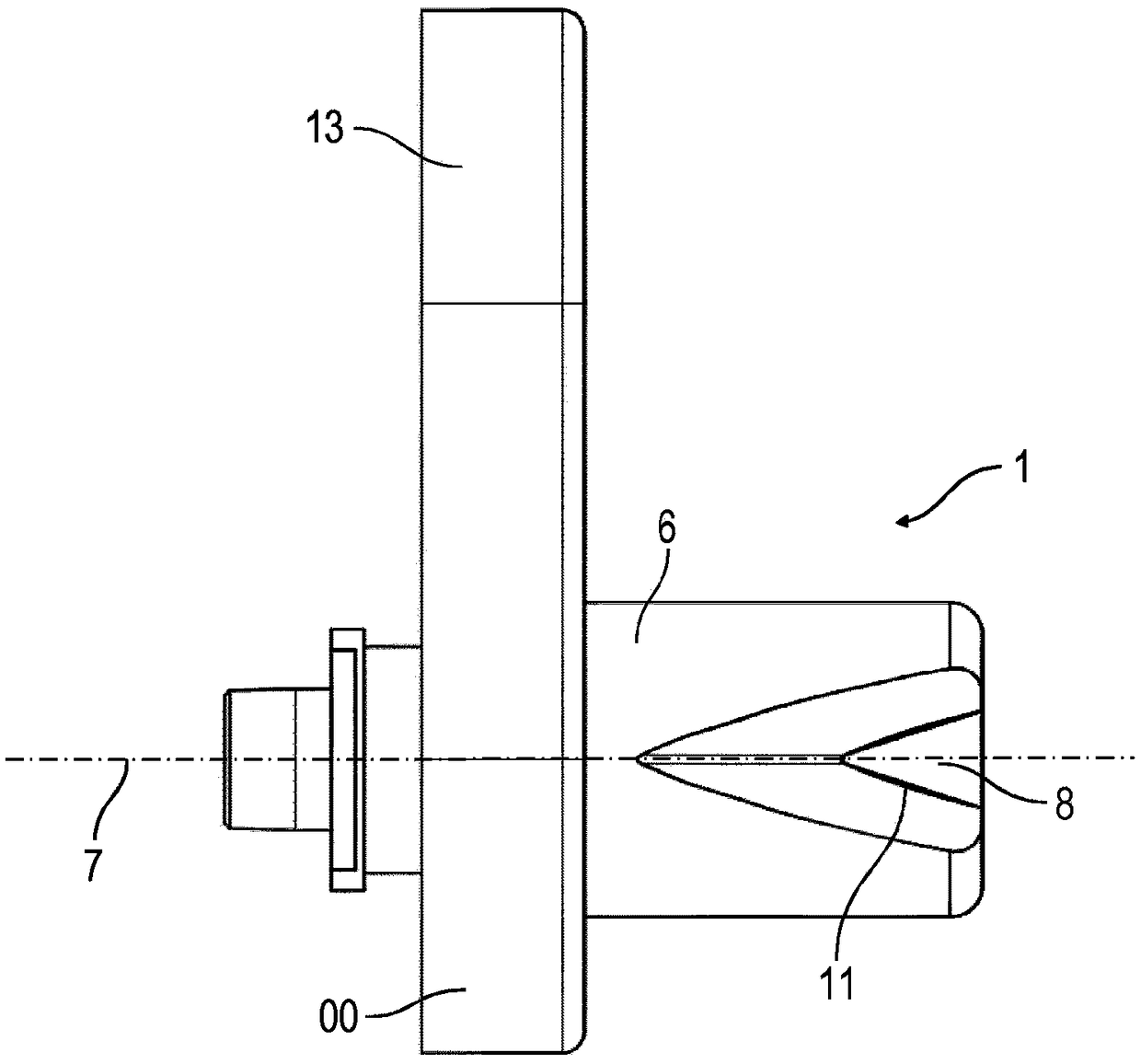

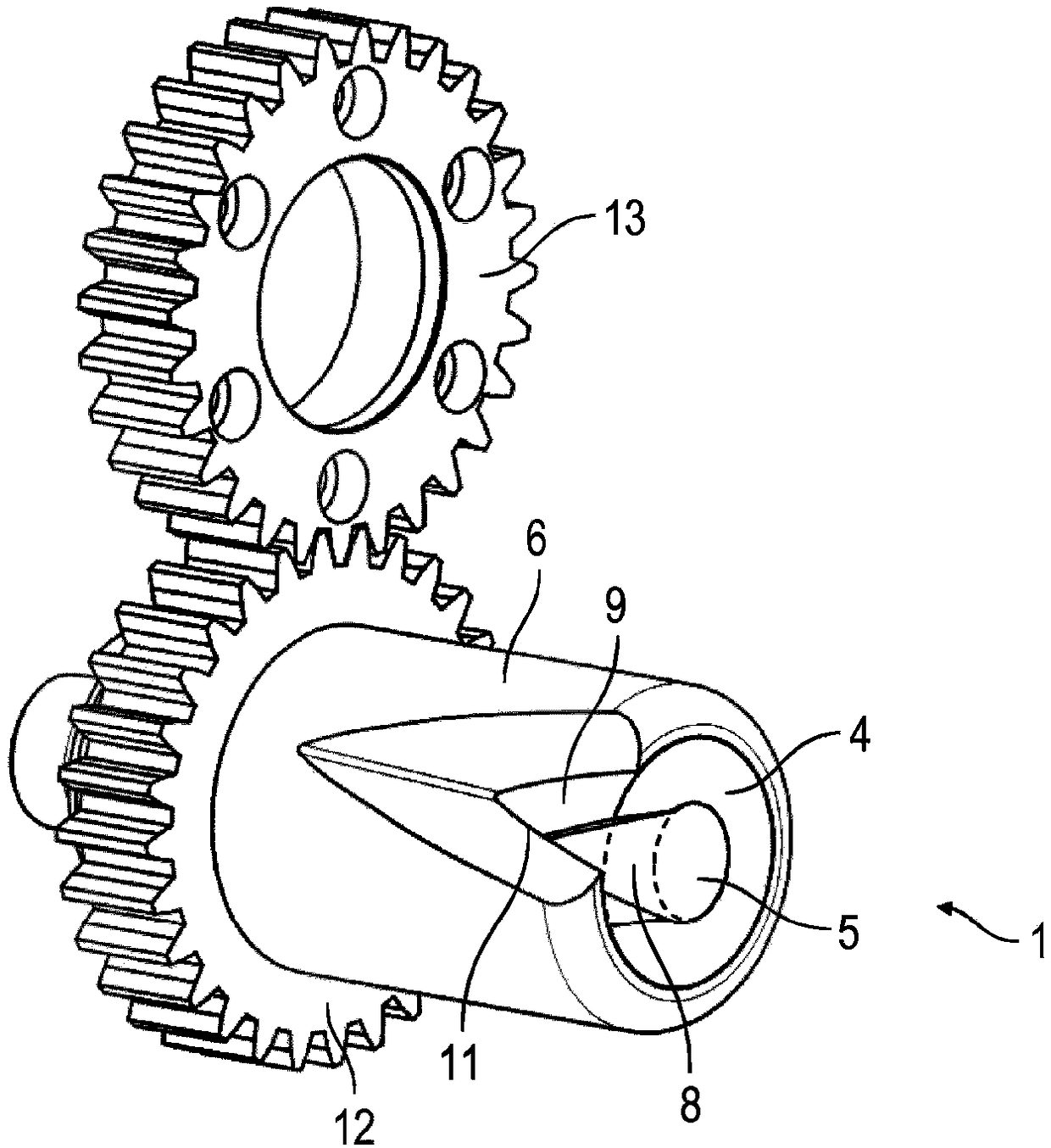

Applicator for the application of a high-viscosity material, exchangeable part therefor and corresponding operating method

PendingCN109475896AOmit a separate descriptionLiquid surface applicatorsCoatingsNozzle geometryViscosity

The invention relates to an applicator (1) for the application of a coating agent (for example a high-viscosity material) to a component (for example a body component of a motor vehicle) comprising anozzle (4-11) having a nozzle opening with a specific nozzle geometry, in particular for applying a bead of high-viscosity material to the surface of a component. The invention provides that the nozzle geometry of the nozzle opening is adjustable without exchanging the nozzle (4-11), in particular by a relative movement of two nozzle parts (4, 6). The invention also comprises an exchangeable part(6, 12) for such an applicator (1) and an operating method therefor.

Owner:DUERR SYST GMBH

Balanced vanes and integrated actuation system for a variable geometry turbocharger

ActiveUS10018107B2Internal combustion piston enginesEngine componentsVariable geometry turbineSpray nozzle

A variable geometry turbine (VGT) for turbochargers incorporates a turbine nozzle having a plurality of vanes, each vane having an airfoil with an inner disc and an outer disc. A first nozzle plate incorporates pockets to receive the inner discs with the inner discs substantially flush with a nozzle surface on the first nozzle plate. A second nozzle plate has pockets to receive the outer discs with outer discs substantially flush with a second nozzle surface. An integral actuation system rotates the plurality of vanes for variation of the nozzle geometry.

Owner:KANGYUE TECH

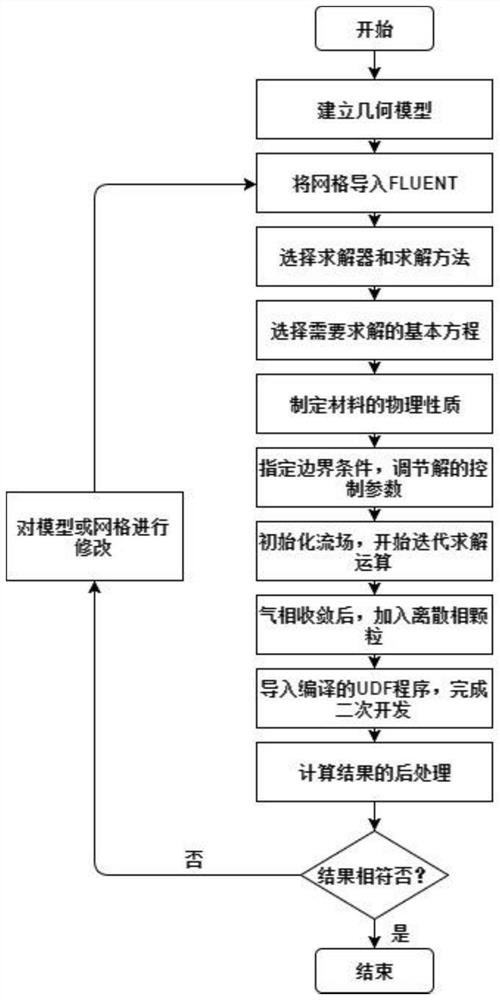

A simulation calculation method for simulating the surface distribution of hard phase particles based on fluent

ActiveCN111324994BAccurate predictionNumerical simulation work is convenientDesign optimisation/simulationCAD numerical modellingGas phaseEngineering

The present invention is a simulation calculation method based on FLUENT to simulate the distribution of hard phase particle matrix surface, belongs to the field of numerical simulation calculation, and comprises the following steps: S1: establish the geometric model of cold spraying Raoult nozzle, S2: divide the grid and divide the grid Import FLUENT, S3: select the solver and solution method, S4: select the basic equation to be solved, S5: specify the physical properties of the material particles, S6: specify the boundary conditions, S7: initialize the flow field, start iterative solution, S8: gas phase convergence Then add discrete phase particles, S9: insert UDF program into DPM, S10: post-processing of calculation results, S11: repeat the above steps as needed; the present invention adopts discrete phase numerical simulation method, by comparing the change law of cold spray gas phase velocity and particle motion Trajectories, accurately complete the distribution of particles sprayed to the substrate surface, and provide a theoretical basis for solving the distribution uniformity and deposition of cold spray particles on the substrate.

Owner:SOUTHWEST JIAOTONG UNIV

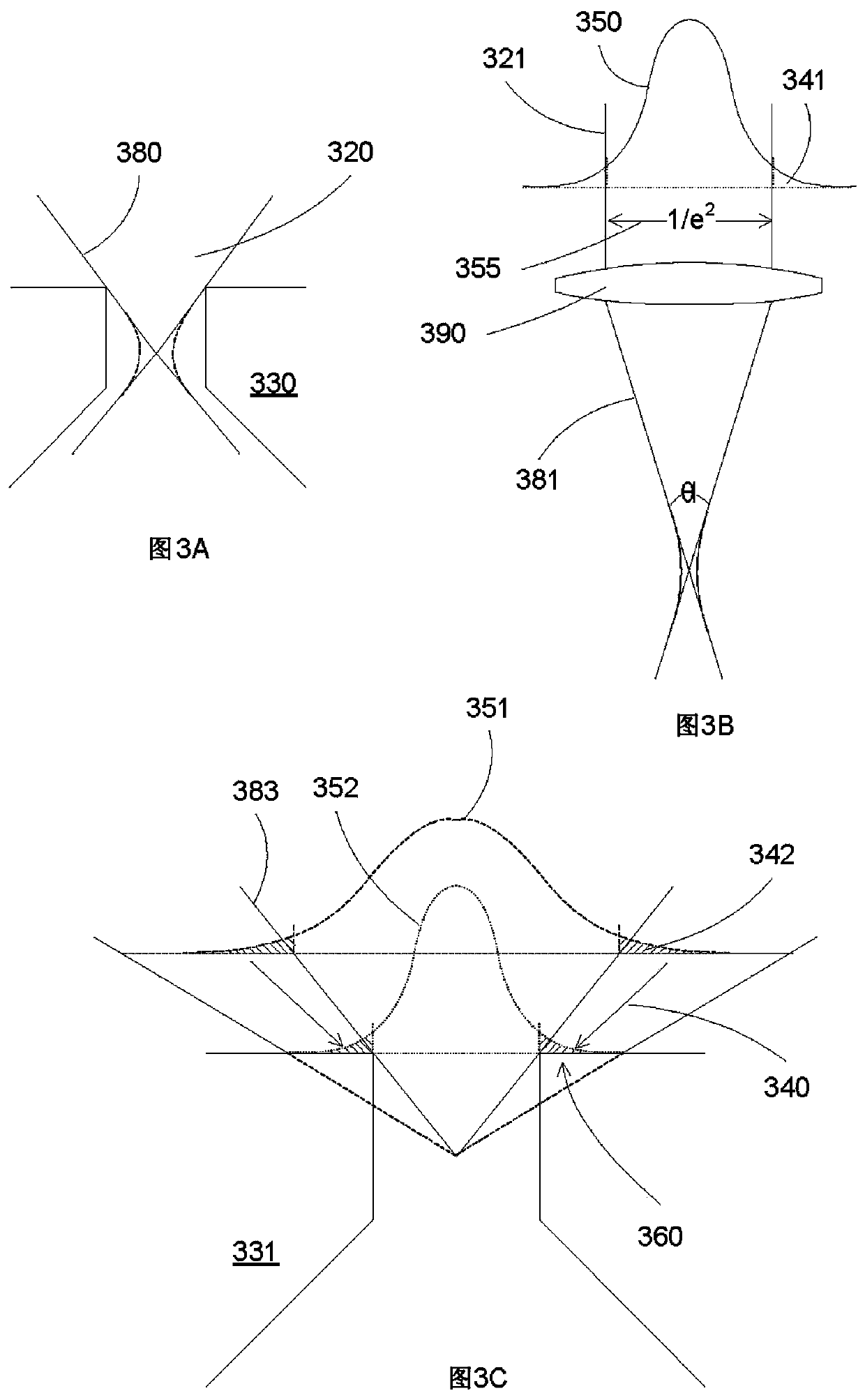

Method for coupling a laser beam into a liquid jet beam

ActiveCN107530828BReliable couplingProtection lifeLaser beam welding apparatusLiquid jetSpray nozzle

By setting the parameters of the liquid jet-guiding laser system according to the best relationship linking the laser focus, focus cone angle, laser beam energy distribution profile and nozzle geometry, high power can be achieved by utilizing the high lifetime performance of nozzles 130, 140 and protective window 170. The laser beam 180 is reliably coupled into the liquid jet 125 in the volume jet guiding laser system.

Owner:AVONISYS AG

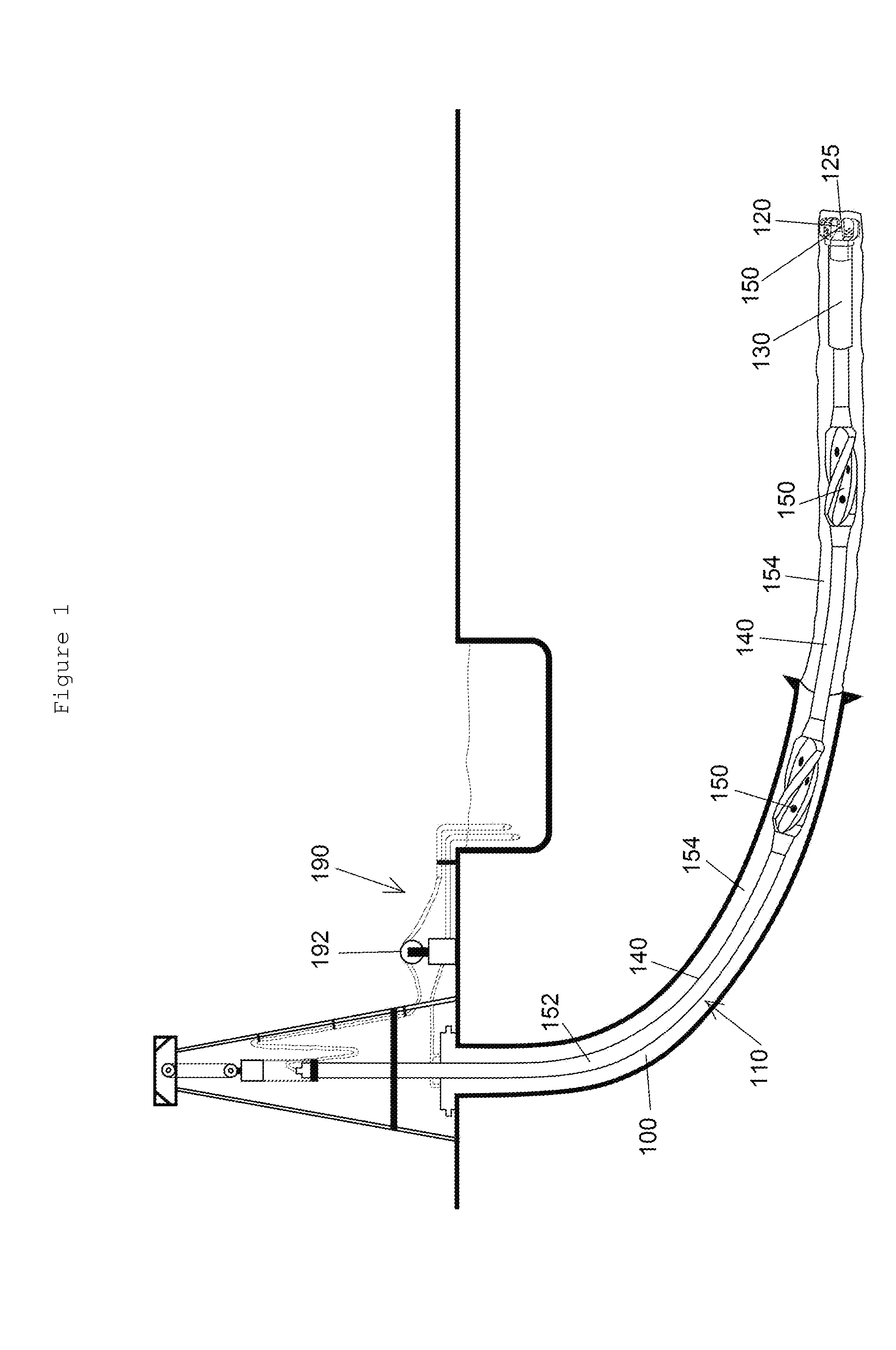

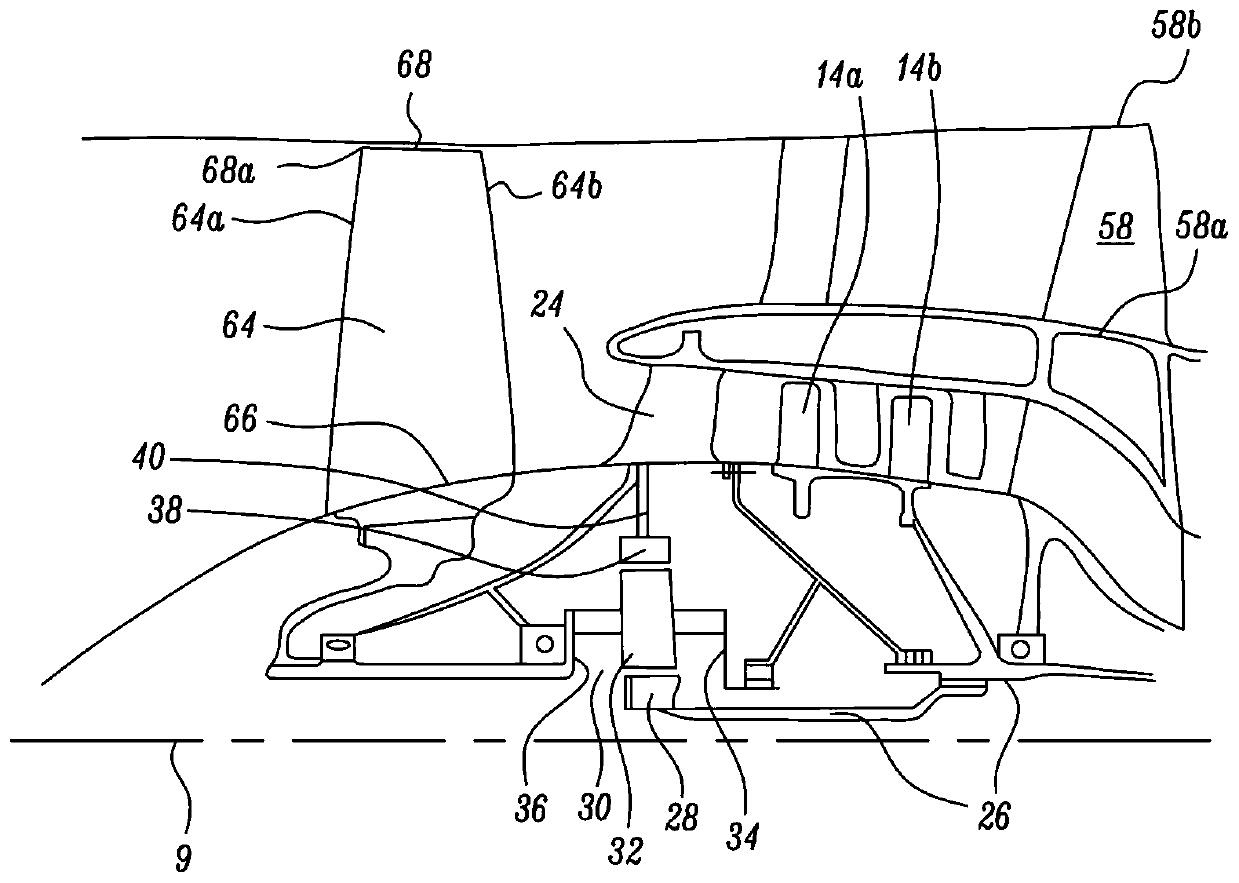

Gas turbine engine fan and nozzle geometry

The invention provides a gas turbine engine fan and a nozzle geometry. A gas turbine engine (10) for an aircraft comprises an engine core (11) comprising a turbine (19), a compressor (14 ), and a coreshaft (26) connecting the turbine to the compressor; a fan (23) located upstream of the engine core, the fan comprising a plurality of fan blades, wherein a fan tip radius (102) of the fan (23) is measured between a centreline of the engine (10) and an outermost tip (68) of each fan blade (64) at its leading edge (64a); and a nacelle (21) surrounding the fan (23) and the engine core (11) and defining a bypass exhaust nozzle (18), the bypass exhaust nozzle having an inner radius (116). The ratio of the inner bypass to the is in the range from 0.4 to 0.65.

Owner:ROLLS ROYCE PLC

Turbine with variable inlet nozzle geometry

Owner:CUMMINS TURBO TECH

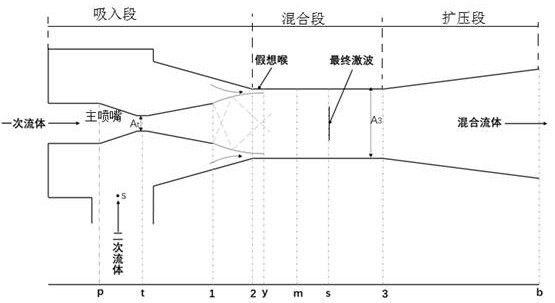

Ejector optimization method and ejector

ActiveCN114798201AAvoid running unstableSpray nozzlesDesign optimisation/simulationComputer Aided DesignComputer-aided

The invention belongs to the technical field of computer aided design, and provides an injector optimization method and an injector, and the method comprises the following steps: determining the throat cross-sectional area of a main nozzle under different primary flow pressures when the mass flow of mixed fluid is constant based on the momentum conservation law before and after the fluid is mixed at a second section and the mass flow of the primary flow; determining the cross sectional areas of the inlet and the outlet of the main nozzle according to the cross sectional area of the throat part of the main nozzle, the angle and the length of the divergent section of the main nozzle and the angle and the length of the convergent section of the main nozzle; according to the method, the geometric structure parameters of the main nozzle for maintaining the mass flow rate of the mixed fluid of the ejector to be constant under different primary flow working conditions can be obtained, and the problem that follow-up equipment operation is unstable due to the ejector along with the change of the primary flow pressure intensity is avoided.

Owner:山东沃德净水科技有限公司

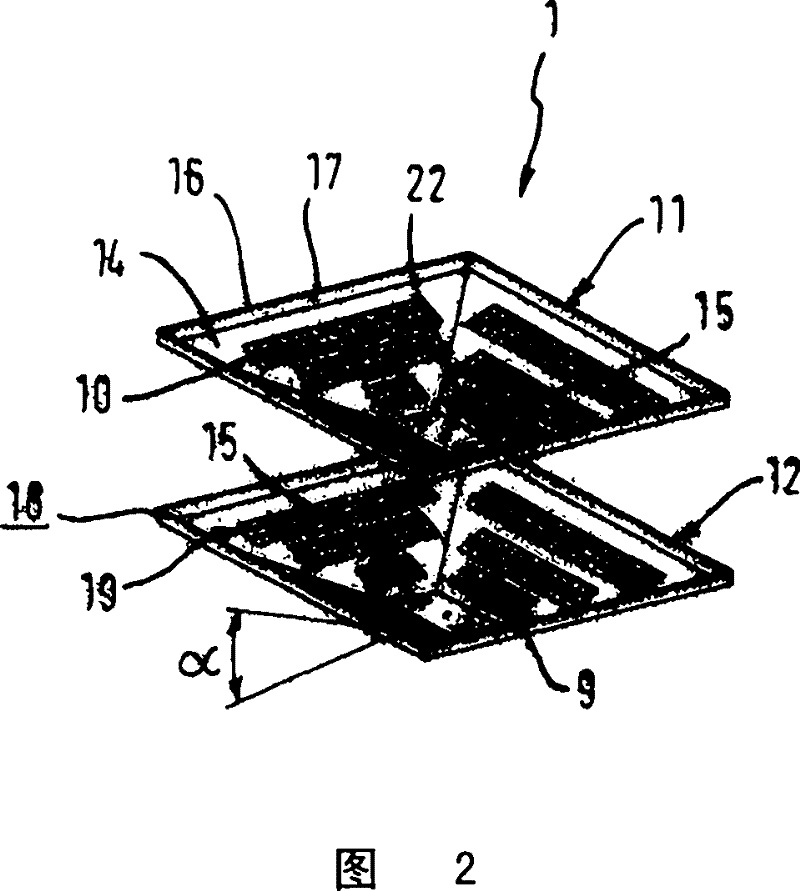

Filter units for exhaust hoods

ActiveCN101166566BAvoid cloggingRegulate flowDomestic stoves or rangesDispersed particle filtrationEngineeringStructural engineering

A filter assembly (1), which separates particles and liquid droplets from the airflow (W) passing through the cooker extraction hood, comprises two dished shells (11, 12). These are detachably connected. One shell (12) carries a spacer (18). The sheet-metal construction of the shells includes filter openings. These are located in the side walls of each shell, which are bent-up from the base (9). Openings in adjacent shells are mutually-offset. At least some of the openings are round holes. Around their edges, nozzle geometries are formed. These formations are integral with the shells. The shells are coated (e.g. with PTFE) and their overall shape is blunt-pyramidal.

Owner:BOSCH SIEMENS HAUSGERATE GMBH

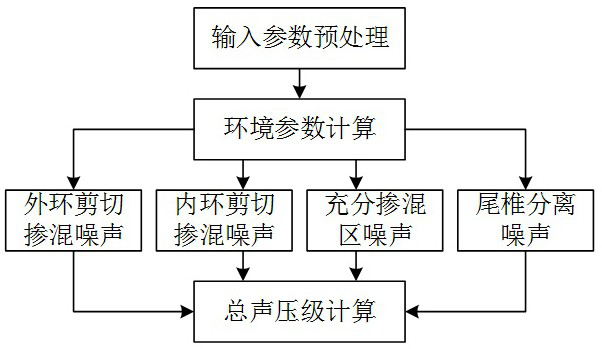

Real-time calculation and prediction method of turbofan engine jet noise based on surrogate model

ActiveCN111079325BMeet real-time simulation requirementsMeet application requirementsSustainable transportationDesign optimisation/simulationAviationElement model

The invention relates to a method for real-time calculation and prediction of jet flow noise of a turbofan engine based on a proxy model. ;Construct the finite element model of turbofan engine jet flow field, simulate the orthogonal test and obtain noise samples; use the noise sample data to solve the proxy model; use the atmospheric conditions, flight speed and nozzle geometry to correct the noise model, and finally get the A real-time model of jet noise with certain accuracy. The invention solves the problems that the traditional computational fluid dynamics method has a huge amount of calculation, cannot cover the noise conditions in the entire flight process, and cannot meet the real-time simulation requirements in the numerical calculation process of the jet flow noise of the aero-engine. basis for control.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com