Gas turbine engine fan and nozzle geometry

A technology for gas turbines and exhaust nozzles, used in gas turbine installations, climate sustainability, jet propulsion, etc., to solve problems such as the unsuitability of engines to be installed under the wings and the impact of aircraft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

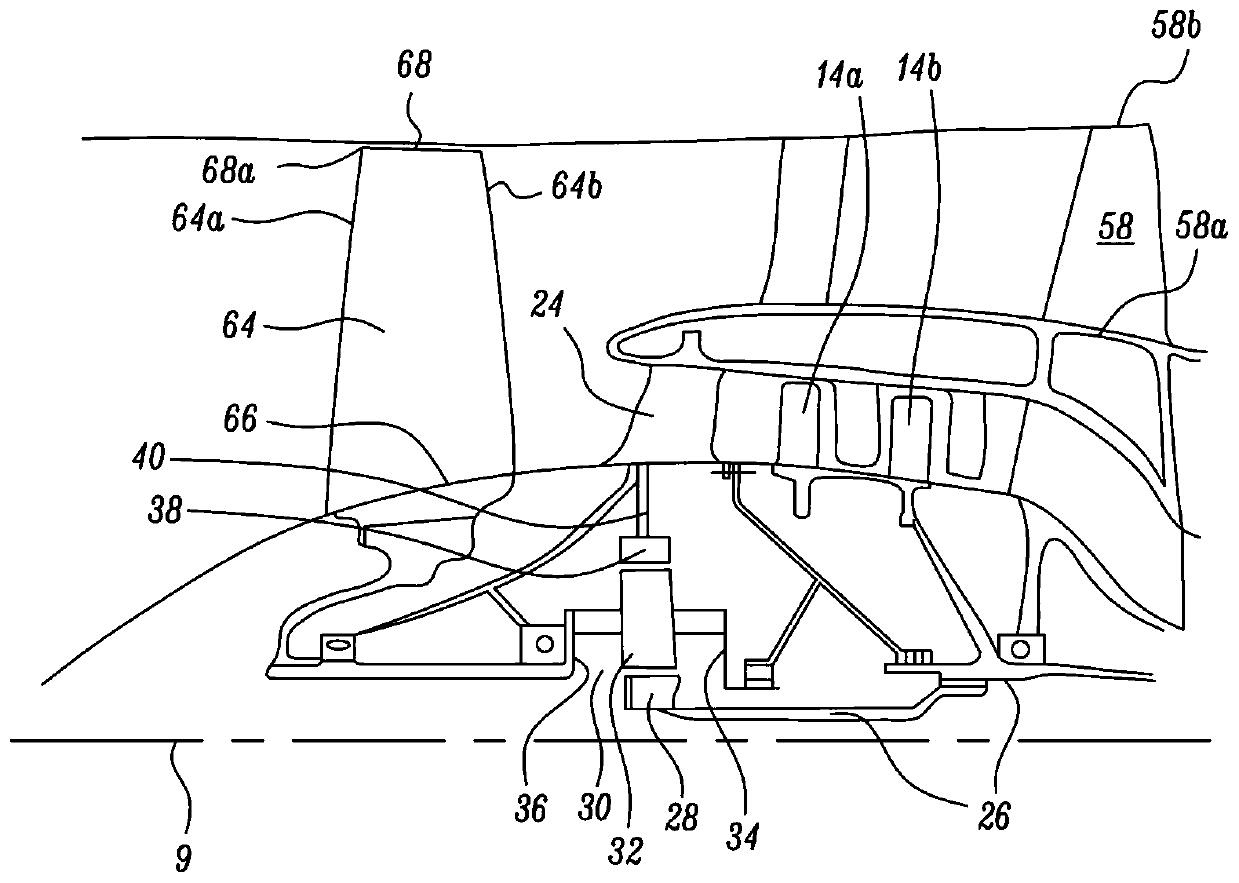

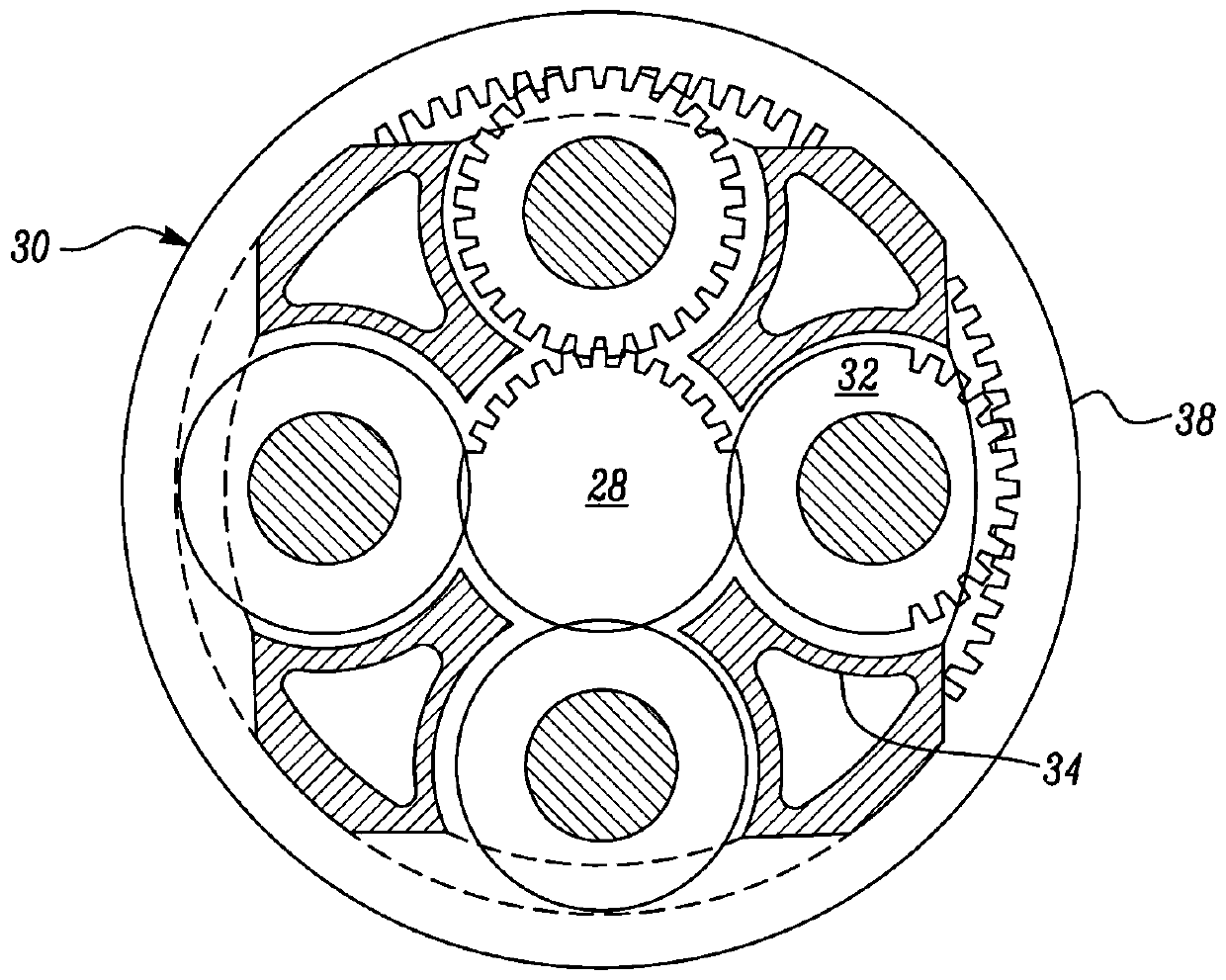

[0432] figure 1 A gas turbine engine 10 with a main axis of rotation 9 is shown. The engine 10 includes an air intake 12 and a propeller fan 23 that generates two airflows: a core airflow A and a bypass airflow B. The gas turbine engine 10 includes a core 11 receiving a core flow A. As shown in FIG. The engine core 11 includes a low-pressure compressor 14 , a high-pressure compressor 15 , a combustion device 16 , a high-pressure turbine 17 , a low-pressure turbine 19 and a core exhaust nozzle 20 in axial series. A nacelle 21 surrounds the gas turbine engine 10 and defines a bypass duct 22 and a bypass exhaust nozzle 18 . The bypass gas flow B flows through the bypass duct 22 . The fan 23 is attached to and driven by the low pressure turbine 19 via a shaft 26 and an epicyclic gearbox 30 .

[0433] In use, the core gas stream A is accelerated and compressed by the low pressure compressor 14 and directed into the high pressure compressor 15 for further compression. The compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com