A simulation calculation method for simulating the surface distribution of hard phase particles based on fluent

A simulation calculation, hard phase technology, applied in the direction of calculation, design optimization/simulation, computer-aided design, etc., can solve the problem that it is difficult to accurately predict the distribution of cold sprayed hard phase particles on the substrate surface, and achieve the effect of accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

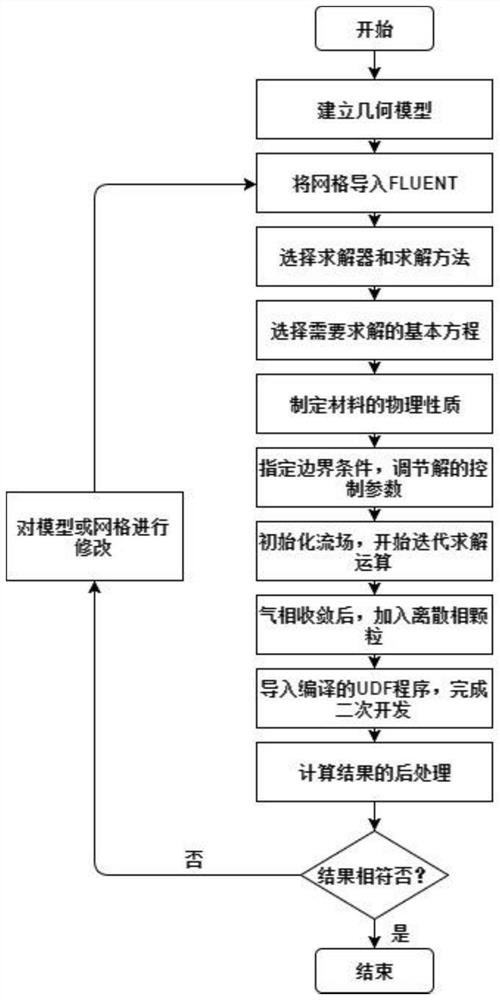

[0042] The invention provides a technical solution: a FLUENT simulation method for calculating the surface distribution of hard phase particles in cold spraying, combined with the attached figure 1 The present invention is described further, comprises the following steps:

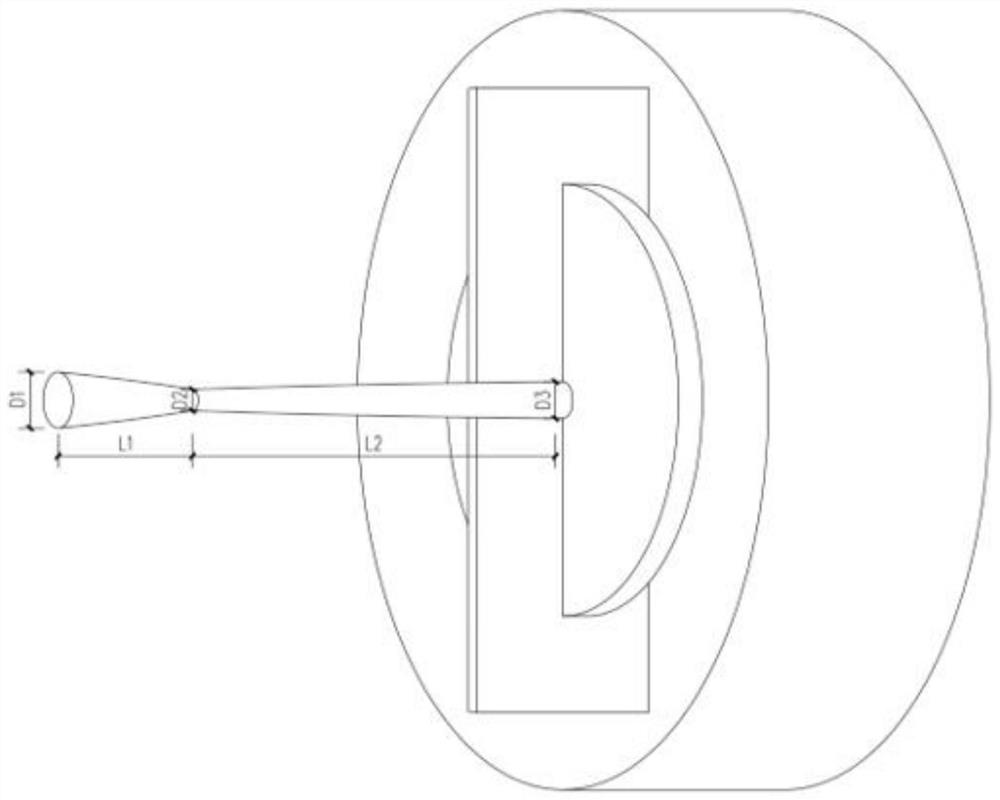

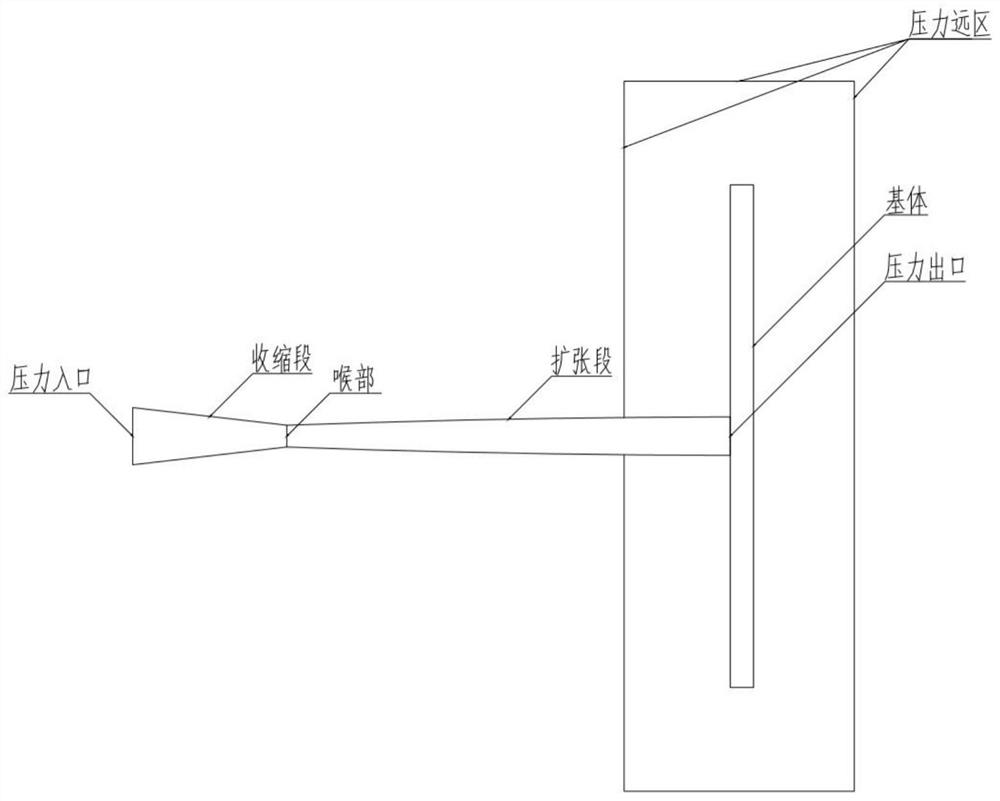

[0043] S1: Establish the geometric model of the solution area, and perform mesh division and boundary condition setting on the model, adopt unstructured grid, and calculate the number of grid units is 654320; name the boundary conditions of the model, the inlet boundary pressure inlet, the outlet boundary pressure outlet, substrate surface, spray gun wall wall1, and other surfaces wall2. figure 2 Schematic diagram of the 3D model of the Raoult nozzle for cold spraying, image 3It is a schematic diagram of the two-dimensional model of the cold spraying Raoult nozzle section, and Table 1 is the dimension drawing of each part of the cold spraying Raoult nozzle. Mesh division refers to dividing a surface or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com