Multi-inlet, multi-spray fluidic cup nozzle with shared interaction region and spray generation method

A technology of nozzles and inlets, applied in the field of multiple inlets with a common interaction area, multiple jet cup nozzles and jet generation, which can solve the problems of increasing cost and increasing assembly complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

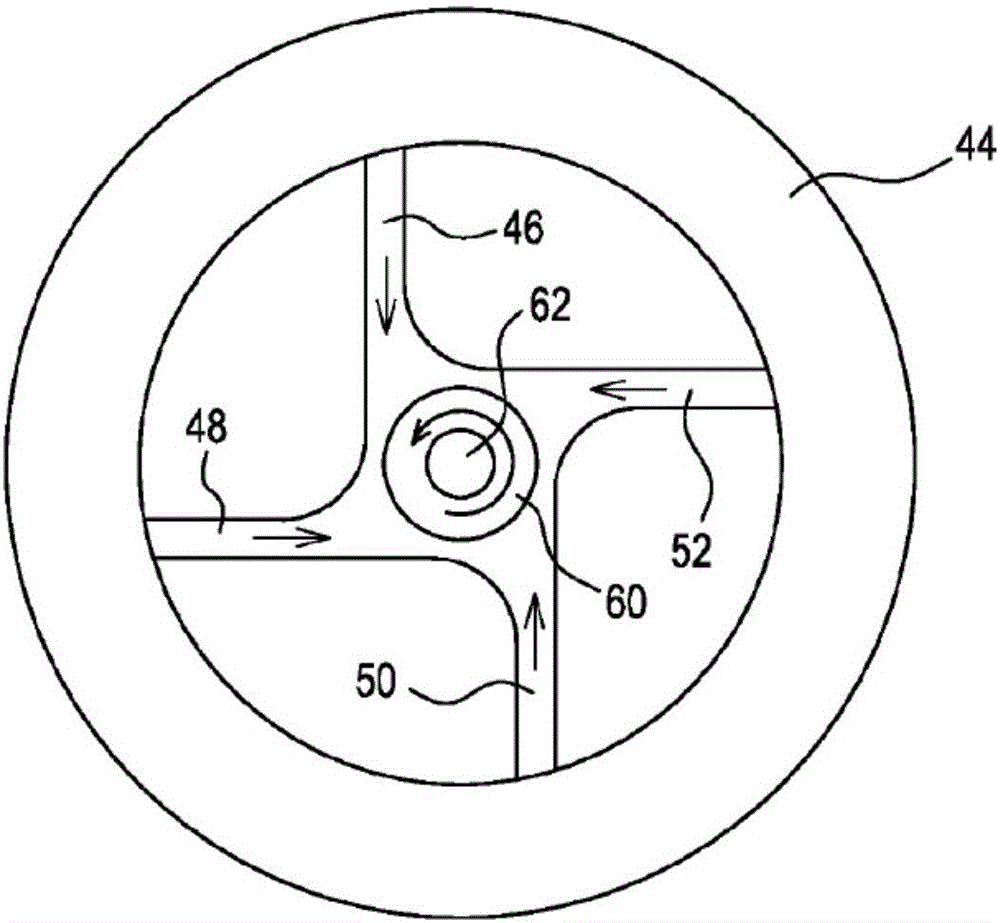

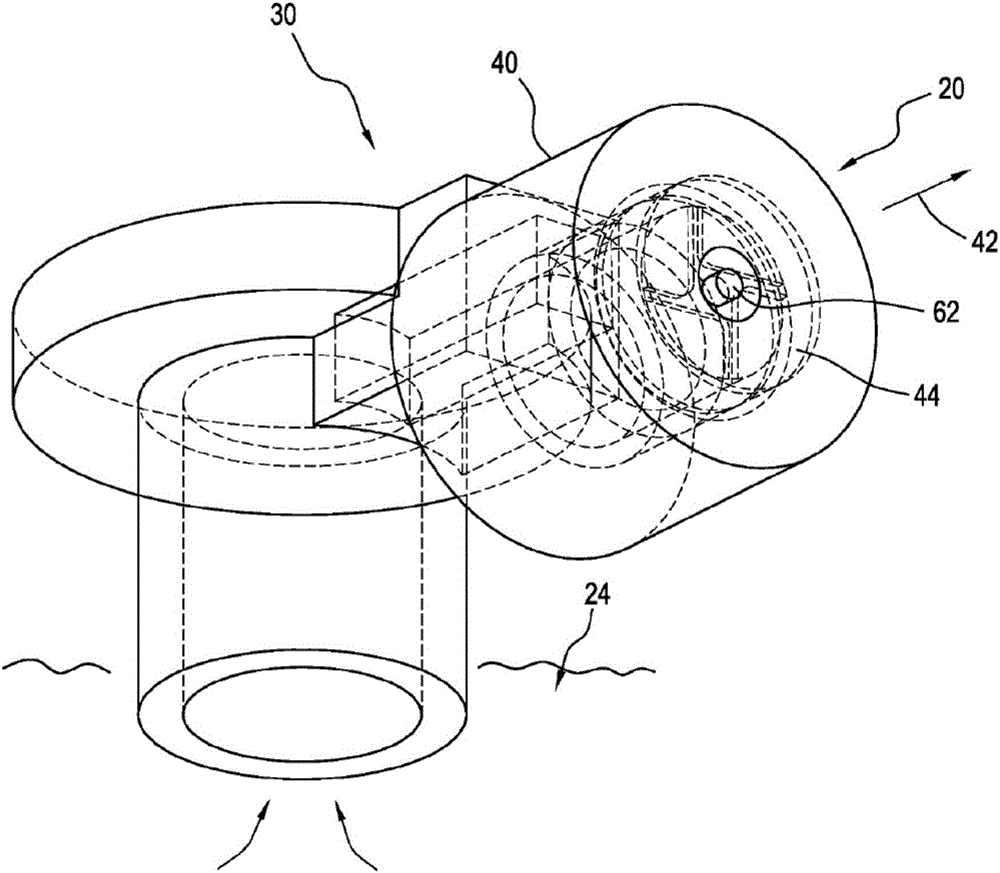

[0050] Figures 1A, 1B, 1C and 1D illustrate typical features of aerosol spray actuators and swirl cup nozzles used in the prior art, and these figures are described here to provide added background and context. Referring specifically to FIG. 1A, a typical transportable disposable propellant pressurized aerosol package 20 has a container 22 enclosing a liquid product 24 and an actuator 30 that controls a valve 32 mounted in a valve seat 34, A valve seat 34 is secured within a neck 36 of the container and is supported by a flange 38 of the container. Actuator 30 is depressed to open the valve and allow pressurized liquid to pass through nozzle 40 fitted with a spin cup to generate aerosol spray 42 . FIG. 1B shows the inner workings of a spin cup 44 used with a typical nozzle 40, where the four lumens 46, 48, 50 and 52 are aimed to produce four tangential flows indicated by the arrows in the lumens, which The tangential flow enters the spin chamber 60, where the continuously spu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com