Applicator for the application of a high-viscosity material, exchangeable part therefor and corresponding operating method

A technology for replacing parts, applicators, applied in coatings, devices for applying liquid to surfaces, etc., can solve problems such as fixed nozzle geometry, time consumption, changing cycle time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

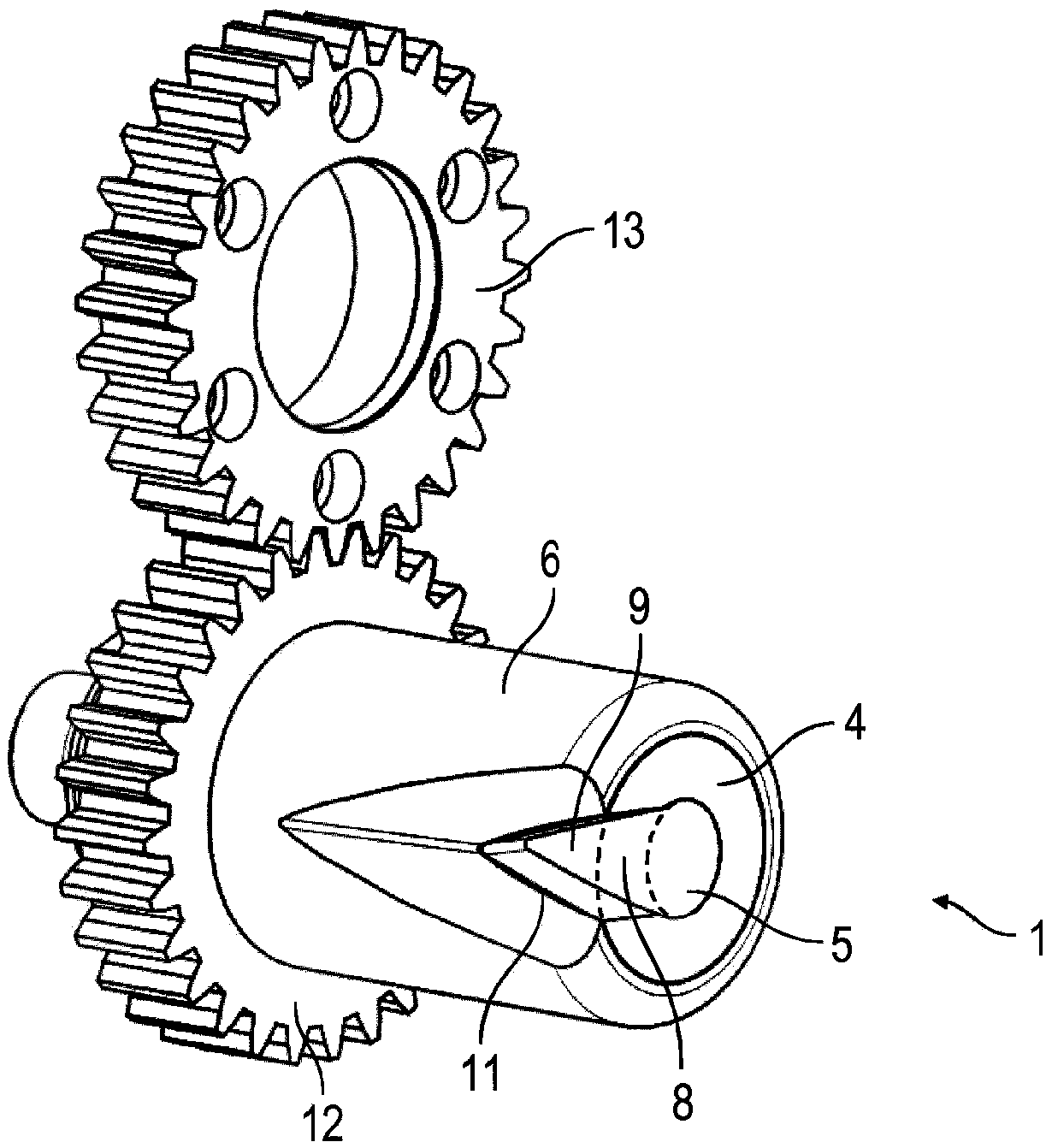

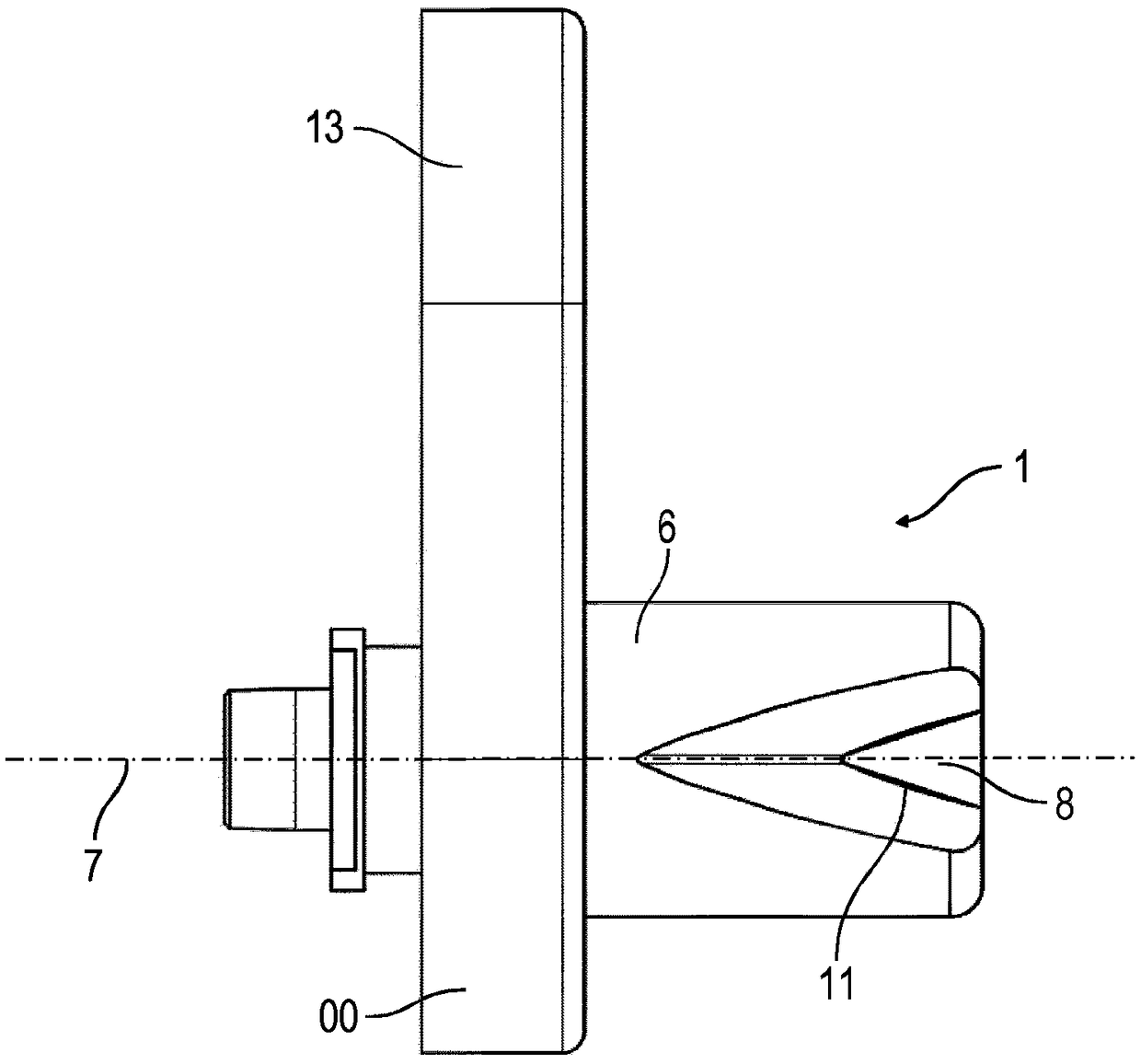

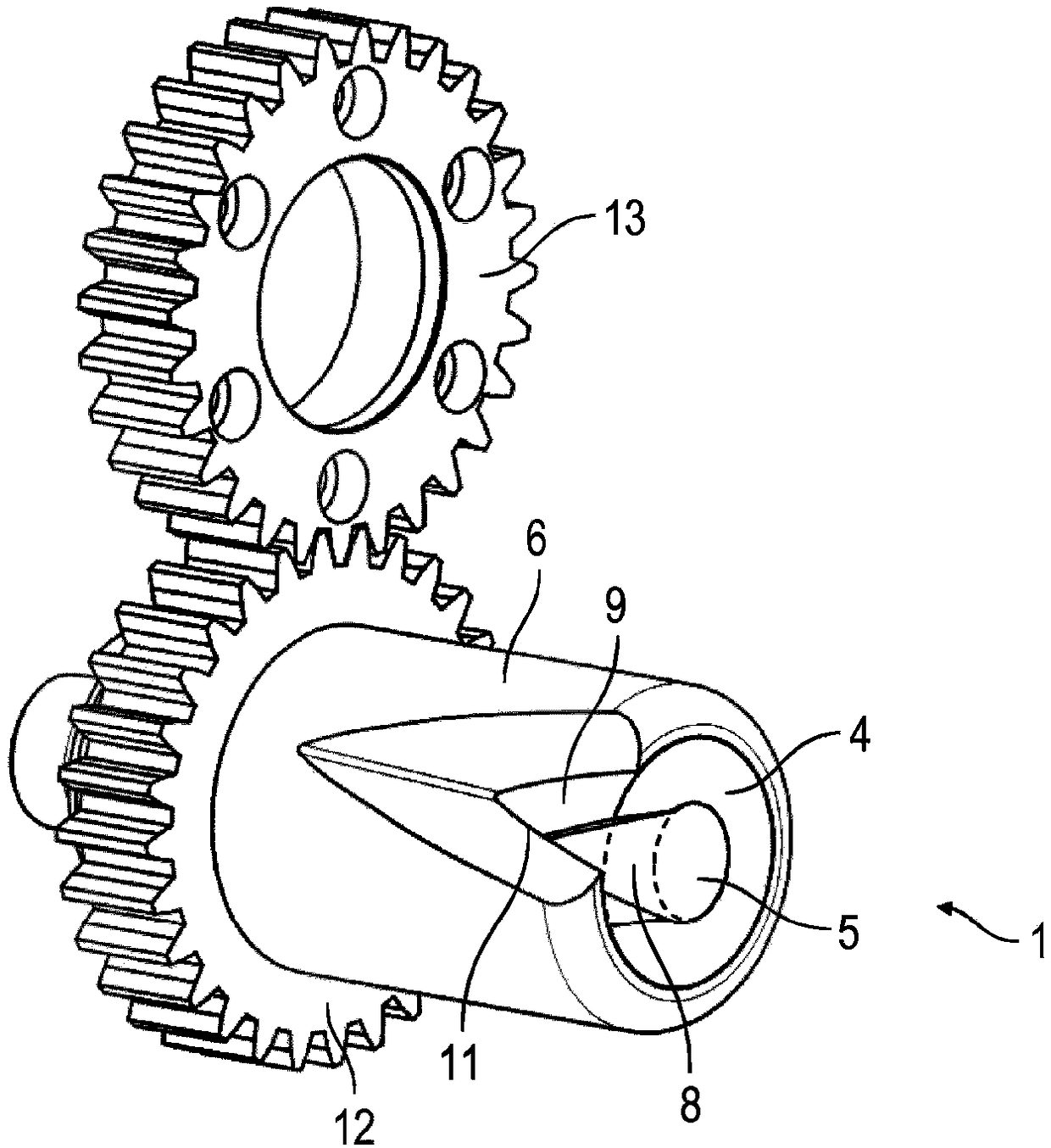

[0034] The figures show different views of an applicator 1 for applying a strip of a thick substance (eg adhesive, sealant) to a component 3 (eg a body component of a motor vehicle). ) on the component surface 2.

[0035] The application of strips of thick substance to component surfaces is theoretically known from the prior art, so a detailed description of the application of strips of thick substance can be omitted, for which reference is made to the prior art in this field.

[0036] Furthermore, it should be mentioned that the drawings illustrate only schematically the principles of the invention, whereby variations in size and design of various components are possible.

[0037] The applicator 1 firstly has a hollow cylindrical inner tube 4 through which the coating agent to be applied flows during operation and which has a front opening 5 at its free end.

[0038]Furthermore, the applicator 1 has an outer tube 6 which surrounds the inner tube 4 on the outside and extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com