Filter units for exhaust hoods

A technology of filter and exhaust hood, which is applied in the direction of filtration separation, dispersed particle filtration, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

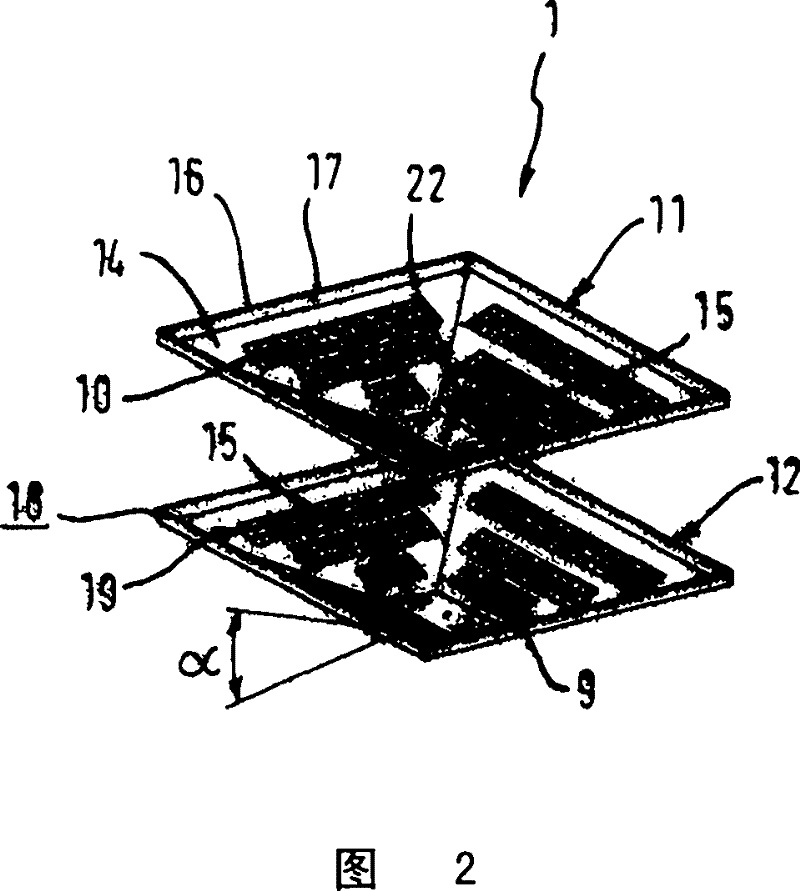

[0036] exist figure 1 An exemplary embodiment of a filter arrangement 1 according to the invention in the installed state in an exhaust hood 2 is shown in . The exhaust hood 2 has an outer shell 3 and a vapor screen 4 arranged below the outer shell 3 . Operating elements such as, for example, switches 5 are provided on the front side of the vapor screen 4 . Furthermore, it is shown that a lighting element 6 is provided on the underside of the vapor screen 4 .

[0037] Formed in the underside of the vapor screen 4 is a suction opening 7 surrounded by a screen 8 which extends towards the suction opening 7 . Water vapor or vapor thus flowing towards the underside of the vapor screen 4 can be directed towards the suction opening 7 . The suction port 7 is covered by the filter device 1 .

[0038] The filter device 1 has a square truncated pyramid shape with edges protruding downward from the suction opening 7 . In the exemplary embodiment shown, the collection container 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com