Compressor blade with nozzle

a compressor blade and nozzle technology, applied in the direction of blade accessories, machines/engines, gas turbine plants, etc., can solve the problems of downstream blade damage, drop impingement erosion,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009]The description and the figures show only exemplary embodiments of the invention.

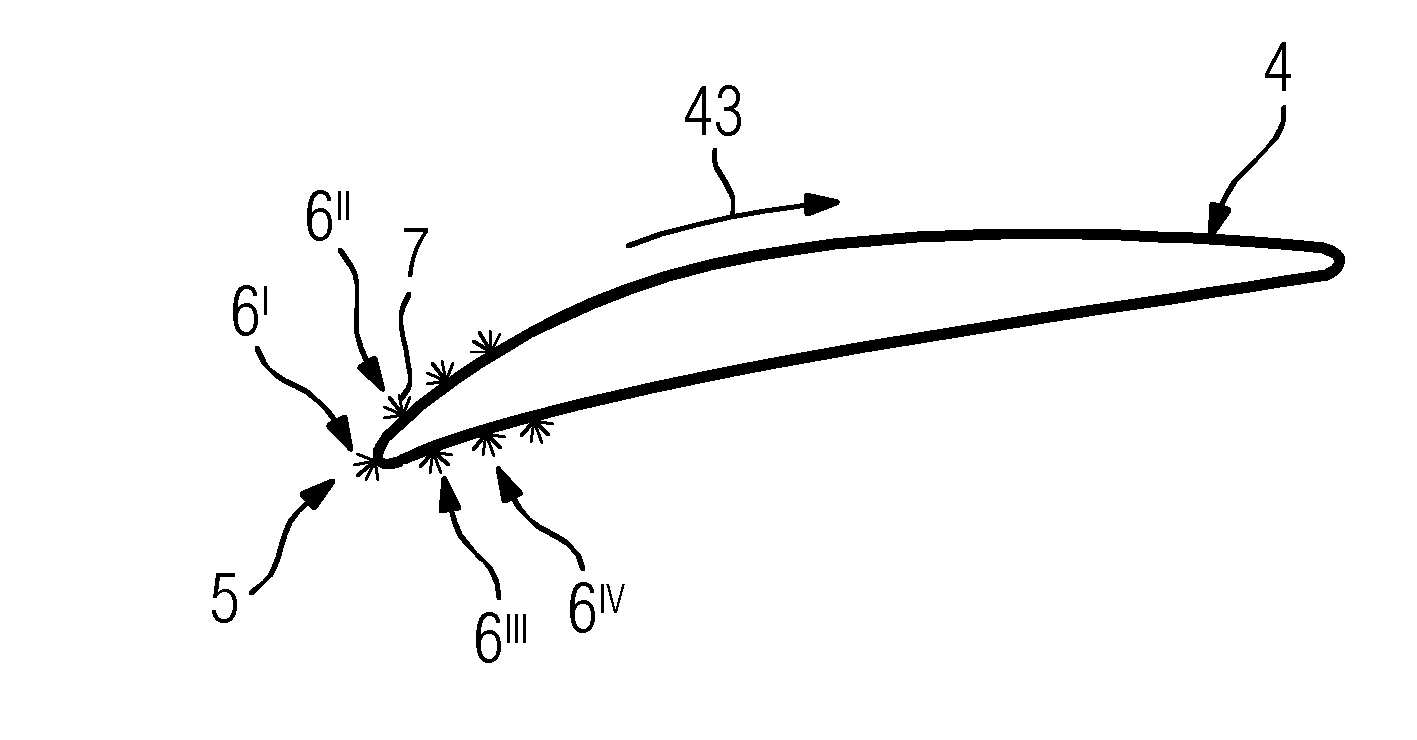

[0010]FIG. 1 shows a cross section of a blade airfoil, in particular of a compressor blade 4, which, in particular at its leading edge or incident flow region 5 and downstream therefrom on the suction face and / or pressure face, has a plurality of nozzles 6, 6I, 6II, . . . , out of which a fluid 7, in particular water, exits.

[0011]This is used for wet compression when operating a gas turbine 100 (FIG. 13).

[0012]The suction and pressure faces can feature the same number or different numbers of nozzles 6, 6I, 6ii. . .

[0013]In particular, a nozzle 6, 6I, . . . is present in the leading edge 5.

[0014]Perpendicular to the plane of the drawing, more nozzles 6, 6I, . . . can be present at the leading edge 5 and / or on the suction face or pressure face.

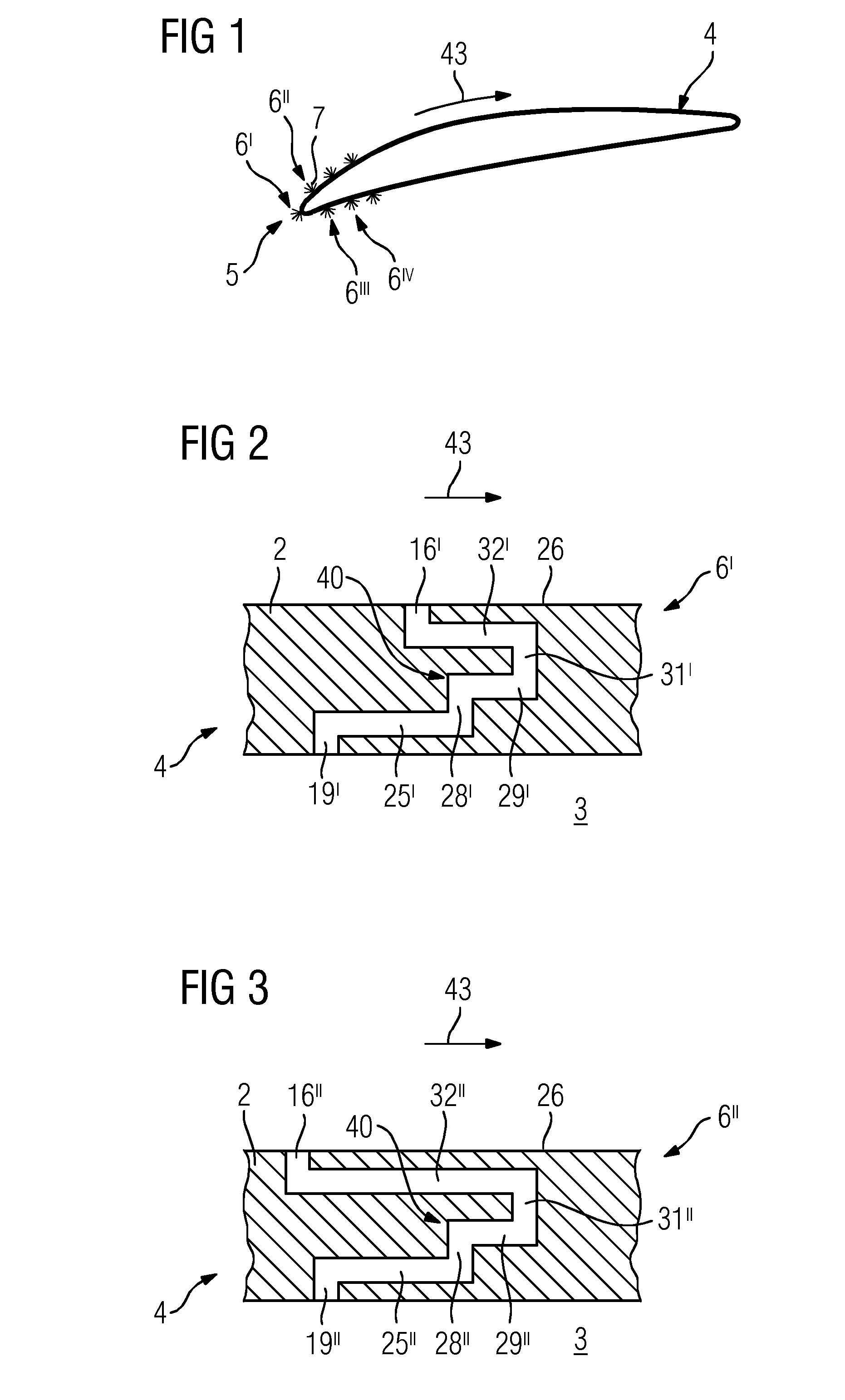

[0015]The compressor blade 4 usually has, inside it, a hollow space 3 which is surrounded by walls 2 and by means of which the fluid can be fed to the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com