Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118 results about "Nickel–zinc battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

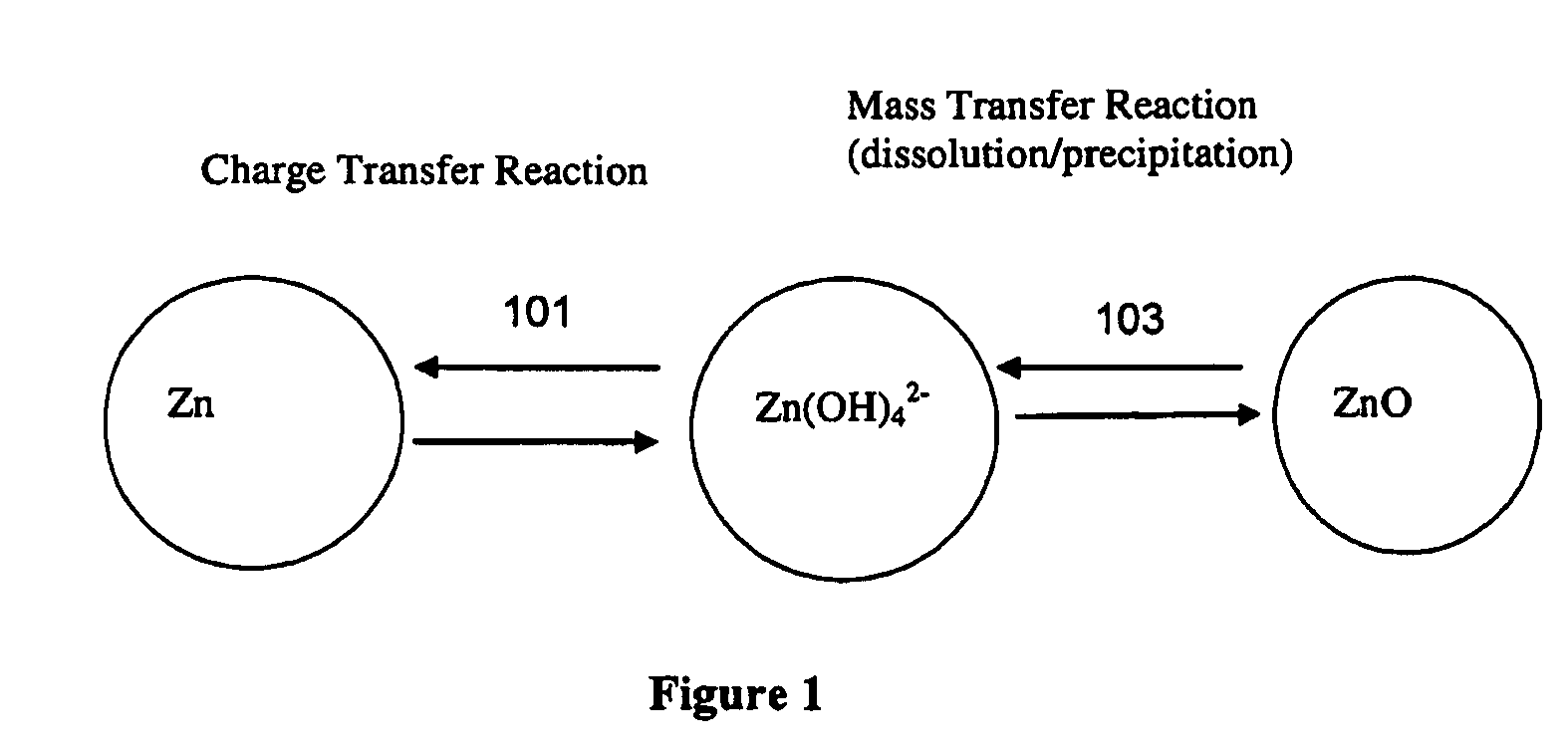

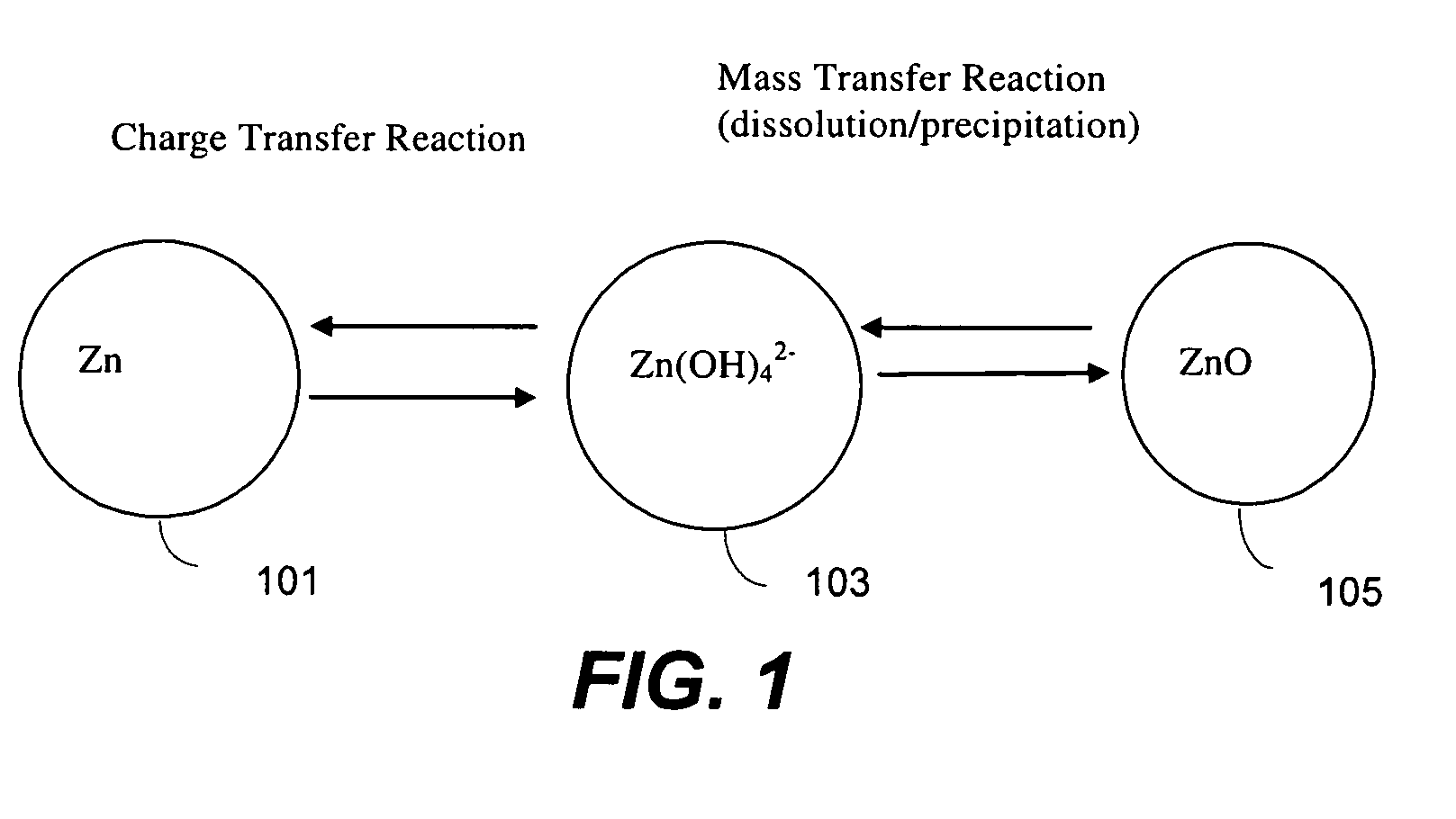

A nickel–zinc battery, abbreviated NiZn, is a type of rechargeable battery similar to NiMH batteries, but with a higher voltage of 1.6 V. Larger nickel–zinc battery systems have been known for over 100 years. Since 2000, development of a stabilized zinc electrode system has made this technology viable and competitive with other commercially available rechargeable battery systems. Unlike some other technologies, trickle charging is not recommended.

Nickel zinc battery design

ActiveUS20060240317A1Resist buildupLower impedanceElectrode carriers/collectorsCell component detailsHydrogenElectrical polarity

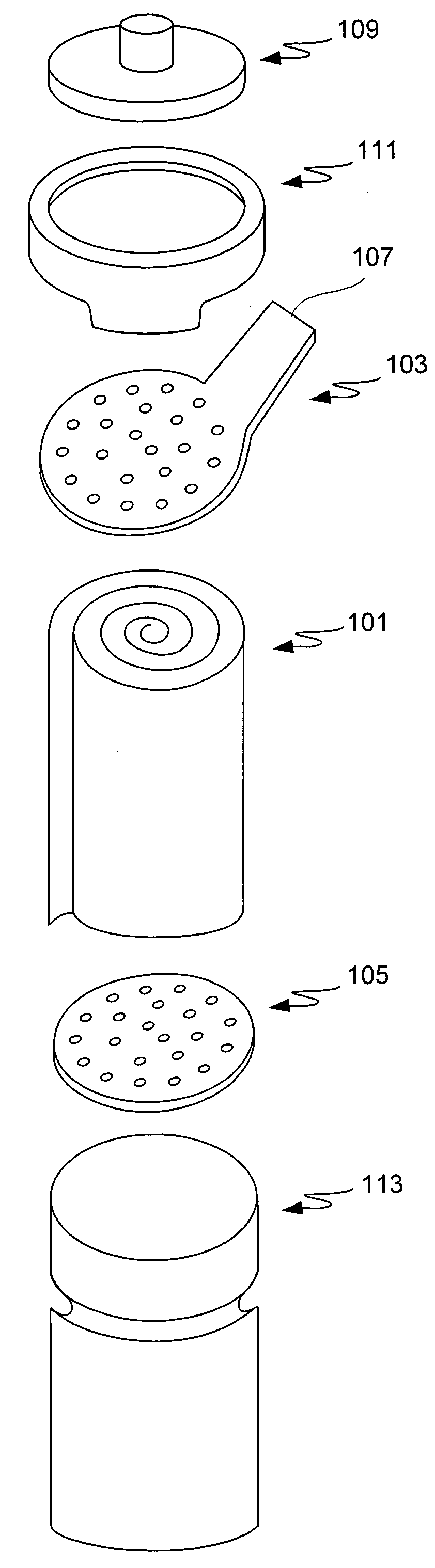

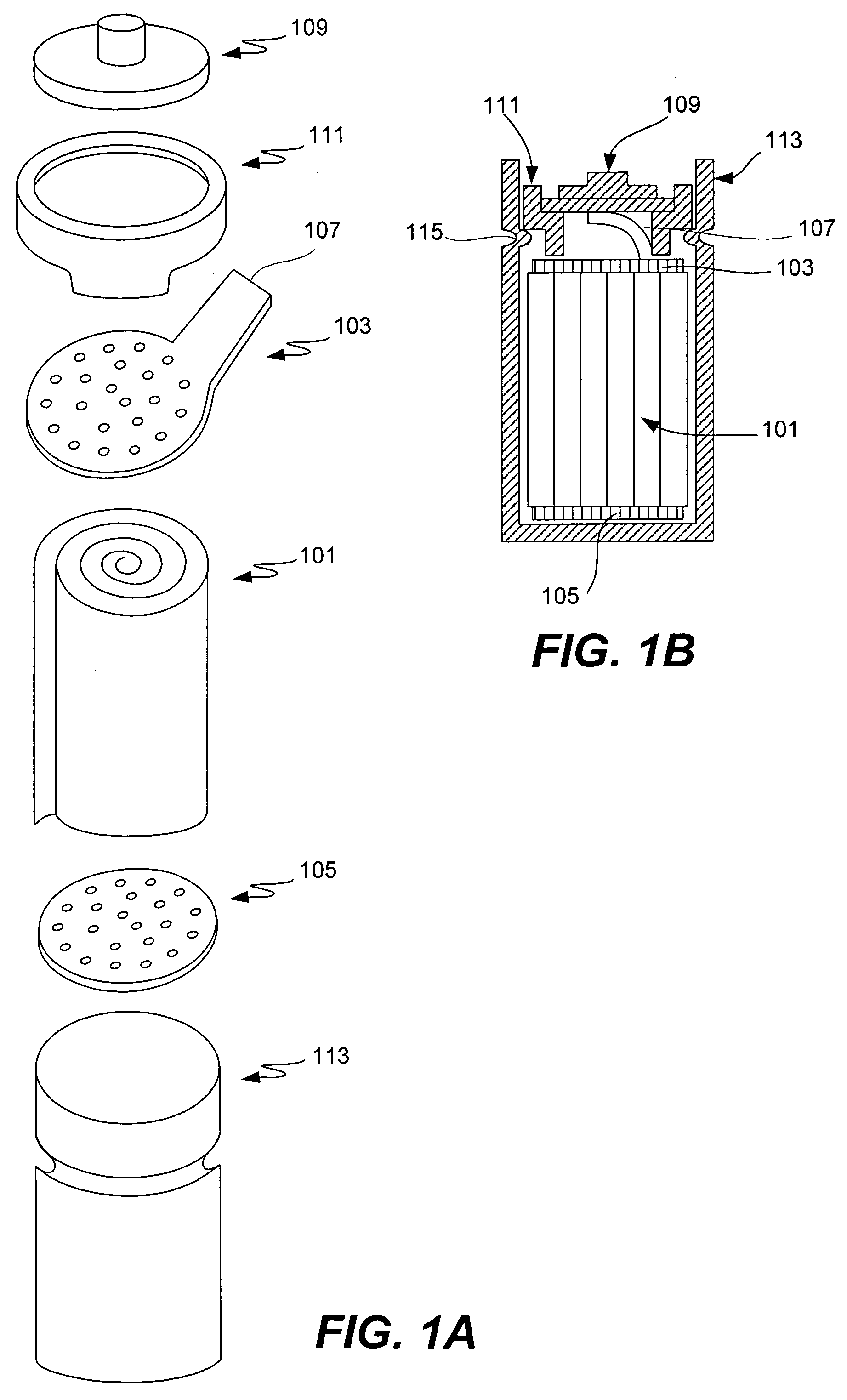

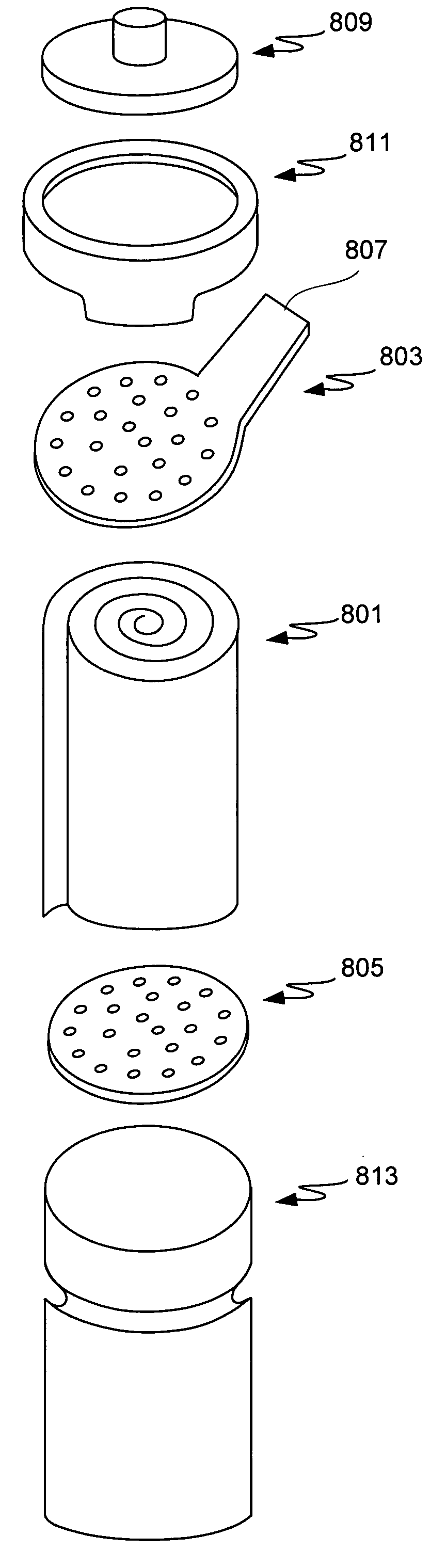

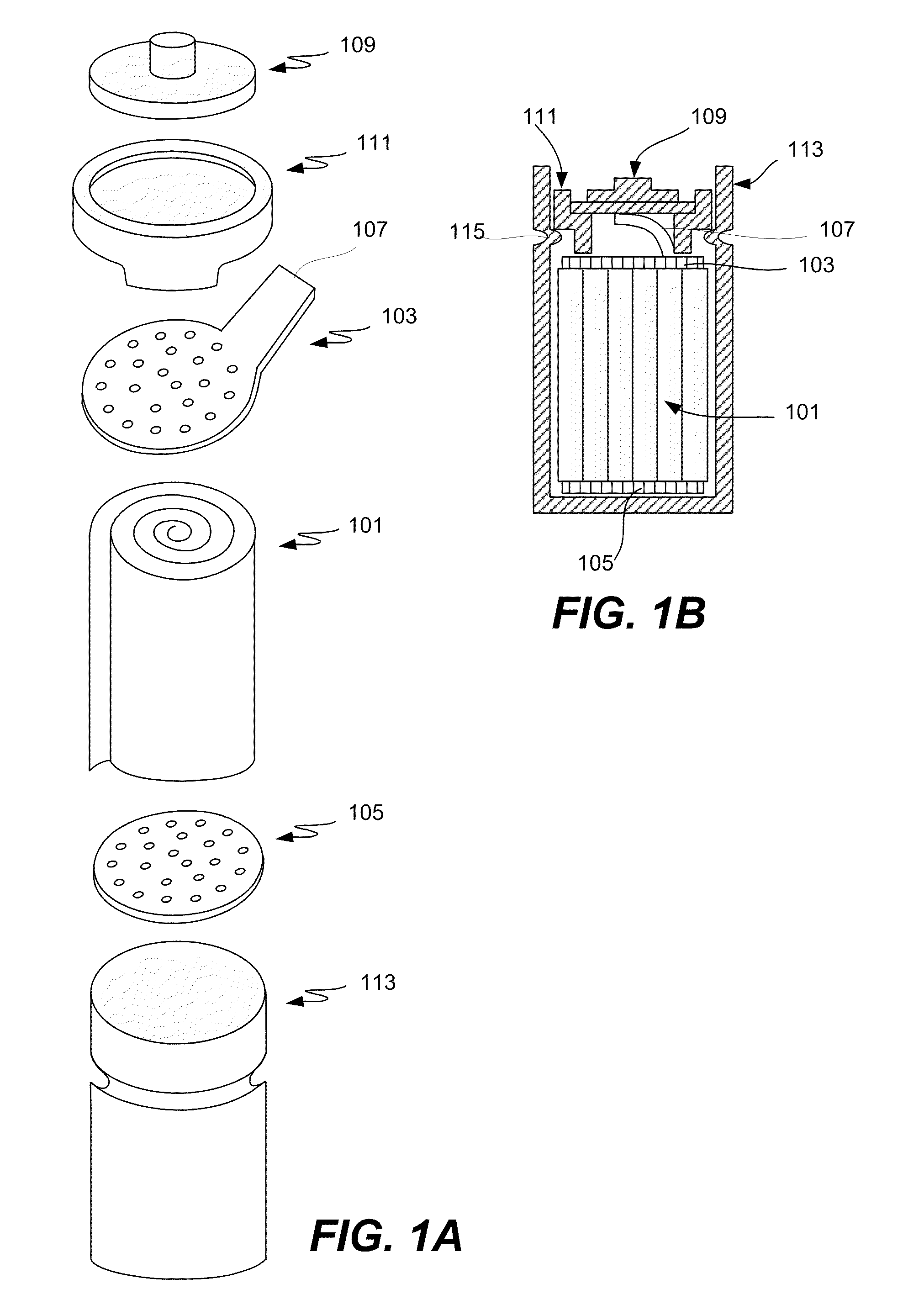

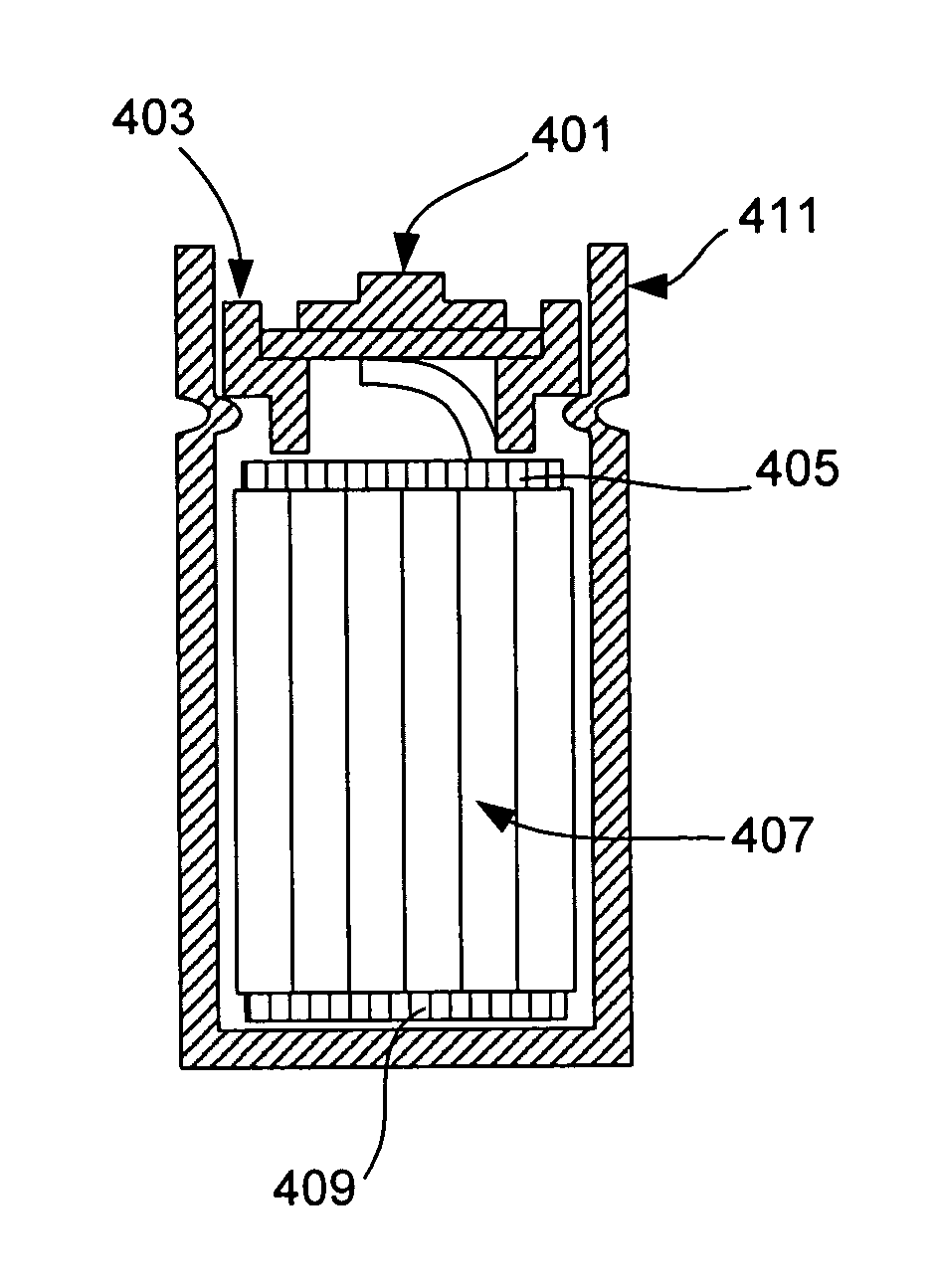

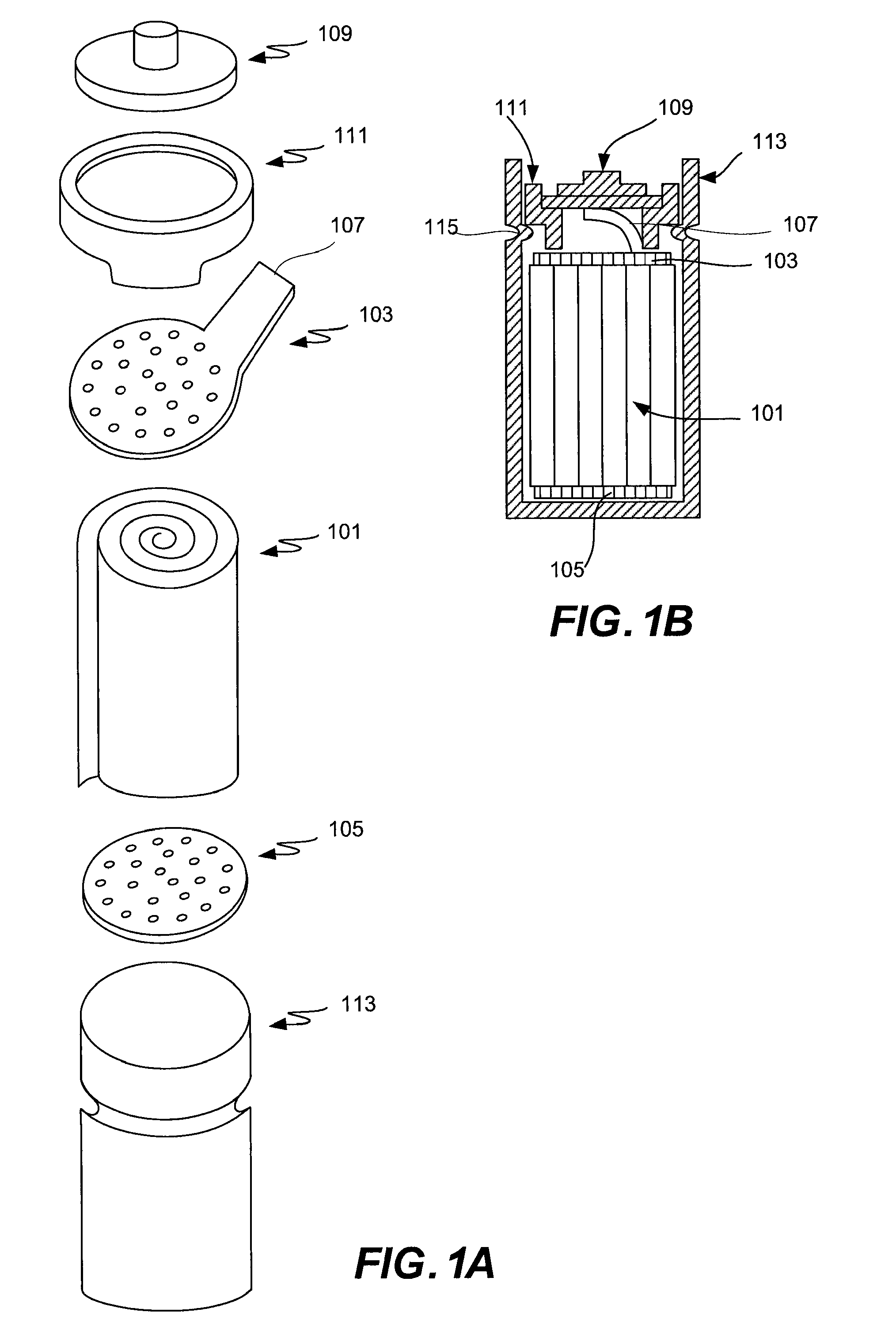

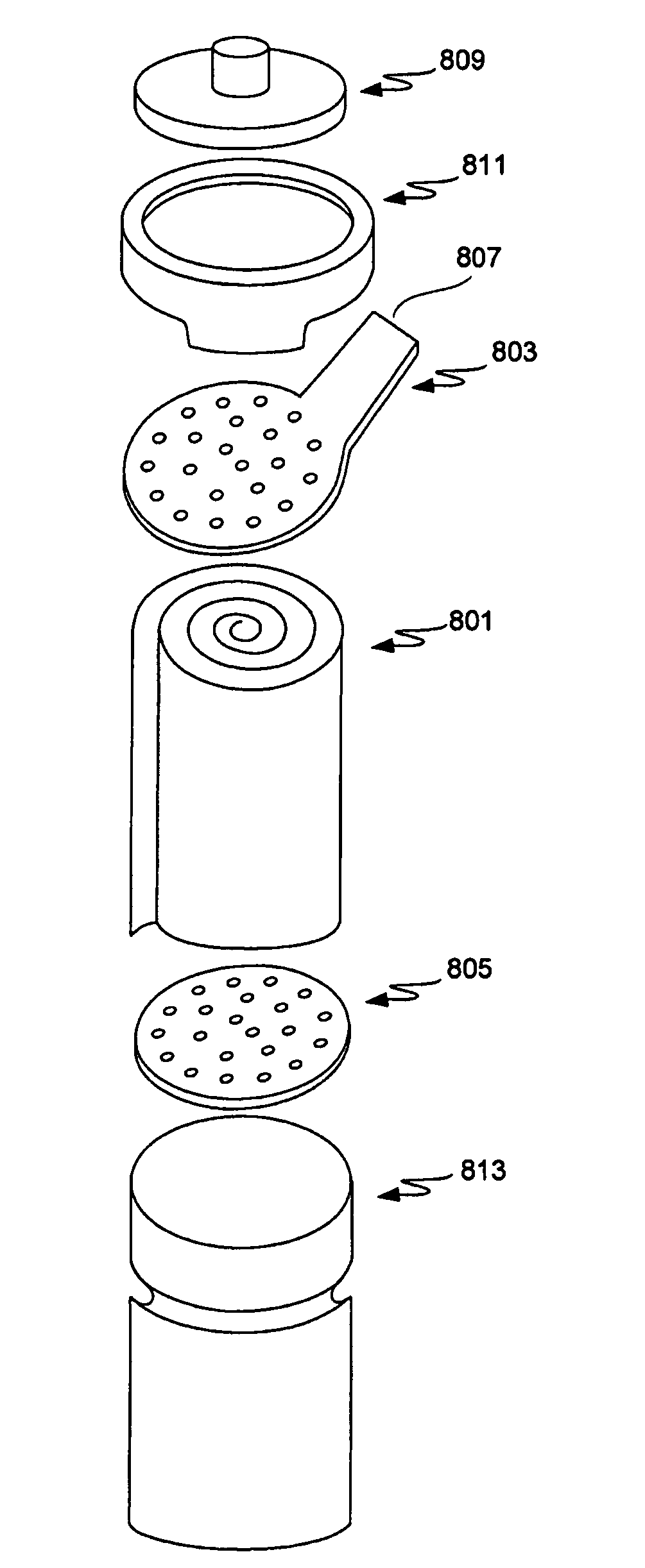

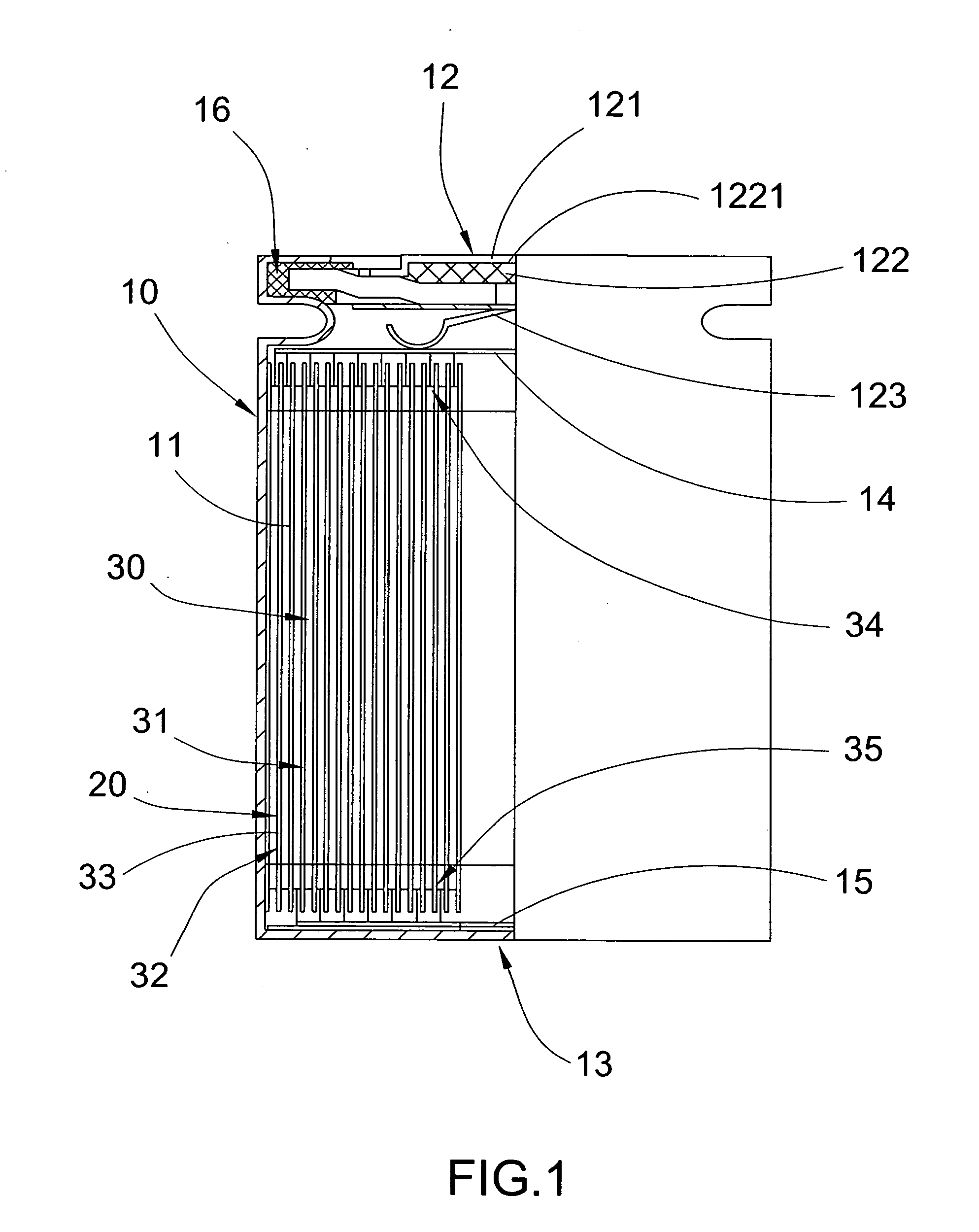

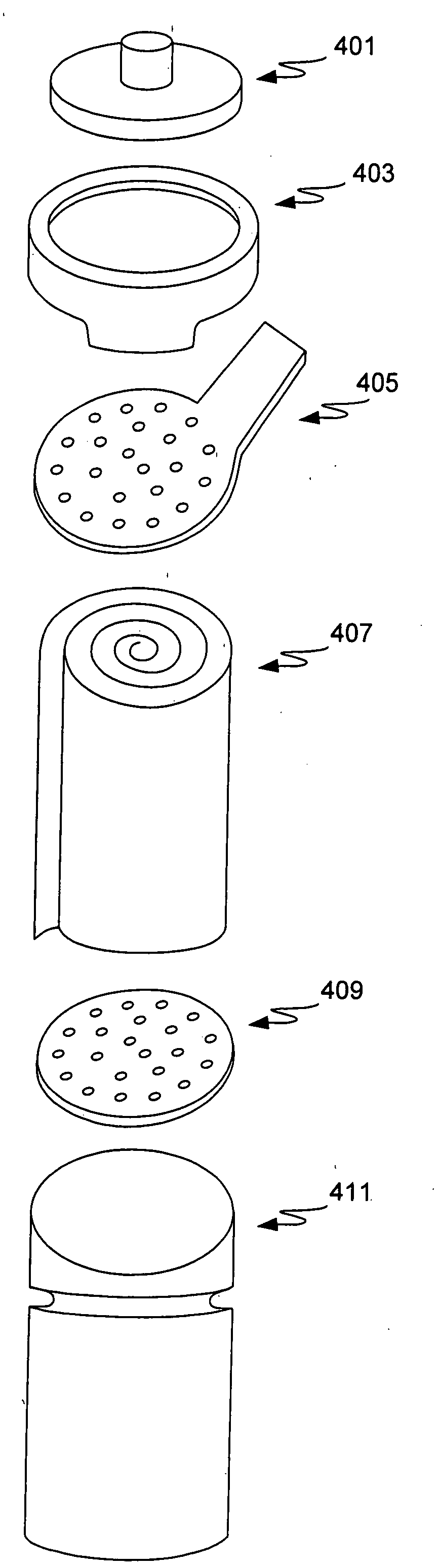

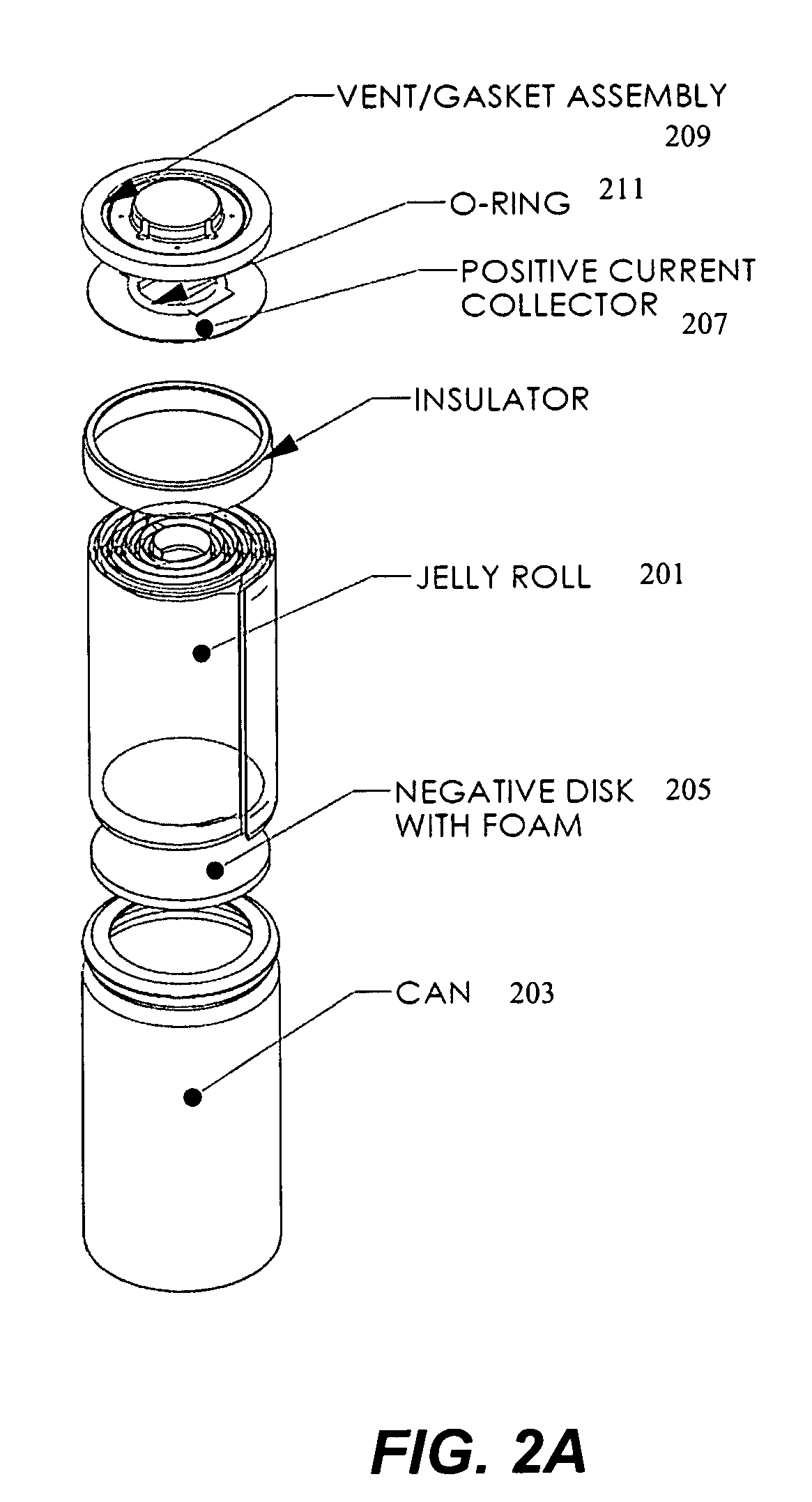

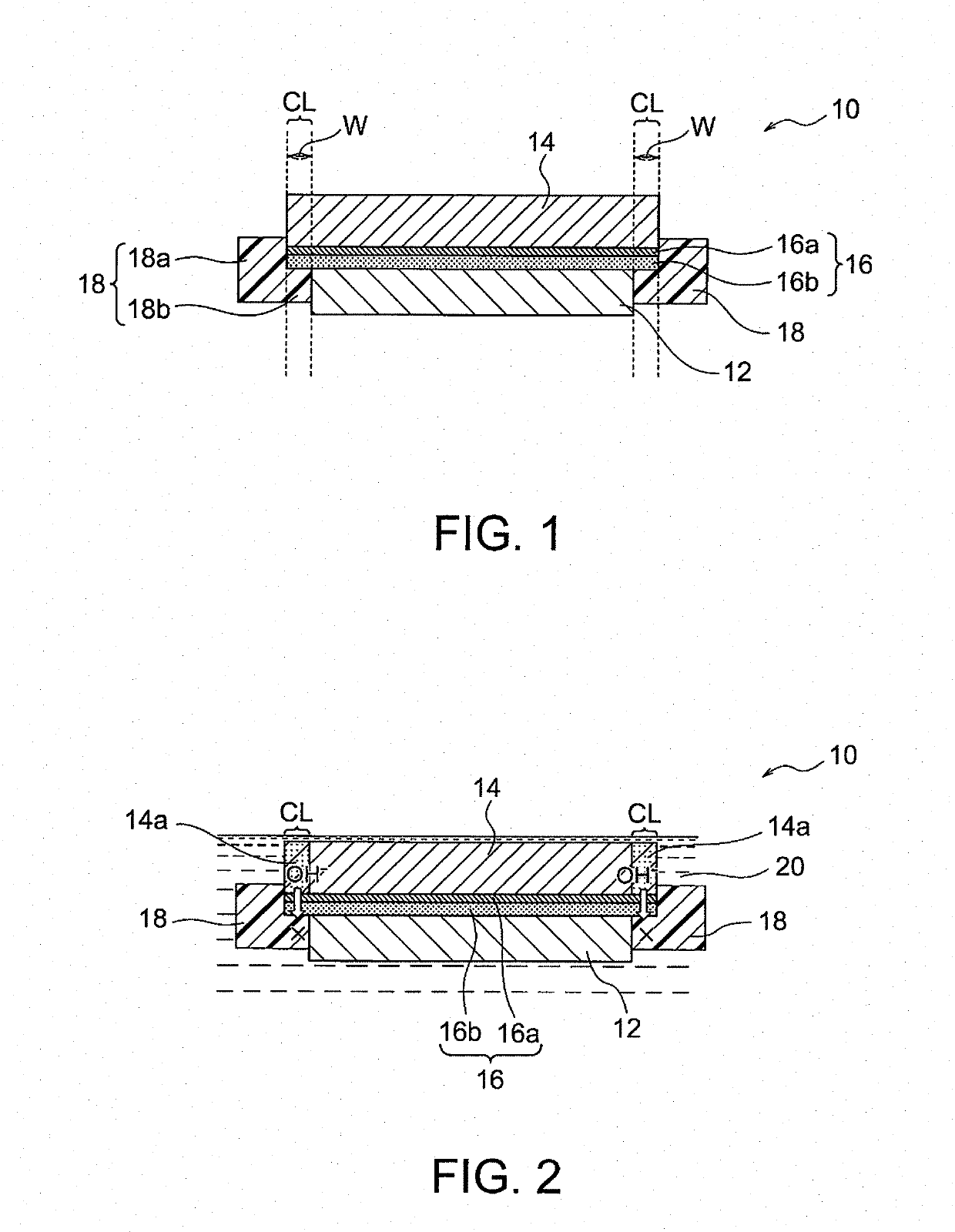

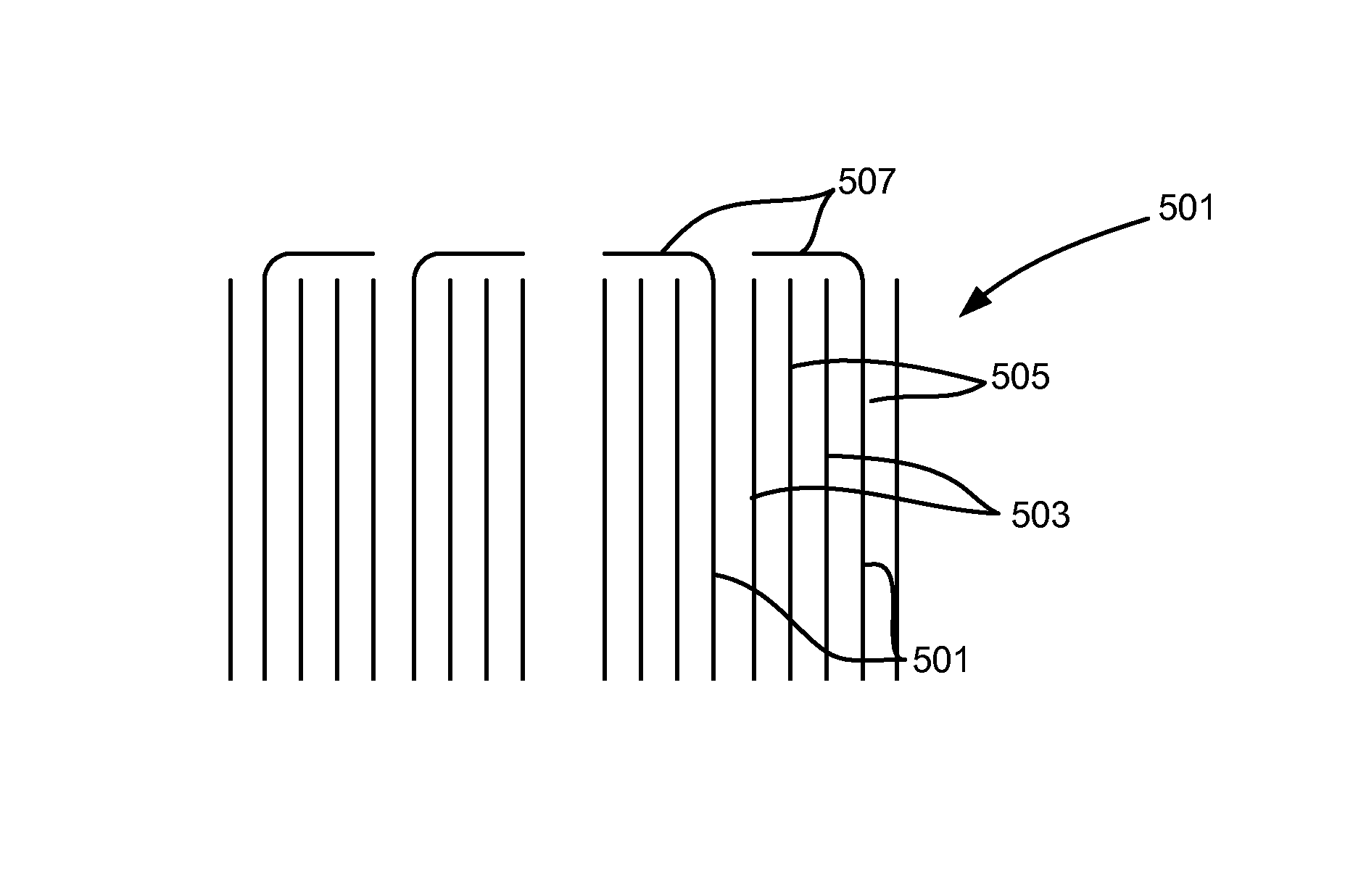

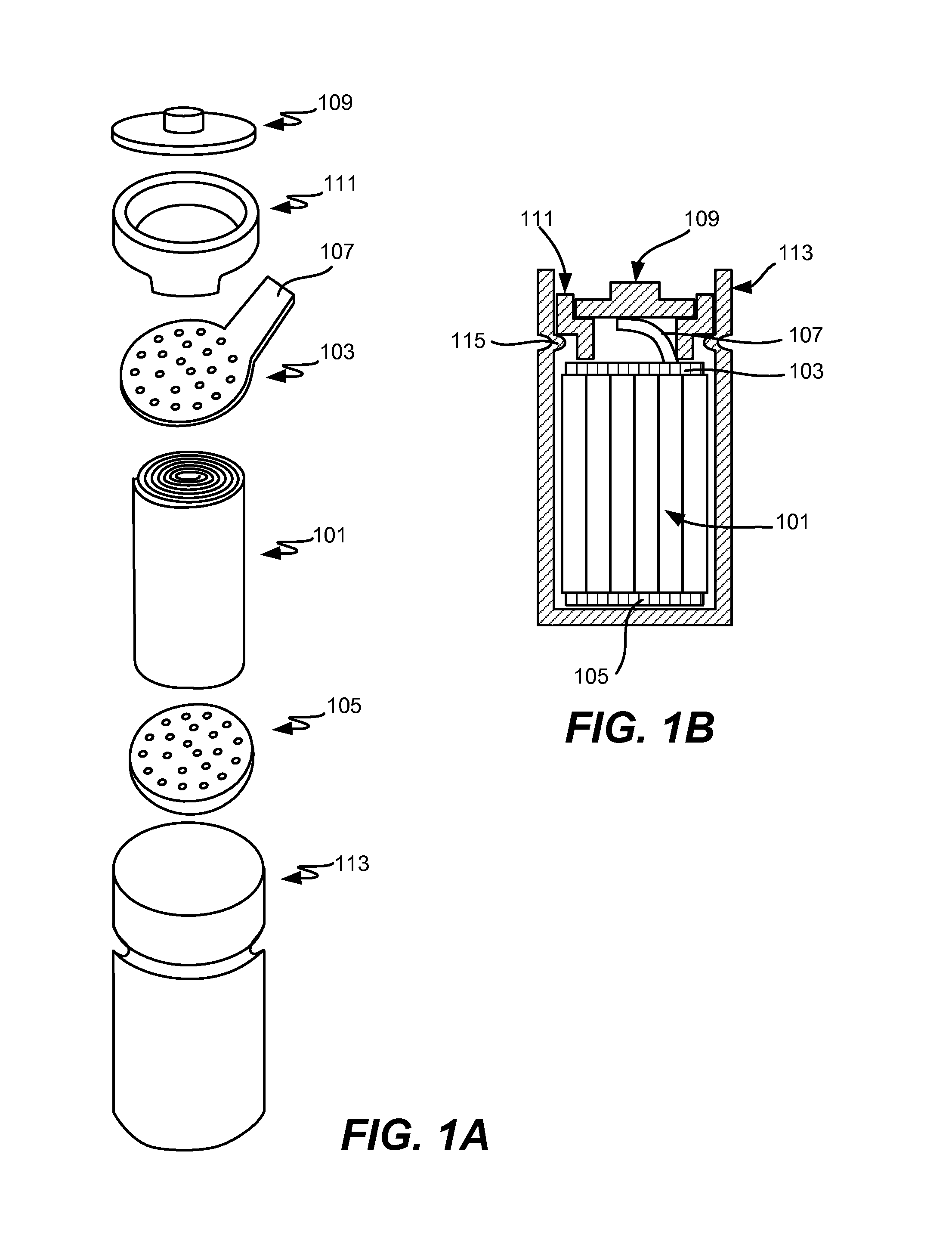

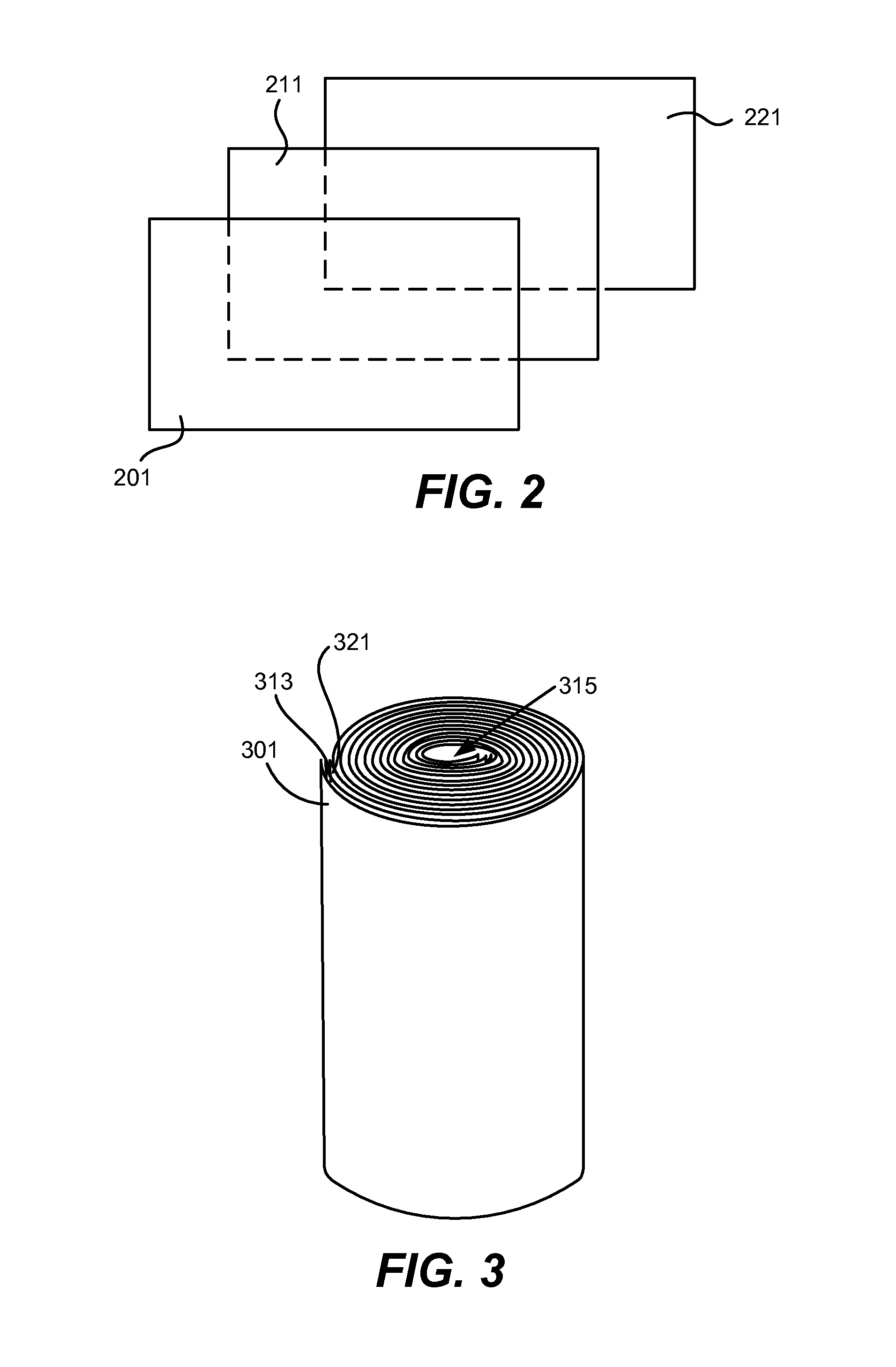

Nickel zinc cylindrical battery cell designs are described. The designs provided limit dendrite formation and prevent build up of hydrogen gas in the cell. The present invention also provides low-impedance cells required by rapid discharge applications. The cylindrical battery cells may have polarity opposite of that of conventional power cells, with a negative cap and positive can. The cylindrical cells may include a gel electrolyte reservoir.

Owner:ZINCFIVE POWER INC

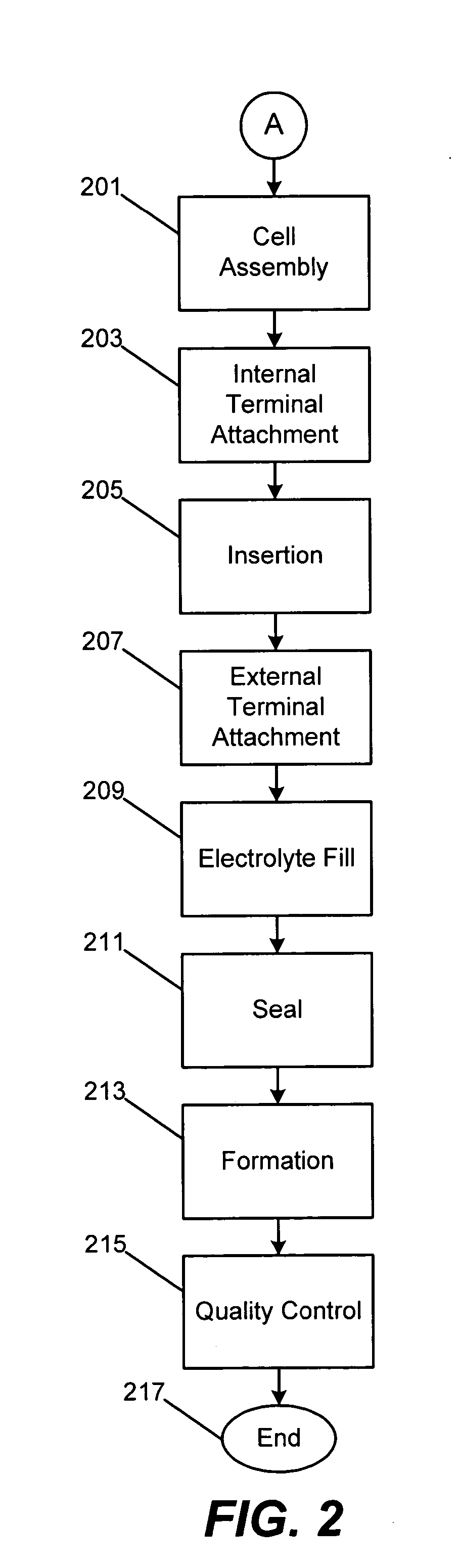

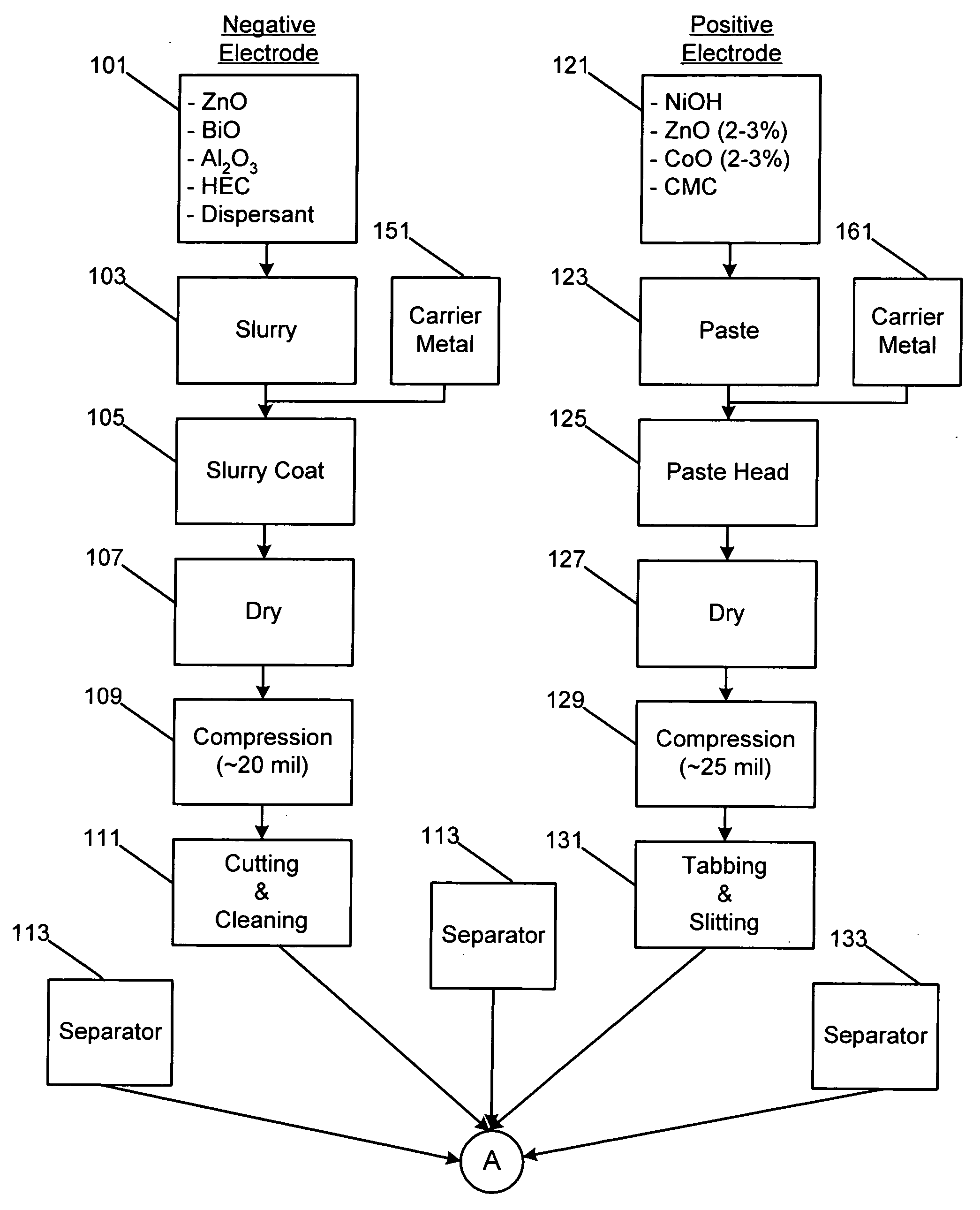

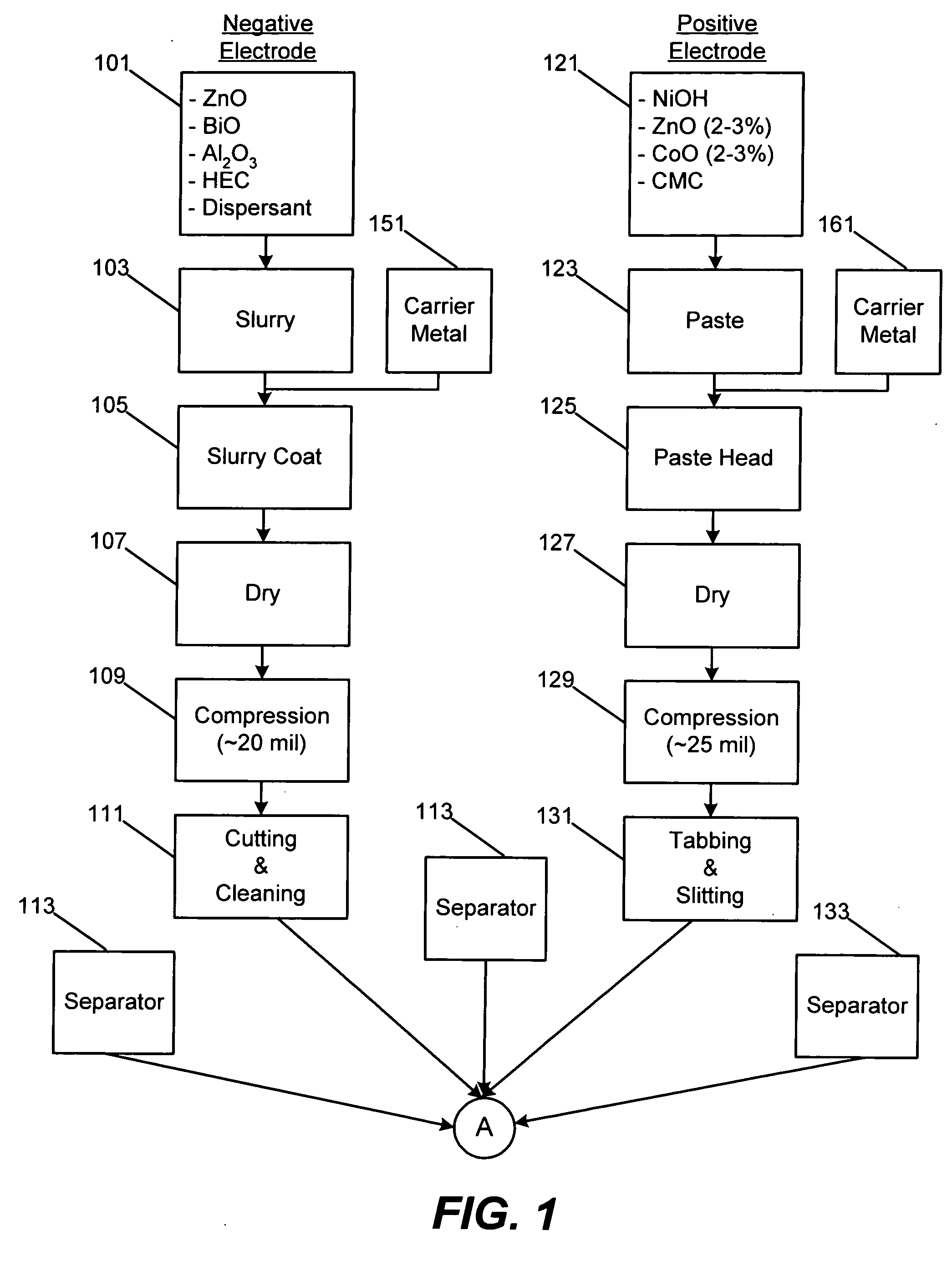

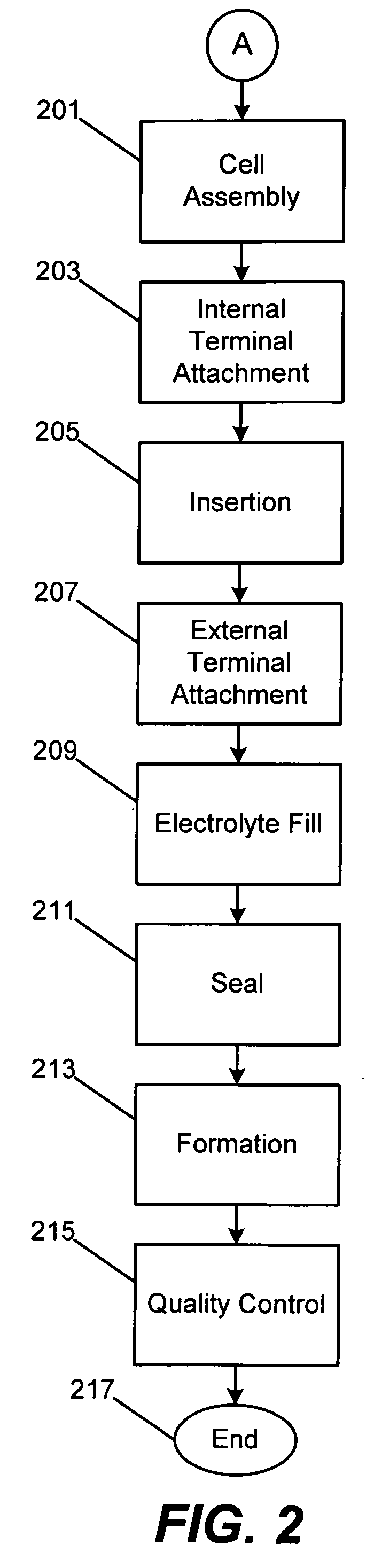

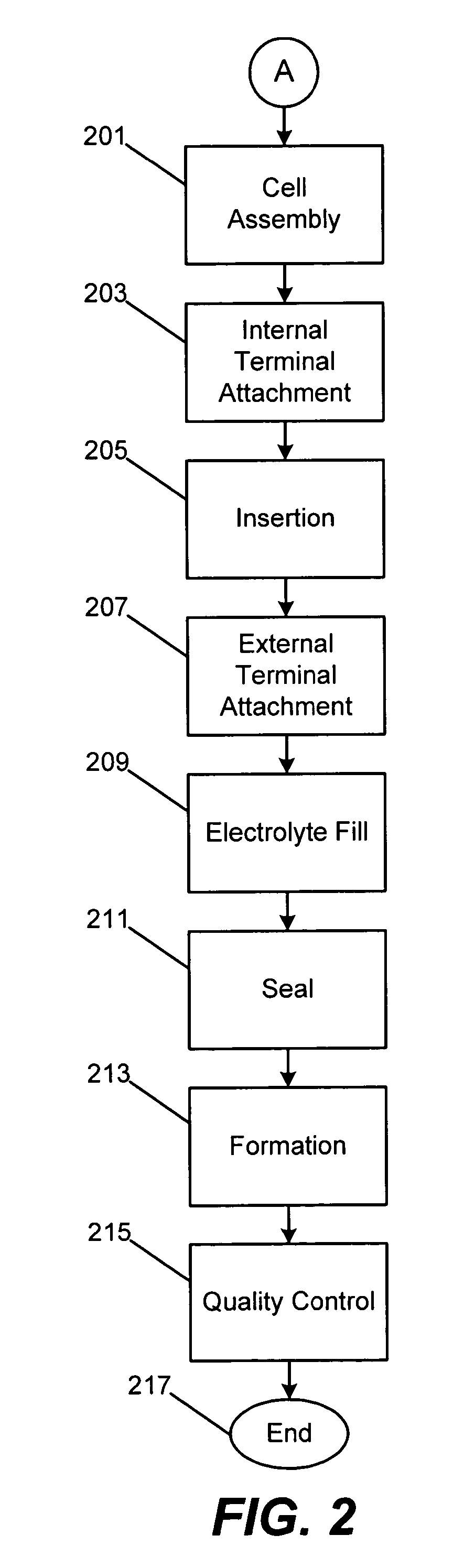

Method of manufacturing nickel zinc batteries

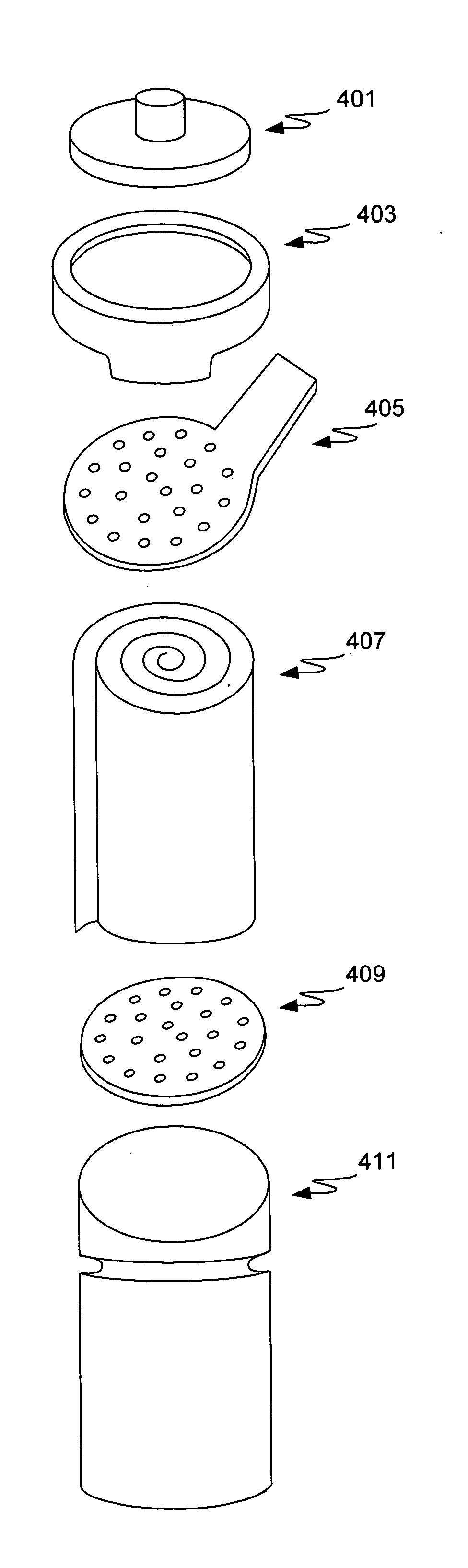

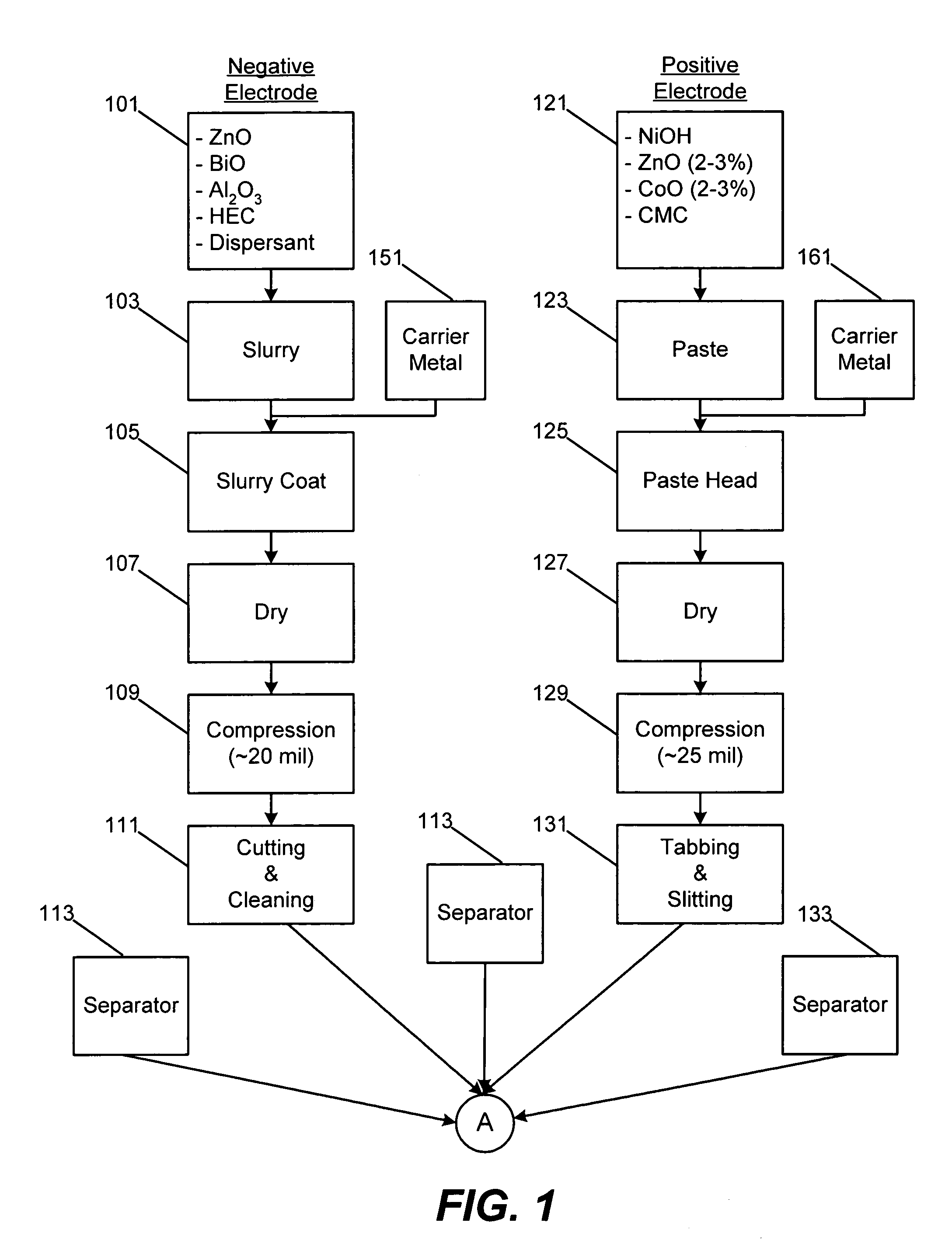

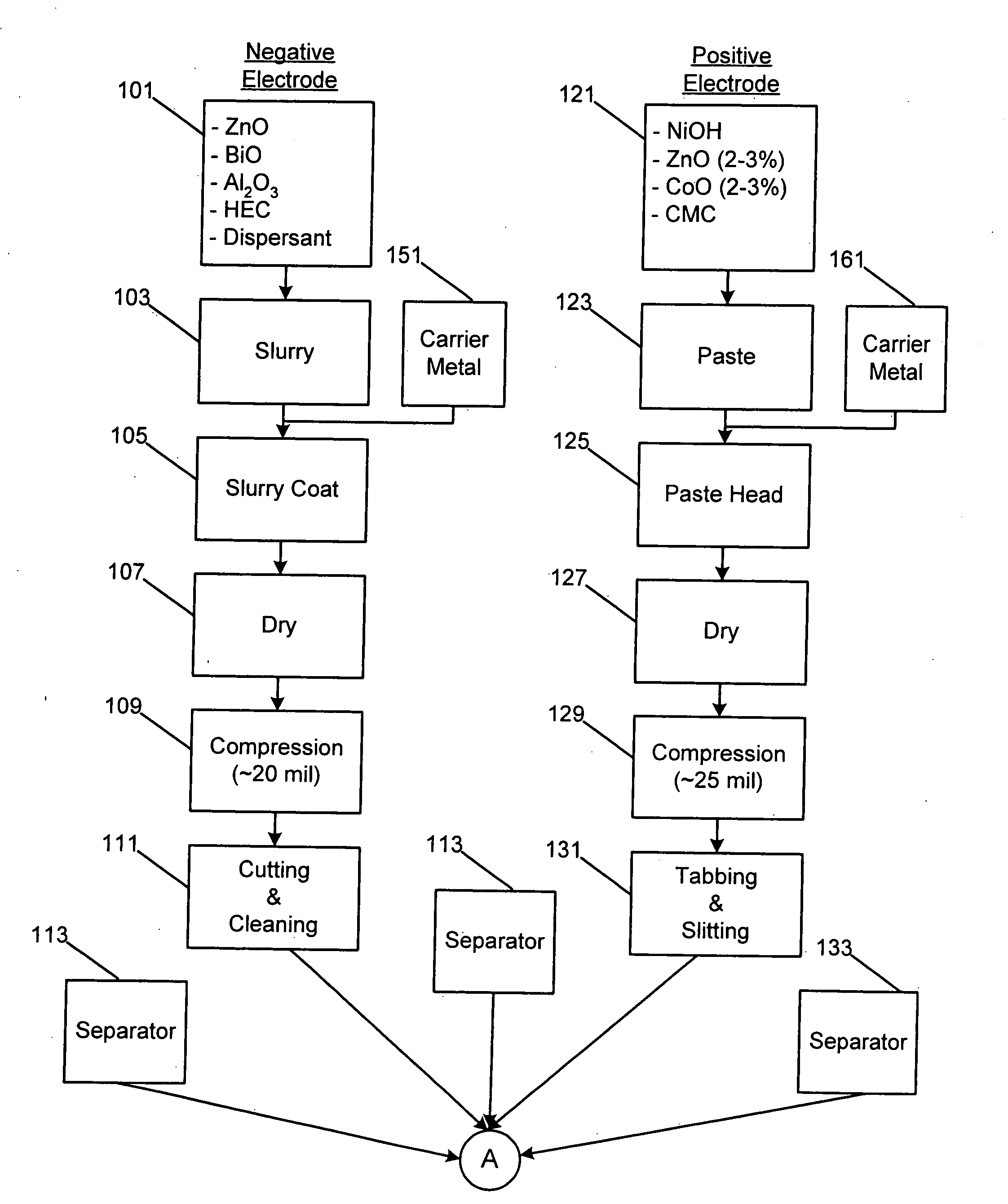

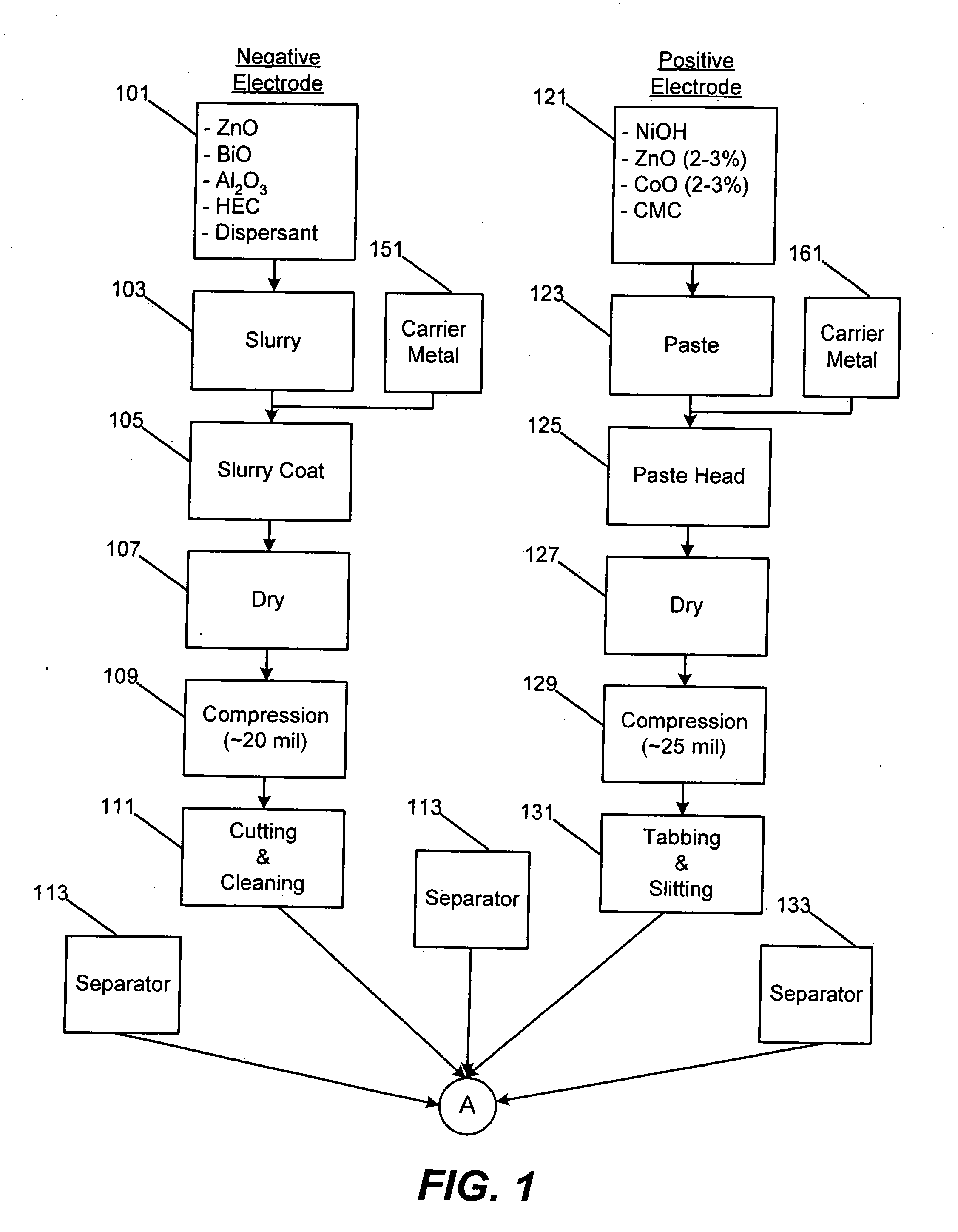

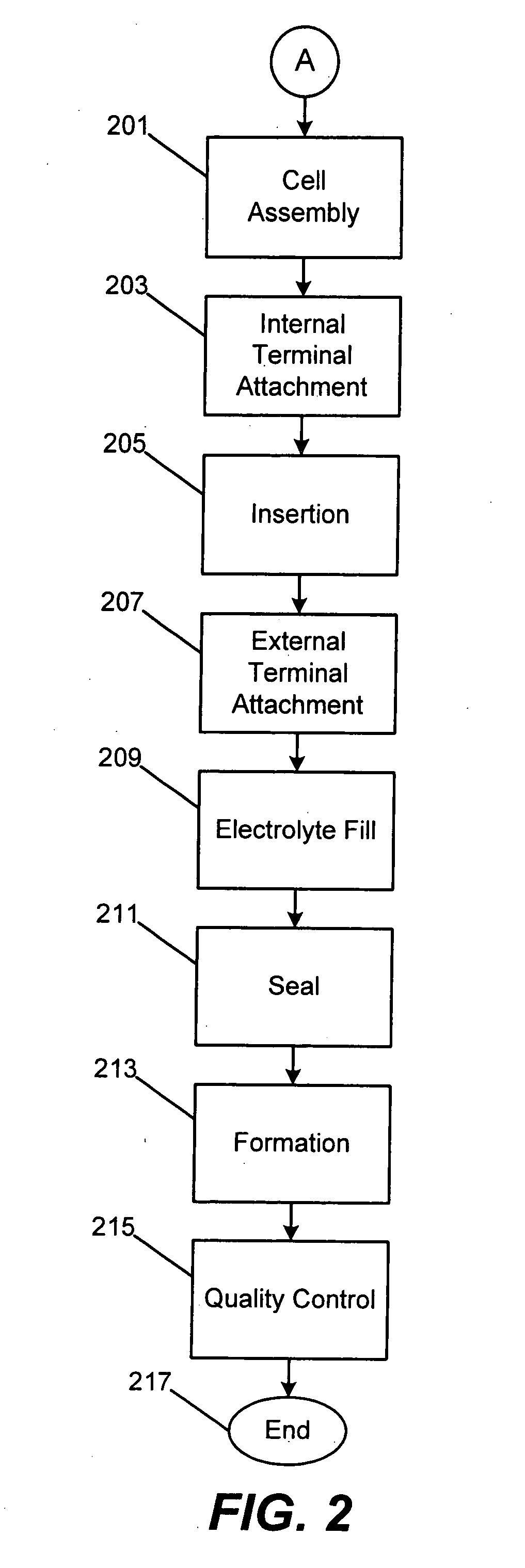

ActiveUS20050064292A1Improve efficiencyFinal product manufactureElectrode carriers/collectorsZinc compoundsSlurry

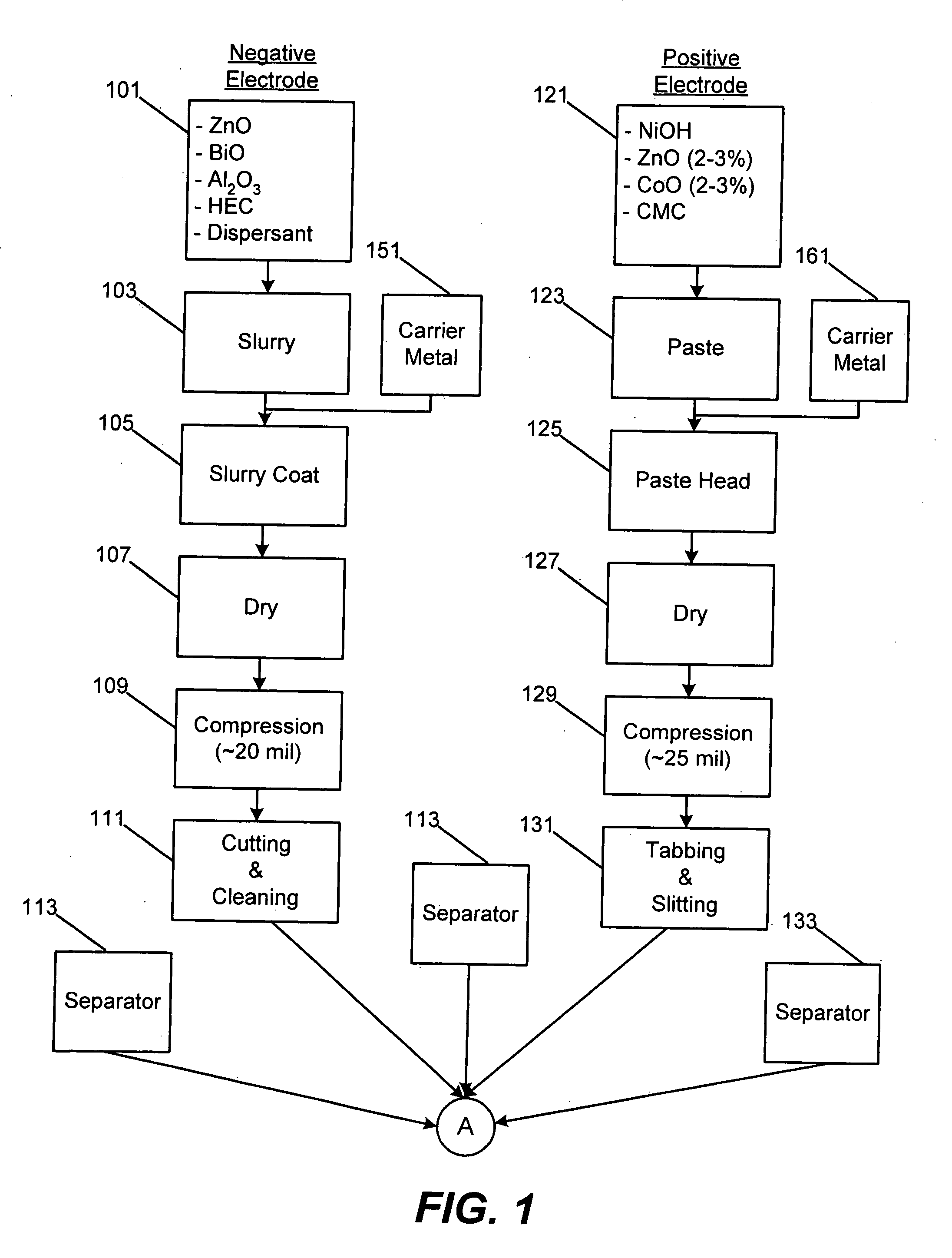

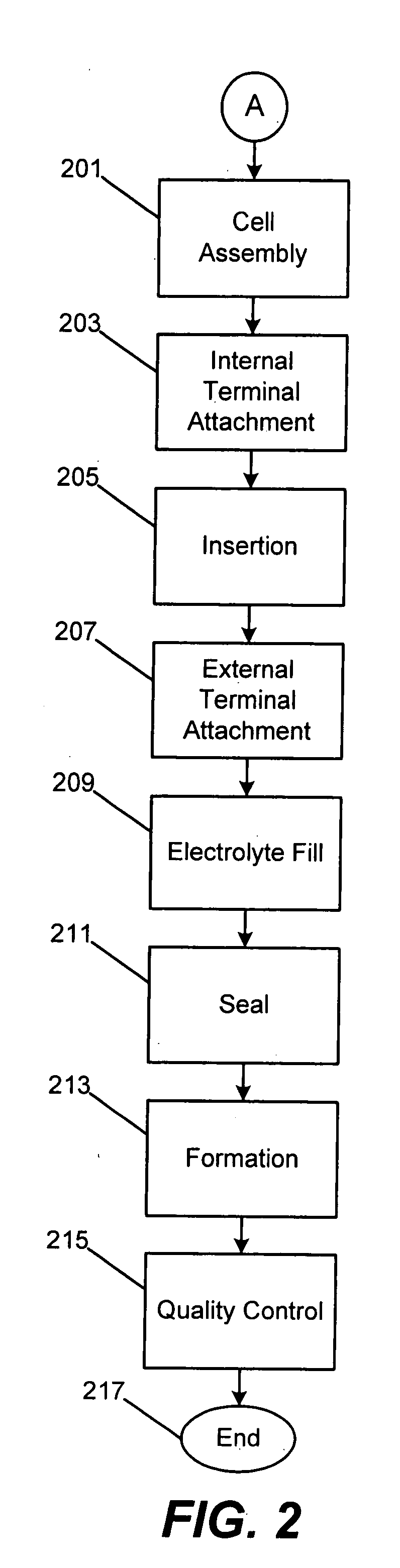

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry or paste of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in NiCad batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:ZINCFIVE POWER INC

Method of manufacturing nickel zinc batteries

InactiveUS20060207084A1Reduce reunionImprove efficiencyFinal product manufacturePrimary cellsZinc compoundsNickel cadmium

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry, paste, or dry mixture of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in nickel cadmium batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:POWERGENIX SYST

Electrolyte composition for nickel-zinc batteries

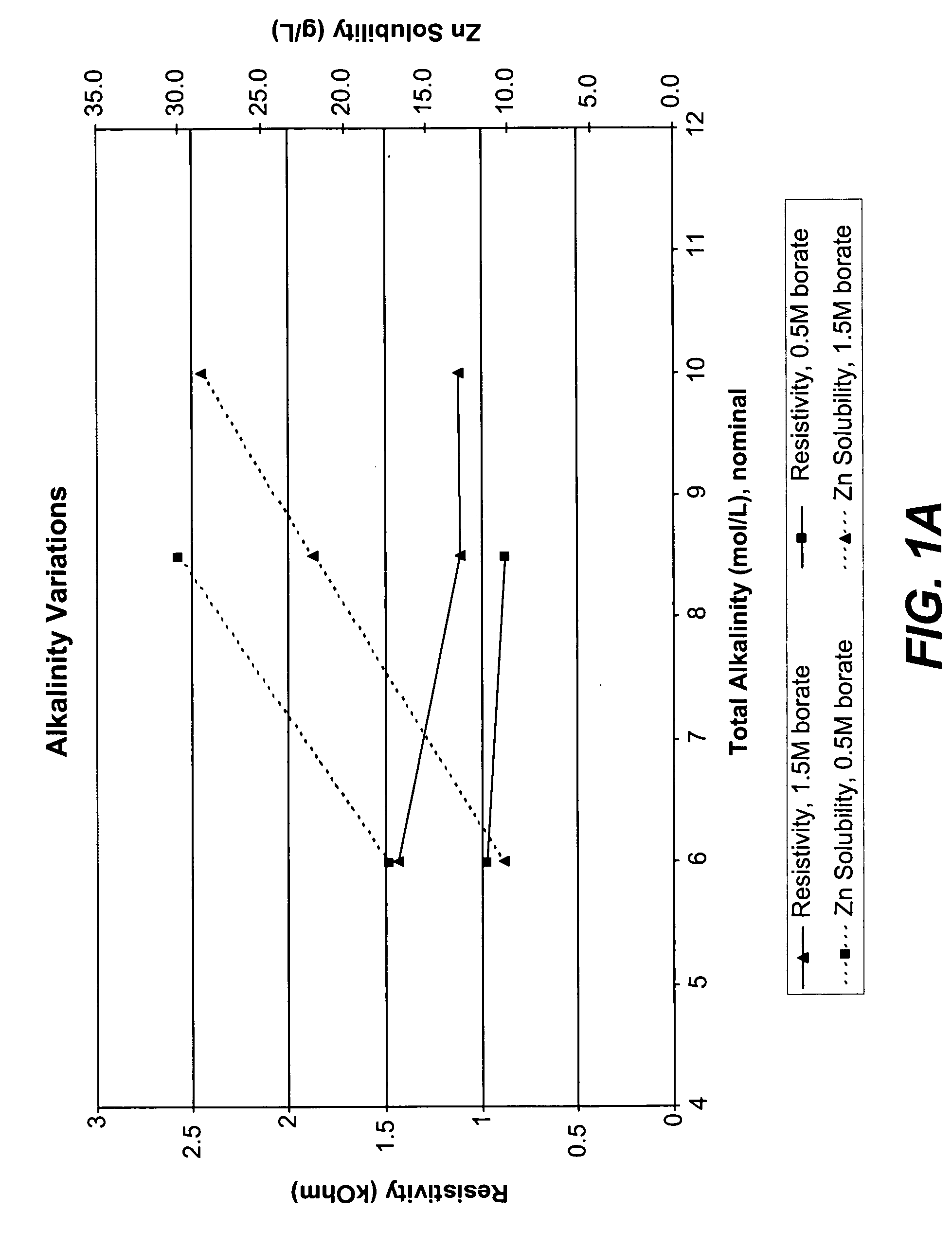

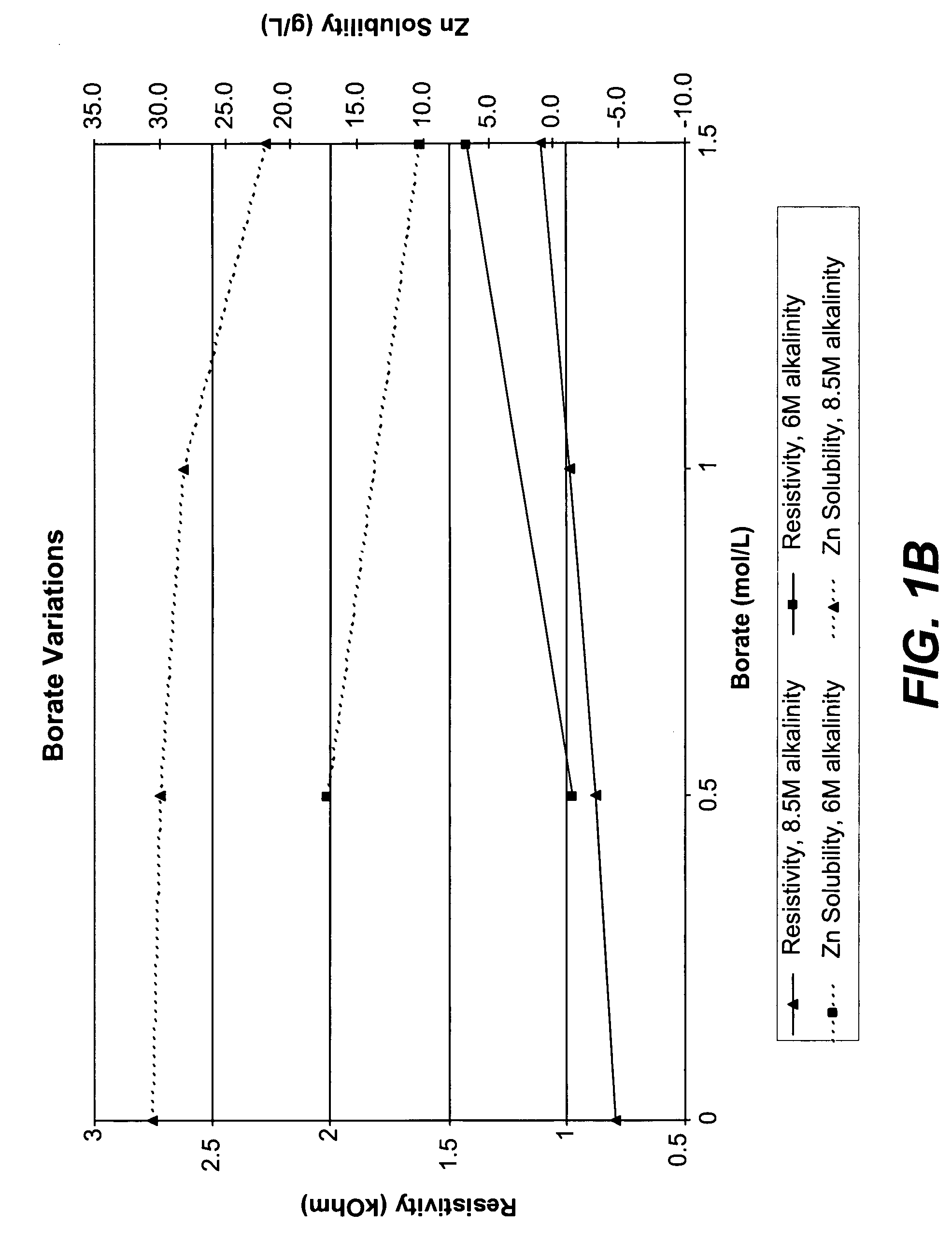

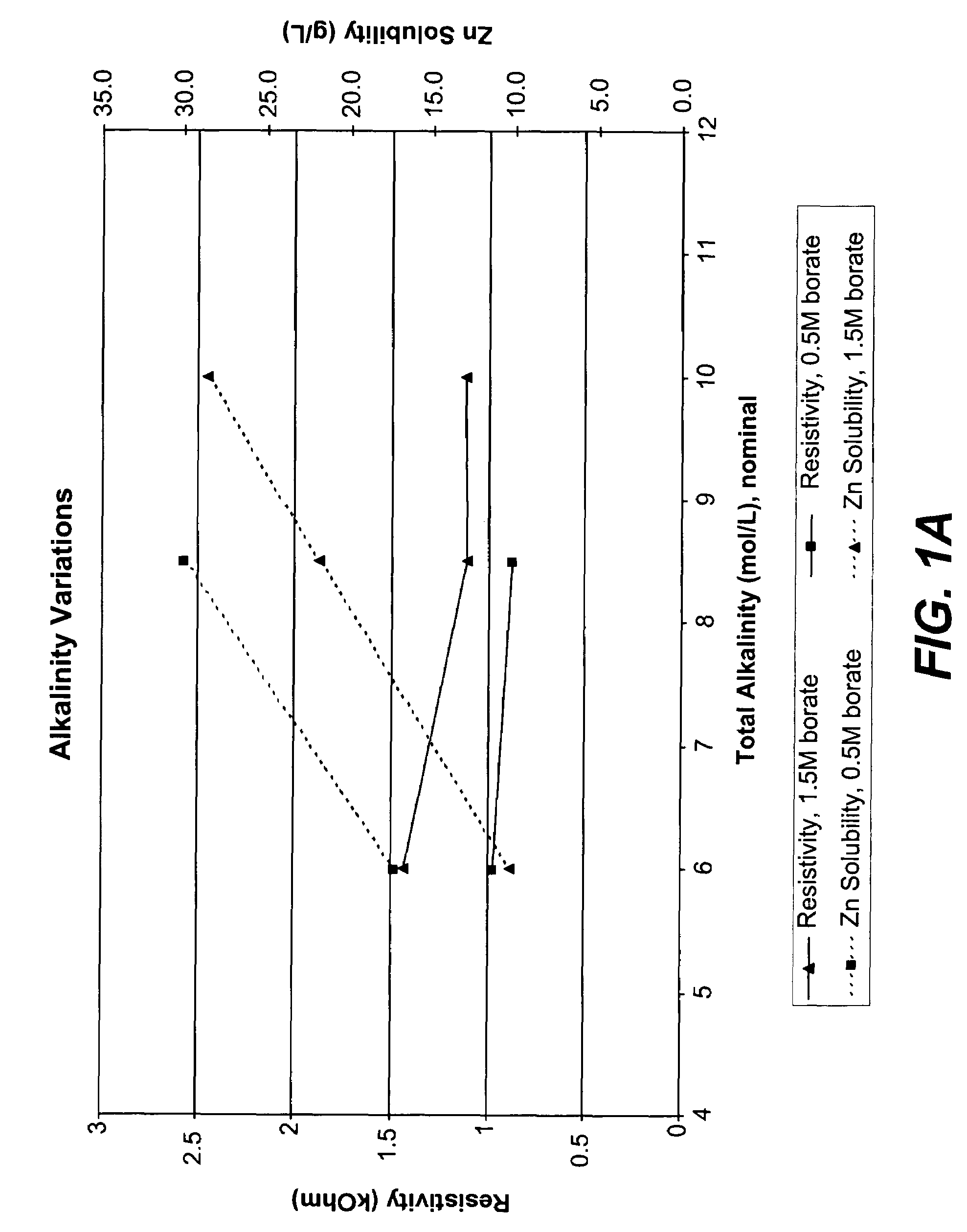

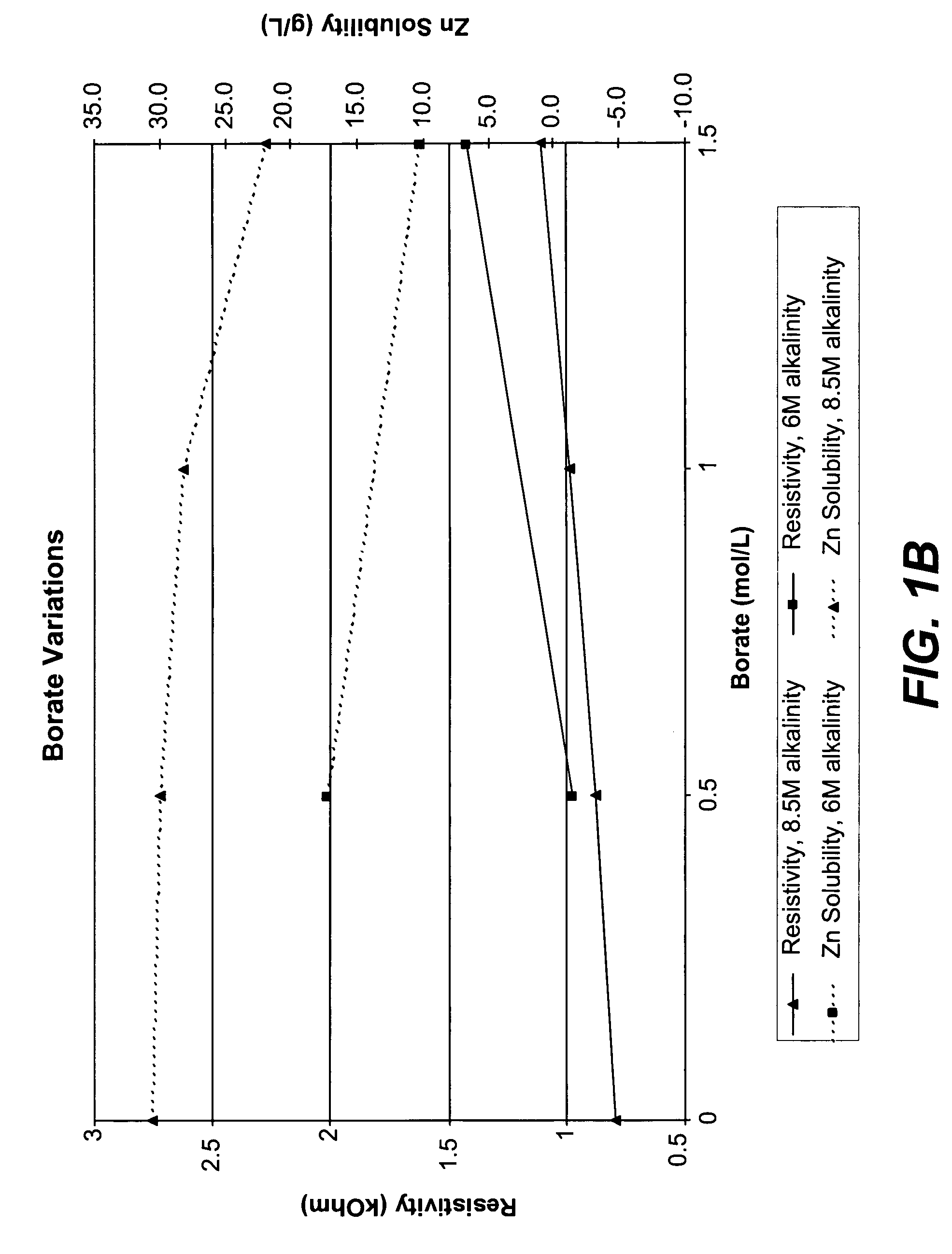

InactiveUS20060127761A1Minimize zinc corrosionFinal product manufactureElectrode carriers/collectorsHigh rateElectrolyte composition

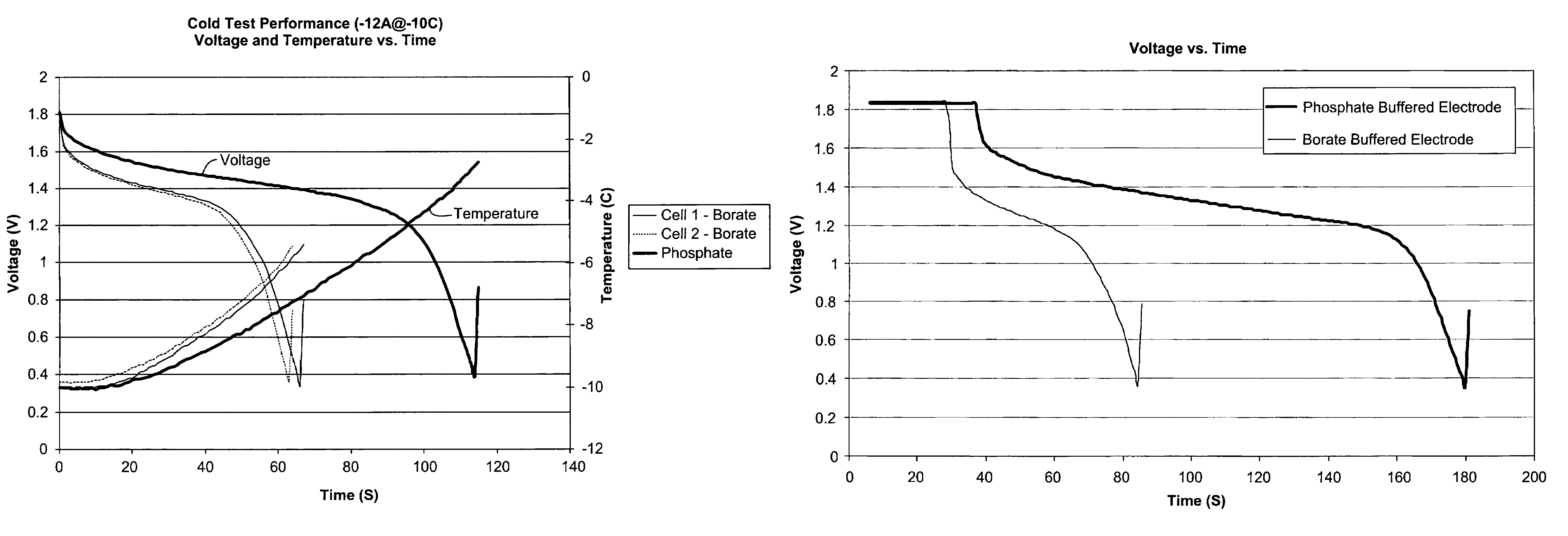

Electrodes and electrolytes for nickel-zinc secondary battery cells possess compositions that limit dendrite formation and other forms of material redistribution in the zinc electrode. In addition, the electrolytes may possess one or more of the following characteristics: good performance at low temperatures, long cycle life, low impedance and suitability for high rate applications.

Owner:ZINCFIVE POWER INC

Pasted zinc electrode for rechargeable nickel-zinc batteries

ActiveUS20100291439A1High viscositySimple working processFinal product manufacturePrimary cellsZinc metalSlurry

Active material for a negative electrode of a rechargeable zinc alkaline electrochemical cell is made with zinc metal particles coated with tin and / or lead. The zinc particles may be coated by adding lead and tin salts to a slurry containing zinc particles, a thickening agent and water. The remaining zinc electrode constituents such as zinc oxide (ZnO), bismuth oxide (Bi2O3), a dispersing agent, and a binding agent such as Teflon are then added. The resulting slurry / paste has a stable viscosity and is easy to work with during manufacture of the zinc electrode. Further, the zinc electrode is much less prone to gassing when cobalt is present in the electrolyte. Cells manufactured from electrodes produced in accordance with this invention exhibit much less hydrogen gassing, by as much as 60-80%, than conventional cells. The cycle life and shelf life of the cells is also enhanced, as the zinc conductive matrix remains intact and shelf discharge is reduced.

Owner:ZINCFIVE POWER INC

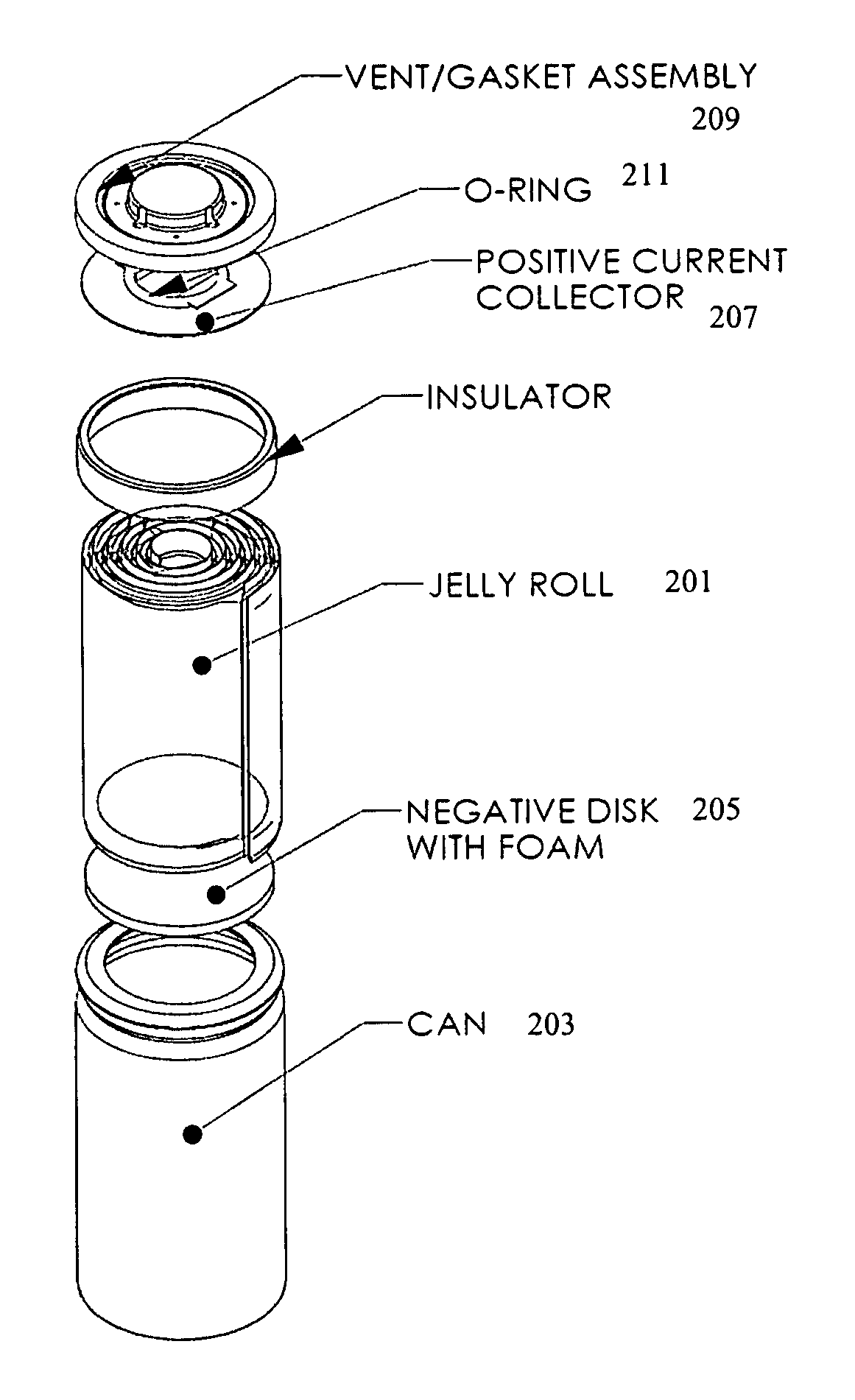

Cylindrical nickel-zinc cell with negative can

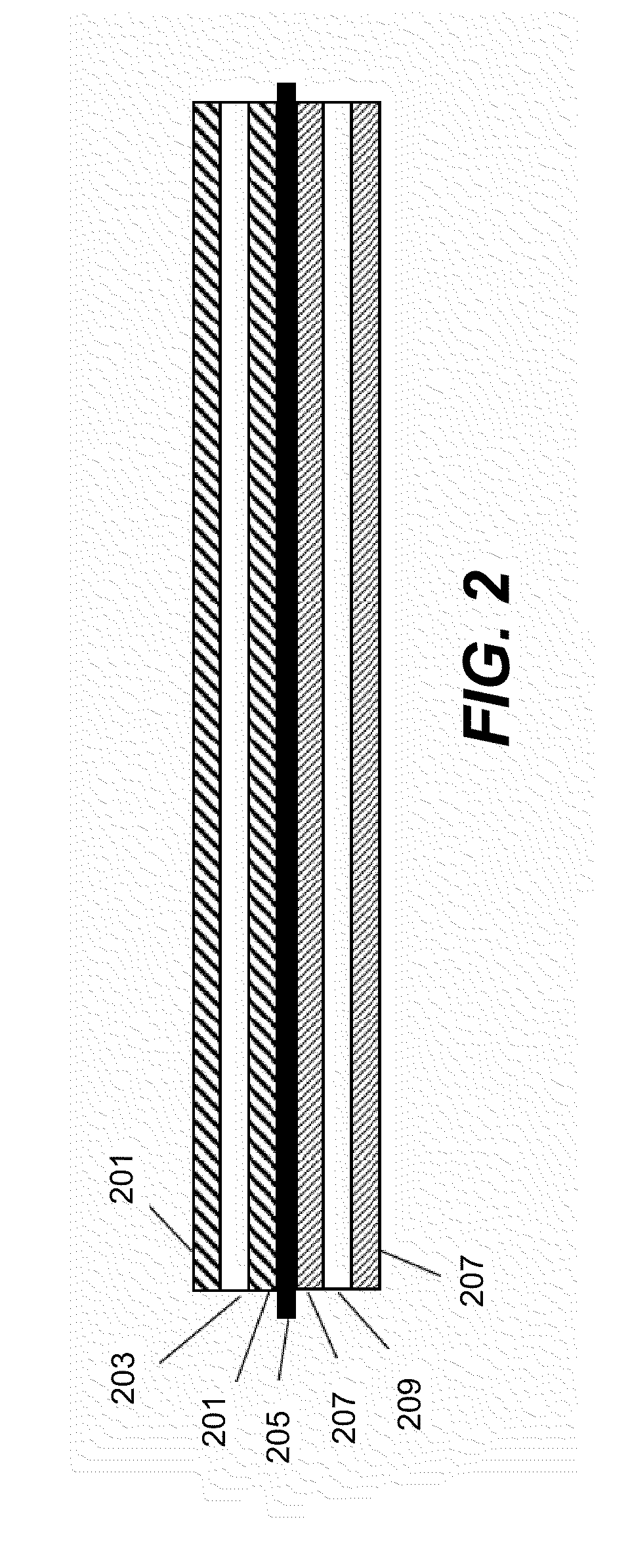

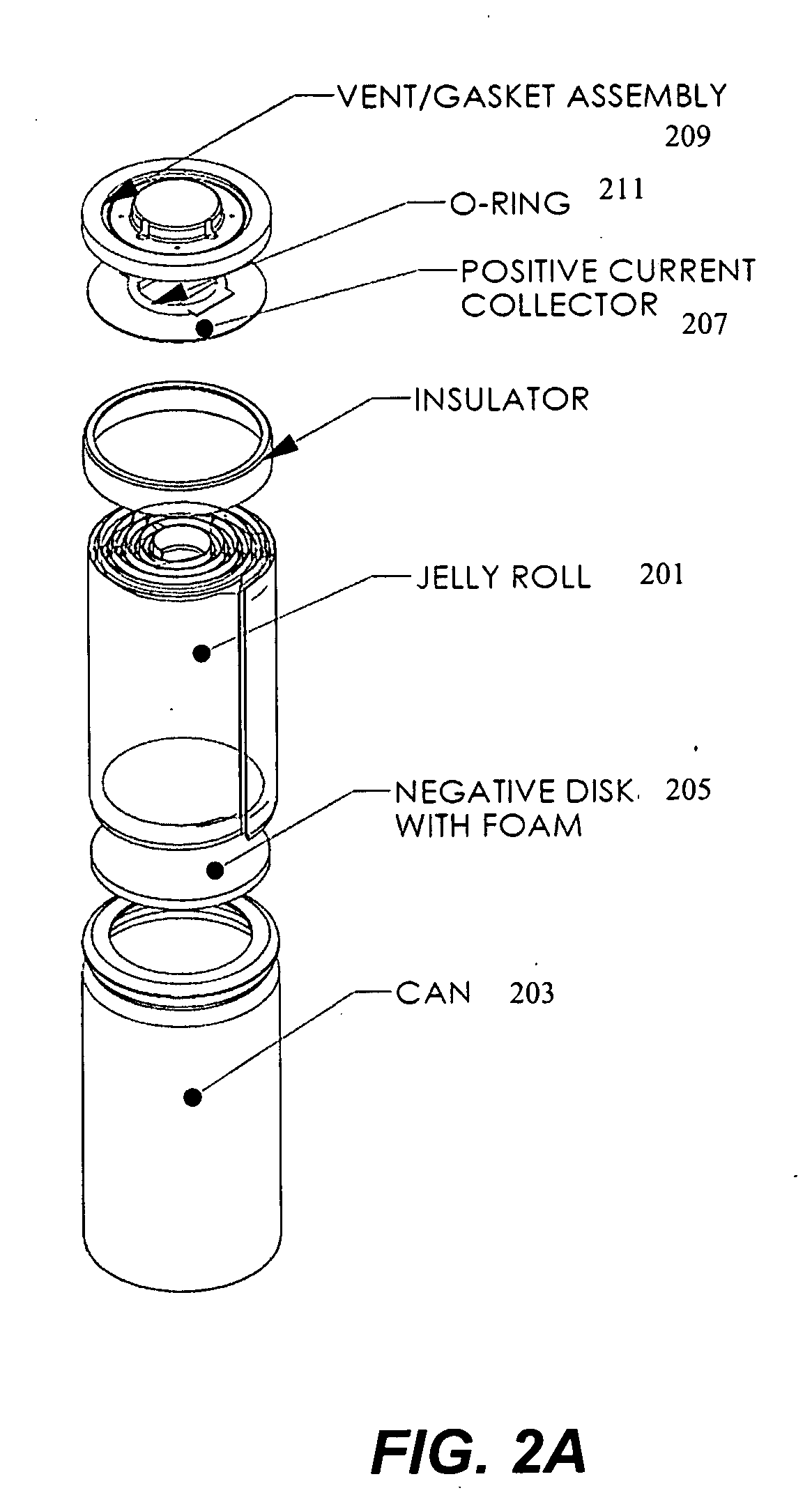

A nickel-zinc battery cell is formed with a negative can, a positive cap, and a jelly roll of electrochemically active positive and negative materials within. The inner surface of the can is protected with an anticorrosive material that may be coated or plated onto the can. Good electrical contact between the jelly roll and the cap is achieved through folding the nickel substrate over to contact a positive current collection disk.

Owner:ZINCFIVE POWER INC

Electrolyte composition for nickel-zinc batteries

InactiveUS7550230B2Minimize zinc corrosionFinal product manufactureWound/folded electrode electrodesHigh rateElectrolyte composition

Electrodes and electrolytes for nickel-zinc secondary battery cells possess compositions that limit dendrite formation and other forms of material redistribution in the zinc electrode. In addition, the electrolytes may possess one or more of the following characteristics: good performance at low temperatures, long cycle life, low impedance and suitability for high rate applications.

Owner:ZINCFIVE POWER INC

Method of manufacturing nickel zinc batteries

ActiveUS7833663B2Improve efficiencyFinal product manufactureElectrode carriers/collectorsZinc compoundsSlurry

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry or paste of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in NiCad batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:ZINCFIVE POWER INC

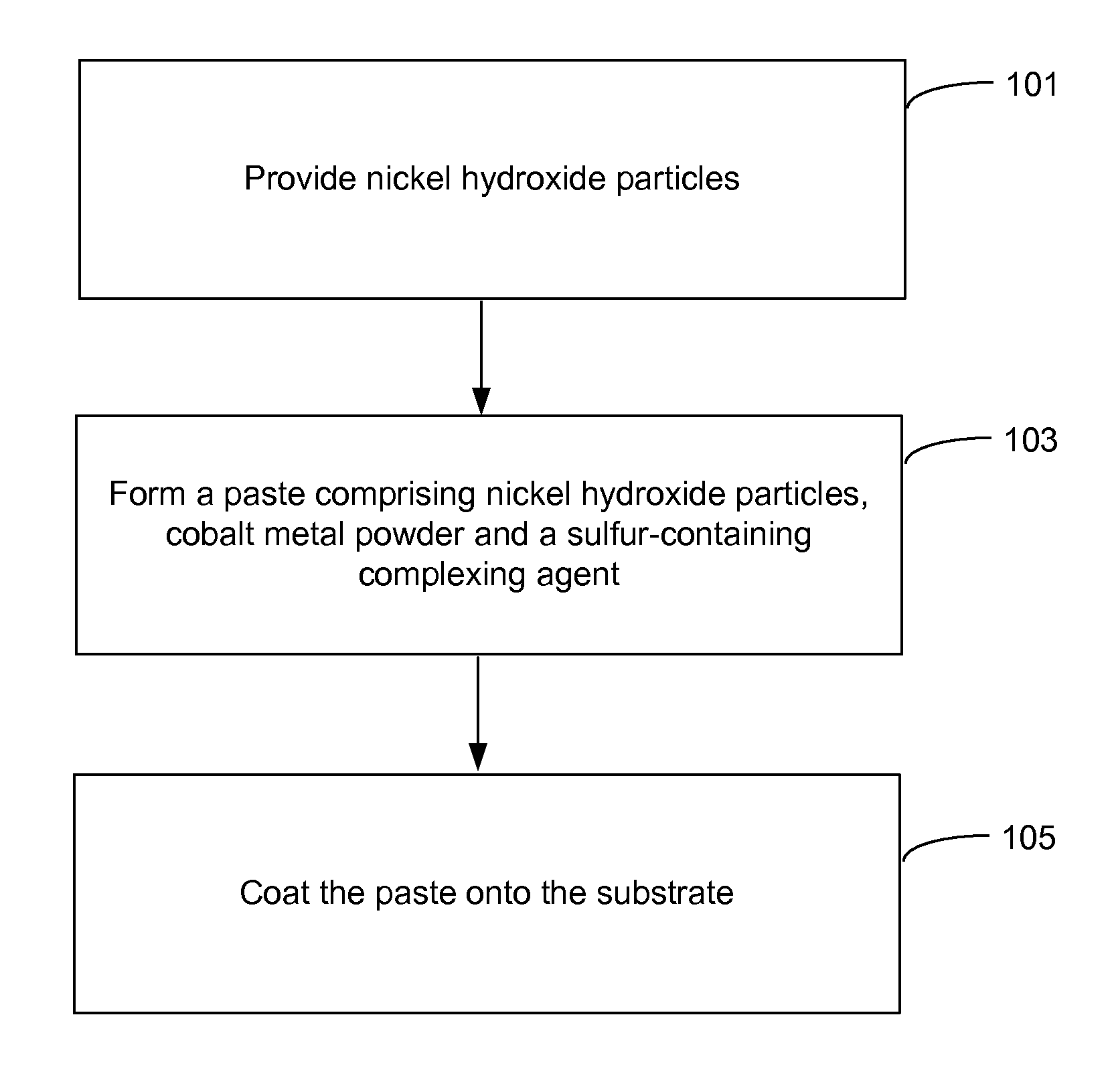

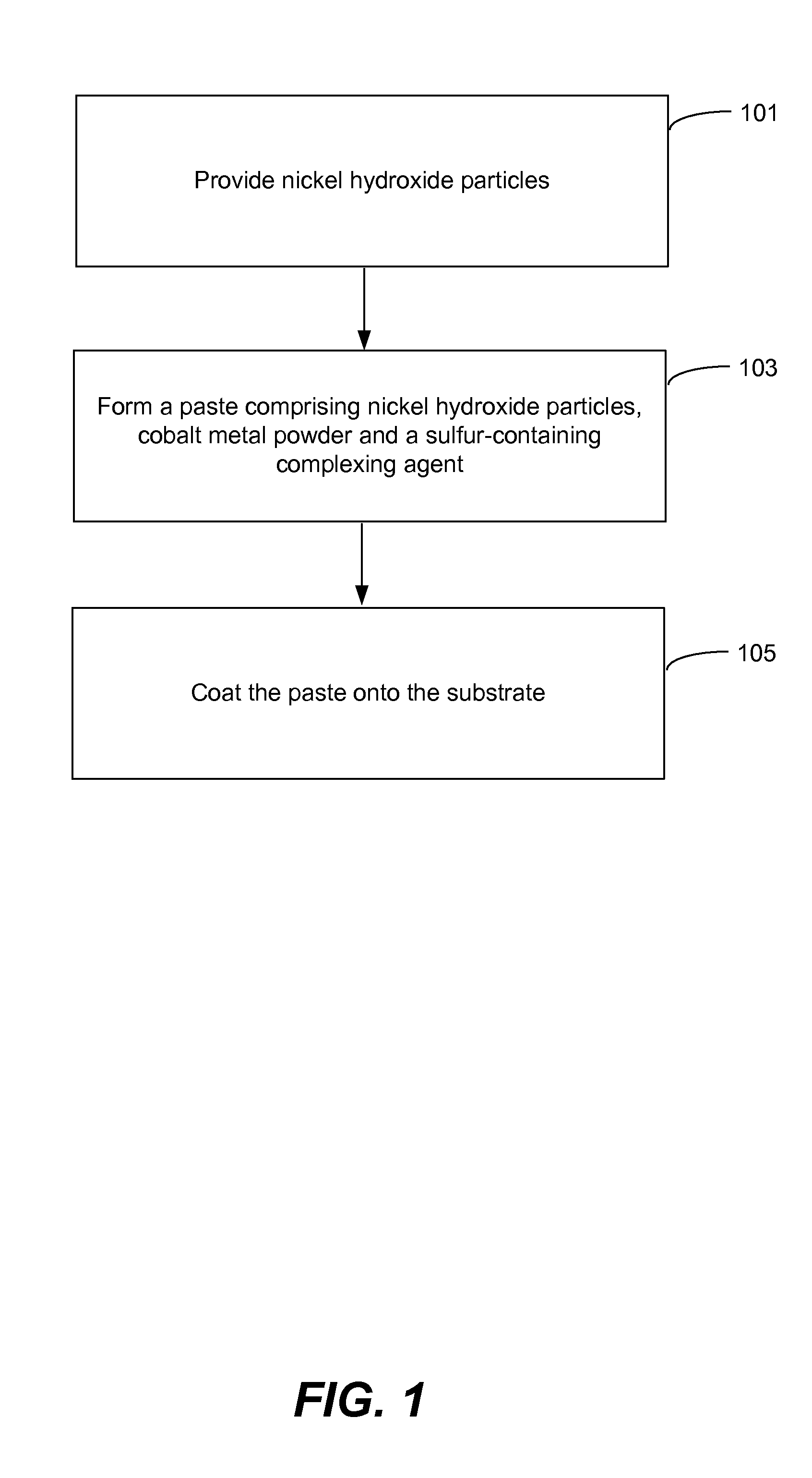

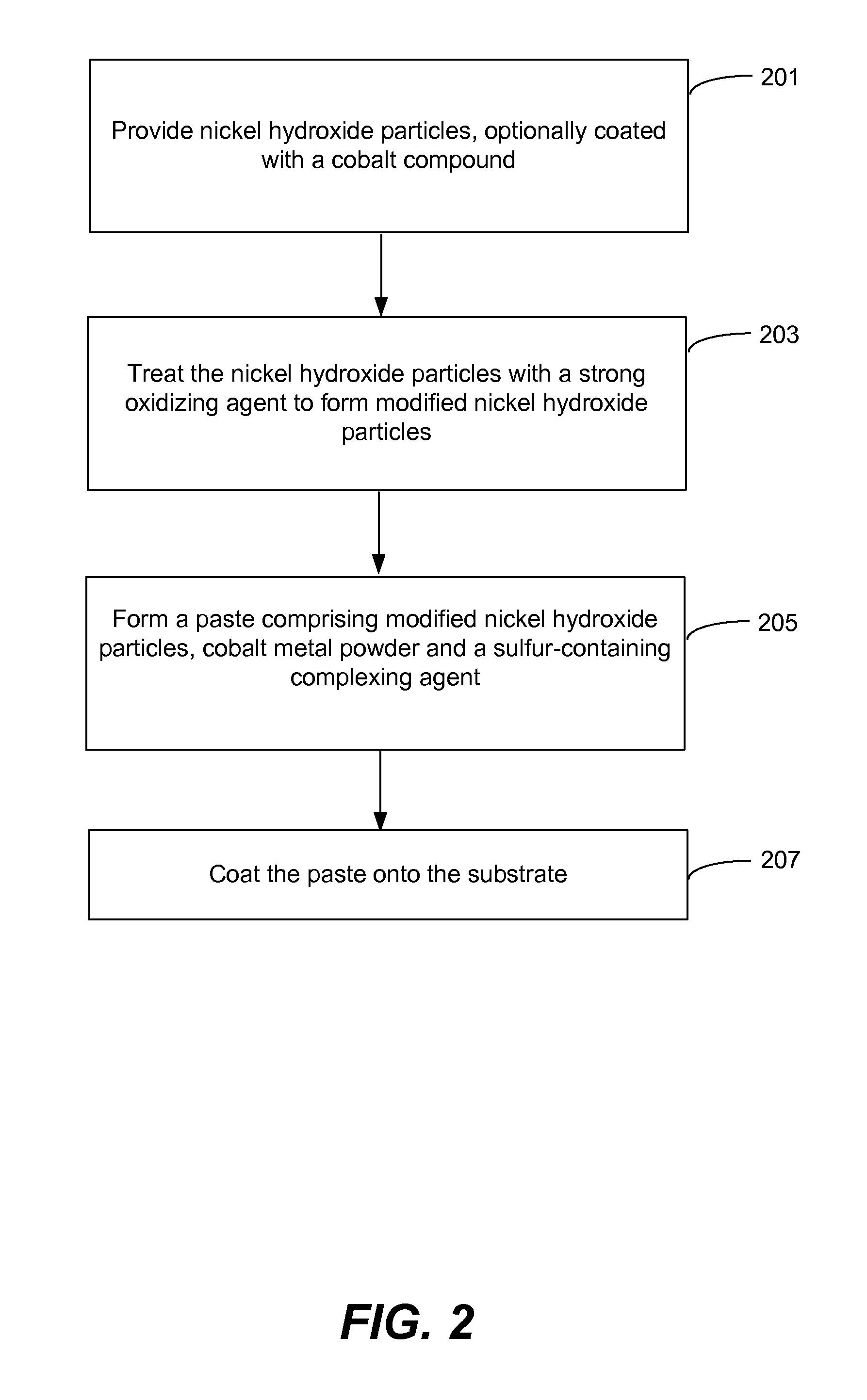

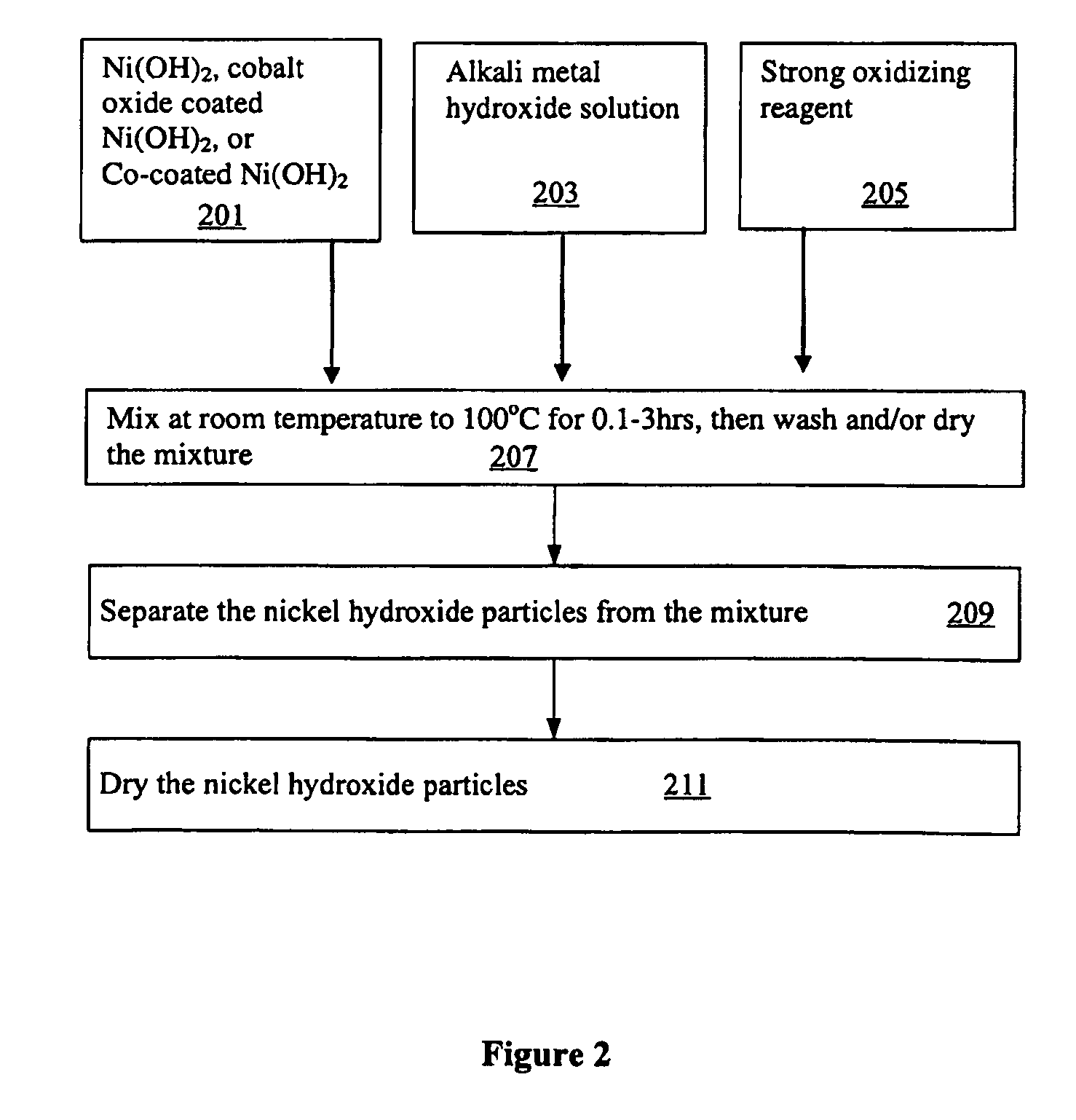

Pasted nickel hydroxide electrode and additives for rechargeable alkaline batteries

ActiveUS20140199591A1Prevent peelingMinimize migrationFinal product manufactureConductive materialNickel electrodeNickel zinc

A pasted positive nickel hydroxide electrode for use in battery cells (e.g., in nickel zinc cells, and nickel metal hydride cells) includes nickel hydroxide particles, a cobalt metal and / or cobalt compound and a sulfur-containing complexing agent capable of forming a complex with cobalt. The presence of the sulfur-containing complexing agent, such as dialkyldithiocarbamate (e.g., sodium diethyldithiocarbamate) improves lifetime and capacity utilization of the nickel electrode. The resulting pasted nickel hydroxide electrode includes a CoOOH conductive matrix after formation. The surface of the nickel hydroxide particles in the electrode is modified in some embodiments by providing a cobalt-containing coating onto the surface of the nickel hydroxide particles, followed by oxidation with a strong oxidizing agent. The complexing agent can be added before, after, or during the oxidation.

Owner:ZINCFIVE POWER INC

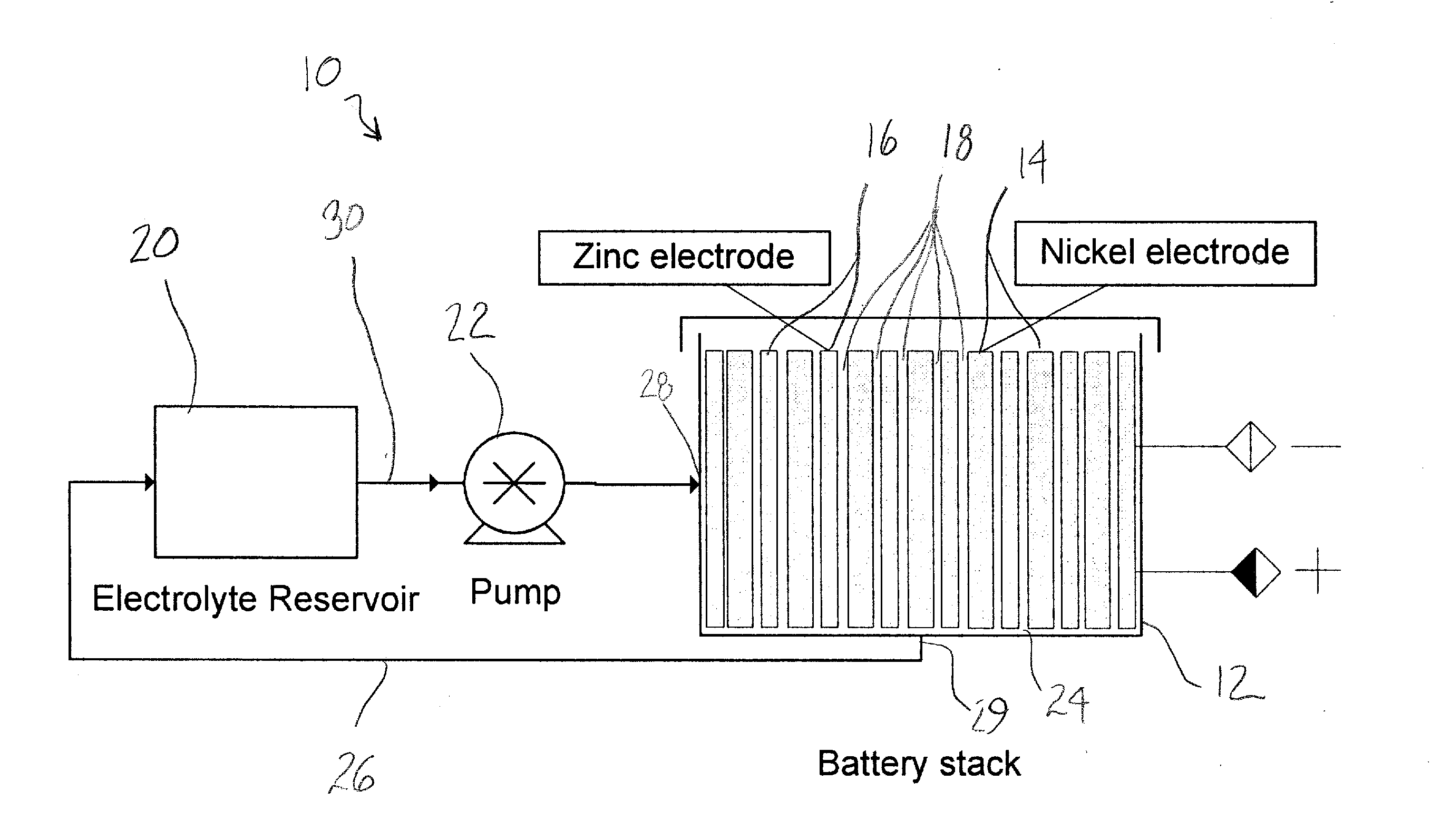

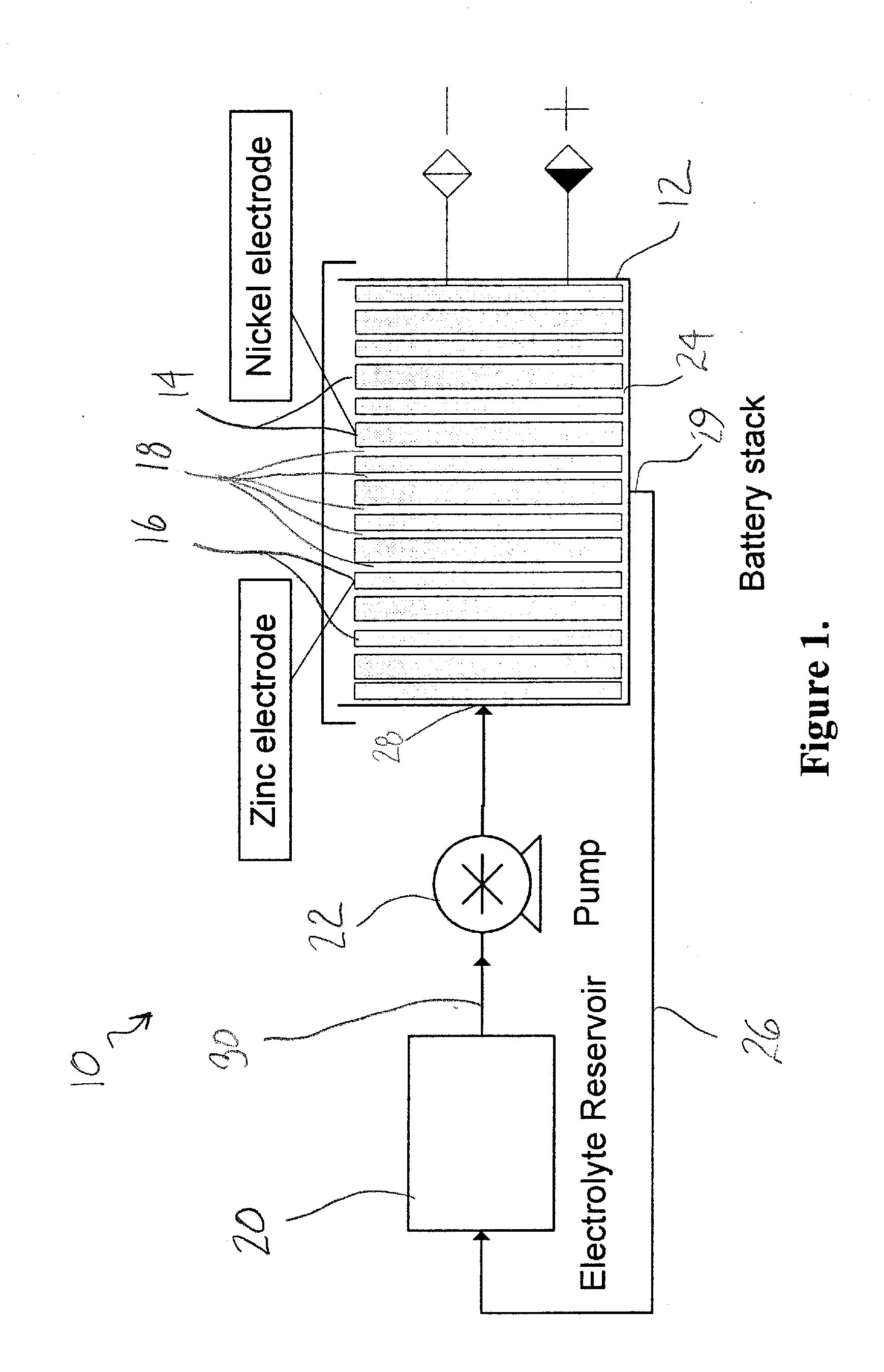

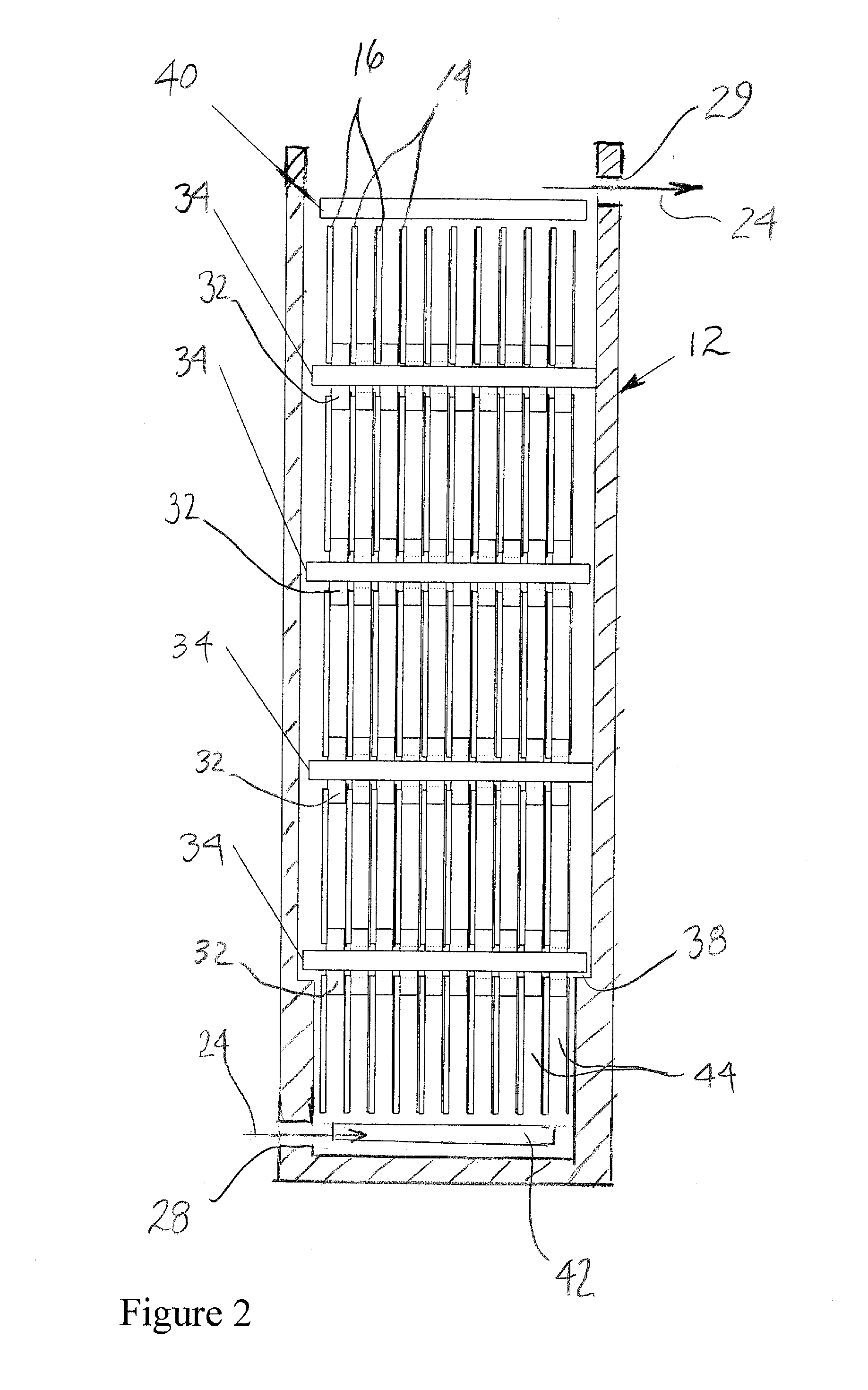

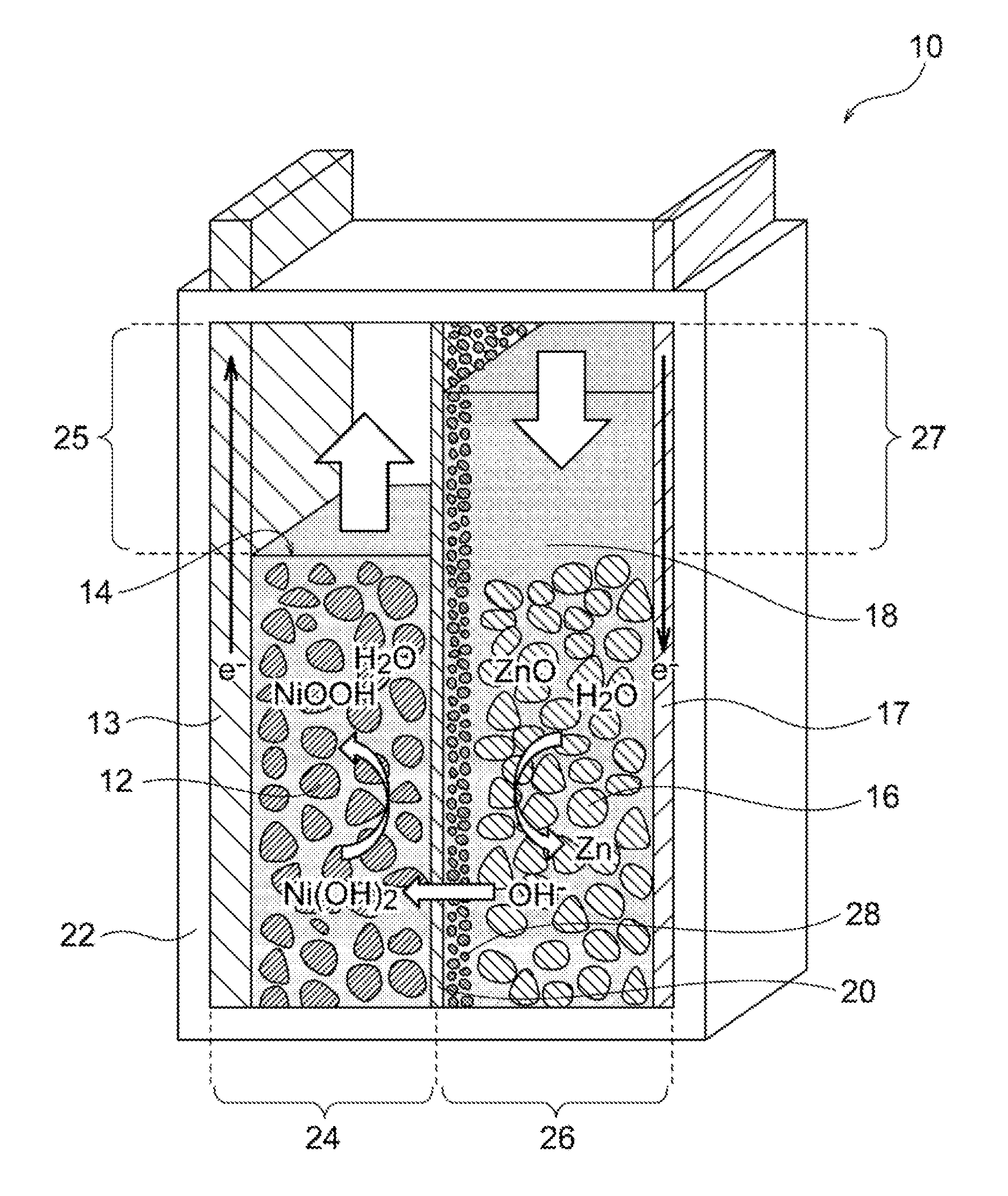

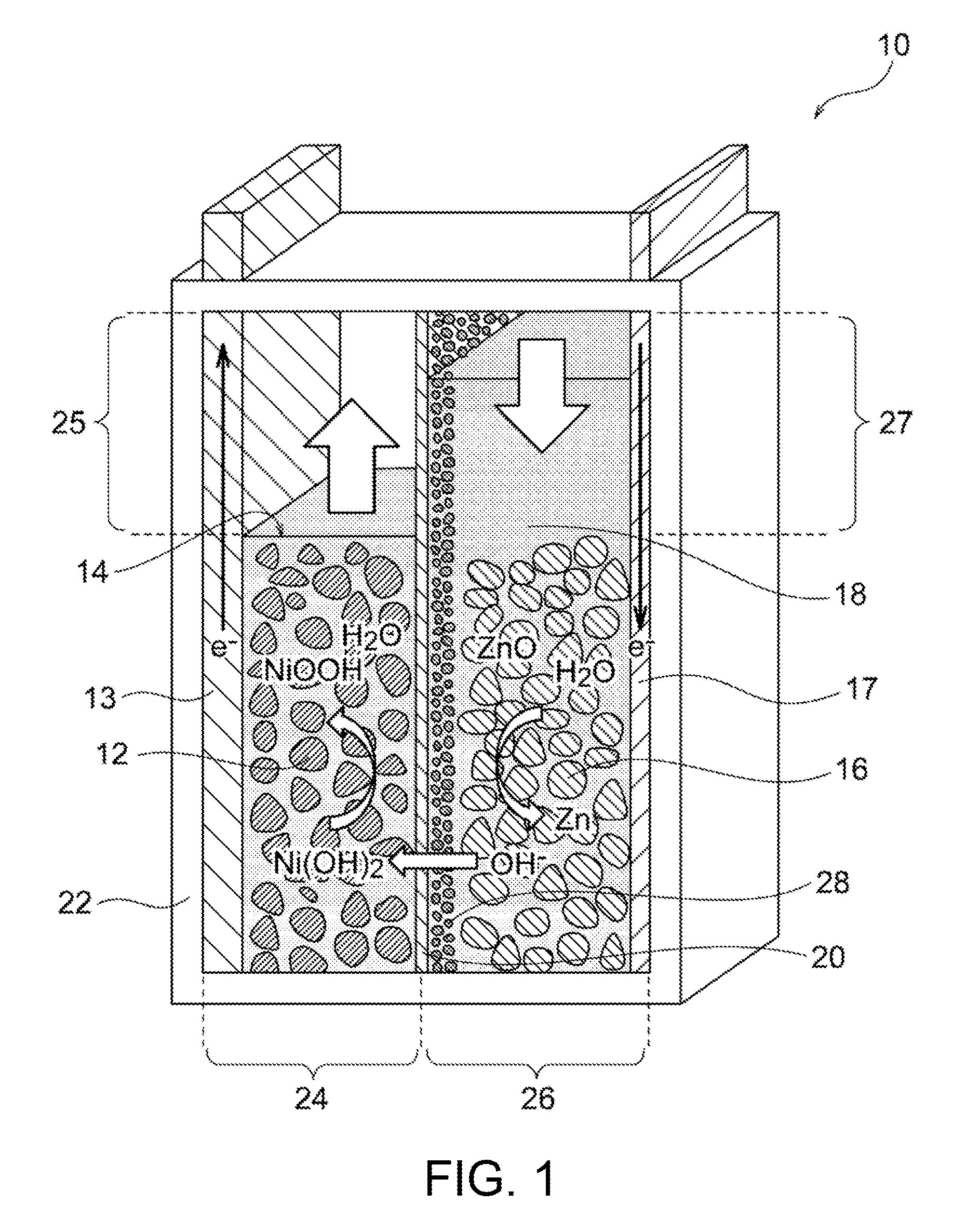

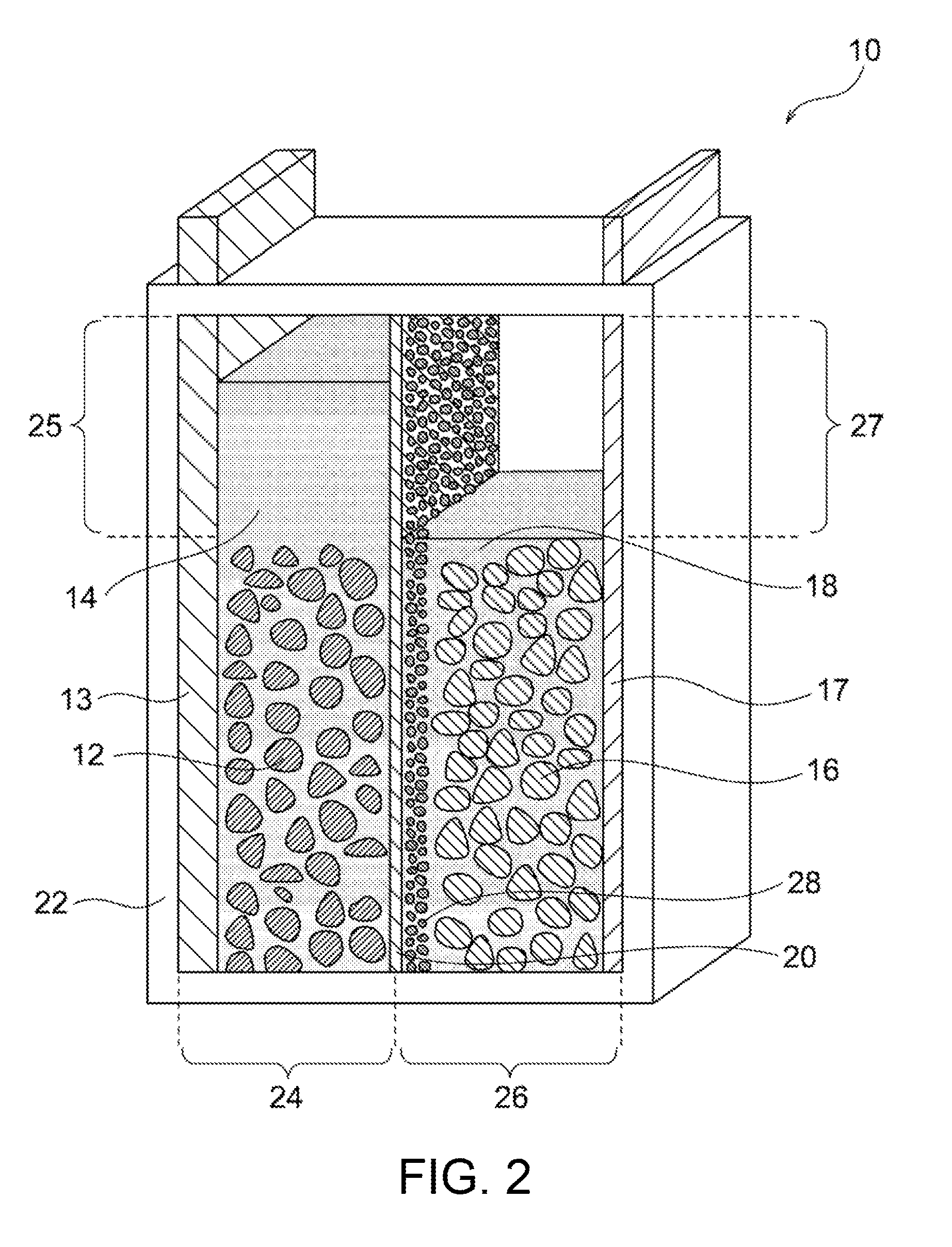

Nickel-Zinc Flow Battery

ActiveUS20130113431A1Improve cycle lifeEffective dissolutionElectrolyte moving arrangementsFinal product manufactureEngineeringNickel zinc

A nickel-zinc battery includes a battery housing, a nickel oxide positive electrode supported in the battery housing, a metal substrate negative electrode supported in the battery housing, a spacer disposed between the positive and negative electrodes, an electrolyte contained within the battery housing and a means for circulating electrolyte in fluid communication with the housing for circulating the electrolyte between the positive and negative electrodes. The electrolyte contains zinc and the metal substrate is adapted for deposition of the zinc during charging of the battery. The spacer maintains the positive electrode in a spaced relationship apart from the negative electrode.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Metallic zinc-based current collector

ActiveUS20100092857A1Raise the ratioLower performance requirementsFinal product manufactureElectrode carriers/collectorsZinc metalZinc alloys

A nickel zinc battery cell includes a metallic zinc-based current collection substrate as a part of the negative electrode. The metallic zinc-based current collector may be made of or be coated with a zinc metal or zinc alloy material and may be a foil, perforated, or expanded material. Battery cells incorporating the zinc-based current collector exhibit good cycle lifetime and initial charge performance.

Owner:POWERGENIX SYST SHENZHEN +1

Pasted nickel hydroxide electrode for rechargeable nickel-zinc batteries

ActiveUS8043748B2Improve manufacturabilityMany timesAlkaline accumulator electrodesNon-aqueous electrolyte accumulator electrodesSolubilityHigh rate

Active material for a positive electrode of a rechargeable alkaline electrochemical cell is made with nickel hydroxide particles or cobalt-coated nickel hydroxide particles treated with strongly oxidizing reagents such as alkali metal persulfate in alkaline solution. The active material also may be made with cobalt-coated nickel hydroxide particles having a high percentage of cobalt(III) on a surface or an average cobalt oxidation state of about 3 measured across the particles. The treated nickel hydroxide or cobalt-coated nickel hydroxide decreases the cobalt solubility in the alkaline electrolyte and increases the high-rate charge and discharge capability. The lower cobalt solubility decreases cobalt migration that can increase self discharge and lead to premature failure.

Owner:ZINCFIVE POWER INC

Method for manufacturing nickel zinc batteries

InactiveUS20080163478A1Reduce reunionImprove efficiencyFinal product manufactureElectrode carriers/collectorsZinc compoundsNickel cadmium

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry, paste, or dry mixture of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in nickel cadmium batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:POWERGENIX SYST

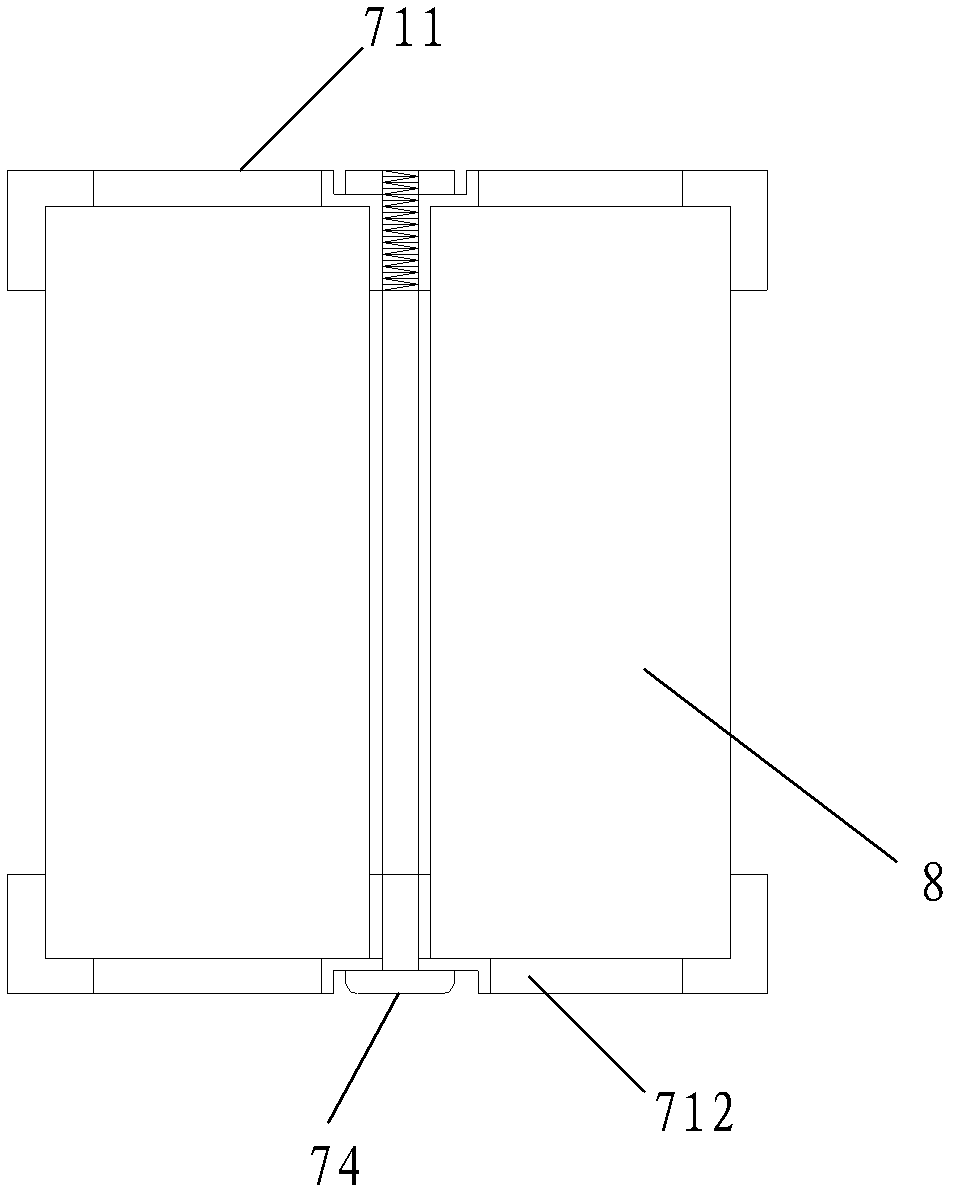

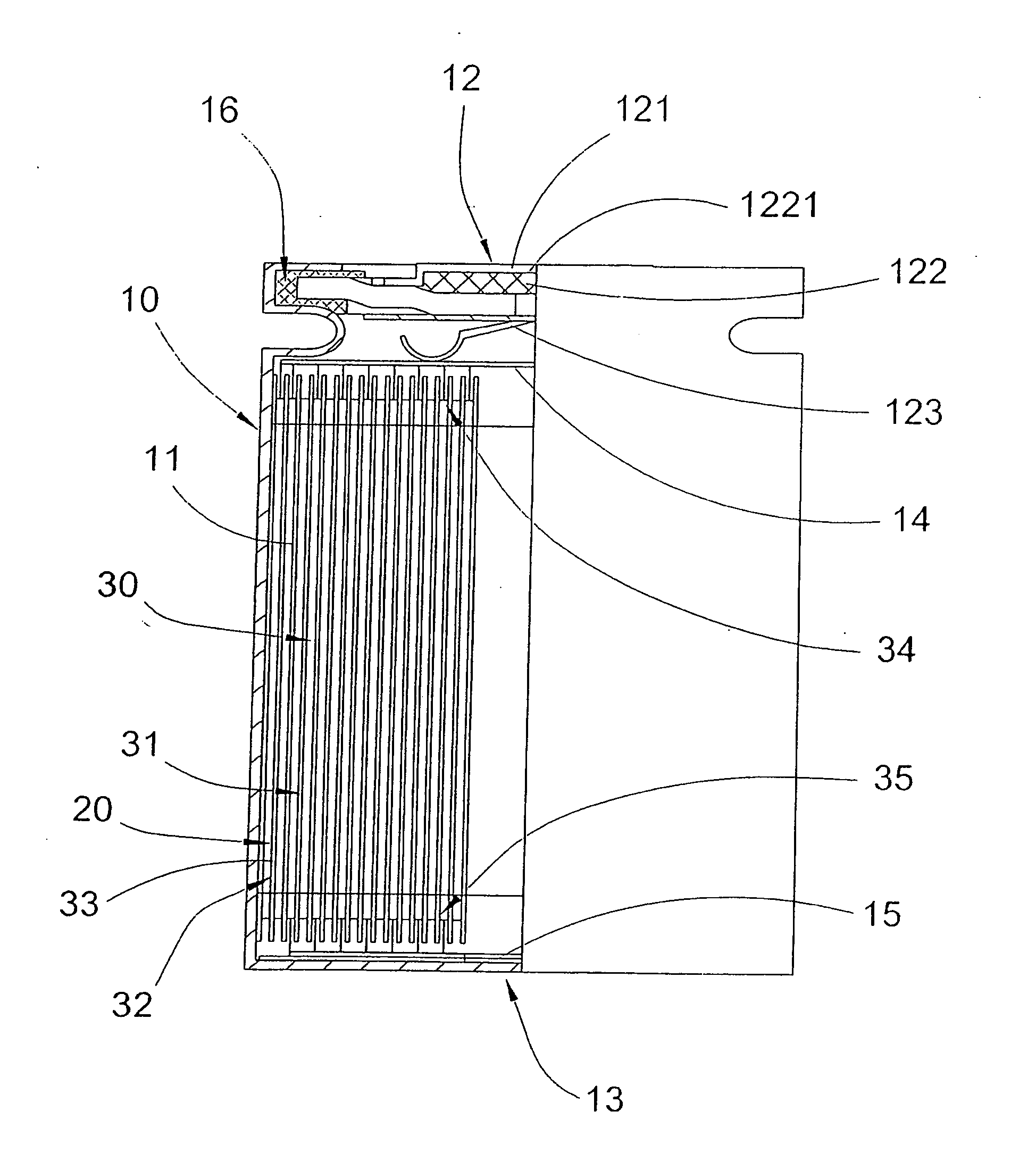

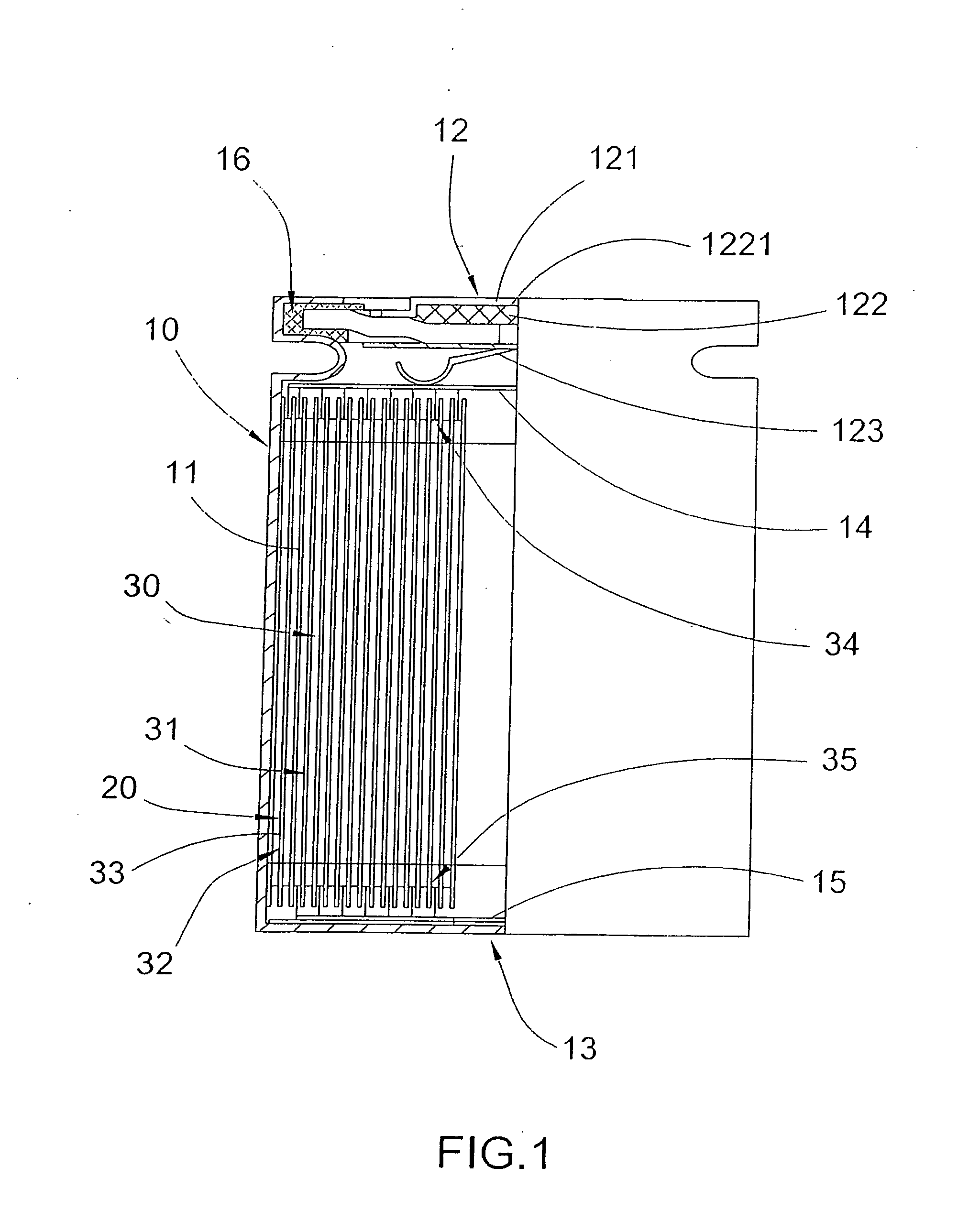

Nickel-zinc battery and manufacturing method thereof

InactiveUS20120171535A1High and adequate powerHigh and adequate and energyElectrode manufacturing processesFinal product manufactureZincFluid electrolytes

A cylindrical Ni—Zn battery includes a battery shell, an electrode assembly and a liquid electrolyte which are sealed within the shell. The electrode assembly, whose upper part is connected to a cap, includes a nickel cathode, zinc anode, and a composite membrane. The nickel cathode and zinc anode have an edge portion which are externally exposed and bent inwardly to form the anode and cathode conductive end respectively, and edges of the composite membranes are sealed together, so that the electrodes are contained in the membranes. The battery is characterized by the simple in structure, convenient installation, low cost, safety, characteristics of long-term storage, effectively preventing the growth of dendrite, long life, strong capability to resist shake, and good performance of large current discharging.

Owner:HANGZHOU NEUCELL ENERGY

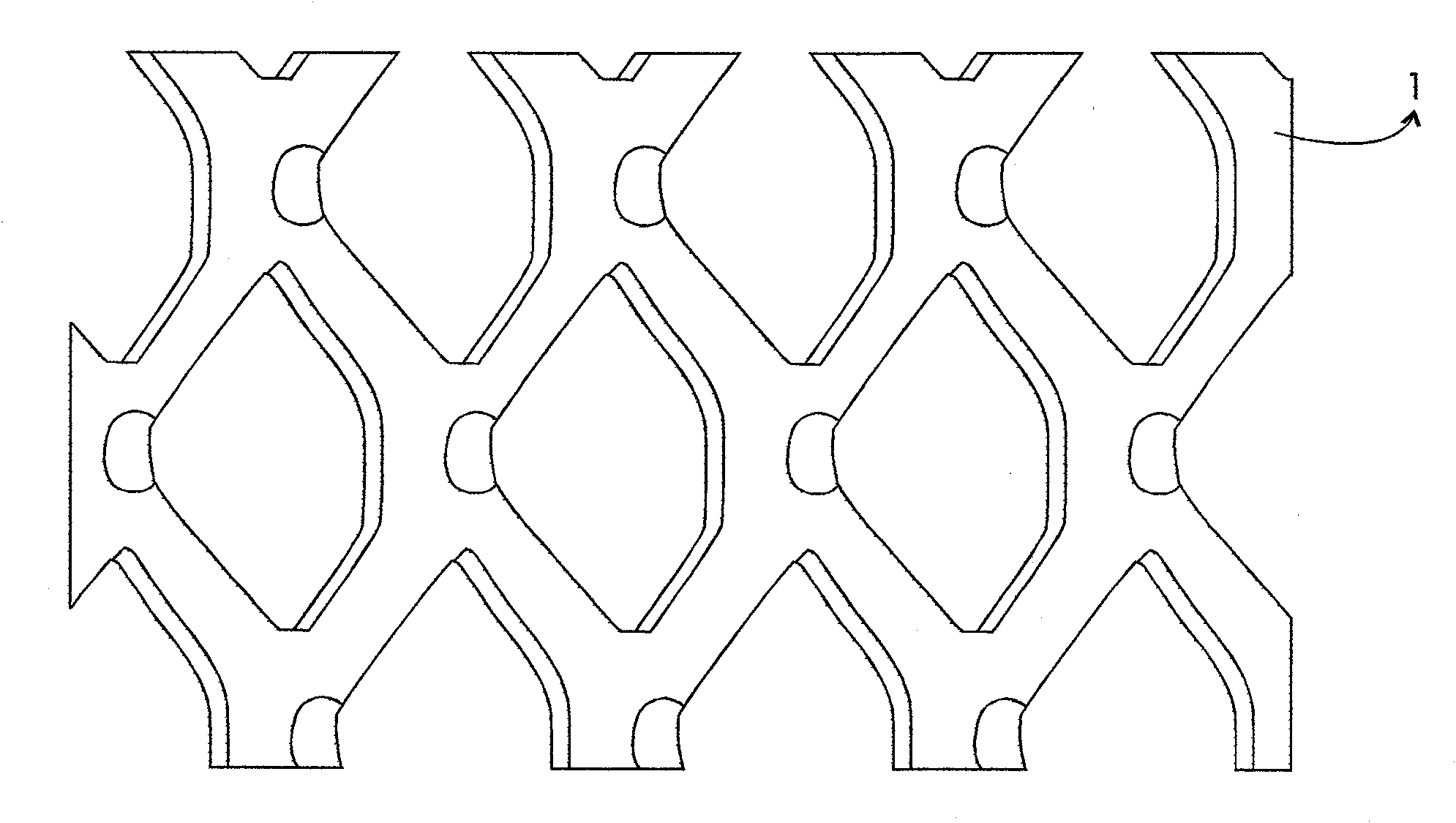

Zinc-nickel battery negative electrode active material, cable-stayed mesh negative electrode substrate, negative electrode and preparation method thereof

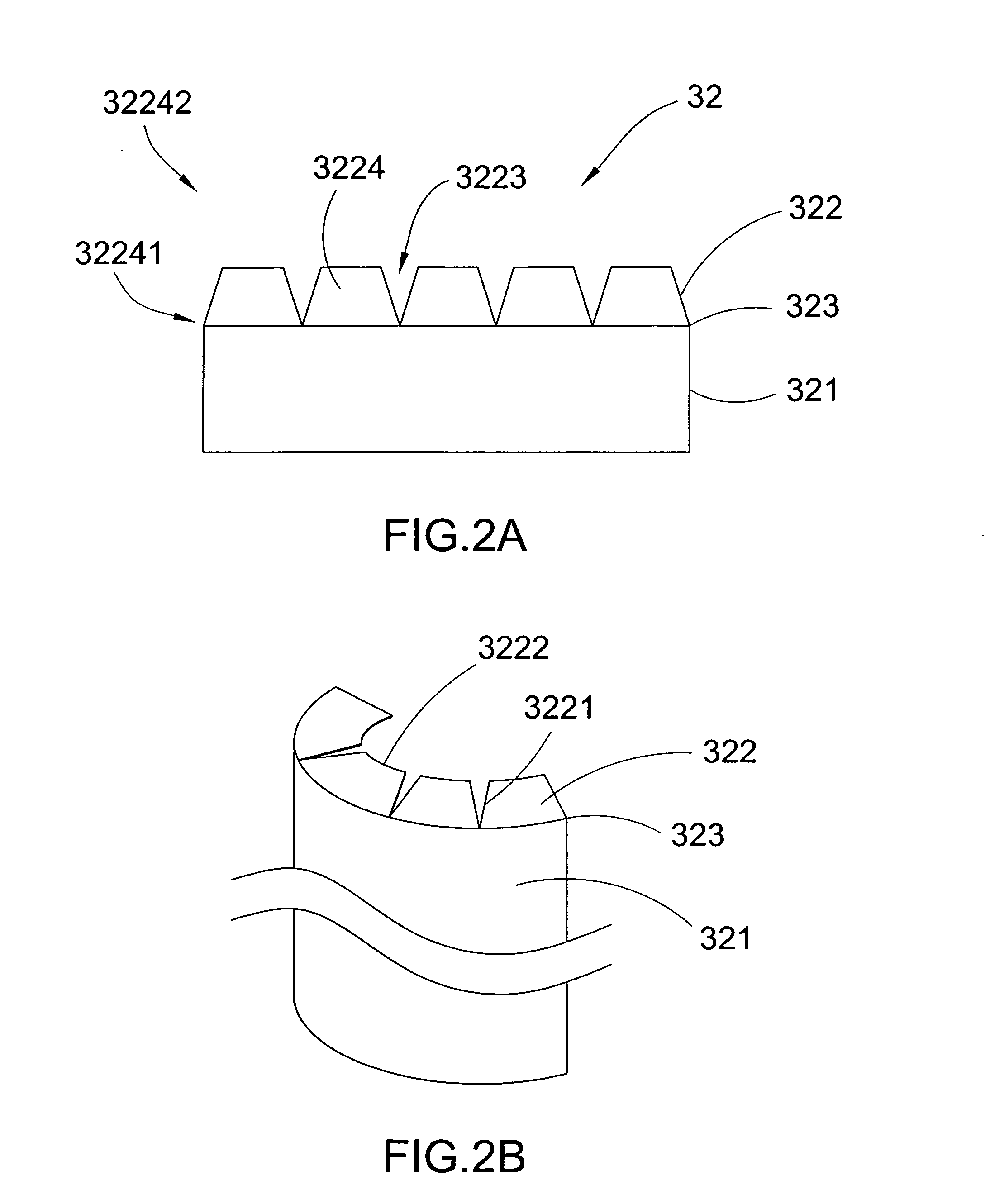

ActiveCN102263269AAvoid failureImprove performanceElectrode carriers/collectorsAlkaline accumulator electrodesCopper foilZinc

The present invention provides a tilted-grid substrate of a negative electrode for a nickel-zinc battery, including a first zinc foil layer; a copper foil layer compounded on the first zinc foil layer; and a second zinc foil layer compounded on the copper foil layer. The present invention further provides an active material composition of a negative electrode for a nickel-zinc battery, a negative electrode for a nickel-zinc battery, the method for preparing the negative electrode, and a nickel-zinc battery. In the tilted-grid substrate of a negative electrode according to the present invention, the surface of zinc eliminates the needs for plating other metal, avoiding the incorporation of impurities. With the use of the nickel-zinc battery, part of the zinc on the surface of the tilted-grid substrate of the negative electrode can participate in the reaction of forming a current in the battery, reducing the fading speed of the battery capacity; and part of the zinc is oxidized to zinc oxide, acting as a conductor to improve the utilization ratio of the active material of the negative electrode. When the zinc layer on the surface of the substrate of the negative electrode participate in the reaction or is oxidized, the copper foil layer can act as the substrate of the negative electrode, so as to improve the performance of the nickel-zinc battery.

Owner:GUANGDONG POWERLINK ENERGY

Method of manufacturing nickel zinc batteries

InactiveUS20080166632A1Improve efficiencyReduce reunionCell electrodesFinal product manufactureZinc compoundsSlurry

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry, paste, or dry mixture of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in nickel cadmium batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:POWERGENIX SYST

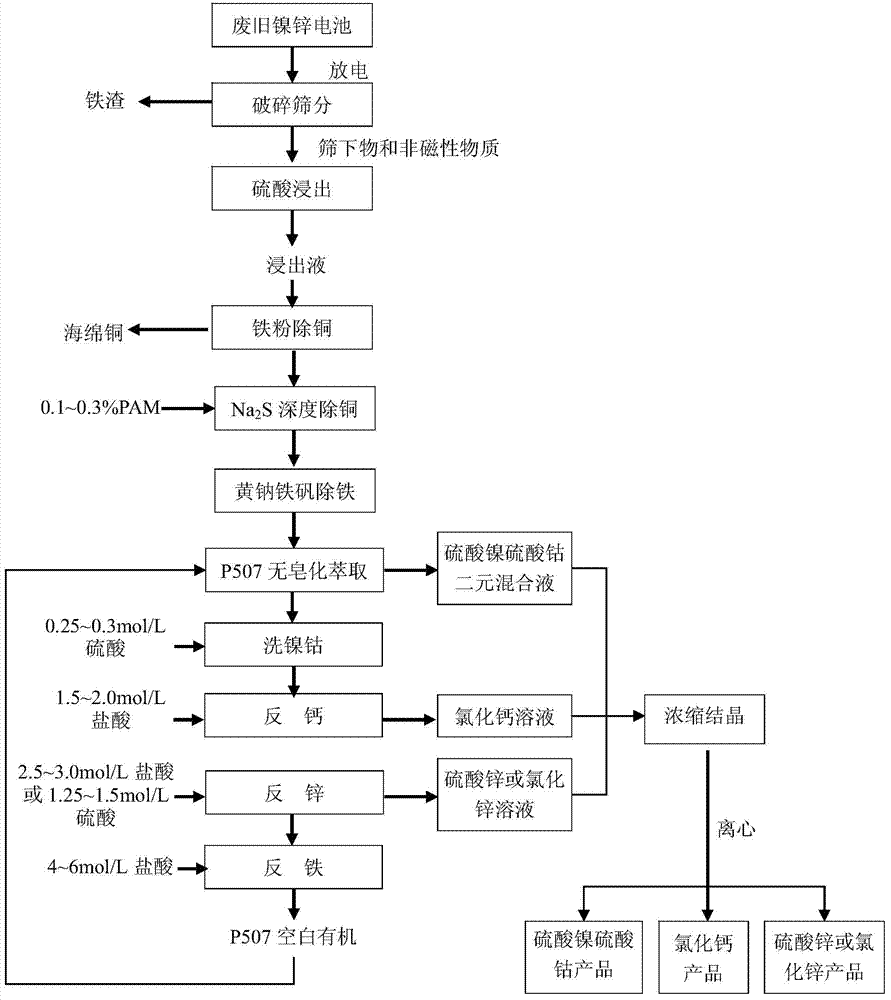

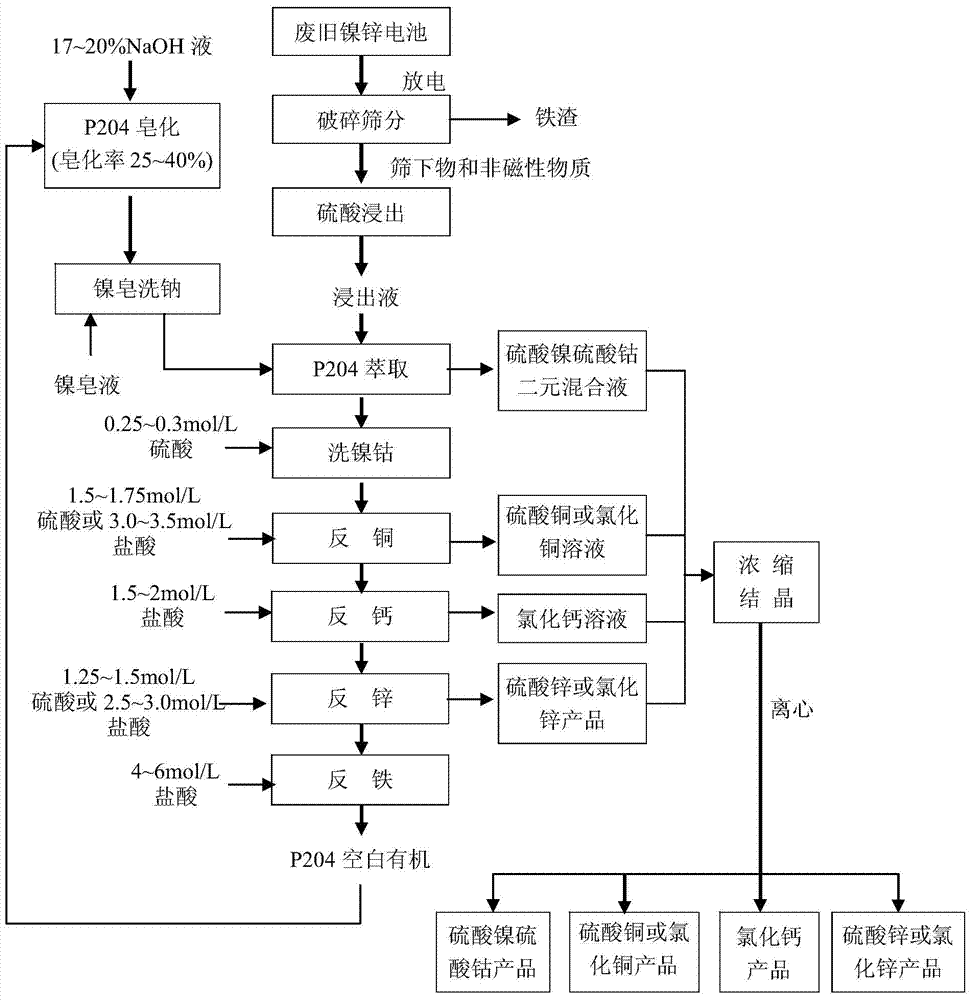

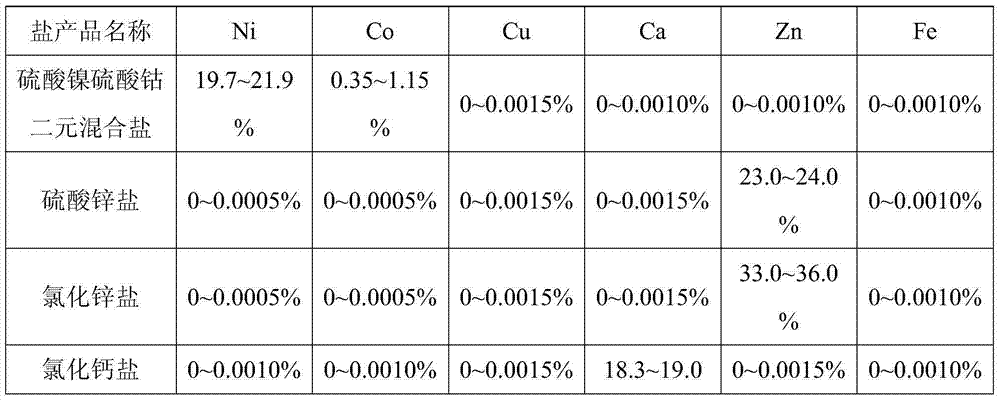

Method for recovering valuable metal from waste nickel-zinc battery

ActiveCN103794833AStrong choice flexibilityLow costWaste accumulators reclaimingProcess efficiency improvementPollutionCopper salt

The invention discloses a method for recovering valuable metal from a waste nickel-zinc battery. The method comprises the following steps: arranging the waste nickel-zinc battery into saturated salt water, and carrying out self-discharge treatment; crushing and screening the nickel-zinc battery subjected to self-discharging treatment to obtain oversize products and undersize products; carrying out magnetic separation on the oversize products to obtain iron residues and nonmagnetic substances; mixing the nonmagnetic substances with the undersize products, then leaching the mixture by sulfuric acid, and filtering to obtain leachate; treating the leachate by a chemical method, carrying out extraction separation to obtain binary mixed liquid of nickel sulfate and cobalt sulfate, zinc salt solution and calcium chloride solution, or binary mixed liquid of nickel sulfate and cobalt sulfate, zinc salt solution, copper salt solution and calcium chloride solution; respectively concentrating and crystallizing the obtained solution, and carrying out centrifugal separation the solution to complete the recovery of the valuable metal. According to the method, secondary pollution to the environment is avoided, the technological process is short, the resource recovery and utilization rate is high, the technical product selection flexibility is high, the cost is low and economical benefits are relatively high.

Owner:HUNAN BRUNP RECYCLING TECH +1

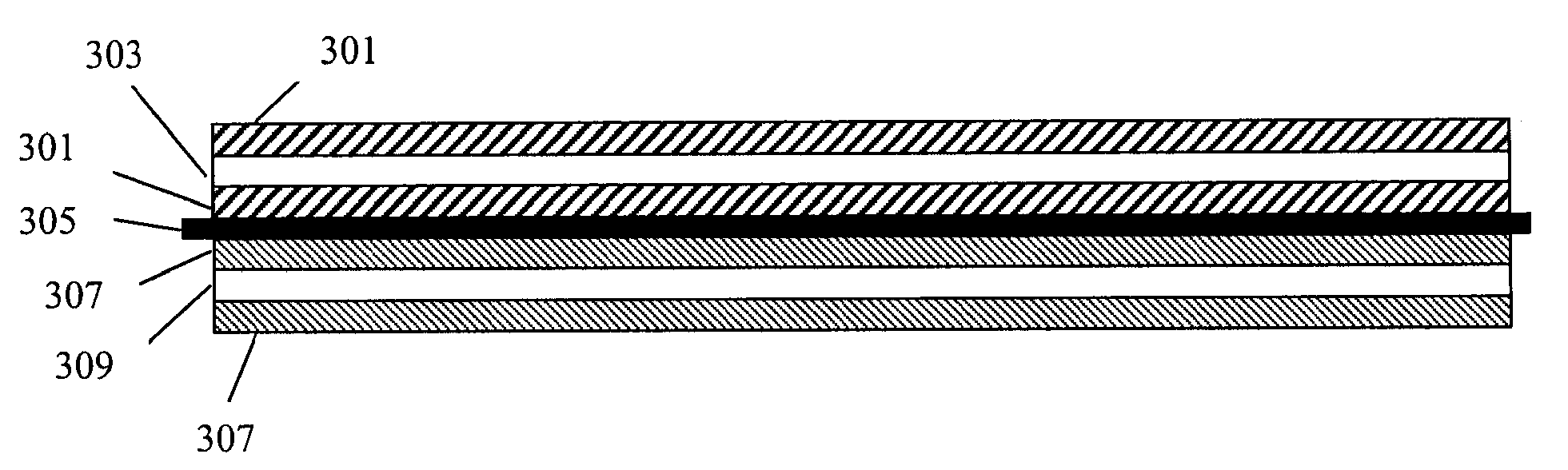

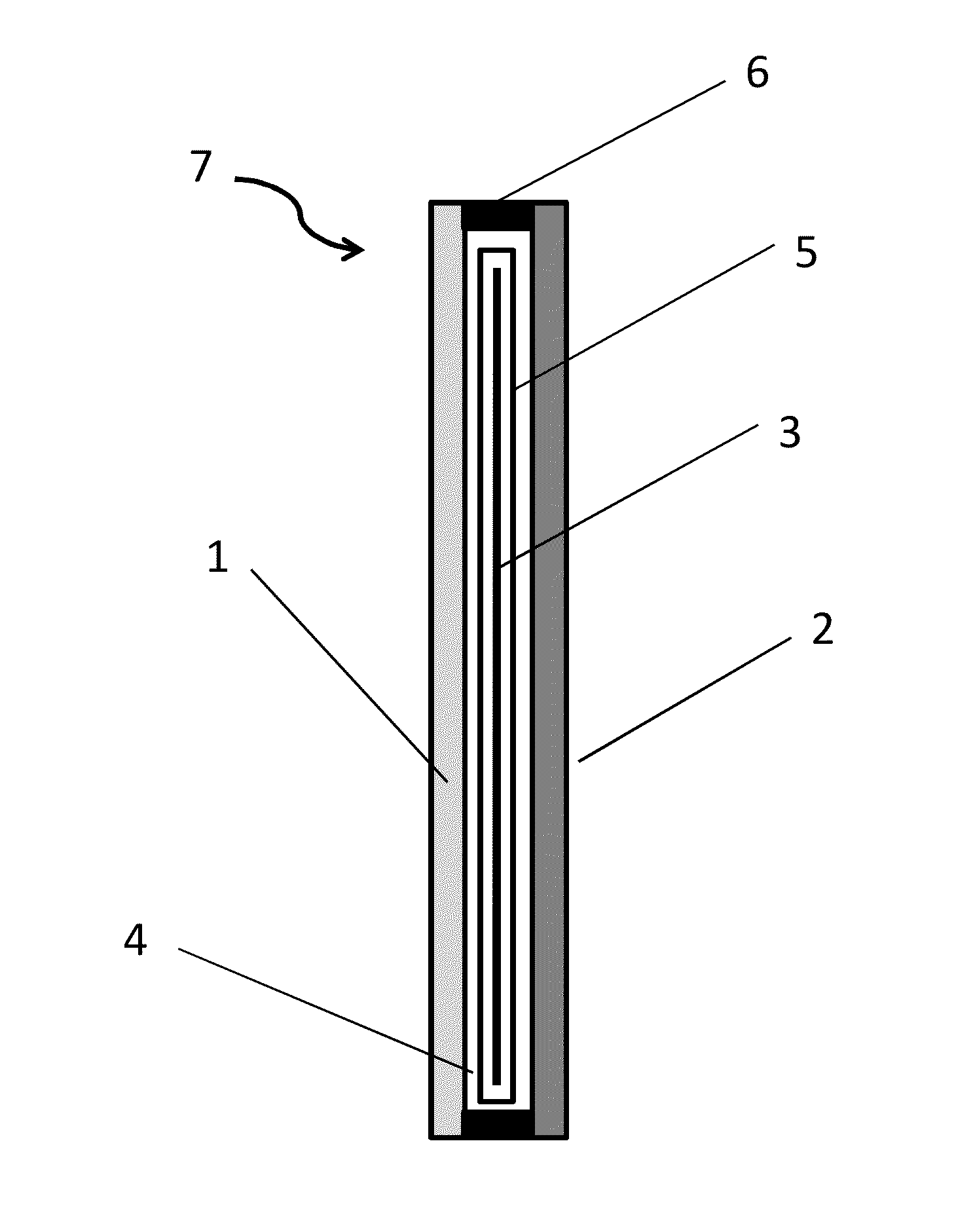

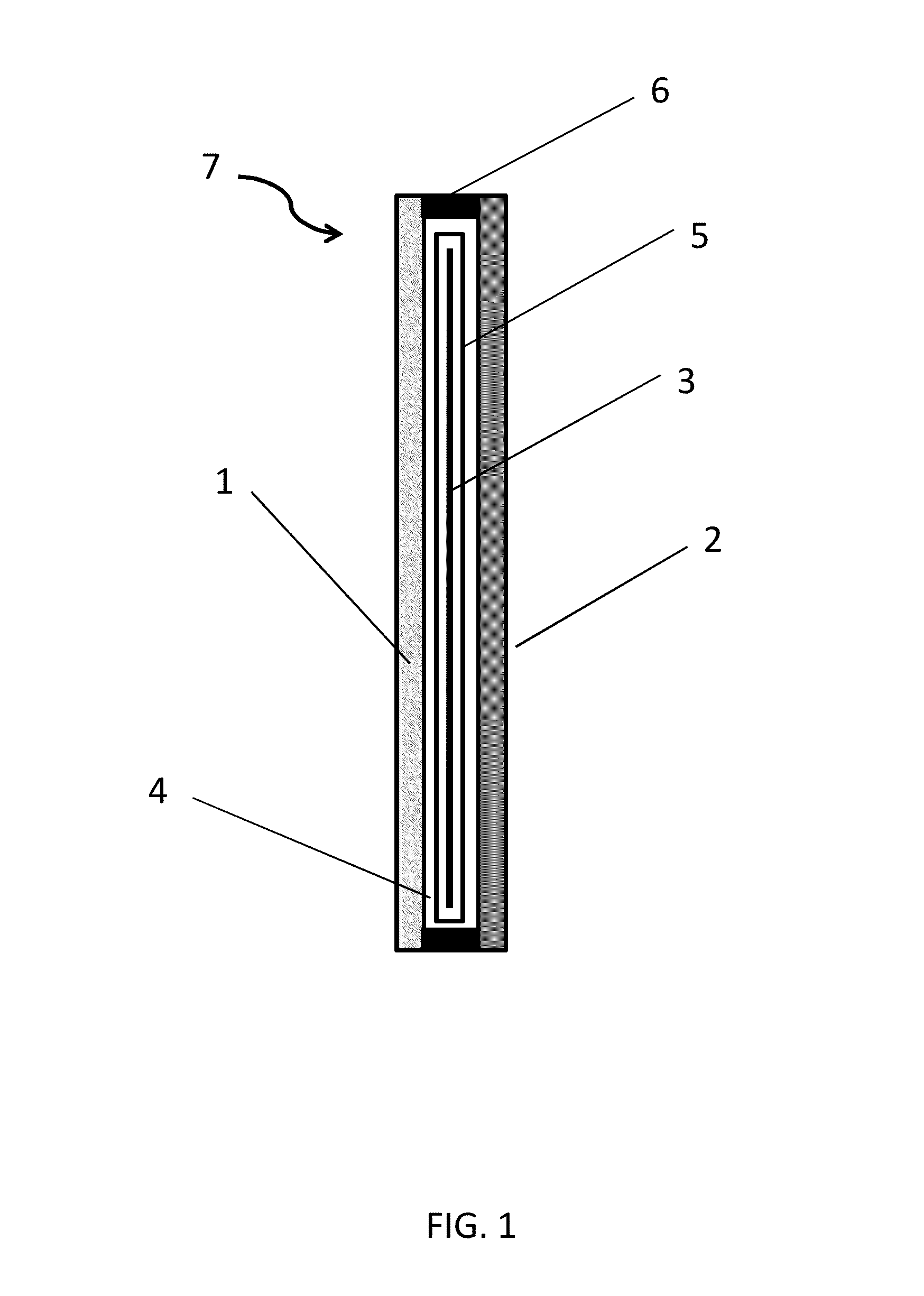

Thin Film Electrodes and Battery Cells, and Methods of Fabrication

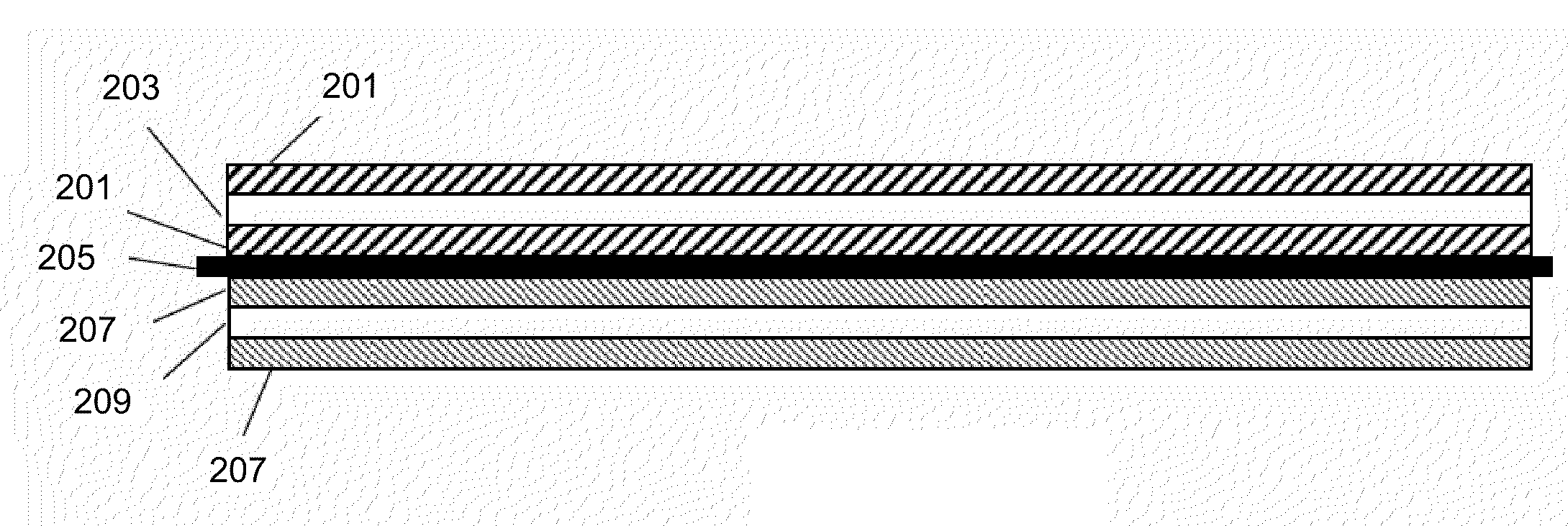

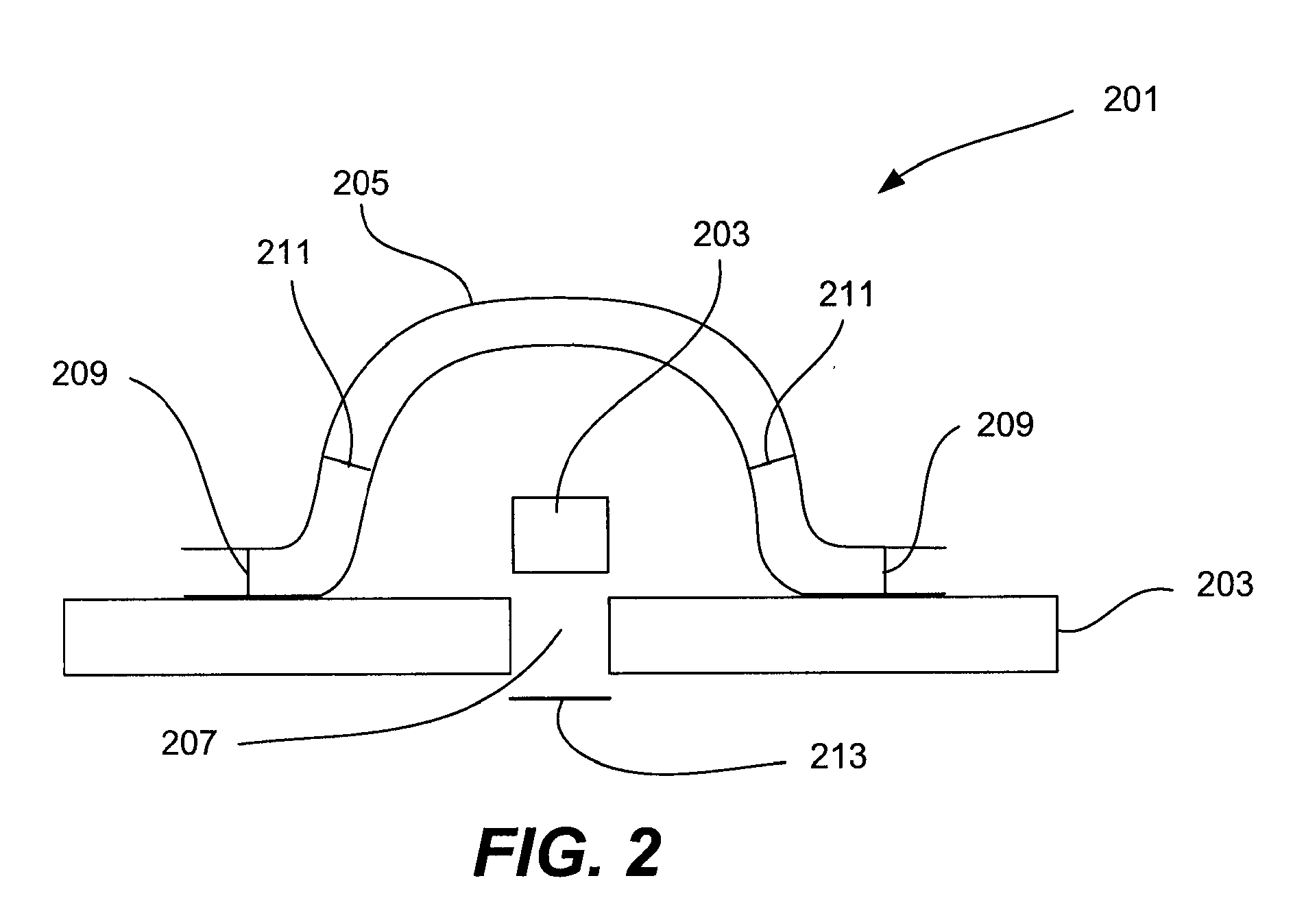

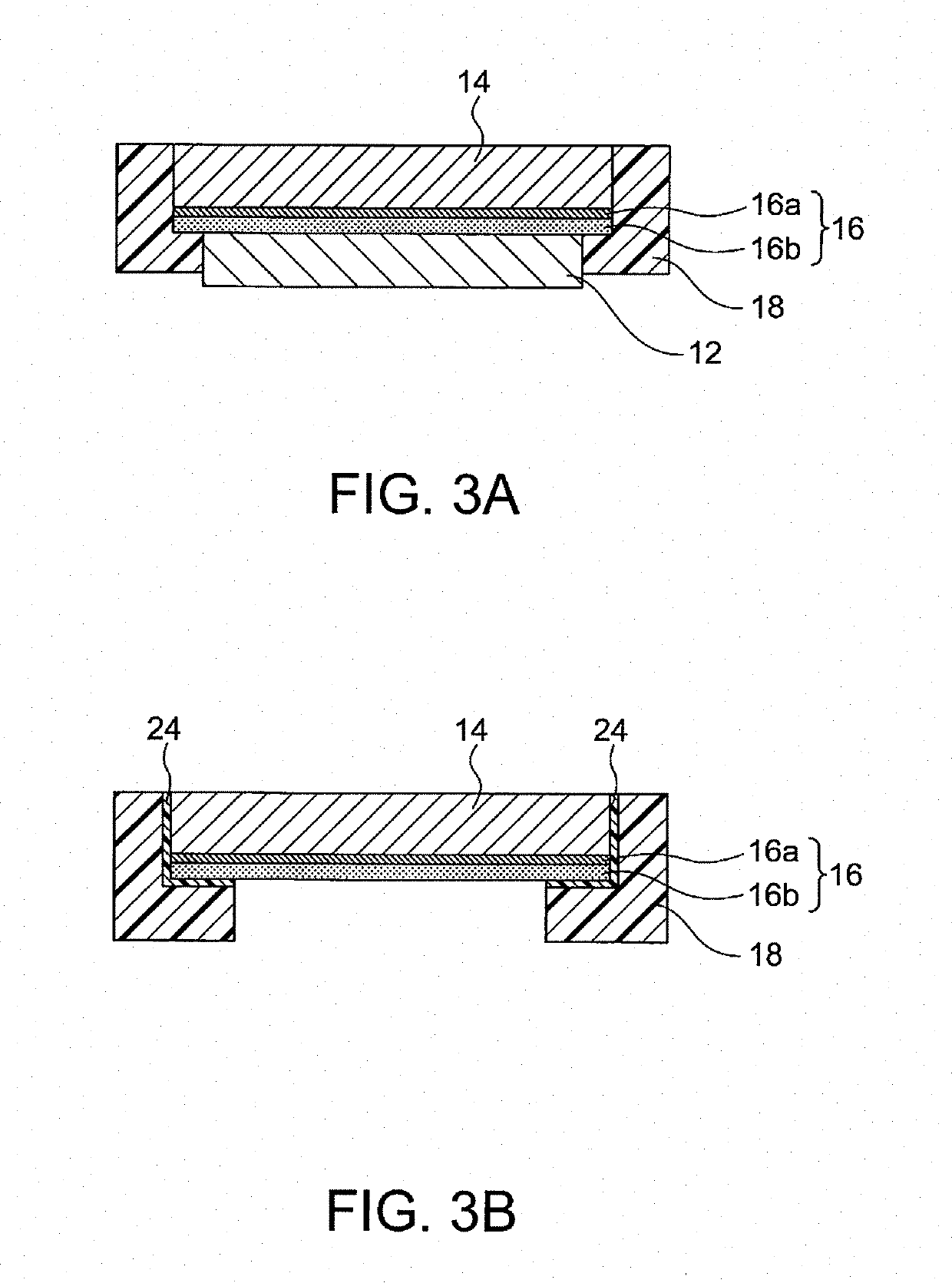

ActiveUS20110123852A1Lower internal resistanceReduce the total massFinal product manufactureFilling tube/pocket electrodesThin film electrodeMicrometer

Thin-film electrodes and battery cells, and methods of fabrication. A thin film electrode may be fabricated from a non-metallic, non-conductive porous support structure having pores with micrometer-range diameters. The support may include a polymer film. A first surface of the support is metalized, and the pores are partially metallized to create metal tubes having a thickness within a range of 50 to 150 nanometers, in contact with the metal layer. An active material is disposed within metalized portions of the pores. An electrolyte is disposed within non-metalized portions of the pores. Active materials may be selected to create an anode and a cathode. Non-metalized surfaces of the anode and cathode may be contacted to one another to form a battery cell, with the non-metalized electrolyte-containing portions of the anode facing the electrolyte-containing portions of the cathode pores. A battery cell may be fabricated as, for example, a nickel-zinc battery cell.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Cylindrical nickel-zinc cell with negative can

Owner:ZINCFIVE POWER INC

Wall Mounted Zinc Batteries

InactiveUS20160204441A1Simple designExtend battery lifeCapacitor and primary/secondary cellsElectrode carriers/collectorsFiberAlloy

Rechargeable and replaceable zinc cartridges have been used as the components of nickel-zinc batteries. The battery life of a zinc battery is extended by periodic replacing of the zinc anodes at about 10% of the battery cost. Flat modules that include several cells interconnected with channels are used as basic elements of a flat battery. A home wall battery is produced by assembling the modules using rotational joints. The performance of the zinc current collectors is improved by deposition of Zn—Cu—Bi alloy. Zinc composition is formulated using additives of polyphenylenediamines and zirconium hollow fibers.

Owner:PANISOLAR

Electrode/separator layered body and nickel zinc battery equipped therewith

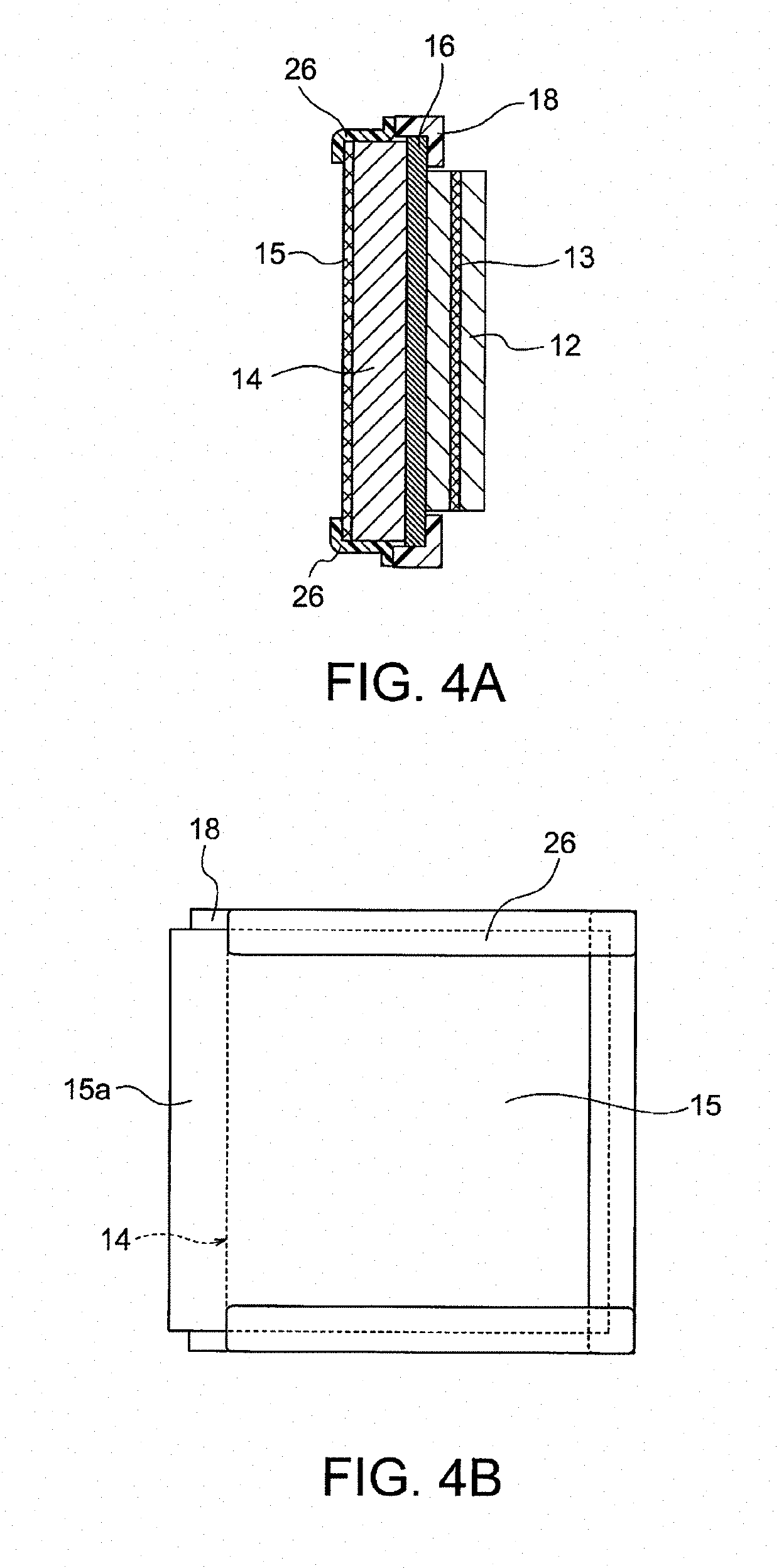

ActiveUS20190267597A1Effectively prevent the short circuit causedExtension of timeCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesZincMechanical engineering

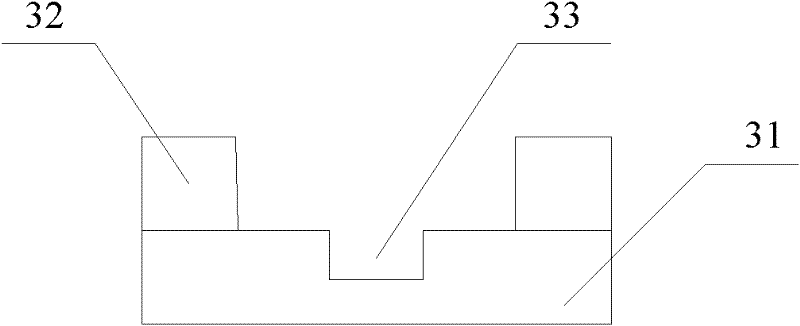

An electrode-separator assembly is provided that can drastically facilitate assembly of a LDH separator-equipped nickel-zinc battery without work, structure, or component for complete separation of a positive-electrode chamber from a negative-electrode chamber. The electrode-separator assembly includes a positive-electrode plate; a negative-electrode plate; a layered double hydroxide (LDH) separator for separation of the positive-electrode plate from the negative-electrode plate; and a resin frame having an opening to which the LDH separator and the positive-electrode plate are fitted or joined. The positive-electrode plate has a smaller face than the negative-electrode plate. The negative-electrode plate has a clearance area that does not overlap with the positive-electrode plate over a predetermined width from the outer peripheral edge of the negative-electrode plate. The peripheral end faces of the LDH separator and a segment, adjacent to the positive-electrode plate and corresponding to the clearance area, of the LDH separator are covered with the resin frame.

Owner:NGK INSULATORS LTD

Nickel zinc battery design

ActiveUS8703330B2Lower impedanceLow impedance copper conductive pathsElectrode carriers/collectorsActive material electrodesHydrogenElectrical polarity

Nickel zinc cylindrical battery cell designs are described. The designs provided limit dendrite formation and prevent build up of hydrogen gas in the cell. The present invention also provides low-impedance cells required by rapid discharge applications. The cylindrical battery cells may have polarity opposite of that of conventional power cells, with a negative cap and positive can. The cylindrical cells may include a gel electrolyte reservoir.

Owner:ZINCFIVE POWER INC

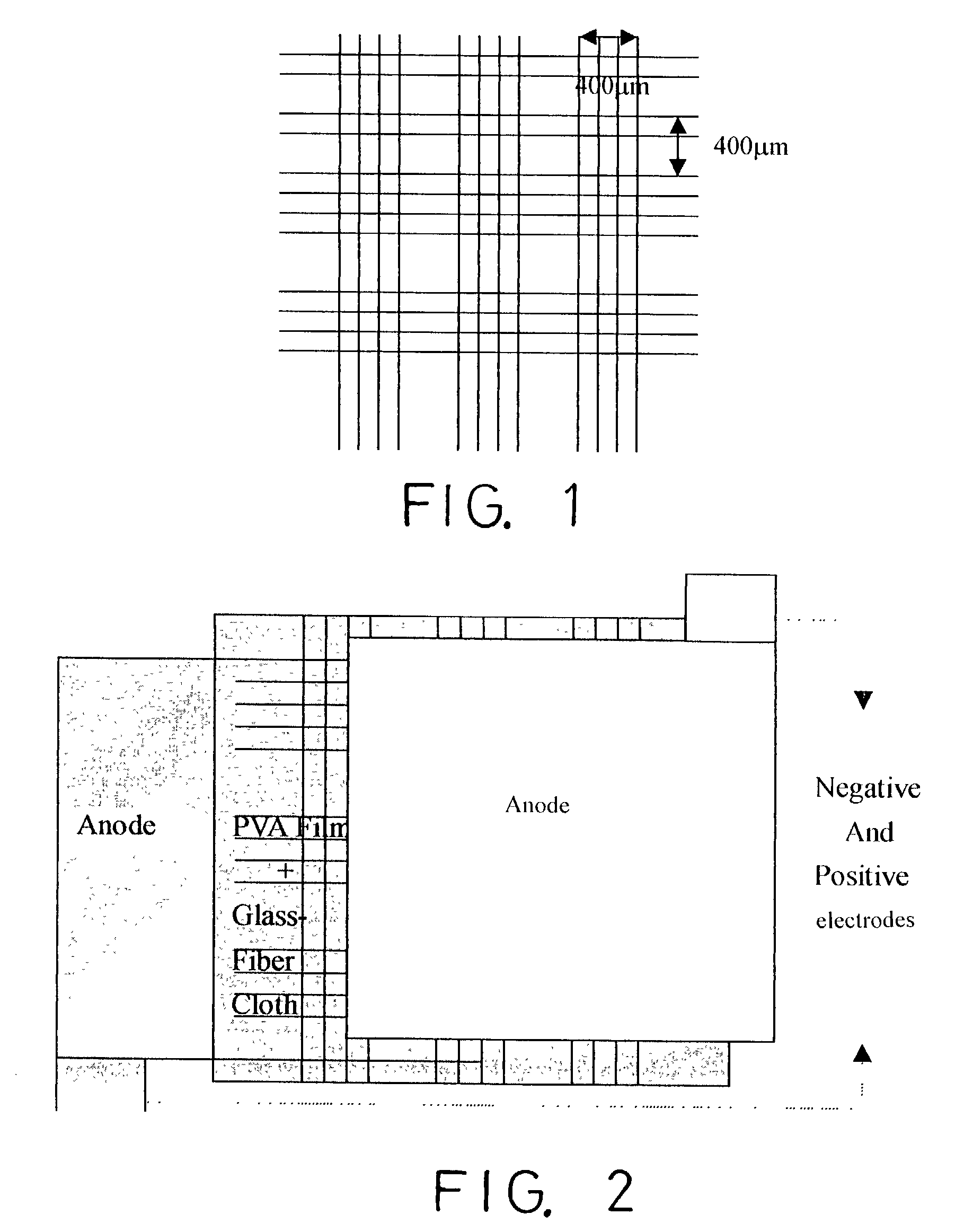

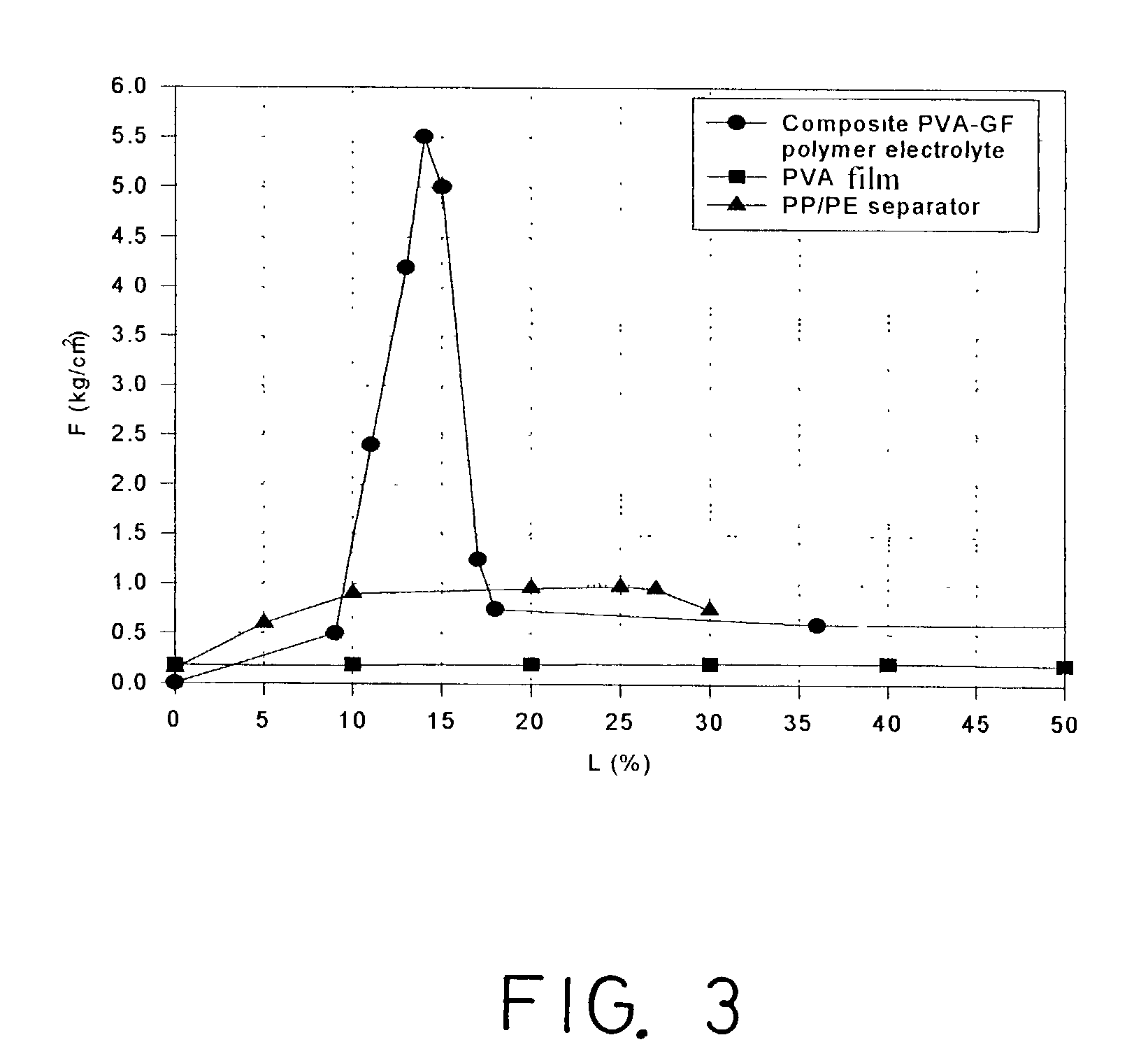

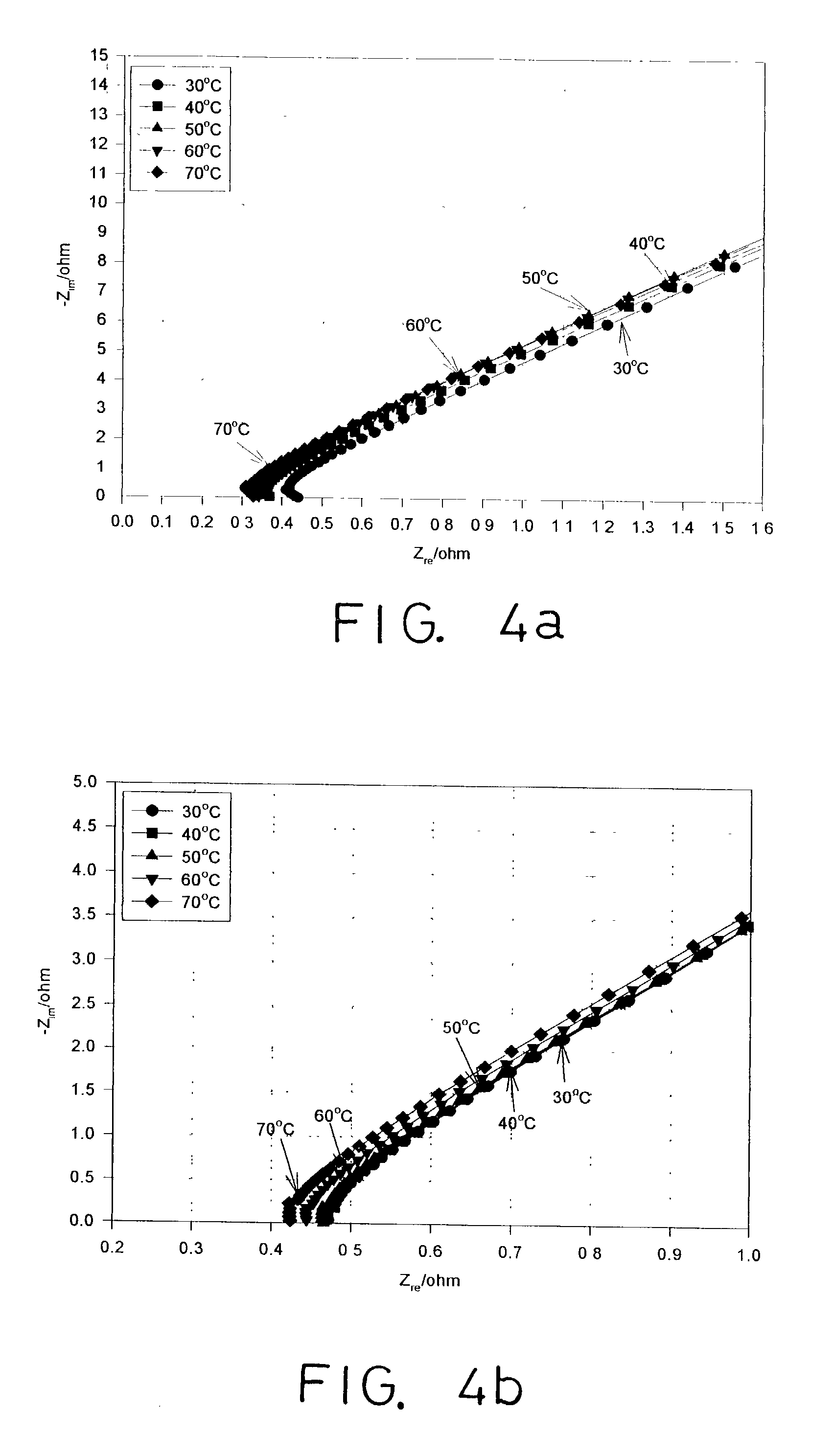

Method for making solid polymer electrolyte and uses thereof

A method for preparing a composite alkaline solid polymer electrolyte from polyvinyl alcohol (PVA) polymer, potassium hydroxide and water is disclosed. Said polymer electrolyte is reinforced with glass-fiber cloth to increase its mechanical strength, thermal stability and electrochemical stability. The glass fiber cloth matrix provides a stable interface between the cathode and the anode to reduce the short circuit problem when the battery discharges at high rate. The processes for polymer electrolyte are controlled by molecular weight of PVA polymer, the sequence of feeding in reactants, the weight proportions of reactants, the reaction time, the reaction temperature, and the drying conditions, i.e. under the specified conditions of relative humidity (RH), temperature and drying time. The resulting electrolyte exhibits ionic conductivity of 0.15 S / cm or better at room temperature and has high mechanical intensity and good electrochemical stability. This polymer electrolyte can replace the conventional PP non-woven fabric separator in primary and secondary alkaline batteries, metal-air battery, nickel-metal hydride battery, nickel-cadmium battery, nickel-zinc battery, fuel cells and capacitors. This composite PVA-GF polymer electrolyte can be used in thin-film alkaline battery system (thickness <4 mm) to reduce the weight and thickness of battery, while significantly increasing the energy and power densities of the battery. It offers another opportunity for making thin and lightweight batteries to be used in future 3C electronic products.

Owner:NANYA PLASTICS CORP

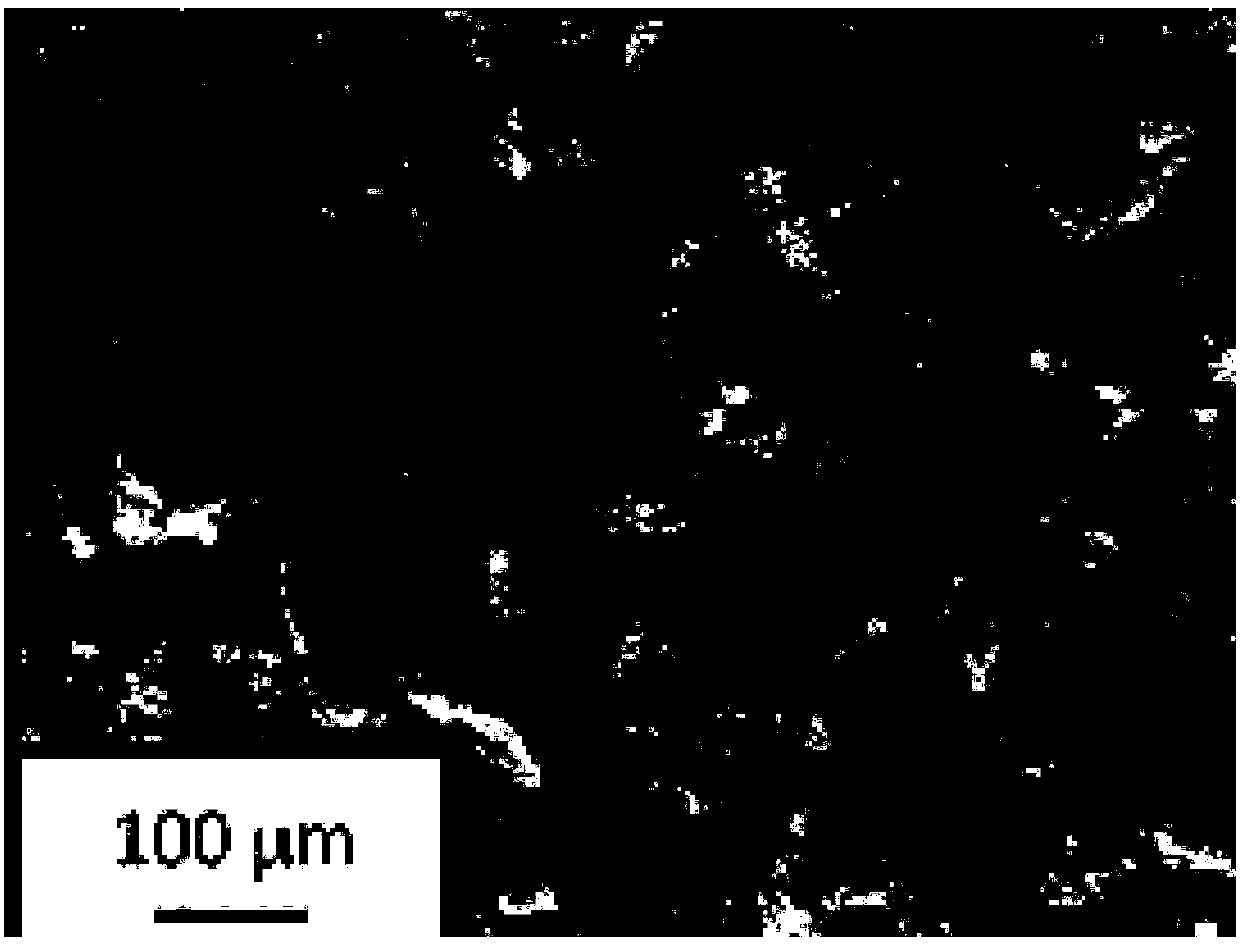

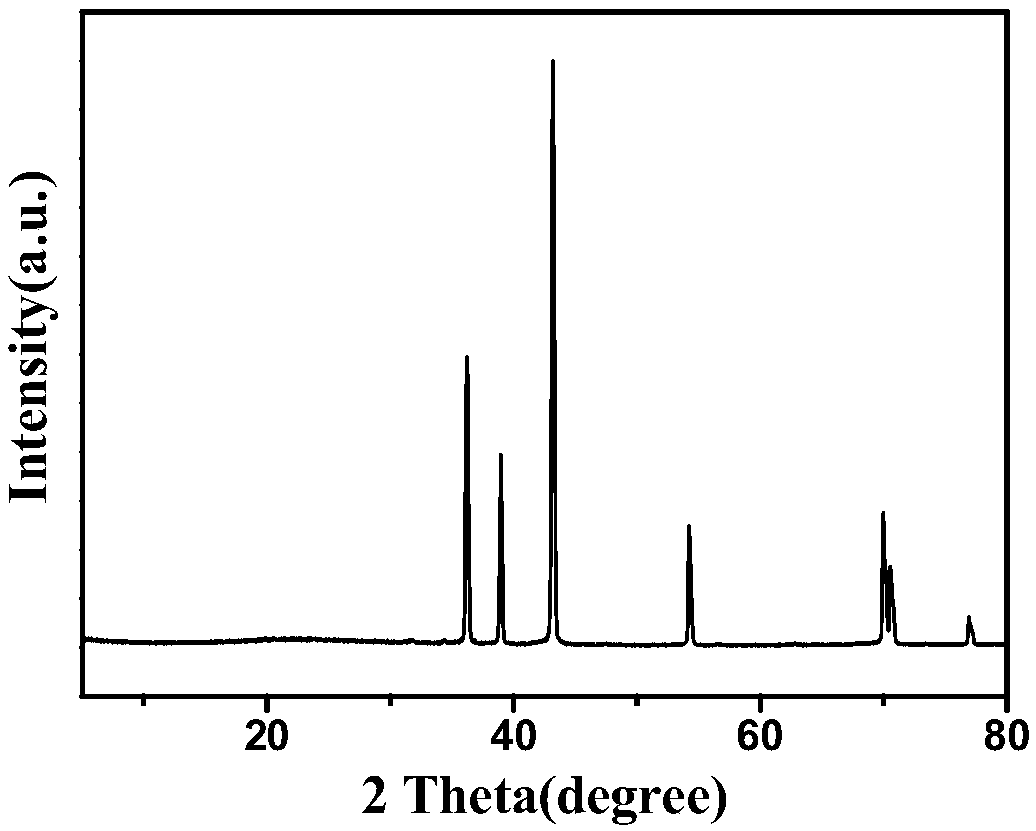

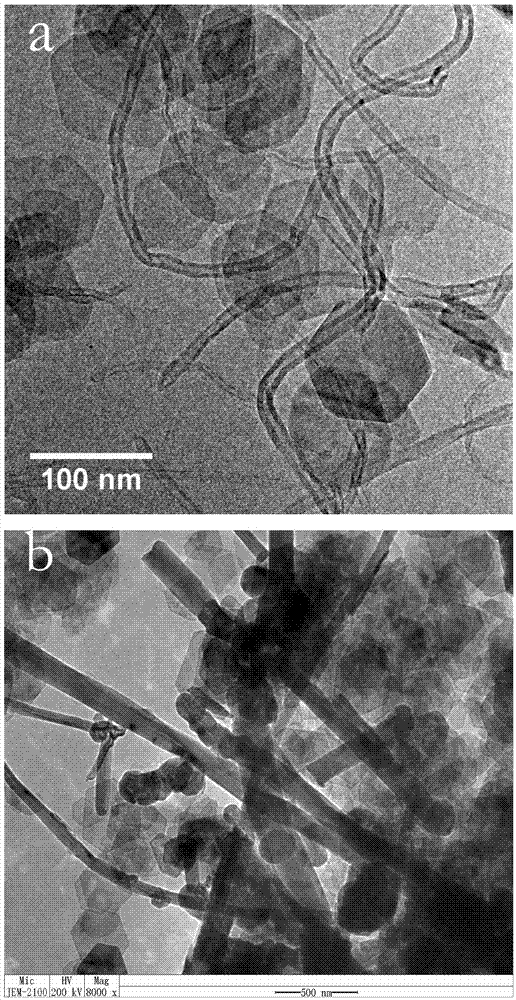

Three-dimensional zinc/carbon composite material for zinc-based battery and preparation method of three-dimensional zinc/carbon composite material

InactiveCN107681129AEasy to prepareShort timeCell electrodesNickel accumulatorsCarbon compositesGlobular shaped

The invention provides a three-dimensional zinc / carbon composite material for a zinc-based battery. The three-dimensional zinc / carbon composite material comprises a carbon conducting network of a three-dimensional multistage structure and zinc and / or zinc oxide loaded on the carbon conducting network, wherein the mass ratio of the zinc and / or the zinc oxide is 50-95%; the three-dimensional carbonconducting network is obtained through carbonization treatment of a polymer and has a macroporous, mesoporous and microporous pore structure; the shapes and forms of the zinc and the zinc oxide loadedon the three-dimensional carbon conducting network are one or more of a globular shape, a rod shape and a needle shape independently; and the sizes of the zinc and the zinc oxide are 10nm to 20 microns. The invention further provides a preparation method of the composite material. The three-dimensional zinc / carbon composite material provided by the invention has an ordered porous structure and high conductivity, has excellent electrochemical properties and cycle stability when used as a negative electrode of a nickel-zinc battery, and can be widely applied to the fields of various portable electronic devices, electric vehicles and aerospace.

Owner:BEIHANG UNIV

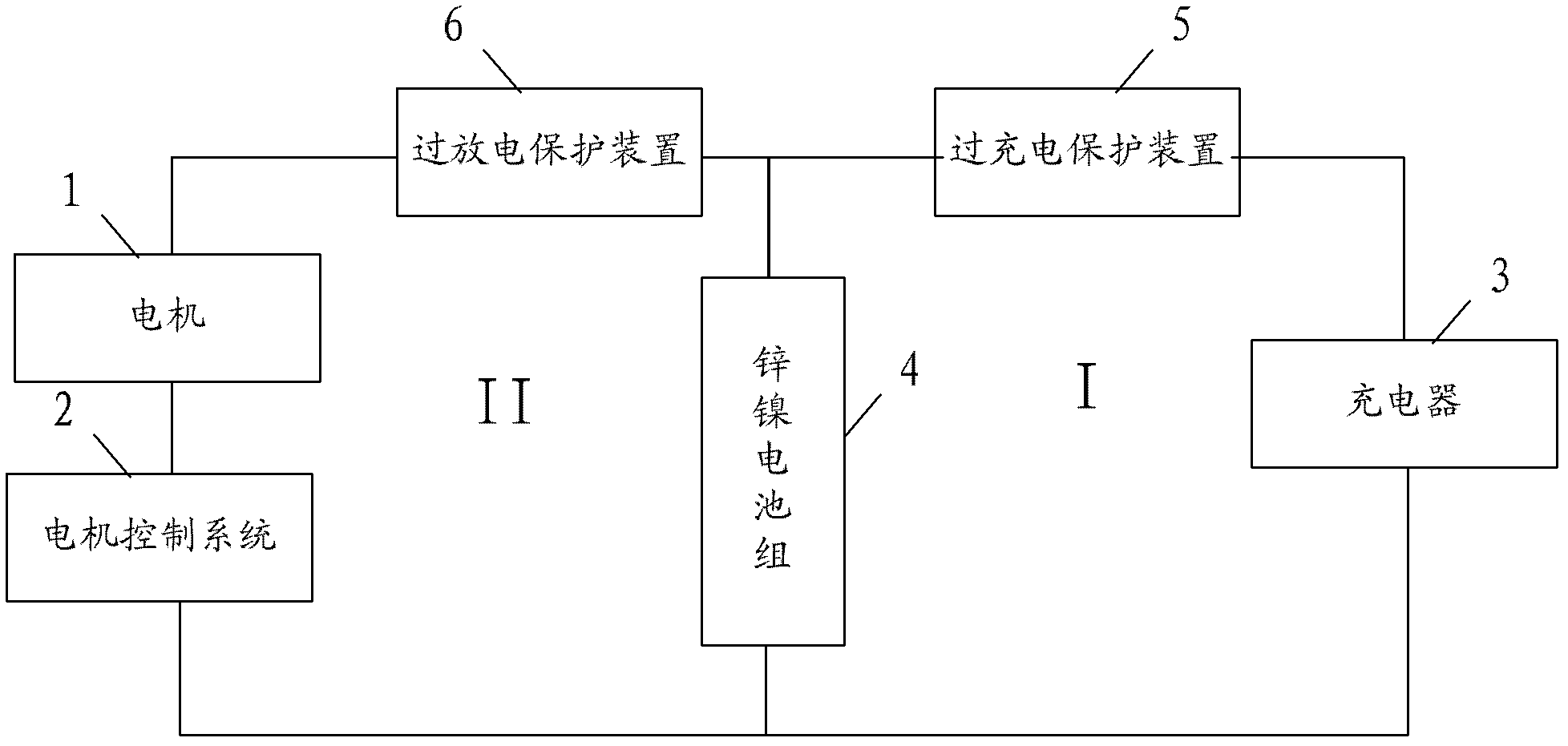

Power system for electrombile

ActiveCN102616143AImprove performanceStable stateElectric devicesVehicular energy storageControl systemElectrical battery

The application discloses a power system for an electrombile, wherein a motor and a motor control system are arranged on the electrombile, the power system for the electrombile comprises an installing support, a nickel-zinc battery pack, an overcharge protector and an overdischarge protector, the nickel-zinc battery pack is fixed in the installing support on the electrombile, a charge protecting loop and a discharge protecting loop are arranged on the nickel-zinc battery pack, the discharge protecting loop is connected with the motor and the motor control system, and the overcharge protector is connected in the discharge protecting loop in series, and is used for detecting the temperature of the nickel-zinc battery pack and controlling the charge protecting loop to be switched on or off according to the detected temperature; and the overdischarge protector is connected in the discharge protecting loop in series, and is used for acquiring the voltage of a nickel-zinc battery single body, and controlling the discharge protecting loop to be switched on or off according to the acquired voltage. According to the power system for the electrombile, the conditions of overcharge and overdischarge can be avoided, the service life of the battery can be prolonged, and the performance of the electrombile can be further improved.

Owner:GUANGDONG POWERLINK ENERGY

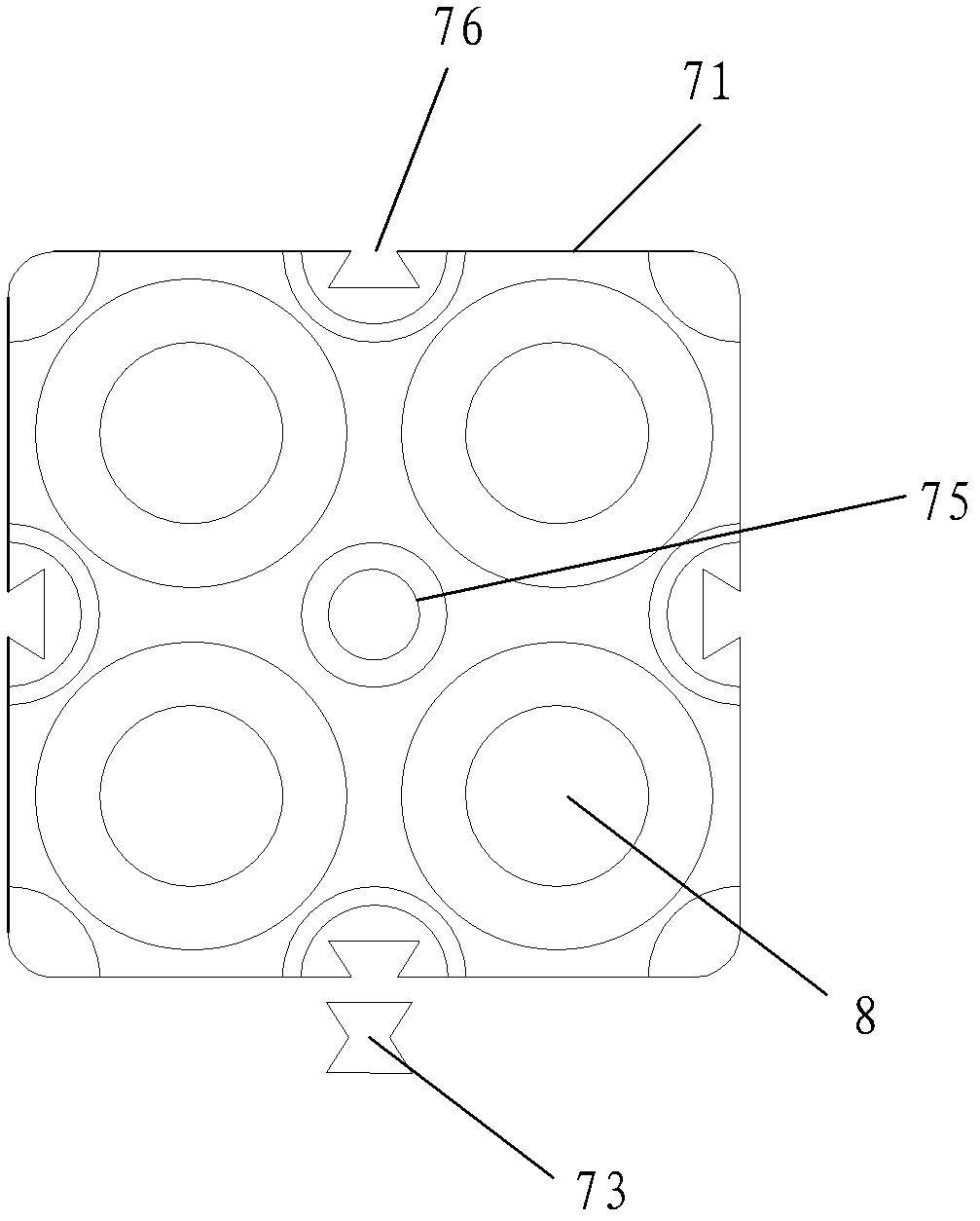

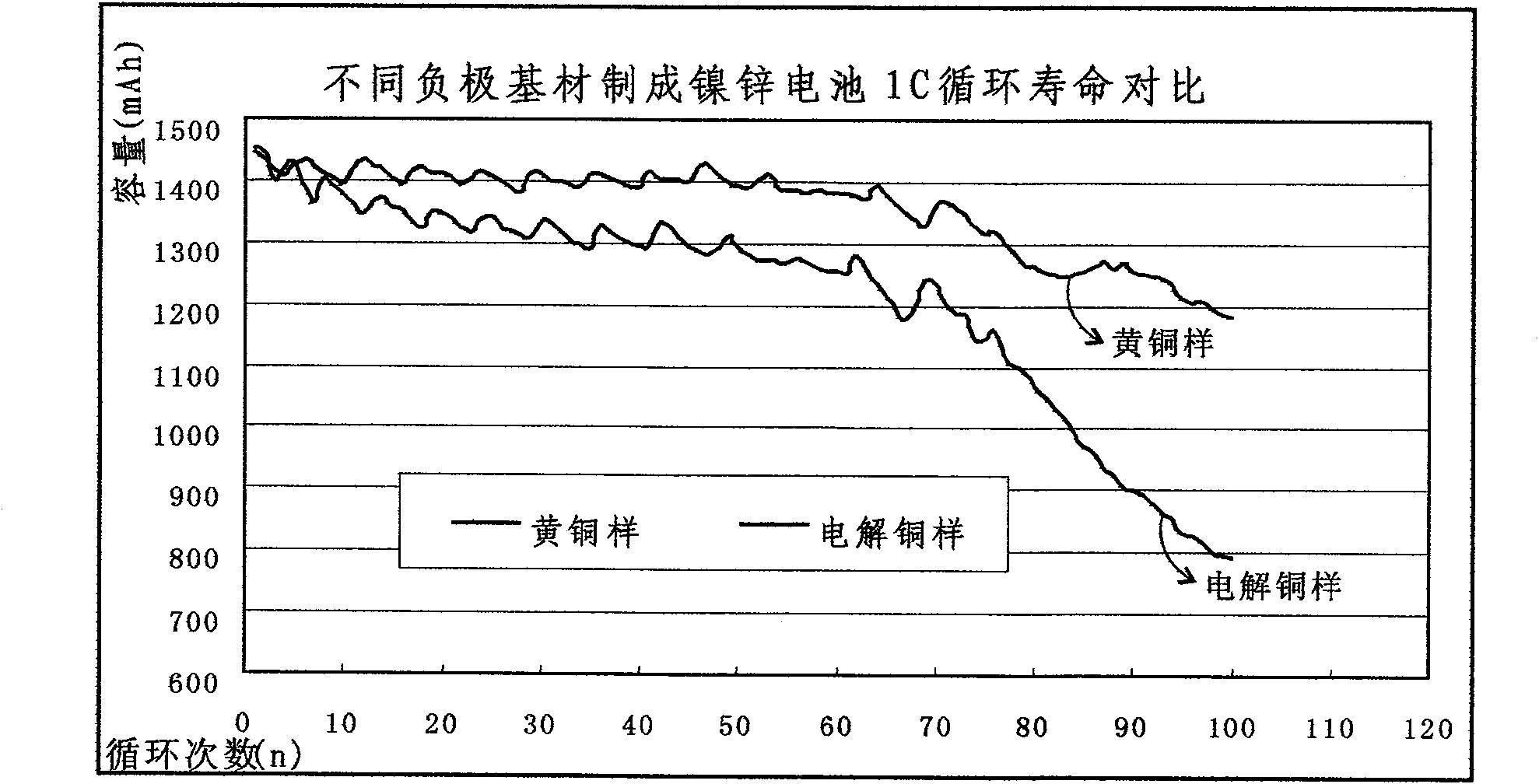

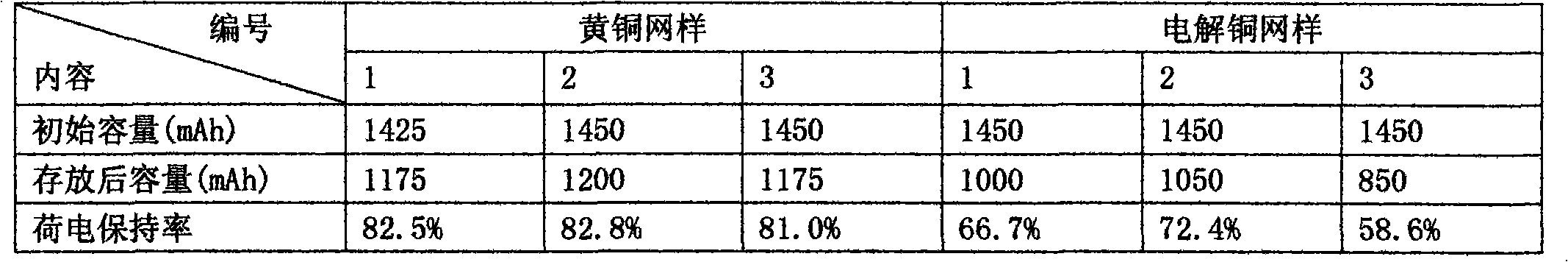

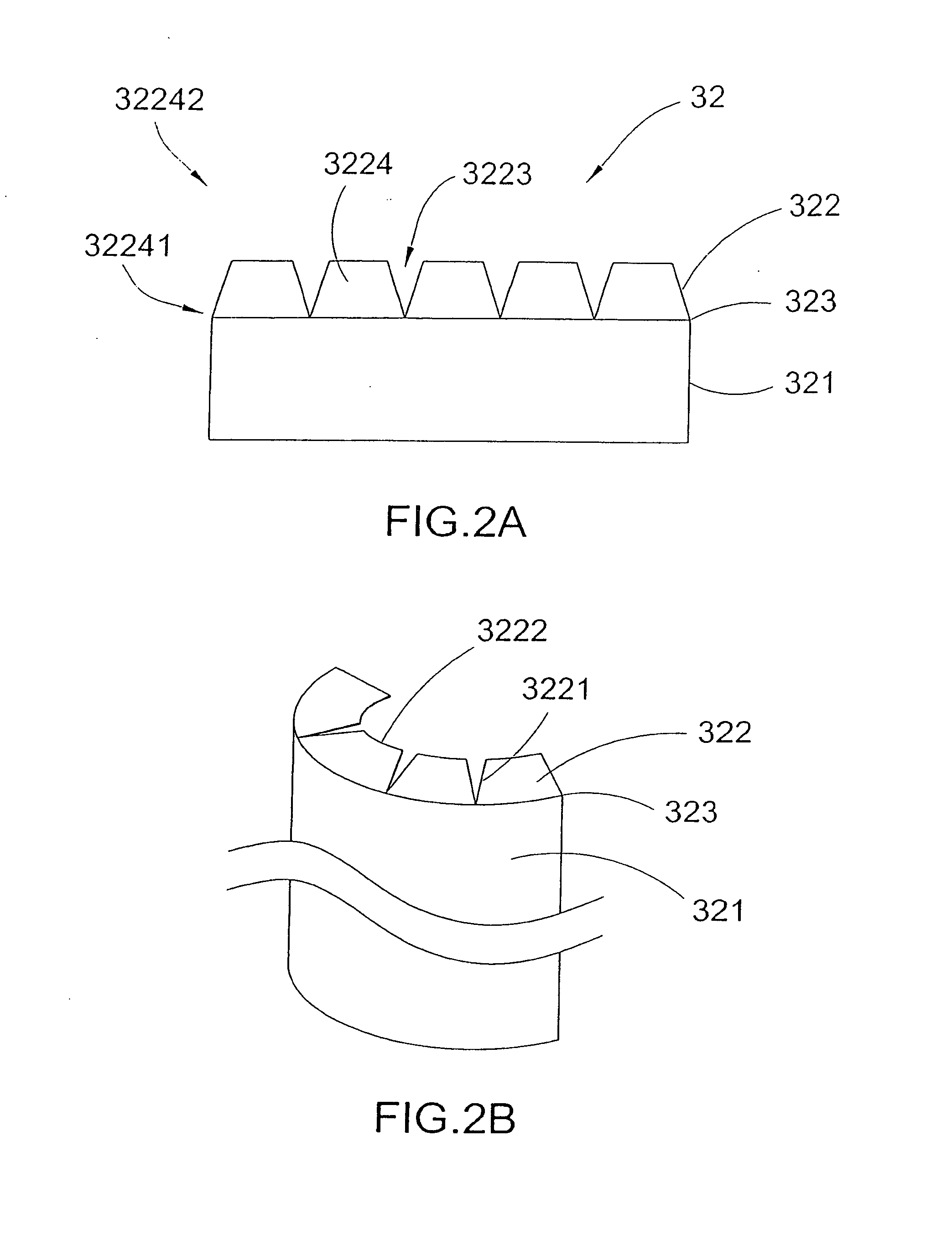

Base material of cathode of nickel zinc battery

The invention discloses a base material of the cathode of a nickel zinc battery. The base material of the cathode of a nickel zinc battery adopts a brass inclined pull net; and the brass inclined pull net comprises 65-75% of copper, 25-25% of zinc and 0.5-1.5% of tin. With the three-dimensional structure, the brass inclined pull net can lead the contact area between the cathode material and the base material to be increased, increases the filling quantity of the active material, and has good current-collecting and electricity-conducting function. The battery has the advantages of stable performance, long cycle life, low cost, simple preparation technology of base material, good electrical conductivity, etc.

Owner:SHENZHEN BETTERPOWER BATTERY

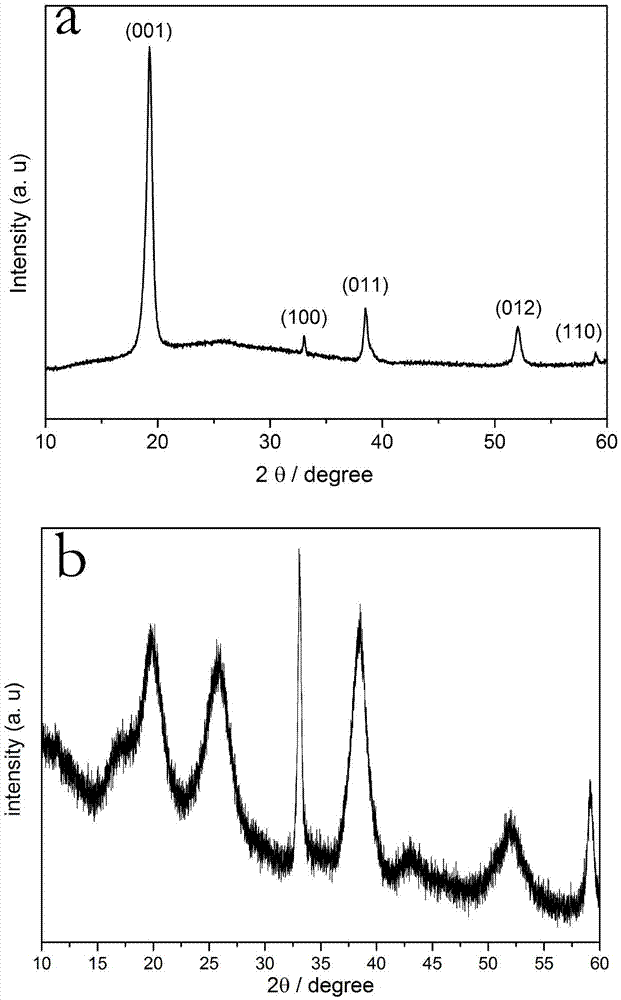

Cathode material for nickel-zinc battery and nickel-zinc battery employing cathode material

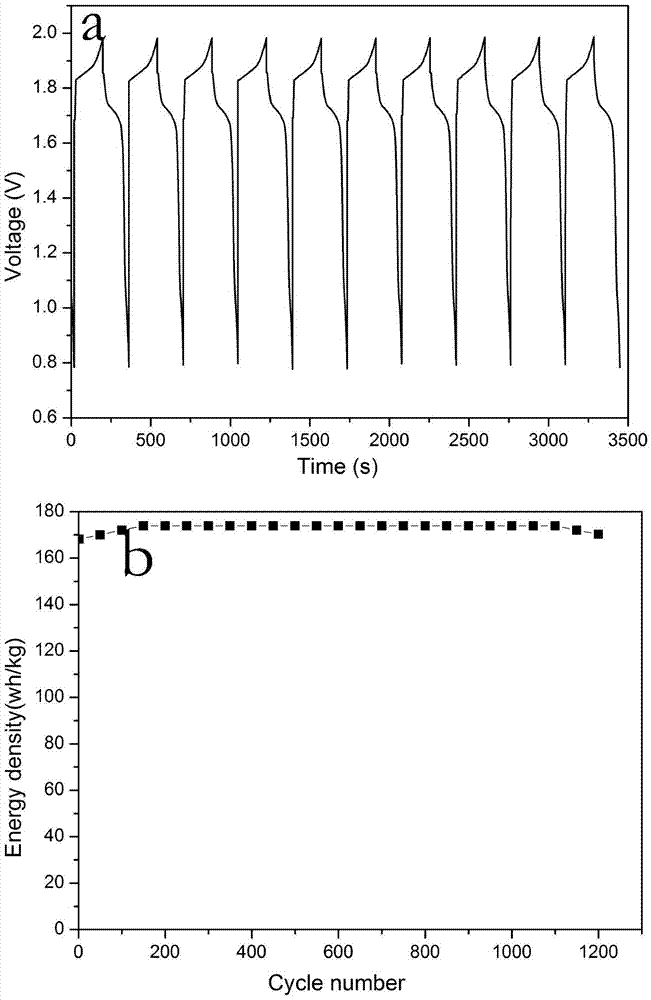

ActiveCN105449194AEasy to getQuick migrationCell electrodesNickel accumulatorsCarbon compositesDispersity

The invention discloses a preparation method of a cathode material for a nickel-zinc battery. The method comprises large-scale modification of a carbon material, so that the surface has an oxygen-containing group, and the carbon material has good dispersity in water or an organic solvent. The invention further discloses a preparation method of an Ni(OH)<2> / carbon composite material. The material is applied to a positive electrode and a Zn negative electrode to construct a soft package NiZn battery. A test result shows that the material improves the electric contact performance of the electrodes when used as an electrode material, so that the overall electrochemical properties of the electrodes and the battery including the material are improved.

Owner:JIANGSU UNIV OF TECH

Nickel-zinc battery and manufacturing method thereof

InactiveUS20120297611A1High and adequate powerHigh and adequate and energyFinal product manufacturePrimary cellsZincFluid electrolytes

A cylindrical Ni—Zn battery includes a battery shell, an electrode assembly and a liquid electrolyte which are sealed within the shell. The electrode assembly, whose upper part is connected to a cap, includes a nickel cathode, zinc anode, and a composite membrane. The nickel cathode and zinc anode have an edge portion which are externally exposed and bent inwardly to form the anode and cathode conductive end respectively, and edges of the composite membranes are sealed together, so that the electrodes are contained in the membranes. The battery is characterized by the simple in structure, convenient installation, low cost, safety, characteristics of long-term storage, effectively preventing the growth of dendrite, long life, strong capability to resist shake, and good performance of large current discharging.

Owner:HANGZHOU NEUCELL ENERGY CO LTD

Nickel-zinc battery

InactiveUS20160276714A1Prevent and inhibit problemDecrease in battery performanceSolid electrolytesCell seperators/membranes/diaphragms/spacersPorous substrateElectrolysis

Provided is a highly reliable nickel-zinc battery including a separator exhibiting hydroxide ion conductivity and water impermeability. The nickel-zinc battery includes a positive electrode containing nickel oxide and / or nickel oxyhydroxide; a positive-electrode electrolytic solution in which the positive electrode is immersed, the electrolytic solution containing an alkali metal hydroxide; a negative electrode containing zinc and / or zinc oxide; a negative-electrode electrolytic solution in which the negative electrode is immersed, the electrolytic solution containing an alkali metal hydroxide; a hermetic container accommodating the positive electrode, the positive-electrode electrolytic solution, the negative electrode, and the negative-electrode electrolytic solution; the separator exhibiting hydroxide ion conductivity and water impermeability and disposed in the hermetic container to separate a positive-electrode chamber accommodating the positive electrode and the electrolytic solution from a negative-electrode chamber accommodating the negative electrode and the electrolytic solution; and a porous substrate on a surface of the separator facing toward the positive electrode.

Owner:NGK INSULATORS LTD

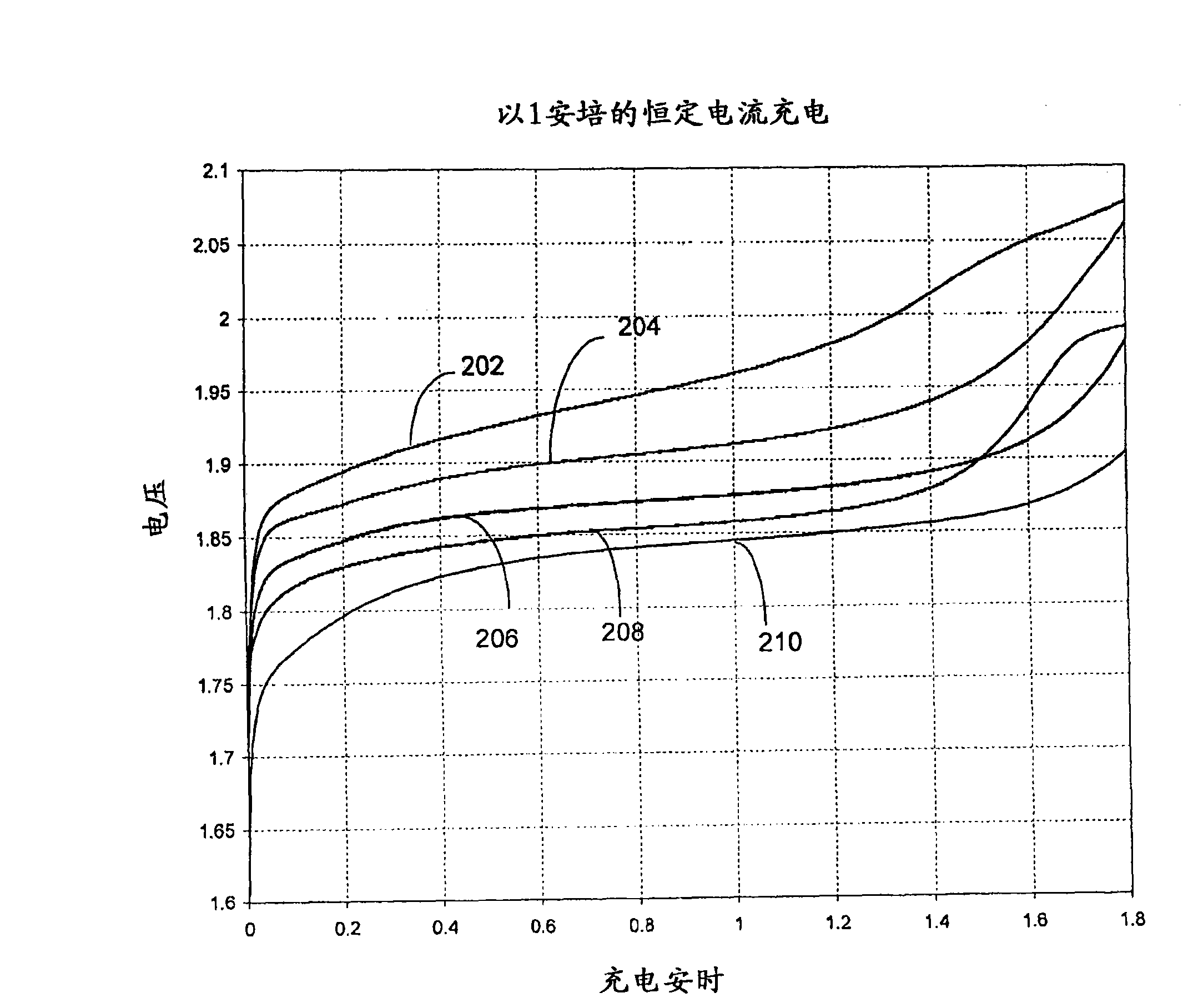

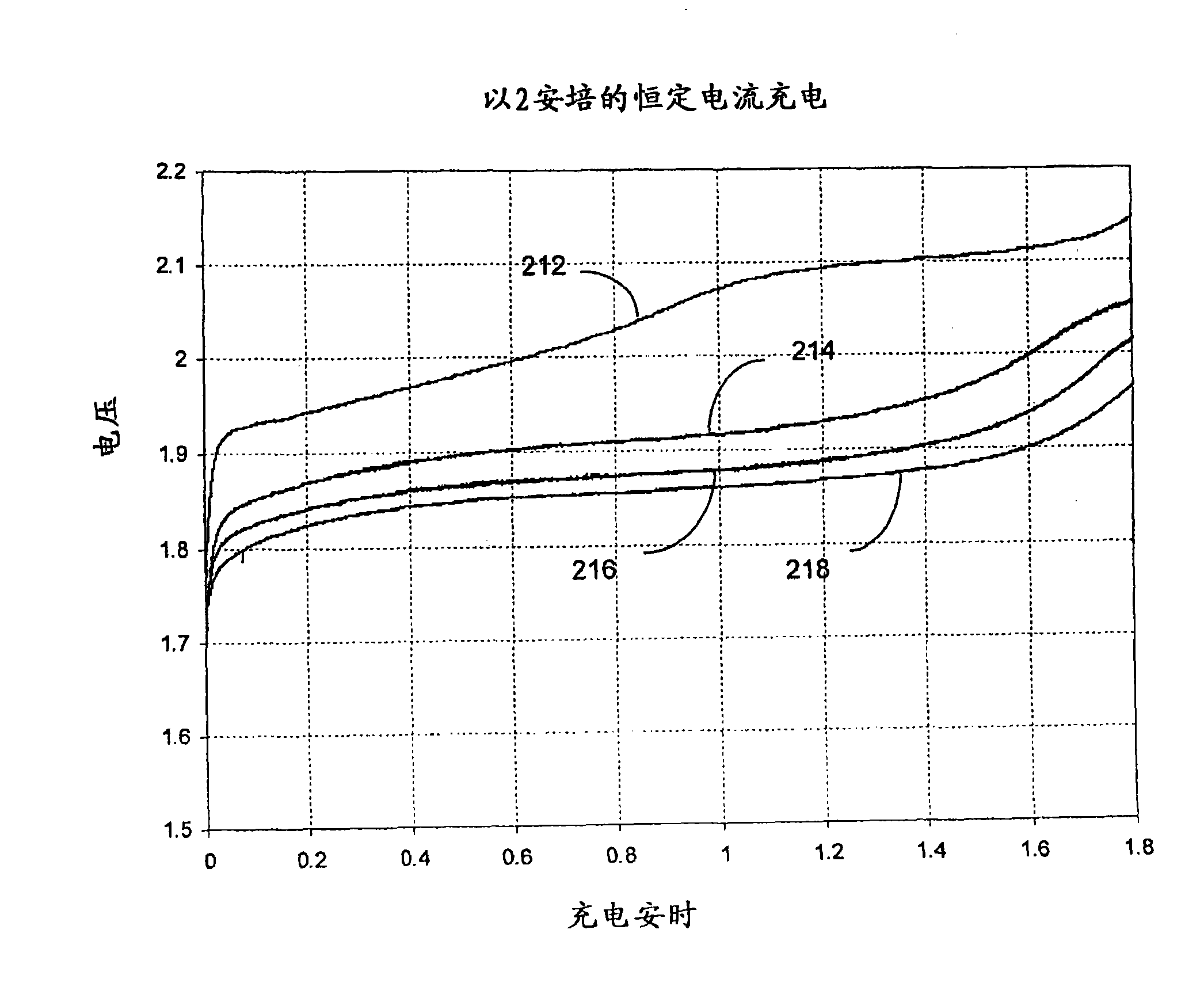

Charging methods for nickel-zinc battery packs

Owner:POWERGENIX SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com