Method for recovering valuable metal from waste nickel-zinc battery

A nickel-zinc battery and valuable metal technology, which is applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of nickel-zinc battery recycling technology that has not been reported yet, large consumption of auxiliary materials, long filtration time, etc. , to achieve the effect of high resource recycling rate, low cost and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

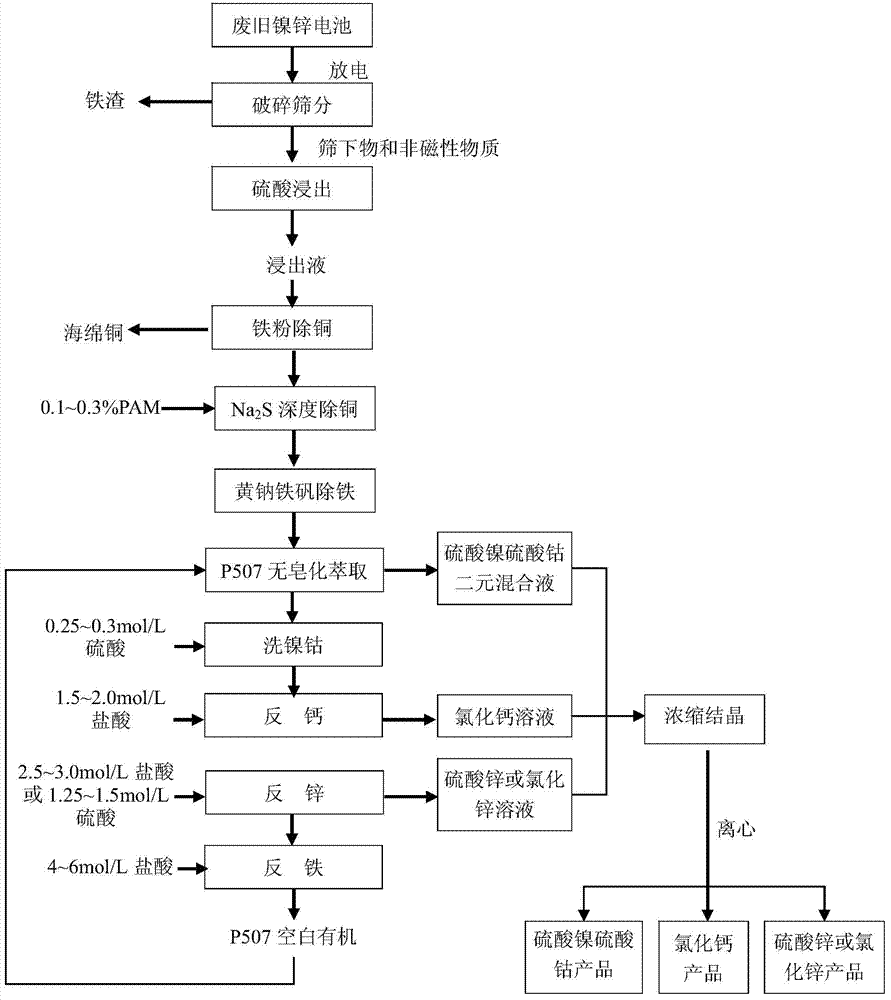

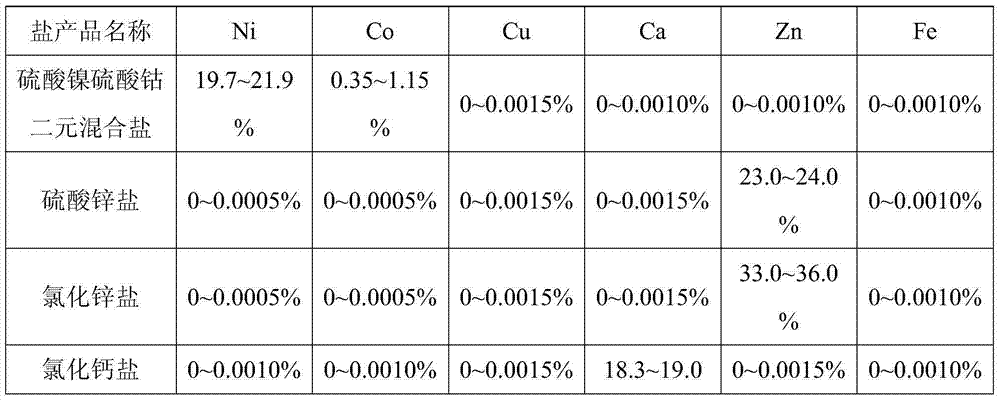

[0052] A method for recovering valuable metals from waste nickel-zinc batteries, the technological process is as follows figure 1 shown, including the following steps:

[0053] (1) Place waste nickel-zinc batteries in saturated salt water for self-discharge treatment;

[0054] (2) Use a crusher to crush and sieve the nickel-zinc battery after self-discharge treatment, and then sieve it with a 120-mesh standard sieve to obtain the oversize and undersize;

[0055] (3) Conduct magnetic separation on the sieve to obtain iron slag and non-magnetic substances;

[0056] (4) Mix the non-magnetic substance and the undersize, then leach the mixture with 206g / L sulfuric acid, and obtain the leachate after filtration; the test results of the mixture and the iron slag after mixing the nonmagnetic substance and the undersize are shown in the table 2; The content of each component in the leachate is shown in Table 3:

[0057] (5) Take 2m 3 leach solution, and then the leach solution is c...

Embodiment 2

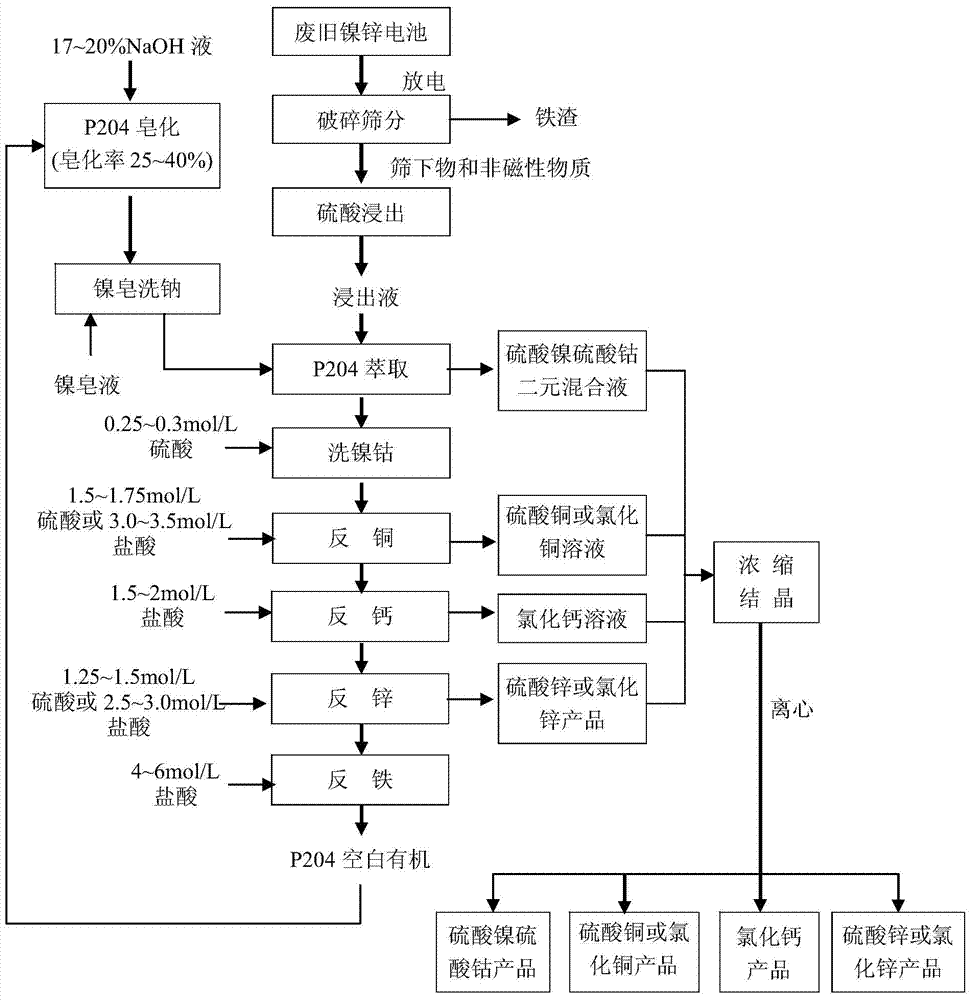

[0082] A method for recovering valuable metals from waste nickel-zinc batteries, the technological process is as follows figure 2 shown, including the following steps:

[0083] (1) Place waste nickel-zinc batteries in saturated salt water for self-discharge treatment;

[0084] (2) Use a crusher to crush and sieve the nickel-zinc battery after self-discharge treatment, and then sieve it with a 120-mesh standard sieve to obtain the oversize and undersize;

[0085] (3) Conduct magnetic separation on the sieve to obtain iron slag and non-magnetic substances;

[0086] (4) Mix the non-magnetic substance and the undersize, then leach the mixture with 220g / L sulfuric acid, and obtain the leachate after filtration; the test results of the mixture and the iron slag after mixing the nonmagnetic substance and the undersize are shown in the table 8; The content of each component in the leachate is shown in Table 9:

[0087] (5) The leaching solution is chemically treated and extracted ...

Embodiment 3

[0114] A method for recovering valuable metals from waste nickel-zinc batteries, comprising the following steps:

[0115] (1) Place waste nickel-zinc batteries in saturated salt water for self-discharge treatment;

[0116] (2) Use a crusher to crush and sieve the nickel-zinc battery after self-discharge treatment, and then sieve it with a 120-mesh standard sieve to obtain the oversize and undersize;

[0117] (3) Conduct magnetic separation on the sieve to obtain iron slag and non-magnetic substances;

[0118] (4) Mix the non-magnetic material and the undersize, then leach the mixture with 225g / L sulfuric acid, and obtain the leachate after filtration; the test results of the mixture and the iron slag after mixing the non-magnetic material and the undersize are shown in the table 15; The content of each component in the leachate is shown in Table 16:

[0119] (5) The leaching solution is chemically treated and extracted to obtain a binary mixture of nickel sulfate and cobalt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com