Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Linolenic acid ethyl ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing alpha-ethyl linolenate with purity more than 80%

InactiveCN1837182AWide range of ways to addConvenient supplementOrganic compound preparationCarboxylic acid esters preparationEthyl esterZinc

The invention relates to a process for preparing alpha-zinc linolenate by using perilla seeds as the raw material, which comprises the steps of squeezing, filtering, saponifying, acidifying, water scrubbing, urea complexing, freezing, filter-pressing, elevating temperature, extracting, esterifying, water scrubbing, dewatering, and vacuum distilling. The obtained product has a purity of over 80%.

Owner:安阳化学工业集团有限责任公司

Technique for producing alpha-linolenic acid ethyl with 90 percent more purity

InactiveCN101139289AAchieve productionEnsure qualityOrganic compound preparationCarboxylic acid esters preparationFiltrationDistillation

The present invention relates to a production process of using the Perilla as the raw material to produce an alpha-flax ethyl ester with the purity more than 90 percent. The alpha-flax ethyl ester with the purity more than 90 percent can be got after the oil squeezing, filtration, saponification, acidification, water washing, twice urea complexes, freezing, compression and filtration, heating, extraction, esterification, water washing, dehydration and molecular distillation. The present invention has the advantages of the high purity, the low cost and the long security period.

Owner:安阳化学工业集团有限责任公司

Process for manufacturing high-purity alpha-ethyl linolenate

ActiveCN104693032AYield maximizationIncrease productionOrganic compound preparationCarboxylic acid esters separation/purificationDistillationEsterification reaction

The invention discloses a process for manufacturing high-purity alpha-ethyl linolenate, and belongs to the field of chemistry. The process comprises esterification reaction; the raw material comprises perilla oil; the perilla oil is saponified, acidified and washed to obtain fatty acid containing alpha-linolenic acid; the esterification reaction is directly carried out by adopting the fatty acid containing alpha-linolenic acid obtained by washing; the alpha-ethyl linolenate in the product is subjected to urea encapsulated purification after esterification; fatty acid ethyl ester of the alpha-ethyl linolenate, 95% ethanol and urea are added to a reactor according to a weight ratio of 1:(1-5):(1-5) during urea encapsulated purification, the mixture is heated to 80-100 DEG C and refluxed for 30-60min, then cooling and purification are carried out stage by stage, and the finished product is obtained by dehydration and molecular distillation. The process greatly simplifies the manufacturing process of the alpha-ethyl linolenate, and improves the yield.

Owner:HENAN LINUO BIOCHEM CO LTD

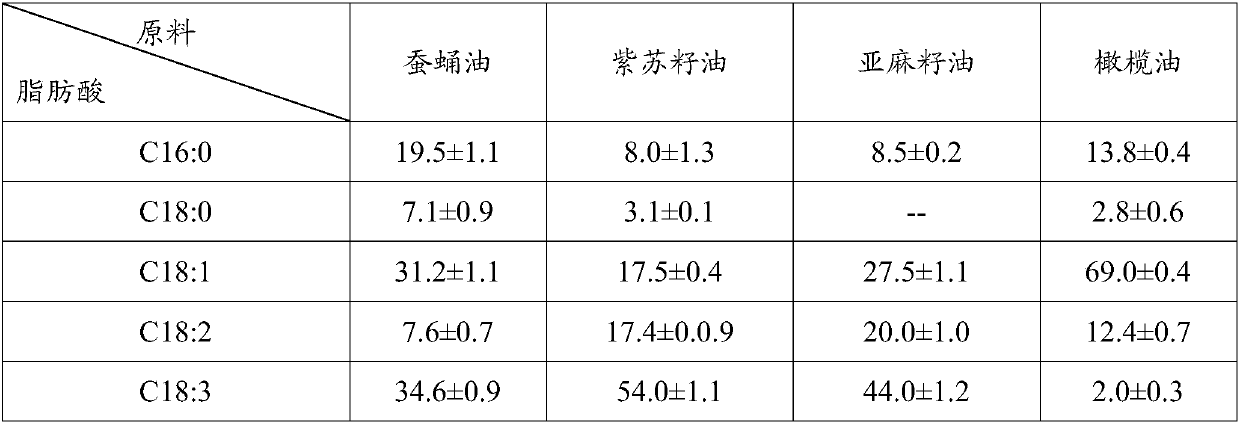

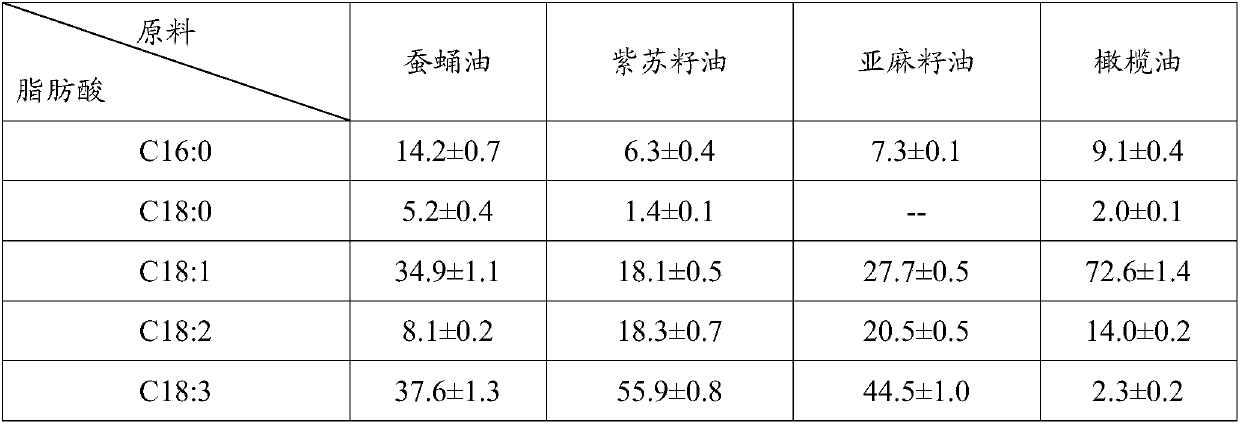

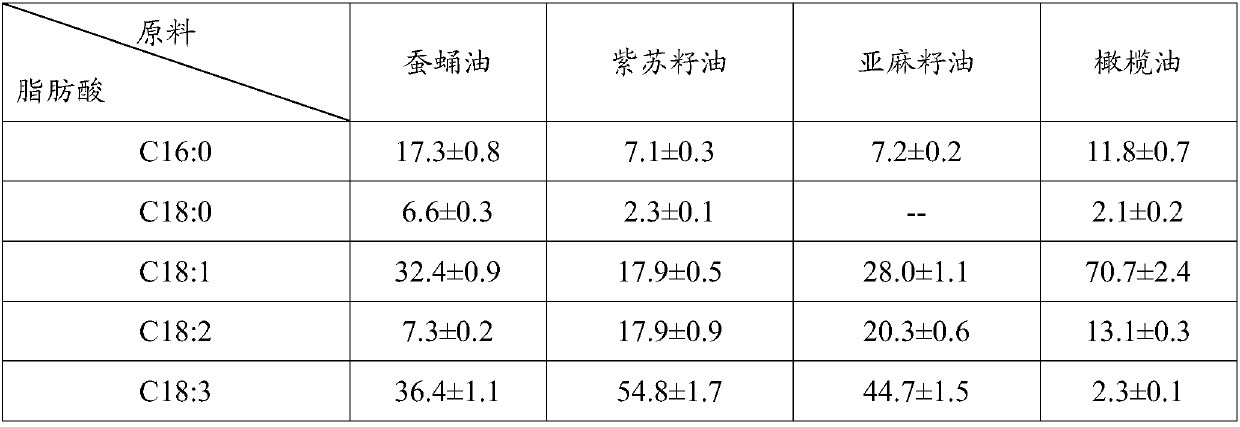

Method for extracting high-purity Alpha-ethyl linolenate from silkworm chrysalis oil

ActiveCN101624345AReduce churnHigh selectivityOrganic compound preparationCarboxylic acid esters preparationAbsorption columnSolvent

The invention provides a method for extracting high-purity Alpha-ethyl linolenate from silkworm chrysalis oil, which realizes the separation of the high-purity Alpha-ethyl linolenate from mixed fatty acid by a complexing absorbing agent of metal ions and comprises the following steps: firstly, performing alcoholysis on the silkworm chrysalis oil under the help of ethanol ultrasonically to preparesilkworm chrysalis mixed ethyl fatty acid; secondly, passing the silkworm chrysalis mixed ethyl fatty acid through a pre-saturated complexing absorption column of metal ions of competitive absorbent,wherein saturated fatty acid and monounsaturated fatty acid freely pass, and polyunsaturated fatty acid and silver ions form a Pi compound; and thirdly, changing elution solvent for eluting. The purity of the obtained Alpha-ethyl linolenate is 95-99 percent.

Owner:ZHEJIANG UNIV OF TECH

Extraction method for alpha-linolenic acid and preparation

InactiveCN101057661AEfficient separationHigh extraction purityOrganic active ingredientsMetabolism disorderMixed fatty acidAcid hydrolysis

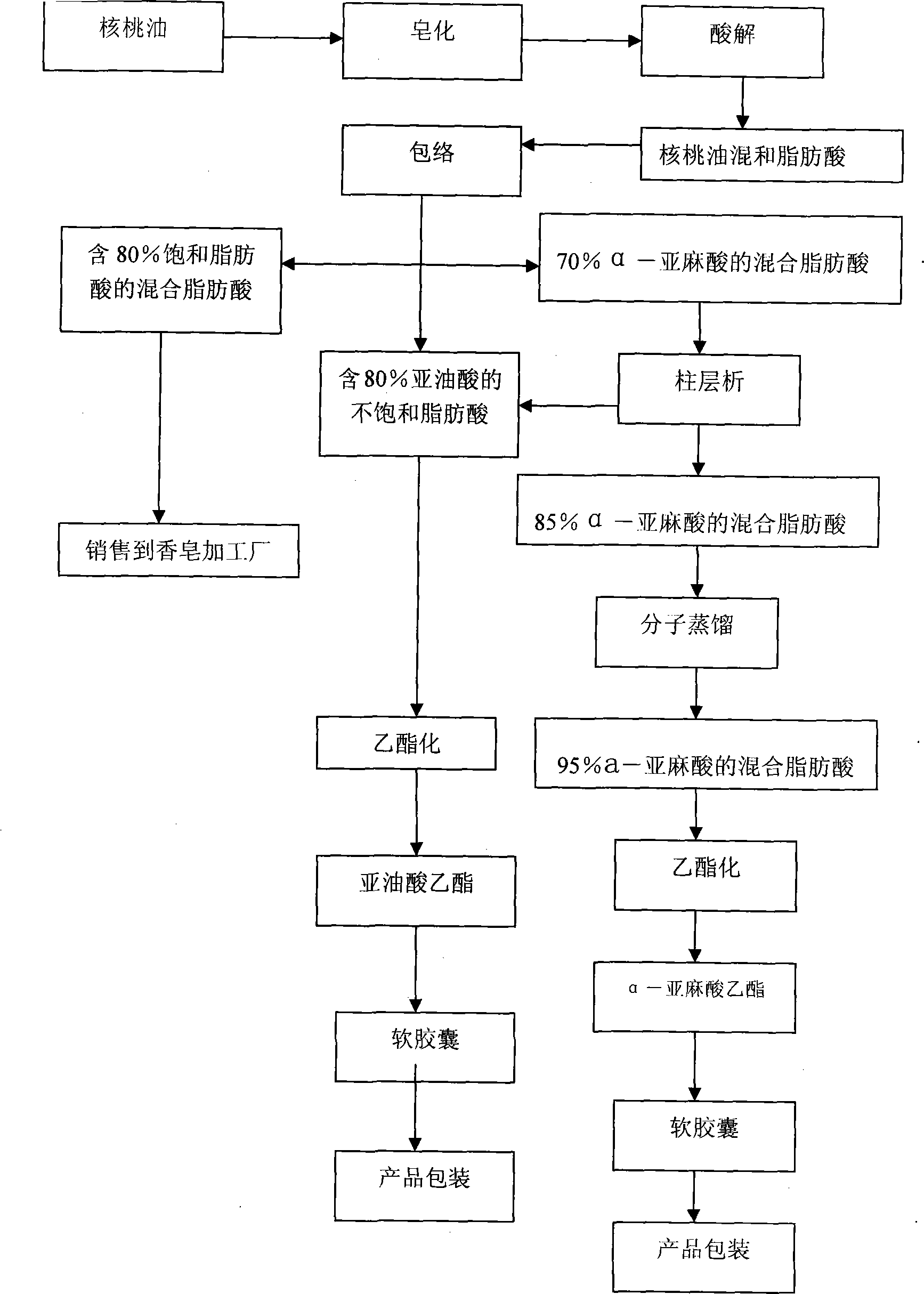

The invention relates to a method for extracting alpha-linolenic acid from walnut oil and alpha-linolenic acid preparation, comprising following steps: a. saponifying walnut oil and getting walnut oil mixed aliphatic acid, adding sulfuric acid for acid hydrolysis and getting walnut oil mixed aliphatic acid, washing and filtering and getting alpha-linolenic acid separation raw material; b. mixing walnut oil mixed aliphatic acid with enveloping agent and solvent at 50 Deg. C, getting mixed aliphatic acid of unsaturated and saturated aliphatic acid of alpha-linolenic acid; c. mixing alpha-linolenic acid-containing unsaturated aliphatic acid with enveloping agent again thoroughly, getting coarse alpha-linolenic acid ester liquid with alpha-linolenic acid content being above 70%, and unsaturated aliphatic acid crystal with linolic acid content being above 80%; d. extracting coarse alpha-linolenic acid ester liquid and getting alpha-linolenic acid ester with purity being above 85%; e. distilling said alpha-linolenic acid ester and getting alpha-linolenic acid ester liquid with alpha-linolenic acid content being above 95%.

Owner:迪庆香格里拉舒达有机食品有限公司

Method for extracting ethyl linolenate from blackberry seed oil

ActiveCN104478714AHigh purityNo harmful residuesOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholDistillation

The invention provides a method for extracting ethyl linolenate from blackberry seed oil. The method comprises the following steps: blackberry seed oil, absolute ethyl alcohol and sodium ethoxide are mixed in the mass ratio of 1: (0.6-0.8): (0.01-0.03) and added to an extraction kettle, the temperature and pressure of the extraction kettle are adjusted, and the mixture reacts; the temperature of the extraction kettle is adjusted to a set process parameter; the pressure of the extraction kettle is adjusted to a set process parameter, and extraction is started; meanwhile, an ultrasonic device is started, and ethyl linolenate is extracted from a sampling port of a distillation device. The method is reasonable in design and convenient to operate, blackberry seed oil is firstly subjected to ethyl esterification, then the traditional supercritical technology and a distillation technology are combined and used for direct extraction of ethyl linolenatefrom the blackberry seed oil, and ultrasonic waves are used for reinforcement in a purification process, so that not only is the technological process simplified, the extraction time is shortened, but also the purity of the obtained ethyl linolenate is high and can reach about 92% at the most, harmful residues are avoided, the activity is high, and foundation is laid for further extraction of linolenic acid oil.

Owner:HUAIHAI INST OF TECH

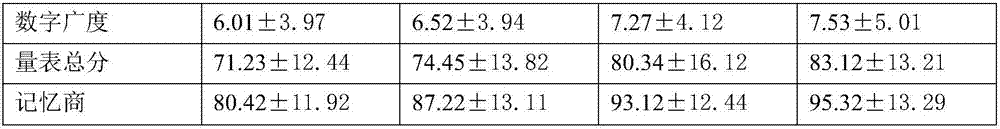

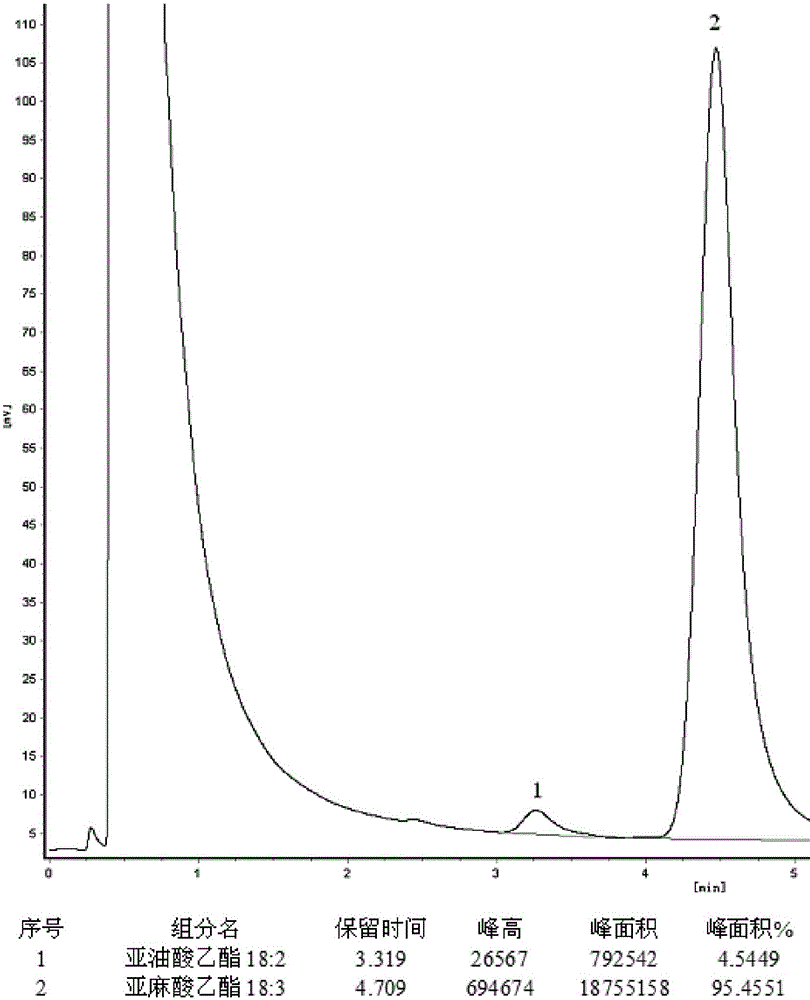

Method of separating alpha ethyl linolenate by cuprous chloride complexation adsorption

InactiveCN1651396AEasy to separateHigh purityOrganic compound preparationCarboxylic acid esters preparationMixed fatty acidAlcohol

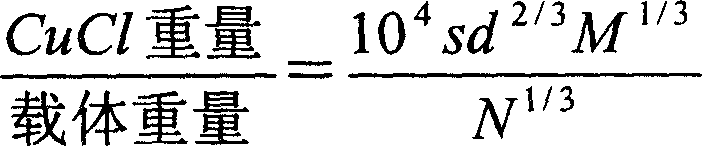

A process for extracting high-purity alpha-ethyl linolenate from the mixed ethyl ester of fatty acid by using cuprous chloride for complexing and adsoptive separating includes alcoholyzing reaction between the plant oil rich in alpha-linoleic acid and alcohol, flowing the resultant through complexing-adsorbing column carrying Cu ions, and eluting with solvent. Its advantage is low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for extracting high-purity alpha-linolenic acid by taking flaxseed as raw material

InactiveCN107473970ASimple processReduce manufacturing costOrganic active ingredientsNervous disorderDistillationΑ-linolenic acid

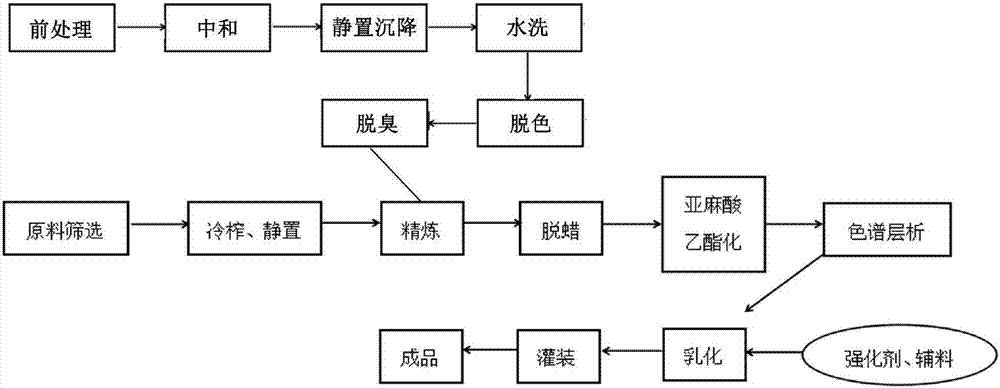

The invention discloses a method for extracting high-purity alpha-linolenic acid by taking flaxseed as a raw material and a prepared alpha-ethyl linolenate preparation. The method comprises the following steps: cold-pressing, refining and de-waxing the flaxseed, thereby acquiring flax seed oil; dissolving the flax seed oil in ethyl alcohol for performing esterification reaction, thereby acquiring a mixed fatty acid; cladding urea, slowly cooling, evaporating and concentrating, thereby acquiring mixed unsaturated fatty acid ethyl ester containing over 70% of alpha-ethyl linolenate; performing molecular distillation on the crude product of alpha-ethyl linolenate, thereby acquiring the alpha-ethyl linolenate in purity above 85%; and purifying the alpha-ethyl linolenate in purity above 85% through column chromatography, thereby acquiring the alpha-ethyl linolenate containing more than 95% of alpha-linolenic acid. The method disclosed by the invention has the advantages of simple process, low production cost, excellent separating effect, high purity and suitability for large-scale production. The alpha-ethyl linolenate preparation prepared according to the method disclosed by the invention is high in purity, is stable and reliable, is convenient for large-scale production and use and has high application value.

Owner:华子昂

Preparation method of alpha-ethyl linolenate

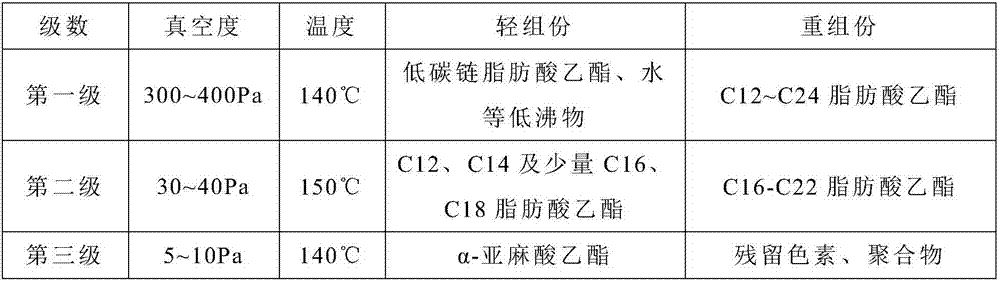

InactiveCN106966902ASufficient sourceWide coverageFatty acid esterificationOrganic compound preparationThree levelVegetable oil

The invention discloses a preparation method of alpha-ethyl linolenate, wherein the preparation method includes steps of performing ester exchange reaction on vegetable oil and ethanol, and acquiring mixed fatty acid ester; performing a three-level molecular distillation on the mixed fatty acid ester, and then performing urea complexing reaction with urea and ethanol, and acquiring the high-purity alpha-ethyl linolenate. The preparation method of alpha-ethyl linolenate uses the method of combining three-level molecular distillation-urea complexing-chromatography purification, avoids the use of massive acid and alkali organic solvents; the organic solvent amount is few, and the method is performed by using the existed device, the equipment requirement is low. Moreover, the loss of the alpha-ethyl linolenate is few and the yield is high; the product purity can reach over 95%; the product purity can reach over 95%, so the method is applicable to the industrial production. Meanwhile, the preparation method takes plant oil as the raw material, reduces the requirement on the content of raw material alpha-linolenic acid, and enriches the raw material source; thus the production cost is reduced effectively, and the method has very strong practicability.

Owner:武汉藤欣生物工程有限公司

Production process of high-purity alpha-ethyl linolenate

ActiveCN104693033AYield maximizationIncrease productionOrganic compound preparationCarboxylic acid esters separation/purificationPerilla oilEthyl ester

The invention discloses a production process of high-purity alpha-ethyl linolenate, and belongs to the field of chemistry. The process is characterized in that esterification reaction is adopted, raw materials include perilla oil, the perilla oil is saponified, acidified and washed to obtain fatty acid containing alpha-linolenic acid, the esterification reaction is directly carried out by adopting the washed fatty acid containing the alpha-linolenic acid, the esterification reaction is carried out at one time and carried out in a reaction device, the reaction device is connected with a water distribution device, azeotrope of ethanol and water is simultaneously evaporated into the water distribution device during the esterification reaction in a period of time, and the urine enveloping purification is carried out for the alpha-ethyl linolenate in a product after the esterification reaction. By adopting the production process, the production process of the alpha-ethyl linolenate is simplified, the productivity is greatly improved, the production time is shortened, and the production efficiency is improved.

Owner:HENAN LINUO BIOCHEM CO LTD

Preparation process of high-purity alpha-ethyl linolenate

InactiveCN109369389ASimple processBig pollutionFatty acid esterificationFatty acids production/refiningDistillationSolvent

The invention discloses a preparation process of high-purity alpha-ethyl linolenate, and belongs to the technical field of preparation of unsaturated fatty acids. The preparation process comprises thefollowing steps: (1) carrying out detection and pretreatment: detecting physical and chemical indexes of raw oil and carrying out preparation treatment; (2) carrying out ethyl esterification on the raw oil; (3) carrying out short-range distillation for primary purification; (4) carrying out freezing crystallization; and (5) carrying out short-range distillation for secondary purification to obtain a high-purity alpha-ethyl linolenate product with the content of alpha-linolenic acid of more than or equal to 83%. The preparation process provided by the invention has the advantages of low energyconsumption, low production cost, small environmental pollution, and capability of carrying out large-scale and continuous industrial production, and the produced alpha-ethyl linolenate is high in purity and yield, almost has no solvent residue, and is clear in color, superior in quality and long in shelf life.

Owner:燕园泽龙(涿鹿)生物科技有限公司

Alpha-linolenic acid ester fat emulsion injection and preparation method thereof

The invention provides alpha-linolenic acid ester fat emulsion injection and a preparation method thereof. Alpha-linolenic acid esters, lecithin, glycerol, sterile purified water, an anti-oxidant, a stabilizing agent, a pH regulating agent and the like are taken as raw materials; and the preparation method comprises the following steps of: under the protection of nitrogen, mixing the raw materials, violently stirring, and shearing at a high speed to form primary emulsion; and emulsifying by using a high pressure homogenizing machine, filtering by using a microporous membrane filter, filling, sealing and sterilizing to obtain the alpha-linolenic acid ester fat emulsion injection. The alpha-linolenic acid esters are alpha-linolenic acid methyl ester, alpha-linolenic acid ethyl ester, alpha-linolenic acid ethylene ester, alpha-linolenic acid ethylene diester, alpha-linolenic acid propylene diester and alpha-linolenic acid triglyceride, and have the alpha-linolenic acid content of over 90 percent. The alpha-linolenic acid ester fat emulsion injection is applied in the fields of medical treatment and health, and can serve as nutritional and therapic medicine to be administrated through abenteric intravenous injection, intestinal tube feed or oral intake.

Owner:王京南

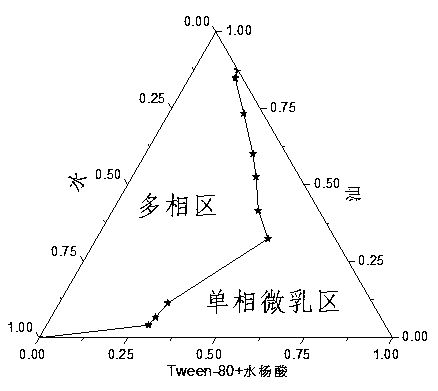

Alpha-ethyl linolenate microemulsion and preparation method thereof

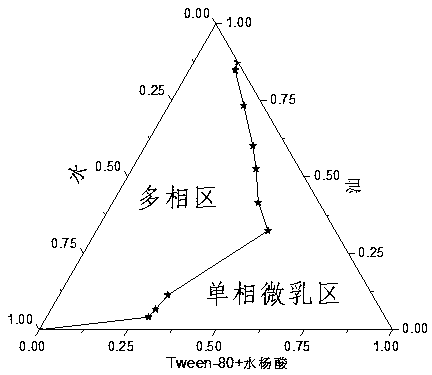

InactiveCN108553419ALow absorption rateImprove absorption rateOrganic active ingredientsSenses disorderInorganic saltsAntioxidant

Disclosed is an alpha-ethyl linolenate microemulsion. The alpha-ethyl linolenate microemulsion is prepared from, by weight, 4-70 parts of alpha-ethyl linolenate or oil phase containing alpha-ethyl linolenate, 6-40 parts of surfactant and co-surfactant, 0-1.5 parts of inorganic salt, 0.1-1.5 parts of antioxidant and the balance water. A preparation method of the alpha-ethyl linolenate microemulsioncomprises the steps of A, accurately weighing all the required components; B, controlling the heating temperature within the range of 20-30 DEG C, mixing alpha-ethyl linolenate or the oil phase containing alpha-ethyl linolenate with the antioxidant to form a mixed oil phase, and adding the surfactant and the co-surfactant to the mixture; C, adding water or water dissolved with inorganic salt intothe mixed system obtained in step B. By means of the method, alpha-linolenic acid in the microemulsion is protected and fully utilized.

Owner:ANYANG INST OF TECH

Stabilized brood pheromone for manipulating the behavior and physiology of honey bees

ActiveUS7727517B2Raise the ratioLower latencyBiocideHydroxy compound active ingredientsMethyl linoleateEthyl stearate

This invention relates to a stabilized honey bee pheromone and methods of stabilizing the honey bee brood pheromone, thereby enabling the production and sustained use of commercial products based on that pheromone. The stabilized pheromone can be used to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive. The pheromone composition comprises two or more of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate and an antioxidant.

Owner:OMS INVESTMENTS INC +1

Gamma-ethyl linolenate soft capsule and preparation thereof

InactiveCN101401800AImprove stabilityNo pollution in the processOrganic active ingredientsPharmaceutical delivery mechanismGlycerolEvening Primrose Oil

The invention discloses a gama-linolenic acid ethyl soft capsule and a process for preparing the same. The components in the soft capsule comprise evening primrose oil, vitamin E oil, and glycerin with the proportion being 392 to 2 to 57. The process for preparing the soft capsule comprises the following: step one, preparing the evening primrose oil through a supercritical extraction method; step two, uniformly mixing the evening primrose oil, the vitamin E oil, and the glycerin according to the proportion of 392 to 2 to 57; and step three, filling the mixture into capsule shells according to the standard that each capsule contains 400 milligrams of content. The stability of gama-linolenic acid can be improved through esterification treatment; the vitamin E is added into the soft capsule to improve the product stability and prevent the soft capsule from being oxidized; the form of soft capsule can separate the content from the external aerobic environment and is convenient to take and carry around. The process adopts the supercritical extraction method to extract the evening primrose oil, thus the preparation process has the advantages of short extraction time, high separation efficiency, low operation temperature, and no solvent pollution.

Owner:沙丽塔娜特·吐尔干

Stabilized Synthetic Brood Pheromone and Race-Specific Ratios of Components for Manipulating the Behavior and Physiology of Honey Bees

ActiveUS20110021622A1Raise the ratioIncrease load weightBiocideDead animal preservationMethyl linoleateEthyl stearate

This invention relates to a 10-component stabilized synthetic honey bee brood pheromone and methods of stabilizing said pheromone by adding one or more antioxidants, thereby enabling the production and sustained use of commercial products based on that pheromone. The 11-component stabilized pheromone composition formed by adding the antioxidant tertiary-butyl hydroquinone to a synthetic blend of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate can be used in generic or race-specific ratios to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive.

Owner:TEXAS A&M UNIVERSITY +1

Stabilized brood pheromone for manipulating the behavior and physiology of honey bees

ActiveUS20080124300A1Raise the ratioIncrease load weightBiocideHydroxy compound active ingredientsMethyl linoleateAntioxidant

This invention relates to a stabilized honey bee pheromone and methods of stabilizing the honey bee brood pheromone, thereby enabling the production and sustained use of commercial products based on that pheromone. The stabilized pheromone can be used to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive. The pheromone composition comprises two or more of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate and an antioxidant.

Owner:OMS INVESTMENTS INC +1

Continuous preparation method of high-quality ethyl linolenate

InactiveCN102433361ARelieve pressureIncrease pressureOrganic compound preparationCarboxylic acid esters preparationSolubilityOxygen

The invention discloses a supercritical continuous processing process from the extraction of linolenic acid-containing oil to the hydrolysis and esterification of thelinolenic acid and the separation and purification of ethyl linolenate. The technical proposal of the continuous processing process comprises the following steps of: crushing a natural plant containing the linolenic acid oil, extracting the oil by means of the characteristics of CO2 supercritical extraction, hydrolyzing the oil using lipase in a supercritical environment so as to release fatty acid, and performing ethyl-esterification on the fatty acid by means of supercritical high pressure catalysis; next, separating out ethyl linolenate by means of an ethanol entrainer; and finally, performing urea column chromatography to obtain high-purity ethyl linolenate by means of the high solubility and low viscosity characteristics of the supercritical fluid. Moreover, contact with oxygen is avoided in the processing process, high-quality ethyl linolenate product can be obtained.

Owner:SHANGHAI ZHONGPEI BIOLOGICAL TECH

Method for preparing high-purity alpha-linolenic acid through beta-cyclodextrin embedded coupling-simulation moving bed chromatographic separation

InactiveCN107556187ASimple and fast operationSeparation is continuously controllableFatty acid esterificationOrganic compound preparationChromatographic separationSimulated moving bed

The invention discloses a method for preparing high-purity alpha-linolenic acid through beta-cyclodextrin embedded coupling-simulation moving bed chromatographic separation. The method comprises the following steps: converting raw oil into free fatty acid ethyl esters, removing impurities through a beta-cyclodextrin embedding method, and separating the pretreated fatty acid ethyl esters by utilizing simulated moving bed preparative chromatography, thereby obtaining the alpha-linolenic acid ethyl ester with the purity of more than 95%. The product prepared by the method disclosed by the invention is high in purity, the process is continuous, the operation is simple and convenient, the technical problems that the conventional alpha-linolenic acid ethyl ester separation process is complicatedand discontinuous, and the purity is difficulty controlled are solved, the industrial production of the alpha-linolenic acid ethyl ester can be realized, and the method is a novel pathway for diversified comprehensive utilization of oil resources and high-efficiency separation of the high-purity alpha-linolenic acid.

Owner:JIANGSU UNIV OF SCI & TECH

Method for separating and extracting hexadecenoic acid from grease

InactiveCN108558649AAchieve recyclingSimple methodOrganic compound preparationCarboxylic compound separation/purificationMixed fatty acidAlcohol

The invention discloses a method for separating and extracting hexadecenoic acid from grease. The method includes the following steps of conducting esterification and ester exchange to obtain mixed aliphatic ester, conducting high-temperature high-vacuum rectification to remove most of stearate, oleate, linoleic acid ester, linolenic acid ethyl ester and the like to obtain coarse hexadecenoic acid, conducting saponification and acidification to obtain fatty acid, mixing the fatty acid with urea and lower alcohol, conducting mixing backflow dissolution, cooling crystallization clathration and suction filtration to obtain filtrate, removing lower alcohol in the filtrate to obtain the high-content hexadecenoic acid. The method is simple, convenient to operate and friendly to the environment,and the obtained hexadecenoic acid is high in purity, good in quality and convenient to produce on a large scale.

Owner:ZHEJIANG UNIV OF TECH

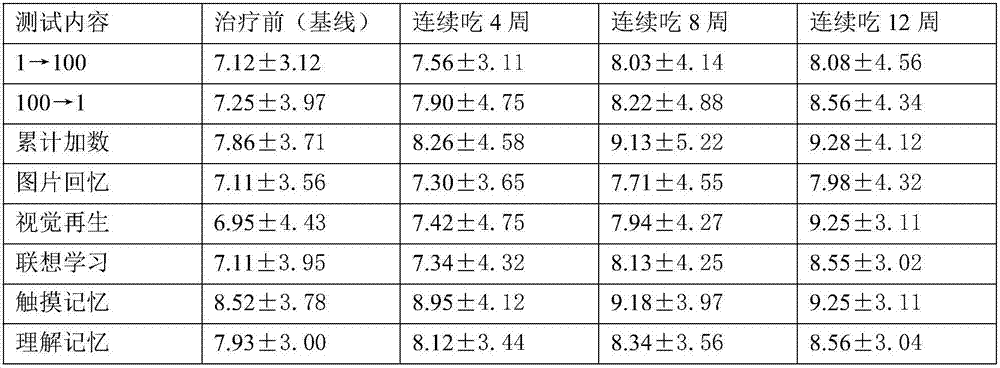

Health-care food with auxiliary memory-improving function and preparation technology thereof

ActiveCN107212386AEasy to eatImprove memory functionNatural extract food ingredientsFood ingredient functionsSide effectSodium ascorbate

The invention discloses a health-care food with an auxiliary memory-improving function and a preparation technology thereof. The preparation technology of the health-care food with the auxiliary memory-improving function comprises the following steps of taking alpha-linolenic acid as a main raw material, wherein the alpha-linolenic acid is obtained by carrying out cold pressing on linseeds, carrying out refining, carrying out dewaxing, performing esterification on the linolenic acid and carrying out chromatography; and then, carrying out emulsification with reinforcing agents or auxiliary materials, and carrying out filling so as to obtain the health-care food. The reinforcing agents comprise thiamine hydrochloride, riboflavin, L-sodium ascorbate, and calcium carbonate; and the auxiliary materials comprise taurine, soybean phospholipids, and a kudzuvine root extract. The alpha-linolenic acid is taken as the main raw material of the health-care food, and nutrients, such as the taurine and the like, are organically compounded so that the prepared health-care food can be conveniently eaten by consumers of all ages; moreover, the health-care food is free of toxic and side effects, and has nutritional values as well as the function of effectively improving memory. The preparation technology of the health-care food with the auxiliary memory-improving function focuses on pure extraction of the alpha-linolenic acid; and the final products are prepared in combination with the auxiliary materials, and thus, the prepared health-care food is stable in active ingredients, and more effective in the auxiliary function of improving memory.

Owner:华子昂

Process for preparing alpha-ethyl linolenate with purity more than 80%

InactiveCN100366601CWide range of ways to addConvenient supplementOrganic compound preparationCarboxylic acid esters preparationEthyl esterZinc

The invention relates to a process for preparing alpha-zinc linolenate by using perilla seeds as the raw material, which comprises the steps of squeezing, filtering, saponifying, acidifying, water scrubbing, urea complexing, freezing, filter-pressing, elevating temperature, extracting, esterifying, water scrubbing, dewatering, and vacuum distilling. The obtained product has a purity of over 80%.

Owner:安阳化学工业集团有限责任公司

Application of lipoic acid as antioxidant in ethyl polyenoate preparation or pupal fat alpha-ethyl linolenate preparation

InactiveCN106729725AGuaranteed curative effectAvoid side effectsOrganic active ingredientsPharmaceutical non-active ingredientsSide effectCurative effect

The invention provides an application of lipoic acid as an ioxidant in ethyl polyenoate preparation or pupal fat alpha-ethyl linolenate preparation. Ehyl polyenoate and pupal fat alpha-ethyl linolenate drugs are both polyunsaturated fatty acid drugs. With a plurality of unsaturated double bonds, the ethyl polyenoate and pupal fat alpha-ethyl linolenate are easily oxidized by contact with oxygen in air. After peroxidation, the curative effect is seriously influenced, and side effects may be generated. Through study and experiment, lipoic acid realizes remarkably effective oxidation resistance against ethyl polyenoate and pupal fat alpha-ethyl linolenate drugs; by replacing vitamin E with lipoic acid, an effective anti-oxidation effect on the two drugs is realized; and unprecedented technical progress and innovation are realized for existing anti-oxidation way of the two drugs.

Owner:北京百慧生化制药有限责任公司

Preparing method of ethyl linolenate capsules

ActiveCN106109436AHigh purityHigh purity high purity 90.0-96.2wt%Organic active ingredientsAntipyreticMass ratioDistillation

The invention provides a preparing method of ethyl linolenate capsules. The preparing method includes the following steps that 1, linseed oil, absolute ethyl alcohol and sodium ethoxide are mixed by the mass ratio of 1:(0.4-0.6):(0.008-0.012) and then put into a reaction tank, nitrogen is introduced at the temperature of 50-70 DEG C, and then the mixture is stirred in a reflux mode for 2-3 h; excessive ethyl alcohol is removed through reduced pressure distillation; sucrose fatty acid ester of 0.5-2% is added, freezing crystallization is carried out on an alpha-crude linolenic acid product for 10-24 h at the temperature of 0- minus 30 DEG C, the crude ethyl linolenate product is obtained through filtering; the pH value is adjusted to 6-7 with hydrochloric acid, the organic phase is separated through washing of saturated salt water, and the refined ethyl linolenate is obtained through drying; 2, purified ethyl linolenate is obtained through molecular distillation; 3, the purified ethyl linolenate serves as soft capsule content to prepare the ethyl linolenate capsules. High-purity ethyl linolenate is obtained through a series of combined processing, and sucrose fatty acid ester will not enter the final product.

Owner:GANSU CHANGQING BIOLOGICAL TECH

A method for preparing chromatographically purified alpha-linolenic acid ethyl ester

ActiveCN103951560BSimple processLess one-time investmentOrganic compound preparationCarboxylic acid esters separation/purificationChromatographic separationWorking temperature

The invention discloses a method for preparing chromatographically purified ethyl alpha-linolenate. The method comprises the following steps of: purifying an ethyl alpha-linolenate crude product with content of not less than 50% as a raw material by preparative chromatography separation equipment, wherein methyl alcohol or ethyl alcohol is used as an eluent, the working temperature of a system is set to 25-30 DEG C, ODS is used as a chromatographic stationary phase, materials are charged by a six-way sampling valve, and the eluent is charged by a constant-pressure and constant-flow pump; fractionally collecting the eluted fractions, and recovering the eluent by reduced pressure concentration to obtain high-purity ethyl alpha-linolenate, wherein the yield is high. The whole process is simple in flow, low in production cost, low in production energy consumption, zero-emission and pollution-free, capable of continuously producing and increasing production efficiency, and suitable for large-scale production. The ethyl alpha-linolenate purified by the method is high in purity, low in solvent residue, and capable of meeting the needs of industries such as chemical analysis, medicines and health products.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Stabilizing agent specially used for alpha-linolenic acid/alpha ethyl linolenate, preparation method and application thereof

ActiveCN101659903ALow requirements for production equipmentSimple production processFatty acid esterificationFatty acids production/refiningAcid valueΑ-linolenic acid

The invention relates to a stabilizing agent specially used for alpha-linolenic acid / alpha ethyl linolenate, which is prepared by mixing active floridin, alkali and reducing agent according to the mass ratio of 1:0.025-0.1:0.125-0.50. The invention also provides a preparation method of the stabilizing agent specially used for the alpha-linolenic acid / the alpha ethyl linolenate, and an applicationthereof. When in use in the production process of the alpha-linolenic acid and the alpha ethyl linolenate with high purity, the stabilizing agent specially used for the alpha-linolenic acid / the alphaethyl linolenate can effectively reduce the peroxide value and the acid value of the product, improve the finished product ratio, and greatly lower the production cost; and furthermore, the stabilizing agent is simple to prepare, convenient for production and use and beneficial to industrialized production.

Owner:河北欣奇典生物科技有限公司

Method of separating alpha ethyl linolenate by cuprous chloride complexation adsorption

InactiveCN100369884CEasy to separateHigh purityOrganic compound preparationCarboxylic acid esters preparationMixed fatty acidAlcohol

A process for extracting high-purity alpha-ethyl linolenate from the mixed ethyl ester of fatty acid by using cuprous chloride for complexing and adsoptive separating includes alcoholyzing reaction between the plant oil rich in alpha-linoleic acid and alcohol, flowing the resultant through complexing-adsorbing column carrying Cu ions, and eluting with solvent. Its advantage is low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for deacidifying alpha-ethylli-nolenate solvent

InactiveCN102584585AReduce dosageEmission reductionOrganic compound preparationCarboxylic acid esters preparationAcid valueEthyl ester

The invention relates to a method for deacidifying an alpha-ethylli-nolenate solvent. The method comprises the following steps of: mixing alpha-ethylli-nolenate with a high acid value and ethanol, standing and layering until two systems are separated, concentrating and dealcoholizing the lower alpha-ethylli-nolenate layer by the conventional mode, and esterifying and deacidifying the upper free acid layer, wherein ethanol is edible ethanol at the concentration of 80 to 95 percent, and the mixing ratio of alpha-ethylli-nolenate to ethanol is 1:(0.5-2). By the method, the acid value of a product can be effectively reduced, the defects of low esterification rate, and large using amount of solvent and acid catalyst and the like in the conventional direct esterifying and deacidifying process are overcome, production cost is reduced, and the alpha-ethylli-nolenate solvent is easy to prepare and convenient to produce and use, and can be industrially produced conveniently.

Owner:河北欣奇典生物科技有限公司

A kind of alpha-linolenic acid ethyl ester microemulsion and preparation method thereof

InactiveCN108553419BLow absorption rateImprove absorption rateOrganic active ingredientsSenses disorderAntioxidantOil phase

Disclosed is an alpha-ethyl linolenate microemulsion. The alpha-ethyl linolenate microemulsion is prepared from, by weight, 4-70 parts of alpha-ethyl linolenate or oil phase containing alpha-ethyl linolenate, 6-40 parts of surfactant and co-surfactant, 0-1.5 parts of inorganic salt, 0.1-1.5 parts of antioxidant and the balance water. A preparation method of the alpha-ethyl linolenate microemulsioncomprises the steps of A, accurately weighing all the required components; B, controlling the heating temperature within the range of 20-30 DEG C, mixing alpha-ethyl linolenate or the oil phase containing alpha-ethyl linolenate with the antioxidant to form a mixed oil phase, and adding the surfactant and the co-surfactant to the mixture; C, adding water or water dissolved with inorganic salt intothe mixed system obtained in step B. By means of the method, alpha-linolenic acid in the microemulsion is protected and fully utilized.

Owner:ANYANG INST OF TECH

Manufacturing process of high-purity ethyl α-linolenic acid

ActiveCN104693032BYield maximizationIncrease productionOrganic compound preparationCarboxylic acid esters separation/purificationDistillationPerilla oil

The invention discloses a process for manufacturing high-purity alpha-ethyl linolenate, and belongs to the field of chemistry. The process comprises esterification reaction; the raw material comprises perilla oil; the perilla oil is saponified, acidified and washed to obtain fatty acid containing alpha-linolenic acid; the esterification reaction is directly carried out by adopting the fatty acid containing alpha-linolenic acid obtained by washing; the alpha-ethyl linolenate in the product is subjected to urea encapsulated purification after esterification; fatty acid ethyl ester of the alpha-ethyl linolenate, 95% ethanol and urea are added to a reactor according to a weight ratio of 1:(1-5):(1-5) during urea encapsulated purification, the mixture is heated to 80-100 DEG C and refluxed for 30-60min, then cooling and purification are carried out stage by stage, and the finished product is obtained by dehydration and molecular distillation. The process greatly simplifies the manufacturing process of the alpha-ethyl linolenate, and improves the yield.

Owner:HENAN LINUO BIOCHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com