Extraction method for alpha-linolenic acid and preparation

An extraction method and technology for linolenic acid, applied in the field of alpha-linolenic acid preparation, can solve the problems of inability to separate, restrict the extraction purity of alpha-linolenic acid, etc., and achieve the effects of improving extraction purity, improving human health, and reducing the number of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

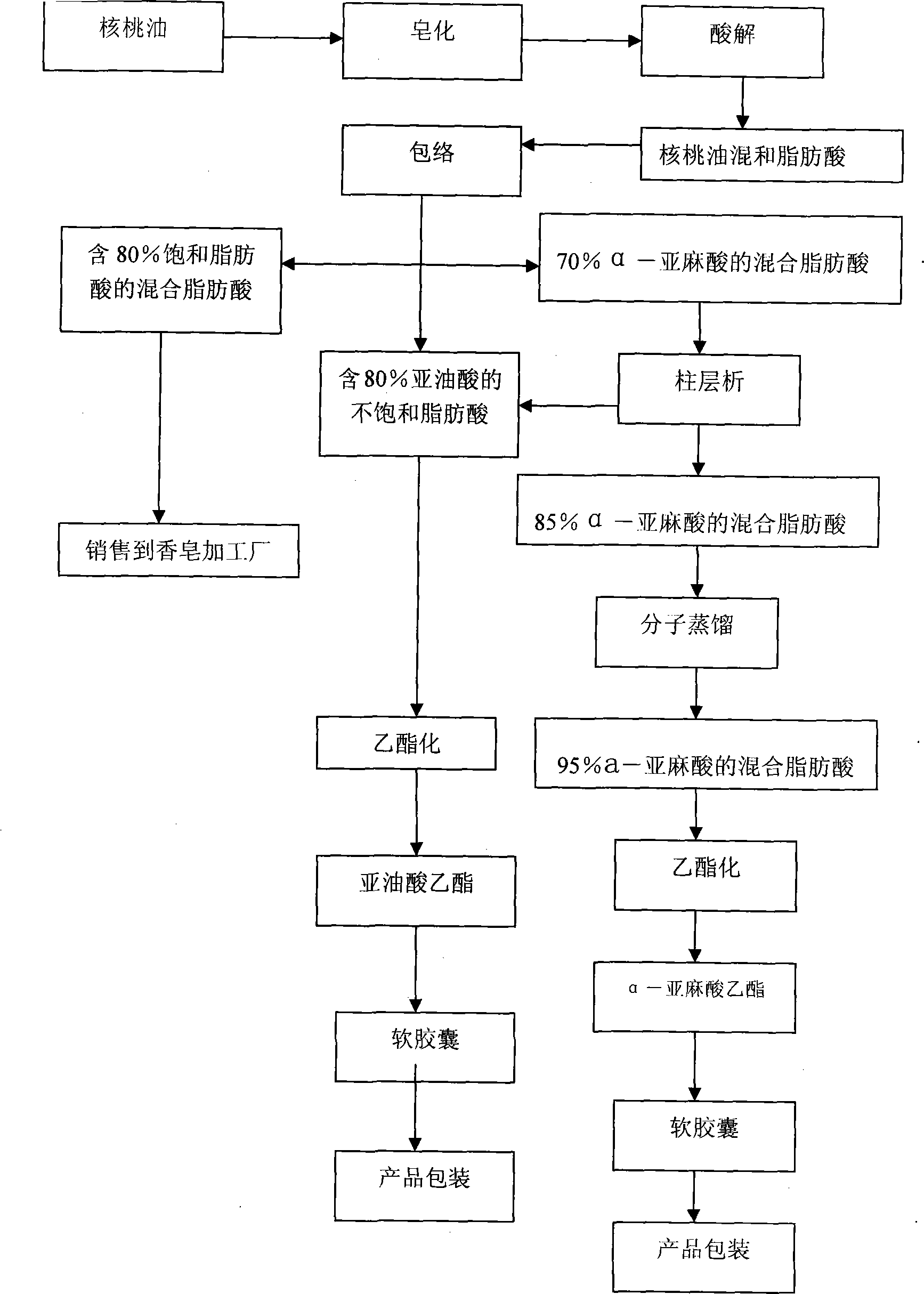

Image

Examples

Embodiment 1

[0022] The extraction method of α-linolenic acid of the present invention comprises walnut oil saponification, enveloping agent enveloping, and its steps are as follows:

[0023] a. Saponification of walnut oil with caustic soda at 15° C. to obtain mixed fatty acids of walnut oil, adding sulfuric acid, and acidolysis at 50° C. to obtain mixed fatty acids of walnut oil, which are used as α-linolenic acid separation raw materials after elution and filtration;

[0024] b. The walnut oil mixed fatty acid is fully mixed with the enveloping agent and solvent at 50°C, the temperature of the mixed solution is lowered from 50°C to 20°C, and the mixed solution is lowered from 20°C to -5°C within 11 hours to precipitate Crystallization, and then filtration to obtain saturated fatty acid crystals and unsaturated fatty acid liquids, saturated fatty acid crystals are dissolved and washed by heating to obtain mixed fatty acids containing 80% saturated fatty acids;

[0025] c. Add the unsatur...

Embodiment 2

[0030] According to the method of Example 1, the ethyl α-linolenic acid with a purity of more than 95% was shot, and a tablet was prepared by a conventional tablet production process.

Embodiment 3

[0032] The extraction method of α-linolenic acid of the present invention, its steps are as follows:

[0033] a. Saponification of walnut oil with caustic soda at 80°C to obtain mixed fatty acids of walnut oil, adding sulfuric acid, and acidolysis at 55°C to obtain mixed fatty acids of walnut oil, which are used as α-linolenic acid separation raw materials after elution and filtration;

[0034] b. The walnut oil mixed fatty acid is fully mixed with the enveloping agent and solvent at 50°C, the temperature of the mixed solution is quickly reduced from 50°C to 20°C, and the mixed solution is reduced from 20°C within 5 hours Lower the temperature to -5°C to precipitate crystals, and then filter to obtain saturated fatty acid crystals and unsaturated fatty acid liquids. The saturated fatty acid crystals are heated to dissolve and washed to obtain mixed fatty acids containing 80% saturated fatty acids. ;

[0035] c. Add the unsaturated fatty acid containing α-linolenic acid, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com