Method for preparing high-purity alpha-linolenic acid through beta-cyclodextrin embedded coupling-simulation moving bed chromatographic separation

A simulated moving bed and chromatographic separation technology, applied in the field of β-cyclodextrin embedding combined with simulated moving bed chromatographic separation to prepare high-purity α-linolenic acid, can solve the problems of unable to separate and purify fatty acids, and facilitate the realization of industrial production , High preparation efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] This example illustrates the process of extracting triglycerides in olives, perilla seeds, linseeds, and silkworm chrysalis.

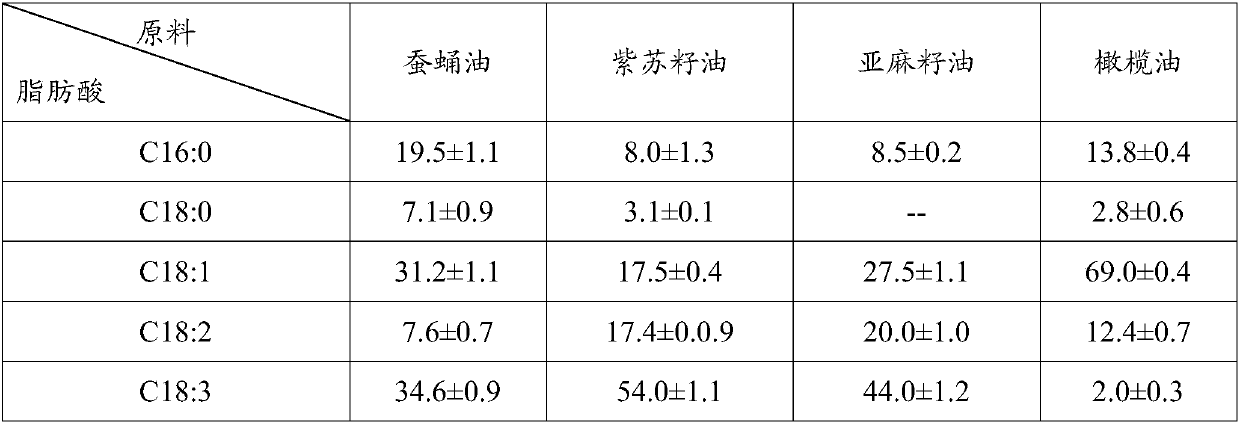

[0015] Mix the dried above-mentioned powders with the solvent diethyl ether at a mass ratio of 1:50, heat and extract for 0.5 h, remove impurities by suction filtration, and spin evaporate under reduced pressure to obtain crude fat, which is dehydrated and then refined to obtain refined triglycerides. The fatty acid compositions of the triglycerides from the four raw materials are shown in Table 1.

[0016] Table 1 Fatty acid composition of different raw materials (%)

[0017]

Embodiment 2

[0019] This example illustrates the process of pretreating fatty acid ethyl esters with β-cyclodextrin to remove impurities.

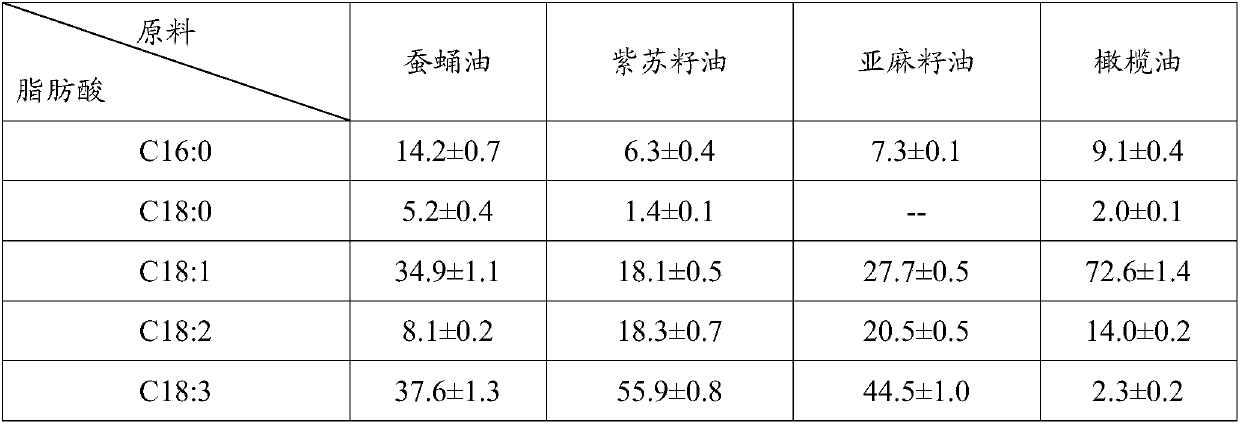

[0020] Mix β-cyclodextrin: free fatty acid ethyl ester (V:V) = 1:1, the reaction temperature is 120°C, the rotor speed is 1000rpm, and the reaction is 10h. After cooling at -20°C for 15h, suction filtration is performed. , after drying for 6 hours, an effective amount of petroleum ether was added for decomplexation reaction, and the collected liquid components were rotary evaporated to obtain refined fatty acid ethyl esters. The obtained refined fatty acid ethyl ester is detected by gas chromatography to obtain the free fatty acid composition and content of each oil after pretreatment. After pretreatment with β-cyclodextrin, the unsaturated fatty acid content of silkworm chrysalis oil, perilla seed oil, linseed oil, and olive oil increased by 7.2%, 1.7%, 1.2%, and 5.5%, respectively, and the purity of α-linolenic acid increased respectively. 3%, 1.9%,...

Embodiment 3

[0024] This example illustrates the process of pretreating fatty acid ethyl esters with β-cyclodextrin to remove impurities.

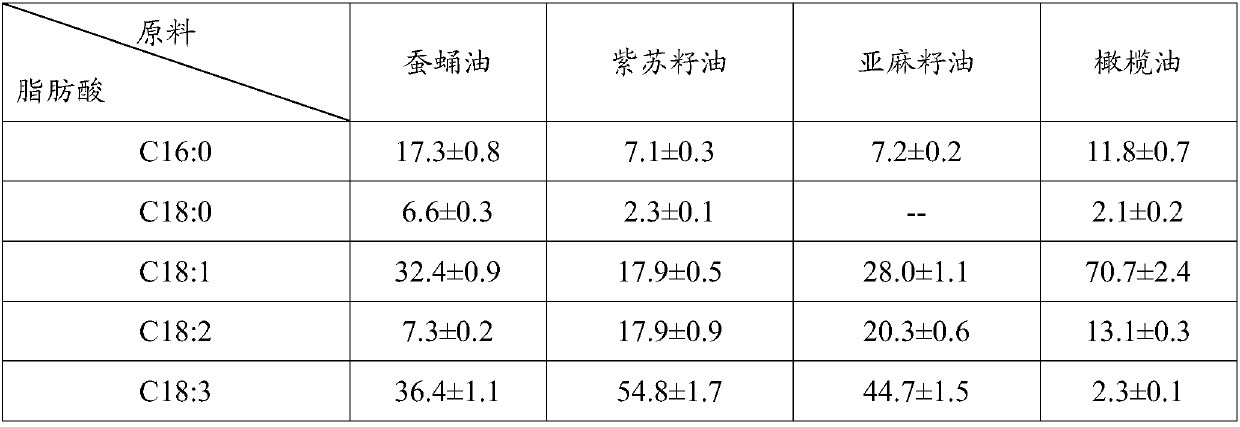

[0025]Mix β-cyclodextrin: free fatty acid ethyl ester (V:V) = 15:1, react at 20°C for 0.5h at a rotor speed of 100rpm, cool at -20°C for 15h and pump After filtering and drying for 6 hours, an effective amount of petroleum ether was added for decomplexation reaction, and the collected liquid components were rotary evaporated to obtain refined fatty acid ethyl esters. The obtained refined fatty acid ethyl ester is detected by gas chromatography to obtain the free fatty acid composition and content of each oil after pretreatment. After β-cyclodextrin pretreatment, the unsaturated fatty acid content of silkworm chrysalis oil, perilla seed oil, linseed oil, and olive oil increased by 2.7%, 3.4%, 1.3%, and 2.7%, respectively, and the purity of α-linolenic acid increased respectively. 1.8%, 0.8%, 0.7%, 0.3%.

[0026] Table 3 Free fatty acid composition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com