Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

917 results about "Infrared probe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

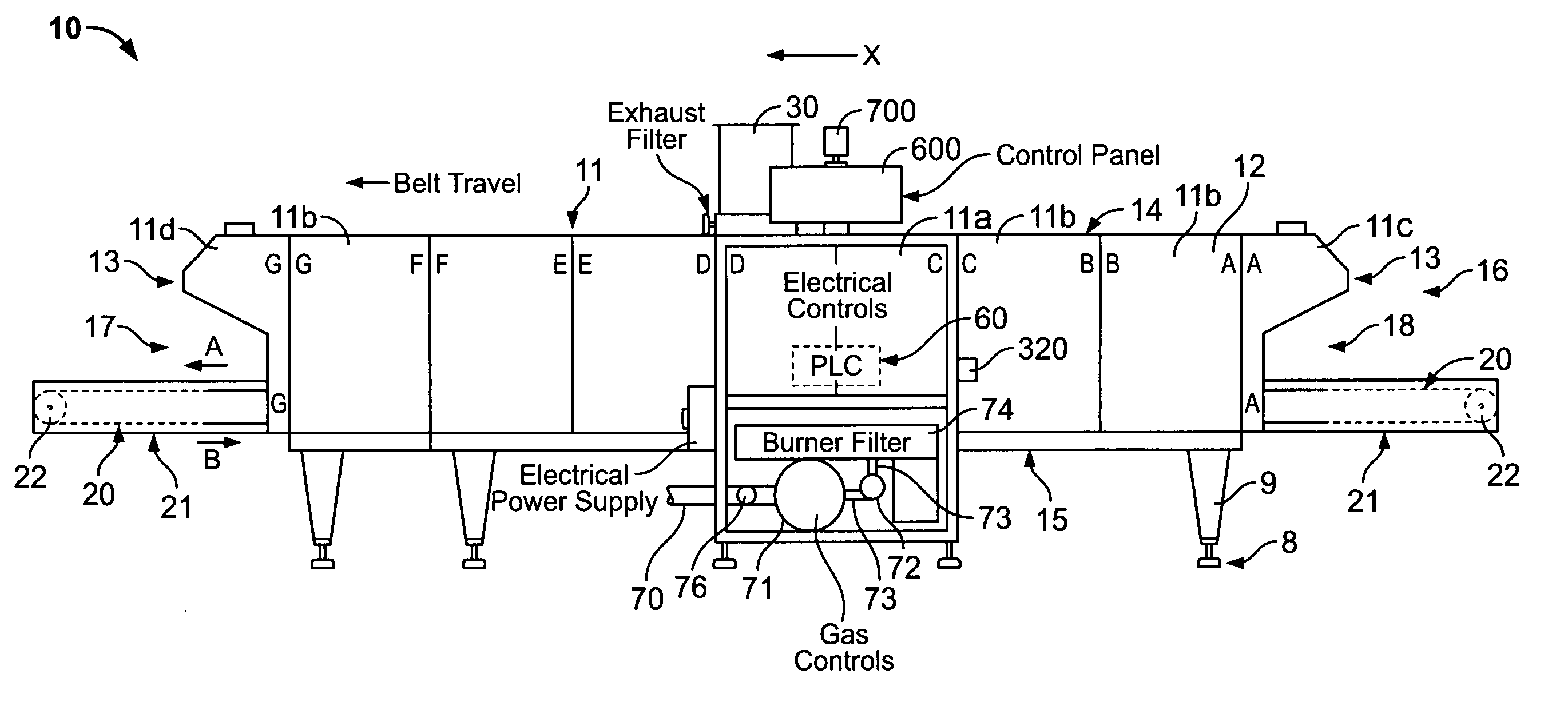

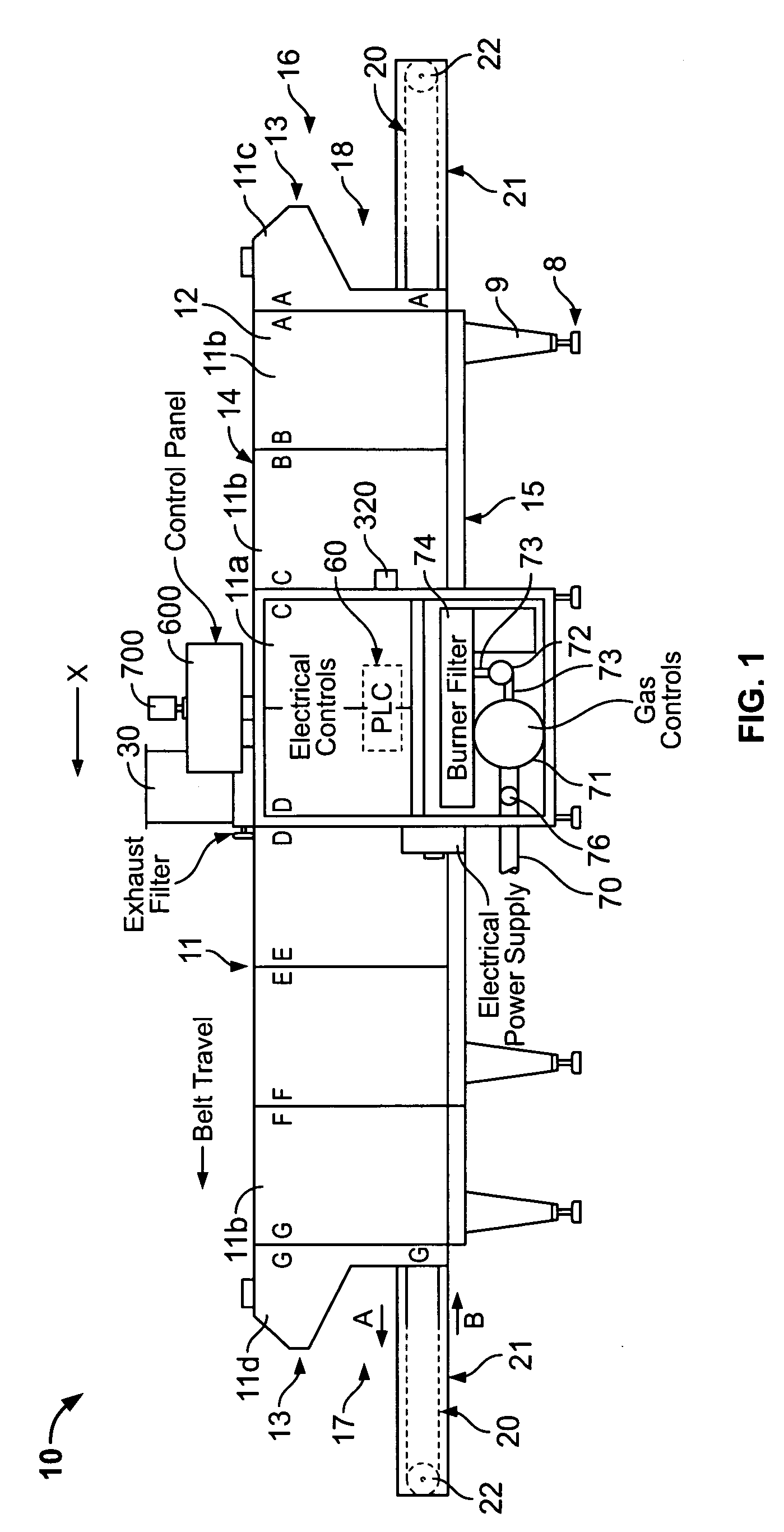

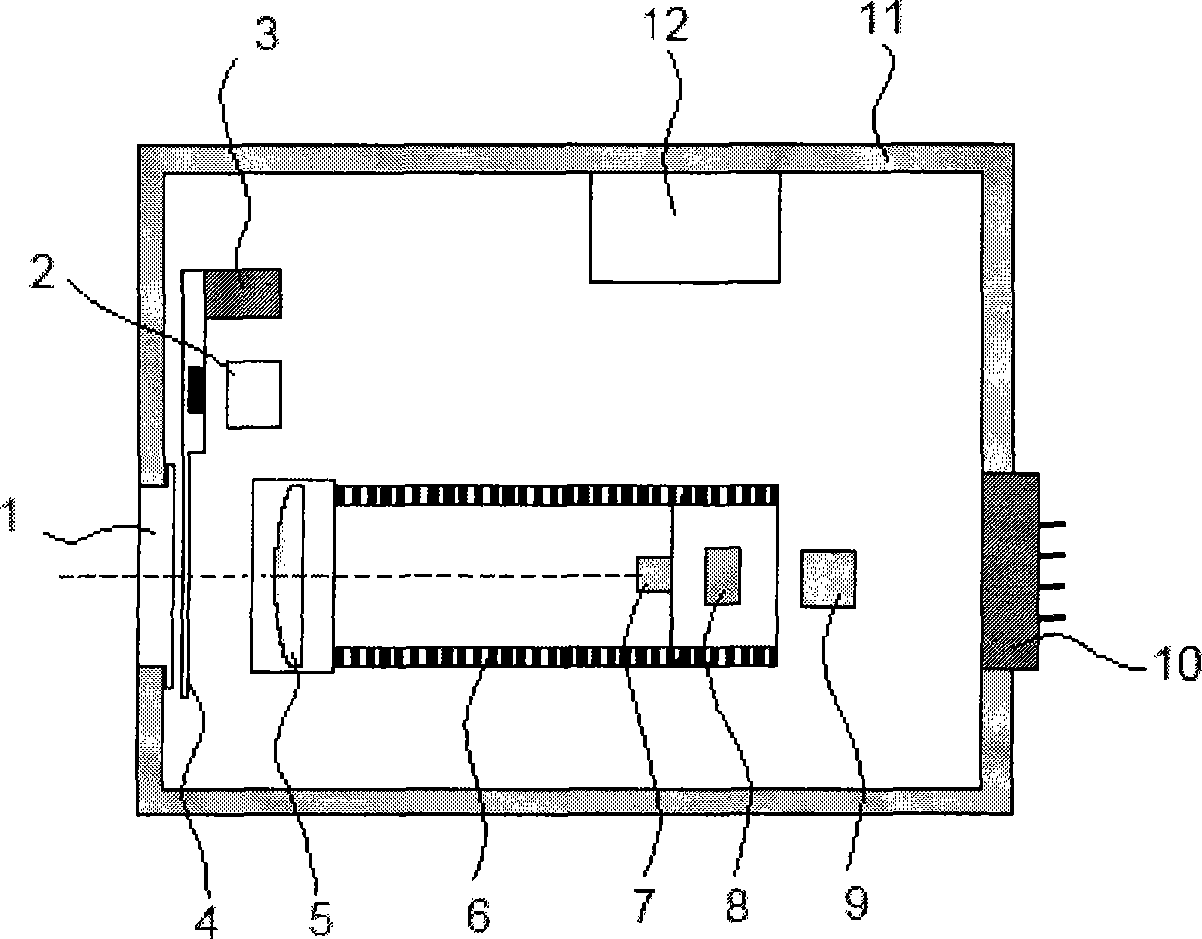

Dryer assembly

InactiveUS20070193056A1Large capacityFast curingDrying solid materials with heatDrying gas arrangementsProcess engineeringThermocouple

A textile dryer capable of monitoring heating chamber temperature (internal thermocouple), peak ink temperature (absorption infrared probe at exit), real-time ink temperature (donut thermocouple) as the textile travels through the chamber, and gas consumption is disclosed. A controller permits one to set numerous parameters and view graphs of the monitored variables over time. Recipes or job settings can be stored for recall and use later. In addition, visual and audible warnings and alarms are incorporated into the system.

Owner:M&R PRINTING EQUIP

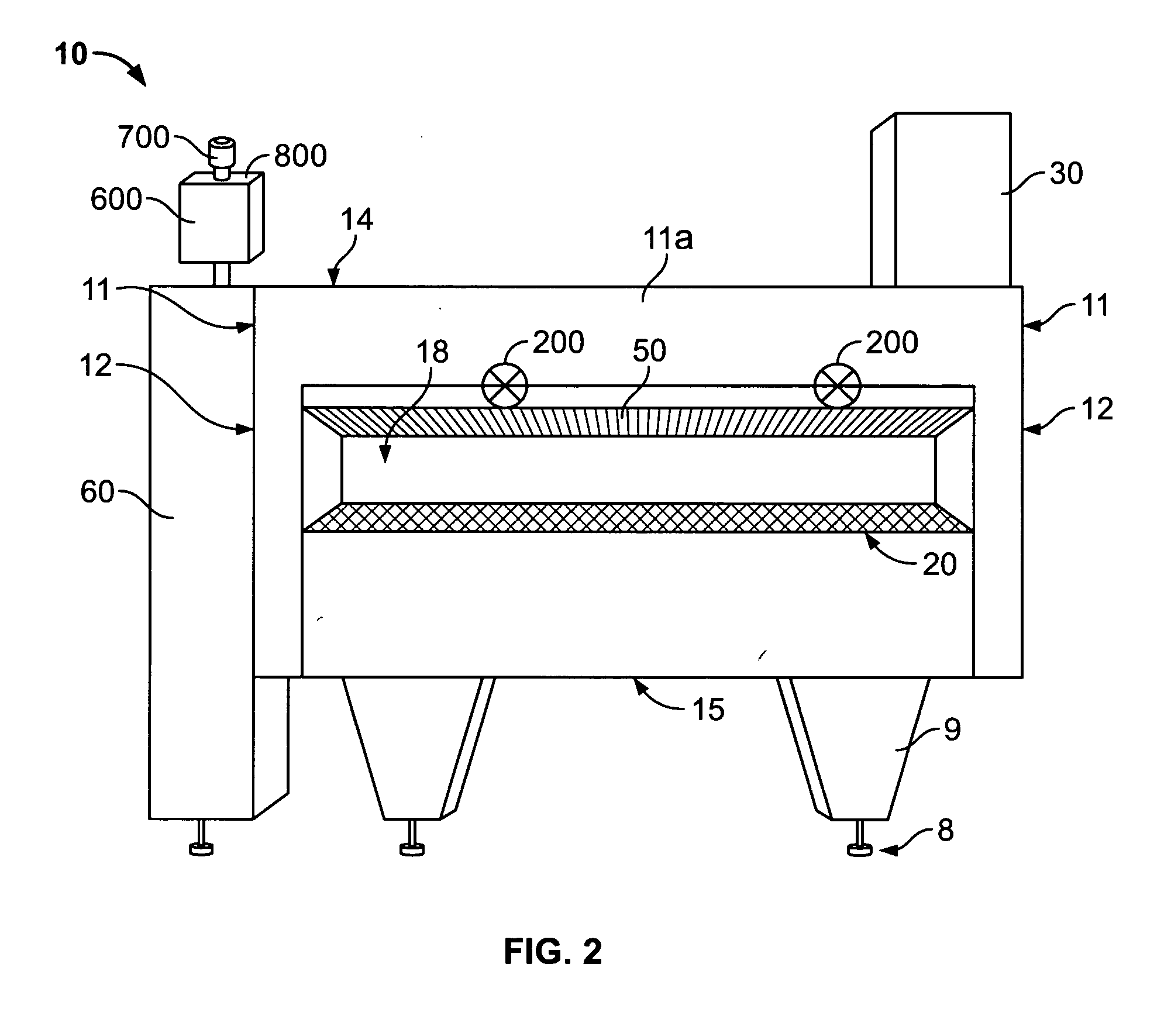

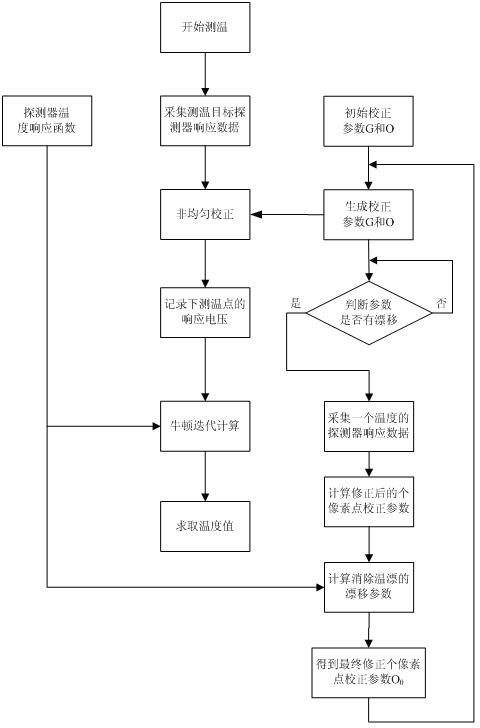

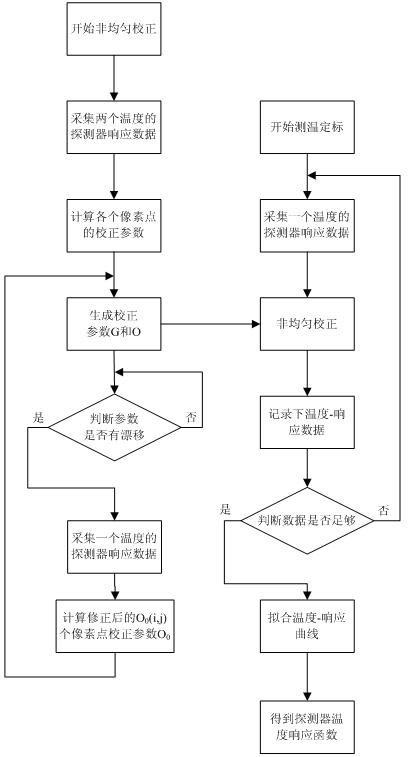

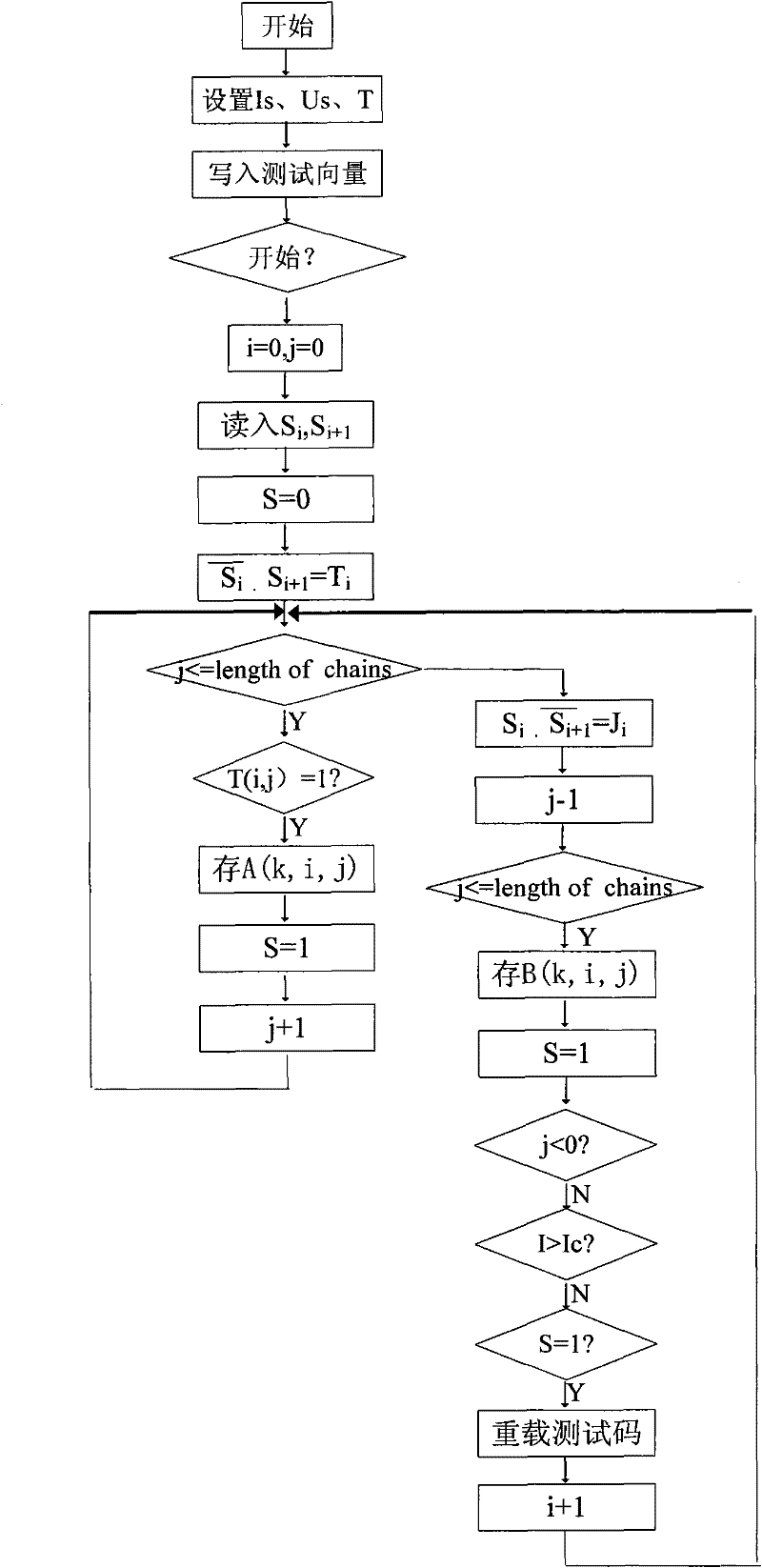

Method for calibrating and correcting temperature measurement of infrared probe as well as corresponding temperature measuring method

ActiveCN102564598AChange in real timeAchieve correctionRadiation pyrometryTemperature responseCorrection method

The invention discloses a method for calibrating and correcting temperature measurement of an infrared probe as well as a corresponding temperature measuring method. The temperature measurement calibration and non-uniform correction process is as follows: the non-uniform correction is carried out firstly; the temperature measurement calibration is carried out after a collection parameter sum is generated; however, the non-uniform correction is not stopped simultaneously; and in the non-uniform correction, a step of circularly judging whether an extrusion exists in a parameter or not is carried out; and if so, the parameter is corrected; otherwise, the judgment is continuously carried out. A temperature measurement calibrating process comprises the following steps of: carrying out the non-uniform correction once by using the calculated non-uniform parameter for each probe response of collecting a temperature; then recording the temperature and probe response data; repeating the processuntil collecting enough data; and fitting the data to obtain a probe temperature response function. By utilizing the method disclosed by the invention, the steps of non-uniformly correcting and calibrating the temperature measurement of the infrared probe are simplified into one step, so that the correction and the calibration which can be previously realized by the two steps are conveniently realized on one hand, and the precision of the temperature measurement can be improved on the other hand.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

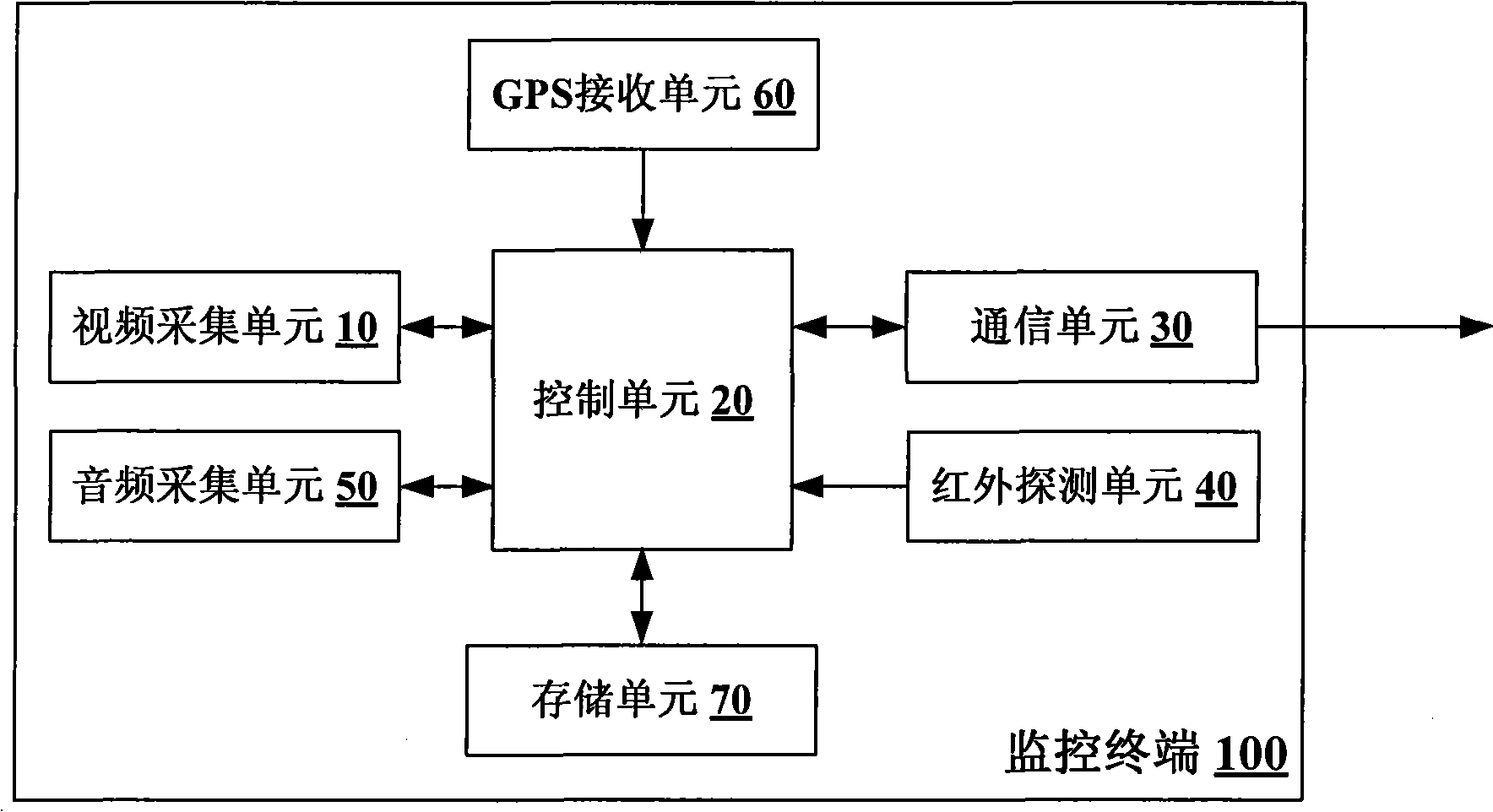

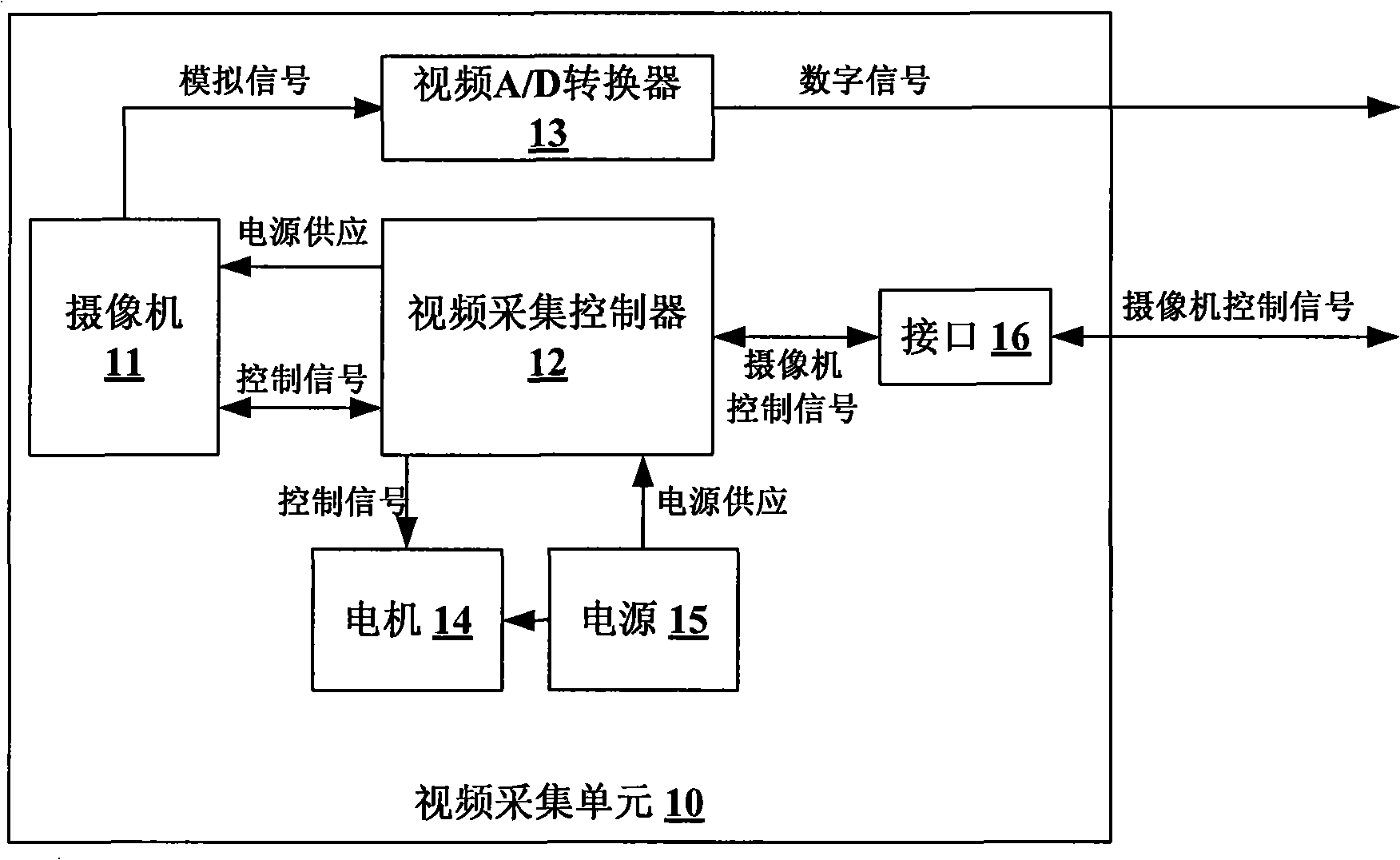

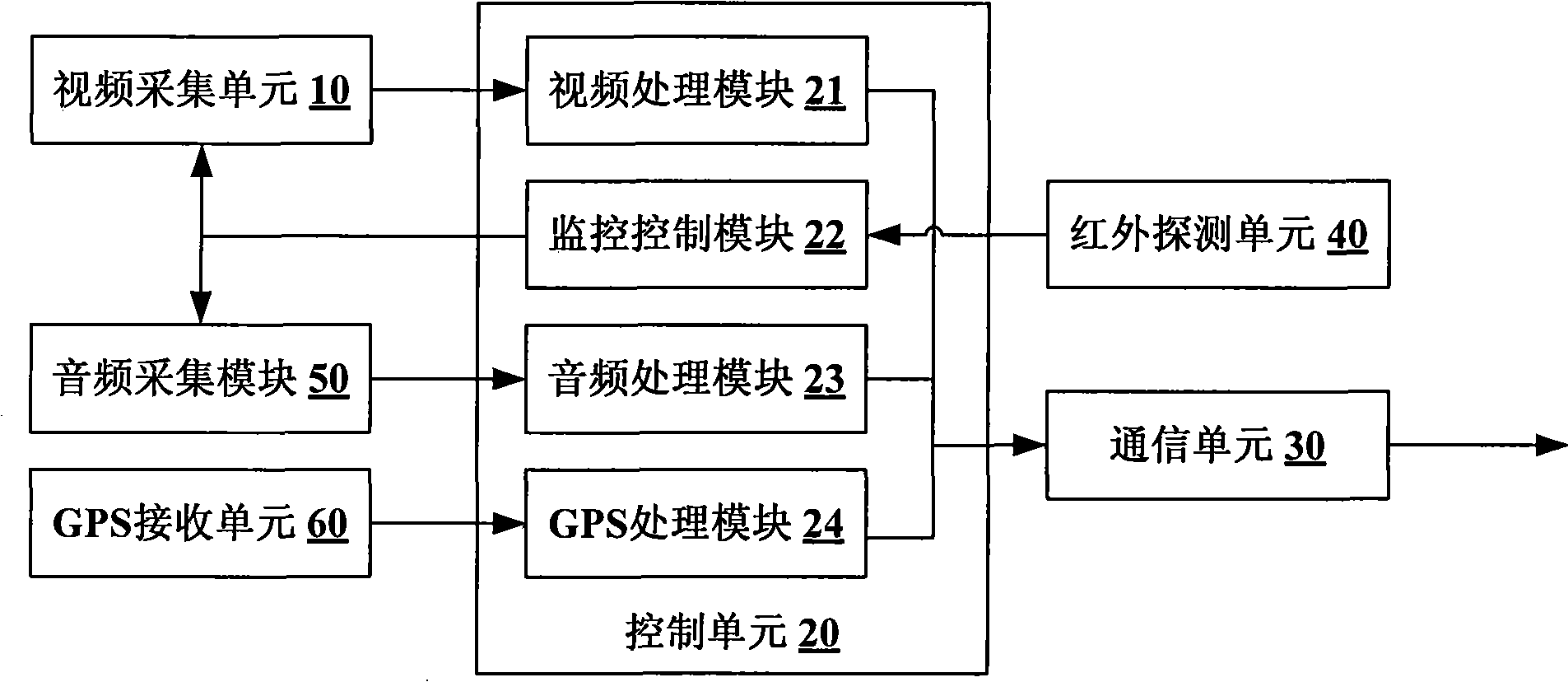

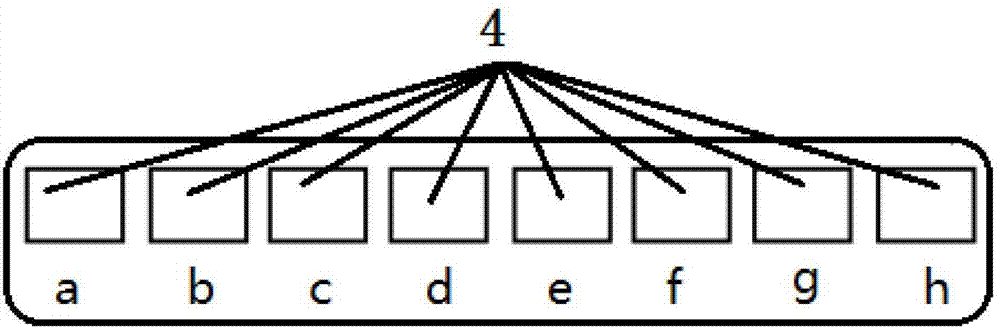

Monitor terminal, monitor method and remote monitor system used for remote monitoring

ActiveCN101640789AIncrease usageReduce dataBeacon systems using radio wavesPosition fixationCommunication unitComputer terminal

The invention provides a monitor terminal, a monitor method and a remote monitor system used for remote monitoring, wherein the monitor terminal comprises a video acquisition unit (10), a control unit(20) and a communication unit (30); the monitor terminal (100) also comprises an infrared probe unit (40) used for probing whether a heating body enters into the monitoring area and sending an alarmsignal to the control unit (20) when the heating body enters into the monitoring area, the control unit (20) controls the video acquisition unit (10) according to whether to receive the alarm signal.The invention uses the infrared probe technology to probe whether the heating body enters into the monitoring area, if the heating body enters into the monitoring area the video acquisition unit (10)is started or continuous shooting is began, otherwise the video acquisition unit (10) is not started or periodical shooting is began, so that the generated data is much fewer compared with continuousshooting so as to improve disk utilization rate of the remote monitoring center.

Owner:BYD CO LTD

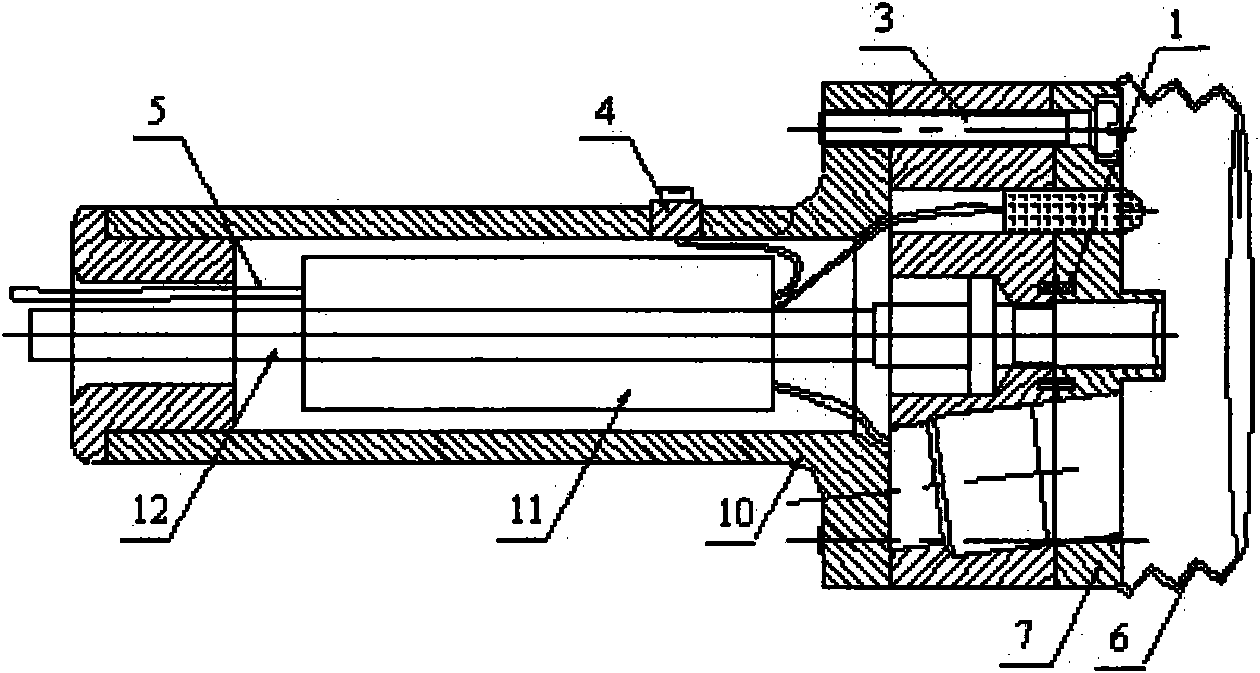

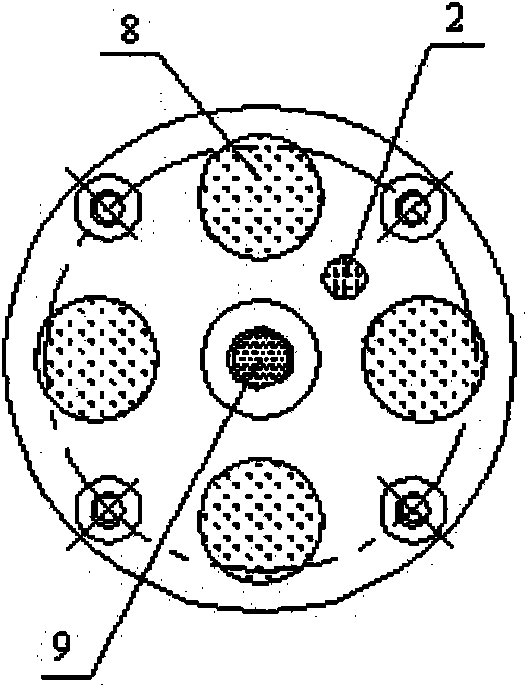

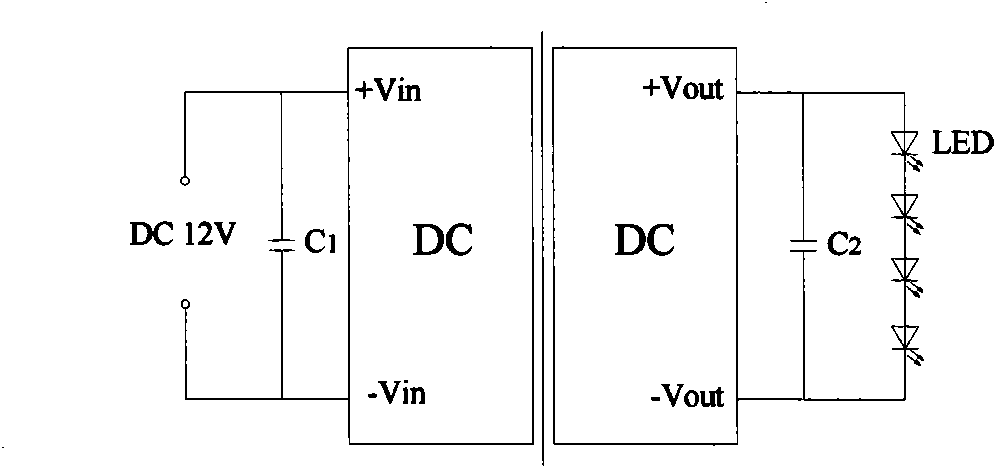

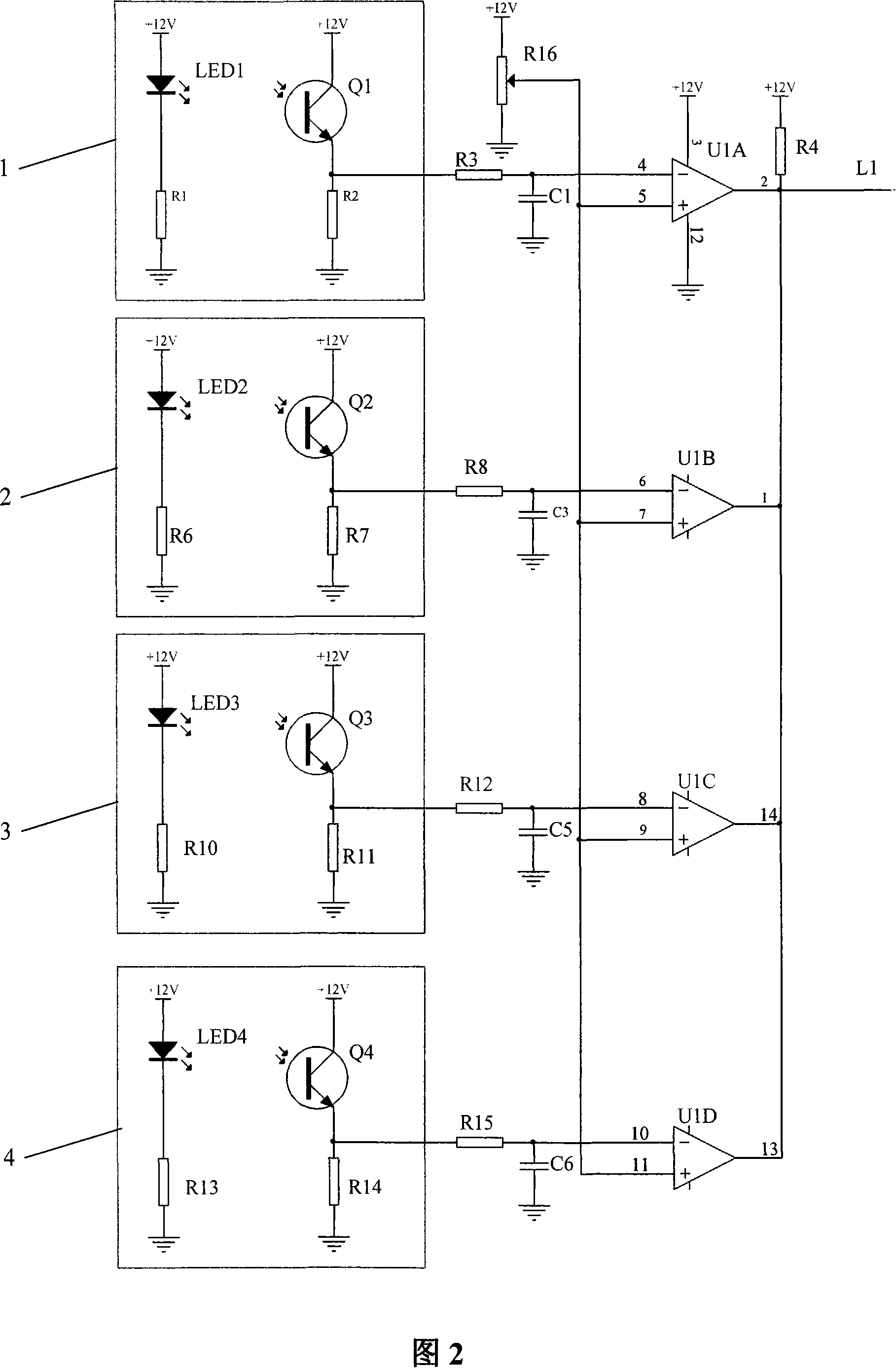

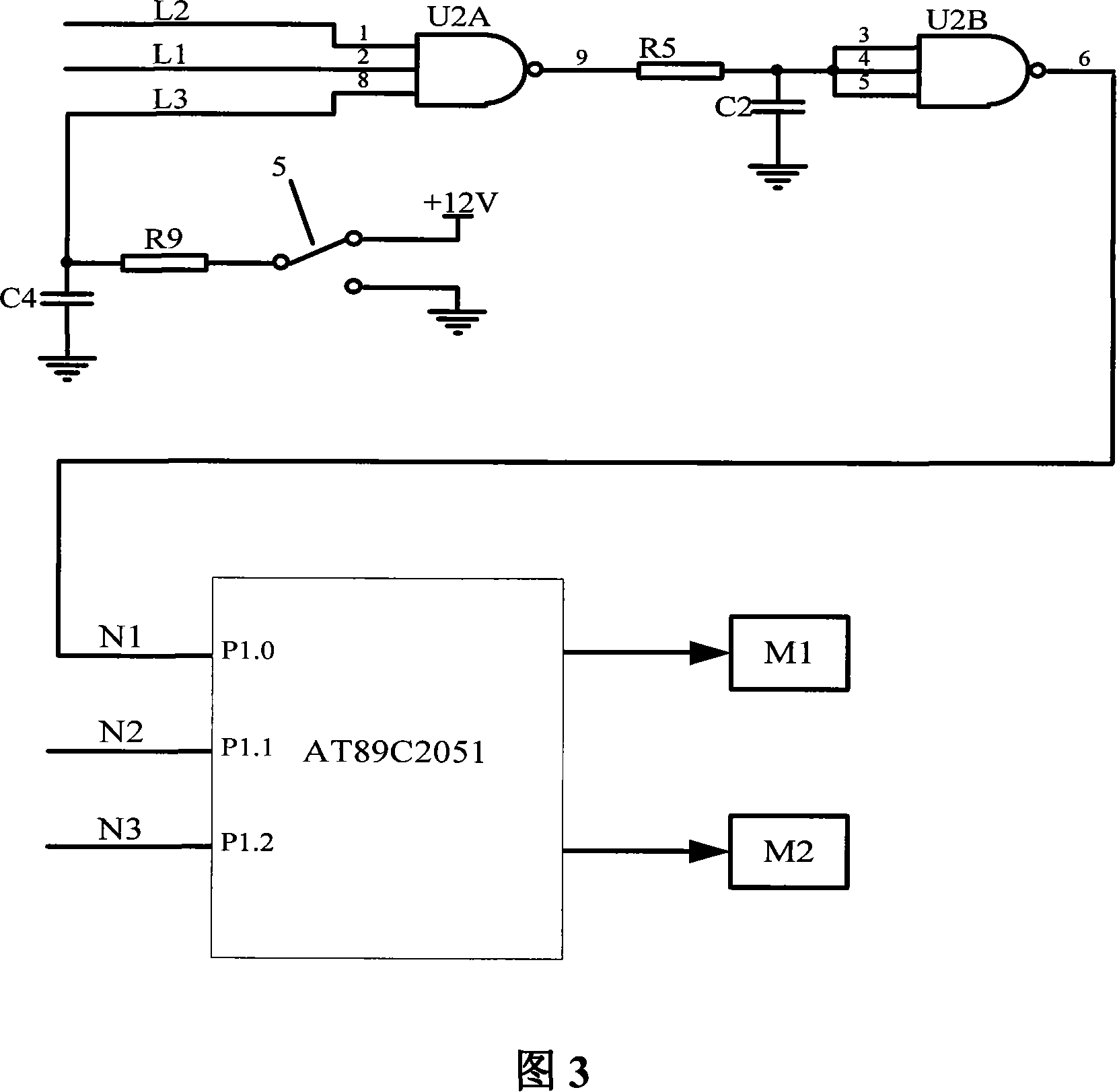

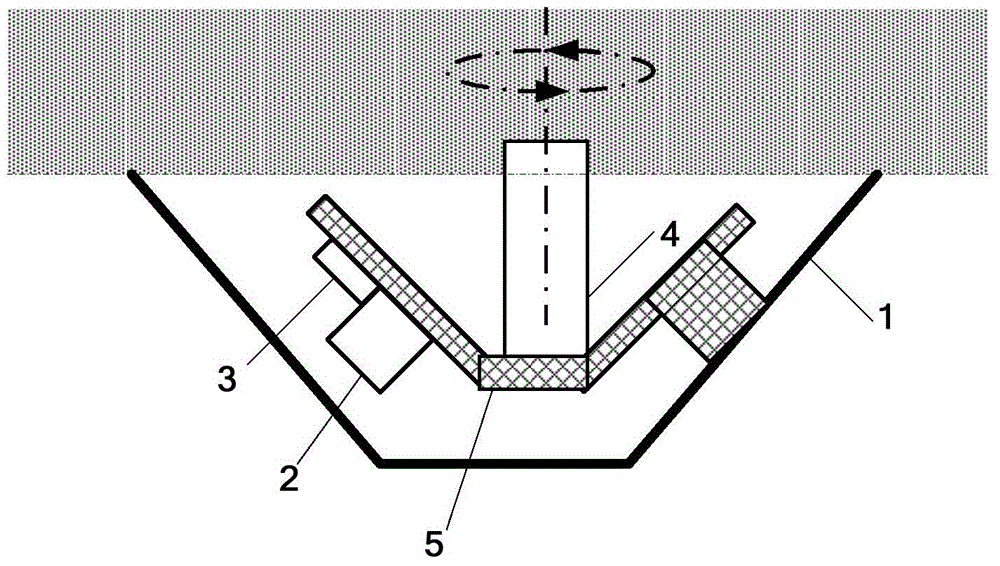

Handheld near-infrared probe for nondestructive internal quality testing of fruit and detection method

InactiveCN101799401AEasy to collectImprove final detection efficiencyPoint-like light sourceScattering properties measurementsHand heldWavelength

The invention relates to a handheld near-infrared probe for nondestructive internal quality testing of fruit and a detection method. The optical fiber probe consists of four LED light sources with different waverlengths, a detection optical fiber, an automatic sampling control system, a light source stabilizing circuit, a digital temperature and humidity sensor, a circular lug boss, a darkening ring, a soft rubber ring, a switch, a circuit box and a shell. The probe has the characteristics of high stability, simple structure, low cost and spectra collecting controllability, and can be widely used for on-line monitoring and on-site sampling of fruit. A voice system and a wireless transmission system can be used for realizing the humanization and easy operation of equipment and effectively expand application space.

Owner:EAST CHINA JIAOTONG UNIVERSITY

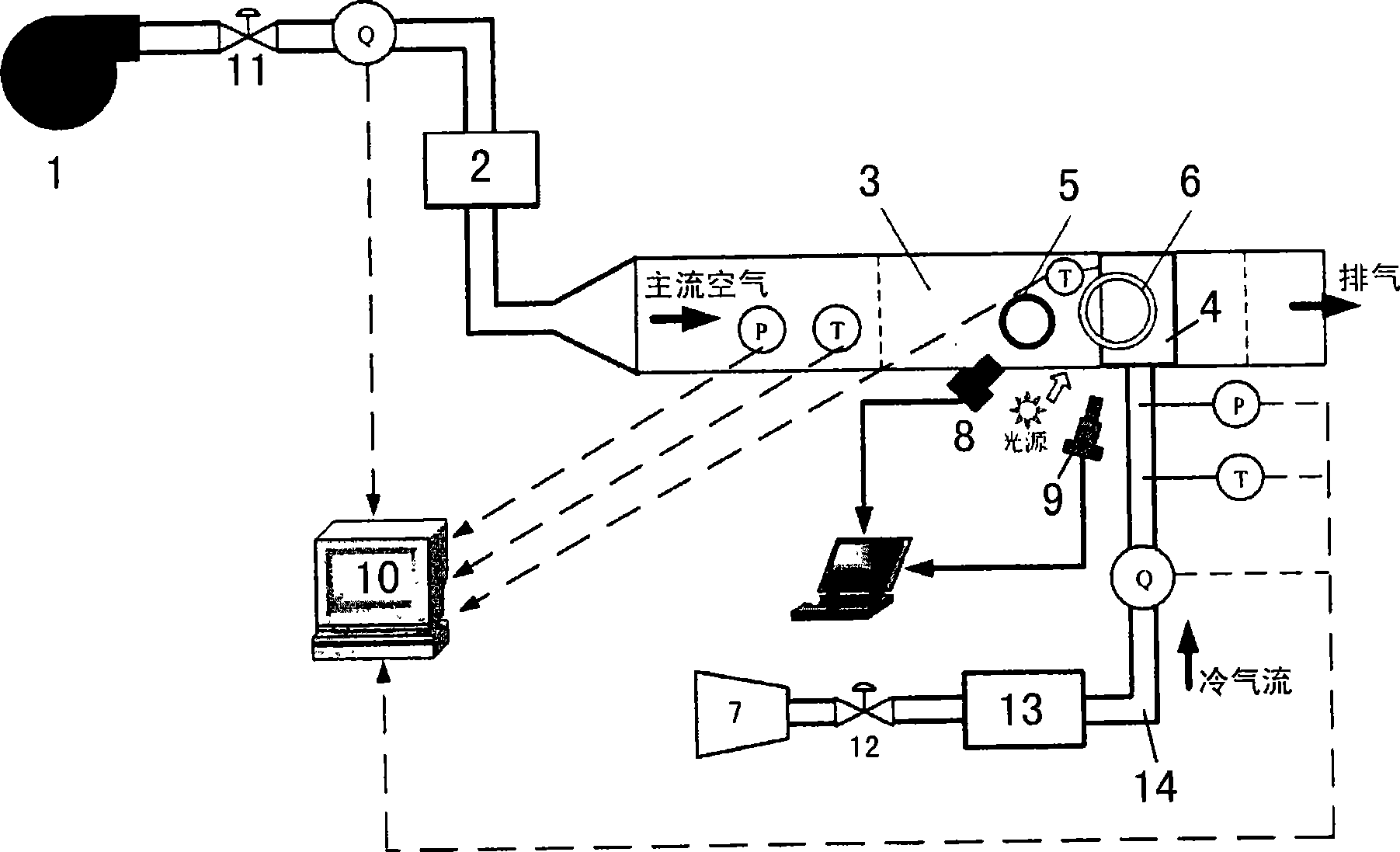

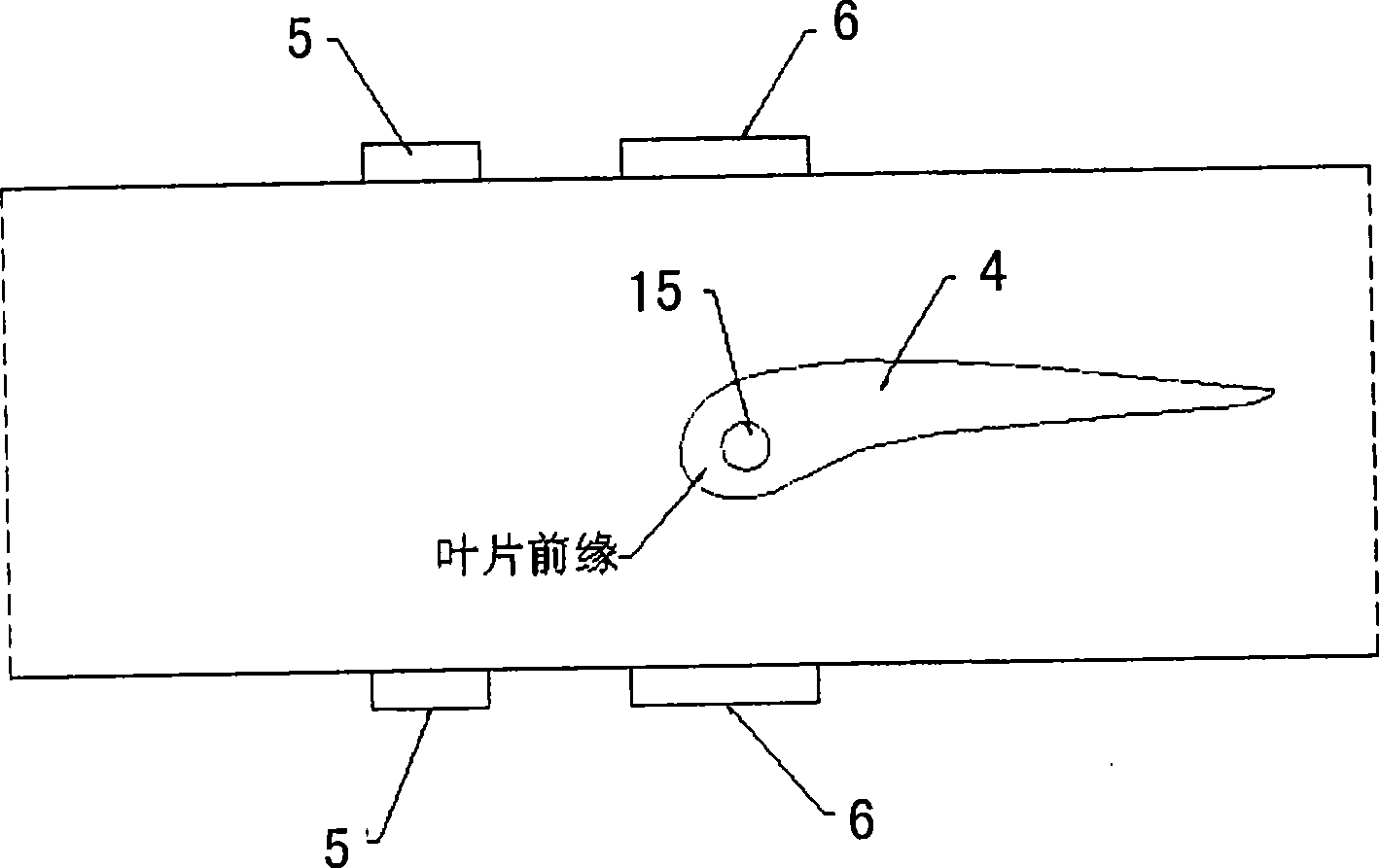

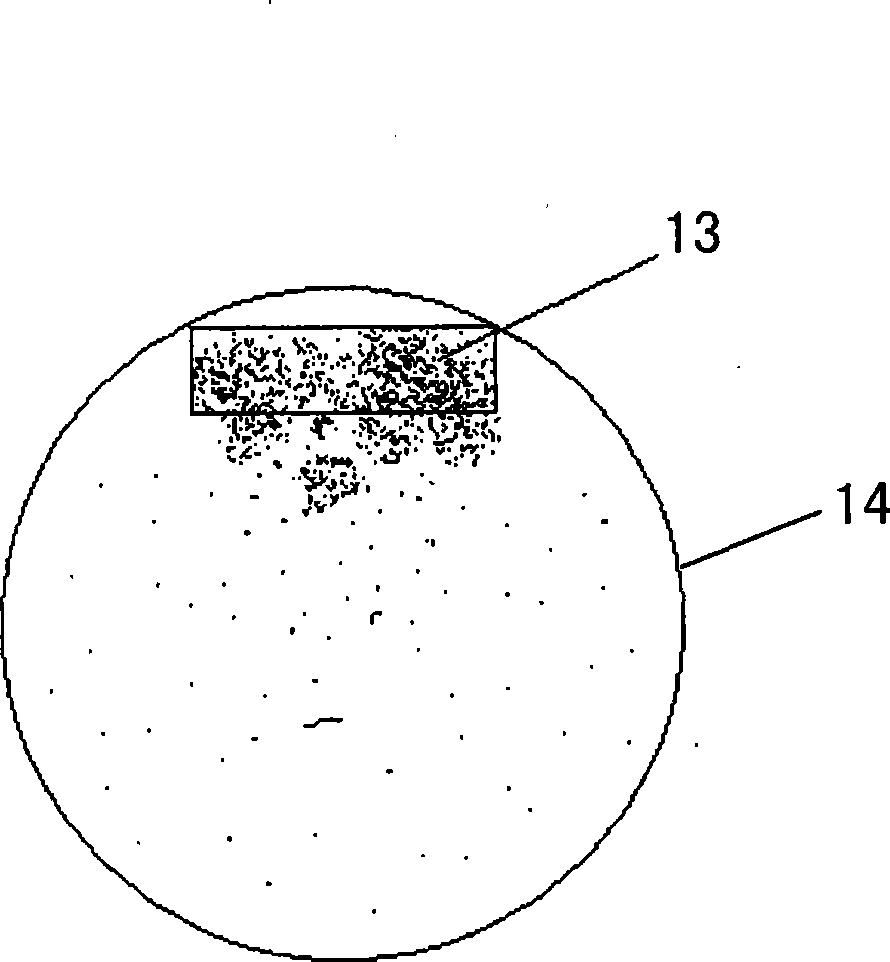

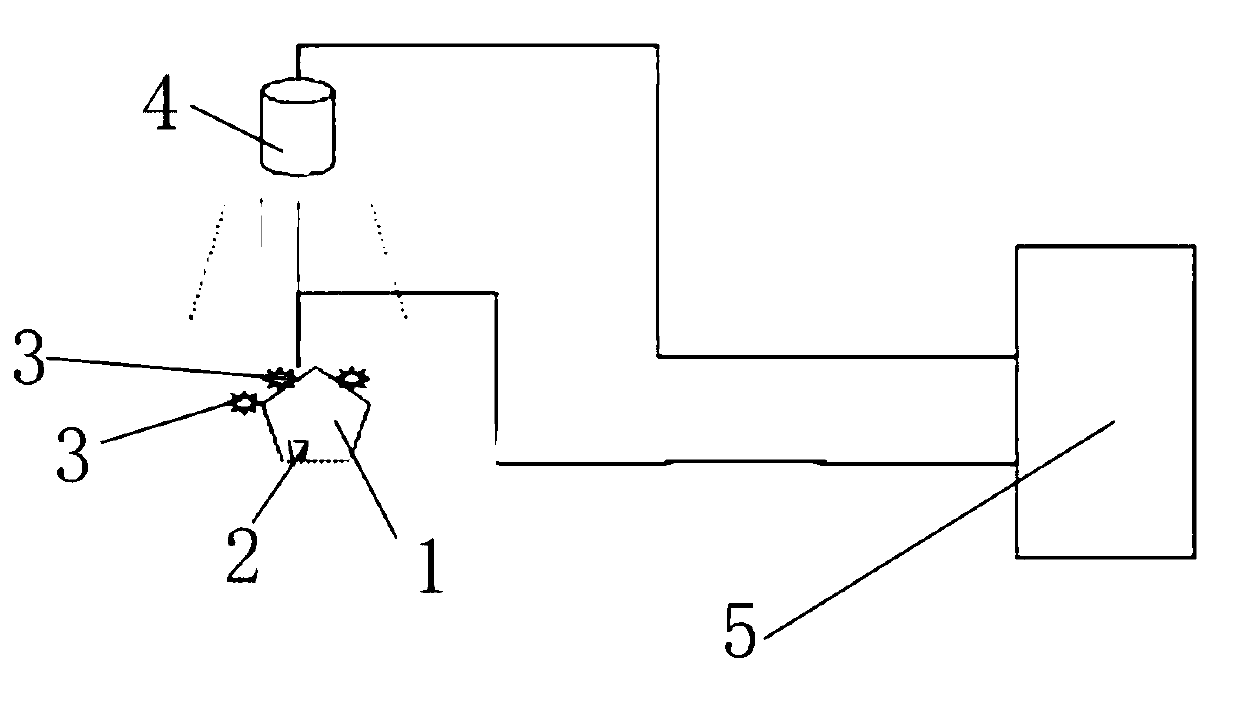

Visual observation and transient measurement method and apparatus for cooling process of turbine blade

The invention relates to a method for carrying out visual observation and transient measurement on a cooling process of a turbine blade, which comprises the following steps: heating main flow air to a pre-determined temperature; introducing cold air flow; allowing the cold air flow to enter to a cooling passage inside the turbine blade first to cool the blade; and allowing the cold air flow to flow to the surface of the turbine blade to form a layer of a cold air film; and recording the temperature and the pressure of each measuring point and observing the conditions of mixing and flowing of the main flow and the cold air flow near the turbine blade. A device for realizing the method comprises an air tunnel, one end of the air tunnel is connected with a hot air source, while the other end is an exhaust port; the turbine blade is placed inside the air tunnel according to an operating state of the blade; a cold air source connected with a jet pipe of the turbine blade in the air tunnel through an air pipe; a pigment feeding device is arranged on the air pipe; infrared probing windows are respectively arranged on two sides of the air tunnel which is positioned in the turbine blade; the infrared probing windows are respectively provided with infrared thermal imagers; visual observing windows are respectively arranged on the two sides of the air tunnel which is positioned in the turbine blade; and the visual observing windows are respectively provided with micro-amplifying photographic devices.

Owner:中科思道(南京)储能技术有限公司

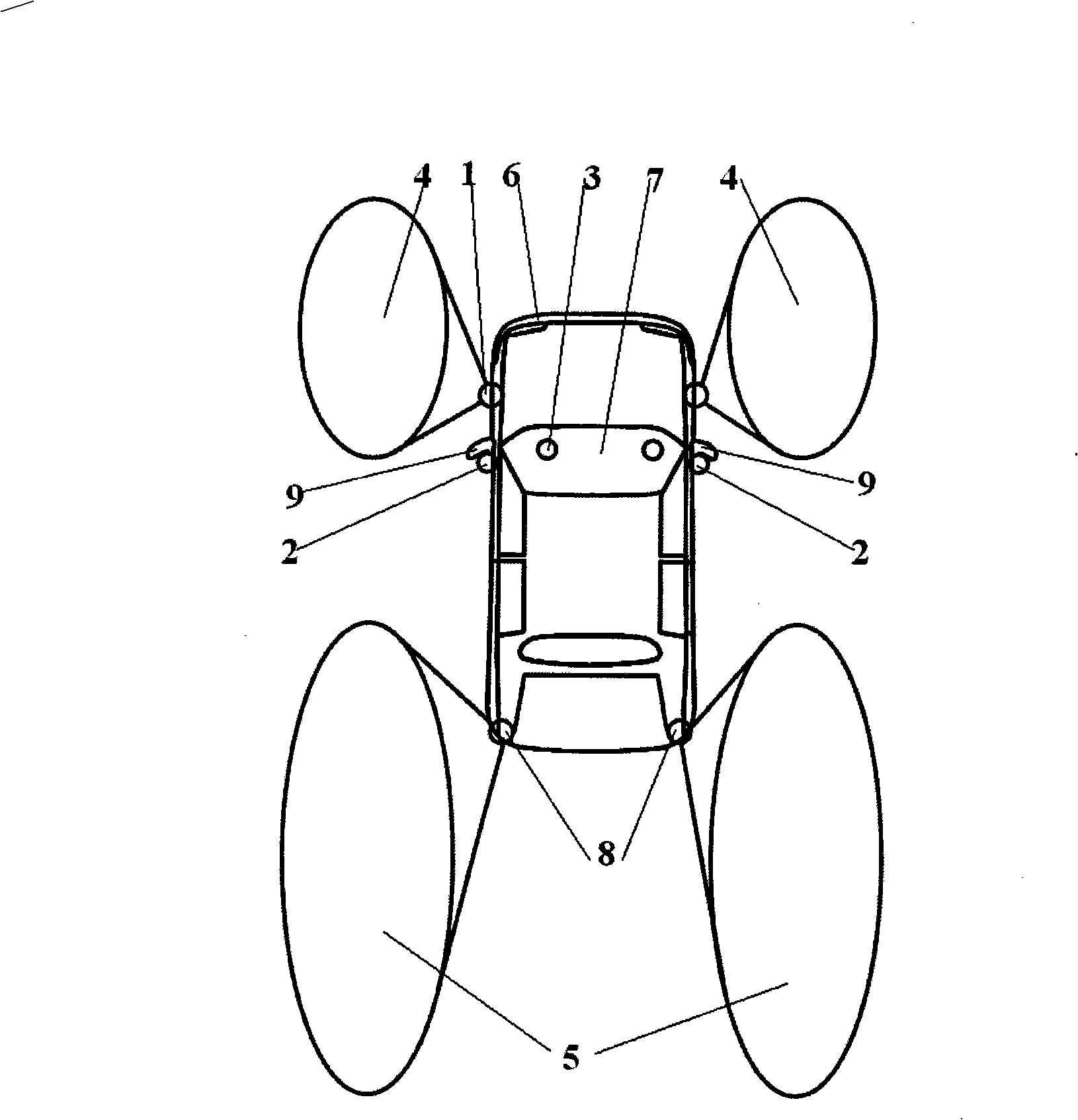

Vehicle blind zone detection, alarm device and detection, alarm method thereof

ActiveCN101311034AReduce power consumptionHigh sensitivityAcoustic signal devicesOptical signallingAnti jammingBlind zone

The invention pertains to the technical field of vehicle construction, discloses a blind zone detecting and alarm device for vehicles, wherein, an infrared probe (1) is multiple passive infrared receivers; the alarm device is divided into an audible alarm device and a light stroboflash alarm device. The infrared probe (1), the audible alarm device and the light stroboflash alarm device are all connected with the operating control unit of the vehicle by signal lines. Detection zones cover an A pole blind zone and blind zones at the side and the back of the vehicle by adopting the technical proposal, and the disadvantages of poor active infrared anti-jamming performance and complex structure are overcome; the passive infrared detector does not emit any radiation and has the advantages of quite low device power consumption, high sensitivity, comparatively good invisibility, low cost, convenient arrangement and being artistic and practical; the mode combined with the audible alarm and the light stroboflash alarm gives drivers sufficient alarm information to guarantee driving safety.

Owner:CHERY AUTOMOBILE CO LTD

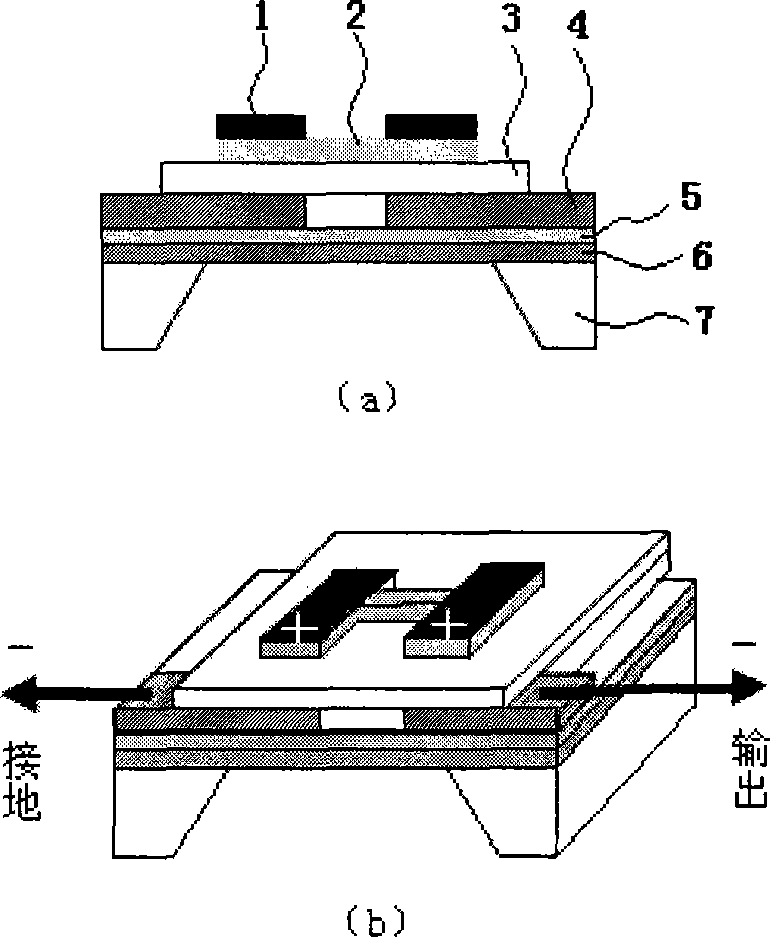

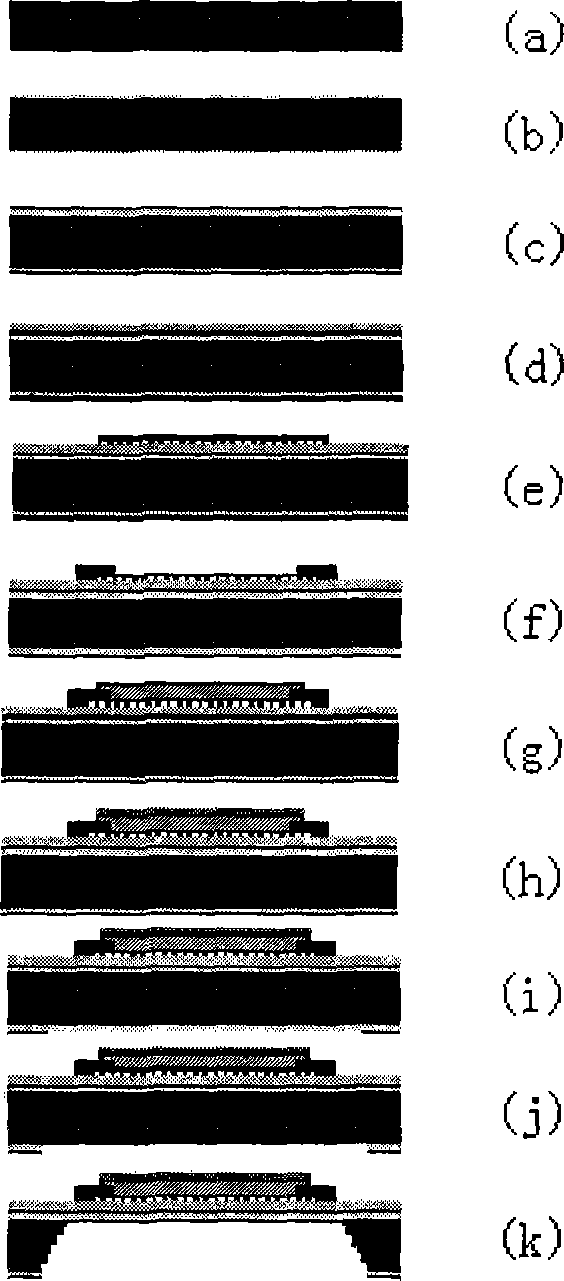

Lithium tantalate thin film infrared detector and manufacturing method

InactiveCN101246055AAchieve Impedance MatchingAchieve modulationRadiation pyrometryLow-pass filterOptoelectronics

The present invention relates to a lithium tantalate film infrared detector and the preparing method thereof. The invention comprises the following components: an infrared filtering window, a resonance chopped wave modulator, a focusing lens, a pyroelectric lithium tantalate film infrared measuring probe, a heat sink cavity, a preamplifier, a low-pass filter, an electric power and signal output interface, a casing and an environment temperature detecting filter. The method for preparing the detector comprises the following steps: selecting a substrate, growing a SiO2 layer on the front and back surface, depositing Si3N4 layer on the front surface in sequence, sputtering a Ti layer, sputtering a photoetching Pt electrode layer, producing a lithium tantalate film layer, depositing a phototeching Al electrode layer, growing a photoetching SiNX antireflection layer and sputtering a black layer to complete the double unit structure infrared probe. The focusing lens is coated with an anti-reflection film. The infrared window is pasted with a narrowband filtering film. The preamplifier is built with a JFET tube or operational amplifier. The low-pass filter is built with an operational amplifier. The resonance chopped wave modulator is driven by piezoelectricity or electromagnet, and the resonance frequency is 1Hz-1000Hz.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

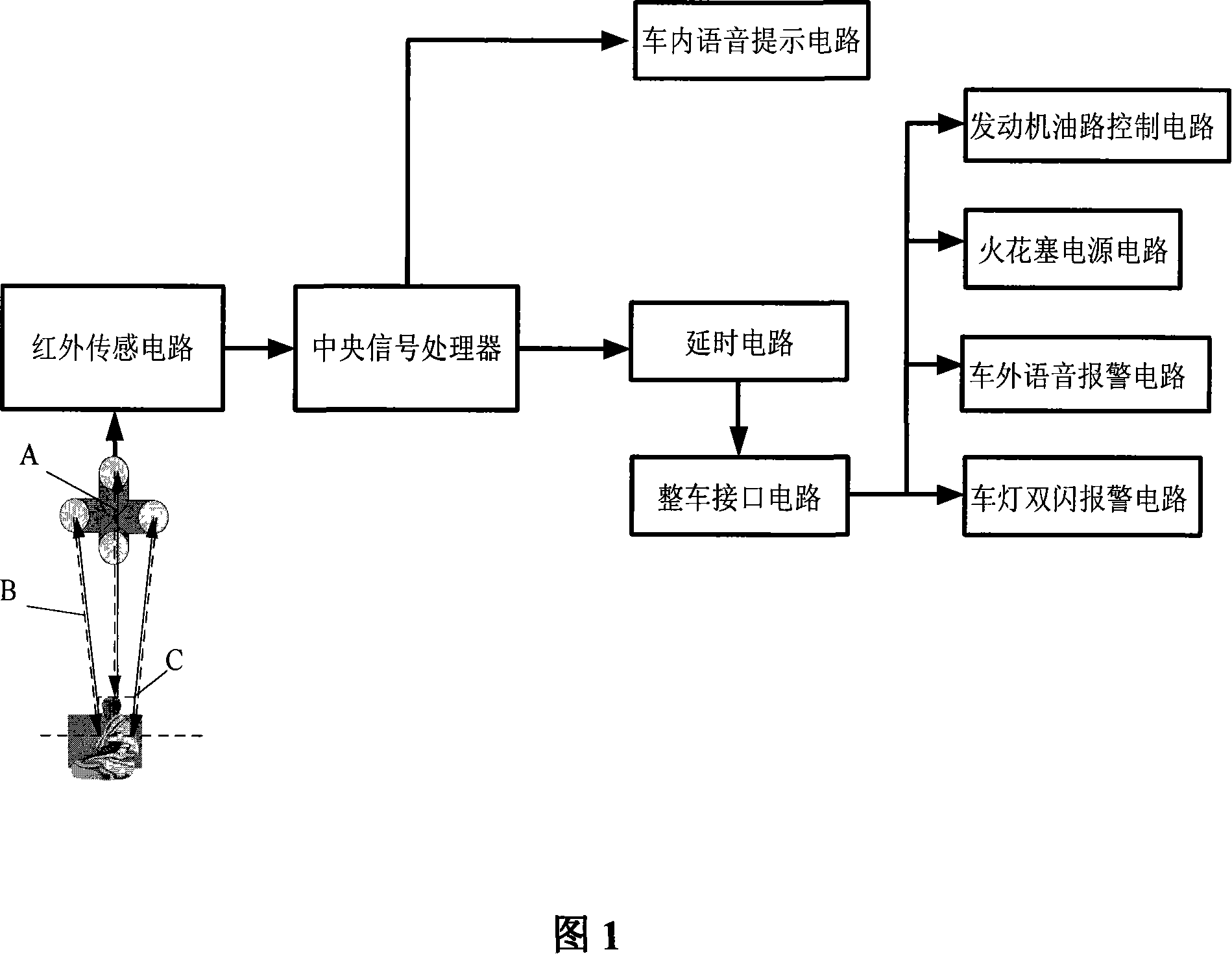

Automobile anti-fatigue driving automatic alarming protection system

InactiveCN101100168AImprove securityEasy detectionDiagnostic recording/measuringSensorsDriver/operatorLight flashes

The automatic alarming protection system for preventing fatigue driving includes one infrared detector, and features that it has one infrared probe beside the driver and controlled by the infrared detector to track the driver's body, the detector has its output connected to the input of the running state sensing circuit and one central signal processor, and the output of the central signal processor is connected through one delay circuit and one interface circuit to engine oil path controlling circuit, spark plug power source circuit, outside phonetic alarm circuit and light flash alarm circuit. After the vehicle is started, the automatic alarming protection system sends out phonetic prompt preventing fatigue driving, tracks driver's body, triggers danger signal after detecting the deviation of the driver's body from normal position, and cuts off the oil path and circuit and sends out acoustic and light alarm in dangerous driving.

Owner:王继军

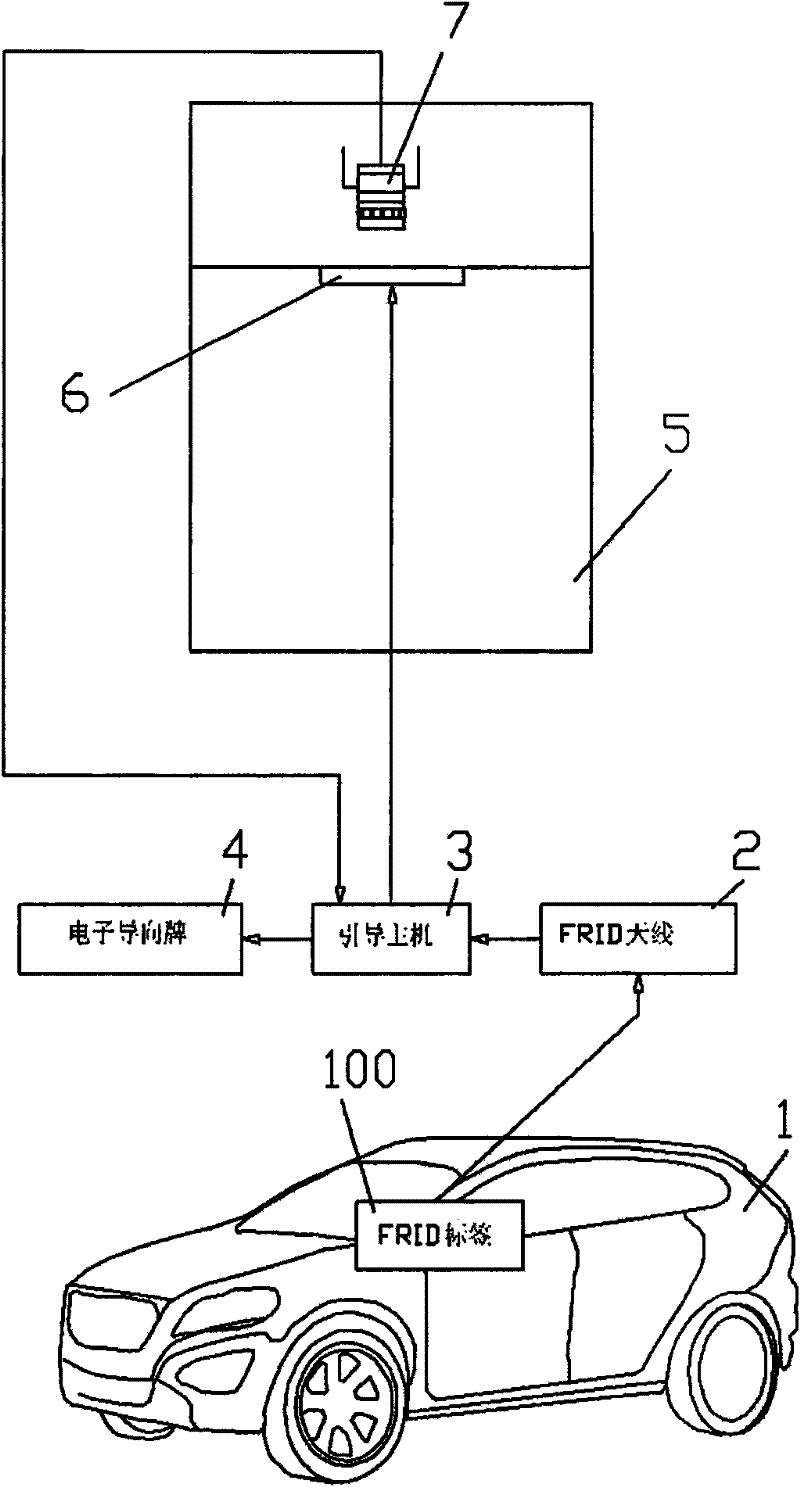

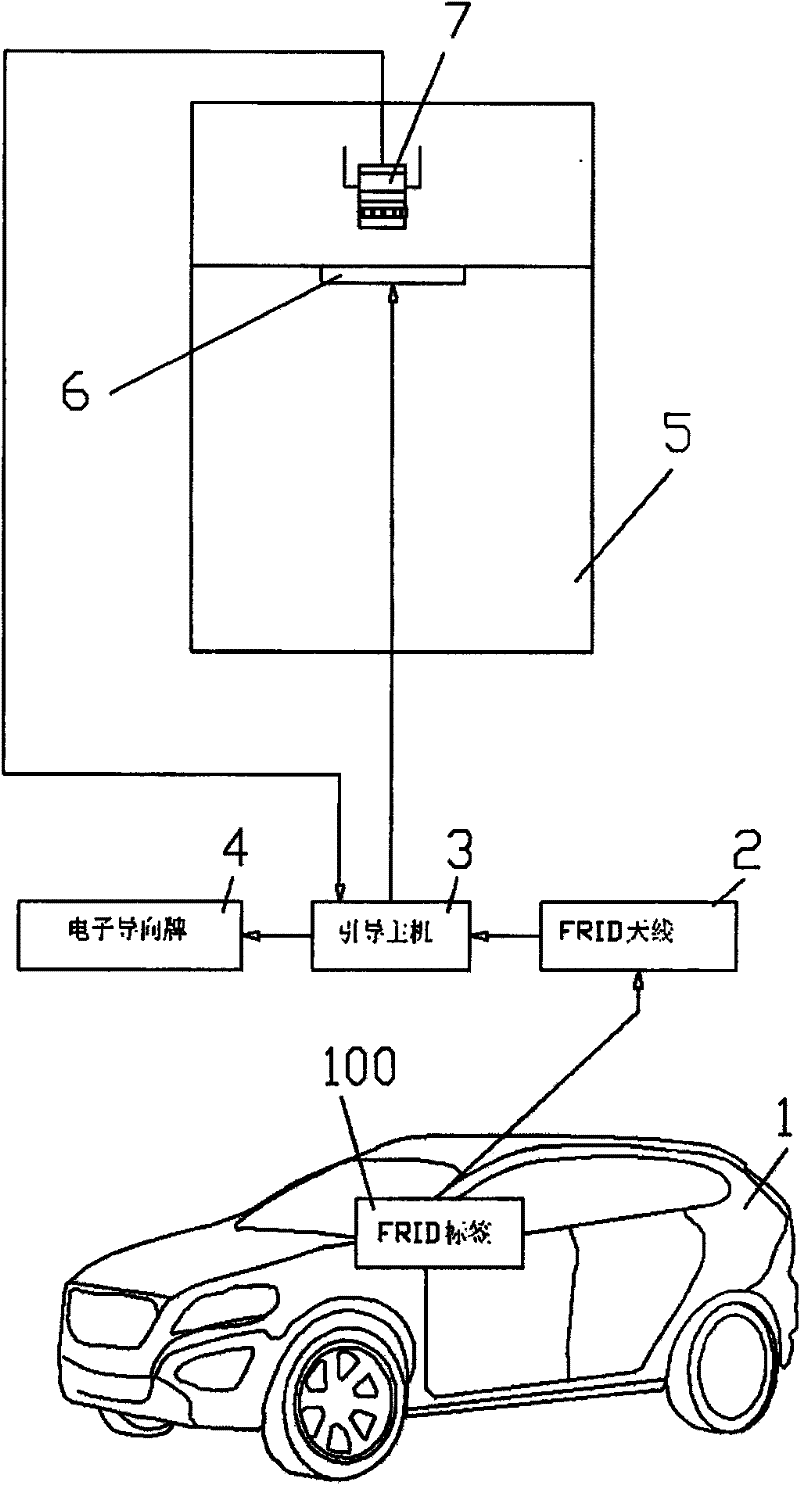

Automatic parking guiding device

InactiveCN102231241AAvoid the problem of driving to a parking spaceAvoid crowdingIndication of parksing free spacesSignal onParking space

The invention relates to an automatic parking guiding device, comprising a parking lot, wherein a plurality of parking spaces are arranged in the parking lot, a lifting type automatic ground lock and an infrared probe are installed in each parking space, the infrared probe is used for detecting whether an object signal is available above the lifting type automatic ground lock and transmitting the object signal to a guiding host, an RFID (Radio Frequency Identification Device) label is placed on a vehicle, a plurality of RFID antennae and an electric guiding plate are arranged in the parking lot, the RFID antennae are used for reading an RFID label signal on the vehicle and then transmitting the RFID label signal to the guiding host, and the guiding host is used for driving the electric guiding plate to display information and controlling locking and unlocking of the lifting type automatic ground lock according to the RFID label signal on the vehicle, read by the RFID antennae, and a detection signal of the infrared probe. According to the automatic parking guiding device, the problem that many vehicles drive up to one parking space can be avoided, and the flow rate congestion and the route jamming of the parking lot are avoided.

Owner:陈飞

Human body detection device based on infrared heat source detection

ActiveCN104422524AImplement detectionHigh-resolutionPyrometry using electric radation detectorsFresnel lensImage resolution

The invention discloses a human body detection device based on infrared heat source detection. The human body detection device comprises a housing, a pyroelectric infrared sensor and a driving motor, wherein the pyroelectric infrared sensor is arranged inside the housing; the housing and the pyroelectric infrared sensor are driven to rotate synchronously by the driving motor; the housing is provided with a strip-shaped slit; the pyroelectric infrared sensor comprises an infrared probe; a Fresnel lens is arranged at the front end of the infrared probe; the Fresnel lens is over against the slit in the housing. According to the technical scheme of the invention, the infrared heat source of a static human body within 360 degrees can be detected, and the detection resolution is high.

Owner:HAIER GRP CORP +1

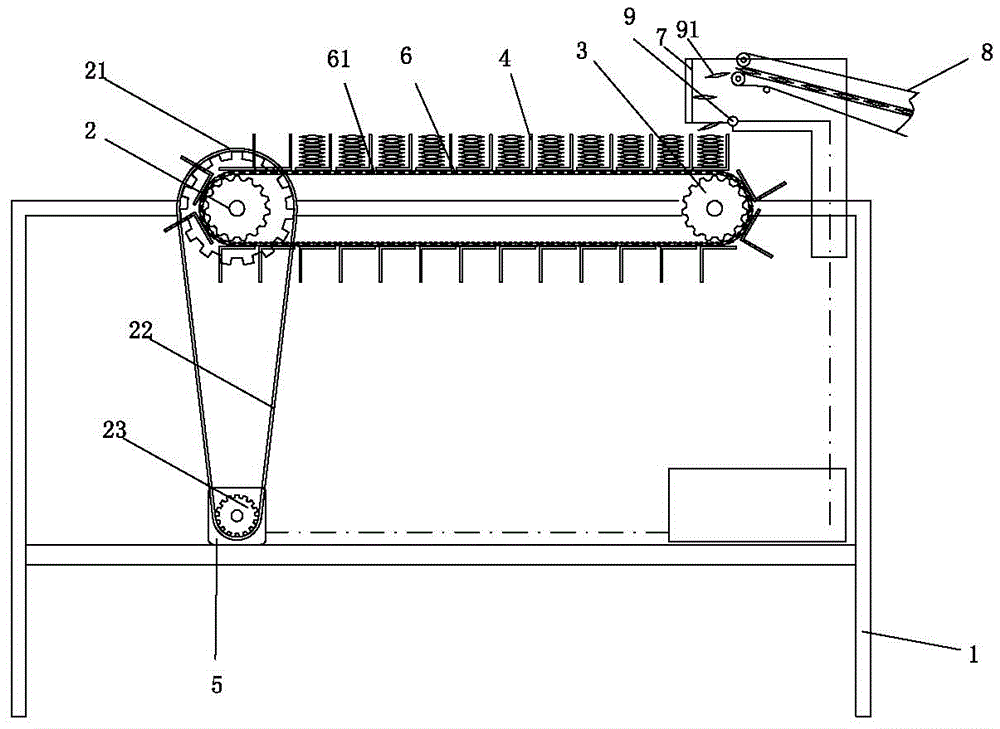

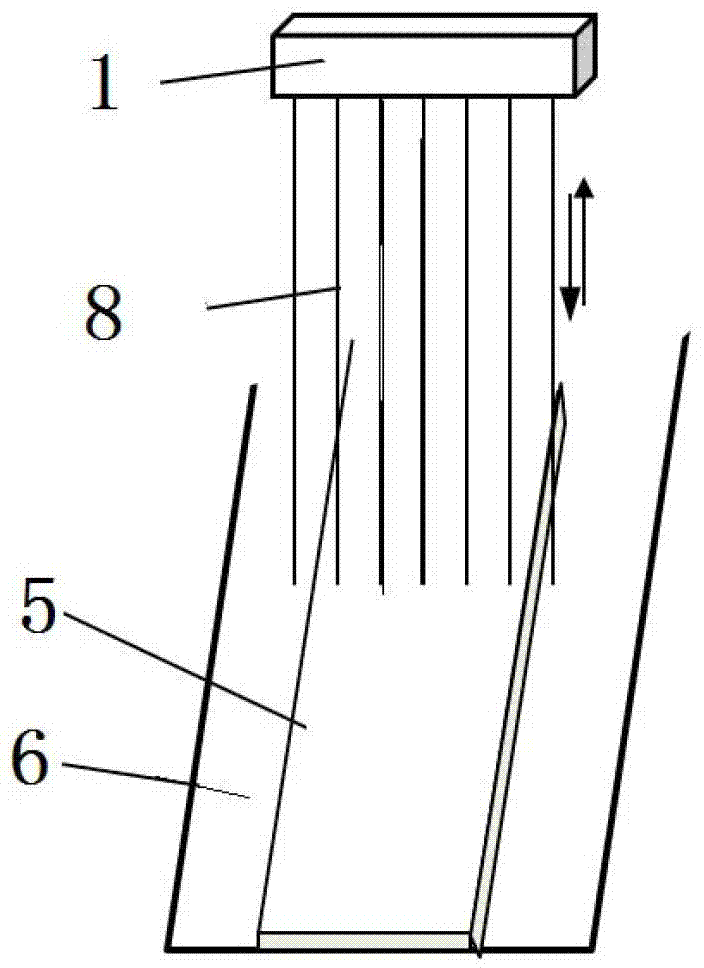

Automatic gauze mask packaging machine

InactiveCN105984612ANeatly stackedHigh degree of automationPaper article packagingConveyorsEngineeringSprocket

An automatic mask packaging machine is characterized in that the top of the frame is provided with a conveyor belt driven by a motor, the head end of the conveyor belt is located directly below the end of the mask piece conveyor belt, and multiple push plates are provided on the conveyor belt, two The vacancy between adjacent push plates constitutes a mask piece stacking area. The invention has the advantages of high degree of automation, neatly stacked mask pieces, good packing effect and the like. When the infrared probe detects that the mask pieces falling from the conveyor belt are stacked to a certain height, the driving sprocket will automatically push forward the length of a mask piece stacking area driven by the stepping motor, so that the operator can take it, and then another The mask sheet stacking area automatically follows up and enters just below the end of the mask sheet conveyor belt to collect the mask sheets for stacking.

Owner:仙桃市道琦塑业股份有限公司

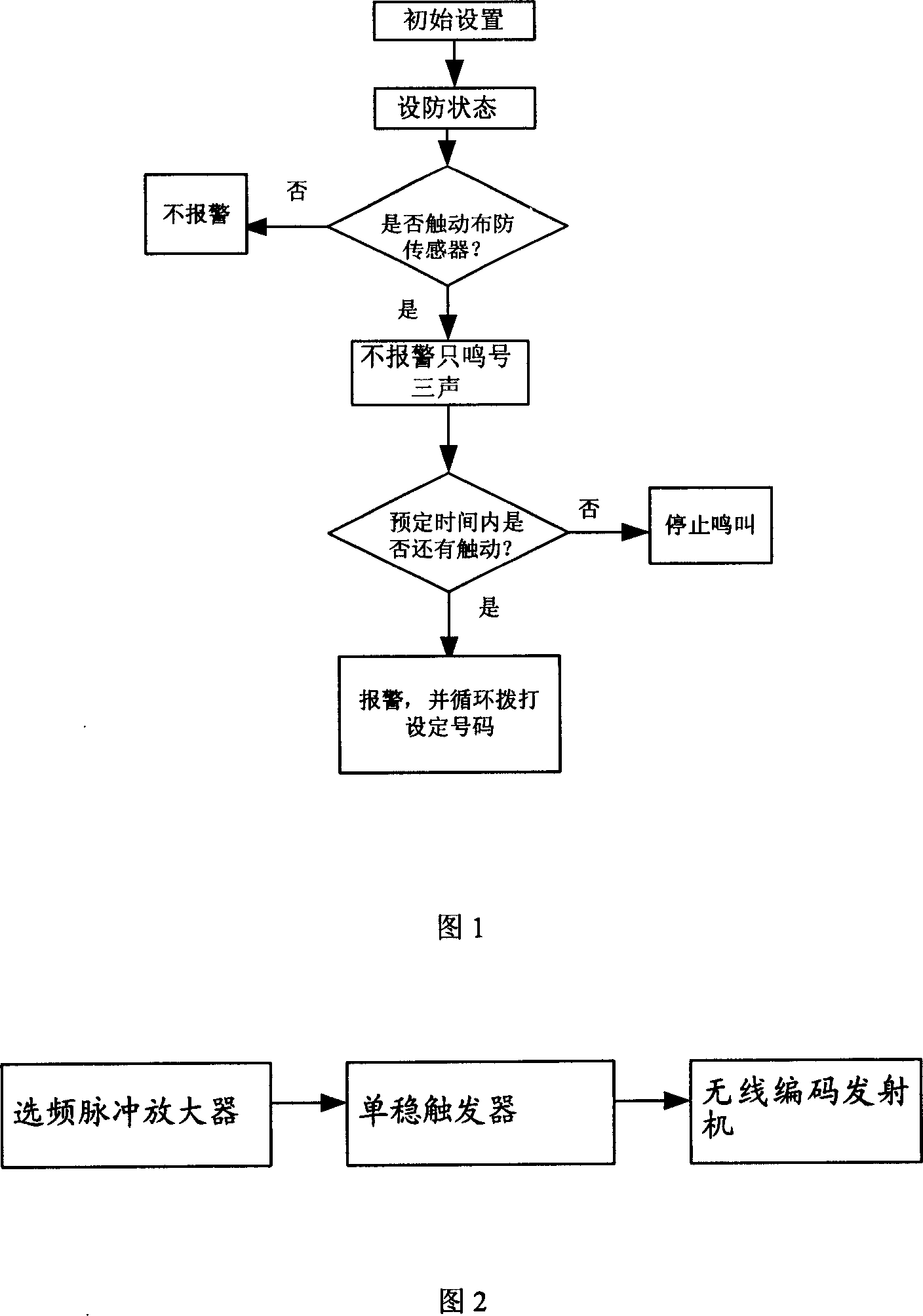

Wireless/wired intelligent logical safety theft-proof system

InactiveCN101136124AEliminate false positivesEfficacy of avoiding stop monitoringBurglar alarm mechanical vibrations actuationBurglar alarm short radiation actuationAlarm statePulse amplifiers

The system comprises: a sensing system and a host machine. When the system is at a defenses state and the radio vibration probe of the sensing system detects an invader attempting to open the door, the host machine doesn't give an alarm but only giving three bell sounds, and meanwhile enters into a pre-alarm state; if the damage goes on, then the host machine gives the alarm and dials the phone number of the master; if in a preset time length, there is no second trigger, the host machine enters the defense state again. After combining the infrared probe with the micro vibration probe to build a logic relation, only at the condition in which both probes are simultaneously triggered, then the host machine gives an alarm. The invention is an energy-saving system; one battery can keep a 1-2 year service time.

Owner:孙逢辉

Three-dimensional ultrasonic positioning and surgery navigation system as well as image processing method thereof

InactiveCN103099678ARealize high-precision positioning and trackingFully automatedDiagnosticsSurgical navigation systemsImaging processingNavigation system

The invention discloses a three-dimensional ultrasonic positioning and surgery navigation system. The three-dimensional ultrasonic positioning and surgery navigation system comprises an ultrasonic probe, wherein an infrared probe is arranged on the ultrasonic probe; and non-collinear three small infrared balls are mounted on the infrared probe. The three-dimensional ultrasonic positioning and surgery navigation system further comprises an infrared positioning device for positioning the infrared probe by measuring the positions of the small infrared balls; and the ultrasonic probe, the infrared probe and the infrared positioning device are connected with a computer. The invention further discloses an image processing method of the three-dimensional ultrasonic positioning and surgery navigation system. The image processing method can be used for virtually displaying three-dimensional scenes, such as a breast, a breast tumor, a puncture needle, and a surgery path, through data establishment and update, elastic registration and virtual reality. The three-dimensional ultrasonic positioning and surgery navigation system provided by the invention carries out data treatment after collecting data through ultrasonic waves and the infrared probe, is used for accurately positioning the breast by using the ultrasonic waves and infrared positioning, is used for diagnosing breast diseases, and further can be used for navigating breast puncture and surgery.

Owner:JIANGSU YADA TECH GRP

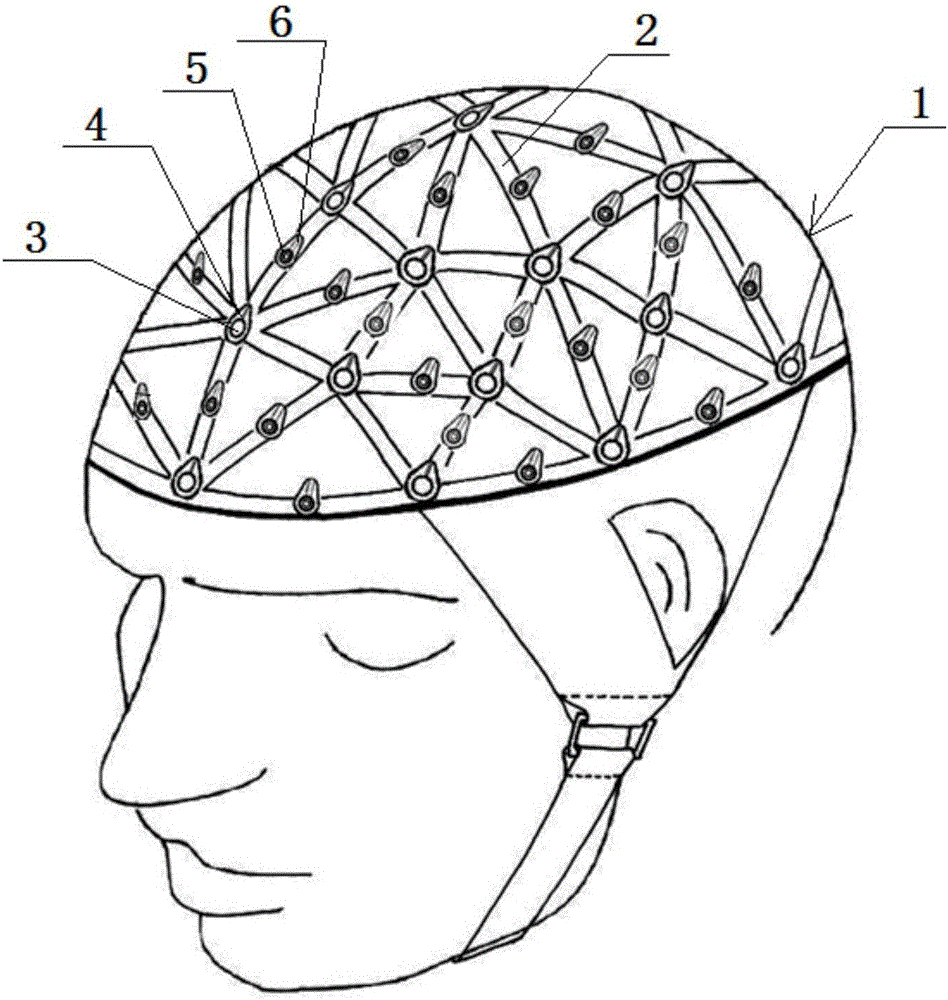

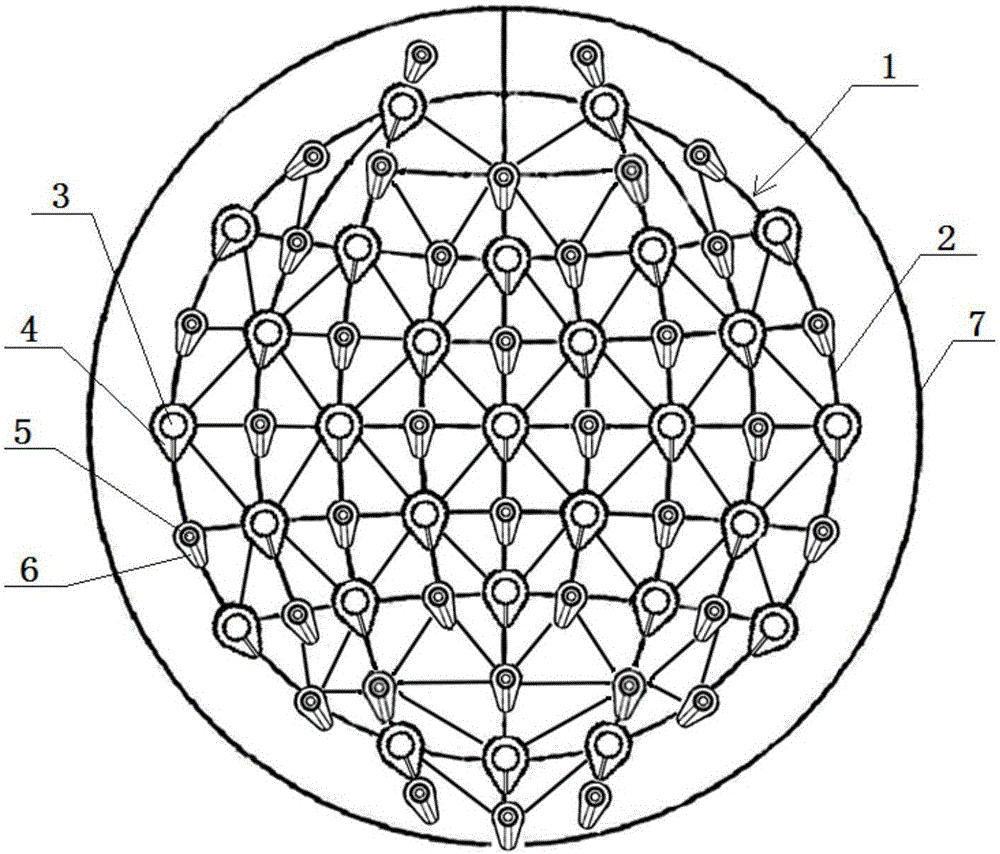

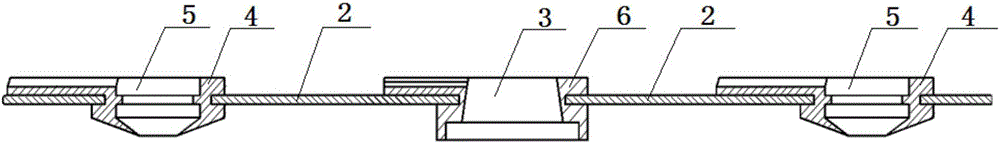

Retaining cap used for acquiring brain signals in photoelectric combined mode and applied to transcranial magnetic stimulation

The invention provides a retaining cap used for acquiring brain signals in photoelectric combined mode and applied to transcranial magnetic stimulation. The retaining cap comprises a flexible net-shaped retaining cap body composed of flexible net belts and capable of covering the scalp, vertically-through penetrating holes are formed in all nodes of the flexible net-shaped retaining cap body respectively, a brain electricity electrode hollow sleeve and a near infrared probe hollow sleeve can be rotationally inserted into the penetrating holes, a brain electricity electrode is placed in the brain electricity electrode hollow sleeve, and a near infrared probe is placed in the brain electricity electrode hollow sleeve. The brain electricity electrode and the near infrared probe are distributed in the flexible net-shaped retaining cap body in the mode that the portions, along the two ends of a flexible net belt on a meridian, of each brain electricity electrode is each provided with one near infrared probe at equal intervals, one of the two near infrared probes at the two ends of each brain electricity electrode is a near infrared probe for emitting infrared rays, and the other of the two near infrared probes is a near infrared probe for receiving the infrared rays. Scalp pulling-out is convenient, the height of the retaining cap is reduced, and the acquisition quality of near infrared signals is improved. The retaining cap can be effectively applied to transcranial magnetic stimulation research.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

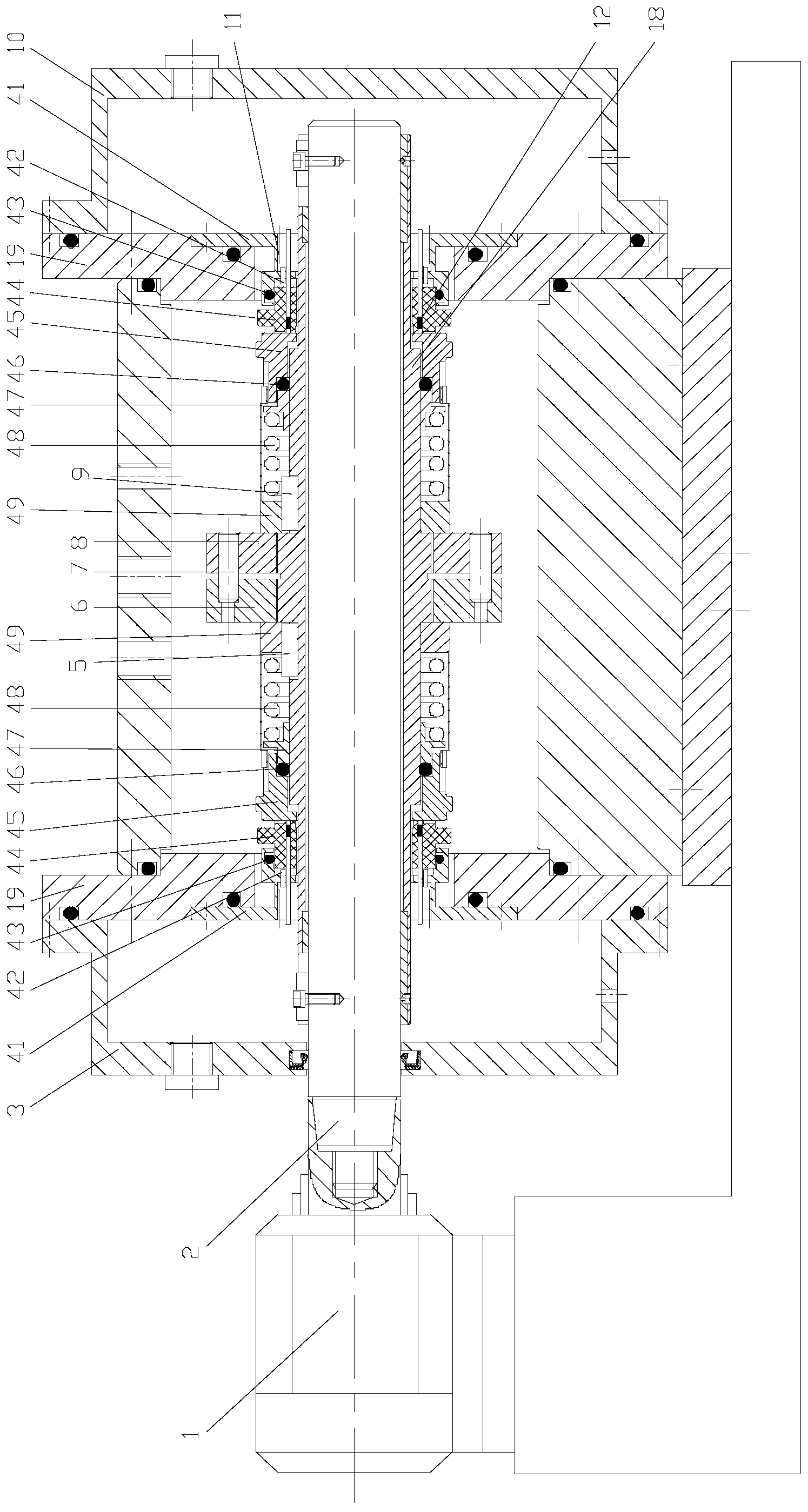

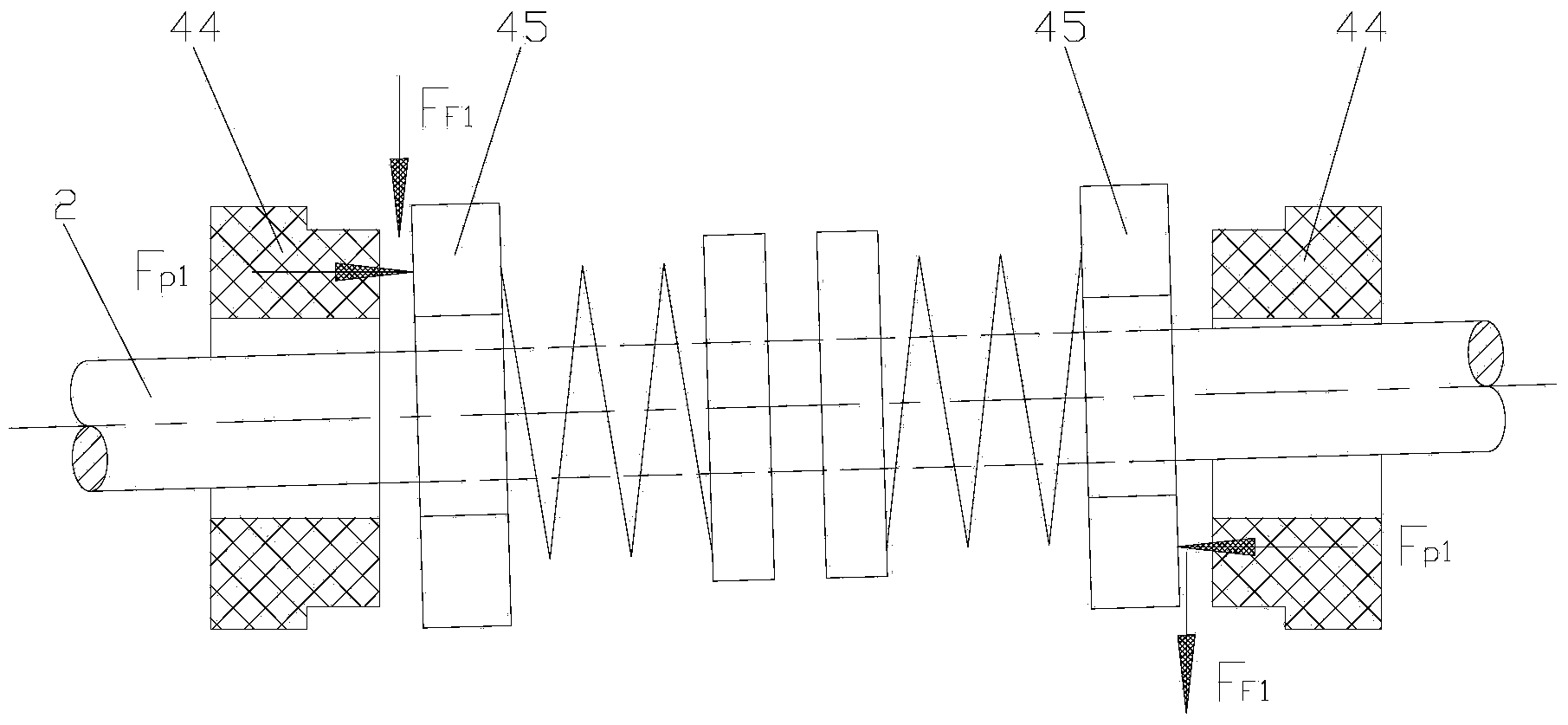

Mechanical sealing property testing device and method for measuring axial force and temperature of sealed end surfaces

ActiveCN104330223AAvoid destructionSimple structureApparatus for force/torque/work measurementPyrometry using electric radation detectorsEngineeringAxial force

The invention discloses a mechanical sealing property testing device. An electric main shaft is connected with a single cantilever working main shaft; floating support of the single cantilever working main shaft is achieved by virtue of the geometric pressure compressing function of a moving ring end surface and a static ring end surface; the edge end of a force measurement sleeve is of a flange structure; an axial force strain piece is arranged on the force measurement sleeve; a shaft sleeve sleeves the single cantilever working main shaft and penetrates through end covers at the left end and right end of a sealing cavity; the shaft sleeve is slidably connected with the single cantilever working main shaft in a sliding manner in the axial direction and in a positioning manner by using an embedding block in the circumferential direction; two sections of threads of which the screw pitches are equal and the spiral lines are in opposite directions are formed in the shaft sleeve; the threads are respectively screwed with a left screw nut and a right screw nut; the back sides of two push rings respectively contact two moving ring bases; the moving ring bases are connected with the shaft sleeve in an sliding manner in the axial direction and in a positioning manner in the circumferential direction; a through hole which is communicated with a sealed end surface is formed inside a static ring; an infrared probe is arranged inside the through hole. Due to the structural design, measurement on property parameters such as large diameter and high rotation speed of mechanical sealing, particularly the measurement on the axial force and the temperature between sealed end surfaces can be achieved.

Owner:NANJING FORESTRY UNIV

Online real-time detection device for thickness of amorphous alloy strip

ActiveCN103398661AImprove test accuracyUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansLaser probeAlloy

The invention discloses an online real-time detection device for the thickness of an amorphous alloy strip. The device comprises a detector, a signal receiving device and a data analysis module, wherein the detector comprises a plurality of detection probes; each detection probe is used for independently detecting a distance between the detection probe and a corresponding point on the surface of a detected object, and feeding back distance data to the signal receiving device; the signal receiving device is used for transmitting the distance data to the data analysis module after receiving the distance data transmitted by each detection probe; the detected object comprises an amorphous alloy strip and a copper roller, which are attached to each other; the data analysis module is used for storing the received data, and analyzing the received data to obtain the single-point thickness, the average thickness, the thickness deviation of different transverse positions and the thickness deviation of different longitudinal positions of the amorphous alloy strip; and the detection probes are laser probes, infrared probes, ultrasonic probes or electromagnetic displacement probes. The online real-time detection device for the thickness of the amorphous alloy strip can be used for multi-point online real-time detection, so that the test accuracy is greatly improved.

Owner:NINGBO ZHONGKE BIPULASI NEW MATERIAL TECH CO LTD

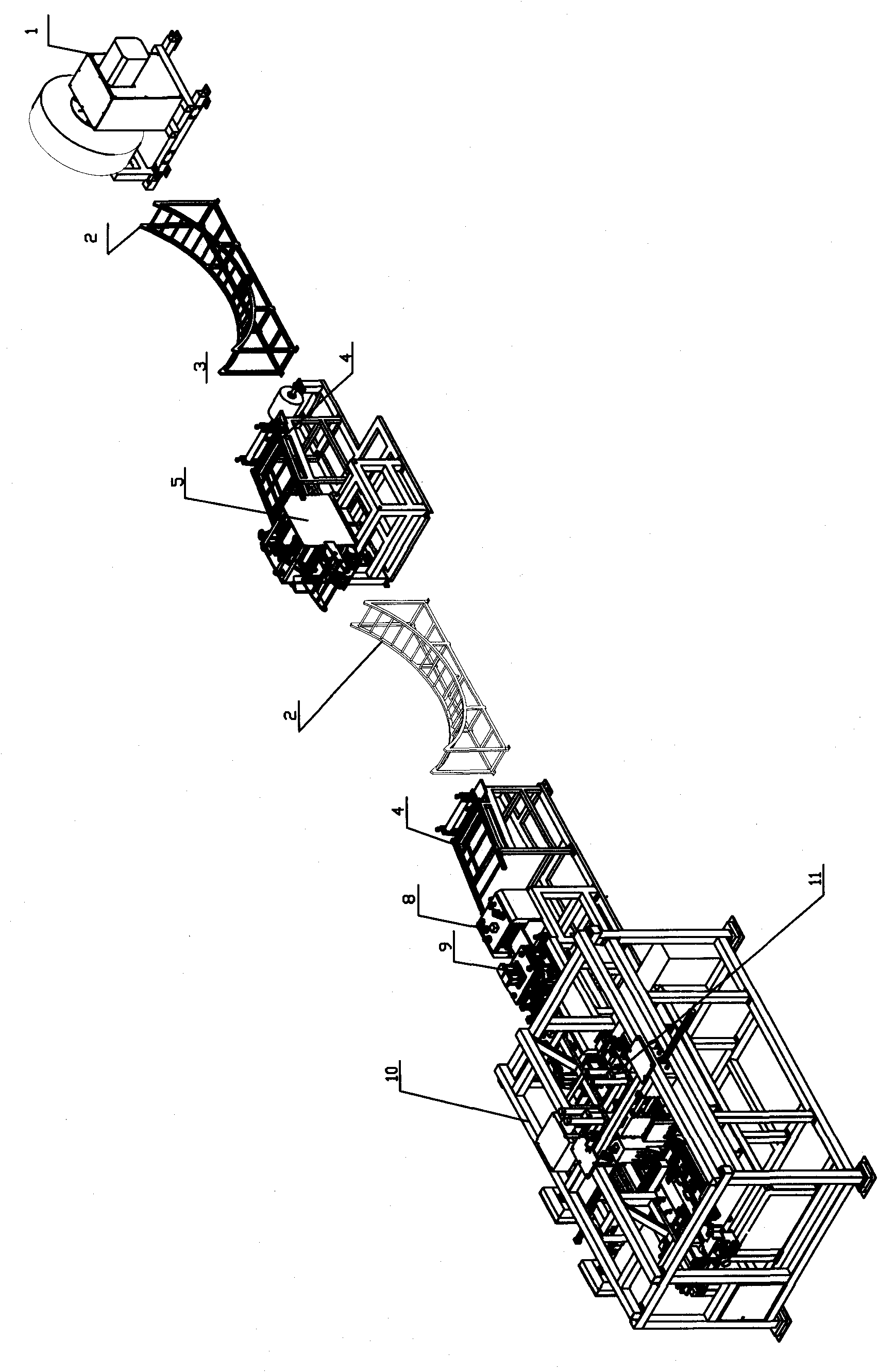

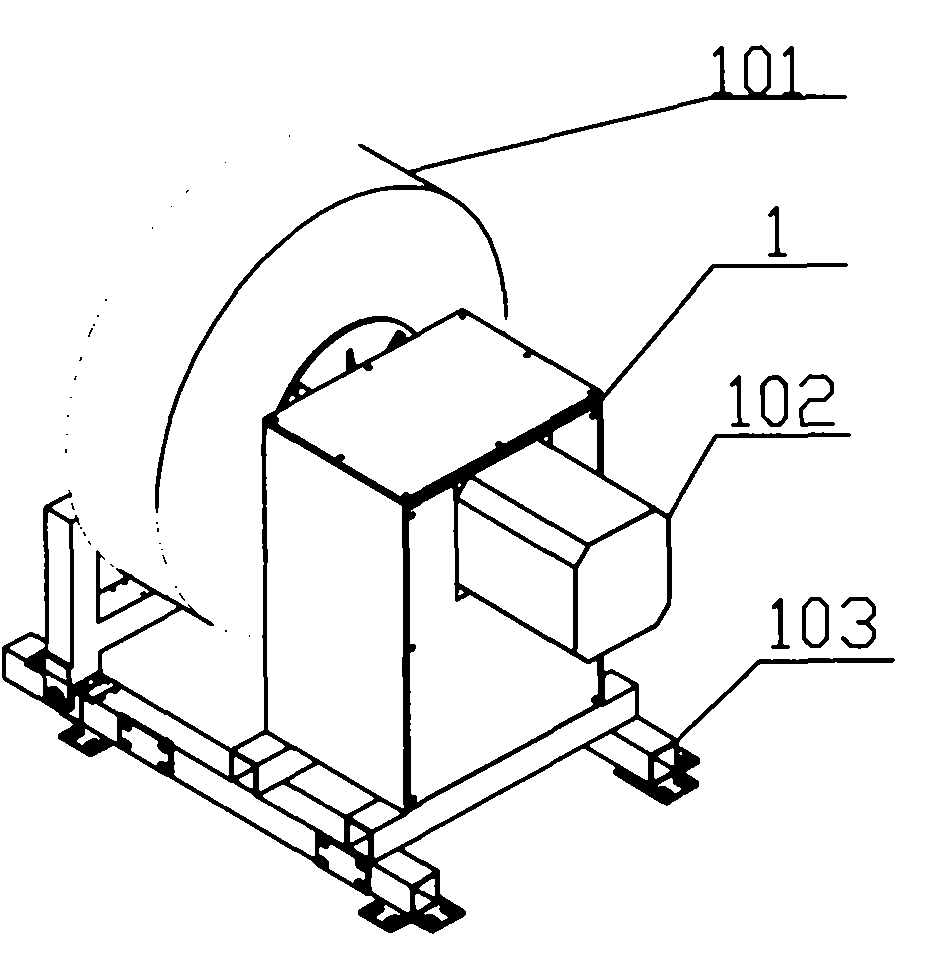

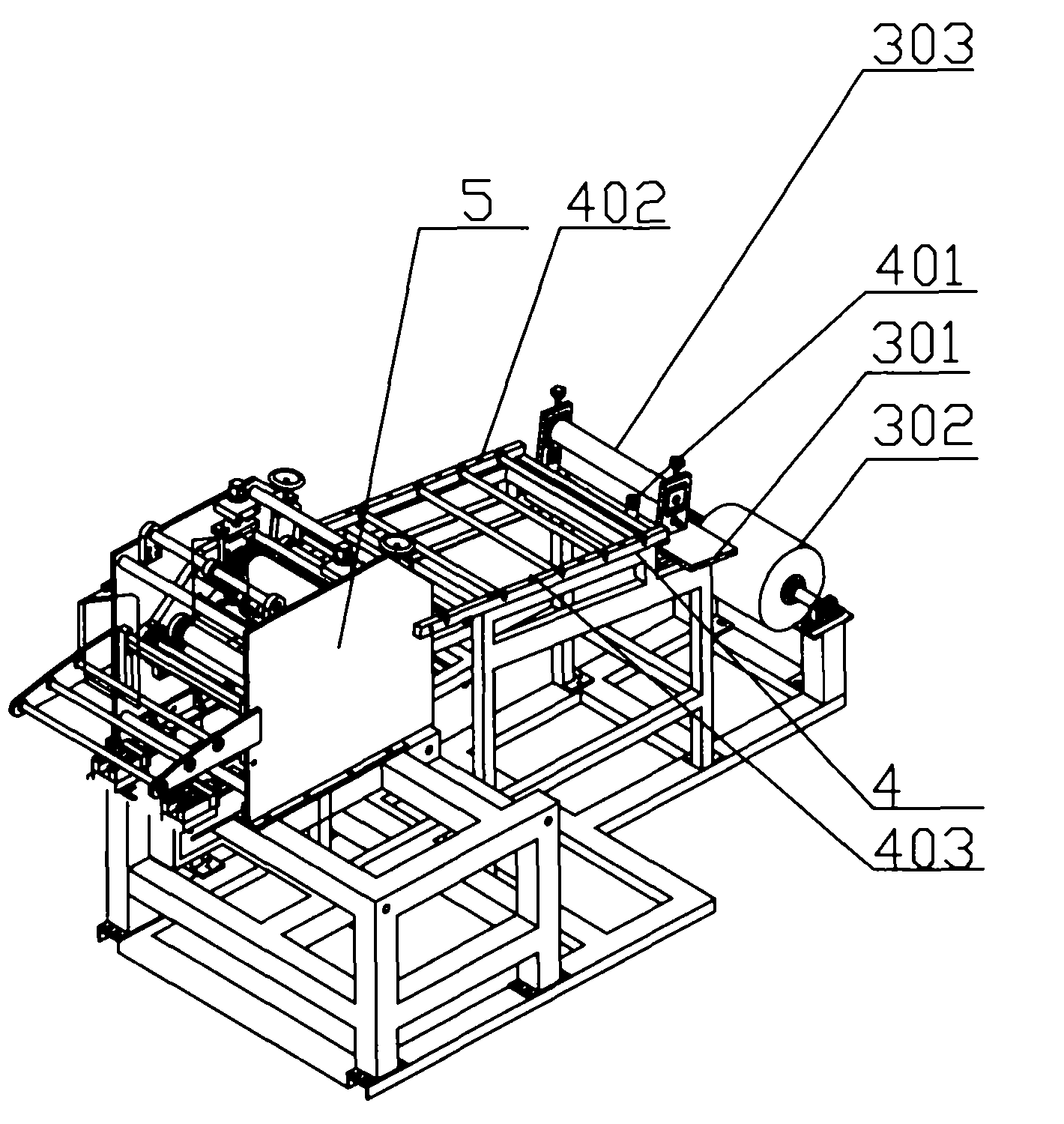

Automatic production line for shells of electrical appliances

InactiveCN102152127AIncrease productivityMeticulous division of laborShaping toolsOther manufacturing equipments/toolsProduction linePunching

The invention discloses an automatic production line for shells of electrical appliances, which comprises a cradle, an edge trimmer, a leveling area, a punching die, a cut-off die, a forming area, and the like. The automatic production line is characterized in that the cradle is composed of a support and a supporting shaft arranged on the support; a position correcting device is composed of a position correcting platform and two sets of infrared probes respectively arranged at the two sides of the position correcting platform; the leveling area is a box body and composed of over two sets of rollers; and a pressing device is tightly connected with the leveling area, a punching area is composed of the punching die and the cut-off die, a sucking disc frame is a rectangular and retractable, the bottom of the retractable sucking disc frame is provided with a sucking disc, and a bending device is composed of a transverse bending bench and a longitudinal bending bench. The automatic production line disclosed by the invention has the advantages that because a full-automatic production process is adopted, the production efficiency is improved; and because the division of labor is detailed, the manual operation process is reduced, and the production quality is enhanced.

Owner:冯炎好

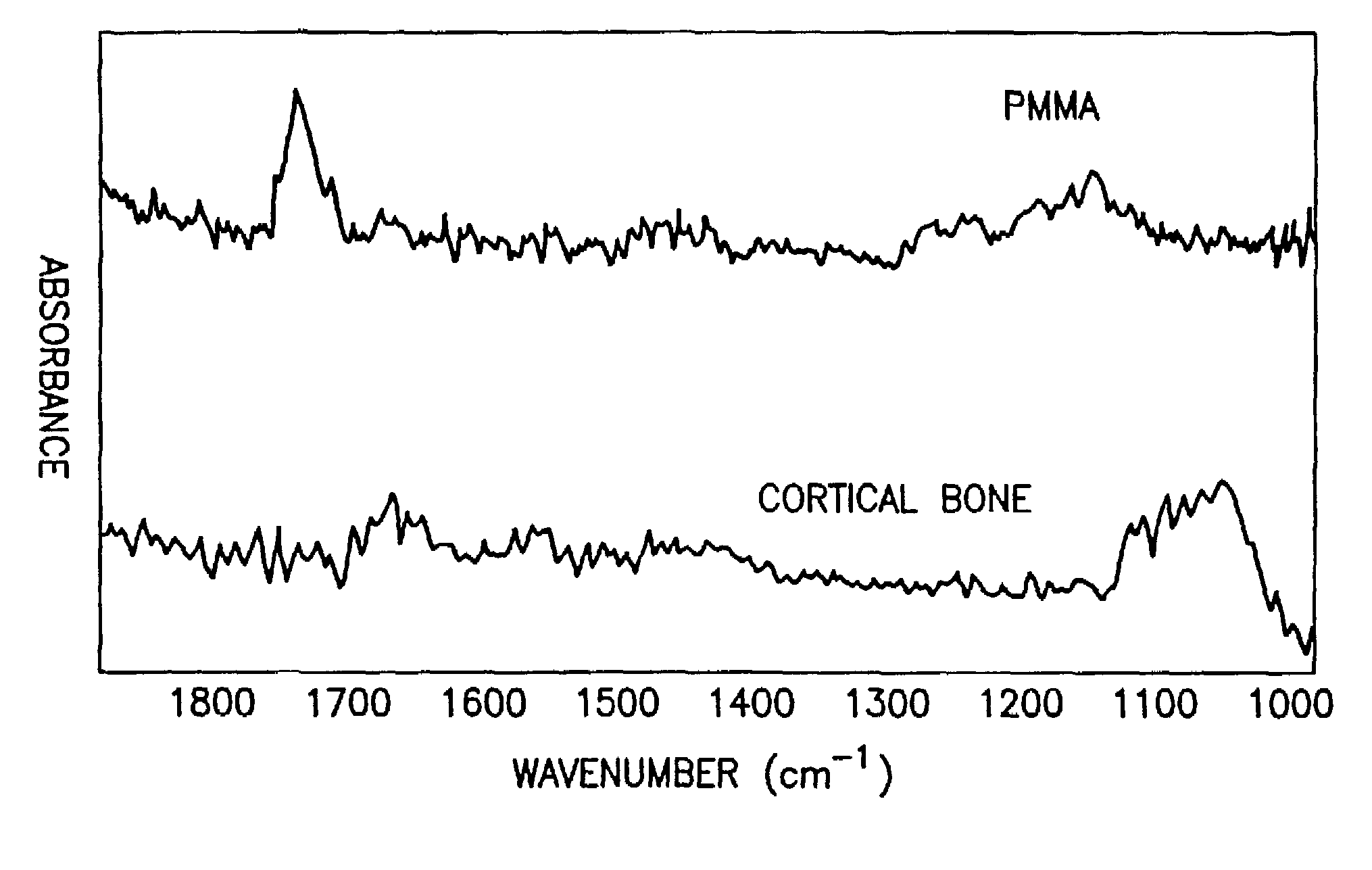

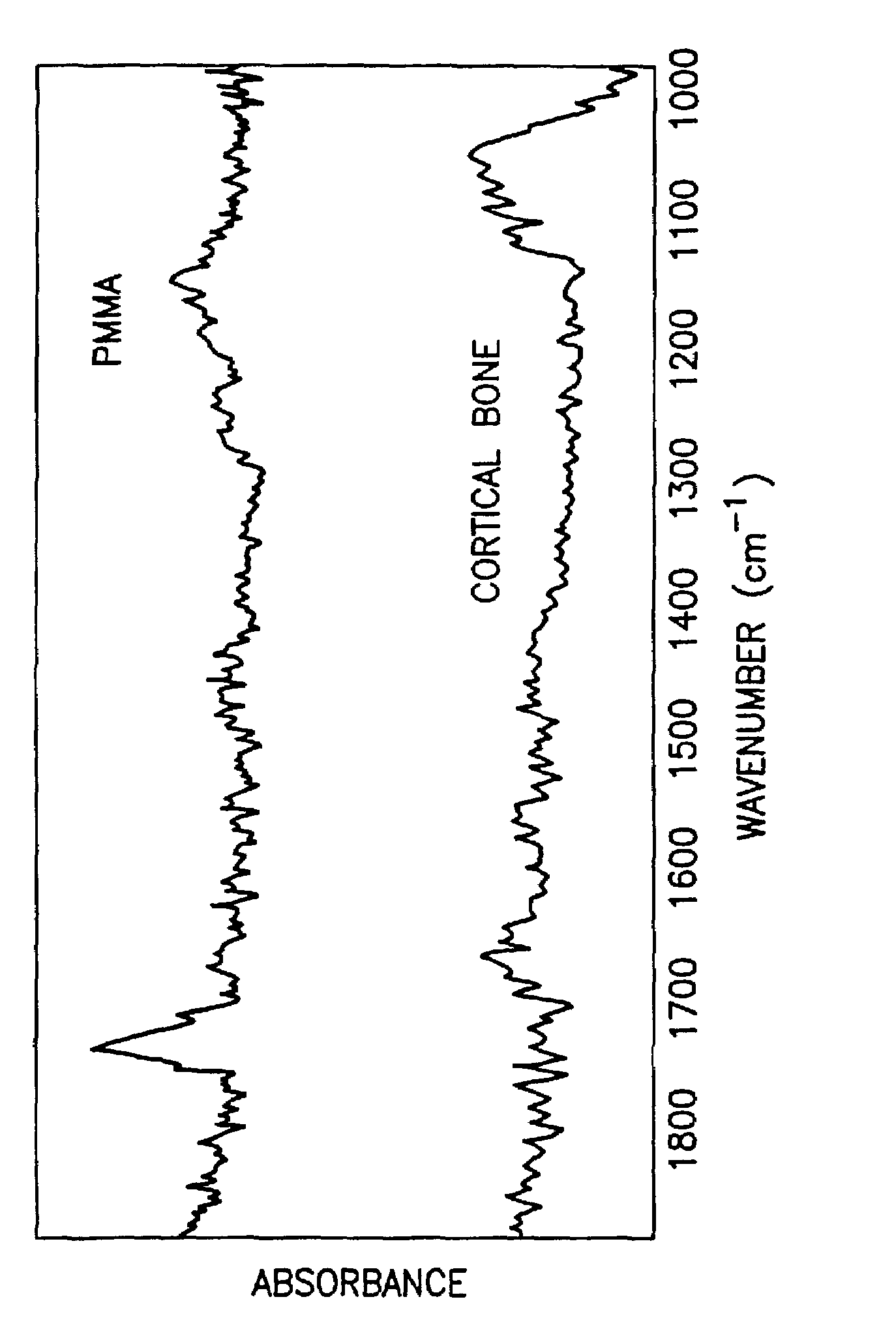

Utilization of an infrared probe to discriminate between materials

A method of evaluating the surface of a material that has a distinguishable infrared spectrum comprising (a) positioning an infrared fiber optic probe to be in contact with a surface of the sample or material at a region of interest for detecting attenuated total reflectance or within a sufficient distance from the surface of the region for detecting reflection, (b) detecting mid- or near-infrared radiation attenuated total reflectance or reflection off of the surface of the sample or the material, (c) analyzing the infrared radiation from step (b) for at least one of peak height, peak area, frequency and chemometric parameters, and (d) actuating the removal device when a signal from the infrared fiber optic probe is between pre-selected values for at least one of peak height, peak area, frequency and chemometric parameters for the sample of the material.

Owner:HOSPITAL FOR SPECIAL SURGERY

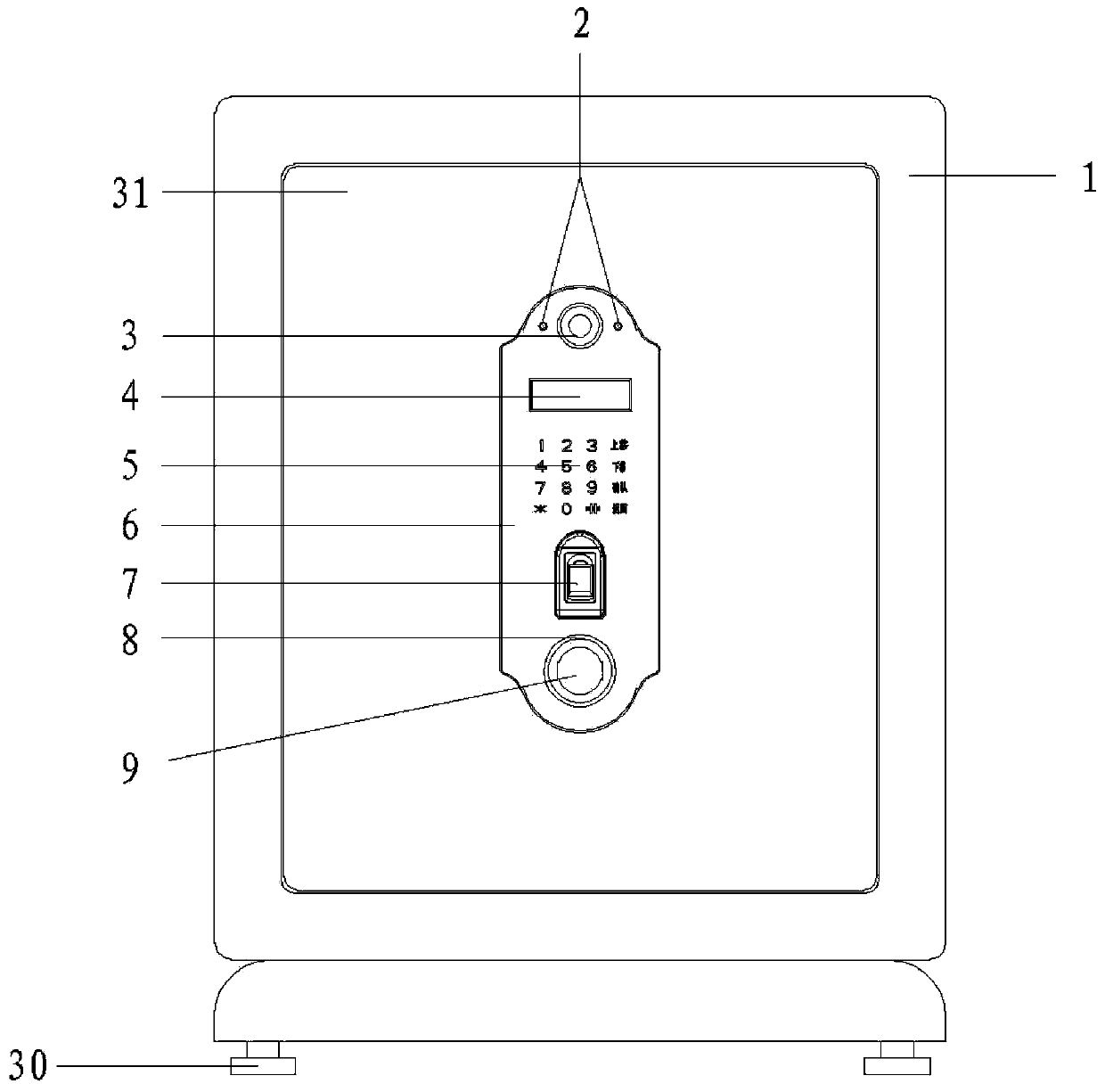

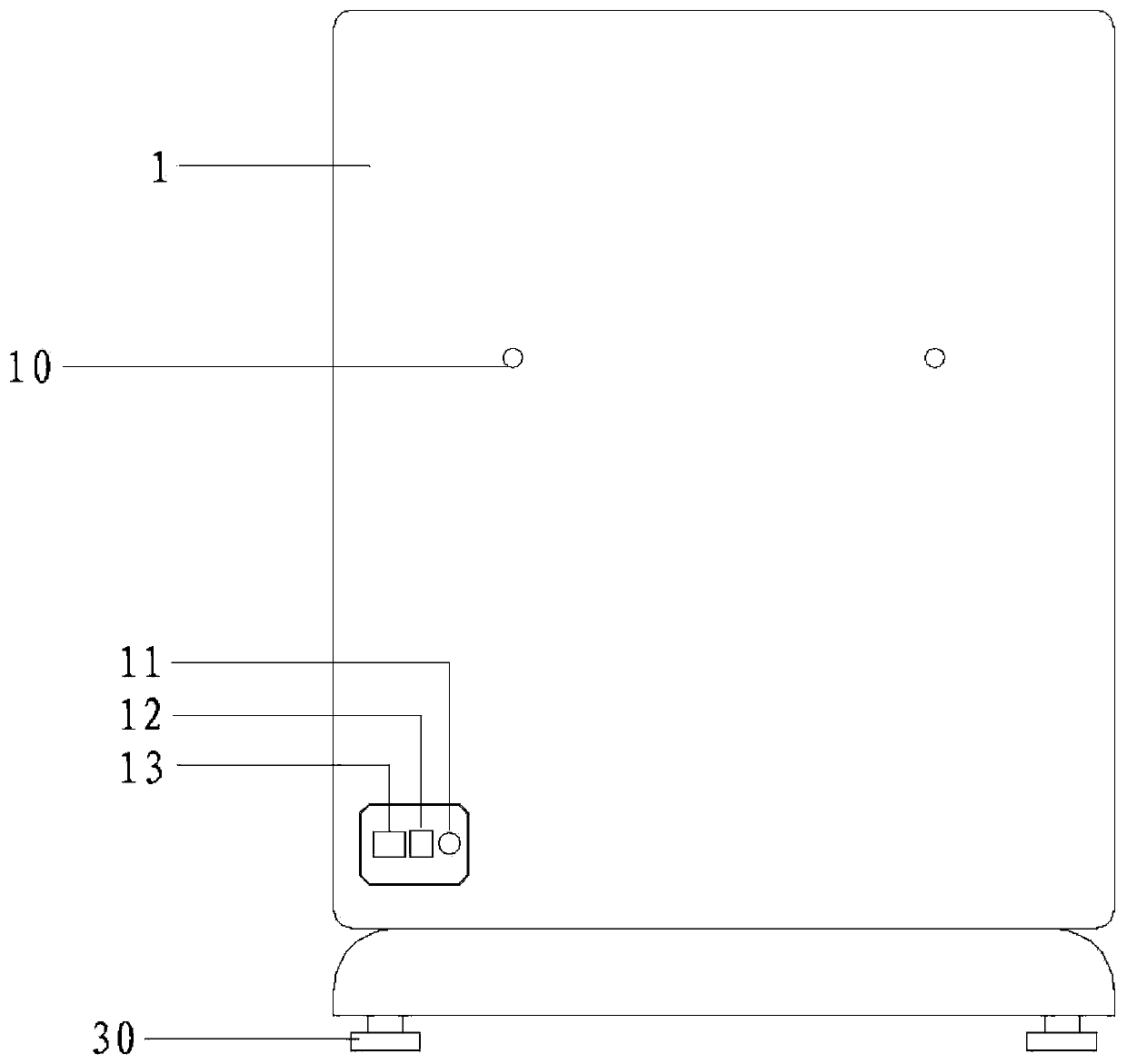

Intelligent safety control system

The invention discloses an intelligent safety control system which comprises a fingerprint password cabinet and a sensing detector. The fingerprint password cabinet comprises a cabinet body, a cabinet door, a panel and a fingerprint collection instrument. A power socket and a network socket are arranged on the back face of the cabinet body, wired / wireless network cards are arranged in the cabinet body, a main control panel and a motor are arranged in the cabinet door, the main control board is connected with the motor, the network socket is connected with the wired / wireless network cards, a wireless module and a fingerprint module are integrated on the panel, the sensing detector is one or any number of a WIFI network camera, a door magnetic probe, a window magnetic probe, a smoke probe, a fuel gas probe, an infrared probe, an emergency help-calling button and a door and window shock displacement wireless detector, and the sensing detector and the wireless module transmit information in a wireless mode. According to the intelligent safety control system, fingerprint passwords, smoke alarming, fuel gas alarming, onsite video recording, remote monitoring, household theft prevention and other technologies are integrated, and the integrated intelligent safety control system is formed.

Owner:LANYANG SCI & TECH ELECTRONICS JIAXING CITY

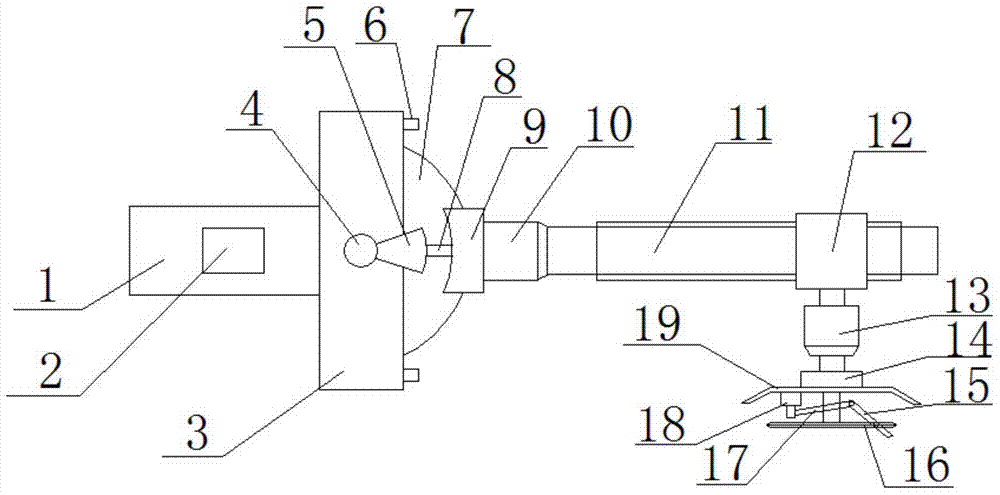

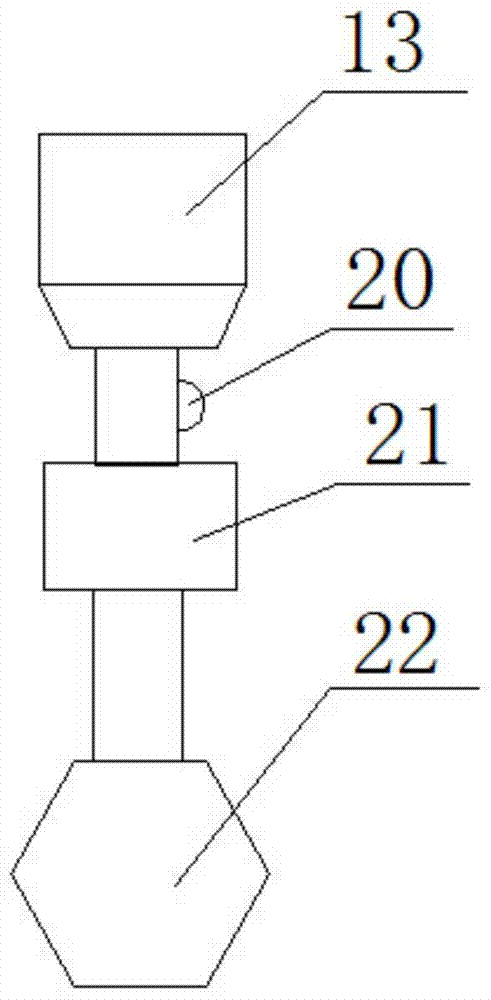

Rotatable telescoping multifunctional trimmer

The invention discloses a rotatable telescoping multifunctional trimmer which comprises a handle, a controller, a supporting base, a telescoping device and a trimming device. The supporting base is provided with an arc sliding rail and infrared probes. The arc sliding rail is connected with a rotating mechanism in a sliding mode. The rotating mechanism comprises a first rotating motor, a rotating block and a sliding block. The first rotating motor is connected with the rotating block, the rotating block is fixedly connected with the sliding block through a locating pin, and the sliding block is connected to the arc sliding rail in a sliding mode. The telescoping device comprises a second rotating motor, a ball screw and a ball screw nut. The second rotating motor is connected with the ball screw. The trimming device is formed by sequentially connecting a third rotating motor, a protective device, a baffle and a trimming cutting head. The third rotating motor is movably connected to the ball screw through the ball screw nut. The multifunctional trimmer is rotatable and telescoping, branches in different spaces in the transverse direction and the longitudinal direction can be trimmed, both the branches and lawns can be trimmed, one machine can achieve multiple purposes, and the multifunctional trimmer is quite efficient and practical.

Owner:毛守玠

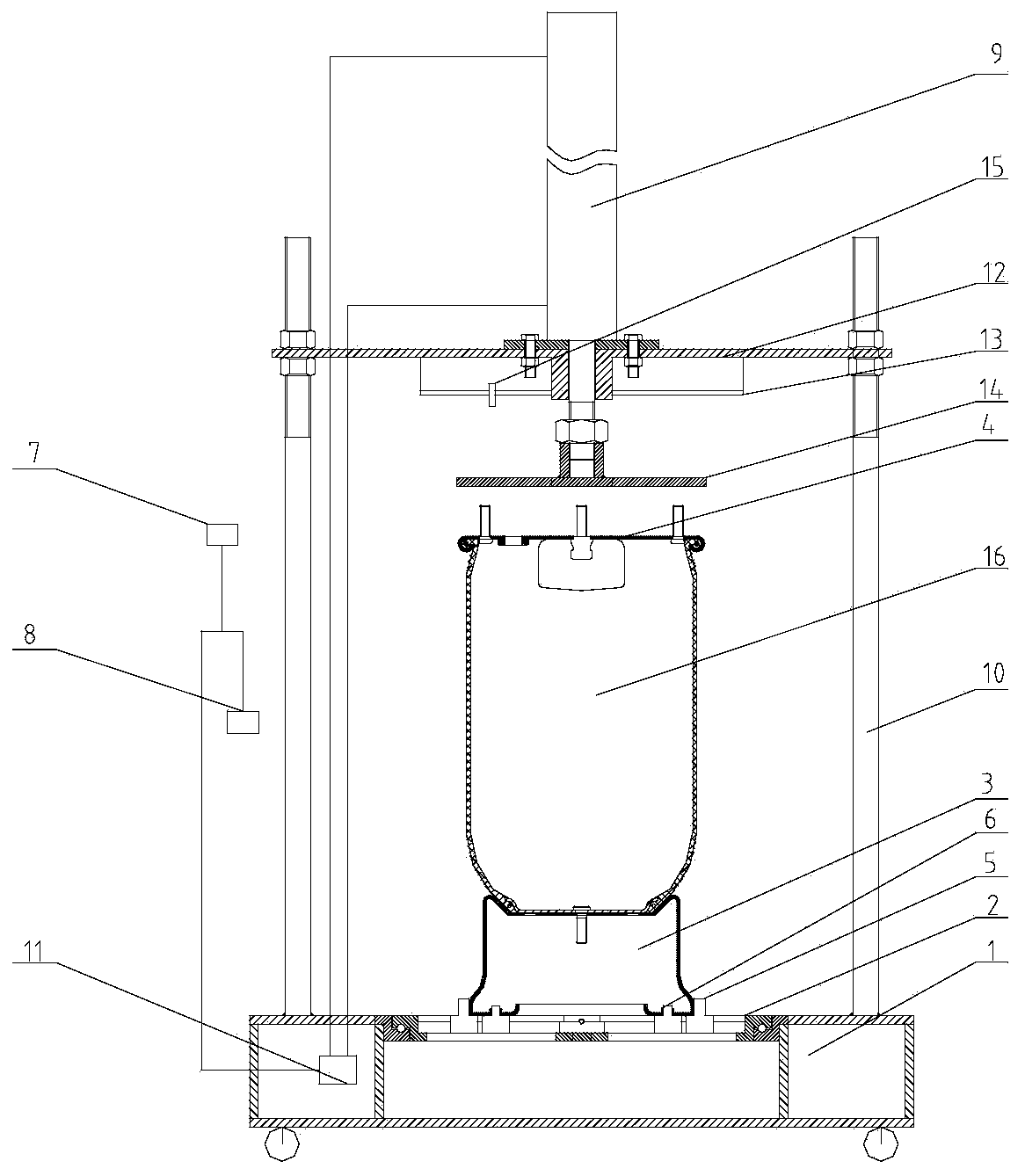

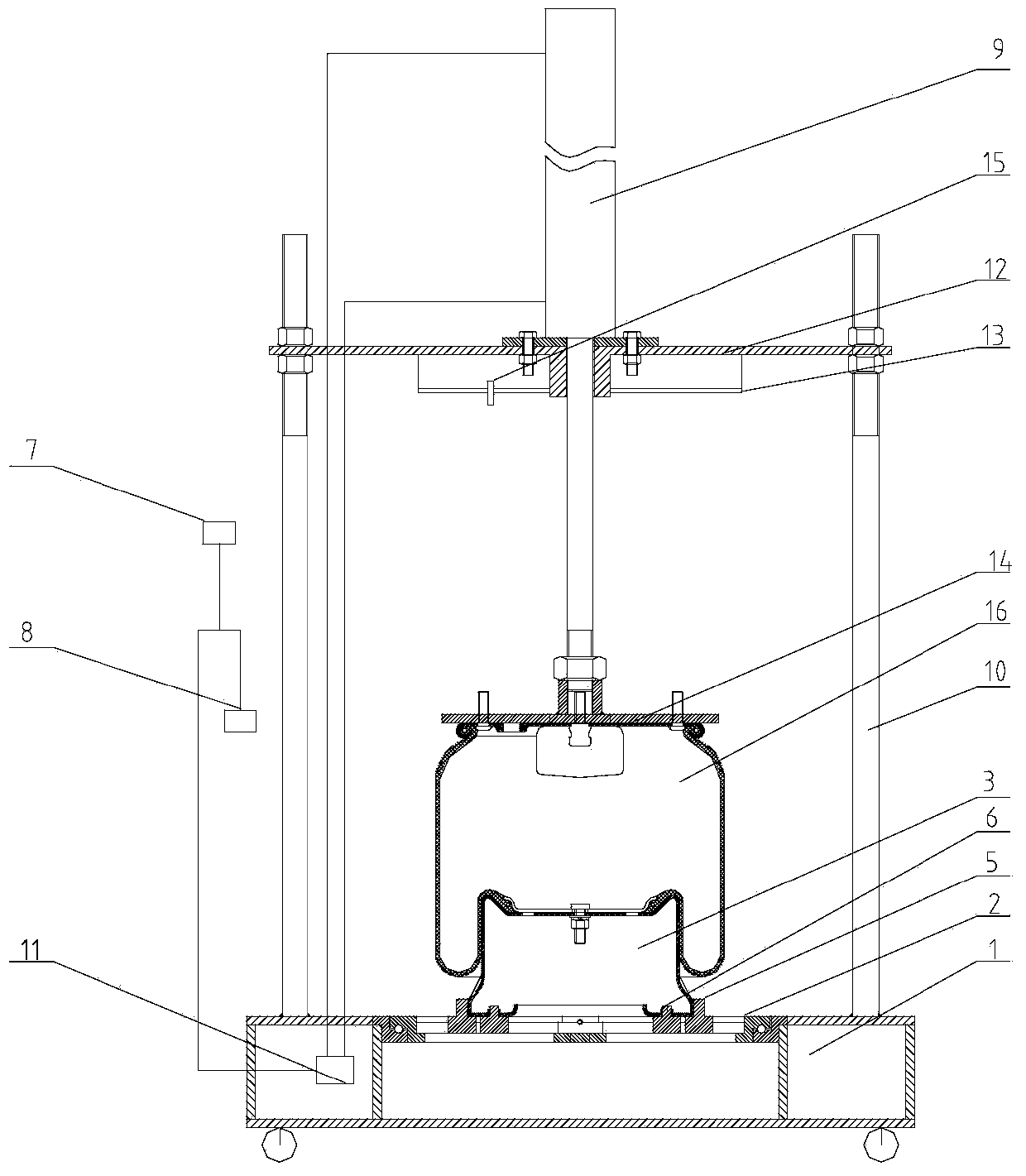

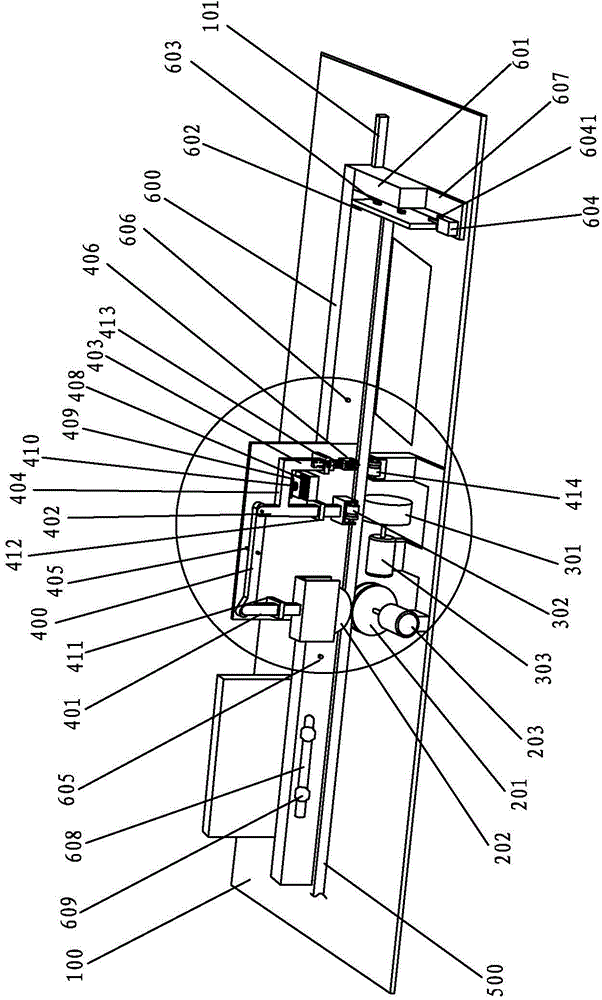

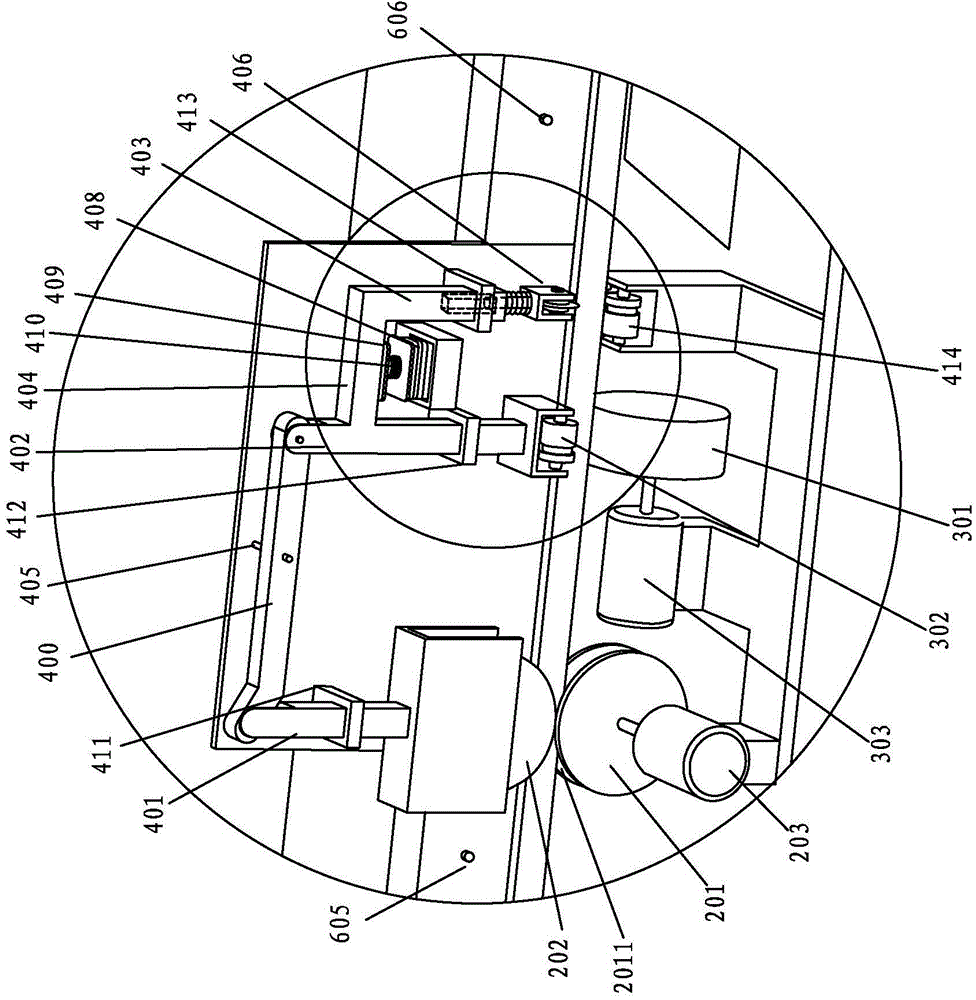

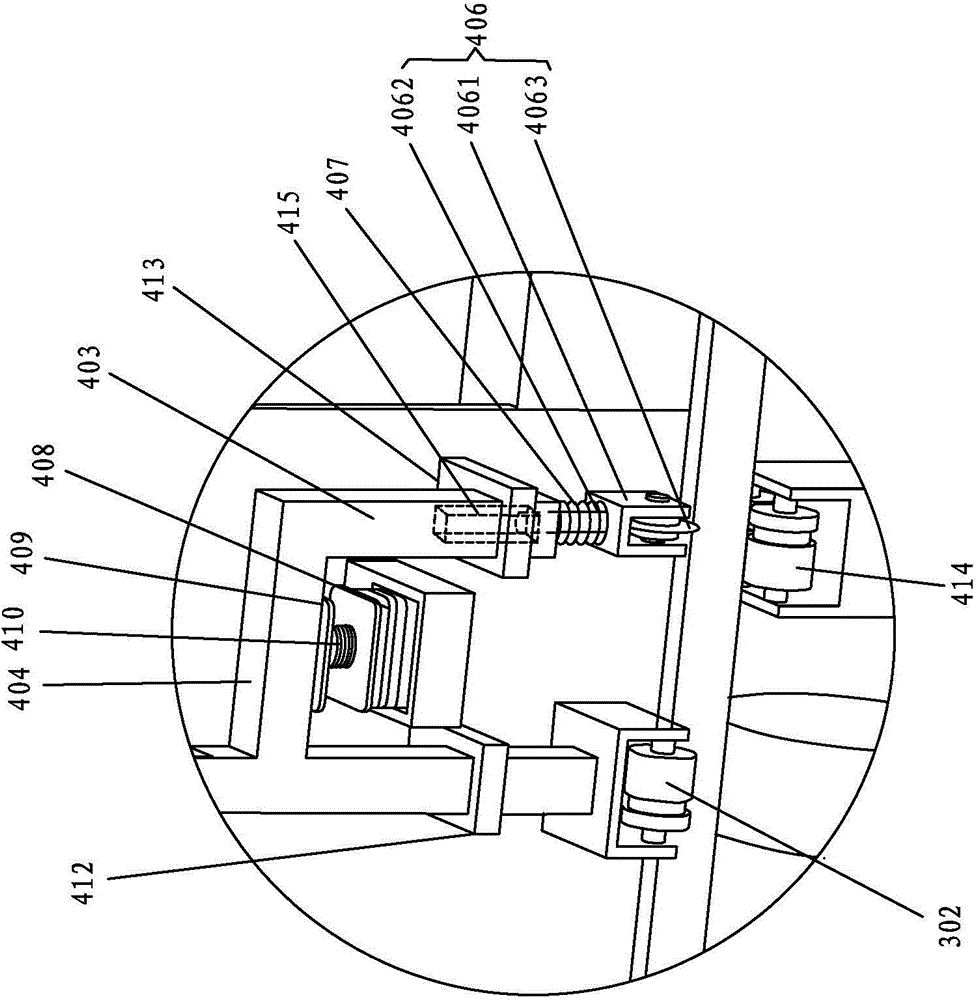

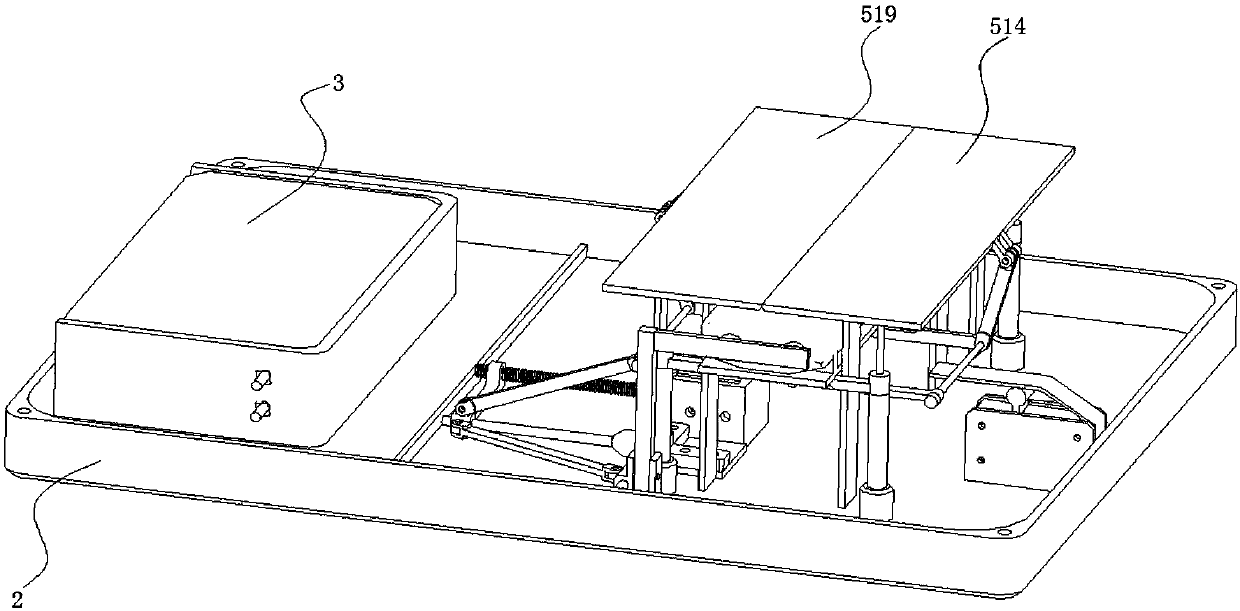

Press fitting device and press fitting method for air spring piston

ActiveCN103802065AHigh precisionPrecise positioningMetal working apparatusMetal-working hand toolsAir springEngineering

The invention relates to an air spring press fitting device, in particular to a press fitting device and method for an air spring piston in the production process of air springs. The press fitting device is mainly composed of a machine platform, a support, a rotary disc, a drive device and a pressure head, wherein the rotary disc is provided with a cross sliding groove, and a fixing sliding block and a locating sliding block which can slide freely are installed on the sliding groove. The air spring piston is placed on the rotary disc, the position of the sliding block is well adjusted, a rubber bag and upper cover assembly of an air spring is placed on the piston, an infrared probe is adjusted well, it is guaranteed that the size counterpoint relation between an upper cover of the air spring and a connector of the piston is accurate, the air spring is inflated through an air gun, and the edge curling operation of a rubber bag is completed. The press fitting device and press fitting method for the air spring piston have the advantages that only one air source is required, press fitting equipment is simplified, press fitting accuracy is improved, the press fitting method is simple and saves time and labor, and the press fitting operation accuracy is largely improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Infrared gas transducer and infrared gas inspection device

ActiveCN101504365AFully absorbedIncrease the optical path lengthColor/spectral properties measurementsPath lengthTransducer

The invention is suitable for the technical field of detection, and provides an infrared gas sensor and an infrared gas detection device. The infrared gas sensor comprises a shell; the inside of the shell is also provided with a sensor shell; the inside of a cavity of the sensor shell is provided with an upper cover body and a lower cover body; the bottom of the upper cover body is provided with a groove; the side wall of the groove at least comprises a first inclined surface and a second inclined surface; the top of the lower cover body is provided with a first opening and a second opening which can correspond to the first inclined surface and the second inclined surface on the groove; and an infrared light source and an infrared probe are arranged in the first opening and the second opening respectively. In the invention, the infrared light emitted by the infrared light source is reflected for many times and then is absorbed by the infrared probe; and the infrared gas sensor increases the light path length of the infrared light and ensures that gas to be tested fully absorbs the infrared light, thereby improving the detection signal-to-noise ratio and measurement accuracy of the infrared gas sensor.

Owner:SHENZHEN EXSAF ELECTRONICS CO LTD

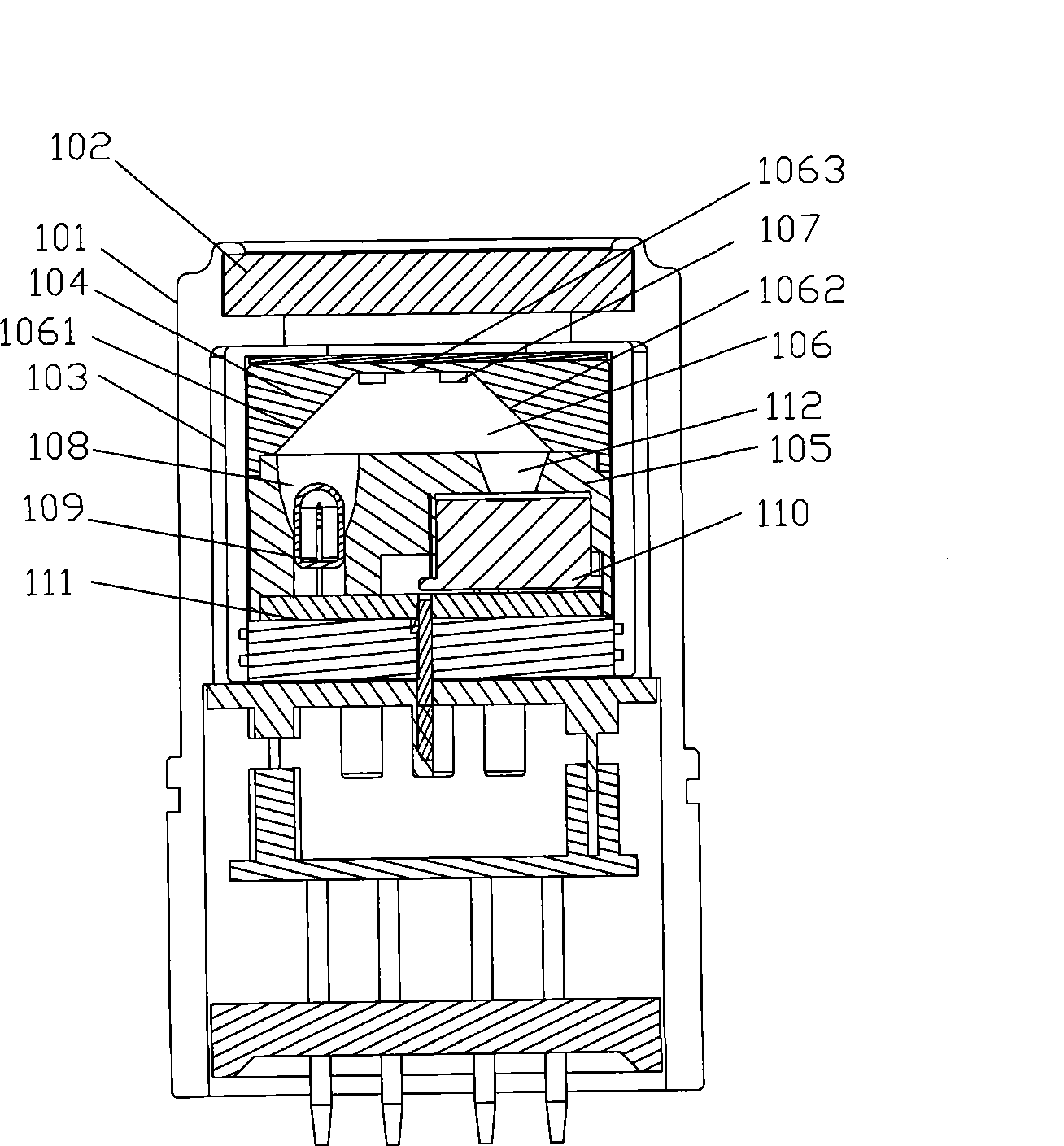

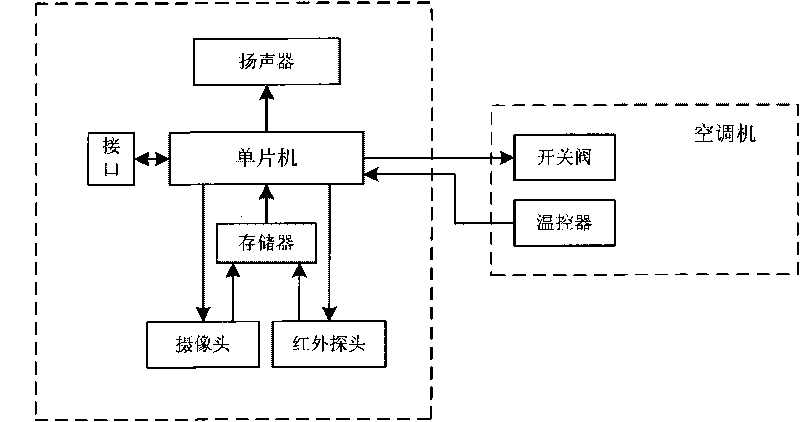

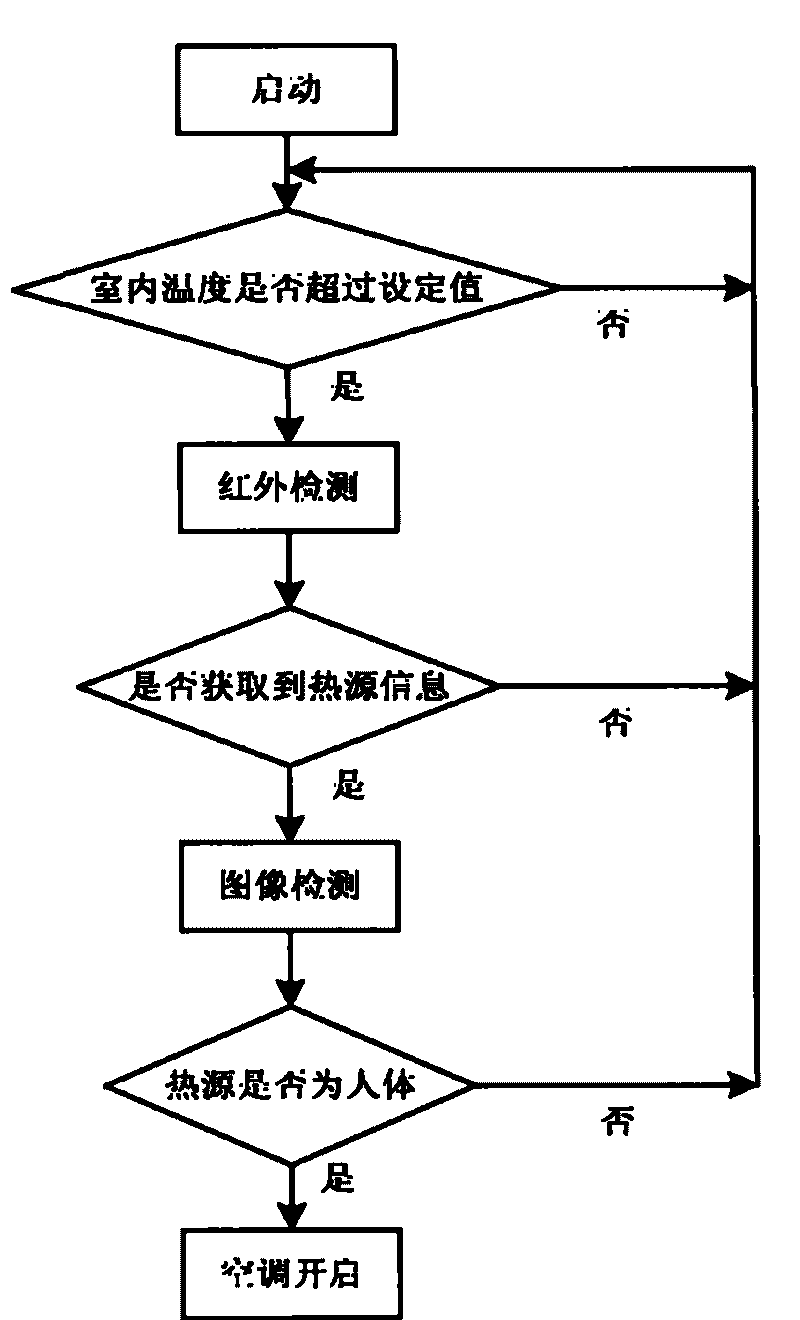

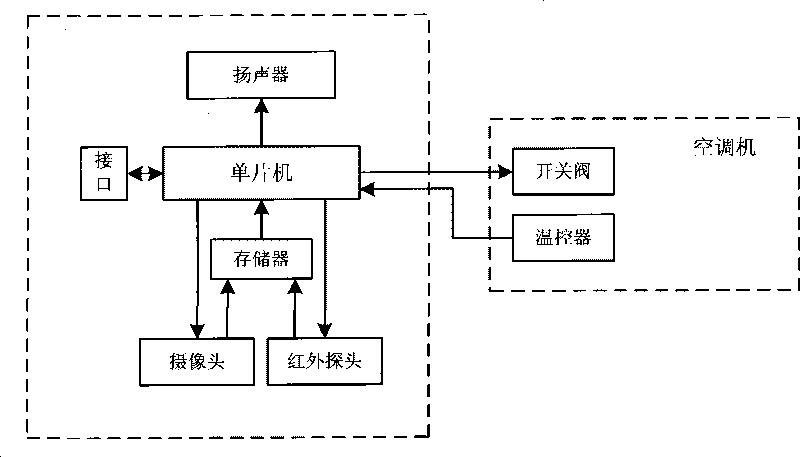

Infrared detection and image processing-based feedback control system

InactiveCN101737904AReduce wasteRealize voice alarmRadiation pyrometrySpace heating and ventilation safety systemsImaging processingControl system

The invention discloses an infrared detection and image processing-based feedback control system, and belongs to the field of intelligent control of electric appliances. The system comprises a singlechip, a camera, an infrared probe, a loudspeaker and interfaces, wherein the singlechip is respectively connected with the camera, the infrared probe and the interfaces bilaterally; the output end of the single chip is connected with the input end of the loudspeaker; a storage device can be added to the system for expanding memory; and the system is connected between a temperature controller and a switching valve of an air conditioner when in use. The infrared detection and image processing-based feedback control system is an externally added device, is used for detecting the existence of a human body and the closing situation of a window without influencing normal use of the air conditioner or redesigning the structure of the air conditioner, can make an alarm prompt sound, and has the characteristics of simple structure, low cost and good expansibility.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

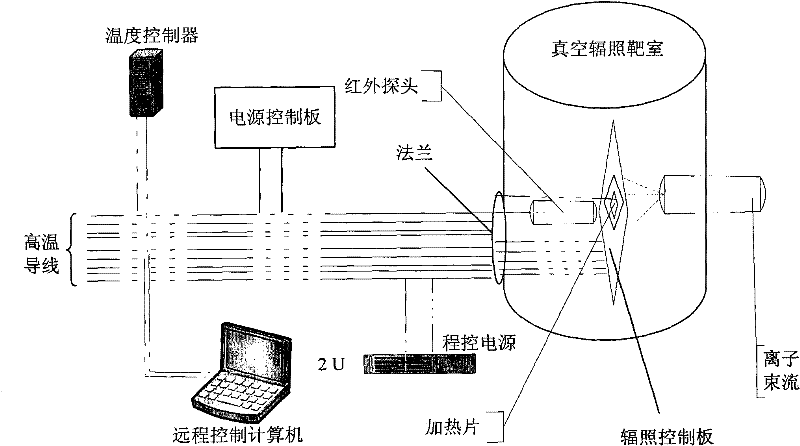

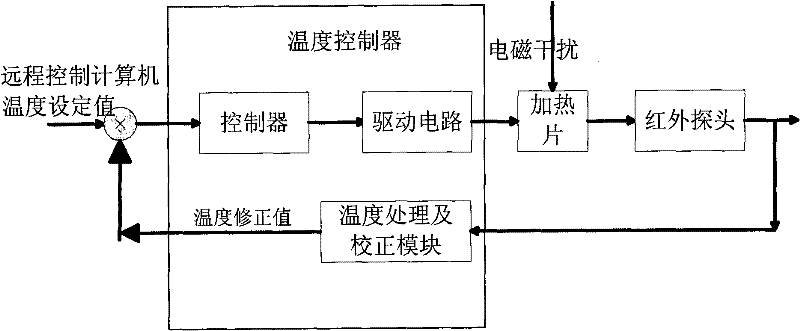

Temperature control system and method for performing single event effect test under same

InactiveCN102243502AAdapt to the needs of developmentIncreased flexibility of useTemperatue controlContactless circuit testingTemperature controlAnti jamming

The invention relates to a method for performing a single event effect test under the same. The temperature control system comprises a remote control computer, a temperature controller, a heating plate, an infrared probe and a high-temperature conducting wire, wherein the temperature controller is respectively connected with the infrared probe and the heating plate through the high-temperature conducting wire and is connected with the remote control computer, the remote control computer sends a temperature control instruction to the temperature controller, the temperature controller controls the heating of the heating plate according to the temperature control instruction, the infrared probe acquires the heating temperature value of the heating plate and feeds the heating temperature value back to the temperature controller, and the temperature controller modifies and regulates the heating temperature of the heating plate according to the fed-back heating temperature value so as to ensure that the heating temperature is identical to a preset temperature value. The temperature control system can be used for remote automatic calibration, has the advantages of accuracy and stability for measurement, strong anti-jamming capability, high reliability, self-protection capability and strong compatibility, and can meet the requirements of the single event effect test under different temperatures.

Owner:BEIJING MXTRONICS CORP +1

Channel security early-warning system and channel early-warning method

The invention discloses a channel security early-warning system comprising a channel security early-warning instrument, a multimedia early-warning terminal and a background monitoring host, wherein the channel security early-warning instrument is intelligent equipment, is used for acquiring videos and audios of a channel and human body infrared information, can automatically send intervention voices to the field and send warning signals to the background monitoring host if the channel security early-warning instrument performs calculation, analysis, study and judgment to find that the videos, audios and human body infrared information reach early-warning threshold values, and can also send data (such as images and sound) of real-time situations of the field to the background monitoring host. According to the channel security early-warning system disclosed by the invention, monitoring areas are subjected to three-factor information monitoring by virtue of infrared probes, cameras and microphones, people can be guided to pass or evacuate orderly by virtue of intervention, and thus the problems of disorder and stampede caused under the condition that people are not commanded in the prior art can be solved. The invention also provides a channel early-warning method, and according to the method, three signal acquisition modes are adopted, and calculation and analysis are performed in field equipment so as to ensure that the early-warning reliability and timeliness can be improved to a great extent.

Owner:YUNNAN ZHITU XUETAI TECH

Rapid tube cutter

The invention belongs to the field of tube cutting equipment, and particularly relates to a rapid tube cutter. The rapid tube cutter comprises a rack, a tube conveying mechanism, a tube clamping synchronous rotation mechanism, a cutter rest, a control system, a linkage rod, a hinge shaft, a first support arm, a second support arm, a third support arm, an electromagnet, an attraction component, an adjustment arm, a limit plate, a stroke switch, a first elastic component, a second elastic component, a third elastic component, a first infrared probe and a second infrared probe. With the adoption of the technical scheme of the invention, the cutting length of a tube is determined by presetting the distance between the limit plate and a blade assembly, thus reducing the errors due to visual assessment; meanwhile, the matching of a first motor, a second motor, the electromagnet and the stroke switch is realized by the control system, and automatic cutting for the tube can be realized only by placing the tube on a support wheel; compared with manual tube cutting, the rapid tube cutter disclosed by the invention is high in working efficiency; moreover, the tube cutter is compact in structure, relatively small in size, and convenient to move.

Owner:FUJIAN SPIRITFOG ENVIRONMENT SCI & TECH CO LTD

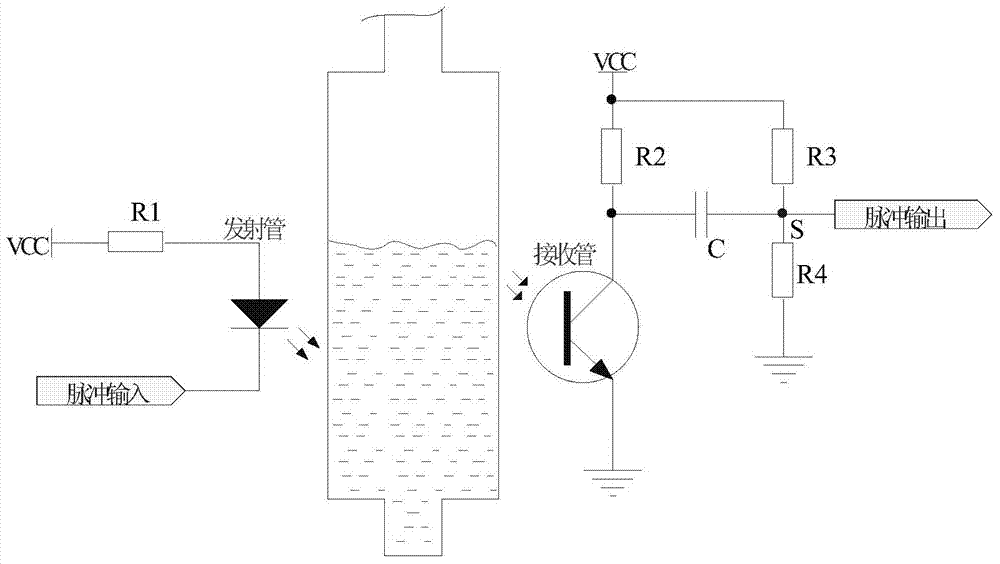

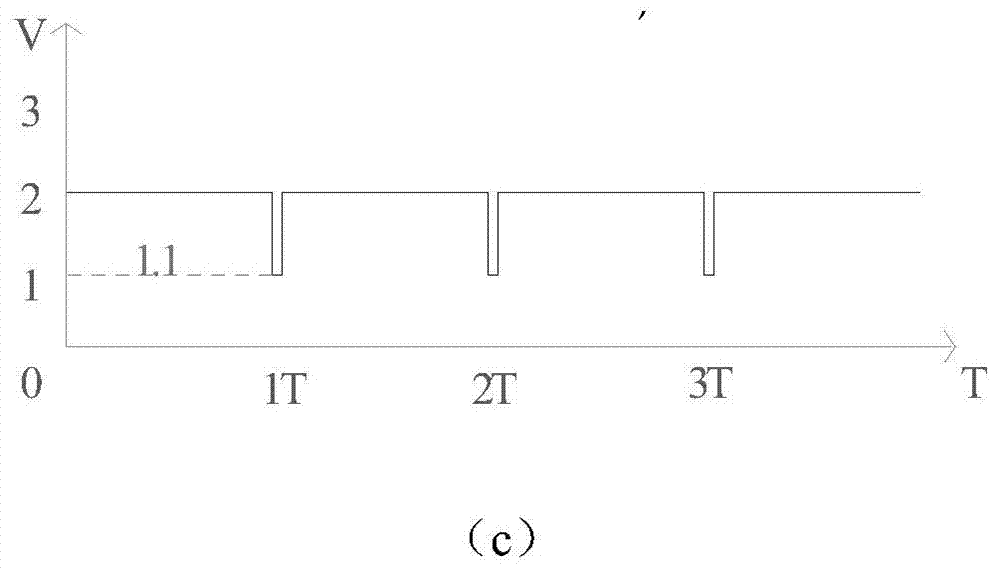

Device and method for detecting liquid level of infusion drip chamber

ActiveCN103520803AImprove anti-interference abilityReduce power consumptionFlow monitorsAverage filterAnti jamming

The invention discloses a device and a method for detecting the liquid level of an infusion drip chamber. The device comprises a fixed shell and a detection circuit unit arranged in the fixed shell, the fixed shell is sleeved on the infusion drip chamber, the detection circuit unit comprises an infrared transmitting tube and an infrared receiving tube, the infusion drip chamber is positioned between the infrared transmitting tube and the infrared receiving tube, an infrared probe irradiates the liquid level by the aid of the principle of rectilinear propagation and refraction of light, pulse signals are transmitted and received by a corresponding receiving device, analog signals received by a pulse receiving end are sampled, and the liquid level is detected according to the received analog signals, so that the method for detecting the liquid level is high in anti-jamming capability and low in power consumption. By the aid of an error comparing and average filtering algorithm, sampling accuracy is improved, and liquid level fluctuation caused by man-made or other factors can be effectively filtered, so that the method for detecting the liquid level is high in accuracy rate and can remove liquid level fluctuation and the like.

Owner:中电湘江数据服务有限公司

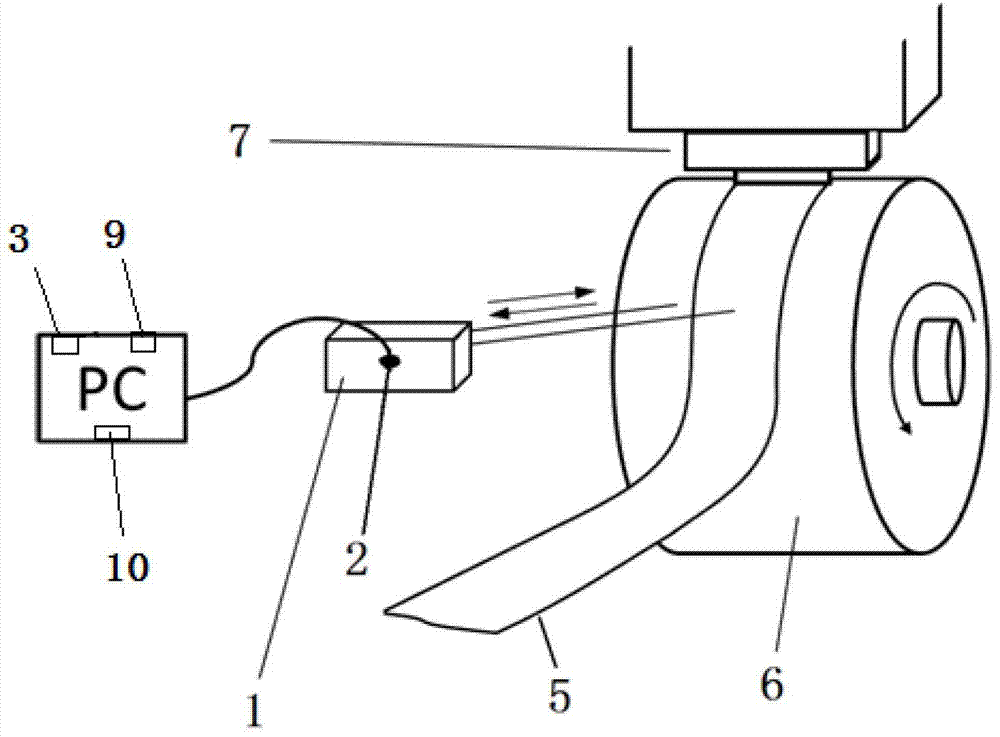

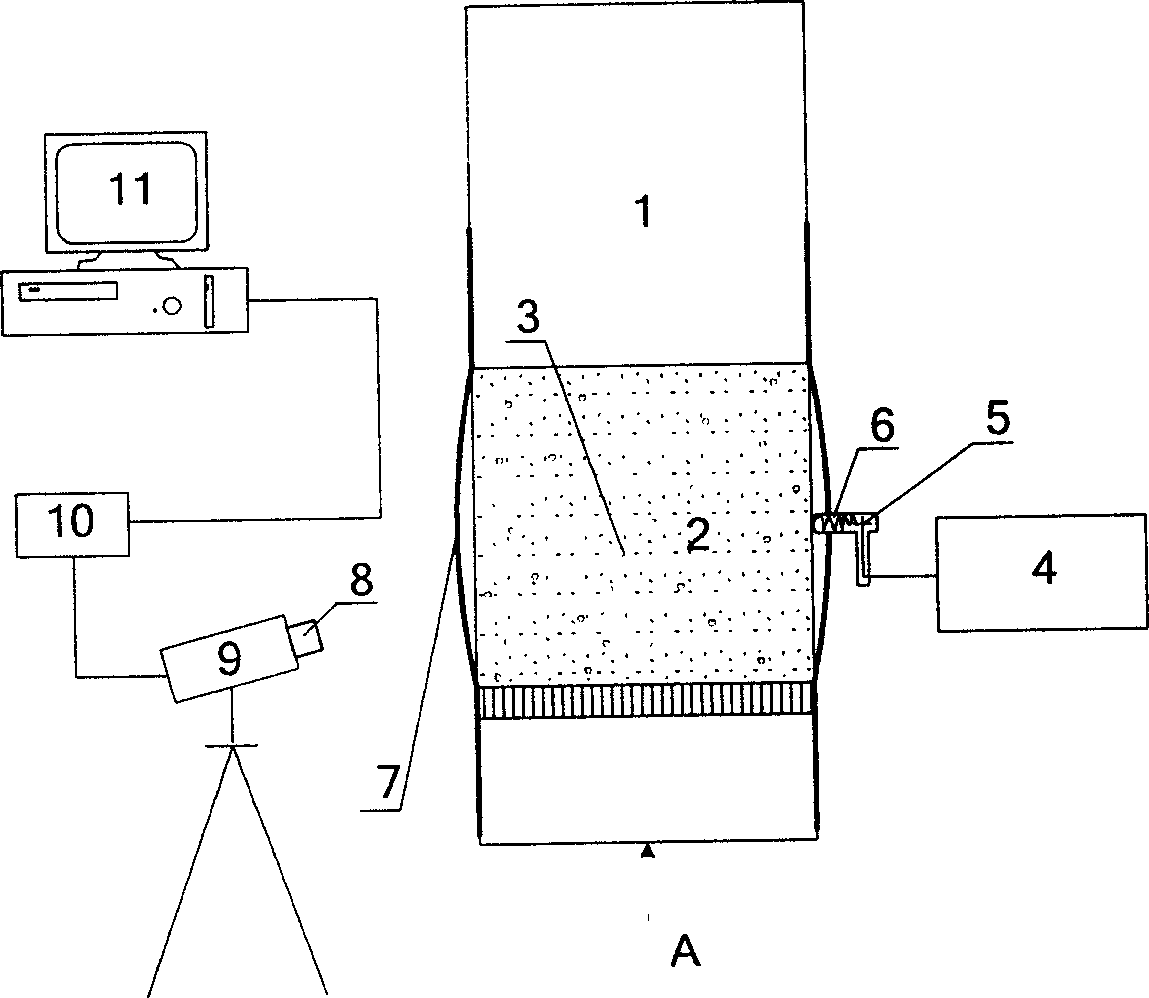

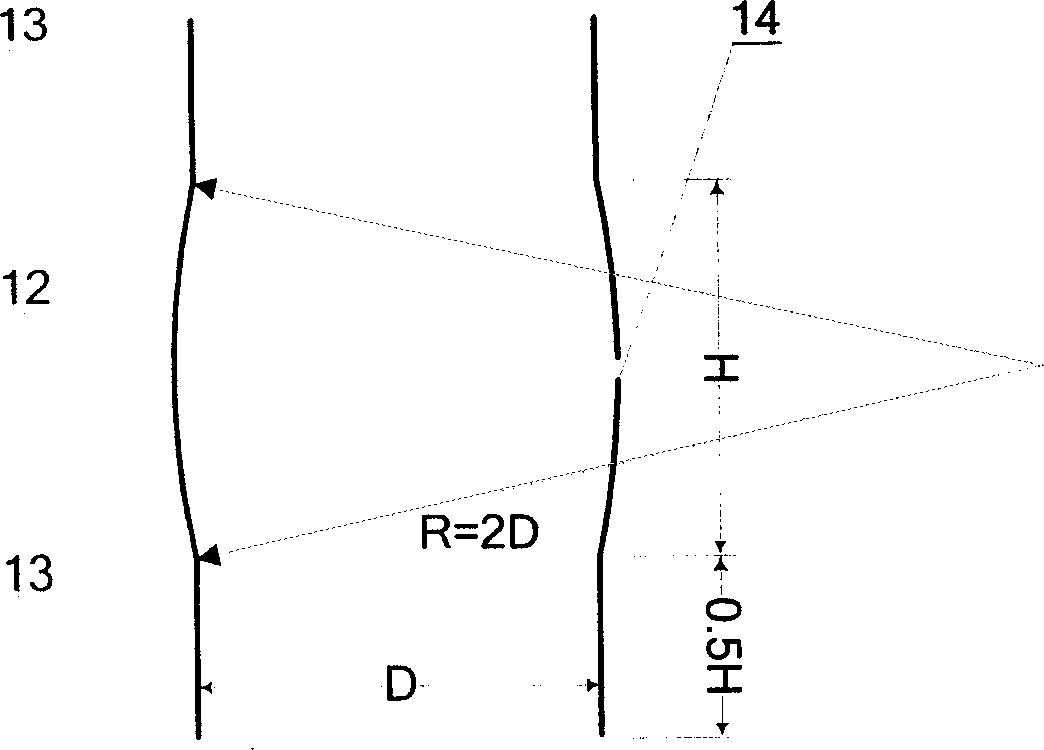

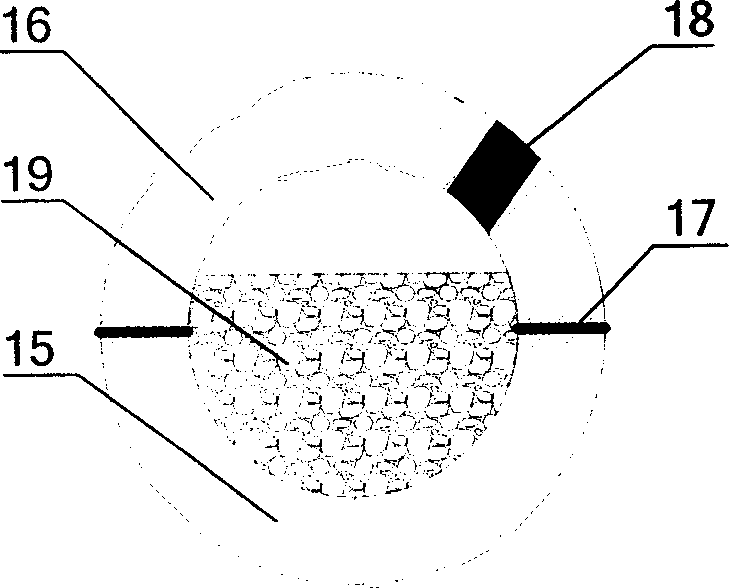

Measuring apparatus and measuring method for gas-solid fluidized bed particle mixing

InactiveCN1877294ADoes not interfere with gas-solid flowUniform microwave radiationHydrodynamic testingMaterial analysis using microwave meansGas solidFluidized bed

Disclosed are a device and a method for measuring air-solid fluidized bed particle mixture. The device comprises a microwave reflecting screen (7) set on the two sides of the fluidized bed (1); a microwave transmitting device is comprised with cascading the microwave generating device (4), a transmitting antenna (5) and a waveguide (6), wherein the waveguide (6) is installed in the middle of the microwave reflecting screen (7); a microwave receiving and processing device is comprised with an optical imaging object lens (8), a infrared probe (9), an amplifier (10) and a computer (11), wherein the optical imaging object lens (8) is locate on the other side of the fluidized bed (1) between two microwave reflecting screens (7). The method comprises that the microwave transmits to the fluidized bed layer via the guidance of the antenna and the waveguide; the tracking particles with polar H2O molecule are heated and employs the optical imaging object lens to receive the infrared radiation power distribution graph and reflect it to the infrared probe.

Owner:SOUTHEAST UNIV

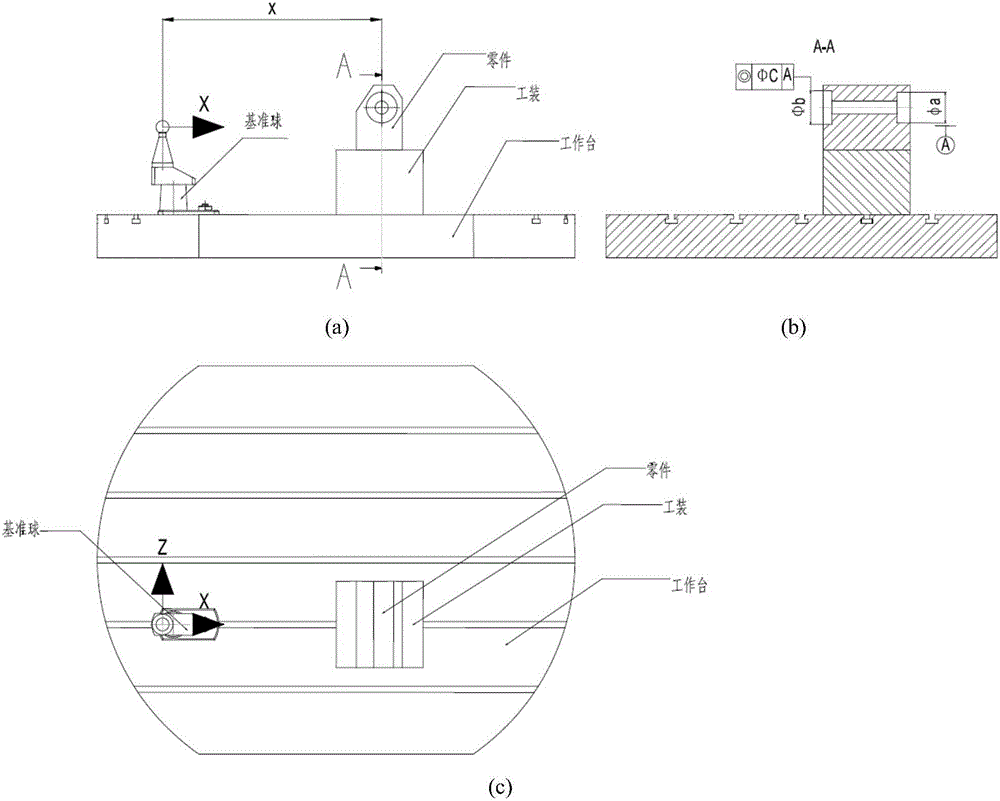

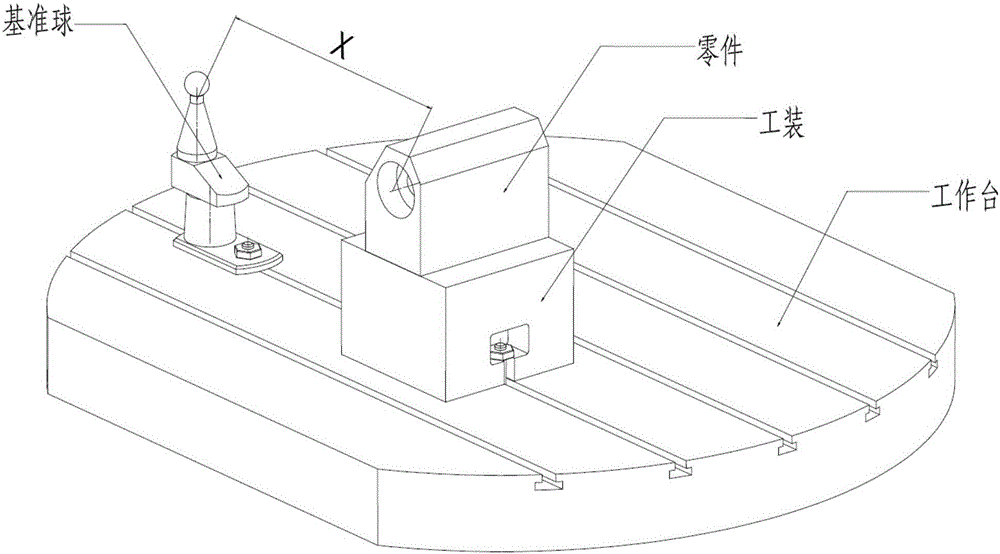

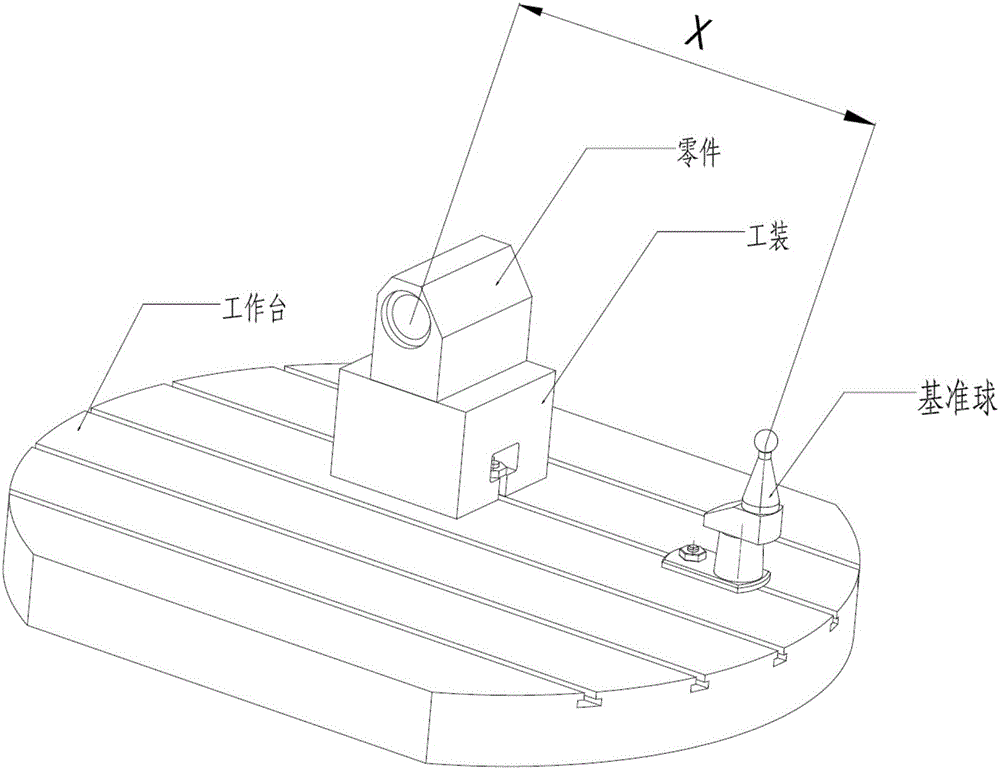

Method for processing precision part by rotating horizontal jig boring machine for 180 degrees

The invention provides a method for processing a precision part by rotating a horizontal jig boring machine for 180 degrees. Firstly, when a workbench of the horizontal jig boring machine is in a 0-degree position, a tool, a part and a reference ball are clamped, and metering is performed so as to align the reference axis of the part, so that the reference axis of the part is perpendicular to the X axis of a coordinate system of the workbench; in the position of which the height is the same as the plane of the workbench, an infrared probe is used for measuring central coordinates of the reference ball, reference axis coordinates of the to-be-processed part are measured, the distance between the center of the reference ball and the to-be-processed reference axis is recorded, and the characteristics and reference of the part are processed when the workbench is in the 0-degree position; then the workbench is rotated for 180 degrees, similarly, in the position of which the height is the same as the plane of the workbench, the infrared probe is used for measuring the center of the reference ball, the central coordinates of the reference ball are used as the reference, and the distance X which is recorded previously is matched, so that numerical control programs are compiled, and the to-be-processed characteristics are processed. According to the method, in the conditions that the programming center of the part is not in the axis rotating center of the workbench and rotary errors exist in the rotary center of the workbench of a machine tool, the processing precision can be effectively increased, and wide popularization and application values are obtained.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

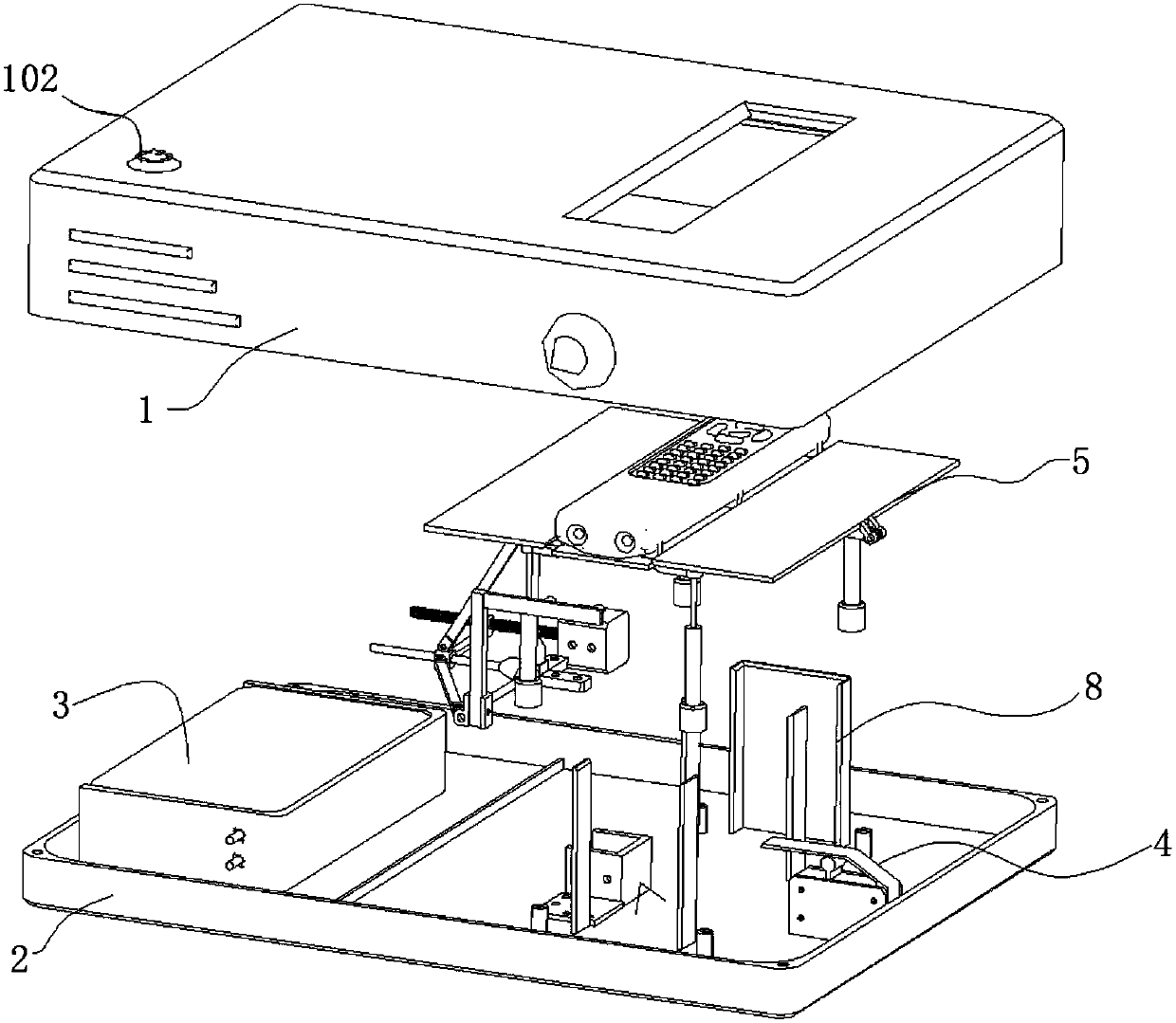

New-type set top box

The invention discloses a new-type set top box, comprising a machine shell, a base, a storage battery, a travel switch, an automatic storage and charge device and a remote controller. The new-type settop box is characterized by that an infrared probe and a mode switch are mounted on the machine shell. The automatic storage and charge device comprises a motor with a screw rod, a power transmissionconnection rod, a first guide rod, a first connection rod, a connection rod fixing base, a second guide rod, a first slide block, a guide rod fixing cap, a charge guide rod, a third guide rod, a second slide rod, a sixth connection rod, a steel bar, a second door, a fourth connection rod, a third connection rod, a fifth connection rod, a second connection rod, a first door, a remote controller carrying plate, a limiting sleeve and a vertical rod fixing cap. The first guide rod, the second guide rod and the third guide rod are mounted on the same connection rod fixing base and are fixed through the guide rod fixing cap. The screw rod on the motor and the first guide rod are connected through the power transmission rod. According to the set top box which is equipped with with a remote controller storage device and can be intelligently charged, a user is helped to develop a habit of placing the remote controller orderly and carrying out charging timely.

Owner:深圳市兆能讯通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com