Method for calibrating and correcting temperature measurement of infrared probe as well as corresponding temperature measuring method

A technology of infrared detector and calibration method, applied in radiation pyrometry, instruments, measuring devices, etc., can solve the problems of temperature measurement accuracy drop, temperature measurement error, deviation of calibration results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

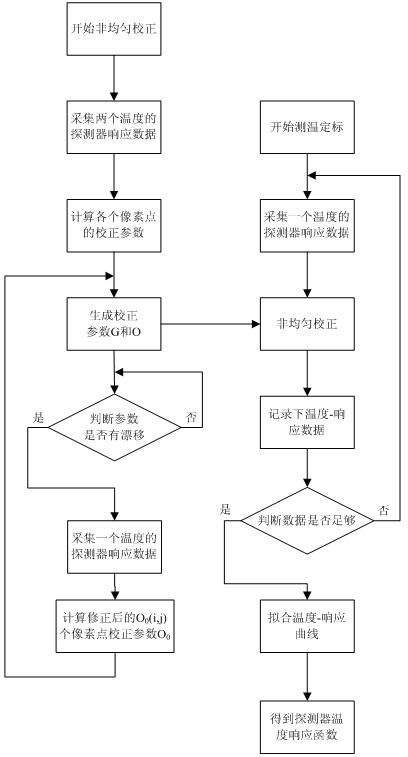

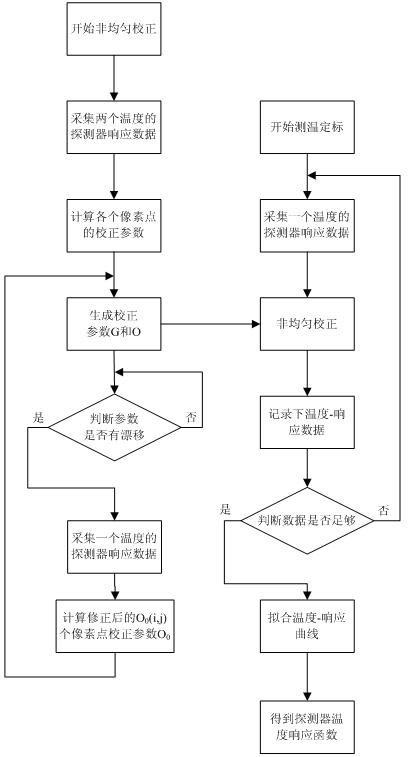

[0037] Such as figure 1 As shown: the process of temperature measurement calibration and non-uniform correction is that the non-uniform correction starts first, and after the calibration parameters G and O are generated, the temperature measurement calibration starts. If there is a drift, correct the parameters if there is a drift, otherwise continue to judge.

[0038] The process of temperature measurement calibration is to collect the detector response of each temperature, perform a non-uniform correction on it using the previously calculated non-uniform parameters, and then record the temperature and detector response data. Repeat this process until enough data is collected, and then fit the data to obtain the detector temperature response function.

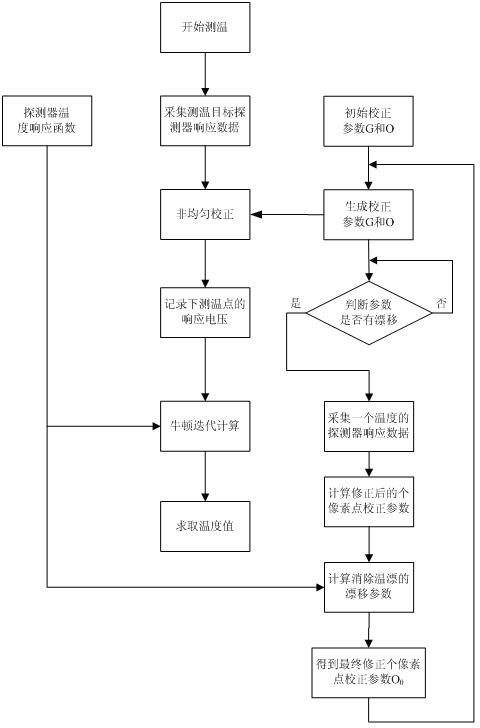

[0039] Such as figure 2 Shown: The previous non-uniform correction parameters and detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com