Rapid tube cutter

A pipe cutter, fast technology, applied in metal processing and other directions, can solve the problems of low incision straightness, low production efficiency, inconvenient movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

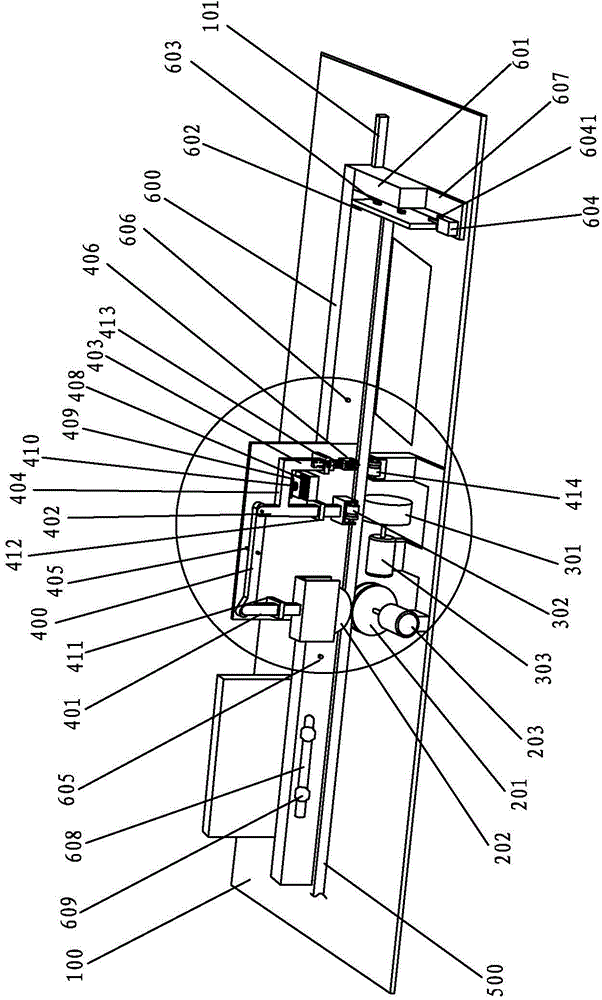

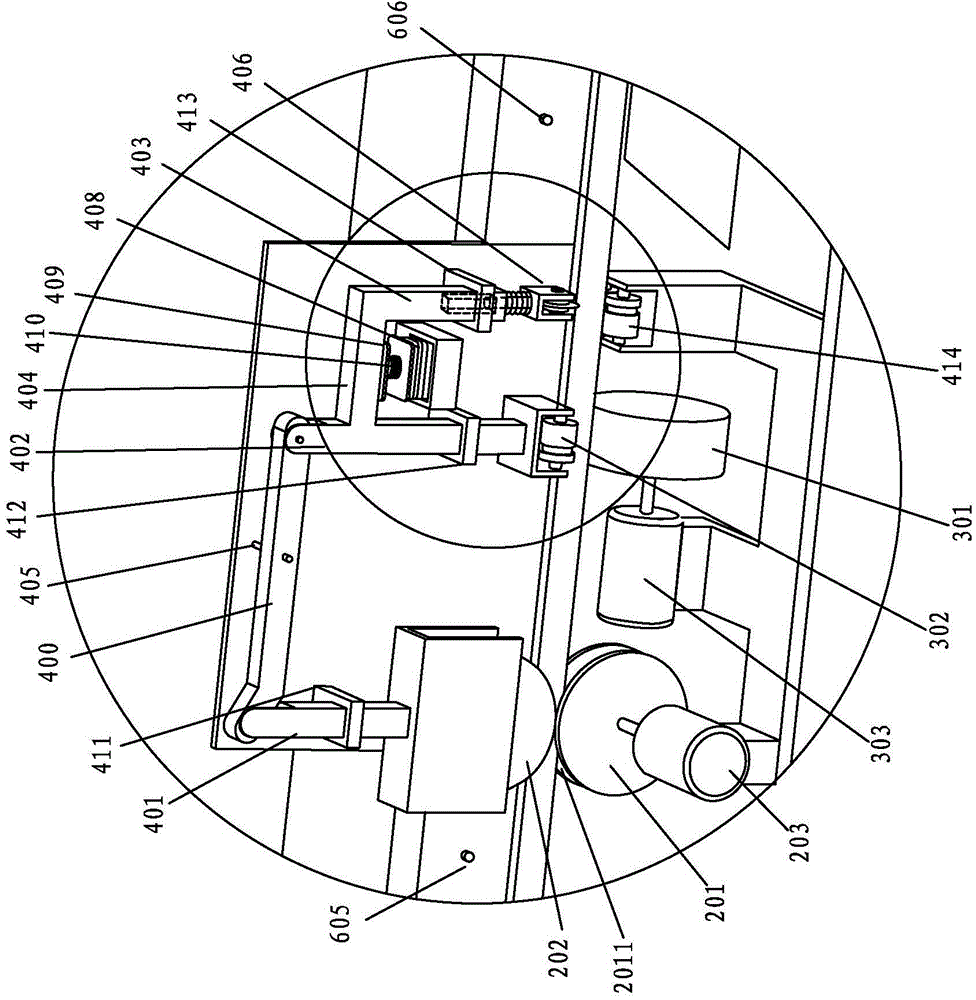

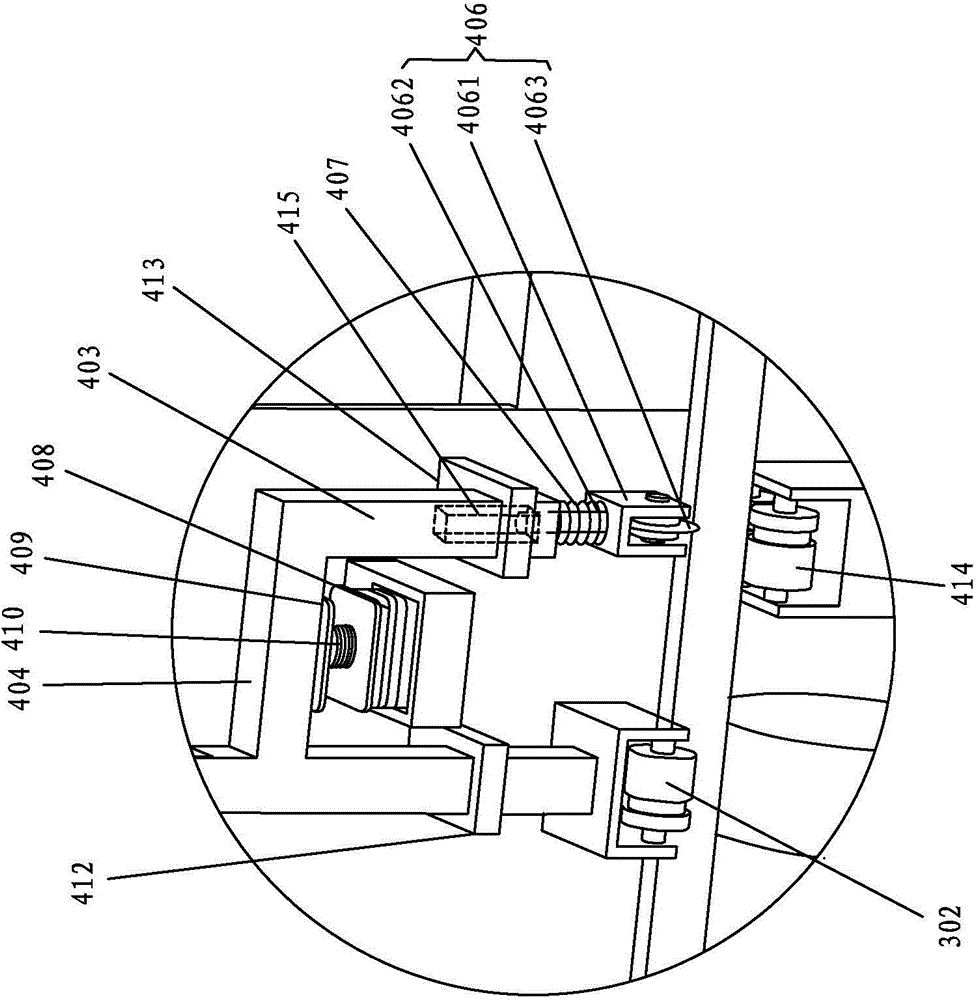

[0047] Such as Figures 1 to 3 As shown, a quick pipe cutter includes a frame 100, a pipe conveying mechanism, a pipe clamping synchronous rotation mechanism, a knife holder 406 for cutting pipes, and a control system (not shown in the figure). The shape of the frame 100 can be set according to the parts in the frame 100, which mainly supports and fixes the parts, and at the same time makes the parts closely and orderly form a whole. Taking the advancing direction of the pipe 500 as the front, the pipe conveying mechanism is used to push the pipe 500 forward along its axis, and the pipe clamping synchronous rotation mechanism is used to drive the pipe 500 to rotate around its axis. The control system integrates the circuits of each component into a unified control box for control, for example, a PLC control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com