Solidified composite and enhancing method of repairing structure and connecting structure of solidified composite

A composite material and connecting structure technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve problems such as inability to apply, and achieve enhanced out-of-plane strength and toughness, improved mechanical properties, and enhanced anti-delamination capabilities. and anti-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

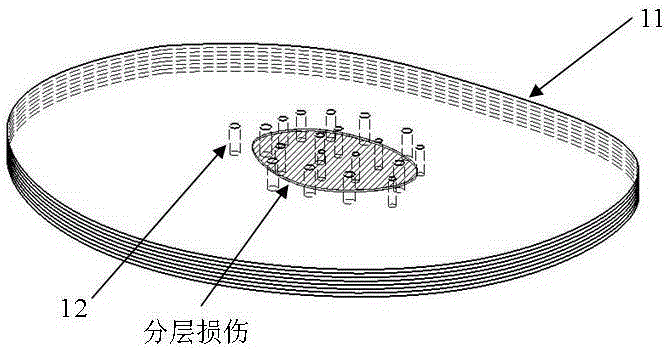

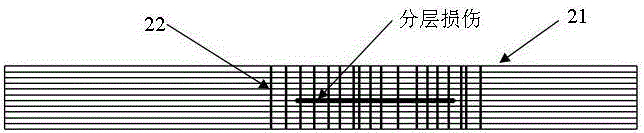

[0042] Application of the proposed method to reinforce 2 mm thick composite laminates with delamination damage, such as figure 1 or 2, the steps are as follows:

[0043](1) The position and degree of delamination damage of the cured composite laminate (11 or 21) are measured by the ultrasonic C-scan method, and the reinforcement range is determined, such as figure 1 shown;

[0044] (2) According to the damage situation, it is determined to use a titanium alloy rod impregnated with the room temperature curing adhesive SY-23B, which has a diameter of 1 mm and a length of 2 mm. The arrangement is as follows figure 1 shown;

[0045] (3) Apply a micro-diamond drill to process a number of small holes with a diameter of 1.2 mm in and around the layered part;

[0046] (4) Insert the thin titanium alloy rod (12 or 22) soaked in adhesive into the processed small hole, such as figure 1 or 2;

[0047] (5) According to the curing requirements of the adhesive SY-23B used, the adhesive ...

Embodiment 2

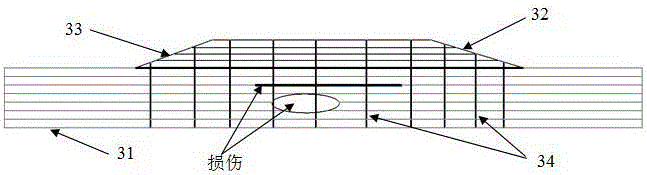

[0050] Larger delamination or fiber fracture damage inside the composite material can be repaired by patching (the thickness of the composite laminate is 2 mm, and the thickness of the patch is 1 mm), such as image 3 and 4 shown. image 3 The method shown is to apply a composite patch directly on the outer surface of the damaged area. Figure 4 The method shown is that after the material in the damaged area is excavated, a patch of composite material is pasted on the outer surface. Applying the proposed method, the steps to enhance the above two subsidized repair structures are as follows:

[0051] (1) Determine the reinforcement position as the patch repair site;

[0052] (2) According to the shape and size of the external patch (32 or 42) and its damage repair plan for the composite laminate (31 or 41), determine the use of carbon fiber rods impregnated with high-temperature curing adhesive J-116, with a diameter of 0.5 mm, The length is 3 mm (the length of the thin rod...

Embodiment 3

[0058] The proposed method was applied to reinforce the composite excavation repair structure with a thickness of 4 mm, such as Figure 5 As shown, the enhancement steps are as follows:

[0059] (1) Determine the enhanced position as the embedded patch site;

[0060] (2) According to the shape and size of the external patch (52) and its damage repair plan for the composite laminate (51), determine the use of carbon fiber rods impregnated with high-temperature curing adhesive J-116, with a diameter of 1.5 mm and a length of 4 mm , the arrangement is as Figure 5 shown;

[0061] (3) According to the enhanced process parameters, a number of small holes with a diameter of 1.8 mm are processed with a TruMicro5050 laser in the area of the patch (52), and the small holes penetrate the patch and the composite laminate overlapping the patch;

[0062] (4) Insert the thin stick (54) soaked in adhesive into the processed small hole;

[0063] (5) According to the curing requirements ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com