Online real-time detection device for thickness of amorphous alloy strip

A strip thickness, amorphous alloy technology, applied in the field of online real-time detection device for amorphous alloy strip thickness, can solve the problem of simultaneous measurement of amorphous alloy strips, strict requirements for fluctuations in thickness of amorphous alloy strips, and low measurement accuracy And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

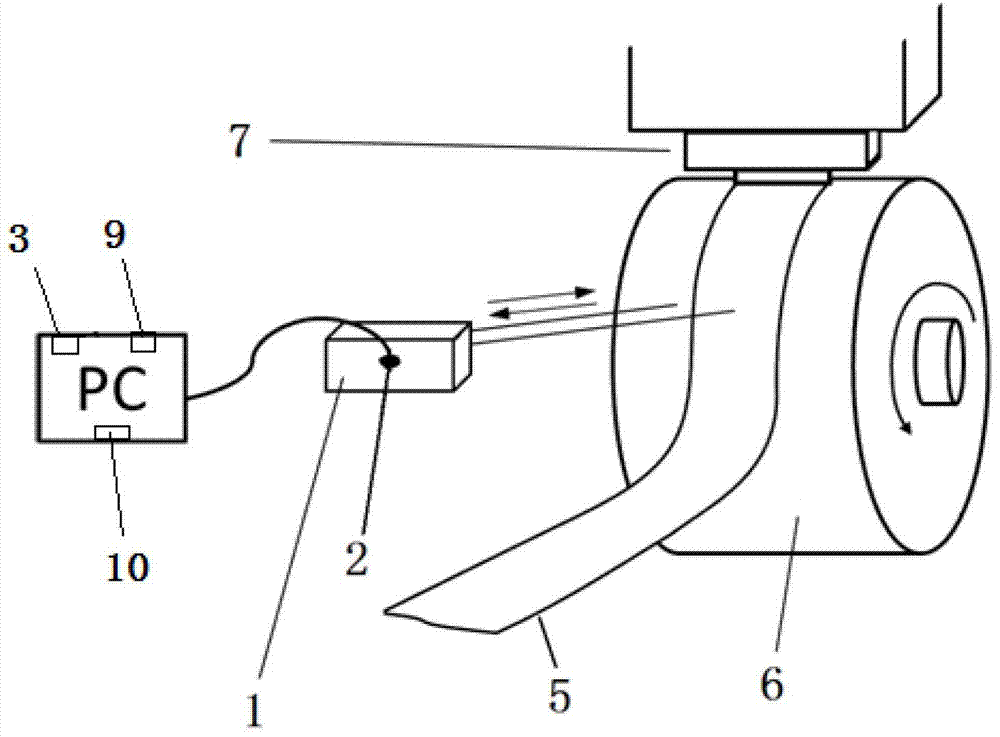

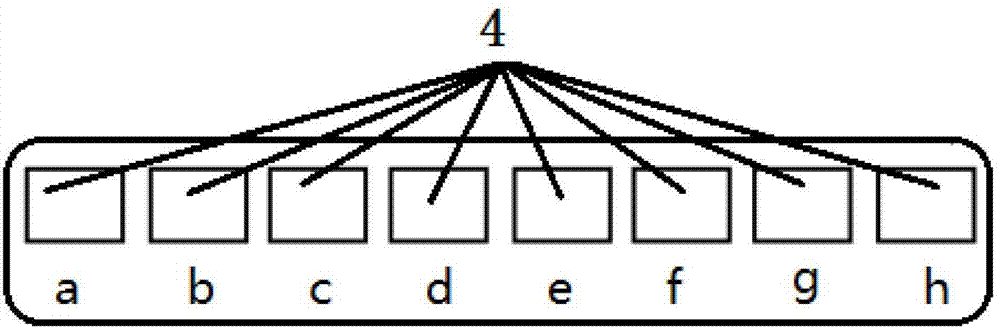

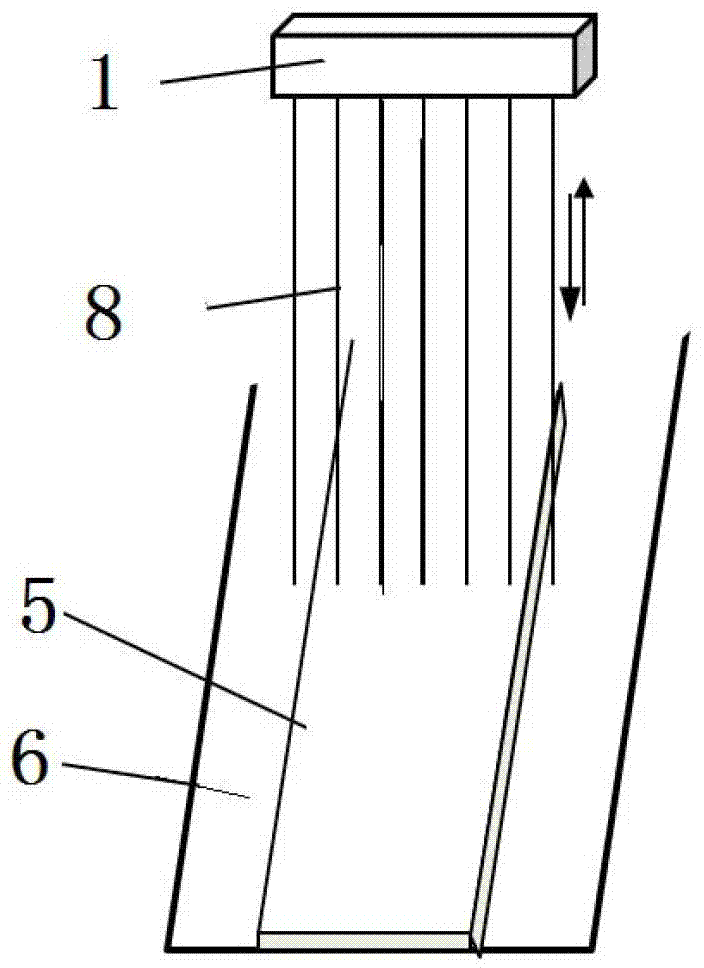

[0027] Such as figure 1 As shown, an online real-time detection device for the thickness of an amorphous alloy strip includes a detector 1, a signal receiving device 2 and a data analysis module 3, and the detector 1 includes a plurality of detection probes 4 arranged in parallel ( figure 2 ), each detection probe 4 emits detection light 8 to separately detect the distance between it and the corresponding point on the surface of the measured object and feeds back the distance data to the signal receiving device 2 ( Figure 3a ); the detected object is an amorphous alloy strip 5 and a copper roll 6 pasted together; the signal receiving device 2 transmits the distance data sent by each detection probe 4 to the data analysis module 3. The data analysis module 3 stores the received data, and analyzes the received data to obtain the single-point thickness, average thickness, thickness deviation at different positions in the horizontal direction and thickness deviation at different...

Embodiment 2

[0035]The difference with the online real-time detection device for the thickness of the amorphous alloy strip in Embodiment 1 is: the online real-time detection device for the thickness of the amorphous alloy strip also includes a control module 9, and the control module 9 is based on the data received from the data analysis module 3. The thickness deviation data at different positions in the horizontal direction and the thickness deviation data in different positions in the longitudinal direction determine whether the deviation is up to standard, and adjust the distance between the nozzle 7 and the copper roller 6 if it is not up to the standard.

[0036] When working: the control module 9 receives the thickness deviation data at different horizontal positions and the thickness deviation data at different longitudinal positions sent by the data analysis module 3, compares whether these two deviation data are within the preset deviation range, and if the deviation exceeds The ...

Embodiment 3

[0039] The difference with the online real-time detection device for the thickness of the amorphous alloy strip in Example 1 is that: the online real-time detection device for the thickness of the amorphous alloy strip also includes a display module 10, and the display module 10 is obtained from the data analysis module 3 Receive the data, and display the relationship between the received single-point thickness, average thickness, thickness deviation at different positions in the horizontal direction, and thickness deviation data at different positions in the longitudinal direction and time respectively.

[0040] The online real-time detection device for the thickness of the amorphous alloy strip can also realize the online display of test data, which is beneficial to the online observation of the change of the thickness of the amorphous alloy strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com