Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Glycine product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycine is an amino acid, one of 20 used to make proteins in the human body. The body produces it naturally. Glycine is also found in high-protein foods such as: Meat. Fish. Dairy products. Legumes.

Recovery of noble metals from aqueous process streams

ActiveUS20060106248A1Reduce operating costsPhysical/chemical process catalystsOrganic anion exchangersIon-exchange resinImidodiacetic acid

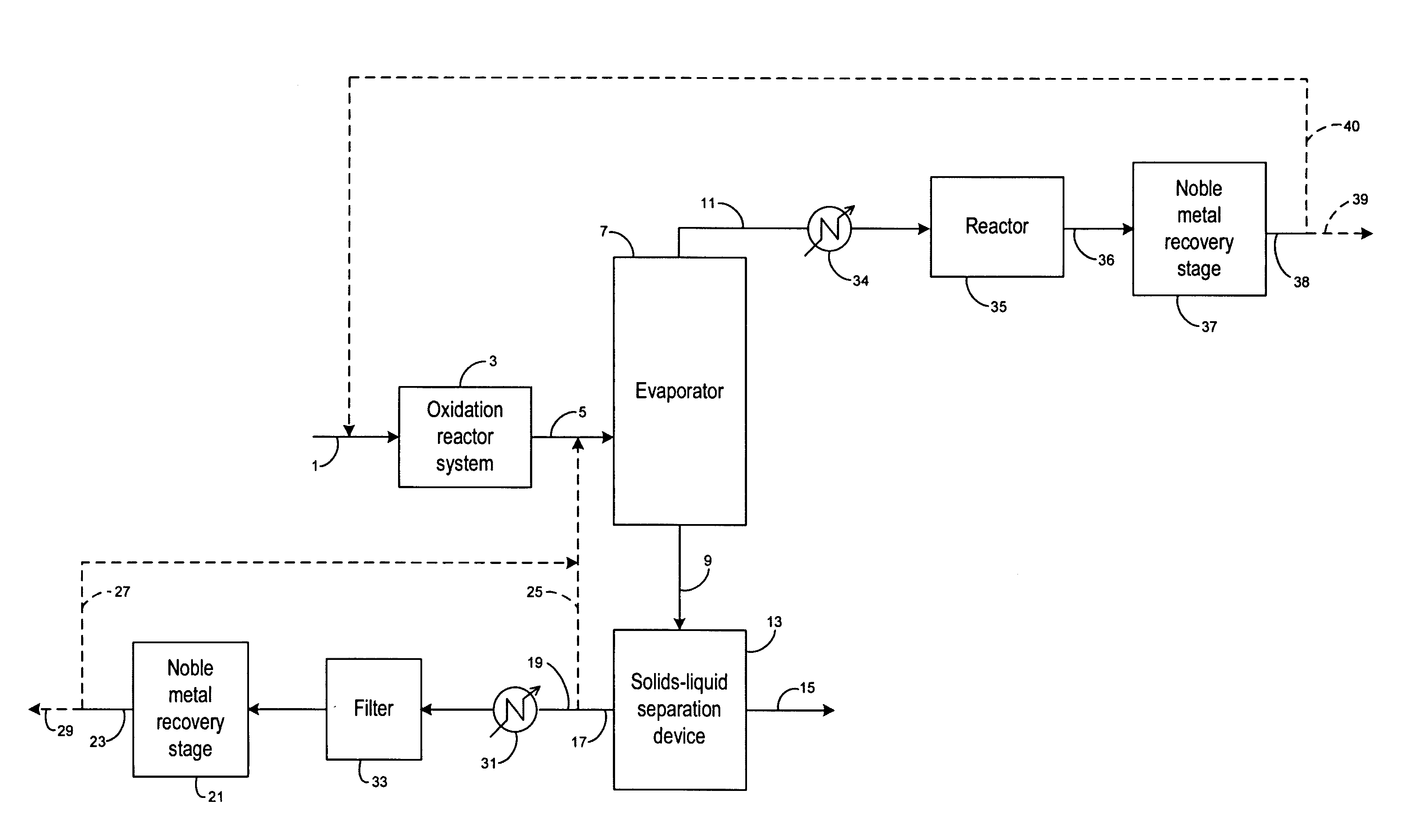

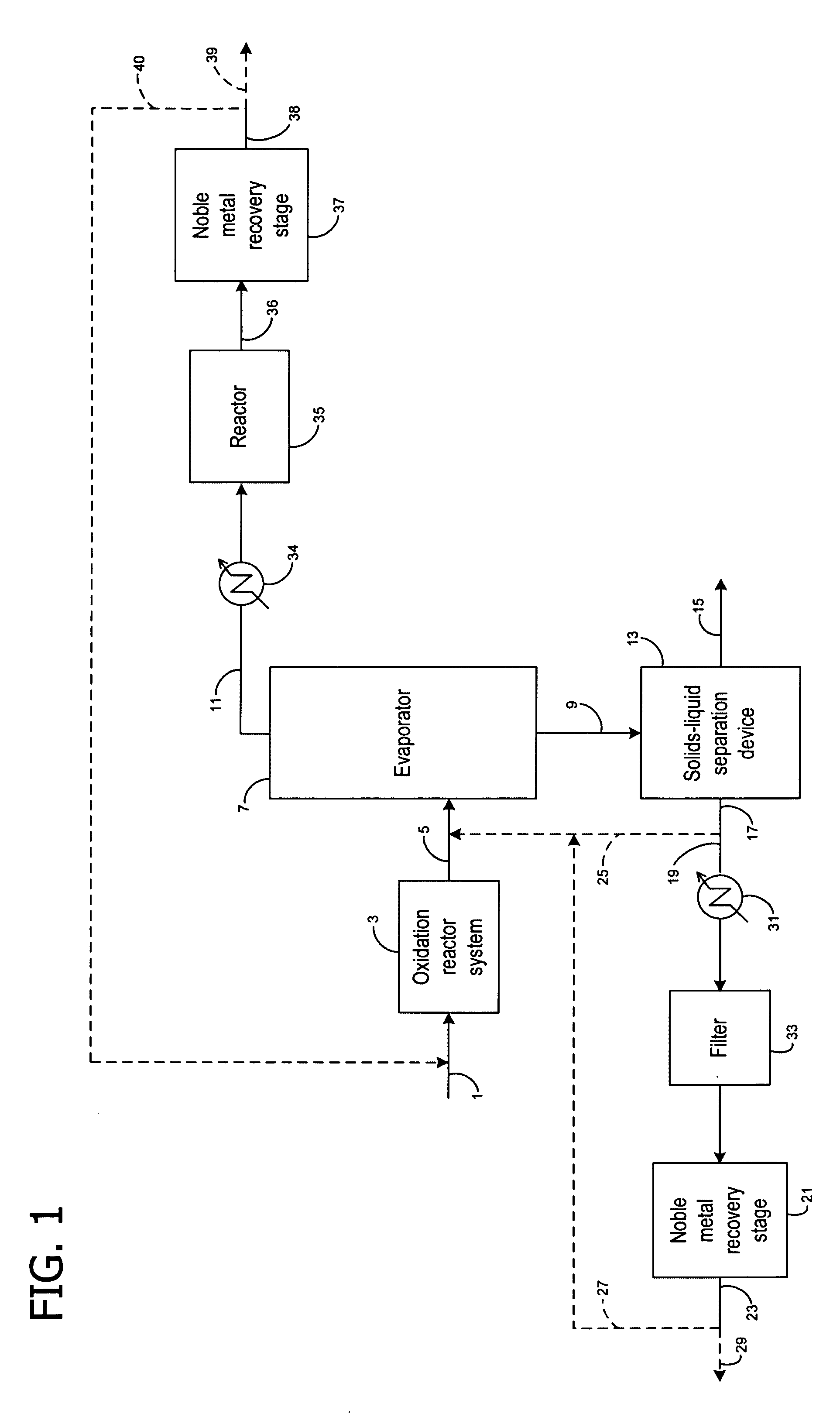

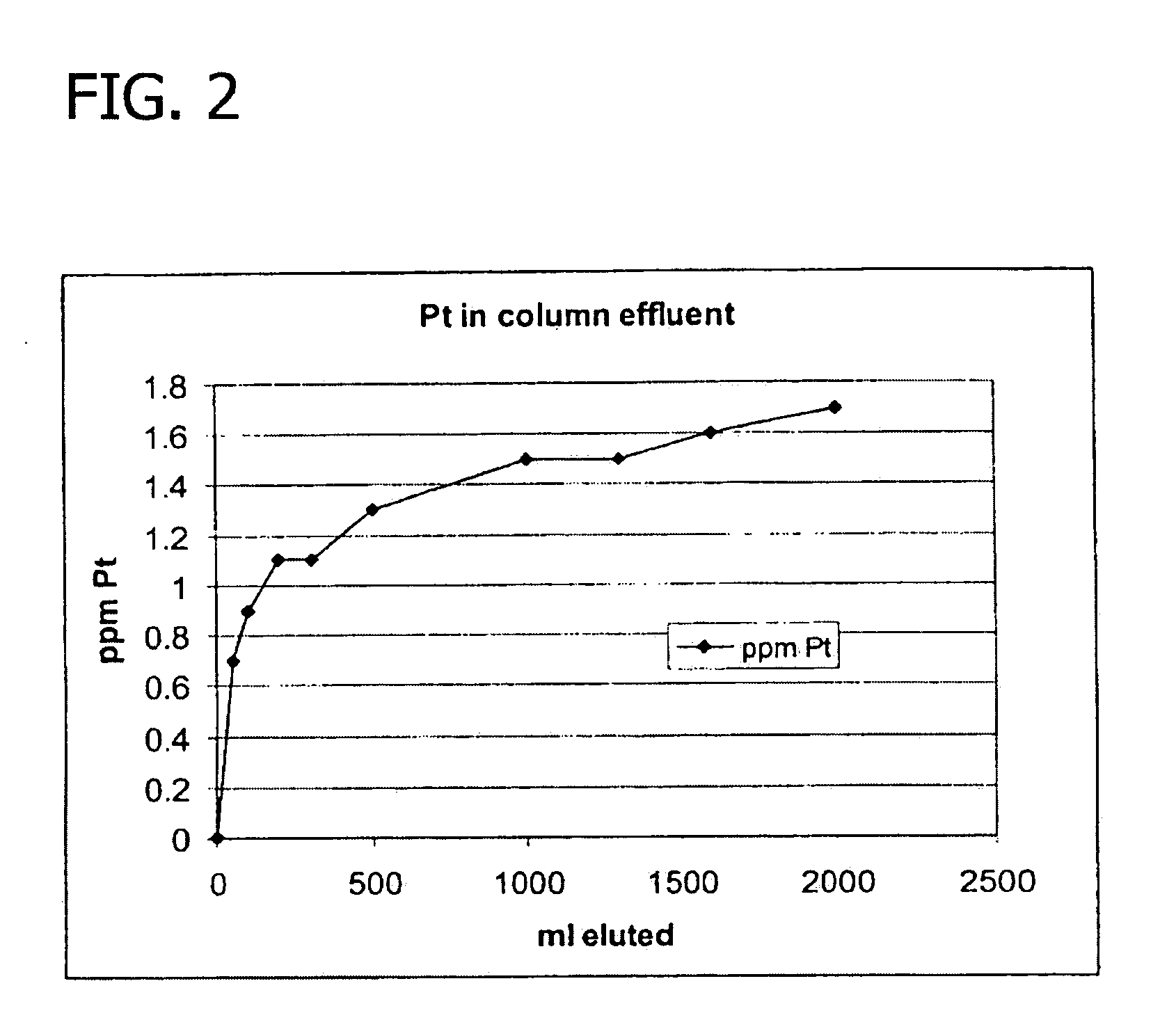

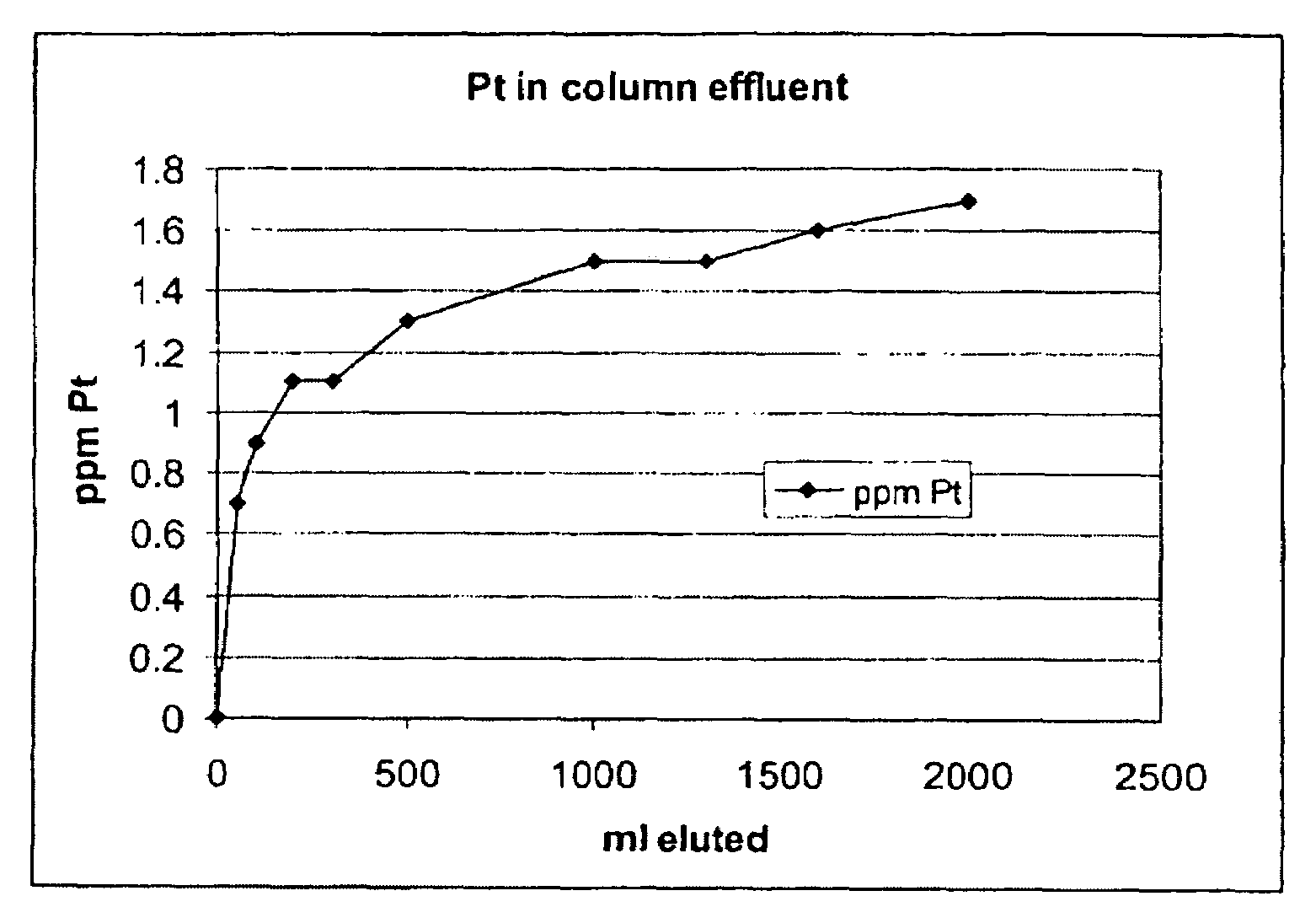

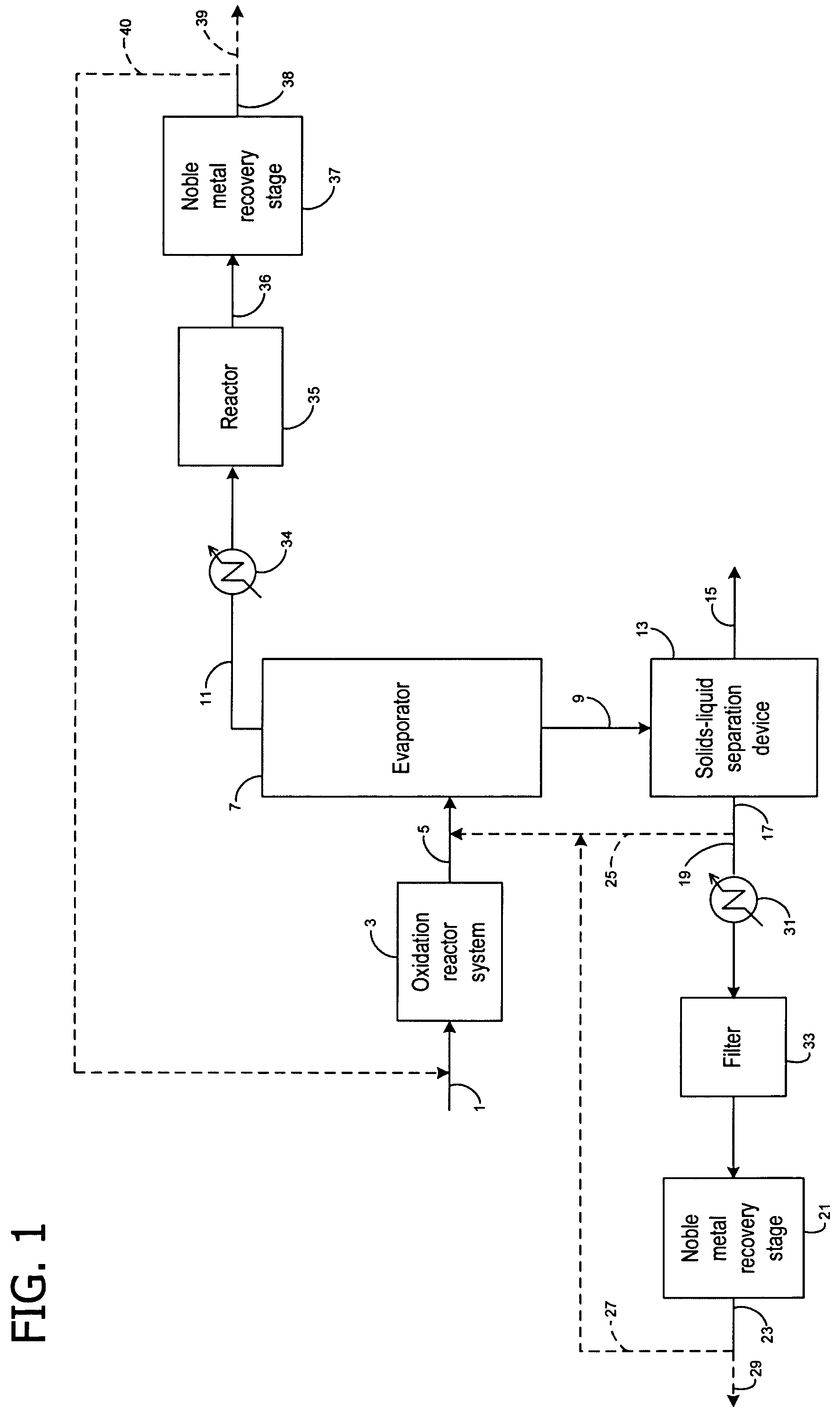

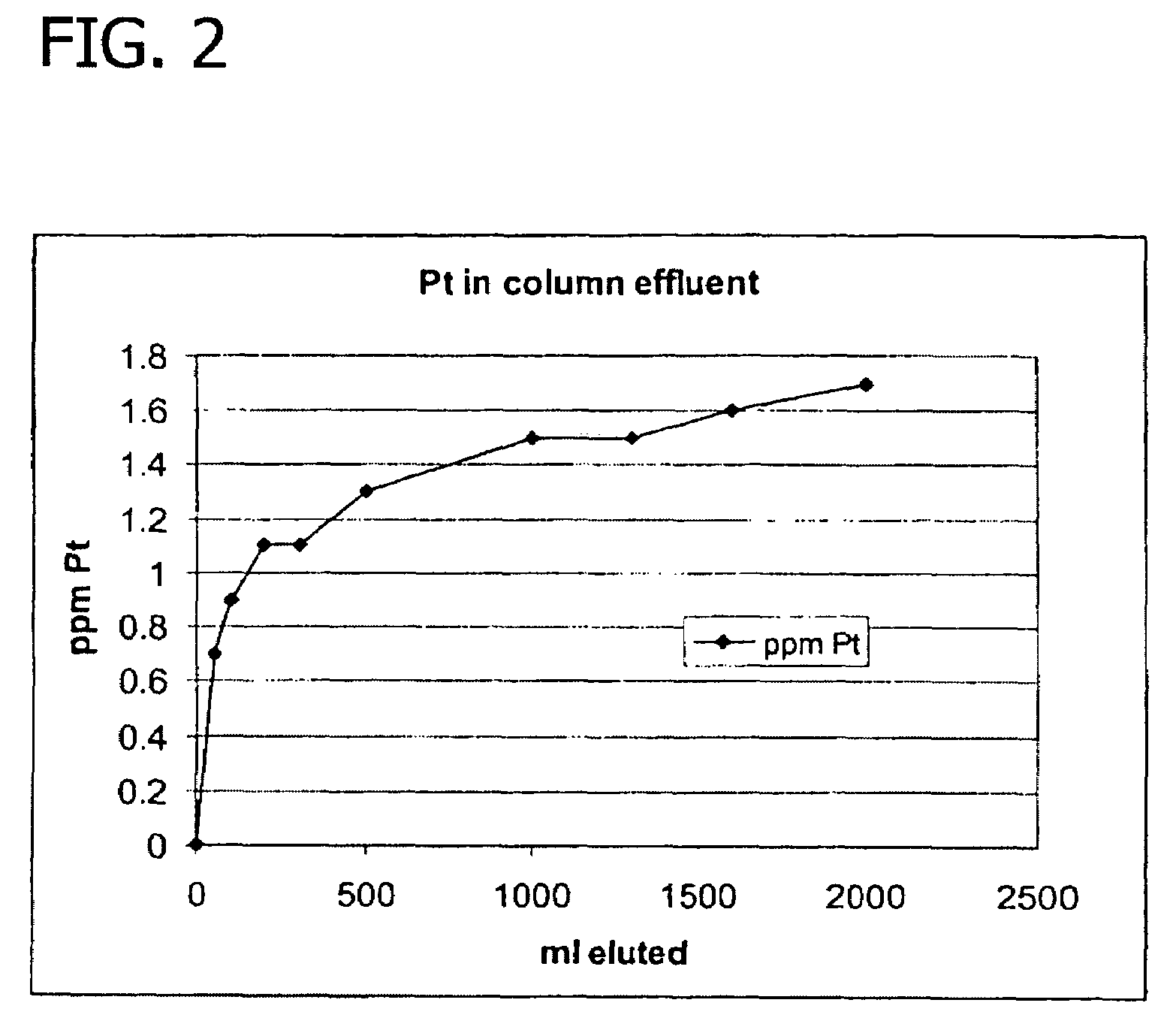

This invention generally relates to processes for recovering solubilized noble metals from aqueous process streams, in particular, aqueous process streams generated in the preparation of an N-(phosphonomethyl)glycine product, for example, by noble metal-catalyzed oxidation of an N-(phosphonomethyl)iminodiacetic acid substrate. The process includes contacting the aqueous process stream with a noble metal adsorption media such as an ion exchange resin to remove solubilized noble metal from the process stream.

Owner:MONSANTO TECH LLC

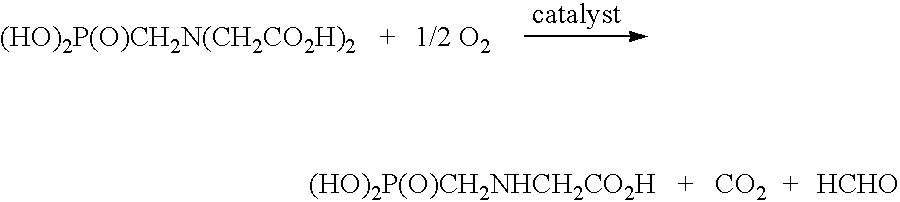

Oxidation catalyst and its use for catalyzing liquid phase oxidation reactions

ActiveUS20100130774A1Group 5/15 element organic compoundsCatalyst activation/preparationCatalytic oxidationImidodiacetic acid

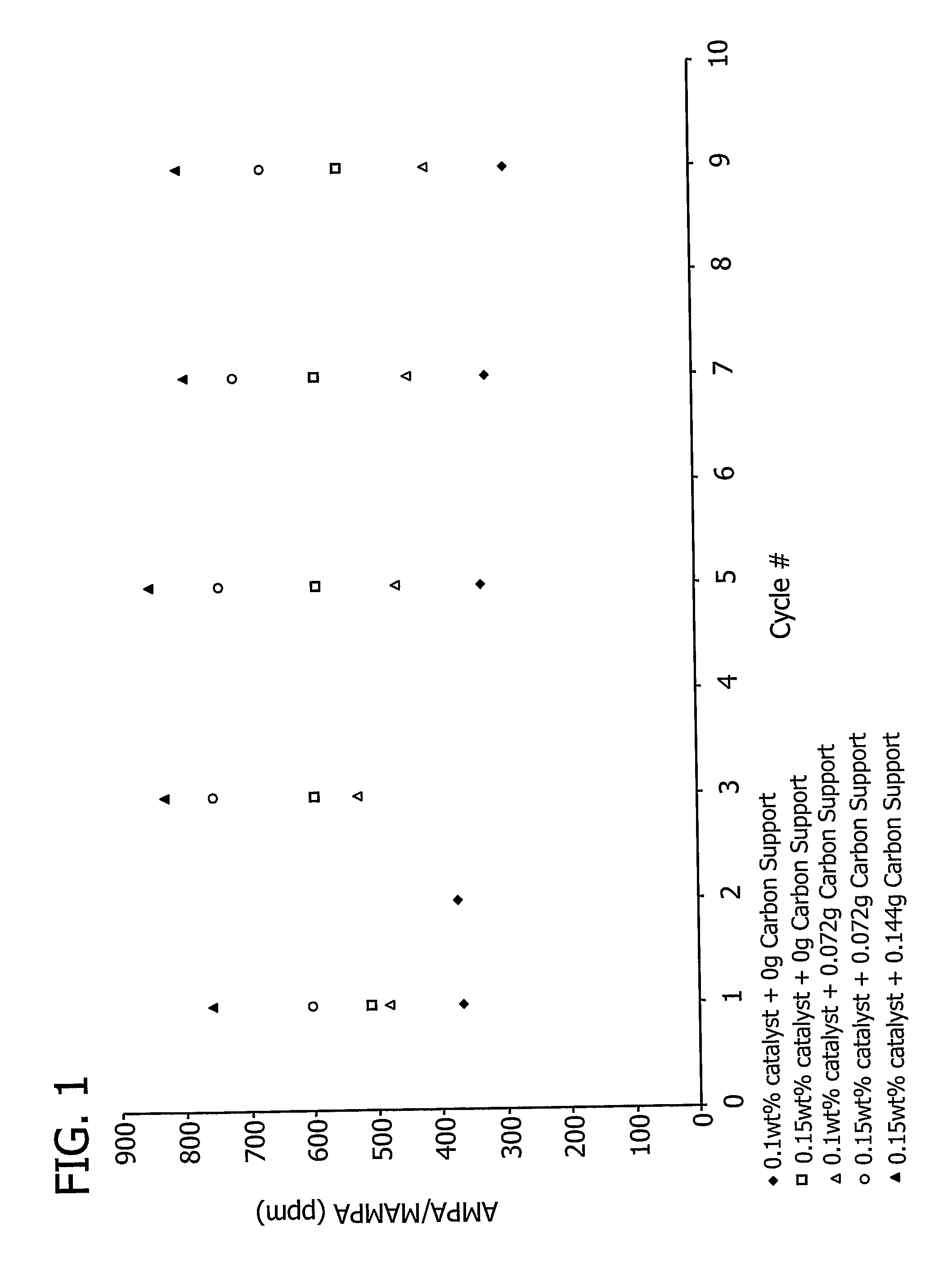

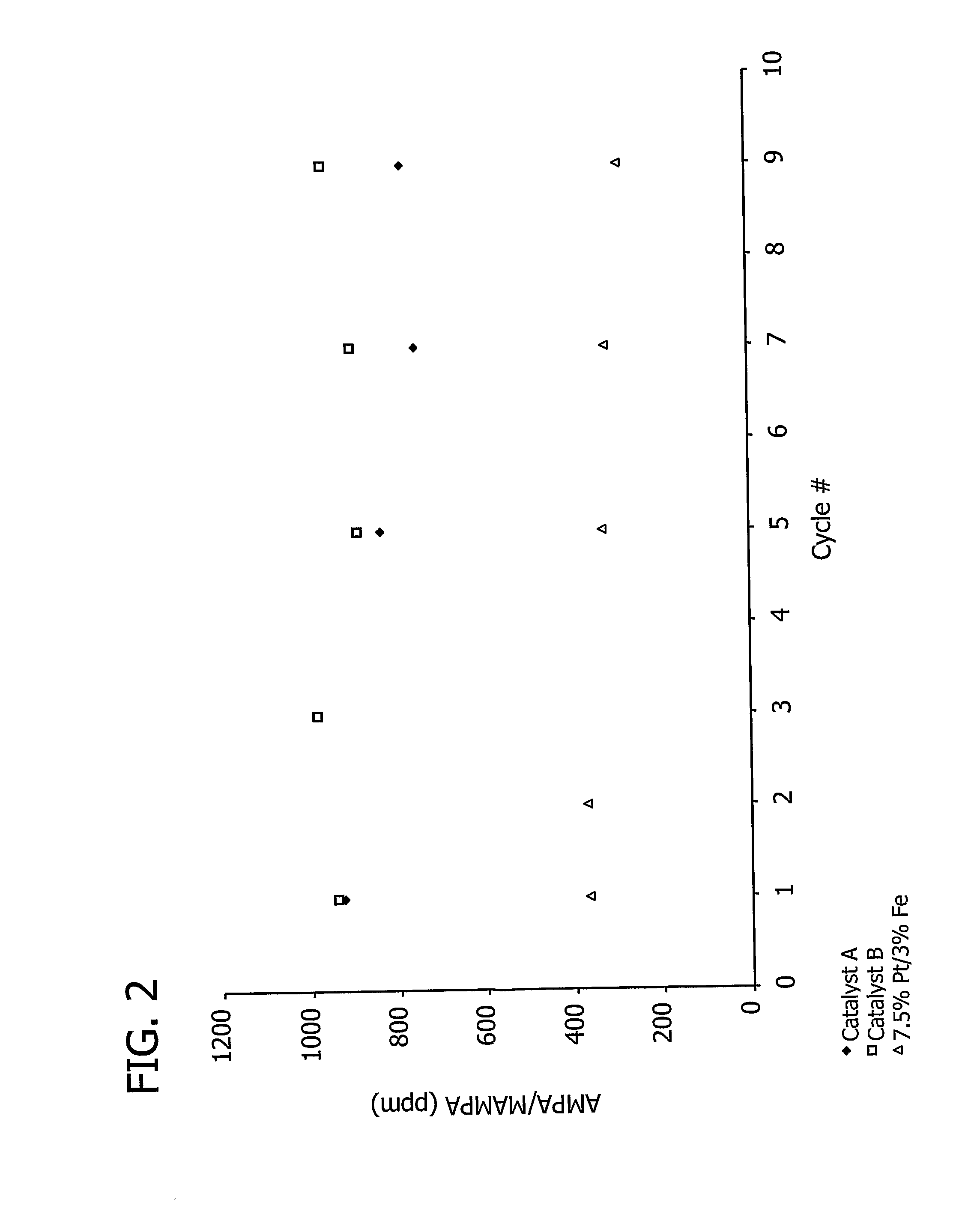

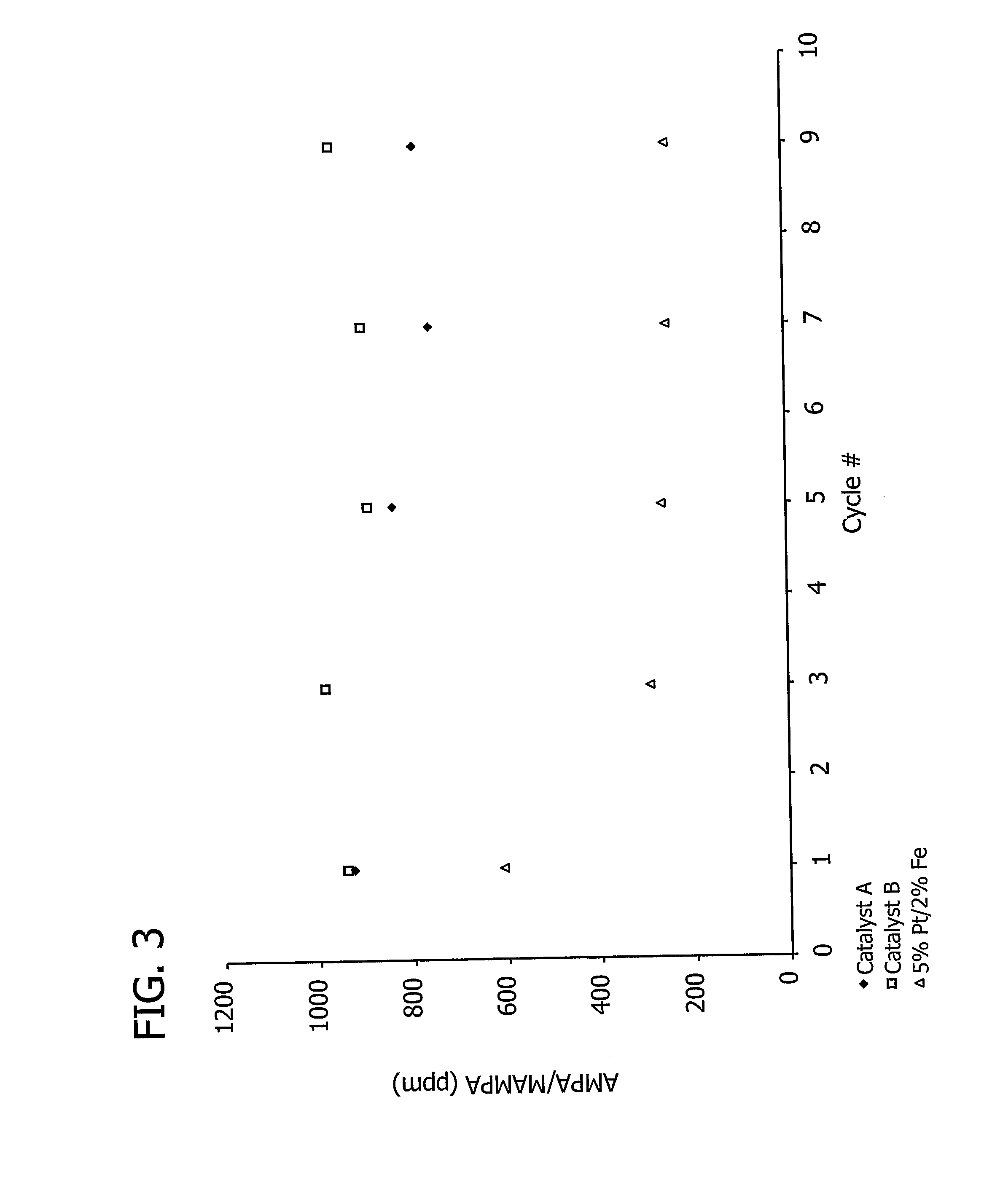

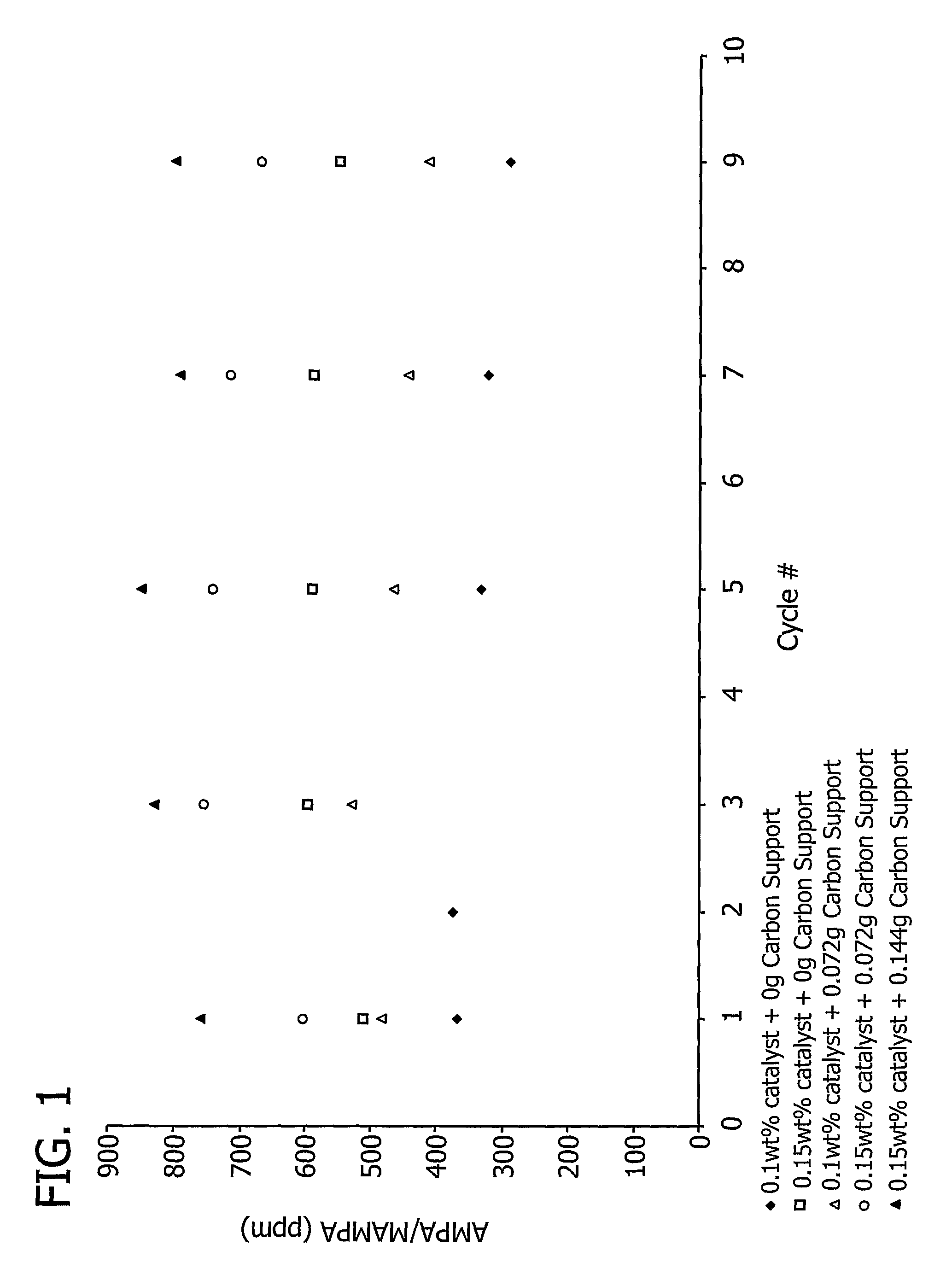

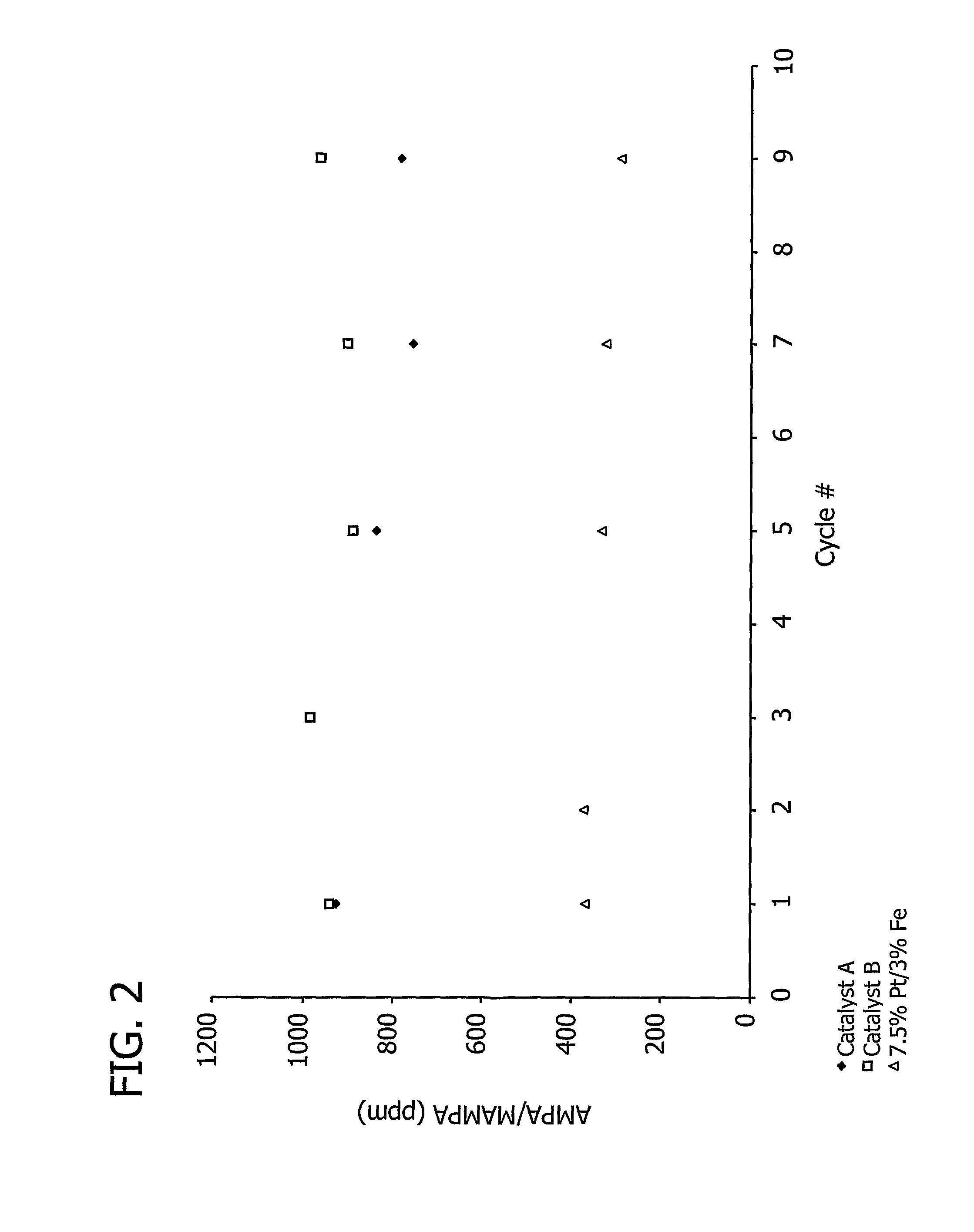

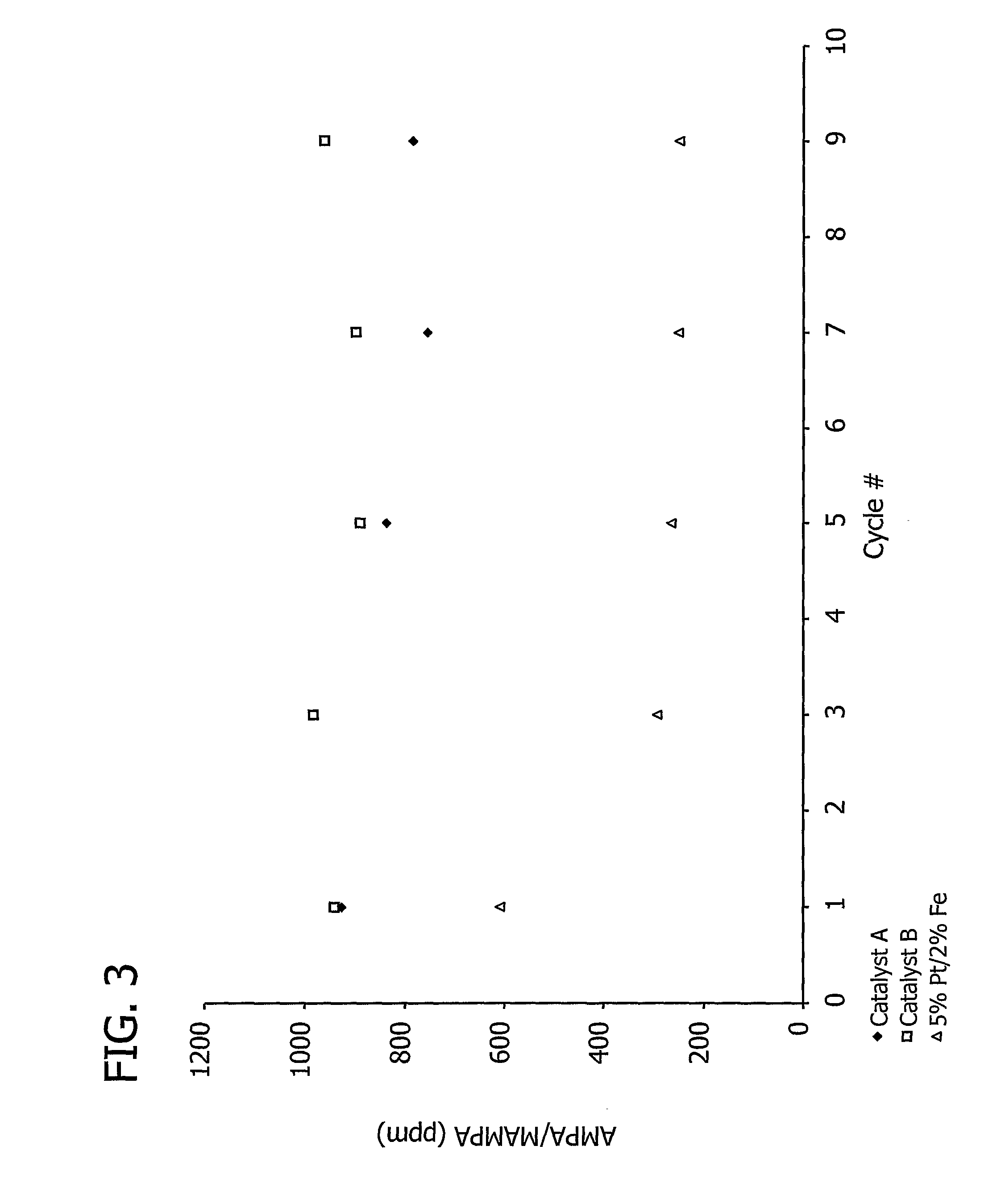

This invention relates to the field of heterogeneous catalysis, and more particularly to oxidation catalysts including carbon supports having deposited thereon a noble metal and one or more optional promoters and to methods for their preparation. The invention further relates to the field of heterogeneous catalytic oxidation reactions, including the preparation of secondary amines by the catalytic oxidation of tertiary amines, such as the oxidation of an N-(phosphonomethyl)iminodiacetic acid to produce an N-(phosphonomethyl)glycine product.

Owner:MONSANTO TECH LLC

Recovery of noble metals from aqueous process streams

ActiveUS7687663B2Reduce operating costsPhysical/chemical process catalystsOrganic anion exchangersIon-exchange resinImidodiacetic acid

This invention generally relates to processes for recovering solubilized noble metals from aqueous process streams, in particular, aqueous process streams generated in the preparation of an N-(phosphonomethyl)glycine product, for example, by noble metal-catalyzed oxidation of an N-(phosphonomethyl)iminodiacetic acid substrate. The process includes contacting the aqueous process stream with a noble metal adsorption media such as an ion exchange resin to remove solubilized noble metal from the process stream.

Owner:MONSANTO TECH LLC

Oxidation catalyst and its use for catalyzing liquid phase oxidation reactions

ActiveUS8703639B2Group 5/15 element organic compoundsCatalyst activation/preparationCatalytic oxidationLiquid phase

This invention relates to the field of heterogeneous catalysis, and more particularly to oxidation catalysts including carbon supports having deposited thereon a noble metal and one or more optional promoters and to methods for their preparation. The invention further relates to the field of heterogeneous catalytic oxidation reactions, including the preparation of secondary amines by the catalytic oxidation of tertiary amines, such as the oxidation of an N-(phosphonomethyl)iminodiacetic acid to produce an N-(phosphonomethyl)glycine product.

Owner:MONSANTO TECH LLC

De-oxygenation treatment for noble metal on carbon catalysts used in liquid phase oxidation reactions

InactiveUS6927304B2Extended service lifeIncrease resistanceGroup 5/15 element organic compoundsLiquid mediumOxidative cleavage

A treatment for de-oxygenating a noble metal on carbon catalyst used in liquid phase oxidation reactions which includes exposing the catalyst to a non-oxidizing environment. The de-oxygenation treatment improves catalyst performance and is particularly suited for noble metal on carbon catalysts used to catalyze the oxidative cleavage of a carboxymethyl substituent from an N-(phosphonomethyl)iminodiacetic acid substrate in an aqueous reaction mixture using an oxygen-containing gas to produce an N-(phosphonomethyl)glycine product. In one embodiment, the catalyst is exposed to a non-oxidizing environment by introducing a non-oxidizing gas and / or reducing gas into a slurry comprising the catalyst in contact with a liquid medium.

Owner:MONSANTO TECH LLC

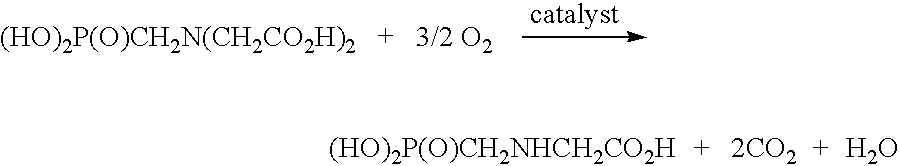

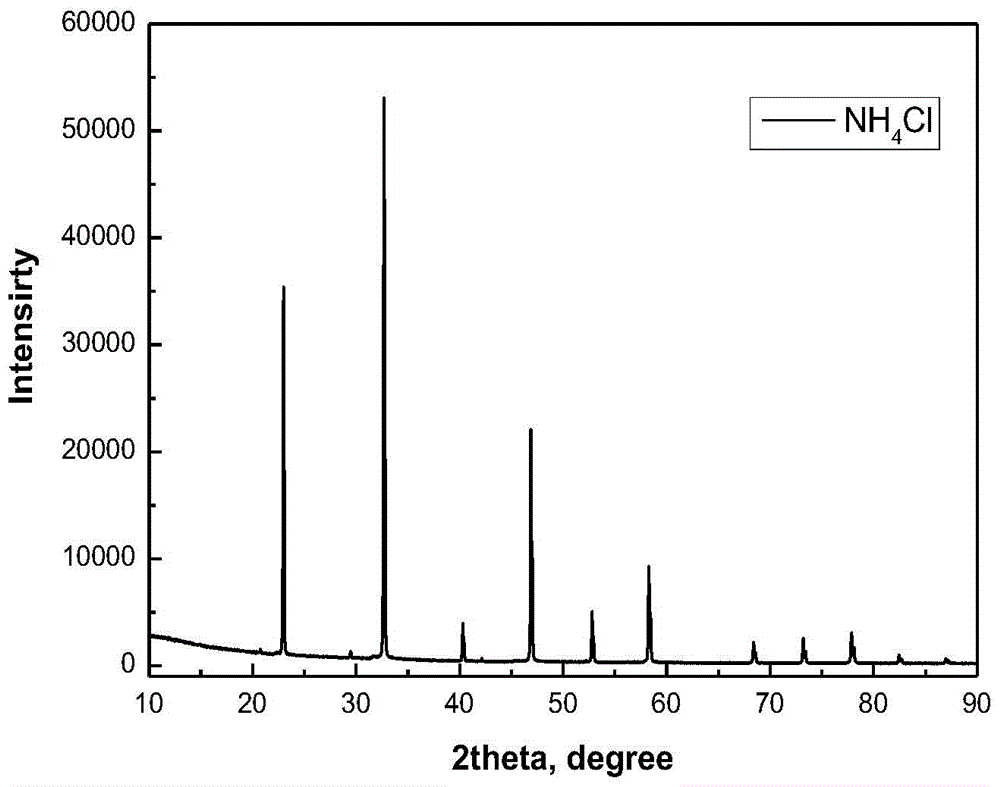

Method for separating mixed crystals of glycine and ammonium chloride

InactiveCN104193634AHigh feasibilityHigh yieldOrganic compound preparationAmino-carboxyl compound preparationSolubilityHigh energy

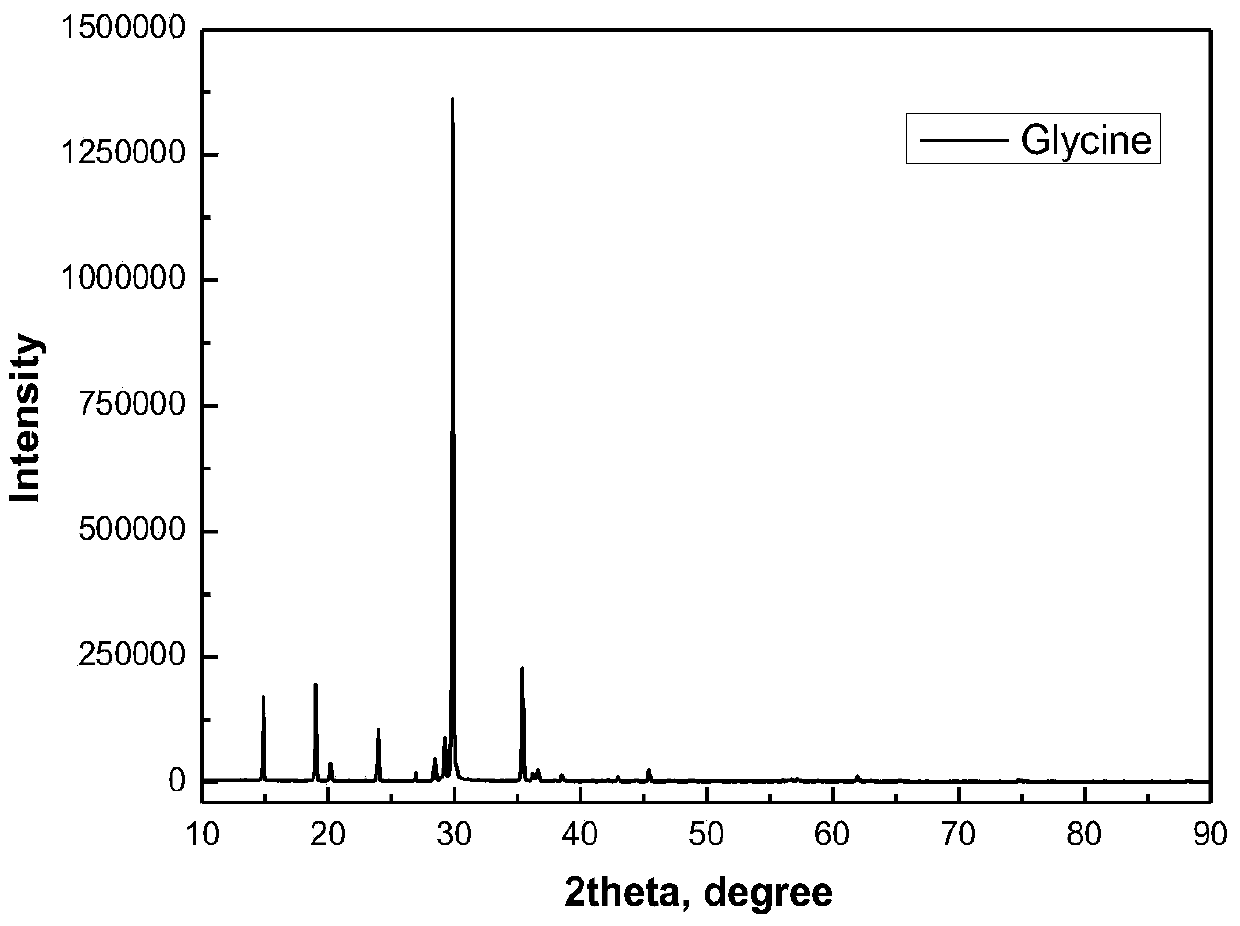

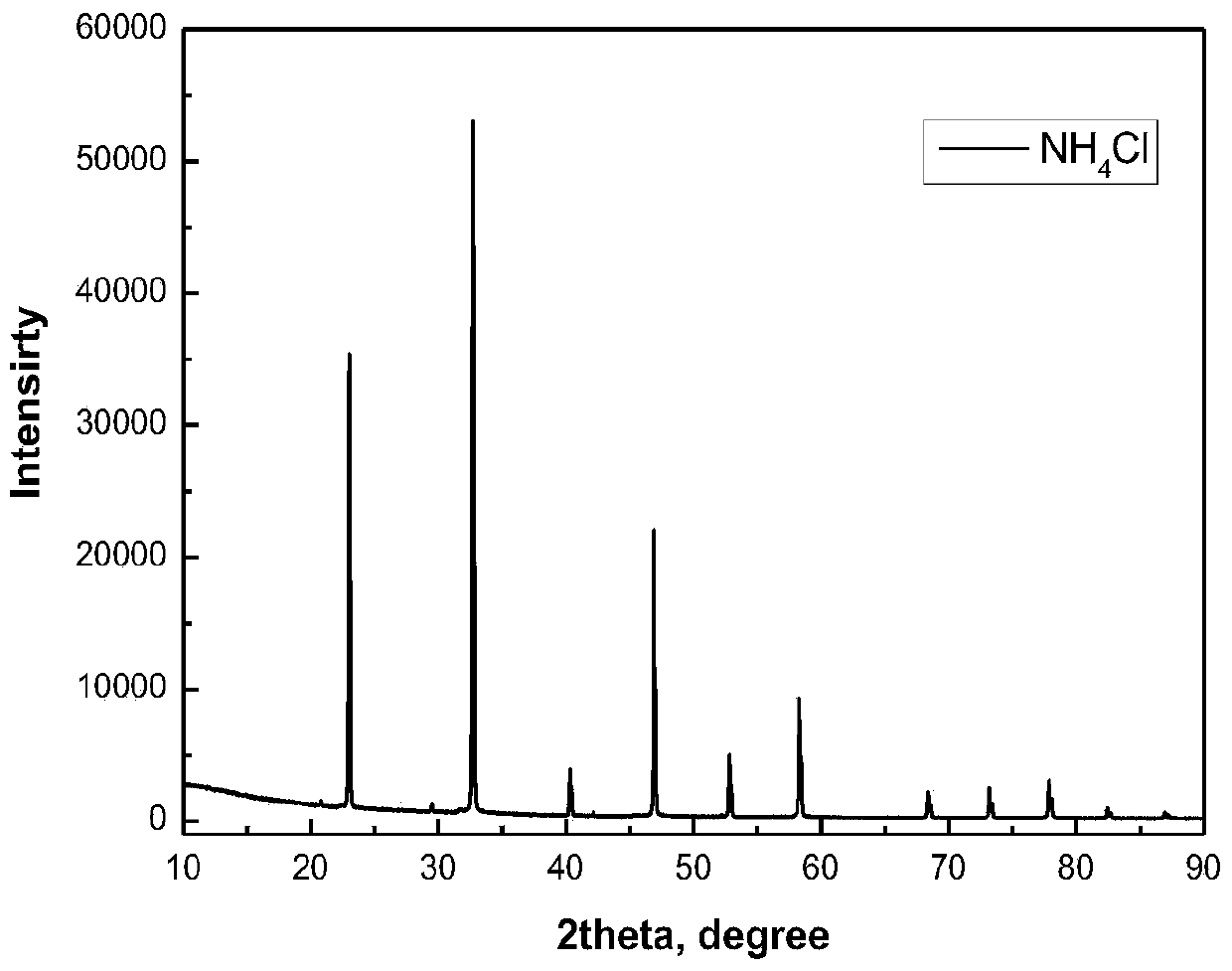

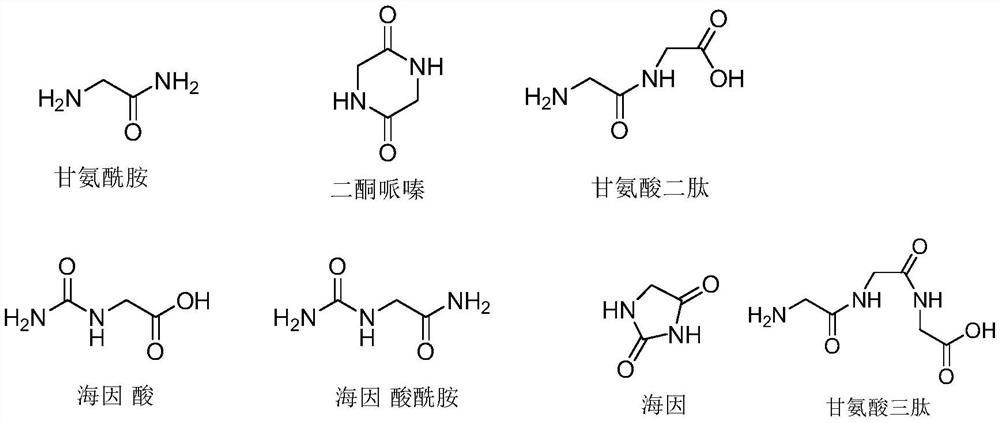

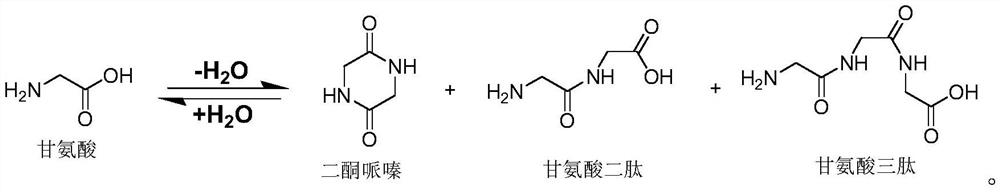

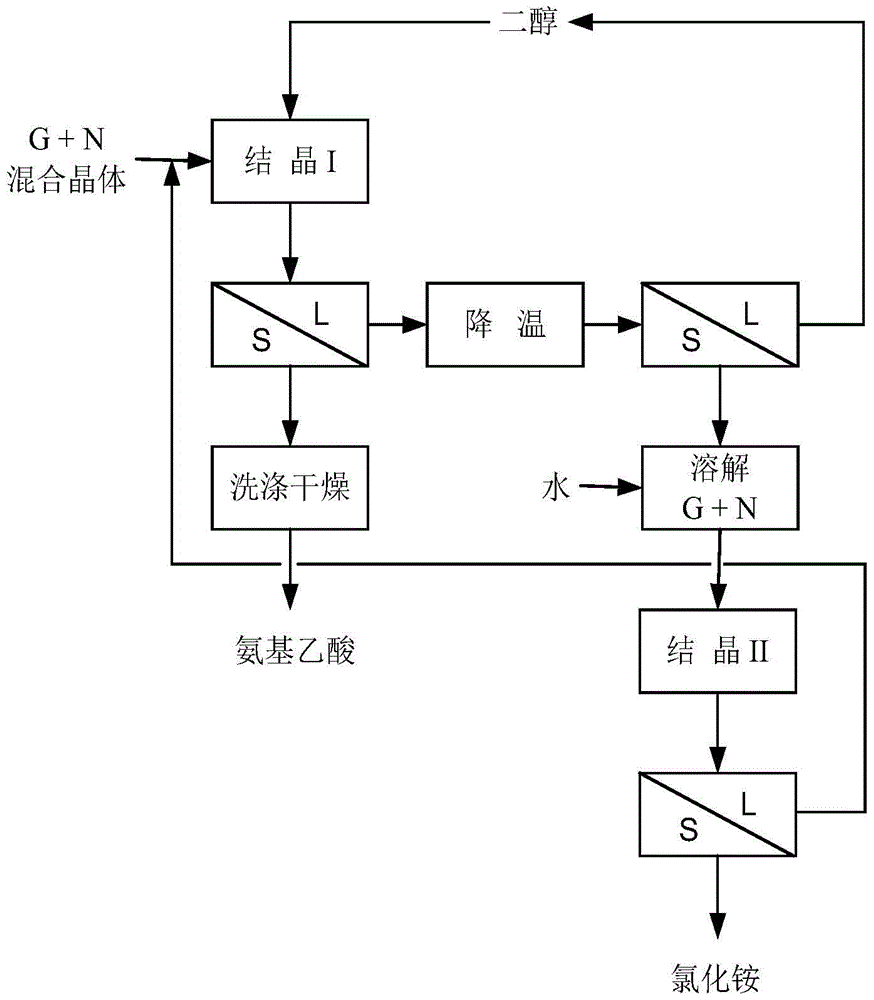

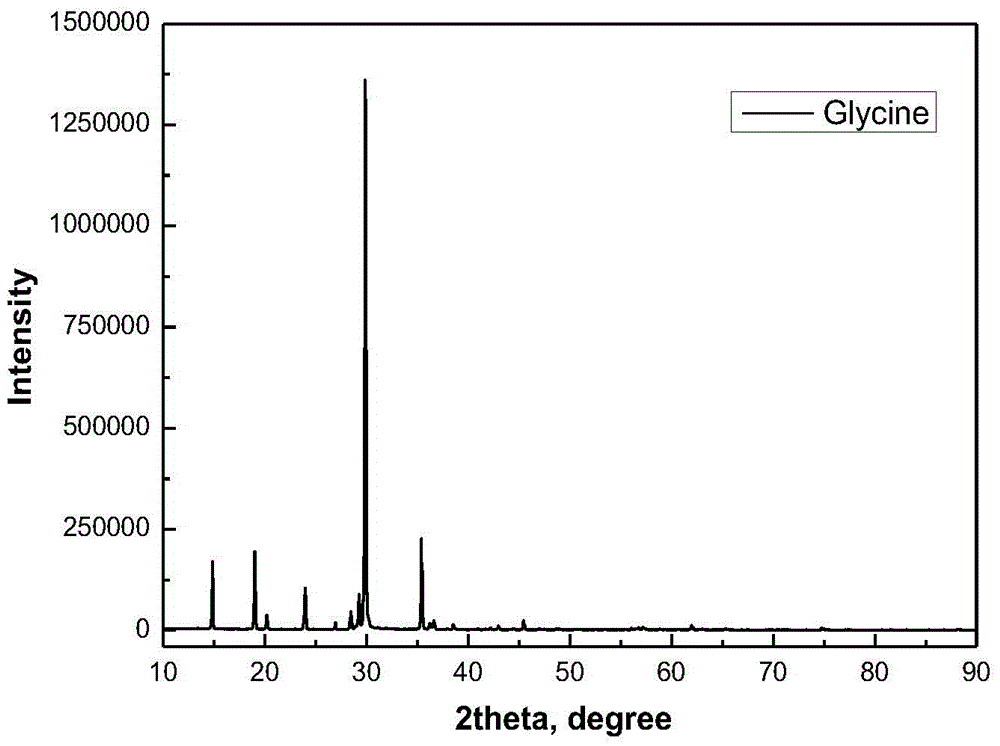

The invention provides a method for separating mixed crystals of glycine and ammonium chloride. According to the method, the mixed crystals of glycine and ammonium chloride are separated by two-step crystallization respectively by using a glycol solvent and a water solution as media, so as to obtain a glycine product with high purity and a by-product ammonium chloride. According to the method, based on good use of the difference between glycine and ammonium chloride in solubility in the glycol solvent and the water solution, glycine and ammonium chloride are separated under the mild operation condition; the used glycol solvent is small in volatility, free of damage in an operation process, and easy to recover, the problems of methyl alcohol volatilization, high energy consumption in evaporation recovery and the like in the methyl alcohol separation process are overcome, and the separation reagent in the whole technical process is recycled, so that the production cost is saved and non-pollution emission is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

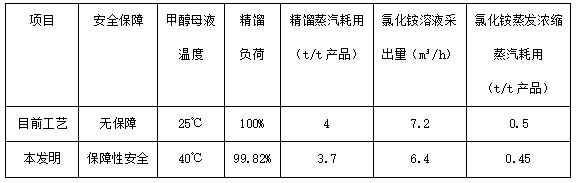

Novel glycine synthesis process

InactiveCN109574864ALow production costGuaranteed qualityOrganic compound preparationAmino-carboxyl compound preparationDistillationHexamethylenetetramine

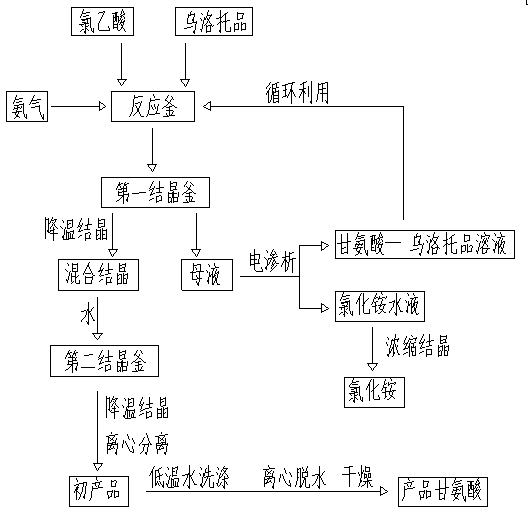

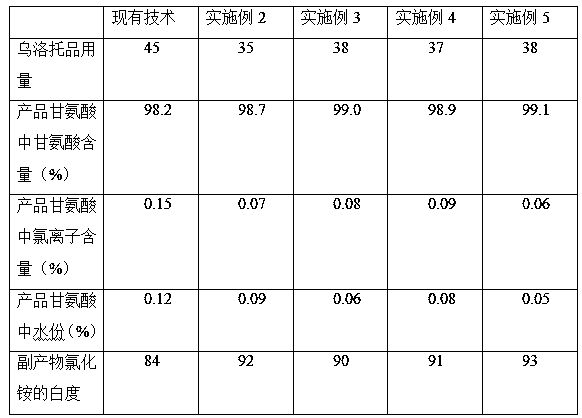

The invention discloses a novel glycine synthesis process, and belongs to the technical field of glycine production. Chloroacetic acid and ammonia gas serve as raw materials, aminolysis reaction is performed in water solution of methenamine serving as a catalyst, first cooling crystallization is performed after reaction to obtain mixed crystals and mother solution, the mixed crystals are dissolvedby water and then subjected to second cooling crystallization, obtained initial products are washed by low-temperature water and then centrifugally separated and dried to obtain a glycine product, the mother solution is separated by electrodialysis to obtain glycine and methenamine mixed solution and ammonium chloride water solution; conveying the glycine and methenamine mixed solution to a preceding procedure for mechanical application; evaporating, concentrating and crystallizing the ammonium chloride water solution to obtain ammonium chloride. The novel glycine synthesis process solves theproblems that production cost is increased by alcohol-water mixture, mother solution distillation needs a large quantity of energy consumption, and by-product ammonium chloride product is low in theprior art.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

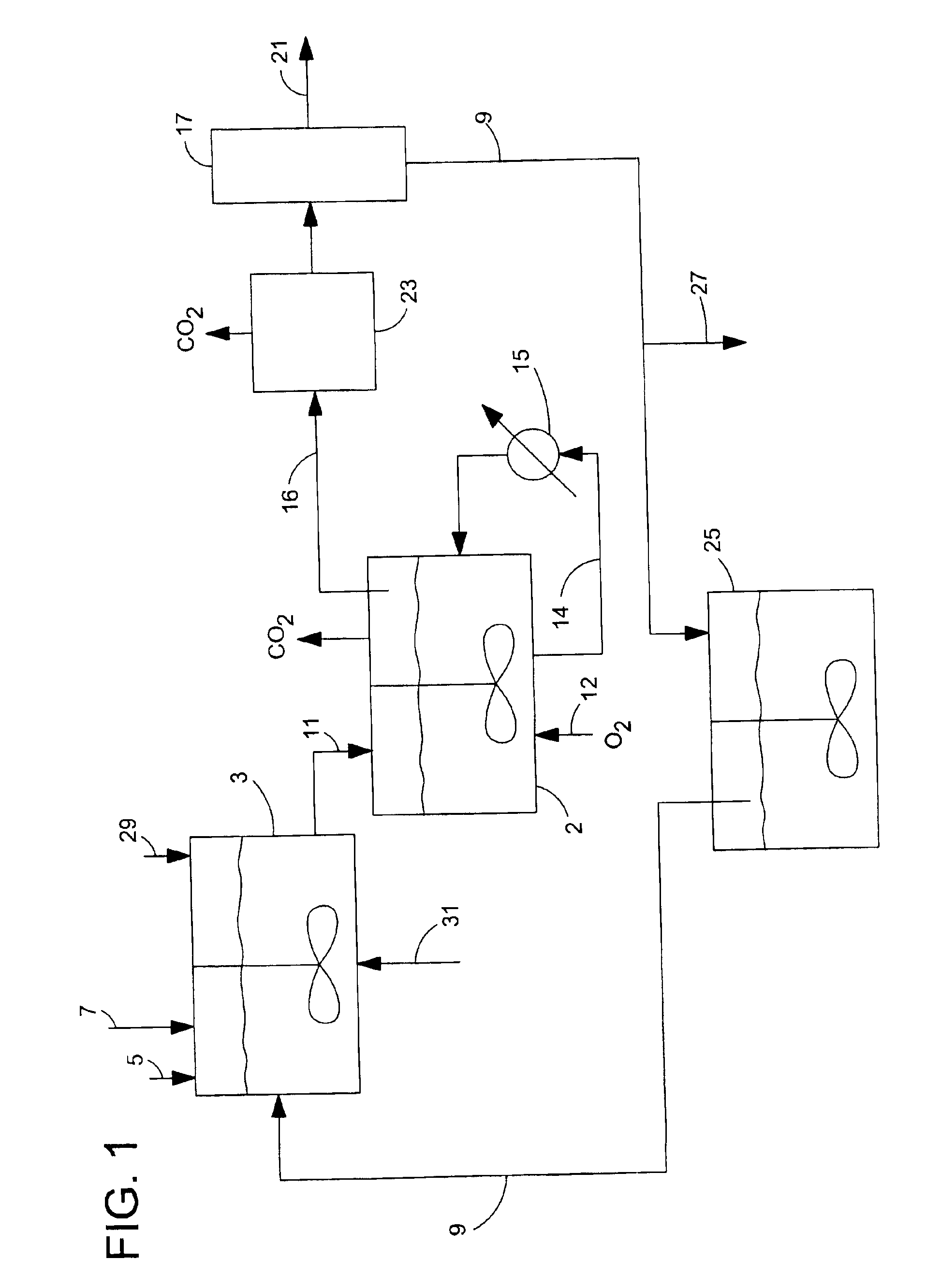

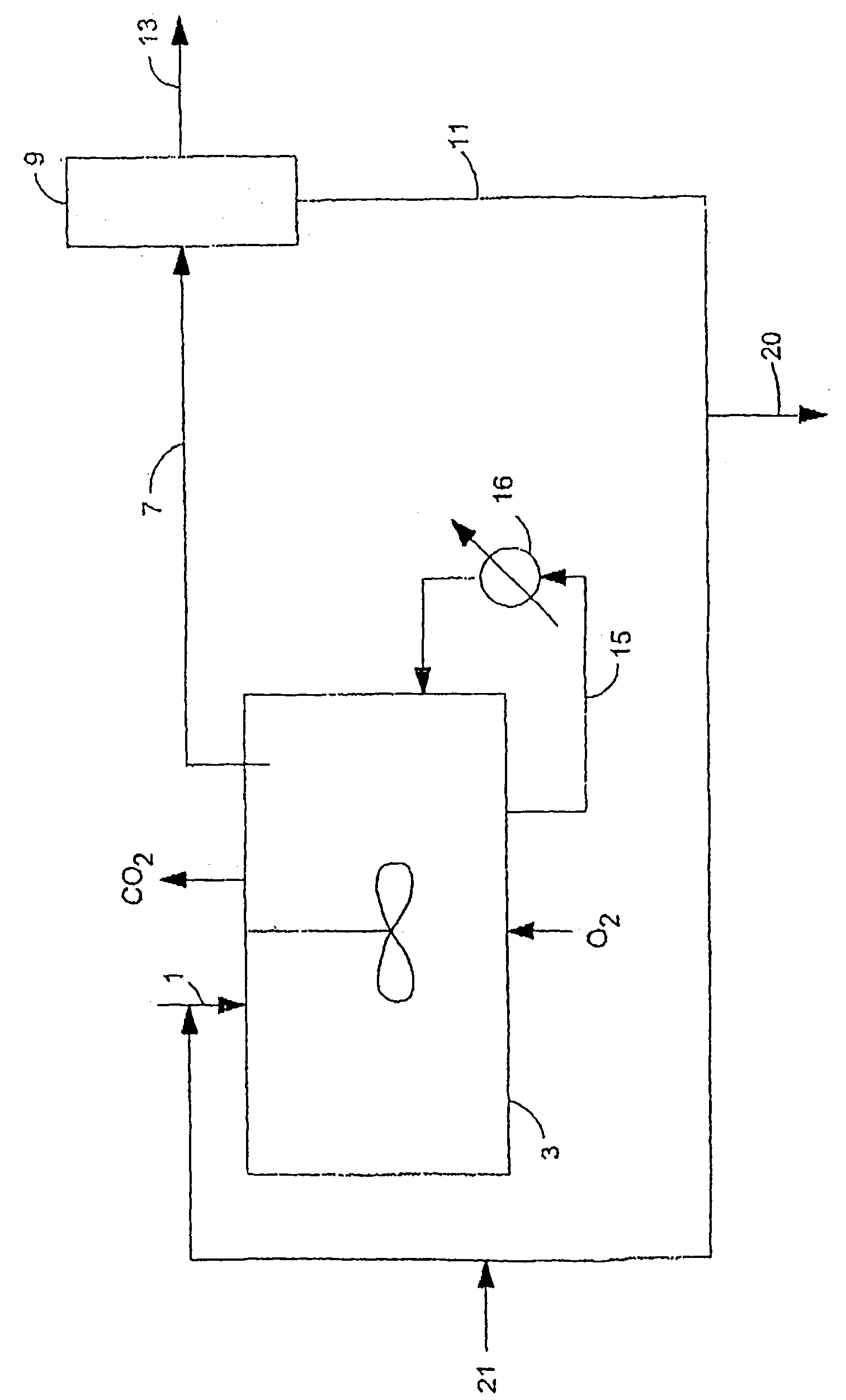

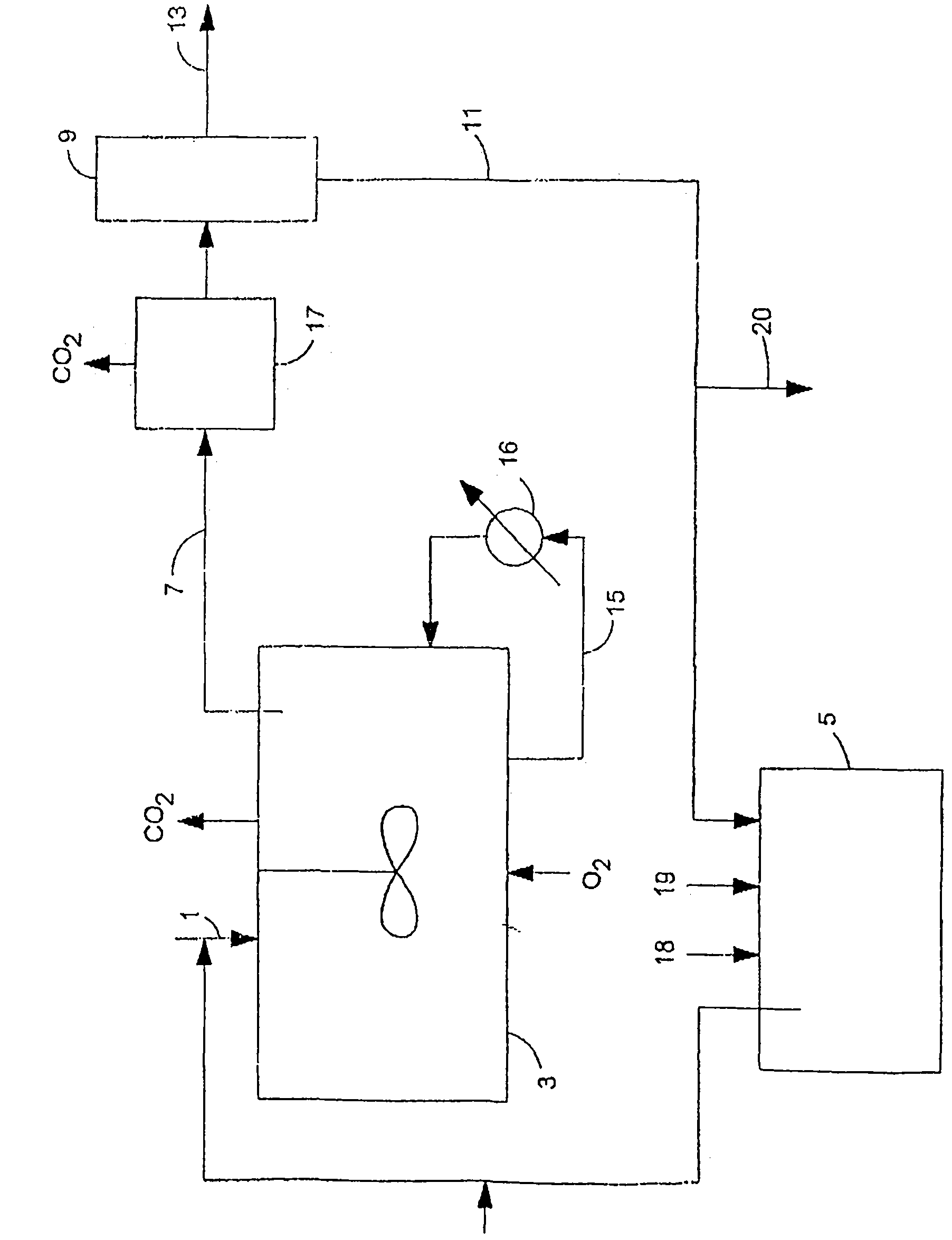

Reaction systems for making n-(phosphonomethyl)glycine compounds

This invention generally relates to liquid-phase oxidation processes for making N-(phosphonomethyl)glycine (also known in the agricultural chemical industry as glyphosate) and related compounds. This invention, for example, particularly relates to processes wherein an N-(phosphonomethyl)iminodiacetic acid (NPMIDA) substrate (i.e., N-(phosphonomethyl)iminodiacetic acid, a salt of N-(phosphonomethyl)iminodiacetic acid, or an ester of N-(phosphonomethyl)iminodiacetic acid) is continuously oxidized to form an N-(phosphonomethyl)glycine product (i.e., N-(phosphonomethyl)glycine, a salt of N-(phosphonomethyl)glycine, or an ester of N-(phosphonomethyl)glycine). This invention also, for example, particularly relates to processes wherein an N-(phosphonomethyl)iminodiacetic acid substrate is oxidized to form an N-(phosphonomethyl)glycine product, which, in turn, is crystallized (at least in part) in an adiabatic crystallizer.

Owner:MONSANTO TECH LLC

Method for producing glycine through organic solvent

InactiveCN104478747AOrganic compound preparationAmino-carboxyl compound preparationHexamethylenetetramineFiltration

The invention provides a cleaning production technology of glycine. The glycine is produced through glycols solvents (ethylene glycol, propylene glycol and butyl glycol) or diol derivative solvents (ethylene glycol monomethyl ether, ethylene glycol monoethyl ether and ethylene glycol monobutyl ether) and methanol (or ethanol) organic solvents. After the organic solvents and catalyst methenamine are added in a reactor for producing the glycine, chloroacetic acid is added, then, nitrogen is slowly fed in, and a reaction for synthesizing the glycine is performed. After the reaction ends, glycine crystals are filtered out at the temperature ranging from 50 DEG C to 75 DEG C, and glycine products are obtained after methanol (or ethanol) washing, filtering and drying. After filtering liquid is cooled, ammonium chloride and mixed crystal solids including a small amount of glycine are obtained through filtration, and ammonium chloride products are obtained through washing. The reaction solvents are cyclically used.

Owner:刘长飞

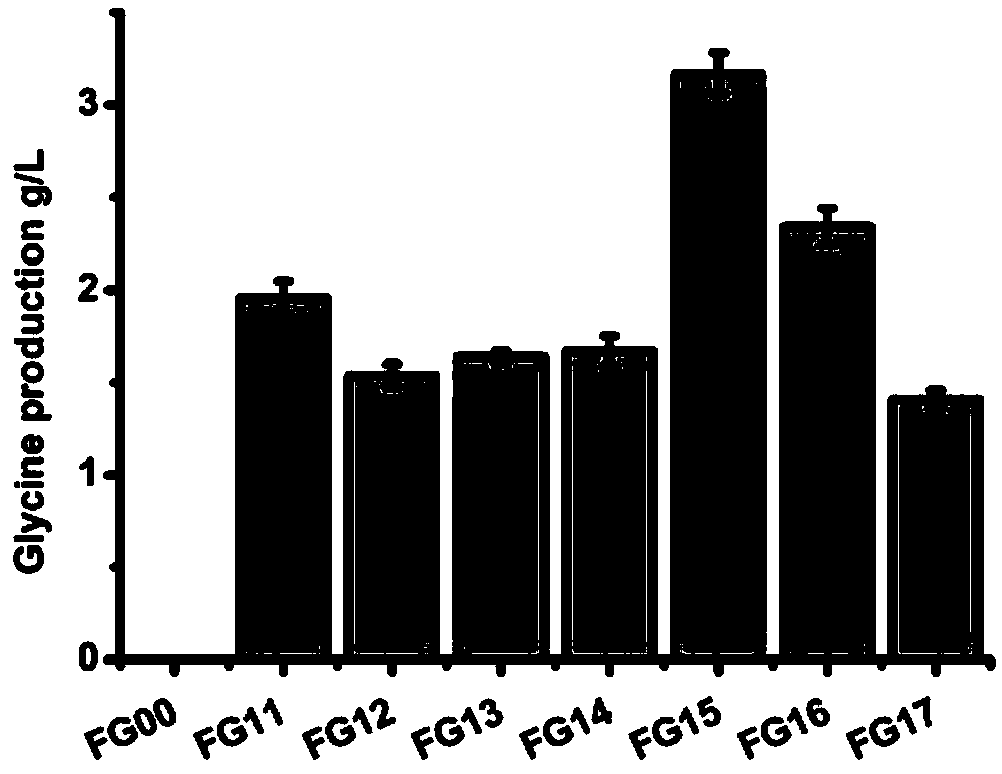

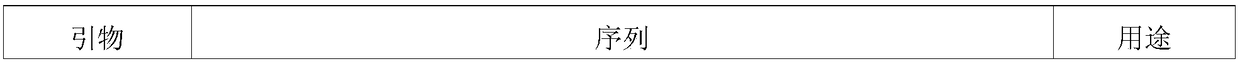

Escherichia coli recombinant bacterium for efficiently utilizing fatty acid to synthesize glycine, and construction method and application thereof

ActiveCN109266596AImprove synthesis abilityReduce manufacturing costBacteriaMicroorganism based processesEscherichia coliGlutamate-glyoxylate aminotransferase

The invention discloses an Escherichia coli recombinant bacterium for efficiently utilizing fatty acids to synthesize glycine and a construction method and application thereof. Escherichia coli recombinant bacterium contains one or more of that following genetic modification: (1) enhancement of fatty acid uptake pathway and fatty acid beta oxidation pathway; (2) glyoxylate cycle-related gene targets were modified to enhance glyoxylate synthesis; (3) introduction / enhancement of glutamate glyoxylate transaminase gene expression. The engineering strain of the invention has the ability to convertwhole cells of fatty acid substrates of different lengths into glycine, which can be stearic acid (C18), palmitic acid (C16), tetradecanoic acid (C14), lauric acid (C12), decanoic acid (C10), octanoicacid (C8) or caproic acid (C6). The ability of the engineered strain to synthesize glycine from fatty acids makes it useful for the industrial production of glycine products.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

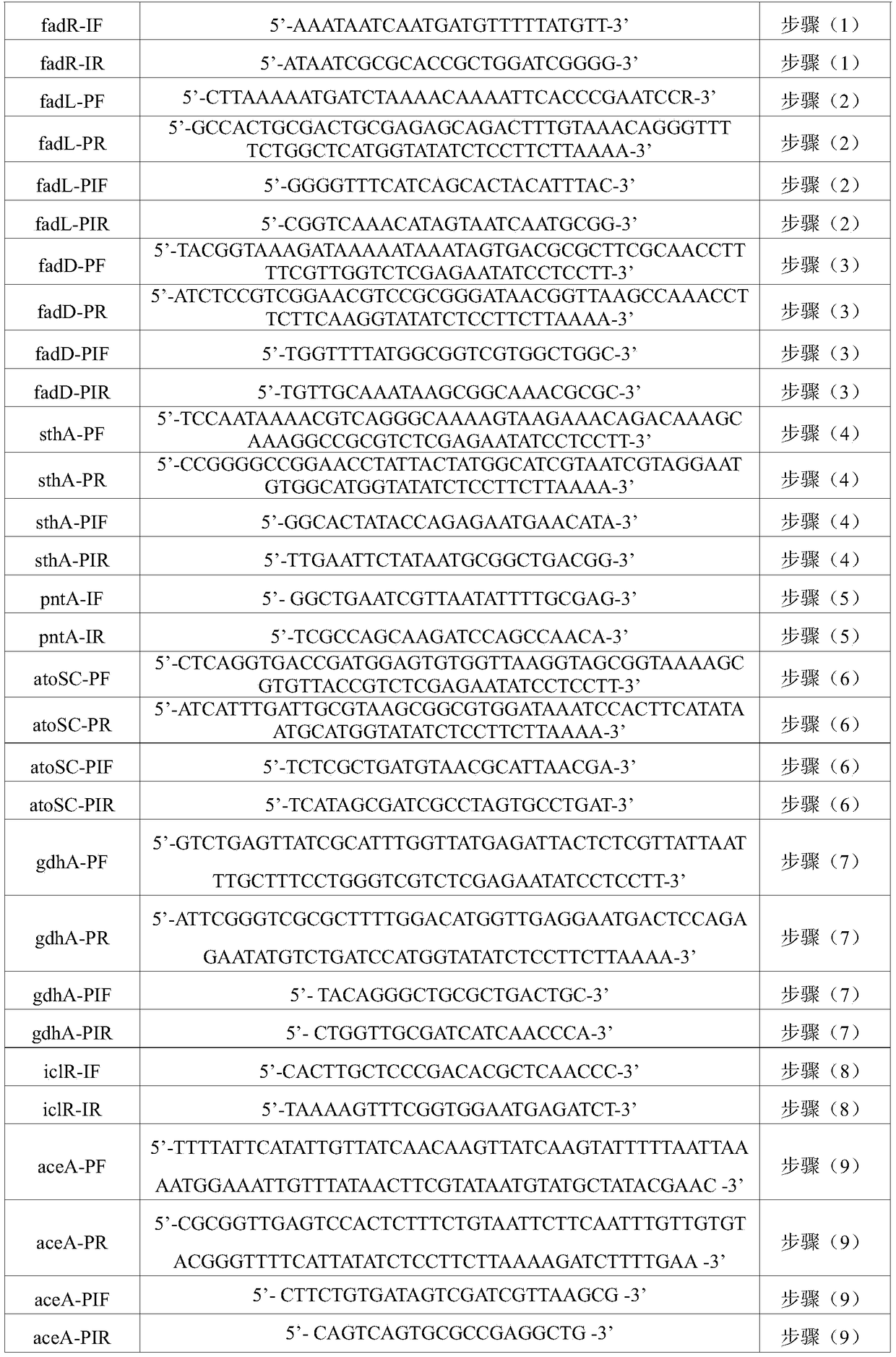

Method for co-producing glycine and hydantoin, and apparatus thereof

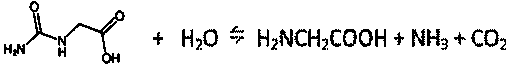

InactiveCN104910031AEasy to adjust outputLess investment in production equipmentOrganic compound preparationAmino-carboxyl compound preparationAmmonium carbonateHydrolysis

The invention discloses a method for co-producing glycine and hydantoin, and an apparatus thereof. The method adopting hydroxyacetonitrile, ammonia, carbon dioxide and water, or hydroxyacetonitrile, ammonia, ammonium bicarbonate and water, or hydroxyacetonitrile, ammonium carbonate, carbon dioxide and water as raw materials comprises the following steps: carrying out an amidocarbonylation reaction on the raw materials at a temperature of 60-120DEG C under a pressure of 1.5-3.0MPa according to a molar ratio of hydroxyacetonitrile: ammonia: carbon dioxide: water of 1:3-5:2-4:46-50 in a reaction system to prepare an amidocarbonylation reaction solution; acidifying the amidocarbonylation reaction solution to obtain a hydantoin product, or carrying out ammonification hydrolysis on the amidocarbonylation reaction solution to prepare a glycine product The method and the apparatus can save the investment of apparatuses for prodcuign glycine and hydantoin, reduce the production cost, are convenient for adjusting the outputs of glycine and hydantoin, and especially overcome the disadvantages of incomplete hydrolysis, generation of iminodiacetic acid, many byproducts, difficult purification of glycine, and low yield of present hydantoin methods for preparing glycine.

Owner:CHONGQING UNISPLENDOUR CHEM

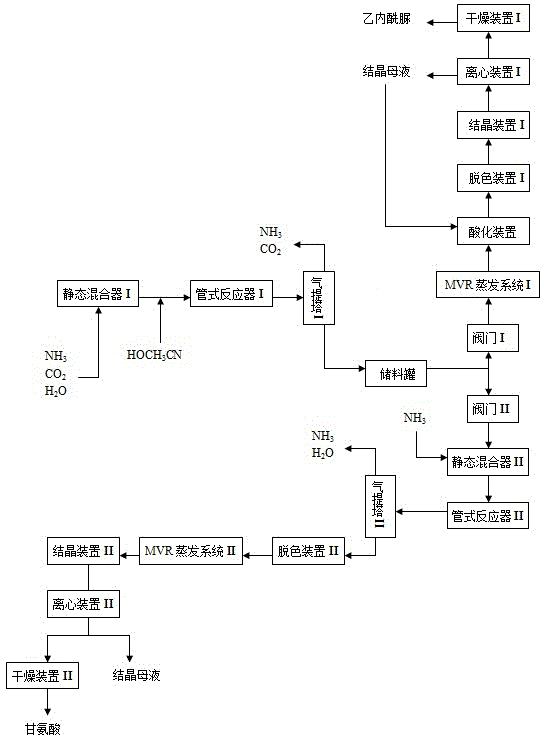

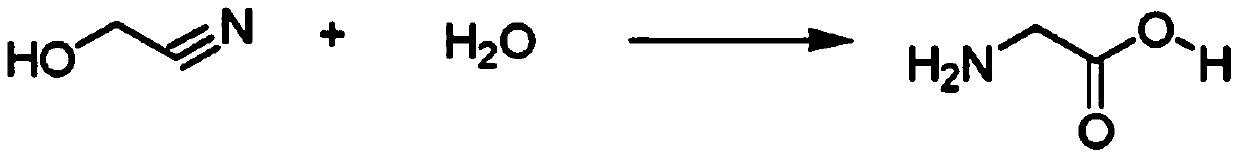

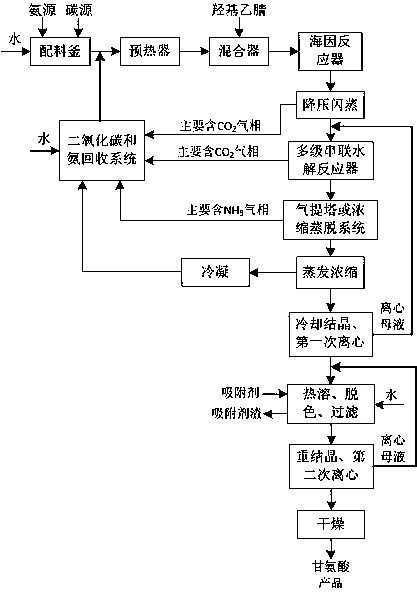

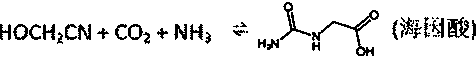

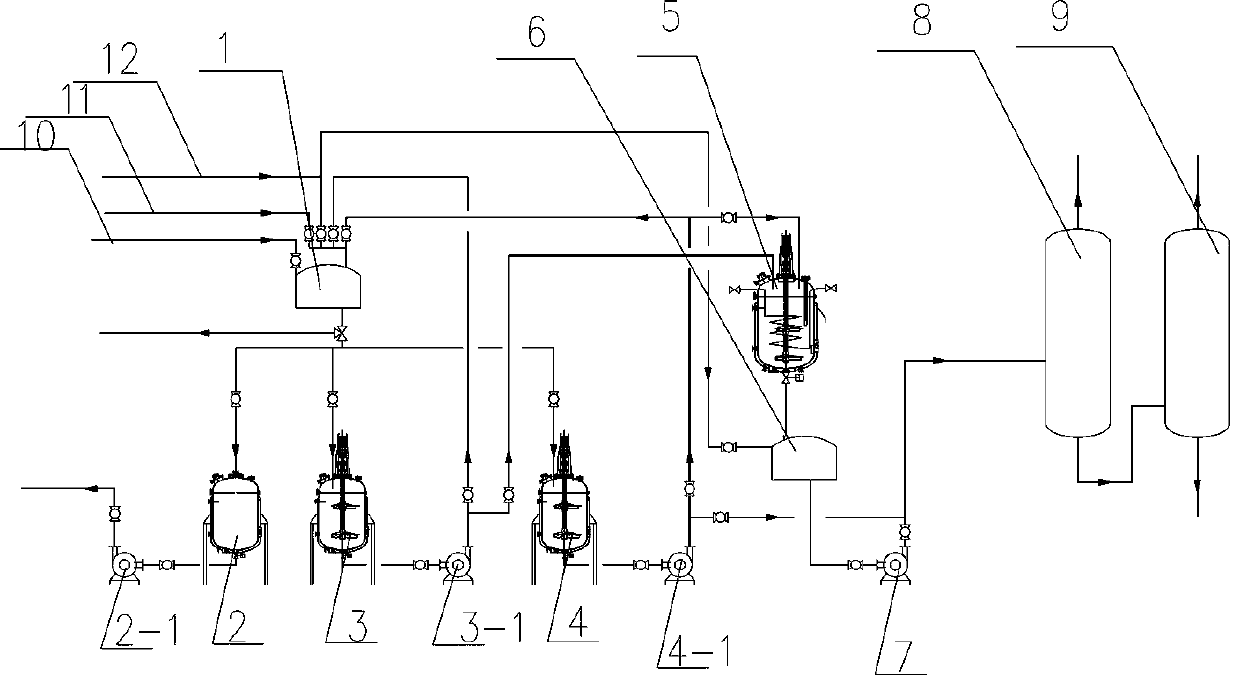

Method for continuously preparing glycine from hydroxyacetonitrile by microchannel reactor

PendingCN110698357AHigh yieldReduce manufacturing costOrganic compound preparationChemical/physical/physico-chemical microreactorsHydrolysisAqueous solution

The invention provides a method for continuously preparing glycine from hydroxyacetonitrile by a microchannel reactor. The method comprises the following steps: preheating and mixing hydroxyacetonitrile, a carbon source and an ammonia source which serve as raw materials, sequentially performing hydantoin synthesis and hydantoin hydrolysis reaction in the microchannel reactor to obtain a glycine aqueous solution, and performing steam stripping, evaporation and concentration, crystallization, separation, decoloration and drying to obtain the glycine product. Compared with an existing method, themethod realizes continuous preparation of the glycine by taking the hydroxyacetonitrile as the raw material, and has the advantages of short reaction time, few byproducts, high glycine yield and lowpreparation cost.

Owner:山西华阳集团新能股份有限公司

Method for producing glycine by using organic solvent

InactiveCN108203390AOrganic compound preparationAmino-carboxyl compound preparationHexamethylenetetramineChloroacetic acids

The invention provides a clean production method for glycine. Glycine is produced by using a glycol solvent (ethylene glycol, propylene glycol and butylene glycol) or a diol derivative solvent (ethylene glycol monomethyl ether, ethylene glycol monoethyl ether and ethylene glycol monobutyl ether) and a methanol (ethanol) organic solvent. The clean production method comprises the steps: adding an organic solvent and a catalyst urotropine into a reactor for producing glycine, then, adding chloroacetic acid, and then, slowly introducing ammonia to carry out a reaction for synthesizing glycine; after ending the reaction, filtering a glycine crystal under the condition of 50-75 DEG C, and carrying out methanol (or ethanol) washing, filtering and drying to obtain a glycine product; and after a filtrate is frozen and cooled, filtering the filtrate to obtain ammonium chloride and a mixed crystal solid containing a small amount of glycine, and carrying out washing to obtain an ammonium chlorideproduct. A reaction solvent is recycled.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

Method for producing glycine by using organic solvent

ActiveCN109836344AOrganic compound preparationClimate change adaptationHexamethylenetetramineFiltration

The invention relates to a method for producing glycine and co-producing ammonium chloride by using an organic solvent, wherein the organic solvent comprises: ethylene glycol, propylene glycol, dimethylacetamide (DMAC), and methanol and ethanol capable of being blended in the previous solvents. According to the present invention, a reaction organic solvent and a catalyst urotropine are added to areactor for producing glycine, chloroacetic acid is added, ammonia is introduced to synthesize glycine, and cooling, filtration, washing and drying are sequentially performed to obtain the glycine product; and chloroacetic acid or ammonium chloroacetate is added to the organic solvent, ammonium chloride is precipitated and crystallized, and washing and drying are performed to obtain the ammonium chloride product, wherein the organic solvent is recycled.

Owner:北京长邦科技有限公司

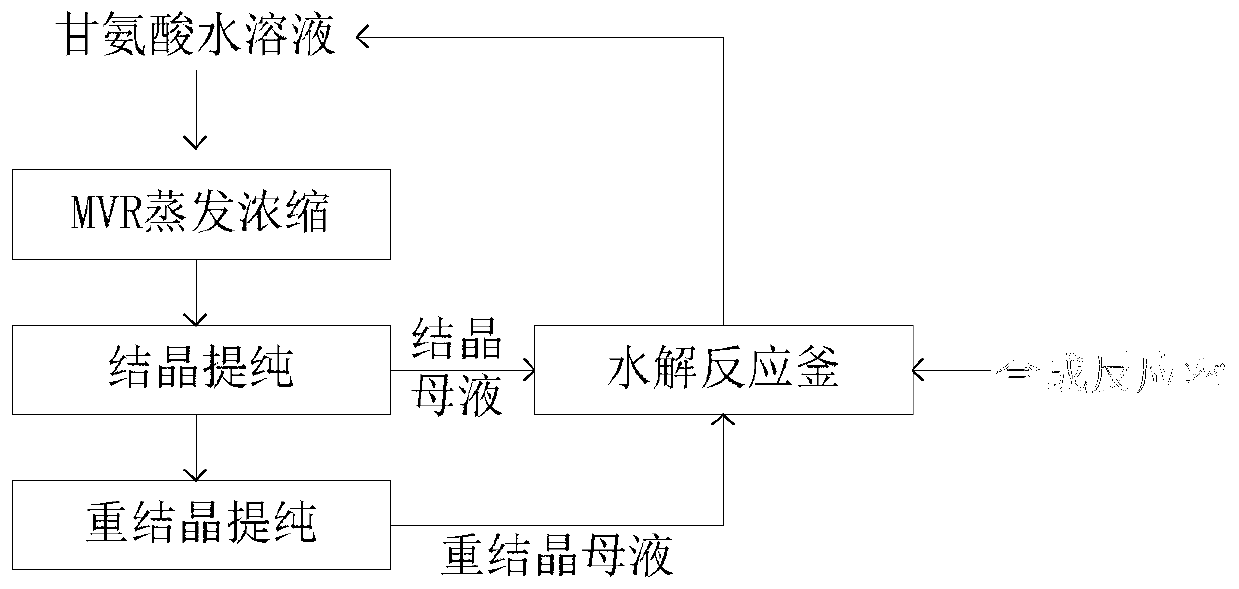

Aftertreatment technology of hydantion serialization preparation of glycine

InactiveCN109942448AReduce lossesImprove qualityOrganic compound preparationAmino-carboxyl compound preparationEvaporationAcetonitrile

The invention provides an aftertreatment technology of hydantion serialization preparation of glycine. The technology comprises the steps that a steam machine re-compression technology is adopted forevaporating and concentrating a glycine aqueous solution to obtain a concentration solution, and the glycine aqueous solution is obtained in the mode that glycollic nitrile, an ammonia source and a carbon source are subjected to synthesis and hydrolysis reactions in sequence; the concentration solution is subjected to crystallization and purification to obtain glycine crystals and a glycine mothersolution; the glycine crystals are subjected to recrystallization and purification to obtain a glycine product and a recrystallization mother solution; the crystallization mother solution and the recrystallization mother solution are circulated to a hydrolysis reaction kettle, and the crystallization mother solution, the recrystallization mother solution and a synthetic reaction solution are hydrolyzed. According to the aftertreatment technology, in the evaporation and concentration process, live steam does not need to be consumed, the crystallization mother solution and the recrystallizationmother solution are circulated to the hydrolysis reaction kettle for continuous hydrolysis, the loss of the glycine can be reduced, and the quality of the glycine can be improved.

Owner:山西华阳集团新能股份有限公司

Method for producing glycine by using organic solvent

InactiveCN106699582AOrganic compound preparationAmino-carboxyl compound preparationOrganic solventChloroacetic acids

The invention relates to a method for producing glycine by using an organic solvent, and provides a clean production technology of the glycine. According to the method, the glycine is prepared by using a glycols solvent (such as ethylene glycol, propylene glycol or butanediol), or a glycol derivative solvent (such as ethylene glycol monomethyl ether, ethylene glycol monoethyl ether or ethylene glycol monobutyl ether) and a methyl alcohol (or ethyl alcohol) organic solvent. The method comprises the steps of adding the organic solvent and a catalyst-urotropine into a reactor used for producing the glycine, then adding chloroacetic acid into the reactor, slowly replenishing the reactor with ammonia, and carrying out a reaction for synthesizing the glycine; after the reaction is finished, filtering out glycine crystals at the temperature of 50-75 DEG C, washing the glycine crystals with methyl alcohol (or ethyl alcohol), filtering, and drying to obtain a glycine product; cooling filtrate by freezing, then filtering to obtain mixed crystal solid of ammonium chloride and a small amount of glycine, and washing to obtain an ammonium chloride product, wherein the reaction solvents can be reused.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

Method for preparing glycine iron(óÄ) chelate for fortified food

InactiveCN1280260CImprove solubilityIncrease concentrationOrganic compound preparationAmino-carboxyl compound preparationAntioxidantNitrogen gas

The invention discloses a preparation method of ferrous glycinate chelate, which is a food nutrition enhancer, and belongs to the technical field of preparation of ferrous amino acid chelate. The present invention uses glycine and ferrous chloride or ferrous carbonate as raw materials, adds antioxidants and nitrogen protection during the chelation reaction process, and adopts different organic solvents for sequential precipitation and elution during the product separation and purification process, thereby effectively The chelated ferrous iron in the product is separated from the inorganic iron, and impurity anions are better removed, and a product with excellent oxidation stability and water solubility is obtained. The ferrous glycinate chelate content in the synthesized product exceeds 80%, and the rehydration rate of the ferrous glycinate chelate is greater than 95%. The oxidation stability and aqueous solution stability of ferrous glycine chelate are far better than that of ferrous sulfate. The method of the invention has the advantages of being capable of industrial scale production, easy separation and purification of reaction products, simple operation, low cost, stable physical and chemical properties of the product, and the like.

Owner:JIANGNAN UNIV

Combined production method and device of glycine and hydantoin

InactiveCN104910031BEasy to adjust outputLess investment in production equipmentOrganic compound preparationAmino-carboxyl compound preparationHydrolysisHydantoin

The invention discloses a method for co-producing glycine and hydantoin, and an apparatus thereof. The method adopting hydroxyacetonitrile, ammonia, carbon dioxide and water, or hydroxyacetonitrile, ammonia, ammonium bicarbonate and water, or hydroxyacetonitrile, ammonium carbonate, carbon dioxide and water as raw materials comprises the following steps: carrying out an amidocarbonylation reaction on the raw materials at a temperature of 60-120DEG C under a pressure of 1.5-3.0MPa according to a molar ratio of hydroxyacetonitrile: ammonia: carbon dioxide: water of 1:3-5:2-4:46-50 in a reaction system to prepare an amidocarbonylation reaction solution; acidifying the amidocarbonylation reaction solution to obtain a hydantoin product, or carrying out ammonification hydrolysis on the amidocarbonylation reaction solution to prepare a glycine product The method and the apparatus can save the investment of apparatuses for prodcuign glycine and hydantoin, reduce the production cost, are convenient for adjusting the outputs of glycine and hydantoin, and especially overcome the disadvantages of incomplete hydrolysis, generation of iminodiacetic acid, many byproducts, difficult purification of glycine, and low yield of present hydantoin methods for preparing glycine.

Owner:CHONGQING UNISPLENDOUR CHEM

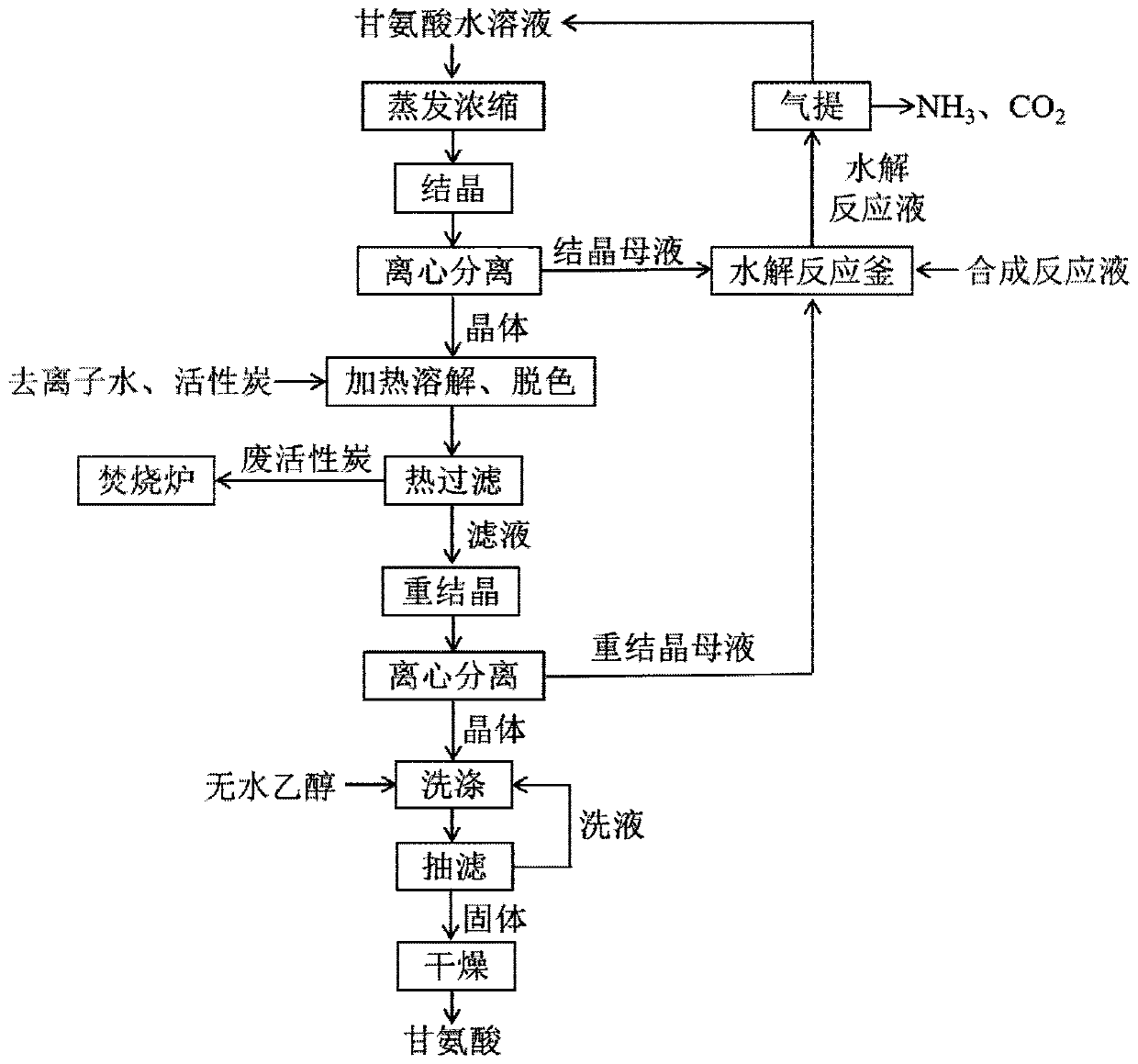

Clean process for continuously synthesizing glycine

InactiveCN111470992APromote generationShorten the hydrolysis reaction timeOrganic compound preparationAmino-carboxyl compound preparationCO2 - Carbon dioxideSide reaction

The invention discloses a clean process for continuously synthesizing glycine. The process comprises the following steps: preheating a carbon dioxide ammonia water solution prepared from an ammonia source, a carbon source and water, mixing the preheated solution with glycolonitrile, performing continuous synthesis, reduced pressure flash evaporation, continuous hydrolysis, gas stripping, concentrating, cooling and crystallizing, centrifuging for the first time, carrying out hot-melting recrystallization, centrifuging for the second time and drying to obtain a glycine product. Part of carbon dioxide generated by hydrolysis in the hydrolysis reaction process is continuously separated; and a carbon dioxide and ammonia recovery system sequentially absorbs the gas phase obtained by gas stripping, hydrolysis separation and reduced pressure flash separation to obtain a carbon dioxide ammonia water solution, and the carbon dioxide ammonia water solution is recycled to the reaction system. According to the process, the yield of glycine is increased by restraining iminodiacetonitrile side reaction; through timely release of each gas phase in the system and reasonable arrangement of the recovery sequence, the difficulty of recycling carbon dioxide and ammonia in the system is reduced, the loss of carbon dioxide and ammonia is reduced, the hydrolysis one-way conversion rate is improved, the hydrolysis time is greatly shortened, and the process is an environment-friendly and clean process for producing glycine.

Owner:龙智

High efficiency production method of glycine

InactiveCN108101799AHigh yieldEasy to recycleOrganic compound preparationAmino-carboxyl compound preparationThermal insulationHexamethylenetetramine

The invention discloses a high efficiency production method of glycine. The high efficiency production method comprises following steps: solvent methanol or ethanol, and catalyst urotropine or paraformaldehyde are introduced into a reactor, Ammonium-monochloracetat is added, the temperature is increased to 60 to 70 DEG C, N,N-Diisopropylethylamine or N,N-Diethylbenzylamine or N, N-di-n-propyl benzylamine or N, N-di-n-butyl benzylamine are added dropwise in 2h, thermal insulation reaction is carried out at 65 to 75 DEG C for 2.5h, the temperature is reduced to 40 to 50 DEG C for precipitation of glycine crystal, or the temperature is reduced to 10 to 25 DEG C for precipitation of a mixture of glycine crystal and an ammonium salt; and then filtering, washing, and drying are carried out successively so as to obtain a glycine product, wherein a washing liquid is adopted for recycling of N,N-Diisopropylethylamine or N,N-Diethylbenzylamine or N, N-di-n-propyl benzylamine or N, N-di-n-butyl benzylamine. The glycine yield is increased by 10% of that in the prior art; energy consumption is reduced; catalyst recycling is realized; recycling of N,N-Diisopropylethylamine or N,N-Diethylbenzylamine or N, N-di-n-propyl benzylamine or N, N-di-n-butyl benzylamine is realized; and combined production of ammonium chloride is realized.

Owner:严世佳

Device and process for washing glycine crude product through alcohol phase method

ActiveCN110305028AWill not affect the overall yieldGuaranteed industrial productionOrganic compound preparationAmino-carboxyl compound preparationChloroacetic acidsSolvent

The invention relates to a device and a process for washing a glycine crude product through an alcohol phase method. A glycine centrifuge is connected with a diluted methanol washing tank which is connected with a glycine extraction kettle through a diluted methanol pump, the glycine extraction kettle is connected with an extracted glycine centrifuge which is connected with a methanol rectifying tower through an extract transfer pump, and the methanol rectifying system is connected to a red ammonium concentration system. Alcohol and chloroacetic acid are taken as a solvent and an initial raw material respectively in the process, a glycine product meeting glyphosate synthesis requirements and reaching national standards (main content being greater than or equal to 98.5% and chlorine root being less than or equal to 0.4%) is obtained by treating the glycine crude product (glycine main content being 93-96%, chlorine root being 2-4% and other impurities being lower than 1%) produced by newprocesses like a mixed solvent or organic amine or novel halogen formula reagent method through a systematic industrial washing process, and glycine synthesis yield is unaffected; wastewater is completely recycled into a system, so that clean production is realized.

Owner:HUBEI TAISHENG CHEM

Production method of feed-grade and food-grade glycine and device for implementing production method

InactiveCN113045441AImprove effective conversion rateControl Decomposition AggregationOrganic compound preparationAmino-carboxyl compound preparationFood gradeOrganosolv

The invention relates to a production method for feed-grade and food-grade glycine and a device for implementing the method. The method comprises the following steps: with an aqueous hydroxyacetonitrile solution and an aqueous ammonium carbonate solution as raw materials, sequentially conducting reacting at 100-135 DEG C and 150-160 DEG C in the presence of a zirconium raw material, and controlling the liquid level of the reactions to be 75% or more; in the presence of the zirconium raw material, concentrating obtained reaction feed liquid under heating, removing ammonia and carbon dioxide, and then performing decoloration; and then in the presence of the zirconium raw material, subjecting the obtained decoloration solution to vacuum concentration and crystallization so as to obtain feed-grade and food-grade glycine products, wherein the yield of glycine is 97% or above in terms of glycolonitrile. The production method has the advantages that almost no three wastes are generated, the method is clean and environment-friendly, no organic solvent is needed, repeated recrystallization is not needed, the yield of feed-grade and food-grade glycine is high, production cost is low, an automation degree is high, and the like.

Owner:BOZUN INVESTMENT GRP LTD

Glycine production technology

InactiveCN106699589AHigh purityHigh yieldOrganic compound preparationAmino-carboxyl compound preparationChromatographic separationChloroacetic acids

The invention discloses a glycine production technology. The glycine production technology comprises steps as follows: a mixed solution is prepared from a crude glycine product which is produced with a chloroacetic acid aminolysis method and contains glycine and inorganic salt through dissolving with deionized water, the mixed solution is subjected to ceramic membrane separation, continuous chromatographic separation, concentration, crystallization, centrifugation and crystal drying, and glycine crystals and ammonium chloride crystals are obtained. With the adoption of the technical scheme of the glycine production technology, glycine production is performed by adopting ceramic membrane separation and continuous chromatographic separation systems, and the glycine production technology has the beneficial effects that the target products, namely, glycine and ammonium chloride, are high in product quality, high in yield and low in energy consumption.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

A kind of method for separating aminoacetic acid and ammonium chloride mixed crystal

InactiveCN104193634BHigh feasibilityAvoid harmOrganic compound preparationAmino-carboxyl compound preparationSolubilityHigh energy

The invention provides a method for separating mixed crystals of aminoacetic acid and ammonium chloride. The method separates mixed crystals of aminoacetic acid and ammonium chloride through two-step crystallization, respectively using glycol solvents and aqueous solutions as media, thereby obtaining high-quality Pure glycine product and by-product ammonium chloride. The invention makes full use of the difference in solubility between aminoacetic acid and ammonium chloride in glycol solvents and aqueous solutions, and realizes the separation of the two under mild operating conditions. The diol reagents used have low volatility, no hazards in the operation process, and are easy to recycle, which overcomes the problems of easy volatilization of methanol and high energy consumption for evaporation and recovery in the methanol separation process. The separation reagent is recycled in the whole process, which saves production cost and realizes pollution-free discharge.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of glycine

PendingCN113185420AHigh purityEasy to prepareOrganic compound preparationAmino-carboxyl compound preparationPtru catalystHexamethylenetetramine

The invention relates to a preparation method of glycine, which belongs to the technical field of chemical production and comprises the following five steps: preparing an ammonium chloroacetate solution, preparing a product glycine solution, preparing a glycine finished product, recovering to obtain an organic amine hydrochloride crystal solid and a filtrate containing urotropine, recovering an organic amine solution and preparing an ammonium chloride solid. The preparation method disclosed by the invention is simple and environment-friendly, the prepared glycine product is high in purity, and meanwhile, an industrial-grade ammonia chloride product can be obtained through co-production; the organic amine, the methanol and the catalyst urotropine used in the preparation process can be recycled, so that the production cost is saved, and the purpose of zero emission is achieved.

Owner:HEBEI DONGHUA JIHENG CHEM

Clean production technology for combined production of glycine and ammonium chloride

InactiveCN107868014AAmino compound purification/separationOrganic compound preparationDecompositionCogeneration

The invention provides a clean production process of glycine, which can co-produce ammonium chloride product while producing glycine; and co-produce triethylamine hydrochloride product while producing glycine. Add solvent methanol and catalyst to the reactor of glycine ammonolysis reaction, add solid ammonium chloroacetate, start adding triethylamine when the temperature rises to 65°C, complete the addition of triethylamine within one and a half hours, keep warm for two and a half hours to pH The value is 7.5. Respectively cool down and freeze to separate glycine and triethylamine hydrochloride. The triethylamine in the triethylamine hydrochloride is recovered by the method of passing through ammonia, and the ammonium chloride product is co-produced at the same time.

Owner:青岛九洲千和机械有限公司

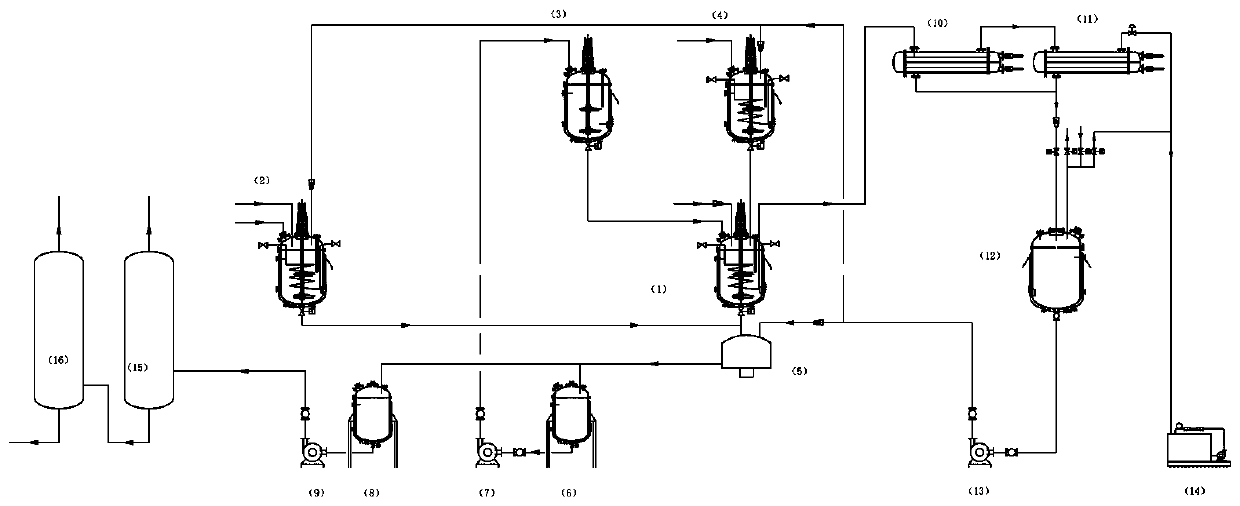

Process and device for producing glycine by alcohol phase method

PendingCN111362819ASignificant environmental benefitsLow cost of industrializationOrganic compound preparationAmino-carboxyl compound preparationPtru catalystAlcohol

The invention relates to a process and a device for producing glycine by an alcohol phase method. The main process comprises the following steps: taking methanol as a solvent, urotropin as a catalystand liquid or solid chloroacetic acid as an initial raw material, firstly introducing ammonia to produce a mixed crystal of glycine and ammonium chloride, centrifuging to obtain a mixed crystal, repeatedly applying the filtrate to synthesis of the mixed crystal, dissolving the mixed crystal by using pure water, extracting a glycine product by using methanol; enabling filtrate after glycine is centrifuged out to enter a rectifying tower to recover methanol, enabling rectified residual liquid to enter a film evaporator, concentrating the rectified residual liquid until water is completely evaporated to directly obtain an ammonium chloride byproduct, and repeatedly using water evaporated from the film evaporator to dissolve mixed crystals. The process mainly uses a glycine synthesis kettle, aglycine extraction kettle, a mixed crystal filtrate elevated tank, a centrifugal machine, a mixed crystal filtrate receiving tank, a chloroacetic acid dissolving kettle, a methanol rectifying tower,a film evaporator, and the like. According to the method, the unit consumption levels of urotropin, liquid ammonia, and steam can be greatly reduced, the production cost is further reduced, and no wastewater is generated.

Owner:HUBEI TAISHENG CHEM

Method for preparing glycine by using environment-friendly novel catalyst

InactiveCN111087316AHigh catalytic efficiencyReduce consumption costOrganic compound preparationAmino-carboxyl compound preparationPtru catalystEthyl group

The invention discloses a method for preparing glycine by using an environment-friendly novel catalyst in a water phase. The novel catalyst is mainly a pyridine base compound, and comprises 4-dimethylaminopyridine (DMAP), 2,4-dimethylpyridine, 3,5-dimethylpyridine, 4-methylpyridine, 2-methylpyridine, 3-methylpyridine, 2,3-dimethylpyridine, 2-methyl-5-ethylpyridine, 3-ethylpyridine and 2-methylaminopyridine. Solid ammonium chloroacetate and chloroacetic acid are used as raw materials, and mixed crystal solids of glycine and ammonium chloride are obtained through an ammoniation reaction in a water solution. The water solution containing the catalyst can be circularly used. A glycine product and a byproduct (ammonium chloride) are prepared from the mixed crystal of glycine and ammonium chloride by adopting an electrodialysis membrane separation or alcohol precipitation separation method.

Owner:北京长邦科技有限公司

Hydantoin precursor solution and method for preparing glycine by using hydantoin precursor solution

PendingCN114507150ACerium oxide content is not lowReduce synthesis energy consumptionOrganic compound preparationAmino-carboxyl compound preparationPtru catalystHydrolysate

The invention relates to the technical field of organic chemical industry, in particular to a hydantoin precursor solution and a method for preparing glycine by using the hydantoin precursor solution, the hydantoin precursor solution is an aqueous solution containing hydantoin amide and hydantoin components, and the molar ratio of the hydantoin amide to the hydantoin in the components is not lower than 2: 1; the method comprises the following steps: reacting a hydroxyacetonitrile material with a carbon dioxide source, an ammonia source and water in a synthesis device at 80-100 DEG C to prepare a hydantoin precursor solution, enabling the obtained hydantoin precursor solution to enter a hydrolysis device to contact with a solid catalyst containing a metal oxide, and hydrolyzing at 70-120 DEG C to obtain glycine hydrolysate; after the solid catalyst is separated from the glycine hydrolysate through the solid-liquid separation device, the glycine hydrolysate is concentrated and deaminated and then fed into the spraying device to be subjected to spray drying to obtain a glycine product, and the separated solid catalyst is returned to the hydrolysate device to be recycled. According to the method, the problem that hydantoin completely depends on self-hydrolysis and is difficult to be fully converted into a glycine product in an existing direct hydantoin method is solved.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

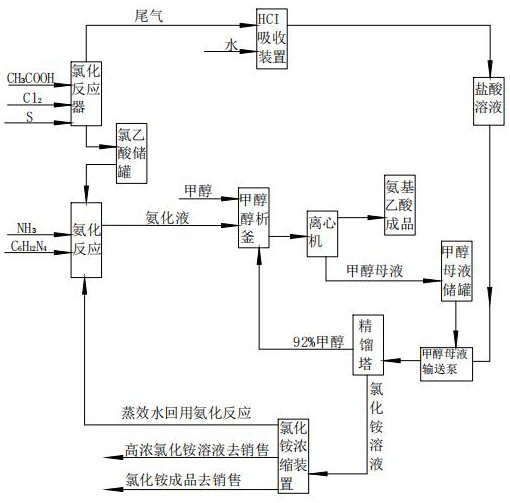

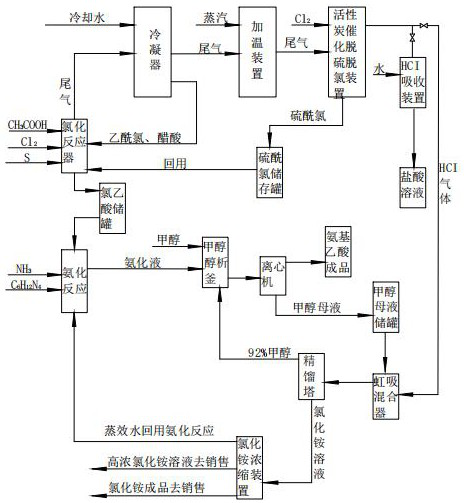

Production process of glycine

PendingCN114671772AReduce consumptionReduce inputChlorine/hydrogen-chloride purificationOrganic compound preparationWater chlorinationEthylic acid

The invention discloses a production process of glycine, and belongs to the technical field of glycine production. Comprising the following steps: (1) adding acetic acid and chlorine into a chlorination reactor to react to generate chloroacetic acid and generate tail gas; (2) adding chloroacetic acid into an ammoniation reactor for reaction to generate ammoniation liquid, and purifying to obtain a glycine product and methanol mother liquor; (3) enabling the tail gas generated in the step (1) to pass through a cooler, so that acetic acid and acetyl chloride in the tail gas are condensed and recycled for chlorination reaction; (4) the uncondensed tail gas enters a desulfurization and dechlorination device to generate sulfuryl chloride, and the sulfuryl chloride is condensed and reused for chlorination reaction; meanwhile, recovering hydrogen chloride gas; and (5) the hydrogen chloride gas enters a hydrochloric acid absorption device to prepare a hydrochloric acid solution, and the hydrogen chloride gas which is not absorbed is mixed with the methanol mother liquor for neutralization reaction. The method has the characteristics of safety, reliability, energy conservation, emission reduction, low consumption of sulfur and acetic acid raw materials, high product quality and the like.

Owner:闫三朋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com