Method for separating mixed crystals of glycine and ammonium chloride

A technology of glycine and mixed crystals, applied in chemical instruments and methods, preparation of organic compounds, ammonium halide and other directions, can solve the problems of low yield of glycine, flammable methanol, low purity, etc., and achieve good economic benefits and savings Process cost, environmental pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

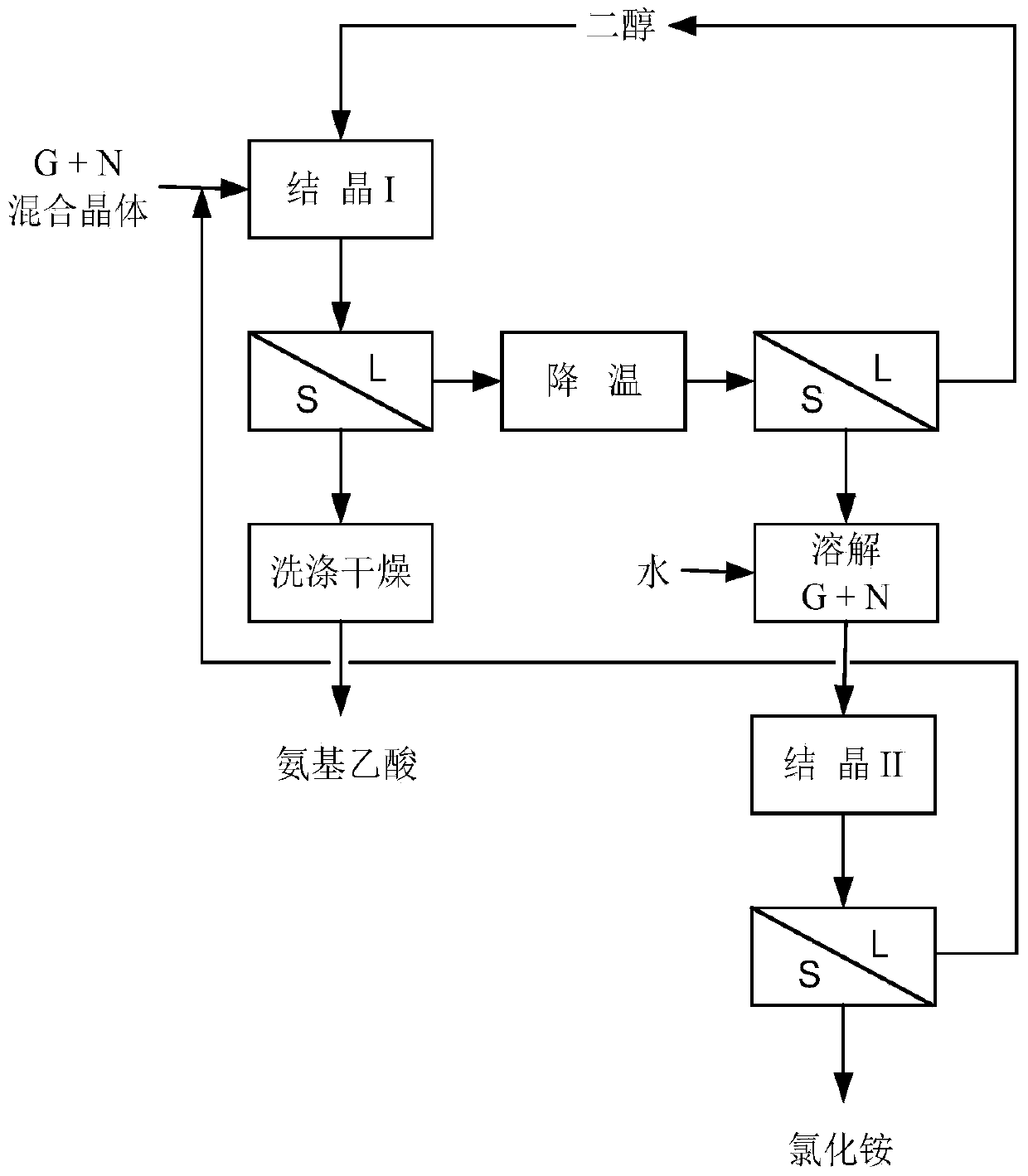

Method used

Image

Examples

Embodiment 1

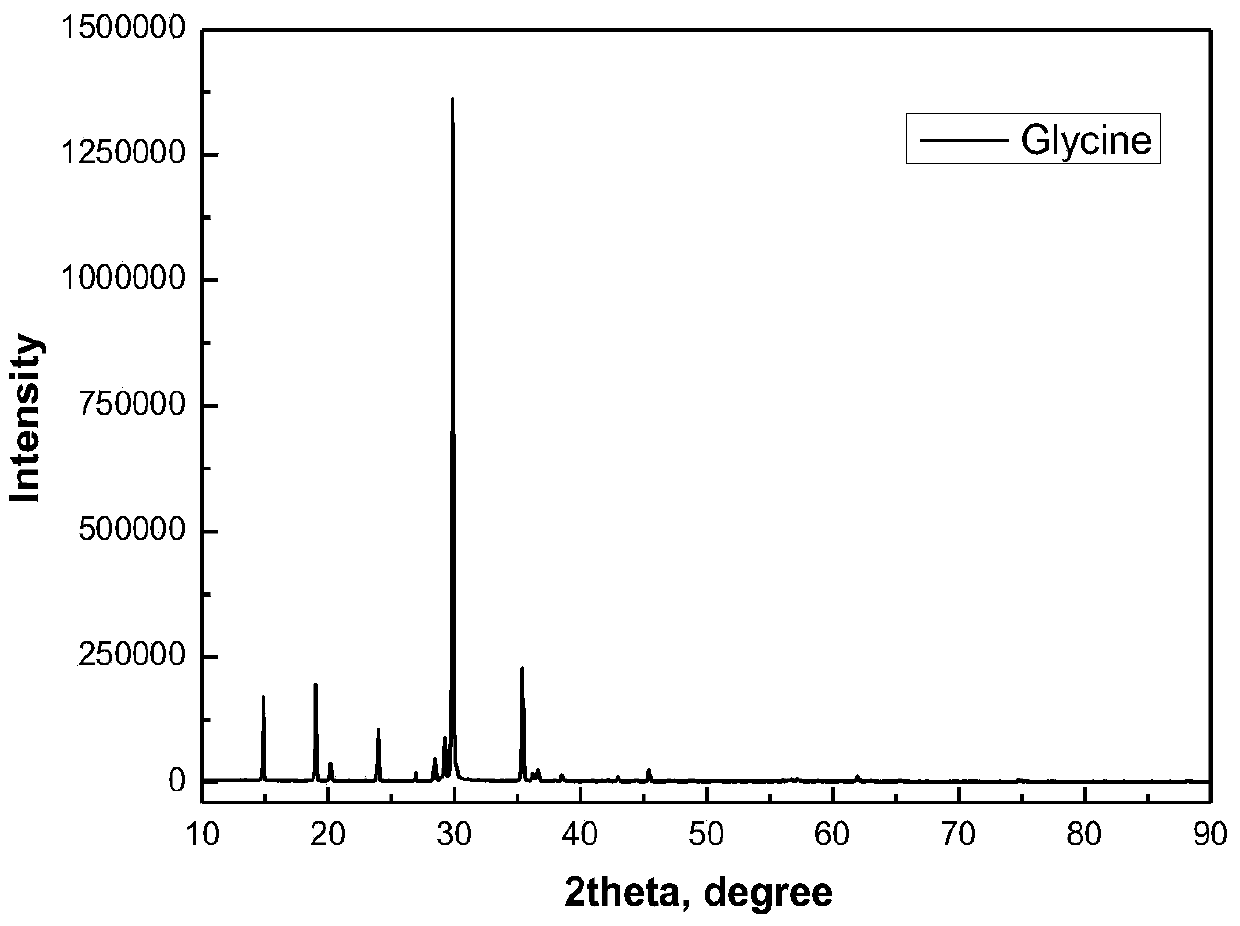

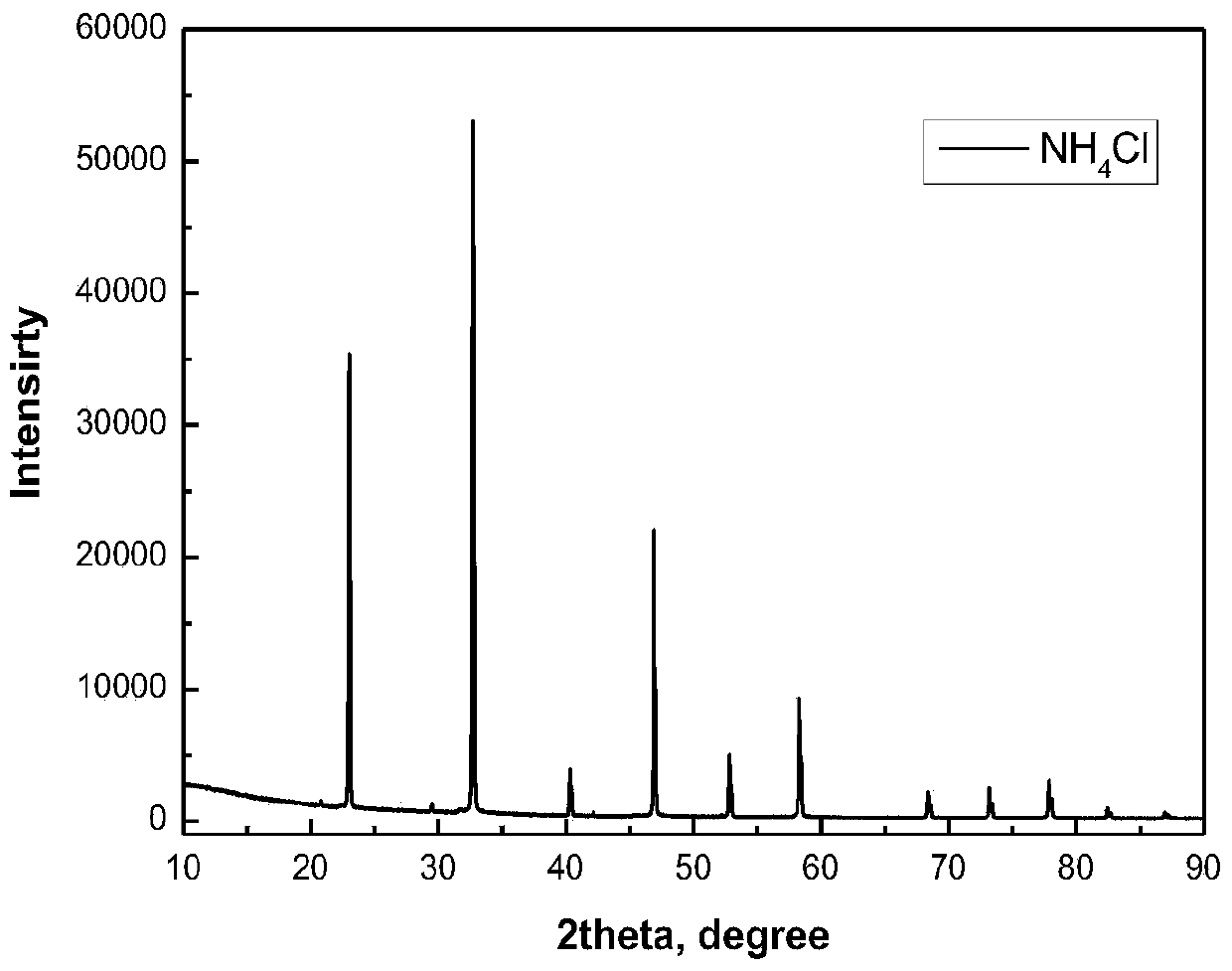

[0042] 500g of mixed crystals containing 60wt% glycine, 39wt% ammonium chloride and 1wt% water were placed in the crystallization tank I, and 1.3L ethylene glycol solution was added, while the stirrer was turned on and the temperature was controlled at 70°C. After 2 hours, the crystal slurry was taken out, and 255 g of aminoacetic acid was obtained after filtration and drying, and its purity was 99.6%. The filtrate was cooled to 15°C, and mixed crystals were precipitated. After filtering, 230 g of mixed crystals were obtained, and the mother liquor of ethylene glycol could be returned for use. The mixed crystals were dissolved in 400 mL of water at 70°C, and then the obtained mixed solution was placed in the crystallization tank II, and the temperature was lowered to 15°C to precipitate ammonium chloride crystals. After 2 hours, the magma was filtered, and the solid was dried to obtain 170g of ammonium chloride with a purity of 99.2%, and the filtrate was returned to be mixed...

Embodiment 2

[0044] Contain 48wt% glycine, 500g of mixed crystals of 50wt% ammonium chloride and 2wt% water are placed in crystallization tank I, add 1.5L propylene glycol solution, open agitator simultaneously and temperature is controlled at 80 ℃. After 2 hours, the crystal slurry was taken out, filtered and dried to obtain 200 g of aminoacetic acid with a purity of 99.7%. The filtrate was cooled to 10°C, and mixed crystals were precipitated. Obtain 255g of mixed crystals after filtration, and the propylene glycol mother liquor can be returned for use. The mixed crystals were dissolved in 500 mL of water at 70°C, and the obtained mixed solution was placed in the crystallization tank II, and the temperature was lowered to 10°C to precipitate ammonium chloride crystals. After 2 hours, the magma was filtered, and the solid was dried to obtain 230 g of ammonium chloride with a purity of 99.1%, and the filtrate was returned to be mixed with the raw material.

Embodiment 3

[0046] 500g of mixed crystals containing 45wt% glycine, 54wt% ammonium chloride and 1wt% water were placed in the crystallization tank I, and 1.8L of butanediol solution was added, while the stirrer was turned on and the temperature was controlled at 60°C. After 2 hours, the crystal slurry was taken out, filtered and dried to obtain 170 g of aminoacetic acid with a purity of 99.5%. The filtrate was cooled to 15°C, and mixed crystals were precipitated. Obtain 300g of mixed crystals after filtration, and the butanediol mother liquor can be returned for use. The mixed crystals were dissolved in 600 mL of water at 65°C, and then the obtained mixed solution was placed in the crystallization tank II, and the temperature was lowered to 10°C to precipitate ammonium chloride crystals. After 2 hours, the magma was filtered, and the solid was dried to obtain 245g of ammonium chloride with a purity of 99.2%, and the filtrate was returned to be mixed with the raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com