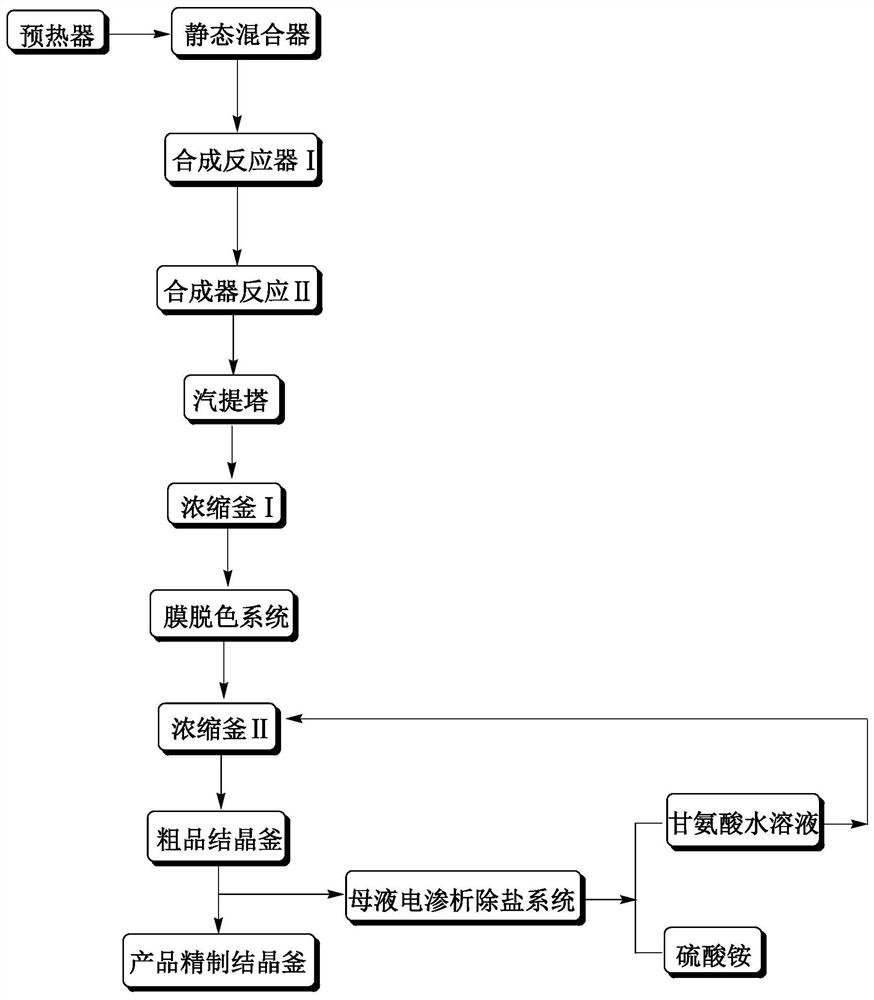

Production method of feed-grade and food-grade glycine and device for implementing production method

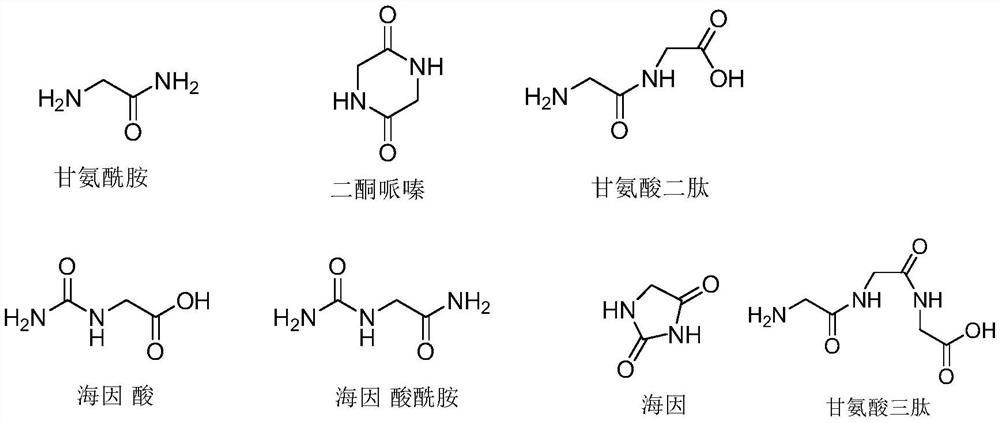

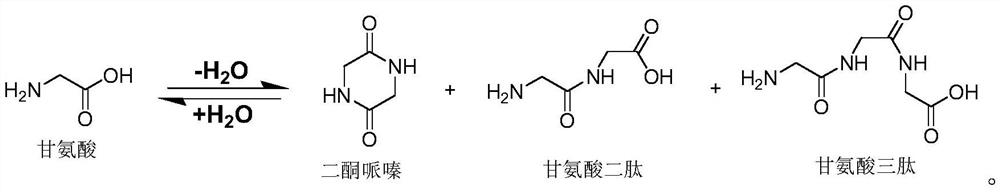

A glycine, food-grade technology, used in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high refining cost, increased by-products, and high energy consumption for crystallization, and achieves high operational flexibility and efficient conversion. The effect of high yield, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0169] 290.91 grams of ammonium carbonate with a purity of 99.0% and 750 grams of deionized water were added to a 1000ml pressure-resistant zirconium-lined reactor with a feeding and stirring device, and the temperature was raised to 65° C. to obtain an aqueous solution of ammonium carbonate. Squeeze 142.5 grams (50 ℃, pH=3.0) of 40wt% hydroxyacetonitrile aqueous solution preheated in advance from the feed port of the reactor with a booster pump, the mol ratio of hydroxyacetonitrile, ammonium carbonate and water is 1:3:46.4, During the process of adding the aqueous solution of hydroxyacetonitrile, the reactor was heated to 100°C for reaction, and the stirring speed was 120r / min, the speed of adding the aqueous solution of hydroxyacetonitrile was 8.0g / min, and the liquid level of the reaction material was 96%. After the addition of the hydroxyacetonitrile aqueous solution was completed, the reactor was closed, and the temperature was raised to 150° C. immediately, the pressure i...

Embodiment 2

[0175] 290.91 grams of ammonium carbonate with a purity of 99.0% and 869.3 grams of deionized water were added to a 1500ml pressure-resistant zirconium-lined reactor with a feeding and stirring device, and the temperature was raised to 50° C. to obtain an aqueous solution of ammonium carbonate. Squeeze 87.7 grams (70 ℃, pH=2.0) of the 65wt% hydroxyacetonitrile aqueous solution that preheats beforehand with booster pump from the inlet of reactor, the mol ratio of hydroxyacetonitrile, ammonium carbonate and water is 1:3:50, During the process of adding the aqueous solution of hydroxyacetonitrile, the temperature of the reactor was raised to 135° C., and the stirring speed was 120 r / min. The rate of adding the aqueous solution of hydroxyacetonitrile was 8.0 g / min, and the liquid level of the reaction material was 76%. After the addition of the hydroxyacetonitrile aqueous solution was completed, the reactor was closed, and the temperature was raised to 150° C. immediately, the pres...

Embodiment 3

[0179] 232.73 grams of ammonium carbonate with a purity of 99.0% and 602.4 grams of deionized water were added to a 1000ml pressure-resistant zirconium-lined reactor with a feeding and stirring device, and the temperature was raised to 65° C. to obtain an aqueous solution of ammonium carbonate. Squeeze 91.2 grams (60 ℃, pH=4.0) of the 50wt% hydroxyacetonitrile aqueous solution that preheats beforehand with pressurized pump from the inlet of reactor, the mol ratio of hydroxyacetonitrile, ammonium carbonate and water is 1:3:45, During the process of adding the aqueous solution of hydroxyacetonitrile, the temperature of the reactor was raised to 120° C., and the stirring speed was 150 r / min. The rate of adding the aqueous solution of hydroxyacetonitrile was 5.0 g / min, and the liquid level of the reaction material was 85%. After the addition of the aqueous solution of hydroxyacetonitrile was completed, the reactor was closed, and the temperature was raised to 152° C. immediately, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com