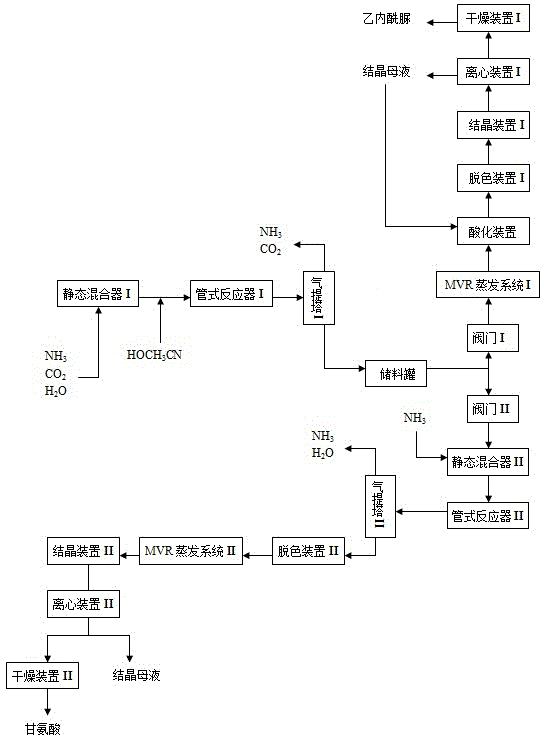

Method for co-producing glycine and hydantoin, and apparatus thereof

A hydantoin and combined production technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult purification of glycine, incomplete hydrolysis, many by-products, etc., to overcome incomplete hydrolysis , saving investment in production equipment and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Production of ammonia carbonylation reaction liquid: In a 5000ml pressure-resistant reactor equipped with a pressurized sampling device and a stirring device, add 2364g of water, then feed in 216.5g of ammonia gas and 420.4g of carbon dioxide gas, raise the temperature to 100°C, and use 5.05g 453.8g of 40wt% hydroxyacetonitrile aqueous solution was added dropwise at a constant rate of 1 / min, and the reaction was completed for 1.5 hours. The pressure of the reaction system was 1.6MPa, and then the unreacted ammonia and carbon dioxide were removed under reduced pressure to obtain the ammonia carbonylation reaction solution. The obtained ammonia carbonylation reaction liquid is equally divided into two parts, and the production of hydantoin and glycine are carried out respectively.

[0031] Production of hydantoin: Concentrate the ammonia carbonylation reaction solution to 40wt% under reduced pressure, add 98wt% concentrated sulfuric acid equivalent to 15wt% of the concentr...

Embodiment 2

[0034] Production of ammonia carbonylation reaction liquid: In a 5000ml pressure-resistant reactor equipped with a pressurized sampling device and a stirring device, add 2364g of water, then feed in 216.5g of ammonia gas and 420.4g of carbon dioxide gas, raise the temperature to 100°C, and use 5.05g Add 453.8g of 40wt% hydroxyacetonitrile aqueous solution dropwise at a constant speed at a rate of 1 / min, and react for 1.5 hours after the addition. The pressure of the reaction system is 1.6MPa, and then the unreacted ammonia and carbon dioxide are removed under reduced pressure to obtain the ammonia carbonylation reaction solution. The obtained ammonia carbonylation reaction liquid is equally divided into two parts, and the production of hydantoin and glycine are carried out respectively.

[0035] Production of hydantoin: Concentrate the ammonia carbonylation reaction solution to 80wt% under reduced pressure, add the hydantoin crystallization mother liquor of Example 1, acidify a...

Embodiment 3

[0038] Production of ammonia carbonylation reaction liquid: In a 5000ml pressure-resistant reactor equipped with a pressurized sampling device and a stirring device, add 2364g of water, then feed in 216.5g of ammonia gas and 420.4g of carbon dioxide gas, raise the temperature to 100°C, and use 5.05g Add 453.8g of 40wt% hydroxyacetonitrile aqueous solution dropwise at a constant speed at a rate of 1 / min, and react for 1.5 hours after the addition. The pressure of the reaction system is 1.6MPa, and then the unreacted ammonia and carbon dioxide are removed under reduced pressure to obtain the ammonia carbonylation reaction solution. The obtained ammonia carbonylation reaction liquid is equally divided into two parts, and the production of hydantoin and glycine are carried out respectively.

[0039] Production of hydantoin: Concentrate the ammonia carbonylation reaction solution to 80wt% under reduced pressure, add the hydantoin crystallization mother liquor of Example 2, acidify a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com