Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

810 results about "Errors measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

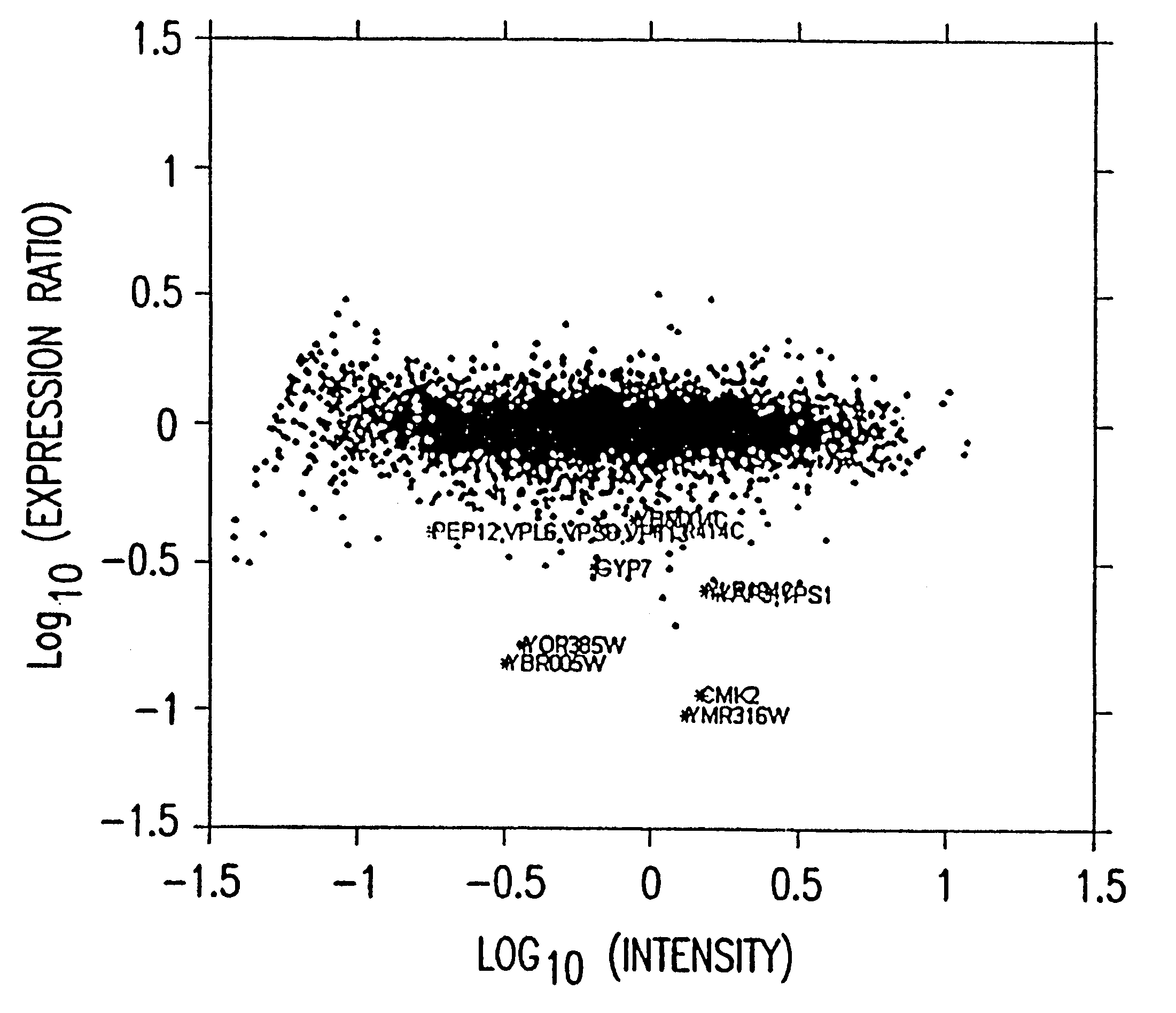

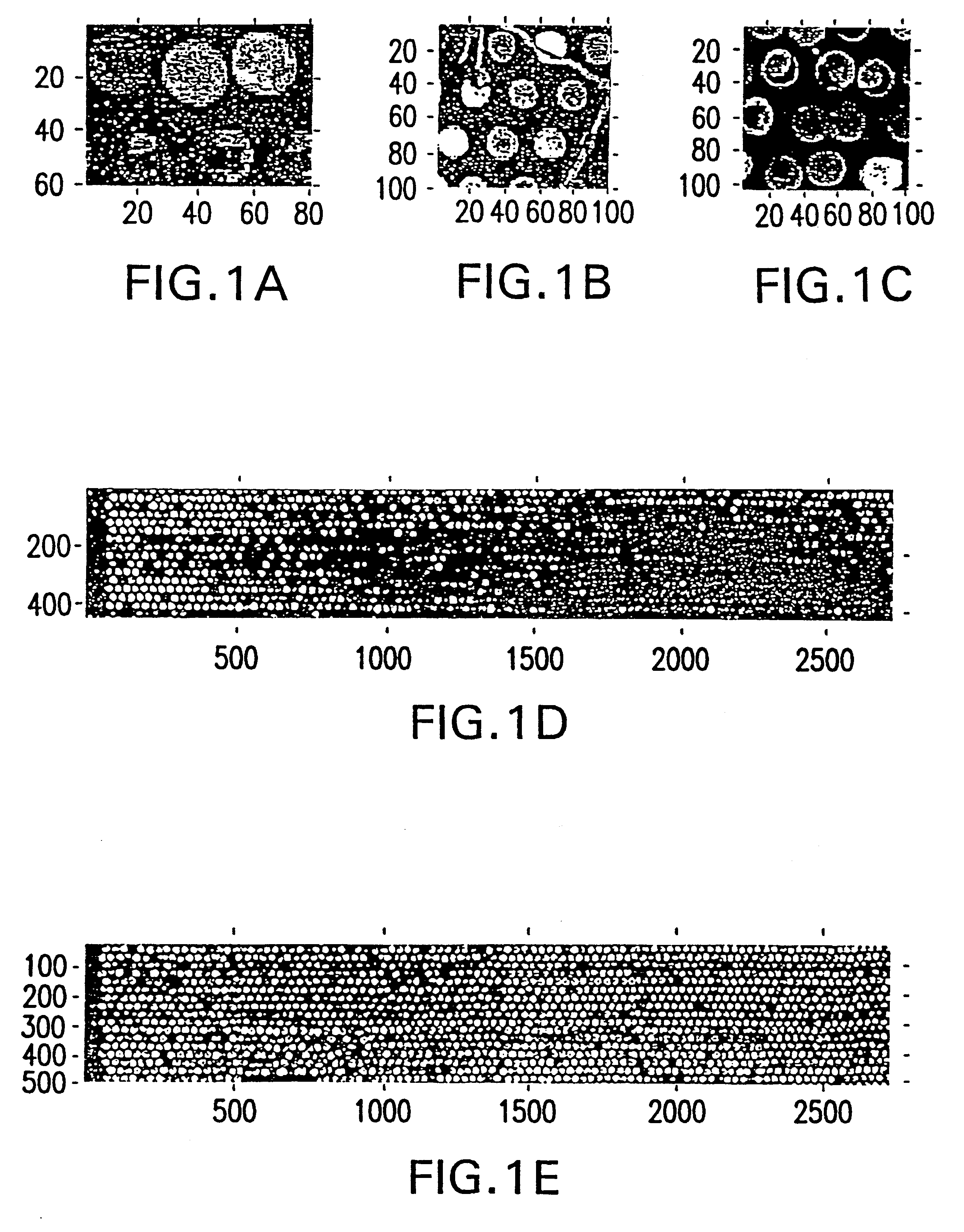

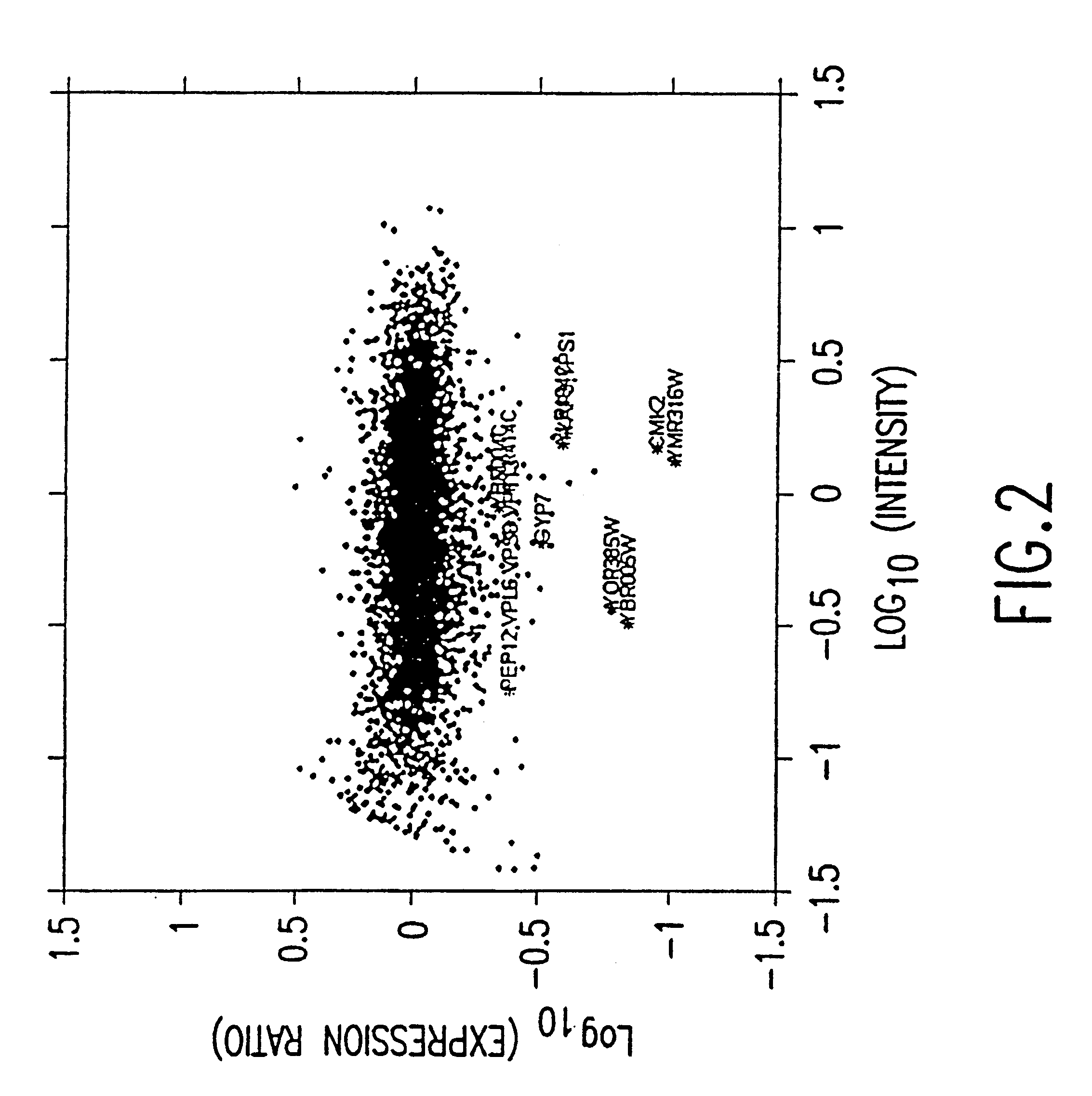

Statistical combining of cell expression profiles

InactiveUS6351712B1Minimize repetitionEliminate errorsMicrobiological testing/measurementRecombinant DNA-technologyFluorophoreErrors and residuals

A method for fluorophore bias removal in microarray experiments in which the fluorophores used in microarray experiment pairs are reversed. Further, a method for calculating the individual errors associated with each measurement made in nominally repeated microarray experiments. This error measurement is optionally coupled with rank based methods in order to determine a probability that a cellular constituent is up or down regulated in response to a perturbation. Finally, a method for determining the confidence in the weighted average of the expression level of a cellular constituent in nominally repeated microarray experiments.

Owner:MICROSOFT TECH LICENSING LLC

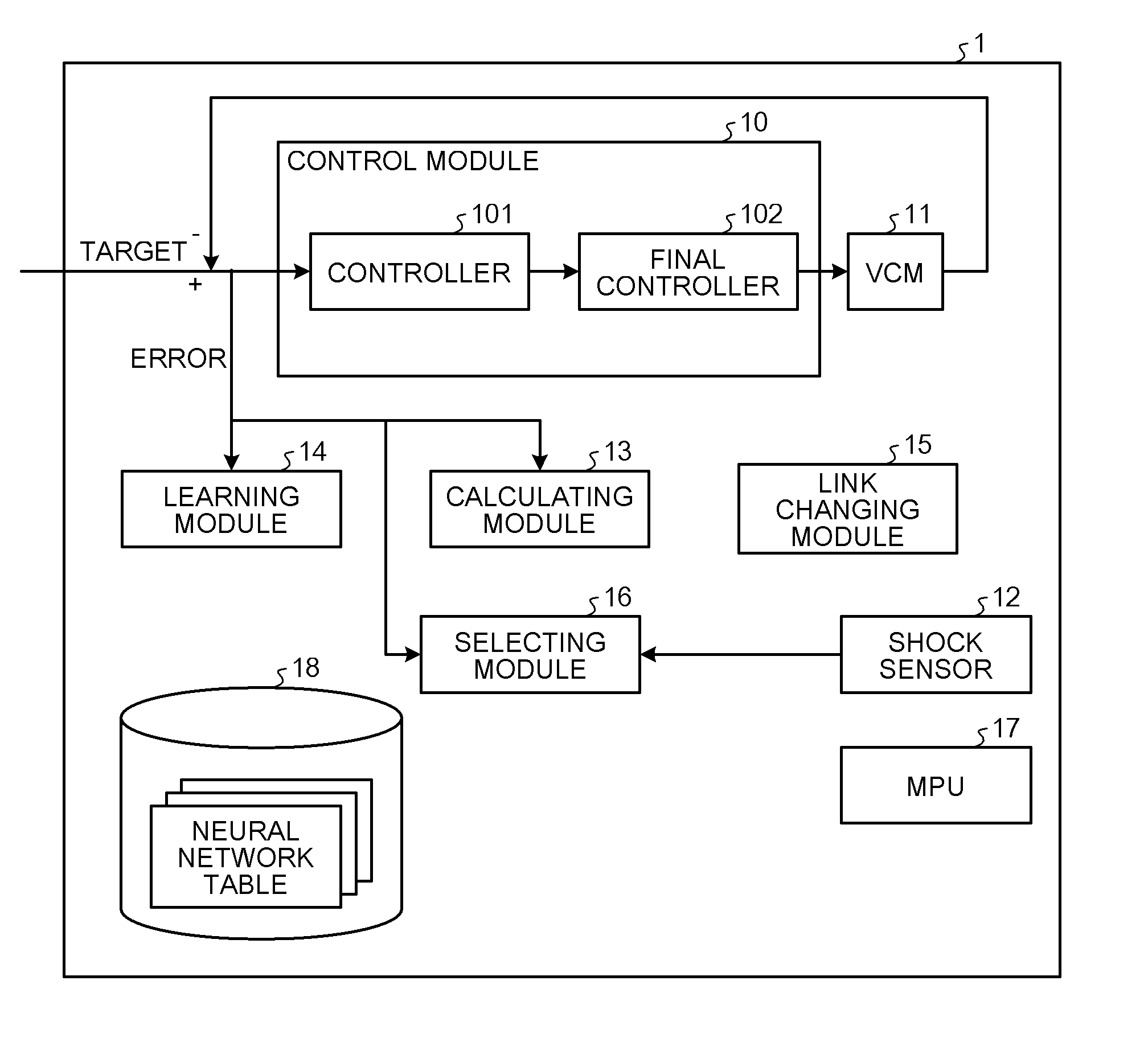

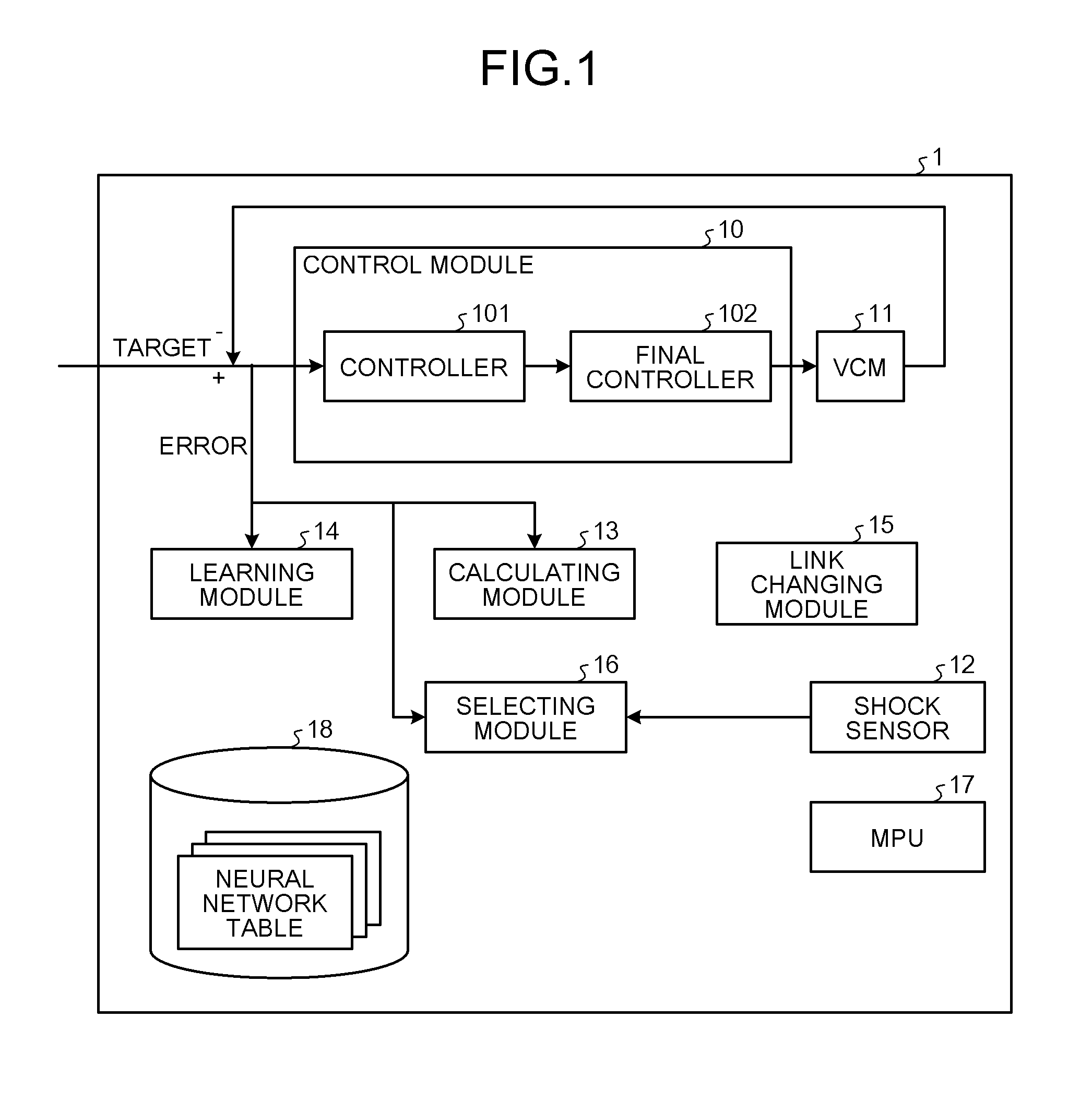

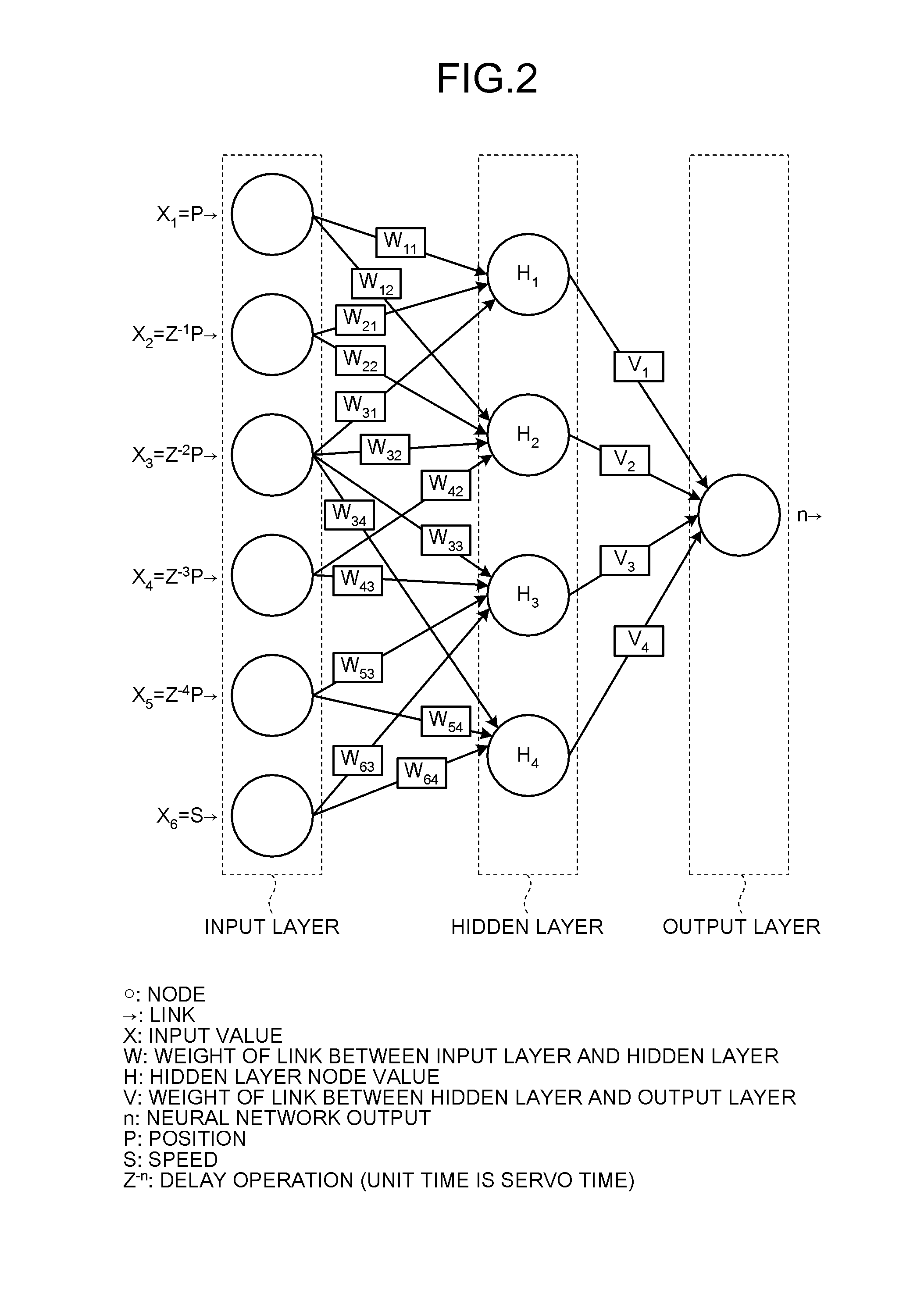

Control device, control program, and control method

According to one embodiment, a control device that controls operation of a system includes a first selecting module, a second selecting module, a control error measuring module, a determining module, and a control module. The first selecting module selects a first neural network from neural networks different in network configuration from each other. The second selecting module selects a second neural network different from the first neural network from the neural networks. The control error measuring module measures first control error in control by the first neural network and second control error in control by the second neural network. The determining module compares the first control error and the second control error measured by the control error measuring module, and determines a neural network with less control error. The control module controls the operation of the system by the neural network with less control error determined by the determining module.

Owner:TOSHIBA STORAGE DEVICE CORP

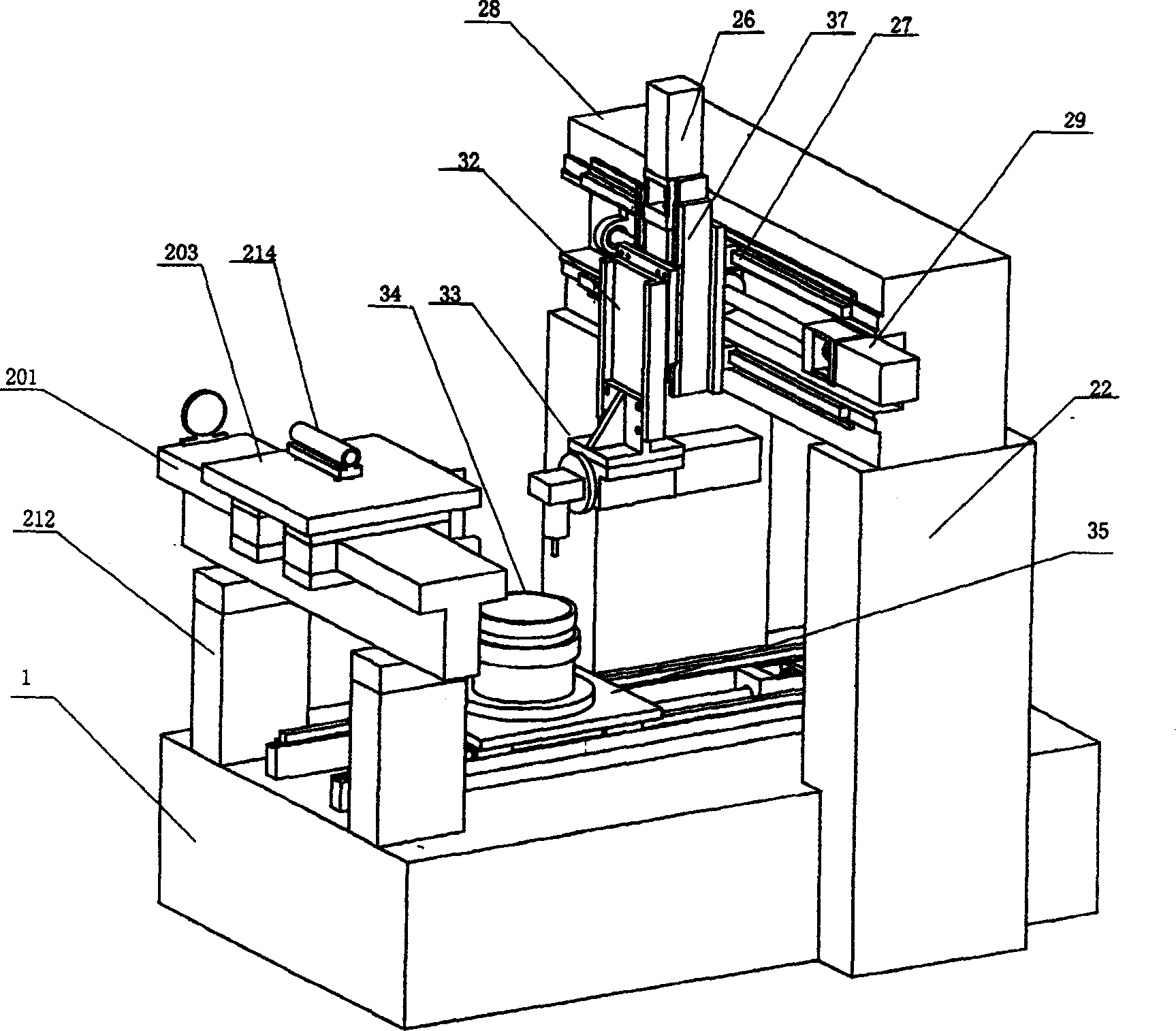

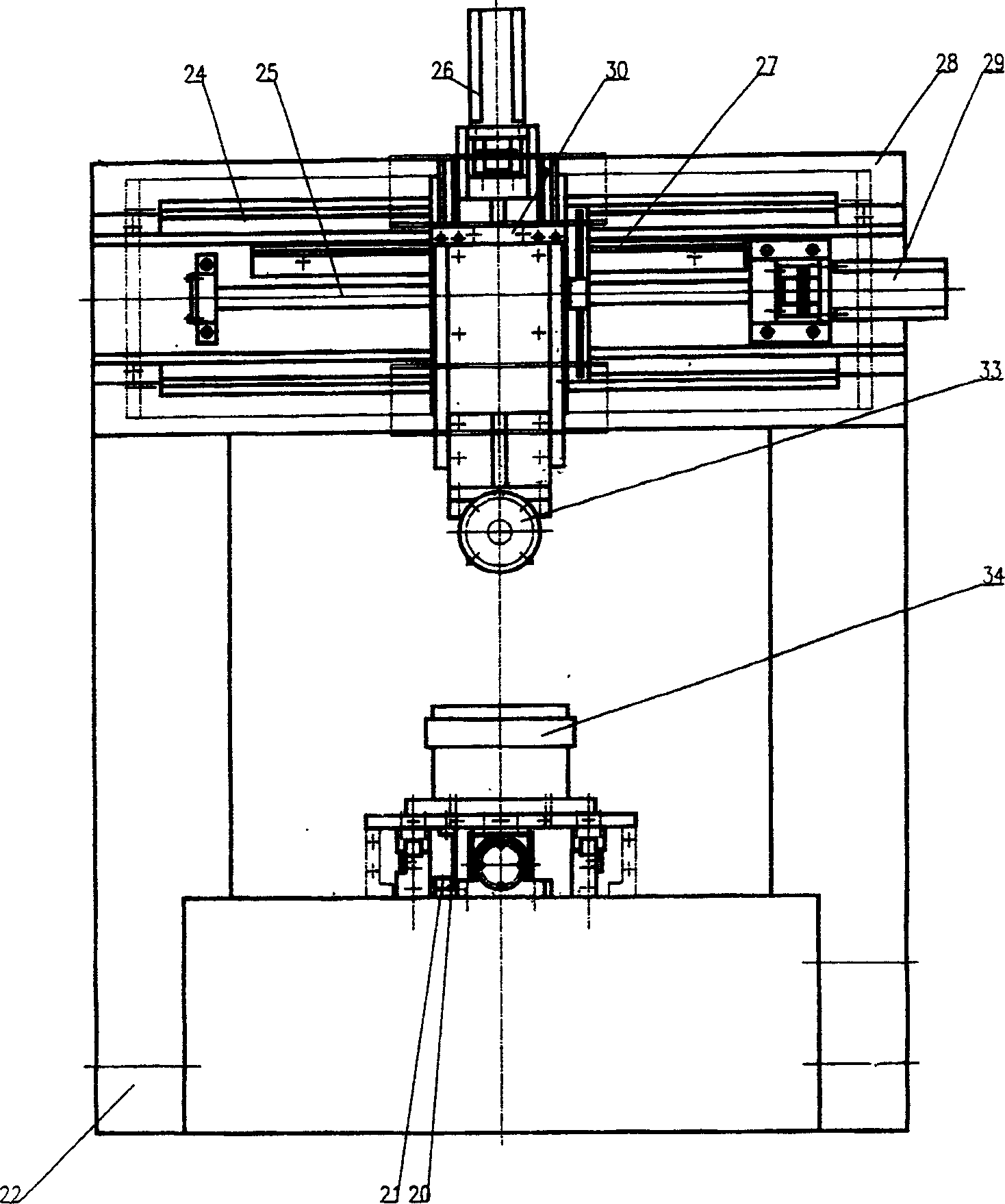

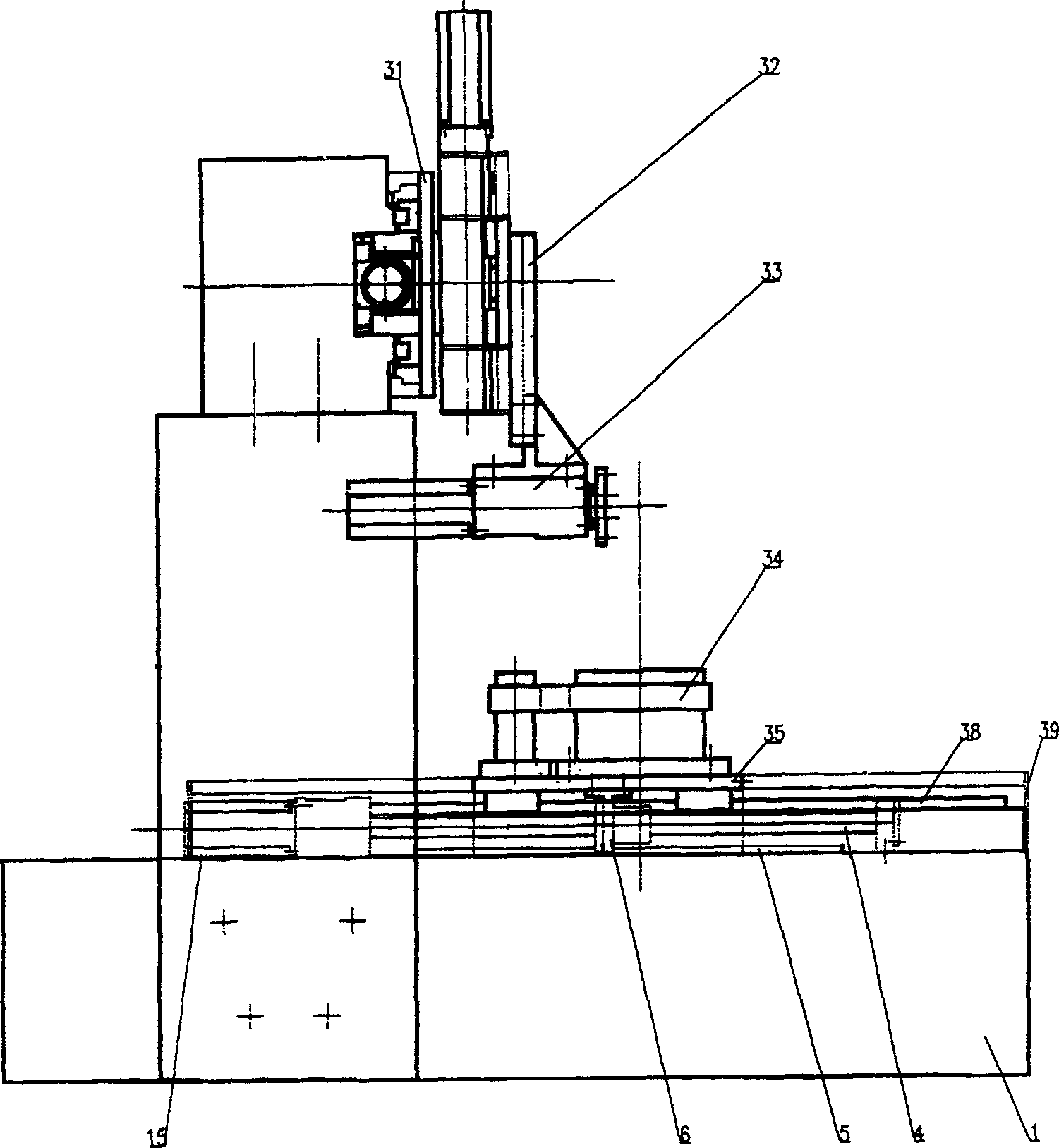

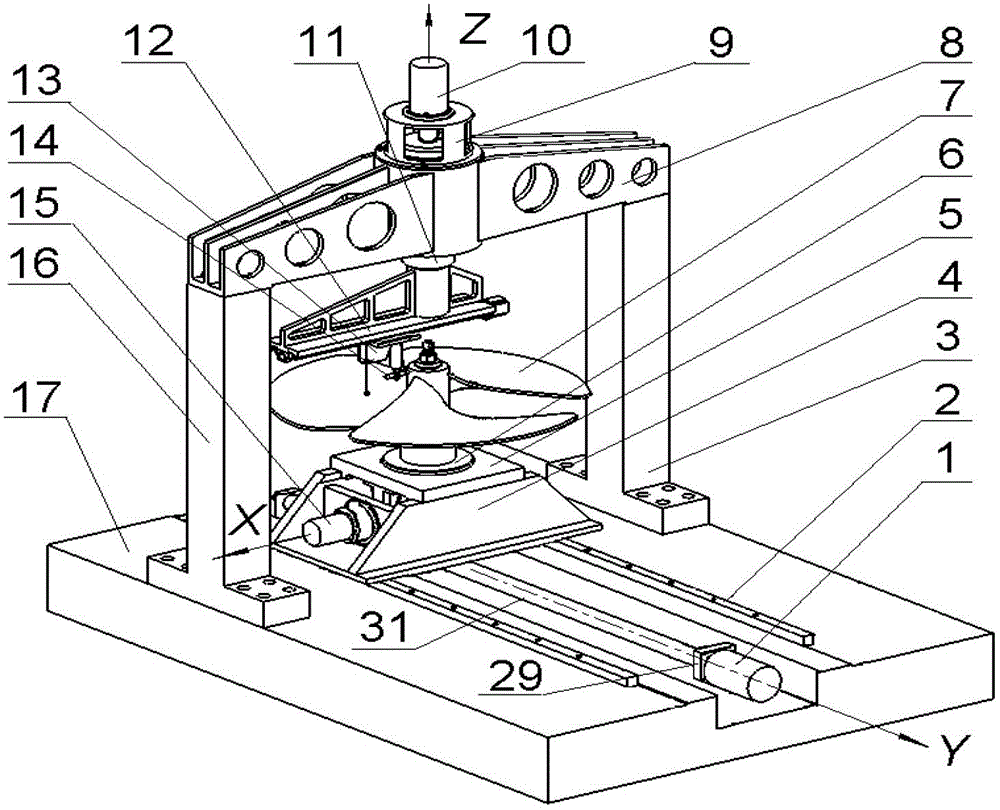

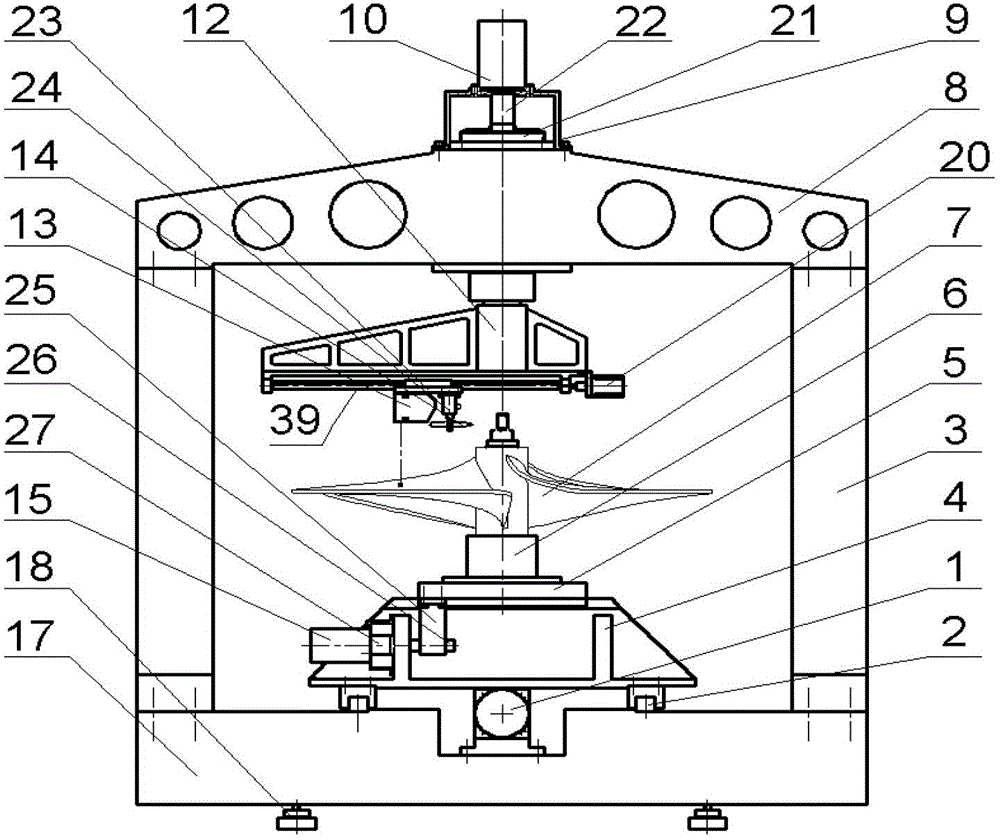

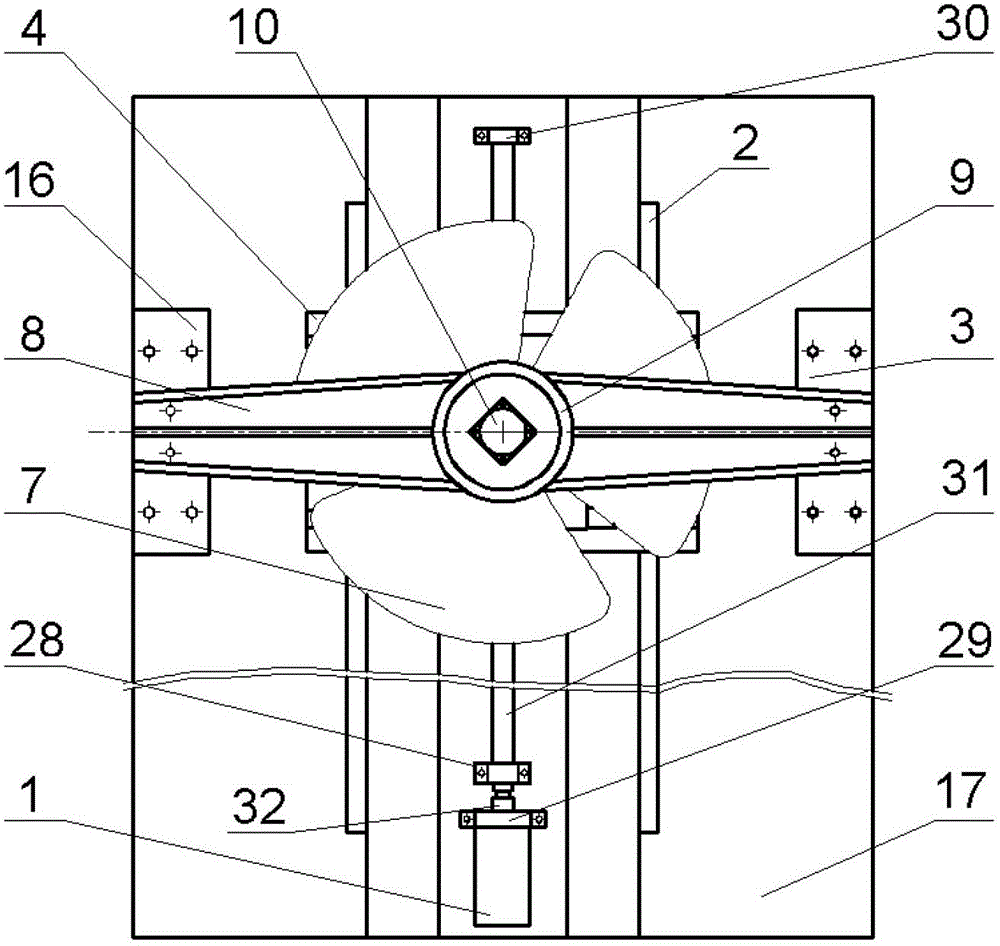

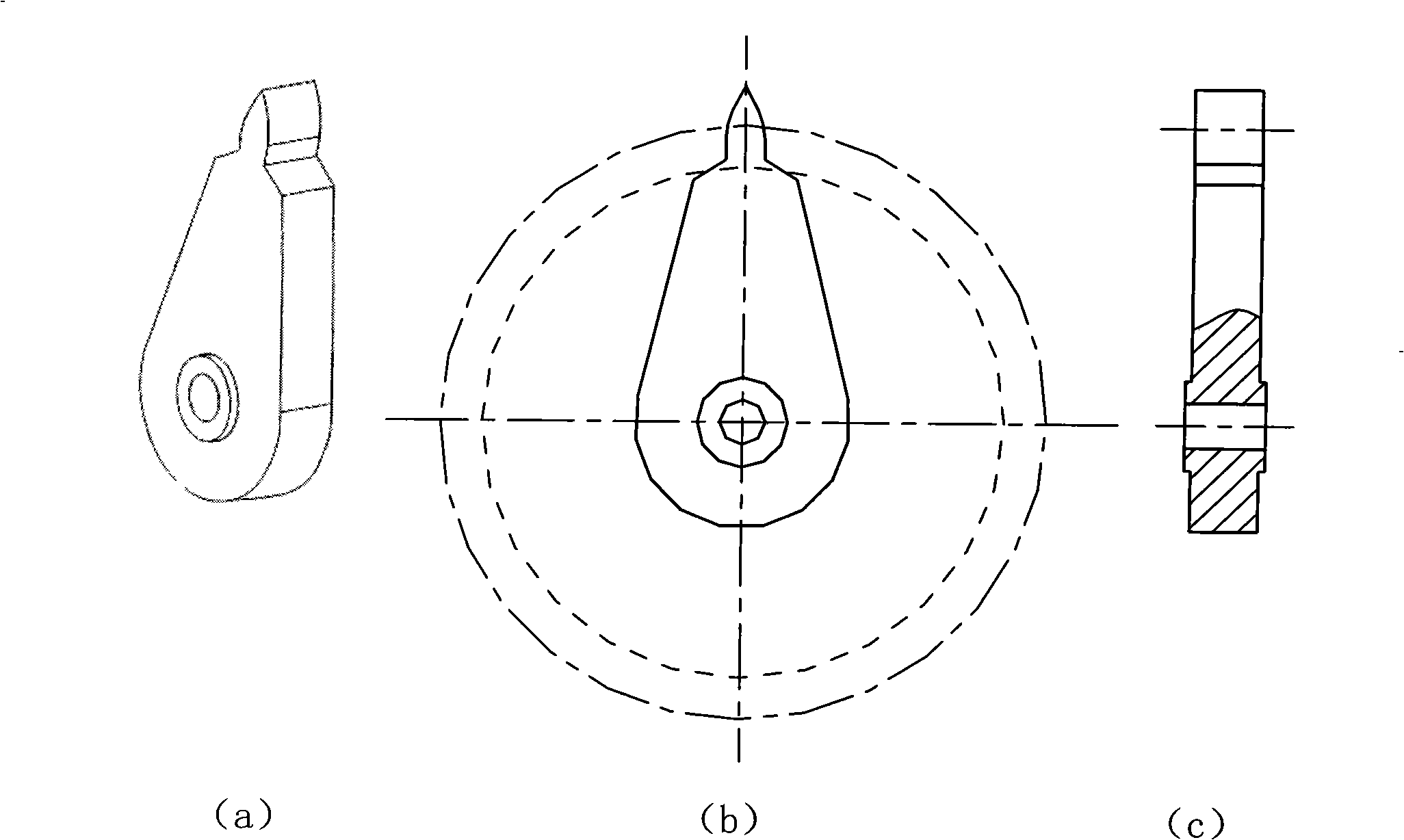

Non-spherical optical component composite machining and testing machine tools

InactiveCN1490125AImprove processing efficiencyOvercome the disadvantage that the revolution speed is difficult to increaseAutomatic control devicesFeeding apparatusEngineeringFloating platform

A machine tool for machining and testing the non-spherical optical part features that its main body has the symmetrical gantry frame structure with X, Y, Z and C axises designed modularly, the milling head or polishing mechanism is installed to the Z-axis bench, and the floating platform equipped with the in-line measuring and error-measuring unit for plane and parallel to Y axis is arranged on main body. Its advantage is high machining precision.

Owner:NAT UNIV OF DEFENSE TECH

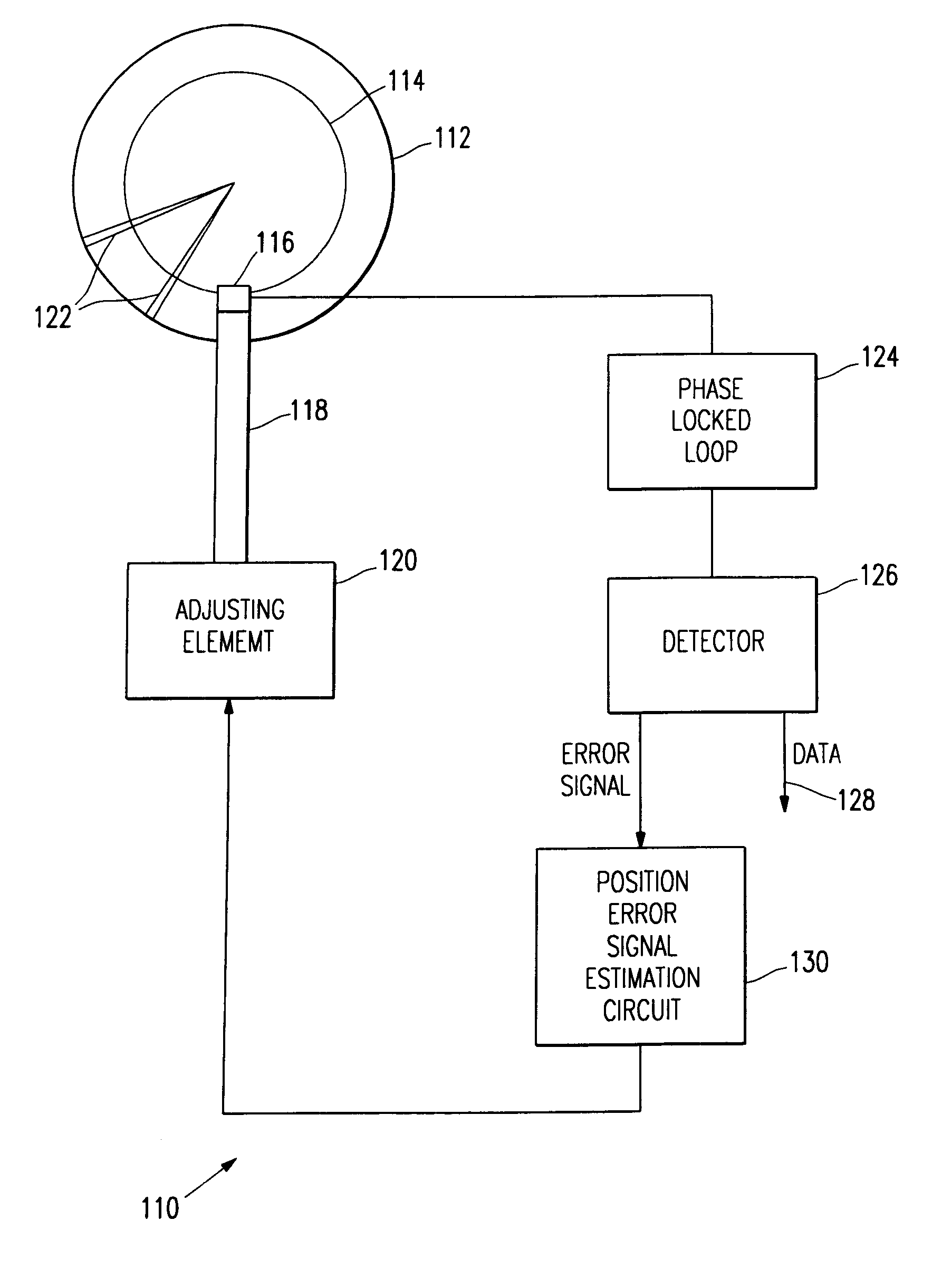

Read channel generating absolute value servo signal

InactiveUS6594103B1Record information storageAlignment for track following on disksHard disc driveMagnetic storage

A servo control system and method controls systems at least partially on the basis of an observable variable that has an absolute value functional relationship with the controlled variable and does not change sign for positive and negative variations from a nominal value. The control system and method find particularly advantageous application in magnetic storage hard disk drive systems because the system allows such hard disk drives to perform servo operations such as track following on the basis of the data signals being read from the track. A particularly useful source of the absolute value observable variable is a read channel chip that performs decoding of data recovered from the disk. Error measures are developed as the data signals from the disk are processed and decoded, including error measures from the slicer used in an adaptive equalization process and from the data decoder, which may be a Viterbi decoder. One or more of these error measures is provided to an output terminal of the read channel chip for use with an absolute value control system and method.

Owner:RATEZE REMOTE MGMT LLC

Propeller type surface contour error measurement instrument and method

ActiveCN102749041AEasy to achieve 3D reconstructionAvoiding Probe Radius Compensation ProblemsElectric/magnetic contours/curvatures measurementsUsing optical meansGeometric errorMeasurement device

The invention discloses propeller type surface contour error measurement instrument and method. The propeller type surface contour error measurement instrument is characterized in that a gantry structure is adopted, a left upright, a right upright and a top cross beam are arranged on a base, and a revolving spindle is arranged on a cross beam; the lower end of the revolving spindle is horizontally and fixedly connected with a measuring arm; a linear guiderail is arranged on the bottom surface of the measuring arm along the radial direction of the revolving plane of the measuring arm, a working platform capable of doing linear movement along the linear guiderail is arranged on the linear guiderail, and a displacement sensor is arranged on the working platform; and a Y-direction working platform and an X-direction working platform are arranged on the base in an overlapping, and the blade of a detected propeller is arranged in a positioning groove at the top surface of the X-direction working platform. The measuring device and the measuring method are established by adopting a cylindrical coordinate system according to the axial symmetry structure characteristics of the propeller blade. The measuring device and the measuring method are fast in data acquisition, have no objective errors of an operator, and are simple in follow-up error processing and analysis, and can be used for precision measurement on size parameters and geometric error parameters of large revolving parts.

Owner:HEFEI UNIV OF TECH

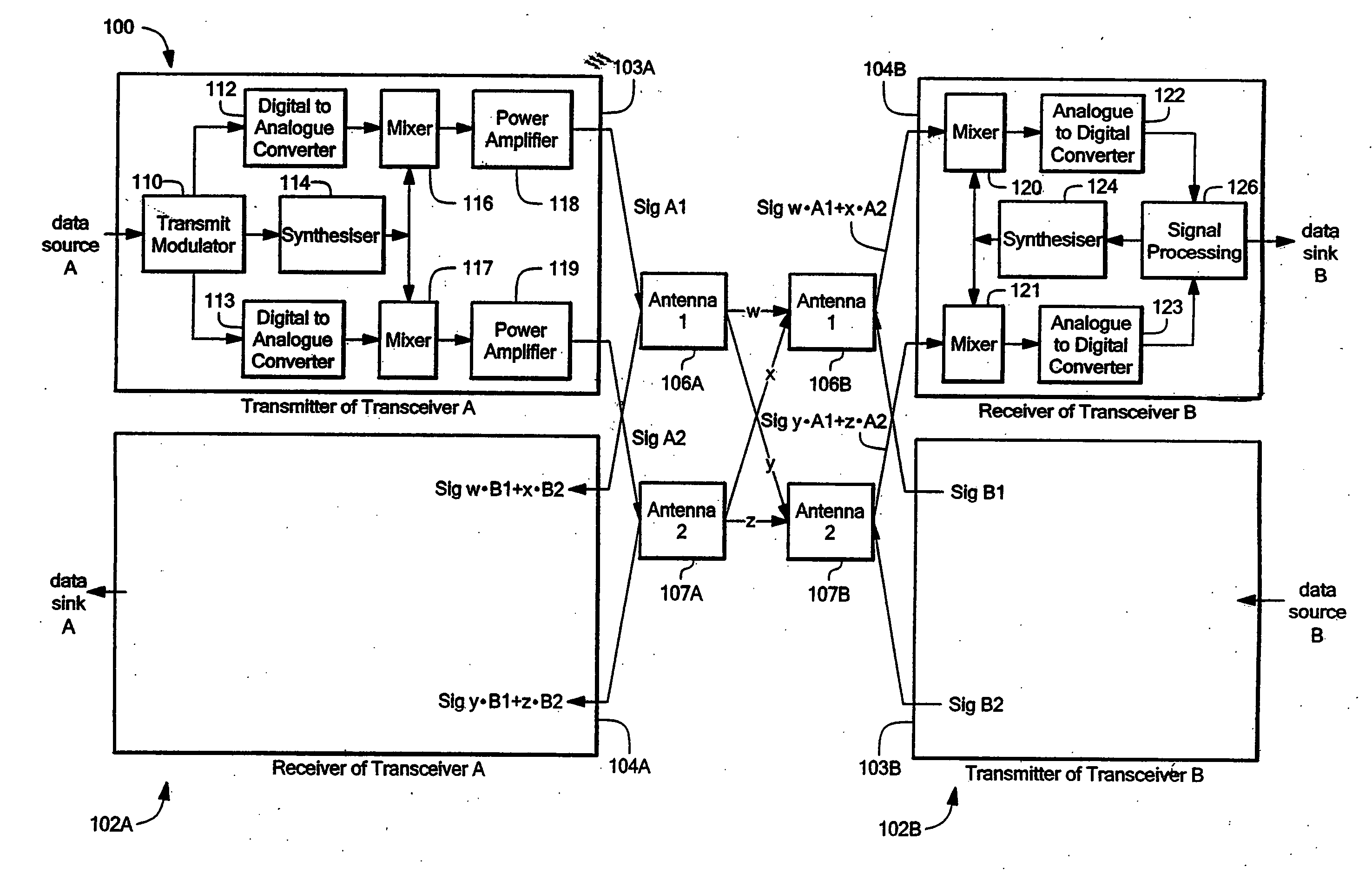

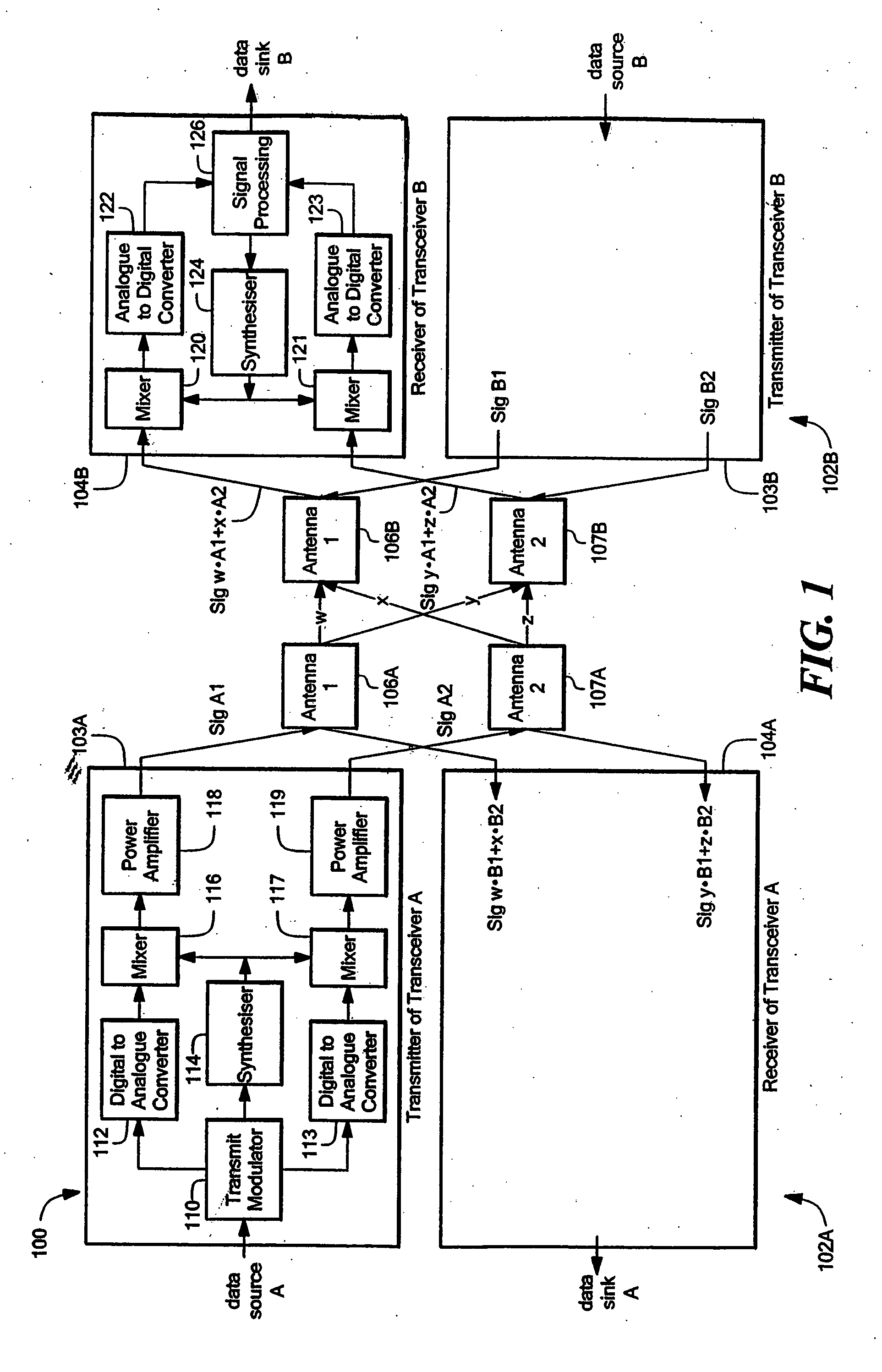

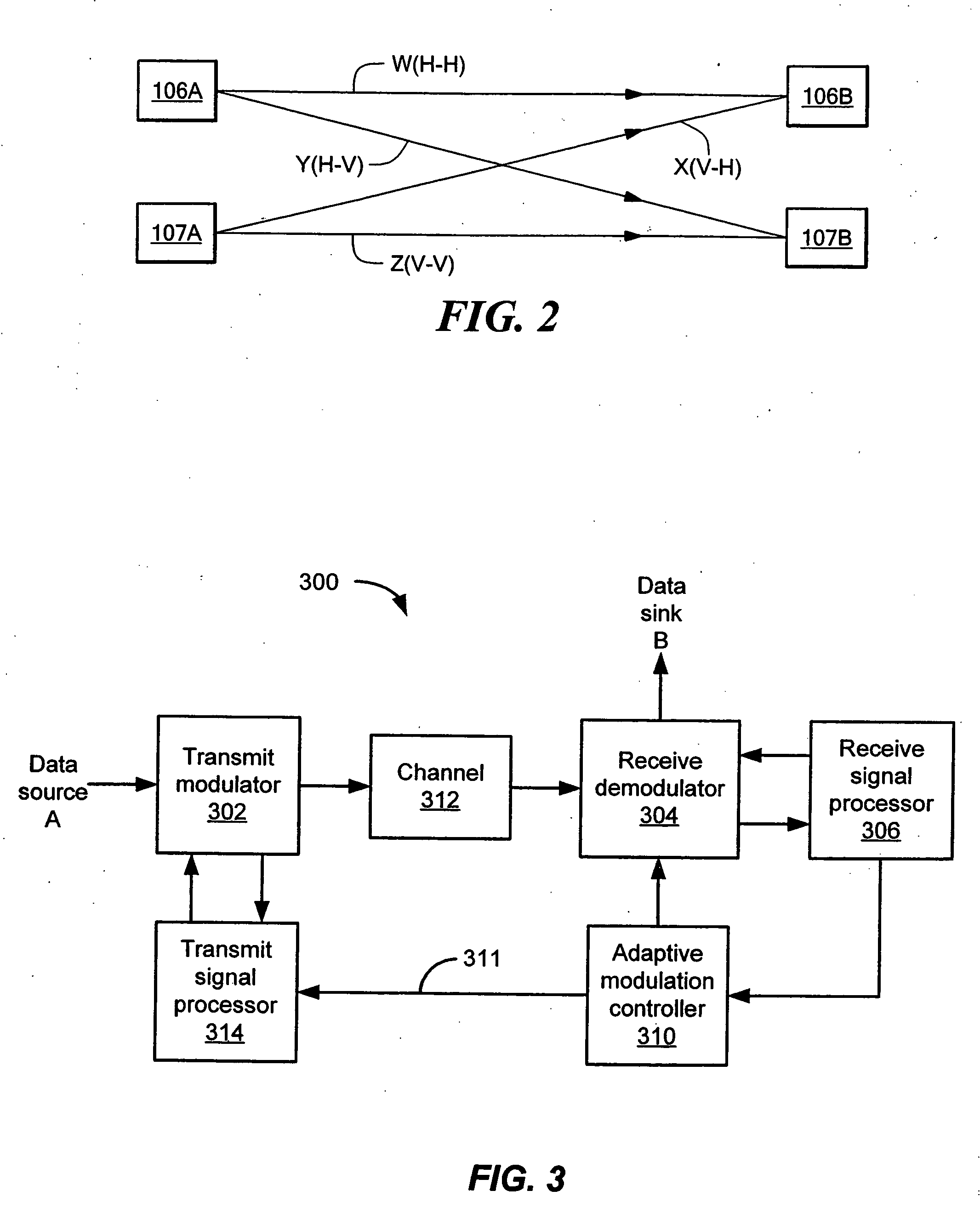

Dual payload and adaptive modulation

ActiveUS20060160495A1Increase ratingsImprove performanceEnergy efficient ICTSpatial transmit diversityFrequency spectrumTransceiver

A wireless broadband communications system that provides higher performance and increased spectral efficiency in point-to-point and point-to-multipoint applications. The wireless communications system includes a plurality of transceivers and a plurality of transmit and receive antennas. The system can be configured as a 1:n SIMO system that transmits and receives signals over a single channel of information flow, or an n:n MIMO system that transmits and receives signals over multiple channels of information flow, based upon channel state information and average vector error measurement values corresponding to the respective channels of information flow, which are determined by the system via an adaptive modulation technique.

Owner:CAMBIUM NETWORKS

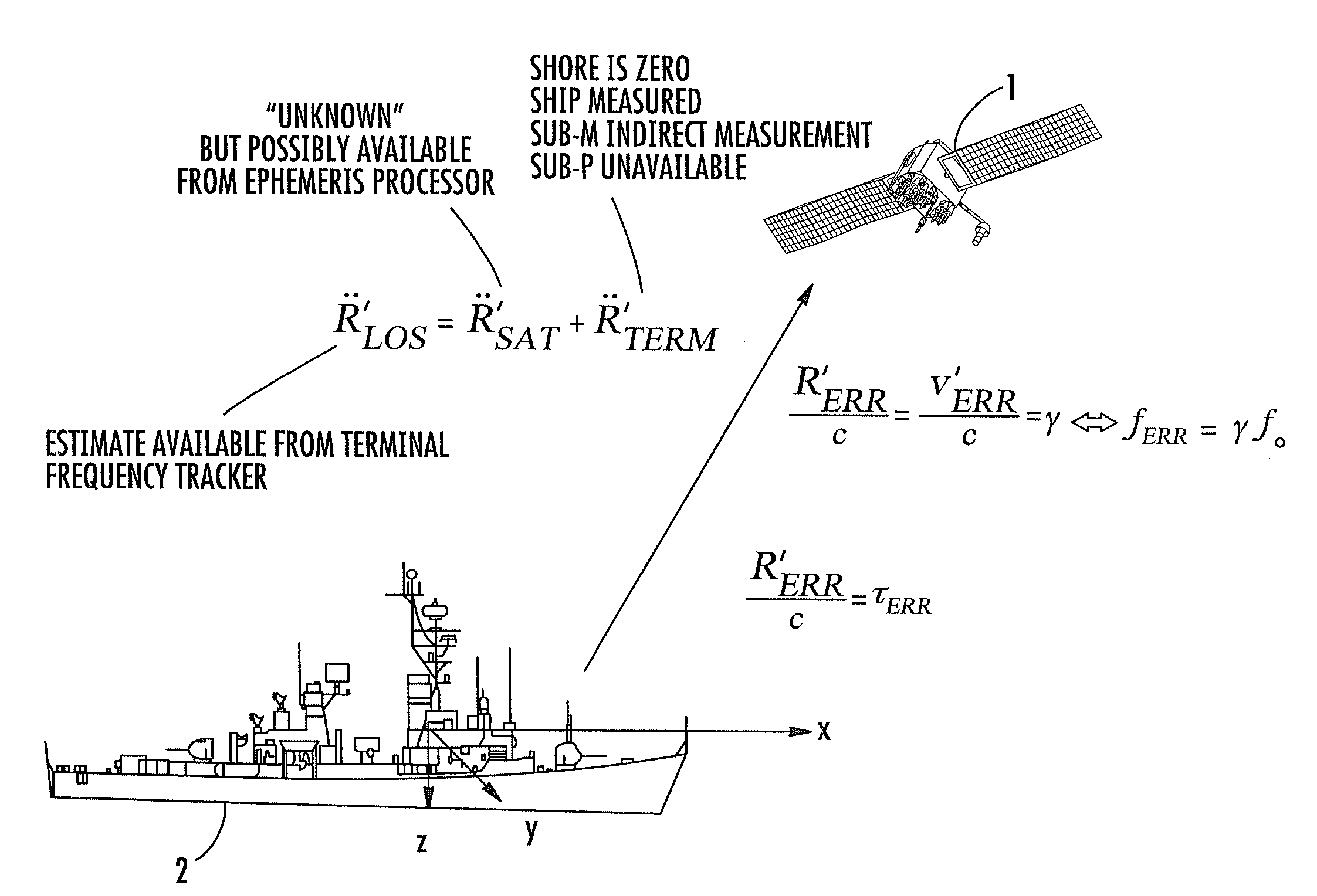

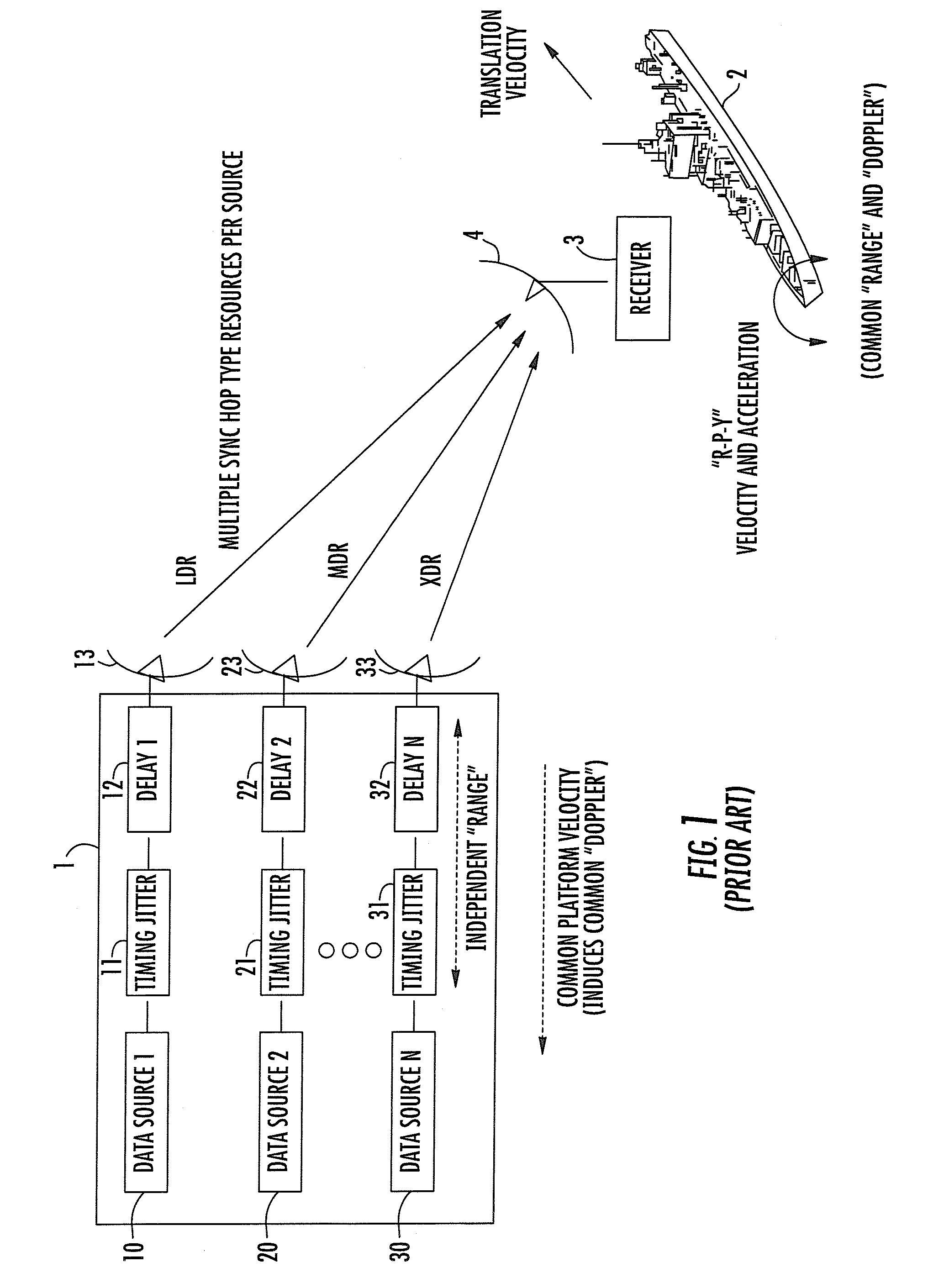

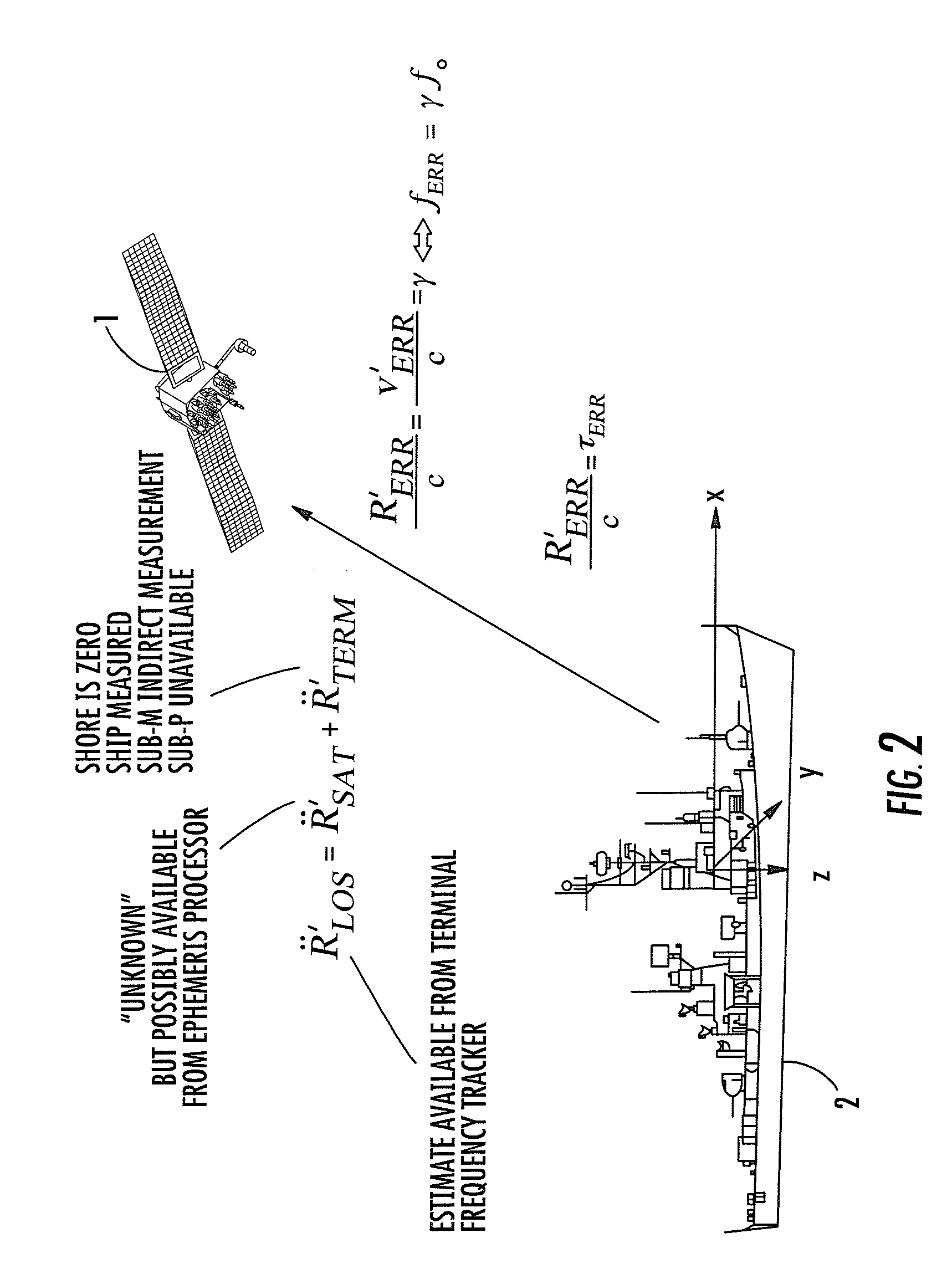

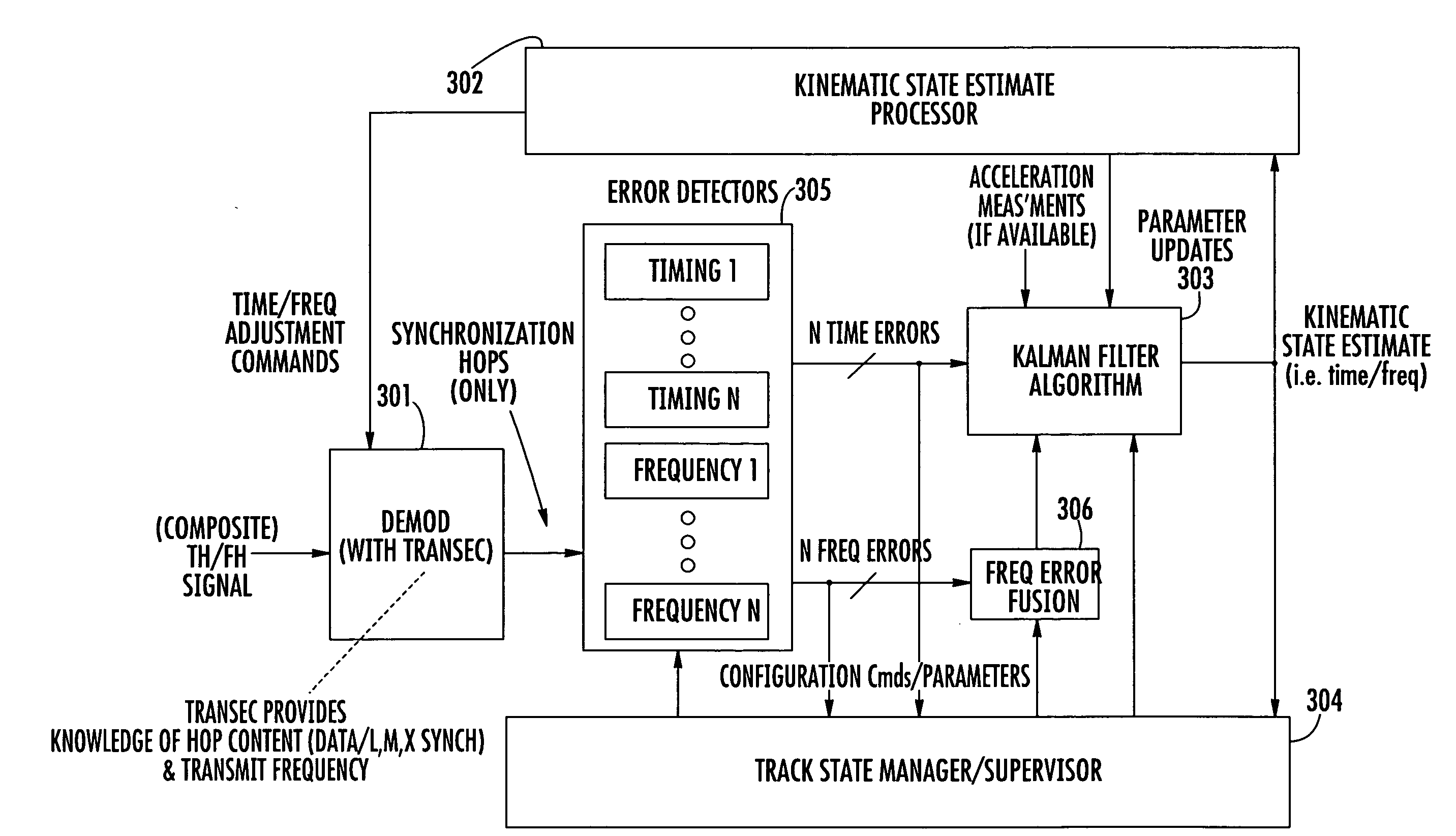

Time/frequency recovery of a communication signal in a multi-beam configuration using a kinematic-based kalman filter and providing a pseudo-ranging feature

InactiveUS20070218931A1Inability to efficientlyEffectively obviatedSynchronisation arrangementRadio transmissionErrors measurementKalman filter

A downlink time / frequency tracker for a receiver terminal, which may be mounted to a static platform on the earth, or to a dynamic platform, such as a ship. The tracker is operative to acquire and track time and frequency variations in time- and frequency-hopped synchronization signals from different data rate sources in a dynamic platform, such as a satellite. Characteristics of the Kalman filter are updated in accordance with data representative of timing error and frequency error measurements carried out on the synchronization signals, as well as data representative of local kinematic domain measurements carried out with respect to the receiver terminal. The Kalman filter outputs minimum mean square error estimates of timing and frequency errors in the receiver terminal's demodulator clock. These error estimates are used to synchronize the demodulator's clock with the clock embedded in the downlink signal, so as to enable demodulation and recovery of data.

Owner:HARRIS CORP

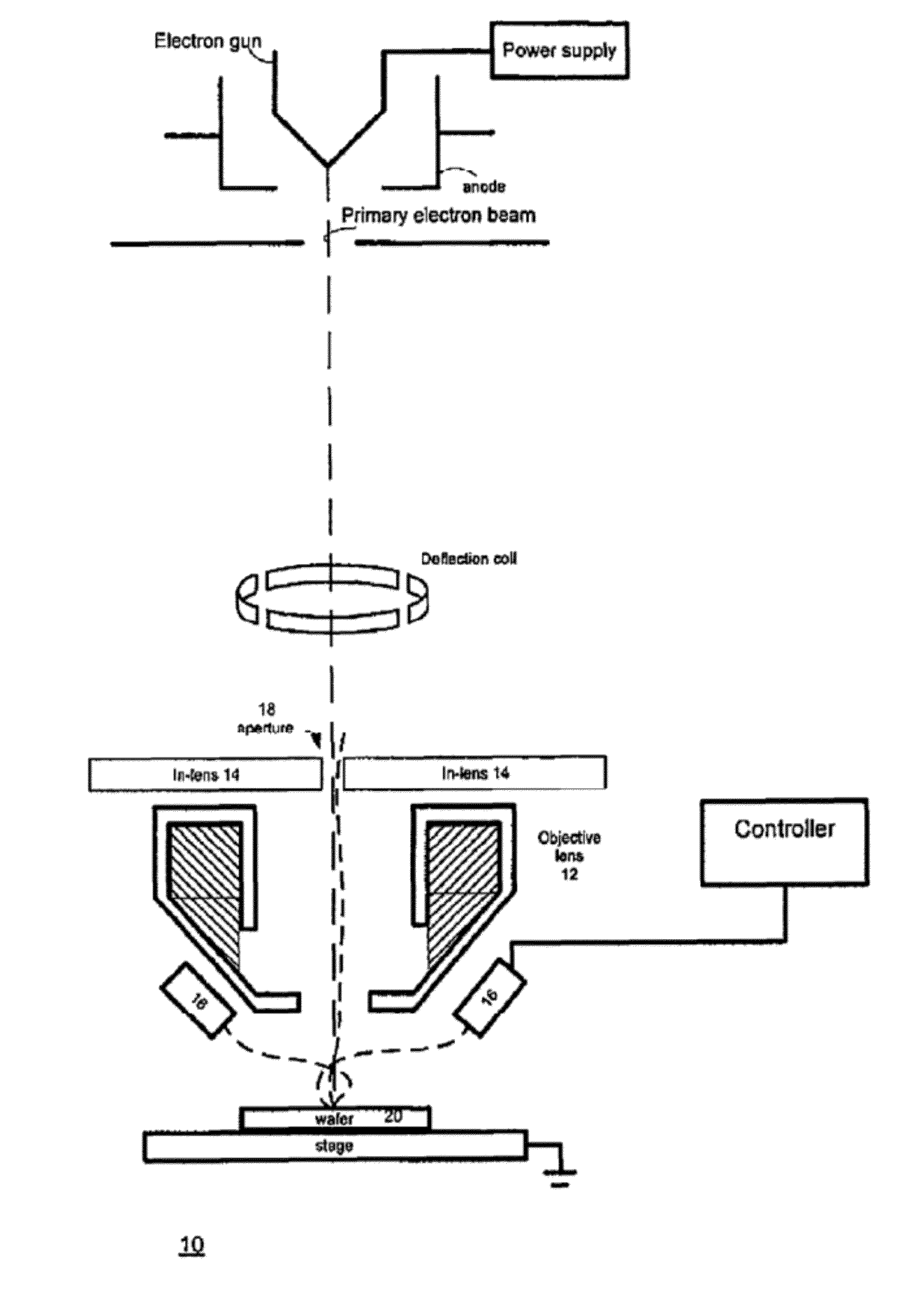

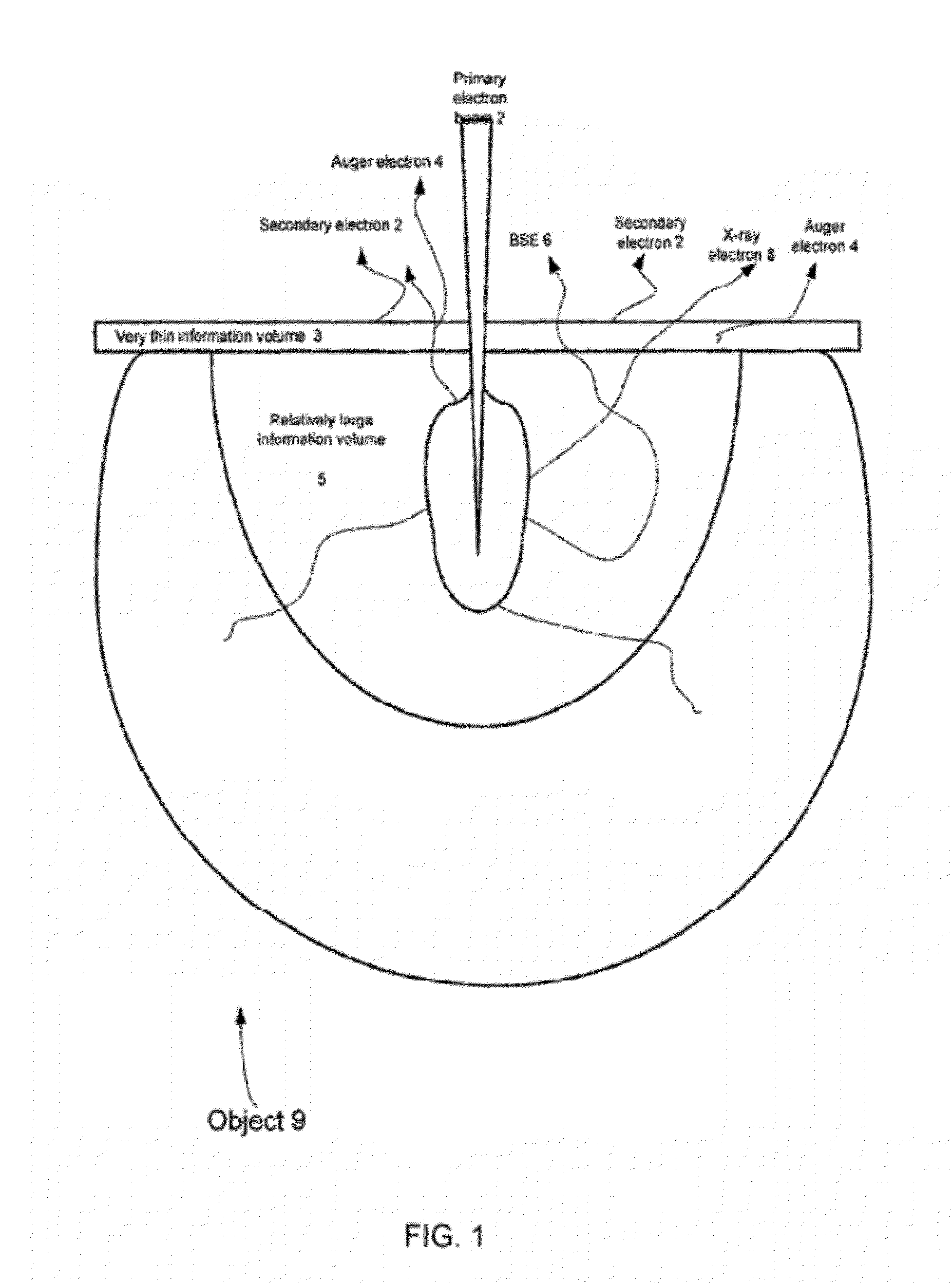

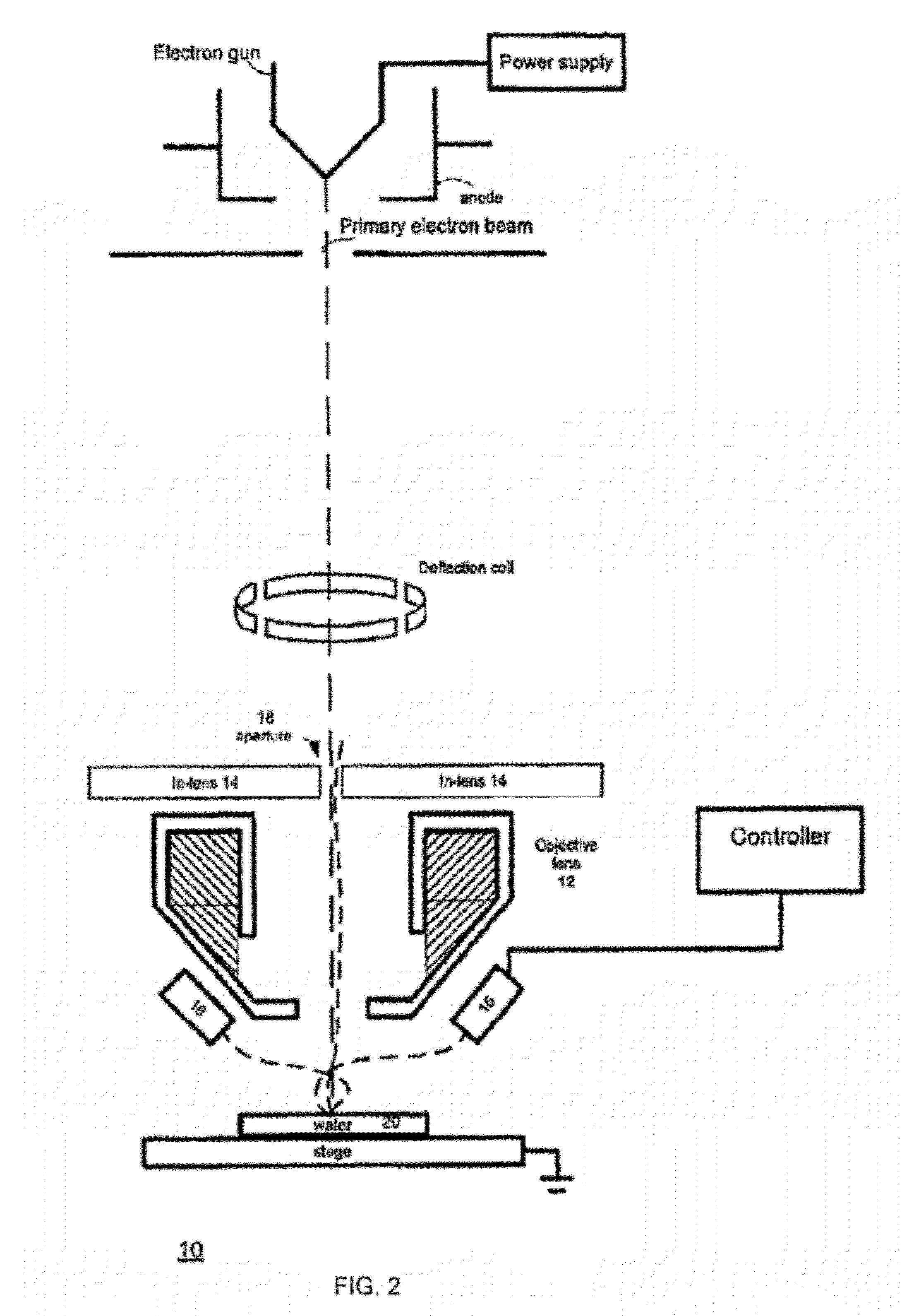

High electron energy based overlay error measurement methods and systems

ActiveUS20120292502A1Easy to collectElectric discharge tubesMaterial analysis using radiation diffractionEnergy basedHigh electron

A method, a system and a computer readable medium are provided. The method may include obtaining or receiving first area information representative of a first area of a first layer of an inspected object; wherein the inspected object further comprises a second layer that comprises a second area; wherein the second layer is buried under the first layer; directing electrons of a primary electron beam to interact with the first area; directing electrons of the primary electron beam to interact with the second area; generating detection signals responsive to electrons that were scattered or reflected from at least one of the first and second areas; and determining at least one spatial relationship between at least one feature of the first area and at least one feature of the second area based on the detection signals and on the first area information.

Owner:APPL MATERIALS ISRAEL LTD

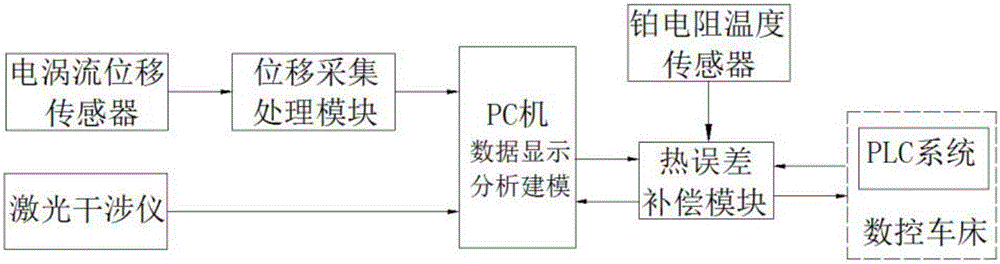

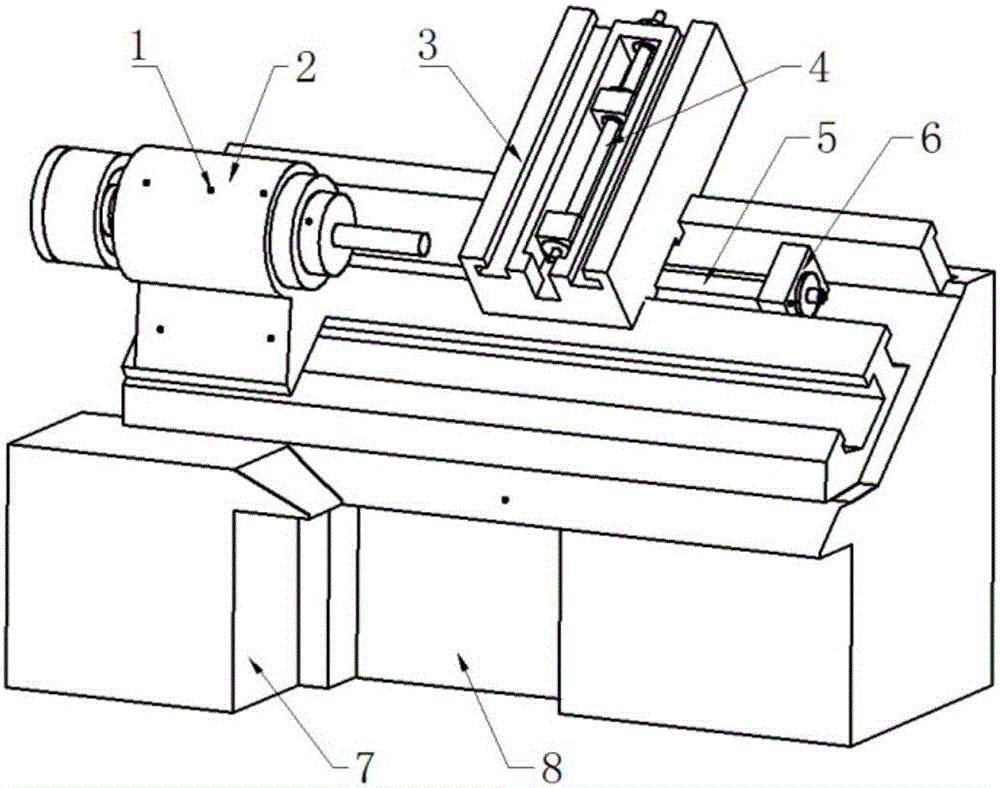

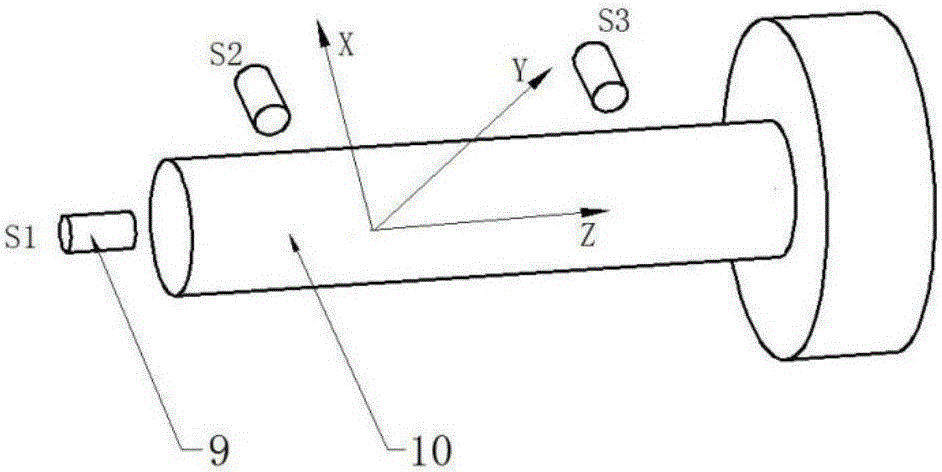

Digital controlled lathe thermal error measuring compensation system and method

ActiveCN106736848AImprove machining accuracyRealize intelligenceAutomatic control devicesMeasurement/indication equipmentsNumerical controlElectrical resistance and conductance

The invention discloses a digital controlled lathe thermal error measuring compensation system and method. The system comprises an eddy current displacement sensor, a platinum resistor temperature sensor, a laser interferometer, a displacement collecting and processing module, a thermal error compensation module and a PC. The platinum resistor temperature sensor measures the temperature of a lathe body heat sensitive point, the eddy current displacement sensor measures heat deformation of a spindle, the laser interferometer measures the locating error of a feeding system, and the spindle and a feeding shaft system are subjected to real-time thermal error comprehensive modeling. The thermal error compensation module compensates for axial heat expansion and radial heat inclination of a spindle workpiece in real time according to the temperature of the heat sensitive point and the coordinate value of a tool. The coupling problem of the digital controlled lathe spindle and the feeding shaft thermal error is solved, the thermal error can be compensated for in real time, and the machining precision of a digital controlled lathe is improved.

Owner:XI AN JIAOTONG UNIV

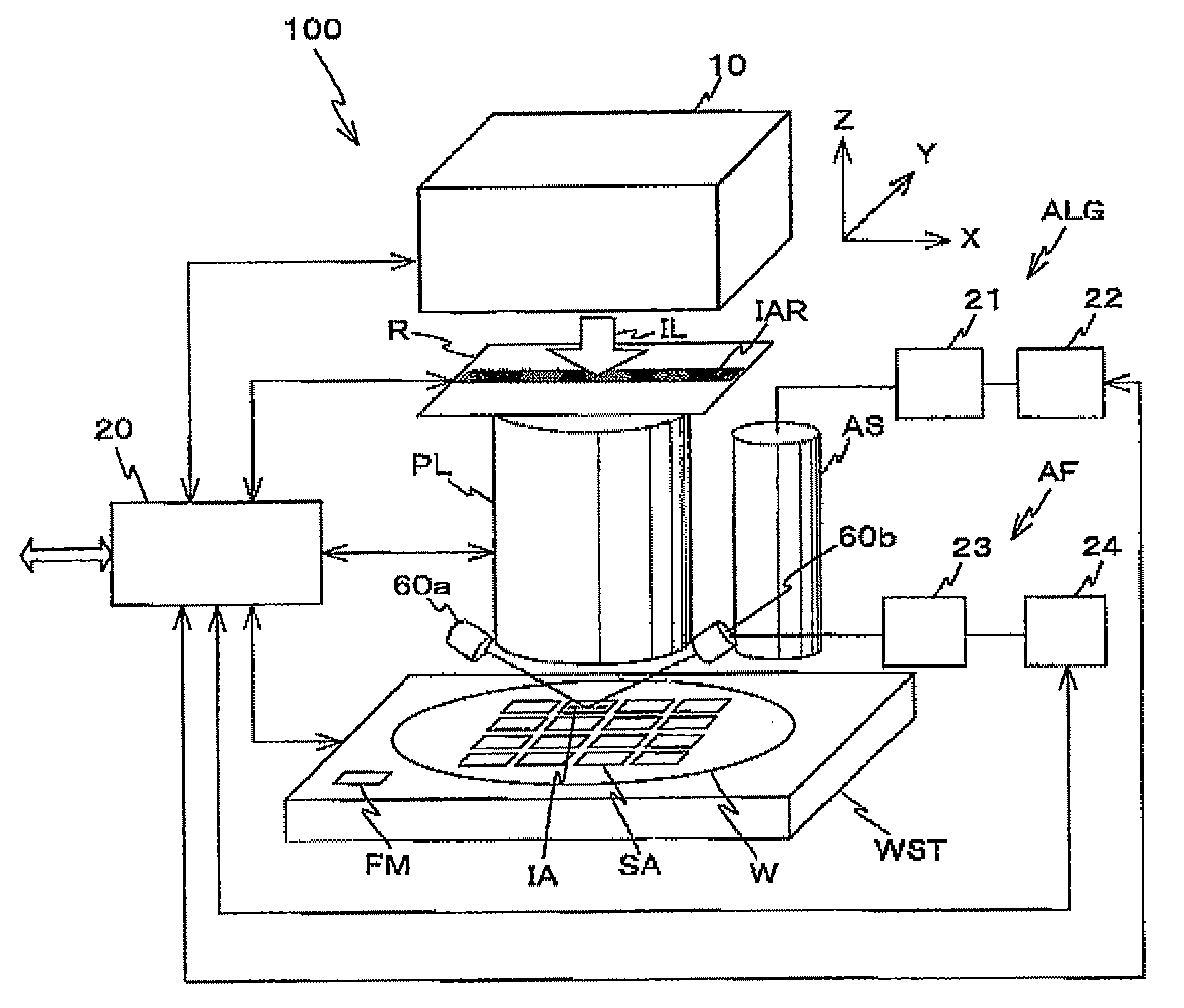

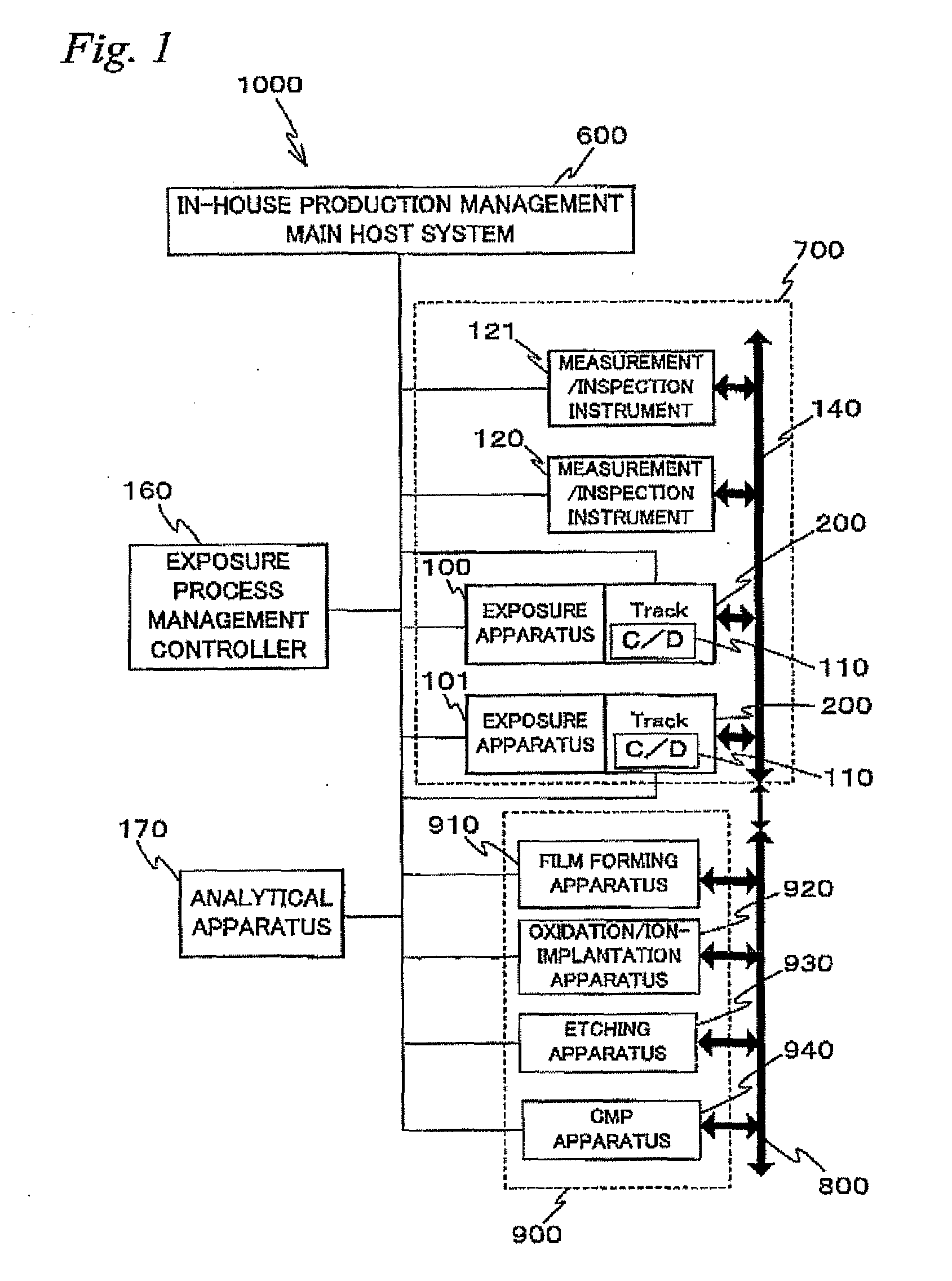

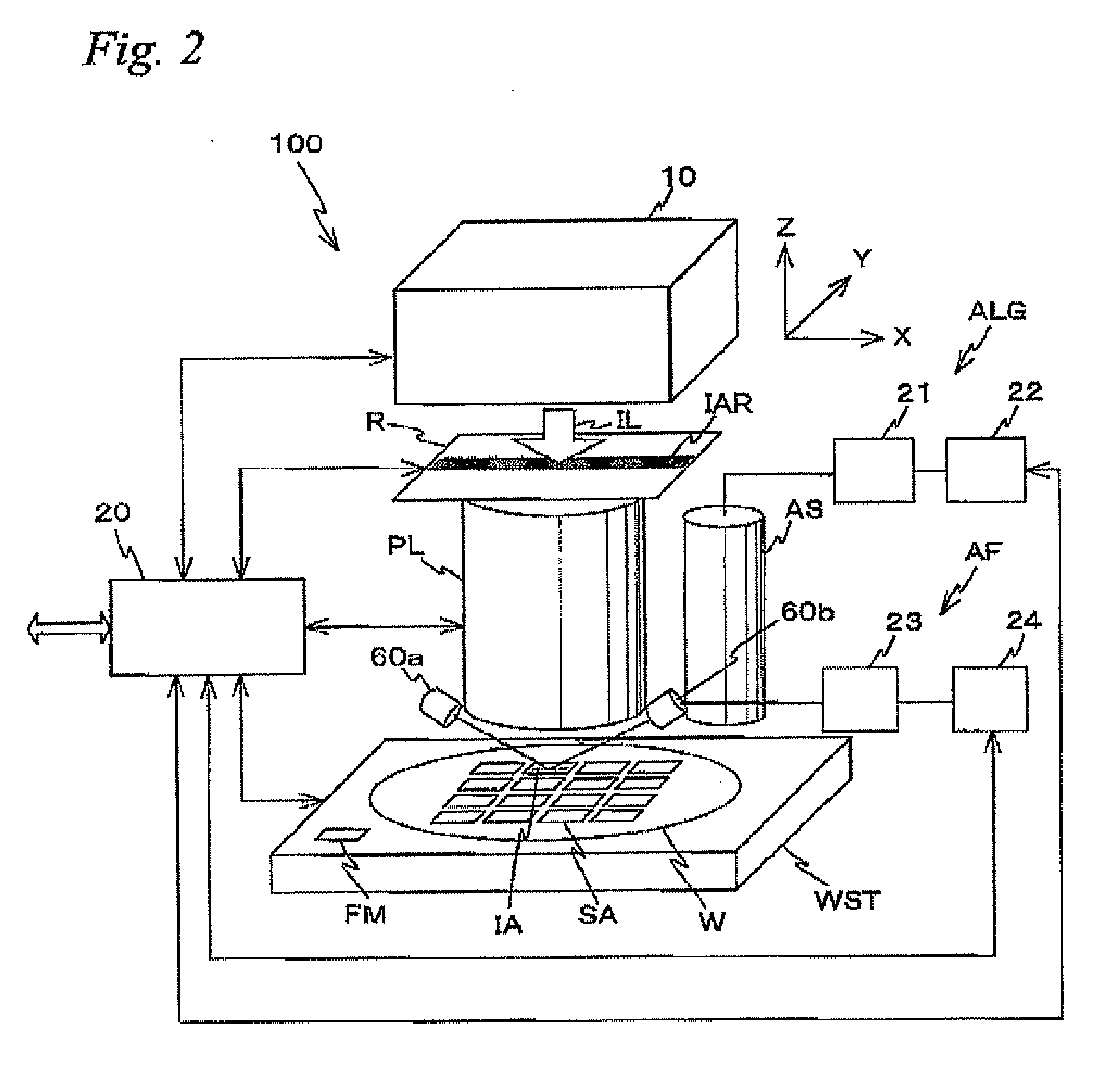

Device manufacturing method, device manufacturing system, and measurement/inspection apparatus

ActiveUS20090009741A1Semiconductor/solid-state device testing/measurementSolid-state devicesMeasurement deviceEngineering

In the case where measurement / inspection of a wafer is performed in a measurement / inspection instrument before and after exposure is performed in an exposure apparatus, various kinds of conditions of the exposure apparatus and the measurement / inspection instrument such as environment in the apparatus / instrument, a measurement condition of an alignment system a measurement condition of an AF measurement device, a wafer grid, and image distortion are made to be matched. In particular, in accordance with a processing state of the exposure apparatus and a coater developer, a measurement result of a film, and the like, exclusion of a mark for overlay error measurement, adjustment of the measurement condition and correction of the measurement result, adjustment of the environment, correction of the measurement result according to the environment, and adjustment of pattern defect inspection are performed. Further, in calibration processing, aberration of a projection optical system of an exposure apparatus that transfers a pattern on a wafer for calibration, and the like are also taken into consideration. Accordingly, the yield of device production can be improved.

Owner:NIKON CORP

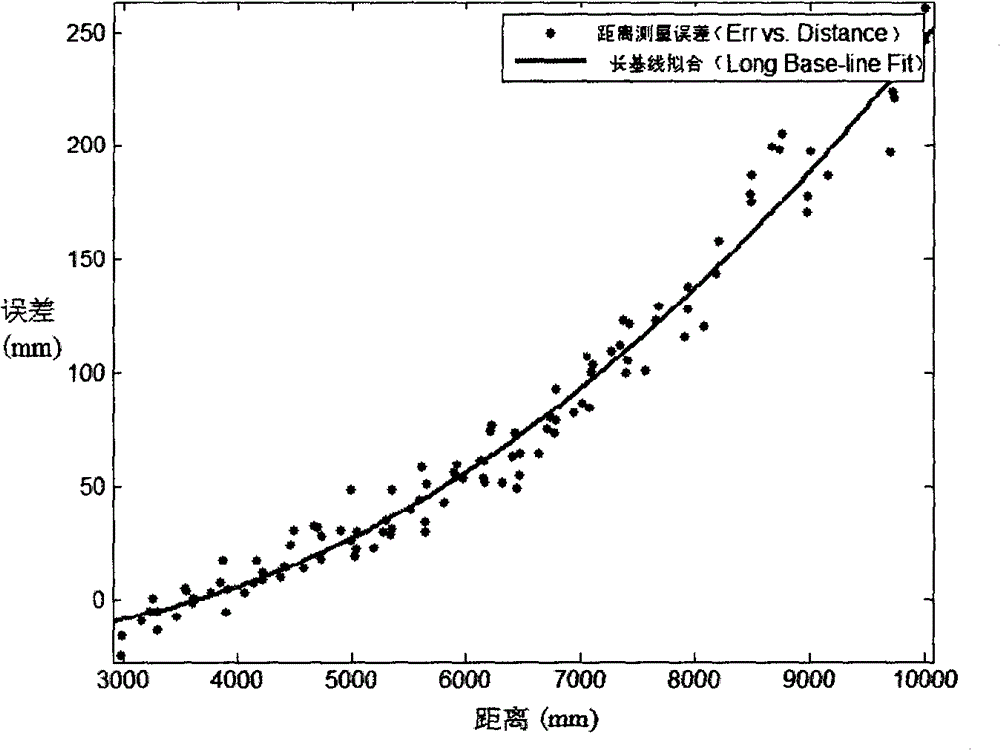

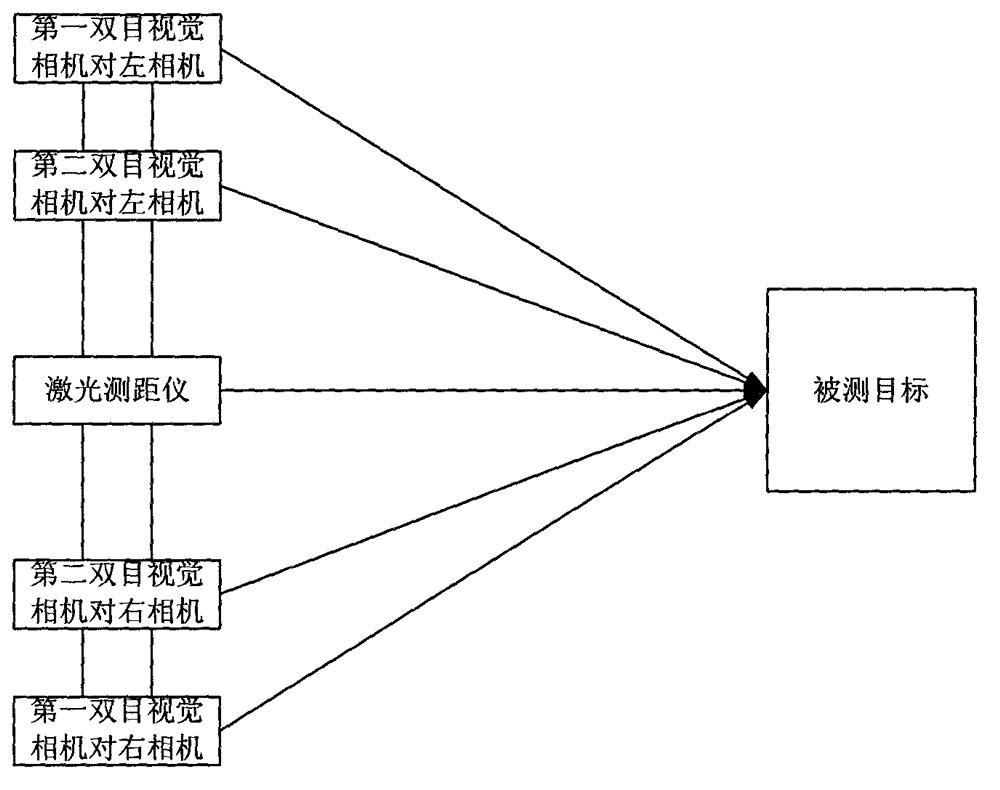

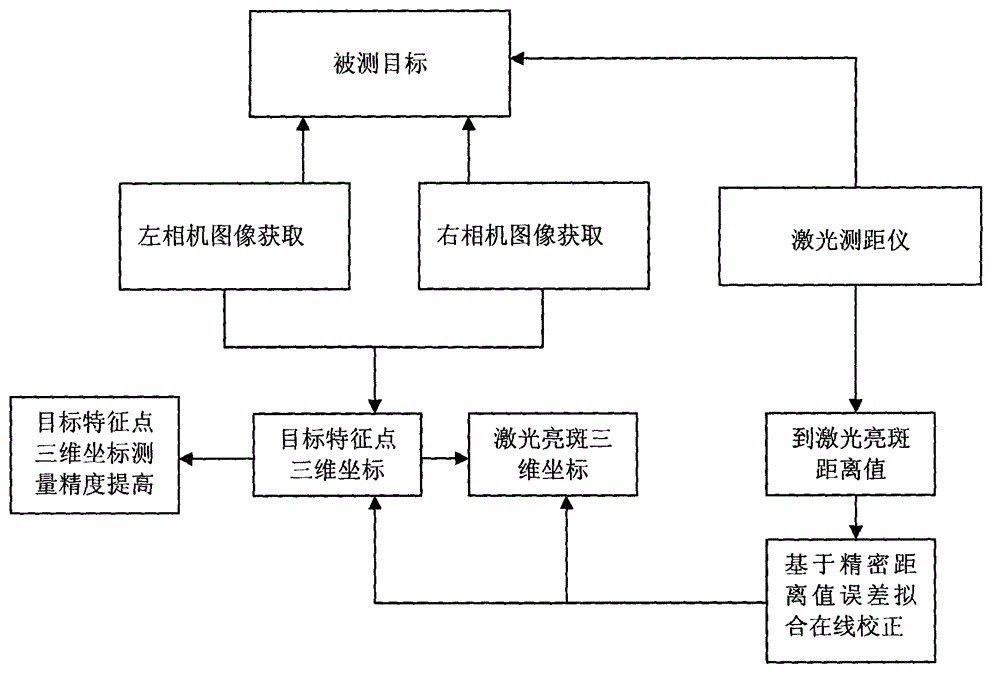

Non-cooperative target abutting measurement method based on additional sighting distance

ActiveCN102914262AMeasurement Error Value EqualizationLower conditions for rendezvous and dockingPhotogrammetry/videogrammetryUsing optical meansLaser lightZ-Coordinate

The invention discloses a non-cooperative target abutting measurement method based on additional sighting distance. The non-cooperative target abutting measurement method is combined by two measurement modes of different principles, i.e. a binocular vision measurement mode and a laser ranging mode, wherein the binocular vision measurement mode is a main measurement means for a six-degree-of-freedom parameter of a target relative position and a relative gesture; the laser ranging mode is mainly characterized in that a laser distance meter provides a laser light beam hot spot emitted on a target surface; and then, a Z coordinate of the hot spot to a laser distance meter coordinate system is obtained. Because measurement precision of the laser distance meter on a relatively long distance is far higher than that of the binocular vision measurement, the Z coordinate measured by a tiny fault of the laser distance meter can be used for correcting the Z coordinate obtained by the binocular vision measurement. X and Y coordinate correction can be carried out by relevance among three position coordinates in the binocular vision measurement, so that the three position coordinates of any characteristic point obtained by vision measurement can be corrected so as to improve binocular vision measurement precision, and especially measurement precision of a long-distance target characteristic point is improved.

Owner:BEIJING INST OF CONTROL ENG

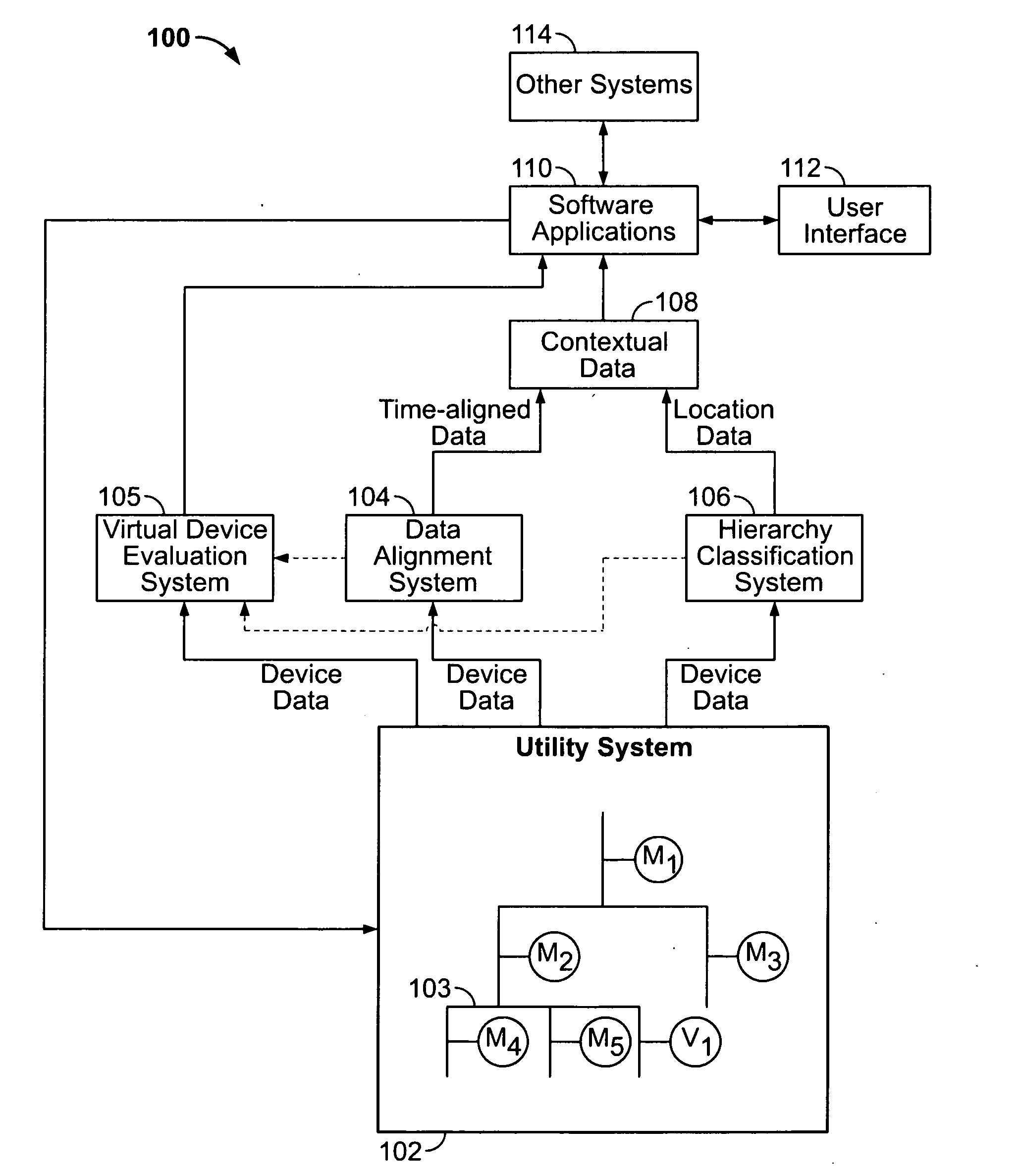

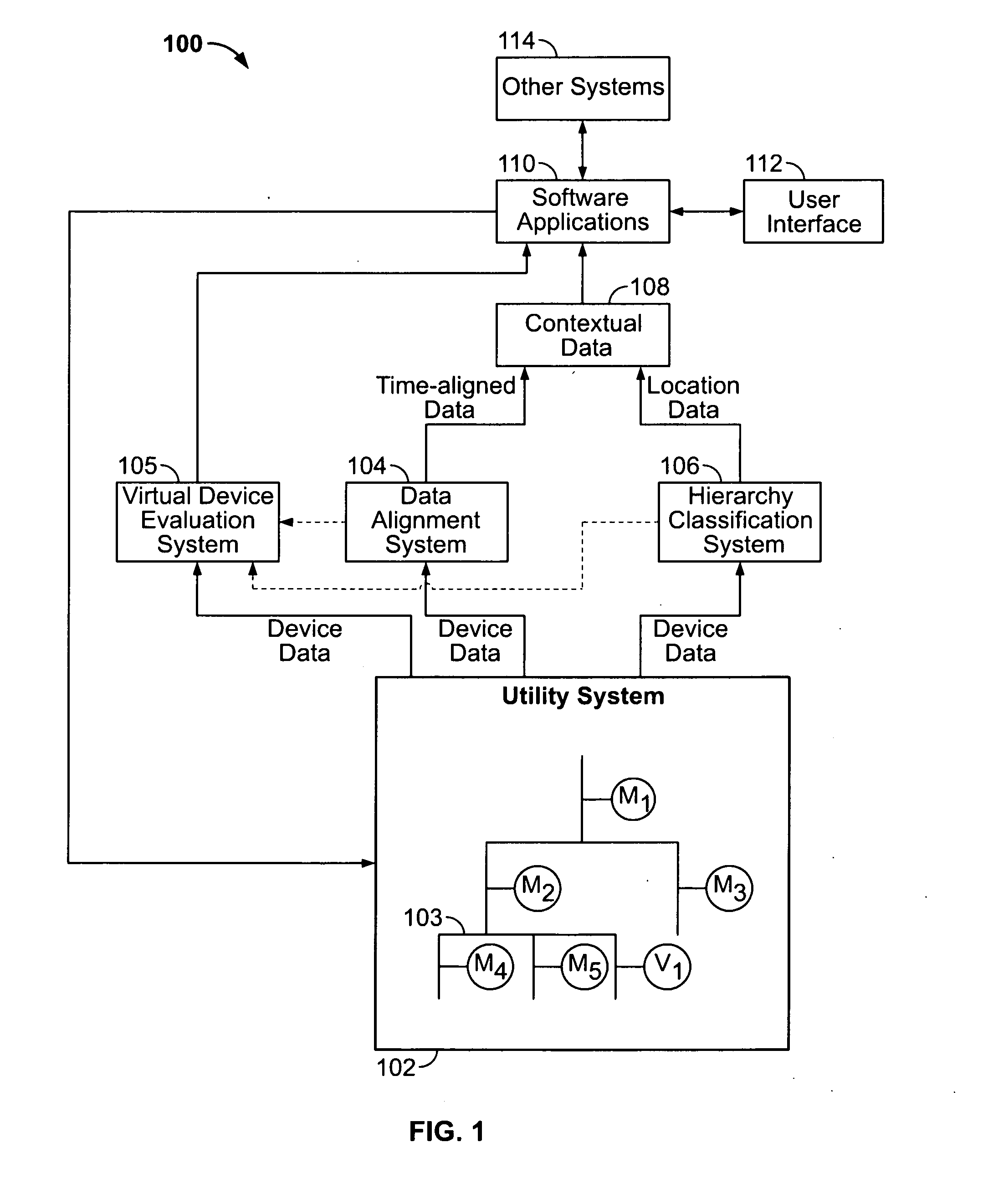

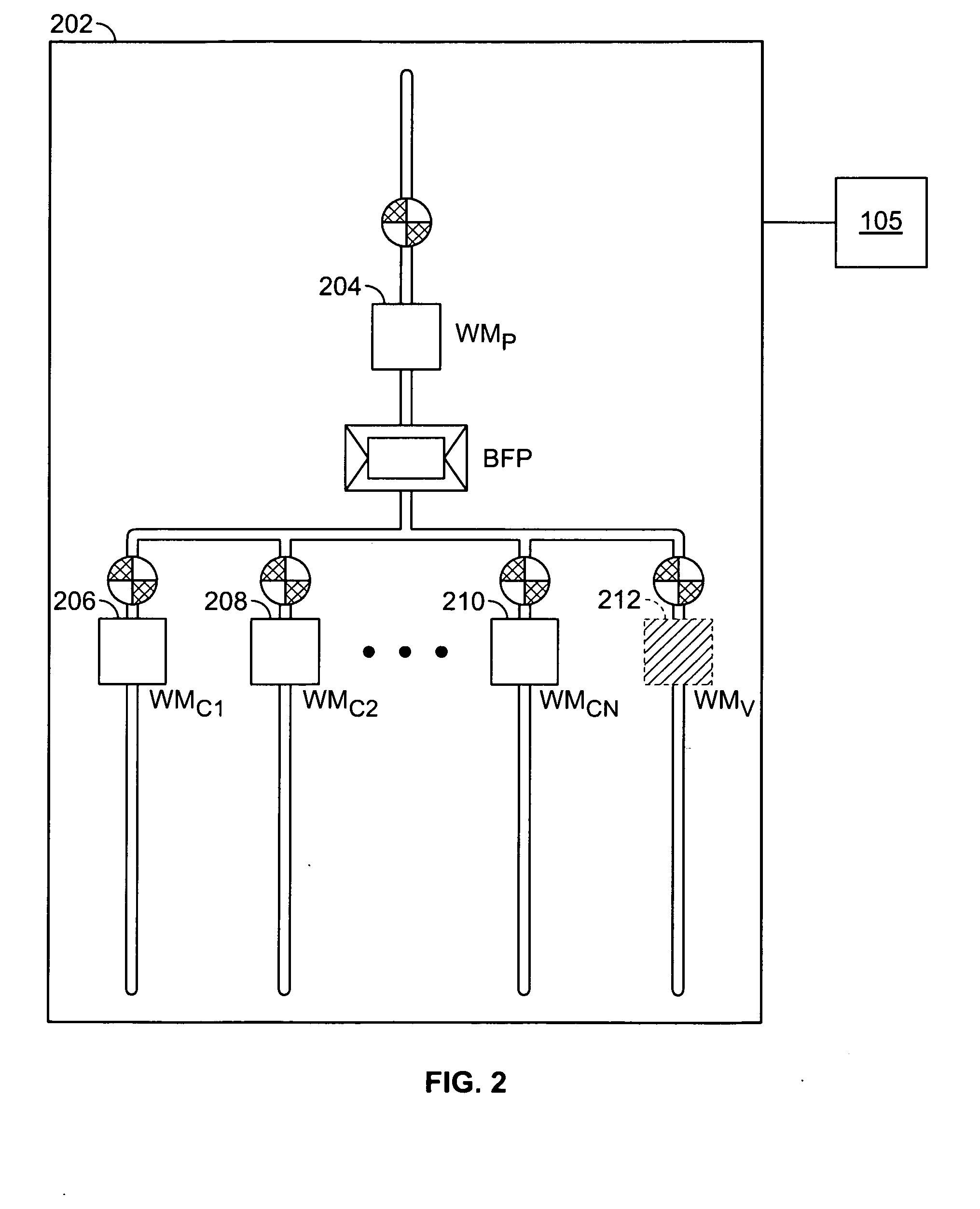

Virtual metering

ActiveUS20100042372A1Simple hierarchyTariff metering apparatusAmplifier modifications to reduce noise influenceSubject matterUtility system

Methods for improving the accuracy of characterizing unmonitored paths or virtual meters in a utility system. The hierarchical arrangement of IEDs in the utility system is determined. Measured quantities of a characteristic of the utility being monitored are received and error-adjusted using statistical or absolute methods. The statistical method accounts for the mean and standard deviation associated with error measurements of the subject IED, and the absolute method uses the absolute value of the error measurement, expressed as a percentage, to produce ranges of measured quantities within an error tolerance. The differences between the error-adjusted quantities are analyzed to determine whether an unmonitored path exists, and if so, whether the virtual meter is consuming or supplying the utility. The order in which IEDs are read is determined so that a parent and its children are read in sequence to increase synchronicity of the received data and the virtual meter evaluation.

Owner:SQUARE D CO

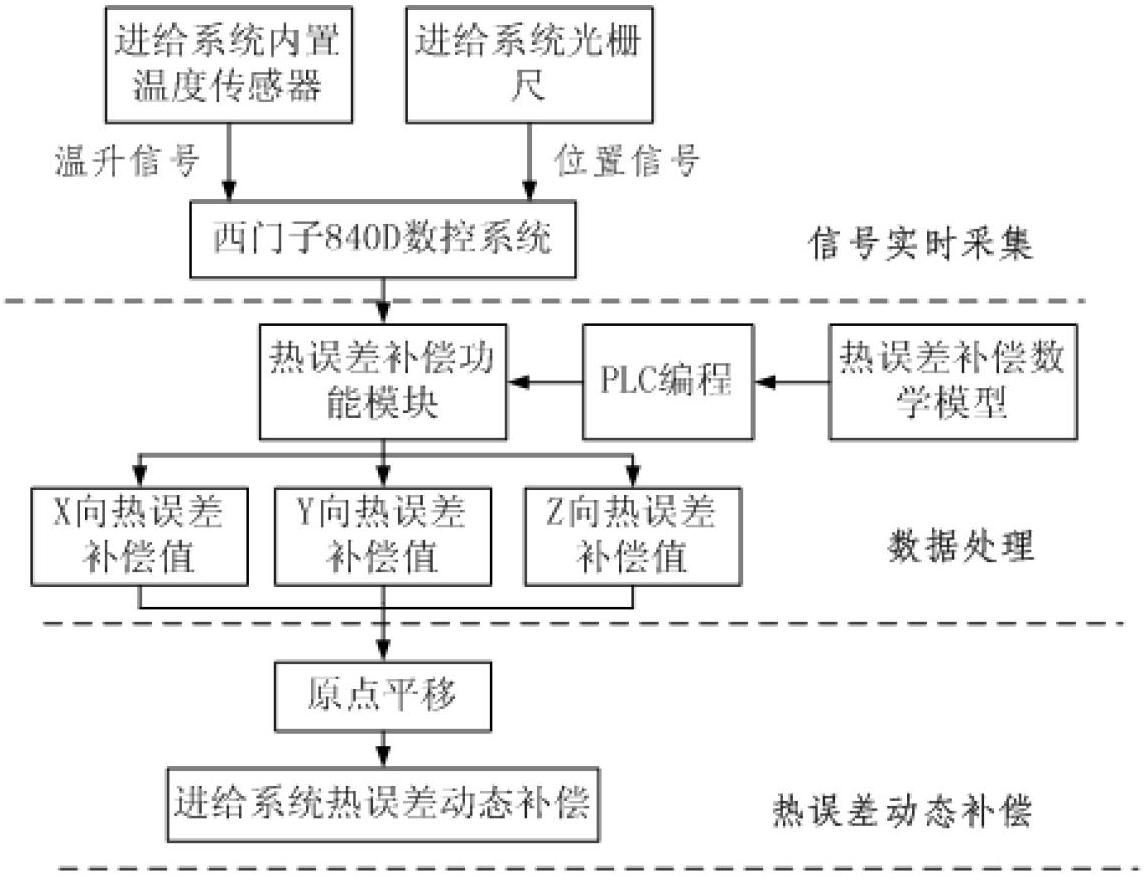

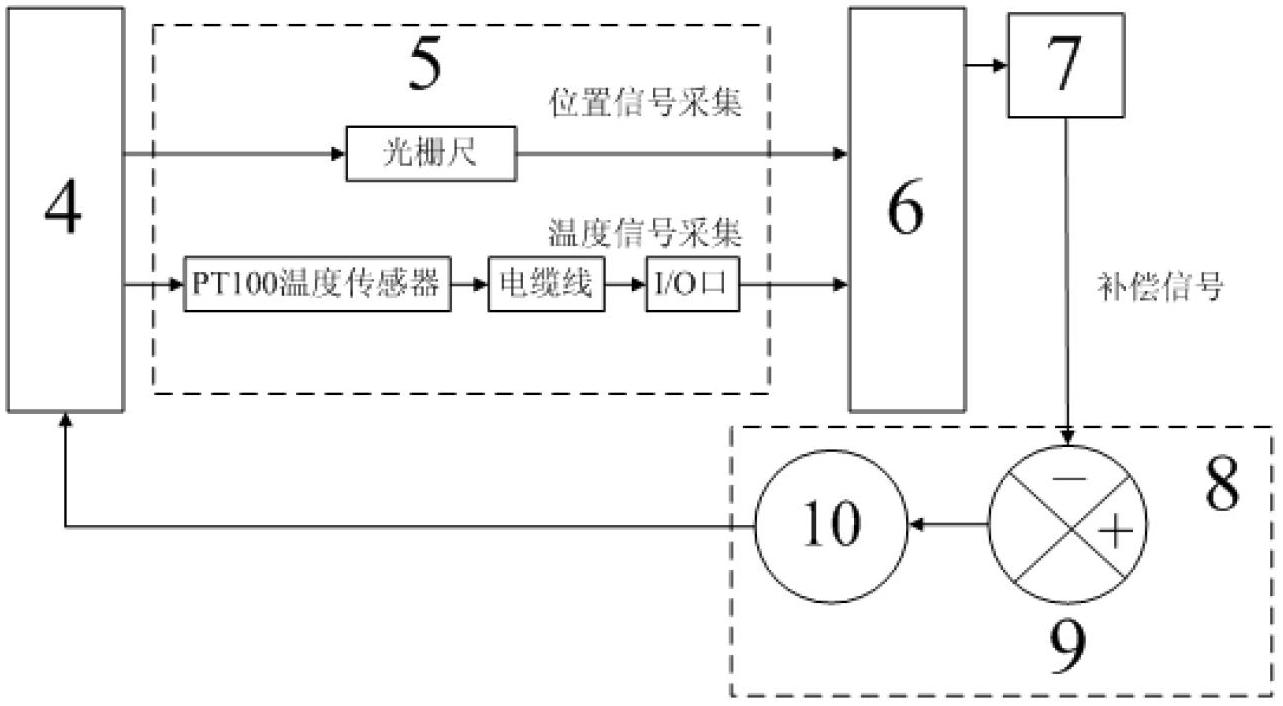

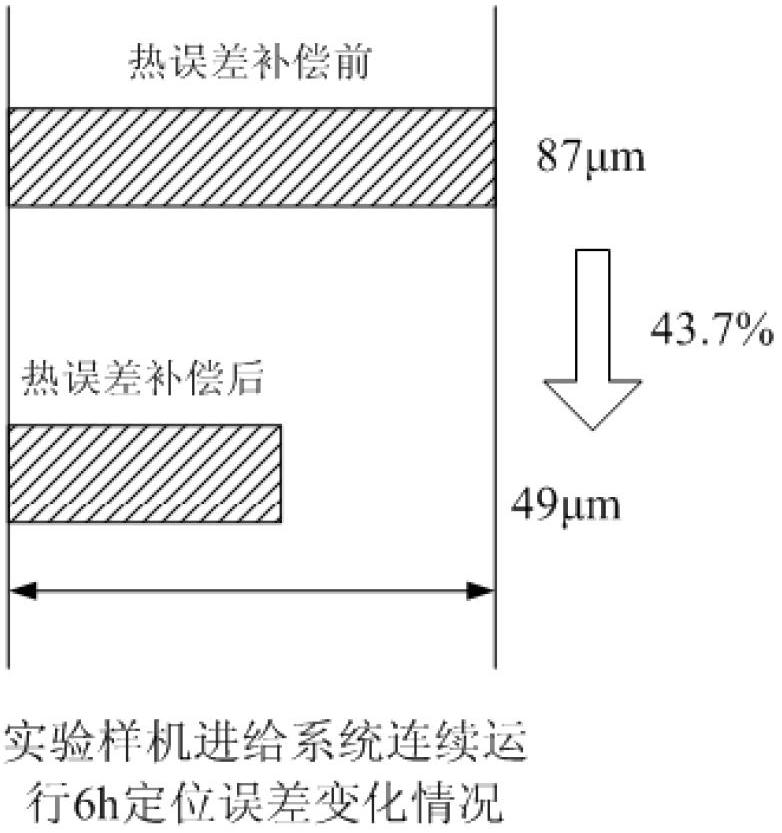

Full working stroke thermal error compensation method of numerically-controlled machine tool feeding system and implementation system thereof

InactiveCN102672527AInfluence of machining accuracyImprove machining accuracyAutomatic control devicesFeeding apparatusNumerical controlCompensation effect

The invention discloses a full working stroke thermal error compensation method of a numerically-controlled machine tool feeding system and an implementation system thereof. Reduction of whole machine machining accuracy is mainly caused by thermal errors of the numerically-controlled machine tool feeding system, and a whole set of the technical scheme for measuring, analyzing and compensating the feeding system is provided. Application techniques of thermal error measurement, thermal key point identification, thermal error compensation modeling and thermal error on-line compensation of the numerically-controlled machine tool feeding system under typical working conditions are surveyed. On that basis, a thermal error on-line compensation system of the numerically-controlled machine tool feeding system is constructed. Taking an X-direction high-speed feeding system of a Longmen numerical control machining center in a certain model as an example, measurement, analysis and modeling compensation of the thermal errors are carried out respectively, and compensation effects are obvious. The full working stroke thermal error compensation method can be used for solving the thermal error compensation problem of the numerically-controlled machine tool feeding system and provides technical supports for machining accuracy and stability of a numerically-controlled machine tool.

Owner:SICHUAN UNIV

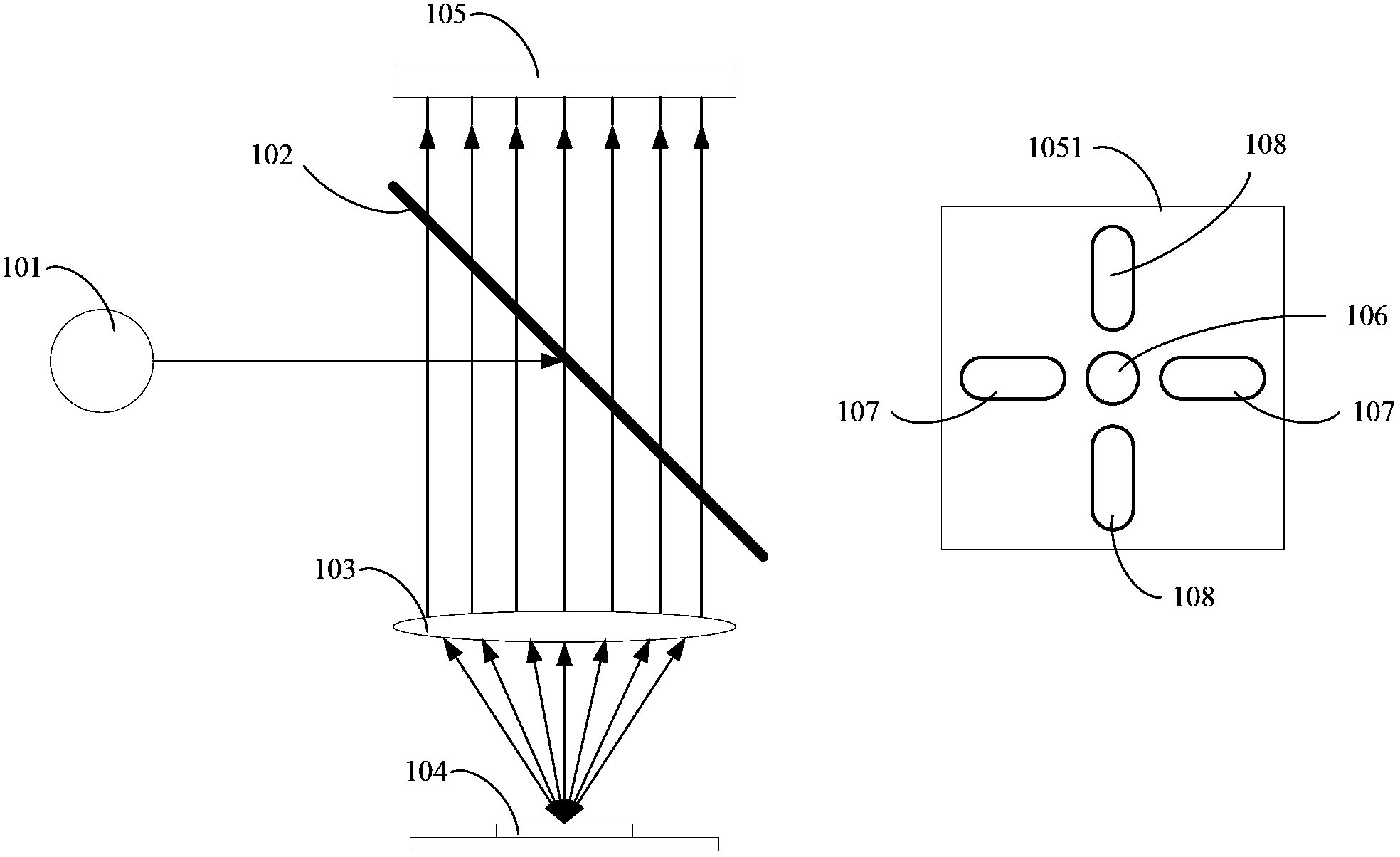

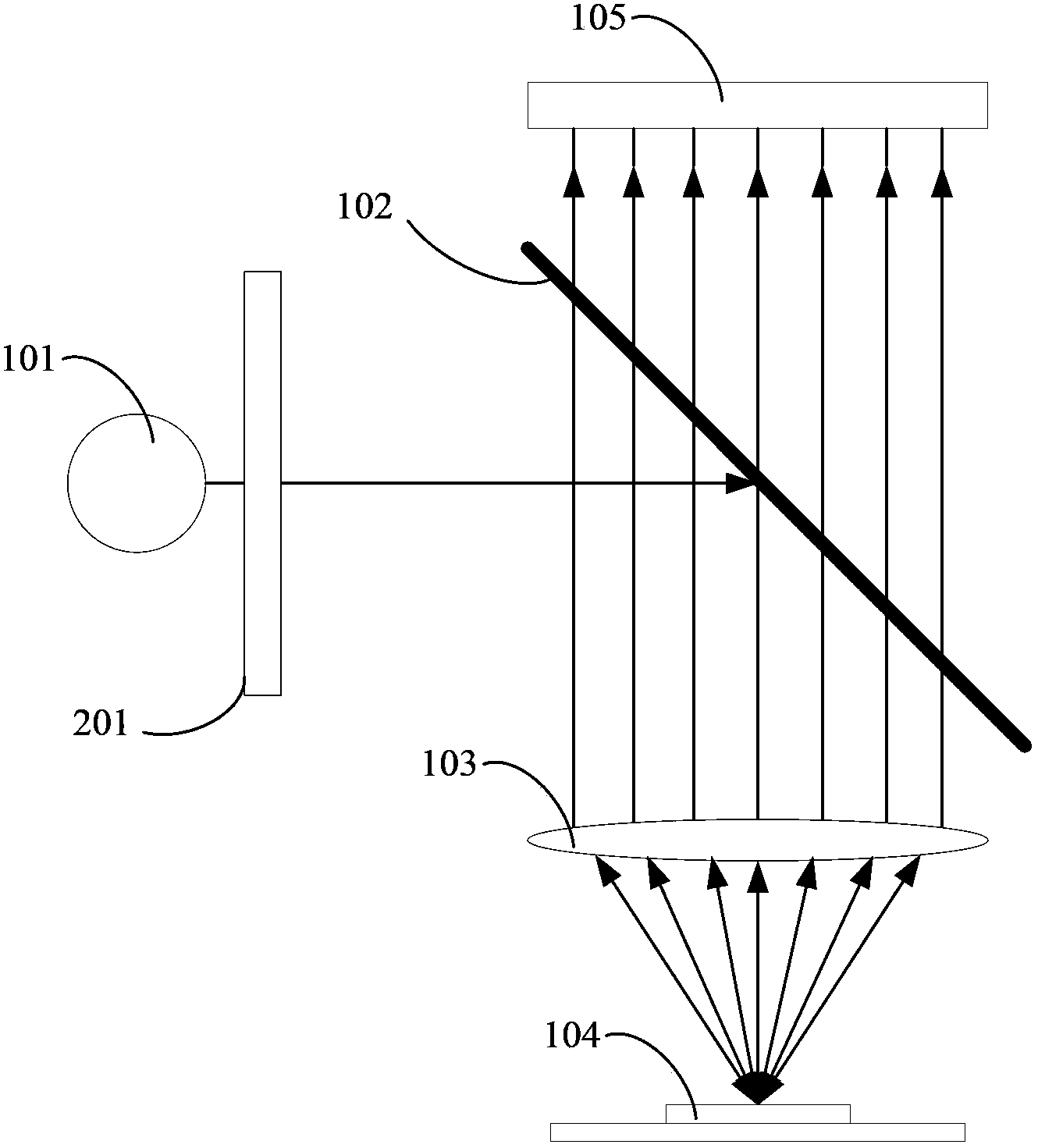

Overlay error measurement apparatus and method

ActiveCN103777467AReduce control difficultyHigh precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splittingLight beam

The invention provides an overlay error measurement apparatus and a method. According to the present invention, a wide waveband light source is adopted, the emitted wide waveband measurement light beam turns through a beam splitting prism, then is subjected to normal incidence on an overlay measurement label through an object lens, and produces diffraction, the diffraction light is received by a first detector after passing through the object lens and the beam splitting prism so as to measure the diffraction light intensity, and the asymmetry of the high-order diffraction light spectral intensity is further calculated so as to obtain the overlay error; and the adopted wide waveband has the wide measurement range, the good process adaptability is provided, and the normally-incident light beam is adopted so as to provide large depth of focus and reduce the control difficulty of the focal plane position measurement, such that the feasibility during actual measurement is increased, and the high precision measurement result can be obtained.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

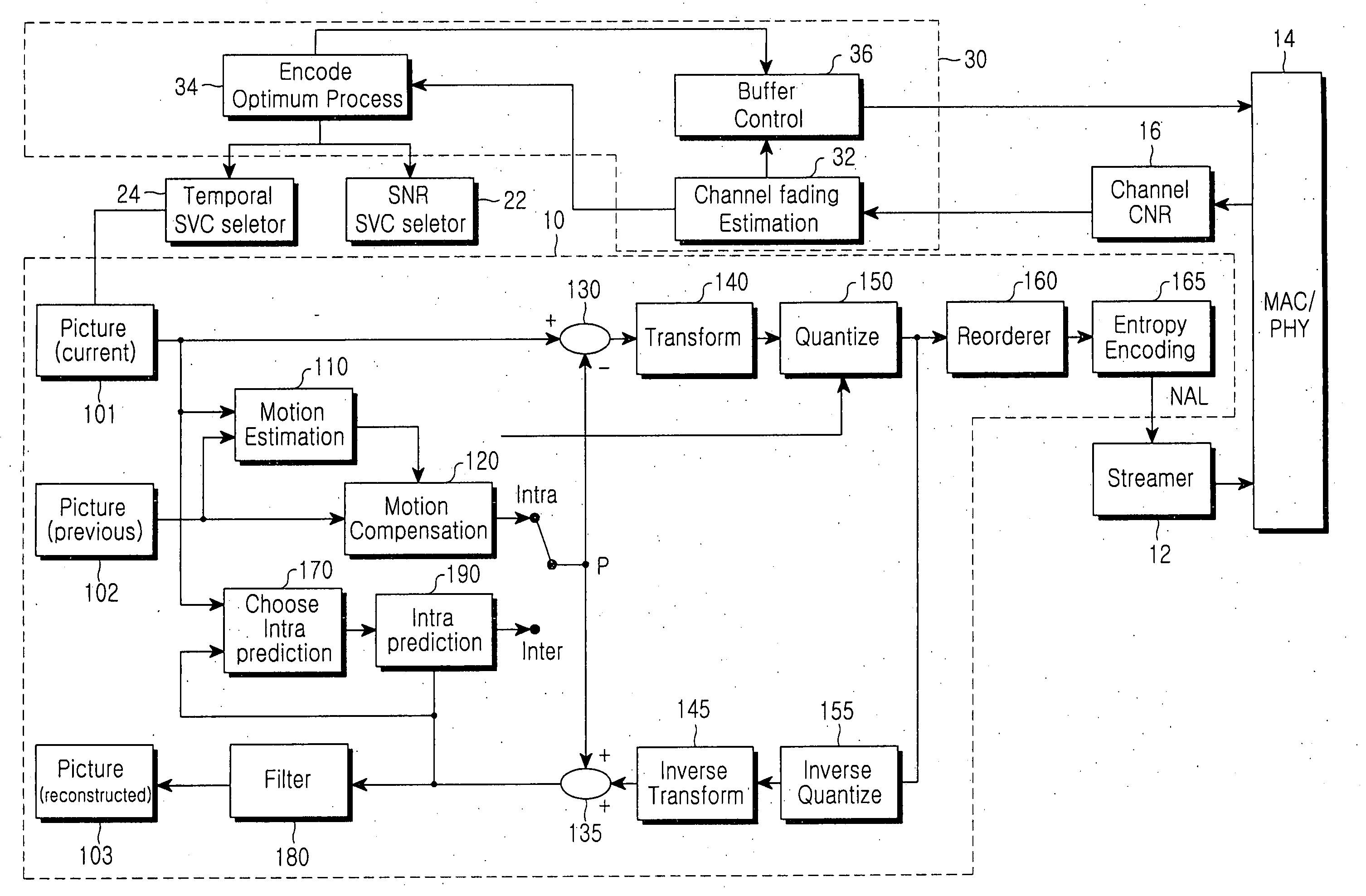

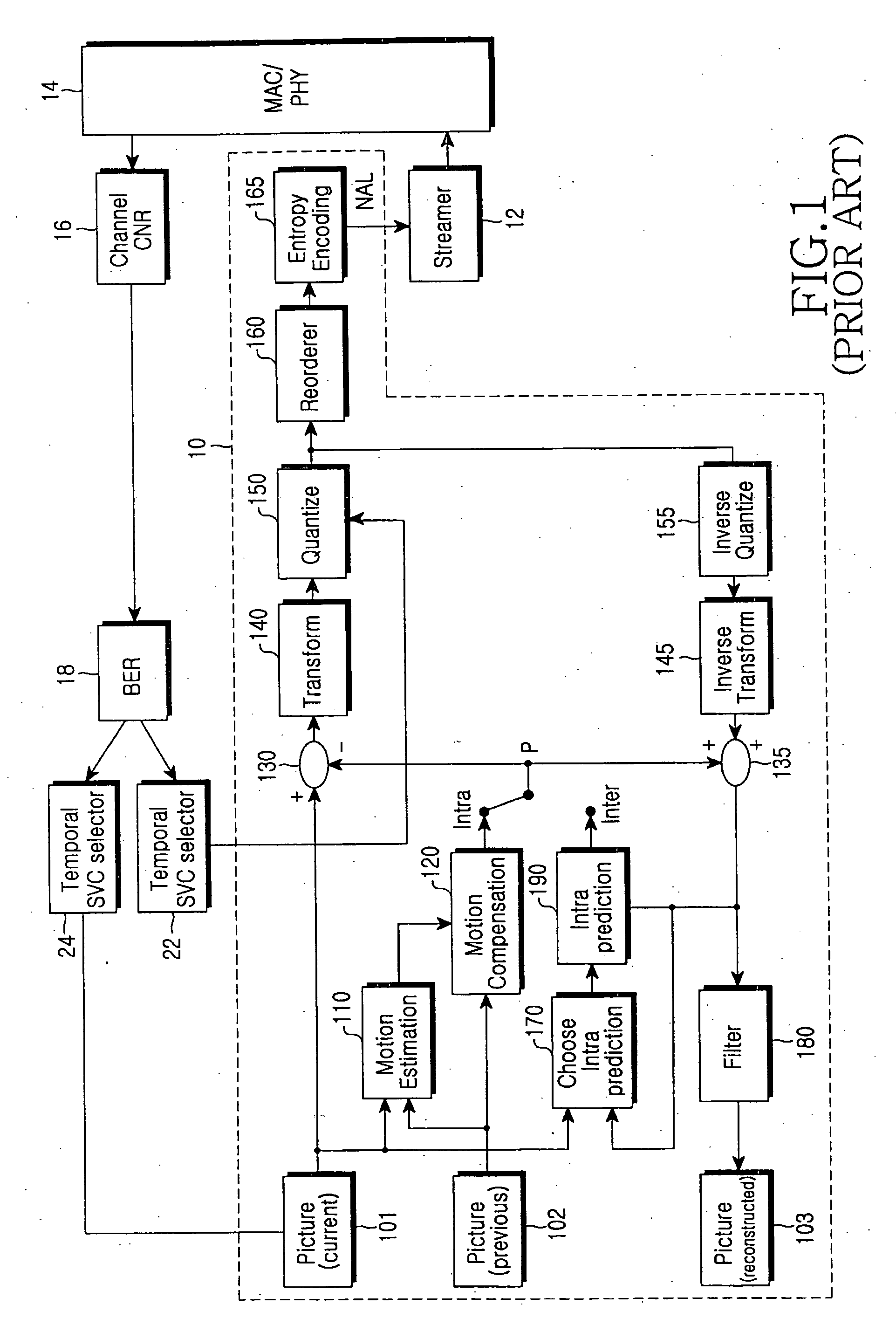

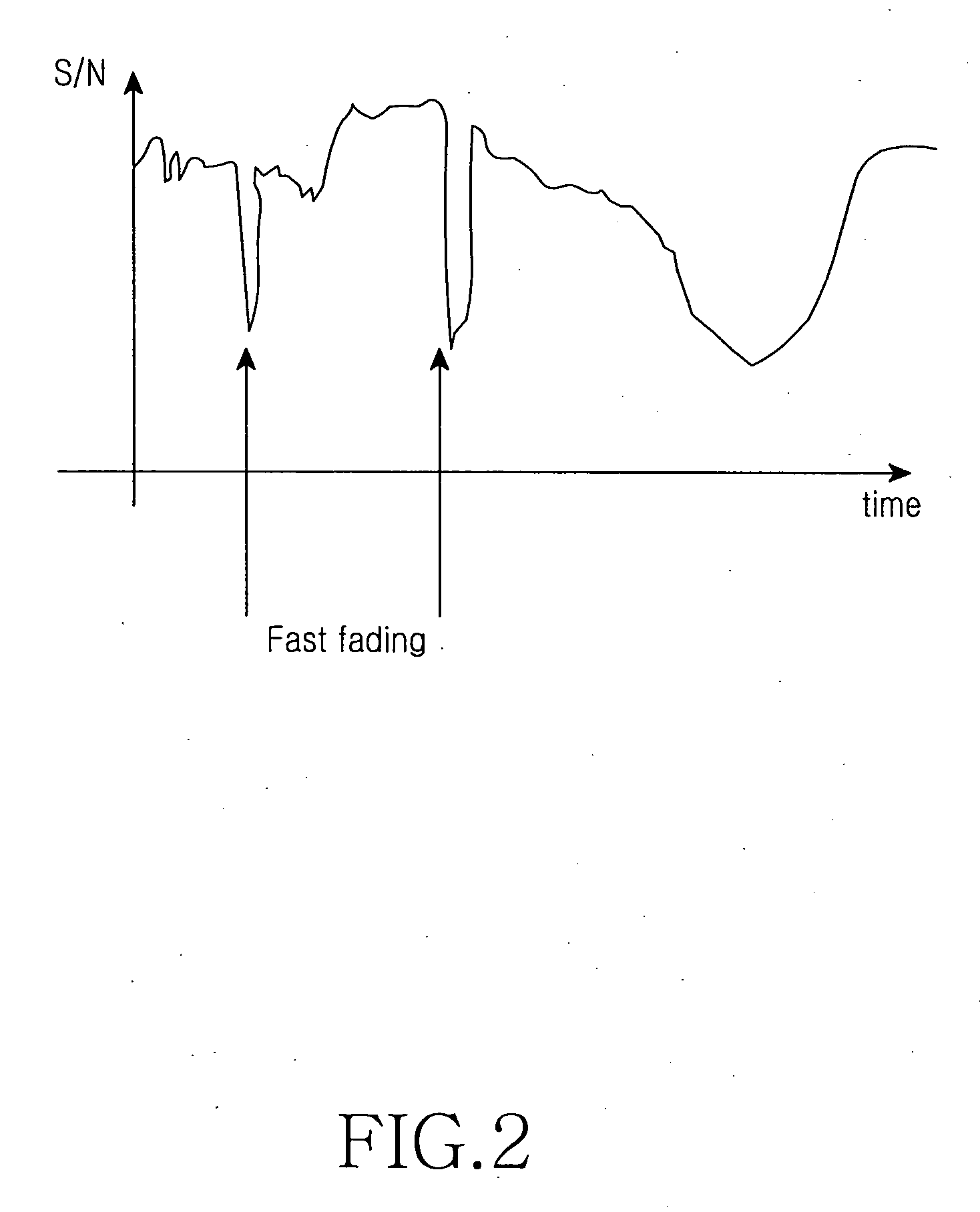

Apparatus and method for matching compressed video data under wireless fading environment

ActiveUS20070195893A1Smooth transmissionPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningControl signalCarrier signal

A method and apparatus for matching compressed video data under a wireless fading environment are disclosed. The apparatus includes an encoder for encoding and outputting the video data as a compressed bit stream, a channel error measurement unit for measuring Signal-to-Noise Ratio (SNR) or Carrier-to-Noise Ratio (CNR) of a wireless channel, and an encoder optimization module for determining if the current fading is slow fading or fast fading. A control signal is output to reduce a frame transmission ratio or to change the quality of the vide data if it is determined that the current fading is slow fading. Another control signal is output to adjust the size of a data output buffer of the wireless channel if it is determined that the current fading is fast fading. The apparatus also includes a temporal Scalable Video Coding (SVC) selector 24 and an SNR SVC selector 22 for selecting the frame transmission ratio or the bit rate according to the control signal output from the encoder optimization module, to provide a frame selection signal or a bit rate selection signal to the encoder.

Owner:SAMSUNG ELECTRONICS CO LTD

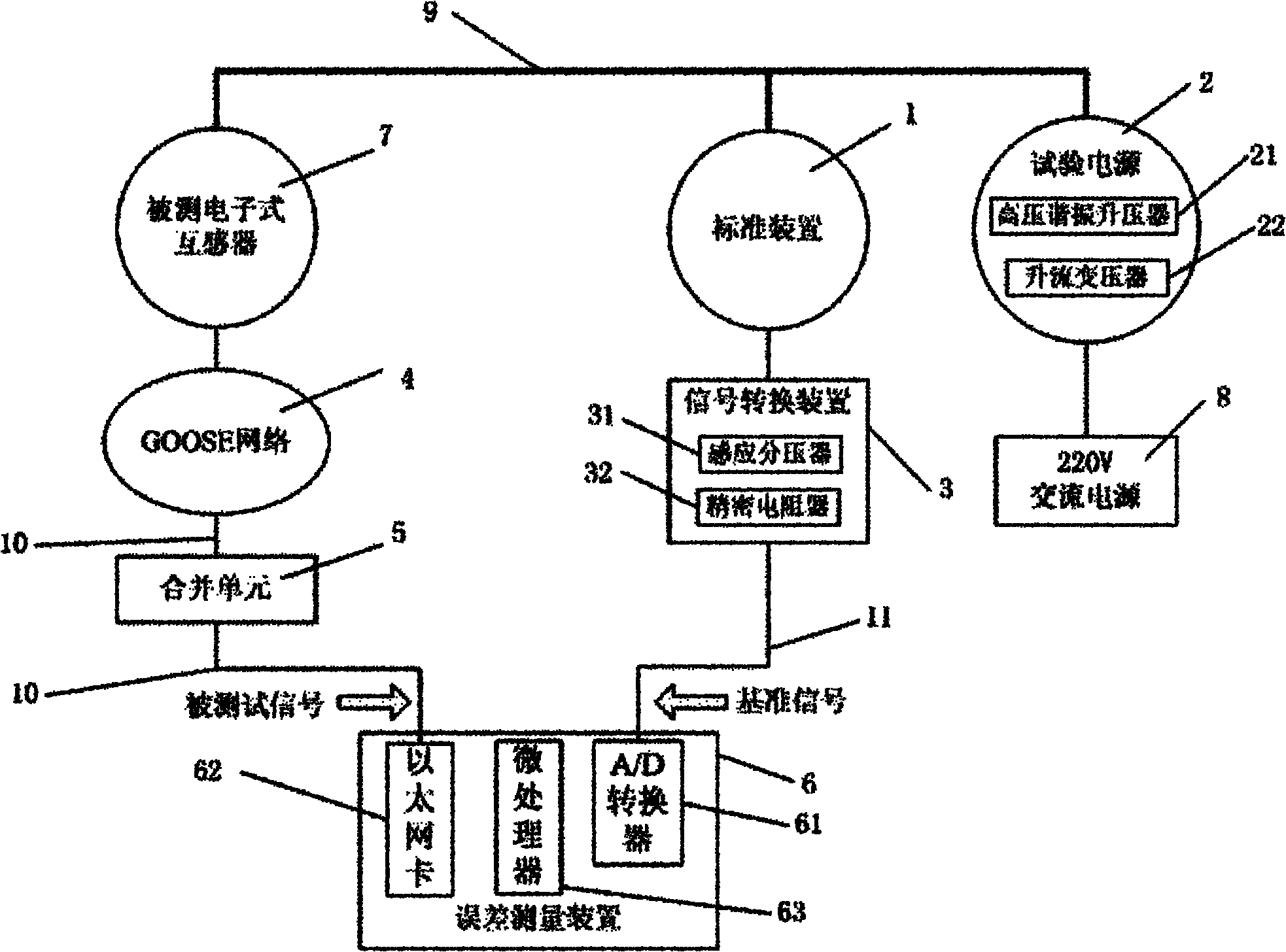

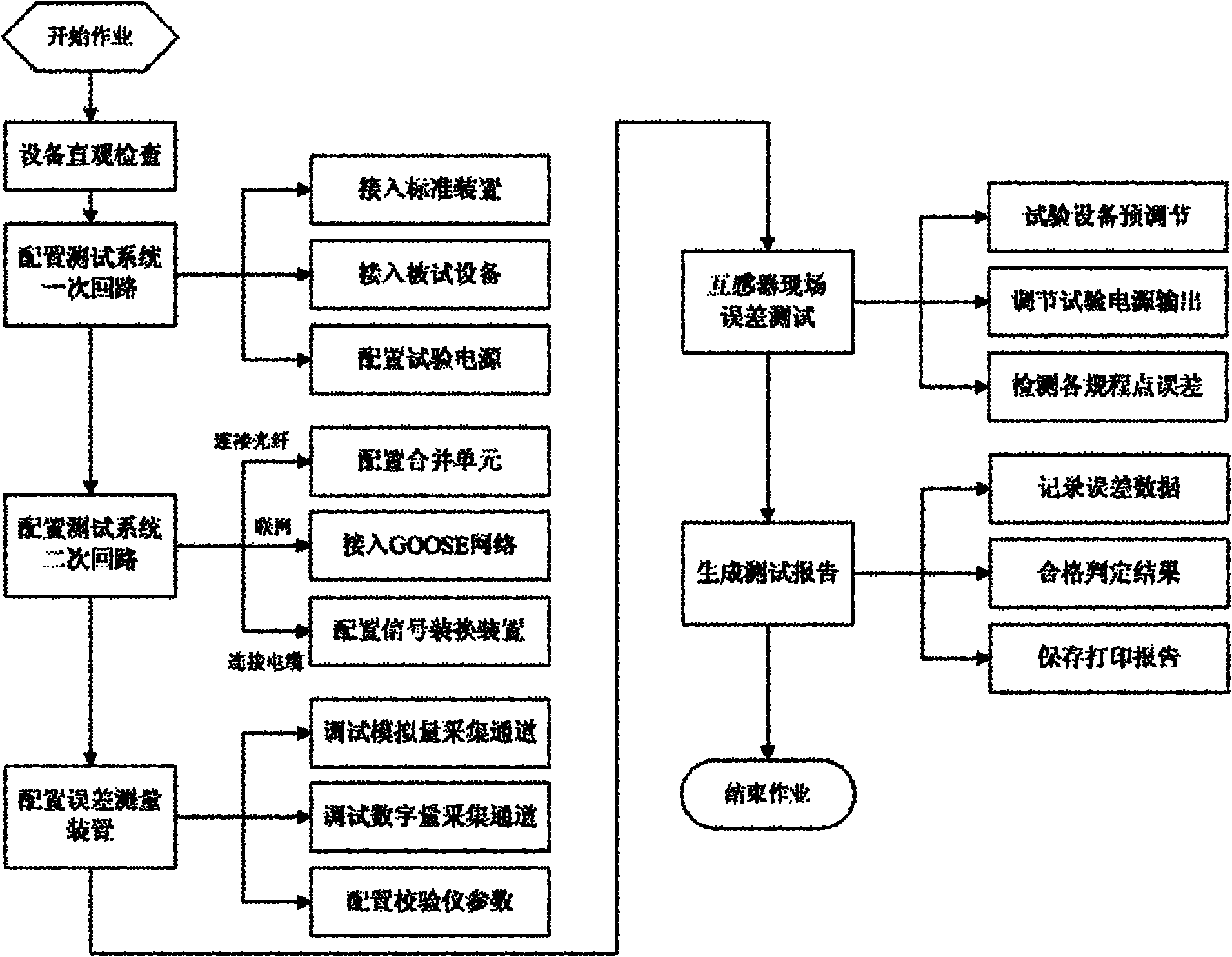

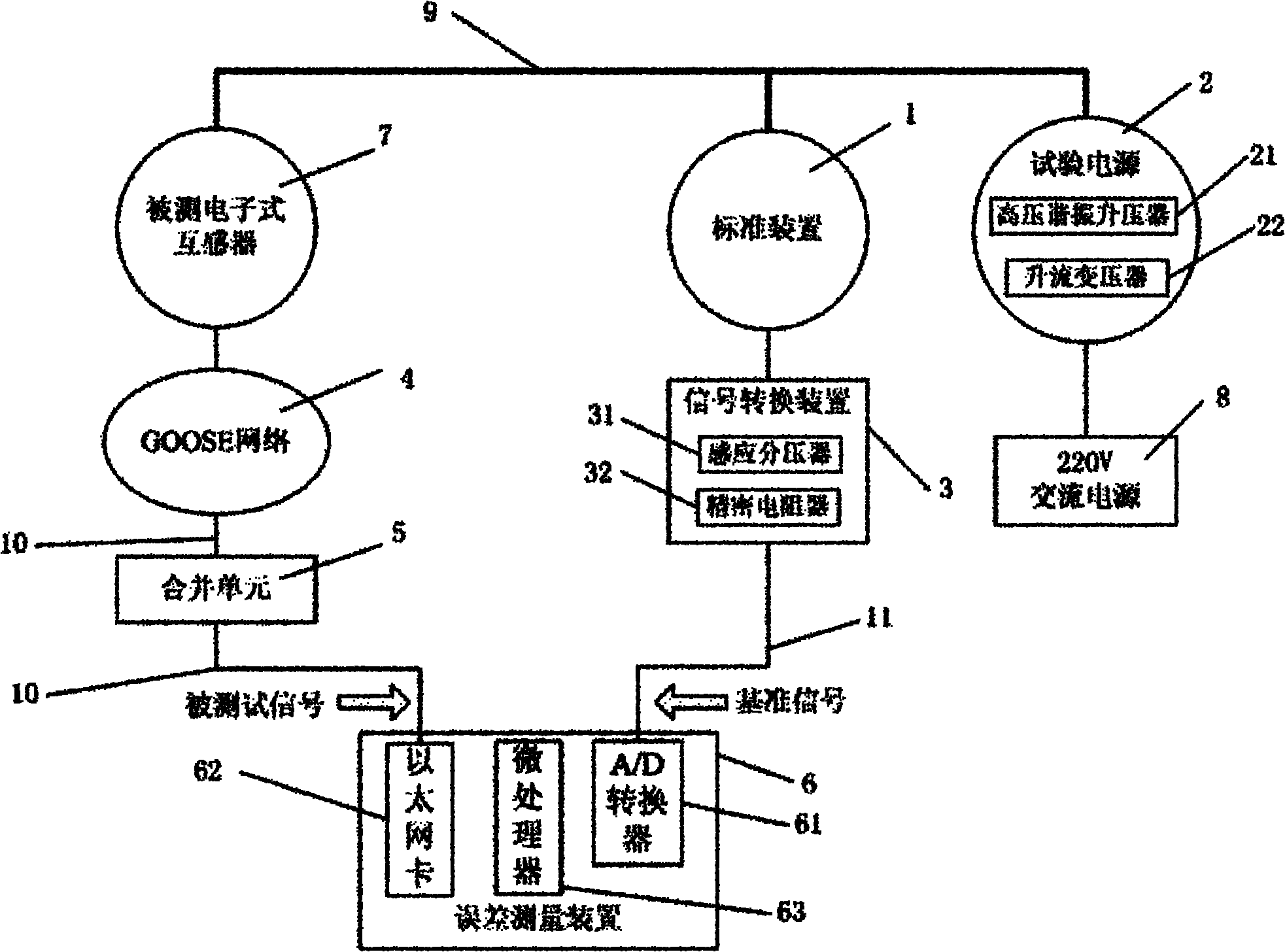

Electronic mutual inductor test system and test method

The invention discloses an electronic mutual inductor test system and a test method. The electronic mutual inductor test system comprises a standard device, a signal conversion device, an error measuring device, a test power supply, a merging unit and a tested electronic mutual inductor, wherein the standard device is used for providing a standard signal serving as a test reference; the signal conversion device is used for receiving the standard signal and converting the standard signal into an analog signal which can be acquired by the error measuring device; the test power supply is used for outputting a primary voltage and a primary current for test use; the merging unit is used for receiving a digital signal output by the tested electronic mutual inductor and processing the digital signal; and the error measuring device is used for receiving the standard signal output by the signal conversion device and the digital signal output by the merging unit, and acquiring the ratio difference and the phase difference of the tested electronic mutual inductor. The electronic mutual inductor test system is particularly suitable for a field error test of the electronic mutual inductor, andhas the advantages of convenient test work, high reliability, small equipment volume, light weight, high test result accuracy and the like.

Owner:HEFEI POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

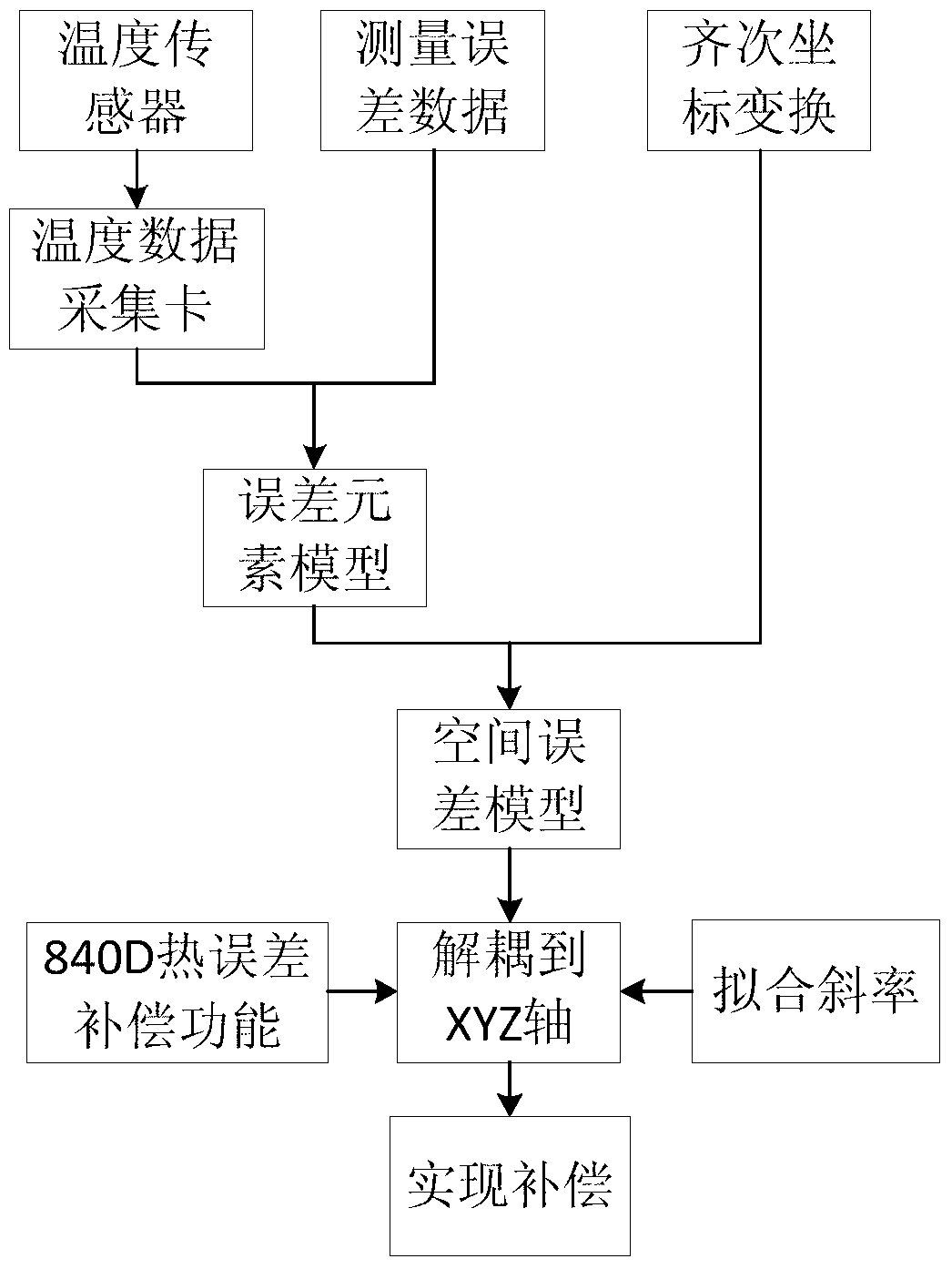

Numerically-controlled machine tool error compensation system and method based on human-computer interface secondary development

ActiveCN103345199ACompensate for spatial errorsEnsure effective implementationProgramme controlComputer controlHuman–machine interfaceData acquisition

The invention discloses a numerically-controlled machine tool error compensation system and method based on human-computer interface secondary development. The numerically-controlled machine tool error compensation system comprises a hardware portion and a software portion integrally arranged in the hardware portion. The hardware portion comprises a Siemens 840D numerical control system PCU, a temperature sensor, a temperature data acquisition card and an error measurement instrument. The software portion comprises a temperature acquisition module, a thermal error compensation module, a space error compensation mould and a state monitoring module. According to the numerically-controlled machine tool error compensation system and method based on the human-computer interface secondary development, the error compensation function of a Siemens 840D numerical control system is effectively used for compensating space errors; the numerically-controlled machine tool error compensation system and method based on the human-computer interface secondary development is convenient and effective to implement, external expansion of compensators is not required, machine tool parameters are read based on a human-computer interface and DDE, and good on-line state monitoring can be achieved without an external upper computer.

Owner:SHANGHAI JIAO TONG UNIV

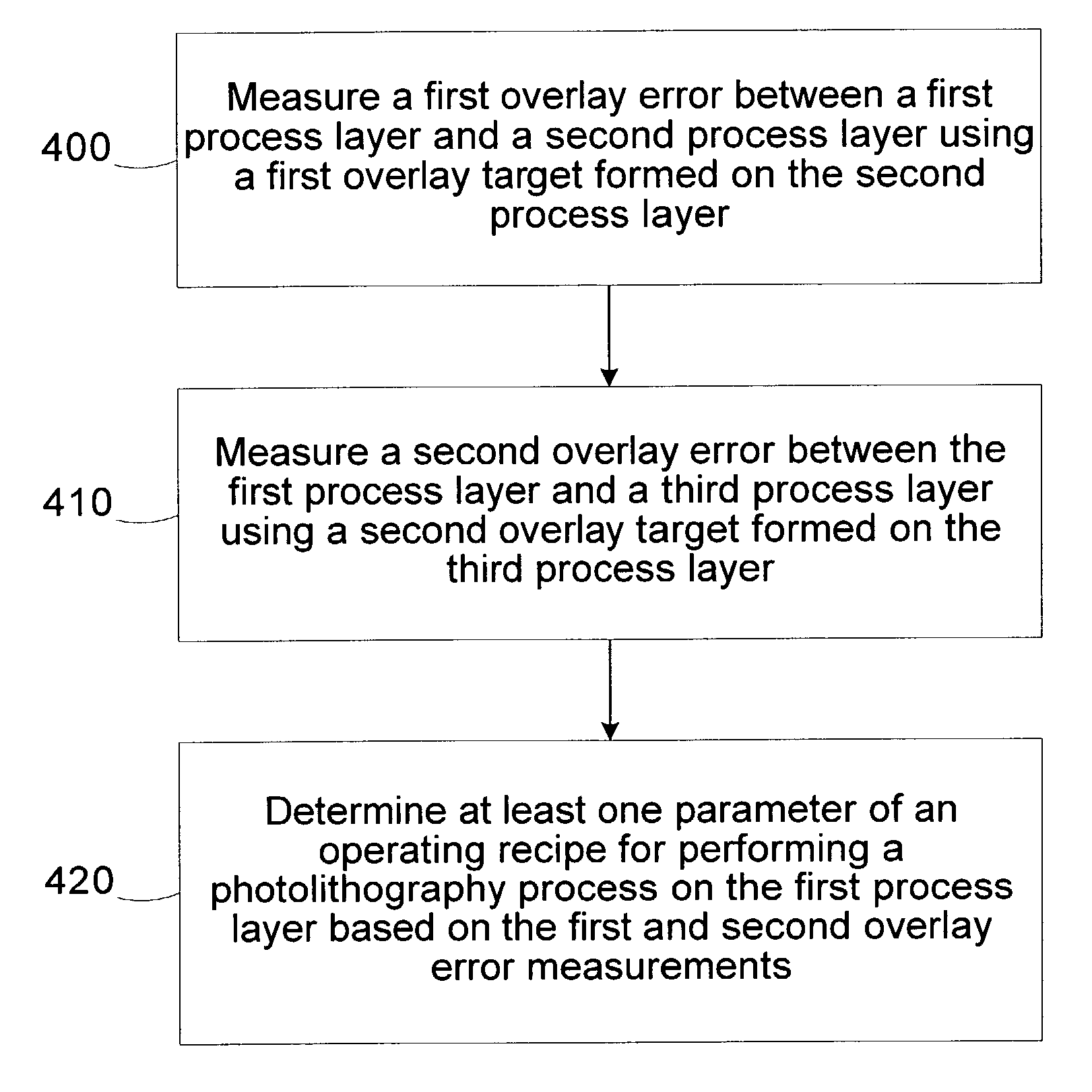

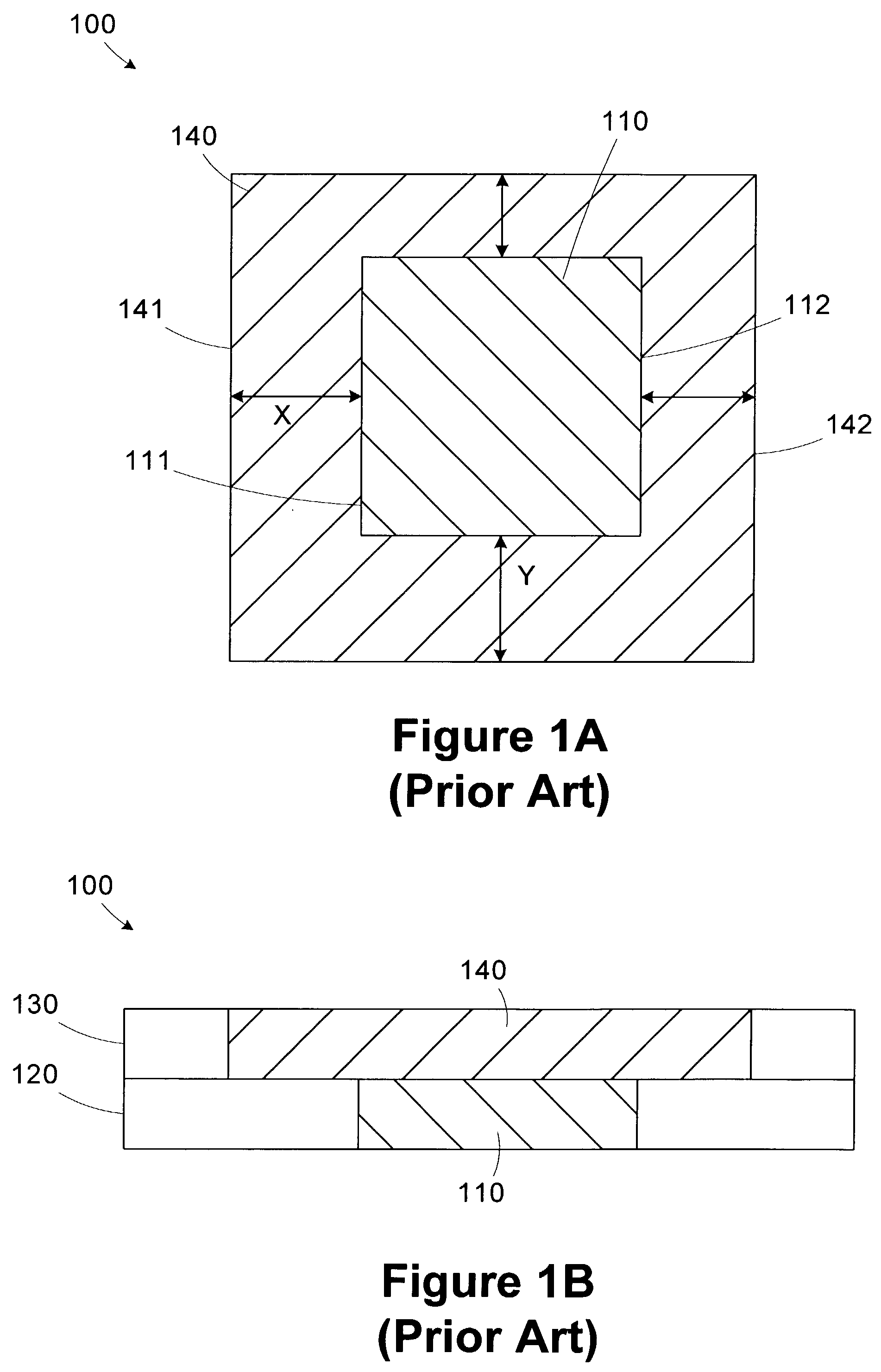

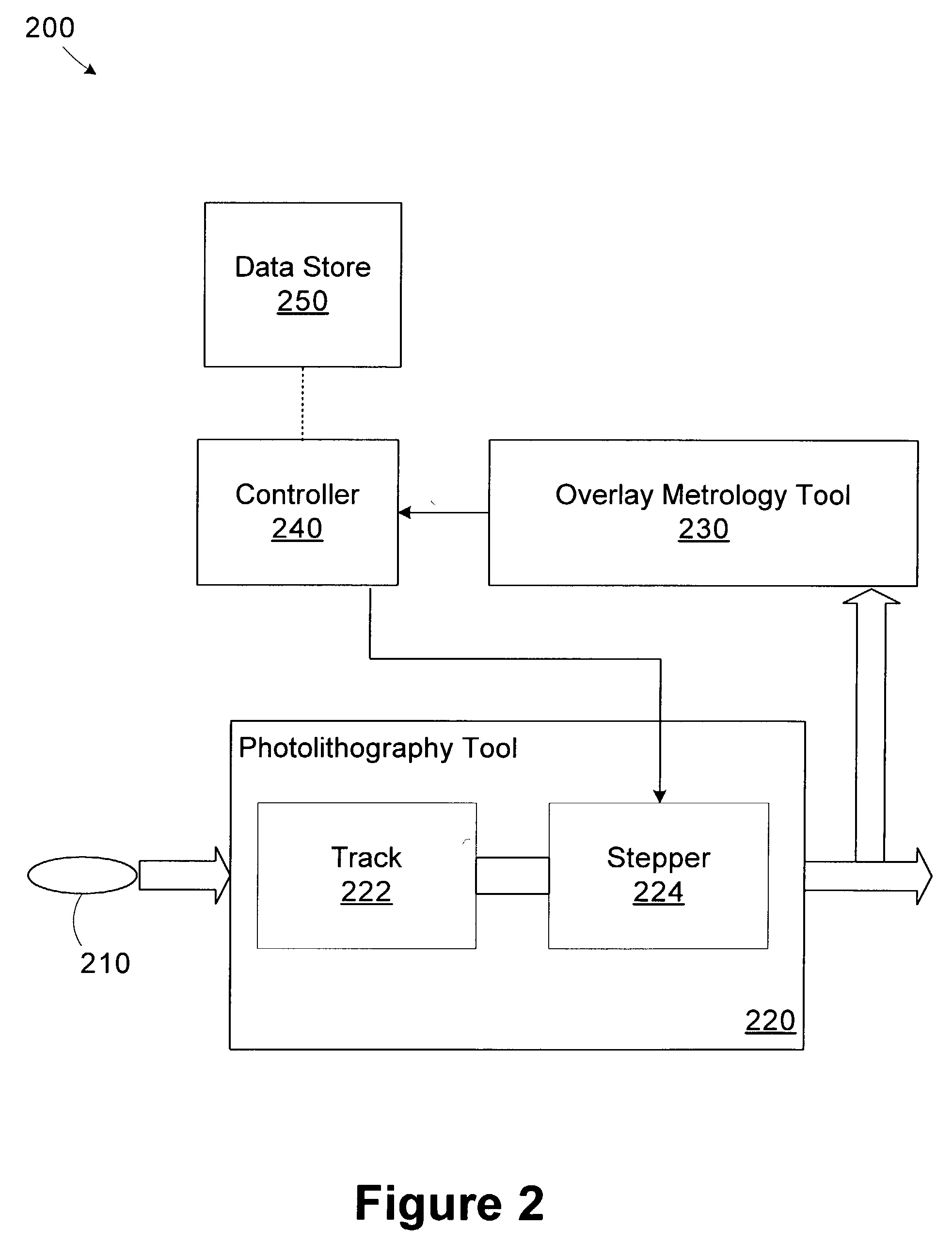

Method and apparatus for overlay control using multiple targets

InactiveUS20040101983A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyPhotolithography

A method includes measuring a first overlay error between a first process layer and a second process layer using a first overlay target formed on the second process layer. A second overlay error between the first process layer and a third process layer is measured using a second overlay target formed on the third process layer. At least one parameter of an operating recipe for performing a photolithography process on the first process layer is determined based on the first and second overlay error measurements. A system includes a metrology tool and a controller. The metrology tool is configured to measure a first overlay error between a first process layer and a second process layer using a first overlay target formed on the second process layer and measure a second overlay error between the first process layer and a third process layer using a second overlay target formed on the third process layer. The controller is configured to determine at least one parameter of an operating recipe for performing a photolithography process on the first process layer based on the first and second overlay error measurements.

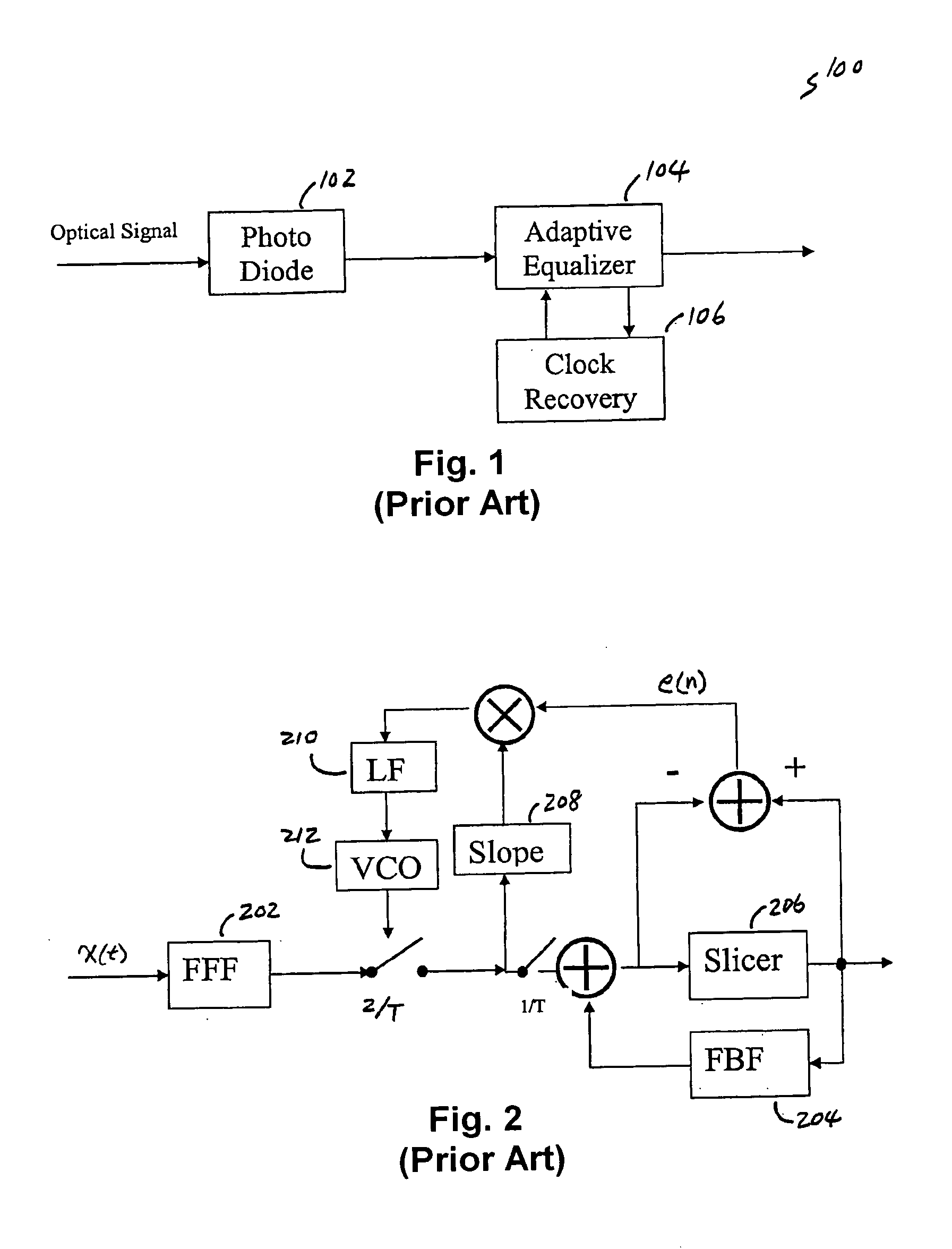

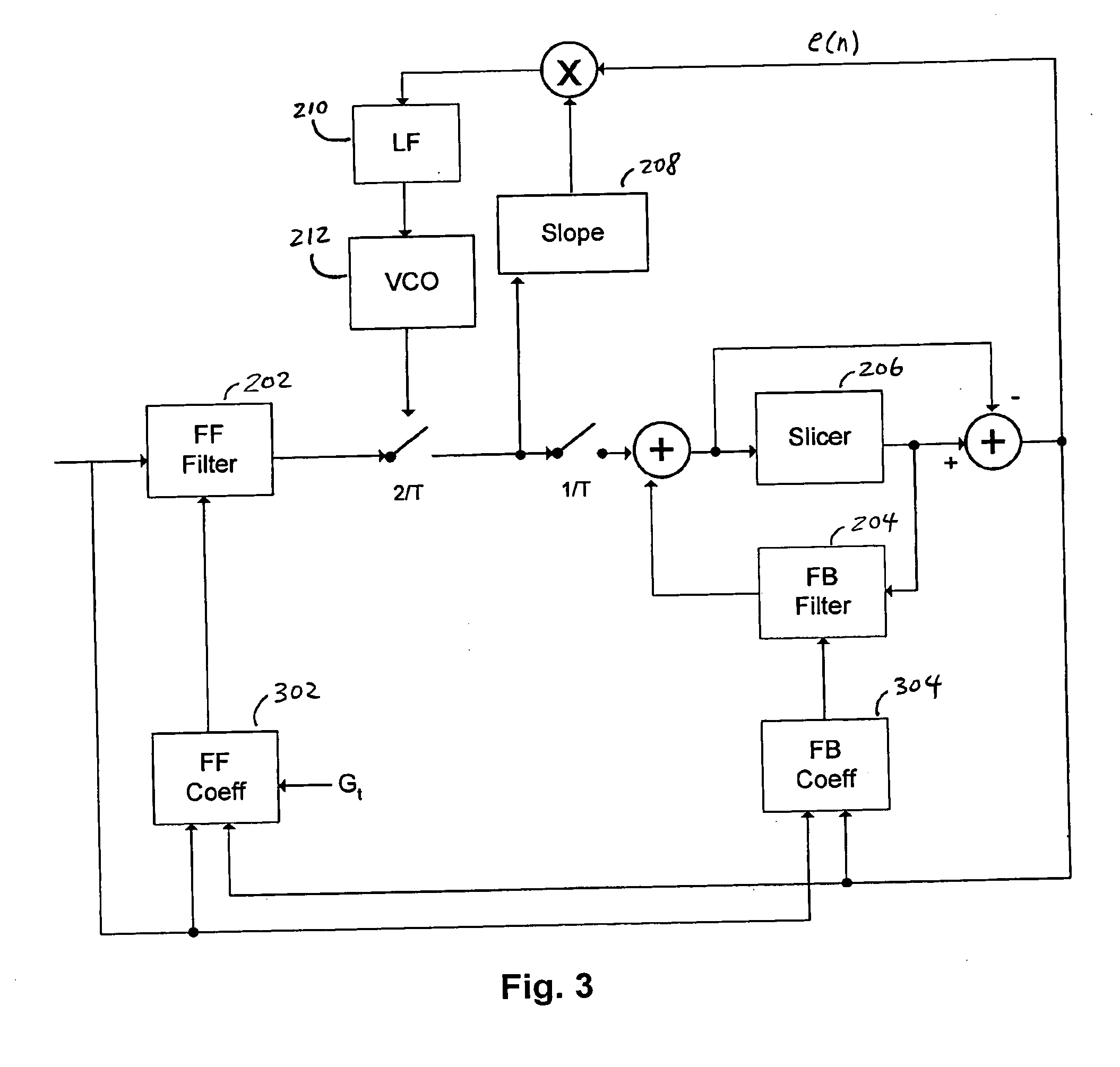

Adaptive equalization with group delay

InactiveUS20060146926A1Reduce impactReduces undesired interactionMultiple-port networksTransversal filtersEqualizationControl theory

Methods, apparatuses, and systems are presented for performing adaptive equalization involving receiving a signal originating from a channel associated with inter-symbol interference, filtering the signal using a filter having a plurality of adjustable tap weights to produce a filtered signal, and adaptively updating each of the plurality of adjustable tap weights to a new value to reduce effects of inter-symbol interference, wherein each of the plurality of adjustable tap weights is adaptively updated to take into account a constraint relating to a measure of error in the filtered signal and a constraint relating to group delay associated with the filter. Each of the plurality of adjustable tap weights may be adaptively updated to drive group delay associated with the filter toward a target group delay.

Owner:MICROSEMI STORAGE SOLUTIONS

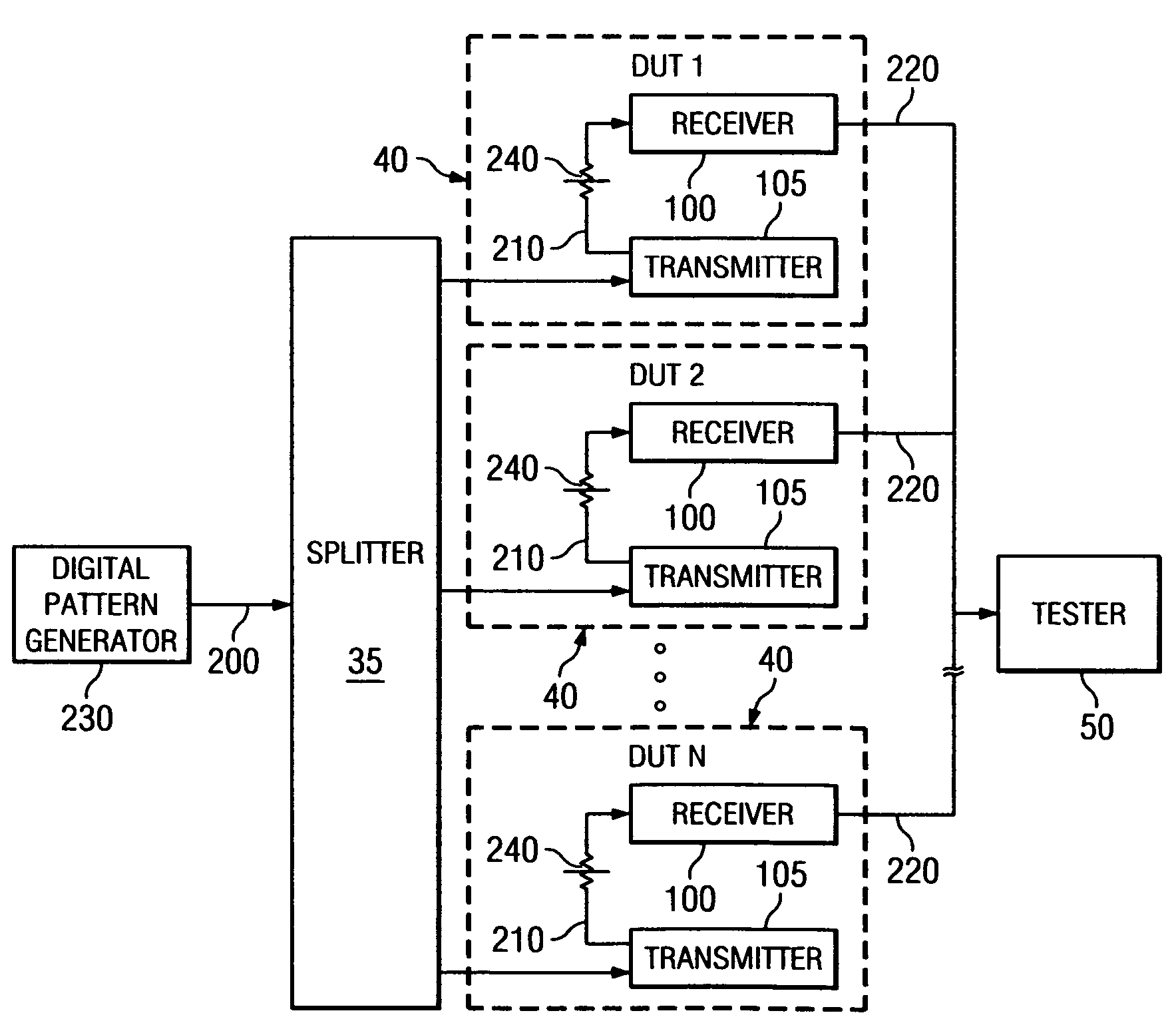

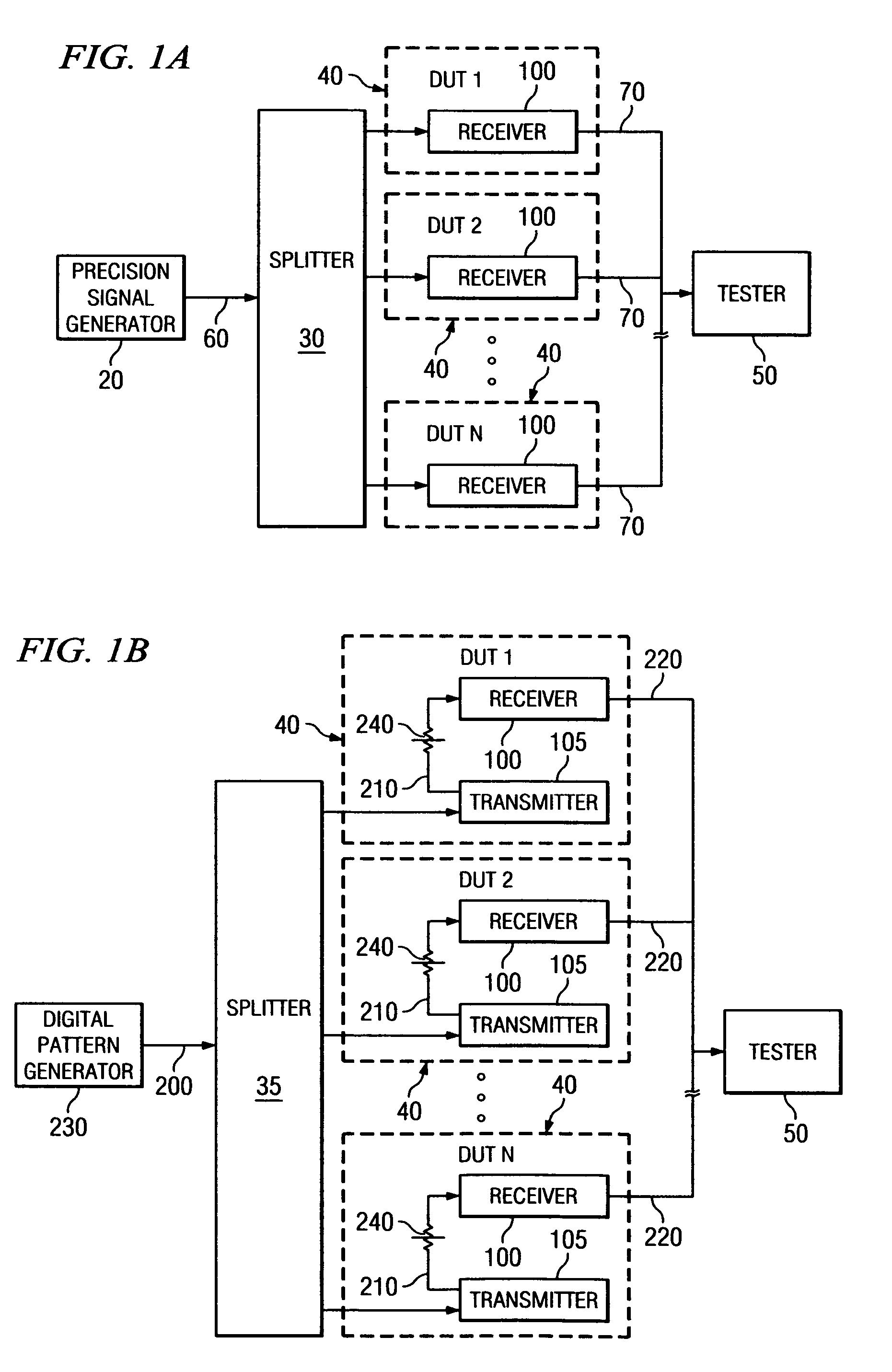

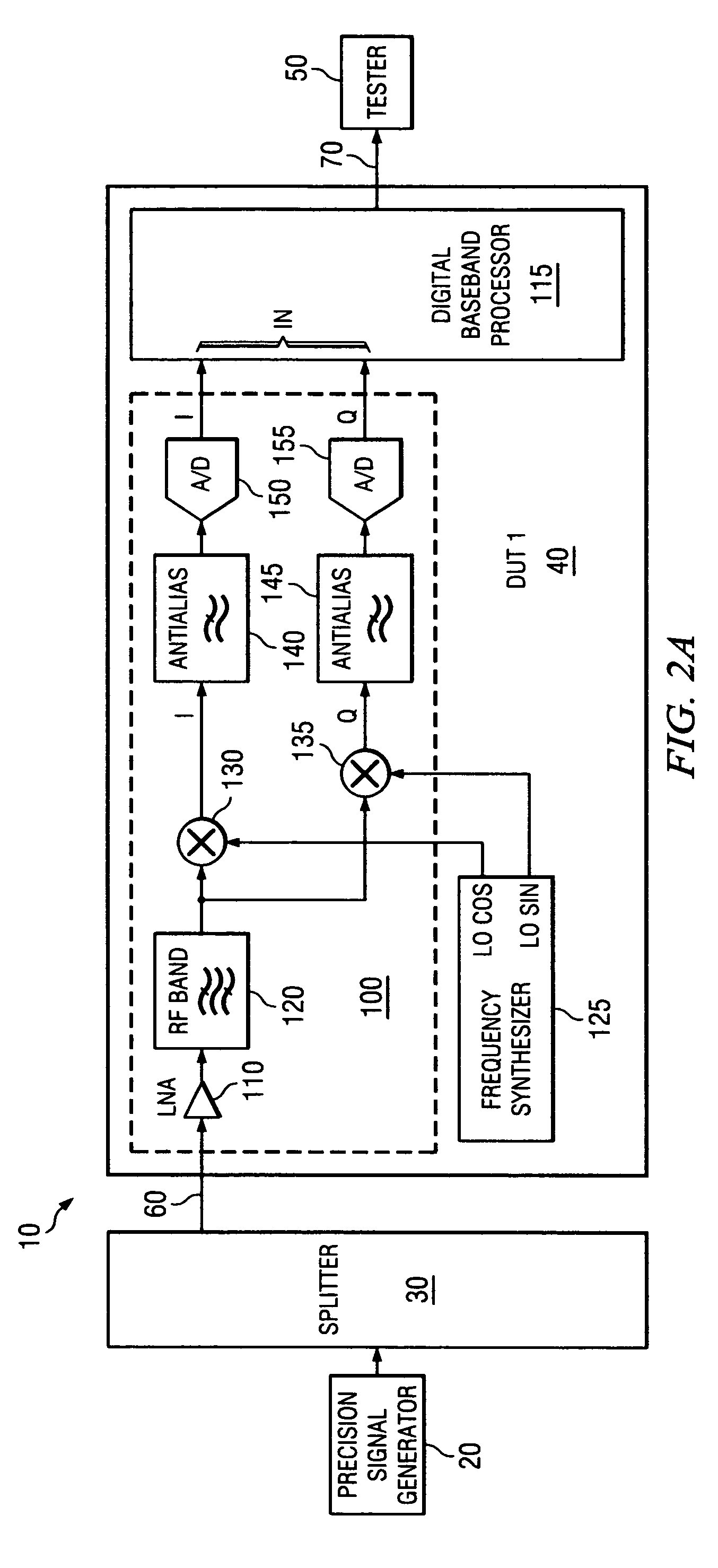

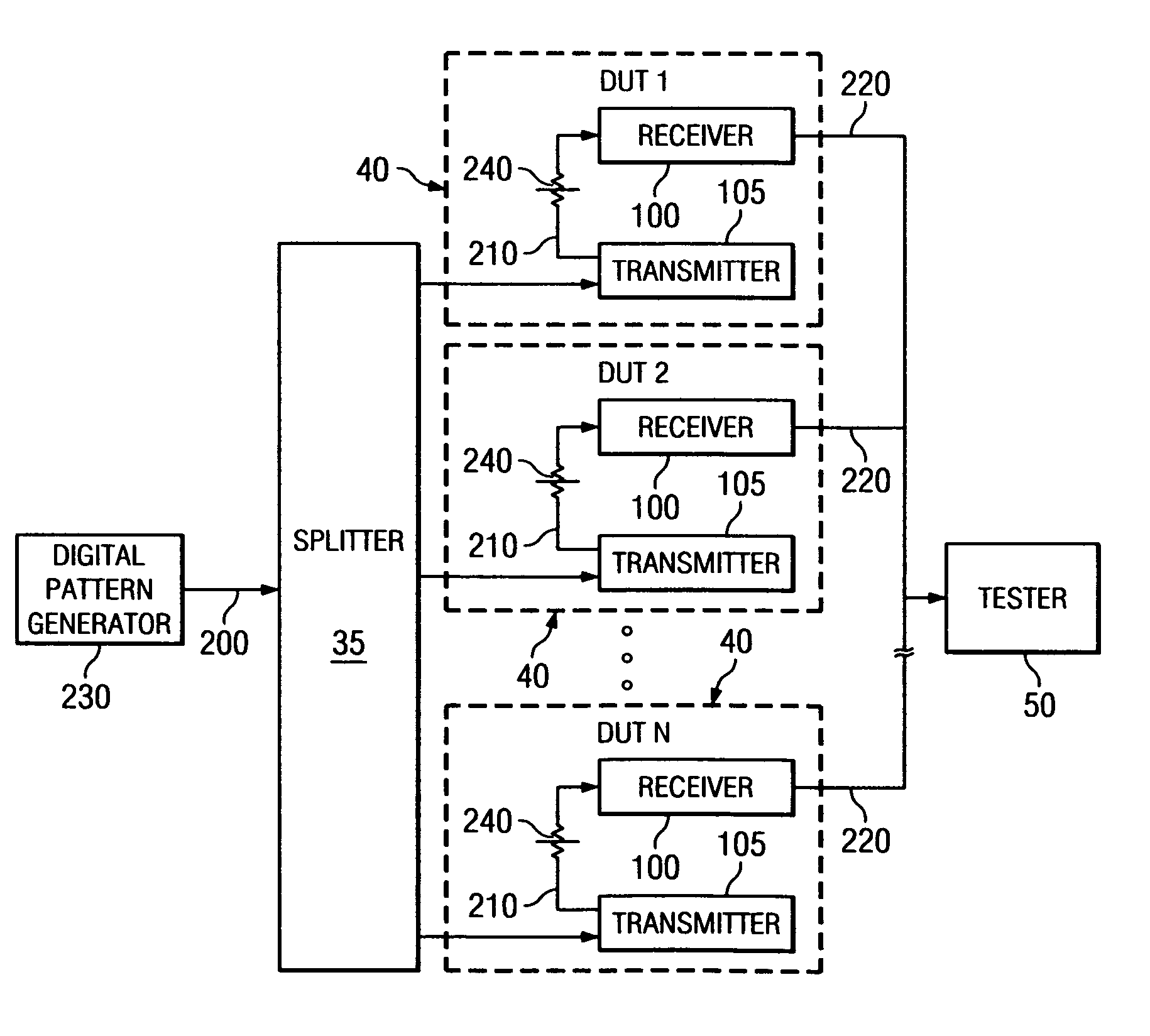

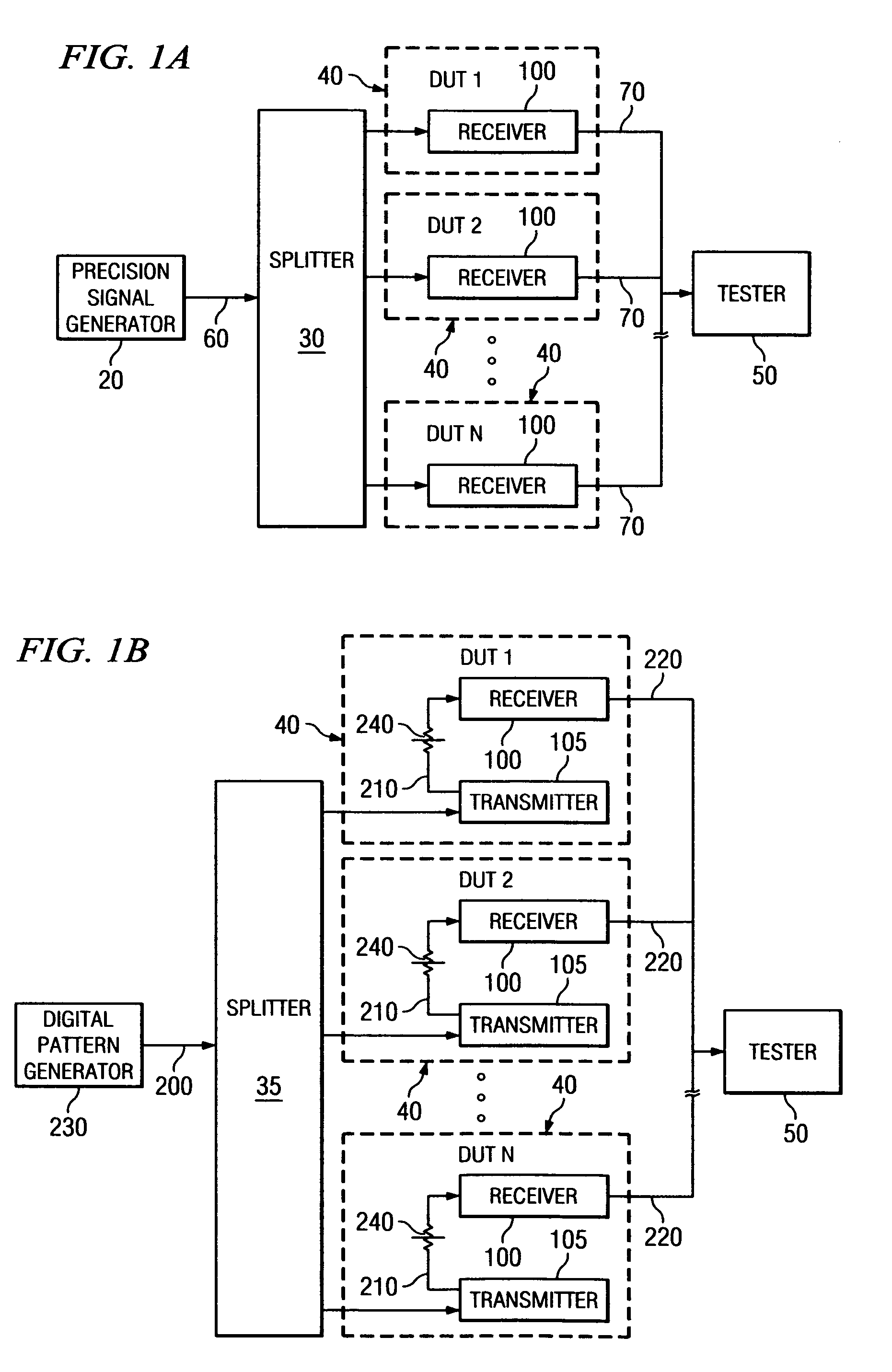

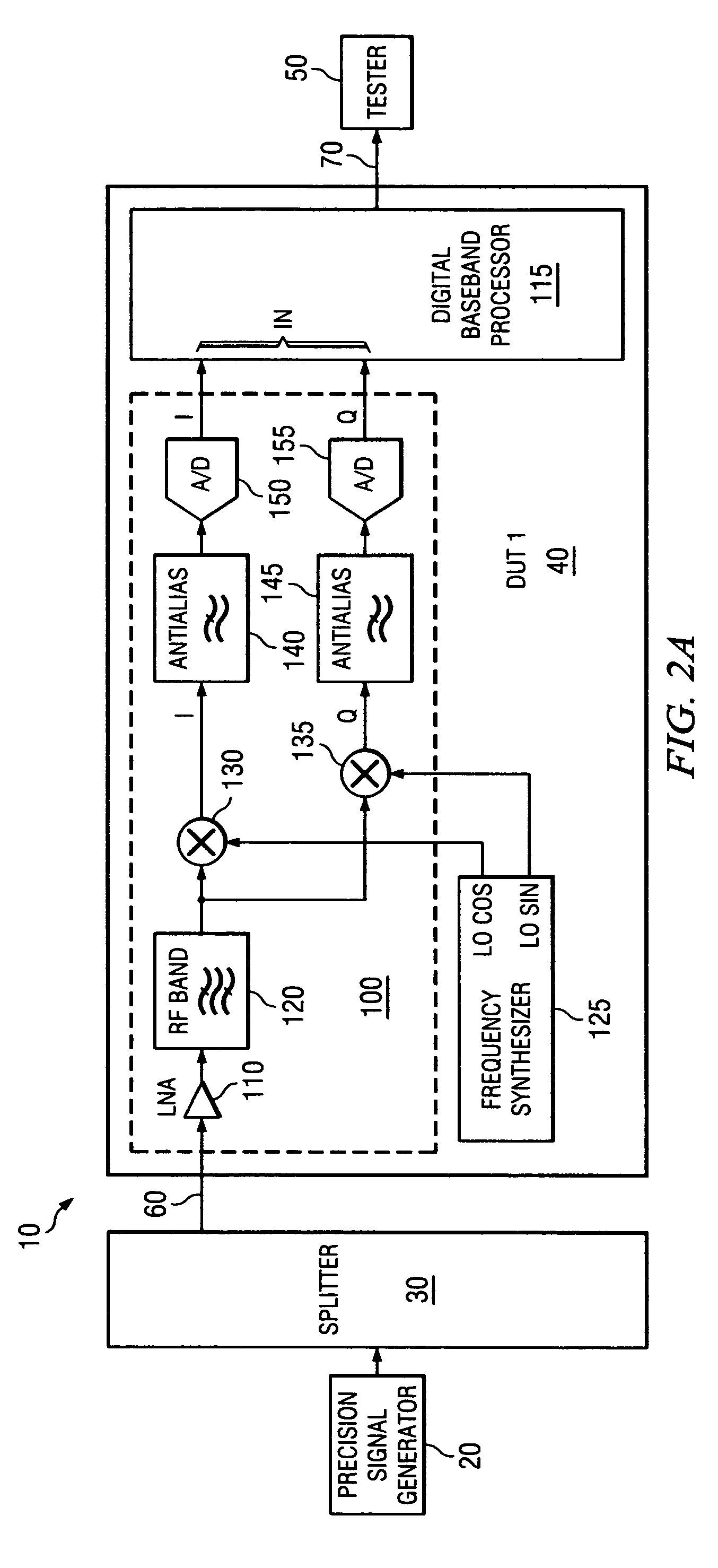

Test system and method for parallel modulation error measurement of transceivers

A test system is capable of performing parallel modulation error measurement of transceivers using a loop-back configuration. Each transceiver includes a transmitter and a receiver. A signal generator generates a first modulated signal for input to the receivers of the transceivers. A tester is operable to measure a first demodulation error produced by the receiver in response to the first modulated signal and to measure a modulation error of the transmitter based on the first demodulation error and a second demodulation error. The second demodulation error is produced by the receiver in response to a second modulated signal generated by the transmitter and coupled from the transmitter to the receiver.

Owner:KEYSIGHT TECH

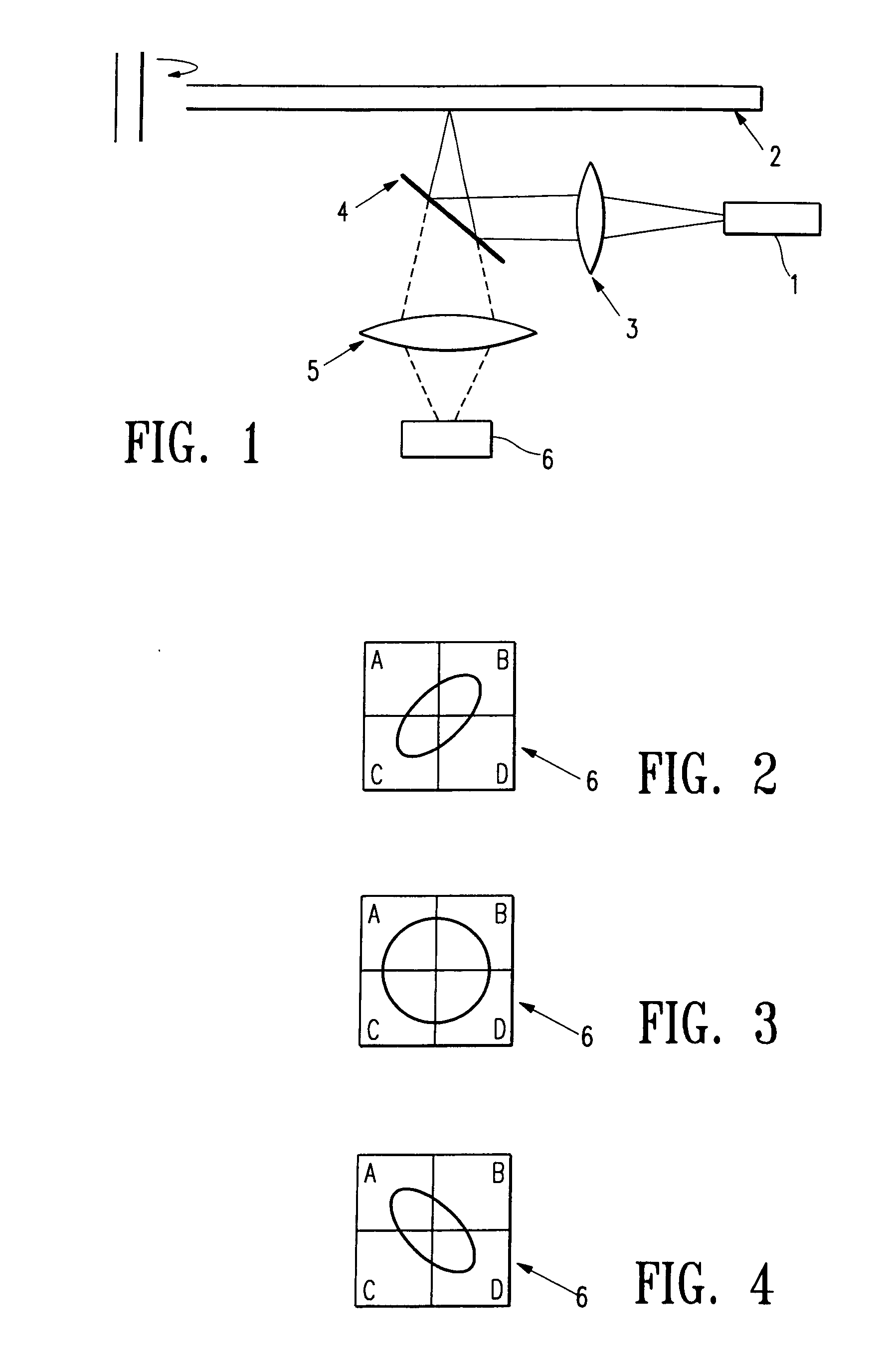

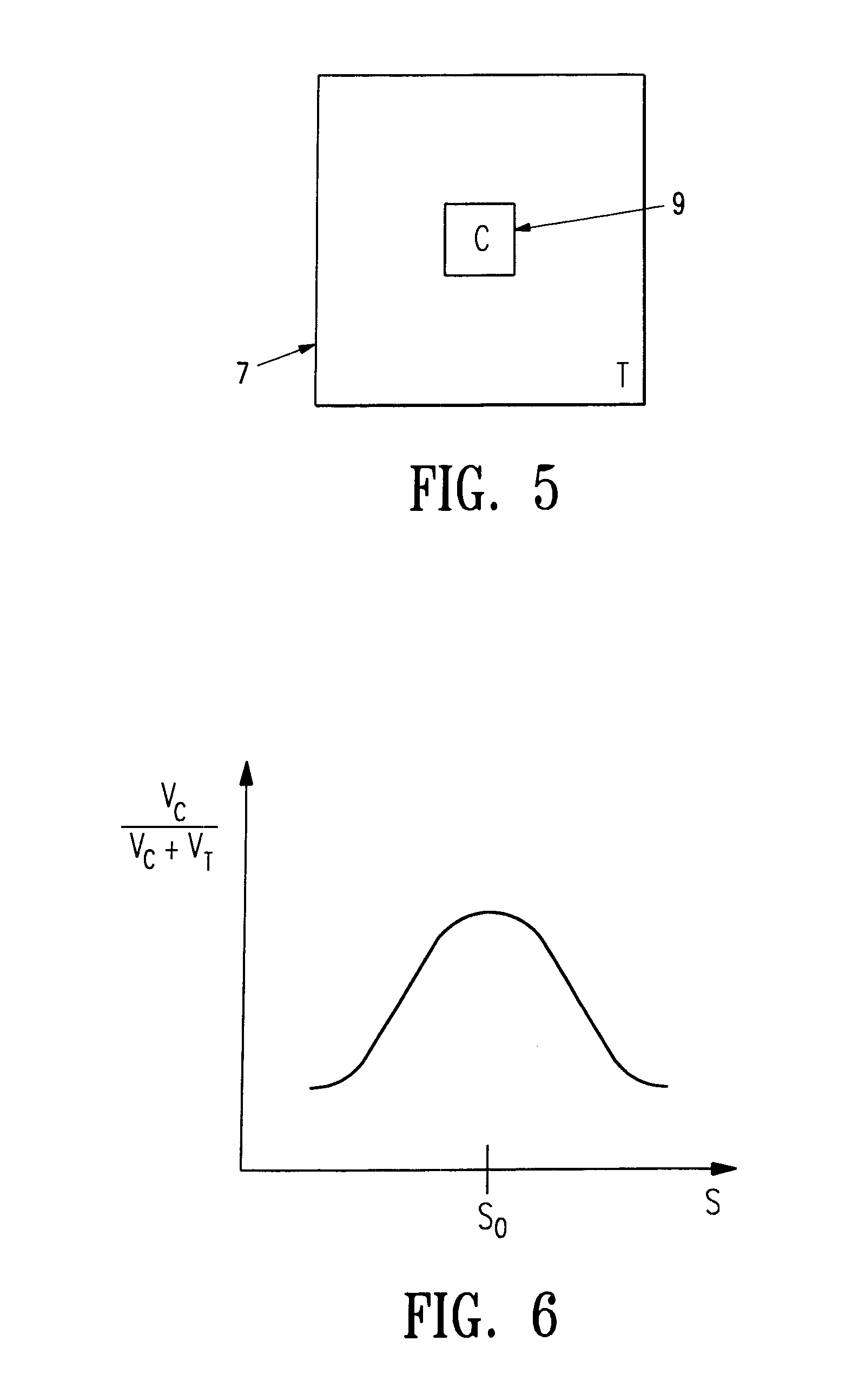

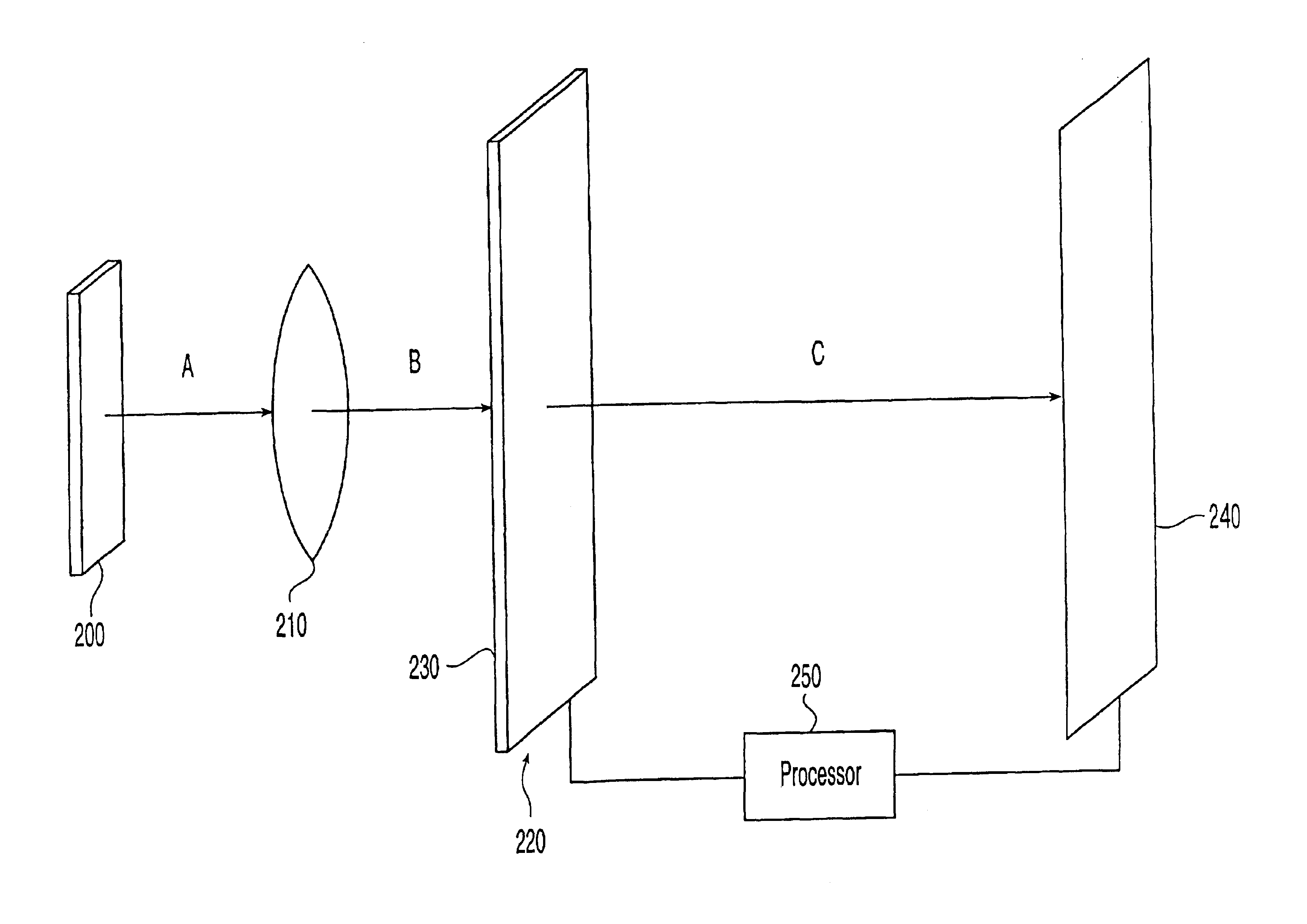

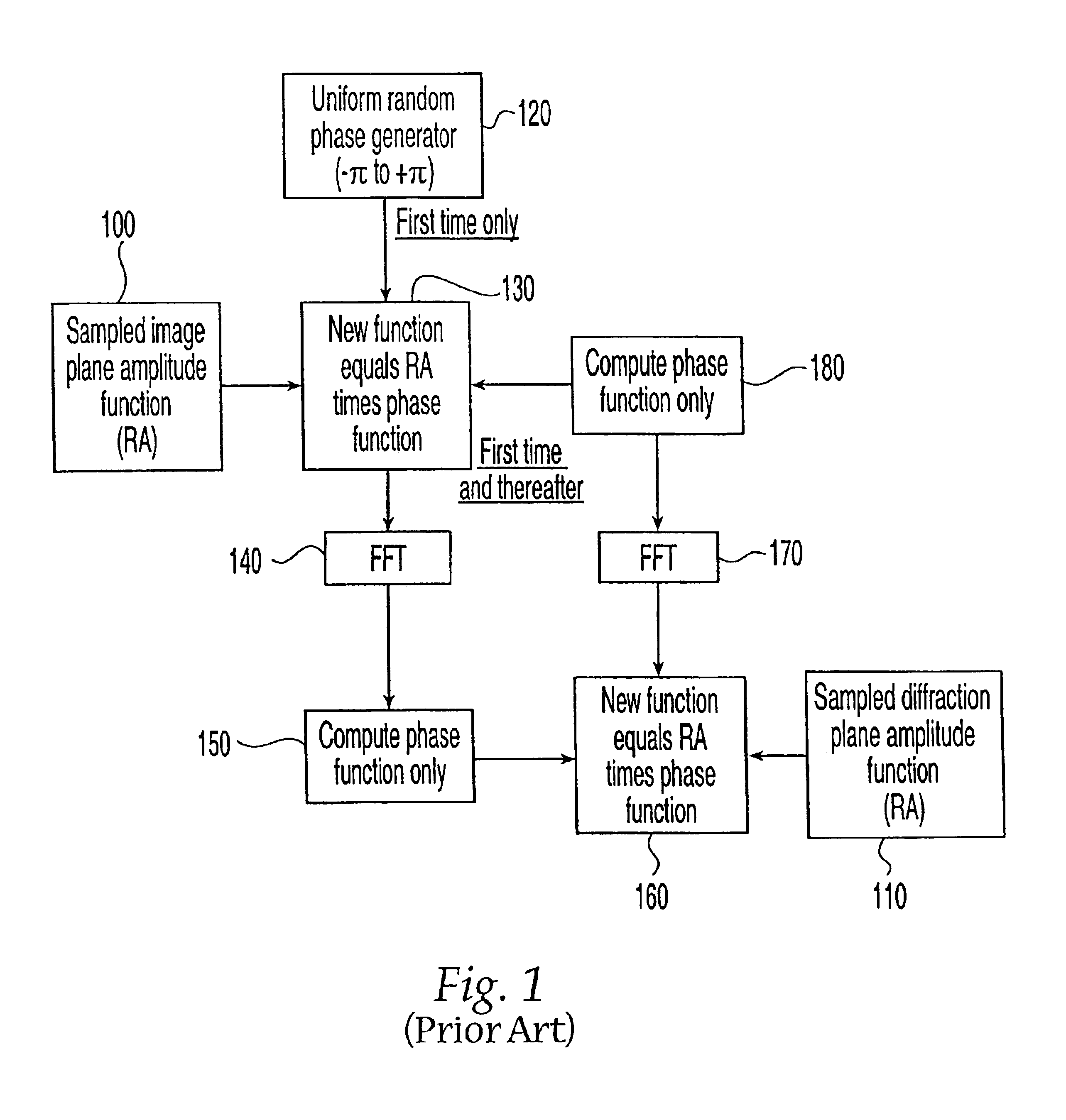

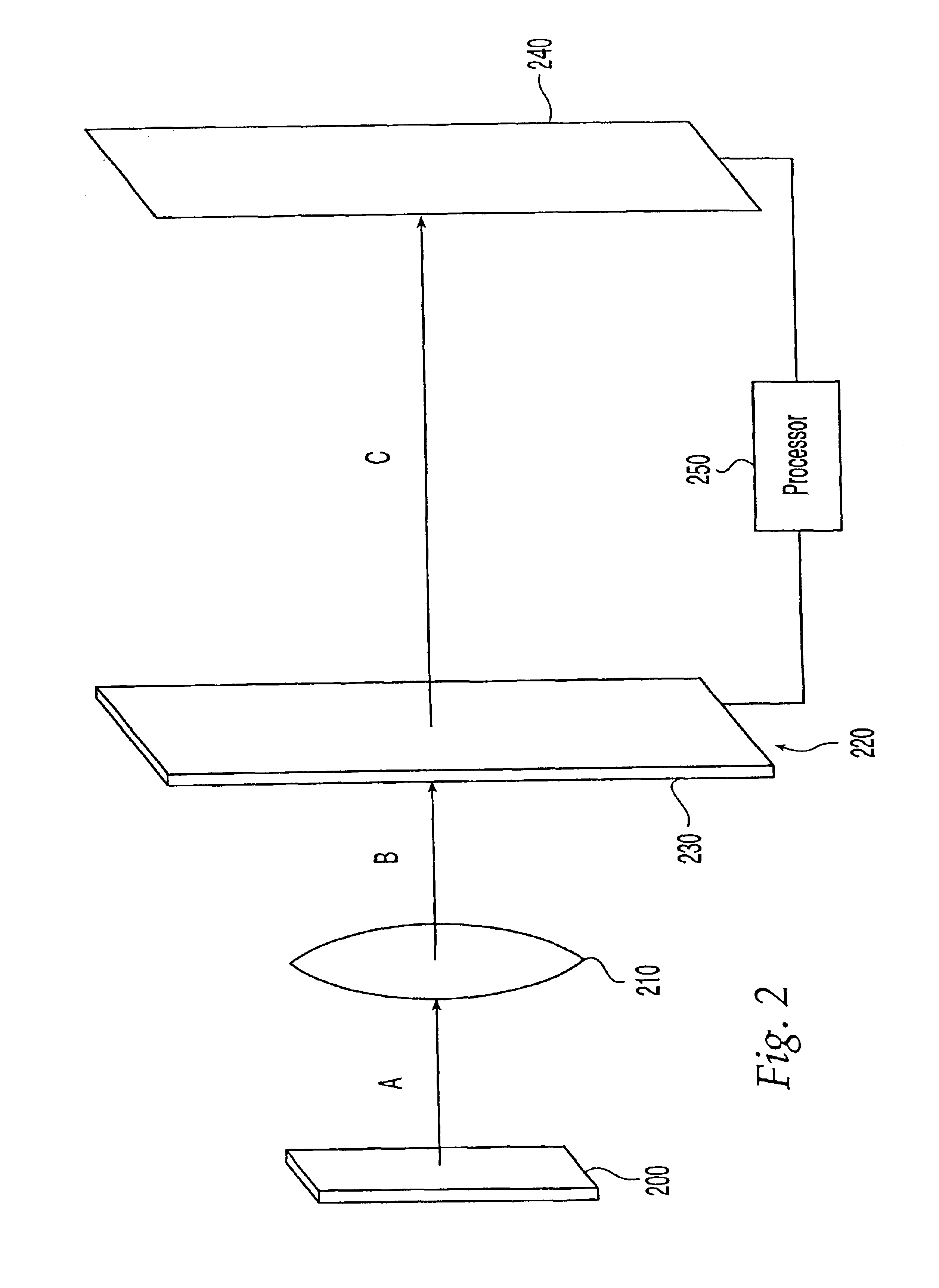

System and method for recovering phase information of a wave front

InactiveUS6906839B2The effect is accurateReduce calculationMaterial analysis by optical meansHandling using diaphragms/collimetersWavefrontPhase filter

A system and method for recovery of phase information from recorded intensity values is disclosed. In one aspect, a phase filter is placed in a plane, which may be the back focal plane (BFP) of a lens used for observing an object. The phase filter changes the phase of a wave front distribution in the BFP in a known manner. Amplitude stops or combinations of phase and amplitude filtering patterns can also be used to capture N different sets of intensity data in a conjugate diffraction plane. The N intensity images are used to obtain an estimate of the wave front at the first plane. This wave front estimate is then used to generate N modified estimates of the wave front at the conjugate plane, each modified estimate corresponding to one of N filtering patterns. In one implementation, the N modified IP estimates are corrected by replacing the estimated amplitudes with the actually measured ones for that image. The process is repeated iteratively until an error measure between the measured values and the synthetically generated ones falls below a known threshold. The resulting phase estimates can be used to display wave front information similar in appearance to holograms, or to create lens-free microscopes.

Owner:WAVEFRONT ANALYSIS

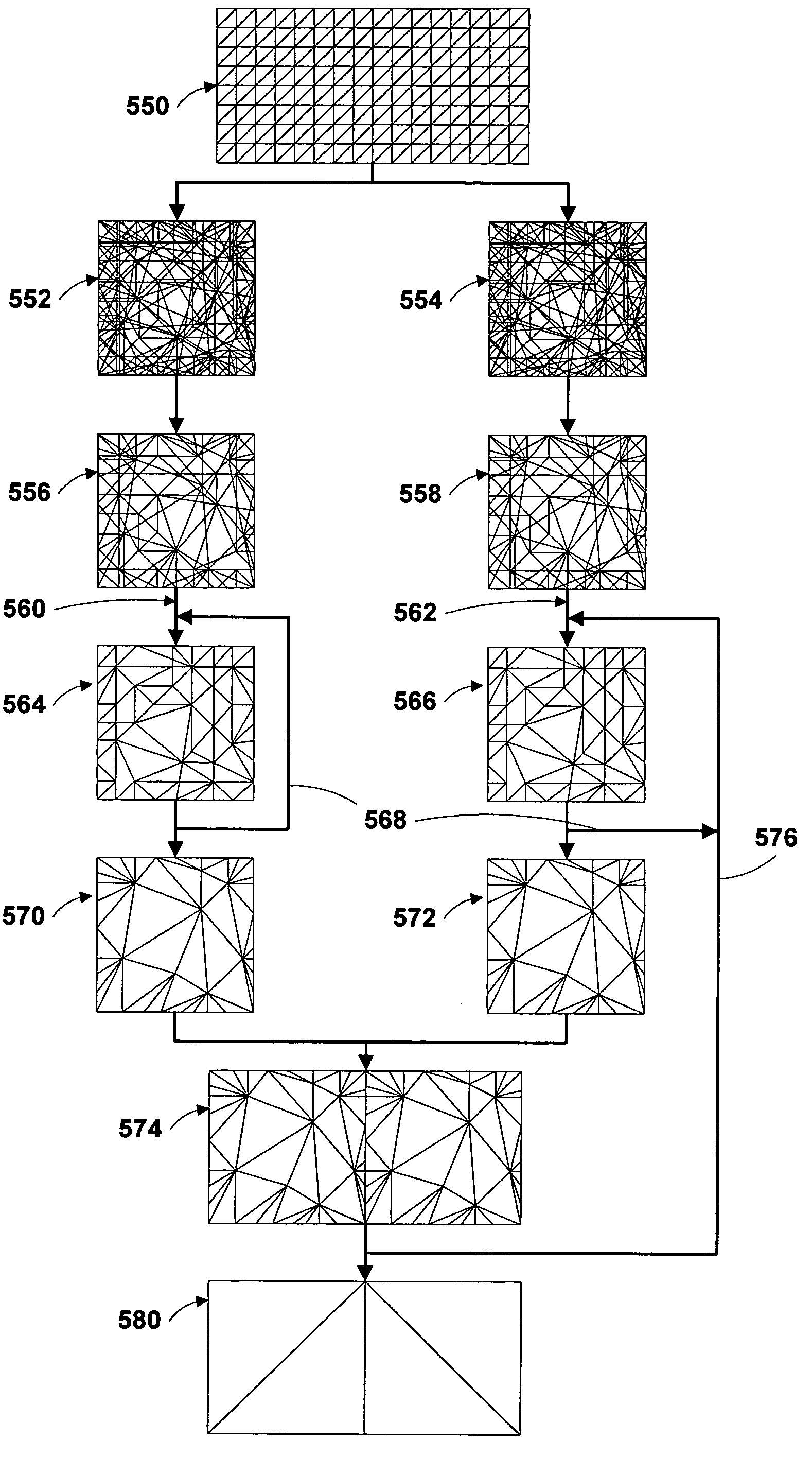

Regional progressive meshes

A regional progressive mesh provides support for real-time rendering of large-scale surfaces with locally adapting surface geometric complexity according to changing view parameters. The regional progressive mesh is constructed by subdividing an initial detailed mesh one or more times into multiple sub-regions as an iterative or recursive process. Each sub-region is separately simplified, and the localized transformations recorded in separate segments in a sequence of mesh refinement transformations that form the progressive mesh representation. The resulting regionalized organization of mesh refinement transformations reduces the working set of memory pages containing progressive mesh data needed for real-time view-dependent adaptation and rendering of the mesh surface. An exact approximate error measurement of a vertex split transformation also is defined as the maximum height deviation at enumerated vertices in the open neighborhood of the transformation relative to a regular triangulation of grid points, where the enumerated vertices include the grid points internal to the faces adjacent the split vertex and the grid line crossings internal to edges adjacent the split vertex.

Owner:MICROSOFT TECH LICENSING LLC

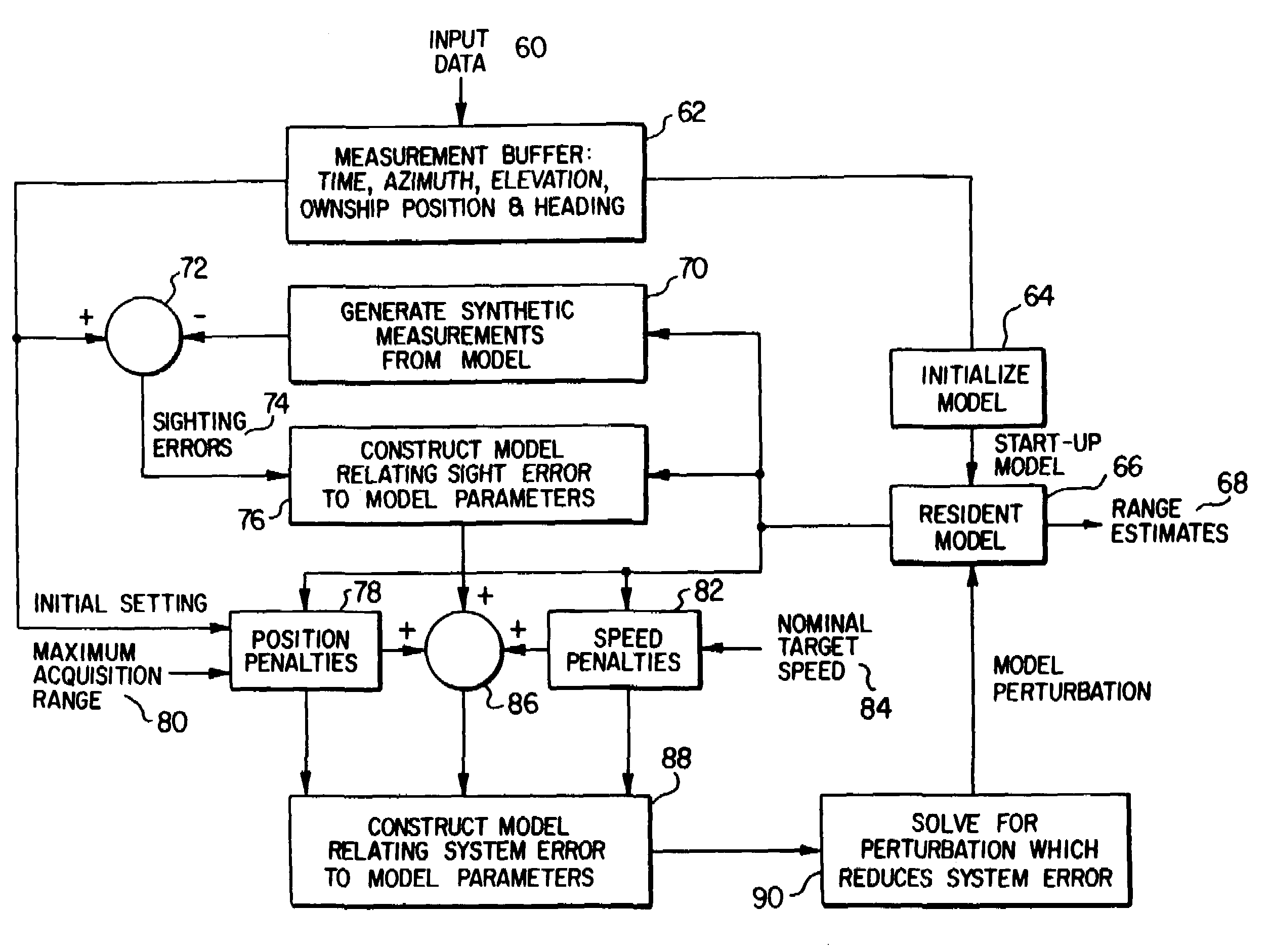

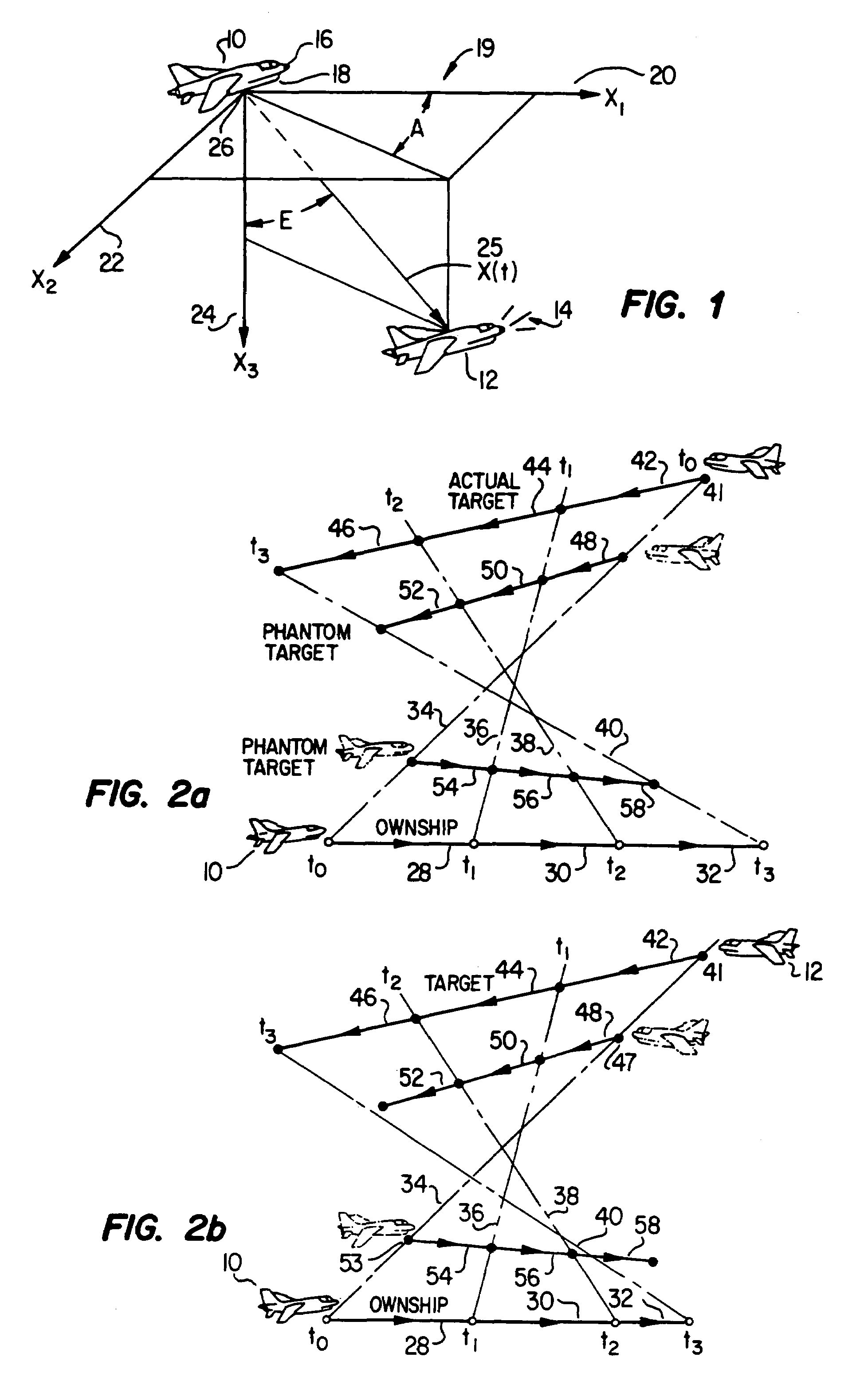

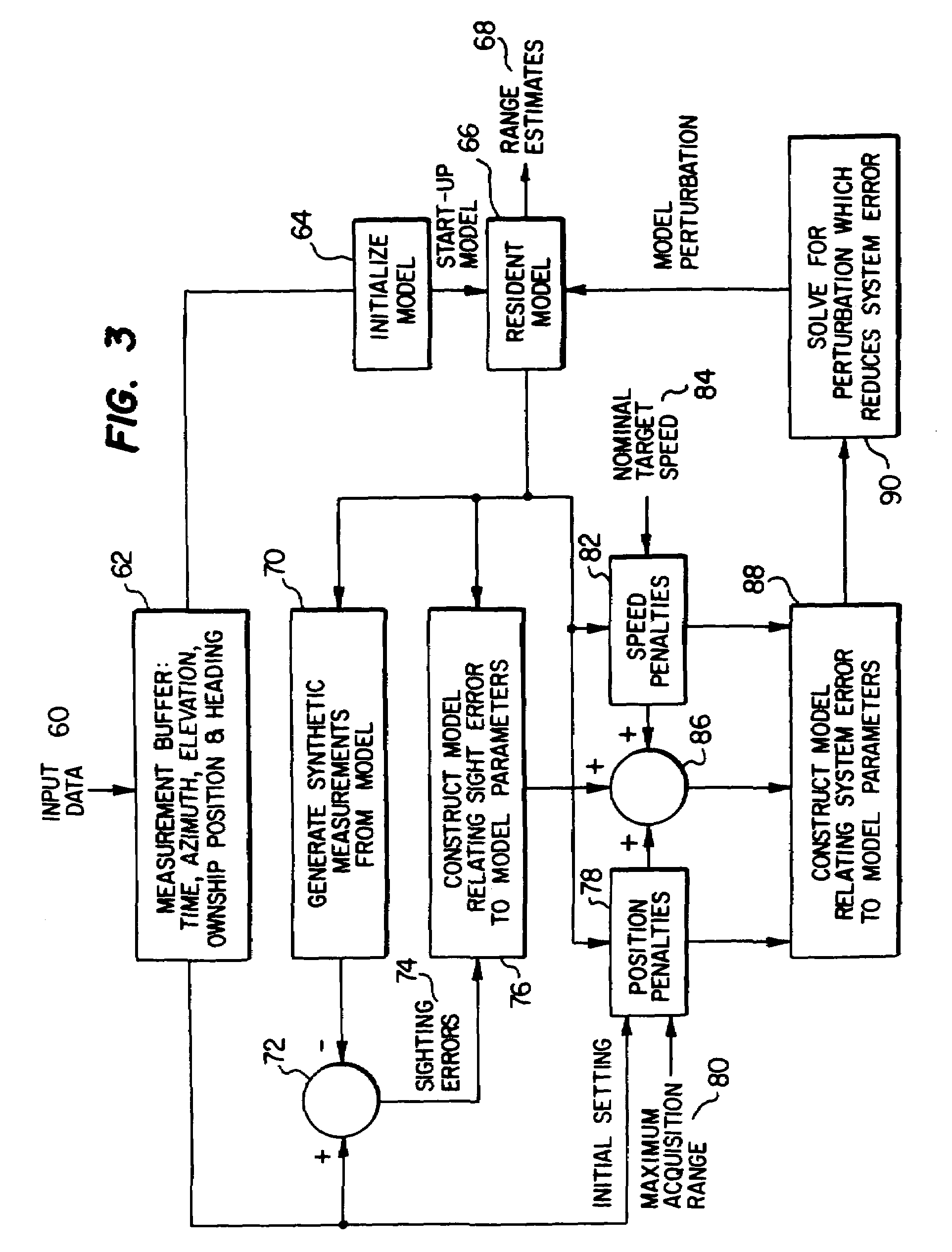

Method and apparatus for air-to-air aircraft ranging

InactiveUS7002510B1Eliminates and prevents disadvantage and problemMinimizes error measurementInstruments for comonautical navigationPosition fixationErrors measurementAirplane

Owner:RAYTHEON CO

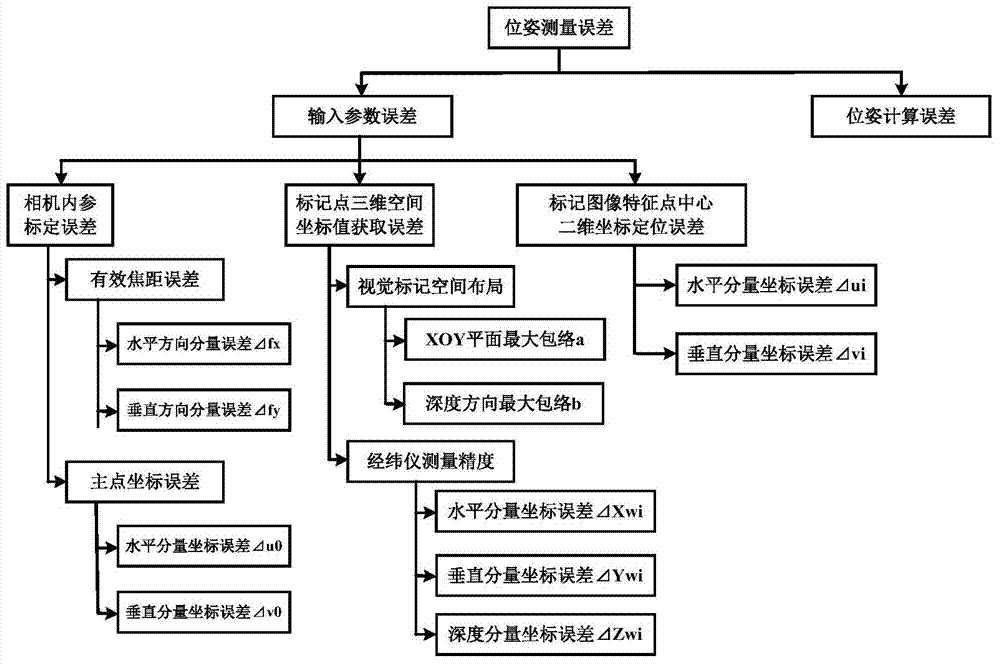

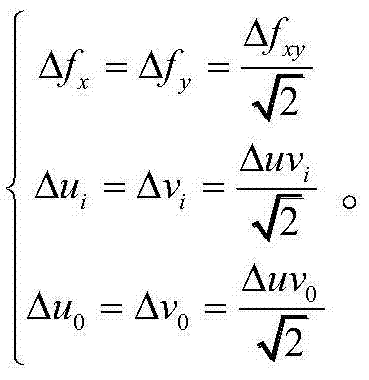

Monocular visual error measurement system for cooperative target and error limit quantification method

ActiveCN104729534AReduce computational difficultyPhotogrammetry/videogrammetryObservational errorTheodolite

The invention discloses a monocular visual error measurement system for a cooperative target and an error limit quantification method. The monocular visual error measurement system is specifically characterized in that visual marker points are formed in the outer surface of the cooperative target, a calibration target adopts a black and white checkerboard like pattern and is used for the intrinsic and extrinsic parameter calibration of a camera, the camera is used for acquiring the images of the visual marker points and the images of the calibration target in one frame and transmitting the images to the computer, a first theodolite and a second theodolite are used for observing the calibration target to obtain an observation value A, observing the visual markers to obtain an observation value B and transmitting the observation value A and the observation value B to a computer, and the computer is used for receiving the calibration target image and marker image acquired by the camera, the observation value A and the observation value B, computing the camera pose measurement value and the real pose value of the cooperative target relative to the camera and computing a measurement error. By adopting the error limit quantification method, the measurement error can be quantified and decomposed so that each key parameter index is in the error limit.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

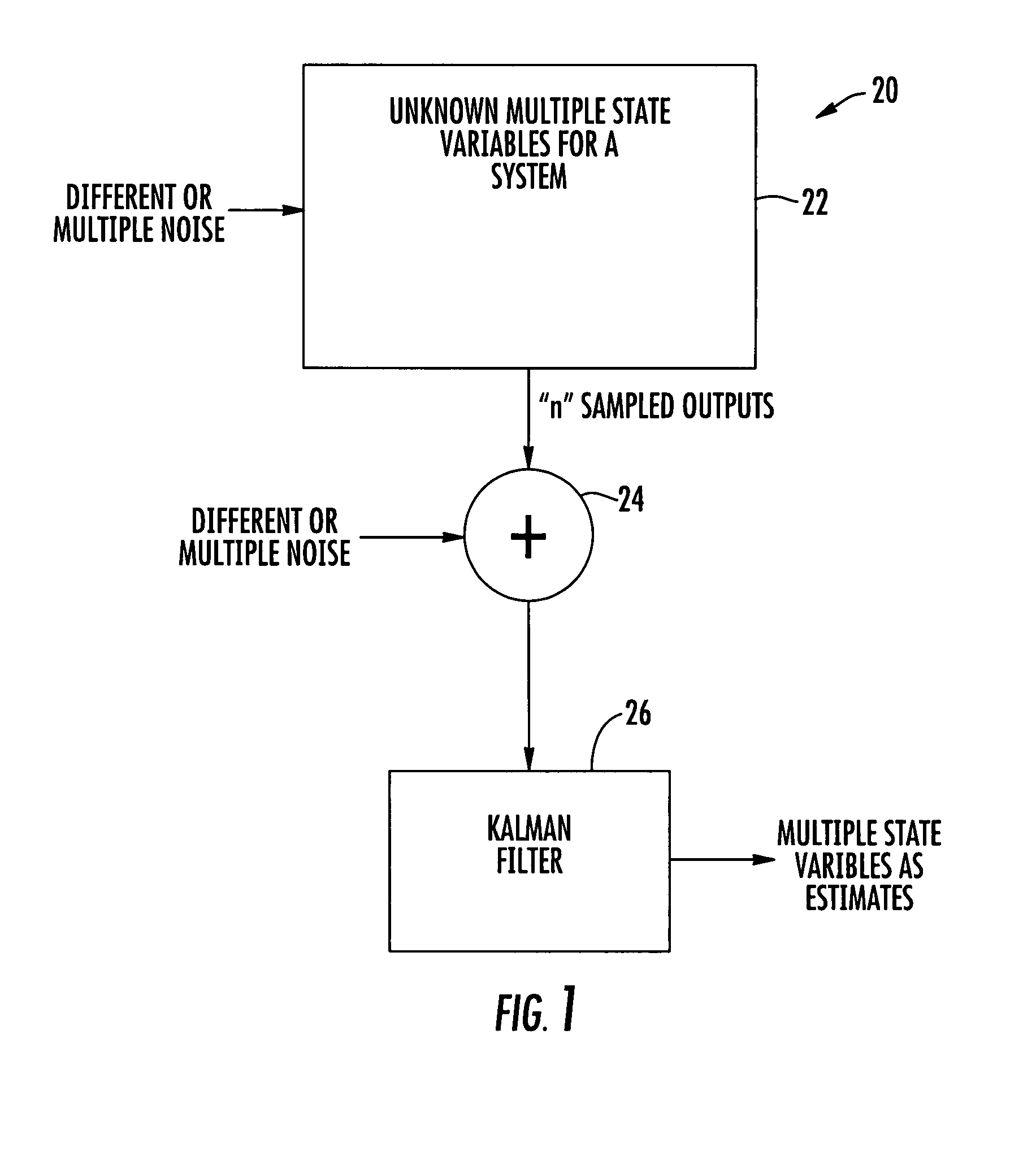

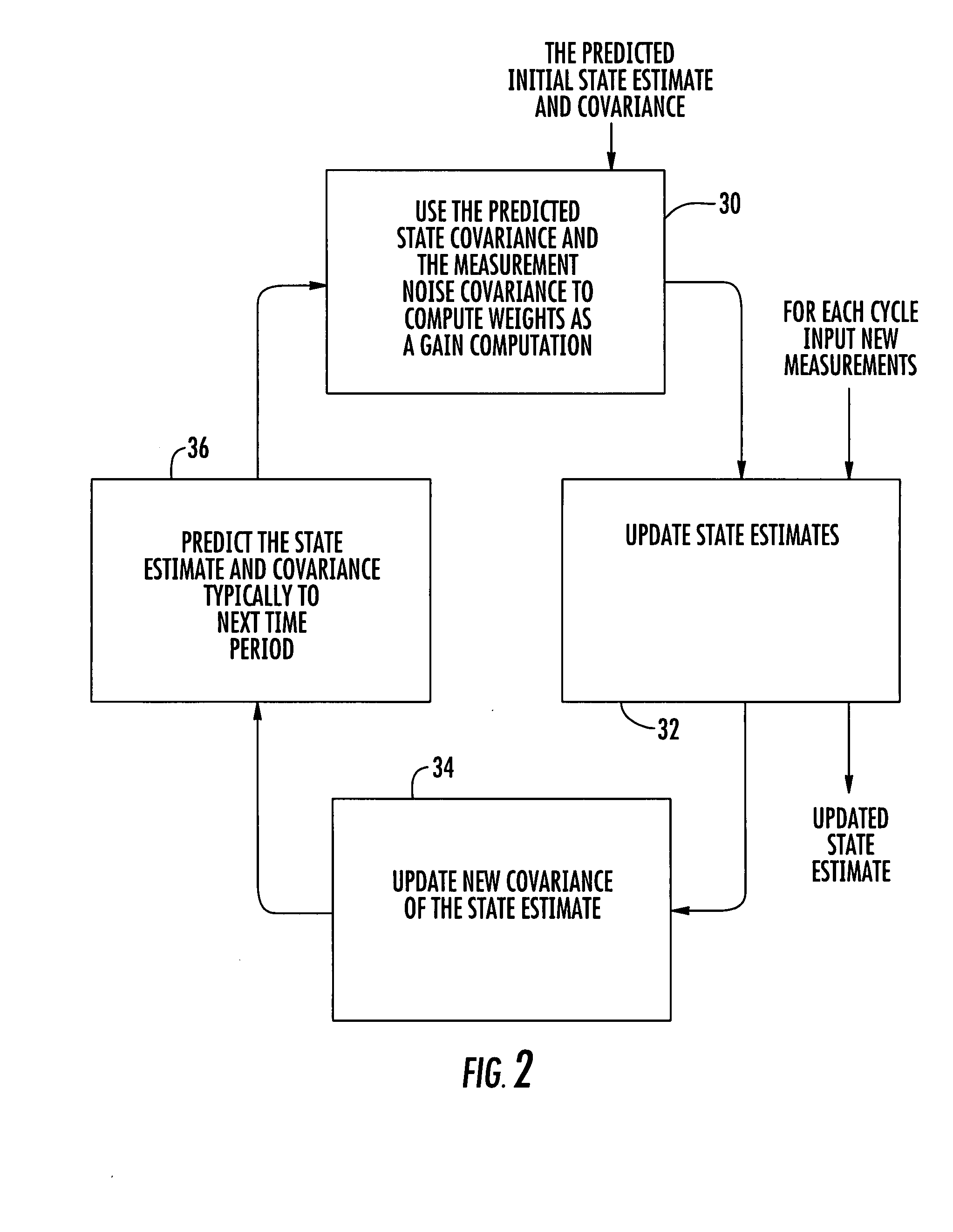

System and method for automatic recovery and covariance adjustment in linear filters

InactiveUS20100027603A1Tighter trackingGood servicePosition fixationTransmission monitoringKaiman filterLinear filter

A communications device includes a time / frequency error measurement circuit that receives a communications signal and measures its timing and frequency errors. A Kalman filter receives the communications signal from the time / frequency error measurement circuit and processes the signal using a multi-level state error covariance matrix P for controlling the Kalman gain in the Kalman filter. An on-line monitoring circuit is operative with the Kalman filter for monitoring the actual state errors in time and frequency and controlling the state error covariance matrix P based on a measured error threshold.

Owner:NORTH SOUTH HLDG

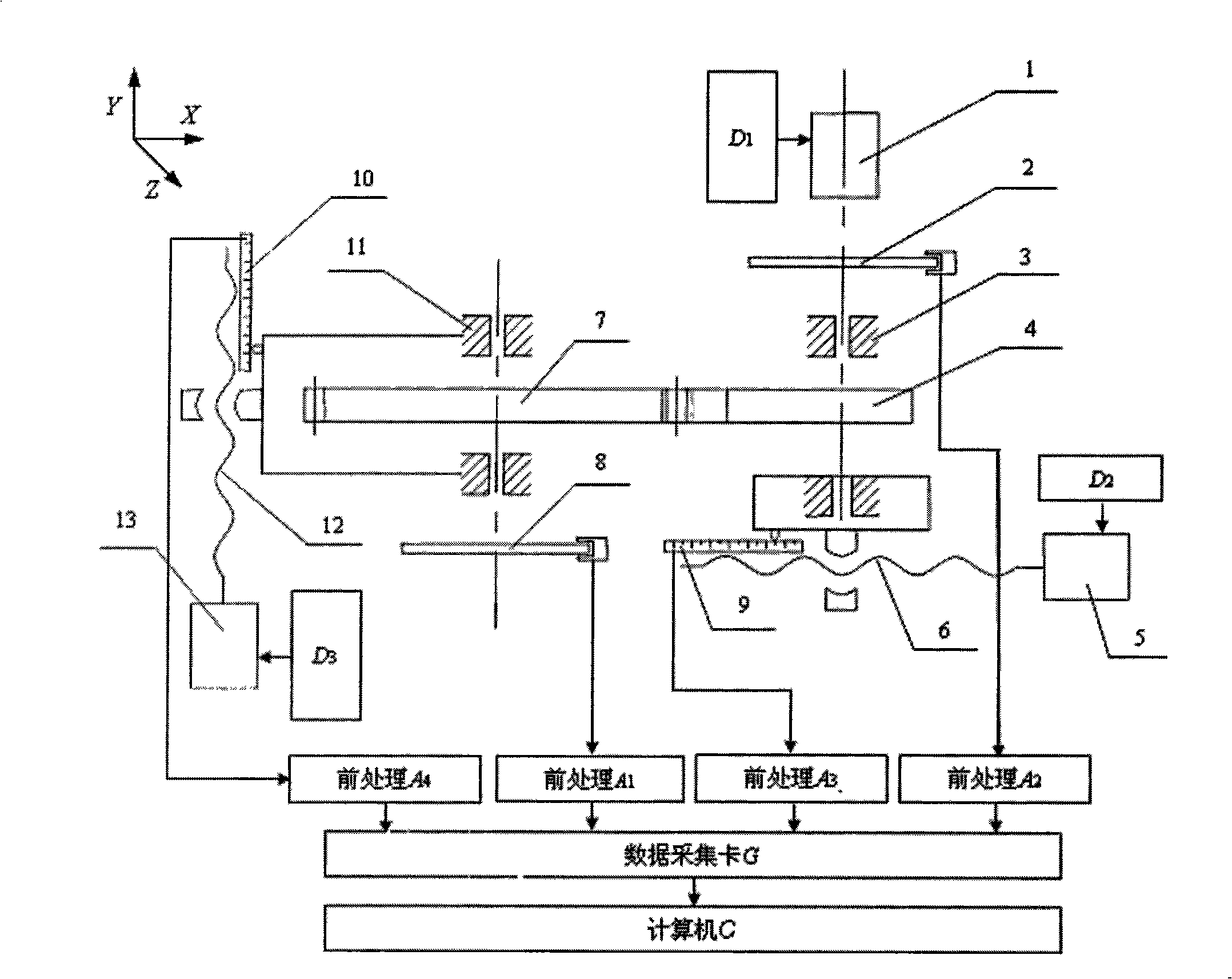

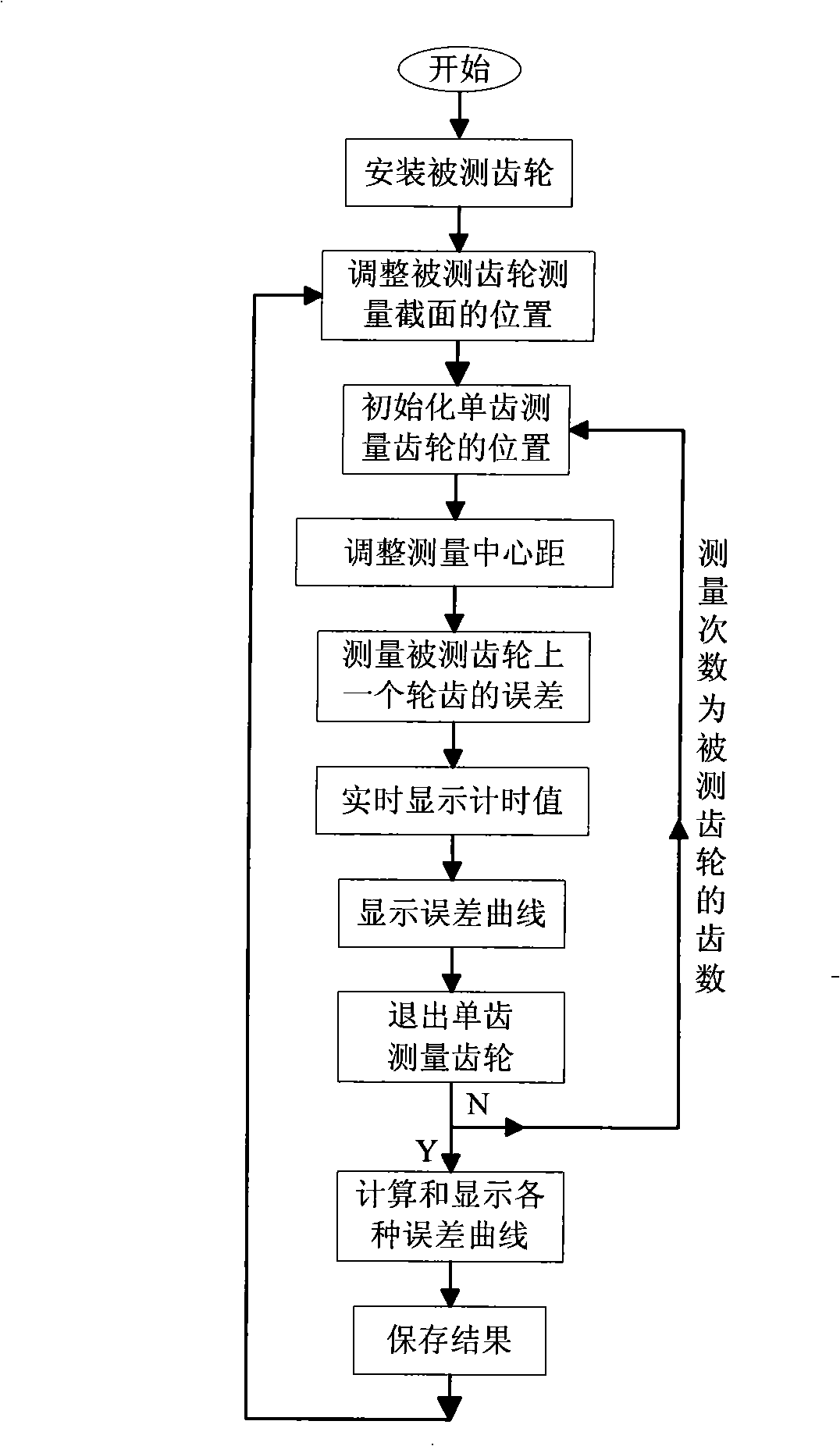

Single tooth type gear global error measuring apparatus and method

ActiveCN101294868AEasy to manufactureLow costMachine gearing/transmission testingGear wheelData acquisition

The invention relates to a single-tooth type gear integrated error measuring device and a method thereof, and belongs to the precision measuring technology and the technology field of mechanical transmission. The method uses a single-tooth measuring gear as a measuring element to realize the rolling point scanning measurement of all gear teeth of gears of different specifications to be measured. Angular displacement signals generated in the transmission process of the sing-tooth measuring gear and the gears to be measured are converted into electrical signals through a sensor; the signals are input into a computer after passing through a pre-processing circuit and a data acquisition board; four types of integrated error curves, the geometrical deviation of each item, the three-dimensional tooth surface typological deviation and the contact zone aspect graph of the gears to be measured are obtained through analysis and data processing; and the error result and the error curve can be shown and printed. According to the method, one measuring gear completes the measurement of the gears of different specifications to be measured and realizes flexible measurement of the gear integrated error. The single-tooth measuring gear has the advantages of convenient manufacture, low cost, high precision, wide application range, ensured measurement precision and extended measuring range.

Owner:BEIJING UNIV OF TECH

Test system and method for parallel modulation error measurement of transceivers

ActiveUS20060215744A1Eliminate needError preventionFrequency-division multiplex detailsTransceiverEngineering

A test system is capable of performing parallel modulation error measurement of transceivers using a loop-back configuration. Each transceiver includes a transmitter and a receiver. A signal generator generates a first modulated signal for input to the receivers of the transceivers. A tester is operable to measure a first demodulation error produced by the receiver in response to the first modulated signal and to measure a modulation error of the transmitter based on the first demodulation error and a second demodulation error. The second demodulation error is produced by the receiver in response to a second modulated signal generated by the transmitter and coupled from the transmitter to the receiver.

Owner:KEYSIGHT TECH

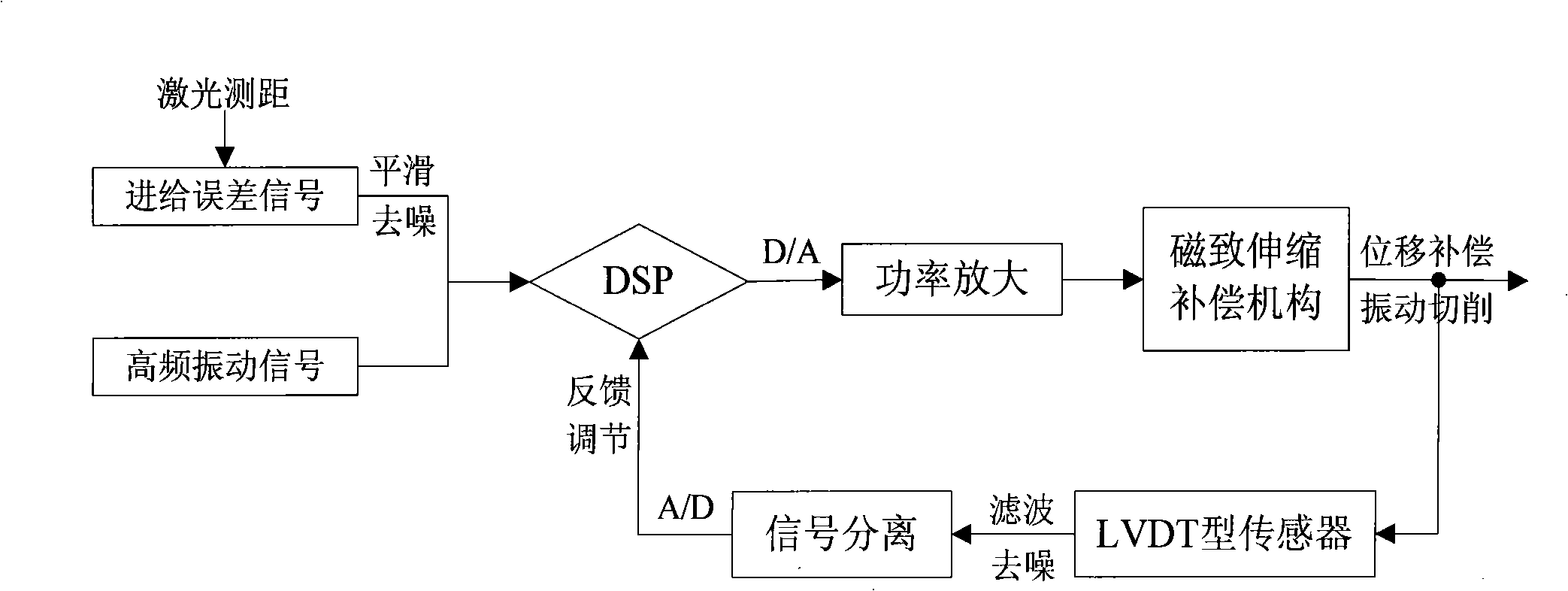

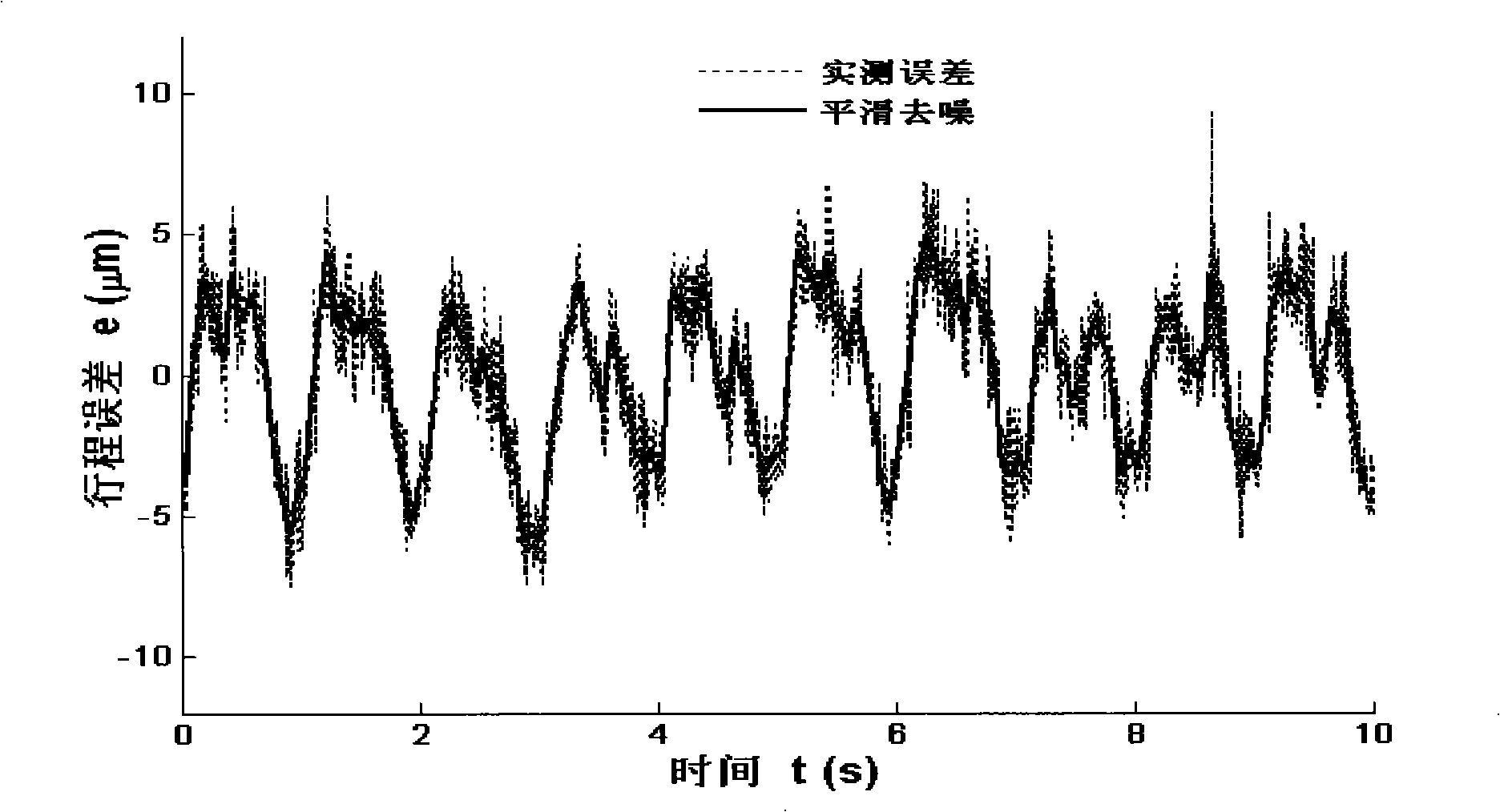

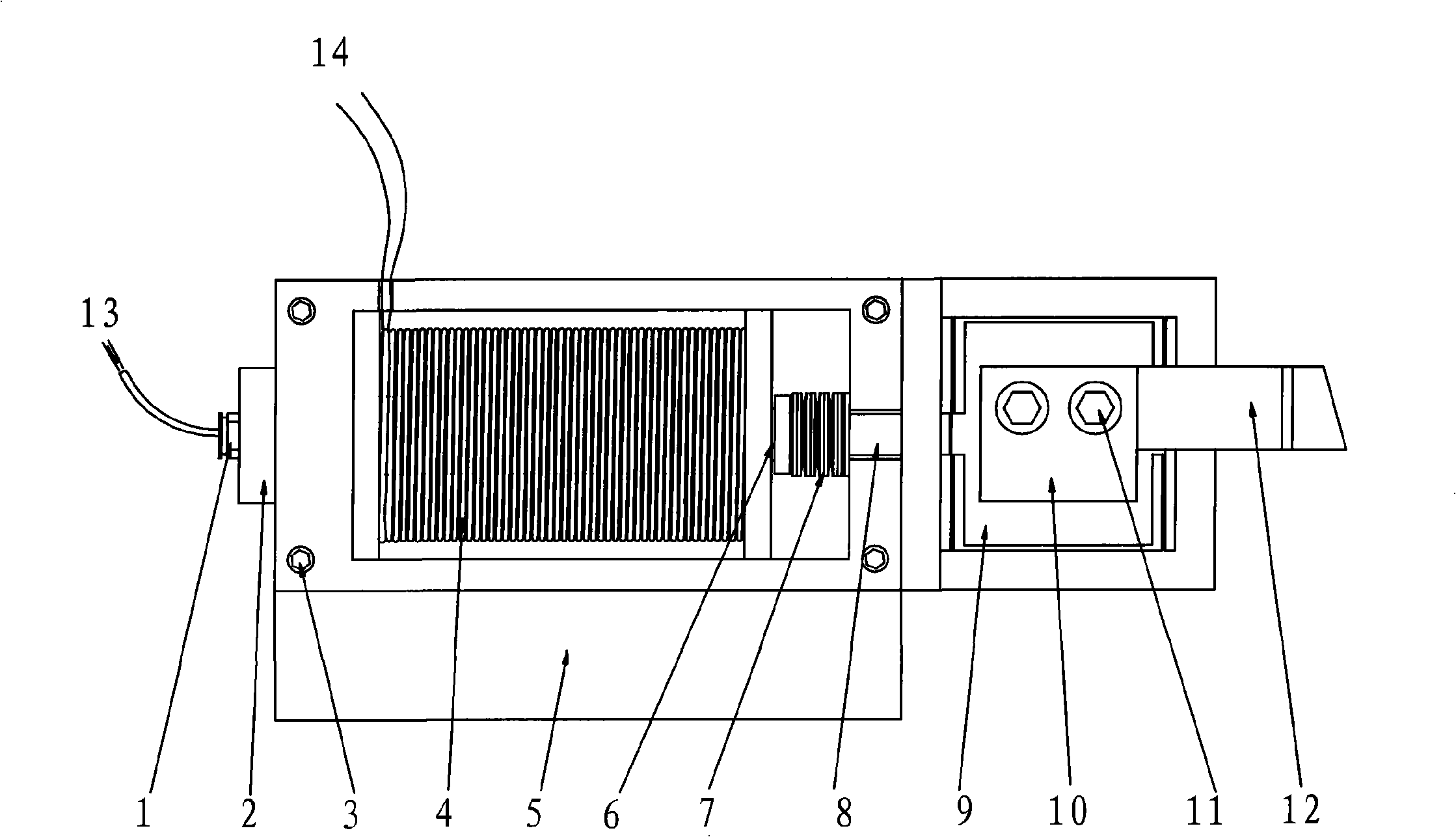

Compensation process capable of increasing machine precision of numerical-controlled lathe and magnetic striction compensation mechanism

ActiveCN101337330AHigh compensation accuracyAvoid breakingAutomatic control devicesMeasurement/indication equipmentsNumerical controlClosed loop

The invention discloses a compensation method for enhancing the machining accuracy of a numerical control machine tool and a magnetostrictive compensation mechanism, in particular to a method for compensating the accuracy of the numerical control machine tool through combined feed and a modularized accuracy compensation mechanism. The method comprises the following steps: aiming to the machine tool, because of a geometrical error formed by a plurality of factors such as manufacture, abrasion, etc., feed errors in a full-stroke range are measured by a dual-frequency laser interferometer; the modularized compensation mechanism is driven to produce the corresponding displacement compensation quantity through power amplification after an error signal is pretreated; the micro-displacement feed is performed in cooperation with the macro displacement feed, so as to correct the accuracy of the machine tool. High-frequency vibration signals are superposed as a drive compensation mechanism for driving the voltage to perform vibration cutting, thereby effectively inhibiting a flutter phenomenon caused by friction during cutting, and enhancing the machining accuracy. An LVDT inductive displacement transducer is mounted at the tail end of an elastic micro-displacement mechanism for position feedback regulation; furthermore, the closed-loop control is formed through real-time control operation in a DSP chip to realize precise positioning.

Owner:JIANGSU HAIJIAN +1

Dynamic error vision measurement method for five-axis numerical control machine tool

ActiveCN105252341ASolve the problem of space trajectory error measurementImprove error measurement accuracyMeasurement/indication equipmentsGeometric errorNumerical control

The invention belongs to the field of geometric error measurement for machine tools and relates to a method for measuring dynamic space track errors of the machine tools by means of binocular vision, in particular to a dynamic error vision measurement method for a five-axis numerical control machine tool. The measurement method includes the steps that according to a three-dimension perceptive function of binocular vision measurement, multiple errors are measured and separated at a single time; and four types of spherical mark points are reasonably distributed at a machine tool cutter end and on the surface of a working table, and the position relation among a vision coordinate system, a machine tool reference coordinate system and a machine tool cutter principal axis coordinate system is calibrated by means of feature information of the spherical mark points. During measurement, a vision measurement system continuously, statically and dynamically collects images of the spherical mark points, then moving errors of all machine tool axes are solved, and the obtained theoretical value and actual machine tool moving amount are combined, so that the moving errors of each axis are solved. According to the dynamic error vision measurement method for the five-axis numerical control machine tool, the machine tool space track errors are measured by means of a binocular high-speed camera, so that the error measurement accuracy is improved, the measurement range of the machine tool moving track is widened, the measurement method is simple and reliable, and the measurement process is simplified.

Owner:DALIAN UNIV OF TECH

Linear axis geometric error detecting method of five-axis numerically-controlled machine tool

ActiveCN106863014ARealize measurementImprove error measurement efficiencyMeasurement/indication equipmentsGeometric errorNumerical control

The invention discloses a linear axis geometric error detecting method of a five-axis numerically-controlled machine tool, belongs to the technical field of machine tool precision detecting and relates to linear axis geometric error detecting and identifying method of the five-axis numerically-controlled machine tool. The detecting method comprises the following steps that a three-eye measuring unit is set up through three high-resolution cameras, and three self-luminous characteristic target sphere images fixed to a working table and making rectilinear motion along with the X axis or the Y axis of the machine tool are collected; and through combination of camera calibrating, characteristic point position information extracting and measured information of the three cameras, a three-dimensional coordinate of the sphere center of a characteristic target sphere is obtained, and the X and Y axis linear axis geometric errors of the machine tool are measured. According to the linear axis geometric error detecting method, linear axis error measuring efficiency of the numerically-controlled machine tool is effectively improved, a complex identifying model and a fussy measuring process are avoided, and linear axis geometric error measuring of the numerically-controlled machine tool is achieved; and the linear axis geometric error detecting method has the characteristics of being convenient, rapid, high in noise-resisting property, good in robustness and capable of simultaneously measuring the geometric errors of the multiple linear axes of the machine tool.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com