Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Influence of machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

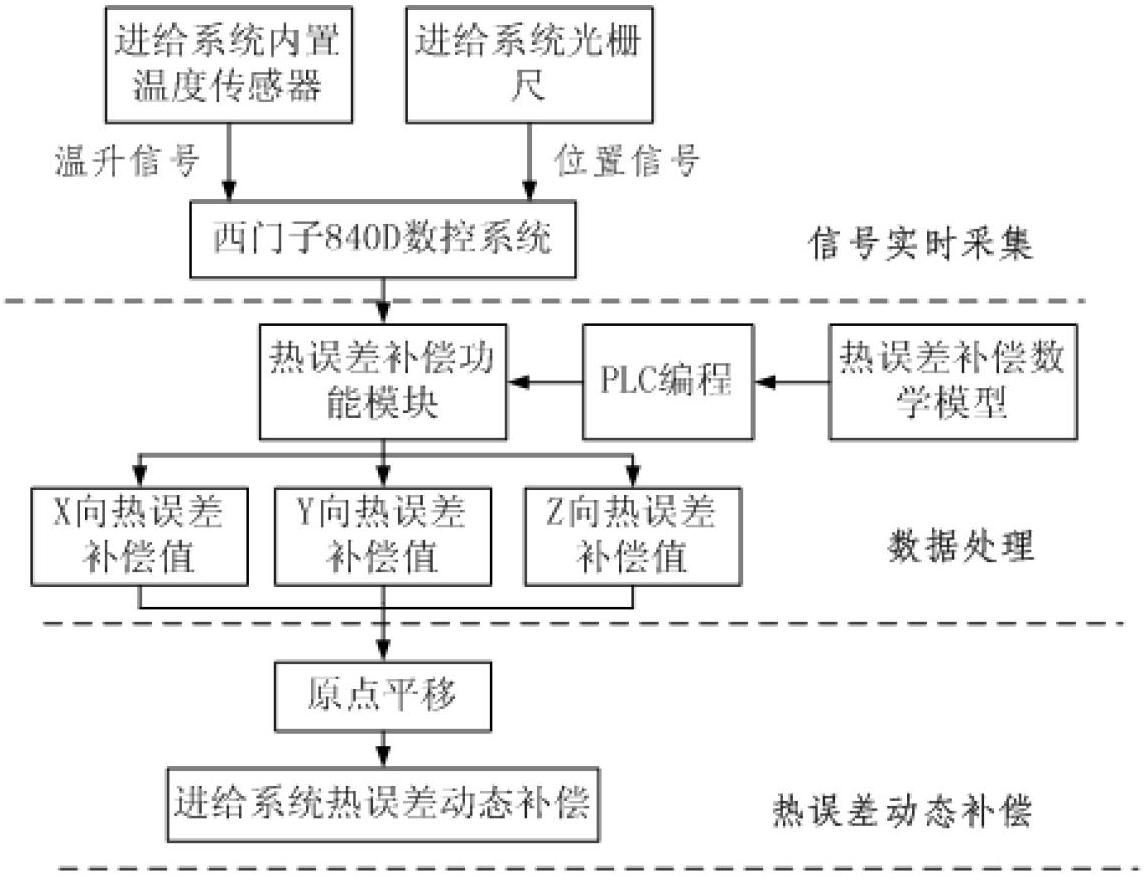

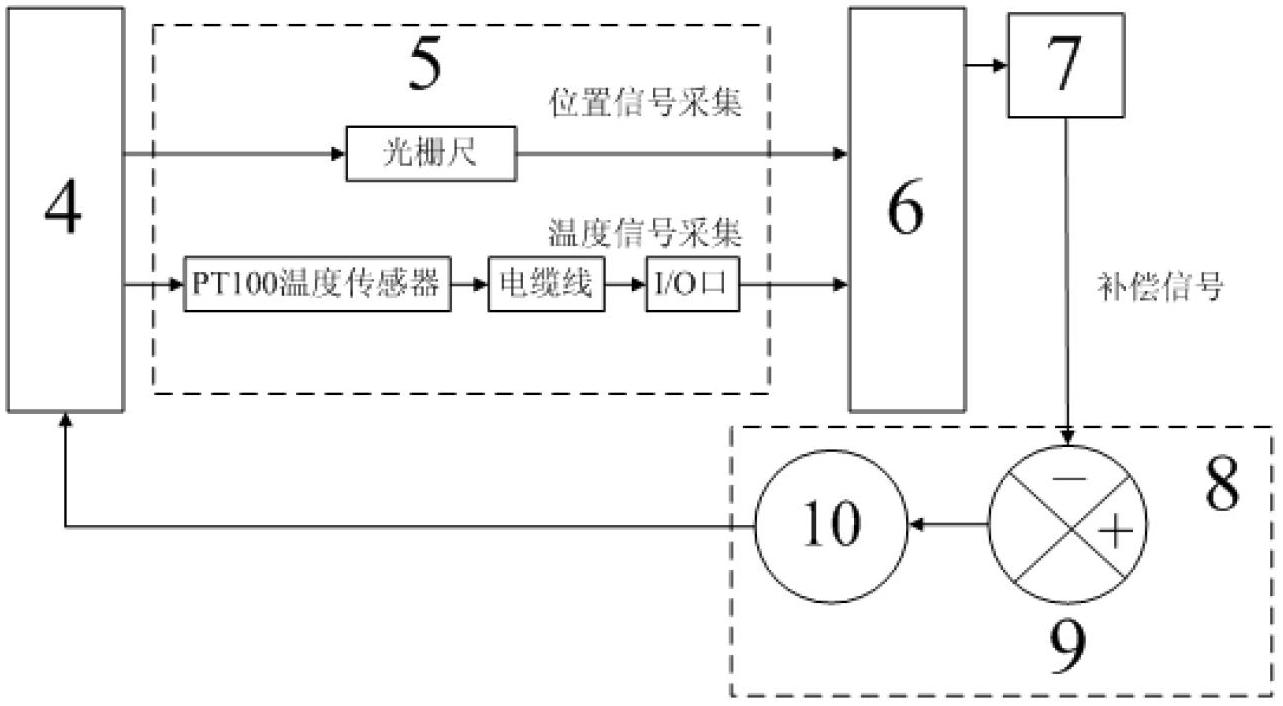

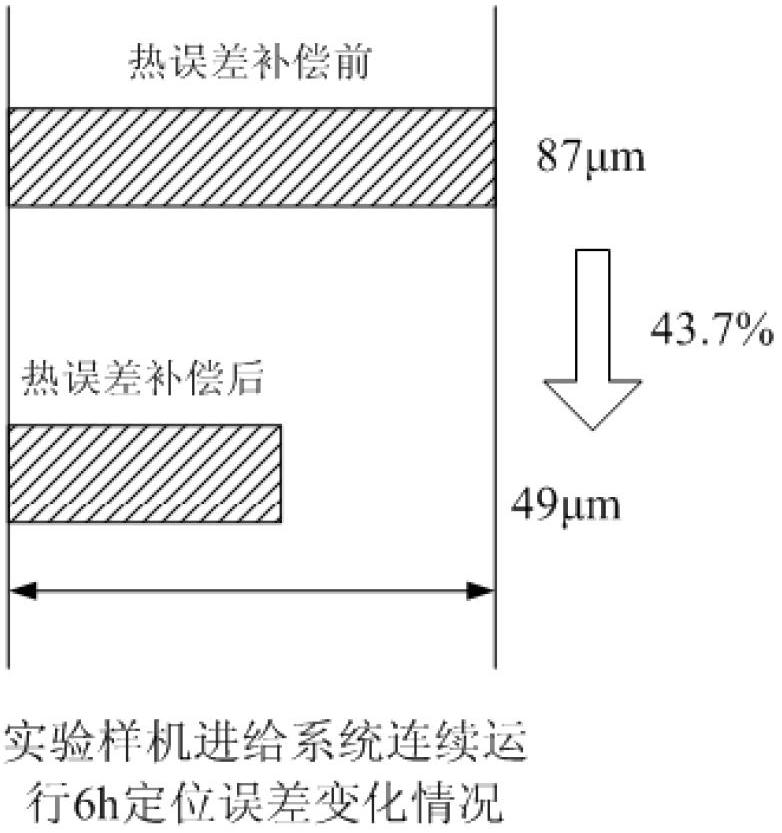

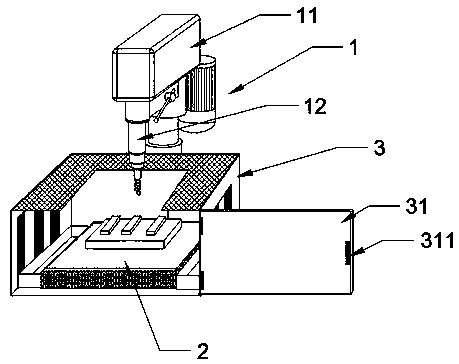

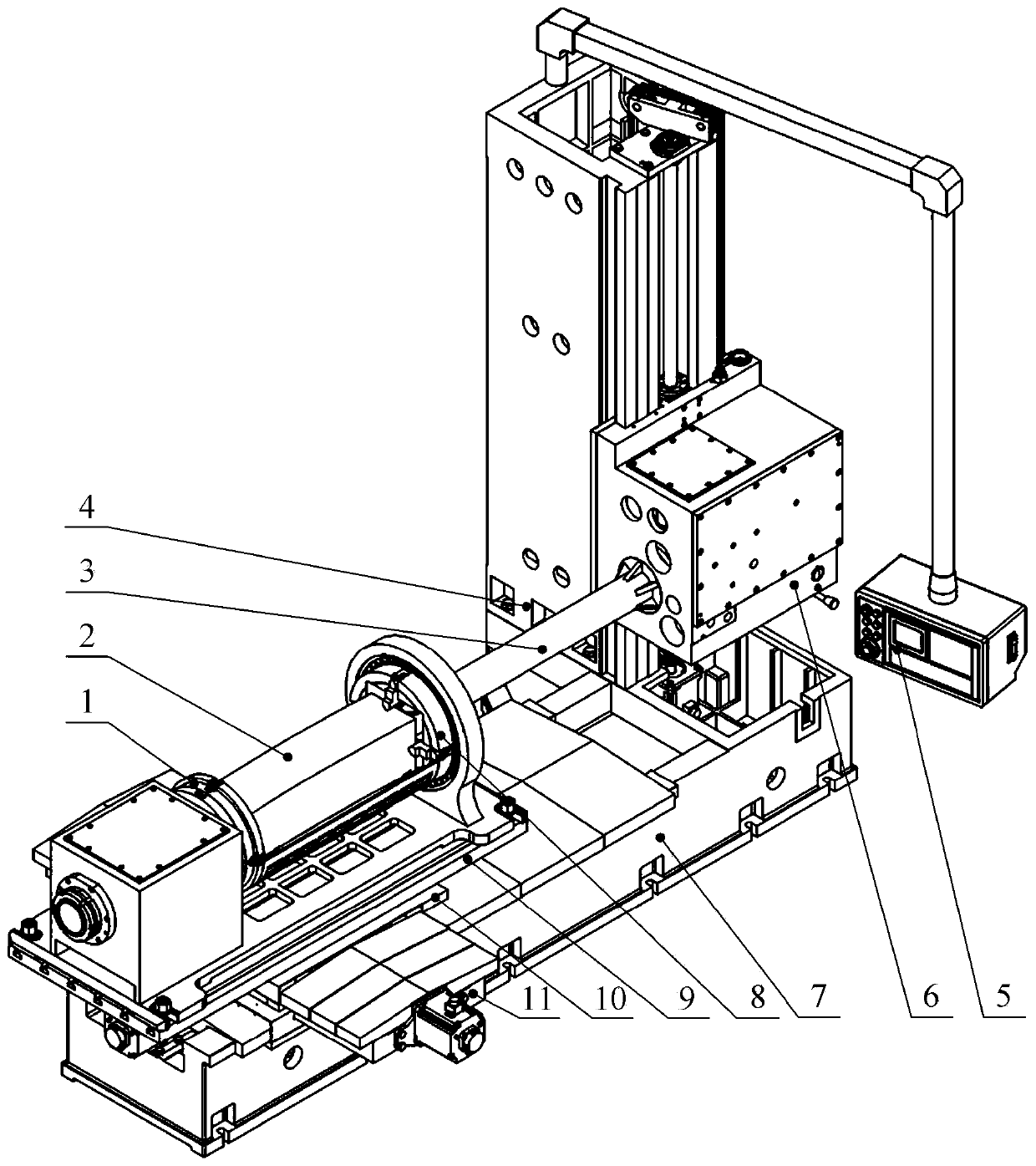

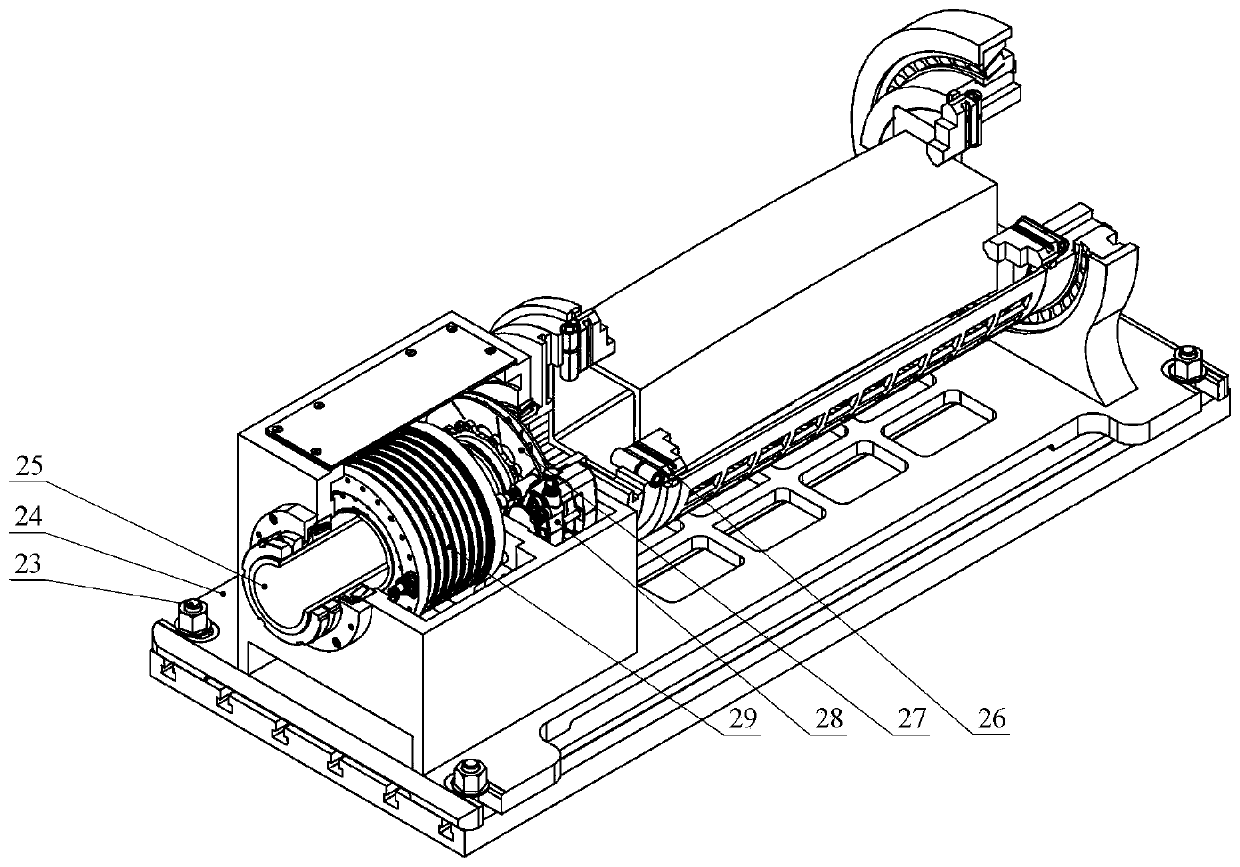

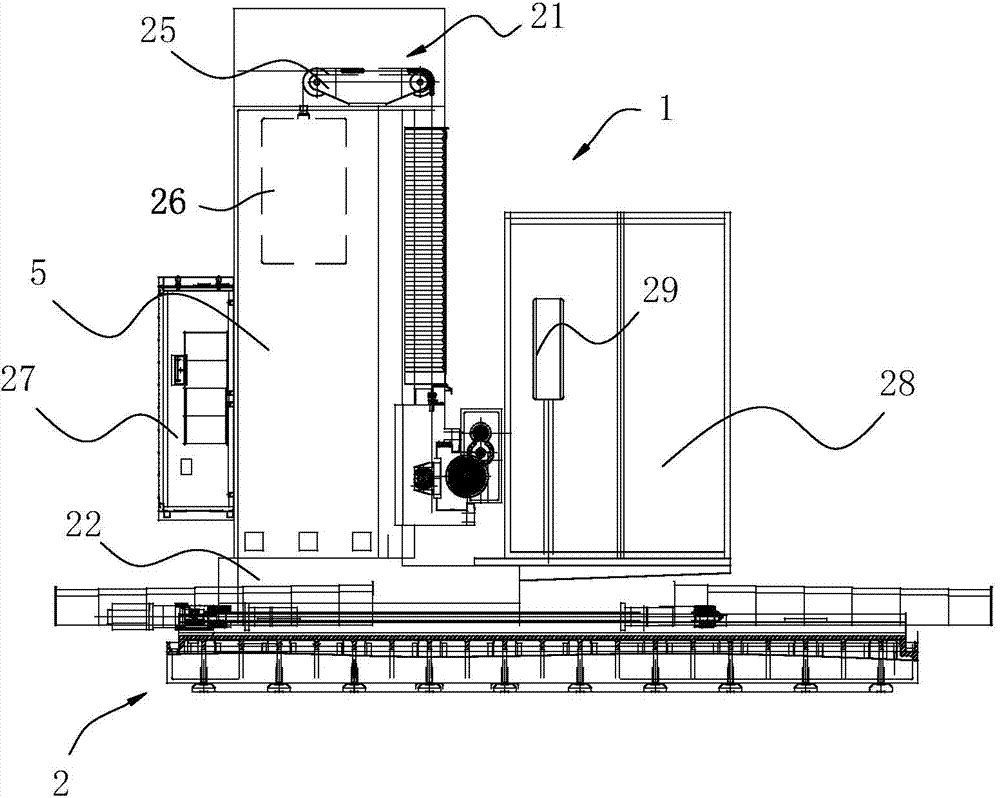

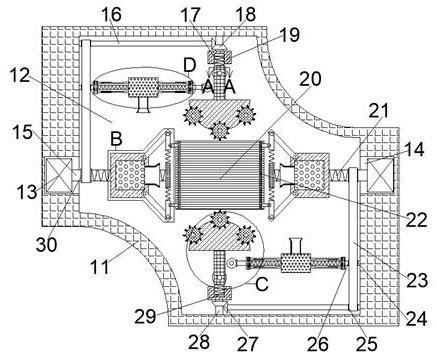

Full working stroke thermal error compensation method of numerically-controlled machine tool feeding system and implementation system thereof

InactiveCN102672527AInfluence of machining accuracyImprove machining accuracyAutomatic control devicesFeeding apparatusNumerical controlCompensation effect

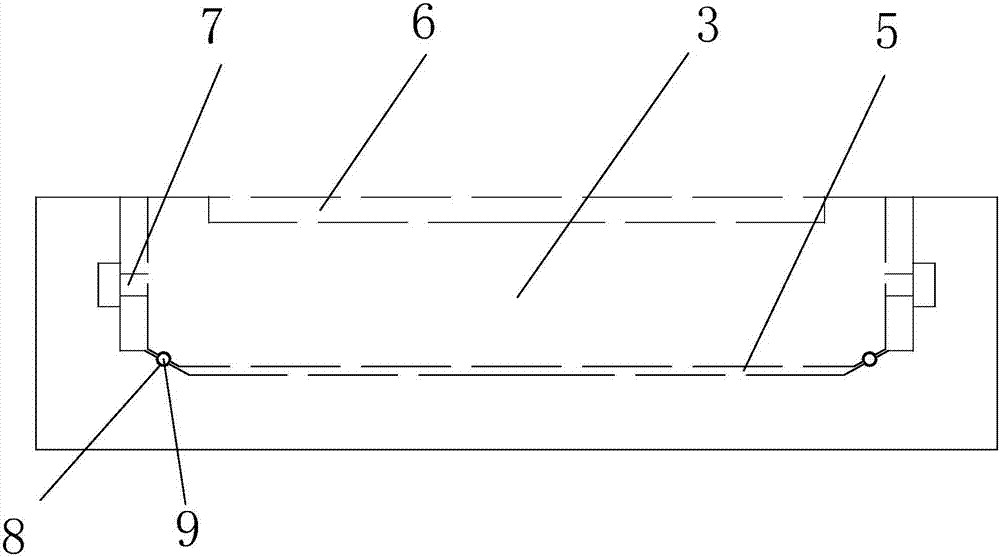

The invention discloses a full working stroke thermal error compensation method of a numerically-controlled machine tool feeding system and an implementation system thereof. Reduction of whole machine machining accuracy is mainly caused by thermal errors of the numerically-controlled machine tool feeding system, and a whole set of the technical scheme for measuring, analyzing and compensating the feeding system is provided. Application techniques of thermal error measurement, thermal key point identification, thermal error compensation modeling and thermal error on-line compensation of the numerically-controlled machine tool feeding system under typical working conditions are surveyed. On that basis, a thermal error on-line compensation system of the numerically-controlled machine tool feeding system is constructed. Taking an X-direction high-speed feeding system of a Longmen numerical control machining center in a certain model as an example, measurement, analysis and modeling compensation of the thermal errors are carried out respectively, and compensation effects are obvious. The full working stroke thermal error compensation method can be used for solving the thermal error compensation problem of the numerically-controlled machine tool feeding system and provides technical supports for machining accuracy and stability of a numerically-controlled machine tool.

Owner:SICHUAN UNIV

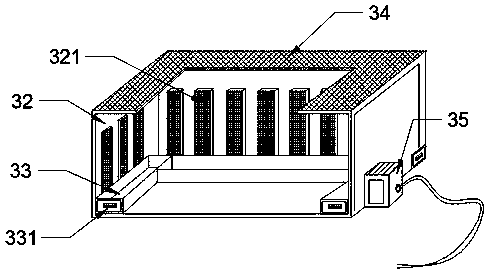

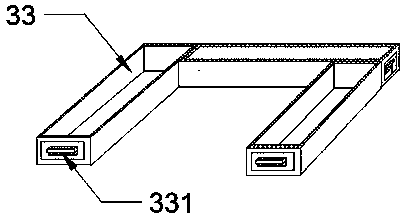

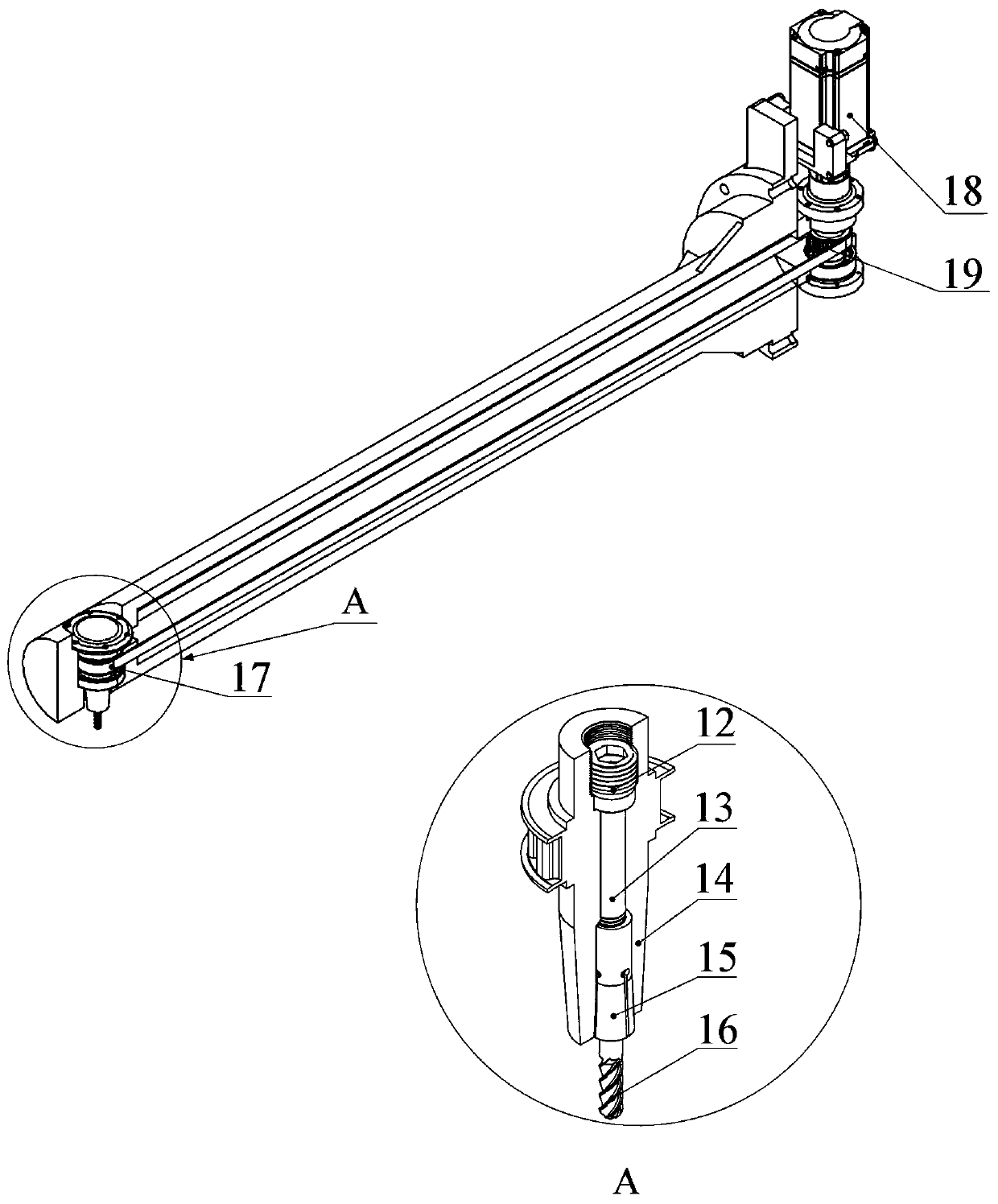

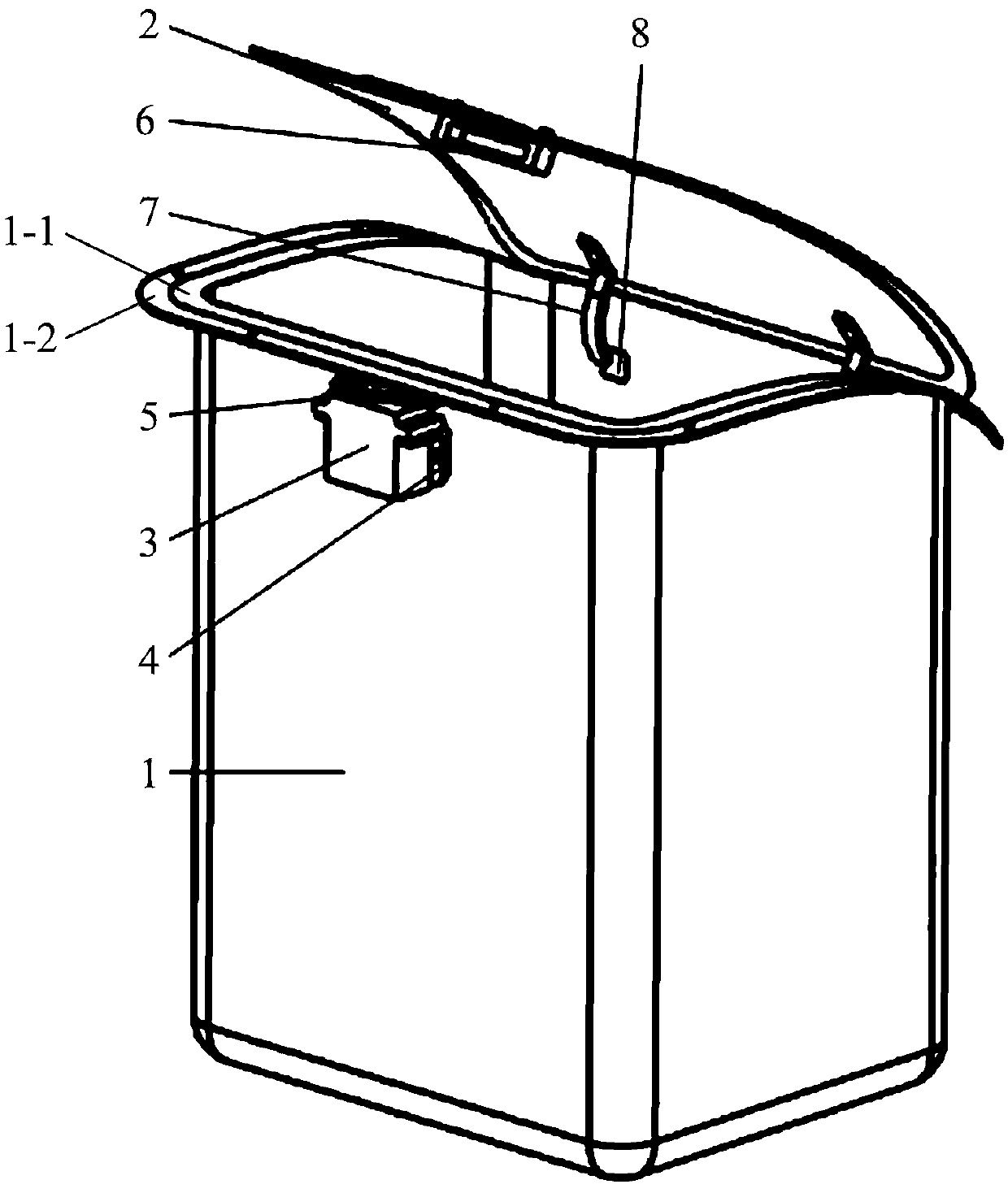

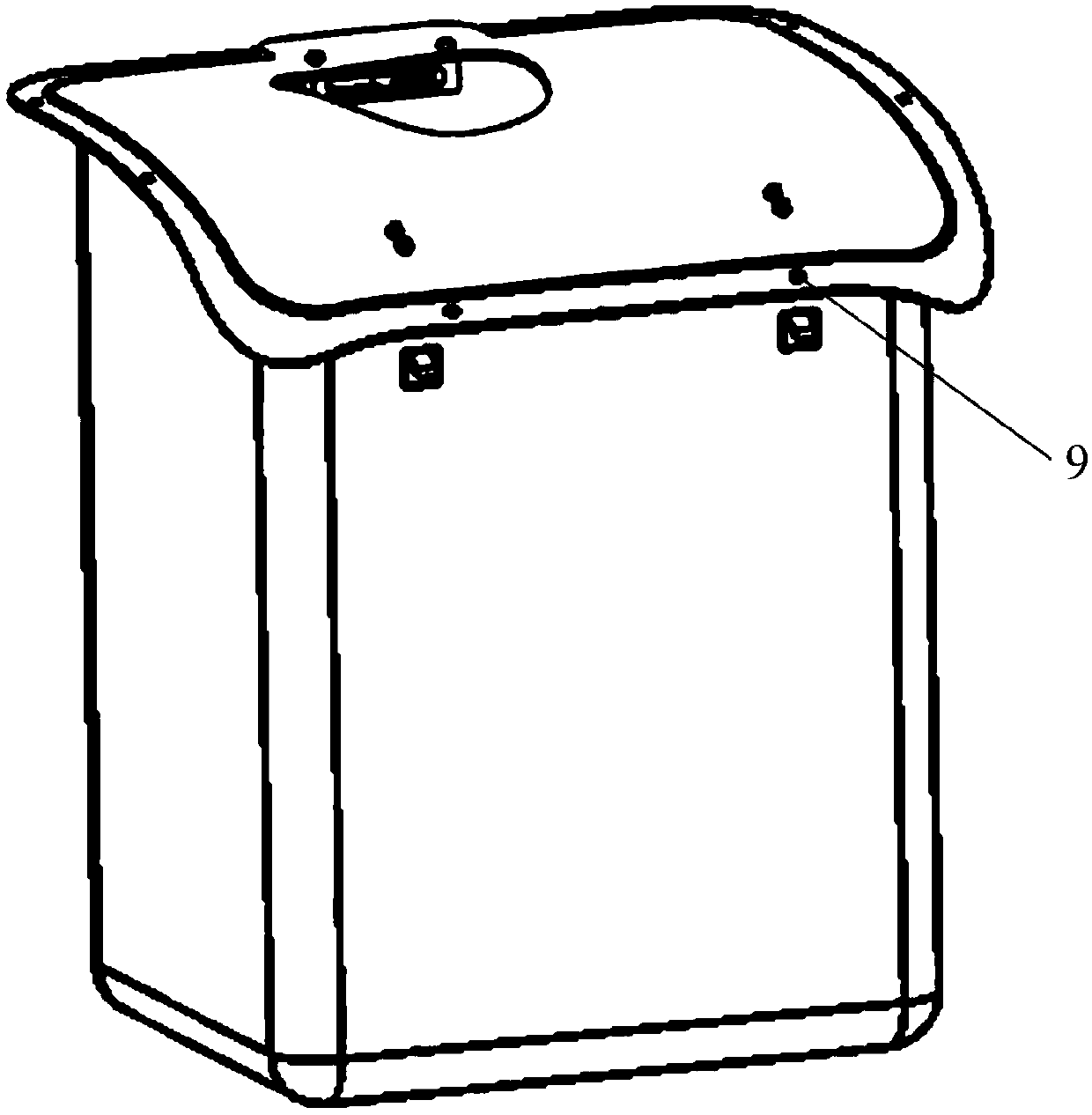

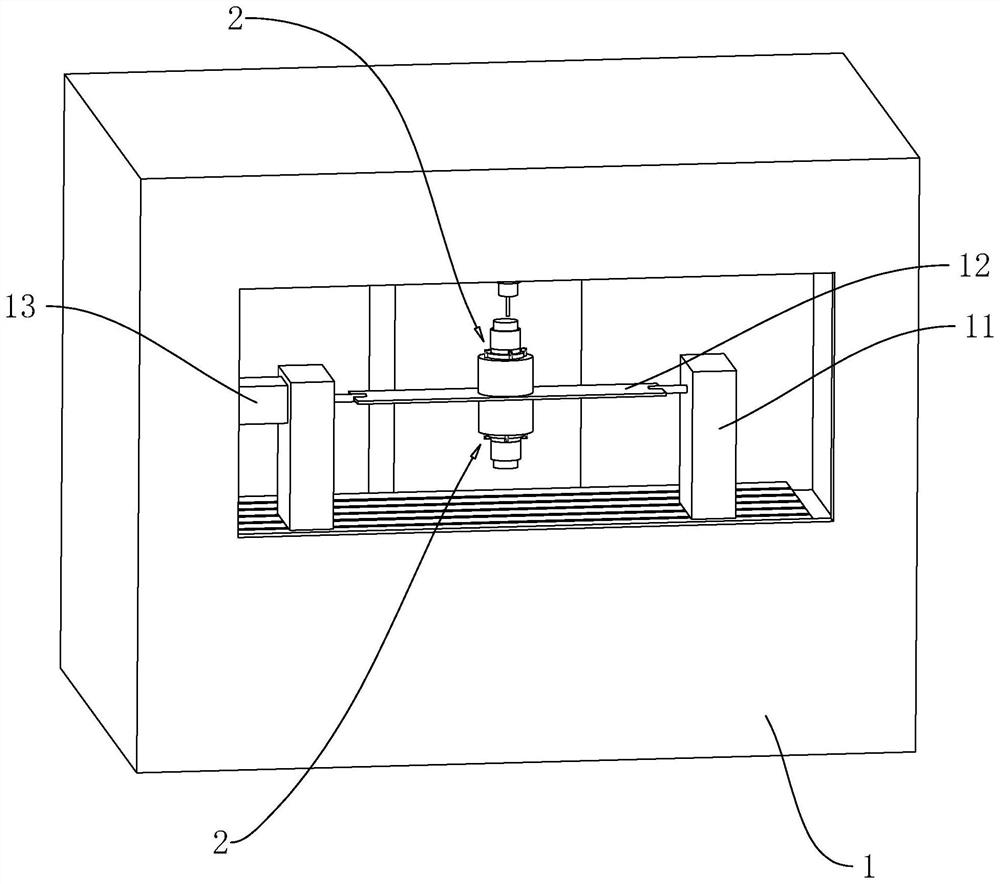

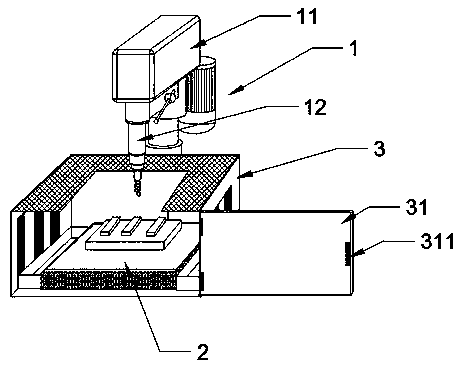

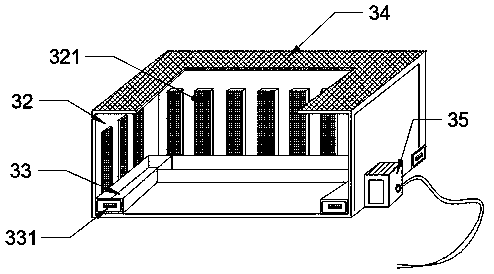

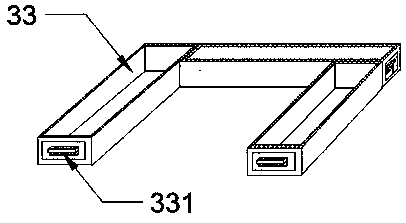

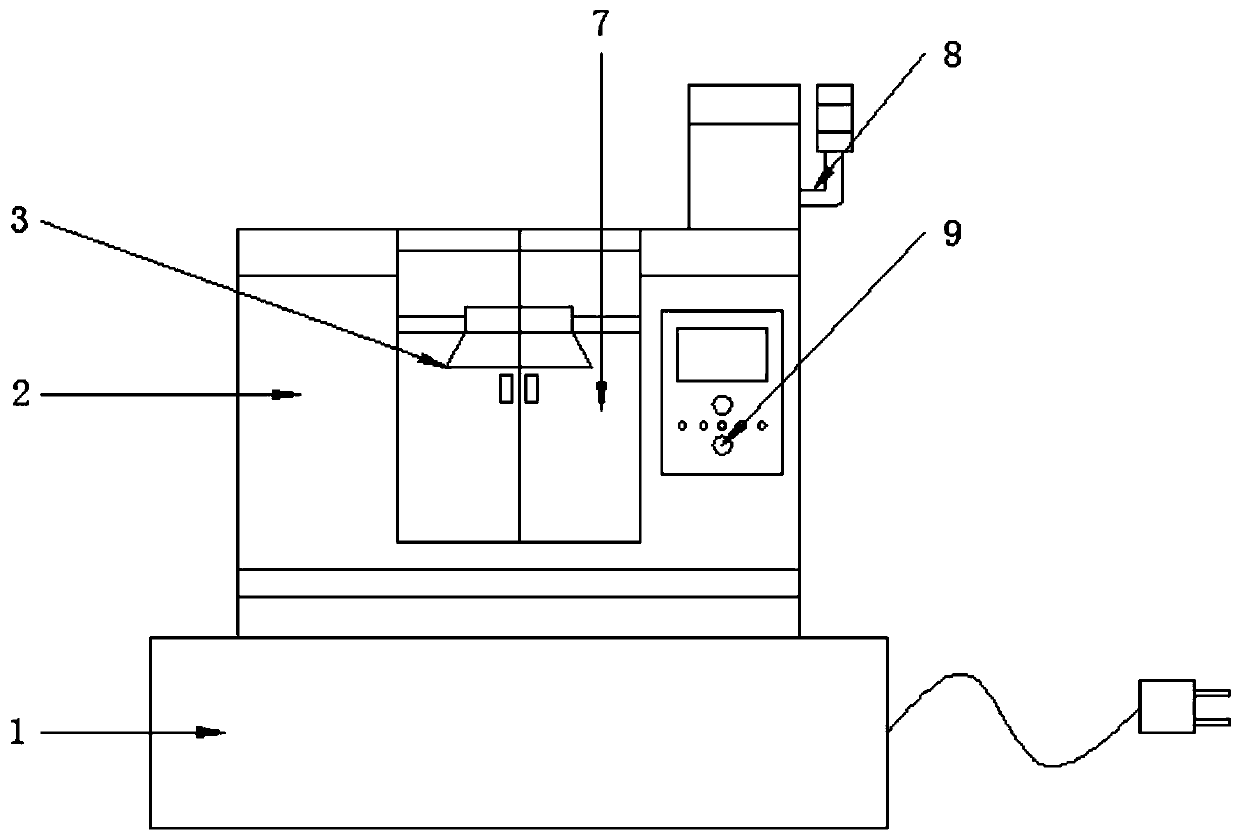

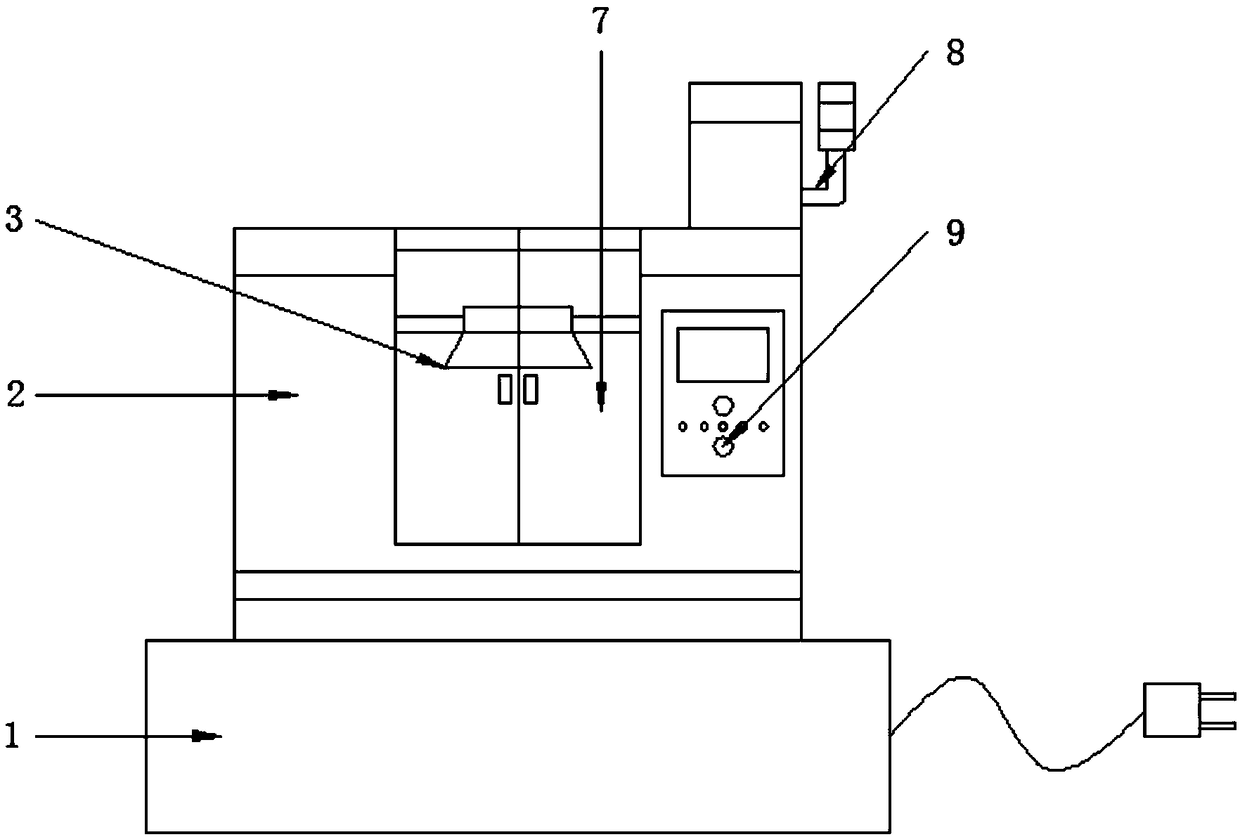

Small splash-proof safe table-type drilling machine

ActiveCN107649939AGuaranteed accuracyQuality assuranceMaintainance and safety accessoriesEngineeringMachining process

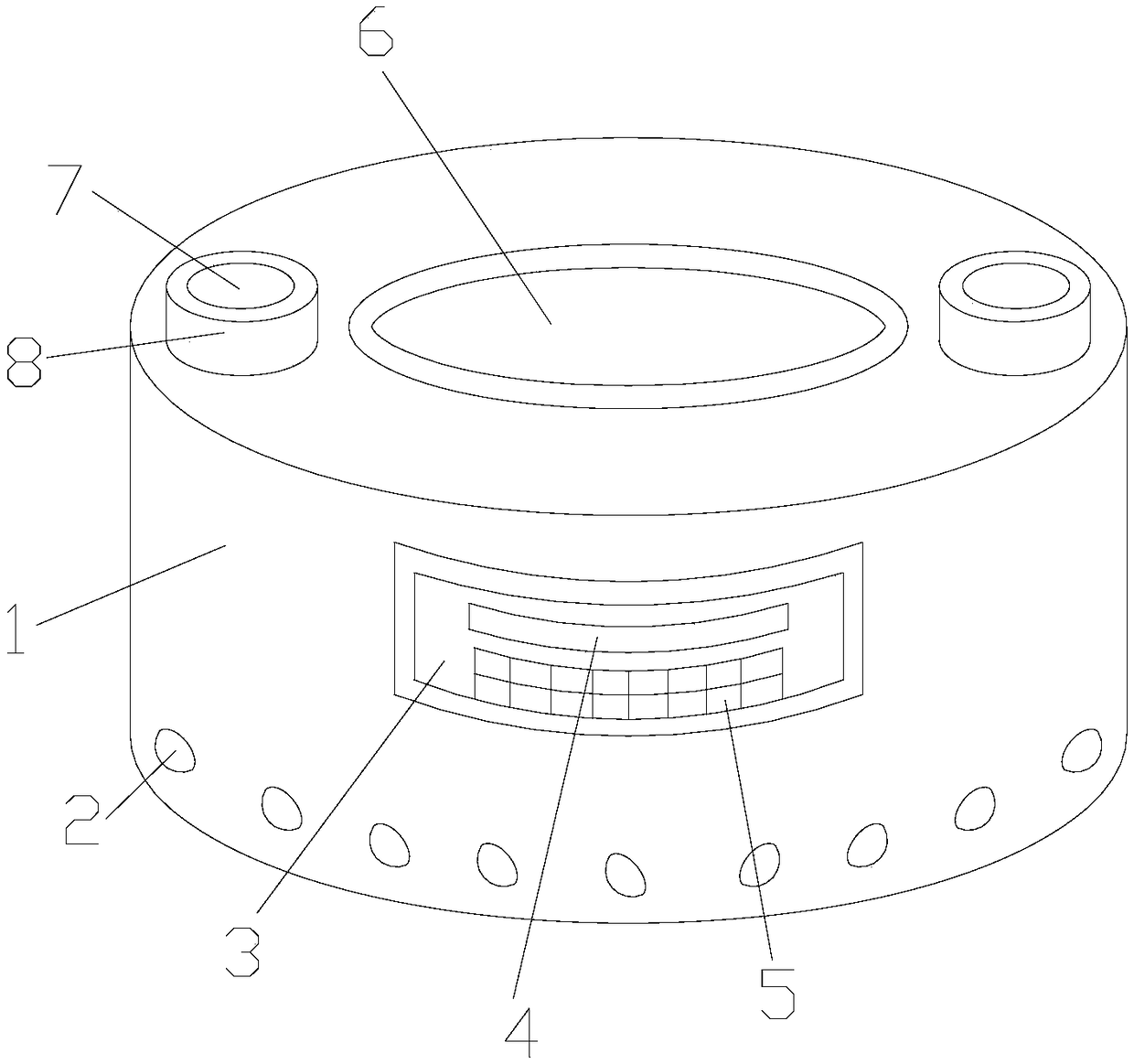

The invention belongs to the technical field of table-type drilling machine equipment and particularly relates to a small splash-proof safe table-type drilling machine. According to the small splash-proof safe table-type drilling machine, a splash-proof device is arranged on the periphery of a work table and is of a box body structure, and an electromagnetic block is mounted on the side wall of the splash-proof device; a headstock of the drilling machine is located above the splash-proof device, a drill bit extends into the position, inside the splash-proof device, above the work table from anopening in a top cover of the splash-proof device, and the splash-proof device is further internally provided with a dust receiving box capable of being taken out; and a transparent observation doorplate is arranged on the front portion of the splash-proof device and provided with an electromagnetic safety lock. According to the table-type drilling machine, the situation that iron scraps generated in the drilling process hurt a human body can be prevented, accurate control over the machining process is facilitated, the machining accuracy of the drilling machine can be improved, and the cleantable face of the equipment can be kept.

Owner:安徽昕悦铸造科技有限公司

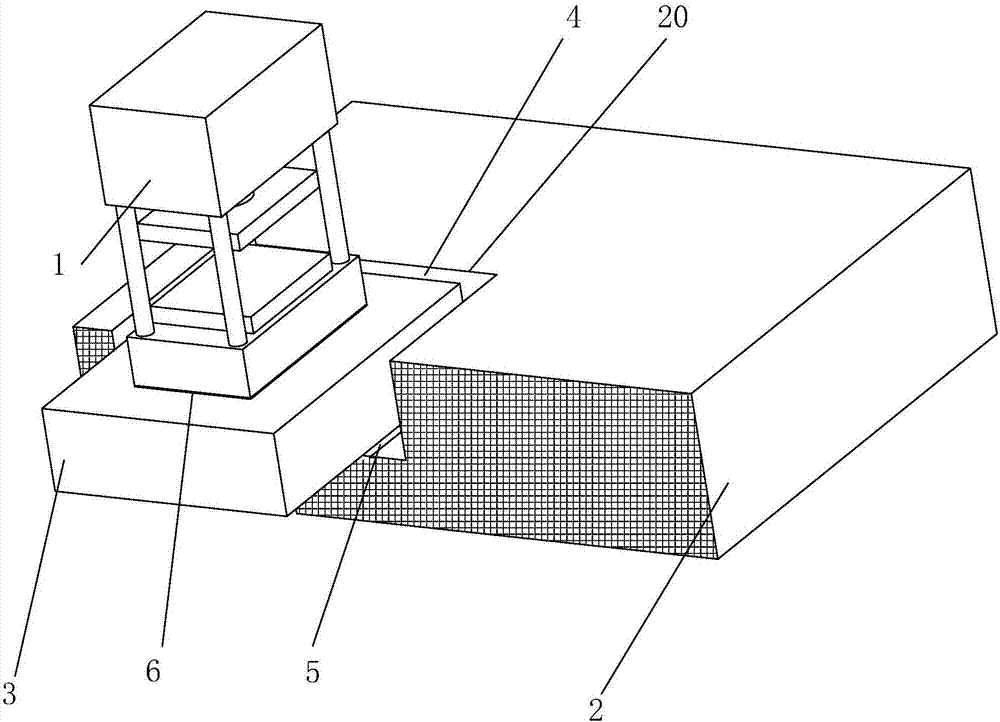

Laser cutting machine

PendingCN110091076AAvoid distributingPrevent stayingWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

The invention discloses a laser cutting machine. The laser cutting machine comprises a base, a box with an opening formed in the top, a clamp, a workpiece feed mechanism, a workpiece discharge mechanism, a cutting head used for cutting workpieces, a first lifting mechanism, a supporting frame arranged on the upper surface of the base and located over the box and smoke pumping pipes used for pumping smoke dust in the box. The first lifting mechanism is in sliding connection with the supporting frame, a first sliding rail is arranged on the upper surface of the base, and the box is in sliding connection with the first sliding rail. The clamp is fixed in the box. The first lifting mechanism is in sliding connection with the supporting frame and is close to the rear end of the first sliding rail. The cutting head is fixedly connected with a lifting shaft of the first lifting mechanism. Butt-joint holes in butt joint with the smoke pumping pipes penetrate through the rear side wall of the box, and the smoke pumping pipes are parallel to the first sliding rail. The laser cutting machine has the advantages that cutting efficiency is high; the smoke pumping pipes adsorb the smoke dust in acentralized manner, and the smoke dust is prevented from being emitted to workshops; and the position between a supporting table and a fixed arm can be adjusted, and therefore the workpieces with different radii can be cut.

Owner:深圳市睿露智能科技有限公司

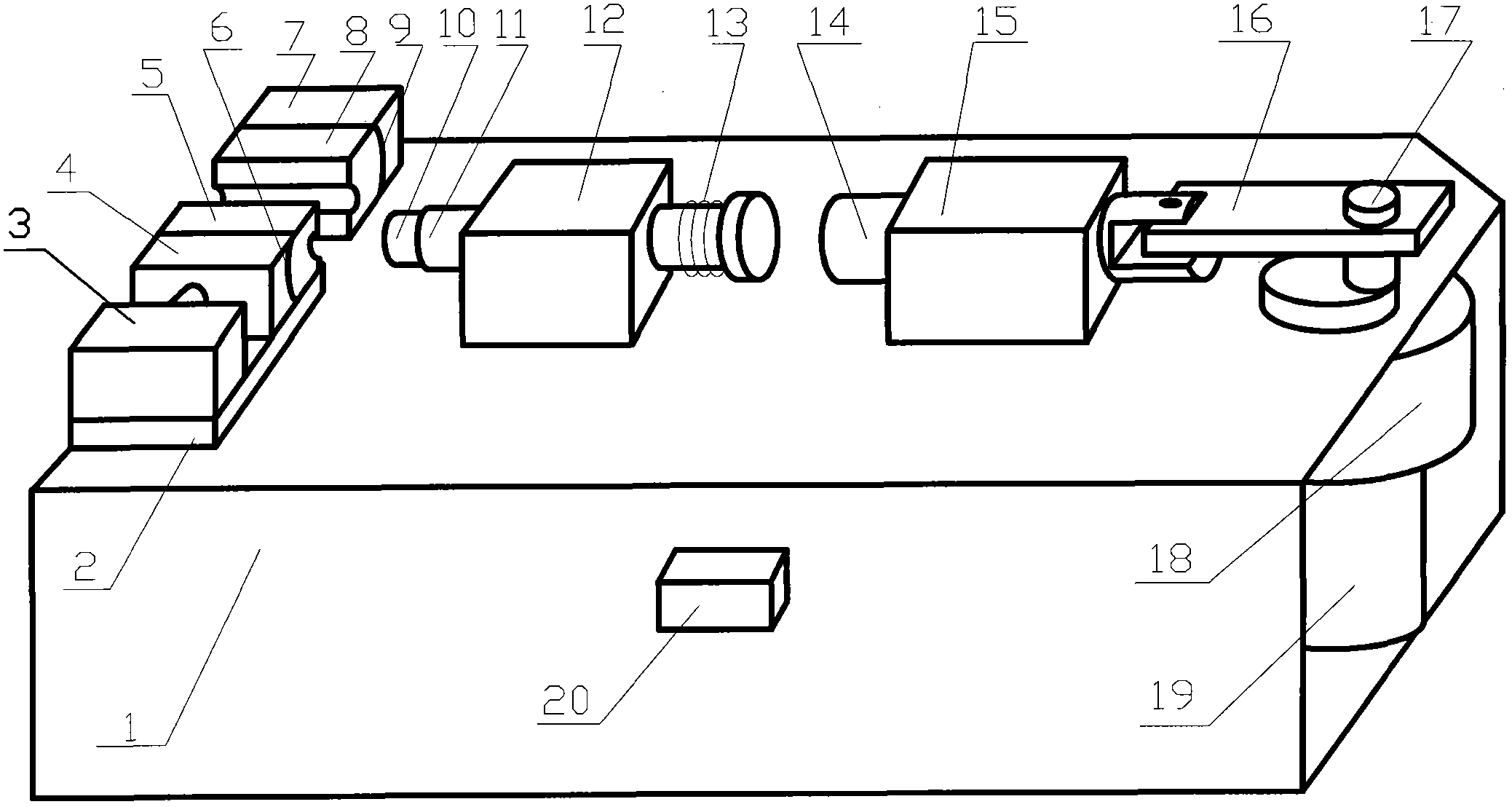

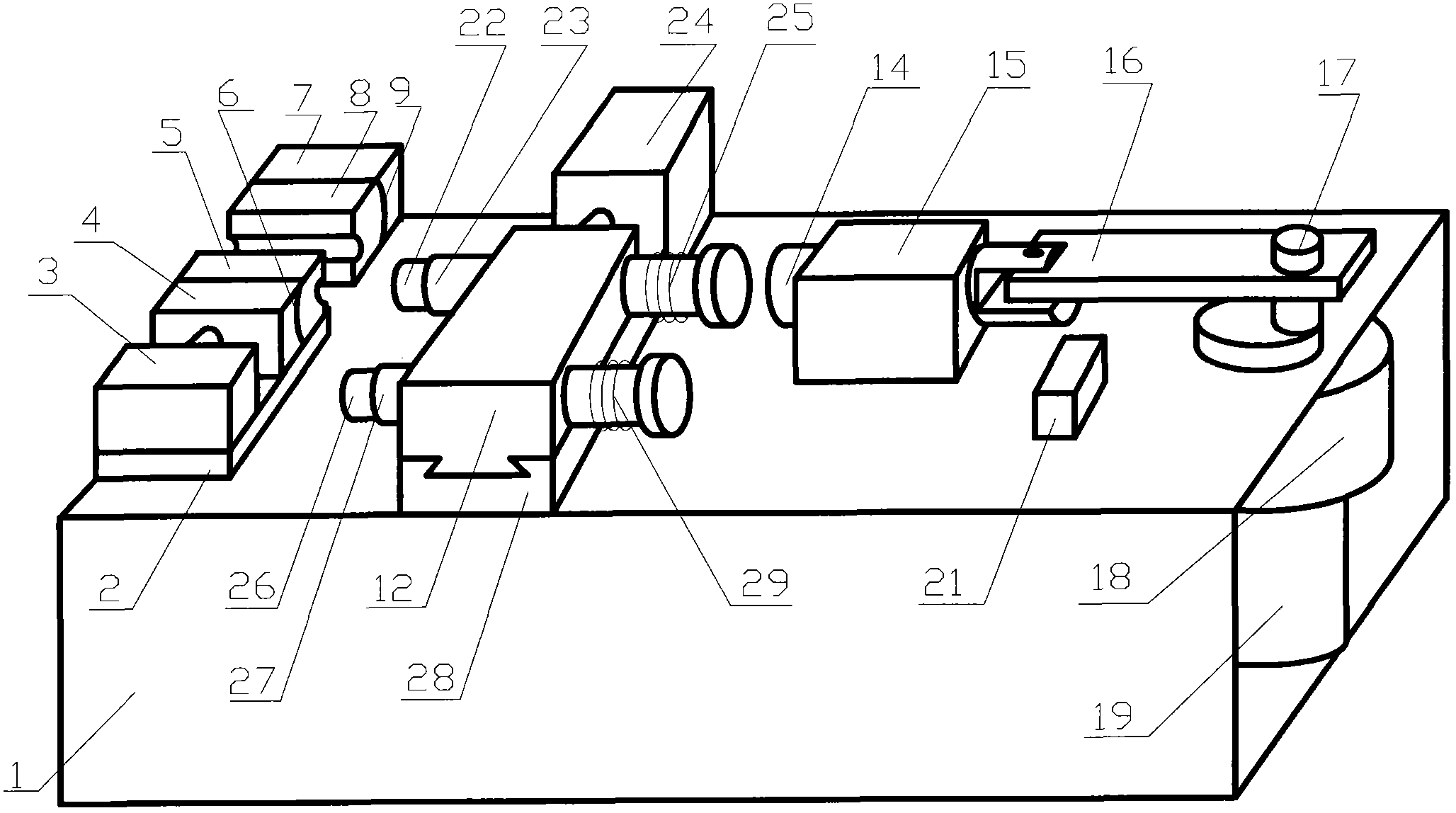

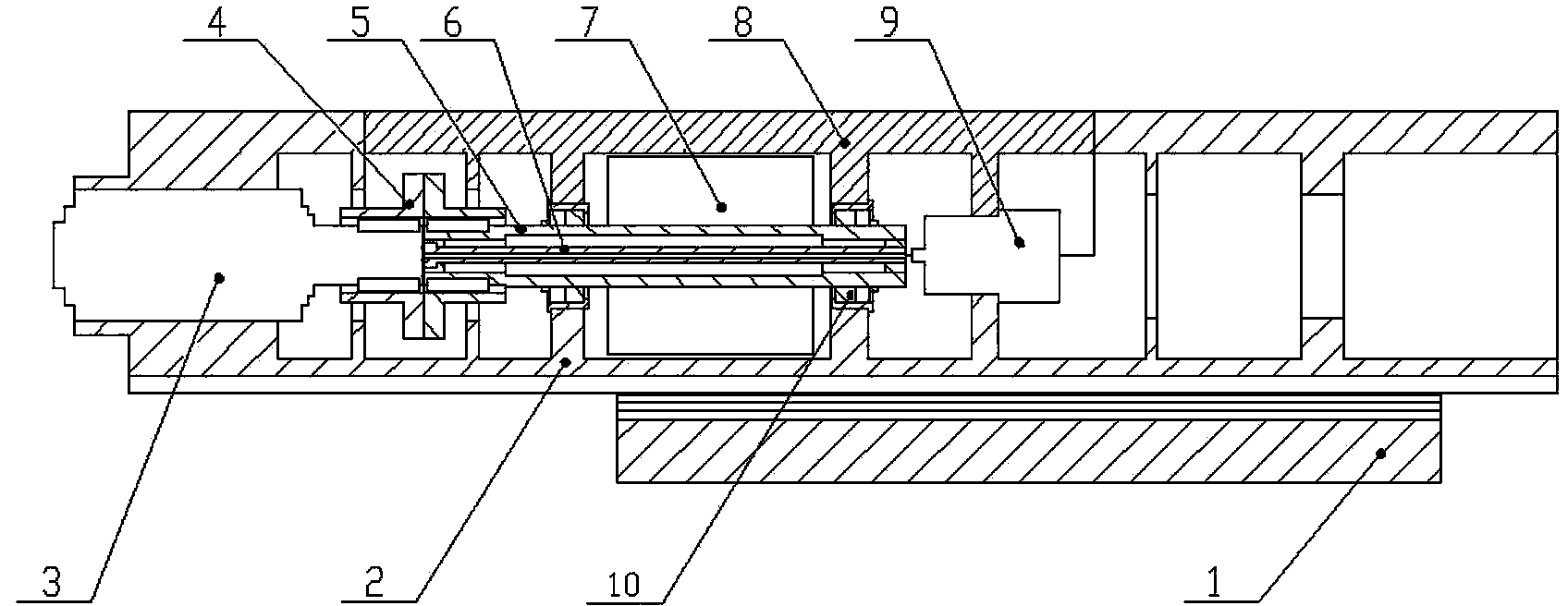

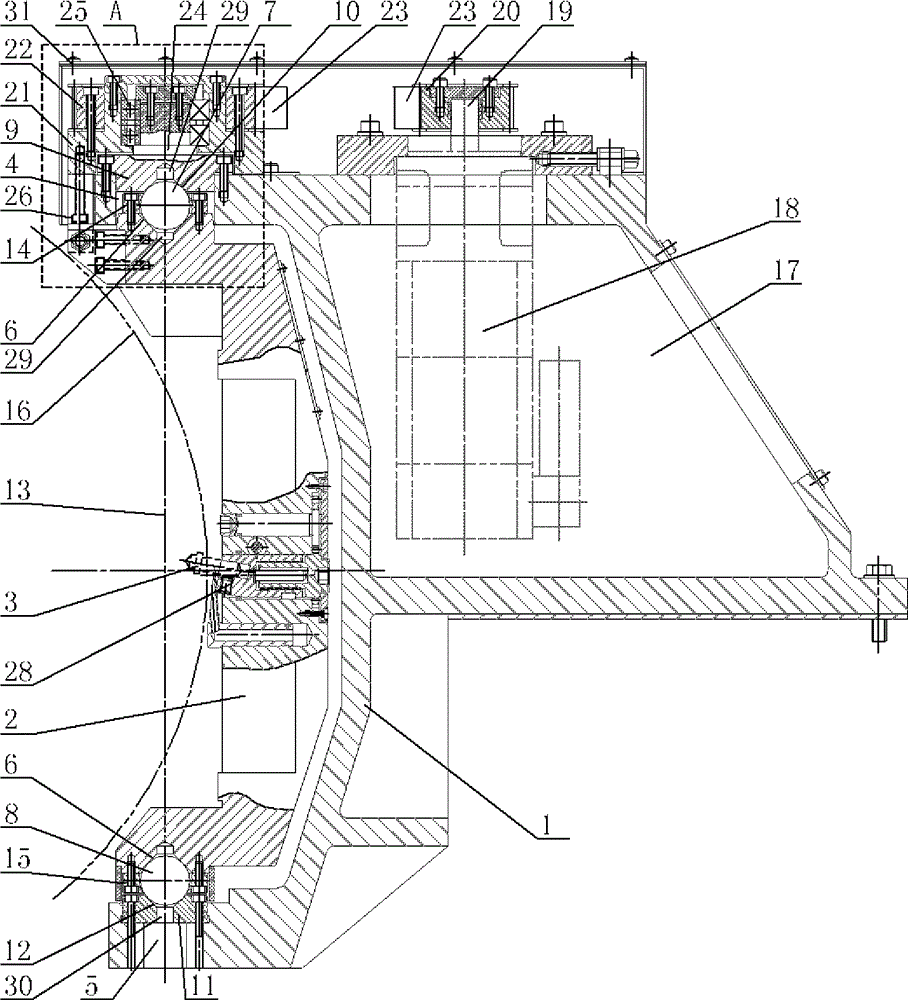

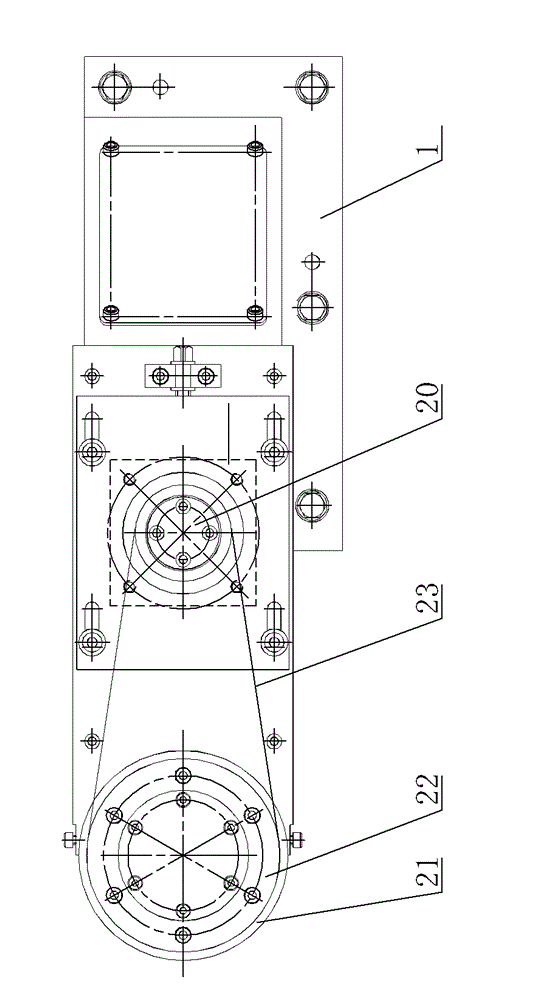

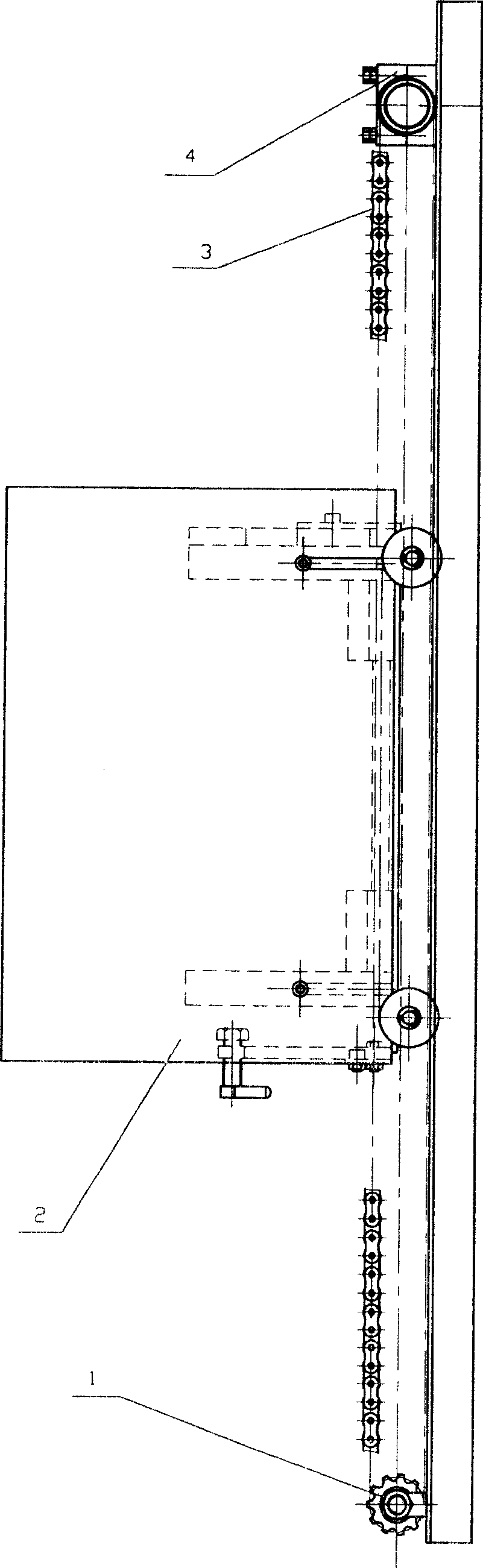

Mechanical pipe fitting end part forming machine

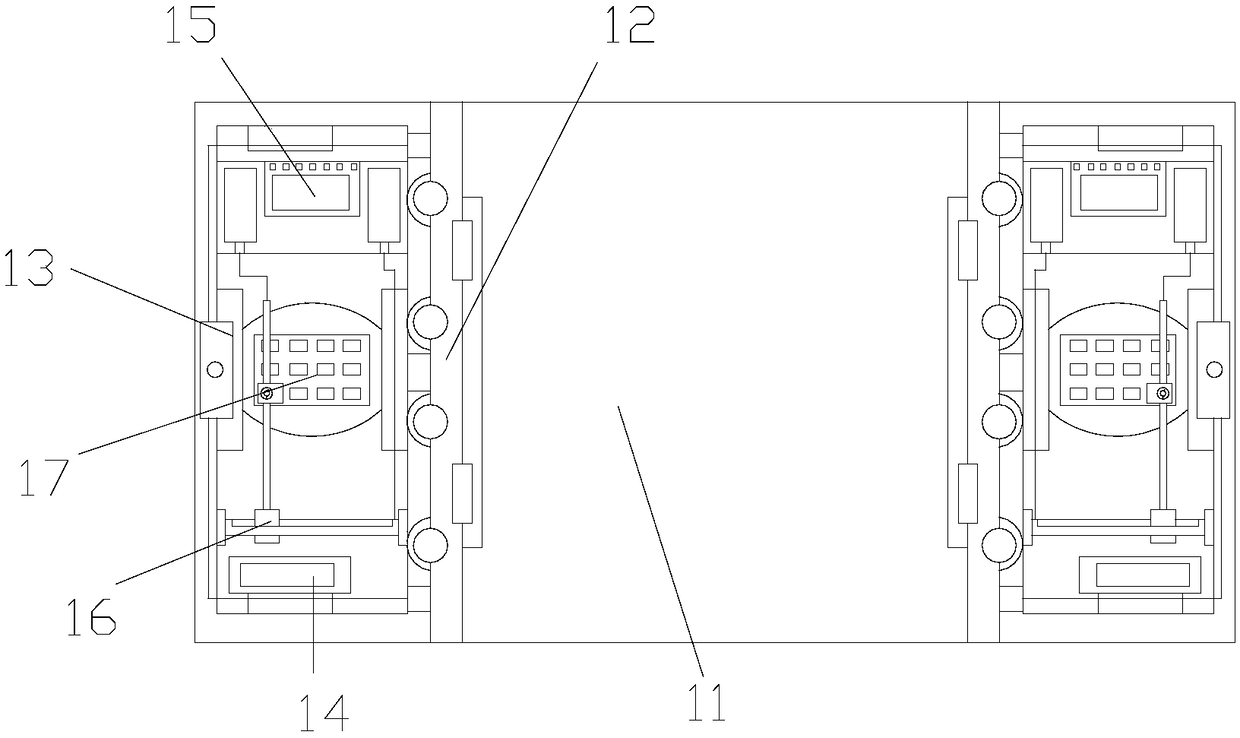

The invention discloses a mechanical pipe fitting end part forming machine for processing pipe fitting end parts, which comprises a machine body (1), a motor (19), a motor operating electrical unit, a deceleration device (18), a slider crank mechanism, a clamp pipe mould device, and a stamping die device for processing the pipe fitting end parts, wherein the stamping die device is mounted on a stamping die sliding block; the stamping die sliding block is not the sliding block (14) of the slider crank mechanism; and the sliding block (14) of the slider crank mechanism drives the stamping die sliding block to move forwards, and is driven by the motor (19) and the deceleration device (18). The stamping die sliding block only bears forward and backward force, so that the pipe fitting machining precision can not be impacted by the abrasion on the sliding block (14) of the slider crank mechanism used for a long time.

Owner:王俊强

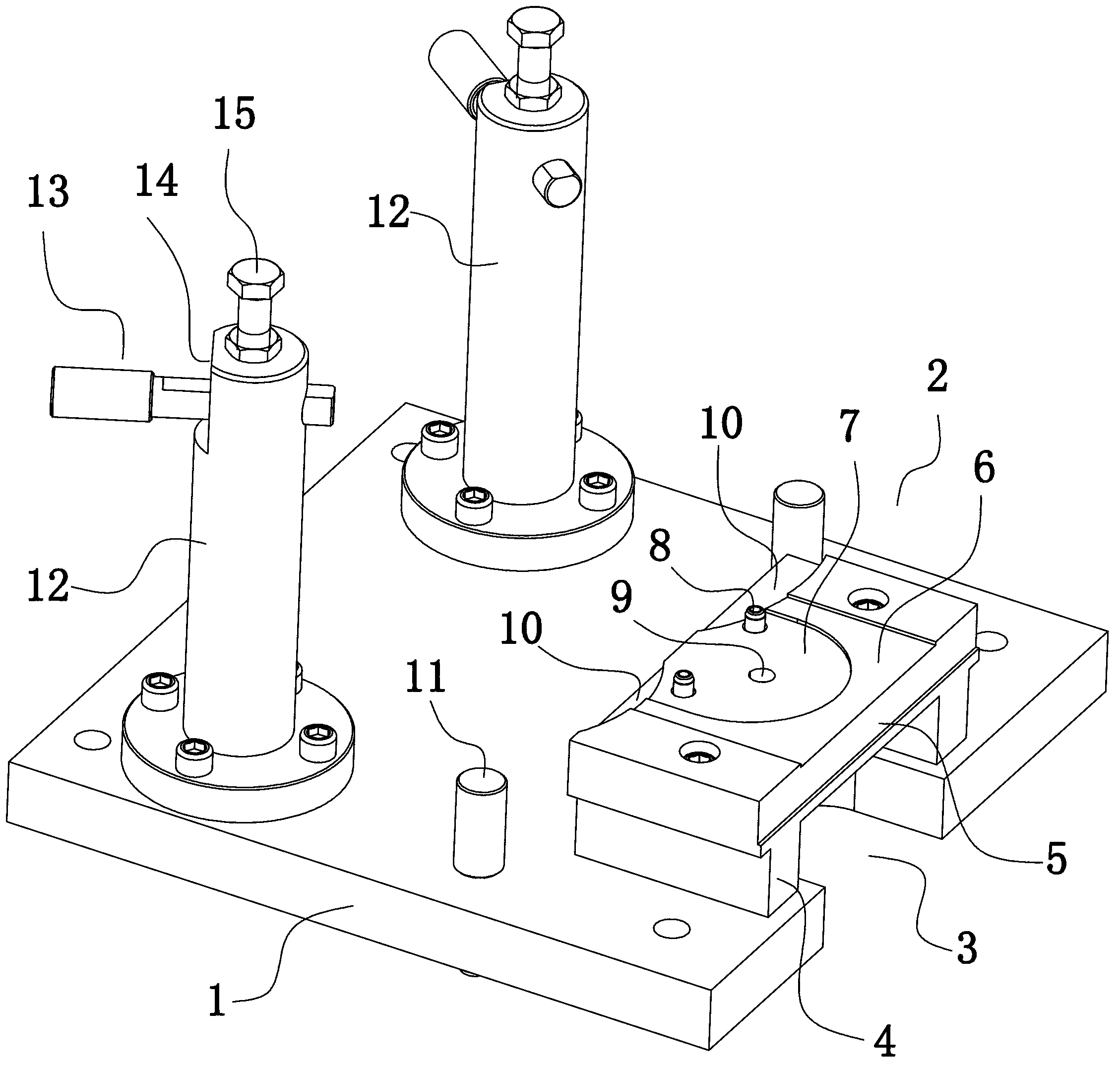

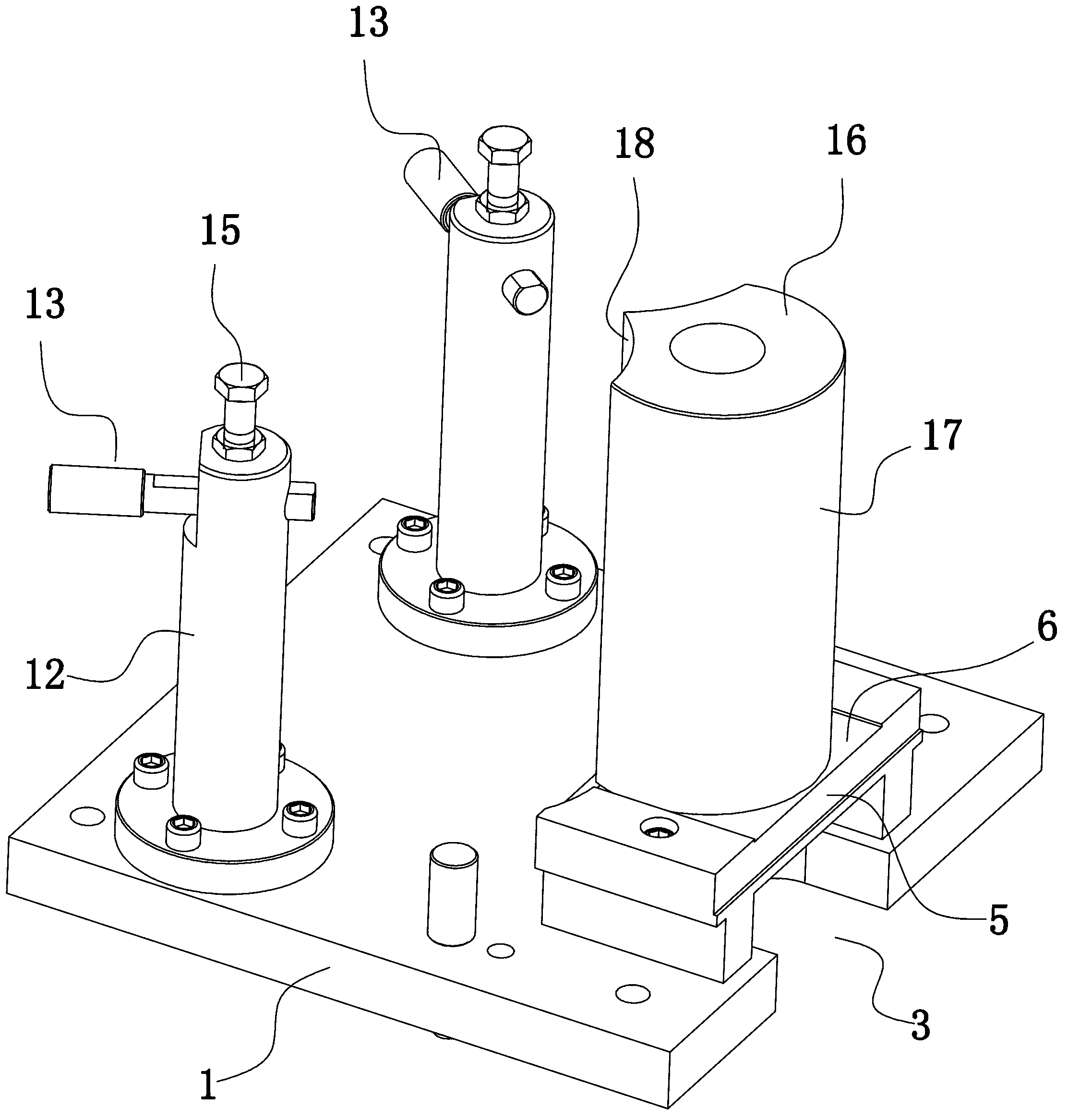

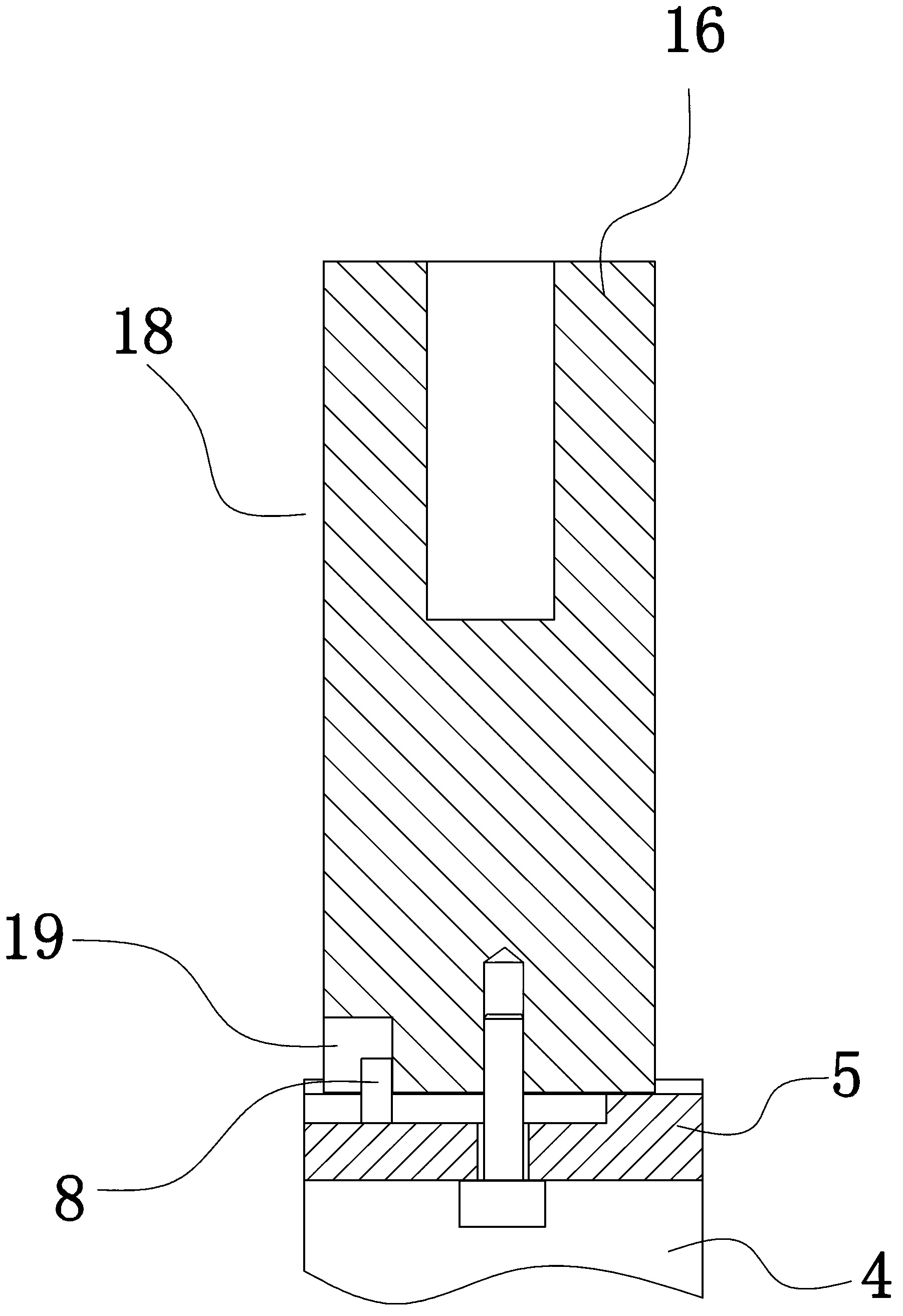

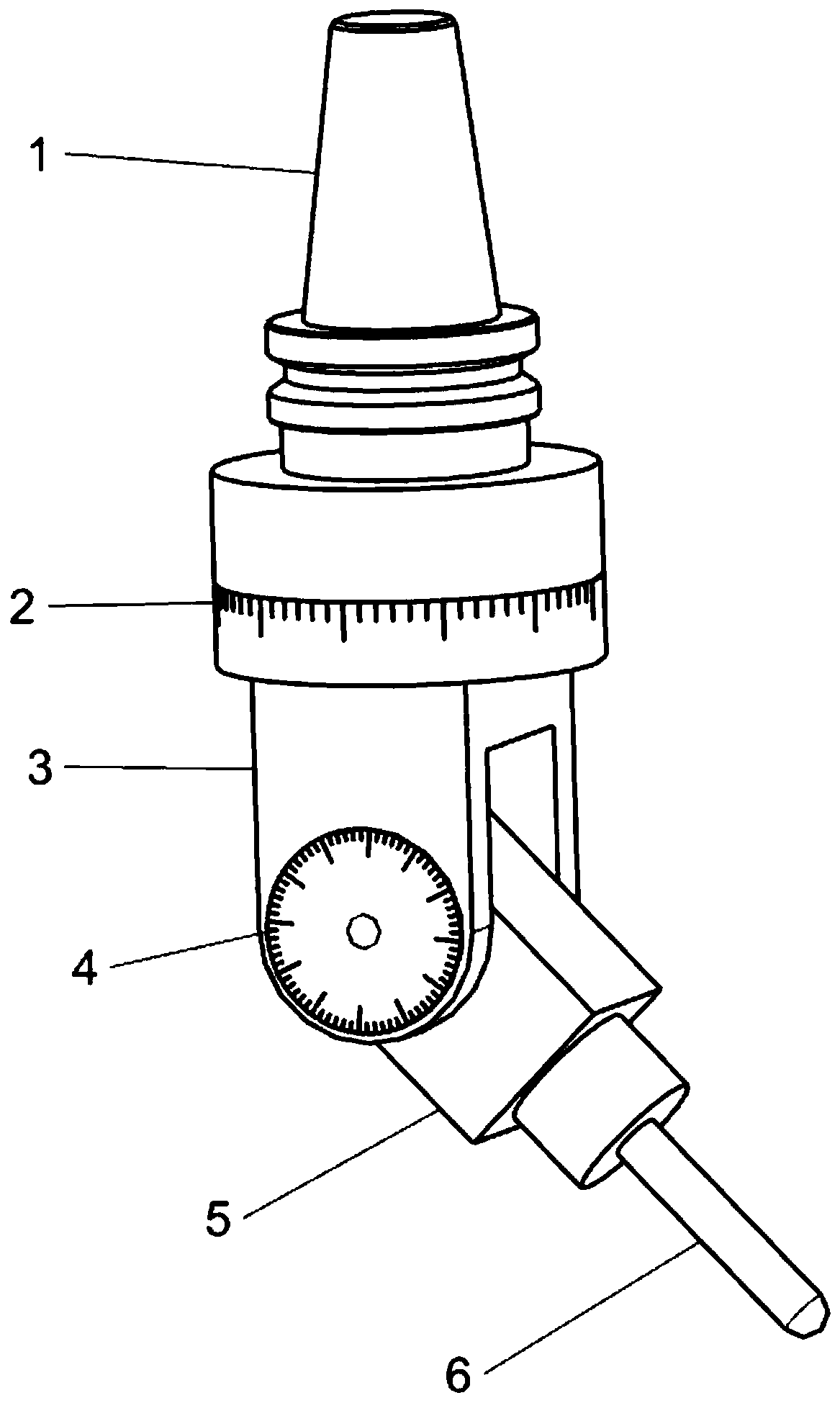

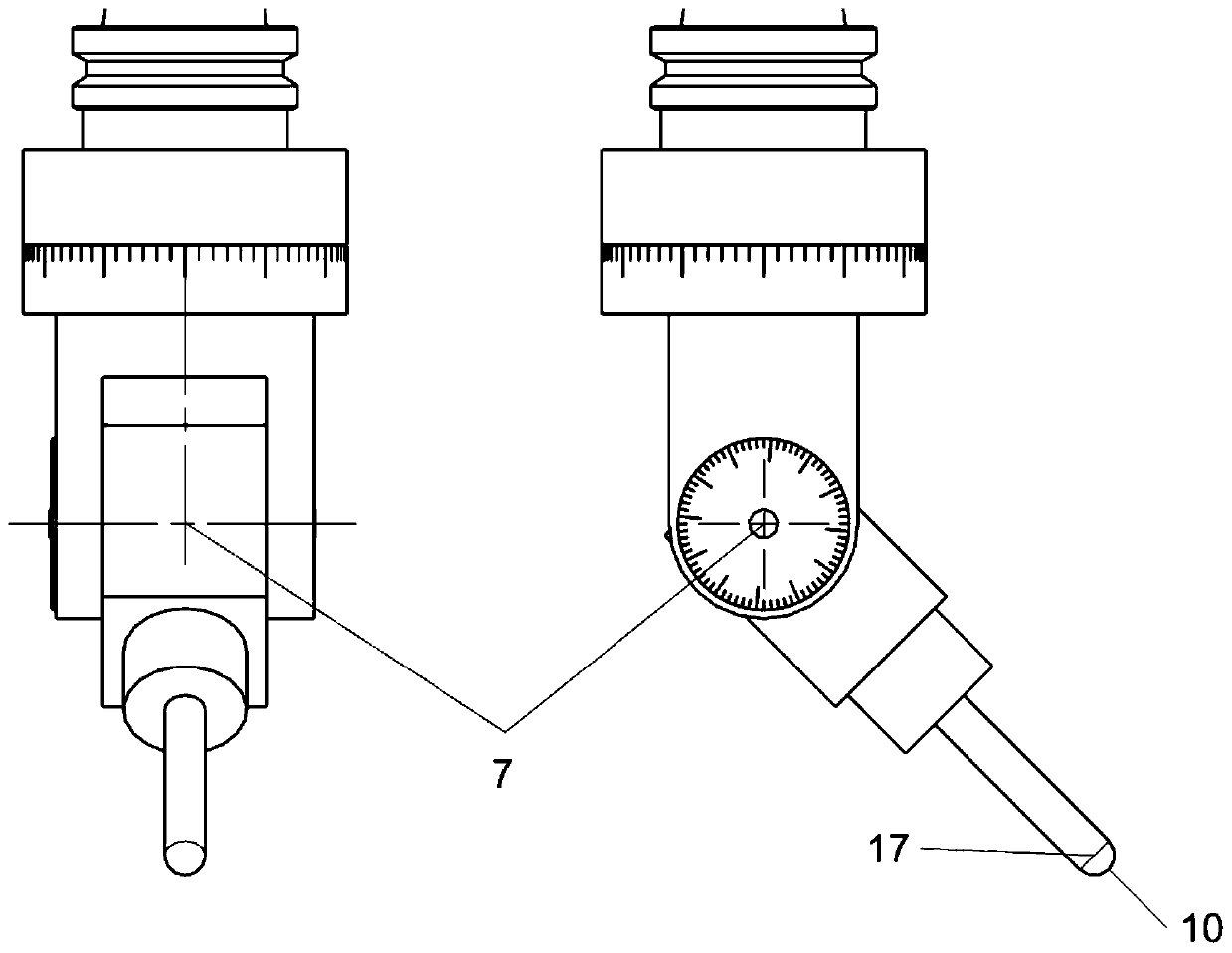

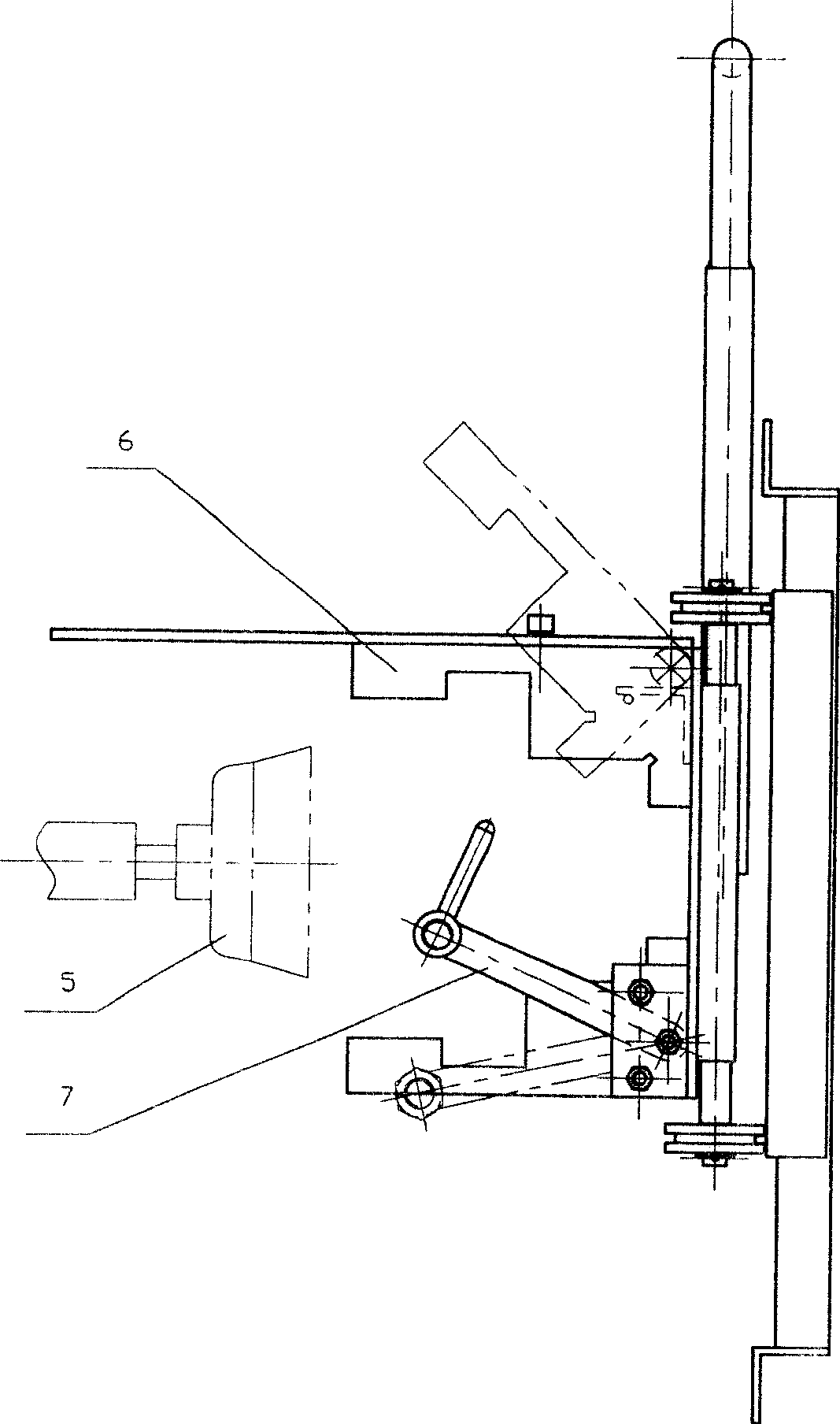

Sliding valve tool for twin-screw compressor and sliding valve processing method

ActiveCN102909580AInfluence of machining accuracyGuaranteed machining accuracyPositioning apparatusMetal-working holdersNumerical controlSpool valve

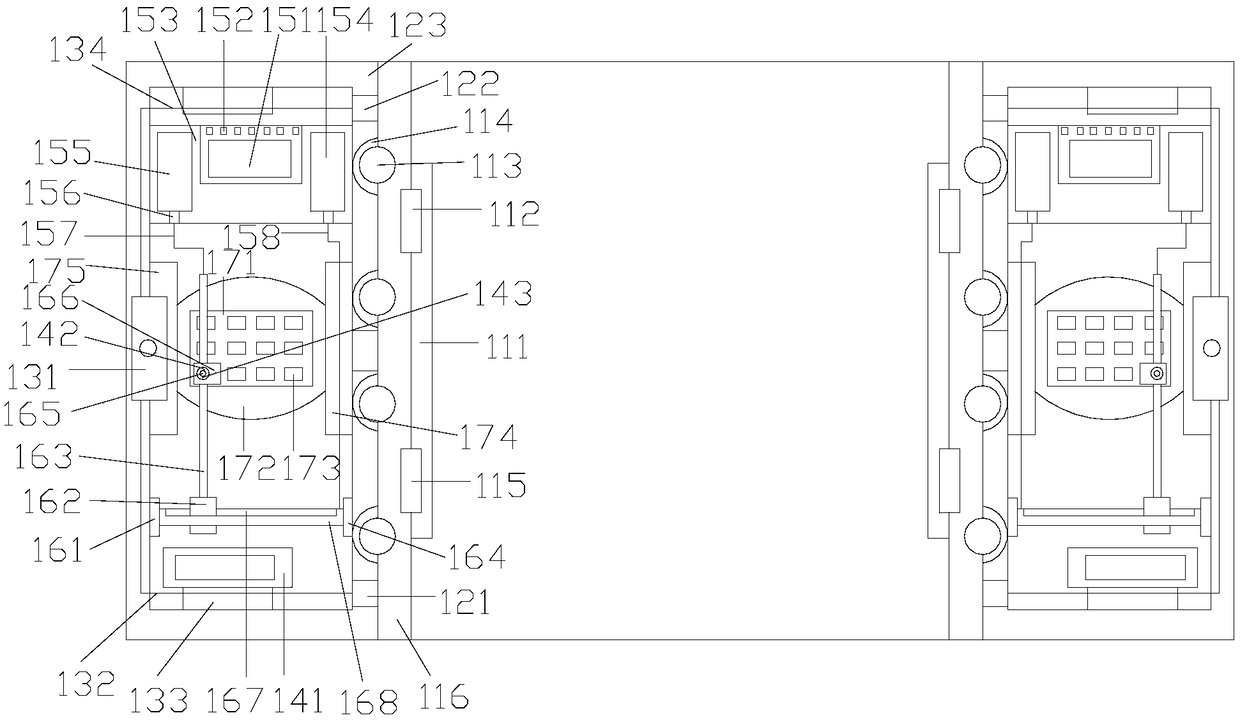

The invention discloses a sliding valve tool for a twin-screw compressor and a sliding valve processing method. The invention aims to provide a sliding valve tool for a twin-screw compressor, which can be used for effectively improving the precision and the percentage of pass of the lambdoidal cambered surface of the sliding valve and guaranteeing to improve the cooperation precision of the lambdoidal cambered surface and screws, and a sliding valve processing method. The sliding valve tool for a twin-screw compressor comprises a bottom plate, a fixing structure and two stand columns, wherein the fixing structure is arranged on one side of the upper surface of the bottom plate and is used for positioning and fixing the sliding valve; the two stand columns are arranged on the other side of the upper surface of the bottom plate; a guide hole is respectively arranged on the side surfaces of the two stand columns; a clock setting pin is respectively arranged in each guide hole in a sliding mode; locking bolts for fixing the clock setting pins are arranged on the stand columns; and one end surface of each clock setting pin respectively faces to the fixing structure. The sliding valve processing method comprises the steps that the sliding valve tool and the sliding valve are fixed on a processing platform of a numerically-controlled machine tool, and the lambdoidal cambered surface of the sliding valve is subjected to fine boring by the boring cutter of the numerically-controlled machine tool.

Owner:杭州联德精密机械股份有限公司

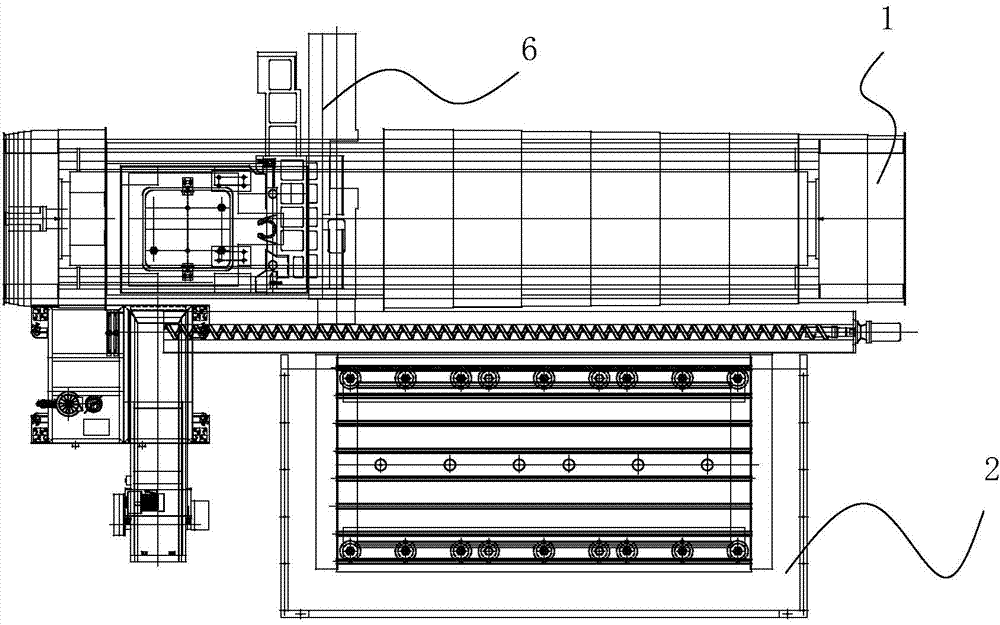

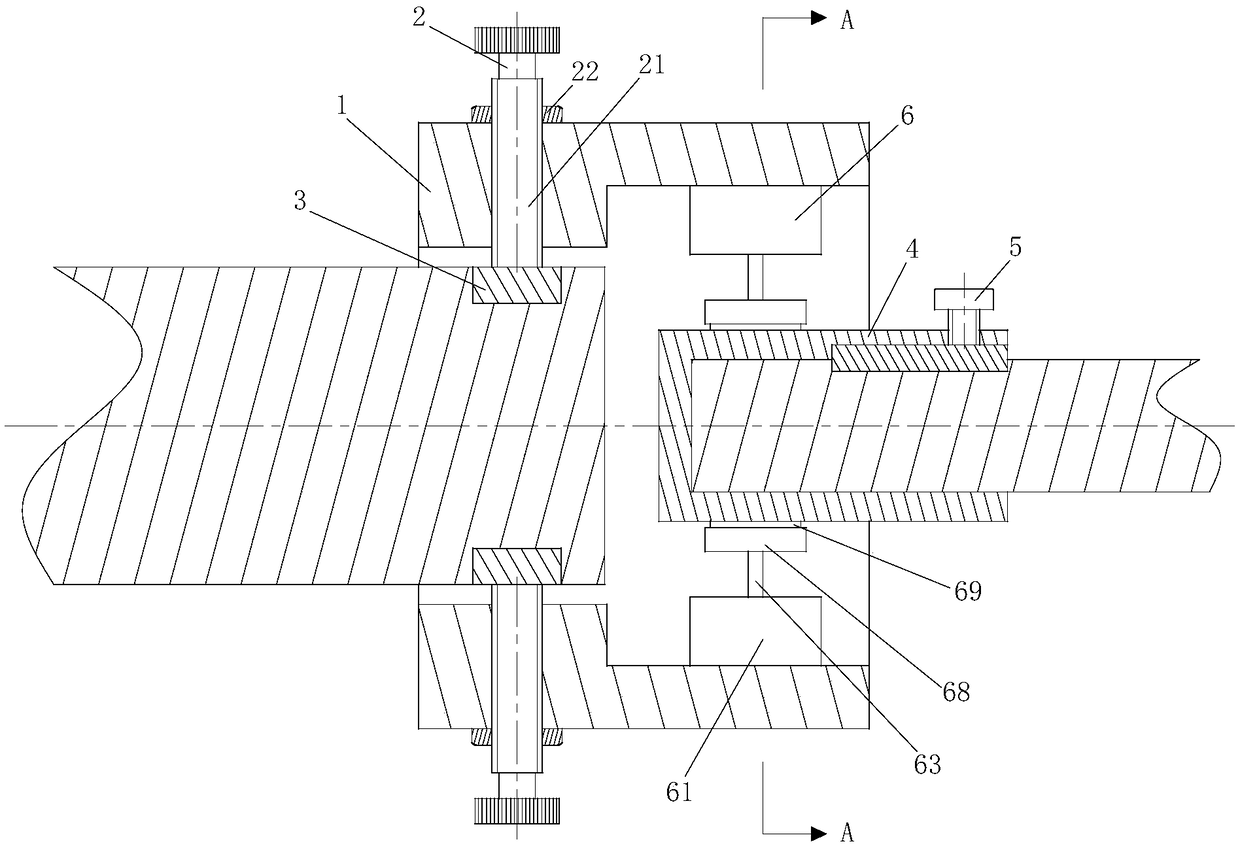

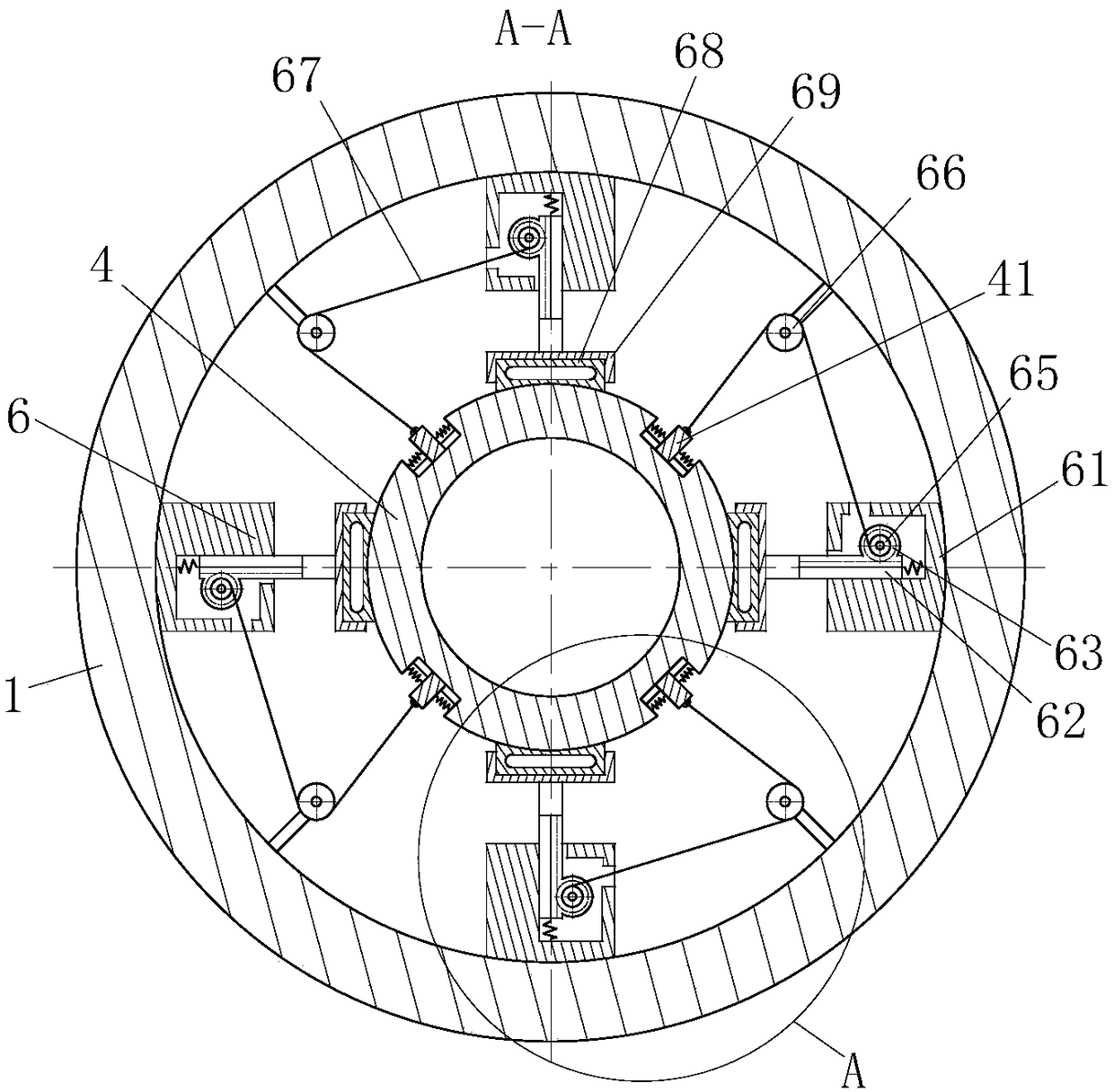

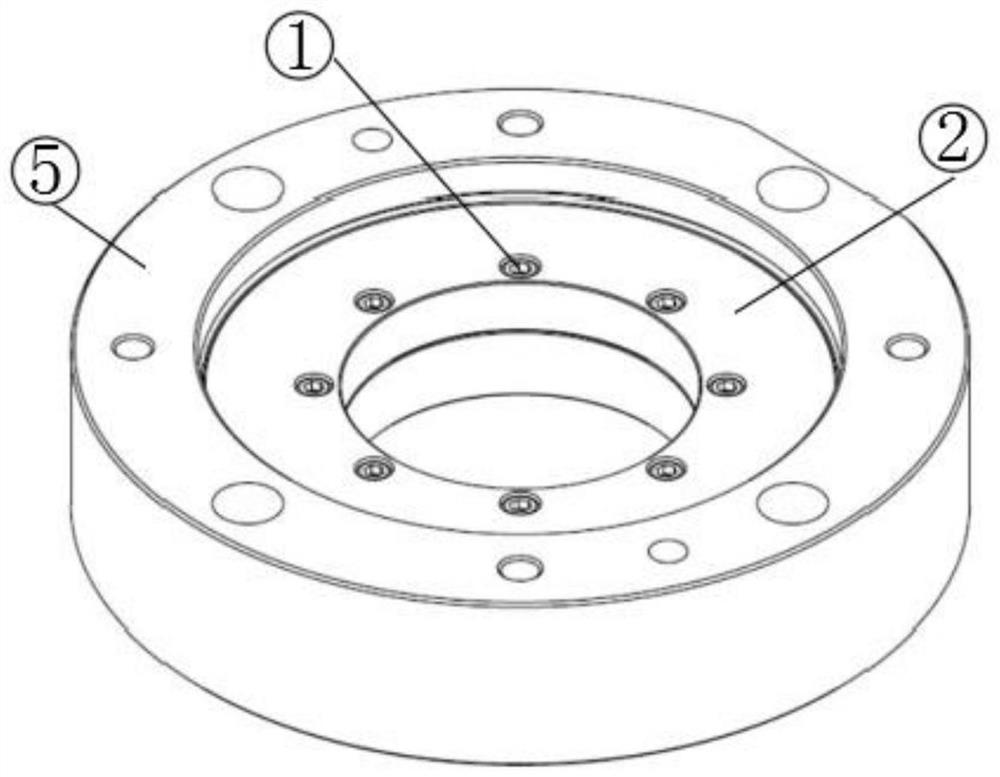

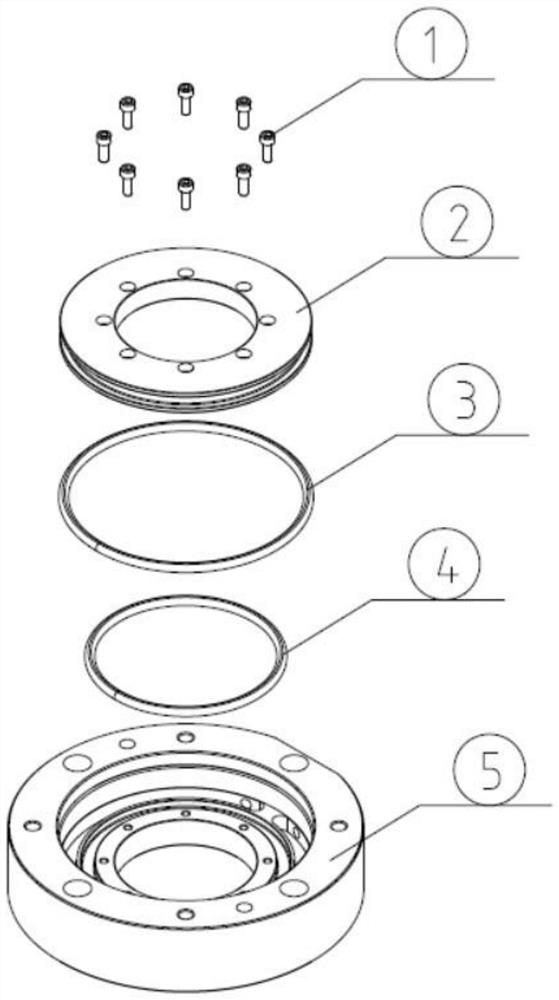

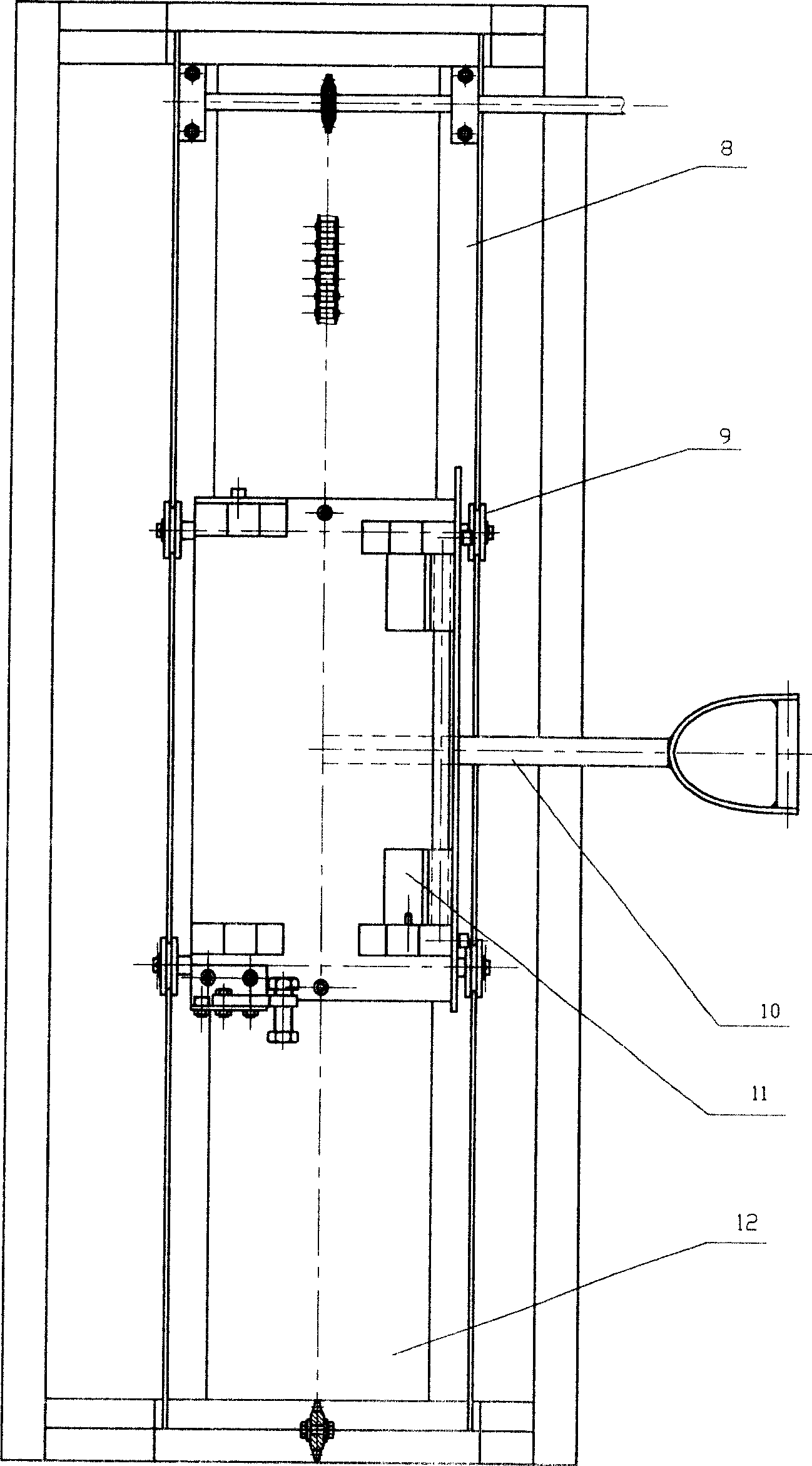

Crystallizer copper pipe inner cavity machine tool

ActiveCN111266635AImprove general performanceHigh dimensional accuracyAutomatic control devicesPrecision positioning equipmentEngineeringMachine tool

The invention provides a crystallizer copper pipe inner cavity machine tool. The crystallizer copper pipe inner cavity machine tool comprises a machine tool body which is placed on a horizontal working face, the upper end of the machine tool body is provided with a longitudinal slideway, a lower slide seat is arranged on the longitudinal slideway, and thus, the lower slide seat can move longitudinally under driving of a longitudinal feeding mechanism; the lower slide seat is provided with a transverse slideway, the transverse slideway is provided with an upper slide seat, and thus, the upper slide seat can move in the transverse direction under driving of a transverse feeding mechanism; the upper slide seat is provided with a workbench, and the workbench is provided with an indexing system; the indexing system comprises an indexing mechanism, an upper opening chuck and a lower opening chuck, and the upper opening chuck and the lower opening chuck are oppositely arranged and cooperate to clamp a copper pipe; and the side edge of the machine tool body is provided with a vertical column, the vertical column is provided with a vertical slideway, the vertical slideway is provided with acutter bar box, and thus, the cutter bar box can be driven by a vertical feeding mechanism to move in the vertical direction. The machine tool has the advantages of being capable of conducting clamping conveniently, good in rigidity, high in precision and the like, and the problems that a single or small batch of copper pipe inner cavities are long in machining cycle, low in precision and the like are solved.

Owner:DALIAN UNIV OF TECH

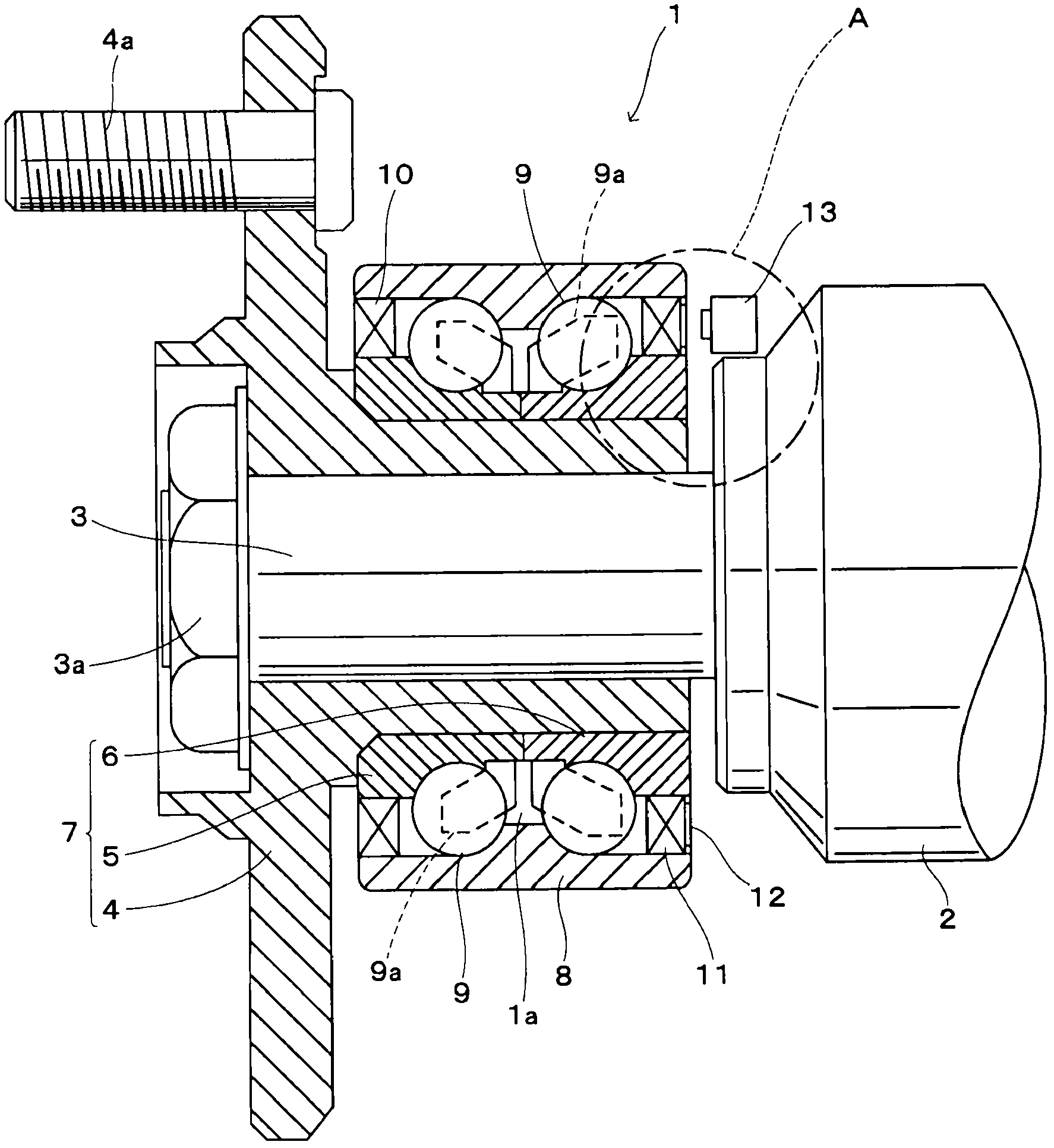

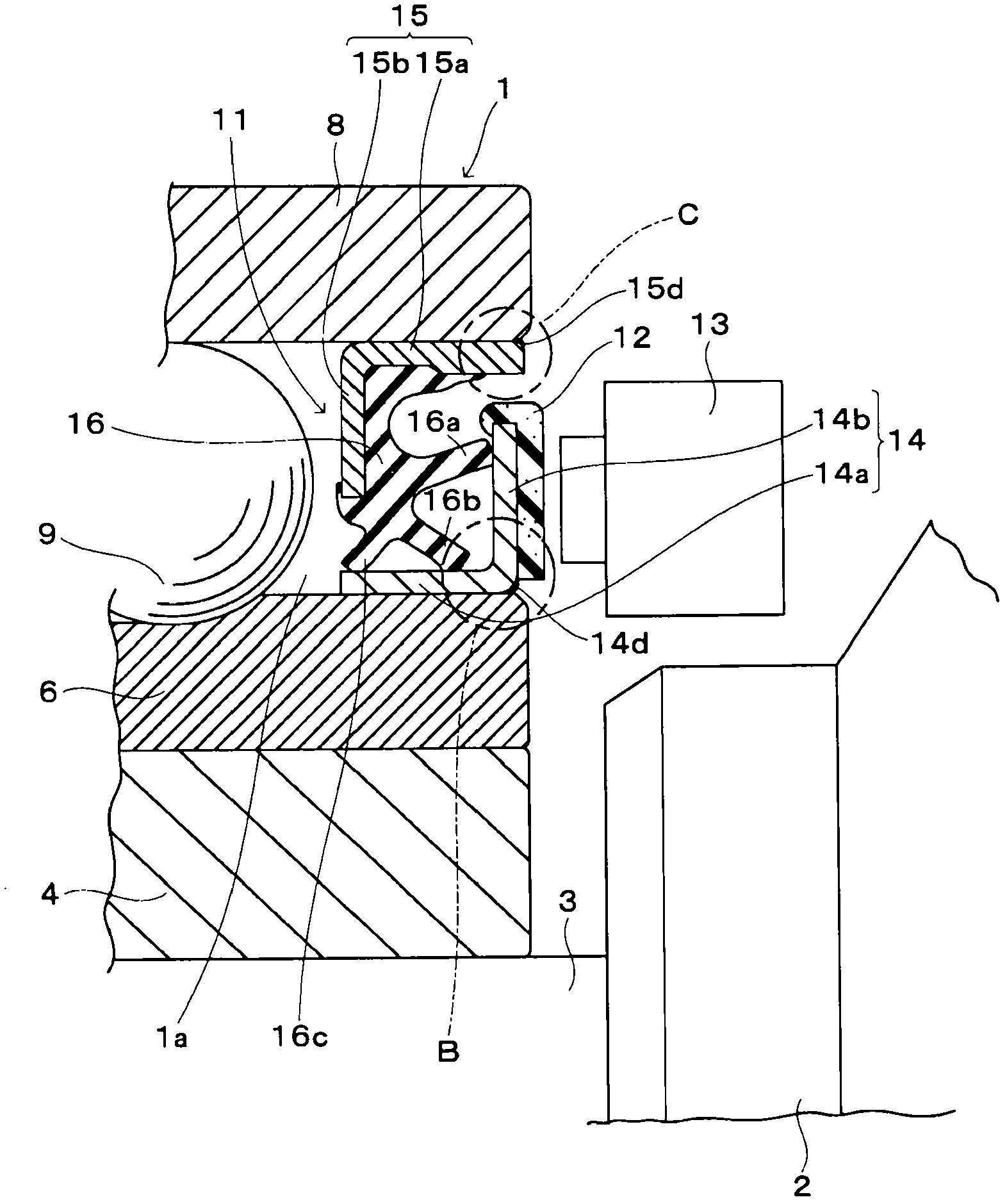

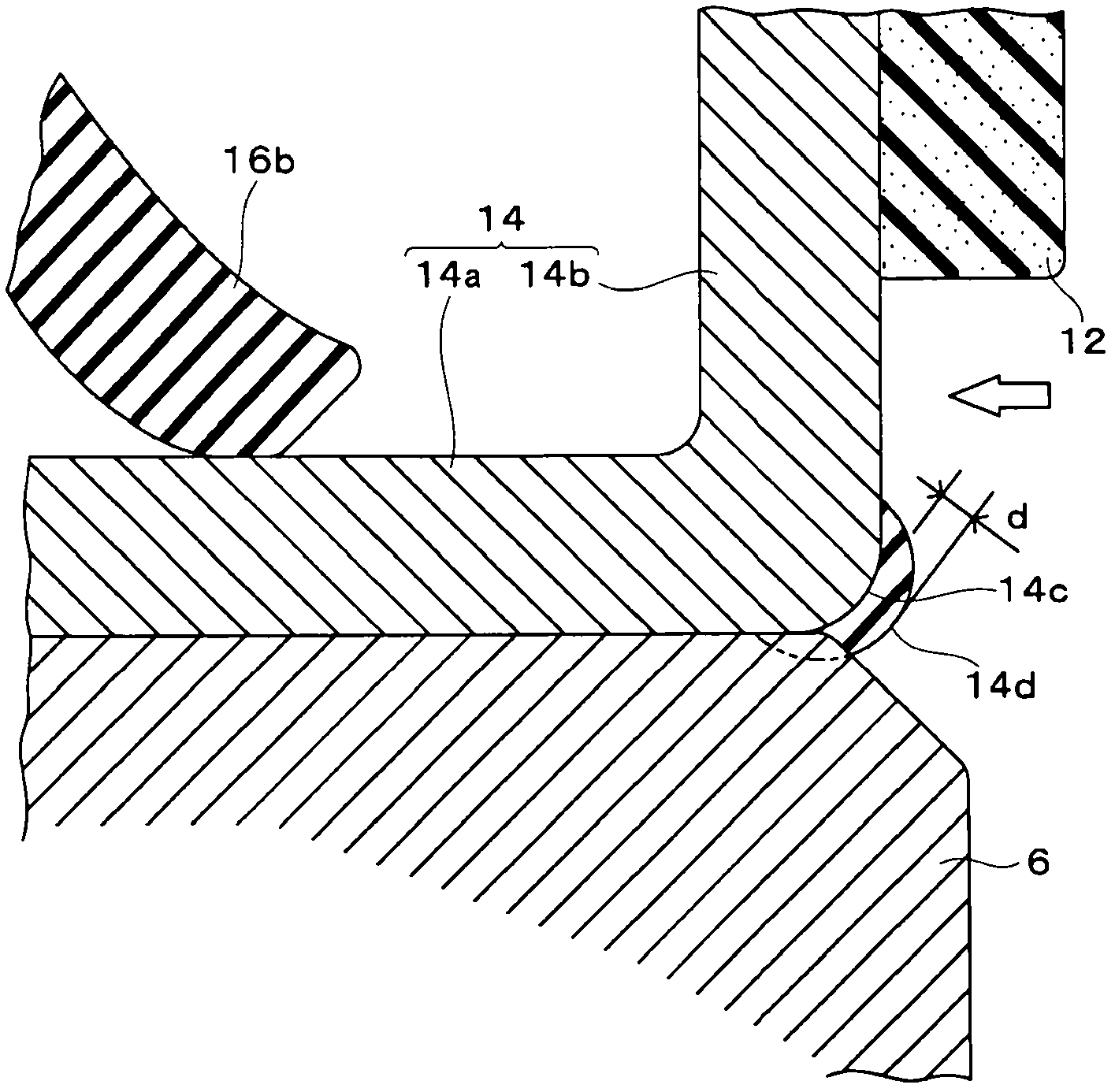

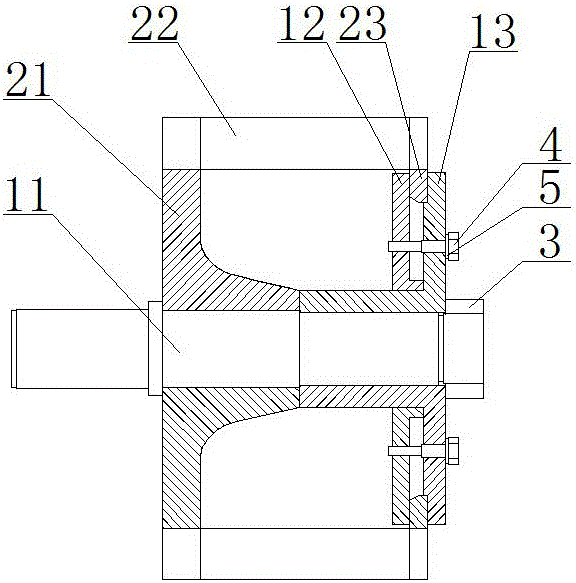

Sealing structure for fitting section

InactiveCN102472389AInfluence of machining accuracyImprove sealingEngine sealsRolling contact bearingsEngineeringLayer thickness

A sealing structure for a fitting portion where an annular member is concentrically fitted to a cylindrical member to be fitted at a cylindrical part of the annular member is disclosed. The sealing structure is characterized by an elastic annular seal layer integrally provided on the backward end part of the annular member or the cylindrical member in fitting direction, by applying elastomeric agent to the backward end part and hardening it, and the elastic annular seal layer is formed such that it has layer thickness of 5 [mu]m to 1 mm and is interposed in a compressed state between the annular member and the cylindrical member when the annular member is fitted to the cylindrical member.

Owner:UCHIYAMA MFG

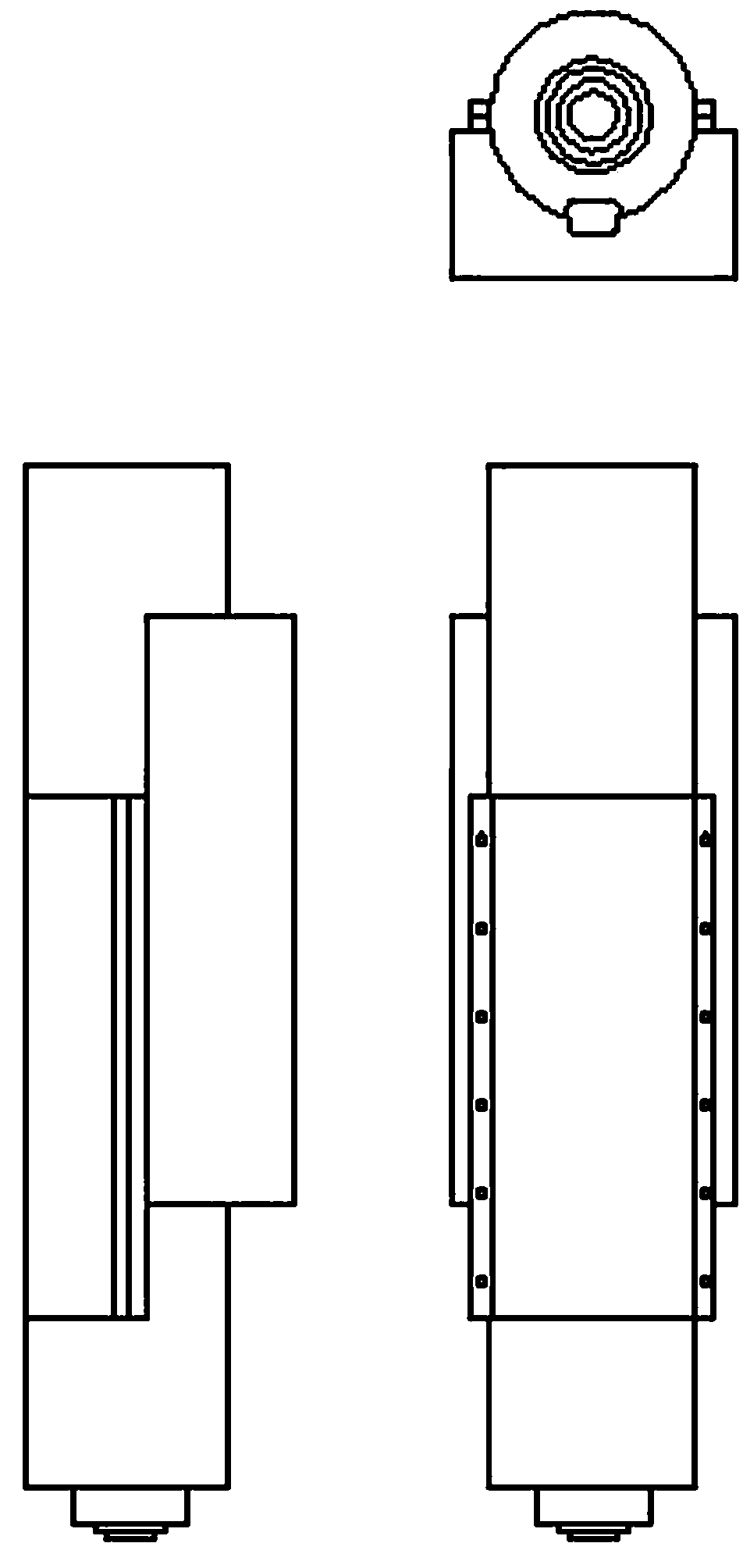

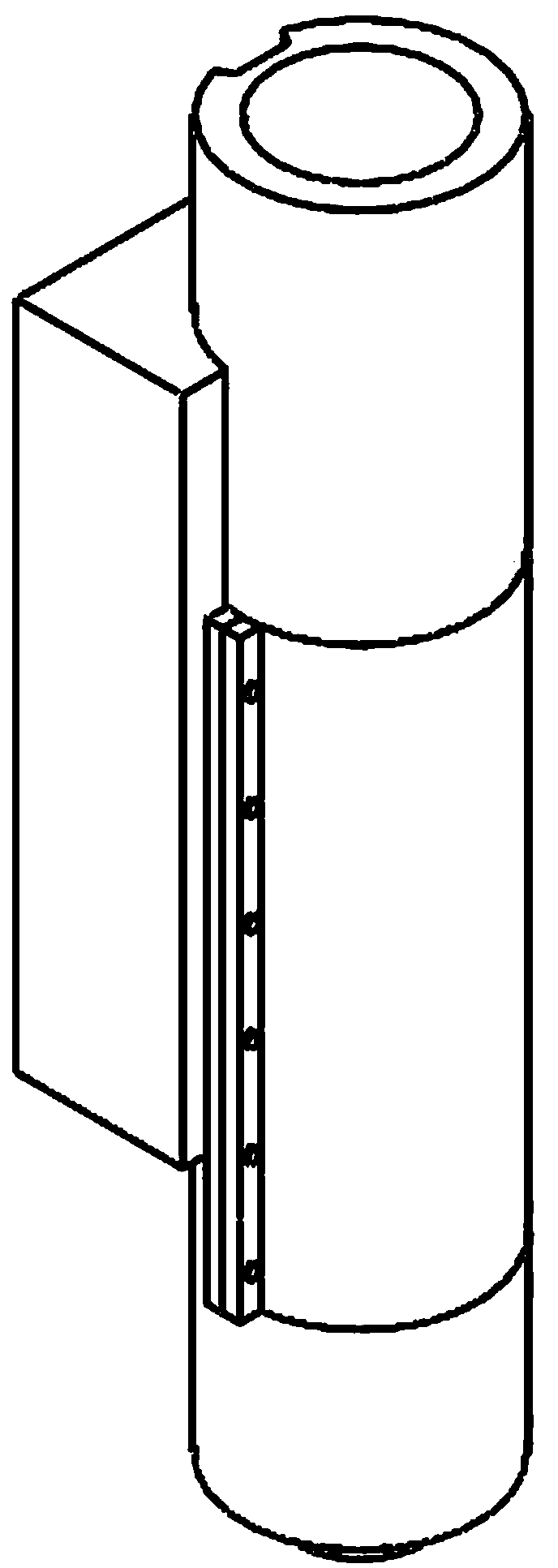

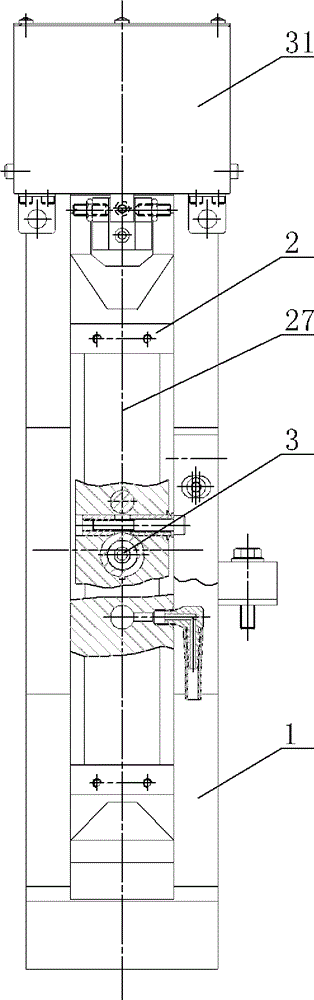

Ram component on processing machine tool

InactiveCN103465036AInfluence of machining accuracyReduce the impact of machining accuracyLarge fixed membersThermal deformationEngineering

The invention discloses a ram component on a processing machine tool. The ram component comprises a ram, a ram base, a jacket, a main shaft and a rotary driving mechanism, wherein the ram and the ram base are connected in a sliding fit manner, and the jacket is arranged at one end of the ram. As the ram adopts the thermal symmetrical structure of an axially hollow cylinder, the influence of thermal deformation on the processing precision of the machine tool can be reduced. The rotary driving mechanism directly drives the main shaft to rotate, so that the traditional mode that the main shaft is driven mainly by an external motor through a speed reduction box can be changed, and further the processing precision of the machine tool can be improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

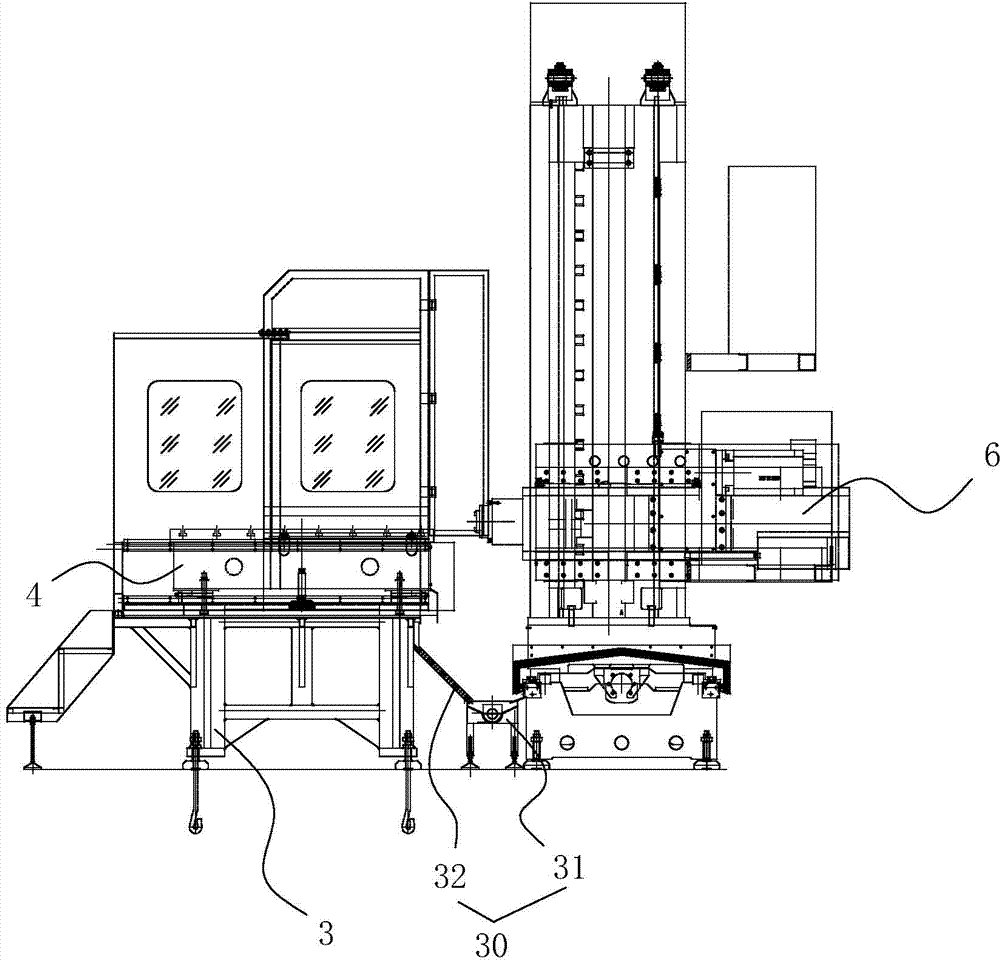

Floor machining center ram

ActiveCN104511752AImprove machining accuracyInfluence of machining accuracyLarge fixed membersEngineeringMachining

The invention discloses a floor machining center ram. The ram comprise a spindle box, a gear box and a counter weight. The counter weight and the spindle box are in an integrated structure. A gear box mounting groove for mounting the gear box is formed between the spindle box and the counter weight. A through hole communicated with the spindle box is formed in one side of the gear box mounting groove close to the spindle box, and an upper sliding rail and a lower sliding rail for enabling the ram to slide in the sliding rail are arranged on the upper and lower sides of the gear box. The thicknesses of planes where the upper sliding rail and the lower sliding rail are disposed are different, and the upper sliding rail and the lower sliding rail are disposed in the different planes to form a triangular structure. By means of the ram, the ram stress performance can be improved effectively.

Owner:昆山华都精工精密机械股份有限公司

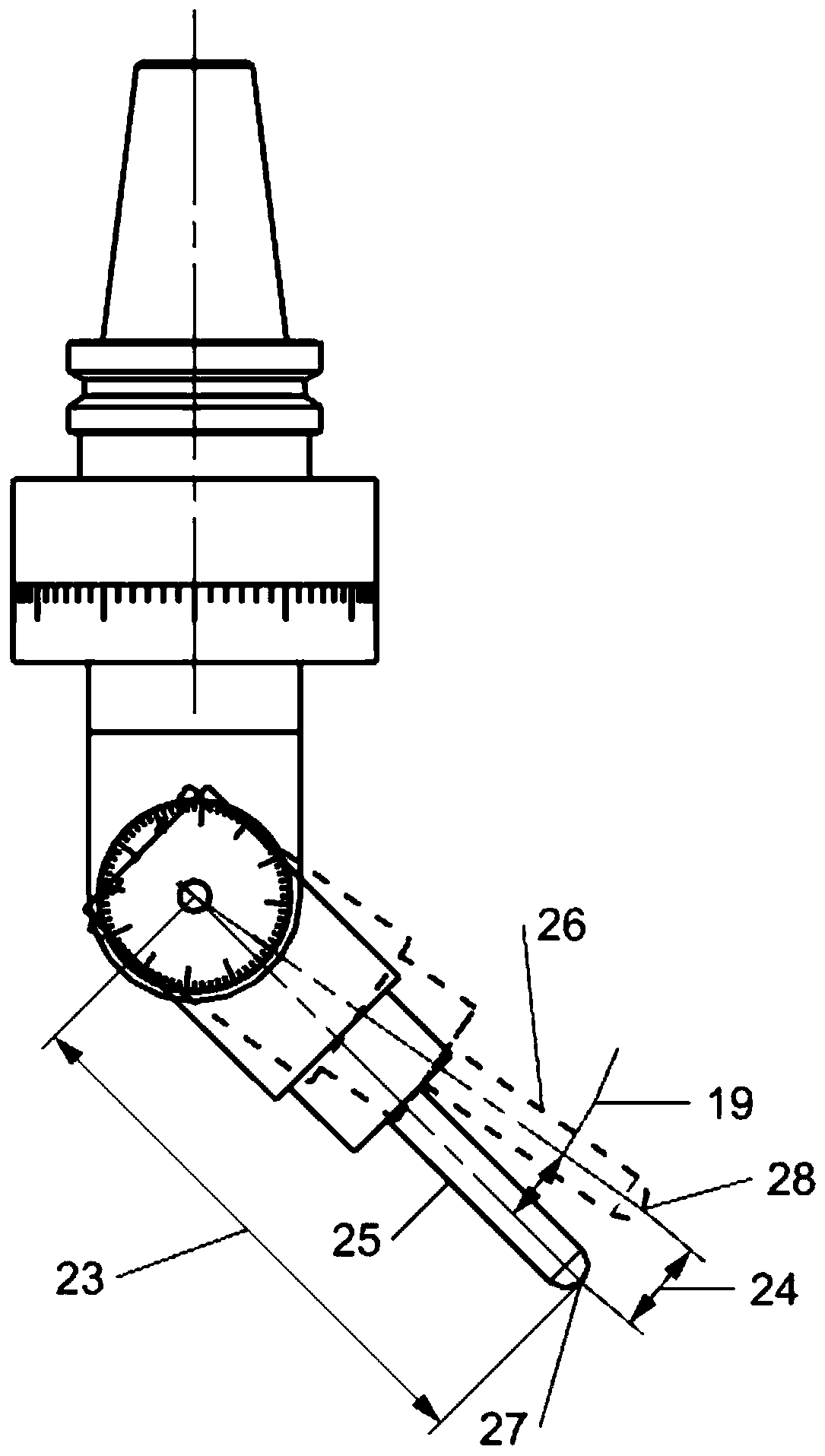

Using method for universal angle milling head

PendingCN110928234AReduce manufacturing precisionReduce assembly accuracyComputer controlSimulator controlRotational axisEngineering

The invention discloses a using method for a universal angle milling head, which comprises the following steps of: 1, manufacturing a machining program of a workpiece, and selecting a cutter locationpoint as a sphere center of a cutter when the program is output; 2, aligning and installing a standard square block on a machine tool, and determining the center point of the upper surface of the square block as the origin of a reference coordinate system; 3, installing the workpiece, measuring the position difference between the original point of the workpiece coordinate system and the original point of the reference coordinate system, taking the position difference as the offset value of the original point of the reference coordinate system and the original point of the workpiece coordinatesystem, and recording the offset value in a numerical control system for subsequent conversion from the original point of the reference coordinate system to the original point of the workpiece coordinate system; 4, importing the machining program into a machine tool, and manually setting the angles of the two rotating shafts on the universal angle head as cutter shaft angles specified in the machining program; 5, setting a tool on the original point of the reference coordinate system by taking the sphere center of the tool as a tool setting point, and establishing a current reference coordinate system; and 6, starting a machining program, and starting machining. According to the invention, the influence of angle deviation of manually operating the universal head on machining is eliminated.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

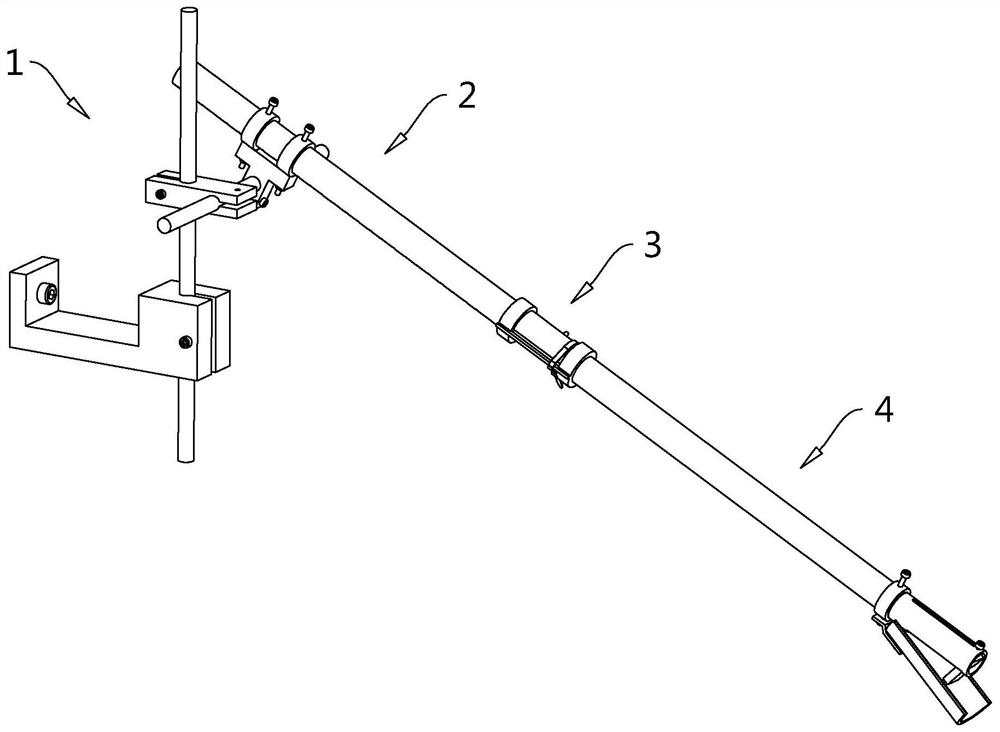

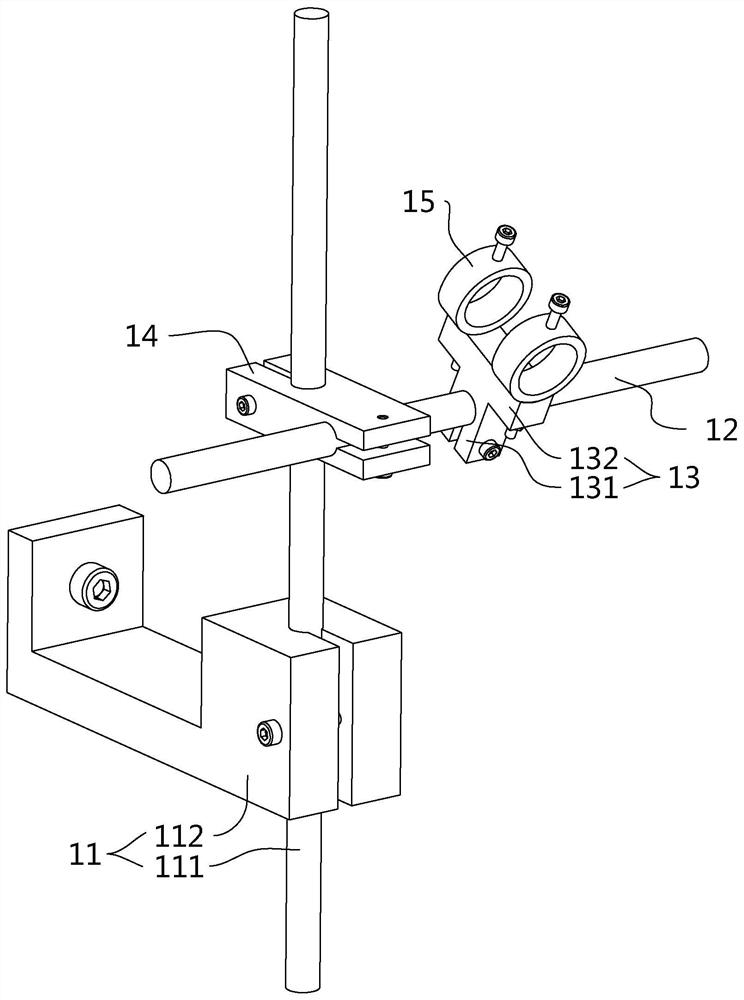

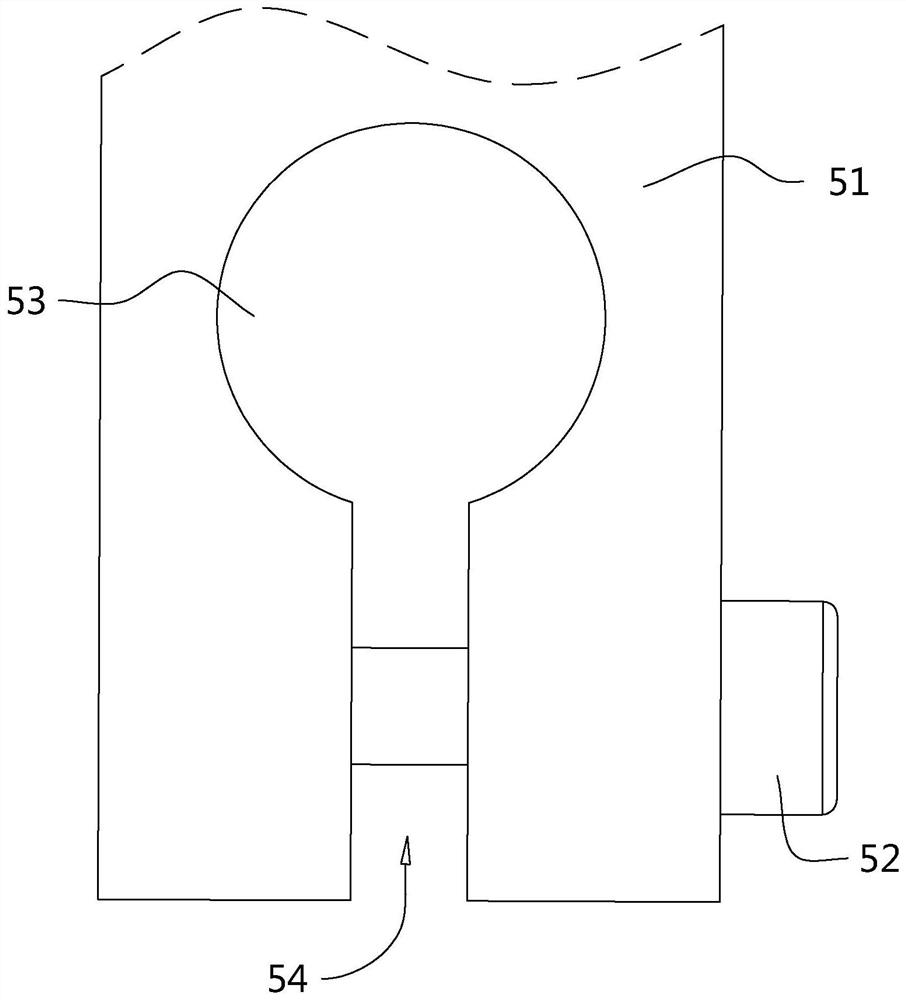

A modular parachute bay system for an unmanned aerial vehicle

The invention relates to a modular parachute bay system for an unmanned aerial vehicle, solving the problem that the unmanned aerial vehicle parachute bay system is not convenient to use, and the preparation and assembly process is complicated. The parachute bay system comprises a parachute bay, a hatch cover, a steering gear, a steering gear adapter, a rocker arm, a front latch and a rear hook, wherein the steering gear, the rocker arm and the steering gear adapter are assembled(the above three constitute the steering gear system) and fixed on the front side wall of the parachute bay, the front locking fastener and the rear hook are fixed on the hatch cover, the interaction between the steering gear system and the front locking fastener ensures the front locking of the hatch cover, and the interaction between the rear hook and the hook hole of the parachute bay ensures the rear locking of the hatch cover. The invention has the advantages of simple structure, good operation convenience, low complexity, high locking and releasing reliability, realizes that the parachute bay system designed by the modularization can complete the preparation work independently of the unmanned aerial vehicle body system, and the modularization design can realize the modularization production of the parachute bay system, and is no longer influenced by the machining precision of the body and the like.

Owner:CHANGGUANG SATELLITE TECH CO LTD

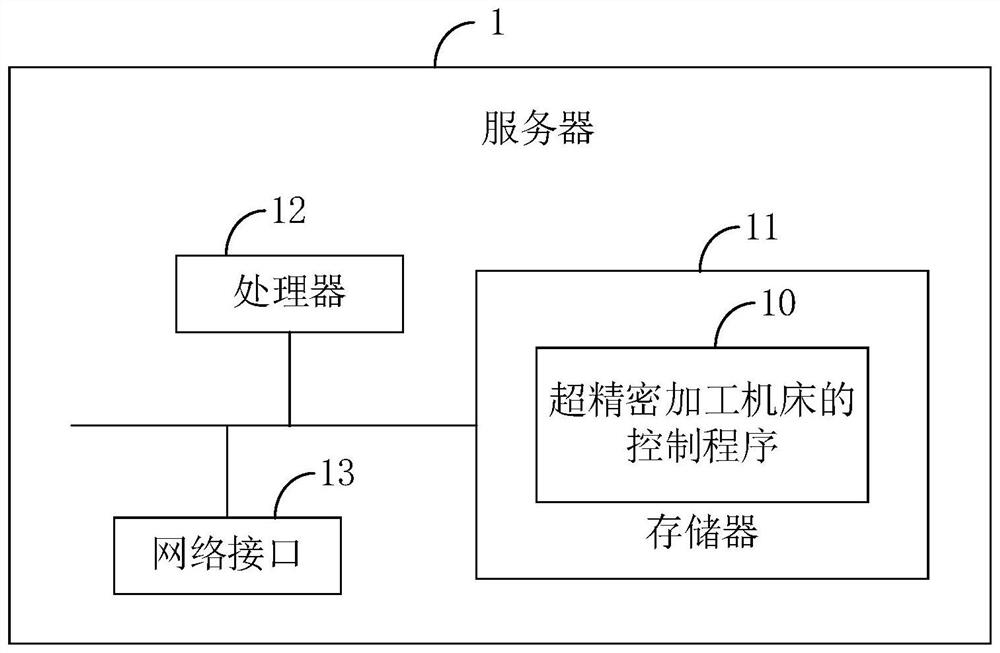

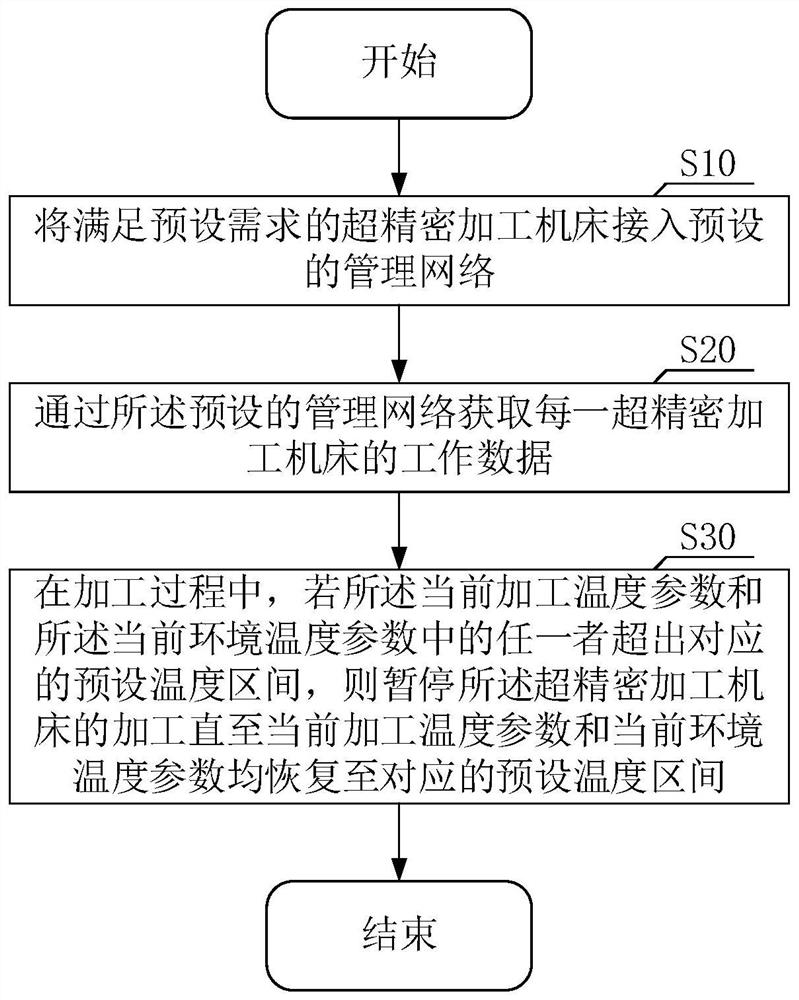

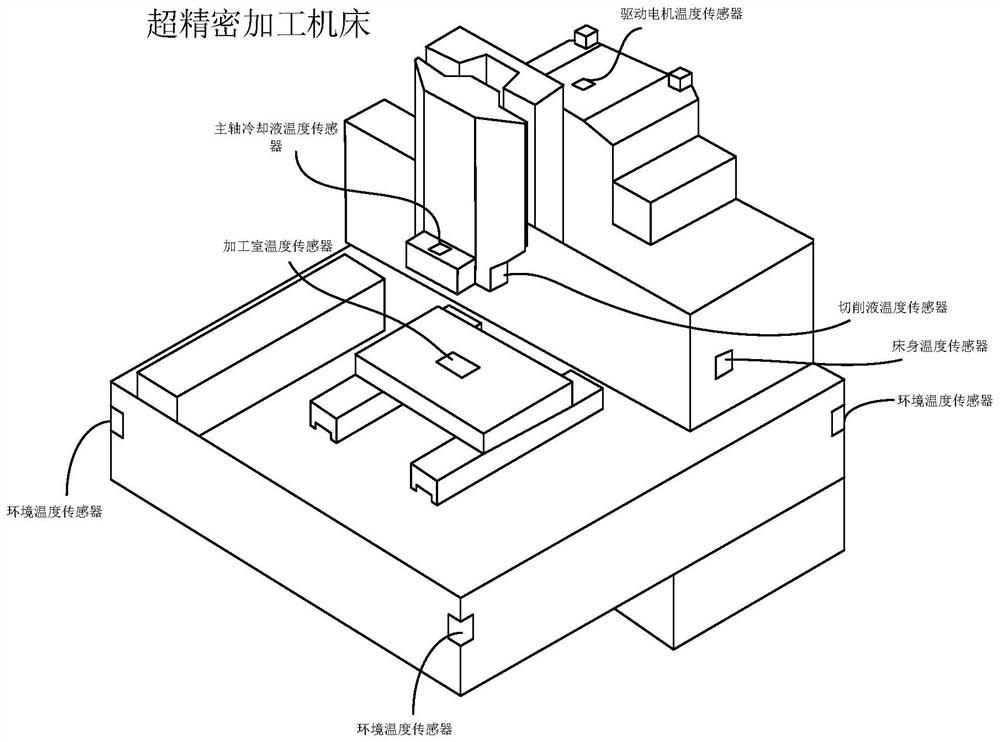

Control method and equipment of ultra-precision machining machine tool and computer readable storage medium

PendingCN113977347AGuaranteed machining accuracyInfluence of machining accuracyAutomatic control devicesMechanical apparatusProcess engineeringMachining process

The invention discloses a control method and equipment of an ultra-precision machining tool and a computer readable storage medium. The method comprises the steps of connecting ultra-precision machining tools meeting a preset requirement to a preset management network; obtaining working data of each ultra-precision machining machine tool through the preset management network, wherein the working data comprises a current machining temperature parameter and a current environment temperature parameter of the ultra-precision machining machine tool in the machining state obtained in real time; and in the machining process, if any one of the current machining temperature parameter and the current environment temperature parameter exceeds the corresponding preset temperature interval, rapidly adjusting the temperature control system so as to enable the current machining temperature parameter and the current environment temperature parameter to be restored to the corresponding preset temperature interval. The method has the advantage of guaranteeing the machining precision of the ultra-precision machining machine tool.

Owner:深圳市万嘉科技有限公司

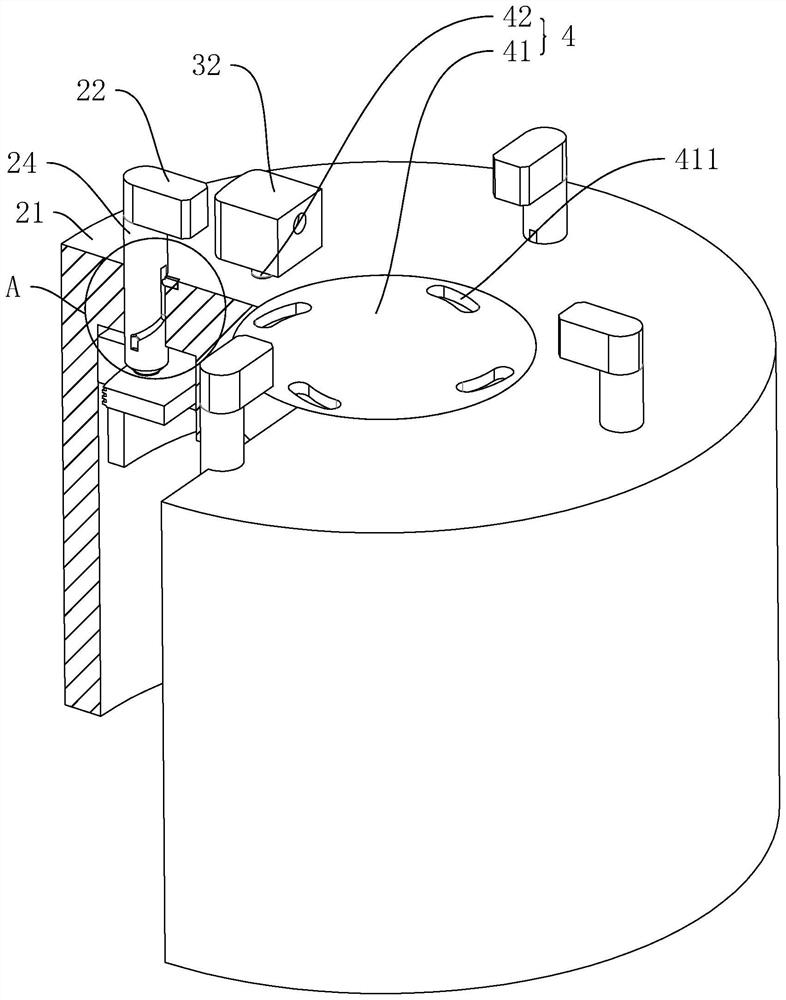

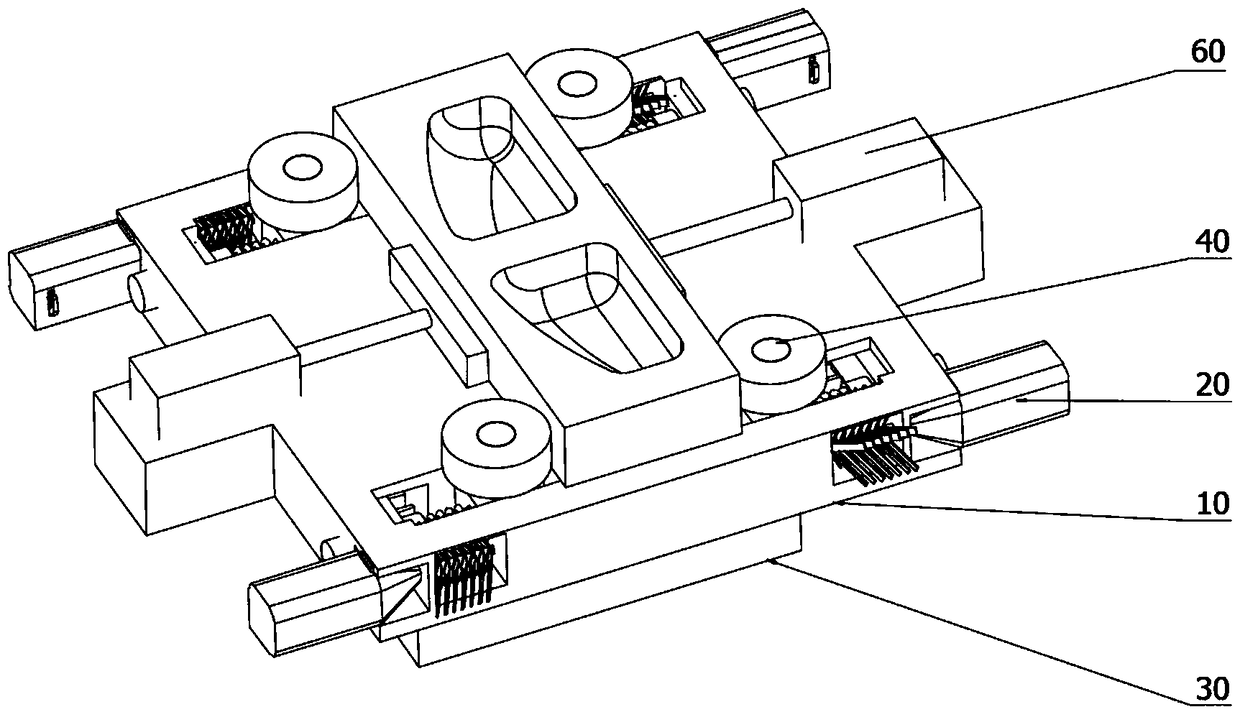

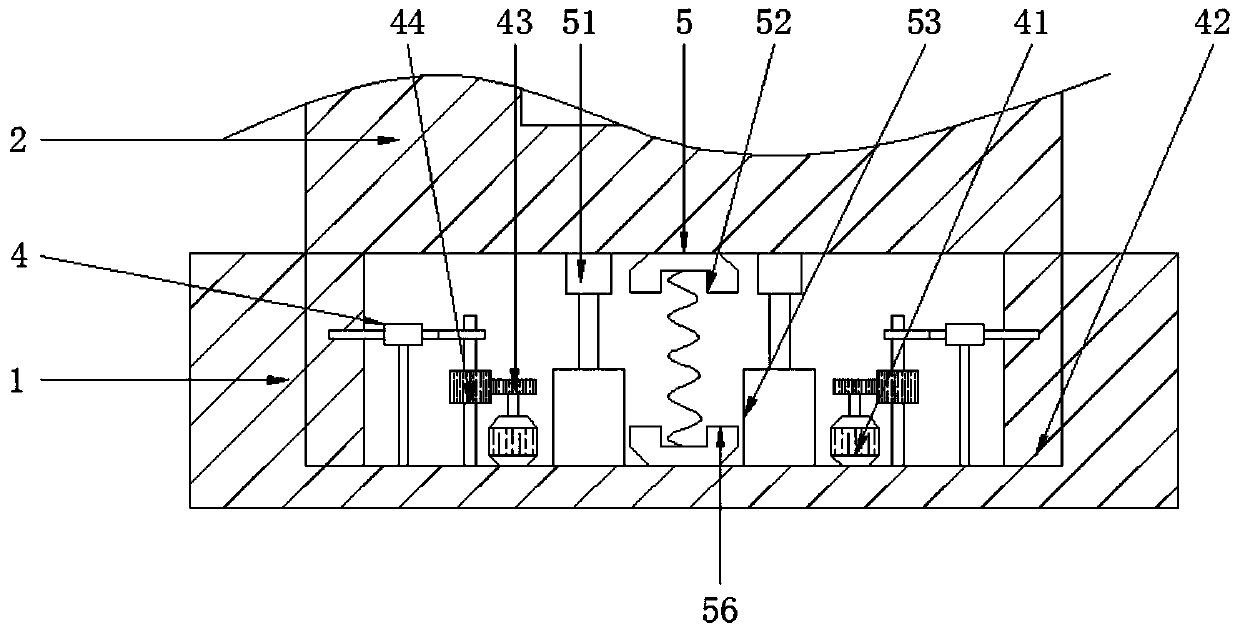

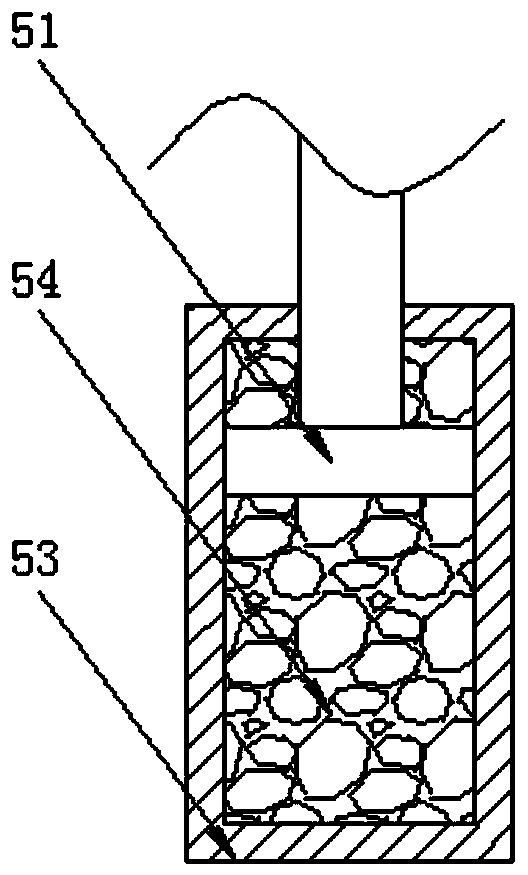

Efficient machining equipment and machining process for high-strength flange

PendingCN114769684AImprove processing efficiencyInfluence of machining accuracyLarge fixed membersMilling equipment detailsEngineeringMachine

The efficient machining equipment comprises a milling machine, a fixed seat, a rotating seat, a rotating piece and clamping mechanisms, the clamping mechanisms are arranged on the two sides of the rotating axis of the rotating seat, the rotating piece is arranged on the fixed seat, and the driving end of the rotating piece is connected with the rotating seat; the clamping mechanism comprises a clamping seat, a plurality of clamping blocks arranged on the clamping seat and a clamping driving part for driving the clamping blocks to move, the clamping blocks move perpendicular to the rotating axis of the rotating seat, and the end faces, close to the clamping seat, of the clamping blocks can abut against the end faces, away from the clamping seat, of the workpieces. Clamping mechanisms used for clamping workpieces can be arranged on the two side walls, away from each other, of the rotating base, at the moment, when the milling machine machines the workpieces clamped on one clamping mechanism, the other clamping mechanism can be used for taking and feeding the workpieces, and at the moment, the situation that the milling machine stops during taking and discharging is avoided; therefore, the overall efficiency of flange machining is improved.

Owner:嘉兴市智刃机械设备有限公司

Cleaning and flushing device for machining table of numerical control milling machine

InactiveCN111993153ASpeed up coolingTimely coolingCleaning using toolsCleaning using gasesElectric machineryDrive motor

The invention discloses a cleaning and flushing device for a machining table of a numerical control milling machine. The cleaning and flushing device comprises a functional box, wherein a treatment cavity with a forward opening is formed in the functional box, hidden cavities with opposite openings are formed in the left side wall and the right side wall of the treatment cavity, driving motors arefixedly connected to the inner walls of the hidden cavities, the ends, close to each other, of the driving motors are in power connection with driving shafts, and the ends, close to each other, of the driving shafts are fixedly connected with transverse screw rods. According to the cleaning and flushing device, when the numerical control milling machine is used for machining workpieces and blanks, waste chips and waste liquid on the surface of the machining table can be cleaned and removed in time, so that the cleanliness and tidiness of the machining table are guaranteed; and the machining table and the machined workpieces are flushed while the waste chips and the waste liquid are removed, so that the workpieces are cooled, the machining precision of the workpieces cannot be influenced by the waste chips and the waste liquid through timely cleaning and flushing of the machining table, the workpieces can be cooled in time, the machining efficiency is improved, and the precision requirement is improved.

Owner:台州市天枢机械科技有限公司

A Small Splash-Proof Safety Benchtop Drilling Machine

ActiveCN107649939BAvoid harmGuaranteed cleanlinessMaintainance and safety accessoriesEngineeringMachining process

The invention belongs to the technical field of table-type drilling machine equipment and particularly relates to a small splash-proof safe table-type drilling machine. According to the small splash-proof safe table-type drilling machine, a splash-proof device is arranged on the periphery of a work table and is of a box body structure, and an electromagnetic block is mounted on the side wall of the splash-proof device; a headstock of the drilling machine is located above the splash-proof device, a drill bit extends into the position, inside the splash-proof device, above the work table from anopening in a top cover of the splash-proof device, and the splash-proof device is further internally provided with a dust receiving box capable of being taken out; and a transparent observation doorplate is arranged on the front portion of the splash-proof device and provided with an electromagnetic safety lock. According to the table-type drilling machine, the situation that iron scraps generated in the drilling process hurt a human body can be prevented, accurate control over the machining process is facilitated, the machining accuracy of the drilling machine can be improved, and the cleantable face of the equipment can be kept.

Owner:安徽昕悦铸造科技有限公司

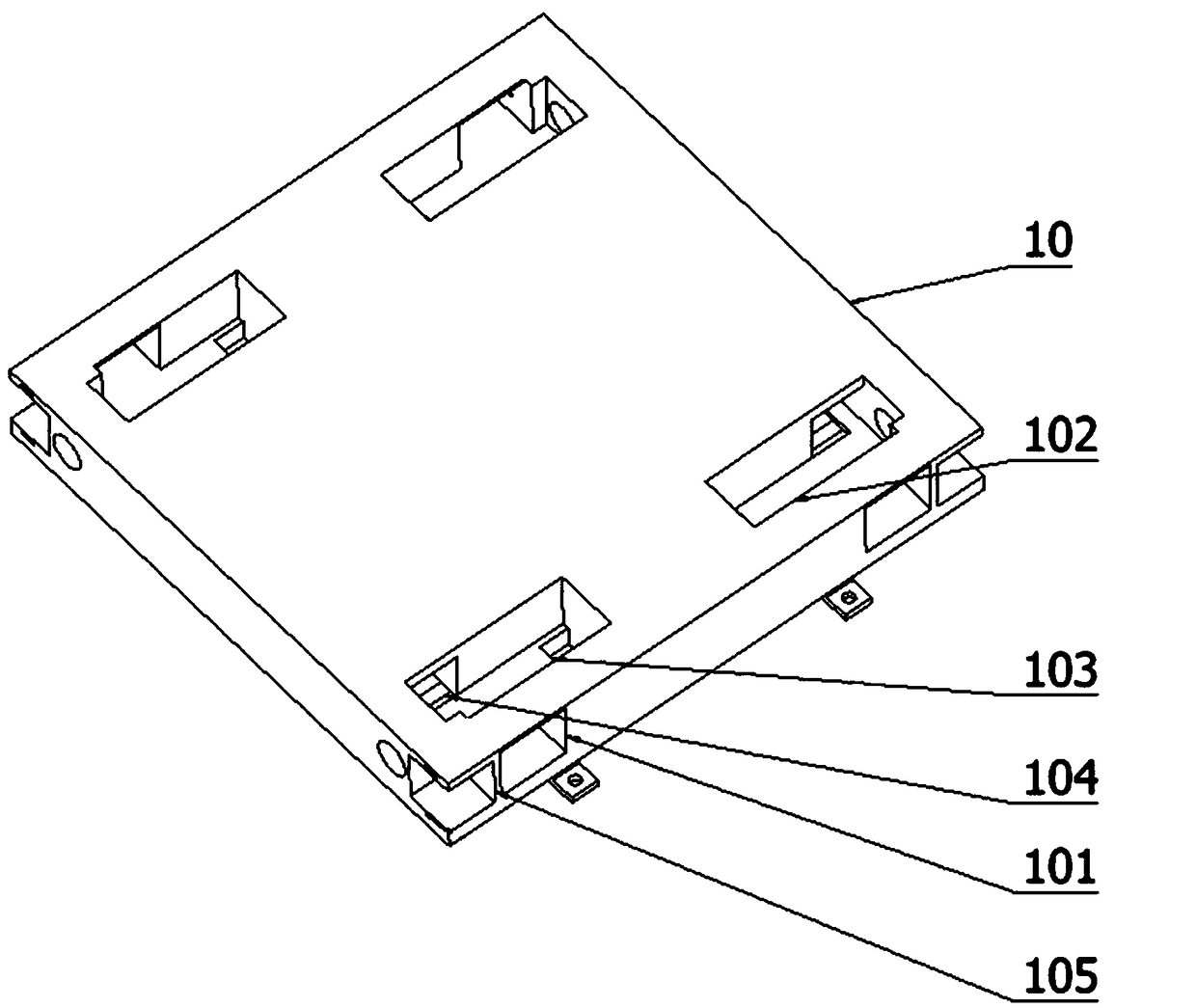

Auxiliary positioning device for automobile die machining and using method thereof

PendingCN109382439AAvoid displacementInfluence of machining accuracyShaping toolsEngineeringMachining

The invention discloses an auxiliary positioning device for automobile die machining and a using method thereof, and relates to the field of die machining. The device comprises an upper placement plate, a lower placement plate, a first push plate, a second push plate, a plurality of fixing pieces fixedly connected to the two ends of the first push plate and the second push plate, a plurality of positioning elastic devices, a plurality of sliding blocks connected with the fixing pieces through positioning elastic devices, a first pulley, a second pulley, a third pulley and a fourth pulley; thefirst pulley, the second pulley, the third pulley and the fourth pulley are installed on the sliding blocks; an automobile die is fixed through a fixing device; the first pulley, the second pulley, the third pulley and the fourth pulley are attached to the two edges of the automobile die to achieve the auxiliary positioning effect; when it is necessary, the automobile die can move under the guiding effect of the first pulley, the second pulley, the third pulley and the fourth pulley when the fixing device is in the loosened state.

Owner:鑫望威科技有限公司

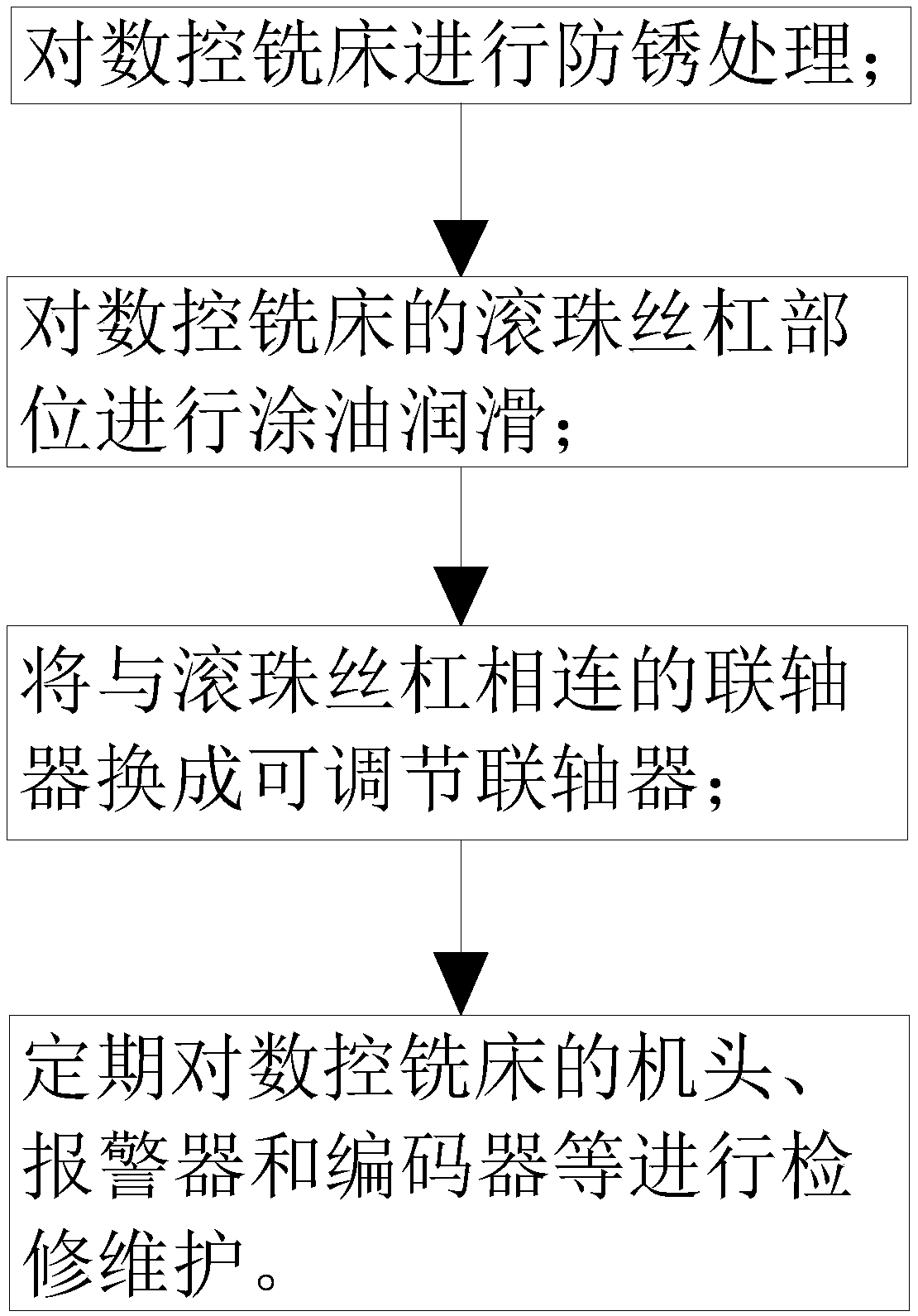

Method for prolonging service life of numerical control milling machine

ActiveCN108788903AExtend your lifeExtended service lifeMilling machinesMaintainance and safety accessoriesNumerical controlCoupling

The invention belongs to the technical field of numerical control milling machines and particularly relates to a method for prolonging the service life of a numerical control milling machine. The method comprises the following steps of conducting rustproof treatment on the numerical control milling machine; greasing and lubricating a ball screw part of the numerical control milling machine; replacing a coupling connected with the ball screw with an adjustable coupling; and conducting overhauling and maintenance on a machine head, a warning device, an encoder and the like of the numerical control milling machine periodically. The method plays a crucial role in prolonging the service life of the numerical control milling machine. The method is applicable to various types of numerical controlmilling machines.

Owner:浏阳市明诚竹业有限公司

A machining center spindle motor connecting plate

ActiveCN112152380BTemperature controlPrevent thermal deformationAssociation with control/drive circuitsEmergency protective arrangements for automatic disconnectionOil canElectric machine

The invention discloses a connecting plate for a spindle motor of a machining center, which includes a connecting plate main body, a sealing cover is arranged on the top of the connecting plate main body, and the sealing cover and the connecting plate main body are threadedly connected by a plurality of inner hexagonal bolts. There is an oil groove inside the main body of the connecting plate, and the oil groove is distributed in a U shape inside the main body of the connecting plate, and the two ends of the oil groove are respectively provided with an oil inlet and an oil outlet, and an axial sealing ring and an oil outlet are arranged inside the main body of the connecting plate. A radial sealing ring, the axial sealing ring is arranged at the joint between the sealing cover and the main body of the connecting plate, and the radial sealing ring is arranged in the oil groove. The invention can inject cooling oil into the motor connection plate through the oil tank, oil inlet and oil outlet, and form a closed-loop cooling system inside the main body of the connection plate through external cooling oil, so as to control the surface temperature of the main body of the connection plate , The purpose of improving the processing accuracy of the equipment.

Owner:凯柏精密机械(嘉兴)有限公司

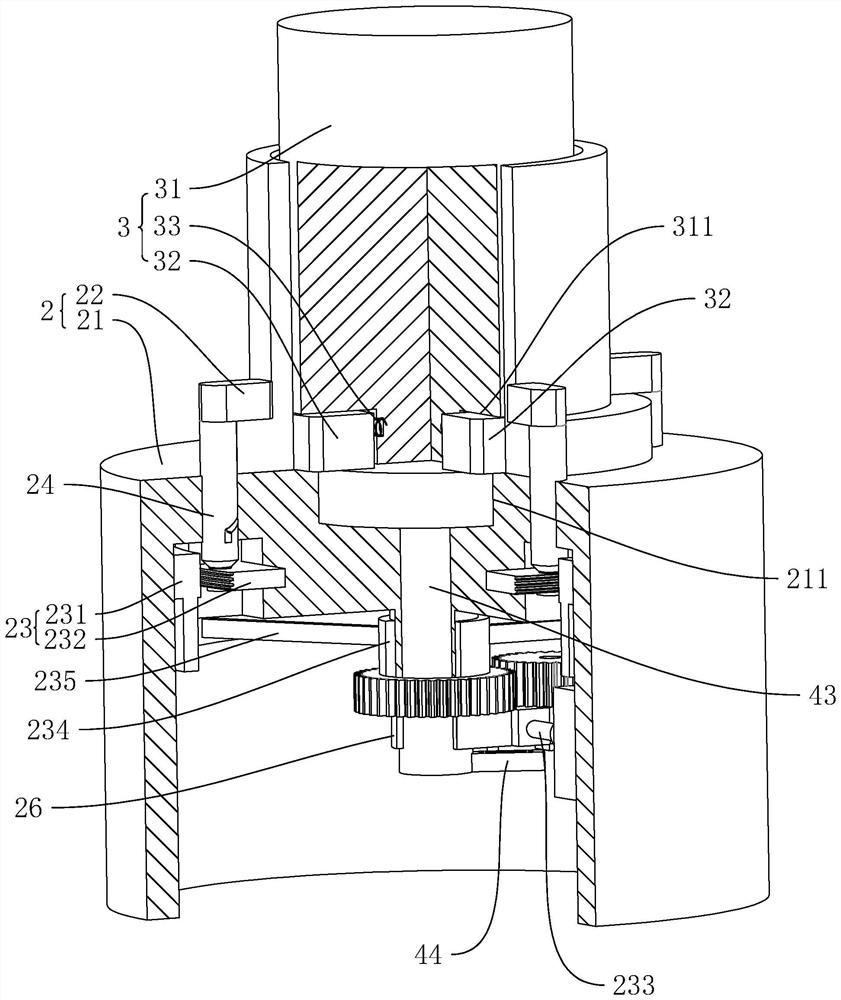

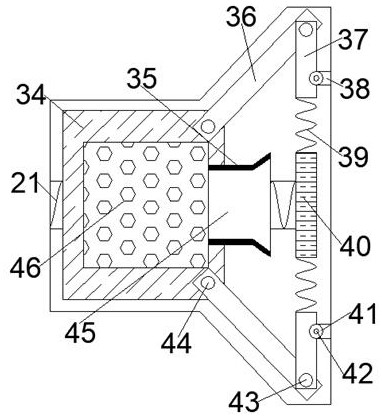

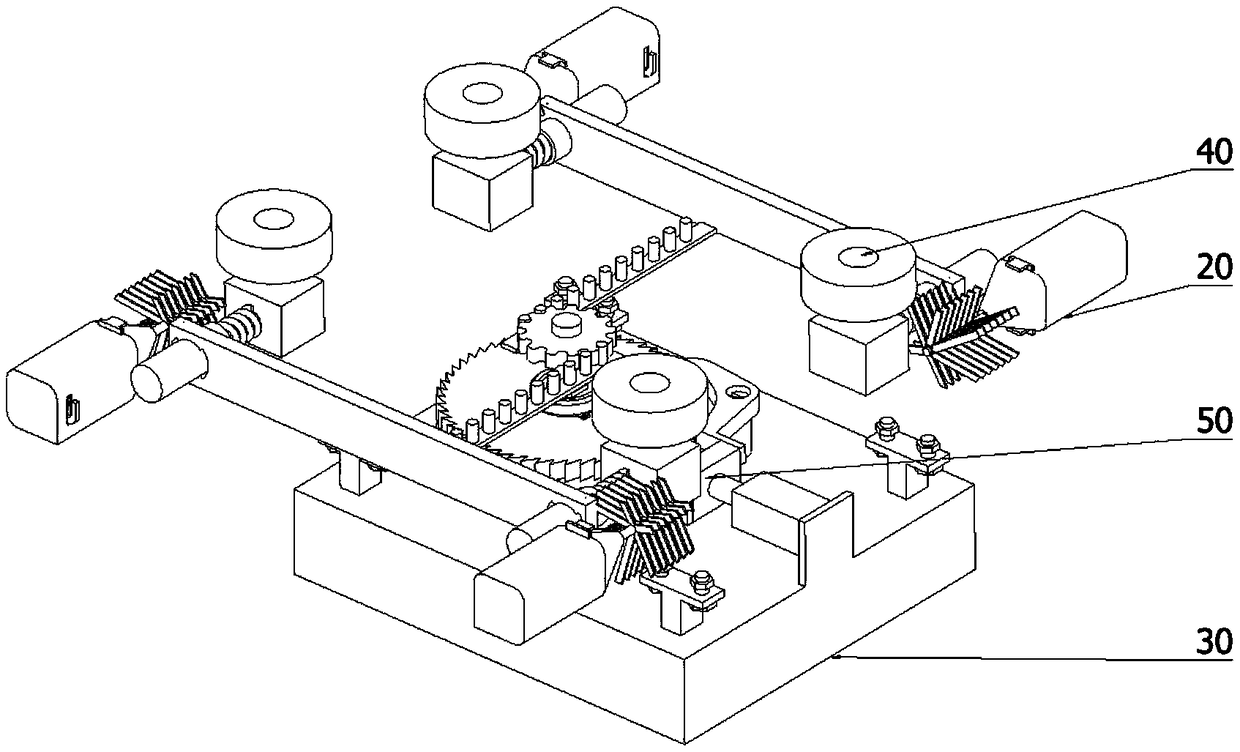

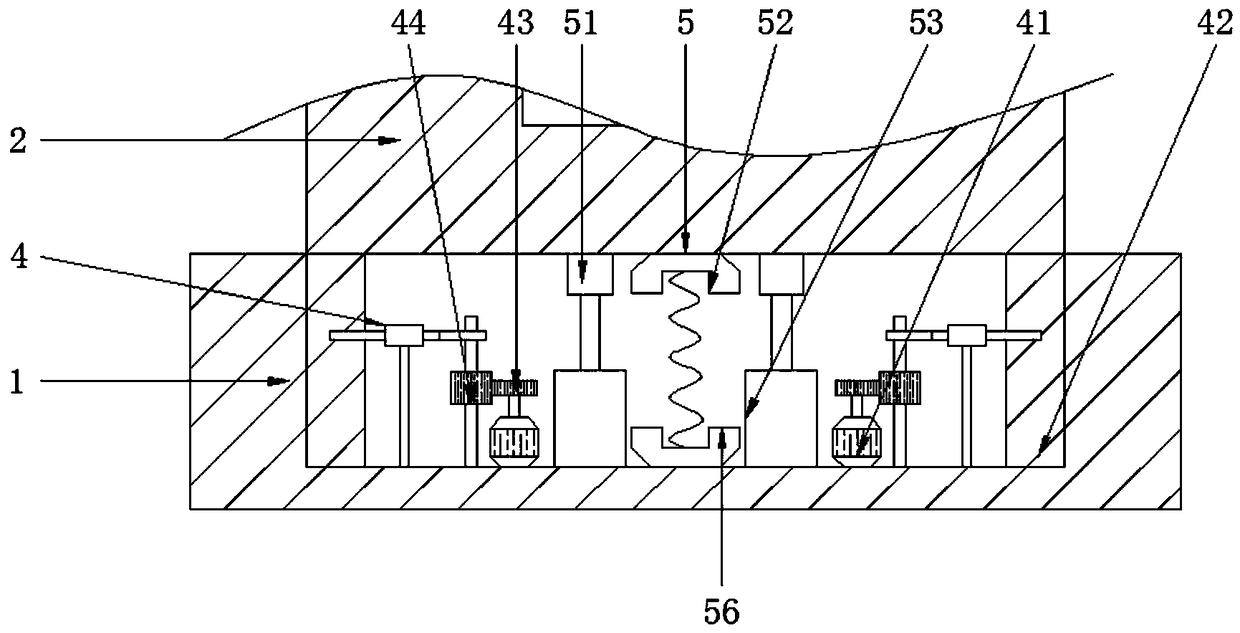

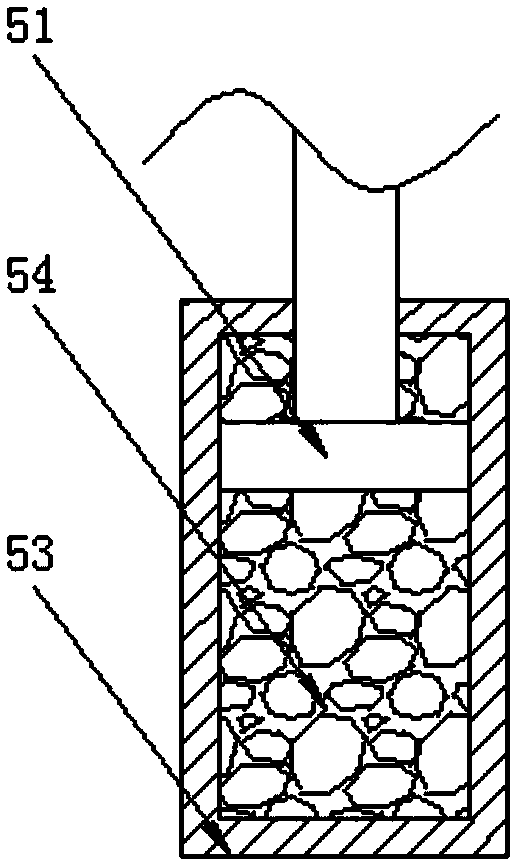

A shock absorbing device for a three-axis CNC intelligent forming machine tool

ActiveCN108655807BReduce the impact of swiping left and rightImprove machining accuracyMaintainance and safety accessoriesNumerical controlGear wheel

The invention discloses a shock absorbing device for a three-axis computer numerical control intelligent forming machine tool. The shock absorbing device comprises a mounting seat, a machine tool body, a moving assembly, an anti-sliding assembly, a first shock absorbing assembly, a second shock absorbing assembly, a box door, a warning light and an electric control box, wherein the top of the mounting seat is connected with the machine tool body through the anti-sliding assembly; the first shock absorbing assembly is mounted at the bottom of the machine tool body; and the anti-sliding assemblycomprises first servo motors, fixing plates, first spur gears, second spur gears, inserting grooves, inserting rods, ring-shaped fixing sleeves, supporting rods, second rotating shafts, eccentric gears, first rotating shafts, limiting grooves, reset springs and mounting grooves. By adoption of the shock absorbing device, the influence that the machine tool body slides left and right due to shockscan be reduced, and the machining accuracy can be improved; the influence that the machine tool body moves downward due to the gravity and shocks, and then the machining precision is lowered can be reduced; and the moving assembly on the machine tool body has the shock absorbing function, so that the accuracy of the mobile machining process can be improved.

Owner:南通迪蒙特科技有限公司

Roller conveying track and roller machining equipment applying same

ActiveCN112917264AFast and efficientAvoid enteringRevolution surface grinding machinesPlane surface grinding machinesStructural engineeringMachining

The invention relates to a roller conveying track and roller machining equipment applying the same. The roller conveying track comprises an adjusting support and a conveying pipe arranged on the adjusting support, the adjusting support comprises a supporting seat, a connecting rod and a fixing seat which are connected with one another, and the fixing seat is in sliding connection with the conveying pipe; and the connecting rod is horizontally arranged, and the fixing seat can rotate by taking the axis of the connecting rod as the axis. The roller conveying track has the effect of conveniently adapting to roller machining equipment with different discharging heights, and meanwhile can stably and efficiently remove waste produced by the roller machining equipment in the debugging stage .

Owner:宁波海亚特滚子有限公司

Abrasion-resistant cast iron plate part surface treatment method and application thereof

The invention provides an abrasion-resistant cast iron plate part surface treatment method and application thereof. The abrasion-resistant cast iron plate part surface treatment method comprises the steps that firstly, a cast iron plate is infiltrated with a carbonitride lanthanum yttrium ion infiltrating agent; the treated cast iron plate is activated with a lanthanum yttrium activation infiltrating agent; oxygen ion infiltrating is carried out with an oxygen ion infiltrating agent; and then, after cooling and cleaning are carried out, sealing treatment is carried out with a sealing agent, and soaking in oil is carried out. According to the abrasion-resistant cast iron plate part surface treatment method and the application thereof, the carbonitride lanthanum yttrium ion infiltrating agent is firstly used for infiltrating treatment to form a compound layer and diffusion layer with a certain thickness, the compound layer and the diffusion layer are composed of a carbonitride compound of metal elements and a solid solution of nitrogen in iron, the hardness and corrosion resistance are higher, the thickness of a compound infiltrating layer is increased, and the fatigue resistance ofthe plate is improved. According to the abrasion-resistant cast iron plate part surface treatment method, the temperature is low, the plate does not deform in the treatment process, the processing precision is not affected, and the effective infiltration of carbonitride lanthanum and yttrium ions can be ensured under a low temperature condition. The application of the surface treatment method in steel backing machining is further provided.

Owner:湖南红宇智能制造有限公司

Cross beam structure and machine tool having same

PendingCN111687648ASolve the stiffness problemSolve technical problems with deformationLarge fixed membersEngineeringMachine tool

The invention provides a cross beam structure and a machine tool having same. The cross beam structure comprises a first support portion and a second support portion, wherein the first support portionextends in a first preset direction, and is provided with a first support end and a second support end oppositely arranged; the second support portion is disposed on the first support portion, and extends in a second preset direction; the second preset direction and the first preset direction are arranged by a preset angle; the second support portion is provided with a connection end and a thirdsupport end oppositely arranged; the connection end is connected to the first support portion; and the third support end is positioned between the first support end and the second support end to implement supporting by means of the first support end, the second support end and the third support end, so that the technical problem of deformation caused by insufficient rigidity of a cross beam structure in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

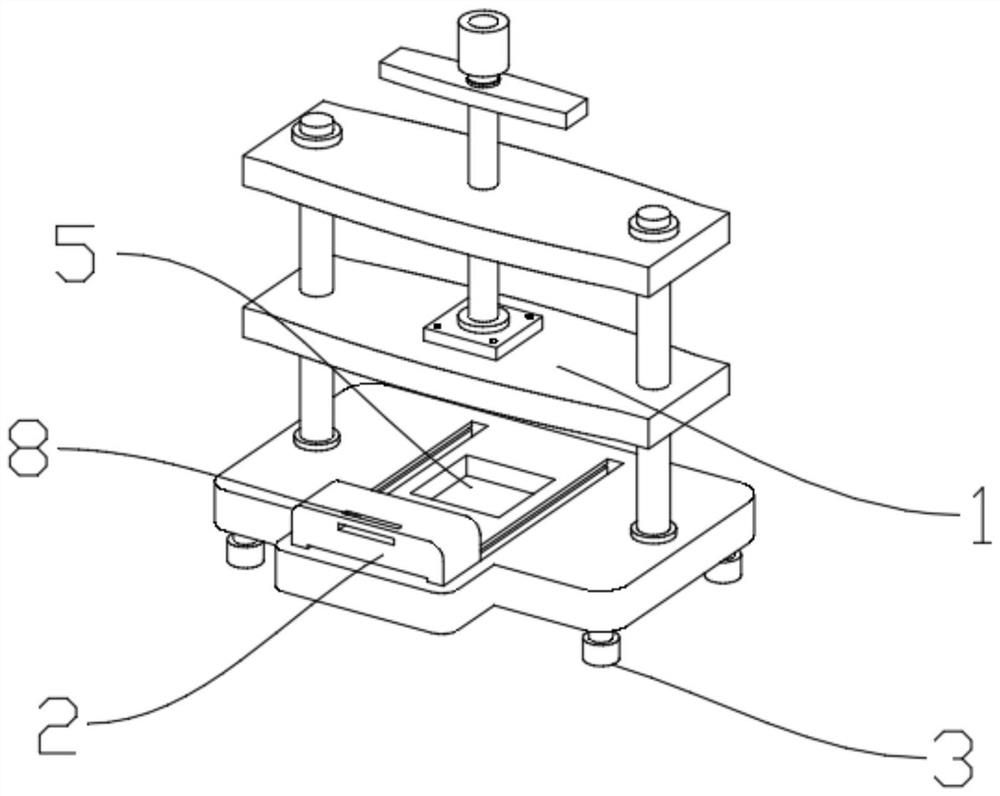

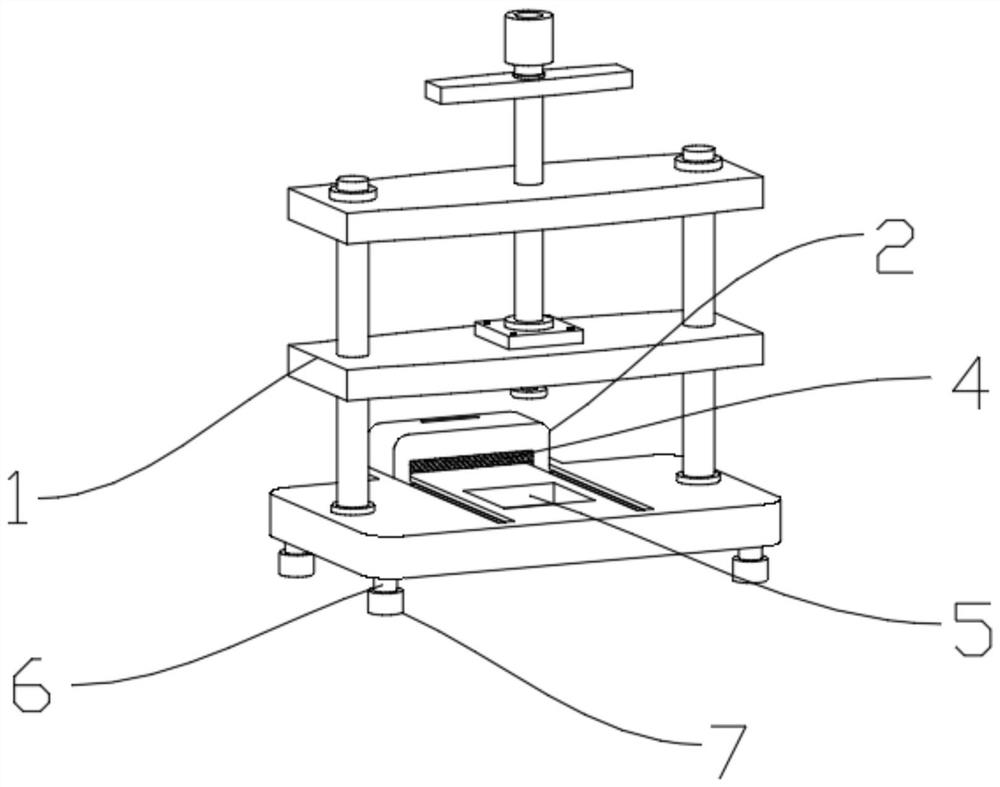

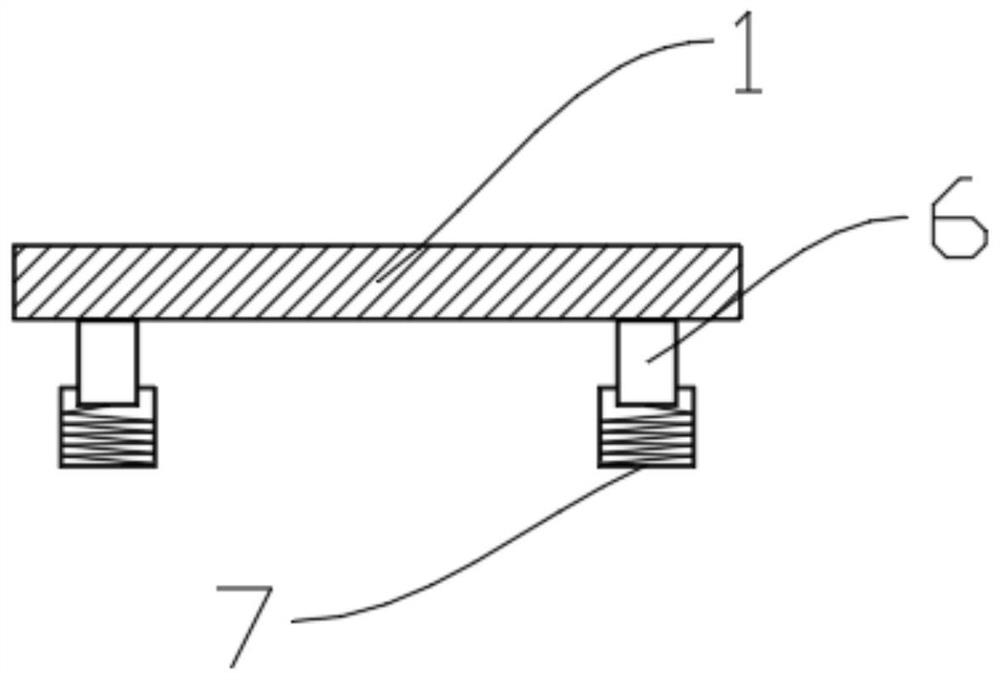

Automobile part press machine with high machining precision

PendingCN114872367AInfluence of machining accuracyEasy to push and pullPressesPush and pullEngineering

The invention discloses an automobile part press with high machining precision, and belongs to the field of press equipment, the automobile part press comprises a press main body, the press main body comprises a three-layer structure, the top end of the lowermost layer of the press main body is slidably connected with a cleaning block, and the bottom end of the lowermost layer of the press main body is fixedly connected with a plurality of buffer assemblies; a cleaning sponge is fixedly connected to the bottom end of the cleaning block, a fixing groove is formed in the corresponding position of the lowermost layer of the press machine body, the number of the buffer assemblies is four, each buffer assembly comprises an ejector rod, a foot pad and a spring, and a push-pull groove is formed in one side of the cleaning block, so that a worker can conveniently push and pull the cleaning block through the push-pull groove; and dust on the surfaces of the automobile parts is cleaned through the cleaning sponge at the bottom end of the cleaning block.

Owner:盐城市万顺汽车配件有限公司

Oscillating bar bearing structure of arc trimmer

InactiveCN104149031AInfluence of machining accuracyMotion trajectory influenceAbrasive surface conditioning devicesCircular coneEngineering

The invention provides an oscillating bar bearing structure of an arc trimmer. By means of the oscillating bar bearing structure, the upper end and the lower end of an oscillating bar can be on the same vertical axis, so that machining precision of a trimmer base cannot influence movement trails of a diamond pen and the manufacturing cost of the arc trimmer is low. The oscillating bar bearing structure comprises the trimmer base, the oscillating bar and the diamond pen, the middle of the oscillating bar is provided with the diamond pen, and the upper end and the lower end of the oscillating bar are located an upper end installation cavity and a lower end installation cavity of the trimmer base respectively. The oscillating bar bearing structure is characterized in that the convex position of the upper end and the convex position of the lower end of the oscillating bar are respectively provided with a cone frustum hole with inwards concave closing-in port, a steel ball structure is distributed in the cone frustum hole and comprises an upper steel ball and a lower end steel ball, the outer ring portion of an upper gland is fixedly connected with the upper wall of the upper end installation cavity of the trimmer base, and the center of the lower portion of the upper gland is provided with a cone frustum upper hole with an inward concave closing-in port.

Owner:WUXI MACHINETOOL

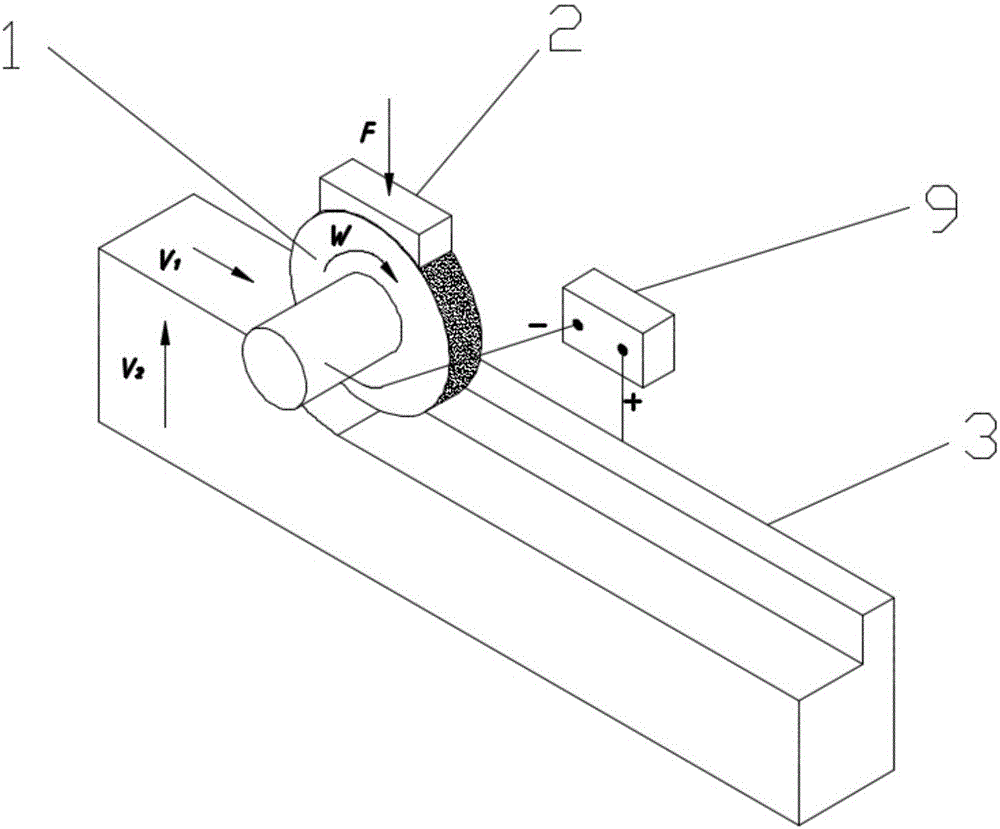

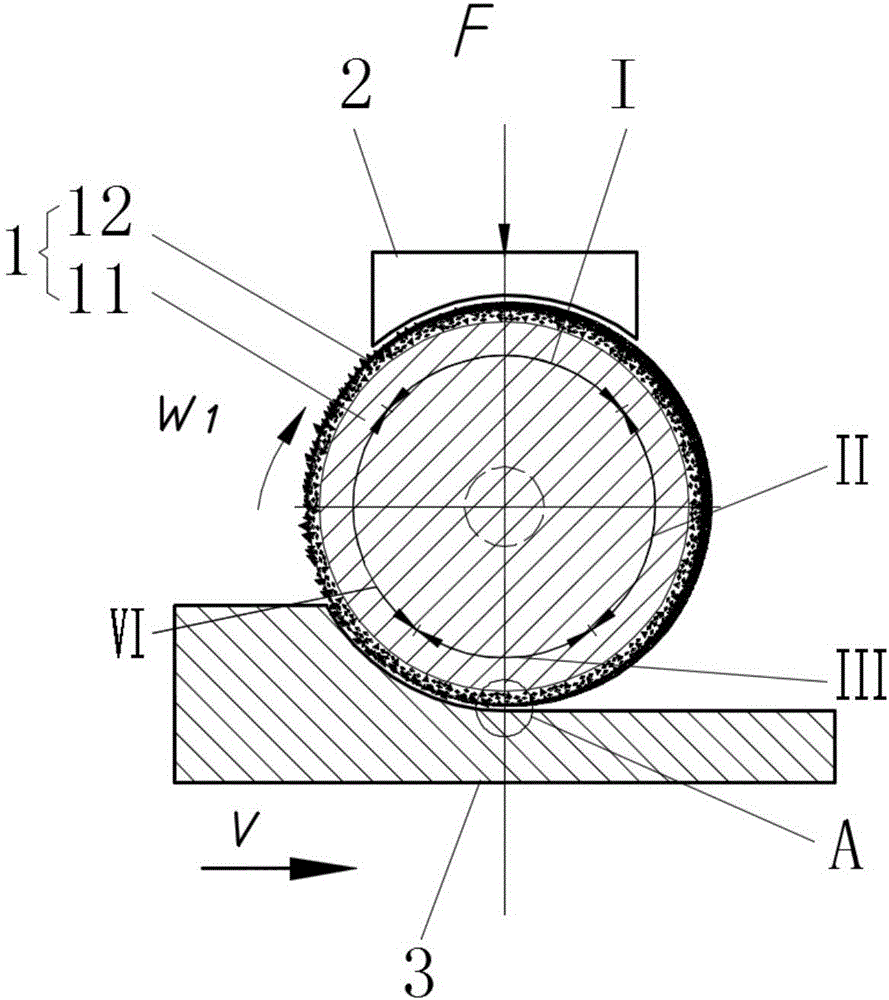

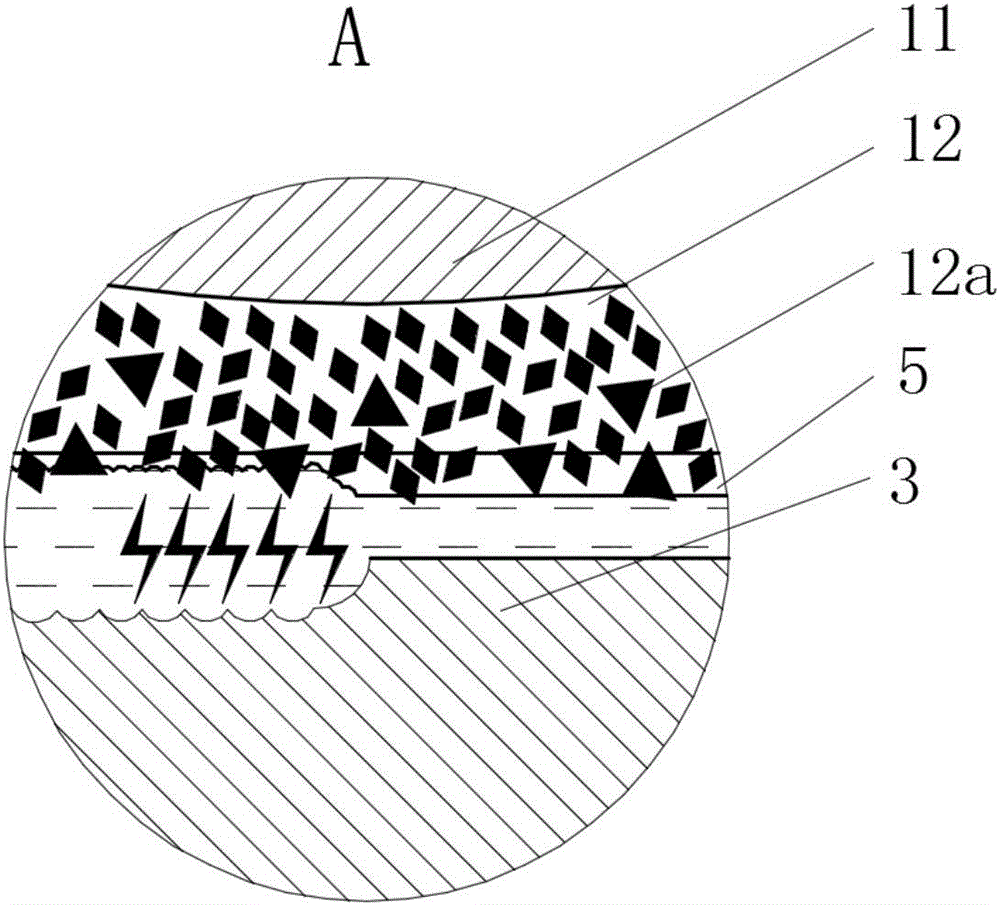

Milling type electrical discharge machining device for self-repairing tool electrode and method

InactiveCN106624216AExtended service lifeInfluence of machining accuracyElectrical-based machining electrodesMachining processElectrical discharge machining

The invention discloses a milling type electrical discharge machining device for a self-repairing tool electrode and a method. The device mainly comprises a tool electrode and a metal block, wherein the tool electrode comprises a metal substrate and an abrasive grain layer fixedly jointed on the surface of the metal substrate through a conductive abrasive grain binding agent; the tool electrode is capable of rotating around a self-axis and can move relative to a workpiece; the metal block is compressed on the abrasive grain layer of the tool electrode. In a use process, the metal block is milled by the rotating tool electrode; the chippings generated in the milling process are adhered to the abrasive grain layer of the tool electrode, so that a metal adhesion layer is formed; the adhesion layer is utilized to perform discharge machining; in the machining process, the loss of the adhesion layer is caused by the spark effect, but the lost adhesion layer is supplemented and reconstructed by the tool electrode in the manner of re-milling the metal block, so that the geometrical shape of the tool electrode can be timely recovered; the service life of the tool electrode is undoubtedly prolonged, the machining precision is increased and the machining cost is lowered.

Owner:GUANGDONG UNIV OF TECH

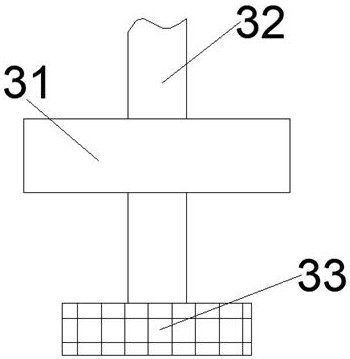

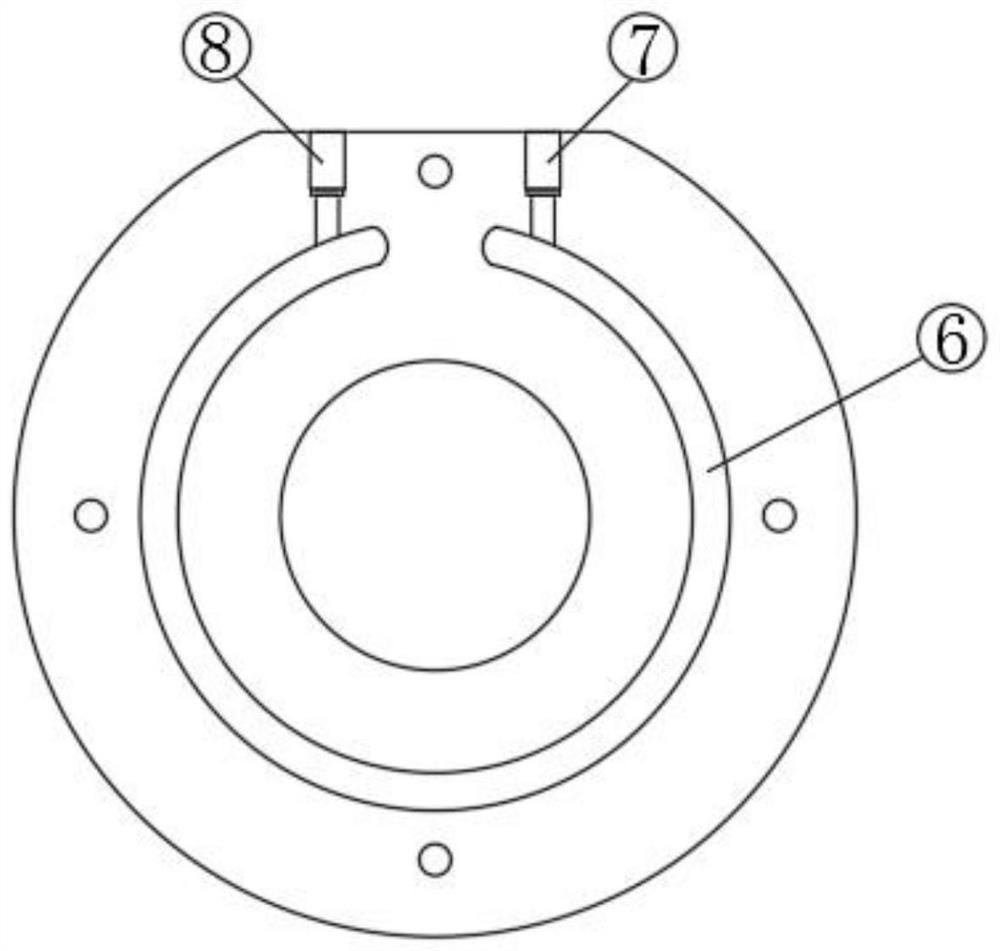

Machining device of grading wheel

ActiveCN106425542AImprove machining accuracyInfluence of machining accuracyWork clamping meansPositioning apparatusDynamic balanceEngineering

The invention discloses a machining device of a grading wheel. The machining device comprises a machining device body, wherein the machining device body comprises a fixed shaft, a separated pressing plate and a positioning disc; the machining device body is used for fixing the grading wheel; the grading wheel comprises a grading wheel hub, a grading wheel blade and a grading wheel end panel; the grading wheel blade is stuck on the grading wheel hub and the grading wheel end panel through super glue; the fixed shaft is used for fixedly connecting the grading wheel hub and the positioning disc through a locking nut; and the positioning disc and the separated pressing plate are used for fixing the grading wheel end panel through fixed bolts. The machining device of the grading wheel is reasonable in structural design and firm and reliable; in a production and machining process, the machining precision can be very easily realized, and the machining precision of the grading wheel is improved; and a condition that weight is increased or reduced excessively in a dynamic balance process so that the grading precision of powder is influenced is avoided.

Owner:大连环球矿产股份有限公司

A burr remover for cylinder lid surfaces

ActiveCN100464950CLow technical requirementsInfluence of machining accuracyEdge grinding machinesHeight differenceMechanical engineering

The invention relates to a device for removing the burr on the surface of cylinder cover. Wherein, it only needs 1.5min / n to complete the operation with one worker, to improve the produce efficiency and save cost. The invention comprises base and above work-piece support. The invention is characterized in that: said support has several pads and compressor at outer end, while at least one pad is movable and the compressor is connected to the fixer; the burr brush and power axle are above the device; the pad is step shaped whose inner high side is concave, while the height difference between high and low parts equals to the difference between height and width of cylinder cover.

Owner:江苏凯元科技有限公司

Shock absorbing device for three-axis computer numerical control intelligent forming machine tool

ActiveCN108655807AReduce the impact of swiping left and rightImprove machining accuracyMaintainance and safety accessoriesNumerical controlGear wheel

The invention discloses a shock absorbing device for a three-axis computer numerical control intelligent forming machine tool. The shock absorbing device comprises a mounting seat, a machine tool body, a moving assembly, an anti-sliding assembly, a first shock absorbing assembly, a second shock absorbing assembly, a box door, a warning light and an electric control box, wherein the top of the mounting seat is connected with the machine tool body through the anti-sliding assembly; the first shock absorbing assembly is mounted at the bottom of the machine tool body; and the anti-sliding assemblycomprises first servo motors, fixing plates, first spur gears, second spur gears, inserting grooves, inserting rods, ring-shaped fixing sleeves, supporting rods, second rotating shafts, eccentric gears, first rotating shafts, limiting grooves, reset springs and mounting grooves. By adoption of the shock absorbing device, the influence that the machine tool body slides left and right due to shockscan be reduced, and the machining accuracy can be improved; the influence that the machine tool body moves downward due to the gravity and shocks, and then the machining precision is lowered can be reduced; and the moving assembly on the machine tool body has the shock absorbing function, so that the accuracy of the mobile machining process can be improved.

Owner:南通迪蒙特科技有限公司

Flexible buffering punching machine

InactiveCN107199279AEffective vibration isolationInfluence of machining accuracyShaping toolsNon-rotating vibration suppressionHydraulic cylinderPunch press

A flexible buffer punch. Provided is a flexible buffer punch with simple structure and improved vibration isolation reliability. It includes a stamping machine, the stamping machine is set on the foundation through a vibration isolation mechanism, and the vibration isolation mechanism is: a vibration isolation groove is provided on the foundation, and the stamping machine is set on the vibration isolation structure through a counterweight platform. In the groove; the bottom surface of the vibration isolation groove is provided with accommodating groove one, and the counterweight platform is located in the accommodating groove one. Slopes are respectively provided on both sides of the lower part of the counterweight platform, so that the cross-section of the lower part of the counterweight platform is trapezoidal, and the counterweight platform is adapted to be arranged in the vibration isolation groove one; the bottom slope of the counterweight platform and the accommodation tank Corresponding semi-circular grooves are provided between the slopes of one, and round rollers are provided in adjacent semi-circular grooves; a gap is provided between the counterweight platform and the vibration isolation groove, and a hydraulic cylinder is provided in the gap. The invention is convenient for processing and reliable in operation.

Owner:高原

Adjustable precision increase device of radial drilling machine

InactiveCN108817444AAvoid damageImprove machining accuracyBoring/drilling componentsMaintainance and safety accessoriesData displayEngineering

The invention discloses an adjustable precision increase device of a radial drilling machine. The adjustable precision increase device structurally comprises a vibration type precision increase device, fixed balance blocks, an adjustable panel, a data display screen, adjusting buttons, a drill bit embedded opening, mounting locating holes and connecting mounting blocks. The drill bit embedded opening is arranged in the center of the vibration type precision increase device, and the drill bit embedded opening and the vibration type precision increase device are of an integrated structure. The fixed balance blocks are arranged on the outer wall of the vibration type precision increase device and are connected with the vibration type precision increase device in a welded manner. The adjustable panel is arranged on the outer wall of the vibration type precision increase device and is connected with the vibration type precision increase device in a fixed manner. The data display screen is electrically connected with the adjustable panel. The adjusting buttons are electrically connected with the adjustable panel. The adjustable precision increase device is provided with a structure for balancing the vibration frequency of the two sides of a drill bit in the drill bit rotating process, and the machining precision of the drill bit can be prevented from being influenced easily; and meanwhile, a structure of buffering and protecting a drill bit shell is arranged, and wear of a locating rack to the drill bit during use of the drill bit is effectively reduced.

Owner:黄红兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com