Sealing structure for fitting section

A technology of sealing structure and fitting part, which is applied to the sealing of engines, vehicle components, bearings of rotating motion, etc., can solve the problem of uncertain sealing performance, and achieve the effect of excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

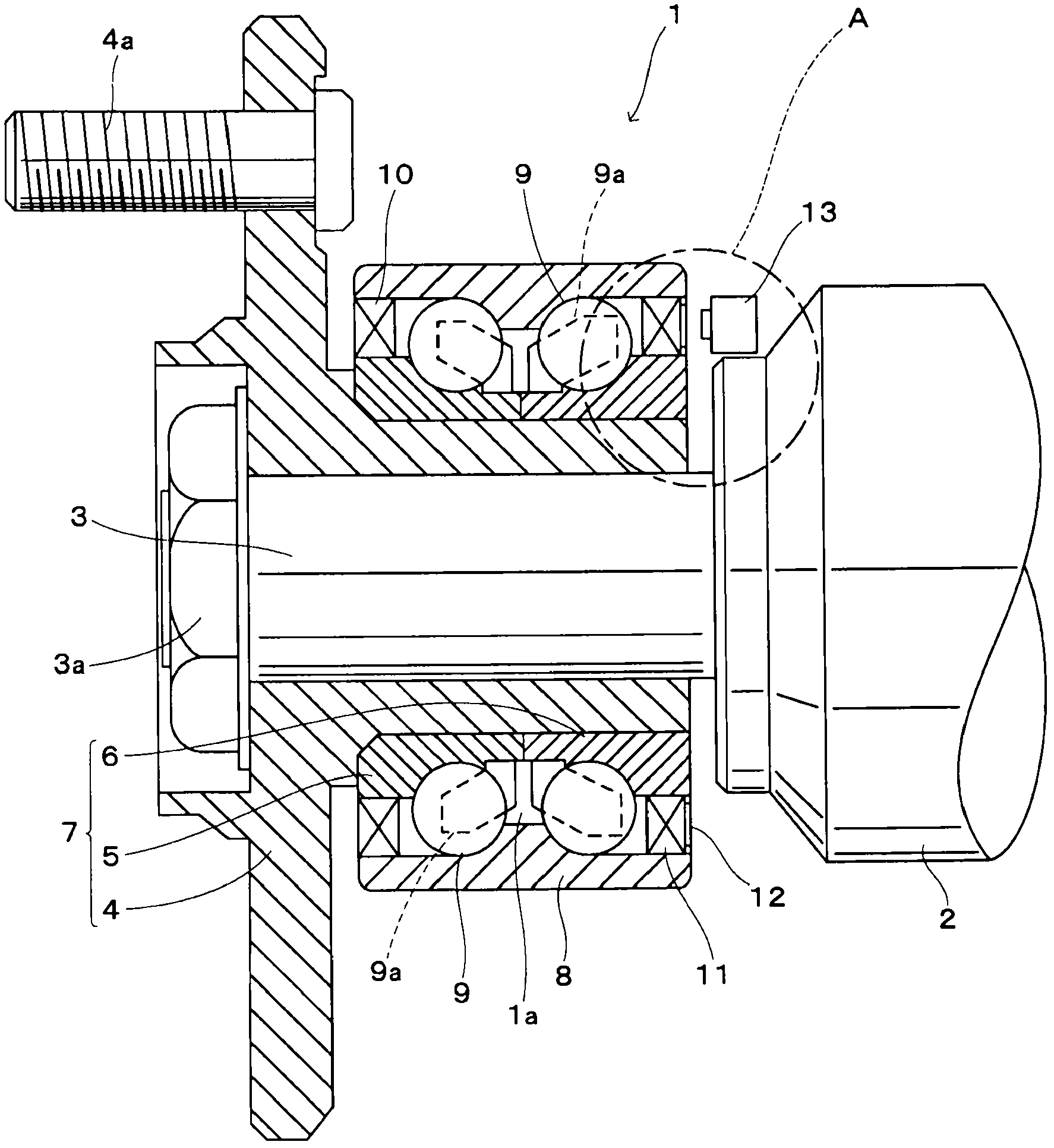

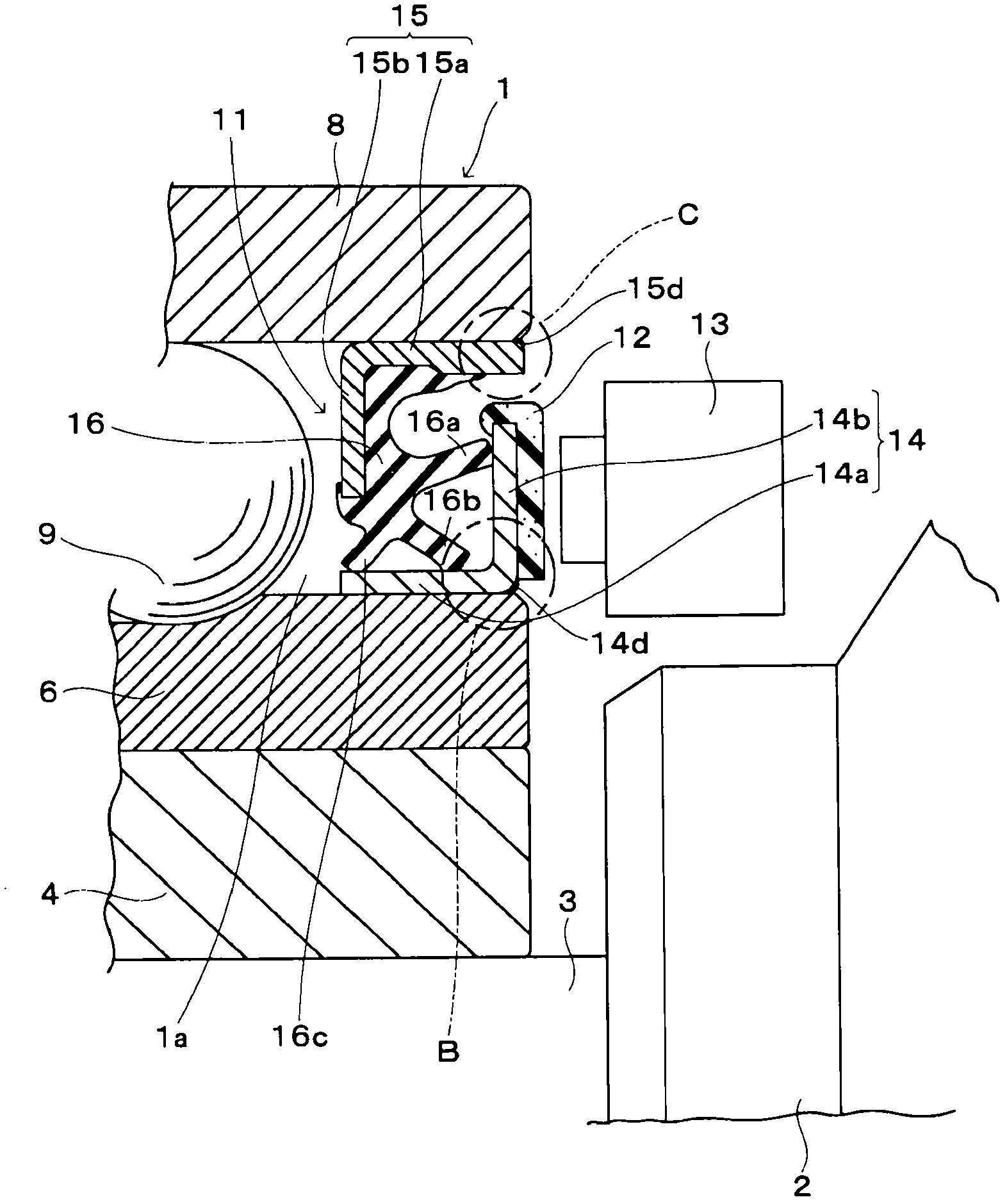

Method used

Image

Examples

experiment example 1

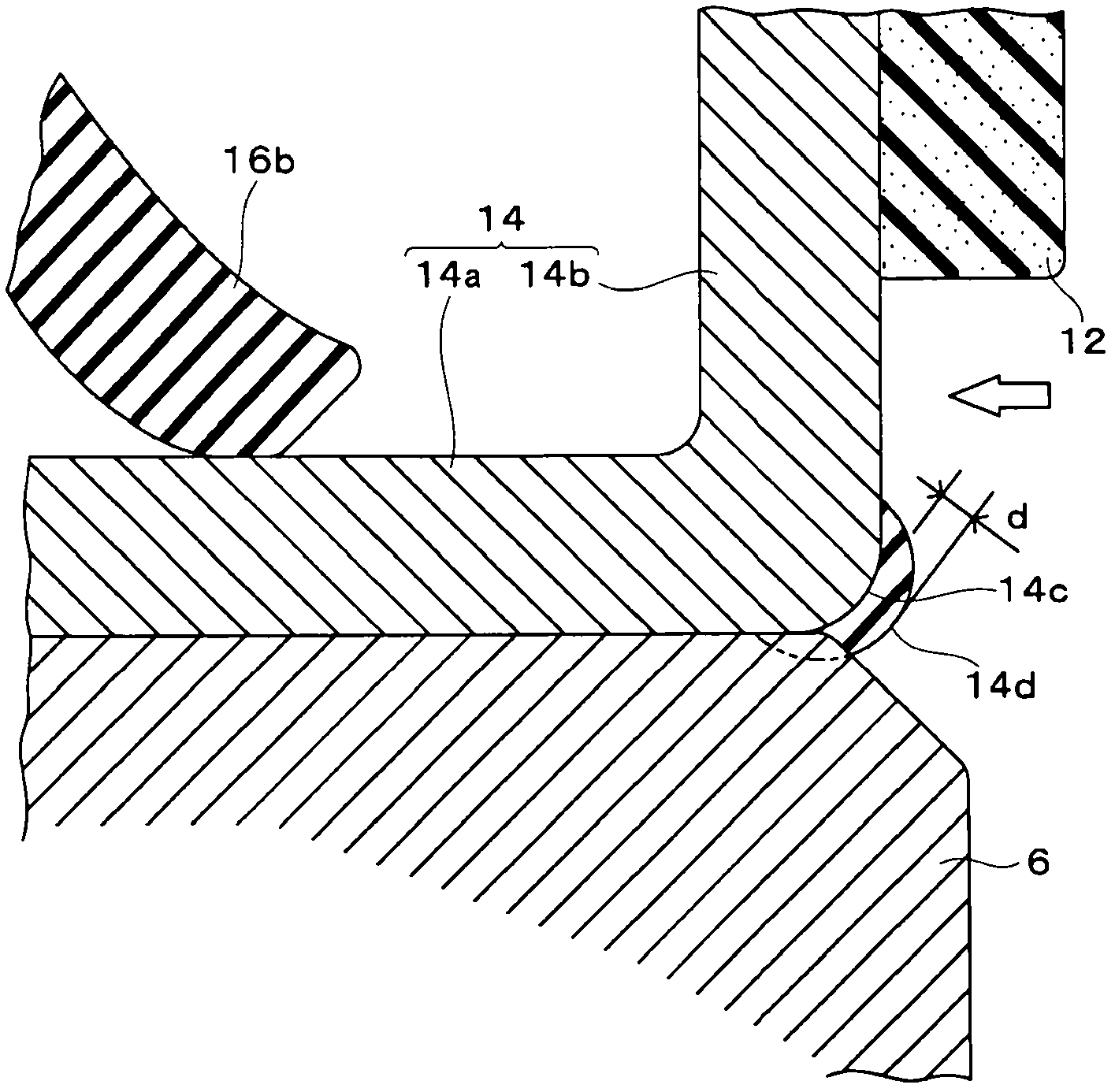

[0047] ready to be image 3 The metallic oil slinger 14 and the inner ring member 6 having the fitting relationship as shown are discharged from the distributor to the corner 14c of the lobes of the oil slinger 14, coated with a liquid hardening type silicone elastomer, and sintered at 150°C. After hardening for 10 minutes, an annular closed portion 14d with a layer thickness d of 0.02-0.10 mm (0.04 mm as the center) is formed. Also, make the flinger 14 with image 3 The inner ring member 6 is fitted in the state shown. The fitting interference (radius value) at this time is 0.02 to 0.15 mm. In addition, the fitting portion of the inner ring member 6 was scratched to a depth of 0.02 mm in the axial direction, and the flinger 14 was similarly fitted. An air leak test was carried out on the fitting structures of the undamaged fitting portion and the wound fitting portion under a pressurized environment, and there was no air leakage even when pressurized to an internal pressur...

experiment example 2

[0052] The above-mentioned elastomer agents of various viscosities were prepared, applied onto test pieces from a dispenser, and cured, and evaluation tests were performed on the moldability of the ring-shaped closed portion during the curing process. Figure 15 It is a figure which put the result of the evaluation test together in the table|surface. Figure 15 In the evaluation of formability, it is visually judged whether the elastomer agent is applied in the state where the test piece is erected, and whether the elastomer agent flows. In addition, the coating performed by the dispenser is stopped, and the nozzle is sprayed from the coated part. When leaving, whether the elastomer agent has a stringing phenomenon is carried out. In the column of formability evaluation, × indicates that the above-mentioned flow and stringing phenomenon occurred, and the annular closed portion has an uneven shape to the extent that the sealing property is affected. ○ indicates that although a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com