A burr remover for cylinder lid surfaces

A deburring and cylinder head technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of labor intensive, low production efficiency, and high cost, and achieve reduced labor intensity, convenient operation, and economical production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

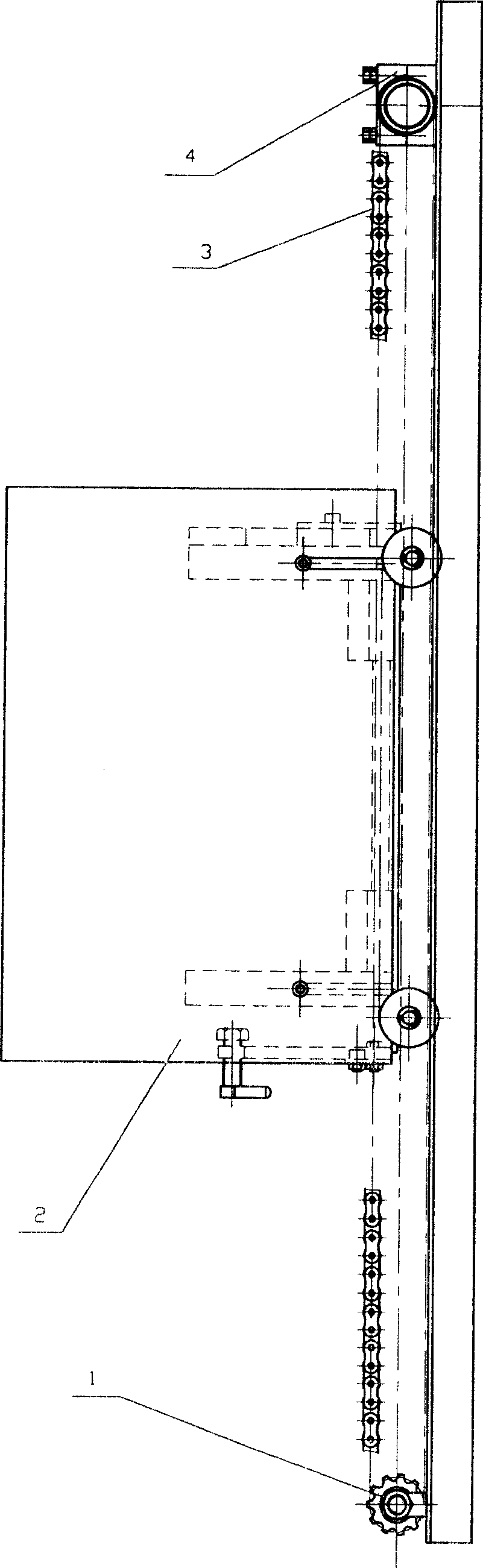

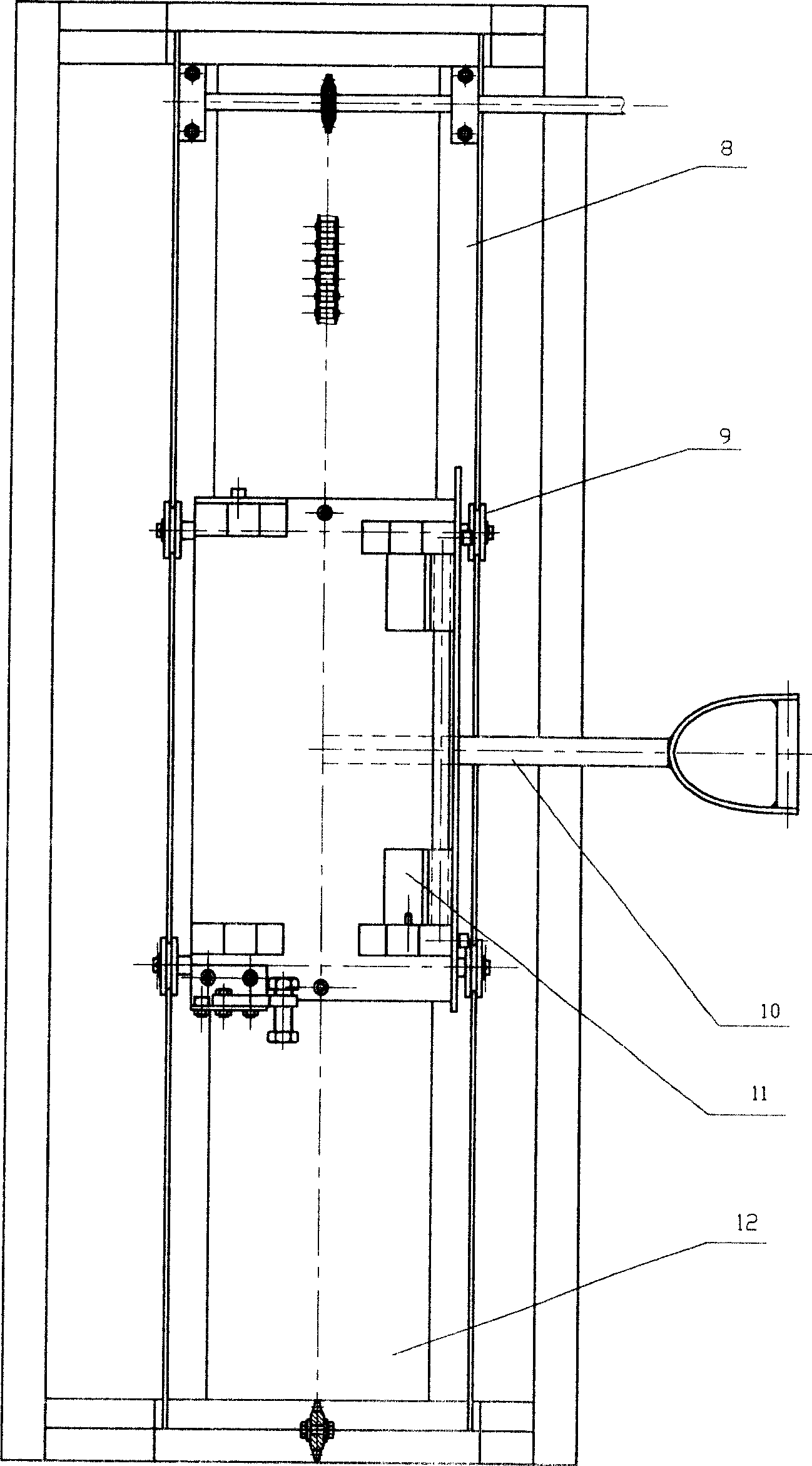

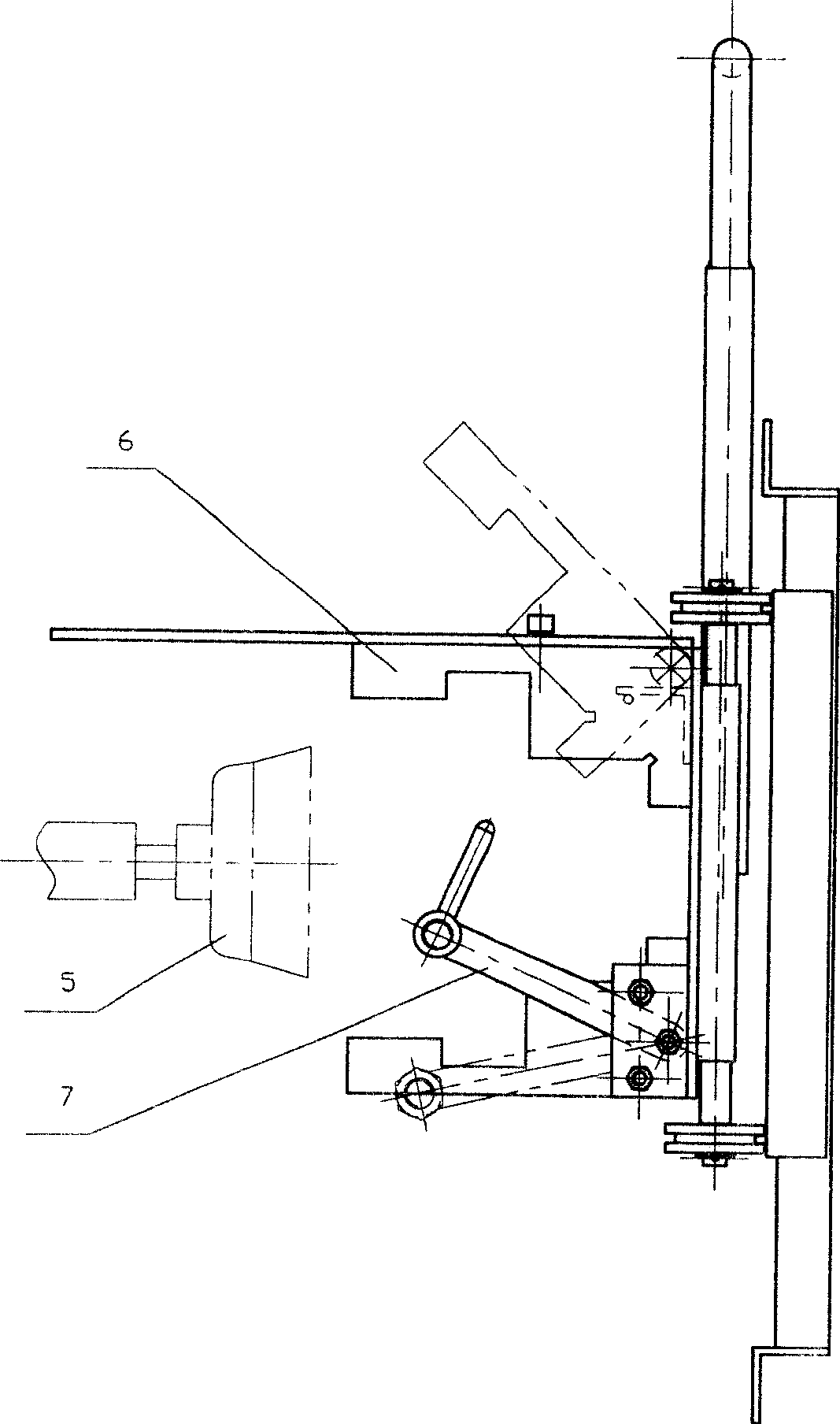

[0020] Example 1. See figure 1 , figure 2 , image 3 , the cylinder head surface deburring device of this example comprises a base (8) and a workpiece placement device and a base plate (12) located thereon, and is characterized in that the workpiece placement device is provided with several spacers (6) and workpieces The pressing mechanism (7) outside one end of the placing device has at least one movable pad (6), the pressing mechanism (7) is movably connected to the fixing device, and a deburring brush (5) and its power shaft are arranged above the workpiece placing device The spacer (6) is stepped, and the inner side of the high part becomes concave, and the height difference between the high and low parts is equal to the difference between the height and width of the cylinder head; the spacer (6) rotates through the rotating mechanism (11); the bottom plate (12) passes through The sprocket (1), the chain (3) are connected to the bearing transmission mechanism (4): a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com